Abstract

Braided composite stent (BCS), woven with nitinol wires and polyethylene terephthalate (PET) strips, provides a hybrid design of stent. The mechanical performance of this novel stent has not been fully investigated yet. In this work, the influence of five main design factors (number of nitinol wires, braiding angle, diameter of nitinol wire, thickness and stiffness of the PET strip) on the surface coverage, radial strength, and flexibility of the BCS were systematically studied using computational models. The orthogonal experimental design was adopted to quantitatively analyze the sensitivity of multiple factors using the minimal number of study cases. Results have shown that the nitinol wire diameter and the braiding angle are two most important factors determining the mechanical performance of the BCS. A larger nitinol wire diameter led to a larger radial strength and less flexibility of the BCS. A larger braiding angle could provide a larger radial strength and better flexibility. In addition, the impact of the braiding angle decreased when the stent underwent a large deformation. At the same time, the impact of the PET strips increased due to the interaction with nitinol wires. Moreover, the number of PET strips played an important role in the surface coverage. This study could help understand the mechanical performance of BCS stent and provides guidance on the optimal design of the stent targeting less complications.

1 Introduction

Peripheral artery disease (PAD), mostly caused by atherosclerosis, reduces the blood flow into the arteries of arms, legs, and feet, further inducing tissue damage and gangrene [1,2]. The stent implantation, due to its minimally invasive nature, is widely adopted for the treatment of PAD [3,4]. The stent is able to push the narrowed arterial wall outward and achieve immediate lumen gain [5]. However, the stent induced abnormal force on the arterial wall, which could overstimulate the proliferation of smooth muscle cells, leading to in-stent restenosis [4,6].

Much efforts have been made to optimize the stent design [7,8] since stent structure and materials influence its clinical efficacy [9,10,11,12]. The ideal stent requires adequate radial stiffness to scaffold the vessel wall [13,14], longitudinal flexibility to pass through tortuous blood vessels, and radial compliance to be conformed to the lesions [15]. Among various stents, braided stents showed superiority in terms of longitudinal flexibility and radial compliance [16,17,18,19]. Covered stents have demonstrated their efficacy in mitigating the tissue ingrowth [20,21]. But it is in the cost of a large profile and reduced flexibility [22,23,24].

Recently, a novel braided composite stent (BCS) was proposed to combine the merits of both braided stent and covered stent for achieving the desirable radial strength, flexibility, and increased surface coverage [25]. It was made of nitinol wires and polyethylene terephthalate (PET) helical strips. Both of these materials have been widely used in the vascular surgery products with good biocompatibility [26,27,28]. Braiding technique contributes to the flexibility of the BCS. Motivated by the performance of a covered stent, the PET strips, with large surface coverage, were adopted to mitigate the tissue ingrowth. The BCS exhibits more flexibility than the covered stent. Specifically, it was reported that the bending moment of the BCS was 17.4% smaller than that of the covered stent when subjected to a bending angle of 30° [25,29]. The presence of wide PET strips of BCS can constrain the relative displacement of the nitinol wires and enhance its radial strength at a large deformation [25,30]. The parameters such as nitinol wire diameter, initial braiding angle, and strip thickness are essential to the mechanical performance of the BCS. But the systematic study of the influence of BCS design parameters on its mechanical performances does not exist. In this study, an orthogonal experimental design was utilized to quantify the influence of five input factors (number of nitinol wires, braiding angle, diameter of nitinol wire, thickness and stiffness of the PET strip) that govern the material property and geometry of the BCS on the surface coverage, radial strength, and flexibility. The response to the stent implantation is patient-specific. One specific goal of this study is to identify patterns that might account for the variability of various patients. In addition, quantitative evaluation of the design sensitivity of the BCS could facilitate an optimal design of the stent.

2 Materials and methods

2.1 The geometrical design of the stent

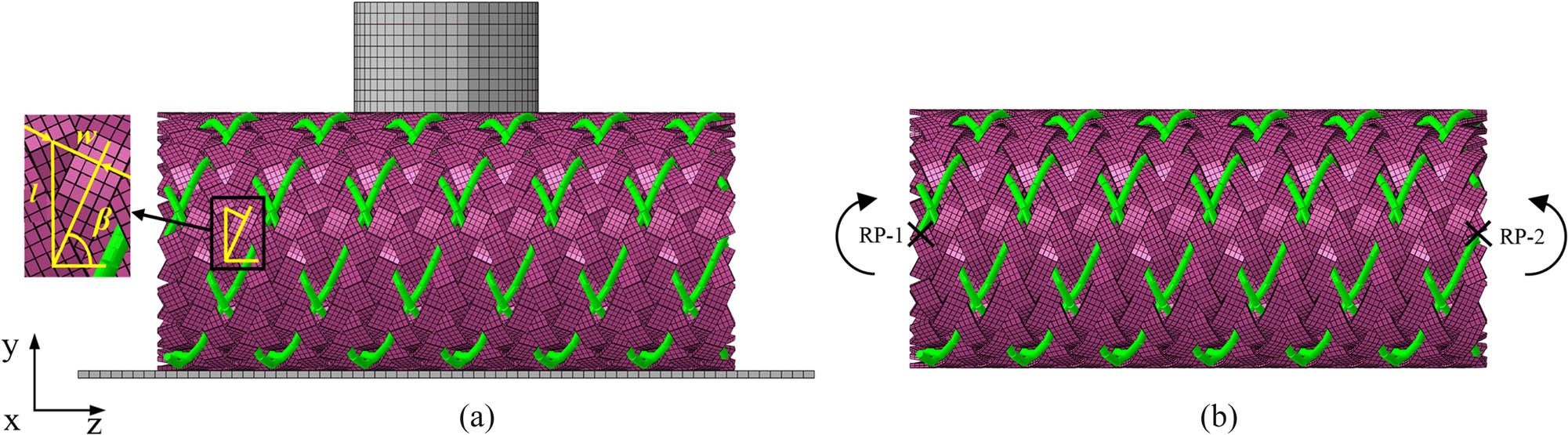

The BCS, braided with 32 strands of nitinol wires and PET strips, has a length of 15 mm and an outer diameter of 7 mm (Figure 1). The stent geometry is mainly defined by four independent parameters: number of the nitinol wires, braiding angle, diameter of the nitinol wire, and the thickness of the PET strip. Two levels of each geometrical parameter are considered, as listed in Table 1. Figure 1 shows one geometrical configuration of the stent with 8 0.15 mm-diameter nitinol wires, 24 0.1 mm-thick polyester fibers, and a braiding angle of 65°.

Three-dimensional model of BCS: (a) compression test and (b) bending test.

Orthogonal experimental factors and levels

| Type | Symbol | Input factors | Levels | |

|---|---|---|---|---|

| Low | High | |||

| Material property | A | PET fiber modulus E (GPa) | 2.5 | 3.0 |

| Geometry | B | Number of nitinol wire n | 8 | 16 |

| C | Initial braiding angle β (°) | 55 | 65 | |

| D | Nitinol wire diameter d (mm) | 0.15 | 0.25 | |

| E | PET fiber thickness t (mm) | 0.1 | 0.15 | |

The braiding angle β is the angle between the helical wire and the axial direction of the stent. The width of the PET strip w could be calculated by:

where l is the distance of the two intersection points along the circumferential direction (Figure 1a) and D is the outer diameter of the stent. The width of PET strip is 0.775 and 0.57 mm for the braiding angle of 55° and 65°, respectively.

The surface coverage μ of the stent characterizes the stent porosity, which is associated with the tissue ingrowth. It is calculated by:

where N refers to the number of intersections, A is the area of intersections; NA can be expressed as (N

1

dw + N

2

d

2 + N

3

w

2)/sin2 β with N

1 as the number of intersections between polyester strip and nitinol wire, N

2 as the number of intersections between nitinol wires, and N

3 as the number of intersections between polyester strips. L is the length of stent, which can be expressed as

2.2 Finite element modeling

Three-dimensional models of the BCSs were constructed on the aforementioned geometrical design. The nitinol wire was adopted as a superelastic material, which was implemented through a built-in Abaqus User Material Subroutine (VUMAT) [32]. The PET strip was an elastoplastic material with Young’s modulus ranging from 2.5 to 3.5 Gpa [33], which is considered as a main factor in the study. The material parameters are summarized in Table 2.

Material properties of nitinol and PET

| Nitinol | |

| Austenite elasticity E A (MPa) | 50,000 |

| Martensite elasticity E M (MPa) | 37,000 |

| Start of transformation loading

|

400 |

| End of transformation loading

|

650 |

| Start of transformation unloading

|

350 |

| End of transformation unloading

|

80 |

| Volumetric transformation strain

|

0.055 |

| PET | |

| Young’s modulus E (GPa) | 2.5/3.0 |

| Poisson ratio ν | 0.4 |

| Yield stress σ s (MPa) | 60 |

| Tensile strength σ t (MPa) | 70 |

Compression tests were carried out to investigate the influence of stent design parameters on the radial strength of the stent (Figure 1a). The stent was placed on a rigid plate (20 mm × 10 mm), which was completely fixed in space by six degrees of freedom. Specifically, the middle section of the stent was radially compressed by a rigid presser foot of 5 mm in diameter. The displacement enforced on the presser foot was 3.5 mm, namely, 50% of the outer diameter of the stent [34] and then released the presser foot at the same rate of 1.75 mm/s. The reaction force of the presser foot, i.e., load applied on the stent was monitored during the loading and unloading process.

The stent flexibility was characterized by the pure bending tests [35] (Figure 1b). A fixed planar end cross-section was enforced by means of a “rigid body” connection bound to a 6 DOF reference point at each end of the stent (RP1 and RP2). The following boundary conditions were applied, restraining five of the six degrees of freedom: (1) restrained translation in X and Y directions, (2) restrained rotation about Y and Z axes, (3) X deflection of RP1 + X deflection of RP2 = 0. (4) Rotation about X axes of RP1 and RP2 reached at 60° [36], respectively, in opposite directions. The bending moments applied at both ends were recorded to evaluate the flexibility of the stent.

The stent wires were meshed with two-node linear beam element (B31) and the PET strips were meshed with reduced 4-node doubly curved shell elements (S4R). The nitinol wire was meshed with 192 elements and 240 elements for the braiding angle of 55° and 65°, respectively. The PET strip was meshed with 2,176 elements and 2,160 elements for the braiding angle of 55° and 65°, respectively. The rigid compressor foot and supporting plate were meshed with 1,645 and 4,622 rigid quadrilateral R3D4 elements, respectively. Mesh-sensitivity analyses were conducted to insure that all results are convergent. A general contact algorithm was adopted among all contact surfaces with a friction coefficient of 0.3 [37]. The kinetic energy of each stent accounted for less than 5% of the internal energy to avoid the inertia effect. Finite element models were solved using a commercial Abaqus/Explicit software (Dassault Systèmes Simulia Corp.).

2.3 Design of computational experiments

An orthogonal experimental design Ln(t q ) was applied to identify the sensitivity of multiple factors with minimal experiments, where L is the orthogonal array, n is the number of study cases, t is the level of factors, and q is the number of factors [38]. In this work, a five-factor two-level array L8(25) was designed to systematically evaluate the sensitivities of five input factors to the mechanical performance of the stent. The modulus of the PET strip and four geometrical design parameters (number of nitinol wire n, initial braiding angle β, nitinol wire diameter d, and PET strip thickness t) served as input factors. The two levels of each input factor are shown in Table 1. The study cases designed according to the L8(25) orthogonal table are shown in Table 3. The surface coverage, compression load, and bending moment of the study cases were examined.

Scheme of orthogonal experimental design

| Case no. | Input factors | ||||

|---|---|---|---|---|---|

| A | B | C | D | E | |

| 1 | 2.5 | 8 | 65 | 0.25 | 0.15 |

| 2 | 3 | 8 | 65 | 0.15 | 0.15 |

| 3 | 2.5 | 16 | 65 | 0.15 | 0.1 |

| 4 | 3 | 16 | 65 | 0.25 | 0.1 |

| 5 | 2.5 | 8 | 55 | 0.25 | 0.1 |

| 6 | 3 | 8 | 55 | 0.15 | 0.1 |

| 7 | 2.5 | 16 | 55 | 0.15 | 0.15 |

| 8 | 3 | 16 | 55 | 0.25 | 0.15 |

3 Results

The validation of the BCS models had been conducted in our previous work [25]. The radial strength of the stent was evaluated while compressing the stent to 50% of the original diameter of 7 mm, and the numerical result agreed well with the experimental result [25,30].

The surface coverage, the compression load, and the bending moment for all eight cases are summarized in Table 4. The range analysis was conducted to quantify the influence of each factor on the mechanical performance of the stent, as shown in Tables 5 and 6. K 1 and K 2 represent the influence of the lower level and higher level of a specific factor on the result measurement, respectively. A specific factor K i value is the average of four values of the result (Table 4) with level i (Table 3). The range value R of each factor is the difference between the K 1 and K 2. The larger R value demonstrates that the corresponding factor is more sensitive to the mechanical performance of the stent. The influence of each factor in the calculation results was finally normalized, according to the ratio between the values of the high and low levels.

Surface coverage, compression load, and bending moment of the cases

| Case no. | Surface coverage (%) | Load (N) | Bending moment (N mm) | ||

|---|---|---|---|---|---|

| 30% | 50% | 30° | 60° | ||

| 1 | 98.6 | 7.391 | 7.625 | 5.396 | 15.070 |

| 2 | 97.3 | 2.780 | 4.268 | 2.338 | 7.356 |

| 3 | 87.6 | 2.472 | 2.731 | 1.302 | 4.344 |

| 4 | 93.1 | 11.963 | 11.301 | 7.013 | 18.364 |

| 5 | 97.8 | 3.349 | 5.705 | 10.892 | 20.125 |

| 6 | 96.8 | 1.596 | 2.814 | 5.713 | 7.610 |

| 7 | 85.0 | 2.127 | 3.907 | 6.722 | 13.004 |

| 8 | 89.7 | 7.427 | 10.040 | 18.481 | 38.137 |

Range analysis for the compression load at 30% and 50% compression deformation

| Input factors | Load at 30% deformation (N) | Load at 50% deformation (N) | ||||

|---|---|---|---|---|---|---|

| K 1 | K 2 | R | K 1 | K 2 | R | |

| A | 3.835 | 5.796 | 1.961 | 4.992 | 7.116 | 2.124 |

| B | 3.779 | 5.851 | 2.072 | 5.103 | 7.005 | 1.902 |

| C | 6.006 | 3.625 | 2.381 | 6.492 | 5.617 | 0.875 |

| D | 2.244 | 7.387 | 5.143 | 3.430 | 8.678 | 5.248 |

| E | 5.733 | 3.625 | 2.109 | 6.593 | 5.617 | 0.977 |

Range analysis for the bending moment at the bending angle of 30° and 60°

| Input factors | Bending moment at the angle of 30° (N mm) | Bending moment at the angle of 60° (N mm) | ||||

|---|---|---|---|---|---|---|

| K 1 | K 2 | R | K 1 | K 2 | R | |

| A | 6.078 | 8.386 | 2.308 | 13.136 | 17.867 | 4.731 |

| B | 6.085 | 8.379 | 2.295 | 12.540 | 18.462 | 5.922 |

| C | 4.012 | 10.452 | 6.440 | 11.283 | 19.719 | 8.436 |

| D | 4.019 | 10.445 | 6.427 | 8.078 | 22.924 | 14.846 |

| E | 6.402 | 10.452 | 4.050 | 14.278 | 19.719 | 5.441 |

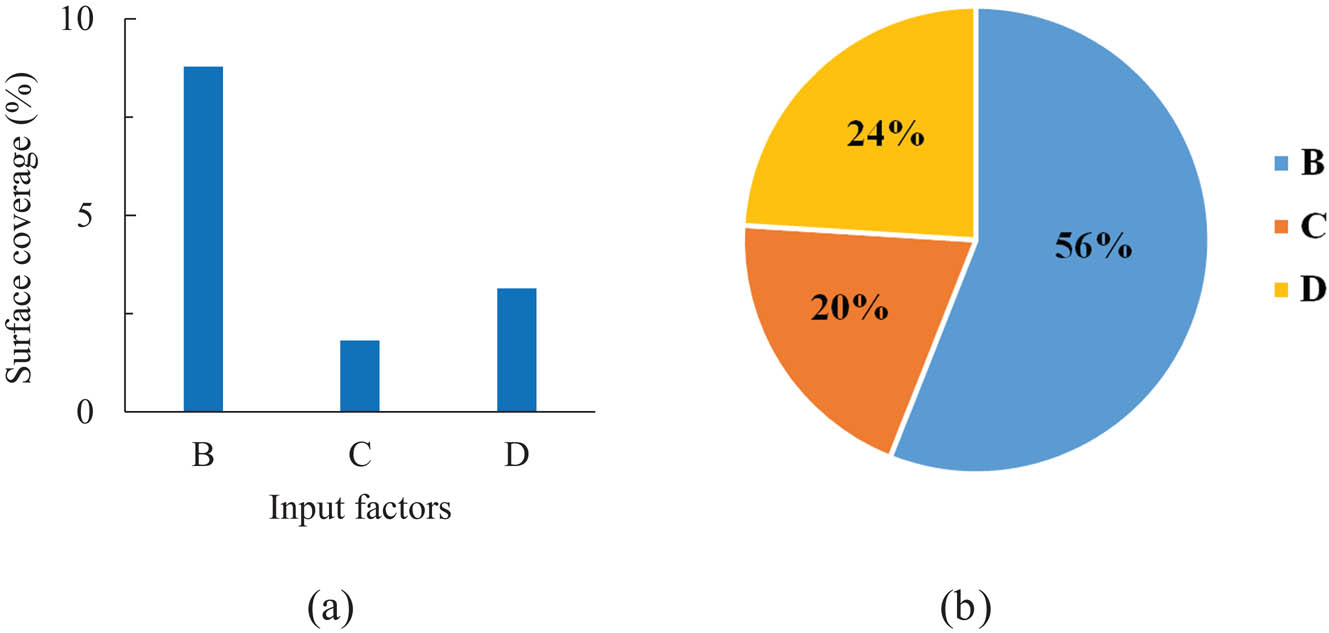

The surface coverage, an important parameter of stent for preventing the growth tissue from entering the stent, is presented in Table 4. As expected, more PET strips give higher surface coverage. Therefore, it is mainly related to the number of nitinol wire (B, 56%) of the stent (Figure 2). If the PET strips in case 2 (97.3%) and case 6 (96.8%) are changed into nitinol wires with a diameter of 0.15 mm, the surface coverage of stent is greatly reduced, which is only 46.7% and 35.8%, respectively. In addition, the effect of initial braiding angle and diameter of the wire on surface coverage of the stent is relatively small (20% vs 24%). The surface coverage is an important character to be considered when comparing a composite stent with a bare metal stent.

Diagram of the range value on surface coverage (a) and normalized (b) at the initial state to various input factors.

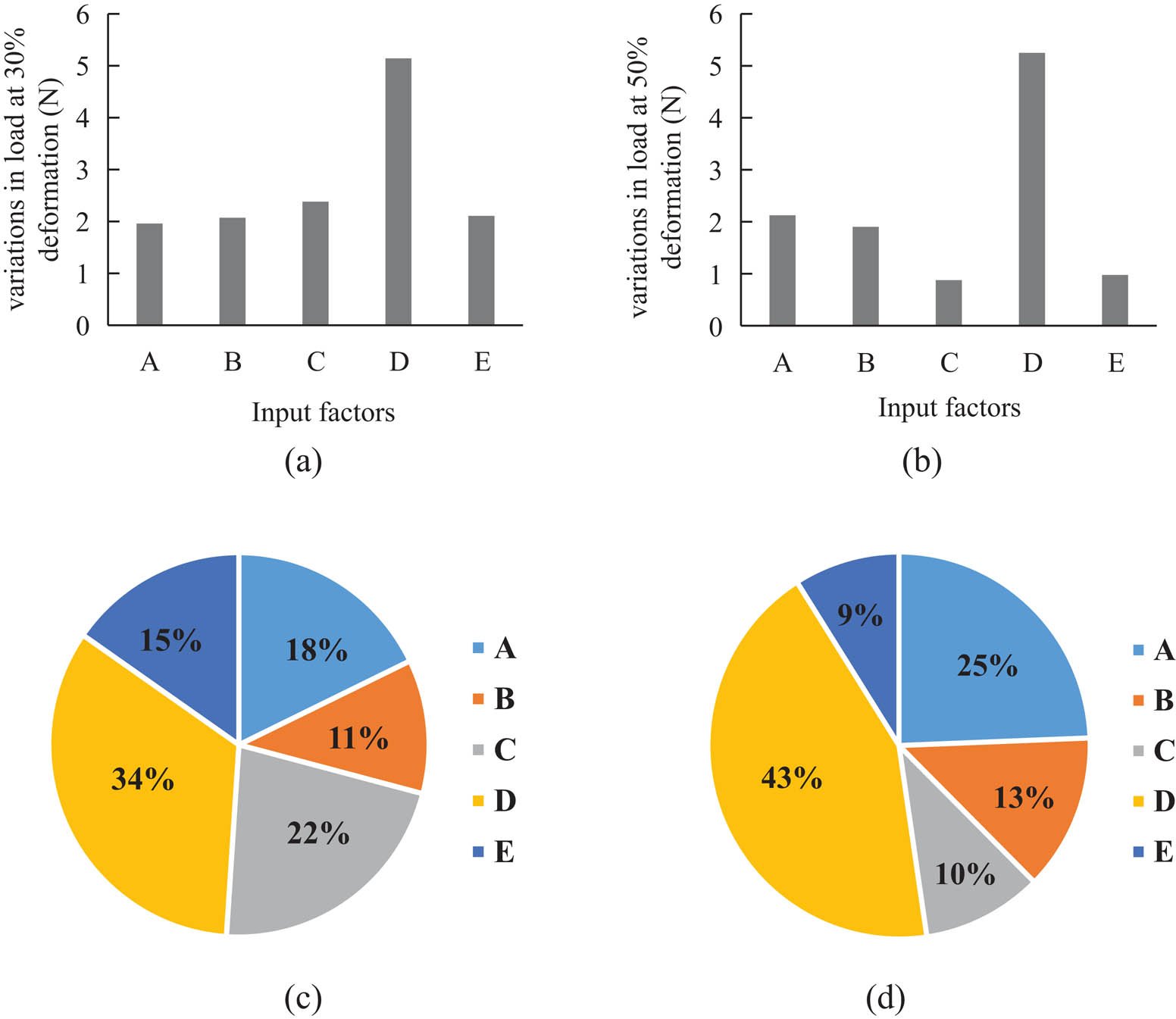

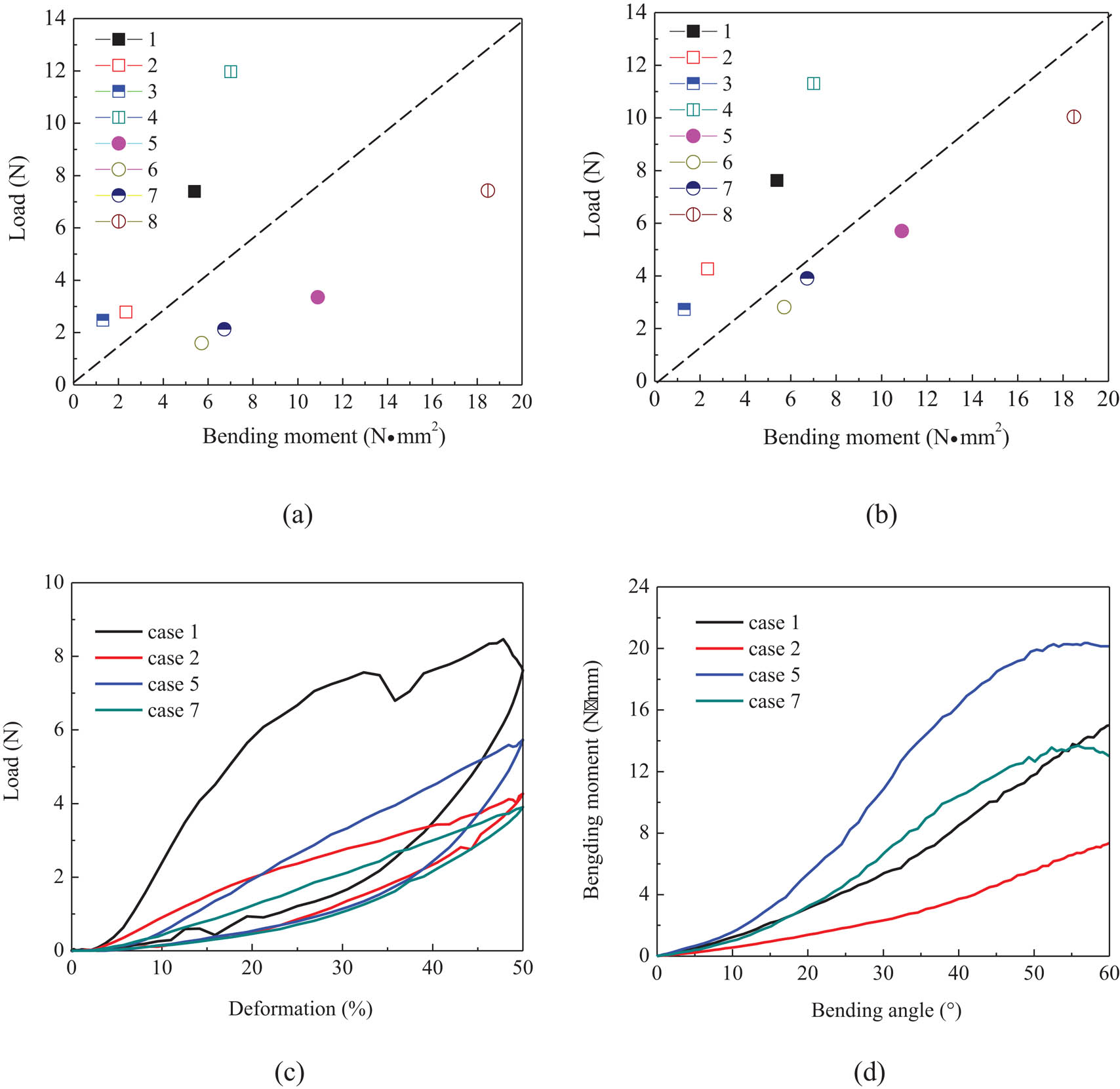

The compression load at the deformation of 30% and 50% of its original diameter during the loading process for all eight cases is summarized in Table 4. The load increases with the increase of compression displacement. It is clear that factor D (nitinol diameter) was the most sensitive one to the compression load among the five factors during the loading process no matter at the small or large deformation (Figure 3), and the influence is getting more important as the deformation increased from 30% to 50%, i.e., the range value normalized to radial strength increased by 9% (34–43%). While the importance of factor C (initial braiding angle) reduced from 22% to 10% at the large deformation, and the value of the factor A (PET strip modulus) becomes prominent from 18% to 25%. The reason is that the radial strength is mainly borne by nitinol wires during the whole compression process, while with the increase of compression deformation, the braiding angle under the presser foot becomes smaller, the PET strips enforced more constrain on the nitinol wires and enhanced the radial strength of the stent.

Diagram of the range value on compression load at 30% (a) and 50% (b) deformation of the original diameter and normalized at 30% (c) and 50% (d) of diameter deformation to various input factors. A– PET strip modulus (GPa), B– number of nitinol wire, C– initial braiding angle (°), D– nitinol wire diameter (mm), and E– PET strip thickness (mm).

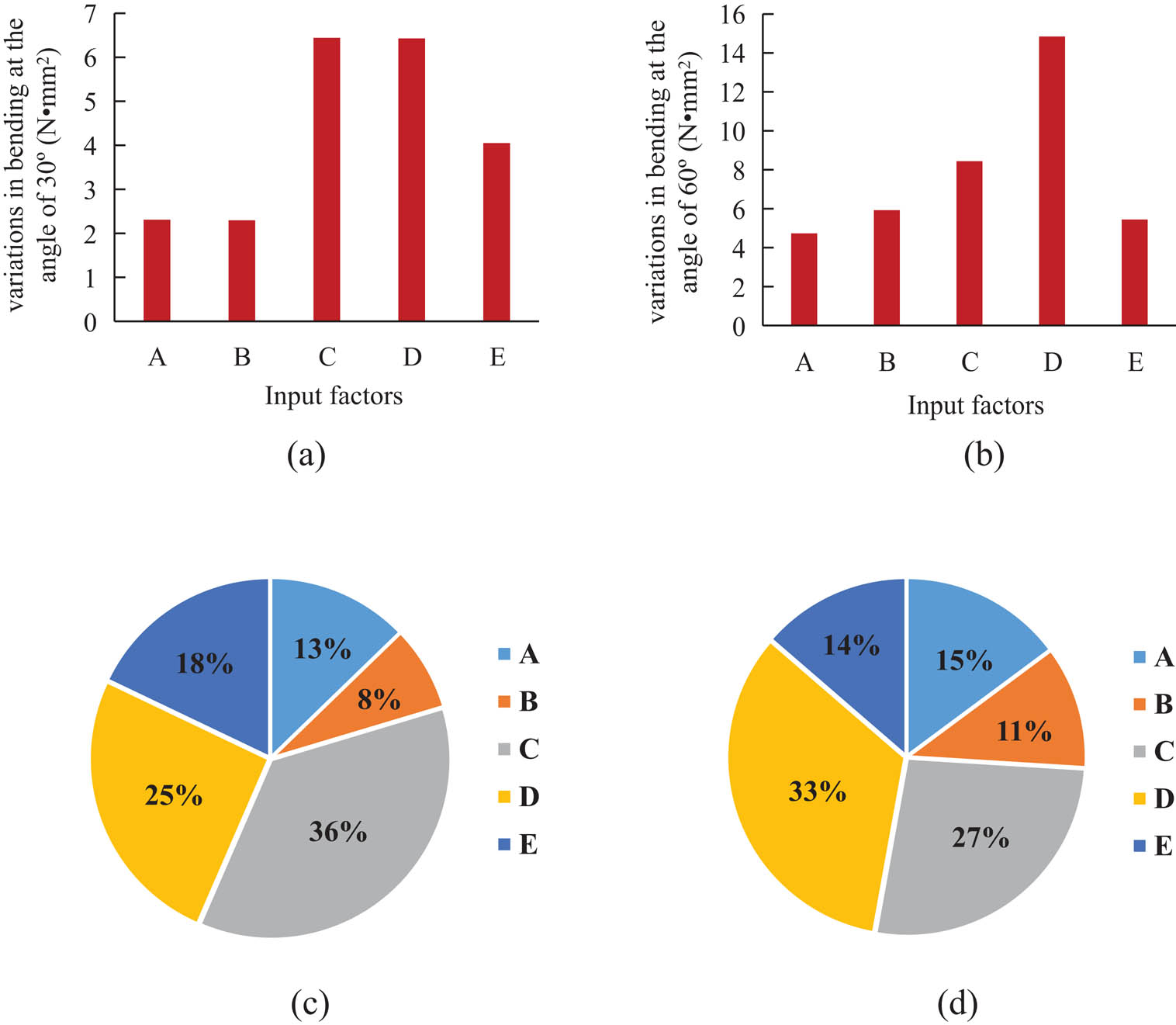

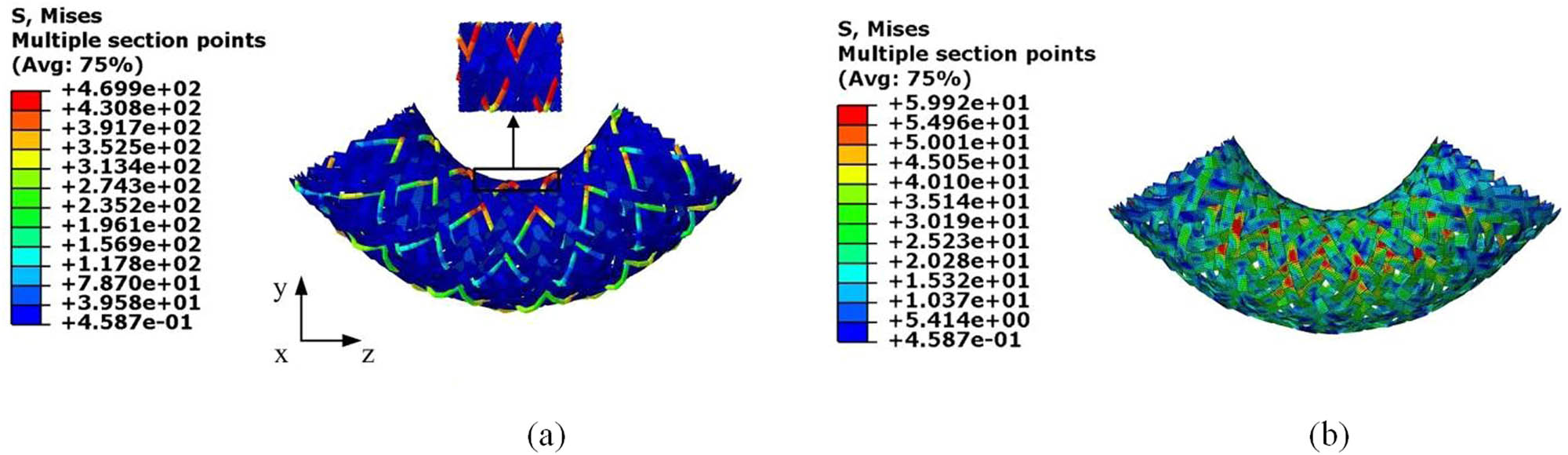

The bending moments at the bending angles of 30° and 60° for all eight cases are summarized in Table 4. The greater bending moment indicated a worse flexibility of the stent. The sensitivities of the five input factors to bending moment are depicted in Figure 4. The proposed results clearly highlight that the bending moment depends strongly on the factor C (initial braiding angle) and factor D (nitinol diameter). Bigger initial braiding angle can achieve better flexibility of the stent, while the increase of the nitinol diameter can reduce the flexibility of the stent. In detail, the initial braiding angle is more sensitive to the bending moment at the bending angle of 30° (36%), while this sensitivity decreases (27%) when the bending angle is up to 60°. By contrast, the influence of the nitinol wire diameter on the bending moment becomes more prominent with the bending angle increase from 30° (25%) to 60° (33%) (Figure 4). It can be explained by the deformed configurations of the stent, in case 1 (Figure 5). It is clear that nitinol wires and PET strips have relative sliding during the bending process. The stress concentrations occur in the region where the stent is under bending and compression. From the XZ plane shown in Figure 5, it can be seen that the porosity of the stent in the bending and compression areas becomes smaller when the bending angle increases, and it reaches a critical value at the bending angle of 48°, and then, the sliding between nitinol wires and PET strips weakens and the importance of the initial braiding angle to the bending moment decreases. It is clear that the whole stent material undergoes an elastic state during the bending process. The peak von Mises stress of nitinol wires is 469.9 MPa at the plateau of phase transformation between austenite and martensite of nitinol and that of PET strips is 59.92 MPa, which well below the ultimate material strength (Figure 5c and d). The bending moment is mainly borne by nitinol wires.

Diagram of the range value on the bending moment at the bending angle of 30° and 60° and normalized at 30° (c) and 60° (d) to various input factors. A– PET strip modulus (GPa), B– number of nitinol wire, C– initial braiding angle (°), D– nitinol wire diameter (mm), and E– PET strip thickness (mm).

Stent deformation of case 1 at the bending angle of 30° (a), 48° (b), 60° (c) (the zoom-in view on the XZ planes), and (d) PET strips at the bending angle of 60°.

To comprehensively evaluate the mechanical properties of the stents in this article, the bending moment as the abscissa axis and radial strength as the ordinate axis were combined, as shown in Figure 6. The model on the upper left of the dotted line shown in the figure is the braiding angle of 65°, while the lower right is the braiding angle of 55°. This indicate that the mechanical performances of the stents with a large braiding angle are better than those with a small braiding angle. The larger radial strength corresponds to the model with larger nitinol wire diameter in the diagram (case 1, 4, 5, and 8.).

Combination diagrams of the bending moment at bending angle of 30° and compression load at the 30% (a) and 50% (b) deformation of the original diameter.

4 Discussion

For peripheral artery stenosis, the implanted stent will be exposed to various “dynamic” loads, such as radial compression, bending, and torsion [27,39]. The dynamic physiological environment requires both the radial strength and the flexibility of the stent, which motivated the design of a novel hybrid BCS. In this work, mechanical behaviors of the BCS were systematically investigated through computational models. An orthogonal experimental design was adopted to quantify the influence of five input factors on the surface coverage, the radial strength, and the flexibility of the stent.

The radial strength is the primary consideration of the stent conceptual design to scaffold the narrow lumen [8]. The nitinol diameter is the most critical factor among the five factors for the radial strength of the BCS. A larger nitinol diameter and the initial braiding angle resulted in a higher radial strength, which applies to all braided stent including the BCS in this article and braided nitinol stent (BNS) [37]. While in BNS, the nitinol diameter has less influence on the radial strength than the initial braiding angle [35]. The influence of factor difference between two stents can be explained by the unique structure of BCS. In BCS, the presence of wide PET strips can constrain the sliding of the nitinol wires and enhance the radial strength of the stent at the large deformation, the radial strength was 52% larger than that of the BNS at the deformation of 50% original diameter [25]. Due to the interaction between the nitinol wire and PET strips, the structure of BCS tends to be more stable. Meanwhile, due to its wide PET strips, the BCS can provide a higher surface coverage that could be considered as a potential alternative to the covered stent, which has a larger radial strength while compromising its flexible performance [24]. The mechanical properties of PET strip could be enhanced by using a drug-loading nanocomposite, which will be investigated in the future work [40].

The longitudinal flexibility of stent was associated with the risk of kinking and incidence of limb thrombosis in tortuous anatomy [15]. Without enough flexibility, the stent does not make full contact with the artery wall when there is knee flexion and this may increase the risk of restenosis due to the interaction between the stent and the artery [41,42]. For BCS, the bigger initial braiding angle can result in a better flexibility, whereas the larger nitinol wire diameter can induce a worse flexibility of stent. The most critical factor for the bending moment of the BCS is the initial braiding and then changed to the nitinol wire diameter when the bending angle changes from 30° to 60°, which is different from the BNS that the nitinol diameter is most sensitive to the bending moment during the whole bending process [35]. The difference may result from the presence of PET strips, which could reduce the sliding between nitinol wires at a small bending angle. The porosity becomes smaller with an increase of the bending angle in the bending and compression areas until they squeeze each other (Figure 5). After that the bending moment is mainly borne by nitinol wires. BCS exhibits better flexibility than the BNS and the covered stent at a small bending angle, i.e., the bending angle at 30° [25,29].

5 Conclusions

The BCS has advantages of good flexibility and high radial strength. To optimize the stent design in different physiological environments is urgently needed based on the understanding the sensitivity of stent parameters. In this study, the orthogonal experimental design was adopted to quantify the influence of five input factors on the surface coverage, radial strength, and flexibility of the stent. Our results show that nitinol diameter and initial braiding angle are two most sensitive factors that affect the mechanical performance of BCS. The influence of the nitinol diameter increased when the stent underwent a large deformation, while the influence of the initial braiding angle was the opposite. At the same time, the impact of PET strips increased due to the interaction with nitinol wires. The surface coverage of BCS mainly depends on the number of the PET strips. In addition, the interaction between stent and a torturous artery in a complex mechanical environment should also be carried out simultaneously to better evaluate the mechanical properties of the stent.

Acknowledgments

The support from the National Natural Science Foundation of China (No. 31870934, 11672199) was acknowledged.

-

Conflict of interest: The authors declare no conflict of interest regarding the publication of this paper.

References

[1] Fowkes FGR, Aboyans V, Fowkes FJI, McDermott MM, Sampson UKA, Criqui MH. Peripheral artery disease: epidemiology and global perspectives. Nat Rev Cardiol. 2017;14:156–70.10.1038/nrcardio.2016.179Search in Google Scholar PubMed

[2] Rooke TW, Hirsch AT, Misra S, Sidawy AN, Beckman JA, Findeiss LK, et al. ACCF/AHA Focused Update of the Guideline for the Management of Patients With Peripheral Artery Disease (Updating the 2005 Guideline) A Report of the American College of Cardiology Foundation/American Heart Association Task Force on Practice Guidelines Developed in Collaboration With the Society for Cardiovascular Angiography and Interventions, Society of Interventional Radiology, Society for Vascular Medicine, and Society for Vascular Surgery. Catheter Cardio Inte. 2011;2012(79):501–31.Search in Google Scholar

[3] Rundback JH, Herman KC, Patel A. Superficial femoral artery intervention: creating an algorithmic approach for the use of old and novel (endovascular) technologies. Curr Treat Opt Cardiovasc Med. 2015;17:42–2.10.1007/s11936-015-0400-3Search in Google Scholar PubMed

[4] Schillinger M, Minar E. Percutaneous treatment of peripheral artery disease: novel techniques. Circulation. 2012;126:2433–40.10.1161/CIRCULATIONAHA.111.036574Search in Google Scholar PubMed

[5] Yang X, Lu X, Ye K, Li X, Qin J, Jiang M. Systematic review and meta-analysis of balloon angioplasty versus primary stenting in the infrapopliteal disease. Vasc Endovasc Surg. 2014;48:18–26.10.1177/1538574413510626Search in Google Scholar PubMed

[6] Biondi-Zoccai G, Sangiorgi G, Lotrionte M, Feiring A, Commeau P, Fusaro M, et al. Infragenicular stent implantation for below-the-knee atherosclerotic disease: clinical evidence from an international collaborative meta-analysis on 640 patients. J Endovasc Ther. 2009;16:251–60.10.1583/09-2691.1Search in Google Scholar PubMed

[7] Wang X, Liu P, Liang H, Zhang M, Li L, Yue Z. Analysis of the whole implementation process and optimization of a Nitinol superelastic stent. Materialwissenschaft Werkstofftechnik. 2019;50:44–51.10.1002/mawe.201800066Search in Google Scholar

[8] Dottori S, Flamini V, Vairo G. Mechanical behavior of peripheral stents and stent-vessel interaction: a computational study. Int J Comput Meth Eng Sci Mech. 2016;17:196–210.10.1080/15502287.2016.1188530Search in Google Scholar

[9] Shen X, Deng Y, Ji S, Zhu H, Jiang J, Gu L. Bending analysis of stented coronary artery: the interaction between stent and vessel. J Mech. 2019;35:455–63.10.1017/jmech.2018.23Search in Google Scholar

[10] Welch T, Eberhart R, Banerjee S, Chuong C-J. Mechanical interaction of an expanding coiled stent with a plaque-containing arterial wall: a finite element analysis. Cardiovasc Eng Techn. 2016;7:58–68.10.1007/s13239-015-0249-3Search in Google Scholar PubMed

[11] Qi Y, Qi H, He Y, Lin W, Li P-Z, Qin L, et al. Strategy of metal-polymer composite stent to accelerate biodegradation of iron-based biomaterials. ACS Appl Mater Interfaces. 2017;10:182–92.10.1021/acsami.7b15206Search in Google Scholar PubMed

[12] Zhao S, Liu X, Gu L. The impact of wire stent fabrication technique on the performance of stent placement. J Med Devices. 2012;6:011007.10.1115/1.4005788Search in Google Scholar

[13] Matsumoto T, Inoue K, Tanaka S, Aoyagi Y, Matsubara Y, Matsuda D. Radial forces of stents used in thoracic endovascular aortic repair and bare self-expanding nitinol stents measured ex vivo – rapid rescue for obstruction of the innominate artery using bare self-expanding nitinol stents. Vascular. 2017;25:36–41.10.1177/1708538116640131Search in Google Scholar

[14] Zhao G, Chen G, Li X, Yuan Z, Ma L, Zhang B. Finite element studies on radial supporting performance of trans-structure Ni–Ti alloy vascular stent. Mat Rep. 2019;33:3050–6.Search in Google Scholar

[15] Carroccio A, Faries P, Morrissey N, Teodorescu V, Burks J, Gravereaux E, et al. Predicting iliac limb occlusions after bifurcated aortic stent grafting: anatomic and device-related causes. J Vasc Surg. 2002;36:679–84.10.1016/S0741-5214(02)00117-9Search in Google Scholar

[16] Armstrong E, Bishu K. Supera self-expanding stents for endovascular treatment of femoropopliteal disease: a review of the clinical evidence. Vasc Health Risk Manag. 2015;11:387–95.10.2147/VHRM.S70229Search in Google Scholar PubMed PubMed Central

[17] Duerig TW, Tolomeo DE, Wholey M. An overview of superelastic stent design. Minim Invas Ther Allied Technol. 2000;9:235–46.10.1080/13645700009169654Search in Google Scholar PubMed

[18] Maleckis K, Deegan P, Poulson W, Sievers C, Kamenskiy A. Comparison of femoropopliteal artery stents under axial and radial compression, axial tension, bending, and torsion deformations. J Mech Behav Biomed Mater. 2017;75:160–8.10.1016/j.jmbbm.2017.07.017Search in Google Scholar PubMed PubMed Central

[19] Goltz JP, Ritter CO, Kellersmann R, Klein D, Hahn D, Kickuth R. Endovascular treatment of popliteal artery segments P1 and P2 in patients with critical limb ischemia: initial experience using a helical nitinol stent with increased radial force. J Endovasc Ther. 2012;19:450–6.10.1583/11-3591MR.1Search in Google Scholar PubMed

[20] Waidmann O, Trojan J, Friedrich-Rust M, Sarrazin C, Bechstein WO, Ulrich F, et al. SEMS vs cSEMS in duodenal and small bowel obstruction: high risk of migration in the covered stent group. World J Gastroentero. 2013;19:6199–206.10.3748/wjg.v19.i37.6199Search in Google Scholar PubMed PubMed Central

[21] Al-Mukhaini M, Panduranga P, Sulaiman K, Riyami A, Deeb M, Riyami M. Coronary perforation and covered stents: an update and review. Heart Views. 2011;12:63–70.10.4103/1995-705X.86017Search in Google Scholar PubMed PubMed Central

[22] Mwipatayi B, Thomas S, Wong J, Temple S, Vijayan V, Jackson M, et al. A comparison of covered versus bare expandable for the treatment of aortoiliac occlusive disease. J Vasc Surg. 2011;54:1561–70.10.1016/j.jvs.2011.06.097Search in Google Scholar PubMed

[23] Weale A, Balasubramaniam K, Hardman J, Horrocks M. Use of the AorfixTM stent graft in patients with tortuous iliac anatomy. J Cardiovasc Surg. 2010;51:461–6.Search in Google Scholar

[24] Wang Y, Dong P, Ke J, Shen X, Li Z, Ren K, et al. Experimental evaluation of self-expandable metallic tracheobronchial stents. Nanotechnol Rev. 2019;8:136–42.10.1515/ntrev-2019-0013Search in Google Scholar

[25] Zheng Q, Dong P, Li Z, Han X, Zhou C, An M, et al. Mechanical characterizations of braided composite stents made of helical polyethylene terephthalate strips and NiTi wires. Nanotechnol Rev. 2019;8:168–74.10.1515/ntrev-2019-0016Search in Google Scholar

[26] Jaziri H, Mokhtar S, Chakf N, Heim F, Abdessalem S. Elastic recovery of polymeric braided stents under cyclic loading: preliminary assessment. J Mech Behav Biomed Mater. 2019;98:131–6.10.1016/j.jmbbm.2019.06.018Search in Google Scholar PubMed

[27] Maleckis K, Anttila E, Aylward P, Poulson W, Desyatova A, Mactaggart J, et al. Nitinol stents in the femoropopliteal artery: a mechanical perspective on material, design, and performance. Ann Biomed Eng. 2018;46:484–704.10.1007/s10439-018-1990-1Search in Google Scholar PubMed PubMed Central

[28] Sharma P. NiTi shape memory alloy: physical and tribological characterization. JMBM. 2018;27:250–69.10.1515/jmbm-2018-0009Search in Google Scholar

[29] Isayama H, Nakai Y, Toyokawa Y, Togawa O, Gon C, Ito Y, et al. Measurement of radial and axial forces of biliary self-expandable metallic stents. Gastrointest Endosc. 2009;70:37–44.10.1016/j.gie.2008.09.032Search in Google Scholar PubMed

[30] Zou Q, Xue W, Lin J, Fu Y, Guan G, Wang F, et al. Mechanical characteristics of novel polyester/NiTi wires braided composite stent for the medical application. Res Phys. 2016;6:440–6.10.1016/j.rinp.2016.07.007Search in Google Scholar

[31] Jedwab MR, Clerc CO. A study of the geometrical and mechanical properties of a self-expanding metallic stent – theory and experiment. J Appl BiomaterI. 1993;4:77–85.10.1002/jab.770040111Search in Google Scholar PubMed

[32] Rebelo N, Gong X, Hall A, Pelton A, Duerig T. Finite element analysis on the cyclic properties of superelastic nitinol. Proceedings of the International Conference on Shape Memory and Superelastic Technologies. Baden, Germany, 2004.Search in Google Scholar

[33] Puskas JE, Chen Y. Biomedical application of commercial polymers and novel polyisobutylene-based thermoplastic elastomers for soft tissue replacement. Biomacromolecules. 2004;5:1141–54.10.1021/bm034513kSearch in Google Scholar PubMed

[34] Zhao F, Xue W, Wang F, Sun J, Lin J, Laijun L, et al. Braided bioresorbable cardiovascular stents mechanically reinforced by axial runners. J Mech Behav Biomed Mater. 2019;89:19–32.10.1016/j.jmbbm.2018.09.003Search in Google Scholar PubMed

[35] Zheng Q, Mozafari H, Li Z, Gu L. Mechanical characterization of braided self-expanding stents: impact of design parameters. J Mech Med Biol. 2019;19:108–13.10.1142/S0219519419500386Search in Google Scholar

[36] Balasubramaniam K, Hardman J, Horrocks M, Bulbulia R. The advantages of Aorfixâ„¢ for endovascular repair of abdominal aortic aneurysm. J Cardiovasc Surg. 2009;50:139–43.Search in Google Scholar

[37] Kim J, Kang T, Yu W-R. Mechanical modeling of self-expandable stent fabricated using braiding technology. J Biomech. 2008;41:3202–12.10.1016/j.jbiomech.2008.08.005Search in Google Scholar PubMed

[38] Taguchi G. The System of Experimental Design Engineering Methods to Optimize Quality and Minimize Cost. White Plains: NY: UNIPUB/Kraus International Publications; 1987.Search in Google Scholar

[39] Ansari F, Pack L, Brooks S, Morrison T. Design considerations for studies of the biomechanical environment of the femoropopliteal arteries. J Vasc Surg. 2013;58:804–13.10.1016/j.jvs.2013.03.052Search in Google Scholar PubMed

[40] Jia F, Li G, Yang B, Yu B, Shen Y, Cong H. Investigation of rare earth upconversion fluorescent nanoparticles in biomedical field. Nanotechnol Rev. 2019;8:1–17.10.1515/ntrev-2019-0001Search in Google Scholar

[41] Smouse HB, Nikanorov A, LaFlash D. Biomechanical forces in the femoropopliteal arterial segment. Endovasc Today. 2005;4:60–6.Search in Google Scholar

[42] Ni Ghriallais R, Heraty K, Smouse B, Burke M, Gilson P, Bruzzi M. Deformation of the femoropopliteal segment. J Endovasc Ther. 2016;23:1526602816669135.10.1177/1526602816669135Search in Google Scholar PubMed

© 2020 Qingli Zheng et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Generalized locally-exact homogenization theory for evaluation of electric conductivity and resistance of multiphase materials

- Enhancing ultra-early strength of sulphoaluminate cement-based materials by incorporating graphene oxide

- Characterization of mechanical properties of epoxy/nanohybrid composites by nanoindentation

- Graphene and CNT impact on heat transfer response of nanocomposite cylinders

- A facile and simple approach to synthesis and characterization of methacrylated graphene oxide nanostructured polyaniline nanocomposites

- Ultrasmall Fe3O4 nanoparticles induce S-phase arrest and inhibit cancer cells proliferation

- Effect of aging on properties and nanoscale precipitates of Cu-Ag-Cr alloy

- Effect of nano-strengthening on the properties and microstructure of recycled concrete

- Stabilizing effect of methylcellulose on the dispersion of multi-walled carbon nanotubes in cementitious composites

- Preparation and electromagnetic properties characterization of reduced graphene oxide/strontium hexaferrite nanocomposites

- Interfacial characteristics of a carbon nanotube-polyimide nanocomposite by molecular dynamics simulation

- Preparation and properties of 3D interconnected CNTs/Cu composites

- On factors affecting surface free energy of carbon black for reinforcing rubber

- Nano-silica modified phenolic resin film: manufacturing and properties

- Experimental study on photocatalytic degradation efficiency of mixed crystal nano-TiO2 concrete

- Halloysite nanotubes in polymer science: purification, characterization, modification and applications

- Cellulose hydrogel skeleton by extrusion 3D printing of solution

- Crack closure and flexural tensile capacity with SMA fibers randomly embedded on tensile side of mortar beams

- An experimental study on one-step and two-step foaming of natural rubber/silica nanocomposites

- Utilization of red mud for producing a high strength binder by composition optimization and nano strengthening

- One-pot synthesis of nano titanium dioxide in supercritical water

- Printability of photo-sensitive nanocomposites using two-photon polymerization

- In situ synthesis of expanded graphite embedded with amorphous carbon-coated aluminum particles as anode materials for lithium-ion batteries

- Effect of nano and micro conductive materials on conductive properties of carbon fiber reinforced concrete

- Tribological performance of nano-diamond composites-dispersed lubricants on commercial cylinder liner mating with CrN piston ring

- Supramolecular ionic polymer/carbon nanotube composite hydrogels with enhanced electromechanical performance

- Genetic mechanisms of deep-water massive sandstones in continental lake basins and their significance in micro–nano reservoir storage systems: A case study of the Yanchang formation in the Ordos Basin

- Effects of nanoparticles on engineering performance of cementitious composites reinforced with PVA fibers

- Band gap manipulation of viscoelastic functionally graded phononic crystal

- Pyrolysis kinetics and mechanical properties of poly(lactic acid)/bamboo particle biocomposites: Effect of particle size distribution

- Manipulating conductive network formation via 3D T-ZnO: A facile approach for a CNT-reinforced nanocomposite

- Microstructure and mechanical properties of WC–Ni multiphase ceramic materials with NiCl2·6H2O as a binder

- Effect of ball milling process on the photocatalytic performance of CdS/TiO2 composite

- Berberine/Ag nanoparticle embedded biomimetic calcium phosphate scaffolds for enhancing antibacterial function

- Effect of annealing heat treatment on microstructure and mechanical properties of nonequiatomic CoCrFeNiMo medium-entropy alloys prepared by hot isostatic pressing

- Corrosion behaviour of multilayer CrN coatings deposited by hybrid HIPIMS after oxidation treatment

- Surface hydrophobicity and oleophilicity of hierarchical metal structures fabricated using ink-based selective laser melting of micro/nanoparticles

- Research on bond–slip performance between pultruded glass fiber-reinforced polymer tube and nano-CaCO3 concrete

- Antibacterial polymer nanofiber-coated and high elastin protein-expressing BMSCs incorporated polypropylene mesh for accelerating healing of female pelvic floor dysfunction

- Effects of Ag contents on the microstructure and SERS performance of self-grown Ag nanoparticles/Mo–Ag alloy films

- A highly sensitive biosensor based on methacrylated graphene oxide-grafted polyaniline for ascorbic acid determination

- Arrangement structure of carbon nanofiber with excellent spectral radiation characteristics

- Effect of different particle sizes of nano-SiO2 on the properties and microstructure of cement paste

- Superior Fe x N electrocatalyst derived from 1,1′-diacetylferrocene for oxygen reduction reaction in alkaline and acidic media

- Facile growth of aluminum oxide thin film by chemical liquid deposition and its application in devices

- Liquid crystallinity and thermal properties of polyhedral oligomeric silsesquioxane/side-chain azobenzene hybrid copolymer

- Laboratory experiment on the nano-TiO2 photocatalytic degradation effect of road surface oil pollution

- Binary carbon-based additives in LiFePO4 cathode with favorable lithium storage

- Conversion of sub-µm calcium carbonate (calcite) particles to hollow hydroxyapatite agglomerates in K2HPO4 solutions

- Exact solutions of bending deflection for single-walled BNNTs based on the classical Euler–Bernoulli beam theory

- Effects of substrate properties and sputtering methods on self-formation of Ag particles on the Ag–Mo(Zr) alloy films

- Enhancing carbonation and chloride resistance of autoclaved concrete by incorporating nano-CaCO3

- Effect of SiO2 aerogels loading on photocatalytic degradation of nitrobenzene using composites with tetrapod-like ZnO

- Radiation-modified wool for adsorption of redox metals and potentially for nanoparticles

- Hydration activity, crystal structural, and electronic properties studies of Ba-doped dicalcium silicate

- Microstructure and mechanical properties of brazing joint of silver-based composite filler metal

- Polymer nanocomposite sunlight spectrum down-converters made by open-air PLD

- Cryogenic milling and formation of nanostructured machined surface of AISI 4340

- Braided composite stent for peripheral vascular applications

- Effect of cinnamon essential oil on morphological, flammability and thermal properties of nanocellulose fibre–reinforced starch biopolymer composites

- Study on influencing factors of photocatalytic performance of CdS/TiO2 nanocomposite concrete

- Improving flexural and dielectric properties of carbon fiber epoxy composite laminates reinforced with carbon nanotubes interlayer using electrospray deposition

- Scalable fabrication of carbon materials based silicon rubber for highly stretchable e-textile sensor

- Degradation modeling of poly-l-lactide acid (PLLA) bioresorbable vascular scaffold within a coronary artery

- Combining Zn0.76Co0.24S with S-doped graphene as high-performance anode materials for lithium- and sodium-ion batteries

- Synthesis of functionalized carbon nanotubes for fluorescent biosensors

- Effect of nano-silica slurry on engineering, X-ray, and γ-ray attenuation characteristics of steel slag high-strength heavyweight concrete

- Incorporation of redox-active polyimide binder into LiFePO4 cathode for high-rate electrochemical energy storage

- Microstructural evolution and properties of Cu–20 wt% Ag alloy wire by multi-pass continuous drawing

- Transparent ultraviolet-shielding composite films made from dispersing pristine zinc oxide nanoparticles in low-density polyethylene

- Microfluidic-assisted synthesis and modelling of monodispersed magnetic nanocomposites for biomedical applications

- Preparation and piezoresistivity of carbon nanotube-coated sand reinforced cement mortar

- Vibrational analysis of an irregular single-walled carbon nanotube incorporating initial stress effects

- Study of the material engineering properties of high-density poly(ethylene)/perlite nanocomposite materials

- Single pulse laser removal of indium tin oxide film on glass and polyethylene terephthalate by nanosecond and femtosecond laser

- Mechanical reinforcement with enhanced electrical and heat conduction of epoxy resin by polyaniline and graphene nanoplatelets

- High-efficiency method for recycling lithium from spent LiFePO4 cathode

- Degradable tough chitosan dressing for skin wound recovery

- Static and dynamic analyses of auxetic hybrid FRC/CNTRC laminated plates

- Review articles

- Carbon nanomaterials enhanced cement-based composites: advances and challenges

- Review on the research progress of cement-based and geopolymer materials modified by graphene and graphene oxide

- Review on modeling and application of chemical mechanical polishing

- Research on the interface properties and strengthening–toughening mechanism of nanocarbon-toughened ceramic matrix composites

- Advances in modelling and analysis of nano structures: a review

- Mechanical properties of nanomaterials: A review

- New generation of oxide-based nanoparticles for the applications in early cancer detection and diagnostics

- A review on the properties, reinforcing effects, and commercialization of nanomaterials for cement-based materials

- Recent development and applications of nanomaterials for cancer immunotherapy

- Advances in biomaterials for adipose tissue reconstruction in plastic surgery

- Advances of graphene- and graphene oxide-modified cementitious materials

- Theories for triboelectric nanogenerators: A comprehensive review

- Nanotechnology of diamondoids for the fabrication of nanostructured systems

- Material advancement in technological development for the 5G wireless communications

- Nanoengineering in biomedicine: Current development and future perspectives

- Recent advances in ocean wave energy harvesting by triboelectric nanogenerator: An overview

- Application of nanoscale zero-valent iron in hexavalent chromium-contaminated soil: A review

- Carbon nanotube–reinforced polymer composite for electromagnetic interference application: A review

- Functionalized layered double hydroxide applied to heavy metal ions absorption: A review

- A new classification method of nanotechnology for design integration in biomaterials

- Finite element analysis of natural fibers composites: A review

- Phase change materials for building construction: An overview of nano-/micro-encapsulation

- Recent advance in surface modification for regulating cell adhesion and behaviors

- Hyaluronic acid as a bioactive component for bone tissue regeneration: Fabrication, modification, properties, and biological functions

- Theoretical calculation of a TiO2-based photocatalyst in the field of water splitting: A review

- Two-photon polymerization nanolithography technology for fabrication of stimulus-responsive micro/nano-structures for biomedical applications

- A review of passive methods in microchannel heat sink application through advanced geometric structure and nanofluids: Current advancements and challenges

- Stress effect on 3D culturing of MC3T3-E1 cells on microporous bovine bone slices

- Progress in magnetic Fe3O4 nanomaterials in magnetic resonance imaging

- Synthesis of graphene: Potential carbon precursors and approaches

- A comprehensive review of the influences of nanoparticles as a fuel additive in an internal combustion engine (ICE)

- Advances in layered double hydroxide-based ternary nanocomposites for photocatalysis of contaminants in water

- Analysis of functionally graded carbon nanotube-reinforced composite structures: A review

- Application of nanomaterials in ultra-high performance concrete: A review

- Therapeutic strategies and potential implications of silver nanoparticles in the management of skin cancer

- Advanced nickel nanoparticles technology: From synthesis to applications

- Cobalt magnetic nanoparticles as theranostics: Conceivable or forgettable?

- Progress in construction of bio-inspired physico-antimicrobial surfaces

- From materials to devices using fused deposition modeling: A state-of-art review

- A review for modified Li composite anode: Principle, preparation and challenge

- Naturally or artificially constructed nanocellulose architectures for epoxy composites: A review

Articles in the same Issue

- Research Articles

- Generalized locally-exact homogenization theory for evaluation of electric conductivity and resistance of multiphase materials

- Enhancing ultra-early strength of sulphoaluminate cement-based materials by incorporating graphene oxide

- Characterization of mechanical properties of epoxy/nanohybrid composites by nanoindentation

- Graphene and CNT impact on heat transfer response of nanocomposite cylinders

- A facile and simple approach to synthesis and characterization of methacrylated graphene oxide nanostructured polyaniline nanocomposites

- Ultrasmall Fe3O4 nanoparticles induce S-phase arrest and inhibit cancer cells proliferation

- Effect of aging on properties and nanoscale precipitates of Cu-Ag-Cr alloy

- Effect of nano-strengthening on the properties and microstructure of recycled concrete

- Stabilizing effect of methylcellulose on the dispersion of multi-walled carbon nanotubes in cementitious composites

- Preparation and electromagnetic properties characterization of reduced graphene oxide/strontium hexaferrite nanocomposites

- Interfacial characteristics of a carbon nanotube-polyimide nanocomposite by molecular dynamics simulation

- Preparation and properties of 3D interconnected CNTs/Cu composites

- On factors affecting surface free energy of carbon black for reinforcing rubber

- Nano-silica modified phenolic resin film: manufacturing and properties

- Experimental study on photocatalytic degradation efficiency of mixed crystal nano-TiO2 concrete

- Halloysite nanotubes in polymer science: purification, characterization, modification and applications

- Cellulose hydrogel skeleton by extrusion 3D printing of solution

- Crack closure and flexural tensile capacity with SMA fibers randomly embedded on tensile side of mortar beams

- An experimental study on one-step and two-step foaming of natural rubber/silica nanocomposites

- Utilization of red mud for producing a high strength binder by composition optimization and nano strengthening

- One-pot synthesis of nano titanium dioxide in supercritical water

- Printability of photo-sensitive nanocomposites using two-photon polymerization

- In situ synthesis of expanded graphite embedded with amorphous carbon-coated aluminum particles as anode materials for lithium-ion batteries

- Effect of nano and micro conductive materials on conductive properties of carbon fiber reinforced concrete

- Tribological performance of nano-diamond composites-dispersed lubricants on commercial cylinder liner mating with CrN piston ring

- Supramolecular ionic polymer/carbon nanotube composite hydrogels with enhanced electromechanical performance

- Genetic mechanisms of deep-water massive sandstones in continental lake basins and their significance in micro–nano reservoir storage systems: A case study of the Yanchang formation in the Ordos Basin

- Effects of nanoparticles on engineering performance of cementitious composites reinforced with PVA fibers

- Band gap manipulation of viscoelastic functionally graded phononic crystal

- Pyrolysis kinetics and mechanical properties of poly(lactic acid)/bamboo particle biocomposites: Effect of particle size distribution

- Manipulating conductive network formation via 3D T-ZnO: A facile approach for a CNT-reinforced nanocomposite

- Microstructure and mechanical properties of WC–Ni multiphase ceramic materials with NiCl2·6H2O as a binder

- Effect of ball milling process on the photocatalytic performance of CdS/TiO2 composite

- Berberine/Ag nanoparticle embedded biomimetic calcium phosphate scaffolds for enhancing antibacterial function

- Effect of annealing heat treatment on microstructure and mechanical properties of nonequiatomic CoCrFeNiMo medium-entropy alloys prepared by hot isostatic pressing

- Corrosion behaviour of multilayer CrN coatings deposited by hybrid HIPIMS after oxidation treatment

- Surface hydrophobicity and oleophilicity of hierarchical metal structures fabricated using ink-based selective laser melting of micro/nanoparticles

- Research on bond–slip performance between pultruded glass fiber-reinforced polymer tube and nano-CaCO3 concrete

- Antibacterial polymer nanofiber-coated and high elastin protein-expressing BMSCs incorporated polypropylene mesh for accelerating healing of female pelvic floor dysfunction

- Effects of Ag contents on the microstructure and SERS performance of self-grown Ag nanoparticles/Mo–Ag alloy films

- A highly sensitive biosensor based on methacrylated graphene oxide-grafted polyaniline for ascorbic acid determination

- Arrangement structure of carbon nanofiber with excellent spectral radiation characteristics

- Effect of different particle sizes of nano-SiO2 on the properties and microstructure of cement paste

- Superior Fe x N electrocatalyst derived from 1,1′-diacetylferrocene for oxygen reduction reaction in alkaline and acidic media

- Facile growth of aluminum oxide thin film by chemical liquid deposition and its application in devices

- Liquid crystallinity and thermal properties of polyhedral oligomeric silsesquioxane/side-chain azobenzene hybrid copolymer

- Laboratory experiment on the nano-TiO2 photocatalytic degradation effect of road surface oil pollution

- Binary carbon-based additives in LiFePO4 cathode with favorable lithium storage

- Conversion of sub-µm calcium carbonate (calcite) particles to hollow hydroxyapatite agglomerates in K2HPO4 solutions

- Exact solutions of bending deflection for single-walled BNNTs based on the classical Euler–Bernoulli beam theory

- Effects of substrate properties and sputtering methods on self-formation of Ag particles on the Ag–Mo(Zr) alloy films

- Enhancing carbonation and chloride resistance of autoclaved concrete by incorporating nano-CaCO3

- Effect of SiO2 aerogels loading on photocatalytic degradation of nitrobenzene using composites with tetrapod-like ZnO

- Radiation-modified wool for adsorption of redox metals and potentially for nanoparticles

- Hydration activity, crystal structural, and electronic properties studies of Ba-doped dicalcium silicate

- Microstructure and mechanical properties of brazing joint of silver-based composite filler metal

- Polymer nanocomposite sunlight spectrum down-converters made by open-air PLD

- Cryogenic milling and formation of nanostructured machined surface of AISI 4340

- Braided composite stent for peripheral vascular applications

- Effect of cinnamon essential oil on morphological, flammability and thermal properties of nanocellulose fibre–reinforced starch biopolymer composites

- Study on influencing factors of photocatalytic performance of CdS/TiO2 nanocomposite concrete

- Improving flexural and dielectric properties of carbon fiber epoxy composite laminates reinforced with carbon nanotubes interlayer using electrospray deposition

- Scalable fabrication of carbon materials based silicon rubber for highly stretchable e-textile sensor

- Degradation modeling of poly-l-lactide acid (PLLA) bioresorbable vascular scaffold within a coronary artery

- Combining Zn0.76Co0.24S with S-doped graphene as high-performance anode materials for lithium- and sodium-ion batteries

- Synthesis of functionalized carbon nanotubes for fluorescent biosensors

- Effect of nano-silica slurry on engineering, X-ray, and γ-ray attenuation characteristics of steel slag high-strength heavyweight concrete

- Incorporation of redox-active polyimide binder into LiFePO4 cathode for high-rate electrochemical energy storage

- Microstructural evolution and properties of Cu–20 wt% Ag alloy wire by multi-pass continuous drawing

- Transparent ultraviolet-shielding composite films made from dispersing pristine zinc oxide nanoparticles in low-density polyethylene

- Microfluidic-assisted synthesis and modelling of monodispersed magnetic nanocomposites for biomedical applications

- Preparation and piezoresistivity of carbon nanotube-coated sand reinforced cement mortar

- Vibrational analysis of an irregular single-walled carbon nanotube incorporating initial stress effects

- Study of the material engineering properties of high-density poly(ethylene)/perlite nanocomposite materials

- Single pulse laser removal of indium tin oxide film on glass and polyethylene terephthalate by nanosecond and femtosecond laser

- Mechanical reinforcement with enhanced electrical and heat conduction of epoxy resin by polyaniline and graphene nanoplatelets

- High-efficiency method for recycling lithium from spent LiFePO4 cathode

- Degradable tough chitosan dressing for skin wound recovery

- Static and dynamic analyses of auxetic hybrid FRC/CNTRC laminated plates

- Review articles

- Carbon nanomaterials enhanced cement-based composites: advances and challenges

- Review on the research progress of cement-based and geopolymer materials modified by graphene and graphene oxide

- Review on modeling and application of chemical mechanical polishing

- Research on the interface properties and strengthening–toughening mechanism of nanocarbon-toughened ceramic matrix composites

- Advances in modelling and analysis of nano structures: a review

- Mechanical properties of nanomaterials: A review

- New generation of oxide-based nanoparticles for the applications in early cancer detection and diagnostics

- A review on the properties, reinforcing effects, and commercialization of nanomaterials for cement-based materials

- Recent development and applications of nanomaterials for cancer immunotherapy

- Advances in biomaterials for adipose tissue reconstruction in plastic surgery

- Advances of graphene- and graphene oxide-modified cementitious materials

- Theories for triboelectric nanogenerators: A comprehensive review

- Nanotechnology of diamondoids for the fabrication of nanostructured systems

- Material advancement in technological development for the 5G wireless communications

- Nanoengineering in biomedicine: Current development and future perspectives

- Recent advances in ocean wave energy harvesting by triboelectric nanogenerator: An overview

- Application of nanoscale zero-valent iron in hexavalent chromium-contaminated soil: A review

- Carbon nanotube–reinforced polymer composite for electromagnetic interference application: A review

- Functionalized layered double hydroxide applied to heavy metal ions absorption: A review

- A new classification method of nanotechnology for design integration in biomaterials

- Finite element analysis of natural fibers composites: A review

- Phase change materials for building construction: An overview of nano-/micro-encapsulation

- Recent advance in surface modification for regulating cell adhesion and behaviors

- Hyaluronic acid as a bioactive component for bone tissue regeneration: Fabrication, modification, properties, and biological functions

- Theoretical calculation of a TiO2-based photocatalyst in the field of water splitting: A review

- Two-photon polymerization nanolithography technology for fabrication of stimulus-responsive micro/nano-structures for biomedical applications

- A review of passive methods in microchannel heat sink application through advanced geometric structure and nanofluids: Current advancements and challenges

- Stress effect on 3D culturing of MC3T3-E1 cells on microporous bovine bone slices

- Progress in magnetic Fe3O4 nanomaterials in magnetic resonance imaging

- Synthesis of graphene: Potential carbon precursors and approaches

- A comprehensive review of the influences of nanoparticles as a fuel additive in an internal combustion engine (ICE)

- Advances in layered double hydroxide-based ternary nanocomposites for photocatalysis of contaminants in water

- Analysis of functionally graded carbon nanotube-reinforced composite structures: A review

- Application of nanomaterials in ultra-high performance concrete: A review

- Therapeutic strategies and potential implications of silver nanoparticles in the management of skin cancer

- Advanced nickel nanoparticles technology: From synthesis to applications

- Cobalt magnetic nanoparticles as theranostics: Conceivable or forgettable?

- Progress in construction of bio-inspired physico-antimicrobial surfaces

- From materials to devices using fused deposition modeling: A state-of-art review

- A review for modified Li composite anode: Principle, preparation and challenge

- Naturally or artificially constructed nanocellulose architectures for epoxy composites: A review