Abstract

Efficiency of the battery pack largely depends on the resistive losses and heat generation between the interconnections of the battery cells. Grouping of battery cells usually is done in different ways in industries. However, losses vary depending on applications or states of electric vehicle (EV). Therefore, it is necessary to determine the efficiency and heat generation in battery cells as well as battery packs. In practical situations, some battery cells are charged rapidly in comparison to other battery cells. On the other hand, when an EV is in running condition some battery cells are discharged rapidly. As a results battery pack cannot provide better efficiency and its life span is reduced. As an alternative option the inter-cell connection of battery package is needed to reconfigure in an optimized way. In this paper firstly, a battery pack with switches is modeled and then efficiency and temperature variation with respect to time are determined. Then, an experimental setup is investigated to measure the efficiency and temperature rise with respect to time. Results, explained in the paper, demonstrate that battery pack with switches increases the efficiency if it is measured after switching (97–98 %), while temperature increases from 25 °C to 50 °C for different C-rates.

Nomenclature

- A

-

surface area [m2]

- C

-

capacitance [F]

- C c

-

the heat capacity of the core [J K−1]

- C p

-

specific heat [J/kg K]

- C s

-

the heat capacity at the surface [J K−1]

- F

-

faraday constant [Coulombs/mole]

- H

-

heat generation [J]

- h

-

heat transfer coefficient [W/m2 K]

- I bat

-

battery current [A]

- I t

-

total current [A]

- m

-

mass of the cell [kg]

- n

-

the number of the transferred electrons in the electrochemical reaction

- P b

-

power of the battery pack [W]

- Q

-

heat generation [W]

- R c

-

heat conduction resistance [Ω]

- R eq

-

equivalent resistance [Ω]

- R i

-

resistance of ith cell [Ω]

- R p

-

resistance of parallel strings [Ω]

- R s

-

series resistance [Ω]

- R se

-

resistance of series strings [Ω]

- R u

-

convection resistance between T s and T f [Ω]

- SoC

-

state of charge [%]

- T

-

temperature [°C or K]

- t

-

time [s]

- T a

-

ambient temperature [°C or K]

- T c

-

temperature at the center of the cell [°C or K]

- T f

-

temperature at coolant convection point [K]

- T s

-

temperature at the surface of the cell [°C or K]

- V bat

-

battery actual voltage [V]

- V oc

-

Open circuit voltage [V]

- V soc

-

battery state of charge voltage [V]

- V t

-

terminal voltage of battery pack [V]

- ΔS

-

change in entropy [J/mol K]

- ε

-

emissivity coefficient

- η

-

efficiency [%]

- σ

-

the Boltzmann constant [J K−1]

- Abbreviation

- AC

-

alternating current

- BMS

-

battery management system

- BTMS

-

battery thermal management system

- C-rate

-

charge/discharge current divided by the rated battery capacity

- DC

-

direct current

- ECM

-

equivalent circuit model

- EV

-

electric vehicle

- GHG

-

green house gas

- HEV

-

hybrid electric vehicle

- Li NMC

-

lithium nickel manganese cobalt oxides

- LiFeYPO4

-

lithium iron phosphate

- Li-Ion

-

lithium ion

- mA

-

mili ampere

- OCV

-

open circuit voltage

- PCM

-

phase change material

- PEV

-

plug in electric vehicle

- SoC

-

state of charge

- TCO

-

total cost of ownership

- TS

-

temperature sensor

1 Introduction

Currently, the world is facing challenges of adverse environmental effects caused by fossil fuel (such as coal, oil, gas etc.) based economy in power system and in transportation sector. The major effects are greenhouse gas (GHG) emission and environmental pollution. In order to minimize greenhouse gas emission, researchers and environmentalists have suggested to shift towards renewable energy based sources (such as solar, wind etc.) in power sector. In transportation, traditional vehicles produce a large amount of GHGs which are harmful for the environment. Moreover, the fuels used in vehicles such as oil and gas are depleting and the cost is rapidly increasing. As an alternative, for a better sustainable environment, fuel economy and energy savings, EVs have obtained increasing attention in recent years. EV, plug in electric vehicles (PEV), hybrid electric vehicles (HEV), fuel cells based vehicles have gained popularity in transportation sector to mitigate the negative impacts of gasoline and diesel oil based engines (Young et al. 2013). Globally electric vehicle market was more than USD 425 billion in 2022, which increased about 50 % compared to the market of 2021 (Alsauskas et al. 2023).

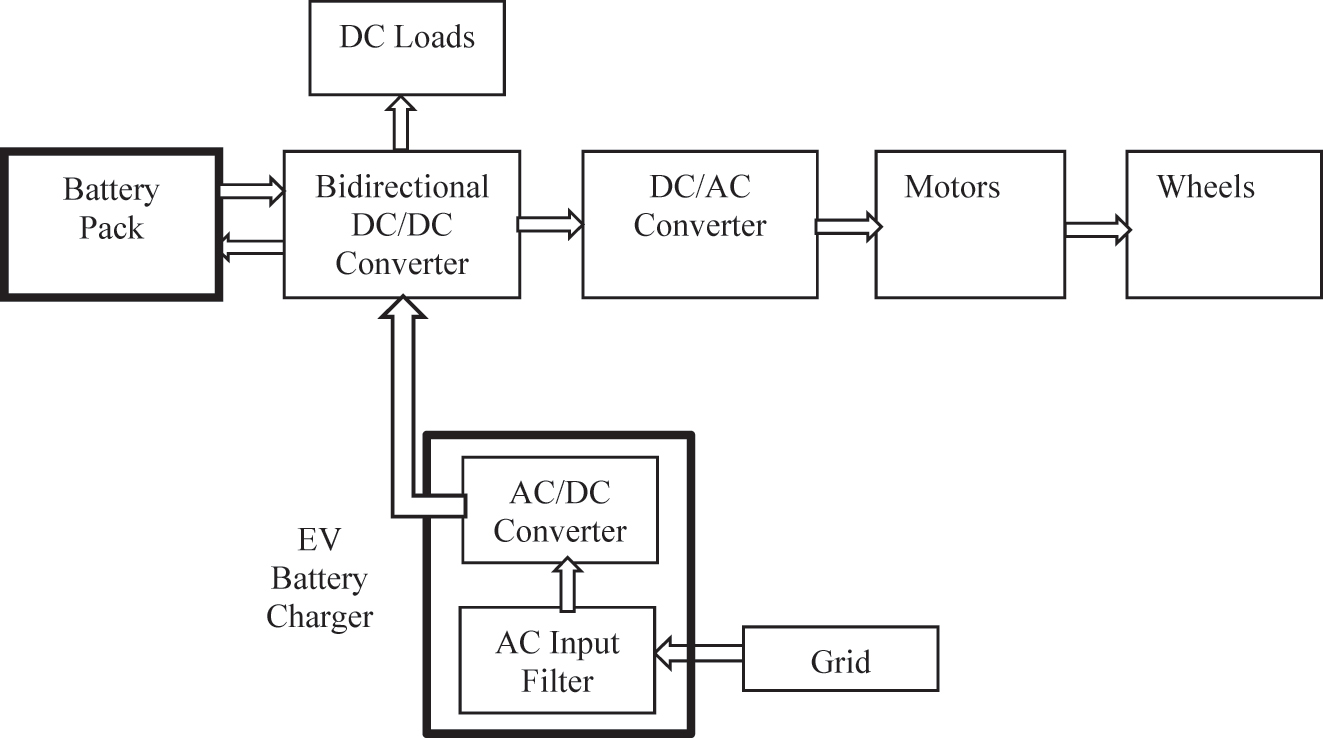

Battery packs are used in EV as the source of energy. Battery packs are connected with power electronic converters and electric motors to drive the electric vehicles as shown in Figure 1. Battery packs of EV consist of multiple cells. EV battery charger includes an AC input filter and an AC/DC converter. The charging power flows from the grid through the charger and bidirectional DC/DC converter to the battery pack. The bidirectional DC/DC converter is used during discharge condition also. Discharging occurs through this converter and a DC/AC converter to the motor. The DC loads are also powered by the battery pack.

Block diagram of an electric car drive train.

Battery cells in EV are designed mainly in three ways such as pouch cells, cylindrical cells, and prismatic cells (Budde-Meiwes et al. 2013). Single cell is not able to drive the load. Several cells in series connection make series strings which enable to achieve the voltage required to run the motor. Series strings are then paralleled for high current requirements. For example, Nissan leaf battery, (96 cells in series, 2 strings in parallel, 96s2p) are made from pouch cells and Tesla uses cylindrical cells (96 cells in series, 74 strings in parallel, 96s74p) for their battery pack (Rothgang et al. 2015). When a large number of cells are used in the battery pack, it becomes difficult to equalize the voltage. This problem is acute, firstly, when hybrid battery super-capacitors with different voltage levels are used (Wang et al. 2018). Secondly, some cells charge/discharge faster than other cells due to slight difference in internal resistance. Innovative methods such as cell balancing strategies have been proposed (Hemavathi 2021; Omariba et al. 2019). However, balancing strategies are helpful to balance the cells during first few cycles and with time when the unbalance is high, balancing becomes inefficient. Usage of large number of cells raises the question and necessity to determine the battery pack efficiency and temperature. These two parameters are of utmost importance to improve the economy of the electric vehicle.

In previous research, necessity to improve battery pack design has been discussed (Rothgang et al. 2015). In that paper, topologies of battery packs have been discussed, and reliability/lifetime of battery packs have been improved considering different part of the battery pack. A mathematical model has been proposed to simulate battery packs and an experimental platform has been built for validation (Chang et al. 2018). The number of paralleled cell has been evaluated in Monte–Carlo experiments in that research work. However, due to the assumption of high quality and homogenous battery cells, the effect of cell unbalance has not been considered. The effect of different paralleled cells on efficiency has not been achieved. A genetic algorithm is applied to optimize the battery pack grouping topology with the view to minimizing the total cost of ownership (TCO) (Chen et al. 2017). In that paper, it has been demonstrated that optimized grouping of number of series parallel configuration can improve electric vehicle economy and performance. A techno-economic analysis of Li NMC prismatic pouch battery and pack design have been conducted for electric vehicle applications (Sakti et al. 2015). Power capability and manufacturing operations have been modeled with the view to finding minimum cost for various PHEVs in that paper. Process based cost breakdown of lithium-ion battery has been projected for future electric vehicles (Berckmans et al. 2017). That paper has compared the present and future sale price of Lithium Ion batteries for electric automotive industries. It has also been recommended to improve energy density and safety of battery packs to be able to drive the force for mass production. Unbalance in parallel connected Lithium Ion cells has been modeled and experimentally evaluated in (Bruen and Marco 2016). Equivalent circuit model (ECM) for the cells has been developed and experiments have been done to explore the effect of parallel connection of four battery cells, instead of series connection among them. A number of system topologies for hybrid electrical energy storage systems were reviewed in (Zimmermann et al. 2016). Cell level and module level reconfiguration were presented for different grouping of series parallel cells. Degradation modeling at various conditions for battery pack asymmetry analysis has been done (Ganesan et al. 2016). The paper has included case studies of physical parameters contributing to asymmetry and control of individual cell has been analyzed with regards to battery pack life extension.

To balance temperature in different parts of the battery pack and to absorb the heat generated from the battery pack advanced battery thermal management system (BTMS) are being developed recently (Thakur et al. 2023). Numerical analysis 18,650 Li-Ion battery (BTMS) has been performed using ANSYS FLUENT software. The impact of phase change material (PCM) on heat transfer has been investigated (Joshi et al. 2023). To improve thermal design and PCM further, novel metallic separator has been coupled which allows to increase temperature delay efficiency (Talele et al. 2023). Combination of PCM, metal foam, and fins of different shapes has been used to investigate the performance of BTMS (Khaboshan et al. 2023).

However, to this date, a few research papers have been found that describe both the electrical and thermal model of a battery pack and determination of the electrical and thermal model parameters. This paper focuses on examination of the thermal behavior and efficiency of EV battery pack. The heat generation is investigated based on the temperature rise for two different battery cells in a simulation model. And the electrical efficiency is examined based on the electrical model and experimental setup of the battery pack.

Rest of the paper is organized as follows, problems in traditional EV battery pack are discussed in Section 2, and battery pack modeling is discussed in terms of electrical and thermal model in Section 3. In Section 4, methodology of the research is presented. Sections 5 and 6 include results obtained and Section 7 includes the discussions, analysis of the results and some recommendations.

2 Problems in traditional EV battery pack

The problems with current battery packs can be described as unbalance and degradation of cells that reduce battery pack performance. The solution to this problem is that the cells should be matched and combined in groups which is known as balancing strategy (Ci et al. 2016; Dubarry et al. 2016; Song et al. 2021).

The problems, that limit the performance of battery packs, can be divided into following categories (Rahman et al. 2022):

2.1 Different aging of different cells

Different cells in a battery pack age differently. From the chemical composition of the battery’s electrolyte aging starts and gives rise to degradation of electrodes (Vetter et al. 2005). The ageing mechanisms are-contaminated materials, lithium plating of the anode, dendric growth between battery electrodes, variation of the electrolyte chemical composition, loss of active material in the electrolyte, dissolving of cathode material, moisture ingress due to vent failure or case seal failure, cracks in the active materials or the cell case, etc. (Barré et al. 2013; Jannesari et al. 2011).

2.2 Cell unbalance

In a battery pack, cell unbalance occurs inevitably (Weiping et al. 2019). Battery management systems (BMS) can provide bidirectional current to the cells to balance cells with each-other. However, in mA range this current is often less than the charging or discharging current.

2.3 Rate capacity effect

More energy can be delivered by smaller discharge current. As mentioned in previous research (He et al. 2013), higher discharge current delivers less energy. On the other hand, low discharge current delivers high energy. If the discharge current is controlled, then it is possible to deliver more energy with an optimum cell capacity.

2.4 Cell failure

Cell failure is an important issue in battery packs. Series connected cells are more prone to failures. Cell failure is also detrimental to the safety and reliability of a battery pack. In those cases, redundant cells add reliability to the pack, although redundant cells come with an additional cost (Li et al. 2014; Rothgang et al. 2015).

2.5 Capacity spread and resistance growth in cells

Two reasons can be associated with the aging of a single cell; one is capacity spread and the other is the growth of resistance (Rumpf et al. 2018). Both capacity spread and the growth of resistance affect the SoC, voltage, current and temperature of a cell with the increase of time.

2.6 Temperature gradients

In a large battery pack, temperature difference happens due to the difference in internal resistance of the cells. Difference in cell temperature between the cells affects the battery pack. Sophisticated cooling system is required to balance the temperature between the hotter cells, which comes at a higher cost.

2.7 Specific design for specific applications

After manufacturing, the battery topology is fixed, due to advanced ageing or malfunction, the battery is replaced entirely by a new one. Flexibility in the topology is therefore limited. The battery is specifically designed to be used in a certain application, requiring a fixed voltage and capacity. Using the battery in second life applications with different voltage and current requirement becomes difficult. Aforementioned problems could be tackled by an improved design of the battery pack with switching circuit. Switching circuit enables the bypassing of the weak cells and keep the good cells delivering the required power.

3 Battery pack modeling

Battery pack model is realized from electrical equivalent circuit model (ECM) of a battery cell and thermal modeling point of view. Battery packs are formed by a limited number of battery modules. A battery module is made through series, parallel, or series-parallel connection of cells. Electrical equivalent resistance, R eq and heat generation, H are assumed as two parameters which are involved in the loss mechanism within the battery pack. Hence, minimization of these two parameters can maximize the battery efficiency.

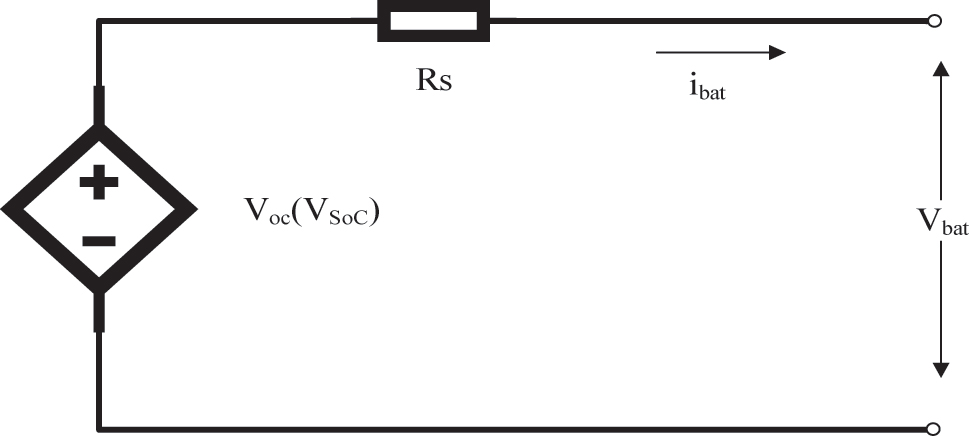

3.1 Electrical model

There are several types of equivalent circuit models of battery available (Zhang et al. 2016). The simplest battery model should consist of a voltage source which depends on the state of the charge (SoC) of the battery, and a series resistance. A battery model, shown in Figure 2, consists of a voltage source which depends on the SoC of the battery, and a series resistance. The battery actual voltage, V bat is modeled by three blocks. First block is the open circuit voltage, V oc. SoC is calculated and open circuit voltage, OCV is computed using a look up table. Second block is the series resistance, R s . This resistance is approximated by another look up table based on the current, i bat, temperature, T and SoC. Finally, the over voltage is represented in the model using RC networks (Andre et al. 2011). However, in Figure 2 the RC networks are not shown for simplicity.

Equivalent circuit model of a battery.

According to the discussions above, following equation of battery voltage with respect to time can be written.

3.1.1 Equivalent resistance

In an EV battery, battery modules are formed by a number of paralleled cells connected in series. Then one or more modules are connected in series to form the battery pack. For the cells connected in parallel, following equation can be written, where R i is the resistance of ith cell of the paralleled string.

And for the paralleled cells, which are connected in series, following equation can be written as the resistance of the module,

The equivalent resistance can be written as the function of R p and R se, as shown in the following equation.

3.1.2 Total discharge current

With series and parallel connected strings the battery pack is formed. Now, the total power of the battery pack, P b can be written in terms of total battery voltage, V t and total current I t and equivalent resistance R eq as following equation.

Due to the loss in the resistances, following equation can be derived for determining the total discharge current from the battery pack to the load.

3.1.3 Efficiency of the battery pack

Efficiency of the battery pack can be written as following equation which is expressed as the ratio of the output power to the input power.

3.2 Thermal model

Inside a battery, heat is produced due to following reasons (Huang et al. 2017)-firstly, internal resistances cause Joule heating by charge transfer reactions, diffusion of ions in electrolyte and electrodes and ohmic resistances. Secondly, thermodynamic process on the electrode (entropy changes) is caused due to lithium intercalation in cathodes and anodes. Thirdly, heat transfer to the ambient condition is caused due to convection.

Governing equation can be written as equation (8) (Ismail et al. 2013).

Value of the entropy change, ΔS can be obtained in the function of state of charge in simplified as a second order polynomial as in equation (9).

A two state thermal model of cylindrical battery is used to model the dynamics, known as lumped thermal model (Lin et al. 2014). Governing equation of T c (Temperature at the center of the cell) and T s (Temperature at the surface of the cell) are,

The heat generation Q in Eq. (10) is a byproduct of the chemical reactions taking place in the electrode assembly during battery operation. The value of Q is calculated based on the electrical model.

R c is the heat conduction resistance in the core, C c and C s are the heat capacity of the core and of the surface respectively. R u is the convection resistance between T s and T f. T f is the temperature at the point where coolant convection occurs.

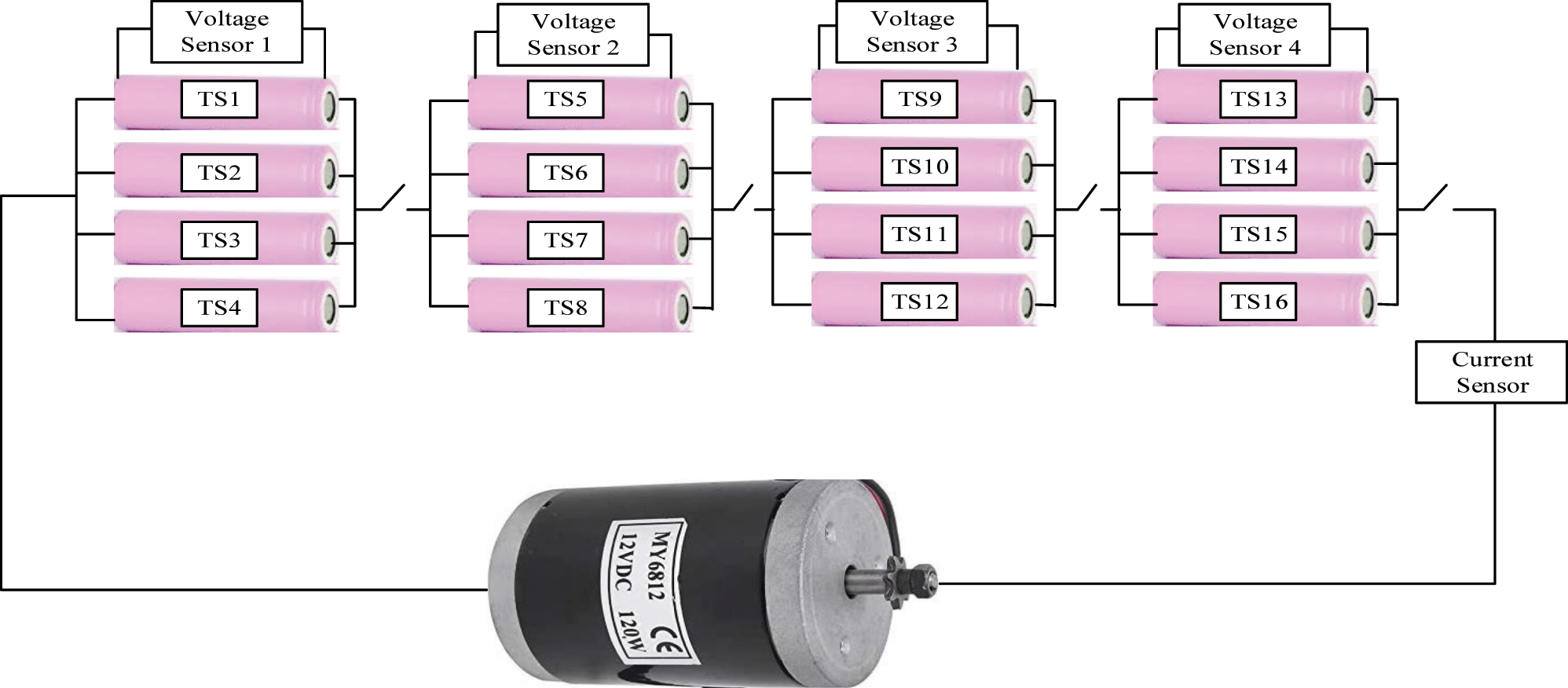

4 Methodology

To measure the electrical and thermal parameters both simulation and experimental setup are implemented. A 4S4P battery pack with 3.7 V, Li-Ion 18,650 cylindrical battery cells is constructed, where one module is kept as reserve. Firstly, voltage, current and temperature of each cell are measured through voltage, current and temperature sensors (Ex:TS1-TS16). Then the data are sent to a microcontroller. The microcontroller has the ability to connect or disconnect a battery module as well as the battery pack from the load through switches. The voltage, current and temperature data can also be monitored through a display. The battery pack is discharged to an e-bike DC motor of 12 V, 120 W as shown in Figure 3.

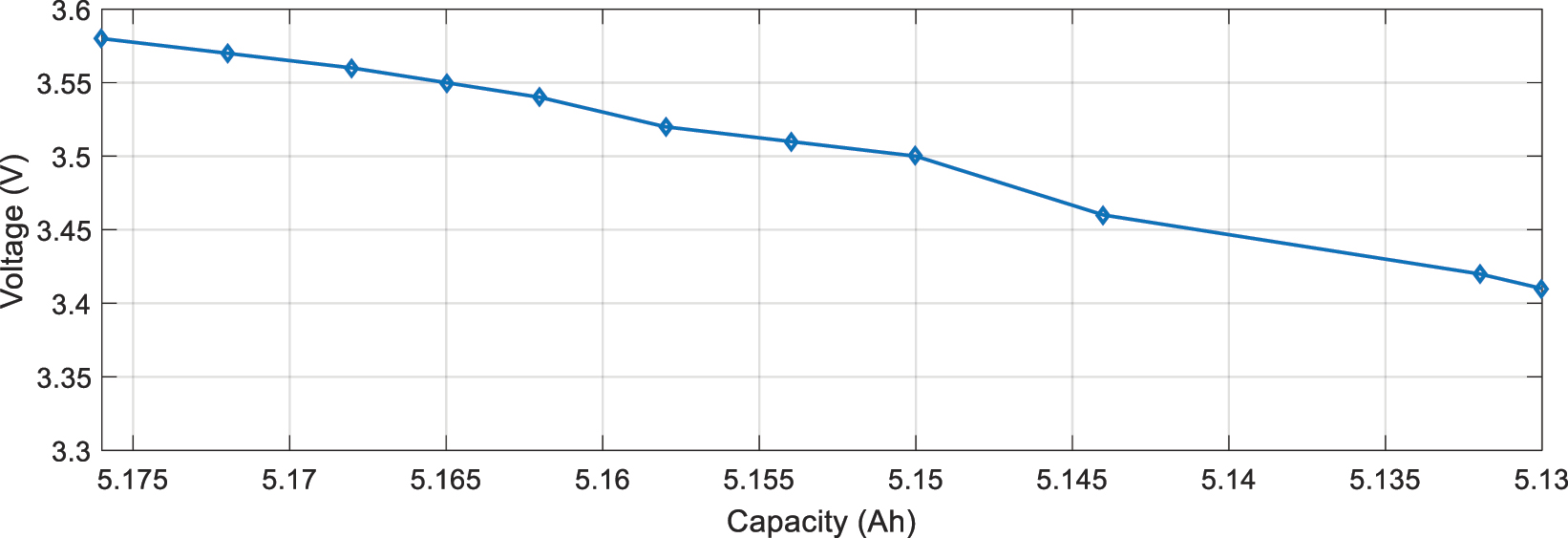

5 Results of the electrical model

Firstly, a single cell is discharged across a 100 Ω resistive load to obtain the discharge characteristics. Figure 4 represents the voltage versus capacity curve of the battery cell.

Experimental setup for measuring voltage, temperature and current of the 4S4P battery pack.

Voltage versus capacity curve of Li-Ion 18,650 cylindrical battery cell.

Secondly, 4 cells are connected in parallel to form a module 3 of these modules are connected in series through switches to deliver to the 12 V motor with no load. Module 4 is kept as reserve. Table 1 represents the voltage of cell groups measured by the voltage sensors for a no load current of 0.23 A.

Module voltages and load voltage at different times.

| Time (minutes) | Module 1 (V) | Module 2 (V) | Module 3 (V) | Module 4 (V) | Load voltage (V) |

|---|---|---|---|---|---|

| 0 | 4.45 | 3.94 | 3.93 | 3.93 | 0 |

| 1 | 4.19 | 3.73 | 3.72 | 3.93 | 11.64 |

| 2 | 4.14 | 3.77 | 3.75 | 3.93 | 11.66 |

| 3 | 4.09 | 3.75 | 3.63 | 3.93 | 11.47 |

| 4 | 4.07 | 3.7 | 3.61 | 3.93 | 11.38 |

| 5 | 3.98 | 3.73 | 3.63 | 3.93 | 11.34 |

| 7 | 4.09 | 3.7 | 3.58 | 3.93 | 11.37 |

| 10 | 4.07 | 3.68 | 3.56 | 3.93 | 11.31 |

| 15 | 3.98 | 3.68 | 3.54 | 3.93 | 11.2 |

| 20 | 3.94 | 3.63 | 3.54 | 3.93 | 11.11 |

| 25 | 3.91 | 3.61 | 3.51 | 3.93 | 11.03 |

| 30 | 3.95 | 3.57 | 3.48 | 3.93 | 11 |

| 35 | 3.91 | 3.59 | 3.45 | 3.93 | 10.95 |

| 40 | 3.9 | 3.63 | 3.41 | 3.93 | 10.94 |

| 45 | 3.93 | 3.61 | 3.41 | 3.93 | 10.95 |

| 50 | 3.94 | 3.62 | 3.44 | 3.93 | 11 |

| 60 | 3.93 | 3.6 | 3.37 | 3.93 | 10.9 |

| 90 | 3.84 | 3.6 | 3.3 | 3.93 | 10.74 |

| 100 | 3.86 | 3.54 | 3.26 | 3.93 | 10.66 |

| 110 | 3.79 | 3.45 | 3.19 | 3.93 | 10.43 |

| 114 | 3.77 | 3.42 | 3.52 | 3.73 | 10.92 |

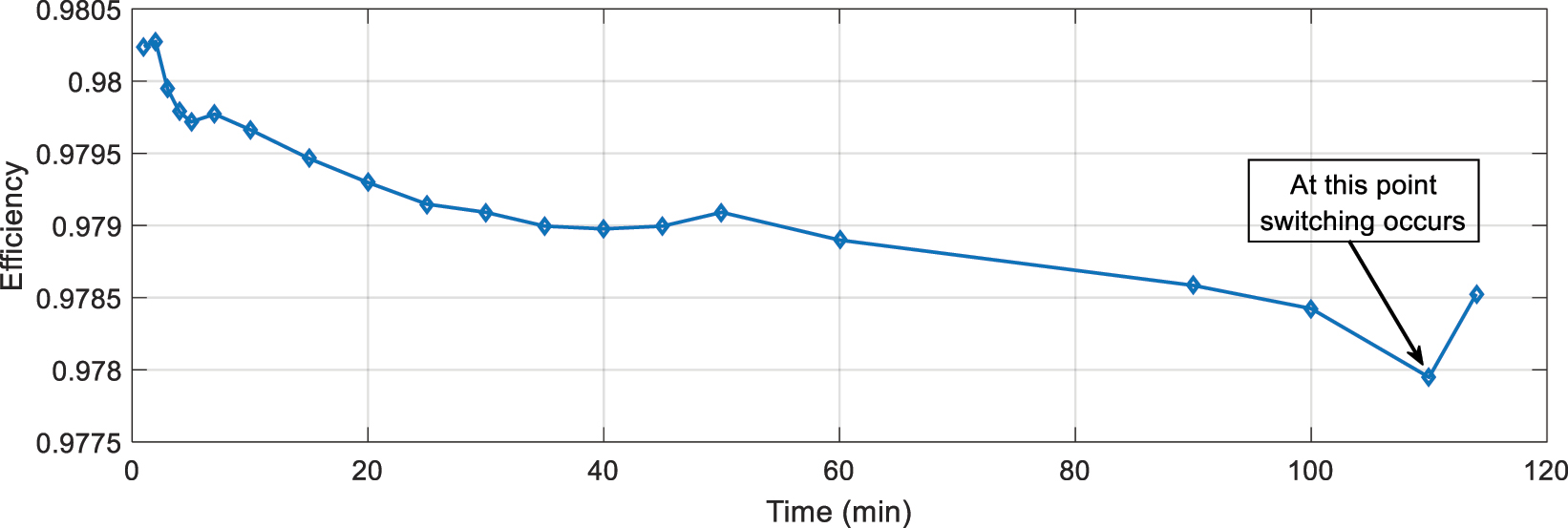

Finally, efficiency of the battery pack can be shown as Figure 5. It can be seen that efficiency drops slightly with respect to time. However, at 110 min efficiency curve increases steeply. This is because of the switching of module 3 to module 4.

Electrical efficiency of the battery pack.

6 Simulation results of the thermal model

The main properties of the battery cells which are used in the thermal model can be found in Table 2. Two types of battery cell are used for simulating the thermal models.

Battery specification.

| Type | Nominal capacity (Ah) | Nominal voltage (V) | Upper cut-off voltage (V) | Lower cut-off voltage (V) | Operating temperature (T) | Mass (gm) |

|---|---|---|---|---|---|---|

| LiFeYPO4 | 40 | 3.7 | 4 | 2.8 | −45 °C–85 °C | 1600 |

| Li-Ion (18,650) | 5.2 | 3.7 | 4.2 | 2.2 | −45 °C–85 °C | 46–51 |

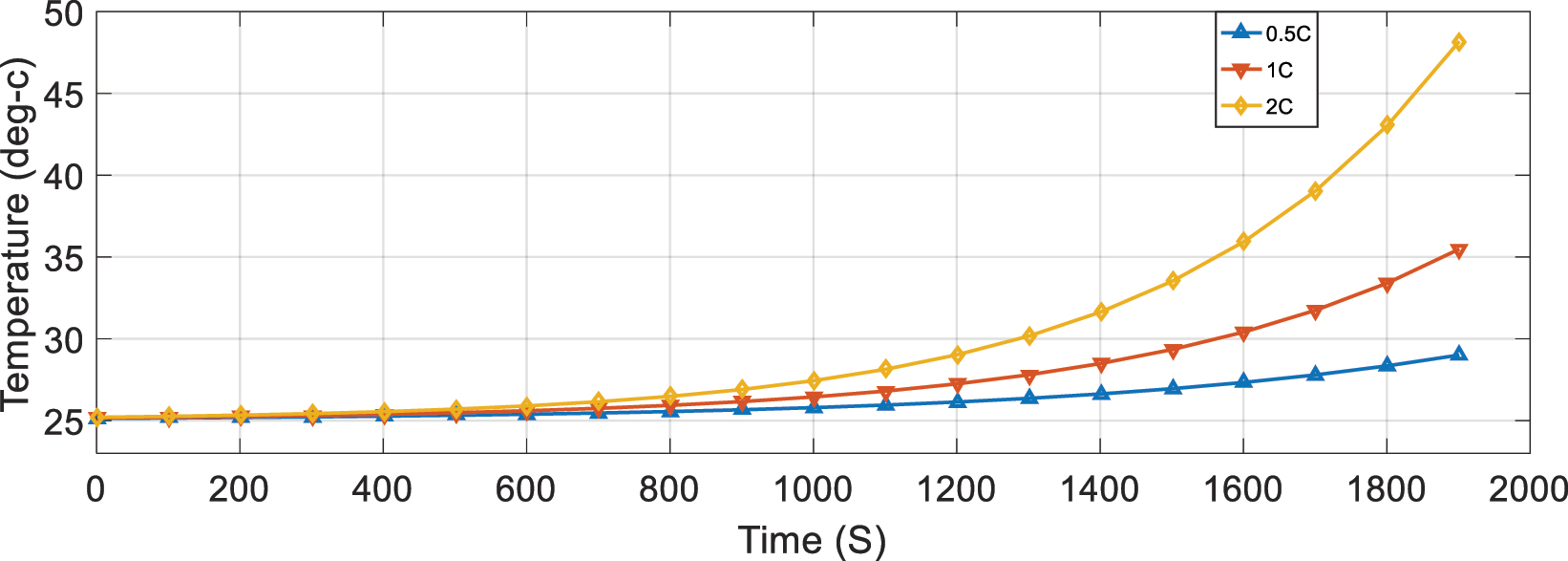

Following Figures 6 and 7 have been plotted to show the temperature rise of the battery (LiFeYPO4 and Li-Ion 18,650) by implementing the governing equation under different C-rates simulated in MATLAB. Ambient temperature is 25 °C. It can be noticed from Figure 6 that temperature rises significantly with a higher C-rate. This is because of the heat loss in the resistive components which increases as the C-rate increases. If the battery cells are discharged at a lower C-rate such as 0.5 C, then the corresponding temperature curve remains flat almost.

LiFeYPO4 cell temperature for C-rate.

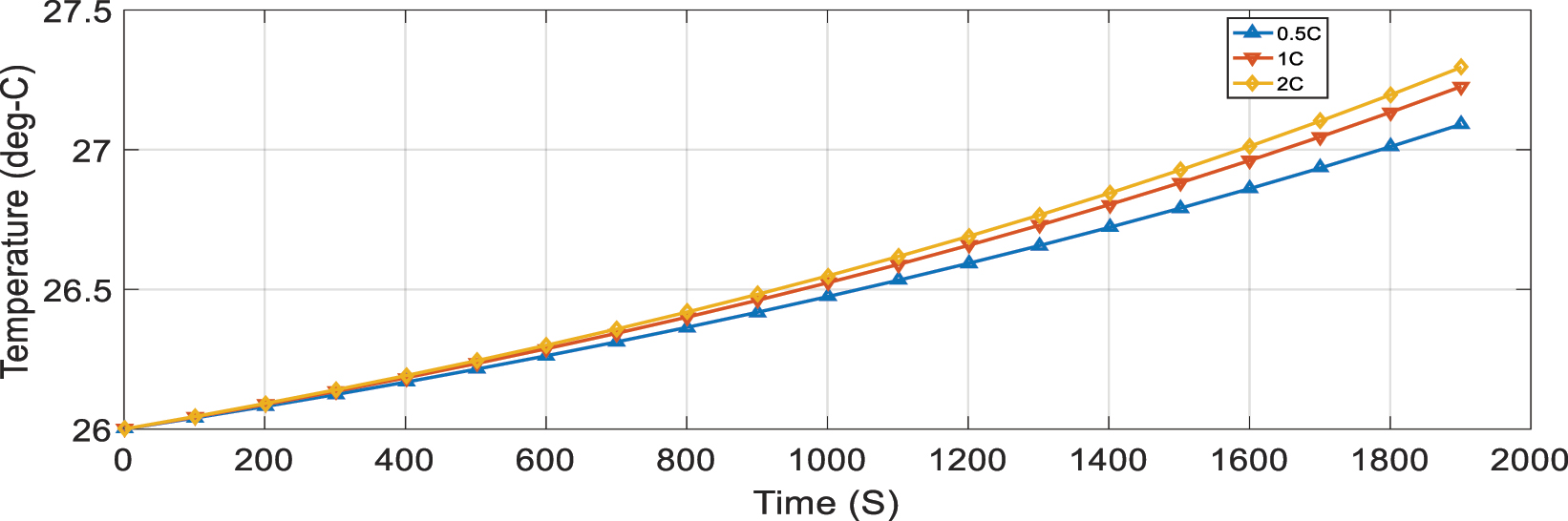

Li-Ion 18,650 cylindrical battery cell temperature for C-rate.

In Figure 7 it can be seen that temperature rise is not much increased with respect to time. Temperature varies from 26 to 27.5 °C in a Li-Ion 18,650 cell. When C-rate is increased temperature also increases, however, at a lower rate than LiFeYPO4 battery cell. This is also compared with the actual temperature sensor data in the experimental setup. Temperature of Li-Ion 18,650 cell does not vary much and remains constant at room temperature.

7 Discussion

From the results, it is evident that the battery pack voltage depends on the series connected cells and the capacity of the battery pack depends on the parallel connected cells. Efficiency is slightly decreased with respect to time. This is why, the efficiency is reduced for the series cells. Also in reality, series connected cells add more internal resistances and switch resistances. As a result, equivalent resistance is increased and efficiency should be decreased. The discharge current from the battery pack depends on the type of load. Higher motor current is required from the battery during acceleration in an electric vehicle. Electric car battery also has to provide this current to the load very quickly. It is recommended that a parallel connected ultra-capacitor or super capacitor branch can be used to deliver this current during high current requirement (Ju et al. 2014). Otherwise, battery cells can be discharged at an abnormal rate and exhibit faulty operation.

The resistance varies with regards to the cell connection, hence, an economic path search algorithm should be employed if battery cells need to change their connection in real time (Hahnsang and Kang 2009). However, changing the connection frequently increases the resistive losses and heat generation. It is suggested that during a 24 h duration of operation time the configuration is changed not more than 2 to 3 times.

Due to the switches the volume and space of the battery pack are increased. In battery packs the electronic components applied are large in number. Addition of the switching is another electronic component which increase placement, component and cost complexities. Moreover, heat production is increased and for safety, expensive and big coolers may need to be employed. However, efficiency is expected to be improved, even at the cost of resistive drop in the switches. During charging the battery, individual cells can be charged if the battery cells contain the switching circuit. Modern safe and reliable semiconductor switches used in EVs such as MOSFETS and solid state relays are used in the circuit design. This enhances the safety and performance of the battery pack. Another important aspect related to the challenge in switching circuit design is the ON and OFF time during switching. It has been analyzed that the efficiency drops when soft switching is employed. On the other hand, hard switching increases the burden and decreases the lifetime of the switches. The major disadvantage of the switching circuit is increased cost and complexity. In this paper, the consideration of switching circuit evaluated is only during the discharging cycle.

8 Conclusions

Battery systems placed in electric vehicles are heavily dependent on the performance of individual battery cells. Real time measurement and control of the battery parameters enable better performance in terms of lifetime, safety and reliability. This paper provides an idea how efficiency and heat may vary if switches are employed in a battery pack in real scenario. For this reason actual data are used for electrical and thermal modeling. Some parameters such as cost and computational complexity rise, while efficiency and heat are optimized in this method. Future work will be focused on the implementation of BTMS and measurement of cell temperature at different parts of the battery pack. In addition, improvement in thermal management by different PCM methods will be investigated.

Funding source: AUST Internal Research Grant.

Award Identifier / Grant number: ARP/2021/EEE/01/1

-

Author contributions: The authors have accepted responsibility for the entire content of this submitted manuscript and approved submission.

-

Research funding: This work has received funding from the AUST internal research grant Ref. ARP/2021/EEE/01/1 for the project “Development of an Intelligent Controller for Battery Energy Storage System for Electric Vehicles (EV)”.

-

Conflict of interest statement: The authors declare no conflicts of interest regarding this article.

References

Alsauskas, O., E. Connelly, A. Daou, A. Gouy, M. Huismans, H. Kim, J. Marois, S. McDonagh, A. Petropoulos, and J. Teter. 2023. “Global EV Outlook 2023 Catching up with Climate Ambitions.” In Global EV Outlook 2023 Catching up with Climate Ambitions. Paris: International Energy Agency.Suche in Google Scholar

Andre, D., M. Meiler, K. Steiner, H. Walz, T. Soczka-Guth, and D. Sauer. 2011. “Characterization of High-Power Lithium-Ion Batteries by Electrochemical Impedance Spectroscopy. II: Modelling.” Journal of Power Sources 196: 5349–56. https://doi.org/10.1016/j.jpowsour.2010.07.071.Suche in Google Scholar

Barré, A., B. Deguilhem, S. Grolleau, M. Gérard, F. Suard, and D. Riu. 2013. “A Review on Lithium-Ion Battery Ageing Mechanisms and Estimations for Automotive Applications.” Journal of Power Sources 241: 680–9. https://doi.org/10.1016/j.jpowsour.2013.05.040.Suche in Google Scholar

Berckmans, G., M. Messagie, J. Smekens, N. Omar, and L. Vanhaverbeke. 2017. “Cost Projection of State of the Art Lithium-Ion Batteries for Electric Vehicles Up to 2030.” Energies 10 (9): 1314, https://doi.org/10.3390/en10091314.Suche in Google Scholar

Bruen, T., and J. Marco. 2016. “Modelling and Experimental Evaluation of Parallel Connected Lithium Ion Cells for an Electric Vehicle Battery System.” Journal of Power Sources 310 (1): 91–101, https://doi.org/10.1016/j.jpowsour.2016.01.001.Suche in Google Scholar

Budde-Meiwes, H., J. Drillkens, B. Lunz, J. Muennix, S. Rothgang, J. Kowal, and D. Sauer. 2013. “A Review of Current Automotive Battery Technology and Future Prospects.” Journal of Automobile Engineering 227 (5): 761–76, https://doi.org/10.1177/0954407013485567.Suche in Google Scholar

Chang, F., F. Roemer, M. Baumann, and M. Lienkamp. 2018. “Modelling and Evaluation of Battery Packs with Different Numbers of Paralleled Cells.” World Electric Vehicle Journal 9 (1). https://doi.org/10.3390/wevj9010008.Suche in Google Scholar

Chen, Z., N. Guo, X. Li, J. Shen, R. Xiao, and S. Li. 2017. “Battery Pack Grouping and Capacity Improvement for Electric Vehicles Based on a Genetic Algorithm.” Energies 10 (4): 439, https://doi.org/10.3390/en10040439.Suche in Google Scholar

Ci, S., N. Lin, and D. Wu. 2016. Reconfigurable Battery Techniques and Systems: A Survey, Vol. 4, 1175–89. New York: IEEE Access.10.1109/ACCESS.2016.2545338Suche in Google Scholar

Dubarry, M., A. Devie, and B. Liaw. 2016. “Cell-balancing Currents in Parallel Strings of a Battery System.” Journal of Power Sources 321: 36–46. https://doi.org/10.1016/j.jpowsour.2016.04.125.Suche in Google Scholar

Ganesan, N., S. Basu, K. Hariharan, S. M. Kolake, T. Song, T. Yeo, D. K. Sohn, and S. Doo. 2016. “Physics Based Modeling of a Series Parallel Battery Pack for Asymmetry Analysis, Predictive Control and Life Extension.” Journal of Power Sources 322 (1): 57–67, https://doi.org/10.1016/j.jpowsour.2016.05.005.Suche in Google Scholar

Hahnsang, K., and G. S. Kang. 2009. “On Dynamic Reconfiguration of a Large-Scale Battery System.” In 15th IEEE Real-Time and Embedded Technology and Applications Symposium. San Francisco.Suche in Google Scholar

He, L., L. Gu, L. Kong, Y. Gu, C. Liu, and T. He. 2013. “Exploring Adaptive Reconfiguration to Optimize Energy Efficiency in Large-Scale Battery Systems.” In Proceedings IEEE 34th Real-Time System Symposium.10.1109/RTSS.2013.20Suche in Google Scholar

Hemavathi, S. 2021. “Overview of Cell Balancing Methods for Li-Ion Battery Technology.” Energy Storage Wiley 3 (2). https://doi.org/10.1002/est2.203.Suche in Google Scholar

Huang, Y., Y. Lu, R. Huang, J. Chen, F. Chen, Z. Liu, X. Yu, and A. P. Roskilly. 2017. “Study on the Thermal Interaction and Heat Dissipation of Cylindrical Lithium-Ion Battery Cells.” In 9th International Conference on Applied Energy. Cardiff: ICAE.10.1016/j.egypro.2017.12.321Suche in Google Scholar

Ismail, N. F., S. F. Toha, N. M. Azubir, N. M. Ishak, M. K. Hassan, and B. Ibrahim. 2013. “Simplified Heat Generation Model for Lithium Ion Battery Used in Electric Vehicle.” IOP Conference Series: Materials Science and Engineering 53: 012014, https://doi.org/10.1088/1757-899x/53/1/012014.Suche in Google Scholar

Jannesari, H., M. Emami, and C. Ziegler. 2011. “Effect of Electrolyte Transport Properties and Variations in the Morphological Parameters on the Variation of Side Reaction Rate across the Anode Electrode and the Aging of Lithium Ion Batteries.” Journal of Power Sources 196 (22): 9654–64, https://doi.org/10.1016/j.jpowsour.2011.07.026.Suche in Google Scholar

Joshi, A., D. Dandotiya, C. S. Ramesh, and S. Panchal. 2023. Numerical Analysis of Battery Thermal Management System Using Passive Cooling Technique. Pennsylvania: SAE Technical Paper.10.4271/2023-01-0990Suche in Google Scholar

Ju, F., Q. Zhang, W. Deng, and J. Li. 2014. “Review of Structures and Control of Battery-Supercapacitor Hybrid Energy Storage System for Electric Vehicles.” In IEEE International Conference on Automation Science and Engineering.10.1109/CoASE.2014.6899318Suche in Google Scholar

Khaboshan, H., F. Jaliliantabar, A. Abdullah, and S. Panchal. 2023. “Improving the Cooling Performance of Cylindrical Lithium-Ion Battery Using Three Passive Methods in a Battery Thermal Management System.” Applied Thermal Engineering 227.10.1016/j.applthermaleng.2023.120320Suche in Google Scholar

Li, R., J. Wu, H. Wang, J. Guo, and G. Li. 2014. “Reliability Assessment and Failure Analysis of Lithium Iron Phosphate Batteries.” Informing Science 259: 359–68. https://doi.org/10.1016/j.ins.2013.06.038.Suche in Google Scholar

Lin, X., H. E. Perez, S. Mohan, J. B. Siegel, A. G. Stefanopoulou, Y. Ding, and M. P. Castanier. 2014. “A Lumped-Parameter Electro-Thermal Model for Cylindrical Batteries.” Journal of Power Sources 257: 1–11, https://doi.org/10.1016/j.jpowsour.2014.01.097.Suche in Google Scholar

Omariba, Z. B., L. Zhang, and D. Sun. 2019. “Review of Battery Cell Balancing Methodologies for Optimizing Battery Pack Performance in Electric Vehicles.” IEEE Access 7: 129335–52. https://doi.org/10.1109/access.2019.2940090.Suche in Google Scholar

Rahman, M. A., A. Baki, and S. Yasar. 2022. “Management and Control Strategies of Battery Switching in a Hybrid Energy Storage System.” In 4th International Conference on Sustainable Technologies for Industry 4.0 (STI). Dhaka.10.1109/STI56238.2022.10103271Suche in Google Scholar

Rothgang, S., T. Baumhöfer, and D. Sauer. 2015. “Necessity and Methods to Improve Battery Lifetime on System Level.” In EVS28 Electric Vehicle Symposium Exhibition, 1–9.Suche in Google Scholar

Rumpf, K., A. Rheinfeld, M. Schindler, J. Keil, T. Schua, and A. Jossen. 2018. “Influence of Cell-To-Cell Variations on the Inhomogeneity of Lithium-Ion Battery Modules.” Journal of the Electrochemical Society 165A: 2587–607. https://doi.org/10.1149/2.0111811jes.Suche in Google Scholar

Sakti, A., J. Michalek, E. Fuchs, and J. Whitacre. 2015. “A Techno-Economic Analysis and Optimization of Li-Ion Batteries for Light-Duty Passenger Vehicle Electrification.” Journal of Power Sources 273: 966–80. https://doi.org/10.1016/j.jpowsour.2014.09.078.Suche in Google Scholar

Song, Z., X. Yang, N. Yang, F. Delgado, H. Hofmann, and J. Sun. 2021. “A Study of Cell-To-Cell Variation of Capacity in Parallel-Connected Lithium-Ion Battery Cells.” ETransportation 7. https://doi.org/10.1016/j.etran.2020.100091.Suche in Google Scholar

Talele, V., M. Patil, S. Panchal, R. Fraser, M. Fowler, and S. Gunti. 2023. “Novel Metallic Separator Coupled Composite Phase Change Material Passive Thermal Design for Large Format Prismatic Battery Pack.” Journal of Energy Storage 58. https://doi.org/10.1016/j.est.2022.106336.Suche in Google Scholar

Thakur, A., R. Sathyamurthy, R. Velraj, R. Saidur, A. Pandey, Z. Ma, P. Singh, and S. Kanti. 2023. “A State-of-the Art Review on Advancing Battery Thermal Management Systems for Fast-Charging.” Applied Thermal Engineering 226. https://doi.org/10.1016/j.applthermaleng.2023.120303.Suche in Google Scholar

Vetter, J., P. Novák, M. Wagner, C. Veit, K. Möller, J. Besenhard, M. Winter, M. Wohlfahrt-Mehrens, C. Vogler, and A. Hammouche. 2005. “Ageing Mechanisms in Lithium-Ion Batteries.” Journal of Power Sources 147: 269–81. https://doi.org/10.1016/j.jpowsour.2005.01.006.Suche in Google Scholar

Wang, X., K. W. E. Cheng, and Y. C. Fong. 2018. “Series-Parallel Switched-Capacitor Balancing Circuit for Hybrid Source Package.” IEEE Access 6: 34254–61. https://doi.org/10.1109/access.2018.2849864.Suche in Google Scholar

Weiping, D., P. Michael, and L. Tao. 2019. “Management of Imbalances in Parallel-Connected Lithium-Ion Battery Packs.” Journal of Energy Storage 24: 100781. https://doi.org/10.1016/j.est.2019.100781.Suche in Google Scholar

Young, K., C. Wang, L. Y. Wang and K. Strunz. 2013. Electric Vehicle Battery Technologies. New York: Springer.10.1007/978-1-4614-0134-6_2Suche in Google Scholar

Zhang, X., W. Zhang, and G. Lei. 2016. “A Review of Li-Ion Battery Equivalent Circuit Models.” Transactions on Electrical and Electronic Materials 17 (6): 311–6. https://doi.org/10.4313/teem.2016.17.6.311.Suche in Google Scholar

Zimmermann, T., P. Keil, M. Hofmann, M. Horsche, S. Pichlmaier, and A. Jossen. 2016. “Review of System Topologies for Hybrid Electrical Energy Storage Systems.” Journal of Energy Storage 8: 78–90, https://doi.org/10.1016/j.est.2016.09.006.Suche in Google Scholar

© 2024 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Solar photovoltaic-integrated energy storage system with a power electronic interface for operating a brushless DC drive-coupled agricultural load

- Analysis of 1-year energy data of a 5 kW and a 122 kW rooftop photovoltaic installation in Dhaka

- Reviews

- Real yields and PVSYST simulations: comparative analysis based on four photovoltaic installations at Ibn Tofail University

- A comprehensive approach of evolving electric vehicles (EVs) to attribute “green self-generation” – a review

- Exploring the piezoelectric porous polymers for energy harvesting: a review

- A strategic review: the role of commercially available tools for planning, modelling, optimization, and performance measurement of photovoltaic systems

- Comparative assessment of high gain boost converters for renewable energy sources and electrical vehicle applications

- A review of green hydrogen production based on solar energy; techniques and methods

- A review of green hydrogen production by renewable resources

- A review of hydrogen production from bio-energy, technologies and assessments

- A systematic review of recent developments in IoT-based demand side management for PV power generation

- Research Articles

- Hybrid optimization strategy for water cooling system: enhancement of photovoltaic panels performance

- Solar energy harvesting-based built-in backpack charger

- A power source for E-devices based on green energy

- Theoretical and experimental investigation of electricity generation through footstep tiles

- Experimental investigations on heat transfer enhancement in a double pipe heat exchanger using hybrid nanofluids

- Comparative energy and exergy analysis of a CPV/T system based on linear Fresnel reflectors

- Investigating the effect of green composite back sheet materials on solar panel output voltage harvesting for better sustainable energy performance

- Electrical and thermal modeling of battery cell grouping for analyzing battery pack efficiency and temperature

- Intelligent techno-economical optimization with demand side management in microgrid using improved sandpiper optimization algorithm

- Investigation of KAPTON–PDMS triboelectric nanogenerator considering the edge-effect capacitor

- Design of a novel hybrid soft computing model for passive components selection in multiple load Zeta converter topologies of solar PV energy system

- A novel mechatronic absorber of vibration energy in the chimney

- An IoT-based intelligent smart energy monitoring system for solar PV power generation

- Large-scale green hydrogen production using alkaline water electrolysis based on seasonal solar radiation

- Evaluation of performances in DI Diesel engine with different split injection timings

- Optimized power flow management based on Harris Hawks optimization for an islanded DC microgrid

- Experimental investigation of heat transfer characteristics for a shell and tube heat exchanger

- Fuzzy induced controller for optimal power quality improvement with PVA connected UPQC

- Impact of using a predictive neural network of multi-term zenith angle function on energy management of solar-harvesting sensor nodes

- An analytical study of wireless power transmission system with metamaterials

- Hydrogen energy horizon: balancing opportunities and challenges

- Development of renewable energy-based power system for the irrigation support: case studies

- Maximum power point tracking techniques using improved incremental conductance and particle swarm optimizer for solar power generation systems

- Experimental and numerical study on energy harvesting performance thermoelectric generator applied to a screw compressor

- Study on the effectiveness of a solar cell with a holographic concentrator

- Non-transient optimum design of nonlinear electromagnetic vibration-based energy harvester using homotopy perturbation method

- Industrial gas turbine performance prediction and improvement – a case study

- An electric-field high energy harvester from medium or high voltage power line with parallel line

- FPGA based telecommand system for balloon-borne scientific payloads

- Improved design of advanced controller for a step up converter used in photovoltaic system

- Techno-economic assessment of battery storage with photovoltaics for maximum self-consumption

- Analysis of 1-year energy data of a 5 kW and a 122 kW rooftop photovoltaic installation in Dhaka

- Shading impact on the electricity generated by a photovoltaic installation using “Solar Shadow-Mask”

- Investigations on the performance of bottle blade overshot water wheel in very low head resources for pico hydropower

- Solar photovoltaic-integrated energy storage system with a power electronic interface for operating a brushless DC drive-coupled agricultural load

- Numerical investigation of smart material-based structures for vibration energy-harvesting applications

- A system-level study of indoor light energy harvesting integrating commercially available power management circuitry

- Enhancing the wireless power transfer system performance and output voltage of electric scooters

- Harvesting energy from a soldier's gait using the piezoelectric effect

- Study of technical means for heat generation, its application, flow control, and conversion of other types of energy into thermal energy

- Theoretical analysis of piezoceramic ultrasonic energy harvester applicable in biomedical implanted devices

- Corrigendum

- Corrigendum to: A numerical investigation of optimum angles for solar energy receivers in the eastern part of Algeria

- Special Issue: Recent Trends in Renewable Energy Conversion and Storage Materials for Hybrid Transportation Systems

- Typical fault prediction method for wind turbines based on an improved stacked autoencoder network

- Power data integrity verification method based on chameleon authentication tree algorithm and missing tendency value

- Fault diagnosis of automobile drive based on a novel deep neural network

- Research on the development and intelligent application of power environmental protection platform based on big data

- Diffusion induced thermal effect and stress in layered Li(Ni0.6Mn0.2Co0.2)O2 cathode materials for button lithium-ion battery electrode plates

- Improving power plant technology to increase energy efficiency of autonomous consumers using geothermal sources

- Energy-saving analysis of desalination equipment based on a machine-learning sequence modeling

Artikel in diesem Heft

- Solar photovoltaic-integrated energy storage system with a power electronic interface for operating a brushless DC drive-coupled agricultural load

- Analysis of 1-year energy data of a 5 kW and a 122 kW rooftop photovoltaic installation in Dhaka

- Reviews

- Real yields and PVSYST simulations: comparative analysis based on four photovoltaic installations at Ibn Tofail University

- A comprehensive approach of evolving electric vehicles (EVs) to attribute “green self-generation” – a review

- Exploring the piezoelectric porous polymers for energy harvesting: a review

- A strategic review: the role of commercially available tools for planning, modelling, optimization, and performance measurement of photovoltaic systems

- Comparative assessment of high gain boost converters for renewable energy sources and electrical vehicle applications

- A review of green hydrogen production based on solar energy; techniques and methods

- A review of green hydrogen production by renewable resources

- A review of hydrogen production from bio-energy, technologies and assessments

- A systematic review of recent developments in IoT-based demand side management for PV power generation

- Research Articles

- Hybrid optimization strategy for water cooling system: enhancement of photovoltaic panels performance

- Solar energy harvesting-based built-in backpack charger

- A power source for E-devices based on green energy

- Theoretical and experimental investigation of electricity generation through footstep tiles

- Experimental investigations on heat transfer enhancement in a double pipe heat exchanger using hybrid nanofluids

- Comparative energy and exergy analysis of a CPV/T system based on linear Fresnel reflectors

- Investigating the effect of green composite back sheet materials on solar panel output voltage harvesting for better sustainable energy performance

- Electrical and thermal modeling of battery cell grouping for analyzing battery pack efficiency and temperature

- Intelligent techno-economical optimization with demand side management in microgrid using improved sandpiper optimization algorithm

- Investigation of KAPTON–PDMS triboelectric nanogenerator considering the edge-effect capacitor

- Design of a novel hybrid soft computing model for passive components selection in multiple load Zeta converter topologies of solar PV energy system

- A novel mechatronic absorber of vibration energy in the chimney

- An IoT-based intelligent smart energy monitoring system for solar PV power generation

- Large-scale green hydrogen production using alkaline water electrolysis based on seasonal solar radiation

- Evaluation of performances in DI Diesel engine with different split injection timings

- Optimized power flow management based on Harris Hawks optimization for an islanded DC microgrid

- Experimental investigation of heat transfer characteristics for a shell and tube heat exchanger

- Fuzzy induced controller for optimal power quality improvement with PVA connected UPQC

- Impact of using a predictive neural network of multi-term zenith angle function on energy management of solar-harvesting sensor nodes

- An analytical study of wireless power transmission system with metamaterials

- Hydrogen energy horizon: balancing opportunities and challenges

- Development of renewable energy-based power system for the irrigation support: case studies

- Maximum power point tracking techniques using improved incremental conductance and particle swarm optimizer for solar power generation systems

- Experimental and numerical study on energy harvesting performance thermoelectric generator applied to a screw compressor

- Study on the effectiveness of a solar cell with a holographic concentrator

- Non-transient optimum design of nonlinear electromagnetic vibration-based energy harvester using homotopy perturbation method

- Industrial gas turbine performance prediction and improvement – a case study

- An electric-field high energy harvester from medium or high voltage power line with parallel line

- FPGA based telecommand system for balloon-borne scientific payloads

- Improved design of advanced controller for a step up converter used in photovoltaic system

- Techno-economic assessment of battery storage with photovoltaics for maximum self-consumption

- Analysis of 1-year energy data of a 5 kW and a 122 kW rooftop photovoltaic installation in Dhaka

- Shading impact on the electricity generated by a photovoltaic installation using “Solar Shadow-Mask”

- Investigations on the performance of bottle blade overshot water wheel in very low head resources for pico hydropower

- Solar photovoltaic-integrated energy storage system with a power electronic interface for operating a brushless DC drive-coupled agricultural load

- Numerical investigation of smart material-based structures for vibration energy-harvesting applications

- A system-level study of indoor light energy harvesting integrating commercially available power management circuitry

- Enhancing the wireless power transfer system performance and output voltage of electric scooters

- Harvesting energy from a soldier's gait using the piezoelectric effect

- Study of technical means for heat generation, its application, flow control, and conversion of other types of energy into thermal energy

- Theoretical analysis of piezoceramic ultrasonic energy harvester applicable in biomedical implanted devices

- Corrigendum

- Corrigendum to: A numerical investigation of optimum angles for solar energy receivers in the eastern part of Algeria

- Special Issue: Recent Trends in Renewable Energy Conversion and Storage Materials for Hybrid Transportation Systems

- Typical fault prediction method for wind turbines based on an improved stacked autoencoder network

- Power data integrity verification method based on chameleon authentication tree algorithm and missing tendency value

- Fault diagnosis of automobile drive based on a novel deep neural network

- Research on the development and intelligent application of power environmental protection platform based on big data

- Diffusion induced thermal effect and stress in layered Li(Ni0.6Mn0.2Co0.2)O2 cathode materials for button lithium-ion battery electrode plates

- Improving power plant technology to increase energy efficiency of autonomous consumers using geothermal sources

- Energy-saving analysis of desalination equipment based on a machine-learning sequence modeling