Abstract

Highly functionalized, high value added bioactive molecules are generally obtained by synthetic procedures that are highly selective, economical, with high atom economy, and environmentally friendly. Following these guidelines, the use of recoverable solid catalysts, nonpolluting substrates, or toxic organic solvent contributes greatly to these demands. In the last three decades, heteropolyacids (HPAs) and its derivatives have received great attention as recyclable solid catalysts, due to their strong Brönsted acidity, excellent oxidizing capacity under mild conditions, and various reuse cycles without appreciable loss of their catalytic activity. However, new activation methods should be investigated to improve the sustainability of a process using HPAs. In this review, we report the latest advances associated with the synthesis of potentially bioactive molecules using more energy efficient alternatives such as microwaves, ultrasound, mechanochemistry, and photochemistry to minimize the energy consumption associated with organic synthesis. The transformations studied include construction reaction, heterocycle synthesis, selective oxidation, and biomass recovery.

1 Introduction

In the 1990’s, a new discipline in chemistry, called green chemistry, emerged, focusing all its efforts on solving the problems associated with pollution. The evolution of this new discipline focused on presenting a change in the strategies for solving environmental problems, associated with the regulatory and mandatory reduction in industrial emissions at the “end of the pipe,” toward the prevention of pollution through the design of production technologies themselves [1]. The 12 principles of green chemistry proposed by Anastas and Warner established the ways to minimize the environmental impacts of chemical production, and also indicate research priorities for the development of green chemistry technologies [2].

Since its inception, green chemistry has grown notably aided by different areas of research. Among them, heterogeneous catalyst-assisted organic synthesis has been one of the fastest growing sciences. Although, some catalytic technologies are almost 100 years old [1], they have been strengthened in the last decade since the principles of green chemistry promote their development in replacement of stoichiometric or catalytic processes. These catalysts, such as NaOH, H2SO4, HCl, HF, AlCl3, BF3, and ZnCl2, pose handling, containment, disposal, and regeneration risks due to their corrosive and toxic nature [3]. Heterogeneous catalysis using solid catalysts has great advantages that include the easy separation of the reaction medium, the possibility of reuse and, in general, it tends to be more selective, reducing the formation of secondary products [4]. A particular class of catalysts are heteropolyoxometalates, particularly heteropolyacids (HPAs) due to the broad range of reactions in which they can be employed.

Heteropolyoxometalates are a very large group of compounds associated with units of transition metal-oxygen octahedral anions, which can join to form innumerable structures. Among all the structures discovered, the most investigated and used HPAs correspond to those of the Keggin-type structure. Their most common structure is represented by the formula α[XM12O40] n−, where X is Si4+ or P5+, and M is Mo6+ or W6+. However, other representative HPAs include Wells–Dawson and Preyssler structure [5].

Another relevant aspect in the optimization of chemical processes in order to make them more sustainable is related to energy consumption. Energy consumption represents a major global challenge to achieve a sustainable planet. For this reason, developing alternative sources of safer, efficient, cleaner, renewable, and controllable energy is a goal of green chemistry, and the utilization of safe and efficient energy is being explored vigorously [6,7].

Taking into account the principles of sustainable chemistry applied to the synthesis of products, notable efforts are being made aimed at the use of heterogeneous catalytic processes with the minimization of energy consumption during transformations through alternative techniques to conventional heating such as microwaves, ultrasounds, photochemistry, electrochemistry, and mechanochemistry, among others [6,7,8].

On the other hand, in synthetic organic chemistry at the laboratory level or on an industrial scale, transformations are normally carried out using catalysts under homogeneous reaction conditions with conventional heating. Thus, these obsolete procedures can be redesigned through the use of catalysts that operate in heterogeneous conditions and also optimize the process through the use of alternative energy techniques to assist in these transformations [9]. Especially in the synthesis of heterocycles, about 90% of the new drugs contain this type of ring in their structures, which increases the interest in redesigning the classic syntheses of this type of compound using cleaner technologies and better yields, as well as obtaining new skeletons, and studying their activities [10]. The literature describes several review articles about the use of HPAs as catalysts in organic chemistry [5,10,11,12,13,14,15]. In addition to the transformations associated with the synthesis of heterocycles, this article also refers to other transformations typical of organic chemistry that include construction reactions, oxidation, and biomass recovery.

In this review, we report the advances associated with different organic transformations, through green procedures, developing more energy-efficient alternatives such as microwaves, ultrasound, mechanochemistry, and photochemistry, plus the use of different materials based on HPAs, updated with the contributions made in the area for the period 2000–2020.

2 Microwave synthesis

The synthetic processes of organic chemistry are perfected every day through new techniques that promote substantial improvements in the yields and selectivity of these transformations. In particular, organic synthesis assisted by the use of a microwave source has revolutionized organic synthesis. Many molecules can be prepared in substantially shorter reaction times compared to classical thermal heating procedures [16,17]. This notably promoted the discovery of new drugs and products of technological interest.

The use of microwave irradiation in organic transformation includes several advantages, collaborating with the development of cleaner synthetic processes, e.g., high heating efficiency, uniform heating throughout the material, increased process speed, low operating cost, final product purity, reduction in unwanted secondary reaction, and no ambient heat loss, among others [16,17].

The importance of this technique as an aid to green chemistry is reflected in the number of publications in the last decade that can be addressed through numerous review articles [18,19,20,21,22,23,24,25,26,27,28]. The different contributions in the synthesis of organic compounds using HPA catalysts and microwaves as an energy source are indicated below.

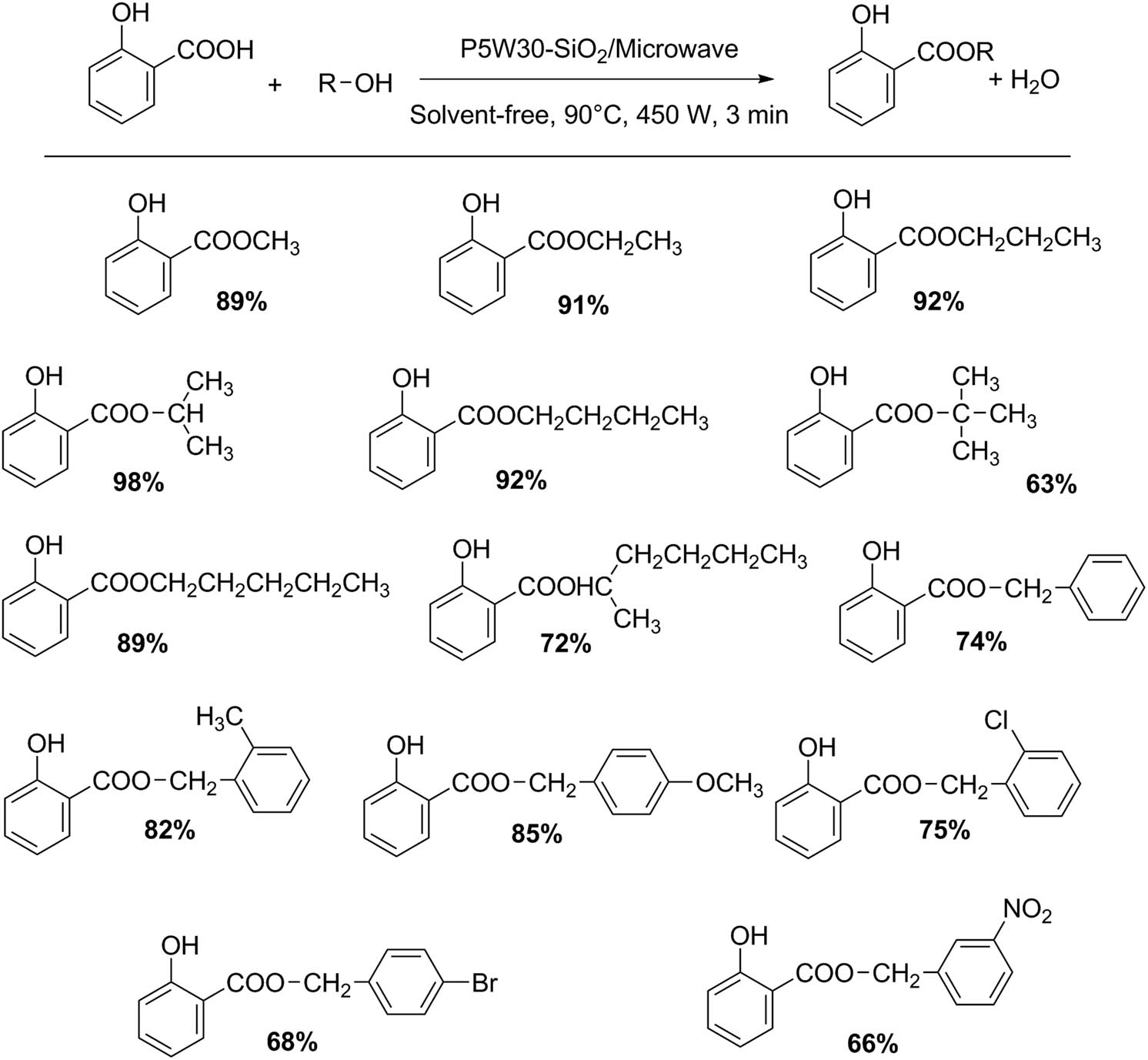

Simple transformations such as esterification, ammoxidation, and acetylation can be easily performed using distinct HPAs assisted with microwave irradiation. For example, Heravi group reported a friendly procedure for the catalytic salicylic acid esterification using aliphatic and benzylic alcohols with a Preyssler HPA supported on nanosilica H14[NaP5W30O110]–SiO2, under microwave irradiation (Scheme 1). This methodology allows obtaining high reaction yields (14 examples, 66–98%) under solvent-free conditions, and the catalyst was reused for several times without appreciable loss in its activity [29].

Esterification of salicylic acid with alcohols.

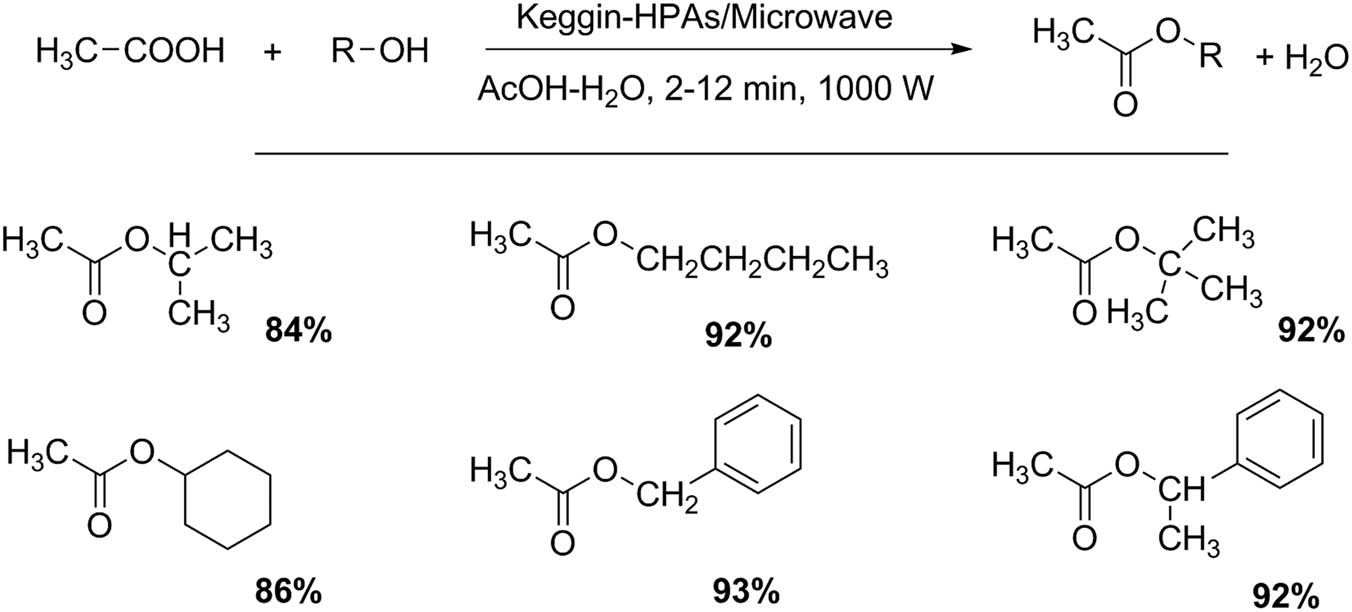

The esterification of acetic acid and fatty acids also has been studied using Keggin HPAs. The influence of several reaction conditions was monitored for the reaction between 1-butanol and acetic acid (Scheme 2). Five alcohols were acetylated with very good yields in shorter reaction times (2–12 min) with a selectivity greater than 97%. To analyze the catalyst recycling and stability, at the reaction end, the catalyst was filtered, washed with dichloromethane, dried at room temperature, and finally activated at 130°C for 3 h. The recovered catalyst retained catalytic activity after several cycles [30,31].

Esterification of acetic acid with alcohols.

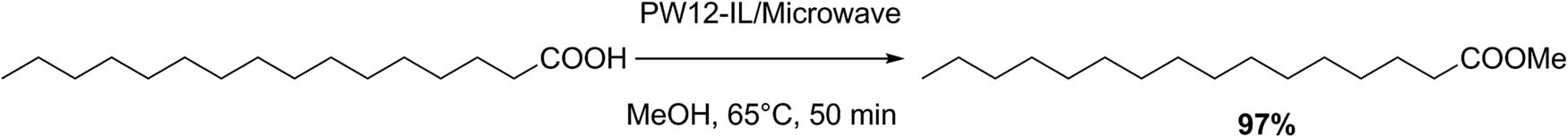

Duan et al. reported the preparation and characterization of a new type of HPA ionic liquid [(CH3)3NCH2CH2OH]H2PW12O40 (phosphotungstic acid [PW12]-IL) using choline chloride and H3PW12O40 (PW12) as precursors. Excellent conversions (97%) for esterification of palmitic acid with methanol were obtained under microwave-accelerated conditions (65°C, 50 min) (Scheme 3) [32]. Besides, this catalyst can be easily removed by lowering the reaction temperature without appreciable activity loss.

Palmitic acid esterification with methanol.

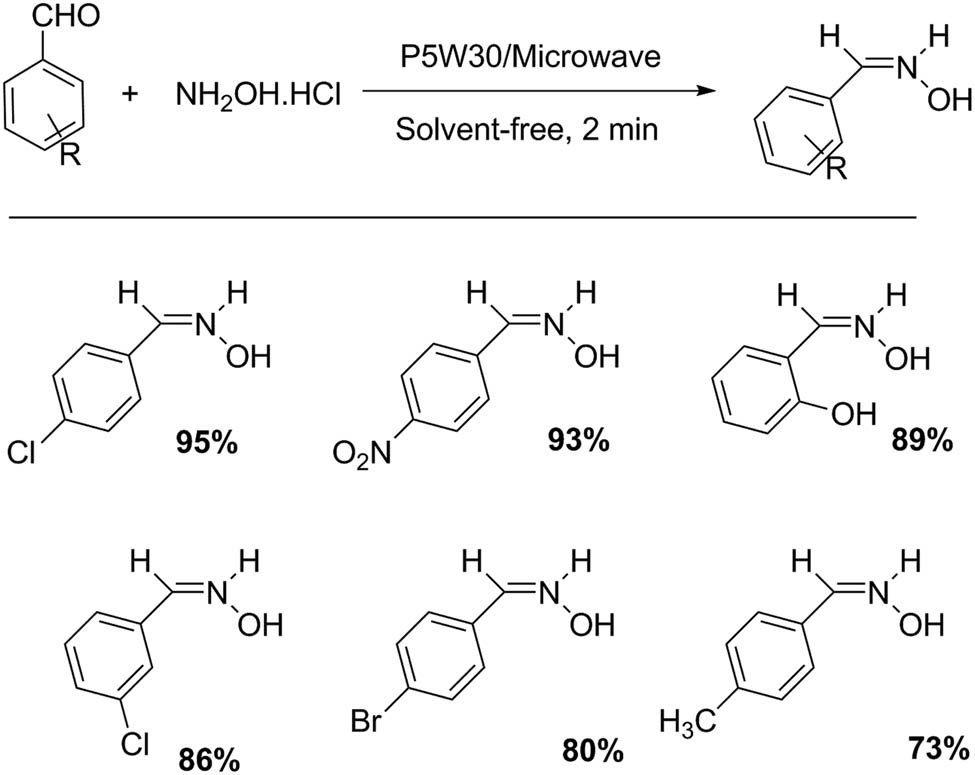

A catalyst with Preyssler structure, H14[NaP5W30O110], promotes the ammoxidation of aldehydes for the synthesis of Z-isomer oximes under microwave irradiation (Scheme 4). The simple methodology involves the addition of a catalytic amount of P5W30 to a mixture of hydroxylamine hydrochloride (3 mmol) and aldehyde (2 mmol), in solvent-free conditions. The reaction mixture was irradiated for 2 min with microwaves. Six examples of Z-oximes were prepared with a variable yield (21–71%) [33].

Ammoxidation of aromatic aldehydes.

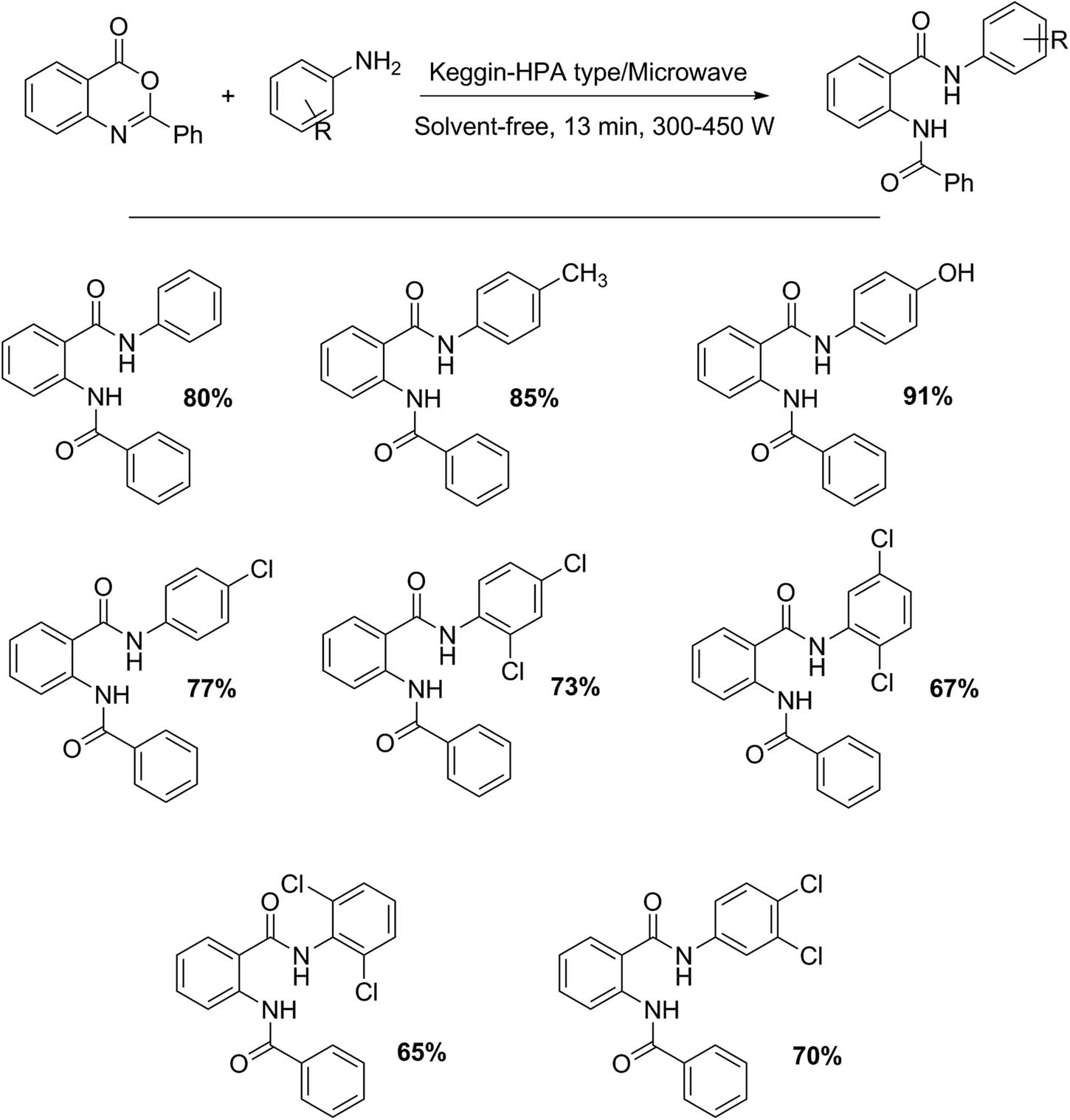

Another interesting example under solvent-free conditions, microwave irradiation, and different Keggin-type HPAs is shown in Scheme 5. Ighilahriz-Boubchir et al. [34] demonstrated that an equimolar mixture of 2-phenyl-3,1-(4H)-benzoxazin-4-one (10 mmol) and amines (10 mmol) a one HPA (1.2 mol%) such as H3PW12O40·13H2O, H4SiW12O40·13H2O, H4SiMo12O40·13H2O, and H3PMo12O40·13H2O can give higher yields to 2-benzoylamino-N-phenylbenzamide derivatives (66–92%) with short reaction times (in some cases, 3 min).

2 Benzoylamino-N-phenyl-benzamide derivative synthesis.

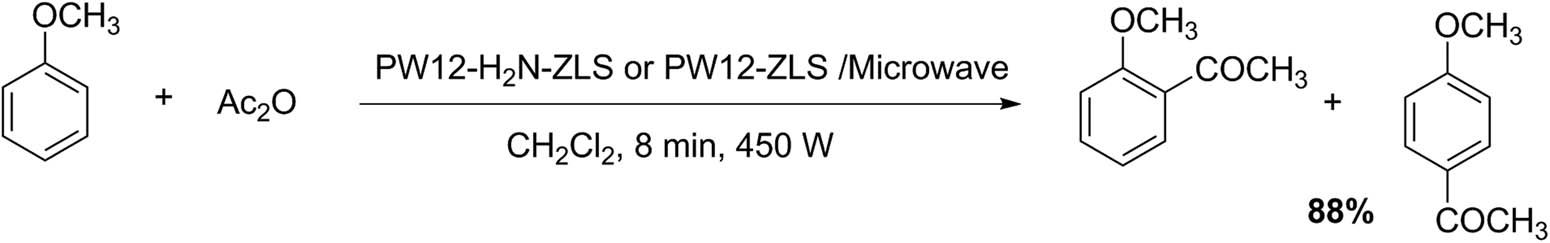

On the other hand, the functionalization of HPAs on mesoporous materials is an attractive strategy to increase proton availability, maintaining the high yields, short reaction time, easy processing, and reusability of the catalysts. Thus, PW12 catalysts supported on amino-functionalized Zr and La-incorporated SBA-15 mesoporous materials (PW12/H N-ZLS) have resulted in efficient heterogeneous catalysts for acetylation of anisole with acetic anhydride under microwave irradiation (Scheme 6). The catalytic tests were performed employing the following amount of reagents: anisole (10 mmol), acetic anhydride (20 mmol), dichloromethane (10 mL), and PW12/H2N-ZLS, or PW12/ZLS (0.6 g). The reaction mixture was irradiated with microware (450 W, 8 min). The 40%PW12/H2N-ZLS-N was the most selective catalyst, showing 84% conversion of anisole and p-methoxyacetophenone selectivity of about 99%. Meanwhile, when using 30% PW12/H2N-ZLS-N as catalyst, the conversion was 88% (10 min) and the selectivity was 96% [35]. Similarly, Ping and Yuchun presented a procedure for p-methoxyacetophenone using PW12 acid catalyst [36].

Anisole acetylation.

Although the transformations described so far represent single bond formation reactions, there is also an abundance of literature about heterocycle synthesis.

3,4-Dihydropyrimidine-2(1H)-ones (a particular class of dihydropyrimidines) are interesting compounds that play an important role in therapeutic and bioorganic chemistry. Some relevant activities include antibacterial and antihypertensive effects, and they also act as calcium channel blockers, α-1a-antagonists, and neuropeptide Y antagonist [37,38]. The Biginelli reaction is the conventional method for preparing these compounds. This multicomponent reaction needs acidic catalysts and involves the condensation of β-dicarbonyl compounds, an aldehyde, and urea or thiourea [37,38].

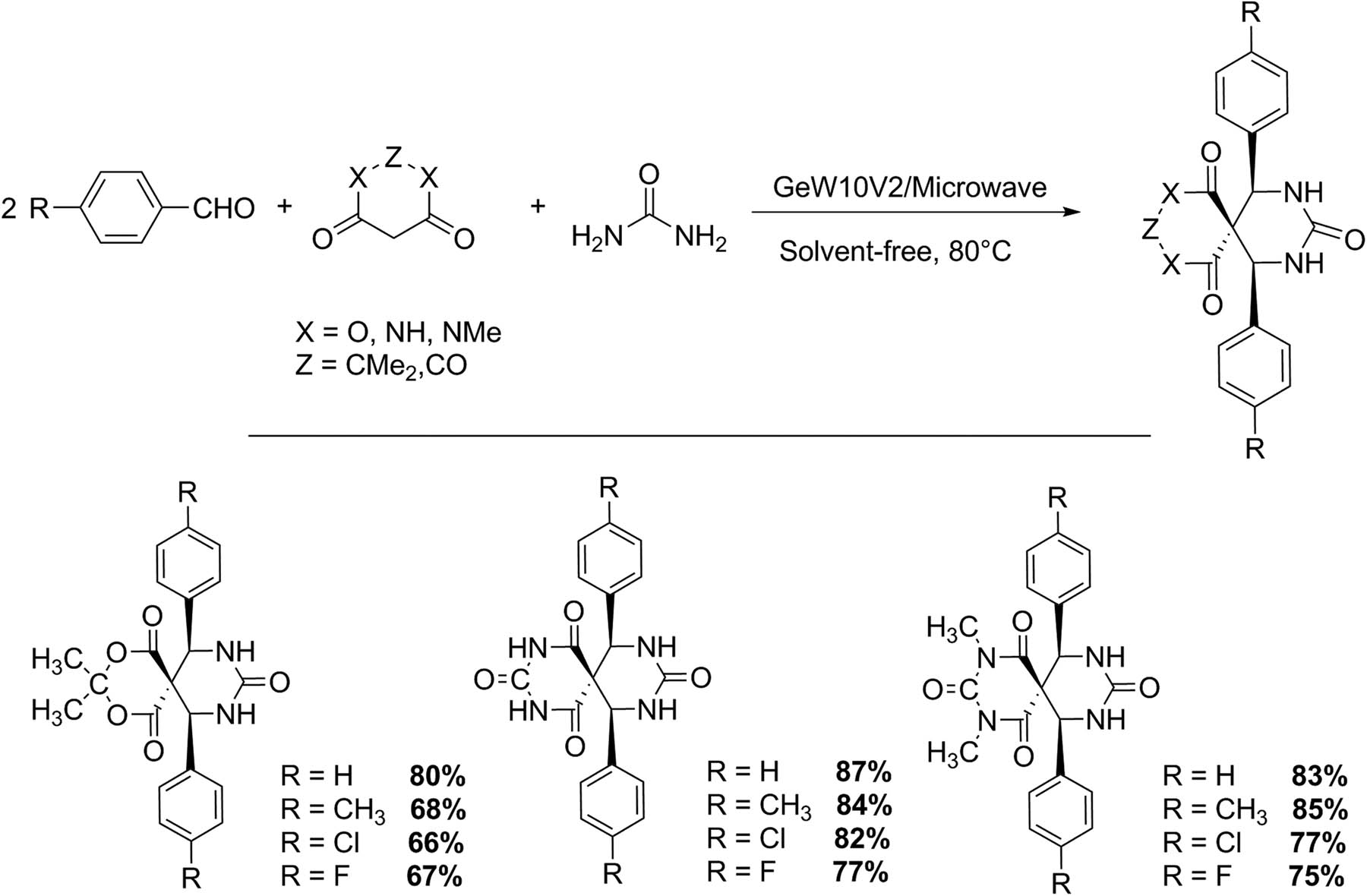

Several variants of Biginelli reaction have been studied during the last two decades. Spiro-fused heterocycles can be obtained from the reaction of cyclic β-diamides with β-ketoesters, Meldrum’s acid, or barbituric acid derivatives with one equivalent of urea and two equivalents of aldehydes, giving the corresponding compounds in the presence of H6GeW10V2O40·22H2O (GeW10V2) as catalyst, under solvent-free conditions at 80°C (900 W, 7 min) (Scheme 7). Twelve compounds were reported with yields between 66% and 87%, free of secondary products; besides, the recovered catalyst retained its catalytic activity after 4 cycles [39].

Synthesis of spiro-fused Biginelli derivatives.

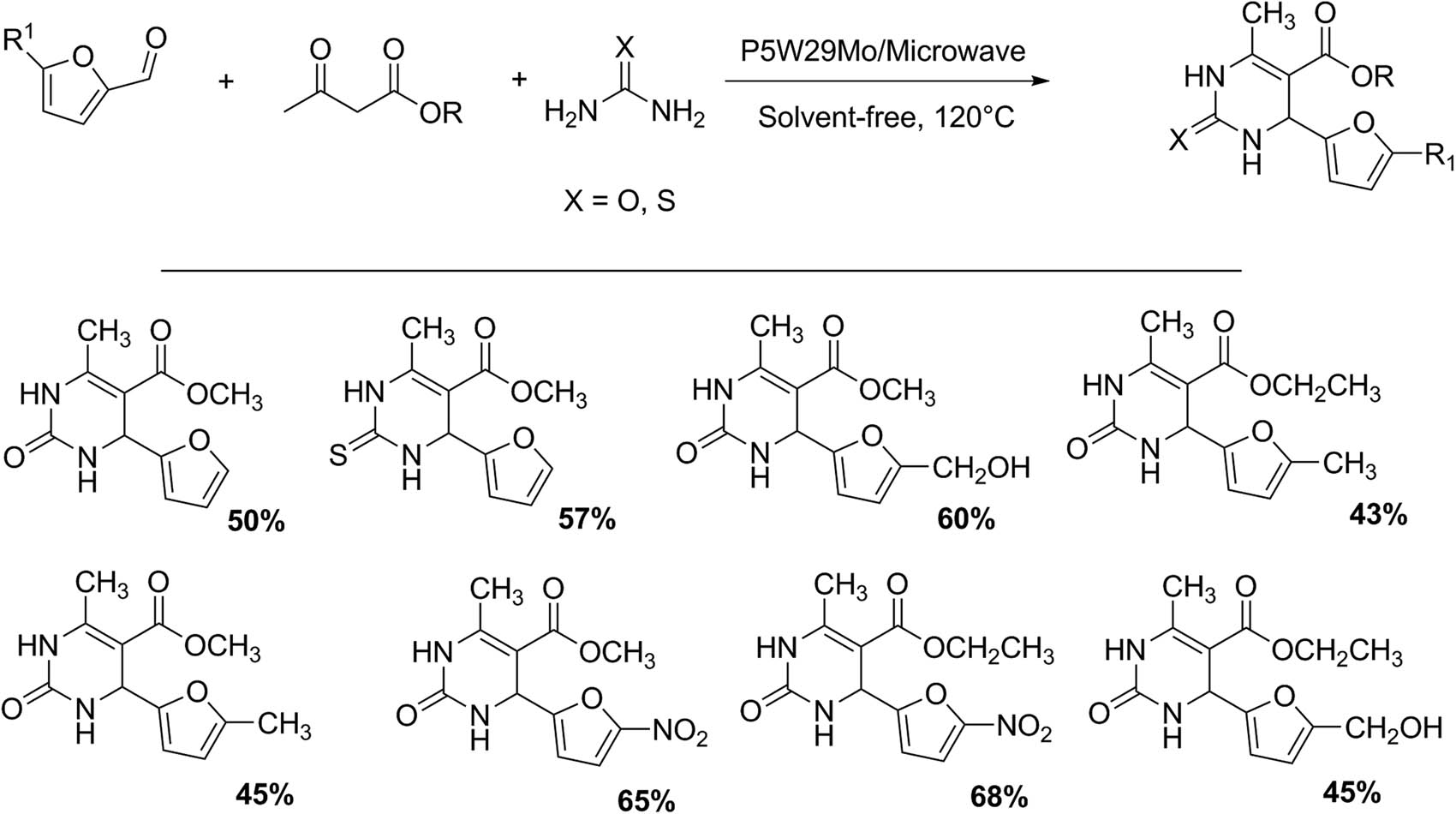

Dihydropyrimidinone derivatives from biomass platform molecules have been studied by our research group. A three-component domino reaction through a combination of furfurals, β-ketoesters, and urea/thiourea using Preyssler HPA H14NaP5W29MoO110 (P5W29Mo) encapsulated in a silica framework as the catalyst can provide moderate yields using microwave irradiation under solvent-free conditions [40]. Eight dihydropyrimidinones were obtained with yields between 45% and 68%. A representative experiment involves a mixture of methyl acetoacetate (1 mmol), 2-furaldehyde (1 mmol), urea (1 mmol), and (P5W29Mo-SiO2) (100 mg, 1 mmol%). The mixture was strongly mixed and heated on microwave at 120°C for 15 min (Scheme 8).

Synthesis of dihydropyrimidinones.

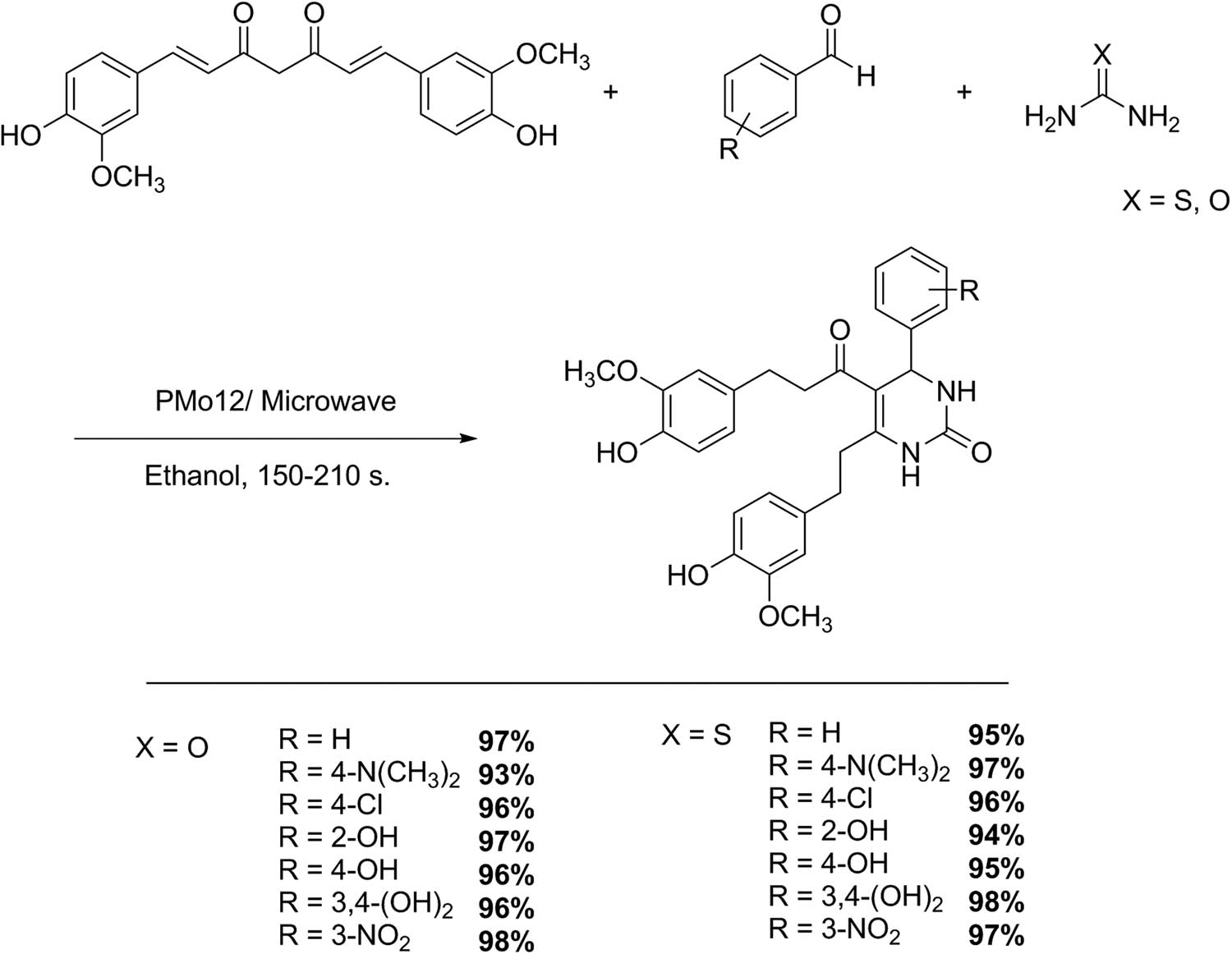

The synthesis of 3,4-dihydropyrimidin-2(1H)-one/thione analogs of curcumin can be performed by a one-pot multicomponent cyclocondensation using curcumin, substituted aromatic aldehydes, and urea/thiourea in ethanol catalyzed by commercial Keggin-type HPA H3PMo12O40 (PMo12) under microwave irradiation (Scheme 9). In a conventional test, a mixture of curcumin (2 mmol), substituted aldehydes (2 mmol), and urea/thiourea (3 mmol) dissolved in ethanol (2 mL) and PMo12 (5 mmol%) was irradiated under microwaves for 150–210 s. After completion of the reaction, the solvent was removed, and the mixture was poured into crushed ice. The precipitate was filtered, washed with hot water, dried, and crystallized with diethyl ether. Fourteen examples of 3,4-dihydropyrimidin-2(1H)-one/thione analogs of curcumin were synthesized with excellent yield (93–98%), using a simple, efficient, and improved Biginelli protocol [41]. These compounds were evaluated for their antioxidant and antibacterial activity, which was excellent and moderate, respectively.

Synthesis of 3,4-dihydropyrimidinones/thiones of curcumin.

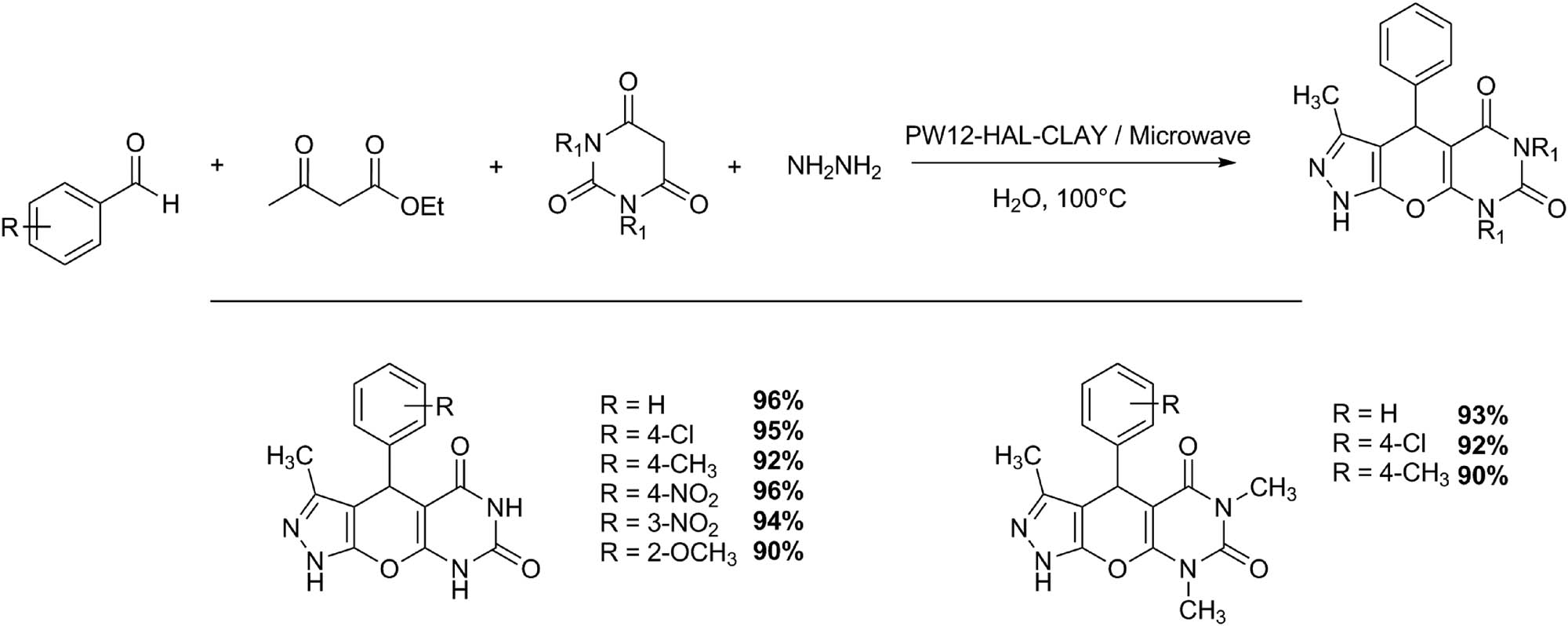

The Biginelli reaction can be slightly modified to obtain pyrazolopyranopyrimidines. This approach has been studied by Heravi group obtaining higher yields (>90%), in times between 35 and 50 min, at 100°C with a tungstophosphoric acid supported on amine-functionalized halloysite nano clay (PW12-HAL-CLAY) (Scheme 10). The procedure only involves the aqueous mixture of barbituric acid (1 mmol), hydrazine hydrate (1.1 mmol), ethyl acetoacetate (1 mmol), and aldehydes (1 mmol) in the presence of a catalytic amount of catalyst (0.03 g). The heterogeneous catalyst was reused for three cycles without significant loss of activity [42].

Synthesis of pyrazolopyranopyrimidines.

This same research group reported the reaction of pyrazoles and formamide under microwave irradiation using various solid acid catalysts such as HY-zeolite, silica-supported sulfuric acid, and silica-supported HPAs as catalyst for the synthesis of 4-amino-pyrazolo[3,4-d] pyrimidine derivatives. H3PW12O40 (PW12) showed the best catalytic activity in terms of yields and reaction times (Scheme 11). A typical procedure involves an appropriate amount of pyrazole (1 mmol) mixed with excess amounts of formamide (2 mmol) and a catalytic amount of PW12. The reaction mixture was placed in a microwave oven for the indicated time (8–12 min). Upon reaction completion, the catalyst was filtered and reused, and the diethyl ether extract was concentrated. The products were purified by liquid chromatography, and recrystallization of ethanol. Five examples of 4-amino-pyrazolo[3,4-d]pyrimidines were obtained with very good yields, between 71% and 88% [43]. Some advantages of this methodology are: reaction performed in solvent-free conditions, short reaction time using microwave irradiation, and use of inexpensive and recyclable catalyst.

![Scheme 11

Synthesis of 4-amino-pyrazolo[3,4-d] pyrimidines.](/document/doi/10.1515/gps-2022-0068/asset/graphic/j_gps-2022-0068_fig_011.jpg)

Synthesis of 4-amino-pyrazolo[3,4-d] pyrimidines.

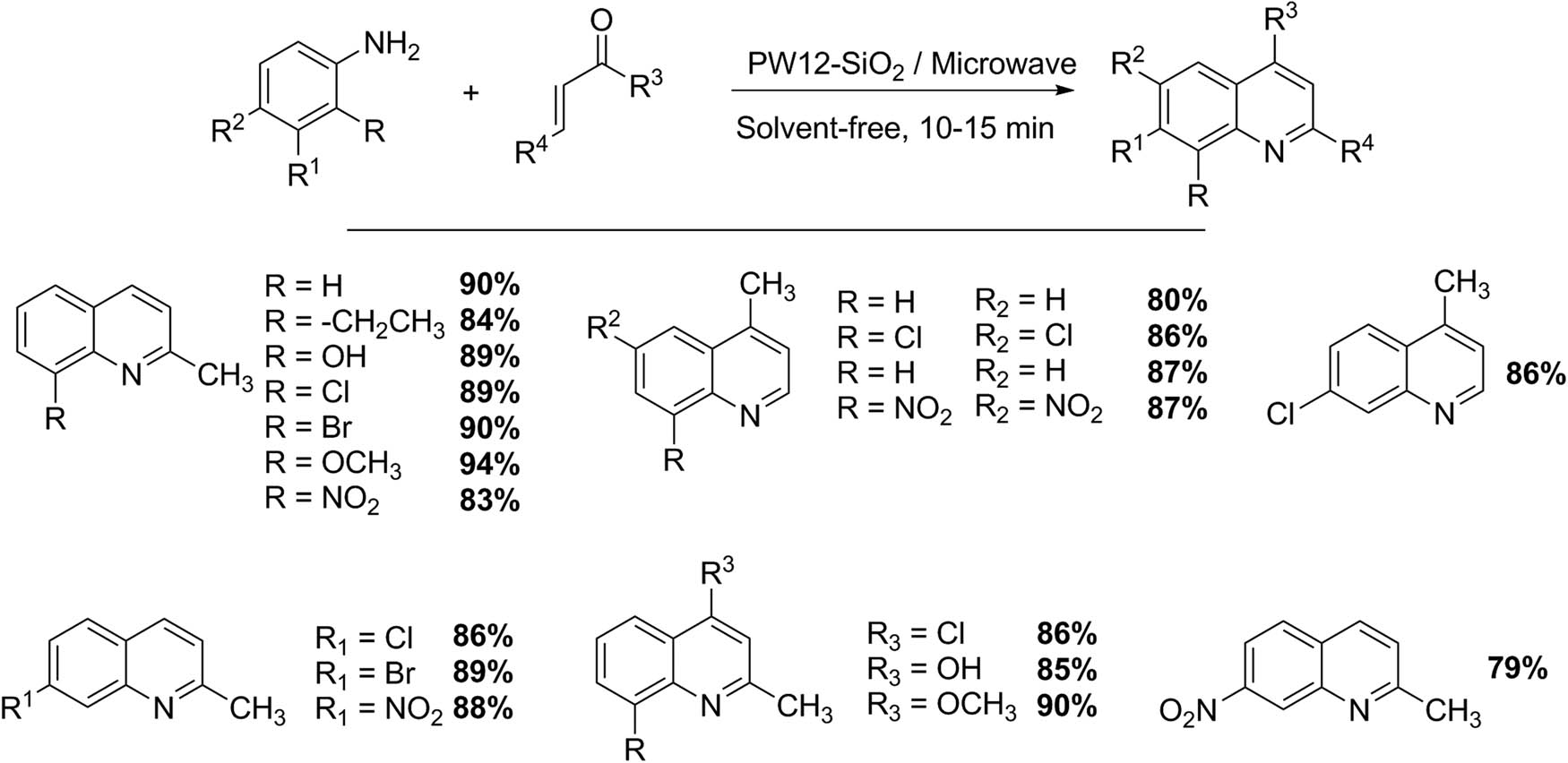

The synthesis of quinoline derivatives by a one-pot reaction of anilines with crotonaldehyde or methyl vinyl ketone using phosphotungstic acid, under microwave irradiation conditions, have also been studied with some detail (Scheme 12) [44,45]. Several quinoline-core compounds have pharmaceutical activities such as antitumor, antimalarial, analgesic, antihypertensive, anti-inflammatory, antibacterial, antiasthmatic, and antiplatelet agents, among others. In addition, quinoline derivatives are a valuable substructure used in a variety of compounds with electronic and photonic functions, polymer chemistry, and agrochemical applications, due to their notable mechanical properties [44,45]. The synthesis using a Keggin HPA (PW12) requires aniline (2 mmol) previously adsorbed on silica gel (0.4 g) and mixed with catalyst (0.2 g). Then crotonaldehyde (3 mmol) is added and mixed again. The mixture is irradiated with microwaves at a power of 80% at a pulse rate of 45 s for 10 min. When the process has finished, the product is extracted with ethyl acetate and purified by liquid chromatography. Under this methodology, 19 quinoline derivatives produced by the Doebner–Miller reaction using PW12 as catalyst and under microwave irradiation conditions of 300 W for 10–15 min can be obtained with very good yields (79–94%) [46].

Synthesis of quinoline derivatives.

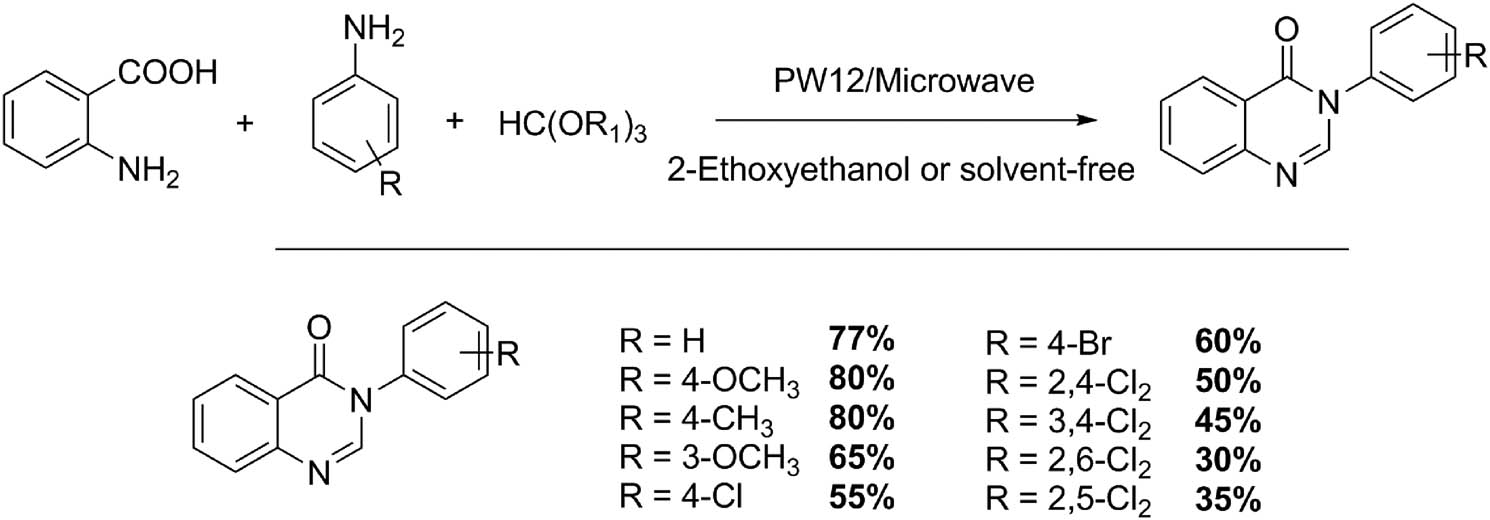

The quinazolinone system is a particular class of quinoxaline derivatives that possess a carbonyl group. This substructure and its derivatives are present in a large family of compounds with important biological activities. They have valuable pharmacological and therapeutic properties such as anticonvulsant, anticancer, anti-inflammatory, antihypertensive, antimalarial, antibacterial, antifungal, and antiviral activities [47,48]. The synthesis of quinazolin-4(3H)-ones in the presence of HPAs (1.2 mol%) under microwave irradiation was carried out from condensation of anthranilic acid (10 mmol), amine (10 mmol), and formic acid or orthoesters (14 mmol) using 2-ethoxyethanol (5 mL) as reaction solvent (Scheme 13). The power of microwave irradiation was initially set to 300 W for 3 min, and was increased to 450 W for 10 min. Similarly, the authors performed a suitable method in solvent-free conditions. Initially, several Keggin HPAs were tested (H3PW12O40·13H2O, H4SiW12O40·13H2O, H4SiMo12O40·13H2O, or H3PMo12O40·13H2O) as catalysts. However, the use of PW12 acid coupled with microwave irradiation showed better yields in solvent-free conditions in 13 min approximately. Ten compounds were obtained with yields of the order of 80% in most of the cases [48].

Synthesis of 4(3H)-quinazolinones.

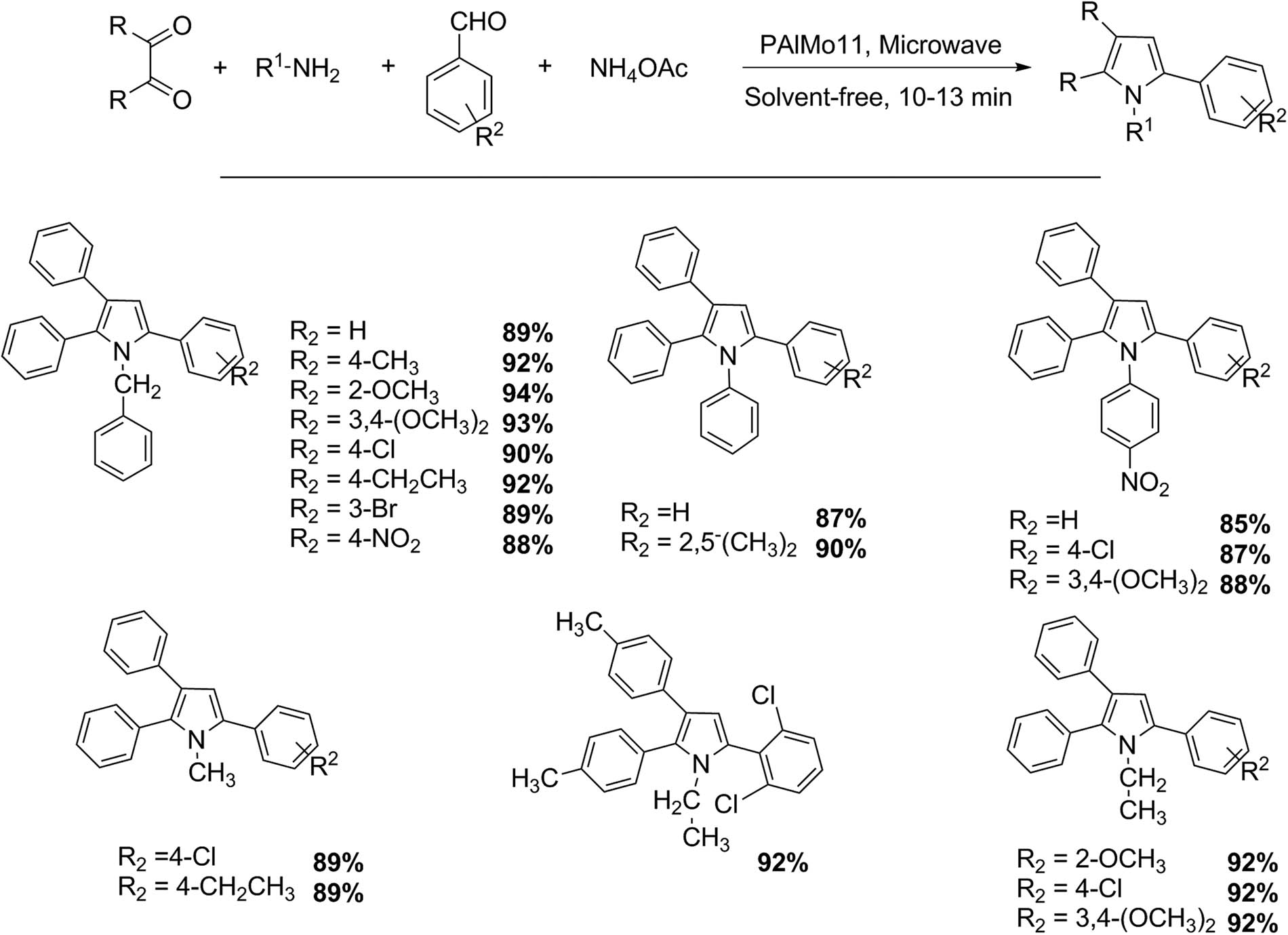

The imidazole substructure has received much attention because of its anti-inflammatory, antimicrobial, antiallergenic, anticonvulsant, analgesic, antithrombotic, hypnotic, and proton pump inhibitor activities. Imidazole derivatives have also been reported in compounds that are used for electronics, fungicides, photography, and as fire retardants [49,50,51,52,53]. Das et al. [53] established the use of defective Keggin-type HPA PAlMo11O40H6 (PAlMo11) as catalyst for efficient one-pot four-component synthesis of 1,2,4,5-tetrasubstituted imidazoles assisted by microwave (Scheme 14). Particularly, a mixture of 1,2-diketone (1 mmol), primary amines (1 mmol), aldehydes (1 mmol), ammonium acetate (or urea) (1.5 mmol), and PAlMo11 (5 mol%) was irradiated with microwave (560 W) for 10 min. The crude products were extracted with CH2Cl2 and then purified by recrystallization from ethanol. Nineteen tetrasubstituted imidazole derivatives were obtained with excellent yields (87–94%). The procedure represents an environmentally friendly alternative: a multicomponent process with high atom economy, reaction in solvent-free conditions, reusable catalyst, absence of secondary products, product of high purity obtained by simple filtration, and an extremely short reaction time (10 min) by using microwave irradiation.

Tetrasubstituted imidazole synthesis.

A similar procedure to that developed previously using p-phenylenediamine allows obtaining tetrasubstituted imidazoles with luminescent properties. In this procedure, a solvent-free microwave-assisted four-component synthesis of 1,2,4,5-tetrasubstituted imidazoles containing a 4-aminophenyl substituent was tested by condensation of p-phenylenediamine (1 mmol), aryl diketone (1 mmol), benzaldehyde derivatives (2 mmol), and ammonium acetate (8 mmol) in the presence of PW12 supported on silica (0.7 mmol%). When the microwave-assisted reaction ended, the residue was cooled to room temperature and purified by liquid chromatography and recrystallized in ethanol to give the pure product. Twelve 1,2,4,5-imidazoles with a 4-amino-phenyl substituent (auxochrome in 1 position) were successfully synthesized (57–74%) using PW12 and silica gel as solid support. The authors highlighted the possibility of using these new types of compounds with luminescence properties as potential applications in metal ion detection, biological, pharmaceutical, and material fields [54].

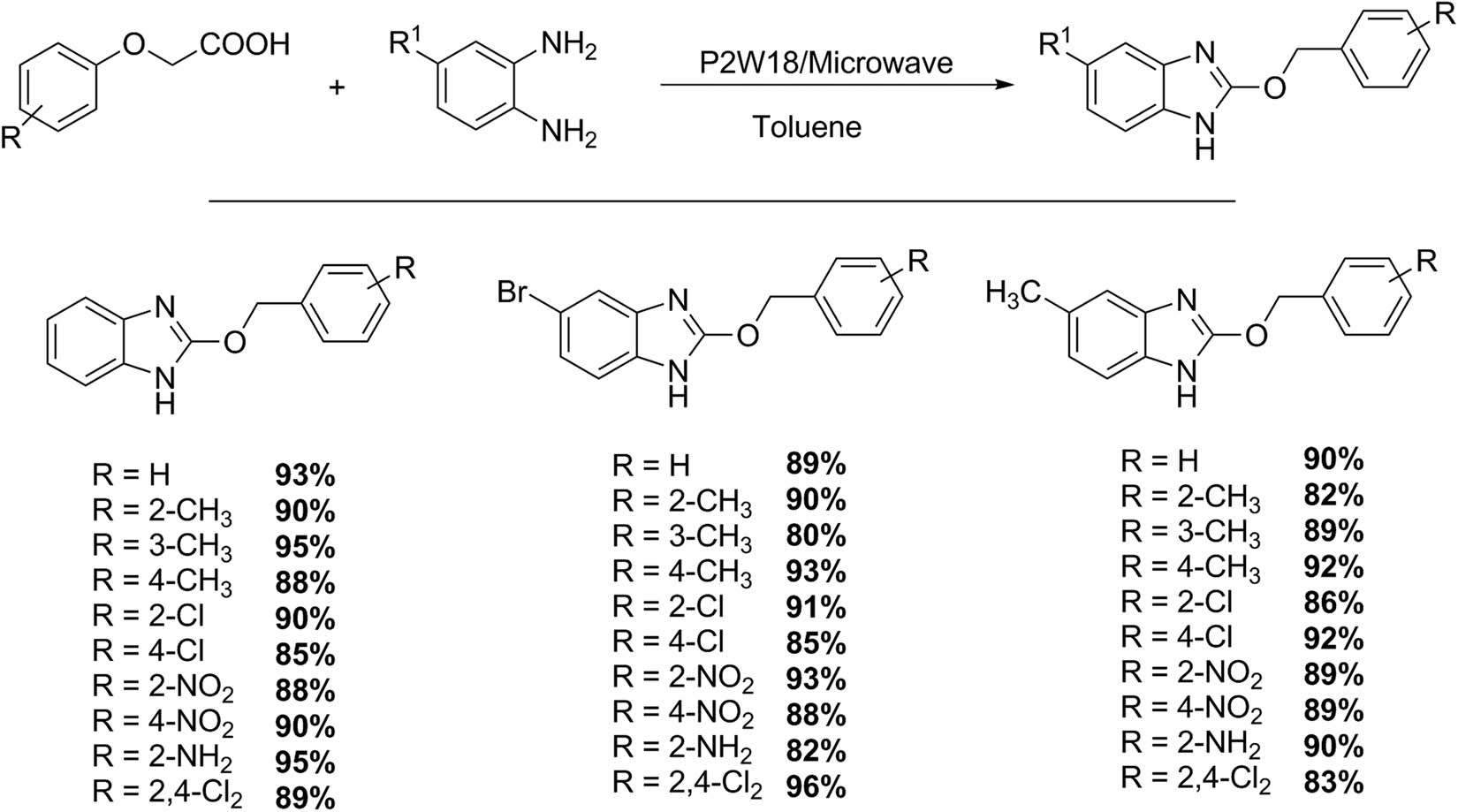

Keri et al. [55] reported an interesting work about an efficient method for 2-arylbenzimidazole preparation from o-phenylenediamines and phenoxyacetic acids under microwave conditions using a HPA with Wells–Dawson structure such as H6P2W18O62·24H2O (P2W18) as catalyst (Scheme 15). The reaction was carried out with o-phenylenediamine (1.0 mmol), different phenoxyacetic acids (1.0 mmol), and a catalytic amount of P2W18 HPA (1 mol%) in 2 mL of toluene. The reaction mixture was irradiated in a microwave oven for an appropriate time (2.5–4.5 min), and then the catalyst was recovered quantitatively after washing with toluene. The reaction mixture was purified by liquid chromatography. Thirty examples were obtained with excellent yields (82–95%) practically free of secondary products.

Synthesis of benzimidazoles.

Coumarins are other highly relevant heterocyclic compounds due to their diversity of applications at industrial level, especially in the pharmaceutical industry. Compounds possessing the coumarin subunit in their structure have been reported to exhibit different biological activities such as inhibitors of platelet aggregation, compounds with antibacterial, antiparasitic, antifungal, and anticancer activities, and selective enzyme inhibitors of HIV-1 protease, among others [56,57]. They are also widely used in the preparation of fragrances, flavors, fluorescent dyes and sensors, food additives, and as starting compounds for the synthesis of other bioactive compounds such as chromones, furocoumarins, and others. The structural modification of the coumarin nucleus leads to changes in the application of the molecule, since this gives it the ability to target various action points, which leads to variations in the normal action of the organism to be treated, and the modification of the molecule increases its cytotoxicity and selectivity.

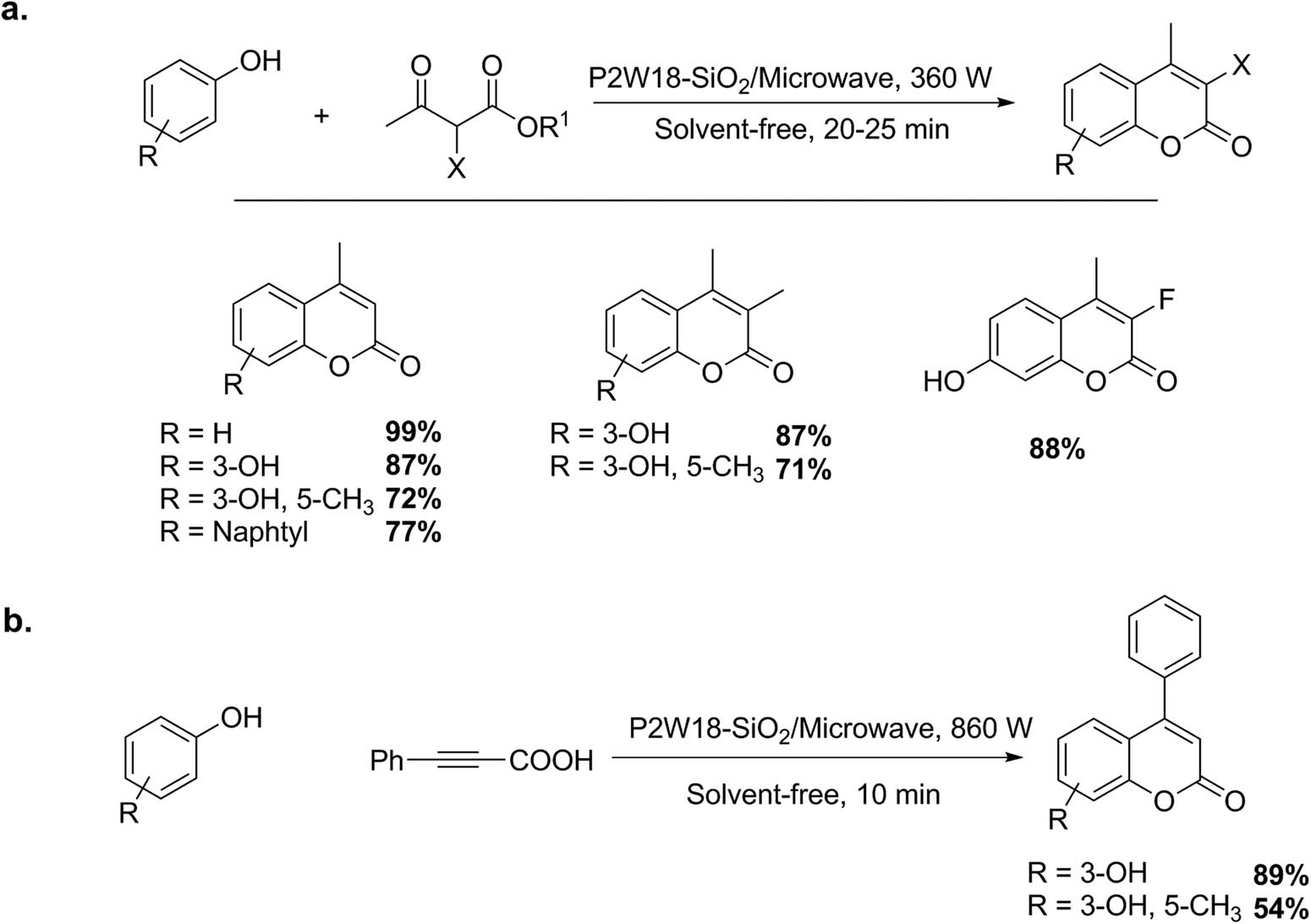

Previous work by our research group allowed obtaining, in a simple way and in friendly environmental conditions, simple coumarins using a domestic microwave oven using silica-supported Wells–Dawson acid (P2W18-SiO2). Solvent-free reactions were performed using phenols (1 mmol) and β-ketoesters (1 mmol) or phenylpropiolic acid (1 mmol) by the Pechmann reaction (Scheme 16a and b). The crude products were extracted with hot toluene (3 mL × 2 mL), and recrystallized from hot ethanol. Nine compounds were obtained with yields between 54% and 99% (10–25 min) [58].

(a and b) Synthesis of simple coumarins.

A recent work of Bennini-Amroun et al. [59] reported a similar procedure for 4-methylcoumarin synthesis using Keggin-type polyoxometalates (POMs) and microwave irradiation. This study was completed with theoretical calculations and the analysis of a probable reaction mechanism. The authors found the best reaction condition using a Keggin-type HPA, H4SiMo12O40, and SiMo12, and obtained 7-hydroxy-4-methylcoumarin with a yield of 97% from and ethyl acetoacetate. Nine 4-methylcoumarin derivatives were obtained with variable yields (25–90%) when the reaction mixture was irradiated between 25% and 90%. Similarly, Cáceres group reported the synthesis of coumarins from phenols and ethylacetoacetate using H3PMo12O40 (PMo12) and H3PW12O40 (PW12) supported on silica. 3,5-Dimethoxyphenol and ethyl acetoacetate in solvent-free conditions were used as test reaction. Comparing the classic thermal procedure, the use of microwave considerably reduced the reaction (60 vs 4 min) with a high yield (95%) [60].

The preparation of 3,4-dihydrocoumarins from α,β-unsaturated carboxylic acids and phenols can be conducted using P2W18-SiO2 as catalyst and solvent-free conditions with microwave irradiation (Scheme 16b). The experiments performed under conventional heating gave null or poor results. Only good yields of the products were obtained using microwave heating in short times (5–15 min) and a power level of 200–960 W depending on the substrate. Five examples of dihydrocoumarins were obtained with a yield of 40–82% [58].

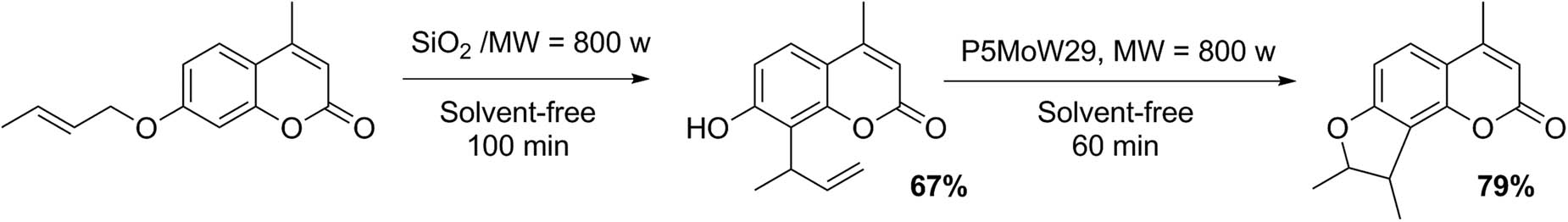

Our research group has also studied the synthesis of dihydrofurocoumarins through the strategy of cycloaddition of allyloxycoumarins under sustainable conditions: absence of solvents, application of microwave irradiation, and insoluble HPAs with Preyssler structure H14(NaP5MoW29O110)] (P5MoW29). Scheme 17 shows a representative example of their preparation [61].

Synthesis of dihydrofurocoumarins.

The synthesis of potentially active organic compounds is actually based on the combination of diverse substructures that enhance the biological activity of already known substances [62]. We have already described the different bioactivities of coumarins; for their part, benzothiazole compounds have received considerable attention in organic synthesis and medicinal chemistry. These substructures were found in various natural marine and terrestrial compounds that are widely used in a great number of applications as antioxidants, plant growth promoters, enzyme inhibitors, imaging reagents, and fluorescence materials. These substances have varied pharmacological activities including anticancer, antiviral, antifungal, antibacterial, antituberculosis, antidiabetic, anthelmintic, anti-inflammatory, antiparkinsonism effects, and so on. Similarly, coumarin derivatives have several pharmacological activities such as antibacterial, antifungal, antiviral, inhibition of HIV-1 protease, anti-inflammatory, neuroprotective, antidiabetic, and others. Their relevance is also clear in the food or pest industry where their fungicide and antioxidant activities are investigated [63,64].

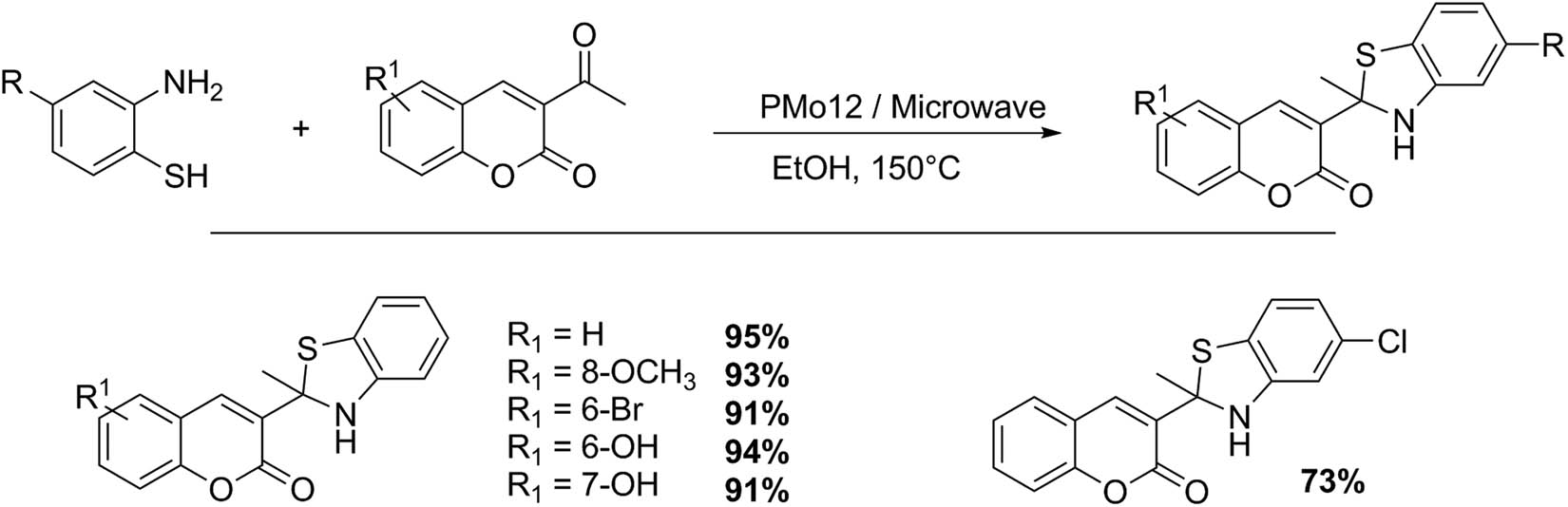

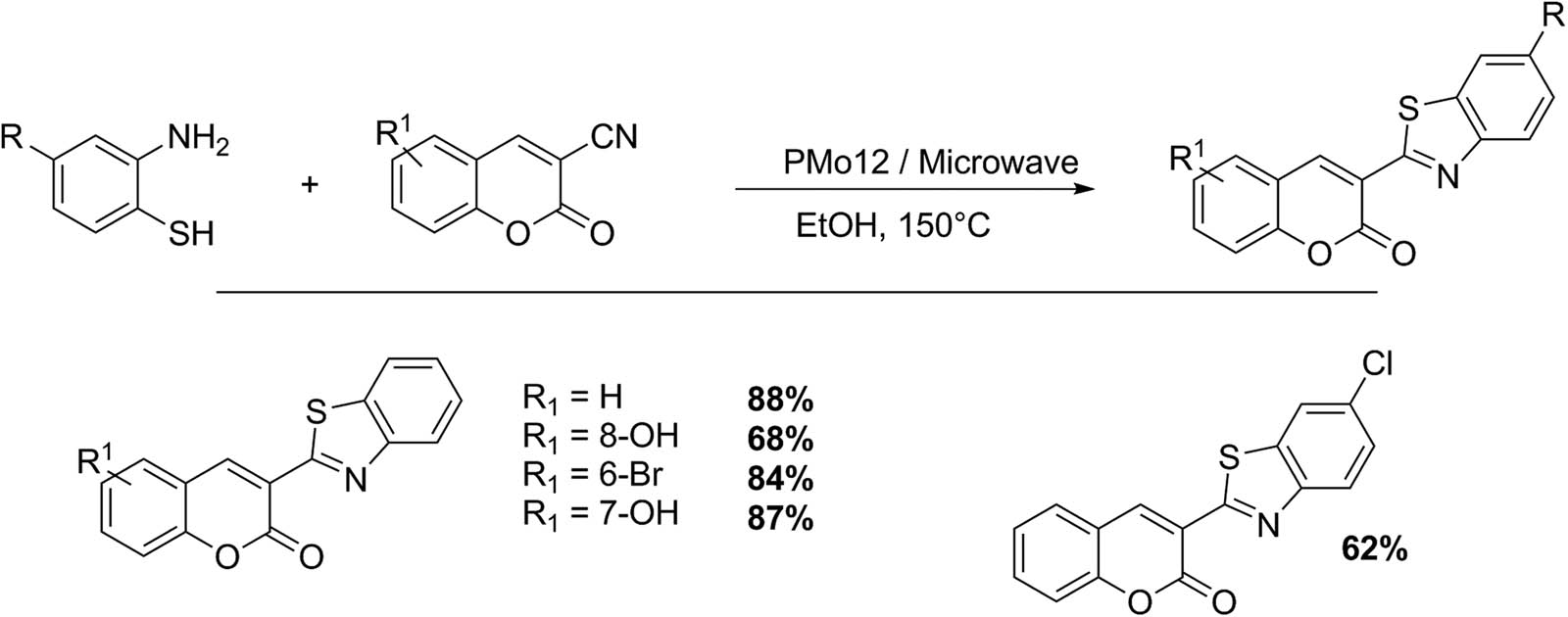

Shafiee and collaborators presented an elegant synthesis of 3-benzothiazolo coumarin and 3-benzothiazolino coumarin compounds, using o-aminothiophenol with 3-acetyl and 3-cyanochromen-2-one catalyzed by Keggin HPAs with very good to excellent isolated yields (62–97%) under microwave irradiation (Schemes 18 and 19). The 3-benzothiazolino coumarins were synthesized from 3-acetylcoumarins 1 (1 mmol) and 2-aminothiophenols 2 (1.2 mmol) in 3 mL of AcOH as solvent and HPA catalyst (1–5 mmol%). The reaction was irradiated with microwaves at 300 W for 7 min. Similarly, the reaction could be performed in absolute ethanol (3 mL). In these cases, the mixture was irradiated for 10 min (5 pulses of 2 min). The compounds were purified by liquid chromatography, and the catalyst was filtered and reused without loss of the catalytic activity. Six examples of 3-benzothiazolino coumarins were presented (73–95%) [64].

3-Benzothiazolino coumarin synthesis.

3-Benzothiazolo coumarin synthesis.

Working under similar reaction conditions and substituting 3-acetyl coumarins for 3-cyano coumarins, the same authors obtained five examples of 3-thiazolo coumarins with very good yields (66–88%) (Scheme 19) [64].

Motamedi group reported a multicomponent procedure that involved an aldehyde, a 1,3-dicarbonyl compound, and an amine as nitrogen source at short reaction time, solvent-free conditions, and free of secondary products [65]. In this reaction, chromeno[4,3-b]quinoline derivatives were obtained with operational simplicity and very good performances (Scheme 20). In a representative experiment, 4-aminocoumarin1 (1 mmol), 1,3-cyclohexadione 3 (1 mmol), aldehyde 4 (1 mmol), and HPA (PW12) (10 mmol%) under solvent-free conditions were maintained for 5 min in a microwave oven at 100°C. The product was extracted with acetone and purified by liquid chromatography. Ten quinolone derivatives were obtained with yields between 80% and 95% [65].

![Scheme 20

Synthesis of chromeno[4,3-b]quinolones.](/document/doi/10.1515/gps-2022-0068/asset/graphic/j_gps-2022-0068_fig_020.jpg)

Synthesis of chromeno[4,3-b]quinolones.

The preparation of xanthene derivatives is important in synthetic organic chemistry due to the great range of bioactivity properties of these compounds, such as bactericide, antiviral, and anti-inflammatory. They have been employed for photodynamic therapy and as fluorescent material for visualization of biomolecules [66]. Their preparation via microwave can be performed using encapsulated molybdophosphoric acid in dealuminated zeolites-Y (PMo12-DAZY) [67] (Scheme 21). The synthesis requires mixing aldehyde (1 mmol), 2-naphthol (2 mmol), and acid catalyst (0.0125 mmol), irradiating at 800 W for 2–3.5 min. The scope of this methodology allowed obtaining 13 compounds with yields between 75% and 95%.

![Scheme 21

Synthesis of 14-substituted-14H-dibenzo[a,j] xanthenes.](/document/doi/10.1515/gps-2022-0068/asset/graphic/j_gps-2022-0068_fig_021.jpg)

Synthesis of 14-substituted-14H-dibenzo[a,j] xanthenes.

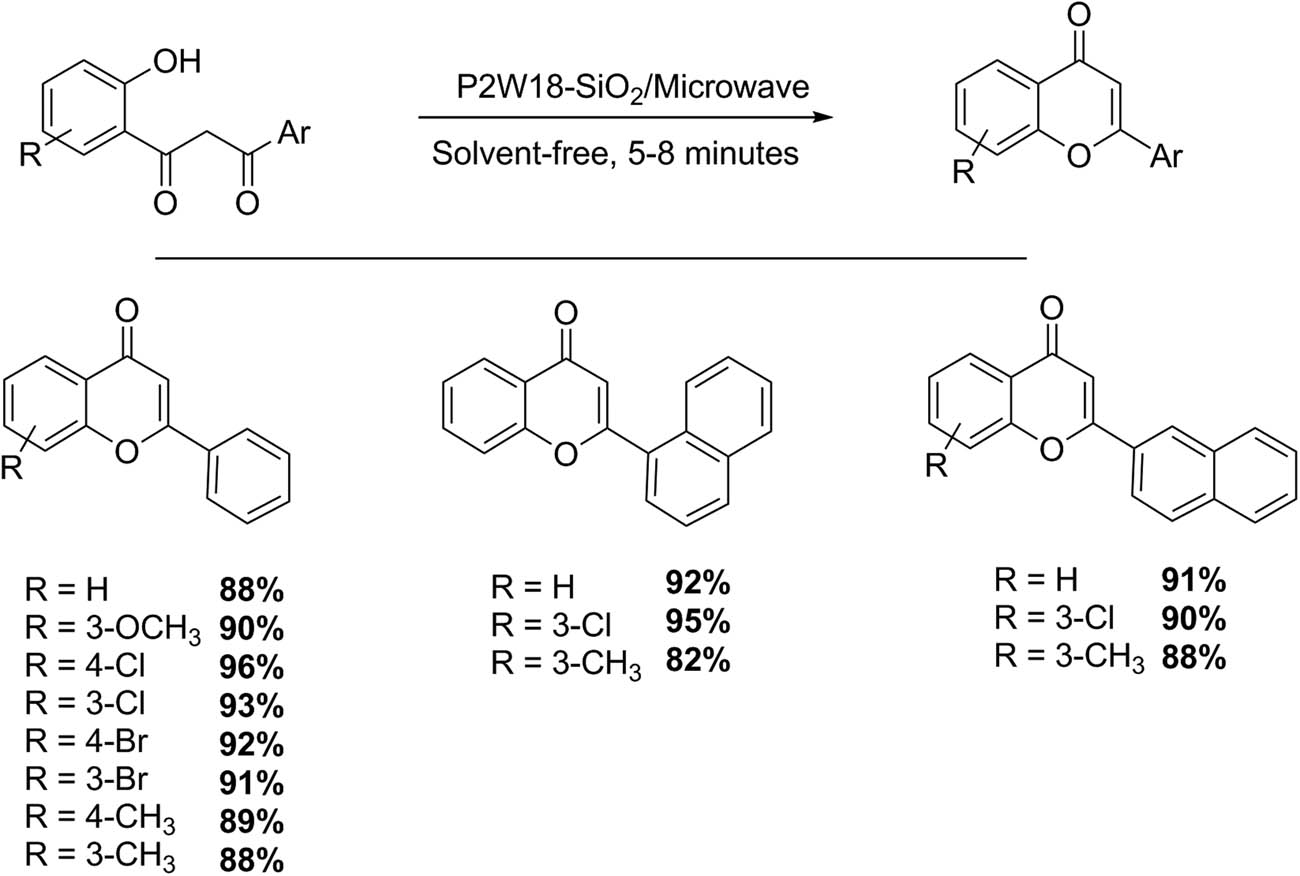

Chromones constitute a group of compounds of the flavonoid family. Their biological and pharmacological properties have been widely documented. Flavones have a repelling property against some phytophagous insects and a Coptotermes sp. subterranean termite [58,68]. In this sense, our research group carried out a green and solvent-free synthesis of substituted flavones and 2-arylchromones via the cyclization of 1-(2-hydroxyphenyl)-3-aryl-1,3-propanediones using a Wells–Dawson HPA (P2W18-SiO2) as catalyst (Scheme 22). When 1-(2-hydroxyphenyl)-3-aryl-1,3-diketone (0.5 mmol) and P2W18-SiO2 catalyst (1% mmol) are submitted to microwave irradiation at 840 W for 5–8 min, higher yields can be reached. In fact, using this methodology 14 examples of chromones and flavones were prepared with excellent yields (82–96%) free of secondary products [58].

Synthesis of chromones and flavones.

During the last decade, the chemistry of calixarenes has aroused increasing interest. Resorcinarene derivatives have been used as stationary phase in achiral capillary gas chromatography (GC) and self-assembled on gold surfaces for nanoscale advances. However, the principal applications of these compounds are in the catalysis area where p-sulfonic acid calix[n]arenes are used as organocatalysts in allylic alkylation, Mannich-type reactions, Biginelli reaction, and in esterification procedures [69].

Calix [4] resorcinarenes by cyclocondensation reaction of resorcinol and aldehydes catalyzed in the presence of PW12 can be carried out via microwave-assisted synthesis [4] (Scheme 23). In a typical procedure, a solution of resorcinol (10 mmol) and aldehydes (10 mmol) was added to a solution of PW12 (1 mmol%) in 2-ethoxyethanol (2 mL). This mixture was irradiated by microwaves for 5 min at a fixed power of 300 W. Excellent isolated yields (up to 88%) were attained without relevant secondary product formation. The pure product was obtained by cooling the reaction mixture. The formed solid was filtered and identified by NMR. Nine products were obtained (88–91% yields) [70].

![Scheme 23

Synthesis of calix (4] resorcinarenes.](/document/doi/10.1515/gps-2022-0068/asset/graphic/j_gps-2022-0068_fig_023.jpg)

Synthesis of calix (4] resorcinarenes.

On the other hand, POMs can in general act as reversible multielectron oxidant catalysts. In the last decade, procedures involving catalysis and clean oxidants such as hydrogen peroxide, organic peroxides, and molecular oxygen have been developed [71,72,73,74,75,76,77]. These are useful systems to oxidize organic substrates and present high efficiency due to their low cost, safety in storage and operation, and mild reaction conditions. Our research group has demonstrated the versatility of these materials in the selective oxidation of organic substrates including alcohols, phenols, amines, and sulfides, among others [78,79,80,81,82,83,84,85]. In this review, we also present the selective oxidation of organic substrates using HPAs as well as microwave irradiation to reduce reaction times.

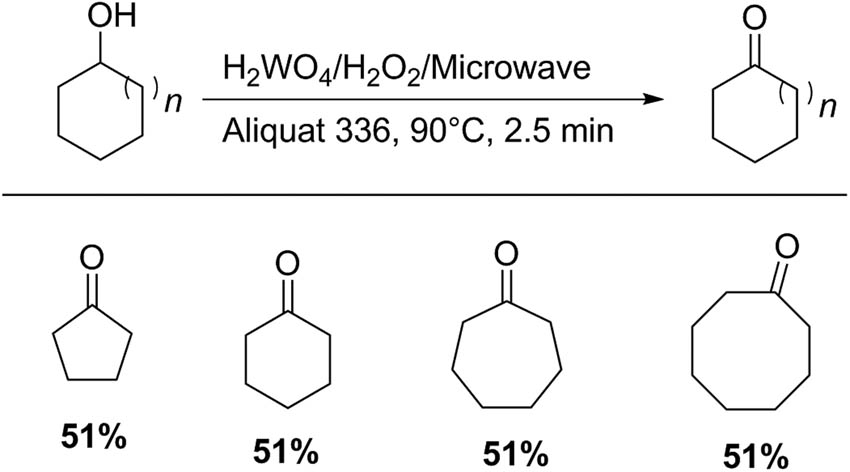

Chatel et al. [86] reported the oxidation of five- to eight-membered cyclanols to the corresponding cyclic ketone, with aqueous hydrogen peroxide in the presence of tungstic acid (H2WO4) as a catalyst and an ammonium-based ionic liquid under organic solvent-free conditions (Scheme 24). In a typical procedure for cyclohexanol oxidation, a mixture of this substrate (10 mmol), tungstic acid (2.4 mol%), Aliquat 336 (6.8 mol%), and 30% hydrogen peroxide (20 mmol) was used. The mixture was stirred under microwave irradiation at 90°C for 2.5 min (P = 80 W). The use of Aliquat 336 associated with a nonconventional method such as microwave led to excellent yields, e.g., cyclohexanone oxidation: 94% [83].

Oxidation of cycloalkanols to cycloalkanones.

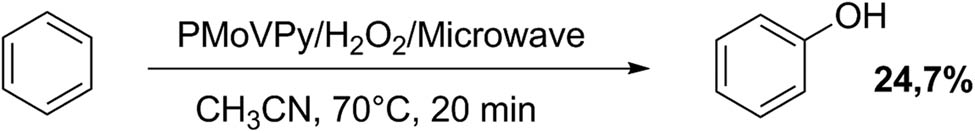

Liu and Hou [87] reported the direct benzene oxidation to phenol over a Keggin HPA containing vanadium in the primary structure and pyridine in the secondary structure (PMoVPy), using microwave irradiation. They found that the optimal conditions were: 1.0 mL of benzene, 0.15 g catalyst, 1.8 mL 30% aqueous solution of H2O2, 15 mL of acetonitrile, 70°C reaction temperature, and 20 min reaction time (Scheme 25). The use of microwave energy and a modified Keggin HPA gives a phenol yield of 24.7% (conventional heating gives only 7.8% of phenol yield) [84].

Direct benzene oxidation to phenol.

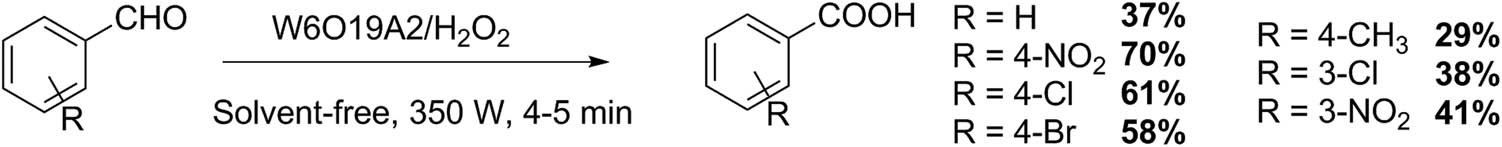

Bamoharram et al. [88] reported the selective oxidation of aldehydes, particularly benzaldehydes to carboxylic acid derivatives, using tetrabutylammoniumhexatungstate (VI), [(n-C4H9)4N]2[W6O19] (W6O19A2) (Scheme 26). For comparative purposes the reactions were alternatively tested using conventional heating and microwave radiation/irradiation. In a representative test, benzaldehyde (1 mmol), catalyst (0.03 g), and hydrogen peroxide (30 mmol) were mixed thoroughly in a small beaker. The reaction mixture was placed in a microwave oven and irradiated for 4–5 min at 350 W. The reaction product was recovered by adding aqueous HCl and filtered. Seven examples of aldehydes were tested, and the carboxylic acids were obtained (45–70%) in a very short time (4–5 min vs 6–8 h, in conventional heating). The reaction yield under microwave irradiation was: 4-nitrobenzaldehyde > 4-chlorobenzaldehyde > 4-bromobenzaldehyde > 3-nitrobenzaldehyde > 3-chlorobenzaldehyde > benzaldehyde > 4-methyl benzaldehyde, indicating that substrates with strong electron-attracting groups lead to better reaction yields.

Aldehyde oxidation to carboxylic acids.

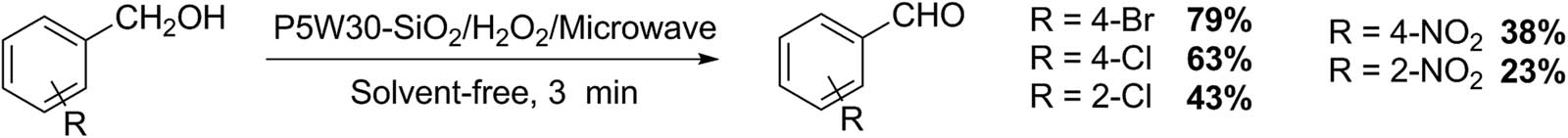

The same group described a suitable procedure for aldehyde oxidation, but in this case the study was carried out using a Preyssler catalyst and H2O2 as oxidizing agent, under microwave irradiation or by conventional heating (70°C) [89]. The catalyst was used in bulk and supported on silica [89,90]. In a classic experiment, benzaldehyde (1 mmol), supported catalyst (0.04 g), and hydrogen peroxide (2 mL) were mixed in a small beaker, and the reaction mixture was irradiated for 1–2 min at 1,100 W. Very good yields of the corresponding carboxylic acids were obtained for 5 aldehydes (70–100%) in less than 2 min, 8 h being the necessary time to reach the maximum yields by means of conventional heating at 70°C. Only traces of the product were obtained by carrying out the reaction using aldehydes that contain −OH groups in their structure [89]. Similarly, these same authors reported the use of nano-SiO2-supported Preyssler (P5W30-SiO2), obtained by sol–gel method (Scheme 27). Benzyl alcohol (1 mmol), P5W30-SiO2 (0.03 g), and hydrogen peroxide (6 mL) were irradiated for 3 min. After cooling to 20°C, the mixture was filtered and analyzed by GC. Five examples of benzaldehydes were obtained with a yield between 15% and 70% depending on the substituent, in a short time of 3 min compared to the classical heating method (6–10 h) [90].

Benzyl alcohol oxidation to benzaldehydes.

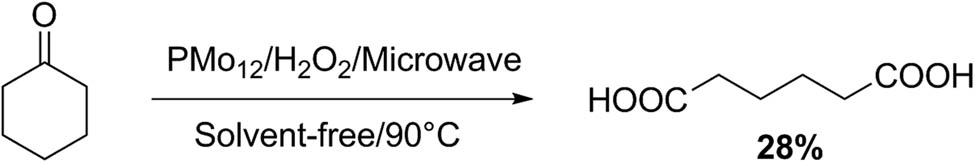

Adipic acid is a relevant precursor in nylon manufacture. Idrissou et al. [91] studied cyclohexanone oxidation using a PMo12 heteropolyacid as catalyst in the presence of H2O2 (Scheme 28). Both procedures, conventional (90°C) and microwave irradiation (100 W) were checked, and several parameters that include solvent, temperature, hydrogen peroxide concentration, and cyclohexanone/catalyst were tested. For both the procedures, the best adipic acid yields (26–28%) were obtained in solvent-free conditions, with H2O2 (30%) as oxidant. Secondary products such as glutaric and succinic acids were also obtained. Microwave technology saves time (30 min vs 20 h) and energy when compared to the usual heating method.

Cyclohexane oxidation to adipic acid.

Adipic acid can be obtained from cyclohexanone in moderate yields under microwave irradiation using ammonium phosphomolybdate with Wells–Dawson structure as catalyst and hydrogen peroxide. The results show that under the optimized conditions, i.e., temperature of 100°C, microwave power of 400 W, irradiation time of 3.5 h, the yield of pure adipic acid was about 73% using a catalytic amount (1%) of catalyst. The reaction yield after five reuses of the catalyst exceeded 43% [92].

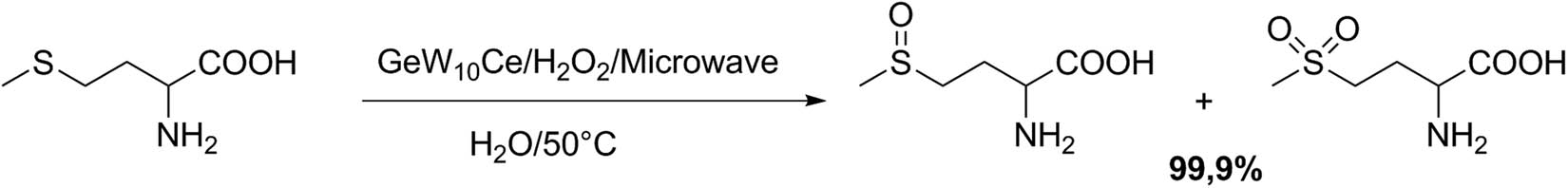

Quasim et al. [93] reported the preparation and characterization of peroxo-cerium-containing POMs via the synthesis of 9-peroxo-6-cerium(iv)-containing 30-tungsto-3-germanate, [Ce iv 6(O2)9(GeW10O37)3]24 − (GeW10Ce). This recyclable homogeneous catalyst was employed successfully in the selective microwave-activated sulfoxidation of the model substrate methionine to sulfoxide (in the absence of hydrogen peroxide), and to sulfone in the presence of hydrogen peroxide/catalyst (Scheme 29). The oxidation of dl-methionine (S) to the corresponding sulfoxide was performed by dissolving the substrate (0.067 mmol) in 2.5 mL of water, then the catalyst (0.009 mmol) was added, and the solution was heated by microwave irradiation (power of 30 W) at 50°C for 50 min. Moreover, the oxidation of dl-methionine to the corresponding sulfone was performed by dissolving the substrate S (0.087 mmol), catalyst (0.0084 mmol), and 0.05 mL of 30% H2O2 (0.75 mmol) in 2.5 mL of water. The reaction mixture was heated by microwave irradiation at 50°C (power of 30 W) for 35 min. The yields of two procedures were practically quantitative [93].

Selective oxidation of methionine.

Bonchio et al. [94,95] studied the organic–inorganic hybrid complexes based on lacunary polyoxotungstates and organosilanes or phosphonic reagents in the selective oxidation of several organic substrates that include alkenes, sulfides, sulfoxides, alcohols, and ketones, using hydrogen peroxide as suitable oxidant. In a representative test for sulfide oxidation, POM (0.8 µmol), substrate (0.25 mmol), 35% H2O2 (0.1 mmol), and CH3CN (0.6 mL) were irradiated with microwave (120°C, 240 W, 25 min). Yields up to 99%, with high selectivity, were obtained in 25–50 min depending both on the POM structure and on the organic moiety, under microwave irradiation [94]. The same group reported the use of transition metal substituted POMs with redox active center (Ru, Fe, and Mn). The microwave irradiation induces an efficient and selective oxidation of DMSO and cyclohexanone oxidation, using different oxidants that include NaIO, KHSO4, and PyClNO, in oxygen atmosphere [95,96]. The inclusion of this type of POM complex salt in bicontinuous microemulsion allowed obtaining materials with self-cleaning properties which enabled to displace fouling, thanks to the oxygenic activity of chemically anchored POM [97]. The surfactants may be used to anchor nanoparticles on the surface of the polymeric membrane surface through noncovalent interactions [98].

Another topic of current relevance is biomass valorization. The preparation and characterization of novel catalytic materials with relevant activity and stability for biomass depolymerization and valorization in chemical products have been a hot topic in chemistry for the last years. Solid catalysts are often the most viable alternative to liquid mineral acid catalysts for waste generation reduction and a very simple catalyst separation. Numerous works have highlighted the use of HPAs and derivatives in biomass valorization. However, there are few works that refer to the use of alternative heat sources such as microwaves [12,99,100,101,102].

One of the most important biomass transformations using microwave irradiation and HPAs as catalysts is the cascade conversion of cellulose to levulinic acid (LA) or alkyl levulinates. In this regard, Zhang et al. [103] reported a series of Lewis metal-substituent phosphotungstic acids PW12L (where, L = Cu, Sn, Cr, Zn, Fe, oxygen is 39) and PW11L (L = Ti, Zr, oxygen is 40) in LA production. PW12Ti was the most active catalyst with the highest cellulose conversion, giving the highest glucose yield in water and the highest LA yield in a mixture of methyl isobutyl ketone (MIBK) and water. The reaction was tested in the XH-800C computer microwave apparatus. In a test experiment, the reaction mixture contained 0.1 g cellulose, 5 mL of MIBK, 0.5 mL of H2O, and 0.08 mmol catalyst. Heterogeneous HOCH2CH2N(CH3)3H4PW11TiO40 (ChH4PWTi) had been synthesized using choline chloride as organic precursor to achieve higher yields of LA due to its temperature-responsive property, and amphiphilic assembly of the nanoreactor to concentrate substrates, stabilization of LA by its environment surroundings. The conversion and yield of LA using ChH4PWTi as catalyst were 93.7% and 70.9%, respectively, using microwave irradiation (100°C, 180 min) [103].

The same group reported a synthesis of a triple-functional POM Cs [HGeNbO] (CsGeNb) and its evaluation for its catalytic activity in the synthesis of methyl levulinate (ML). High conversion of cellulose (86.0%) and a higher yield of ML (55.4%) were obtained under the optimized reaction conditions: 0.1 g cellulose, 0.04 mmol catalyst, and 6 mL of methanol at 165°C for 3 h [104].

Analogously, this group reported the use of a series of Lewis acid metals monosubstituted phosphotungstic acids PW12L and PW11L in the direct production of ML from cellulosic biomass. PW11Ti was found to be highly efficient for the generation of ML from mono- or polysaccharides, reaching 62.6% ML yield directly from cellulose (microwave irradiation, 2 h) [105].

Finally, Quereshi et al. reported the use of Keggin silicotungstic acid (SiW12) catalyst over zirconia support in LA production. The catalyst evaluation tests were performed using LA and anhydrous ethanol as substrates, under microwave irradiation. Under optimum operating conditions, more than 90% LA conversion with 100% of ethyl levulinate selectivity was obtained at 110°C temperature, 30 min, in the presence of 100 mg of ESZN-4 in a solution containing LA and ethanol in a 1:43 ratio [106].

3 Sonochemistry

Sonochemistry is a broad area of research in chemistry, characterized by the study of chemical transformations associated with the use of ultrasound irradiation (20 kHz to 10 MHz). The chemical effects of ultrasound do not originate from a direct coupling of the acoustic field to the molecular species. Instead, they come from nonlinear acoustic phenomena, primarily acoustic cavitation. The acoustic cavitation generates bubbles in liquids, and the violent bubble collapse during cavitation causes extreme local temperatures (up to ∼5,000°C), heating/cooling rates (up to ∼10 billion°C·s−1), and pressures (up to ∼1,000 atm), giving rise to many chemical (sonochemical) reactions [107,108,109].

During the last three decades, substantial academic and industrial efforts have been made to protect the environment by redesigning polluting processes and reducing waste generation. Sonochemistry has gained considerable importance in a lot of research areas including nanomaterial synthesis, spent nuclear fuel, biodiesel production, and food chemistry. Due to these versatile properties, ultrasound is a powerful tool to carry out different chemical organic reactions, for example, bioactive heterocycles in high yield and selectivity, shorter reaction times, and easier work-up conditions compared to the conventional procedure. The literature reports several review articles associated with the use of microwaves in organic synthesis and more recently, environmentally friendly conditions as well [6,110,111,112,113,114,115,116,117,118].

In addition, the important thing about this technology is that it not only allows assisting in chemical transformations, but also in the synthesis of materials that can be used as catalysts in the respective transformations, contributing to the reduction in energy consumption in both stages of the process [119,120,121].

The different contributions in the synthesis of organic compounds using HPA catalysts, and the use of ultrasound as an energy source are indicated below.

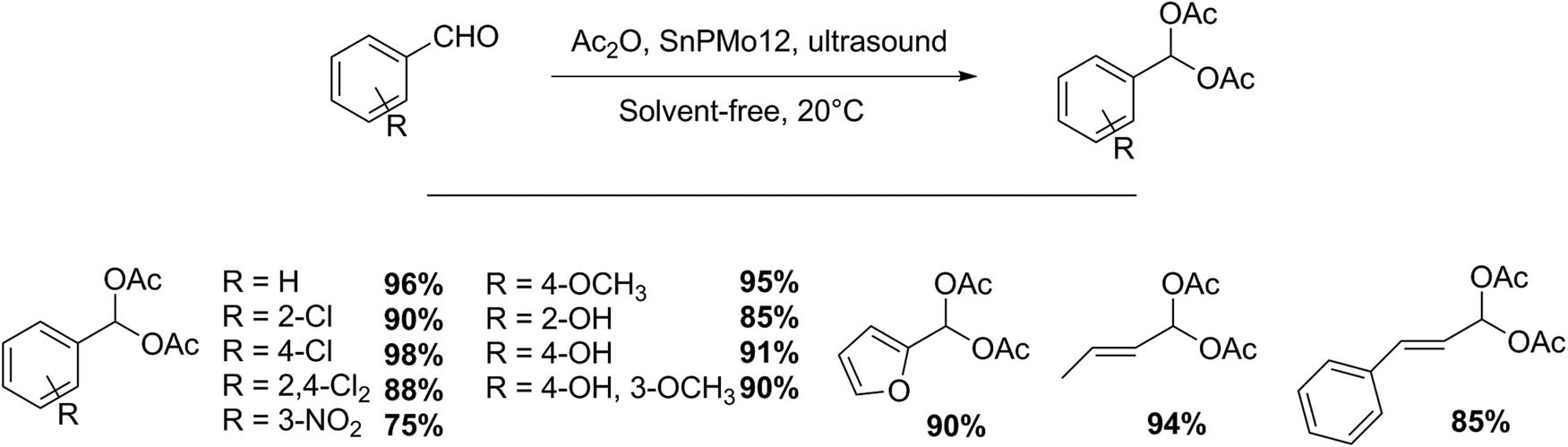

Several simple transformations have been studied using HPAs as catalysts and ultrasound as promoter, for example, Ai et al. [122] obtained acylals from different aldehydes and acetic anhydride in the presence of Keggin-type stannum(iv) phosphomolybdate at 20°C under ultrasound irradiation (Scheme 30). In an experiment test, a mixture of aldehyde (30 mmol), Ac2O (60 mmol), and 0.50 g SnPMo12 was irradiated with ultrasound. The products were monitored by GC, and purified by recrystallization. Twelve acylals were obtained with excellent yields (75–98%, 0.2–2.5 h). In the same conditions, aldehyde containing hydroxyl groups were triacetylated [122].

Acylal synthesis.

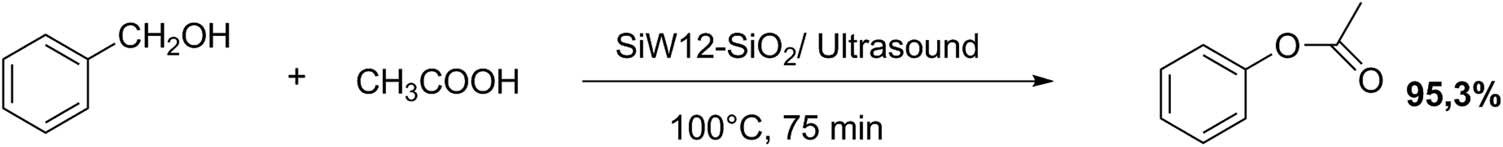

Chen et al. [123] reported a kinetic study about the preparation of benzyl acetate from benzyl alcohol and glacial acetic acid using SiW12 supported on silica (Scheme 31). Under optimized conditions, the esterification yield was 95.3%. The optimized conditions were 10 kHz ultrasonic frequency and 1.0 W·cm−2 ultrasonic intensity; reaction temperature, 110°C; amount of catalyst used, 1.5 g; molar ratio of benzyl alcohol to glacial acetic acid, 1.5; reaction time, 75 min.

Esterification reaction for benzyl acetate synthesis.

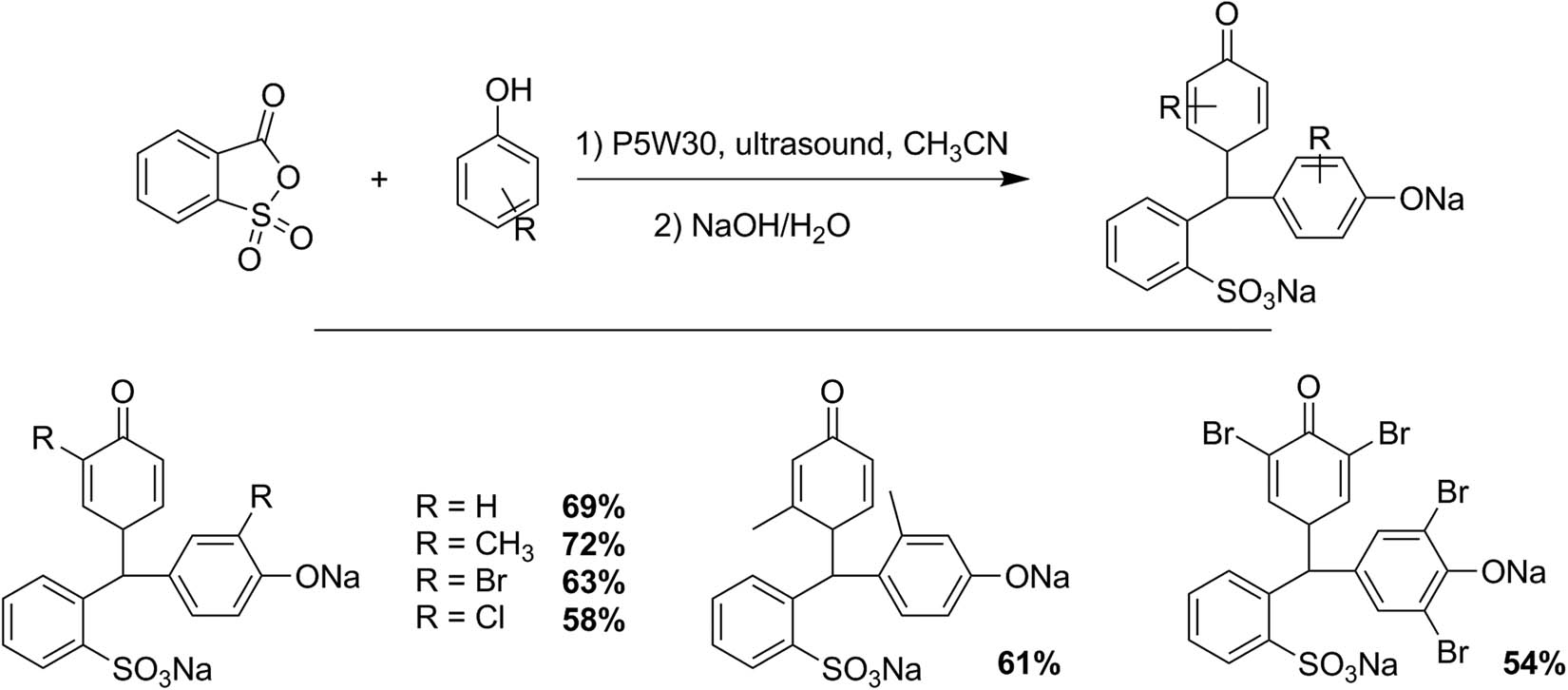

Hamidian et al. [124] reported a synthesis procedure of hydroxytriarylmethane derived from the reaction between 2-sulfobenzoic anhydride and phenols with Preyssler HPAs under ultrasonic irradiation (Scheme 32). The general procedure involves a mixture of 2-sulfobenzoic anhydride (20 mmol), phenol derivatives (60 mmol), and a catalytic amount of P5W30 (0.03 mmol) in acetonitrile (10 mL). The reaction mixture was irradiated under ultrasound at 55–65°C. When the reaction ended (TLC), the catalyst was filtered, and the isolated product was purified and characterized. Six products were obtained with yields between 54% and 72% (reaction time: 60–150 min). The P5W30 catalyst was recovered and reused without appreciable loss of the catalytic activity [124].

Hydroxytriarylmethane synthesis.

Undoubtedly, the great contribution of ultrasound coupled with HPAs is given in the synthesis of potentially active heterocycles. Different heterocycle structures have been prepared through sustainable processes such as multicomponent reactions with high atom economy. Some of the synthesized heterocycles include: pyridines, pyrimidines, thiazoles, indoles, quinoxalines, and pyrans.

Compounds containing pyridine substructure have great importance in organic synthesis due to their medicinal and biological activities, for example, neuroprotective, anti-inflammatory, antitubercular, hepatoprotective, cardiovascular, antidiabetic, and antianginal activities, among others [5,125]. Particularly, 2-amino-3-cyanopyridines possess different bioactivities, such as antibacterial, antimicrobial, antiviral, antifungal, and antihypertensive, among others [126,127].

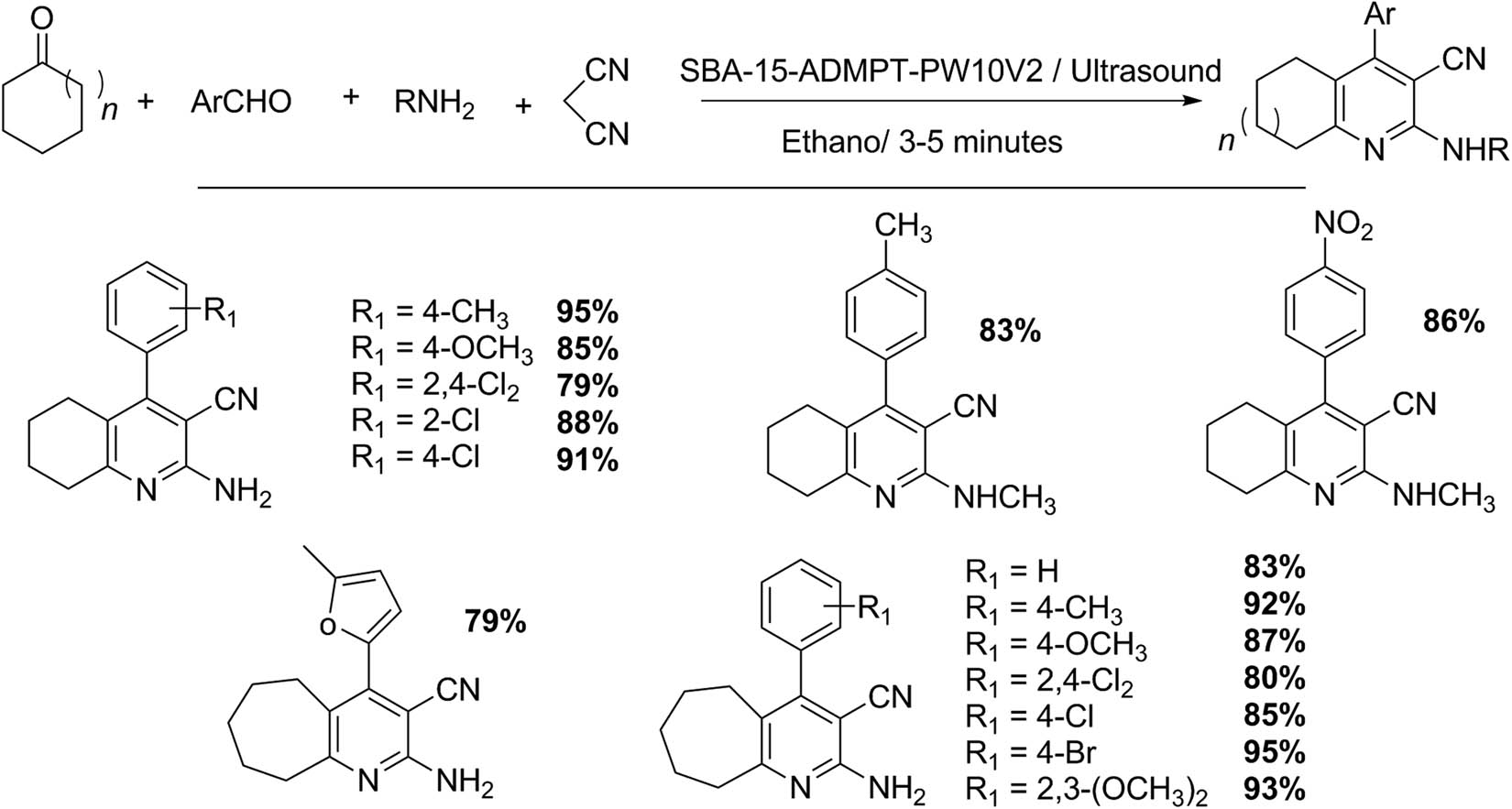

These compounds were obtained via one-pot, four-component condensation reaction (Scheme 33) using hybrid catalysts composed of vanadium Keggin HPA anchored on mesoporous materials such as SBA-15 under ultrasound green approach [126]. The HPA (H5PW10V2O40) was immobilized on SBA-15@ADMPT, where AMDMT (4,6-bis(3,5-dimethyl-1H-pyrazol-1-yl)-1,3,5-triazine) acts as anchoring agent. The test reaction was studied with malononitrile (1 mmol), ketone (1 mmol), and ammonium acetate or amine (1.5 mmol) in 5 mL ethanol solution containing the aromatic aldehyde 1 (1 mmol) with SBA-15-ADMPT-PW10V2. The reaction mixture was irradiated with ultrasound with a power of 50 W (3–5 min). The product was recrystallized from aqueous ethanol, and the catalyst was recycled, dried at room temperature, and activated at 80°C for 2 h. The catalyst reuse gave similar results in comparison to the fresh one. By using this methodology, 15 examples (77–95%) were reported, which include several operating advantages compared to other previous methods, for example, very short reaction time (3–5 min), mild reaction conditions, and simple catalyst recycling [126].

2-Amino-3-cyanopyridine synthesis.

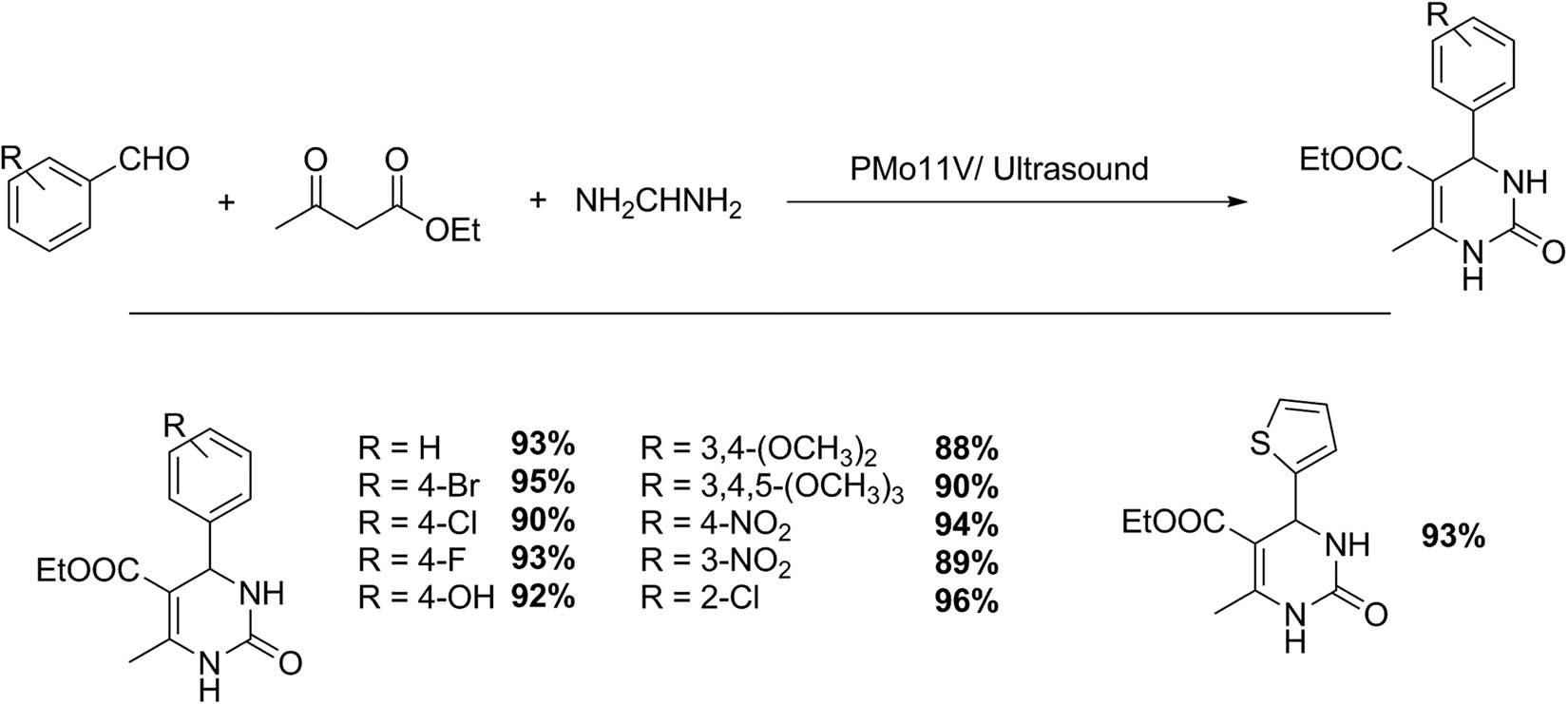

The synthesis of 3,4-dihydropyrimidin 2(1H)-ones through Biginelli reaction between aldehydes, urea, and ethyl acetoacetate (Scheme 34) was also performed using a kegging HPA H4PMo11VO40 (PMo11V) that was prepared and characterized appropriately and assisted with ultrasonic irradiation. The mixture of ethyl acetoacetate (1 mmol), aromatic aldehyde (1 mmol), and urea (1.5 mmol) in the presence of PMo11V (0.1 g), and ethanol, as reaction solvent, was irradiated with ultrasonic waves for 20–42 min at 20°C. The catalyst was recovered from the reaction mixture by filtration and dried (4 h at 120°C) in an oven prior to its reuse. The conversion decreased from 90% to 81% between the first and third catalytic cycles. The product was recovered from the reaction mixture by adding water and filtering the resulting solid. Then, it was recrystallized from ethanol to give the pure product. Eleven 3,4-dihydropyrimidin 2(1H)-ones were obtained with very good yields (88–96%) and excellent selectivity [128].

3,4-Dihydropyrimidin 2(1H)-ones.

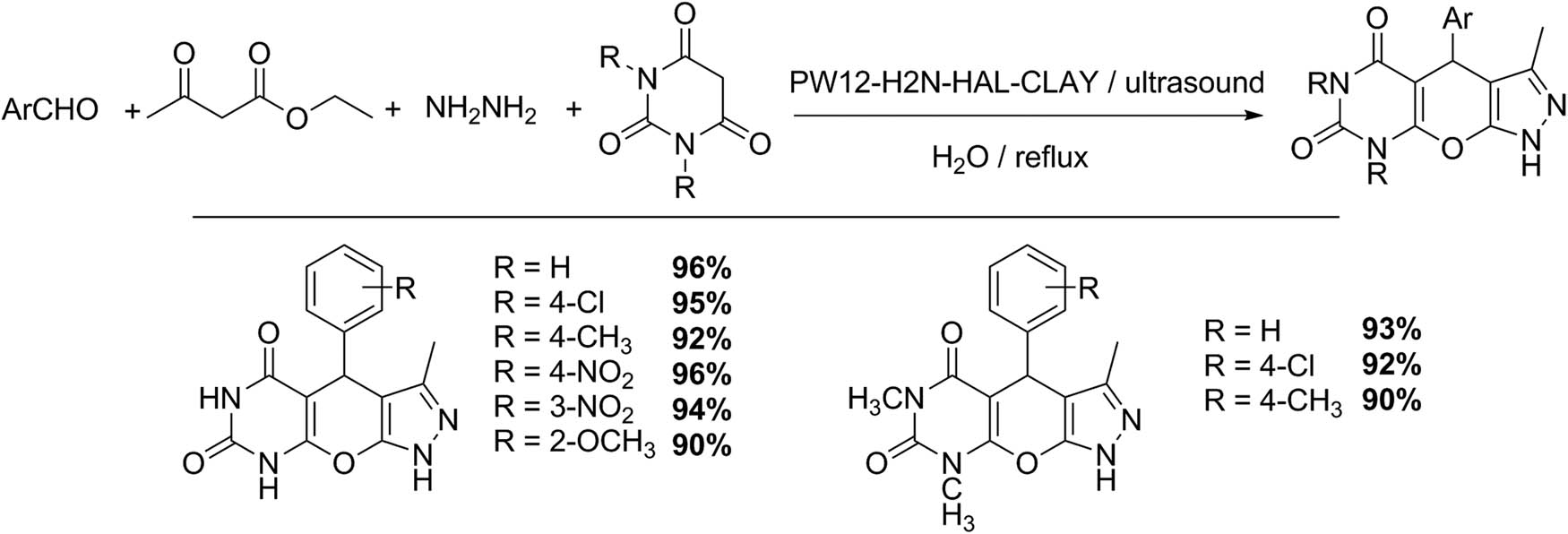

Heravi et al. [42] reported the synthesis and characterization of a Keggin HPA PW12 supported on amine-functionalized halloysite nano clay (PW12–H2N–HAL–CLAY) as a suitable catalyst for the pyrazolopyranopyrimidine synthesis through a domino multicomponent reaction. The four-component procedure involved the reaction between an aldehyde, hydrazine hydrate, ethylacetoacetate, and barbituric acid (Scheme 35). In a classic test for pyrazolopyranopyrimidine synthesis, a solution of hydrazine hydrate (1.1 mmol) was added to ethyl acetoacetate (1 mmol). Then, barbituric acid (1 mmol), the aldehyde (1 mmol), and the PW12–H2N–HAL–CLAY catalyst were added, and the mixture was refluxed in water (similarly, for comparative purposes, the reaction was tested using ultrasound and microwave irradiation). The pyrazole derivative was purified by recrystallization from ethanol. The catalyst was easily recycled, and no changes in the catalytic activity were detected [42].

Pyrazolopyranopyrimidine synthesis.

Nine examples of pyrazolopyranopyrimidines were obtained with excellent yields (90–96%), and a reaction time between 30 and 50 min.

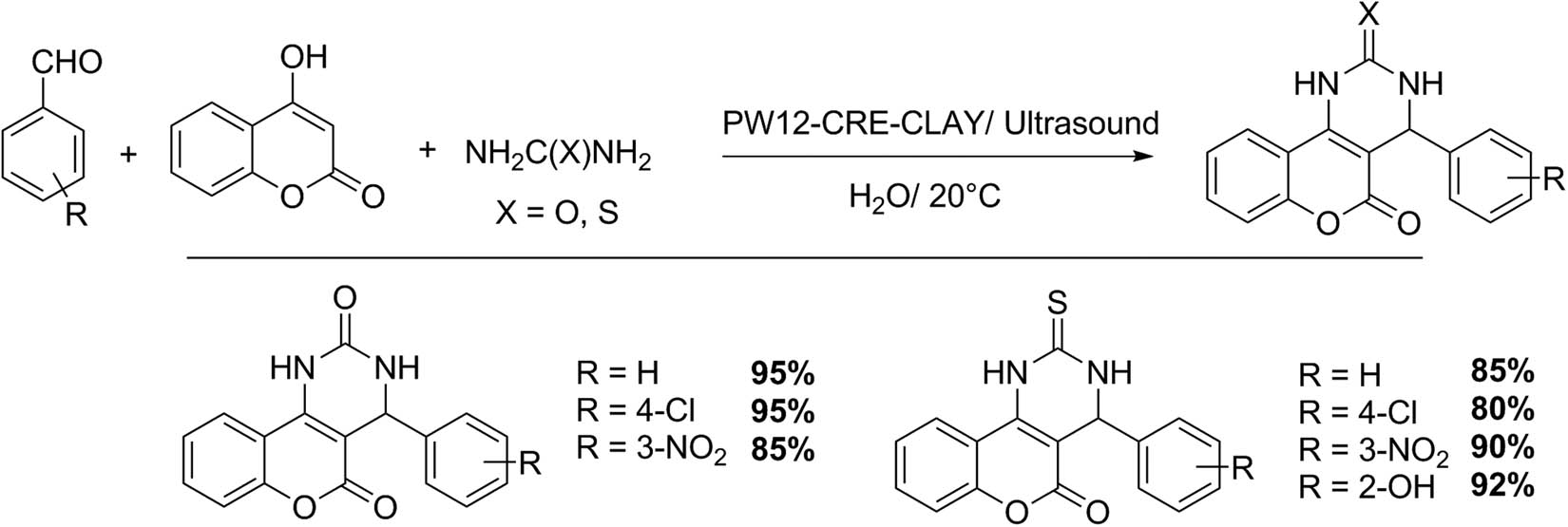

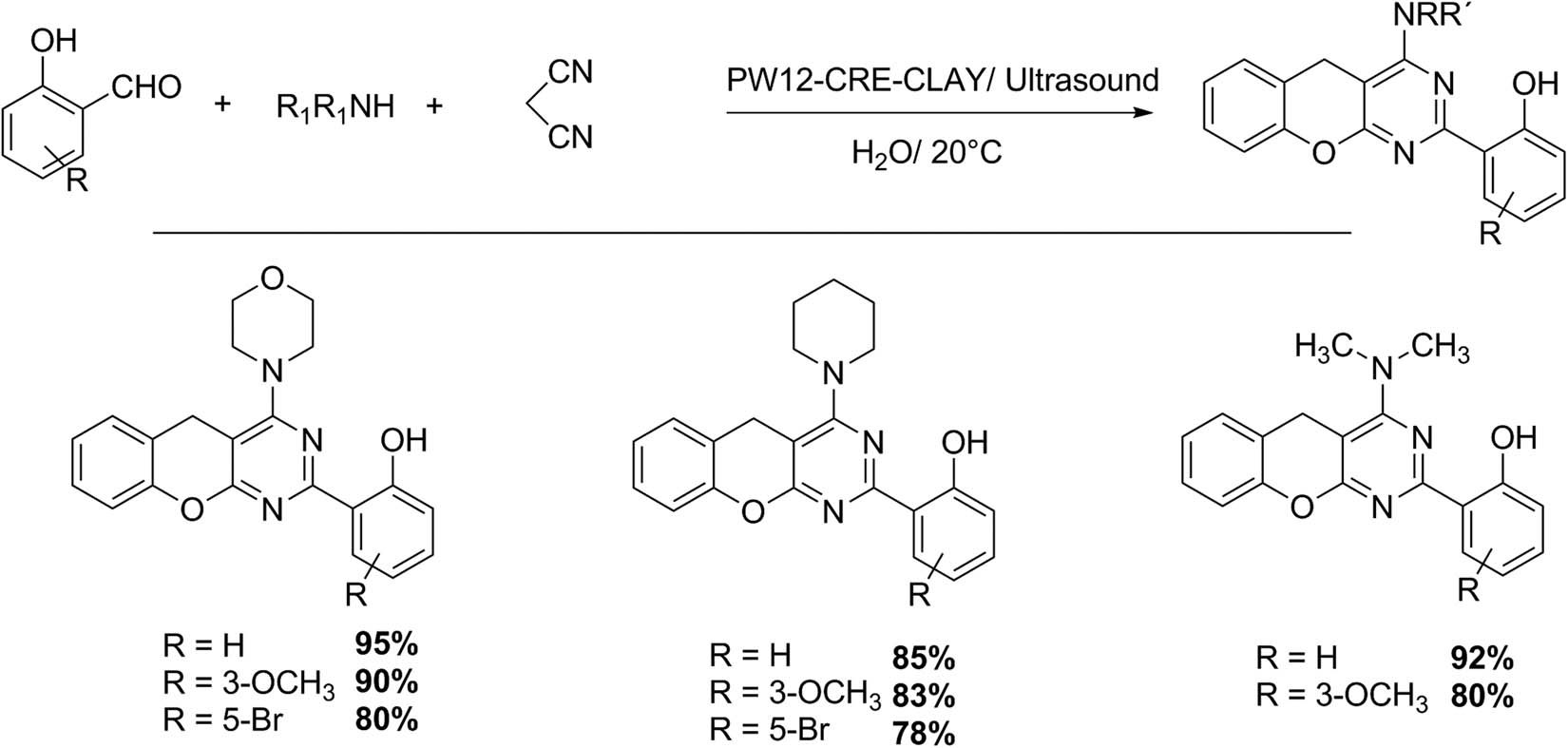

Similarly, the same group studied the synthesis of two families of benzopyranopyrimidines with a hybrid catalyst based on the incorporation of Keggin HPA into creatin-functionalized halloysite clay (PW12-CRE-CLAY). Ultrasonic irradiation and the use of water as a solvent were two main aspects to consider this process more environmentally friendly (Schemes 36 and 37). The first series of benzopyranopyrimidines was synthetized by the following protocol: a mixture of a corresponding aldehyde (1 mmol), urea or thiourea (1 mmol), 4-hydroxycoumarin (1 mmol), and a catalytic amount of Keggin-based materials, in water (10 mL), was irradiated with ultrasonic irradiation at 20°C (4–22 min). Ethanol was used to obtain the recrystallized product, showing seven examples with yields of 80–95% [129].

Benzopyranopyrimidine synthesis.

Benzopyranopyrimidine synthesis (family two).

The second series of benzopyranopyrimidines was synthesized using malononitrile (1 mmol), 2-hydroxybenzaldehydes (2 mmol), and amines (1 mmol) in the presence of PW12-CRE-CLAY. Eight examples illustrate the scope of this procedure, obtaining yields of 78–95% [129]. Both protocols represent a clean alternative for benzopyranopyrimidine synthesis in terms of short reaction time, high yields, environmentally friendly solvent, and reusable catalyst [129].

It is well known that the indole skeleton is present in natural products of the alkaloid family. Indoles and their related molecules have a wide range of pharmacological properties, for example, antibacterial, antihypertensive, antitumor, and anti-Alzheimer’s, among others. Recently, bis-indoles (molecules that contain two interconnected indole substructure residues), presenting novel and very relevant properties, such as powerful anticancer agents, have been found. They are also intermediate products in research and medicinal industry, and important building blocks in pharmaceutical ingredients [130,131].

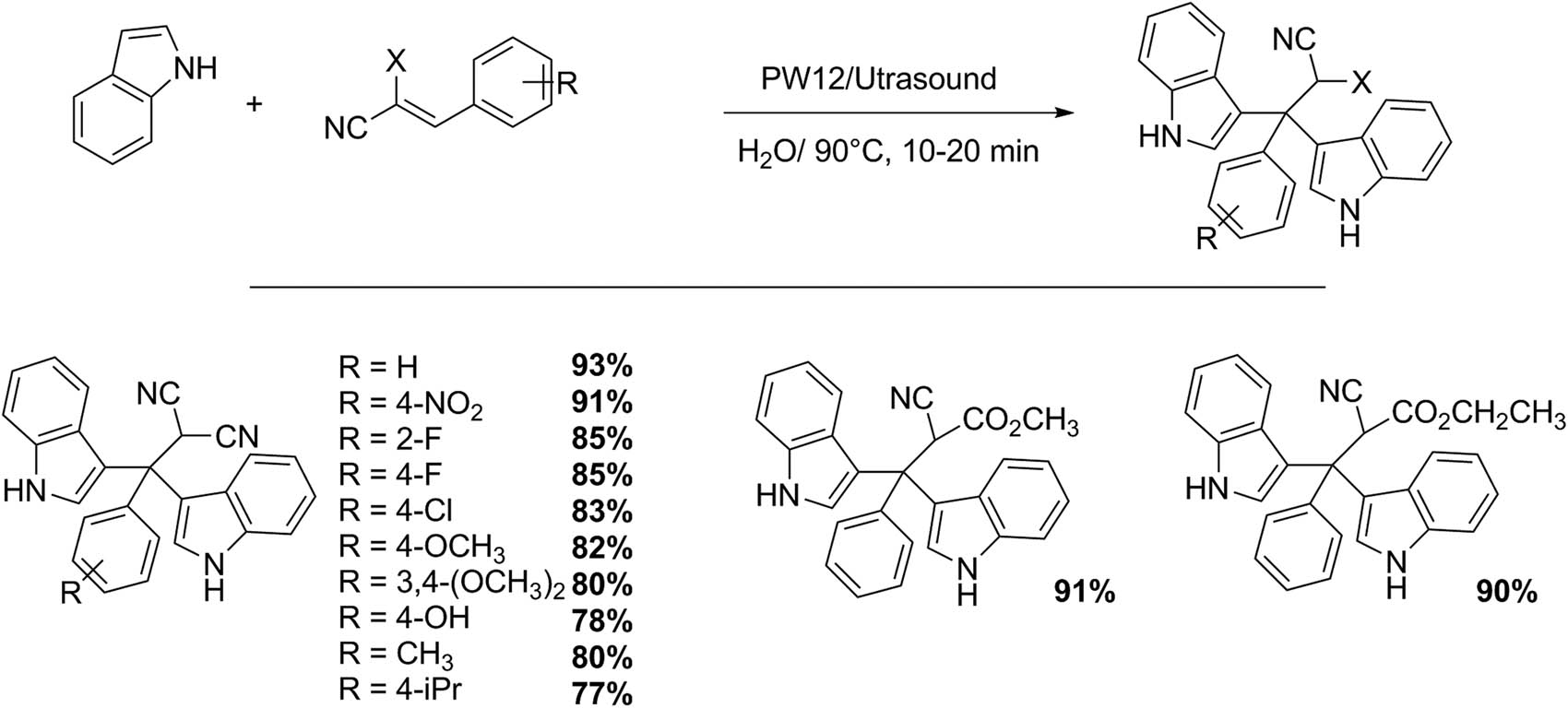

Rahimi et al. [131] reported the reaction of indole with electron-deficient alkenes (Scheme 38). This protocol allows the bis(indole) compound synthesis using water as solvent and ultrasound irradiation. This methodology is assisted by 12-tungstophosphoric (PW12). A mixture of indole (1 mmol), alkene (0.5 mmol), and PW12 (3 mmol) was irradiated (70 W) at 90°C to obtain a solid product after purification by liquid chromatography. Sixteen examples were obtained with excellent yields (77–93%) in 10–20 min. The methodology reported has several advantages such as short reaction time, operational simplicity, environmentally friendly solvent and catalyst, and high selectivity and product yields.

Bis-indole synthesis.

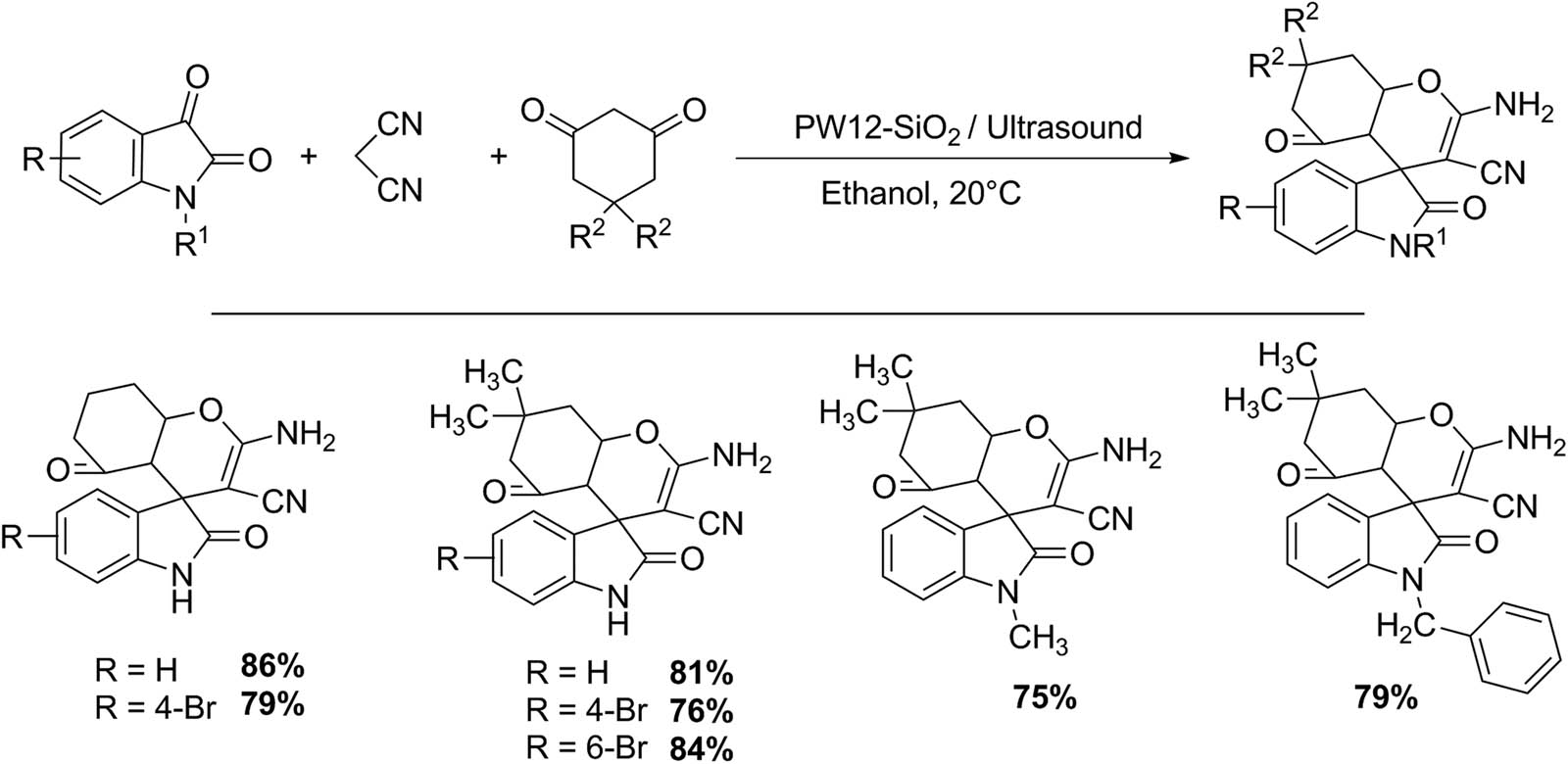

Spirooxindoles can be obtained by multicomponent preparation with isatin (1 mmol), malononitrile (1 mmol), and cyclohexane-1,3-dione (1 mmol) in the presence of a Keggin HPA supported on silica (PW12-SiO2, 8 mmol%) as catalyst, and ethanol as solvent (5 mL) (Scheme 39). The reaction mixture was irradiated by ultrasound. At the end of reaction, the catalyst was separated by filtration, and the residue was recrystallized from a mixture of ethanol/dioxane. Seven spirooxindoles were prepared in a time (6–10 min) with good yields (75–86%). The catalyst can be reused without loss of catalytic activity [132].

Spirooxindole synthesis.

The molecules with benzothiazole core play a vital role in pharmacology, and a great number of compounds present this moiety, including fungicides, antibiotics, anti-inflammatory, antiviral, and anticarcinogenic drugs [133,134].

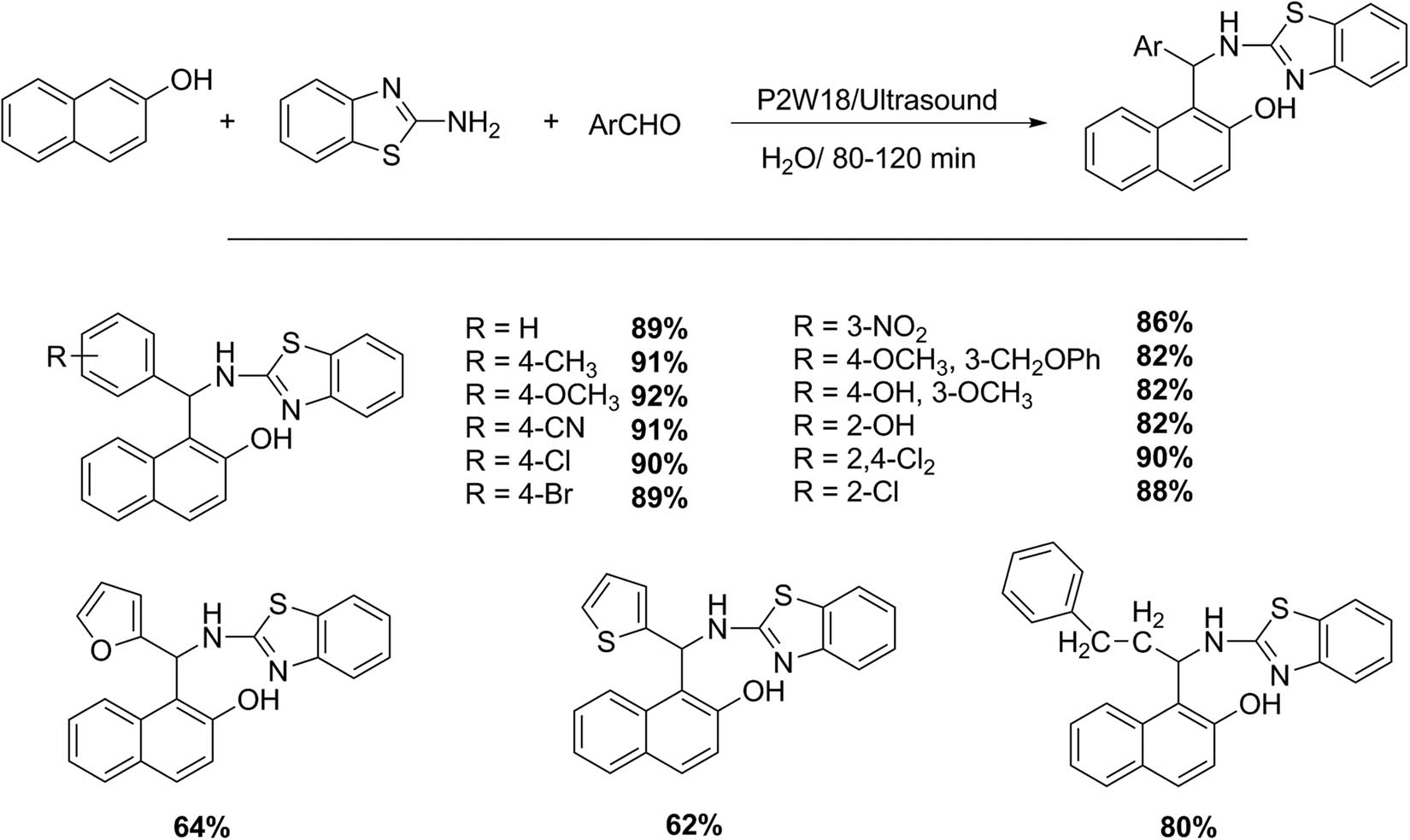

Javanshir et al. [133], using 2-aminobenzothiazole, different aldehydes, 2-naphthol and Wells–Dawson HPA (P2W18) as catalyst at 45°C under ultrasound irradiation, were able to obtain 2-aminobenzothiazolomethylnaphthols (Scheme 40). In a representative experiment, the equimolar mixture of the reagents, in the presence of a 3 mmol% of P2W18 in water (3 mL) as reaction solvent, was sonicated at 45°C for 80–120 min. The reaction mixture was washed with water, and the crude was crystallized from a mixture of water/acetone (Scheme 40). The procedure is very simple and provides very good yields of benzothiazole derivatives (15 examples, 62–92%).

2-Aminobenzothiazolomethylnaphthols.

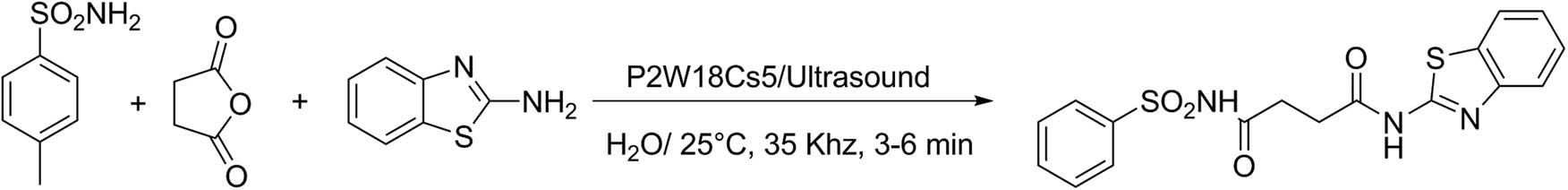

Bougheloum et al. [135] reported a very interesting and efficient work on the synthesis of benzothiazole derivatives containing sulfonamide or cyclic imide moieties (Scheme 41). The reaction was assisted by a Wells–Dawson catalyst (cesium salt of Wells–Dawson HPA, Cs5HP2W18O62 or P2W18Cs5), and ultrasound irradiation in water as reaction solvent. In a representative test, sulfonamide (1 mmol) was added to a mixture of cyclic anhydride (2 mmol) and P2W18Cs5 (10 mmol%), and the mixture was irradiated by ultrasound (35 kHz at 25°C). Then, 2-aminobenzothiazole derivatives were added (additional irradiation, 10 min). At the reaction end, the catalyst was recovered by filtration, and the product was purified by liquid chromatography and recrystallization. Through this protocol, twenty two derivatives of benzothiazoles were prepared, many of which are not reported in the literature (48–92%) [135]. The procedure represents a clean, useful and efficient alternative: one-pot reaction, under ultrasound, and water as reaction solvent.

Benzothiazole synthesis.

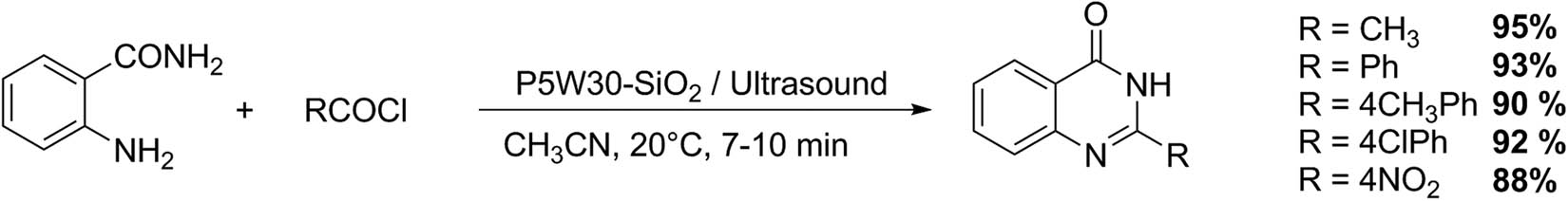

Quinazolinones can be obtained from the reaction between 2-amino-benzamide and acyl chlorides in the presence of silica-supported Preyssler catalyst (Scheme 42). In a test reaction, a mixture of 2-amino-benzamide (10 mmol), acyl chlorides (10 mmol), and silica-supported Preyssler catalyst (3 mmol%), in acetonitrile (10 mL), was irradiated by ultrasound at 20°C (7–10 min). The catalyst was filtered off and reused three times with low loss of catalytic activity. Five examples of quinazolinones were obtained with excellent yields (88–95%), without secondary product formation in a short reaction time. The performance of the Preyssler catalyst included in silica (P5W30-SiO2) was significantly higher than that obtained with the bulk Preyssler HPA (88–95% vs 81–91%) [136].

Quinazolinone synthesis.

The pyran heterocycle represents a very important type of 6-membered heterocycles containing oxygen and are an outstanding scaffold for preparing a wide range of heterocycles with biochemical and technological applications. In particular, 4-H-chromenes and pyrazoles are promising medicament precursors [5].

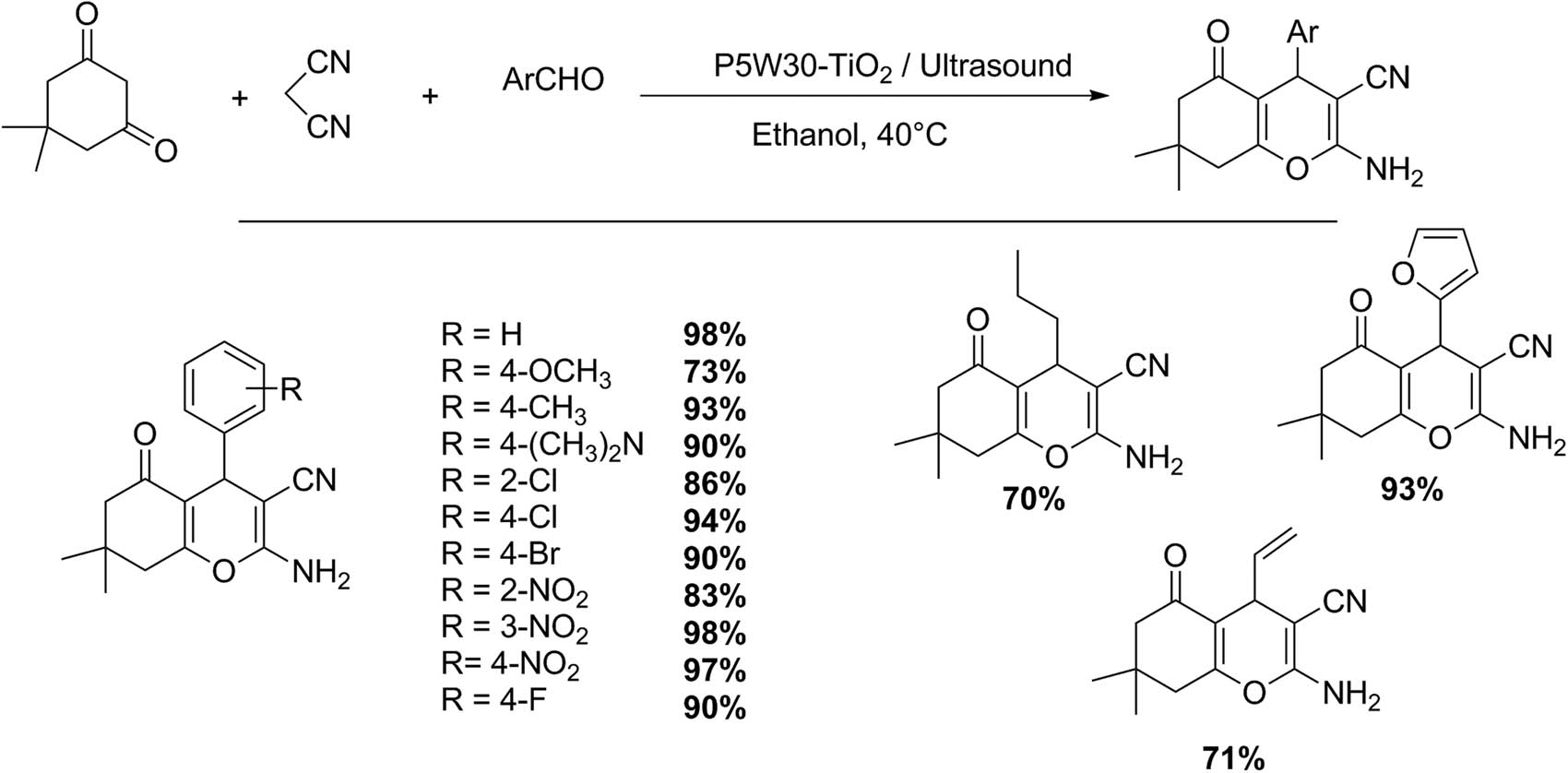

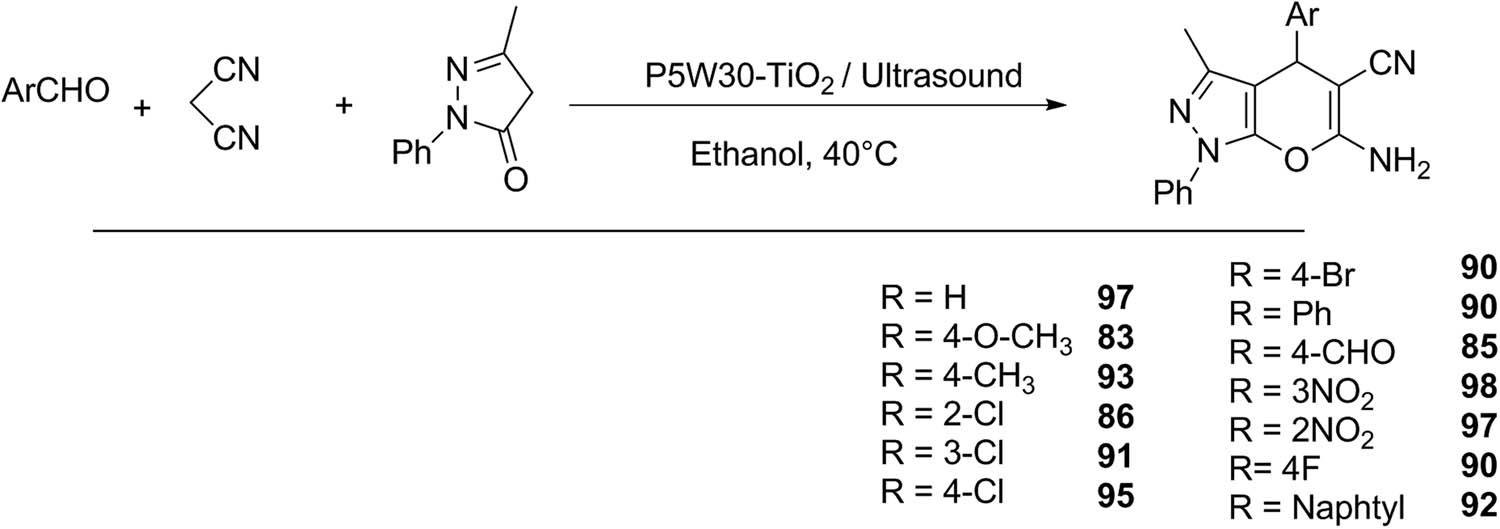

Azarifar group reported the preparation of a new nanotitania-supported Preyssler-type HPA and presented its application in efficient procedures for the synthesis of 4-H-chromene and pyrazole derivatives (Schemes 43 and 44). The reaction is performed using ultrasound, giving quantitative yields of both products. In a representative test, a mixture of malononitrile (1 mmol), dimedone (1 mmol) or 3-methyl-1-phenylpyrazolin-5-one, and an aldehyde (1 mmol), in absolute ethanol (5 mL), was stirred in the presence of catalyst (P5W30-TiO2, 0.0056 mmol%). The reaction mixture was sonicated at 40°C (15–40 min for 4-H-chromenes, and 10–30 min for pyrazole derivatives). After reaction completion the products were purified by ethanol crystallization, and the catalyst was recovered and reused for three consecutive batches without loss of catalytic activity.

4-H-Chromene synthesis.

2,3-Dihydropyranopyrazole synthesis.

In this methodology ultrasound accelerated the multicomponent synthesis of tetrahydrobenzo[b]pyrans (15 examples, 70–98%), and 1,4-dihydropyrano[2,3-c]pyrazole derivatives (13 examples, 83–97%), in the presence of nanotitania-supported Preyssler-type HPA as heterogeneous catalyst [137].

Maleki et al. [138] studied the one-pot synthesis of different functionalized pyran derivatives with NiFe2O4–SiO2–P5W30 in ethanol, at 20°C, under ultrasonic irradiation. The HPA P5W30 (H14[NaP5W30O110]) was immobilized on a nanoparticle core shell with magnetic properties. The authors carried out different types of transformations by alternately changing one or two substrates. In this way, they obtained four families of highly functionalized pyrans.

Initially, the authors optimized the procedure for the synthesis of tetrahydrobenzo[b]pyrans and 2-amino-3-cyano-4H-pyrans, and later used the optimal reaction conditions for the synthesis of various family compounds (Scheme 45). In a representative experiment, ethanol (5 mL) was added to a mixture of aldehyde (1 mmol), malononitrile (1.2 mmol), dimedone (1 mmol), and the catalyst (0.02 g), and the mixture was irradiated under sonication (ultrasonic power 250 W, irradiation frequency 40 kHz), at 20°C. The magnetic catalyst was separated by an external magnetic field. The solution was poured into crushed ice, and the formed product was separated by filtration, and recrystallization from ethanol to give the pure products. Fifteen tetrahydrobenzo[b]pyrans (5–10 min, 80–94%) and six examples (15–35 min, 83–92%) were obtained with very good yield free of secondary products [138].

![Scheme 45

Tetrahydrobenzo[b]pyran and 2-amino-3-cyano-4H-pyran synthesis.](/document/doi/10.1515/gps-2022-0068/asset/graphic/j_gps-2022-0068_fig_045.jpg)

Tetrahydrobenzo[b]pyran and 2-amino-3-cyano-4H-pyran synthesis.

Similarly, through a three-component process that in this particular case involves the reaction between an aldehyde, malononitrile, and 3-methyl-1-phenyl-2-pyrazoline-5-one, six examples of pyrano[2,3-c]pyrazoles were obtained with excellent yields (89–94%, ultrasonic irradiation, 5 min) (Scheme 46) [138].

![Scheme 46

Ultrasound assisted one pot three component synthesis of pyrano[2,3-c]pyrazoles.](/document/doi/10.1515/gps-2022-0068/asset/graphic/j_gps-2022-0068_fig_046.jpg)

Ultrasound assisted one pot three component synthesis of pyrano[2,3-c]pyrazoles.

Finally, the authors explored a one-pot tetracomponent procedure replacing 3-methyl-1-phenyl-2-pyrazoline-5-one with hydrazine hydrate and ethyl acetoacetate in similar reaction conditions. A series of 7 pyrano[2,3-c]pyrazoles was obtained with yields between 90% and 94% (ultrasonic irradiation, 10 min) (Scheme 47) [138].

![Scheme 47

Ultrasound assisted one pot tetra-component synthesis of pyrano[2,3-c]pyrazoles.](/document/doi/10.1515/gps-2022-0068/asset/graphic/j_gps-2022-0068_fig_047.jpg)

Ultrasound assisted one pot tetra-component synthesis of pyrano[2,3-c]pyrazoles.

Tetrahydrobenzo-[b]-pyrans using ultrasonic irradiations and HPA deposited on a magnetic support have been reported by Mozafari and Heidarizadeh (Scheme 48) [139]. The catalyst was prepared using silica-coated manganese ferrite nanoparticles modified previously with diamine groups to obtain a core shell structure labelled MnFe2O4–SiO2@NHPhNH2. The phosphotungstic acid (PW12) was anchored on this support. The reaction is very simple and only requires the mixture of the aromatic aldehyde (1 mmol), malononitrile (1.2 mmol), dimedone (1 mmol), and catalyst (0.04 g). The reaction mixture was sonicated at 80°C in water as reaction solvent. The catalyst was magnetically separated, and the product was extracted with ethyl acetate, and recrystallized from ethanol. Nine tetrahydrobenzo-[b]-pyrans were obtained with excellent yields and a short time (87–94%, 8–12 min) [139]. This same catalyst was used to obtain indazolo[2,1-b]phthalazine-triones. Phthalazine and its derivatives exhibit some bioactivity such as anticancer, antifungal, anticonvulsant, and anti-inflammatory, and are also used in hypertensive therapy [139].

![Scheme 48

Tetrahydrobenzo-[b]-pyrans.](/document/doi/10.1515/gps-2022-0068/asset/graphic/j_gps-2022-0068_fig_048.jpg)

Tetrahydrobenzo-[b]-pyrans.

Then, using the same catalyst, another multicomponent procedure was evaluated. In this case, 2H-indazolo[2,1-b]phthalazine-triones were obtained using easily available starting materials (dimedone, phthalhydrazide, and an aromatic aldehyde) (Scheme 49). In a representative test a mixture of aldehyde (1 mmol), dimedone (1 mmol), phthalhydrazide (1 mmol), and the catalyst (0.03 g) was sonicated at 80°C in the presence of H2O. When the reaction was complete, the catalyst was separated magnetically, the product was extracted with ethyl acetate, and recrystallized. Nine examples of 2H-indazolo[2,1-b]phthalazine-triones were obtained with very good yields (86–95%, 6–12 min) [139].

![Scheme 49

2H-indazolo[2,1-b]phthalazine-triones.](/document/doi/10.1515/gps-2022-0068/asset/graphic/j_gps-2022-0068_fig_049.jpg)

2H-indazolo[2,1-b]phthalazine-triones.

Through this procedure, the synthesis was done under environmentally friendly conditions that include the use of a recoverable magnetic catalyst, ultrasound irradiation as an energy source, and the use of water as a reaction solvent. Furthermore, both procedures were carried out through a one-pot-multicomponent process with high atom economy.

The use of ultrasound irradiation is not limited to organic synthesis; on the contrary, it is a very useful technique in different types of processes that include the manufacture of materials, the degradation of contaminants, assistance in emulsification and extraction processes, and sustainable organic synthesis processes [121,140–143]. The bibliography presents some reviews about synthesis processes related to the oxidation of organic substrates [118,144–146].

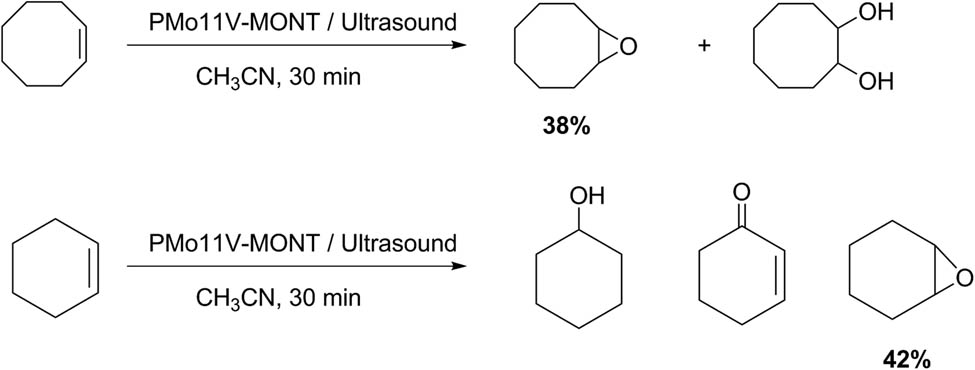

The literature reports some work-related selective oxidation processes in organic synthesis assisted by the use of ultrasound and materials based on HPAs as catalysts. Among them, it is important to highlight the oxidation of alkenes, alcohols, and sulfides, which is of special interest in oxidative desulfurization (ODS) processes of fossil fuels. The approach consists in the deposition of a Keggin-type heteropolyanion compound (PMo11V) on clay supports such as montmorillonite (MONT). Salavati et al. [147] reported that this type of solid (PMo11V–MONT) resulted in efficient and selective catalysts for oxidation of alkenes under ultrasonic irradiation conditions (Scheme 50). The reactions were conducted with 4.76 mmol% of PMo11V-MONT, 0.8 mmol of alkene, 5 mL of acetonitrile, and 1 mL of H2O2. The degree of advancement of the reaction and the selectivity toward the formation of the epoxide were determined by GC analysis. When the reaction was complete, the catalyst was filtered, and the product was purified by liquid chromatography. For cyclooctene oxidation the results showed a conversion of 58% with an epoxide selectivity of 65%. Similarly, the cyclohexene oxidation showed 58% epoxide selectivity with a conversion of 72%. In this case, cyclohexene-1-one and cyclohexene-1-ol were detected as secondary products [147].

Selective alkene oxidation.

By supporting heteropolyanion nanoparticles on materials such as MMT, a recoverable and reusable catalyst was obtained for the selective oxidation of alkenes with hydrogen peroxide. Ultrasonic irradiation notably increased the conversions and reduced the reaction times (for example, from 10 h to 30 min). Seven examples with structural variety were tested with good conversion (28–92%) and selectivity (30–96%).

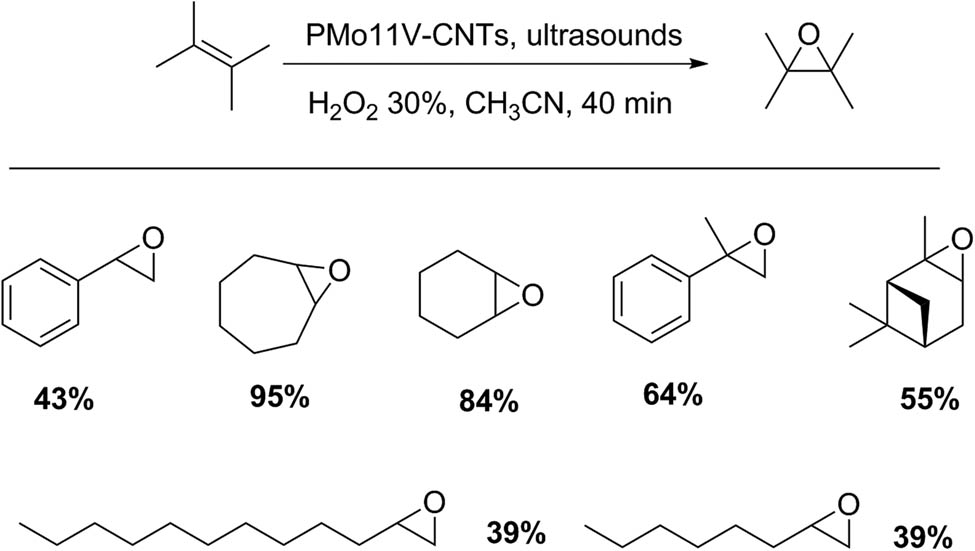

The same authors prepared new materials composed of vanadium-containing polyphosphomolybdate immobilized on multiwall carbon nanotubes (PMo11V-CNTs). Then, the obtained composites were characterized and were found to be an efficient catalyst for selective alkene oxidation under ultrasonic irradiation conditions. In a typical experiment, for example, hydrogen peroxide (1 mL, 30%) was added to styrene (0.8 mmol) and the supported catalysts (2.86 mmol% of PMo11V) in acetonitrile (5 mL), and the mixture was exposed to ultrasound irradiation (frequency, 24 kHz, and output power, 0–400 W). The reaction was monitored by GC. The products were purified by liquid chromatography and identified by 1H and 13C-NMR. For the reaction of styrene oxidation, a yield of epoxide of 43% was detected in a reaction time of 40 min (conversion of 71% and selectivity to epoxide of 60%). The optimal reaction conditions were extended to other substrates of different structural nature, obtaining yields to epoxides between 39% and 84% (Scheme 51) [148].

Epoxidation of olefins.

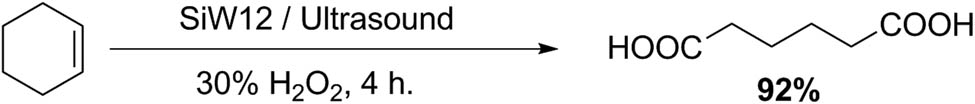

Lin group reported a suitable procedure for adipic acid preparation using a system formed by aqueous hydrogen peroxide and SiW12 under ultrasonication (Scheme 52). In a representative experiment, a round flask was charged with cyclohexene (2 mmol), SiW12 (0.04 mmol), and 30% H2O2 (10 mmol). The reaction flask was irradiated in a cleaning bath for 4 h. The reaction products were isolated by filtration of the reaction mixture, with a yield of 92% [149].

Adipic acid synthesis.

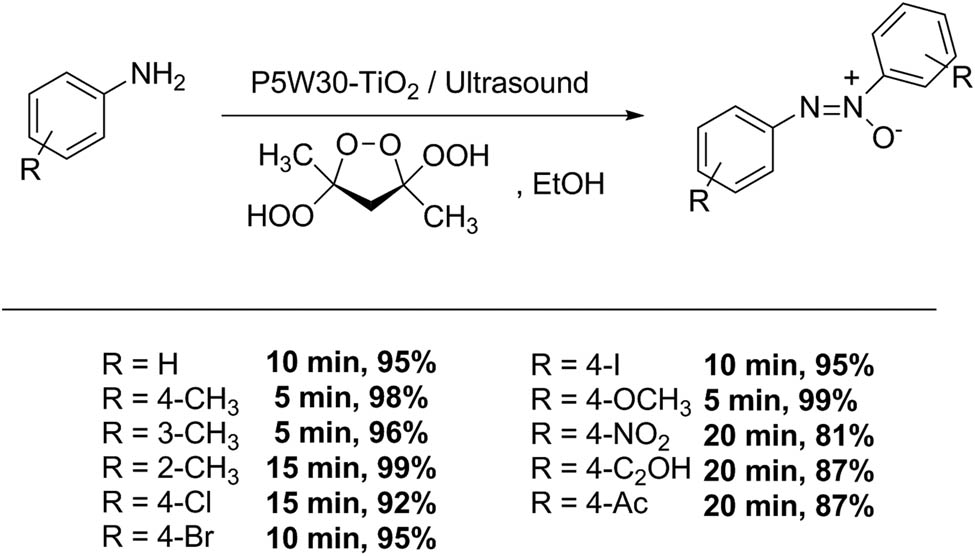

Azarifar et al. reported the use of a Preyssler-type HPA supported on TiO2 nanoparticles as catalyst in the selective oxidation of primary aromatic amines to azoxy derivatives using trans-3,5-dihydroperoxy-3,5-dimethyl-1,2-dioxolane as oxidant (Scheme 53). The transformation proceeded in green conditions assisted by ultrasound irradiation to afford the product with high selectivity. The general procedure consisted in the dissolution of an aromatic amine (1 mmol) and P5W30 nano-TiO2 catalyst (25 mg) in absolute ethanol (5 mL), sonication at 20°C for 5 min, and then trans-3,5-dihydroperoxy-3,5-dimethyl-1,2-dioxolane (2 mmol) was added to the mixture in one portion. After completion (TLC), the catalyst was separated by filtration, and the products were purified by liquid chromatography and recrystallization. Twelve examples were obtained with excellent yields and selectivity (reaction yields between 81% and 98%, reaction time 5–20 min) [150].

Aromatic amine oxidation.

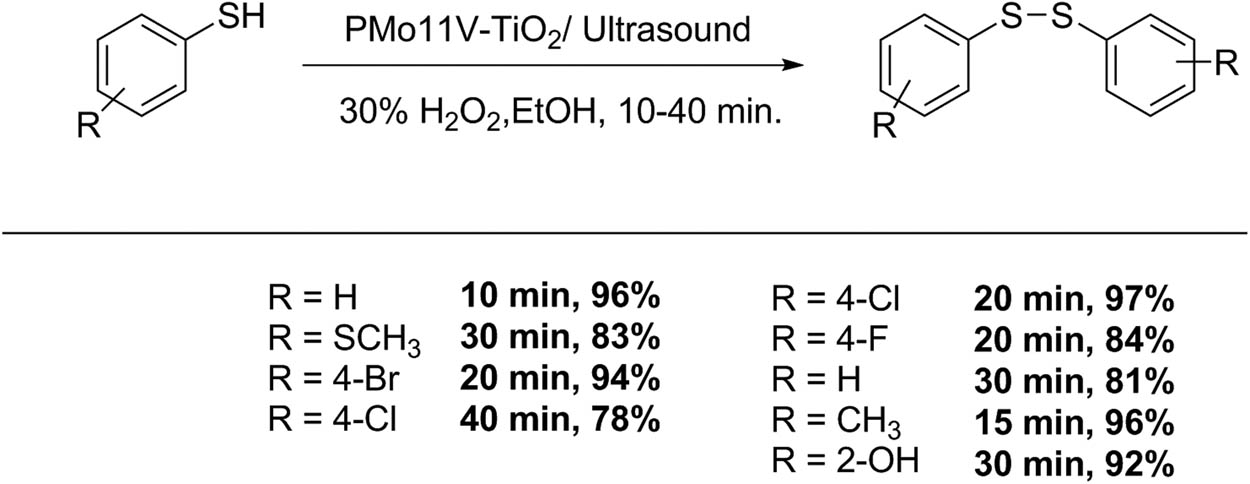

Rezvani et al. [151] described the synthesis and characterization of nanocomposite mixed-addenda vanadium substituted POM-TiO2 and its use as suitable catalyst for a rapid and efficient synthesis of symmetric disulfides for thiol oxidation under ultrasound irradiation, and hydrogen peroxide as green oxidant (Scheme 54). In a representative test of a mixture of thiol (0.5 mmol), and PMo11V–TiO2 (16 mg) in EtOH (8 mL), 2 mL of 30% hydrogen peroxide was added. The reaction was monitored by TLC, and the reaction product was purified by liquid chromatography. Nine examples were obtained (78–97%, 10–40 min) [151].

Disulfide synthesis.

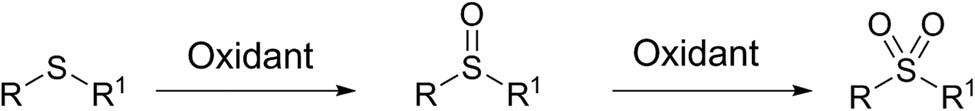

The selective oxidation of compounds containing sulfur in their structure is undoubtedly the most important oxidative process, especially the selective oxidation of sulfides to sulfoxides and sulfones. This is substantially associated with the need to eliminate sulfur-containing compounds that are present in fossil fuels. The elimination of refractory compounds, such as derivatives of thiophene or dibenzothiophenes, present in fuels, is necessary, due to the requirements imposed by current governments related to caring for the environment. Although there are numerous processes that help to comply with these regulations, for example, selective adsorption, extractive distillation, hydrodesulfurization, biodesulfurization, and ODS, among others, in this review we will focus on those associated with ODS, in which HPAs and ultrasounds are used to assist in the process. Most of the proposed works promote the synthesis and characterization of new materials based on HPAs, with the aim of improving the process (Scheme 55).

Oxidation of sulfides to sulfoxides and sulfones.

Specifically, we will focus on highlighting the contributions associated with the oxidation of sulfides assisted with HPAs and ultrasounds [152,153]. Afzalinia et al. [154] reported the ultrasound-assisted oxidative desulfurization (UAOD) of liquid fuels performed with a novel material based on a Keggin-type phosphotungstic acid (PW12) encapsulated into an amino-functionalized MOF (TMU-17-NH2). The experiment tests were performed in a biphasic system, for example, acetonitrile and model fuel, using BT, DBT, or 4,6-DMDBT as substrates. For example, 5 mg of PW12-TMU-17-NH2 was placed in the vessel, then a mixture of acetonitrile (5 mL) and model fuel (5 mL, 2.5 mg of DBT) and finally, H2O2 30% (1:1 oxidant/S-containing compound molar ratio) were added. The mixture was irradiated for 5 min at room temperature, and the reaction progress was evaluated by GC analysis. The best result indicated that the conversions of DBT to DBTO2 achieved 98% after 15 min. The catalyst retained its activity even after six cycles.

Liu et al. [155] reported the application of PW12 supported on activated carbon (AC) in the oxidation-desulfurization of fuel oil assisted by ultrasound. DBT was 100% converted using a volume ratio of H2O2:model oil of 1:10 catalyzed by 1.25% of PW12-AC-10 after ultrasound irradiation for 9 min at 70°C. The reaction catalyzed by supported HPW avoided the use of a phase transfer agent, and the materials were easily separated and reused [155].

Similarly, Gildo et al. [156] presented the use of AC-supported phosphotungstic acid as oxidation synthesis in the selective oxidation of sulfide to sulfoxides and sulfones. In an experiment test, the fuel was prepared using dibenzothiophene, benzothiophene, and thiophene. About 2,800 ppm of sulfur with a fixed composition of DBT, BT, and T was prepared by dissolving certain amounts of these compounds in toluene, then the catalyst and hydrogen peroxide were added, and the reaction was irradiated with ultrasound. The optimal conditions were found to be 25.52 wt% H2O2, 983.9 mg catalyst, 9.52 mL of aqueous phase per 10 mL of organic phase, and 76.6 min of ultrasonication producing 94.7% conversion. Also, the authors reported the use of kerosene and, in this case, the sulfur content was reduced from 1,370 to 14 ppm S, equivalent to 99.0% desulfurization [156].

Wang et al. [157] performed a systematic ozonation (assisted by ultrasound) procedure for desulfurization of diesel oil with some metal salts of Keggin-type HPAs, H3PW12O40. Fe0.8H0.6PW12O40 exhibited the best catalytic activity, and the difficulty of removing sulfur compounds depended on the electron density of sulfur atoms. Sulfur compounds with high electron density were more easily removed. The catalyst could be used four times without appreciable loss of catalytic activity [157].

Yu et al. [158] reported the use of ultrasound in the oxidative desulfurization of diesel fuel in a mixture formed by commercial aqueous hydrogen peroxide and methanol. When the system containing 2 mmol% PW12 was irradiated with 400 W ultrasound for 10 min, the sulfur content dropped from 211 to 19 ppm. The protocol is very simple, rapid, and inexpensive.

Zhao and Wang [159] reported a procedure for ultrasound-assisted catalytic ozonation combined with an extraction process for the removal of dibenzothiophene using acetonitrile as extracting agent. Keggin-type heteropolycompounds, including H3PW12O40, H5BW12O40, Cs2.5H0.5PW12O40, and Ce0.8H0.6PW12O40, were used. The Ce0.8H0.6PW12O40 catalyst exhibited the best catalytic activity (93.2% in 60 min). The catalyst was also recoverable, reusable, and showed activity similar to the fresh material. The result indicates that the assisted ultrasonic-catalytic ozonation process combined with extraction is promising for deep desulfurization of diesel oil [159].

The transformations associated with the valorization of biomass are also important, including processing of biomass and the valorization of its building blocks. The literature reports several examples of the use of catalysis with HPAs assisting in esterification procedures for fuel production. However, there are practically no reports on the use of HPAs-ultrasound for the valorization of building blocks present in biomass [160,161].

Lee group performed numerous studies on the transesterification of crude Jatropha oil to fatty acid methyl esters in an ultrasound-assisted process, in the presence of different HPA-based catalysts [162]. The first studies involve the fatty acid methyl ester synthesis from crude Jatropha oil using an ultrasound-assisted process with different gamma alumina (Al) supported tungstophosphoric acid (PW12-γAl2O3) catalysts. The highest reaction yield of 84% was achieved under the optimum conditions: ultrasonic amplitude of about 60%, a molar ratio of 19:1, and a reaction temperature of 65°C, for 50 min.

The mathematical representation of fatty acid methyl ester (FAME) yield was successfully generated and statistically validated [163]. In this case, the crude Jatropha oil transformation was performed in the presence of tungstophosphoric acid supported on AC (PW12-AC) using ultrasound-assisted process. The catalyst with 20% TPA loading achieved the best methyl ester yield (87.3%, 40 min). The catalysts showed 1% w/w water tolerance, and their reusability and leaching were analyzed on PW12(20)-AC, revealing that the reaction was mainly heterogeneous in nature with an appreciable contribution of homogeneous reaction [164].

Another similar study about transesterification of crude Jatropha oil in the presence of cesium-doped HPA catalyst and assisted by ultrasonic irradiation was conducted by these authors. Different Cs HPA catalysts with different levels of cesium exchange were synthesized, characterized, and tested in order to identify the most relevant catalyst. The most active catalyst (Cs1.5H1.5PW12O40) showed the highest FAME yield of 90.5% (34 min). The reaction was principally of heterogeneous nature, and the yield was constant after three successive reaction cycles [165].

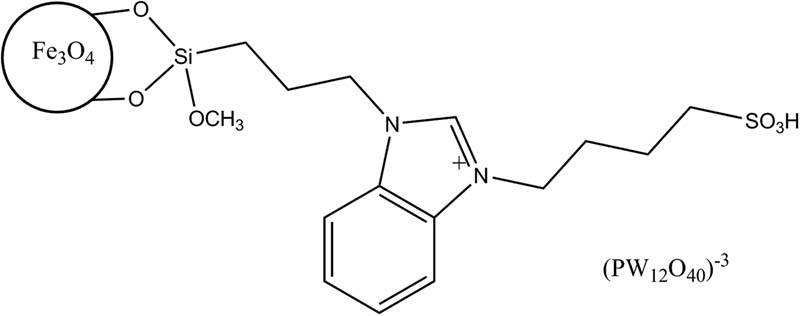

Dadhania et al. [166] presented the synthesis of a magnetically separable heteropolyanion based ionic liquid (MNP@HPAIL, Figure 1), and its catalytic activity was evaluated for biodiesel production through the esterification of long-chain fatty acid under ultrasonic irradiation [166].

Magnetically separable heteropolyanion-based ionic liquid (MNP@HPAIL).

The MNP@HPAIL catalyst showed the maximum conversion in the presence of 150 mg catalyst, an acid-alcohol ratio of 1:10 at 70°C and 60 min. The new material was used in 6 consecutive reaction cycles with the same biodiesel yield.

Another aspect of great interest in the recovery of biomass is the depolymerization of products derived from lignin to monomers of the phenolic type. Du et al. [167] reported the effect of a catalyst (MCM-41 supported phosphotungstic acid) on the yields and characteristics of various depolymerization products of organosolv lignin, using ultrasound irradiation. In general, ultrasound irradiation played important roles in promoting lignin depolymerization and reducing char yield. The best reaction conditions were: temperature, 310°C; reaction time, 6 h; solvent, isopropanol; ultrasound frequency, 30%, and catalyst, 50%. In these conditions, conversions of 95.52% and 98.54% were obtained using liquid fuel and lignin, respectively. The catalyst could be reused five times without loss of catalytic activity.

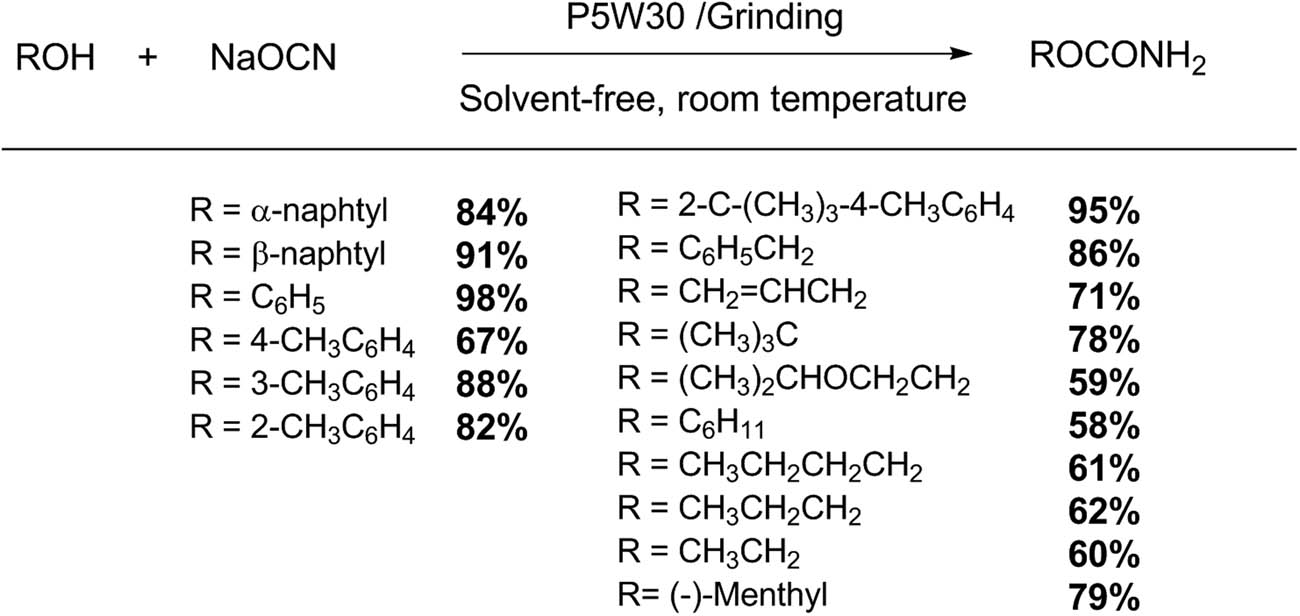

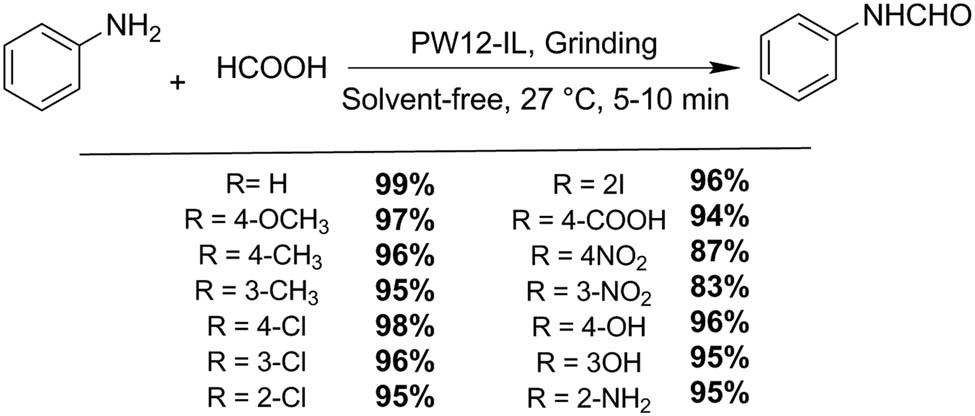

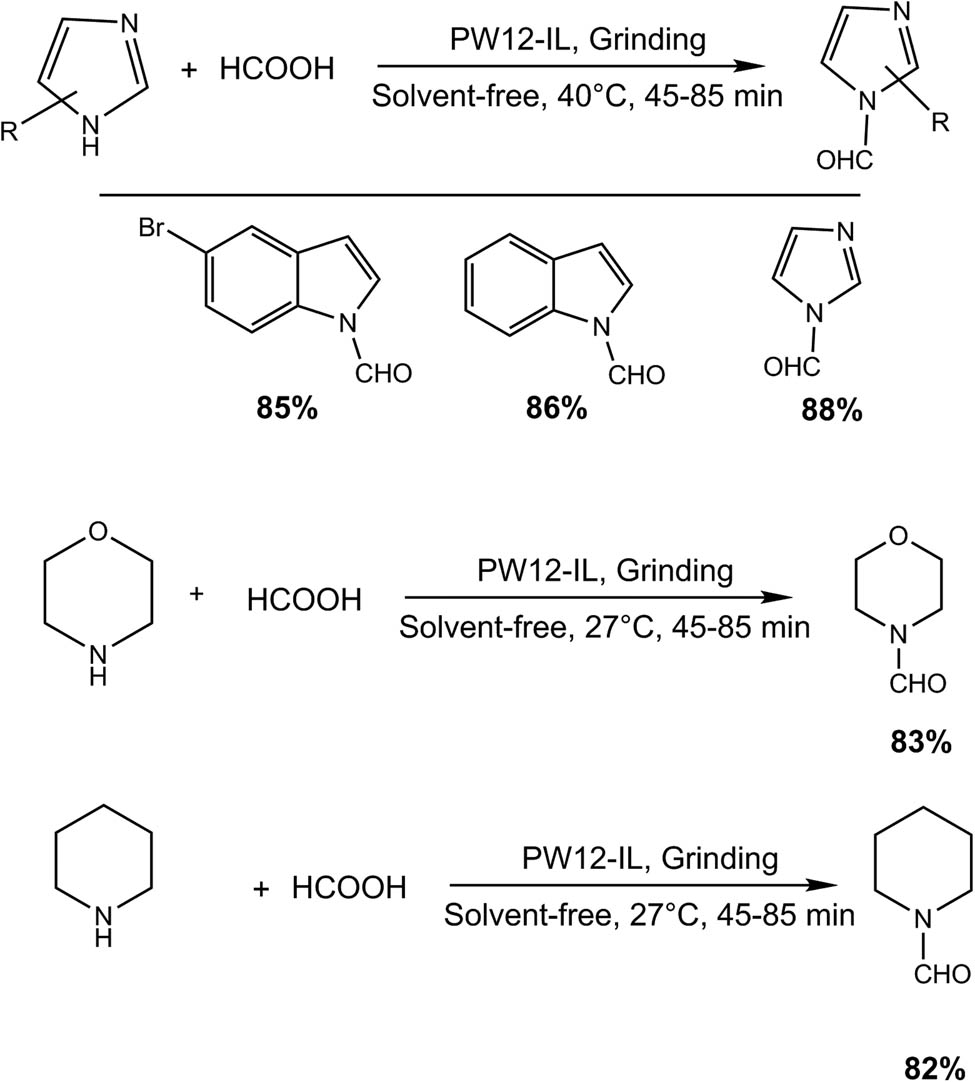

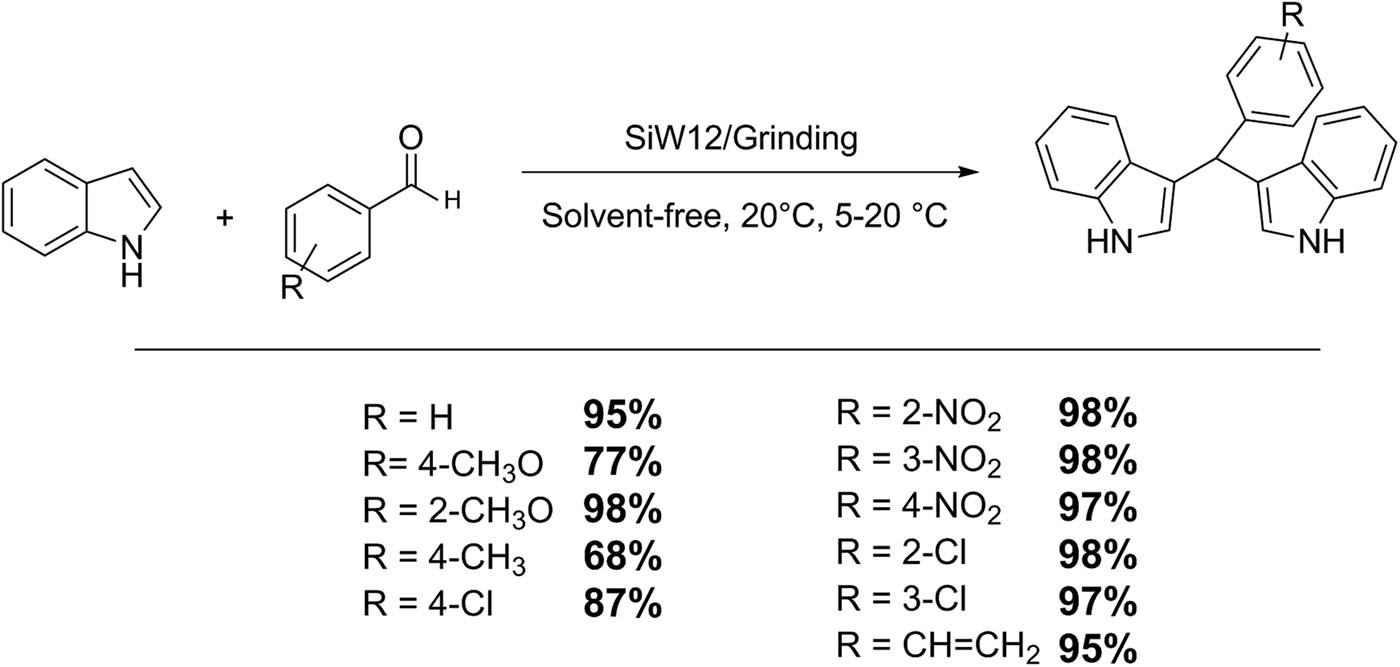

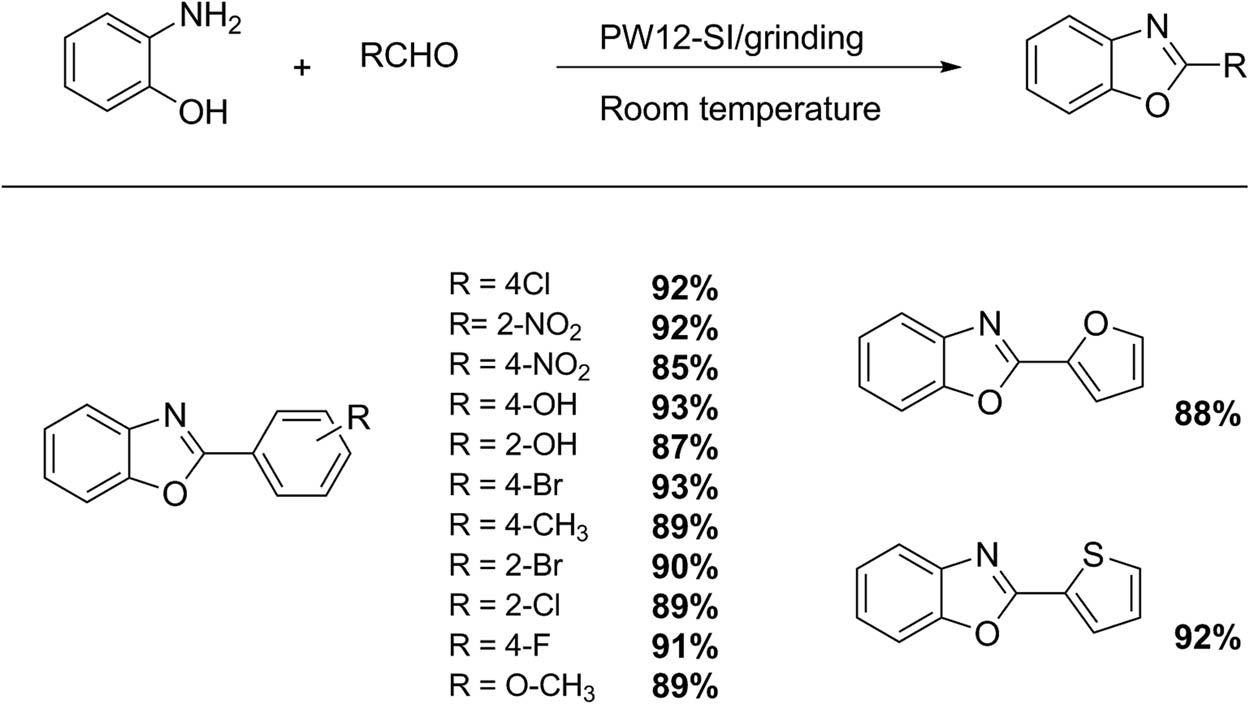

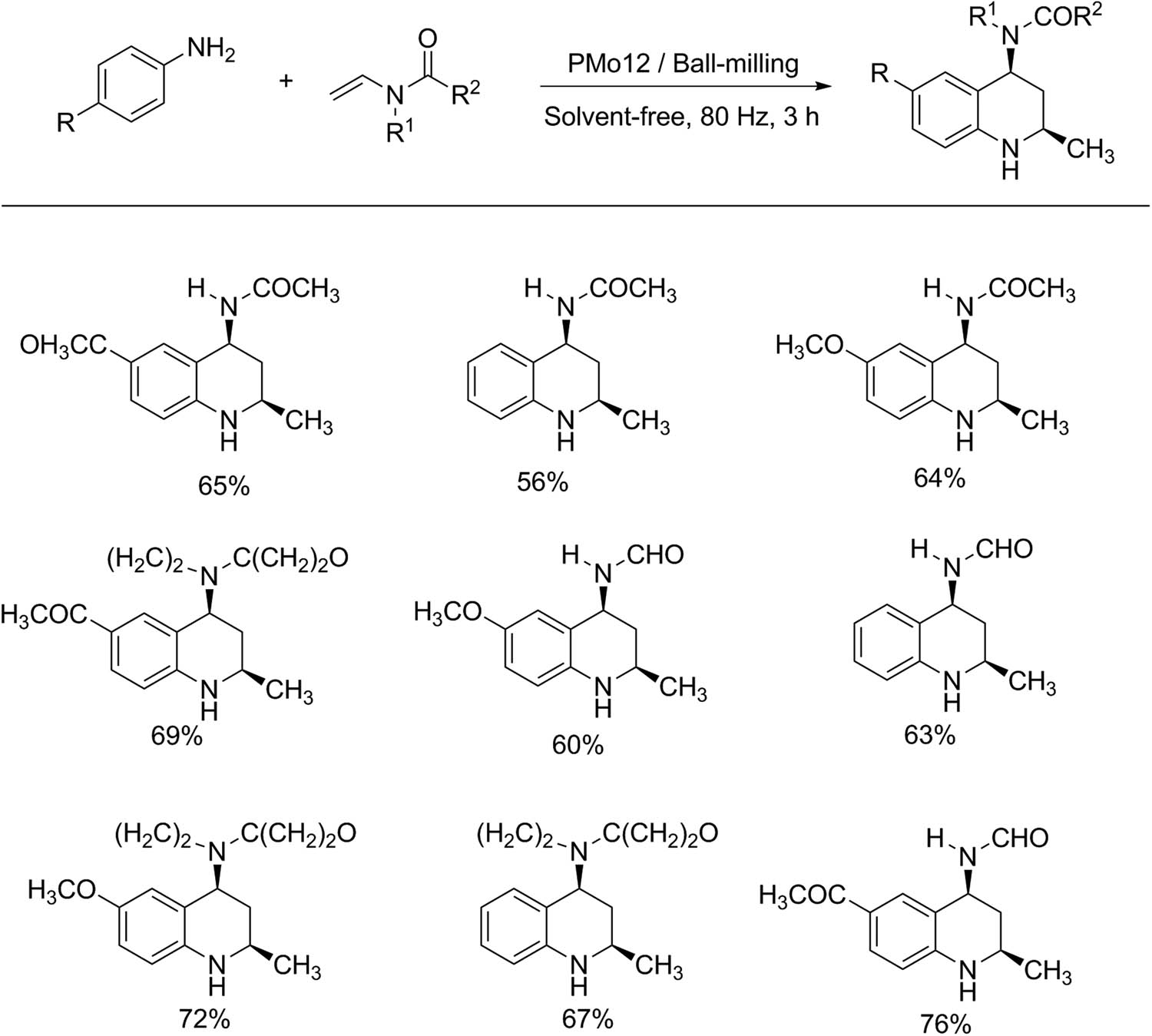

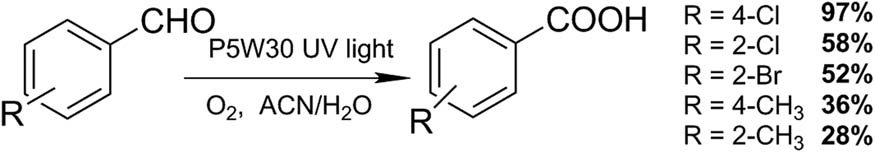

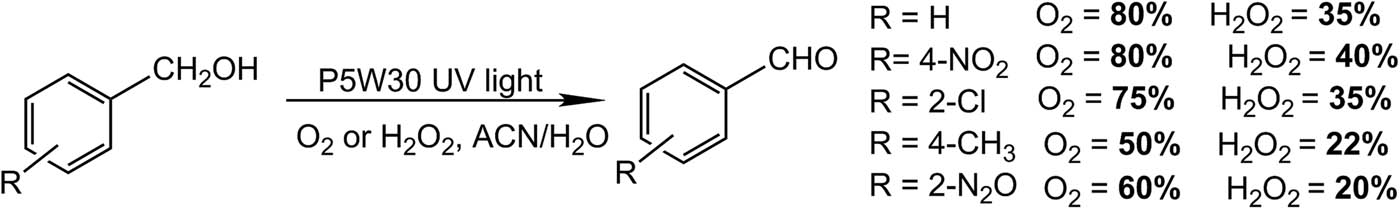

4 Mechanochemistry