Abstract

Recent advances in biomedicine largely rely on the development in nanoengineering. As the access to unique properties in biomaterials is not readily available from traditional techniques, the nanoengineering becomes an effective approach for research and development, by which the performance as well as the functionalities of biomaterials has been greatly improved and enriched. This review focuses on the main materials used in biomedicine, including metallic materials, polymers, and nanocomposites, as well as the major applications of nanoengineering in developing biomedical treatments and techniques. Research that provides an in-depth understanding of material properties and efficient enhancement of material performance using molecular dynamics simulations from the nanoengineering perspective are discussed. The advanced techniques which facilitate nanoengineering in biomedical applications are also presented to inspire further improvement in the future. Furthermore, the potential challenges of nanoengineering in biomedicine are evaluated by summarizing concerned issues and possible solutions.

Graphical abstract

1 Introduction

The development in materials science as well as the innovations in engineering and technologies has shaped the evolution in the biomedical industry in recent decades. The diagnostics and therapeutics have been revolutionized ranging from human implants to drug design and delivery, which boost more potential possibilities in treating difficult and miscellaneous diseases [1,2,3]. While previous studies focus on the search of the desired physical and chemical properties from these materials, more and more attention has been focused on the relationship among material structures, properties, and function from a bottom-up perspective. The ability to control material architectures for desired properties and improved performance is found to play an important role in the design of novel materials, which can bring future prospects for advanced technologies in the biomedical industry.

Nanoengineering enables the manipulation of nanostructures from the atomistic and molecular levels and the production of nanomaterials with programmed functions. The importance of nanoengineering is that it can be used to discover the micro and nanoscale clues hidden behind material performance at the macroscale. The presentation of biomaterials from nanoscale modeling to macroscale observation in the multiscale analysis is shown in Figure 1. The recent contributions of nanoengineering in other fields, such as civil engineering, have been discussed and summarized in previous reviews [4,5]. With advances in nanoengineering, the mystery of properties and the underlying mechanisms have been unraveled. Based on molecular-scale control and tailoring, new materials and desired properties can be achieved. In addition, the intricate structure can be designed without a trial-and-error process, which fastens the application process. Owing to the powerful capability of computational modeling from the nanoengineering perspective, molecular dynamics (MD) simulations have been recognized as a vital approach to the analysis of material properties and the discovery of molecular interactions for research in recent decades [6,7]. MD simulations can predict the dynamics and response of atoms based on the accurate atomic models. This method captures the trajectory of atoms in the modeling system, outputting sequential snapshots which involve time evolution of material nanostructures and reflect properties under external conditions. MD simulations contribute not only to the key missing piece for understanding interactions and dynamics at nanoscale but also to the possibility of obtaining novel material synthetics and design, which significantly complement fundamental knowledge from nanoscale in biomedicine.

Structure of materials in life at different length scales. DNA is a long molecule within the cell nucleus at the nanoscale. Sections of DNA code for specific proteins which are usually modeled from mesoscale. These proteins work in the cells which can be seen by a microscope. Groups of cells come together to form tissues, and tissues organize together for organs which are vital for human bodies at the macroscale.

Molecular functions of biomaterials generally depend on structural configurations and behaviors. As nanoengineering allows researchers to focus on the conformational changes in different material systems and dynamic responses to external stimuli, the structures, properties, and functions of biomedical materials can be well characterized. Metallic materials and polymers are among the common materials related to biomedicine, as they are the main components in human body and biomedical devices [8,9]. The organized crystalline or amorphous structures in these systems at the nanoscale offer various special properties which contribute to practical biomedical applications. In addition, nanocomposites usually feature hierarchical structures which map unique properties of elementary building blocks toward macroscopic material performance. The systematic manipulation enabled in MD simulations facilitates the tailoring of composites with improvements. The development of nanoengineering on different material systems has progressed rapidly in recent years, which has opened up new possibilities in both prevention and treatment of diseases.

In this paper, the state-of-the-art process and development of nanoengineering using computational simulations in biomedicine are reviewed. The common materials encountered in biomedical applications, including metallic materials, polymers, and nanocomposites, are selected and summarized with their special functions in human body and biomedical devices. The structure–property relationship in these materials is understood and evaluated using the nanoengineering approach. In addition, the modeling and design processes of biomaterials can be accelerated efficiently through MD simulations combined with advanced computational techniques based on artificial intelligence (AI). The challenges of the nanoengineering are also discussed to distribute the urgent tasks for future research. The review presents the capability of nanoengineering in biomedical applications and gathers useful information for the build-up of database and investigations in the next stages. The comprehensive overview of the existing research findings and current limitations in biomedicine can help to speed up the development of nanoengineering for efficient and potential medicine and therapeutic schedule.

2 Development of materials in biomedicine using nanoengineering

The function and performance of medical devices and therapeutics strongly rely on the properties of constituent materials. Metallic materials, polymers, and nanocomposites are the three common types of materials used in biomedical applications. The fundamental question of how design parameters of materials control physical, chemical, and mechanical properties has not been fully elucidated from traditional experiments. The understanding of the common materials in biomedicine based on nanoengineering is summarized in this section, and the results from MD simulations will streamline the construction and design of advanced biomaterials for applications.

2.1 Metallic materials

Metallic materials are essential for biomedical devices as shown in Figure 2. Metallic materials present many advantages in strength, elasticity, stiffness, toughness, and electrical conductivity, which facilitate applications in different branches, including cardiovascular systems, orthopedic implants, dentistry, otorhinology and biosensing [10,11,12]. Although excellent physical and mechanical properties lead to widespread applications of metallic materials as necessary components for biomedical devices, there are still limitations in biofunctionality and biocompatibility for special requirements. To response to additional needs for biomedical applications, many techniques and designs have been proposed, in which nanoengineering powers further modification and improvement of performance and compatibility for metallic materials. The accuracy of forcefield determines the reliability of the calculated structural and mechanical properties from MD simulations. The embedded-atom method (EAM) is a semi-empirical method for representing metallic bonding in pure metallic systems [13]. This potential has been further modified to fit in more metallic materials and widely used in simulations of point defects, diffusion, and deformation [14,15,16]. Due to the limitations in EAM such as no treatment in covalency or charge transfer, the second nearest-neighbor modified embedded atom method (MEAM) is developed for pure metals and alloys [17,18,19]. MEAM potential is adopted to predict the thermal and mechanical properties of metallic thin films, which achieves a good agreement with experimental measurements [20]. The material phenomena in multicomponent high-entropy alloy and composites are also investigated based on this potential [21,22]. These studies provide appropriate forcefields and corresponding validations for various metallic systems in nanoengineering.

Nanoengineering of metallic materials using MD simulations, demonstrating general biomedical applications and concerned challenges.

Various types of metallic materials have been investigated using MD simulations. The mechanical properties of metals are related to dislocations, and the atomic motion is captured in MD simulations which quantify the limits of dislocation-mediated plasticity [23]. The availability of multigraphics processing unit parallel computation combined with rapid progress in high-performance computational environments enables the billion-atom MD simulation of homogeneous nucleation of pure metal from an undercooled melt, which demonstrates that the local accumulation of the icosahedral structure in the undercooled melt can cause the local heterogeneity in the distribution of grains [24]. The temperature- and stress-induced phase transformations in shape memory alloys are probed using multimillion-atom MD simulations [25]. Due to the ordered structure with specific lattice spacing in metallic materials, the interfacial properties between two adjoining phases are affected by lattice mismatch, which can be well characterized by nanoengineering. The effect of film structure on interfacial structure and intrinsic residual stress caused by interfacial lattice mismatch in layered metallic composites is figured out using MD simulations, and the atomistic origin of atom arrangement is pointed out for the consideration of composite design with desired properties [26]. In addition, protein and other biomolecules usually tend to adsorb on the surface of inorganic materials. For the interface between polymer and metal substrate, the influence of lattice spacing, polymer chain length, and adhesive strength on the interfacial structure and elastic properties are examined, which reveals interfacial interactions and strength of amorphous materials bonded metallic substrate [27]. The adsorption and free energy profiles of amino acid side chain analogues and a titanium binding peptide on the TiO2 surface are evaluated using MD simulations with enhanced sampling methods for safe medical implants in biological environments [28]. Biocontamination or biofouling can cause health-associated infections in applications including water purification systems and surgical equipment. To reduce the adhesion between bacteria and solid surface, the superhydrophobic coating with antibacterial property is introduced on the stainless-steel substrate, and results from MD simulations suggest how the surface with antimicrobial activity adsorb on the substrate and interact with water molecules [29]. The corrosion-resistant properties of hydrophobic peptide-coated stainless steel in chloride solution are characterized with the combination of MD simulations and experimental measurements, and a promising anticorrosion coating is suggested for metal-containing medical devices [30]. The dynamical information involving conformation changes of biopolymers mediated by metal ion binding is provided in simulations for the development of efficient inhibitors to decrease drug resistance toward antibiotics [31]. The interactions and competition between monovalent metal ions for DNA sequences are also reported through simulations to understand how mobile metal ions regulate conformational behavior and functional dynamics of nucleic acids [32]. The nanoengineering has extended the exploration of metallic materials at the nanoscale, which provides more valuable information for industrial applications of biomedical devices and therapeutics using metallic materials.

2.2 Polymeric materials

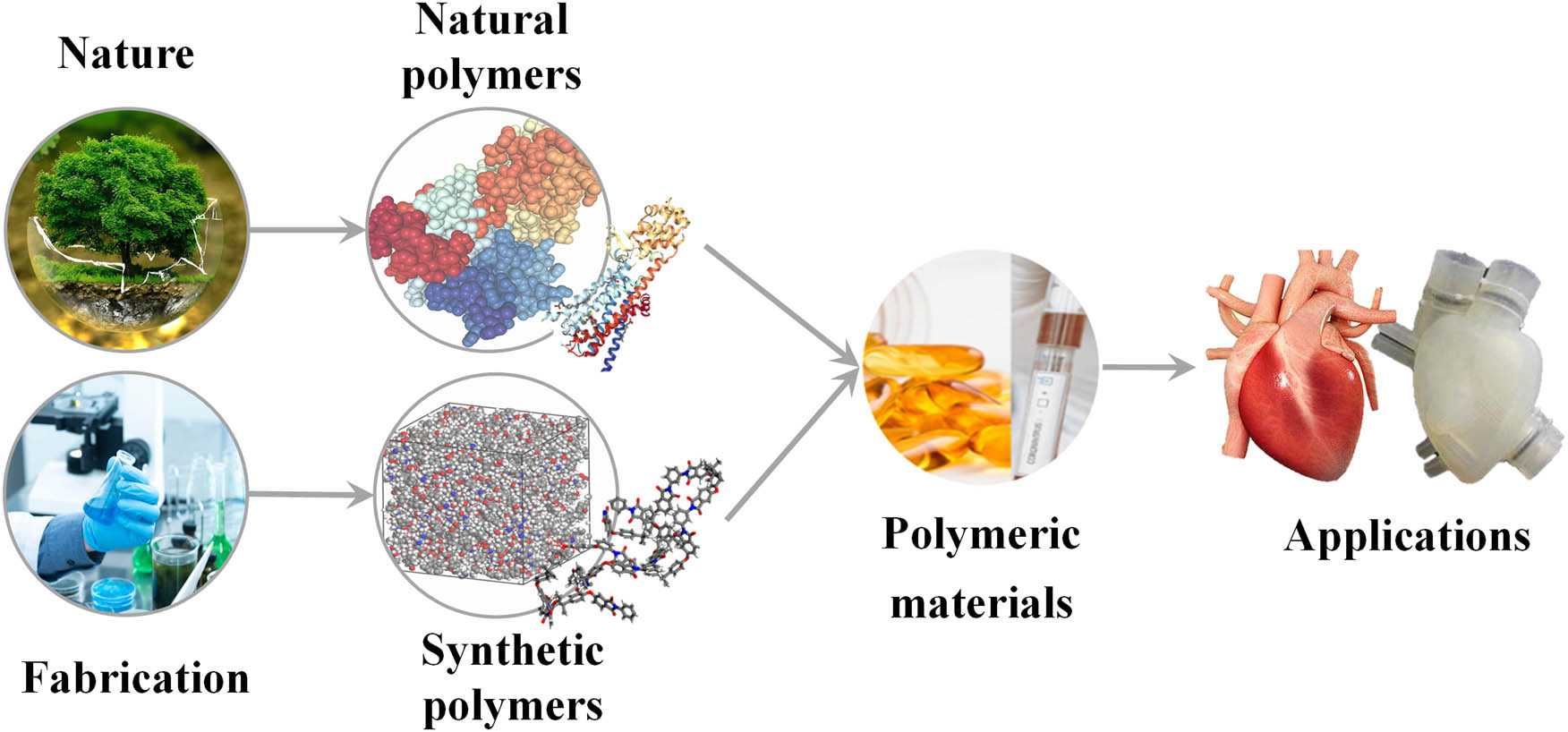

Polymeric materials are found broadly in every material encountered in daily life, from structural organics and living cells to electronic packaging and civil constructions. They have also been extensively involved in biomedical applications, such as lenses, implantation, artificial organs, dental materials, drug delivery, and tissue engineering. Polymers can be divided into two major categories as shown in Figure 3: one category includes natural polymers, which can be found from nature, while the other category contains synthetic polymers, which are man-made in fabrication to meet desired functions. Nanoengineering plays an important role in the manipulation of polymeric materials by providing optimal selection of molecules, reliable estimation of desired properties, and efficient guideline for processing. To ensure the accuracy of needed information in MD simulations, various forcefields have been developed to describe different polymer systems. The effort in understanding how nanostructures of polymeric materials govern material properties and behaviors to ensure functions and performance in service is reported in this subsection.

Nanostructures of polymeric materials in modeling. Polymers are separated into two types. One is natural polymer that can be found in a natural environment, and the other one is synthetic polymer from man-made fabrication.

2.2.1 Natural polymers

Natural polymers are vital for living creatures. Typical natural polymers in human bodies are nucleic acids which store genetic information, proteins which induce biochemical transformations, and lipids which provide cell membrane structure and resilience. Various forcefields have been developed for the simulations of conformations and structural behaviors of different natural polymers. CHARMM and OPLS are typical condensed phase biomolecular forcefields which are parameterized for nucleic acids and other biomolecules [33,34,35]. AMBER forcefield is derived from quantum mechanical calculations to describe the interactions in nucleic acids and proteins [36,37]. GROMOS forcefield can reproduce thermodynamic properties of pure liquids and the solvation free enthalpies of amino acid based on the free enthalpy of hydration and solvation [38]. AMOEBA polarizable atomic multipole forcefield is developed for modeling structural diversity and transitions of nucleic acids [39]. The availability of these forcefields for various interactions between different types of material structures is validated [40], and the modifications to simulate special configurations such as disordered proteins are consistent with experimental observations [41,42,43]. These advances have enabled a lot of biomedical research on natural polymers using nanoengineering.

The conformations and related heterogeneity of natural polymers are key elements in unraveling their biofunctions. The structures of proteins determined by specified sequences of amino acid building blocks and the related folding mechanism have been extensively investigated over the past few decades through MD simulations [44]. Elastin, an important type of protein materials, has exquisite flexibility and possesses inverse temperature transition with folded structural form at high temperatures, which motivates applications in drug delivery, shape change materials, and biomimetic devices [45,46]. Nanoengineering has enhanced the understanding of elasticity and recoil provided by elastin in body tissues [47]. The atomistic model for tropoelastin is validated with experiments, and the conformational changes and variations in hierarchical assembly are explained for molecular mechanisms behind disease [48]. The different disease-causing mutations in the single gene that control the formation of tropoelastin are found to change the molecule’s stiffness and dynamic responses from MD simulations, which can ultimately help in the design of treatments or countermeasures for these conditions [49]. Many diseases, such as Alzheimer’s, Parkinson’s, and prion diseases, are linked to the self-assembly of peptides; thus, the understanding of the fibril formation by such peptides is of great importance for cures and preventives. The self-assembly process of a pentapeptide inhibitor on the surface of highly oriented pyrolytic graphite is studied through simulations combined with experiments to reveal the mechanism of peptide-based fibrillization in amyloid diseases and inspire new design for well-ordered nano- and microstructures [50]. The process of uptake of ferrous ions into human ferritin protein and the catalytic ferroxidase sites via pores in the interior of the protein are captured in simulations [51]. The protein-related composites also present diverse mechanical behaviors and serve for multiple functions. It is found from MD results that the chitin–protein composite becomes stiffer with longer embedded chitin fibers, and the ductility is mainly contributed to interlocked zigzag nanostructure between chitin fibers [52]. In addition, the solvent environment as well as the concentration of chemical ions controls the properties and behaviors at chitin–protein interface, and the atomistic mechanism behind is elucidated using MD simulations [53]. The molecular structure of interface between lipid bilayers and graphene as well as the diffusivity of water is analyzed for the thermal dissipation from bio-nanodevices [54]. The structural rigidity of carbohydrate-based polymers is investigated through MD simulations, which is consistent with experimental observations and conduces to the comprehensive understanding of carbohydrate-based systems [55]. These results using atomistic models in simulations provide fundamental information toward the relationship between structures and material properties as well as solid foundation for the modeling construction of natural polymers.

As the size dimension of biomacromolecular systems (e.g. proteins and lipid) is larger than that in traditional atomistic models, the bottom-up approach is applied for large-scale simulations. Coarse-grained (CG) modeling technique is developed and applicable for natural polymers [56,57]. The framework of MARTINI forcefield is applied to build CG models of natural polymers, which are helpful for the investigation of protein systems and protein-related interactions at mesoscale [58,59]. MARTINI-based framework is also used to construct CG model for tropoelastin assembly to investigate chemical details of protein–protein interactions and macromolecular self-assembly systems [60]. Based on MARTINI CG forcefield, the molecular details of interaction between phthalocyanines and membranes of various compositions are demonstrated, and the process of special molecules suggests twofold cytotoxic effect on bacterial cells [61]. The interactions between free graphene and biological cell are declared through CG MD simulations, which is to achieve selectively patterned, aligned, confined, and electrically anisotropic graphene winkles by the bacterium scaffold [62]. In addition to CG modeling, a quantitatively accurate microscopic model for protein–protein association is developed based on unbiased all-atom MD simulations and Markov modeling, which reveals kinetic and mechanical details of the association mechanism [63]. The combination of computational technique and multiscale analysis further extends the model size and simulation timescale for macromolecules in MD simulations.

2.2.2 Synthetic polymers

Synthesis polymers are formed by linking repeated structural monomers, and their material properties can be tailored by altering the molecular weight or setting specific environment in applications. Similar to natural polymers, various forcefield types, such as consistent valance forcefield (CVFF) [64], polymer consistent forcefield (PCFF) [65], Dreiding [66], and COMPASS [67], have been developed to be suited in polymer systems. The material properties of crosslinked epoxy structure based on these forcefields are compared, which are in reasonable accord with experimental measurements [68]. For chemical processes which involve bond break and formation within polymer chains, the reactive forcefield (ReaxFF) can be used to describe these reactions [69]. The cross-linking and thermomechanical properties of epoxy are simulated using ReaxFF, showing good agreement with experimental results [70,71,72]. The chemical reaction pathway of oxidation is figured out by ReaxFF, and the formation of carbon monoxide is found to be related to the concentration of carboxyl and formyl groups [73]. These research works have reported appropriate forcefields which can describe chemical properties of synthetic polymers for nanoengineering.

Schematic diagram of nanocomposites reinforced with nanosized additives in MD simulations and biomedical applications.

As synthetic polymers are necessary components for artificial organs, stents, and implants, the structure–property relationship as a significant consideration in applications has been widely investigated. The mechanical properties of thermoplastic polyimide are explored with the influence of cooling and deformation rates, external temperature, and pressure [74]. The glass transition temperatures of shape memory polymers with different molecular weights have been predicted through theoretical analysis and MD simulations, and the results are in a good agreement with experiment results [75]. Epoxy and its systems are widely used as biological sutures, stents, and bladder sensors for tissue engineering [76,77]. The performance of epoxy-related materials is the interest in biomedical applications. The macroscopic fracture energy of epoxy is predicted with scale-bridging approach that links MD simulations and macroscopic fracture properties [78]. The simulations of liquid-phase exfoliation of phosphorene in the solvents emphasize the role of solvent molecular geometry and ordering for effective nanomaterial exfoliation media [79]. The interfacial integrity of epoxy-bonded system plays an important role in mechanical properties [80,81]. How interfacial structures as well as chemical molecules affect interfacial properties are elucidated in combination of MD simulations and experiments [82,83,84]. The change of microstructure and the analytical relationship between creep displacement and energy barrier during interfacial creep are also investigated for the predictions of materials in long-term service [85]. The solid-state polymerization of crystalline two-dimensional conjugated aromatic polymers with well-defined repeating units and in-built porosity is captured by MD simulations, and such approach is beneficial for the construction of novel polymers in synthetic chemistry [86]. Plenty of research works on material properties of synthetic polymers have been beneficial to the application and design of biomedical devices.

2.3 Nanocomposites

Nanocomposites are multicomponent materials which contain different phase domains with at least one-dimension of the order of nanometers, providing various chemical and mechanical properties with unique features, as shown in Figure 4. Nanoparticles composed of general materials or fabricated from nanomaterials are commonly applied as the reinforcement for metallic or polymer matrix. The diversity in the constitutes and dimensions of nanocomposites has brought great potential in the significant improvement of performance and advancement of biomedical applications. However, the heterogeneous structures of nanocomposites make it difficult to characterize material behaviors directly and describe the interfacial interactions among different phase domains in detail. Nanoengineering is required for further understanding of the structure–property relationship in nanocomposites. The engineering of nanoparticles and the reinforcement on nanocomposites using MD simulations are introduced in this subsection.

Due to the nanometer dimension, nanoparticles can penetrate tissues or be untaken by cells; thus, they provide immense opportunity in drug delivery, imaging, and biosensing [87,88,89]. Nanoengineering helps to understand the atomistic structures of nanoparticles and the interactions with targeted materials. Metallic and polymeric materials can be engineered into particles. Metallic nanoparticles are commonly used for catalysis, optics, and medicine therapeutics [90,91]. The microscopic origin of the growth mechanism, self-assembly, and thermal stability in metallic nanoparticles is demonstrated using nanoengineering approach for the tailored design [92,93]. The deformation mechanisms and the possible formation of a dislocation network in MgO nanotube are interpreted by MD simulations [94]. Microscopic origin of asymmetric growth mechanism in copper nanoparticles is understood by MD simulations, and the particle size and shape can be manipulated and controlled to tune material properties [95]. The solvation of metal nanoparticles in deep eutectic solvents considering is analyzed with the effects of type of metal, type of deep eutectic solvent, particle size and shape [96]. The atomistic structural and dynamical information of inorganic nanoparticles stabilized by organic molecules is uncovered for controllable functionalization of nanoparticles [97]. The microscopic understanding of the direct self-assembly process of functionalized nanofibers is explained through MD simulations with CG models to guide robust target-specified design of nanofibrous materials into organized network structures [98]. The biomedical applications of polymeric nanoparticles include biosensing and drug delivery [99,100]. The effect of aggregation behavior in solution on the interactions between fluorinated polymeric nanoparticles and living cells is investigated using the combination of computational and experimental approaches, and it is found that the improved drug delivery efficiency to living cells is caused by the larger proportion of polymeric segments exposed to the cell surface [101]. The interactions in the polymeric nucleic acid nanoparticles are elucidated through MD simulations, and the key features contributing to response of the short interfering RNA nanoparticle to heparin are identified for the role of glycosaminoglycans in the delivery [102]. The uncovered mechanism and nanoscale details have facilitated the tuning of polymeric nanoparticles for biomedical applications. The nanoengineering serves as an efficient platform for the development of nanoparticle technologies.

Nanoparticles have been found to be the potential reinforcement for material matrices, which causes particular interest in new generation of nanocomposites [103,104]. The enhancement in mechanical properties of polymer nanocomposites is convinced through the combination of experiments and simulations, and the simulation results provide atomistic details in the reinforcement mechanism [105,106,107]. The exploration of the interfacial properties between two dissimilar material systems at the molecular level is allowed by nanoengineering. It is found that the adsorption of collagen like peptides with gold nanoparticles depends on the amino acid composition, and gold nanoparticles can be exploited to detect breast cancer, which provides information for designing collagen-based scaffolds for tissue engineering [108]. In addition, the nanoparticle size, shape, and the interfacial interactions between nanoparticle and matrix have a significant influence on the properties of nanomaterials [109]. It is found from the parametric study that CNTs with longer length and higher weight fraction can improve creep behavior of epoxy nanocomposites, and dispersion state is another controlling parameters in the enhancement of mechanical properties [110]. The functionalization of CNT is found to modify the interfacial properties between CNT and epoxy matrix, which can further improve mechanical performance [111]. The interfacial adhesion between nanocellulose and poly(methyl methacrylate) is systematically examined, and the structural properties and relaxation dynamics of polymer chains near the interface are presented for intentional surface engineering [112]. The effect of stiffened interphase region on the mechanical response of polymer composites is evaluated through multiscale computational analysis for the microscopic failure mechanism [113]. It is expected that the molecular information achieved from nanoengineering can boost the advanced design of nanocomposites in biomedicine.

To achieve more biofunctionality and biocompatibility for biomedical applications, the effort to integrate special structures from metallic materials and polymers into composite materials has been undertaken. Metal–organic frameworks (MOFs), known as organic–inorganic hybrid composites, have been considered as promising materials [114]. One of the advantages is that the porous structures of MOFs provide more drug loading capacity in delivery [115]. The thermomechanical and viscoelastic properties of MOF materials are measured from simulations, and the obtained results are consistent with experiments [116]. The storage and release of drug, ibuprofen, cosmetic molecules, caffeine, and urea are evaluated using MD simulations, and the flexibility of the MOF structure is further predicted in simulations [117]. Gas diffusion [118] and absorption [119] in MOF are investigated for further understanding of MOF structures. Multiscale simulations also reveal MOF as a potent drug carrier for gemcitabine delivery [120]. The understanding of breathing mechanism in redox-switchable breathing MOFs can facilitate the new design of stimuli-responsive MOFs [121]. For the development of MOF-related materials, the liquid MOF is introduced with structural, dynamical, and thermodynamical information for wider MOF family using experiments and MD simulations [122]. MOF can also be used as nanoparticles in mixed matrix membranes, and the carbon capture in polymer reinforced by functionalized MOF is modeled [123]. Furthermore, the ultrafast and selective ion transport in MOF-based membranes is suggested by simulation results for ion separation [124]. The microscopic interfacial structures of MOF–polymer composites are explored to unravel the structure–compatibility relationship of MOF–polymer pairs [125]. The atomistic level understanding using nanoengineering benefits to enrich design guidelines for MOF with enhanced functions.

3 Development of advanced computational techniques in nanoengineering

MD simulations provide a great deal of information on structure and function of biomaterials that are necessary for modeling and design, but a larger number of results make it hard to extract the useful information immediately. Advanced computational techniques are needed for data collection and analysis. The development of AI has enabled computers to learn from massive data sets. Especially, machine learning (ML) brings about mind-blowing achievements in everyday life, such as ranking web search results, speech recognition, optical character recognition, and recommending videos. The series of AI techniques have also been applied in nanoengineering, which can provide scaling up and transferable prediction based on existing database and facilitate the material modeling and design process [126]. The additive manufacture of materials, known as three-dimensional (3D) printing, can generate complex structures with high resolution [127]. Nanoengineering helps in identifying the interplay between design parameters to calibrate material properties and distributes engineering rules to meet accuracy requirements [128]. The integration of AI research into nanoengineering approach can provide superior efficacy in the modeling and design for biomedical materials.

3.1 Modeling approach with ML

The precise forcefield and structural information are significant for the description of material systems. Although classical forcefields mentioned in the previous section can model the properties and dynamics of general types of materials, they cannot fit well to some complicated systems. The development of a new forcefield based on the electronic-structure theory usually requires a large amount of computational resources, and its accuracy is not ensured immediately. ML algorithms to develop forcefields for MD simulations have been proposed in recent studies [129,130,131]. A general and universal strategy is proposed to generate ML forcefields for the performance of high-fidelity MD simulations, which is successfully applied to six elemental bulk solids with chemical accuracy [132]. Based on ML approach for atomic force reconstruction, crystalline and liquid phases of aluminum and uranium are modeled, which are in a good agreement with experimental data [133]. The integration of ML-based stacked ensemble model with MD simulations is proposed to get the on-the-fly analysis of MD simulation trajectory while developing forcefield parameters, and the computational framework makes it possible the analysis of large size MD simulation trajectories [134]. To bridge the gap between the developed new forcefields and the applications in academia and industry, ML framework with data-driven approach is employed by including the extensive training data sets from first-principle calculations for a wide range of materials [135]. The CG free energy functions trained by ML are also formulated to capture the crucial features of the free energy surface in CG models [136]. The practical computational framework with ML approach is applied to the CG modeling of epoxy systems, which can predict the mechanical properties over wide range of cross-linking degree and temperature [137].

AI techniques integrated with MD simulations are applied effectively to examine the detailed structures and understand the molecular modes of actions in biomaterials. Protein structures in human body are complex with various functions, and the bioinformation is still incomplete in the current stage. The first application of ML techniques to simulate the dynamics of a peptide has been reported, which is to predict molecular infrared spectra and account for the effects being neglected in conventional approach [138]. To further understand the formation and related properties of proteins, nanoengineering combined with ML approach has been applied for the analysis. The application of ML algorithms in protein dynamics studies has been investigated [139,140]. Protein kinase C isoforms, one type of membrane-associated proteins evaluated clinically for the treatment of cancer and Alzheimer’s disease and the eradication of HIV/AIDS, is modeled through long-timescale MD simulations integrated with ML optimization, demonstrating different membrane states in biological effects [141]. To predict the structure of folded protein for any given amino-acid sequence, researchers have developed a multiplayer online game to recruit human abilities for this large task [142,143].

3.2 Material design using ML

Compared with traditional material design methods using trial-and-error experiments, the combination of AI techniques and MD simulations in nanoengineering can reduce both the time and the cost on the materials and tests. This is because material properties under different conditions are predicted systematically so that material options in the design can be compared directly. The data analysis and simulation are applied to create new tools for the design of novel antimicrobial peptides, and the important features in antimicrobial activity which enlighten the design are discovered [144]. The first virtual library of elastin-like protein models for sampling is reported, which is beneficial for polymer design based on elastin protein mutability [145]. A novel approach that translates amino acid sequences to musical compositions and trains a neural network using audible representation in the musical space is proposed, and it can be applied to generate protein designs from AI [146]. Based on the translation from protein sequences and structural information to musical score with pitches, a deep learning model is further introduced to design de novo protein materials [147]. In addition, ML model based on the dataset of the natural frequency of over 1,00,000 known protein molecular structures from the Protein Data Bank is used to investigate the correlation between their structural features and natural frequency, which can bring computation efficient and predict the functions of unknown protein molecules [148]. The design of a sequence folded into a predictable structure for specific material function is conducted using AI techniques without using a template or co-evolutional information [149]. Moreover, the bio-inspired design [4], motivated by insights from nature, generally requires high computational expense in optimization. To accelerate the evolutionary process, the computational framework guided by ML is employed into the design of bioinspired hierarchical structures with desired mechanical properties [150]. ML-based inverse design approach is introduced for much faster identification of candidate materials and optimization [151]. AI algorithm is also helpful in the design of nanoparticles and nanocomposites with specific mechanical functions [152,153]. The general design flowchart of nanoengineering with AI techniques is summarized in Figure 5. While AI techniques promote engineering design, 3D printing can accelerate the manufacturing process with freedom of shapes, forms, and quantity. Heparin-functionalized collagen gels supported by 3D printed bioceramic scaffolds as bone extracellular matrix-mimetic matrices with osteogenic capacity are developed for cell-based patient-specific bone tissue engineering [154]. It is demonstrated that the nanocellulose with printability and possibility to support living cells allows 3D bioprinting for biomedical applications in future [155,156,157]. It is speculated that the additive manufacturing of biomaterials with design based on AI techniques speeds up the innovation of biomaterials and medical devices.

Flowchart of nanoengineering combined with AI for material modification and design. The process mainly involves the following steps. The first step is to get the material concept for modification and design, and to obtain the information of material structures. The dataset of designed materials is then collected from experiments or ab initio simulations based on the density functional theory. The AI techniques are integrated into MD simulations to characterize material properties and predict material behaviors. The simulation testing is repeated for further optimization. Finally, the optimal design model is turned into new products with additive manufacturing for practical applications.

4 Key challenges

While nanoengineering has fastened the development of biomedicine in recent years, there are still limitations in the employment of new techniques as well as safety and environmental concerns over the applied materials. Despite of favorable performance of nanoengineering equipped with AI techniques, the existing well-structured training dataset is still required for optimization. Since some biomedical devices, such as artificial bones and stents, are in close contact with parts of human body for a long period of time. How newly developed materials affect health during service becomes an urgent problem to be solved for safety concern in practical applications. In addition, the scale-up design of materials and technologies from nanoengineering to large productions with low costs and shortened processing time is another challenge in biomedical applications. The three major challenges, including the lack of comprehensive database, the toxicity, and the conversion from research to industry, should be overcome to keep pace with the breakthrough in research of materials and the urgent need for techniques and products in market.

Although the integration of AI into nanoengineering has been limited in the modeling and design processes, the training data for AI is still insufficient to all the materials or to meet all the requirements. The availability of large amount and good quality of data becomes essential for the successful adoption of AI techniques. This requires the gathering and organization of experimental measurements from existing research. To ensure the data can be found and accessed by researchers from different disciplines, the findability, accessibility, interoperability, and repurposability of data are required [158]. The results shown in different manners (e.g., unit) can bring about inconvenience. Furthermore, the variance in ML models is sensitive to small fluctuation in the data set, which can create errors arising from these noises even in well-trained models [159]. Such uncertainty generates doubts in the results from AI-equipped nanoengineering.

The toxicity of nanocomposites containing nanoparticles remains unclear as nanoengineering cannot report their toxic effects directly. Although the safety monitoring of biomedical materials has been taken before applications, the available information of toxic effects from nanomaterials on human health in a long run is still insufficient. With smaller size, the nanoparticles are able to penetrate biological membranes into blood stream, tissues, and organs, with potential to access the brain and the nuclei of cell, which can lead to both genotoxicity and biochemical toxicity [160,161]. The solubility and persistence of nanocomposites, especially insoluble nanoparticles which cannot be digested or degraded, will accumulate in human body and cause damage to organs. In addition, higher surface area to mass ratio of nanoparticles brings higher reactivity to materials; in turn, it can trigger some unknown chemical reactions which can alter their physicochemical properties. The potential nanotoxicity of nanomaterials is indicated in the MD simulations by revealing the destructive effect of nanomaterials on proteins [162]. The non-nanotoxicity of new nanomaterials toward genetic materials is demonstrated through simulations [163]. Researchers have undertaken innovations for effective materials which are nontoxic and effective. The polymeric nanoparticles named Accurins are used to deliver a cancer inhibitor for the control of the release to cancer cells, which can enhance the safety and antitumor activity of inhibitor and other molecularly targeted drugs [164]. The nanoengineering approach can help in tracking the movements of the nanomaterials and understand the reactions with proteins which can infer the toxicity in the simulation timescale. The performance for long timescale still remains to be predicted in a multiscale manner.

Aside from the problems toward safety issues which cause doubts of nanoengineering in practical applications, the transformation from nanoengineering research work to large productions for clinical trials turns out to be one of the major challenges. Nanoengineering offers greater efficiency and accuracy compared with conventional approach, but the large production requires the transition from nanoscale to macroscale. The developed additive manufacture with functional prototypes from AI-aided MD simulations plays an important role in the connection with industrial applications. Future biomedical research using nanoengineering techniques should be directed toward problems demanding prompt and optimal solutions so that the concerns and hesitation from the public toward the immersion of nanotechnology into biomedicine can be reduced.

5 Conclusions

In this paper, the main progress of nanoengineering approach in biomedicine has been reviewed. Based on the concept of nanoengineering, MD simulations are powerful in uncovering nanoscale conformational information and molecular interactions during physical and chemical processes which control macroscopic properties behind symptoms induced by diseases in human body and degradation caused by environmental factors in devices. The accuracy in modeling of biomedical materials including metallic materials, polymers, and nanocomposites are crucial in the promotion of nanoengineering. The relationship between molecular structures and functional behaviors in these biomedical materials can be revealed through MD simulations. Aided with advanced AI techniques, nanoengineering has already become an efficient approach with profound impact for biomedical applications in recent years, and it also has presented great potential as the pioneer technology for the next generation in this field. The review based on adequate studies can provide fundamental information for an in-depth understanding of the development in biomedicine. However, the lack of sophisticated database for ML training, and the uncertainty of safety issue of newly developed materials as well as the industrial production in practice become the main challenges which hinder the pace from moving forward. Future tasks should be aligned with these challenges in the AI-equipped nanoengineering approach, and it is believed that the impact from such movement will be tremendous. The effort of connecting research using MD simulations in nanoscale and large productions in macroscale for biomedical practice is also under way, and it is envisioned that current difficulties in diagnose and treatment can be overcome with great efficacy.

Acknowledgments

The work described in this paper was supported by a grant from the Research Grants Council of the Hong Kong Special Administrative Region, China (Project No. CityU 11207617).

-

Conflict of interest: The authors declare no conflict of interest regarding the publication of this paper.

References

[1] Kim D, Shin K, Kwon SG, Hyeon T. Synthesis and biomedical applications of multifunctional nanoparticles. Adv Mater. 2018;30(49):1802309.10.1002/adma.201802309Search in Google Scholar

[2] Yan Q, Dong H, Su J, Han J, Song B, Wei Q, et al. A review of 3D printing technology for medical applications. Engineering. 2018;4(5):729–42.10.1016/j.eng.2018.07.021Search in Google Scholar

[3] Li J, Liu Y, Ren J, Tay BZ, Luo T, Fan L, et al. Antibody-coated microstructures for selective isolation of immune cells in blood. Lab Chip. 2020;20:1072–82.10.1039/D0LC00078GSearch in Google Scholar

[4] Lau D, Jian W, Yu Z, Hui D. Nano-engineering of construction materials using molecular dynamics simulations: prospects and challenges. Composites Part B. 2018;143:282–91.10.1016/j.compositesb.2018.01.014Search in Google Scholar

[5] Sanchez F, Sobolev K. Nanotechnology in concrete – a review. Constr Build Mater. 2010;24(11):2060–71.10.1016/j.conbuildmat.2010.03.014Search in Google Scholar

[6] Karplus M, McCammon JA. Molecular dynamics simulations of biomolecules. Nat Struct Biol. 2002;9(9):646–52.10.1038/nsb0902-646Search in Google Scholar

[7] Buehler M. Atomistic modeling of materials failure. New York: Springer Science & Business Media; 2008.10.1007/978-0-387-76426-9Search in Google Scholar

[8] Ramakrishna S, Mayer J, Wintermantel E, Leong KW. Biomedical applications of polymer-composite materials: a review. Compos Sci Technol. 2001;61(9):1189–224.10.1016/S0266-3538(00)00241-4Search in Google Scholar

[9] Niinomi M. Recent metallic materials for biomedical applications. Metall Mater Trans A. 2002;33(3):477.10.1007/s11661-002-0109-2Search in Google Scholar

[10] Tibbitt MW, Rodell CB, Burdick JA, Anseth KS. Progress in material design for biomedical applications. Proc Natl Acad Sci U S A. 2015;112(47):14444.10.1073/pnas.1516247112Search in Google Scholar PubMed PubMed Central

[11] Jain PK, Huang X, El-Sayed IH, El-Sayed MA. Noble metals on the nanoscale: optical and photothermal properties and some applications in imaging, sensing, biology, and medicine. Acc Chem Res. 2008;41(12):1578–86.10.1021/ar7002804Search in Google Scholar PubMed

[12] Pardeep S. NiTi shape memory alloy: physical and tribological characterization. J Mech Behav Mater. 2018;27(1–2):20180009.10.1515/jmbm-2018-0009Search in Google Scholar

[13] Daw MS, Baskes MI. Embedded-atom method: derivation and application to impurities, surfaces, and other defects in metals. Phys Rev B Condens Matter Mater Phys. 1984;29(12):6443–53.10.1103/PhysRevB.29.6443Search in Google Scholar

[14] Mishin Y, Mehl MJ, Papaconstantopoulos DA. Embedded-atom potential for B2-NiAl. Phys Rev B Condens Matter Mater Phys. 2002;65(22):224114.10.1103/PhysRevB.65.224114Search in Google Scholar

[15] Mendelev MI, Han S, Srolovitz DJ, Ackland GJ, Sun DY, Asta M. Development of new interatomic potentials appropriate for crystalline and liquid iron. Philos Mag. 2003;83(35):3977–94.10.1080/14786430310001613264Search in Google Scholar

[16] Williams PL, Mishin Y, Hamilton JC. An embedded-atom potential for the Cu–Ag system. Model Simul Mater Sci. 2006;14(5):817–33.10.1088/0965-0393/14/5/002Search in Google Scholar

[17] Lee B-J, Baskes MI. Second nearest-neighbor modified embedded-atom-method potential. Phys Rev B Condens Matter Mater Phys. 2000;62(13):8564–7.10.1103/PhysRevB.62.8564Search in Google Scholar

[18] Lee B-J, Baskes MI, Kim H, Koo Cho Y. Second nearest-neighbor modified embedded atom method potentials for bcc transition metals. Phys Rev B Condens Matter Mater Phys. 2001;64(18):184102.10.1103/PhysRevB.64.184102Search in Google Scholar

[19] Jang H-S, Kim K-M, Lee B-J. Modified embedded-atom method interatomic potentials for pure Zn and Mg–Zn binary system. Calphad. 2018;60:200–7.10.1016/j.calphad.2018.01.003Search in Google Scholar

[20] Hao H, Lau D. Atomistic modeling of metallic thin films by modified embedded atom method. Appl Surf Sci. 2017;422:1139–46.10.1016/j.apsusc.2017.05.011Search in Google Scholar

[21] Elkhateeb MG, Shin YC. Molecular dynamics-based cohesive zone representation of Ti6Al4V/TiC composite interface. Mater Des. 2018;155:161–9.10.1016/j.matdes.2018.05.054Search in Google Scholar

[22] Choi W-M, Jo YH, Sohn SS, Lee S, Lee B-J. Understanding the physical metallurgy of the CoCrFeMnNi high-entropy alloy: an atomistic simulation study. npj Comput Mater. 2018;4(1):1.10.1038/s41524-017-0060-9Search in Google Scholar

[23] Zepeda-Ruiz LA, Stukowski A, Oppelstrup T, Bulatov VV. Probing the limits of metal plasticity with molecular dynamics simulations. Nature. 2017;550(7677):492–5.10.1038/nature23472Search in Google Scholar PubMed

[24] Shibuta Y, Sakane S, Miyoshi E, Okita S, Takaki T, Ohno M. Heterogeneity in homogeneous nucleation from billion-atom molecular dynamics simulation of solidification of pure metal. Nat Commun. 2017;8(1):10.10.1038/s41467-017-00017-5Search in Google Scholar PubMed PubMed Central

[25] Morrison KR, Cherukara MJ, Kim H, Strachan A. Role of grain size on the martensitic transformation and ultra-fast superelasticity in shape memory alloys. Acta Mater. 2015;95:37–43.10.1016/j.actamat.2015.05.015Search in Google Scholar

[26] Hao H, Lau D. Evolution of interfacial structure and stress induced by interfacial lattice mismatch in layered metallic nanocomposites. Adv Theory Simulat. 2018;1(8):1800047.10.1002/adts.201800047Search in Google Scholar

[27] Sebeck K, Shao C, Kieffer J. Alkane–metal interfacial structure and elastic properties by molecular dynamics simulation. ACS Appl Mater Interfaces. 2016;8(26):16885–96.10.1021/acsami.6b01665Search in Google Scholar PubMed

[28] Brandt EG, Lyubartsev AP. Molecular dynamics simulations of adsorption of amino acid side chain analogues and a titanium binding peptide on the TiO2(100) surface. J Phys Chem C. 2015;119(32):18126–39.10.1021/acs.jpcc.5b02670Search in Google Scholar

[29] Li S, Liu Y, Zheng Z, Liu X, Huang H, Han Z, et al. Biomimetic robust superhydrophobic stainless-steel surfaces with antimicrobial activity and molecular dynamics simulation. Chem Eng J. 2019;372:852–61.10.1016/j.cej.2019.04.200Search in Google Scholar

[30] Muruve NGG, Cheng YF, Feng Y, Liu T, Muruve DA, Hassett DJ, et al. Peptide-based biocoatings for corrosion protection of stainless steel biomaterial in a chloride solution. Mater Sci Eng C. 2016;68:695–700.10.1016/j.msec.2016.06.053Search in Google Scholar PubMed

[31] Chen J, Wang J, Zhu W. Zinc ion-induced conformational changes in new Delphi metallo-β-lactamase 1 probed by molecular dynamics simulations and umbrella sampling. Phys Chem Chem Phys. 2017;19(4):3067–75.10.1039/C6CP08105CSearch in Google Scholar

[32] Savelyev A, MacKerell AD. Competition among Li+, Na+, K+, and Rb+ monovalent ions for DNA in molecular dynamics simulations using the additive CHARMM36 and drude polarizable force fields. J Phys Chem B. 2015;119(12):4428–40.10.1021/acs.jpcb.5b00683Search in Google Scholar

[33] MacKerell Jr AD, Banavali N, Foloppe N. Development and current status of the CHARMM force field for nucleic acids. Biopolymers. 2000;56(4):257–65.10.1002/1097-0282(2000)56:4<257::AID-BIP10029>3.0.CO;2-WSearch in Google Scholar

[34] Damm W, Frontera A, Tirado-Rives J, Jorgensen WL. OPLS all-atom force field for carbohydrates. J Comput Chem. 1997;18(16):1955–70.10.1002/(SICI)1096-987X(199712)18:16<1955::AID-JCC1>3.0.CO;2-LSearch in Google Scholar

[35] Shivakumar D, Williams J, Wu Y, Damm W, Shelley J, Sherman W. Prediction of absolute solvation free energies using molecular dynamics free energy perturbation and the OPLS force field. J Chem Theory Comput. 2010;6(5):1509–19.10.1021/ct900587bSearch in Google Scholar

[36] Wang J, Wolf RM, Caldwell JW, Kollman PA, Case DA. Development and testing of a general amber force field. J Comput Chem. 2004;25(9):1157–74.10.1002/jcc.20035Search in Google Scholar

[37] Pérez A, Marchán I, Svozil D, Sponer J, Cheatham TE, Laughton CA, et al. Refinement of the AMBER force field for nucleic acids: improving the description of α/γ conformers. Biophys J. 2007;92(11):3817–29.10.1529/biophysj.106.097782Search in Google Scholar

[38] Oostenbrink C, Villa A, Mark AE, Van Gunsteren WF. A biomolecular force field based on the free enthalpy of hydration and solvation: The GROMOS force-field parameter sets 53A5 and 53A6. J Comput Chem. 2004;25(13):1656–76.10.1002/jcc.20090Search in Google Scholar

[39] Zhang C, Lu C, Jing Z, Wu C, Piquemal J-P, Ponder JW, et al. AMOEBA polarizable atomic multipole force field for nucleic acids. J Chem Theory Comput. 2018;14(4):2084–108.10.1021/acs.jctc.7b01169Search in Google Scholar

[40] Cao L, Ren H, Miao J, Guo W, Li Y, Li G. Validation of polarizable force field parameters for nucleic acids by inter-molecular interactions. Front Chem Sci Eng. 2016;10(2):203–12.10.1007/s11705-016-1572-4Search in Google Scholar

[41] Henriques J, Cragnell C, Skepö M. Molecular dynamics simulations of intrinsically disordered proteins: force field evaluation and comparison with experiment. J Chem Theory Comput. 2015;11(7):3420–31.10.1021/ct501178zSearch in Google Scholar PubMed

[42] Horta BAC, Merz PT, Fuchs PFJ, Dolenc J, Riniker S, Hünenberger PH. A GROMOS-compatible force field for small organic molecules in the condensed phase: the 2016H66 parameter set. J Chem Theory Comput. 2016;12(8):3825–50.10.1021/acs.jctc.6b00187Search in Google Scholar PubMed

[43] Aytenfisu AH, Spasic A, Grossfield A, Stern HA, Mathews DH. Revised RNA dihedral parameters for the amber force field improve RNA molecular dynamics. J Chem Theory Comput. 2017;13(2):900–15.10.1021/acs.jctc.6b00870Search in Google Scholar PubMed PubMed Central

[44] McCammon JA, Gelin BR, Karplus M. Dynamics of folded proteins. Nature. 1977;267(5612):585–90.10.1038/267585a0Search in Google Scholar PubMed

[45] Tarakanova A, Huang W, Qin Z, Kaplan DL, Buehler MJ. Modeling and experiment reveal structure and nanomechanics across the inverse temperature transition in B. mori silk-elastin-like protein polymers. ACS Biomater Sci Eng. 2017;3(11):2889–99.10.1021/acsbiomaterials.6b00688Search in Google Scholar PubMed

[46] Tarakanova A, Yeo GC, Baldock C, Weiss AS, Buehler MJ. Tropoelastin is a flexible molecule that retains its canonical shape. Macromol Biosci. 2019;19(3):1800250.10.1002/mabi.201800250Search in Google Scholar PubMed

[47] Tarakanova A, Buehler MJ. Molecular modeling of protein materials: Case study of elastin. Model Simul Mater Sci. 2013;21(6):063001.10.1088/0965-0393/21/6/063001Search in Google Scholar

[48] Tarakanova A, Yeo GC, Baldock C, Weiss AS, Buehler MJ. Molecular model of human tropoelastin and implications of associated mutations. Proc Natl Acad Sci U S A. 2018;115(28):7338.10.1073/pnas.1801205115Search in Google Scholar PubMed PubMed Central

[49] Yeo GC, Tarakanova A, Baldock C, Wise SG, Buehler MJ, Weiss AS. Subtle balance of tropoelastin molecular shape and flexibility regulates dynamics and hierarchical assembly. Sci Adv. 2016;2(2):e1501145.10.1126/sciadv.1501145Search in Google Scholar PubMed PubMed Central

[50] Li N, Jang H, Yuan M, Li W, Yun X, Lee J, et al. Graphite-templated amyloid nanostructures formed by a potential pentapeptide inhibitor for Alzheimer’s disease: a combined study of real-time atomic force microscopy and molecular dynamics simulations. Langmuir. 2017;33(27):6647–56.10.1021/acs.langmuir.7b00414Search in Google Scholar PubMed PubMed Central

[51] Laghaei R, Evans DG, Coalson RD. Metal binding sites of human H-chain ferritin and iron transport mechanism to the ferroxidase sites: a molecular dynamics simulation study. Proteins Struct Funct Bioinformat. 2013;81(6):1042–50.10.1002/prot.24251Search in Google Scholar PubMed

[52] Yu Z, Lau D. Molecular dynamics study on stiffness and ductility in chitin-protein composite. J Mater Sci. 2015;50(21):7149–57.10.1007/s10853-015-9271-ySearch in Google Scholar

[53] Yu Z, Xu Z, Lau D. Effect of acidity on chitin-protein interface: a molecular dynamics study. BioNanoScience. 2014;4(3):207–15.10.1007/s12668-014-0138-5Search in Google Scholar

[54] Wang Y, Qin Z, Buehler MJ, Xu Z. Intercalated water layers promote thermal dissipation at bio–nano interfaces. Nat Commun. 2016;7(1):12854.10.1038/ncomms12854Search in Google Scholar PubMed PubMed Central

[55] Chin SL, Lu Q, Dane EL, Dominguez L, McKnight CJ, Straub JE, et al. Combined molecular dynamics simulations and experimental studies of the structure and dynamics of poly-amido-saccharides. J Am Chem Soc. 2016;138(20):6532–40.10.1021/jacs.6b01837Search in Google Scholar PubMed

[56] Kmiecik S, Gront D, Kolinski M, Wieteska L, Dawid AE, Kolinski A. Coarse-grained protein models and their applications. Chem Rev. 2016;116(14):7898–936.10.1021/acs.chemrev.6b00163Search in Google Scholar PubMed

[57] Yeo J, Jung G, Tarakanova A, Martín-Martínez FJ, Qin Z, Cheng Y, et al. Multiscale modeling of keratin, collagen, elastin and related human diseases: perspectives from atomistic to coarse-grained molecular dynamics simulations. Extreme Mech Lett. 2018;20:112–24.10.1016/j.eml.2018.01.009Search in Google Scholar PubMed PubMed Central

[58] Yu Z, Lau D. Development of a coarse-grained α-chitin model on the basis of MARTINI forcefield. J Mol Model. 2015;21(5):128.10.1007/s00894-015-2670-9Search in Google Scholar PubMed

[59] Monticelli L, Kandasamy SK, Periole X, Larson RG, Tieleman DP, Marrink SJ. The MARTINI coarse-grained force field: extension to proteins. J Chem Theory Comput. 2008;4:819.10.1021/ct700324xSearch in Google Scholar PubMed

[60] Tarakanova A, Ozsvar J, Weiss AS, Buehler MJ. Coarse-grained model of tropoelastin self-assembly into nascent fibrils. Mater Today Bio. 2019;3:100016.10.1016/j.mtbio.2019.100016Search in Google Scholar PubMed PubMed Central

[61] Orekhov PS, Kholina EG, Bozdaganyan ME, Nesterenko AM, Kovalenko IB, Strakhovskaya MG. Molecular mechanism of uptake of cationic photoantimicrobial phthalocyanine across bacterial membranes revealed by molecular dynamics simulations. J Phys Chem B. 2018;122(14):3711–22.10.1021/acs.jpcb.7b11707Search in Google Scholar PubMed

[62] Deng S, Gao E, Wang Y, Sen S, Sreenivasan ST, Behura S, et al. Confined, oriented, and electrically anisotropic graphene wrinkles on bacteria. ACS Nano. 2016;10(9):8403–12.10.1021/acsnano.6b03214Search in Google Scholar PubMed

[63] Plattner N, Doerr S, De Fabritiis G, Noé F. Complete protein–protein association kinetics in atomic detail revealed by molecular dynamics simulations and Markov modelling. Nat Chem. 2017;9(10):1005–11.10.1038/nchem.2785Search in Google Scholar PubMed

[64] Maple JR, Dinur U, Hagler AT. Derivation of force fields for molecular mechanics and dynamics from ab initio energy surfaces. Proc Natl Acad Sci U S A. 1988;85(15):5350–4.10.1073/pnas.85.15.5350Search in Google Scholar PubMed PubMed Central

[65] Sun H, Mumby SJ, Maple JR, Hagler AT. An ab initio CFF93 all-atom force field for polycarbonates. J Am Chem Soc. 1994;116(7):2978–87.10.1021/ja00086a030Search in Google Scholar

[66] Mayo SL, Olafson BD, Goddard WA. DREIDING: a generic force field for molecular simulations. J Phys Chem. 1990;94(26):8897–909.10.1021/j100389a010Search in Google Scholar

[67] Sun H. COMPASS: An ab initio force-field optimized for condensed-phase applications overview with details on alkane and benzene compounds. J Phys Chem B. 1998;102(38):7338–64.10.1021/jp980939vSearch in Google Scholar

[68] Tam L-h, Lau D. A molecular dynamics investigation on the cross-linking and physical properties of epoxy-based materials. RSC Adv. 2014;4(62):33074–81.10.1039/C4RA04298KSearch in Google Scholar

[69] van Duin ACT, Dasgupta S, Lorant F, Goddard WA. ReaxFF: a reactive force field for hydrocarbons. J Phys Chem A. 2001;105(41):9396–409.10.1021/jp004368uSearch in Google Scholar

[70] Odegard GM, Jensen BD, Gowtham S, Wu J, He J, Zhang Z. Predicting mechanical response of crosslinked epoxy using ReaxFF. Chem Phys Lett. 2014;591:175–8.10.1016/j.cplett.2013.11.036Search in Google Scholar

[71] Vashisth A, Ashraf C, Bakis CE, van Duin ACT. Effect of chemical structure on thermo-mechanical properties of epoxy polymers: comparison of accelerated ReaxFF simulations and experiments. Polymer. 2018;158:354–63.10.1016/j.polymer.2018.11.005Search in Google Scholar

[72] Chowdhury SC, Elder RM, Sirk TW, Gillespie JW. Epoxy resin thermo-mechanics and failure modes: effects of cure and cross-linker length. Composites Part B. 2020;186:107814.10.1016/j.compositesb.2020.107814Search in Google Scholar

[73] Hao H, Chow CL, Lau D. Carbon monoxide release mechanism in cellulose combustion using reactive forcefield. Fuel. 2020;269:117422.10.1016/j.fuel.2020.117422Search in Google Scholar

[74] Nazarychev VM, Lyulin AV, Larin SV, Gurtovenko AA, Kenny JM, Lyulin SV. Molecular dynamics simulations of uniaxial deformation of thermoplastic polyimides. Soft Matter. 2016;12(17):3972–81.10.1039/C6SM00230GSearch in Google Scholar PubMed

[75] Wang X, Jian W, Lu H, Lau D, Fu Y-Q. Modeling strategy for enhanced recovery strength and a tailorable shape transition behavior in shape memory copolymers. Macromolecules. 2019;52(16):6045–54.10.1021/acs.macromol.9b00992Search in Google Scholar

[76] Ming L, Zhen C, Haibao L, Kai Y. Recent progress in shape memory polymer composites: methods, properties, applications and prospects. Nanotechnol Rev. 2019;8(1):327–51.10.1515/ntrev-2019-0031Search in Google Scholar

[77] Bobby S, Samad MA. Chapter 5 – Epoxy composites in biomedical engineering. In: Grumezescu V, Grumezescu AM, editors. Materials for Biomedical Engineering. Amsterdam: Elsevier; 2019.10.1016/B978-0-12-816874-5.00005-0Search in Google Scholar

[78] Meng Z, Bessa MA, Xia W, Kam Liu W, Keten S. Predicting the macroscopic fracture energy of epoxy resins from atomistic molecular simulations. Macromolecules. 2016;49(24):9474–83.10.1021/acs.macromol.6b01508Search in Google Scholar

[79] Sresht V, Pádua AAH, Blankschtein D. Liquid-phase exfoliation of phosphorene: design rules from molecular dynamics simulations. ACS Nano. 2015;9(8):8255–68.10.1021/acsnano.5b02683Search in Google Scholar PubMed

[80] Zhou A, Büyüköztürk O, Lau D. Debonding of concrete-epoxy interface under the coupled effect of moisture and sustained load. Cem Concr Compos. 2017;80:287–97.10.1016/j.cemconcomp.2017.03.019Search in Google Scholar

[81] Zhou A, Qiu Q, Chow CL, Lau D. Interfacial performance of aramid, basalt and carbon fiber reinforced polymer bonded concrete exposed to high temperature. Composites Part A. 2020;131:105802.10.1016/j.compositesa.2020.105802Search in Google Scholar

[82] Lau D, Broderick K, Buehler MJ, Büyüköztürk O. A robust nanoscale experimental quantification of fracture energy in a bilayer material system. Proc Natl Acad Sci U S A. 2014;111(33):11990–5.10.1073/pnas.1402893111Search in Google Scholar PubMed PubMed Central

[83] Zhou A, Tam L-h, Yu Z, Lau D. Effect of moisture on the mechanical properties of CFRP-wood composite: an experimental and atomistic investigation. Composited Part B. 2015;71:63–73.10.1016/j.compositesb.2014.10.051Search in Google Scholar

[84] Tam L-h, Zhou A, Yu Z, Qiu Q, Lau D. Understanding the effect of temperature on the interfacial behavior of CFRP-wood composite via molecular dynamics simulations. Composites Part B. 2017;109:227–37.10.1016/j.compositesb.2016.10.030Search in Google Scholar

[85] Jian W, Tam L-h, Lau D. Atomistic study of interfacial creep behavior in epoxy-silica bilayer system. Composites Part B. 2018;132:229–36.10.1016/j.compositesb.2017.09.006Search in Google Scholar

[86] Liu W, Luo X, Bao Y, Liu YP, Ning G-H, Abdelwahab I, et al. A two-dimensional conjugated aromatic polymer via C–C coupling reaction. Nat Chem. 2017;9(6):563–70.10.1038/nchem.2696Search in Google Scholar PubMed

[87] Lee B, Lee K, Panda S, Gonzales-Rojas R, Chong A, Bugay V, et al. Nanoparticle delivery of CRISPR into the brain rescues a mouse model of fragile X syndrome from exaggerated repetitive behaviours. Nat Biomed Eng. 2018;2(7):497–507.10.1038/s41551-018-0252-8Search in Google Scholar PubMed PubMed Central

[88] Hussain S, Joo J, Kang J, Kim B, Braun GB, She Z-G, et al. Antibiotic-loaded nanoparticles targeted to the site of infection enhance antibacterial efficacy. Nat Biomed Eng. 2018;2(2):95–103.10.1038/s41551-017-0187-5Search in Google Scholar PubMed PubMed Central

[89] Padmanabhan P, Kumar A, Kumar S, Chaudhary RK, Gulyás B. Nanoparticles in practice for molecular-imaging applications: an overview. Acta Biomater. 2016;41:1–16.10.1016/j.actbio.2016.06.003Search in Google Scholar PubMed

[90] Irena B, Janja S, Uroš M. NiCu magnetic nanoparticles: review of synthesis methods, surface functionalization approaches, and biomedical applications. Nanotechnol Rev. 2018;7(2):187–207.10.1515/ntrev-2017-0193Search in Google Scholar

[91] Ibrahim Y. Applications of magnetic nanoparticles in biomedical separation and purification. Nanotechnol Rev. 2016;5(3):331–40.Search in Google Scholar

[92] Wen Y-H, Huang R, Shao G-F, Sun S-G. Thermal stability of Co–Pt and Co–Au core–shell structured nanoparticles: insights from molecular dynamics simulations. J Phys Chem Lett. 2017;8(17):4273–8.10.1021/acs.jpclett.7b01880Search in Google Scholar PubMed

[93] Sridhar DB, Gupta R, Rai B. Effect of surface coverage and chemistry on self-assembly of monolayer protected gold nanoparticles: a molecular dynamics simulation study. Phys Chem Chem Phys. 2018;20(40):25883–91.10.1039/C8CP04044CSearch in Google Scholar PubMed

[94] Issa I, Amodeo J, Réthoré J, Joly-Pottuz L, Esnouf C, Morthomas J, et al. In situ investigation of MgO nanocube deformation at room temperature. Acta Mater. 2015;86:295–304.10.1016/j.actamat.2014.12.001Search in Google Scholar

[95] Meena SK, Sulpizi M. From gold nanoseeds to nanorods: The microscopic origin of the anisotropic growth. Angew Chem Int Ed. 2016;55(39):11960–4.10.1002/anie.201604594Search in Google Scholar PubMed

[96] Atilhan M, Aparicio S. Molecular dynamics simulations of metal nanoparticles in deep eutectic solvents. J Phys Chem C. 2018;122(31):18029–39.10.1021/acs.jpcc.8b02582Search in Google Scholar

[97] Salorinne K, Malola S, Wong OA, Rithner CD, Chen X, Ackerson CJ, et al. Conformation and dynamics of the ligand shell of a water-soluble Au102 nanoparticle. Nat Commun. 2016;7(1):10401.10.1038/ncomms10401Search in Google Scholar PubMed PubMed Central

[98] Xie B, Buehler MJ, Xu Z. Directed self-assembly of end-functionalized nanofibers: from percolated networks to liquid crystal-like phases. Nanotechnology. 2015;26(20):205602.10.1088/0957-4484/26/20/205602Search in Google Scholar PubMed

[99] Elsabahy M, Wooley KL. Design of polymeric nanoparticles for biomedical delivery applications. Chem Soc Rev. 2012;41(7):2545–61.10.1039/c2cs15327kSearch in Google Scholar PubMed PubMed Central

[100] Kaufman JJ, Ottman R, Tao G, Shabahang S, Banaei E-H, Liang X, et al. In-fiber production of polymeric particles for biosensing and encapsulation. P Natl Acad Sci U S A. 2013;110(39):15549–54.10.1073/pnas.1310214110Search in Google Scholar PubMed PubMed Central

[101] Zhang C, Liu T, Wang W, Bell CA, Han Y, Fu C, et al. Tuning of the aggregation behavior of fluorinated polymeric nanoparticles for improved therapeutic efficacy. ACS Nano. 2020;14(6):7425–34.10.1021/acsnano.0c02954Search in Google Scholar PubMed

[102] Meneksedag-Erol D, Tang T, Uludağ H. Mechanistic insights into the role of glycosaminoglycans in delivery of polymeric nucleic acid nanoparticles by molecular dynamics simulations. Biomaterials. 2018;156:107–20.10.1016/j.biomaterials.2017.11.037Search in Google Scholar PubMed

[103] Yang G, Gong H, Liu T, Sun X, Cheng L, Liu Z. Two-dimensional magnetic WS2@Fe3O4 nanocomposite with mesoporous silica coating for drug delivery and imaging-guided therapy of cancer. Biomaterials. 2015;60:62–71.10.1016/j.biomaterials.2015.04.053Search in Google Scholar PubMed

[104] Zhang H, Wu H, Wang J, Yang Y, Wu D, Zhang Y, et al. Graphene oxide-BaGdF5 nanocomposites for multi-modal imaging and photothermal therapy. Biomaterials. 2015;42:66–77.10.1016/j.biomaterials.2014.11.055Search in Google Scholar PubMed

[105] Li Y, Wang S, Wang Q. Enhancement of tribological properties of polymer composites reinforced by functionalized graphene. Composites Part B. 2017;120:83–91.10.1016/j.compositesb.2017.03.063Search in Google Scholar

[106] Li Y, Wang S, Wang Q, Xing M. A comparison study on mechanical properties of polymer composites reinforced by carbon nanotubes and graphene sheet. Composites Part B. 2018;133:35–41.10.1016/j.compositesb.2017.09.024Search in Google Scholar

[107] Li Y, Wang S, Wang Q, Xing M. Enhancement of fracture properties of polymer composites reinforced by carbon nanotubes: a molecular dynamics study. Carbon. 2018;129:504–9.10.1016/j.carbon.2017.12.029Search in Google Scholar

[108] Gopalakrishnan R, Azhagiya Singam ER, Vijaya Sundar J, Subramanian V. Interaction of collagen like peptides with gold nanosurfaces: a molecular dynamics investigation. Phys Chem Chem Phys. 2015;17(7):5172–86.10.1039/C4CP04969ASearch in Google Scholar

[109] Albanese A, Tang PS, Chan WCW. The effect of nanoparticle size, shape, and surface chemistry on biological systems. Annu Rev Biomed Eng. 2012;14(1):1–16.10.1146/annurev-bioeng-071811-150124Search in Google Scholar PubMed

[110] Jian W, Lau D. Creep performance of CNT-based nanocomposites: a parametric study. Carbon. 2019;153:745–56.10.1016/j.carbon.2019.07.069Search in Google Scholar

[111] Jian W, Lau D. Understanding the effect of functionalization in CNT-epoxy nanocomposite from molecular level. Compos Sci Technol. 2020;191:108076.10.1016/j.compscitech.2020.108076Search in Google Scholar

[112] Xia W, Qin X, Zhang Y, Sinko R, Keten S. Achieving enhanced interfacial adhesion and dispersion in cellulose nanocomposites via amorphous interfaces. Macromolecules. 2018;51(24):10304–11.10.1021/acs.macromol.8b02243Search in Google Scholar

[113] Sun Q, Meng Z, Zhou G, Lin S-P, Kang H, Keten S, et al. Multi-scale computational analysis of unidirectional carbon fiber reinforced polymer composites under various loading conditions. Compos Struct. 2018;196:30–43.10.1016/j.compstruct.2018.05.025Search in Google Scholar

[114] McKinlay AC, Morris RE, Horcajada P, Férey G, Gref R, Couvreur P, et al. BioMOFs: metal–organic frameworks for biological and medical applications. Angew Chem Int Ed. 2010;49(36):6260–6.10.1002/anie.201000048Search in Google Scholar PubMed

[115] Wang L, Zheng M, Xie Z. Nanoscale metal–organic frameworks for drug delivery: a conventional platform with new promise. J Mater Chem B. 2018;6(5):707–17.10.1039/C7TB02970ESearch in Google Scholar PubMed

[116] Heinen J, Ready AD, Bennett TD, Dubbeldam D, Friddle RW, Burtch NC. Elucidating the variable-temperature mechanical properties of a negative thermal expansion metal–organic framework. ACS Appl Mater Interfaces. 2018;10(25):21079–83.10.1021/acsami.8b06604Search in Google Scholar PubMed

[117] Erucar I, Keskin S. Efficient storage of drug and cosmetic molecules in biocompatible metal organic frameworks: a molecular simulation study. Ind Eng Chem Res. 2016;55(7):1929–39.10.1021/acs.iecr.5b04556Search in Google Scholar

[118] Skoulidas AI. Molecular dynamics simulations of gas diffusion in metal–organic frameworks: argon in CuBTC. J Am Chem Soc. 2004;126(5):1356–7.10.1021/ja039215+Search in Google Scholar PubMed

[119] Watanabe T, Sholl DS. Accelerating applications of metal–organic frameworks for gas adsorption and separation by computational screening of materials. Langmuir. 2012;28(40):14114–28.10.1021/la301915sSearch in Google Scholar PubMed

[120] Kotzabasaki M, Galdadas I, Tylianakis E, Klontzas E, Cournia Z, Froudakis GE. Multiscale simulations reveal IRMOF-74-III as a potent drug carrier for gemcitabine delivery. J Mater Chem B. 2017;5(18):3277–82.10.1039/C7TB00220CSearch in Google Scholar

[121] Su J, Yuan S, Wang H-Y, Huang L, Ge J-Y, Joseph E, et al. Redox-switchable breathing behavior in tetrathiafulvalene-based metal–organic frameworks. Nat Commun. 2017;8(1):2008.10.1038/s41467-017-02256-ySearch in Google Scholar PubMed PubMed Central

[122] Gaillac R, Pullumbi P, Beyer KA, Chapman KW, Keen DA, Bennett TD, et al. Liquid metal–organic frameworks. Nat Mater. 2017;16(11):1149–54.10.1038/nmat4998Search in Google Scholar PubMed

[123] Ghalei B, Sakurai K, Kinoshita Y, Wakimoto K, Ali I, Song Q, et al. Enhanced selectivity in mixed matrix membranes for CO2 capture through efficient dispersion of amine-functionalized MOF nanoparticles. Nat Energy. 2017;2(7):17086.10.1038/nenergy.2017.86Search in Google Scholar

[124] Zhang H, Hou J, Hu Y, Wang P, Ou R, Jiang L, et al. Ultrafast selective transport of alkali metal ions in metal organic frameworks with subnanometer pores. Sci Adv. 2018;4(2):eaaq0066.10.1126/sciadv.aaq0066Search in Google Scholar PubMed PubMed Central

[125] Semino R, Moreton JC, Ramsahye NA, Cohen SM, Maurin G. Understanding the origins of metal–organic framework/polymer compatibility. Chem Sci. 2018;9(2):315–24.10.1039/C7SC04152GSearch in Google Scholar PubMed PubMed Central

[126] Jackson NE, Webb MA, de Pablo JJ. Recent advances in machine learning towards multiscale soft materials design. Curr Opin Chem Eng. 2019;23:106–14.10.1016/j.coche.2019.03.005Search in Google Scholar

[127] Vyatskikh A, Delalande S, Kudo A, Zhang X, Portela CM, Greer JR. Additive manufacturing of 3D nano-architected metals. Nat Commun. 2018;9(1):593.10.1038/s41467-018-03071-9Search in Google Scholar PubMed PubMed Central

[128] Zong H, Pilania G, Ding X, Ackland GJ, Lookman T. Developing an interatomic potential for martensitic phase transformations in zirconium by machine learning. npj Comput Mater. 2018;4(1):48.10.1038/s41524-018-0103-xSearch in Google Scholar

[129] Li Y, Li H, Pickard FC, Narayanan B, Sen FG, Chan MKY, et al. Machine learning force field parameters from ab initio data. J Chem Theory Comput. 2017;13(9):4492–503.10.1021/acs.jctc.7b00521Search in Google Scholar PubMed PubMed Central

[130] Chmiela S, Tkatchenko A, Sauceda HE, Poltavsky I, Schütt KT, Müller K-R. Machine learning of accurate energy-conserving molecular force fields. Sci Adv. 2017;3(5):e1603015.10.1126/sciadv.1603015Search in Google Scholar PubMed PubMed Central

[131] Chmiela S, Sauceda HE, Müller K-R, Tkatchenko A. Towards exact molecular dynamics simulations with machine-learned force fields. Nat Commun. 2018;9(1):3887.10.1038/s41467-018-06169-2Search in Google Scholar PubMed PubMed Central

[132] Huan TD, Batra R, Chapman J, Krishnan S, Chen L, Ramprasad R. A universal strategy for the creation of machine learning-based atomistic force fields. npj Comput Mater. 2017;3(1):37.10.1038/s41524-017-0042-ySearch in Google Scholar

[133] Kruglov I, Sergeev O, Yanilkin A, Oganov AR. Energy-free machine learning force field for aluminum. Sci Rep. 2017;7(1):8512.10.1038/s41598-017-08455-3Search in Google Scholar PubMed PubMed Central

[134] Singh SK, Bejagam KK, An Y, Deshmukh SA. Machine-learning based stacked ensemble model for accurate analysis of molecular dynamics simulations. J Phys Chem A. 2019;123(24):5190–8.10.1021/acs.jpca.9b03420Search in Google Scholar PubMed

[135] Chan H, Narayanan B, Cherukara MJ, Sen FG, Sasikumar K, Gray SK, et al. Machine learning classical interatomic potentials for molecular dynamics from first-principles training data. J Phys Chem C. 2019;123(12):6941–57.10.1021/acs.jpcc.8b09917Search in Google Scholar

[136] Wang J, Olsson S, Wehmeyer C, Pérez A, Charron NE, de Fabritiis G, et al. Machine learning of coarse-grained molecular dynamics force fields. ACS Central Sci. 2019;5(5):755–67.10.1021/acscentsci.8b00913Search in Google Scholar PubMed PubMed Central

[137] Duan K, He Y, Li Y, Liu J, Zhang J, Hu Y, et al. Machine-learning assisted coarse-grained model for epoxies over wide ranges of temperatures and cross-linking degrees. Mater Des. 2019;183:108130.10.1016/j.matdes.2019.108130Search in Google Scholar

[138] Gastegger M, Behler J, Marquetand P. Machine learning molecular dynamics for the simulation of infrared spectra. Chem Sci. 2017;8(10):6924–35.10.1039/C7SC02267KSearch in Google Scholar PubMed PubMed Central

[139] Mittal S, Shukla D. Recruiting machine learning methods for molecular simulations of proteins. Mol Simul. 2018;44(11):891–904.10.1080/08927022.2018.1448976Search in Google Scholar