Abstract

Using molecular dynamics simulations, we investigate the movement behavior of double-walled carbon nanotube containing single atom vacancy defect and Stone–Wales defect. The carbon nanotube thermal actuator consists of a short outer tube and a long inner tube driven under temperature gradient. It is found that the presence of these defects introduces resistance of the nanotube systems, which affects their amplitude and speed. The oscillation motion of the outer nanotube is found possible to be produced, which can be achieved by devising proper initial position of the outer tube, the defect type and the temperature gradient. Our results demonstrate the effect of defects on the motion of carbon nanotubes and show that it is possible to control and tune the motion behavior of nanotubes through the introduction of defects.

1 Introduction

Due to their remarkable stiffness, strength,elasticity and extremely low interlayer friction, carbon nanotubes (CNTs) have attracted great attention in engineering applications. Their excellent wear resistance quality and limited movement ability (rotation or translation) make them key components of various applications in the field of nanotechnology.There are many new nano-devices based on double-walled carbon nanotubes (DWNTs) and multi-walled carbon nanotubes (MWNTs), such as nano-robots [1], nano-bearings [2], nano-switches [3, 4, 5, 6, 7] and nano-oscillators [8, 9, 10, 11].

CNTs were first discovered in 1991. Iijima [12] found MWNTs in the products of graphite arc discharge. Then in 1993, Iijima and Bethune [13, 14] et al. found single-walled CNTs in the prepared products independently by mixing transition metals into the graphite electrode during arc discharge. In the field of nanoscience, the DWNTs plays an important role in driving the movement of the nanotubes, which is fundamental to the applications of bearings, switches and oscillators [2, 4, 9]. A controllable nanoscale rotating actuator system consisting of a double CNT and graphene driven by a temperature gradient is proposed by Huang et al. [15]. The movement characteristics and the instability of CNT containing a long outer tube and a short inner tube have been studied extensively [10, 16]. It is found that the oscillatory characteristics markedly depend on the nanotube types and geometries. Mechanical properties like tensile strength and tensile failure strain of single-walled CNTs(SWCNTs) containing defects are studied by Kamal Sharma et al. [17]. In addition, there are also studies on CNTs containing a long outer tube and a short inner tube whichalso contain defects. The effect of defects on the oscillatory behaviors and instability of double- and triple-walled CNTs based oscillators is discussed by Liu et al. [18]. It is confirmed that the existence of these defects markedly affects the oscillation period and amplitude. The oscillatory characteristics of the oscillators containing sp3-hybridized Stone-Wales defects is studied by Guo et al. [19], and their results show that it is possible to control the motion of the inner nanotube by introducing sp3-hybridized defects on the outer nanotube. Stochastic modeling procedure is employed to evaluate the influence of vacancy defects on the Young’s modulus of CNT by Roham Rafiee and Mohammad Mahdavi [20]. And the nano-scale continuum modeling is used to predict Young’s modulus of graphene sheet , also, the finite element (FE) model of the CNT is built using the same approach and then structural defects are applied randomly to obtain the Young’s modulus of defected CNTs and compare with non-defected ones [21, 22]. Systematical molecular statics and dynamics simulations

are performed on the interlayer friction and energy dissipation of double-walled carbon nanotubes by Guo et al., and they demonstrate the coupled effects of system registration, size, and defects [23]. Also, the oscillatory behaviors of an oscillator made from DWCNTs with vacancy defects were investigated by Luo et al., they show that the vacancies cannot improve the performance of DWCNT-based oscillators [24]. And then a model containing a long inner tube and a short outer tube is designed by Hou et al. [25], and temperature gradient is applied to the inner tube, this is what we said “thermal actuator”. In their study, molecular dynamics simulation is used to study the relationship between driving force and thermal gradient in DWCNT, and it is proved that temperature gradient is an effective driving mechanism. It is also concluded that the driving force is approximately proportional to the temperature gradient. Much effort is devoted to studying the system consisting of the long outer tube and the short inner tube and the effects of defects on this nanoscale device so far, there is, however, limited research about the thermal gradient induced actuation of nano-device consisting of the long inner tube and the short outer tube with single atom vacancydefect and Stone–Wales (SW) defect. Due to the imperfection of material production processes, defects are ubiquitous in CNTs and have an unneglectable effect on the motion of the system. Therefore, research about effects of defects on motion of CNT thermal actuator must be done.

In this paper, the effect of single atom vacancy defects and Stone–Wales defects on the movement behavior of CNTs is studied by performing a series of molecular dynamics simulations. We study different types of the defects by arranging different distribution and number of defects. The introduction of these defects has been found to increase damping of the system, which further affects their amplitude and speed of motion. It is found that the proper initial position of the outer tube, the type of defect and the temperature gradient can be set to achieve its oscillation motion.

2 Simulation model

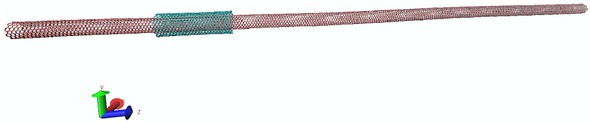

In our simulations, the thermal actuator system consists of a (9, 9) inner nanotube with length of 60 nm and a (14, 14) outer nanotube with length of 6 nm. The initial center of mass position of the outer tube is 13nm from theleft boundary of the inner tube, as shown in Figure 1. The two ends of the inner tube are fixed. The regions adjacent to the fixed ends are attached to Nose–Hoover thermostats to be maintained at different temperatures respectively. Actuated by this temperature difference, the outer tube moves along and/or around the inner tube. This system, which causes the outer tube to move due to the temperature gradient of the inner tube, is called a thermal actuator. The Verlet leap frog scheme is applied to integrate the motion equations with a time step of 2 fs. The algorithm for minimizing is conjugate gradient(cg). The C–C bond interaction of the CNT is described by the adaptive intermolecular reactive empirical bond order AIREBO potential [26], The van der Waals interaction between the carbon atoms are via the Lennard-Jones potential in the form of

Schematic of the simulated system constructed by a DWNT

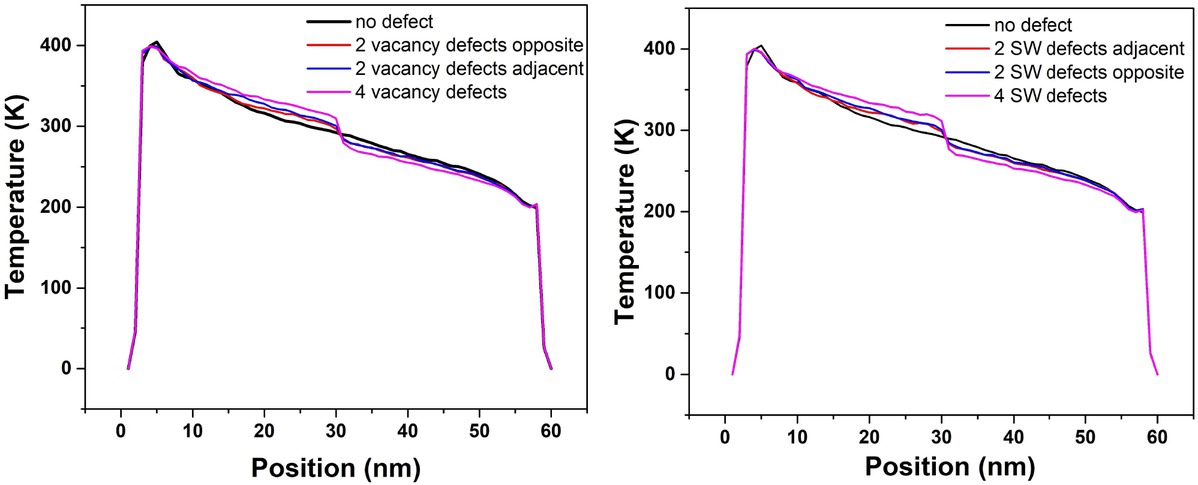

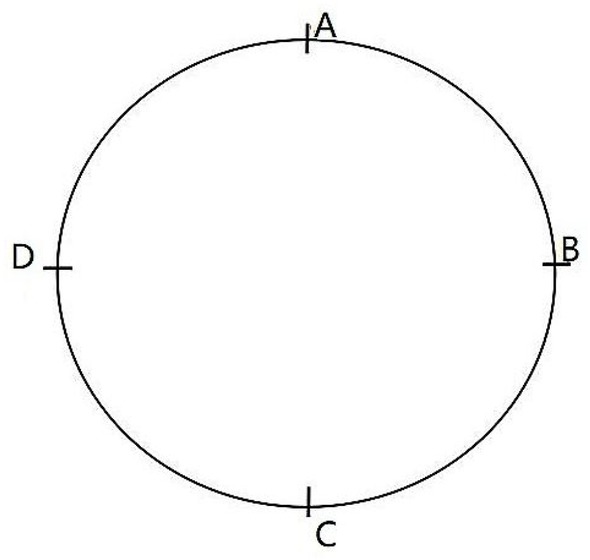

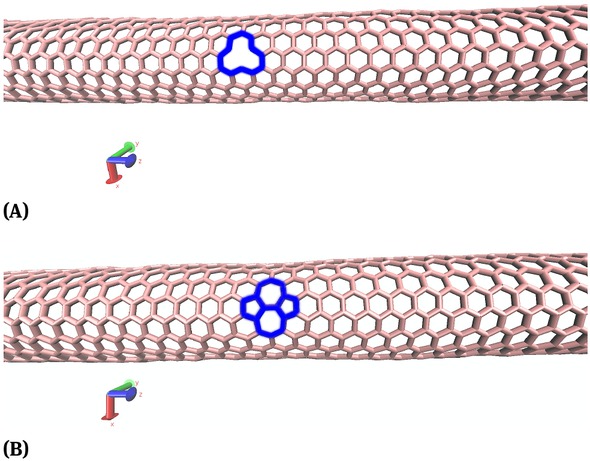

in which ∈ = 2.968 meV, σ = 0.3407 nm [27]. After the initial configuration energy minimization, the system is relaxed at 300 K under canonical (NVT) ensemble. And then, the heat flux is imposed across the inner tube and the system is switched to the micro-canonical (NVE) ensemble. Then the thermal transport in the simulation system is established during a run of 200 ps while the outer tube is restricted from moving rotationally and translationally by rescaling the velocities of its atoms. The temperature gradient is 3.3K/nm. After the restriction is removed, the outer tube moves under the actuation of the inner tube. The average temperature of the inner tube varying with the position of the mass center is shown in Figure 2. Then defects are applied on the center section of the inner tube. The four different distributions of defects are shown in Figure 3, 1 defect is applied on position A, 2 defects adjacent are applied on position AB, 2 defects opposite are applied at position AC, 3 defects are applied at position ABC, and 4 defects are applied at position ABCD. Figure 4 shows a vacancy and a SW defect, respectively.

The average temperature of the inner tube varying with the position of the mass center

Schematic diagram of the defect position of the inner tube center section

Types of single defect in nanotubes. (A) a single atom vacancy in nanotube, (B) a SW defect in nanotube

3 Results and discussion

Molecular dynamics simulations are performed, considering variations in the distribution and number of defects on the inner nanotube of the system.

3.1 Single atom vacancy defect

In order to investigate the effect of single atom vacancy defect on the movement behavior of nanotube, the following

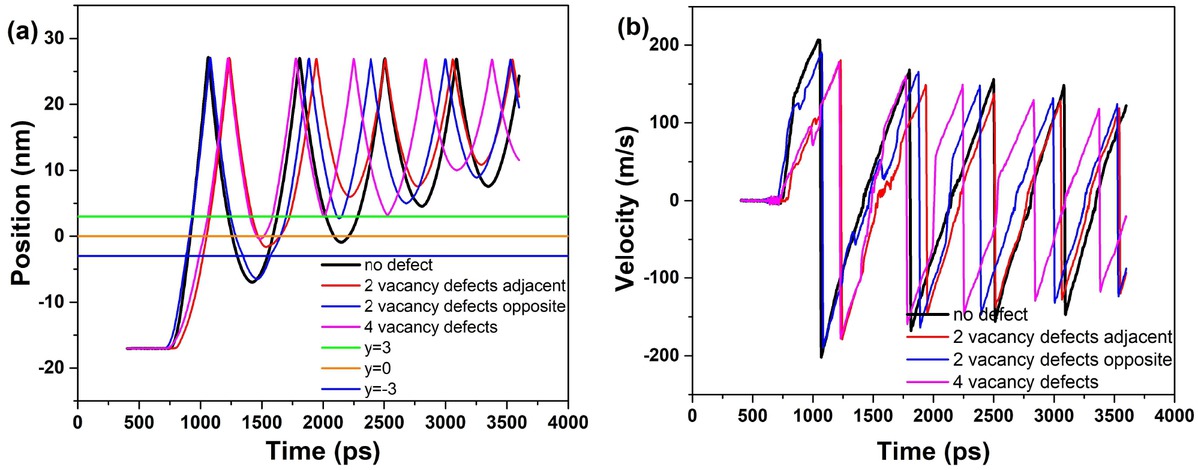

three defect types are used, 2 vacancy defects adjacent, 2 vacancy defects opposite, 4 vacancy defects. The variation of position, velocity of the outer nanotube versus time during the process are shown in Figures 5(a) and (b) respectively. It can be seen from Figure 5(a) and (b) that the presence of single atom vacancy defects reduces the movement magnitude and increases the cycle time, which indicates that energy dissipation and damping effect are introduced to the system by the single atom vacancy defects. It shows that the extent of damping is different for different situations. The system with 4 defects undergoes the largest reduction in magnitude and also the largest increase in cycle time, while less damping effects are observed in the systems with 2 defects opposite and 2 defects adjacent. The degree of the resistance is largely dependent on the number and distribution of the defects.

Variation of the movement behaviors with time for the system containing no defect, 2 vacancy defects adjacent, 2 vacancy defects opposite,4 vacancy defects in the inner nanotube: (a) The position with time. (b) The velocity with time

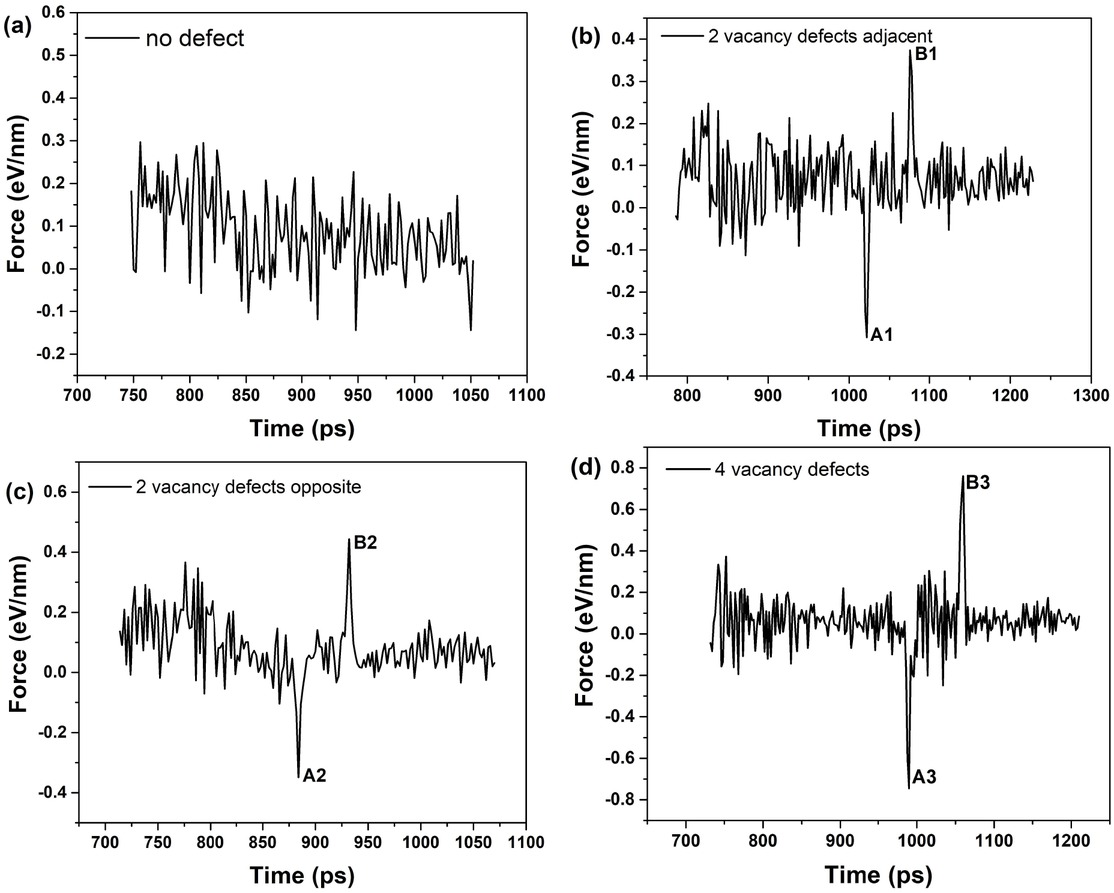

The external force in the direction of movement of the outer tube fluctuations during the first move period are shown in Figure 6(a)-(d), It is seen clearly that, in the case of no defect, the external force fluctuation range is small, leading to small energy dissipation.However, the presence of single atom vacancy defect causes a large fluctuation of the external force, which causes larger energy dissipation. From Figure 6(b)-(d), it can be seen that due to the region of defects is localized at the center of the inner nanotube, the most significant energy loss occurs only when the outer nanotube passes through that region, which can be seen from the two points A and B in the figure. During the first move period, there are three forces in the system. FT is the driving force induced by the thermal gradient, f is the friction and fd is the friction caused by the defects. To study the effect of the defects on the motion of the outer tube, we ignore the friction f here. The driving force has been demonstrated to be proportional to the system temperature [19], and it is a constant because of the stable temperature. So the fluctuation of force in point A and B are caused by the defects.At point A, the outer tube overcomes the energy barrier generated by the defect, and the defect performs negative work on the outer tube, which acts as resistance. And at point B, the outer tube is about to leave the defect, the defect performs positive work on the outer tube, and the external force is expressed as thrust. From Figure 6(a)-(d), we can roughly calculate the amount of resistance caused by defects in various situations. The average value of external force in the absence of defects is 0.08630 eV/nm. While in other cases, when the outer tube is far from the defect, the average value of the external force is equal to the average value of the external force in system without the defect approximately. The magnitude of the resistance calculated from the external force diagrams is as follow, The damping in the system with 2 vacancy defects adjacent, 2 vacancy defects opposite and 4 vacancy defects is 0.4482eV/nm, 0.4068 eV/nm and 0.8449 eV/nm respectively. This calculation result is consistent with the result obtained from the position and velocity diagrams. It can therefore be concluded that the damping force follows the order of f4 vacancy defects > f2 vacancy defects adjacent > f2 vacancy defects opposite > fno defect.

Comparison of the external force acting on the outer tube during the first period of movement for the double-walled system containing no defect, 2 vacancy defects adjacent, 2 vacancy defects opposite,4 vacancy defects in the inner nanotube. The direction of the external force points to the positive direction of the coordinate

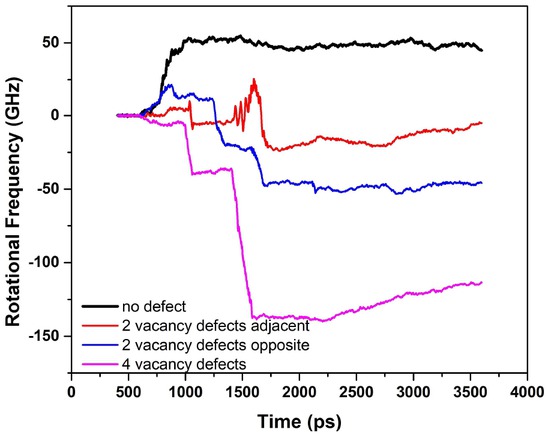

To understand the discrepancies in energy dissipation of the different cases, the rotational speed with respect to time of the outer nanotube is calculated. From Figure 7, we can see that the defect-free system achieves a stable rotational speed in the short start of the movement. While in the system containing defect, we can see that the introduction of defects changes the direction of the rotational speed, and the rotational speed of the outer tube increases each time the defect passes. We can find that the trajectory of the outer tube is not just a straight line along the central axis of nanotube, but also undergoes the self-rotation motion. The introduction of vacancy defect damages circular symmetry of the inner tube. The potential energy barriers originate in the asymmetry configuration. The first principles calculations [28] showed that the formation energy of a single atom vacancy defect is 7.6 eV. The presence of persistent rotation motion leads to persistent energy dissipation, eventually the outer nanotube is unable to pass through the energy barrier.

Rotational frequencies of outer tube for the double-walled system containing no defect, 2 vacancy defects adjacent, 2 vacancy defects opposite, 4 vacancy defects in the inner nanotube

3.2 Stone–Wales defect

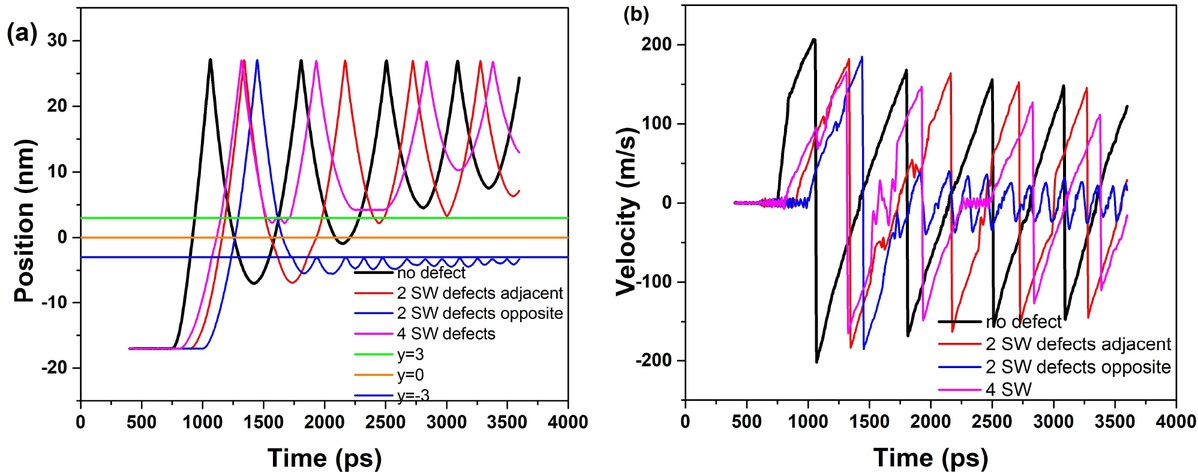

Next, we study the cases where the different number of Stone–Wales defects are distributed around the inner nanotube. Unlike the single atom vacancy defect, in the situation of system with Stone–Wales defect, the centroid circumference of inner nanotube is deformed and the deformations can be observed obviously. The following three defect types are used, 2 SW defects adjacent, 2 SW defects opposite, 4 SW defects. The graphs of position, velocity of the outer nanotube versus time during the process are shown in Figures 8(a) and (b), respectively. It can be seen from Figure 8(a) and (b) that the presence of SW defects reduces the movement magnitude and increases the cycle time, which indicates that energy dissipation and damping effect are introduced to the system by the SW defects. It shows that the extent of damping is different for different situations. The system with 4 defects undergoes the largest reduction in magnitude and also the largest increase in cycle time, while less damping effects are observed for the systems with 2 defects opposite and 2 defects adjacent. The degree of the resistance is largely dependent on the number and distribution of the defects.

Variation of the movement behaviors with time for the system containing no defect, 2 SW defects adjacent, 2 SW defects opposite, 4 SW defects in the inner nanotube: (a) The position with time. (b) The velocity with time

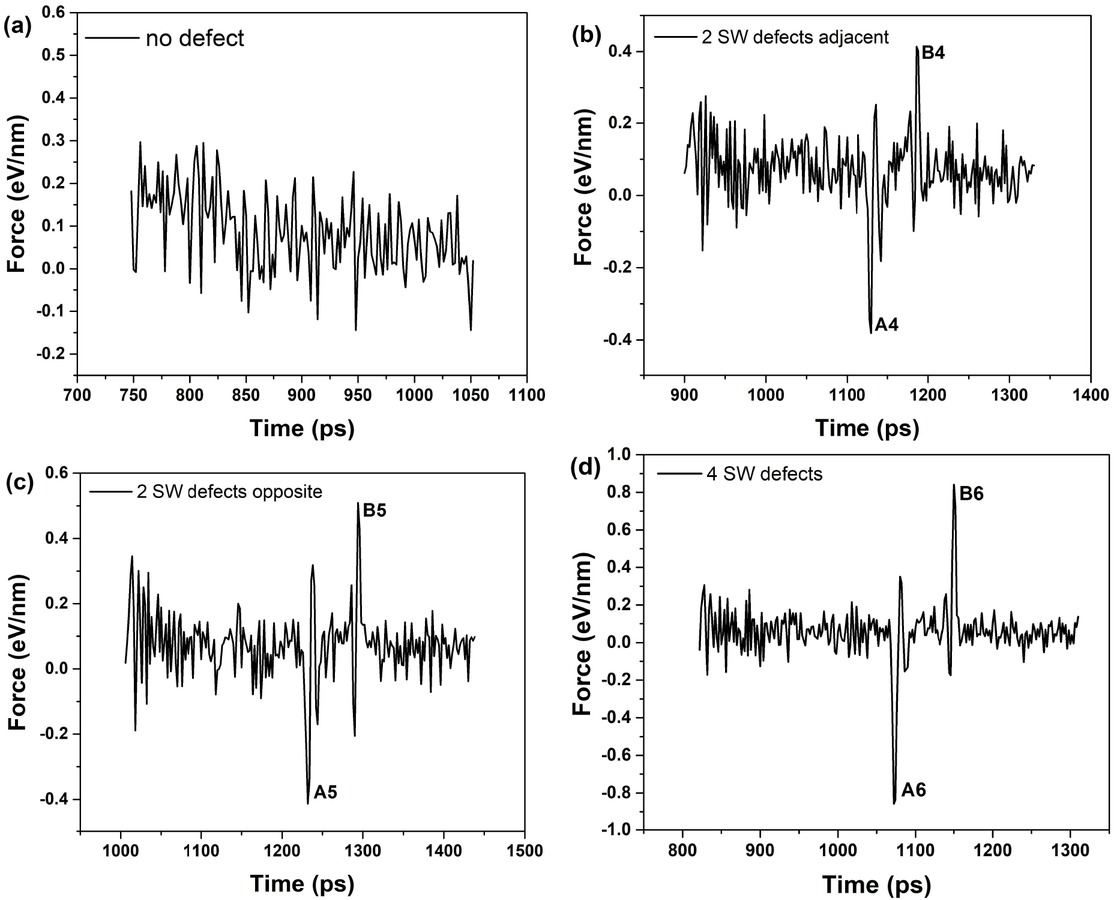

The external force in the direction of movement of the outer tube fluctuations during the first move period are shown in Figure 9(a)-(d), It is seen clearly that, in the case of no defect, the external force fluctuation range is small, leading to small energy dissipation. However, the presence of SW defect causes a large fluctuation of the external force, which causes larger energy dissipation. From Figure 9(b)-(d), it can be seen that due to the region of defects is localized at the center of the inner nanotube, the most significant energy loss occurs only when the outer nanotube passes through that region, which can be seen from the two points A and B in the figure. As described earlier, during the first move period, there are three forces in the system, and the fluctuation of force at point A and B are caused by the defects. From Figure 9(a)-(d),we can roughly calculate the amount of resistance caused by defects in various situations. The average value of external force in the absence of defects is 0.08630 eV/nm. While in other cases, when the outer tube is far from the defect, the average value of the external force is approximately equal to the average value of the external force without the defect. The magnitude of the resistance calculated from the external force diagrams is as follow: The damping in the system with 2 SW defects adjacent, 2 SW defects opposite and 4 SW defects is 0.4812 eV/nm, 0.5132 eV/nm and 0.9567 eV/nm respectively. This calculation result is consistent with the result obtained from the position and velocity diagrams. It can therefore be concluded that the damping force follows the order of f4 SW defects > f2 SW defects opposite > f2 SW defects adjacent > fno defect.

Comparison of the external force acting on the outer tube during the first period of movement for the double-walled system containing no defect, 2 SW defects adjacent, 2 SW defects opposite,4 SW defects in the inner nanotube. The direction of the external force points to the positive direction of the coordinate

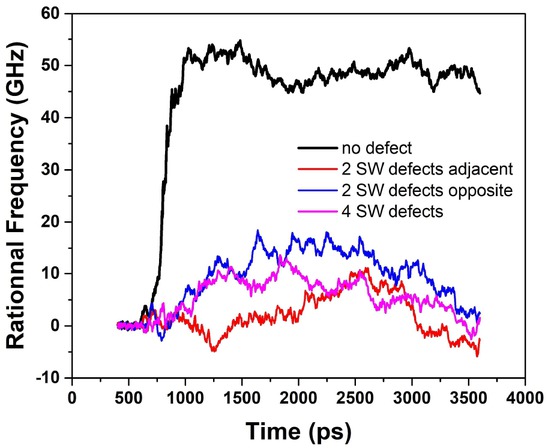

To understand the discrepancies in energy dissipation of the different cases, we also calculate the rotational speed with respect to time of the outer nanotube. From Figure 10. However, we found that the effect of SW defects on the speed of rotation is not obvious, the SW defects do not change the direction of the rotation speed, and the influence on the magnitude of the amplitude is not obvious. The effect of the SW defect on the system stems from its high energy barrier. The presence of the circumference-distributed SW defects gives rise to a potential barrier when the outer nanotube telescopes through the inner nanotube. Depending on the number of SW defects distributed along the nanotube circumference, the energy barrier profile and magnitude of the defect cluster will be different. The formation of an SW defect involves the rotation of a pair of carbon atoms from the circumferential direction to the axial direction. As a result, the number of carbon atoms in the circumferential direction is reduced, and the nanotube contracts radially at the defected region. This deformation also affects the inner nanotube motion behavior in two ways. On one hand, the first principles calculations [28] showed that the formation energy of an SW defect is 9.2 eV. It exerts an energy barrier at the defect location that the inner nanotube must overcome in order to pass through. On the other hand, the self-rotation motion caused by deformation also leads to energy dissipation as the inner nanotube passes through the site of SW defect, eventually the outer nanotube is unable to pass through the energy barrier.

(a) Rotational frequencies of outer tube for the double-walled system containing no defect, 2 SW defects adjacent, 2 SW defects opposite, 4 SW defects in the inner nanotube

3.3 The effect of temperature and chirality

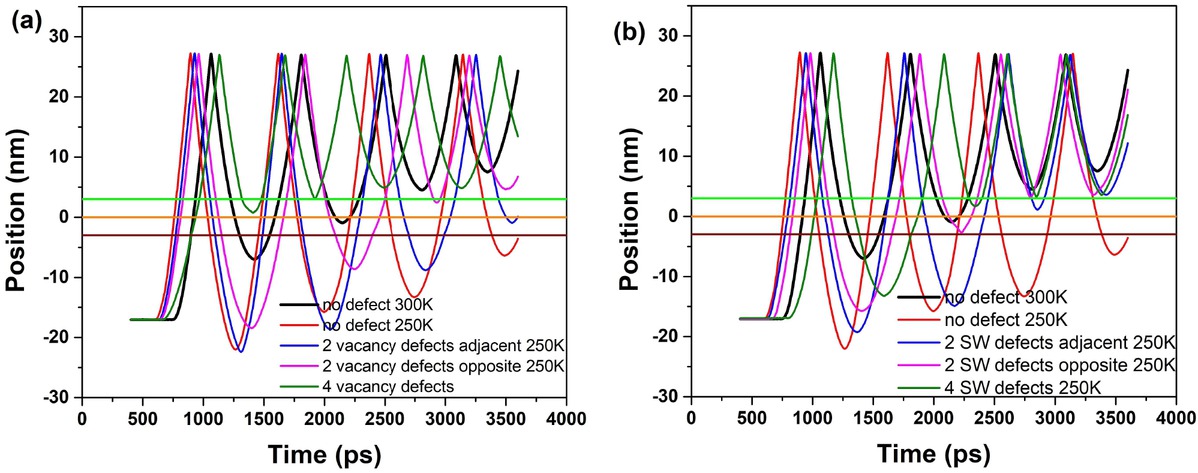

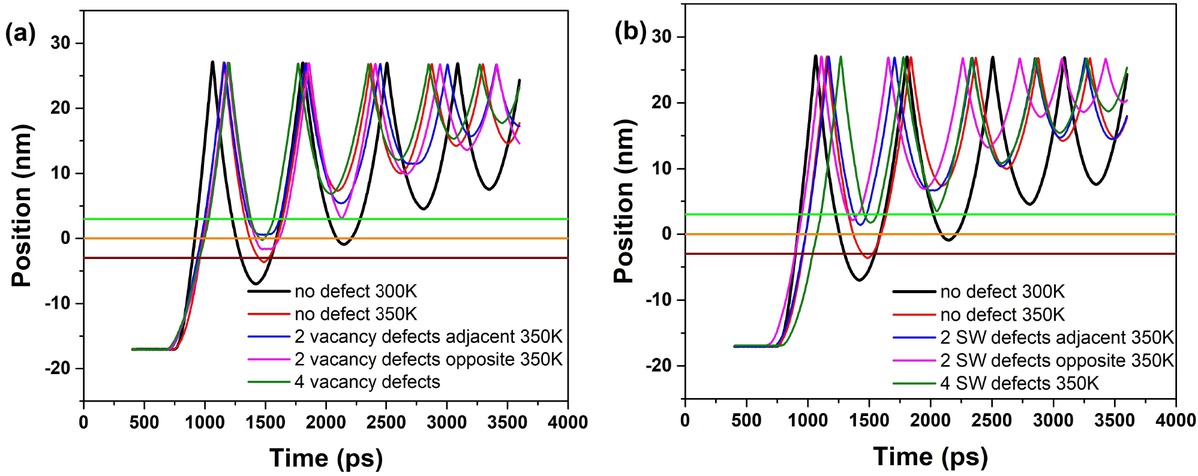

In the discussion above, we only considered the case where the average system temperature is 300K, but did not consider the situation at other average temperatures. But system average temperature is very important to this thermal actuator. So we also consider the case where the system temperature is 250K and 350K and molecular dynamics were used to simulate the motion of the systems with no defect and the systems with different kind of defects. The variation of position of the outer nanotube versus time during the process in the system temperature of 250K are shown in Figures 11(a) and (b) respectively. And The variation of position of the outer nanotube versus time during the process in the system temperature of 350K are shown in Figures 12(a) and (b) respectively. Comparing Figure 11 and 12 with Figure 5 and 8, it can be found that when the system temperature increases from 250K to 350K, the energy loss of the system increases. Further, the reason for

Variation of the movement behaviors with time for the system in 250K and 300K: (a) The system containing no defect, 2 vacancy defects adjacent, 2 vacancy defects opposite, 4 SW defects in the inner nanotube, (b) The system containing no defect, 2 SW defects adjacent, 2 SW defects opposite, 4 SW defects in the inner nanotube

Variation of the movement behaviors with time for the system in 350K and 300K: (a) The system containing no defect, 2 vacancy defects adjacent, 2 vacancy defects opposite, 4 SW defects in the inner nanotube, (b) The system containing no defect, 2 SW defects adjacent, 2 SW defects opposite, 4 SW defects in the inner nanotube

this phenomenon is that the higher the temperature, the greater the interlayer friction between the inner CNT and the outer CNT, so the energy loss is larger.

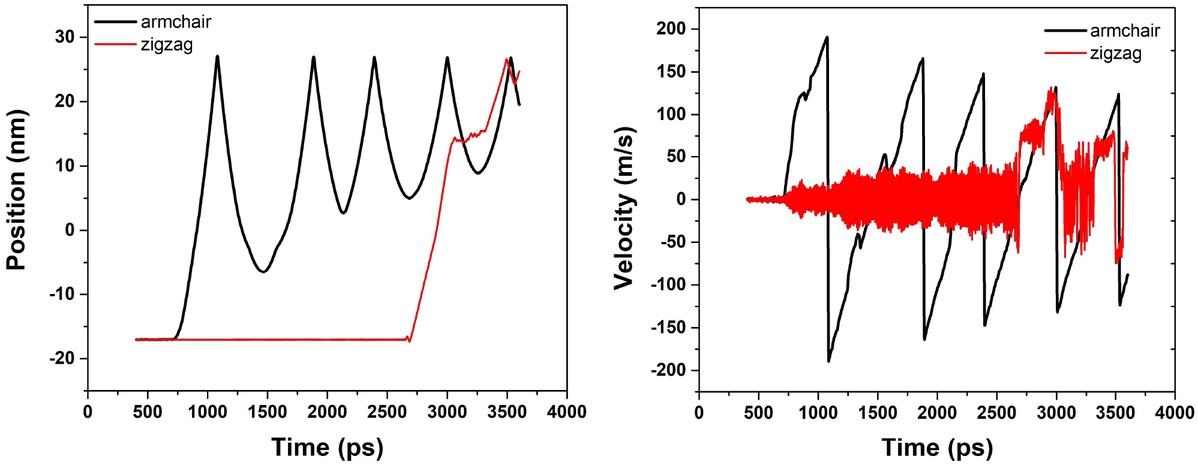

It is well known that chirality has a great influence on the properties of carbon nanotubes, so we have further considered zigzag chirality and perform molecular dynamics simulation. The added model is that the thermal actuator system consisting of a (9, 0) inner nanotube with length of 60 nm and a (18, 0) outer nanotube with length of 6 nm. The results are very surprising. Under the seven conditions we simulated: no defect, 2 vacancy defects adjacent, 2 vacancy defects opposite, 4 vacancy defects, 2 SW defects adjacent, 2 SW defects opposite and 4 SW defects, there was only one case (2 vacancy defects opposite) where the outer tube could move in translation, while in other cases, the outer tube could not move. And The variation of position and the velocity of the outer nanotube versus time during the process in the case of 2 vacancy defects opposite of two kinds chirality are shown in Figures 13(a) and (b) respectively. From the figure we can see that although the outer tube of the zigzag chirality carbon nanotube with 2 vacancy defects can move in translation, the time to start moving is much longer than the system of armchair chirality, and the speed of movement is much slower. The reason for this phenomenon is that in armchair–armchair DWNTs, the nanotube axis direction is

Variation of the movement behaviors with time for the system of armchair chirality and zigzag chirality containing 2 vacancy defects: (a) The position with time. (b) The velocity with time

an easy direction of movement, while for zigzag–armchair or zigzag–zigzag DWNTs, the circumferential direction is an easy direction [27]. Therefore, in the thermal actuator system, the occurrence of the translational movement of the outer tube is related to the chirality of the inner and outer tubes.

3.4 Oscillation

In the process of studying various cases of the SW defect, we found an interesting phenomenon. In the system with 2 SW defects opposite, the outer tube can oscillate in the vicinity of the defect. Finally, we turn our attention to the oscillation in the system containing the 2 SW defects opposite. The factors that caused the oscillation phenomenon are studied. From the above simulation results, when the conditions other than the defect type are the same, only the system with the 2 SW defects opposite is oscillated, so we can see that the occurrence of the oscillation phenomenon is related to the type of the defect.

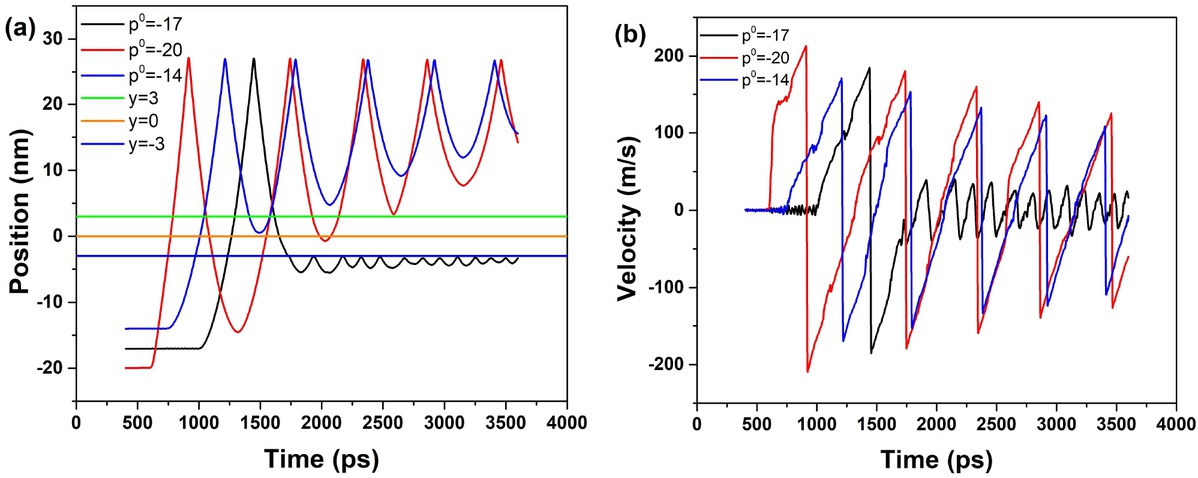

Then we change the initial position of the outer tube and placed the center of mass of the outer tube at 10 nm and 16 nm from the left boundary of the inner tube for molecular dynamics simulation. The results obtained are shown in Figure 14. It can be seen from the position diagram that when the initial position of the outer tube is p0 = −20nm, the outer tube is accelerated by the temperature gradient force for a longer distance, the kinetic energy of the system is higher, and the outer tube can pass

Variation of the movement behaviors with time for the initial position of the outer tube in system is p0 = −20nm, p0 = −14nm and p0 = −17nm respectively: (a) The position with time. (b) The velocity with time

the defect to the front of the defect three times, but cannot cross the energy barrier the fourth time, so the oscillation phenomenon cannot be generated, and when the initial position of the outer tube is p0 = −14nm, the outer tube is accelerated by the temperature gradient force for a shorter distance, and the kinetic energy of the system is lower, so that the outer tube can only cross the defect to the front of the defect once, when the second time the outer tube passes through the defect, it cannot cross the energy barrier and therefore cannot produce oscillation phenomenon. While when the initial position of the outer tube is p0 = −17nm, the outer tube crosses the defect to the back of the defect twice. When the third time the outer tube passes through the defect, it cannot cross the energy barrier, and the temperature gradient force acts to form an oscillation phenomenon. The above results indicate that the generation of the oscillation phenomenon is related to the initial position of the outer tube.

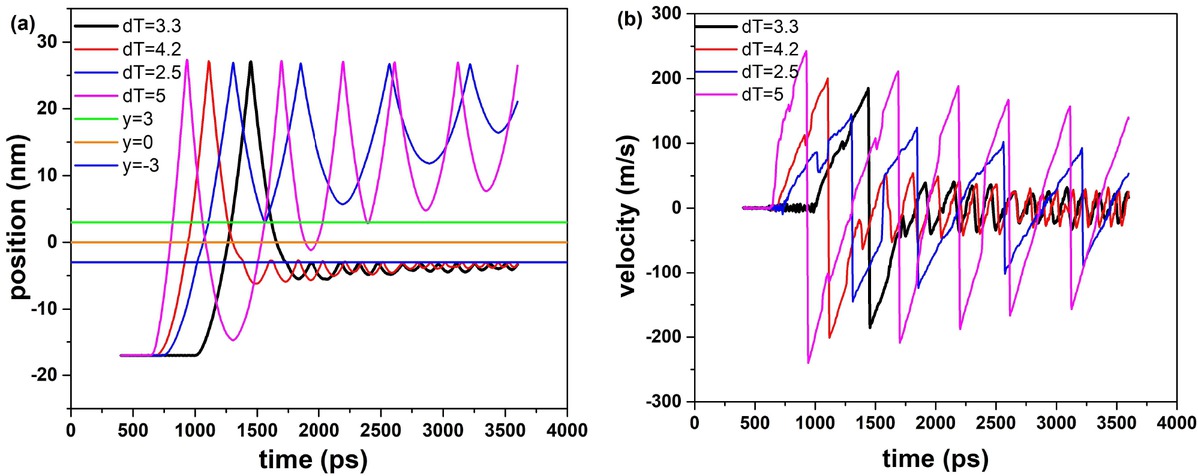

We also change the temperature gradient of the system and set the temperature gradient to 4.2 K/nm, 2.5 K/nm, 5 K/nm. The simulation results are shown in Figure 15. It can be seen from the figure that when the temperature gradient is 5K/nm, the temperature gradient driving force is larger, so the work is more in the same distance, and the kinetic energy of the system is higher, and the outer tube can pass the defect to the front of the defect three times, but cannot cross the energy barrier the fourth time, so the oscillation phenomenon cannot be generated; And the temperature gradient is 2.5K/nm, the temperature gradient driving force is smaller, so the work is less in the same distance, and the kinetic energy of the system is lower, so that the outer tube can only cross the defect to the front of the defect once, when the second time the outer tube passes through the defect, it cannot cross the energy barrier and therefore cannot produce oscillation phenomenon, while when the temperature gradient is 3.4K/nm and 4.2K/nm, the outer tube crosses the defect to the back of the defect twice. When the third time the outer tube passes through the defect, it cannot cross the energy barrier, and the temperature gradient force acts to form an oscillation phenomenon. The above analysis shows that the generation of oscillations is also related to the system temperature gradient.

Variation of the movement behaviors with time for the temperature gradient of the system is 3.3K/nm, 4.3K/nm,5K/nm and 2.5K/nm respectively: (a) The position with time. (b) The velocity with time

In summary, the occurrence of the oscillation phenomenon is related to the initial position of the outer tube, the type of the defect, and the magnitude of the temperature gradient.

4 Conclusions

We have performed systematic molecular dynamics simulations to study the movement behavior of CNT containing single atom vacancy defect and SW defect. It is found that the presence of these defects introduces resistance of the nanotube systems, which affects the move amplitude and speed of the outer tube. The mechanism of the energy dissipation is the introduction of defect damages circular symmetry of the inner tube. Therefore the axial rotation speed of outer tube is greater, then generate greater translational energy dissipation. The results also show that the degree of influence can be adjusted by the number distribution of the defects and average temperature. Moreover, the chirality of the inner and outer tubes plays a vital role in the movement of the thermal actuator system. We have also found that it is possible to produce oscillation motion of the outer nanotube by designing proper initial position of the outer tube, the defect type and the temperature gradient. Our results show that it is possible to control and tune the movement behavior of CNT by introducing different defects into the system.

Acknowledgement

The authors wish to acknowledge the support from the Natural Science Foundation of China (11472108 and 11772130).

Conflict of interest

Declaration of interest: The authors declare that they have no conflict of interest.

References

[1] Cavalcanti A, Shirinzadeh B, Freitas Jr R A and Hogg T Nanorobot architecture for medical target identification Nanotechnology 2008 19 01510310.1088/0957-4484/19/01/015103Search in Google Scholar

[2] Barreiro A, Rurali R, Hernandez E R, Moser J, Pichler T, Forro L and Bachtold A Subnanometer Motion of Cargoes Driven by Thermal Gradients Along Carbon Nanotubes Science 2008 320 775–810.1126/science.1155559Search in Google Scholar PubMed

[3] Yang J, Jia XL and Kitipornchai S Pull-in instability of nano-switches using nonlocal elasticity theory Journal of Physics D: Applied Physics 2008 41 03510310.1088/0022-3727/41/3/035103Search in Google Scholar

[4] Valle MD, Guitierrez R, Tejedor C and Cuniberti G Tuning the conductance of a molecular switch Nature Nanotechnol. 2007 2 17610.1038/nnano.2007.38Search in Google Scholar PubMed

[5] Ke C and Espinosa H D Feedback controlled nanocantilever device Applied Physics Letters 2004 85 681-310.1063/1.1767606Search in Google Scholar

[6] Kinaret J M, Nord T and Viefers S A carbon-nanotube-based nanorelay Applied Physics Letters 2003 82 1287-910.1063/1.1557324Search in Google Scholar

[7] Kaul A B, Wong EW, Epp L and Hunt B D Electromechanical Carbon Nanotube Switches for High-Frequency Applications Nano Lett 2006 6 94210.1021/nl052552rSearch in Google Scholar PubMed

[8] Zheng Q and Jiang Q Multiwalled carbon nanotubes as gigahertz oscillators Physical review letters 2002 88 04550310.1103/PhysRevLett.88.045503Search in Google Scholar PubMed

[9] Guo W, Guo Y, Gao H, Zheng Q and Zhong W Energy dissipation in gigahertz oscillators from multiwalled carbon nanotubes Physical review letters 2003 91 1255010.1103/PhysRevLett.91.125501Search in Google Scholar PubMed

[10] Liu P, Zhang Y W and Lu C Analysis of the oscillatory behavior of double-walled carbon nanotube-based oscillators Carbon 2006 44 27-3610.1016/j.carbon.2005.07.022Search in Google Scholar

[11] Liu P, Gao H J and Zhang Y W Effect of defects on oscillation characteristics and instability of carbon nanotube-based oscillators Applied Physics Letters 2008 93 08310710.1063/1.2976127Search in Google Scholar

[12] Iijima S Helical microtubules of graphitic carbon Nature 1991 354(6348): 56-58.10.1038/354056a0Search in Google Scholar

[13] Bethune D.S., Kiang C.H., De Vries M.S., et al. Cobalt-catalysed growth of carbon nanotubes with single-atomic-layer walls Nature 1993 363(6430): 605-607.10.1038/363605a0Search in Google Scholar

[14] Iijima S., Ichihashi T. Single-shell carbon nanotubes of 1-nm diameter Nature 1993 363(6430): 603-605.10.1038/363603a0Search in Google Scholar

[15] Huang J and Han Q Controllable nanoscale rotating actuator system based on carbon nanotube and graphene Nanotechnology 2016 27 15550110.1088/0957-4484/27/15/155501Search in Google Scholar PubMed

[16] Dresselhaus M.S., Dresselhaus G., Saito R. Physics of carbon nanotubes Carbon 1995 33(7): 883-89110.1016/B978-0-08-042682-2.50009-6Search in Google Scholar

[17] Kamal S, Kuldeep KS and Mukul S Effect of Multiple Stone-Wales and Vacancy Defects on the Mechanical Behavior of Carbon Nanotubes Using Molecular Dynamics Procedia Engineering 2012 38 3373-8010.1016/j.proeng.2012.06.390Search in Google Scholar

[18] Liu P and Zhang Y-W Motion control in double-walled carbon nanotube systems using a Stone–Thrower–Wales defect cluster Journal of Physics D: Applied Physics 2010 43 44540410.1088/0022-3727/43/44/445404Search in Google Scholar

[19] Guo T, Ding T W, Pei Q-X and Zhang Y-W Effect of sp3-hybridized defects on the oscillatory behavior of carbon nanotube oscillators Physics Letters A 2011 375 2400-410.1016/j.physleta.2011.05.003Search in Google Scholar

[20] Rafiee R and Mahdavi M Molecular dynamics simulation of defected carbon nanotubes Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications 2015 230 654-6210.1177/1464420715584809Search in Google Scholar

[21] Rafiee R and Eskandariyun A Comparative study on predicting Young’s modulus of graphene sheets using nano-scale continuum mechanics approach Physica E: Low-dimensional Systems and Nanostructures 2017 90 42-810.1016/j.physe.2017.03.006Search in Google Scholar

[22] Rafee R, Reza Pourazizi Evaluating the influence of defects on the Young’s modulus of carbon nanotubes using stochastic modeling, Journal of Materials Research 2014 17(3):758-76610.1590/S1516-14392014005000071Search in Google Scholar

[23] Guo W L, Zhong W Y, Dai YT, and Li SN Coupled defect-size effects on interlayer friction in multiwalled carbon nanotubes, Phys. Rev. B 2005 72, 07540910.1103/PhysRevB.72.075409Search in Google Scholar

[24] Luo Q H, Jiang W G and Qin Q H Possibility of Improving Oscillation Performance of Double-Walled Nanotube Oscillators via Tuning Vacancy Defects Journal of Nano Research 2017 48: 148-15510.4028/www.scientific.net/JNanoR.48.148Search in Google Scholar

[25] Hou QW, Cao BY and Guo Z Y Thermal gradient induced actuation in double-walled carbon nanotubes Nanotechnology 2009 20 49550310.1088/0957-4484/20/49/495503Search in Google Scholar PubMed

[26] Stuart SJ, Tutein A B and Harrison J A A reactive potential for hydrocarbons with intermolecular interactions The Journal of Chemical Physics 2000 112 6472-8610.1063/1.481208Search in Google Scholar

[27] Saito R, Matsuo R, Kimura T, Dresselhaus G and Dresselhaus M S Anomalous potential barrier of double-wall carbon nanotube Chem. Phys. Lett. 2001 348 187–9310.1016/S0009-2614(01)01127-7Search in Google Scholar

[28] Li L, Reich S and Robertson J Defect energies of graphite: Density-functional calculations Phys. Rev. B 2005 72 18410910.1103/PhysRevB.72.184109Search in Google Scholar

© 2019 X. Lin et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 Public License.

Articles in the same Issue

- Research Articles

- Investigation of rare earth upconversion fluorescent nanoparticles in biomedical field

- Carbon Nanotubes Coated Paper as Current Collectors for Secondary Li-ion Batteries

- Insight into the working wavelength of hotspot effects generated by popular nanostructures

- Novel Lead-free biocompatible piezoelectric Hydroxyapatite (HA) – BCZT (Ba0.85Ca0.15Zr0.1Ti0.9O3) nanocrystal composites for bone regeneration

- Effect of defects on the motion of carbon nanotube thermal actuator

- Dynamic mechanical behavior of nano-ZnO reinforced dental composite

- Fabrication of Ag Np-coated wetlace nonwoven fabric based on amino-terminated hyperbranched polymer

- Fractal analysis of pore structures in graphene oxide-carbon nanotube based cementitious pastes under different ultrasonication

- Effect of PVA fiber on durability of cementitious composite containing nano-SiO2

- Cr effects on the electrical contact properties of the Al2O3-Cu/15W composites

- Experimental evaluation of self-expandable metallic tracheobronchial stents

- Experimental study on the existence of nano-scale pores and the evolution of organic matter in organic-rich shale

- Mechanical characterizations of braided composite stents made of helical polyethylene terephthalate strips and NiTi wires

- Mechanical properties of boron nitride sheet with randomly distributed vacancy defects

- Fabrication, mechanical properties and failure mechanism of random and aligned nanofiber membrane with different parameters

- Micro- structure and rheological properties of graphene oxide rubber asphalt

- First-principles calculations of mechanical and thermodynamic properties of tungsten-based alloy

- Adsorption performance of hydrophobic/hydrophilic silica aerogel for low concentration organic pollutant in aqueous solution

- Preparation of spherical aminopropyl-functionalized MCM-41 and its application in removal of Pb(II) ion from aqueous solution

- Electrical conductivity anisotropy of copper matrix composites reinforced with SiC whiskers

- Miniature on-fiber extrinsic Fabry-Perot interferometric vibration sensors based on micro-cantilever beam

- Electric-field assisted growth and mechanical bactericidal performance of ZnO nanoarrays with gradient morphologies

- Flexural behavior and mechanical model of aluminum alloy mortise-and-tenon T-joints for electric vehicle

- Synthesis of nano zirconium oxide and its application in dentistry

- Surface modification of nano-sized carbon black for reinforcement of rubber

- Temperature-dependent negative Poisson’s ratio of monolayer graphene: Prediction from molecular dynamics simulations

- Finite element nonlinear transient modelling of carbon nanotubes reinforced fiber/polymer composite spherical shells with a cutout

- Preparation of low-permittivity K2O–B2O3–SiO2–Al2O3 composites without the addition of glass

- Large amplitude vibration of doubly curved FG-GRC laminated panels in thermal environments

- Enhanced flexural properties of aramid fiber/epoxy composites by graphene oxide

- Correlation between electrochemical performance degradation and catalyst structural parameters on polymer electrolyte membrane fuel cell

- Materials characterization of advanced fillers for composites engineering applications

- Humic acid assisted stabilization of dispersed single-walled carbon nanotubes in cementitious composites

- Test on axial compression performance of nano-silica concrete-filled angle steel reinforced GFRP tubular column

- Multi-scale modeling of the lamellar unit of arterial media

- The multiscale enhancement of mechanical properties of 3D MWK composites via poly(oxypropylene) diamines and GO nanoparticles

- Mechanical properties of circular nano-silica concrete filled stainless steel tube stub columns after being exposed to freezing and thawing

- Arc erosion behavior of TiB2/Cu composites with single-scale and dual-scale TiB2 particles

- Yb3+-containing chitosan hydrogels induce B-16 melanoma cell anoikis via a Fak-dependent pathway

- Template-free synthesis of Se-nanorods-rGO nanocomposite for application in supercapacitors

- Effect of graphene oxide on chloride penetration resistance of recycled concrete

- Bending resistance of PVA fiber reinforced cementitious composites containing nano-SiO2

- Review Articles

- Recent development of Supercapacitor Electrode Based on Carbon Materials

- Mechanical contribution of vascular smooth muscle cells in the tunica media of artery

- Applications of polymer-based nanoparticles in vaccine field

- Toxicity of metallic nanoparticles in the central nervous system

- Parameter control and concentration analysis of graphene colloids prepared by electric spark discharge method

- A critique on multi-jet electrospinning: State of the art and future outlook

- Electrospun cellulose acetate nanofibers and Au@AgNPs for antimicrobial activity - A mini review

- Recent progress in supercapacitors based on the advanced carbon electrodes

- Recent progress in shape memory polymer composites: methods, properties, applications and prospects

- In situ capabilities of Small Angle X-ray Scattering

- Review of nano-phase effects in high strength and conductivity copper alloys

- Progress and challenges in p-type oxide-based thin film transistors

- Advanced materials for flexible solar cell applications

- Phenylboronic acid-decorated polymeric nanomaterials for advanced bio-application

- The effect of nano-SiO2 on concrete properties: a review

- A brief review for fluorinated carbon: synthesis, properties and applications

- A review on the mechanical properties for thin film and block structure characterised by using nanoscratch test

- Cotton fibres functionalized with plasmonic nanoparticles to promote the destruction of harmful molecules: an overview

Articles in the same Issue

- Research Articles

- Investigation of rare earth upconversion fluorescent nanoparticles in biomedical field

- Carbon Nanotubes Coated Paper as Current Collectors for Secondary Li-ion Batteries

- Insight into the working wavelength of hotspot effects generated by popular nanostructures

- Novel Lead-free biocompatible piezoelectric Hydroxyapatite (HA) – BCZT (Ba0.85Ca0.15Zr0.1Ti0.9O3) nanocrystal composites for bone regeneration

- Effect of defects on the motion of carbon nanotube thermal actuator

- Dynamic mechanical behavior of nano-ZnO reinforced dental composite

- Fabrication of Ag Np-coated wetlace nonwoven fabric based on amino-terminated hyperbranched polymer

- Fractal analysis of pore structures in graphene oxide-carbon nanotube based cementitious pastes under different ultrasonication

- Effect of PVA fiber on durability of cementitious composite containing nano-SiO2

- Cr effects on the electrical contact properties of the Al2O3-Cu/15W composites

- Experimental evaluation of self-expandable metallic tracheobronchial stents

- Experimental study on the existence of nano-scale pores and the evolution of organic matter in organic-rich shale

- Mechanical characterizations of braided composite stents made of helical polyethylene terephthalate strips and NiTi wires

- Mechanical properties of boron nitride sheet with randomly distributed vacancy defects

- Fabrication, mechanical properties and failure mechanism of random and aligned nanofiber membrane with different parameters

- Micro- structure and rheological properties of graphene oxide rubber asphalt

- First-principles calculations of mechanical and thermodynamic properties of tungsten-based alloy

- Adsorption performance of hydrophobic/hydrophilic silica aerogel for low concentration organic pollutant in aqueous solution

- Preparation of spherical aminopropyl-functionalized MCM-41 and its application in removal of Pb(II) ion from aqueous solution

- Electrical conductivity anisotropy of copper matrix composites reinforced with SiC whiskers

- Miniature on-fiber extrinsic Fabry-Perot interferometric vibration sensors based on micro-cantilever beam

- Electric-field assisted growth and mechanical bactericidal performance of ZnO nanoarrays with gradient morphologies

- Flexural behavior and mechanical model of aluminum alloy mortise-and-tenon T-joints for electric vehicle

- Synthesis of nano zirconium oxide and its application in dentistry

- Surface modification of nano-sized carbon black for reinforcement of rubber

- Temperature-dependent negative Poisson’s ratio of monolayer graphene: Prediction from molecular dynamics simulations

- Finite element nonlinear transient modelling of carbon nanotubes reinforced fiber/polymer composite spherical shells with a cutout

- Preparation of low-permittivity K2O–B2O3–SiO2–Al2O3 composites without the addition of glass

- Large amplitude vibration of doubly curved FG-GRC laminated panels in thermal environments

- Enhanced flexural properties of aramid fiber/epoxy composites by graphene oxide

- Correlation between electrochemical performance degradation and catalyst structural parameters on polymer electrolyte membrane fuel cell

- Materials characterization of advanced fillers for composites engineering applications

- Humic acid assisted stabilization of dispersed single-walled carbon nanotubes in cementitious composites

- Test on axial compression performance of nano-silica concrete-filled angle steel reinforced GFRP tubular column

- Multi-scale modeling of the lamellar unit of arterial media

- The multiscale enhancement of mechanical properties of 3D MWK composites via poly(oxypropylene) diamines and GO nanoparticles

- Mechanical properties of circular nano-silica concrete filled stainless steel tube stub columns after being exposed to freezing and thawing

- Arc erosion behavior of TiB2/Cu composites with single-scale and dual-scale TiB2 particles

- Yb3+-containing chitosan hydrogels induce B-16 melanoma cell anoikis via a Fak-dependent pathway

- Template-free synthesis of Se-nanorods-rGO nanocomposite for application in supercapacitors

- Effect of graphene oxide on chloride penetration resistance of recycled concrete

- Bending resistance of PVA fiber reinforced cementitious composites containing nano-SiO2

- Review Articles

- Recent development of Supercapacitor Electrode Based on Carbon Materials

- Mechanical contribution of vascular smooth muscle cells in the tunica media of artery

- Applications of polymer-based nanoparticles in vaccine field

- Toxicity of metallic nanoparticles in the central nervous system

- Parameter control and concentration analysis of graphene colloids prepared by electric spark discharge method

- A critique on multi-jet electrospinning: State of the art and future outlook

- Electrospun cellulose acetate nanofibers and Au@AgNPs for antimicrobial activity - A mini review

- Recent progress in supercapacitors based on the advanced carbon electrodes

- Recent progress in shape memory polymer composites: methods, properties, applications and prospects

- In situ capabilities of Small Angle X-ray Scattering

- Review of nano-phase effects in high strength and conductivity copper alloys

- Progress and challenges in p-type oxide-based thin film transistors

- Advanced materials for flexible solar cell applications

- Phenylboronic acid-decorated polymeric nanomaterials for advanced bio-application

- The effect of nano-SiO2 on concrete properties: a review

- A brief review for fluorinated carbon: synthesis, properties and applications

- A review on the mechanical properties for thin film and block structure characterised by using nanoscratch test

- Cotton fibres functionalized with plasmonic nanoparticles to promote the destruction of harmful molecules: an overview