Abstract

Cellulose is the most abundant natural polymer on earth, which has obtained increasing interest in the field of functional materials development for its renewable, high mechanical performance and environmental benign. In this study, the traditional processing method (wet spinning and film production) of cellulose-based materials was applied by using cellulose solution for 3D printing, which can directly build complex 3D patterns. Herein, a natural cellulose is dissolved in an effective mixed aqueous solution of dimethyl sulfoxide (DMSO) and tetrabutylammonium hydroxide (TBAH). The cellulose solution extrusion was controlled by a modified fused deposition modeling (FDM) 3D printer. During the controlled extrusion 3D printing process, the viscous cellulose solution will gelifies and further solidifies into a predetermined 3D pattern at room temperature in air. Subsequently, a cellulose hydrogel skeleton was obtained, when the 3D pattern was solvent-exchanged with deionized water. Finally, the mechanical and swelling performance of the cellulose hydrogel scaffold was improved by a cross-linking agent treatment method. With treatment of the 3D printed scaffolds in 0.8 wt% cross-linking agent solution, the obtained cellulose hydrogel could absorb 28 g/g water, and the compression strength was 96 kPa. This work provided an efficient way to prepare natural cellulose hydrogel by 3D printing under room temperature.

1 Introduction

3D printing is an important additive manufacturing (AM) method, which can produce complex geometries according to the computer design. During the past years, some revolutionary techniques have been created to realize rapid and scalable 3D printing with high resolution by new stereolithography, tomographic reconstruction techniques [1, 2, 3]. The development of the materials in tissue engineering [4, 5, 6] provides opportunities for 3D printing, since it is able to construct high precision and complex shapes [7, 8, 9]. The 3D bio-printing has also obtained great progress in building components of human organs [10, 11, 12, 13, 14]. As a biomass derived natural organic polymer, cellulose has been considered an attractive material for the fabrication of bio-compatible and bio-degradable multifunctional products. But the processes are always complex and time consuming. It is particularly difficult to dissolve the cellulose in common solvents and it cannot be melted with heating. Because of the recalcitrant property, it is difficult to efficiently extract the cellulose, in order to apply it. Hence, the lignocellulose biomass has also been refined into bioethanol and biodiesel by chemical or biological catalysis process [15, 16, 17], or been prepared into biomass based carbon materials for supercapacitor electrode [18, 19]. A specific cellulose such as nanocrystal [20, 21, 22] or nanofibers cellulose hydrogels [23, 24, 25] has been applied for 3D printing to fabricate 3D structures.

The challenges still exist for direct utilization of natural cellulose for 3D printing. Except the stubborn properties of cellulose itself, the obstacle also comes from the work modes of present 3D printer. 3D printer with fused deposition modeling (FDM) is commonly used for thermoplastic polymer filaments 3D printing, such as polylactic acid (PLA) [26, 27, 28, 29], acrylonitrile butadiene styrene (ABS) [30, 31, 32, 33], and polycarbonate (PC) [34, 35]. Those reactive thermal-setting polymers like epoxy [36, 37] are also applied for 3D printing, cured by irradiation of UV, laser, or heat. Besides, other 3D printers of different work principles include powder bed and ink-jet head 3D printing (3DP), stereolithography (SLA), 3D plotting/direct-write, and selective laser sintering (SLS) has been detailed summarized [38]. In the field of shape memory polymer composite, 3D printing also presents promising advantages for obtaining complicated three-dimensional structures [39, 40, 41].

In this work, the mixed aqueous solution consisting of dimethyl sulfoxide and tetrabutylammonium hydroxide (DMSO/TBAH/H2O) has been adopted as a solvent for natural cellulose. It has been discovered as an outstanding room temperature solvent for cellulose in our previous research [42]. The favorable rheological properties required for 3D printing can be provided by convenient tuning the concentration of the natural cellulose solution. The gelation of the cellulose solution during the extrusion proceeds 3D printing in the air to produce a solid shape, which was then conducted by a solvent exchange with water to obtain the cellulose hydrogel skeleton. Different from the widely used nanocrystal or nanofibril cellulose hydrogel in recent days, a facile procedure is provided to realize the direct 3D printing of natural cellulose viscous solution.

2 Materials and methods

The cotton cellulose was provided by Xinxiang Chemical Fiber Co., Ltd (Henan, China), which was dried at 105∘C for 4 hours and smashed into cotton fibers for dissolving. The degree of polymerization (DP) of this cotton cellulose was measured by the gel permeation chromatography (GPC) in our previous work [43] and the result was DPGPC = 731. Dimethyl sulfoxide (DMSO, Mw = 78.13 g·mol−1) purchased from Chengdu Kelong Chemical Reagent Co., Ltd (Sichuan, China) and Tetrabutyl ammonium hydroxide (TBAH, 15wt% aqueous solution) was purchased from Runjing Chemical Co. Ltd (Jiangsu, China), which was condensed into 50wt% under reduced pressure. N, N’-Methylenebisacrylamide (MBA,Mw= 154.17 g·mol−1) was supplied by Chengdu Haihong Chemical Reagent Co., Ltd (Sichuan, China). All chemicals used in this work were of an analytical grade, and were applied without further purification.

2.1 Preparation of viscous cellulose solution

The refined 50wt% TBAH aqueous solution was mixed with DMSO to make the mixed solvent of DMSO/TBAH/H2O in the weight ratio of 8:1:1. The 6.3 wt% and 6.7 wt% cellulose solutions were prepared by adding the certain amount of cellulose into the solvent under stirring at 1600 rpm for 12 minutes at room temperature into transparent solution. Before 3D printing, the cellulose solution was further conducted with vacuum defoaming treatment.

2.2 3D printing

The 3D printer applied in this work was a modified plastic 3D printer MakerBot Replicator 2X with a solution extruder, which replaced the plastic extruder. The solution extruder was combined with a syringe filled with cellulose solution and was powered by an injection pump. The modified printer is shown in Figure 1. The Simplify 3D software was used to control the printing routes. A CAD file in stl mode was converted to a g code file to be read by the printer. A nozzle with diameter of 564μm was selected to conduct the printing with an injecting speed of 30 μl/s to match the printing speed of 2 mm/s.

The viscous solution extrusion 3D printer for printing cellulose hydrogel scaffolds. A is the controllable pump fixed with a syringe and needle to pipe out the cellulose solution by extrusion

2.3 Processing of cellulose hydrogel scaffolds

The 6.7 wt% cellulose solution was adopted for the 3D printing. The 3D printed scaffold was put into deionized water (DI water) to conduct solvent exchange to obtain the cellulose hydrogel scaffold. For improving the reswellability of the 3D printed scaffold, before the solvent exchange in DI water, the 3D printed scaffold was kept in the MBA/DMSO solution with different concentrations for 12 hours at 50∘C to form chemical cross-linkage inside the cellulose scaffold. The final 3D printed cellulose hydrogel scaffolds were freeze-dried to observe the morphology by SEM.

3 Characterization

3.1 The rheological property analysis

To find out the suitable concentration of the cellulose solution for 3D printing, the rheological behavior was studied. The rheological propertywas tested by a Control Stress Rheometer (TA instruments, America). The viscosity of the cellulose solution was measured in steady state with the shear rate ranging from 0 to 100 s−1. To test the storage moduli (G′) and loss moduli (G′′), a logarithmic stress sweep was plotted at a frequency of 1 Hz. The frequency sweep was performed in the range from 0 to 100 Hz, at a constant strain rate of 1%. This strain rate was chosen after performing the linear viscoelastic region sweep.

3.2 Chemical structure characterization

To analyze the interactions between the functional groups of the components consisted in the hydrogel scaffolds, with and without crosslink agent treatment, Fourier transform infrared spectroscopy (FT-IR) was recorded on a FT-IR spectrometer equipped with ATR accessory (Nicolet 6700, Nicolet, America). The spectra were recorded in hydrogel samples with a resolution of 4 cm−1 and an accumulation of 50 scans in the spectral range of 400-4000 cm−1 at room temperature.

3.3 Morphology analysis

The morphology of the freeze-dried 3D printed hydrogel scaffoldswas studied with a scanning electron microscope (QUANPA200, FEI, Holland). To observe the morphology of cross section part of the scaffolds, which were dipped in liquid N2 before cutting. All the samples were coated with gold powder by spraying for 60 seconds at 10 mA.

3.4 The aggregation structure analysis

To compare the aggregation structures with and without crosslinking treatment of the 3D printed scaffolds, the XRD was performed on a X-ray diffractometer (X’pert PRO, PAN alytical, Holland) with copper radiation (λ = 0.154056 nm). The scan range was from 5 to 60∘, with a scanning speed of 10∘/min.

3.5 Mechanical properties

To evaluate the mechanical properties of the cellulose hydrogel scaffolds, the compression tests were performed on an electronic universal testing machine (CMT4000, Sansitaijie, China) with a compressing speed of 5 m/min. The average value of five samples was taken as the final result.

3.6 Re-swelling performance

The re-swelling performance of cellulose hydrogel scaffolds was evaluated by drying the samples and then dipping into DI water to swell, and calculate the swelling ration (SR) using the Eq. (1),

where Ws is the wet weight of hydrogel after absorbing DI water to a swelling balance, and Wd is the weight of the dried 3D printed cellulose scaffolds. The average value of three testing results was taken as the final result.

4 Results and discussion

4.1 The rheological property of the cellulose solution

The rheological properties of cellulose solutions were tested, and the results were collected in Figure 2. As shown in Figure 2a, the 6.7 wt% cellulose solution appeared as a semisolid. The rheological properties of the cellulose solutions under different temperatures (Figure 2b, 6.7 wt% cellulose solution) and with different concentrations (Figure 2c, 20∘C) were tested separately as a function of shear rate. With the increasing of the shear rate, the viscosity of the cellulose solution decreased obviously, which presented a strong non-Newtonian shear thinning behavior. The characteristics of the viscous cellulose solution was beneficial for the extrusion 3D printing under room temperature. They were easy to be extruded out through the printing nozzle and then changed into solid-like to form a prescribed shape. As summarized in the Figure 2c, the solid lines, presented the storage modulus (G′),were above the loss modulus (G′′) within measuring range. The rheological behavior of the cellulose solution was more like a solid, so they were suitable for conducting 3D printing under room temperature. It could be explained that the entanglement force and hydrogen bond between molecular chains decreased, and the molecular chains would move easily with increasing the shear rate. In the meantime, with increasing the temperature, more free volume would be produced for the molecular chains to move easier. Such rheological properties of the cellulose viscous solutions provided the necessities their 3D printing to keep the stable dimension and precise shape.

The rheological properties of the viscous cellulose solutions: (a) optical picture of the 6.7 wt% cellulose solution; (b) the viscosity of the 6.7 wt% cellulose solution as a function of shear rate under different temperatures; (c) the viscosity of the cellulose solutions with different concentrations (6.3 wt% and 6.7 wt%) as a function of shear rate; (d) the storage modulus (G′, the hard line) and the loss modulus (G′′, the dotted line) of the cellulose solutions with different concentrations (6.3 wt% and 6.7 wt%) under room temperature

4.2 The morphology of the 3D printed cellulose hydrogel scaffolds

The 6.7 wt% cellulose solution was applied for the 3D printing under room temperature. The 3D printed scaffolds were immersed in DI water to conduct regeneration and solvent exchange to produce the aim cellulose hydrogel scaffolds, as shown in Figure 3. As it could been seen that the 3D printed scaffolds, both the as printed samples (a and b) and the hydrogels (a1 and b1) after solvent exchange with DI water kept the prescribed shape according to the designed CAD models. While, the freeze-dried samples (a2 and b2) showed some shrinkage.

The digital pictures of the 3D printed cellulose scaffolds: a, b – as-printed samples; a1, b1 – the hydrogel scaffolds; a2, b2 – the freeze-dried samples

In order to take observation into the morphology of the layer by layer printed 3D cellulose scaffolds, the SEM was applied, the images were shown in Figure 4. As shown in Figure 4a and 4b, the side view presented apparent layer by layer stacked structure. The cross section was shown in Figure a2, the regenerated cellulose fibers in different diameters agglomerated and formed hierarchical pores, which contributed micro and macro chambers to contain water.

SEM images of the freeze-dried 3D printed cellulose scaffold: (a) the layer by layer printed 3D grid shape; (a1) the morphology of the surface of the layers; (a2) the cross section

4.3 The impact of the crosslinking agent treatment on the properties of the 3D printed cellulose hydrogel scaffolds

The re-swelling ability is one of the most important property for hydrogel materials. While, the re-swelling ratio of the as prepared cellulose hydrogel scaffold is only 14 wt%. To improve the re-swelling ability, the crosslinking agent (N, N’-Methylenebisacrylamide,MBA) was introduced into the 3D printed cellulose hydrogel scaffolds, by immersing the printed cellulose scaffolds into the MBA/DMSO solution with concentrations ranging from 0 to 1.0 wt%. The pictures of the re-swelled samples were shown in Figure 5. The sample treated in the 0.8 wt% cross link agent solution had the best re-swelling property, which adsorbed 28 g/g DI water of its own weight. With increasing the concentration of the MBA content to 1.0%, the re-swelling ability of the 3D printed cellulose hydrogel decreased to 24 g/g. The re-swelling results of the samples treated by MBA/DMSO solution with different concentrations were summarized in Table 1, and the photos were shown in Figure 5.

The re-swelled 3D printed cellulose hydrogel samples treated by cross linking agent solutions with different concentrations

The re-swelling property of the 3D printed cellulose hydrogel scaffolds treated by MBA/DMSO solution.

| MBA content (wt%) | 0 | 0.2 | 0.4 | 0.6 | 0.8 | 1.0 |

|---|---|---|---|---|---|---|

| RS (g/g) | 14 | 19 | 22 | 24 | 28 | 26 |

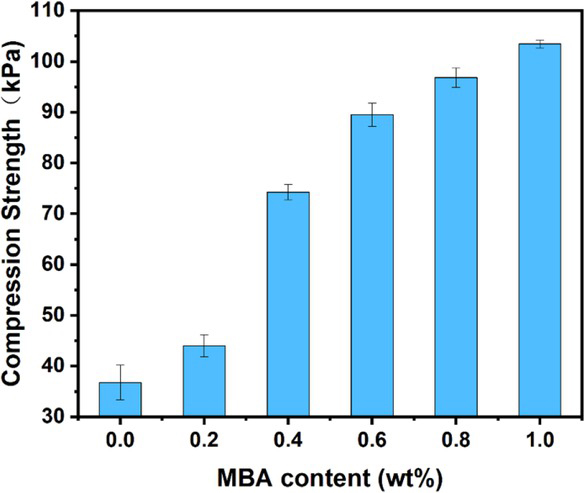

4.4 The compression properties of the cross-linking agent treated 3D printed cellulose hydrogel scaffolds

The mechanical property is important for the practical utilization of the hydrogel materials, which has also been tested, taking the reported method [44] as reference. As shown in Figure 6, with increasing the concentration of the MBA in the solution, the compression strength was increased from 36 to 103 kPa. Especially, the compression strength considerably increased from 45 to 75 kPa when the concentration of MBA in the cross-linking medium increased from 0.4 to 0.6 wt%.

The compression strength of the cross-linking agent treated cellulose hydrogel scaffolds

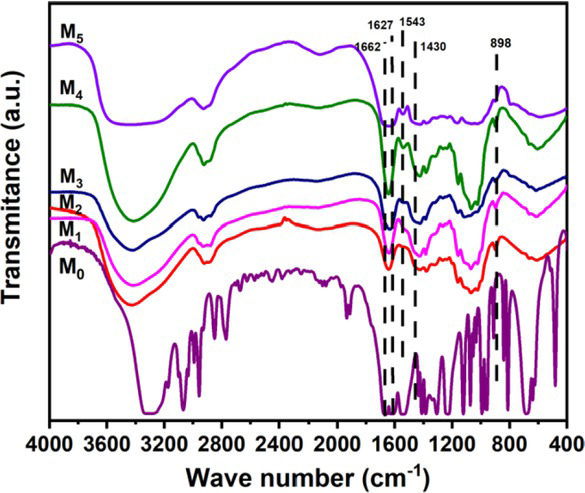

4.5 Chemical structure analysis by FTIR spectra

In order to understand the interact of the cross-linking agent with the cellulose, the MBA treated cellulose hydrogel scaffolds were freeze dried and analyzed by FTIR, as shown in Figure 7.

FTIR spectra of the cross-linking agent treated cellulose hydrogel scaffolds. M0: the MBA, M1-M5: the cellulose hydrogel scaffolds treated with 0.2, 0.4, 0.6, 0.8, and 1.0 wt% MBA solutions, respectively

The strong adsorption at 1662 and 1627 cm−1, ascribed to the stretching vibration of C=C and C=O in MBA, respectively. The peak at 1543 cm−1 and 1430 cm−1 represented to the bending vibration of N-H and C-N in MBA [44]. Those typical vibrations presented amide structure of MBA. As shown in the M1-M5 of Figure 7, with the increasing of the MBA in the cross-linking agent solution, the representative adsorptions at 1543 cm−1 and 1430 cm−1 became enhanced. The characteristic adsorption of β-1,4-D-glycosidic bond in cellulose at 897 cm−1 were obvious in the M1-M5 of Figure 7. Additionally, with the introduction of cross-link agent, the stretching vibration in about 3400 cm−1 became wider and some red shift, which indicated the hydrogen bonds formed between the carbonyl groups of MBA and the hydroxyl groups of cellulose. As a result, the MBA was successfully introduced into the cellulose scaffolds.

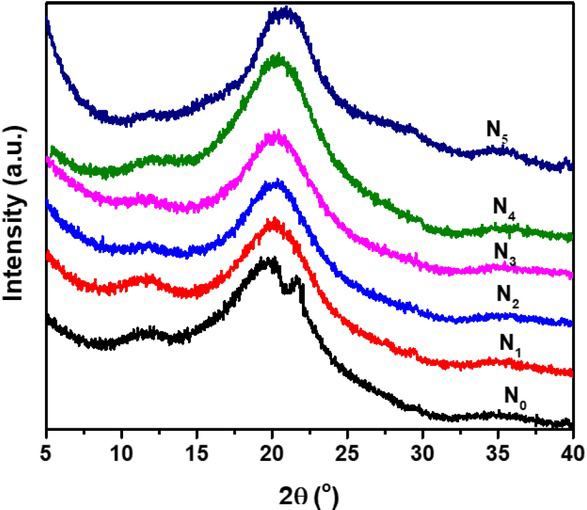

4.6 The crystal structure analysis by XRD diffraction

The cross-linking agent treated cellulose scaffolds were freeze dried to conduct the XRD analysis to study the effect of the MBA on the crystal structures of cellulose, as shown in Figure 8.

XRD patterns of the cross-linking agent treated cellulose scaffolds. N0-N5 corresponding to the cellulose scaffolds treated with 0, 0.2, 0.4, 0.6, 0.8, 1.0 wt% MBA solutions, respectively

According to the XRD diffraction patterns in Figure 8, with the increase of MBA content in the cross-linking solution, the diffraction peaks of the cellulose in the 110 and 200 crystal planes decreased in intensity, while the 110 crystal plane gradually disappeared. As mentioned before, the cross-linking interaction between cellulose and MBA consumed the -OH at C6 in cellulose, which caused the decrease of hydrogen bonds, and hence decreased the crystallinity.

5 Conclusion

In summary, the natural cotton cellulose solution in dimethyl sulfoxide and tetrabutylammonium hydroxide aqueous solution (DMSO/TBAH/H2O) was found to be suitable for extrusion 3D printing for its special rheological properties. It presented solid-like behavior under room temperature, and a strong non-Newtonian shear thinning property. With introduction of N, N’Methylenebisacrylamide (MBA) into the 3D printed cellulose hydrogel scaffolds, the compression as well as the re-swelling properties were considerably improved. This work provides a new way for construct complex cellulose hydrogel scaffolds for practical application by 3D printing.

Acknowledgement

The authors acknowledge the financial support from the International Cooperation Project of Sichuan Province (NO.2018HH0087) and the Sichuan Major Science and Technology Project (NO.2019ZDZX0018).

References

[1] Kelly BE, Bhattacharya I, Heidari H, Shusteff M, Spadaccini CM, Taylor HK. Volumetric additive manufacturing via tomographic reconstruction. Science. 2019 Mar;363(6431):1075–9.10.1126/science.aau7114Suche in Google Scholar PubMed

[2] Saha SK, Wang D, Nguyen VH, Chang Y, Oakdale JS, Chen SC. Scalable submicrometer additive manufacturing. Science. 2019 Oct;366(6461):105–9.10.1126/science.aax8760Suche in Google Scholar PubMed

[3] Walker DA, Hedrick JL, Mirkin CA. Rapid, large-volume, thermally controlled 3D printing using a mobile liquid interface. Science. 2019 Oct;366(6463):360–4.10.1126/science.aax1562Suche in Google Scholar PubMed PubMed Central

[4] Kelly CN, Miller AT, Hollister SJ, Guldberg RE, Gall K. Design and Structure-Function Characterization of 3D Printed Synthetic Porous Biomaterials for Tissue Engineering. Adv Healthc Mater. 2018 Apr;7(7):e1701095.10.1002/adhm.201701095Suche in Google Scholar PubMed

[5] Li RQ, McCarthy A, Zhang YS, Xie JW. Decorating 3D Printed Scaffolds with Electrospun Nanofiber Segments for Tissue Engineering. Adv. Biosys. 2019;3(12):1900137.10.1002/adbi.201900137Suche in Google Scholar PubMed PubMed Central

[6] Richards DJ, Tan Y, Jia J, Yao H, Mei Y. 3D Printing for Tissue Engineering. Isr J Chem. 2013 Oct;53(9-10):805–14.10.1002/ijch.201300086Suche in Google Scholar

[7] Pearre BW, Michas C, Tsang JM,Gardner TJ, Otchy TM. Fast micron-scale 3D printing with a resonant-scanning two-photon microscope. Addit. Manuf. 2019;30:100887.10.1016/j.addma.2019.100887Suche in Google Scholar PubMed PubMed Central

[8] Kalms M, Narita R, Thomy C, Vollertsen F, Bergmann RB. New approach to evaluate 3D laser printed parts in powder bed fusion-based additive manufacturing in-line within closed space. Addit. Manuf. 2019;26:161–5.10.1016/j.addma.2019.01.011Suche in Google Scholar

[9] Gelber MK, Hurst G, Comi TJ, Bhargava R. Model-guided design and characterization of a high-precision 3D printing process for carbohydrate glass. Addit. Manuf. 2018;22:38–50.10.1016/j.addma.2018.04.026Suche in Google Scholar

[10] Grigoryan B, Paulsen SJ, Corbett DC, Sazer DW, Fortin CL, Zaita AJ, et al. Multivascular networks and functional intravascular topologies within biocompatible hydrogels. Science. 2019 May;364(6439):458–64.10.1126/science.aav9750Suche in Google Scholar PubMed PubMed Central

[11] Lee A, Hudson AR, Shiwarski DJ, Tashman JW, Hinton TJ, Yerneni S, et al. 3D bioprinting of collagen to rebuild components of the human heart. Science. 2019 Aug;365(6452):482–7.10.1126/science.aav9051Suche in Google Scholar PubMed

[12] Bose S, Vahabzadeh S, Bandyopadhyay A. Bone tissue engineering using 3D printing. Mater Today. 2013;16(12):496–504.10.1016/j.mattod.2013.11.017Suche in Google Scholar

[13] Murphy SV, Atala A. 3D bioprinting of tissues and organs. Nat Biotechnol. 2014 Aug;32(8):773–85.10.1038/nbt.2958Suche in Google Scholar PubMed

[14] Mannoor MS, Jiang Z, James T, Kong YL, Malatesta KA, Soboyejo WO, et al. 3D printed bionic ears. Nano Lett. 2013 Jun;13(6):2634–9.10.1021/nl4007744Suche in Google Scholar PubMed PubMed Central

[15] Rai M, dos Santos JC, Soler MF, Marcelino PR, Brumano LP, Ingle AP, et al. Strategic role of nanotechnology for production of bioethanol and biodiesel. Nanotechnol Rev. 2016;5(2):231–50.10.1515/ntrev-2015-0069Suche in Google Scholar

[16] Lemée L, Kpogbemabou D, Pinard L, Beauchet R, Laduranty J. Biological pretreatment for production of lignocellulosic biofuel. Bioresour Technol. 2012 Aug;117:234–41.10.1016/j.biortech.2012.04.056Suche in Google Scholar PubMed

[17] Zhao X, Luo K, Zhang Y, Zheng Z, Cai Y, Wen B, et al. Improving the methane yield of maize straw: focus on the effects of pretreatment with fungi and their secreted enzymes combined with sodium hydroxide. Bioresour Technol. 2018 Feb;250:204–13.10.1016/j.biortech.2017.09.160Suche in Google Scholar PubMed

[18] Li ZH, Xu K, Pan YS. Recent development of Supercapacitor Electrode Based on Carbon Materials. Nanotechnol Rev. 2019;8(1):35–49.10.1515/ntrev-2019-0004Suche in Google Scholar

[19] Gao T, Xu C, Li R, Zhang R, Wang B, Jiang X, et al. Biomass-Derived Carbon Paper to Sandwich Magnetite Anode for Long-Life Li-Ion Battery. ACS Nano. 2019 Oct;13(10):11901–11.10.1021/acsnano.9b05978Suche in Google Scholar PubMed

[20] Sultan S, Mathew AP. 3D printed scaffolds with gradient porosity based on a cellulose nanocrystal hydrogel. Nanoscale. 2018 Mar;10(9):4421–31.10.1039/C7NR08966JSuche in Google Scholar PubMed

[21] Li VC, Kuang X, Hamel CM, Roach D, Deng YL, Qi HJ. Cellulose nanocrystals support material for 3D printing complexly shaped structures via multi-materials-multi-methods printing. Addit. Manuf. 2019;28:14–22.10.1016/j.addma.2019.04.013Suche in Google Scholar

[22] Hausmann MK, Rühs PA, Siqueira G, Läuger J, Zimmermann T, Studart AR. 3D printed cellulose nanocrystal composites through digital light processing. ACS Nano. 2018;12(7):6926–37.10.1021/acsnano.8b02366Suche in Google Scholar PubMed

[23] Hakansson KM, Henriksson IC, Vazquez CD, Kuzmenko V, Markstedt K, Enoksson P, et al. Solidification of 3D Printed Nanofibril Hydrogels into Functional 3D Cellulose Structures, Adv. Mater Technol. 2016;1(7):1600096.Suche in Google Scholar

[24] Xu C, Zhang Molino B, Wang X, Cheng F, Xu W, Molino P, et al. 3D printing of nanocellulose hydrogel scaffolds with tunable mechanical strength towards wound healing application. J Mater Chem B Mater Biol Med. 2018 Nov;6(43):7066–75.10.1039/C8TB01757CSuche in Google Scholar PubMed

[25] Huang L, Du X, Fan S, Yang G, Shao H, Li D, et al. Bacterial cellulose nanofibers promote stress and fidelity of 3D-printed silk based hydrogel scaffold with hierarchical pores. Carbohydr Polym. 2019 Oct;221:146–56.10.1016/j.carbpol.2019.05.080Suche in Google Scholar PubMed

[26] Giordano RA, Wu BM, Borland SW, Cima LG, Sachs EM, Cima MJ. Mechanical properties of dense polylactic acid structures fabricated by three dimensional printing. J Biomater Sci Polym Ed. 1996;8(1):63–75.10.1163/156856297X00588Suche in Google Scholar PubMed

[27] Kiendl J, Gao C. Controlling toughness and strength of FDM 3D-printed PLA components through the raster layup, Compos. Pt. B-Eng. 2020;180:107562.10.1016/j.compositesb.2019.107562Suche in Google Scholar

[28] Kaygusuz B, Ozerinc S. Improving the ductility of polylactic acid parts produced by fused deposition modeling through polyhydroxyalkanoate additions. J Appl Polym Sci. 2019;136(43):48154.10.1002/app.48154Suche in Google Scholar

[29] Tian XY, Liu TF, Wang QR, Dilmurat A, Li DC, Ziegmann G. Recycling and remanufacturing of 3D printed continuous carbon fiber reinforced PLA composites. J Clean Prod. 2017;142(4):1609–18.10.1016/j.jclepro.2016.11.139Suche in Google Scholar

[30] Torrado AR, Shemelya CM, English JD, Lin YR, Wicker RB, Roberson DA. Characterizing the effect of additives to ABS on the mechanical property anisotropy of specimens fabricated by material extrusion 3D printing. Addit. Manuf. 2015;6:16–29.10.1016/j.addma.2015.02.001Suche in Google Scholar

[31] Dilberoglu UM, Simsek S, Yaman U. Shrinkage compensation approach proposed for ABS material in FDM process. Mater Manuf Process. 2019;34(9):993–8.10.1080/10426914.2019.1594252Suche in Google Scholar

[32] Samykano M, Selvamani SK, Kadirgama K, Ngui WK, Kanagaraj G, Sudhakar K. Mechanical property of FDM printed ABS: influence of printing parameters. Int J Adv Manuf Technol. 2019;102(9-12):2779–96.10.1007/s00170-019-03313-0Suche in Google Scholar

[33] Levenhagen NP, Dadmun MD. Improving Interlayer Adhesion in 3D Printing with Surface Segregating Additives: Improving the Isotropy of Acrylonitrile-Butadiene-Styrene Parts. ACS Appl. Polym. Mater. 2019;1(4):876–84.10.1021/acsapm.9b00051Suche in Google Scholar

[34] Park SJ, Lee JE, Park JH, Lyu MY, Park K, Koo MS, et al. FDM 3D Printing of Environmental Friendly and High Strength Bio-based PC Filaments for Baby Toys. Elastom. Compos. 2017;52(2):99–104.Suche in Google Scholar

[35] Yap YL, Toh W, Koneru R, Lin KH, Yeoh KM, Lim CM, et al. A non-destructive experimental-cum-numerical methodology for the characterization of 3D-printed materialspolycarbonate-acrylonitrile butadiene styrene (PC-ABS). Mech Mater. 2019;132:121–33.10.1016/j.mechmat.2019.03.005Suche in Google Scholar

[36] Shi Q, Yu K, Kuang X,Mu XM, Dunn CK, Dunn ML, et al. Recyclable 3D printing of vitrimer epoxy. Mater Horiz. 2017;4(4):598–607.10.1039/C7MH00043JSuche in Google Scholar

[37] Pierson HA, Celik E, Abbott A, De Jarnette H, Gutierrez LS, Johnson K, et al. Mechanical Properties of Printed Epoxy-Carbon Fiber Composites. Exp Mech. 2019;59(6):843–57.10.1007/s11340-019-00498-zSuche in Google Scholar

[38] Wang X, Jiang M, Zhou ZW, Gou JH, Hui D. 3D printing of polymer matrix composites: A review and prospective, Compos. Pt. B-Eng. 2017;110:442–58.10.1016/j.compositesb.2016.11.034Suche in Google Scholar

[39] Lei M, Chen Z, Lu HB, Yu K. Recent progress in shape memory polymer composites: methods, properties, applications and prospects. Nanotechnol Rev. 2019;8(1):327–51.10.1515/ntrev-2019-0031Suche in Google Scholar

[40] Yang H, Leow WR, Wang T, Wang J, Yu J, He K, et al. 3D Printed Photoresponsive Devices Based on Shape Memory Composites. Adv Mater. 2017 Sep;29(33):1701627.10.1002/adma.201701627Suche in Google Scholar PubMed

[41] Wu W, Ye W, Wu Z, Geng P, Wang Y, Zhao J. Influence of Layer Thickness, Raster Angle, Deformation Temperature and Recovery Temperature on the Shape-Memory Effect of 3D-Printed Polylactic Acid Samples. Materials (Basel). 2017 Aug;10(8):E970.10.3390/ma10080970Suche in Google Scholar PubMed PubMed Central

[42] Cao J, Wei W, Gou GJ, Jiang M, Cui YH, Zhang SL, et al. Cellulose films from the aqueous DMSO/TBAH-system. Cellulose. 2018;25(3):1975–86.10.1007/s10570-017-1639-5Suche in Google Scholar

[43] Bu D, Hu X, Yang Z, Yang X, WeiW, Jiang M, et al. Elucidation of the Relationship between Intrinsic Viscosity and Molecular Weight of Cellulose Dissolved in Tetra-N-Butyl Ammonium Hydroxide/Dimethyl Sulfoxide. Polymers (Basel). 2019 Oct;11(10):E1605.10.3390/polym11101605Suche in Google Scholar PubMed PubMed Central

[44] Geng H. A one-step approach to make cellulose-based hydrogels of various transparency and swelling degrees. Carbohydr Polym. 2018 Apr;186:208–16.10.1016/j.carbpol.2018.01.031Suche in Google Scholar PubMed

© 2020 Xiangzhou Hu et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Generalized locally-exact homogenization theory for evaluation of electric conductivity and resistance of multiphase materials

- Enhancing ultra-early strength of sulphoaluminate cement-based materials by incorporating graphene oxide

- Characterization of mechanical properties of epoxy/nanohybrid composites by nanoindentation

- Graphene and CNT impact on heat transfer response of nanocomposite cylinders

- A facile and simple approach to synthesis and characterization of methacrylated graphene oxide nanostructured polyaniline nanocomposites

- Ultrasmall Fe3O4 nanoparticles induce S-phase arrest and inhibit cancer cells proliferation

- Effect of aging on properties and nanoscale precipitates of Cu-Ag-Cr alloy

- Effect of nano-strengthening on the properties and microstructure of recycled concrete

- Stabilizing effect of methylcellulose on the dispersion of multi-walled carbon nanotubes in cementitious composites

- Preparation and electromagnetic properties characterization of reduced graphene oxide/strontium hexaferrite nanocomposites

- Interfacial characteristics of a carbon nanotube-polyimide nanocomposite by molecular dynamics simulation

- Preparation and properties of 3D interconnected CNTs/Cu composites

- On factors affecting surface free energy of carbon black for reinforcing rubber

- Nano-silica modified phenolic resin film: manufacturing and properties

- Experimental study on photocatalytic degradation efficiency of mixed crystal nano-TiO2 concrete

- Halloysite nanotubes in polymer science: purification, characterization, modification and applications

- Cellulose hydrogel skeleton by extrusion 3D printing of solution

- Crack closure and flexural tensile capacity with SMA fibers randomly embedded on tensile side of mortar beams

- An experimental study on one-step and two-step foaming of natural rubber/silica nanocomposites

- Utilization of red mud for producing a high strength binder by composition optimization and nano strengthening

- One-pot synthesis of nano titanium dioxide in supercritical water

- Printability of photo-sensitive nanocomposites using two-photon polymerization

- In situ synthesis of expanded graphite embedded with amorphous carbon-coated aluminum particles as anode materials for lithium-ion batteries

- Effect of nano and micro conductive materials on conductive properties of carbon fiber reinforced concrete

- Tribological performance of nano-diamond composites-dispersed lubricants on commercial cylinder liner mating with CrN piston ring

- Supramolecular ionic polymer/carbon nanotube composite hydrogels with enhanced electromechanical performance

- Genetic mechanisms of deep-water massive sandstones in continental lake basins and their significance in micro–nano reservoir storage systems: A case study of the Yanchang formation in the Ordos Basin

- Effects of nanoparticles on engineering performance of cementitious composites reinforced with PVA fibers

- Band gap manipulation of viscoelastic functionally graded phononic crystal

- Pyrolysis kinetics and mechanical properties of poly(lactic acid)/bamboo particle biocomposites: Effect of particle size distribution

- Manipulating conductive network formation via 3D T-ZnO: A facile approach for a CNT-reinforced nanocomposite

- Microstructure and mechanical properties of WC–Ni multiphase ceramic materials with NiCl2·6H2O as a binder

- Effect of ball milling process on the photocatalytic performance of CdS/TiO2 composite

- Berberine/Ag nanoparticle embedded biomimetic calcium phosphate scaffolds for enhancing antibacterial function

- Effect of annealing heat treatment on microstructure and mechanical properties of nonequiatomic CoCrFeNiMo medium-entropy alloys prepared by hot isostatic pressing

- Corrosion behaviour of multilayer CrN coatings deposited by hybrid HIPIMS after oxidation treatment

- Surface hydrophobicity and oleophilicity of hierarchical metal structures fabricated using ink-based selective laser melting of micro/nanoparticles

- Research on bond–slip performance between pultruded glass fiber-reinforced polymer tube and nano-CaCO3 concrete

- Antibacterial polymer nanofiber-coated and high elastin protein-expressing BMSCs incorporated polypropylene mesh for accelerating healing of female pelvic floor dysfunction

- Effects of Ag contents on the microstructure and SERS performance of self-grown Ag nanoparticles/Mo–Ag alloy films

- A highly sensitive biosensor based on methacrylated graphene oxide-grafted polyaniline for ascorbic acid determination

- Arrangement structure of carbon nanofiber with excellent spectral radiation characteristics

- Effect of different particle sizes of nano-SiO2 on the properties and microstructure of cement paste

- Superior Fe x N electrocatalyst derived from 1,1′-diacetylferrocene for oxygen reduction reaction in alkaline and acidic media

- Facile growth of aluminum oxide thin film by chemical liquid deposition and its application in devices

- Liquid crystallinity and thermal properties of polyhedral oligomeric silsesquioxane/side-chain azobenzene hybrid copolymer

- Laboratory experiment on the nano-TiO2 photocatalytic degradation effect of road surface oil pollution

- Binary carbon-based additives in LiFePO4 cathode with favorable lithium storage

- Conversion of sub-µm calcium carbonate (calcite) particles to hollow hydroxyapatite agglomerates in K2HPO4 solutions

- Exact solutions of bending deflection for single-walled BNNTs based on the classical Euler–Bernoulli beam theory

- Effects of substrate properties and sputtering methods on self-formation of Ag particles on the Ag–Mo(Zr) alloy films

- Enhancing carbonation and chloride resistance of autoclaved concrete by incorporating nano-CaCO3

- Effect of SiO2 aerogels loading on photocatalytic degradation of nitrobenzene using composites with tetrapod-like ZnO

- Radiation-modified wool for adsorption of redox metals and potentially for nanoparticles

- Hydration activity, crystal structural, and electronic properties studies of Ba-doped dicalcium silicate

- Microstructure and mechanical properties of brazing joint of silver-based composite filler metal

- Polymer nanocomposite sunlight spectrum down-converters made by open-air PLD

- Cryogenic milling and formation of nanostructured machined surface of AISI 4340

- Braided composite stent for peripheral vascular applications

- Effect of cinnamon essential oil on morphological, flammability and thermal properties of nanocellulose fibre–reinforced starch biopolymer composites

- Study on influencing factors of photocatalytic performance of CdS/TiO2 nanocomposite concrete

- Improving flexural and dielectric properties of carbon fiber epoxy composite laminates reinforced with carbon nanotubes interlayer using electrospray deposition

- Scalable fabrication of carbon materials based silicon rubber for highly stretchable e-textile sensor

- Degradation modeling of poly-l-lactide acid (PLLA) bioresorbable vascular scaffold within a coronary artery

- Combining Zn0.76Co0.24S with S-doped graphene as high-performance anode materials for lithium- and sodium-ion batteries

- Synthesis of functionalized carbon nanotubes for fluorescent biosensors

- Effect of nano-silica slurry on engineering, X-ray, and γ-ray attenuation characteristics of steel slag high-strength heavyweight concrete

- Incorporation of redox-active polyimide binder into LiFePO4 cathode for high-rate electrochemical energy storage

- Microstructural evolution and properties of Cu–20 wt% Ag alloy wire by multi-pass continuous drawing

- Transparent ultraviolet-shielding composite films made from dispersing pristine zinc oxide nanoparticles in low-density polyethylene

- Microfluidic-assisted synthesis and modelling of monodispersed magnetic nanocomposites for biomedical applications

- Preparation and piezoresistivity of carbon nanotube-coated sand reinforced cement mortar

- Vibrational analysis of an irregular single-walled carbon nanotube incorporating initial stress effects

- Study of the material engineering properties of high-density poly(ethylene)/perlite nanocomposite materials

- Single pulse laser removal of indium tin oxide film on glass and polyethylene terephthalate by nanosecond and femtosecond laser

- Mechanical reinforcement with enhanced electrical and heat conduction of epoxy resin by polyaniline and graphene nanoplatelets

- High-efficiency method for recycling lithium from spent LiFePO4 cathode

- Degradable tough chitosan dressing for skin wound recovery

- Static and dynamic analyses of auxetic hybrid FRC/CNTRC laminated plates

- Review articles

- Carbon nanomaterials enhanced cement-based composites: advances and challenges

- Review on the research progress of cement-based and geopolymer materials modified by graphene and graphene oxide

- Review on modeling and application of chemical mechanical polishing

- Research on the interface properties and strengthening–toughening mechanism of nanocarbon-toughened ceramic matrix composites

- Advances in modelling and analysis of nano structures: a review

- Mechanical properties of nanomaterials: A review

- New generation of oxide-based nanoparticles for the applications in early cancer detection and diagnostics

- A review on the properties, reinforcing effects, and commercialization of nanomaterials for cement-based materials

- Recent development and applications of nanomaterials for cancer immunotherapy

- Advances in biomaterials for adipose tissue reconstruction in plastic surgery

- Advances of graphene- and graphene oxide-modified cementitious materials

- Theories for triboelectric nanogenerators: A comprehensive review

- Nanotechnology of diamondoids for the fabrication of nanostructured systems

- Material advancement in technological development for the 5G wireless communications

- Nanoengineering in biomedicine: Current development and future perspectives

- Recent advances in ocean wave energy harvesting by triboelectric nanogenerator: An overview

- Application of nanoscale zero-valent iron in hexavalent chromium-contaminated soil: A review

- Carbon nanotube–reinforced polymer composite for electromagnetic interference application: A review

- Functionalized layered double hydroxide applied to heavy metal ions absorption: A review

- A new classification method of nanotechnology for design integration in biomaterials

- Finite element analysis of natural fibers composites: A review

- Phase change materials for building construction: An overview of nano-/micro-encapsulation

- Recent advance in surface modification for regulating cell adhesion and behaviors

- Hyaluronic acid as a bioactive component for bone tissue regeneration: Fabrication, modification, properties, and biological functions

- Theoretical calculation of a TiO2-based photocatalyst in the field of water splitting: A review

- Two-photon polymerization nanolithography technology for fabrication of stimulus-responsive micro/nano-structures for biomedical applications

- A review of passive methods in microchannel heat sink application through advanced geometric structure and nanofluids: Current advancements and challenges

- Stress effect on 3D culturing of MC3T3-E1 cells on microporous bovine bone slices

- Progress in magnetic Fe3O4 nanomaterials in magnetic resonance imaging

- Synthesis of graphene: Potential carbon precursors and approaches

- A comprehensive review of the influences of nanoparticles as a fuel additive in an internal combustion engine (ICE)

- Advances in layered double hydroxide-based ternary nanocomposites for photocatalysis of contaminants in water

- Analysis of functionally graded carbon nanotube-reinforced composite structures: A review

- Application of nanomaterials in ultra-high performance concrete: A review

- Therapeutic strategies and potential implications of silver nanoparticles in the management of skin cancer

- Advanced nickel nanoparticles technology: From synthesis to applications

- Cobalt magnetic nanoparticles as theranostics: Conceivable or forgettable?

- Progress in construction of bio-inspired physico-antimicrobial surfaces

- From materials to devices using fused deposition modeling: A state-of-art review

- A review for modified Li composite anode: Principle, preparation and challenge

- Naturally or artificially constructed nanocellulose architectures for epoxy composites: A review

Artikel in diesem Heft

- Research Articles

- Generalized locally-exact homogenization theory for evaluation of electric conductivity and resistance of multiphase materials

- Enhancing ultra-early strength of sulphoaluminate cement-based materials by incorporating graphene oxide

- Characterization of mechanical properties of epoxy/nanohybrid composites by nanoindentation

- Graphene and CNT impact on heat transfer response of nanocomposite cylinders

- A facile and simple approach to synthesis and characterization of methacrylated graphene oxide nanostructured polyaniline nanocomposites

- Ultrasmall Fe3O4 nanoparticles induce S-phase arrest and inhibit cancer cells proliferation

- Effect of aging on properties and nanoscale precipitates of Cu-Ag-Cr alloy

- Effect of nano-strengthening on the properties and microstructure of recycled concrete

- Stabilizing effect of methylcellulose on the dispersion of multi-walled carbon nanotubes in cementitious composites

- Preparation and electromagnetic properties characterization of reduced graphene oxide/strontium hexaferrite nanocomposites

- Interfacial characteristics of a carbon nanotube-polyimide nanocomposite by molecular dynamics simulation

- Preparation and properties of 3D interconnected CNTs/Cu composites

- On factors affecting surface free energy of carbon black for reinforcing rubber

- Nano-silica modified phenolic resin film: manufacturing and properties

- Experimental study on photocatalytic degradation efficiency of mixed crystal nano-TiO2 concrete

- Halloysite nanotubes in polymer science: purification, characterization, modification and applications

- Cellulose hydrogel skeleton by extrusion 3D printing of solution

- Crack closure and flexural tensile capacity with SMA fibers randomly embedded on tensile side of mortar beams

- An experimental study on one-step and two-step foaming of natural rubber/silica nanocomposites

- Utilization of red mud for producing a high strength binder by composition optimization and nano strengthening

- One-pot synthesis of nano titanium dioxide in supercritical water

- Printability of photo-sensitive nanocomposites using two-photon polymerization

- In situ synthesis of expanded graphite embedded with amorphous carbon-coated aluminum particles as anode materials for lithium-ion batteries

- Effect of nano and micro conductive materials on conductive properties of carbon fiber reinforced concrete

- Tribological performance of nano-diamond composites-dispersed lubricants on commercial cylinder liner mating with CrN piston ring

- Supramolecular ionic polymer/carbon nanotube composite hydrogels with enhanced electromechanical performance

- Genetic mechanisms of deep-water massive sandstones in continental lake basins and their significance in micro–nano reservoir storage systems: A case study of the Yanchang formation in the Ordos Basin

- Effects of nanoparticles on engineering performance of cementitious composites reinforced with PVA fibers

- Band gap manipulation of viscoelastic functionally graded phononic crystal

- Pyrolysis kinetics and mechanical properties of poly(lactic acid)/bamboo particle biocomposites: Effect of particle size distribution

- Manipulating conductive network formation via 3D T-ZnO: A facile approach for a CNT-reinforced nanocomposite

- Microstructure and mechanical properties of WC–Ni multiphase ceramic materials with NiCl2·6H2O as a binder

- Effect of ball milling process on the photocatalytic performance of CdS/TiO2 composite

- Berberine/Ag nanoparticle embedded biomimetic calcium phosphate scaffolds for enhancing antibacterial function

- Effect of annealing heat treatment on microstructure and mechanical properties of nonequiatomic CoCrFeNiMo medium-entropy alloys prepared by hot isostatic pressing

- Corrosion behaviour of multilayer CrN coatings deposited by hybrid HIPIMS after oxidation treatment

- Surface hydrophobicity and oleophilicity of hierarchical metal structures fabricated using ink-based selective laser melting of micro/nanoparticles

- Research on bond–slip performance between pultruded glass fiber-reinforced polymer tube and nano-CaCO3 concrete

- Antibacterial polymer nanofiber-coated and high elastin protein-expressing BMSCs incorporated polypropylene mesh for accelerating healing of female pelvic floor dysfunction

- Effects of Ag contents on the microstructure and SERS performance of self-grown Ag nanoparticles/Mo–Ag alloy films

- A highly sensitive biosensor based on methacrylated graphene oxide-grafted polyaniline for ascorbic acid determination

- Arrangement structure of carbon nanofiber with excellent spectral radiation characteristics

- Effect of different particle sizes of nano-SiO2 on the properties and microstructure of cement paste

- Superior Fe x N electrocatalyst derived from 1,1′-diacetylferrocene for oxygen reduction reaction in alkaline and acidic media

- Facile growth of aluminum oxide thin film by chemical liquid deposition and its application in devices

- Liquid crystallinity and thermal properties of polyhedral oligomeric silsesquioxane/side-chain azobenzene hybrid copolymer

- Laboratory experiment on the nano-TiO2 photocatalytic degradation effect of road surface oil pollution

- Binary carbon-based additives in LiFePO4 cathode with favorable lithium storage

- Conversion of sub-µm calcium carbonate (calcite) particles to hollow hydroxyapatite agglomerates in K2HPO4 solutions

- Exact solutions of bending deflection for single-walled BNNTs based on the classical Euler–Bernoulli beam theory

- Effects of substrate properties and sputtering methods on self-formation of Ag particles on the Ag–Mo(Zr) alloy films

- Enhancing carbonation and chloride resistance of autoclaved concrete by incorporating nano-CaCO3

- Effect of SiO2 aerogels loading on photocatalytic degradation of nitrobenzene using composites with tetrapod-like ZnO

- Radiation-modified wool for adsorption of redox metals and potentially for nanoparticles

- Hydration activity, crystal structural, and electronic properties studies of Ba-doped dicalcium silicate

- Microstructure and mechanical properties of brazing joint of silver-based composite filler metal

- Polymer nanocomposite sunlight spectrum down-converters made by open-air PLD

- Cryogenic milling and formation of nanostructured machined surface of AISI 4340

- Braided composite stent for peripheral vascular applications

- Effect of cinnamon essential oil on morphological, flammability and thermal properties of nanocellulose fibre–reinforced starch biopolymer composites

- Study on influencing factors of photocatalytic performance of CdS/TiO2 nanocomposite concrete

- Improving flexural and dielectric properties of carbon fiber epoxy composite laminates reinforced with carbon nanotubes interlayer using electrospray deposition

- Scalable fabrication of carbon materials based silicon rubber for highly stretchable e-textile sensor

- Degradation modeling of poly-l-lactide acid (PLLA) bioresorbable vascular scaffold within a coronary artery

- Combining Zn0.76Co0.24S with S-doped graphene as high-performance anode materials for lithium- and sodium-ion batteries

- Synthesis of functionalized carbon nanotubes for fluorescent biosensors

- Effect of nano-silica slurry on engineering, X-ray, and γ-ray attenuation characteristics of steel slag high-strength heavyweight concrete

- Incorporation of redox-active polyimide binder into LiFePO4 cathode for high-rate electrochemical energy storage

- Microstructural evolution and properties of Cu–20 wt% Ag alloy wire by multi-pass continuous drawing

- Transparent ultraviolet-shielding composite films made from dispersing pristine zinc oxide nanoparticles in low-density polyethylene

- Microfluidic-assisted synthesis and modelling of monodispersed magnetic nanocomposites for biomedical applications

- Preparation and piezoresistivity of carbon nanotube-coated sand reinforced cement mortar

- Vibrational analysis of an irregular single-walled carbon nanotube incorporating initial stress effects

- Study of the material engineering properties of high-density poly(ethylene)/perlite nanocomposite materials

- Single pulse laser removal of indium tin oxide film on glass and polyethylene terephthalate by nanosecond and femtosecond laser

- Mechanical reinforcement with enhanced electrical and heat conduction of epoxy resin by polyaniline and graphene nanoplatelets

- High-efficiency method for recycling lithium from spent LiFePO4 cathode

- Degradable tough chitosan dressing for skin wound recovery

- Static and dynamic analyses of auxetic hybrid FRC/CNTRC laminated plates

- Review articles

- Carbon nanomaterials enhanced cement-based composites: advances and challenges

- Review on the research progress of cement-based and geopolymer materials modified by graphene and graphene oxide

- Review on modeling and application of chemical mechanical polishing

- Research on the interface properties and strengthening–toughening mechanism of nanocarbon-toughened ceramic matrix composites

- Advances in modelling and analysis of nano structures: a review

- Mechanical properties of nanomaterials: A review

- New generation of oxide-based nanoparticles for the applications in early cancer detection and diagnostics

- A review on the properties, reinforcing effects, and commercialization of nanomaterials for cement-based materials

- Recent development and applications of nanomaterials for cancer immunotherapy

- Advances in biomaterials for adipose tissue reconstruction in plastic surgery

- Advances of graphene- and graphene oxide-modified cementitious materials

- Theories for triboelectric nanogenerators: A comprehensive review

- Nanotechnology of diamondoids for the fabrication of nanostructured systems

- Material advancement in technological development for the 5G wireless communications

- Nanoengineering in biomedicine: Current development and future perspectives

- Recent advances in ocean wave energy harvesting by triboelectric nanogenerator: An overview

- Application of nanoscale zero-valent iron in hexavalent chromium-contaminated soil: A review

- Carbon nanotube–reinforced polymer composite for electromagnetic interference application: A review

- Functionalized layered double hydroxide applied to heavy metal ions absorption: A review

- A new classification method of nanotechnology for design integration in biomaterials

- Finite element analysis of natural fibers composites: A review

- Phase change materials for building construction: An overview of nano-/micro-encapsulation

- Recent advance in surface modification for regulating cell adhesion and behaviors

- Hyaluronic acid as a bioactive component for bone tissue regeneration: Fabrication, modification, properties, and biological functions

- Theoretical calculation of a TiO2-based photocatalyst in the field of water splitting: A review

- Two-photon polymerization nanolithography technology for fabrication of stimulus-responsive micro/nano-structures for biomedical applications

- A review of passive methods in microchannel heat sink application through advanced geometric structure and nanofluids: Current advancements and challenges

- Stress effect on 3D culturing of MC3T3-E1 cells on microporous bovine bone slices

- Progress in magnetic Fe3O4 nanomaterials in magnetic resonance imaging

- Synthesis of graphene: Potential carbon precursors and approaches

- A comprehensive review of the influences of nanoparticles as a fuel additive in an internal combustion engine (ICE)

- Advances in layered double hydroxide-based ternary nanocomposites for photocatalysis of contaminants in water

- Analysis of functionally graded carbon nanotube-reinforced composite structures: A review

- Application of nanomaterials in ultra-high performance concrete: A review

- Therapeutic strategies and potential implications of silver nanoparticles in the management of skin cancer

- Advanced nickel nanoparticles technology: From synthesis to applications

- Cobalt magnetic nanoparticles as theranostics: Conceivable or forgettable?

- Progress in construction of bio-inspired physico-antimicrobial surfaces

- From materials to devices using fused deposition modeling: A state-of-art review

- A review for modified Li composite anode: Principle, preparation and challenge

- Naturally or artificially constructed nanocellulose architectures for epoxy composites: A review