Abstract

The importance of diversified energy production lies in addressing the fuel shortage resulting from high prices, high temperatures, and environmental pollution associated with its production and consumption. Vibrational energy plays a crucial role in generating electrical power. This paper introduces a new concept based on utilizing the vibration forces of chimneys caused by wind and earthquakes. A mechatronic energy-absorbing system was designed, analyzed, and the output power was calculated using SolidWorks and Matlab programs. The design of the Regenerative Damping Chimney (RDC) primarily focuses on converting vibrations into rotational movement of the chimney, which is generated by wind forces. This is achieved by using a metal rope and pulleys to transmit motion to a set of gears. The opposite direction rotation is facilitated by bevel gears and clutches, and a planetary gearbox is employed to increase the rotation of the DC 24 V 400 W generator. The use of a high-watt generator aims to enhance energy production and the damping factor, ensuring the stability of the chimney during storms and vortex winds. The results show the efficiency of 35 % may reach 45 % watts under test to verify that the proposed system is effective and suitable for chimneys and renewable energy applications in factories and companies.

1 Introduction

Nowadays, energy is one of the primary drivers for the economic development of any country (Mann and Singh 2020). The increasing demand for fossil fuels has resulted in rising prices. As a result, many researchers have shifted their focus to renewable energy technologies instead of fossil fuel research. This shift is motivated by various factors, including the release of toxic gases and the generation of high heat through the consumption of fuels, such as the combustion of vehicle engine fuels, which contributes to severe environmental pollution (Abdulwasea et al. 2022; Salman et al. 2022). Increased fossil fuel consumption and the consequent environmental pollutants have served as the primary driving force behind research on renewable energies (Habibollahzade et al. 2018). Power generation technology based on renewable energy resources has emerged as a new trend in energy utilization (Maia et al. 2013; Xu et al. 2011). The energy source of vehicles is changing rapidly and significantly in recent years with the increase in renewable energy technologies, especially in the case of electric vehicles (EVs) (Salman et al. 2018; Zhang et al. 2016). There are many energy regenerative systems kinds based on various energies, energy-regenerative suspension using a rotary DC motor as an actuator was proposed by Suda and Shiiba (2007) and Zhang, Cao, and Yu (2012). The solar chimney power plant is a simple solar thermal power plant that is capable of converting solar energy into thermal energy in the solar collector. The solar chimney power plant with 350 m chimney height and 1000 m collector diameter can produce a monthly average of 1–2 MW electric power over a year (Sangi 2012).

As an effective way to protect the environment and save energy in buildings, the passive ventilation method has generated intense interest in improving the indoor thermal environment in recent years. Among these passive ventilation solutions (Andersen 1995), the design of solar chimneys in buildings is a promising approach for guiding natural ventilation orderly (Jianliu and Weihua 2013). Many studies about solar chimneys have mainly focused on achieving a better ventilation performance both experimentally and theoretically in ideal conditions (Zha, Zhang, and Qin 2017). The method of using solar radiation to enhance natural ventilation appeared in the 16th century in Italy, and scholars have made researched theoretical models, numerical simulations, and experiments with solar chimney (Zha, Zhang, and Qin 2017). The force of the wind dramatically affects the chimneys, so it generates high stress, especially if the chimney’s height is tall (Elias, Matsagar, and Datta 2016). When compared to rigid reinforced concrete chimneys, industrial steel chimneys prove to be more susceptible to aerodynamic excitation (Kuras et al. 2016). An original vibrational energy harvesting device concerning vibrational performance, the device was confirmed to have successfully harvested the vibrational energy of the cable in several directions on its radial plane, showing good prospects in supplying power (Wang et al. 2018). In measurements at four steel stacks and fatigue calculations in Germany, the real vortex-induced cross-wind vibration amplitude collectives have been measured (Lupi, Niemann, and Höffer 2017; Ruscheweyh, Langer, and Verwiebe 1998). Some solar chimney has been widely used in industry for solar heating and cooling and in power generation (Li, Liu, and Shukla 2016; Oró et al. 2012). Energy harvesting using non-traditional media has also been reported. Jia et al. designed a human kinetic energy harvesting device based on liquid metal magneto hydrodynamic (Jia, Liu, and Zhou 2009). The design of a lightweight wearable Bowden-cable-actuated soft exoskeleton robot with energy harvesting capability (Shi et al. 2022).

The aims of this paper is that the wind’s force dramatically affects the chimneys; this leads to high stress, especially if the chimney’s height is large (Wang et al. 2020). The damping of the wind force resulting from storms and earthquakes affects the chimneys. For this reason, the importance of damping the chimneys to prevent the chimney from bending or collapsing is paramount, as we see the results in one of the previous research projects, where the measurements made from verification of the dynamic characteristics of a new steel chimney structure with a height of 60 m. Where the vibrational kinetic energy is utilized to produce energy and is used in lighting and operating the sensors, and managing the cameras, the main element for converting the vibrating movement into a rotational motion is the metal ropes and balls (Shi et al. 2022). A continuous aero elastic chimney model with the DEVCON plastic steel liquid (Liang et al. 2018). The design has undergone several tests using (Solid work and MATLAB) programs. These values vary according to the location of the chimney in the world due to the difference in wind speed and weather (John et al. 2011; Menon and Rao 1997).

An energy-harvesting shock absorber that uses a barrel cam follower mechanism to convert vehicle suspension system vibration into electrical power (Ali et al. 2021). Yuhua proposes a self-powered rail corrugation monitor. An improved energy harvester detected defects from rail vibrations using wavelets, enabling sustainable monitoring without batteries or manual work (Sun 2020). Cheng liang uses an HC-EH to power safety monitoring sensors for freight trailers on heavy railways. The HC-EH has three modules and stores energy in supercapacitors by converting motion into unidirectional rotations. Its H-type structure prevents damage from impact force between couplings. Full-scale prototypes had a peak and average output power of 9.67 W and 5.14 W, respectively, with a peak efficiency of 56.49 %. The practical applications of the HC-EH in the Datong-Qinhuangdao Railway were also studied (Fan 2022). The research provides guidance for designing piezoelectric energy harvesters in railway systems for self-powered wireless sensor networks to ensure the train operation safety (Wang et al. 2015). This paper discusses energy harvesting solutions for railways, including vibration, wind, solar, thermal, magnetic field, and acoustic energy. Energy harvesting reduces costs in areas without access to electrical power supply and promotes green and intelligent railways. The paper covers design and realization of energy harvesters, technical challenges, and future research directions (Zuo 2022). Reviews dual-function devices that combine vibration control and energy harvesting, covering the concept, designs, feasibility studies, and potential applications (Cai 2021), an energy harvesting mechanism that uses a mechanical vibration rectifier (MVR) to power the freight train track monitoring network. The MVR has four modules and the MVR can generate up to 28.0416 W of power with a mechanical efficiency of 75.92 % (Liu et al. 2022).

The rest of this paper is organized as follows. The system architecture in Section 2, the design system is described in Section 3, dynamic analysis of RDCs and analysis of the generator in Section 4, data experimental and simulation results in Section 5; finally, the collusions is given in Section 6.

2 System architecture

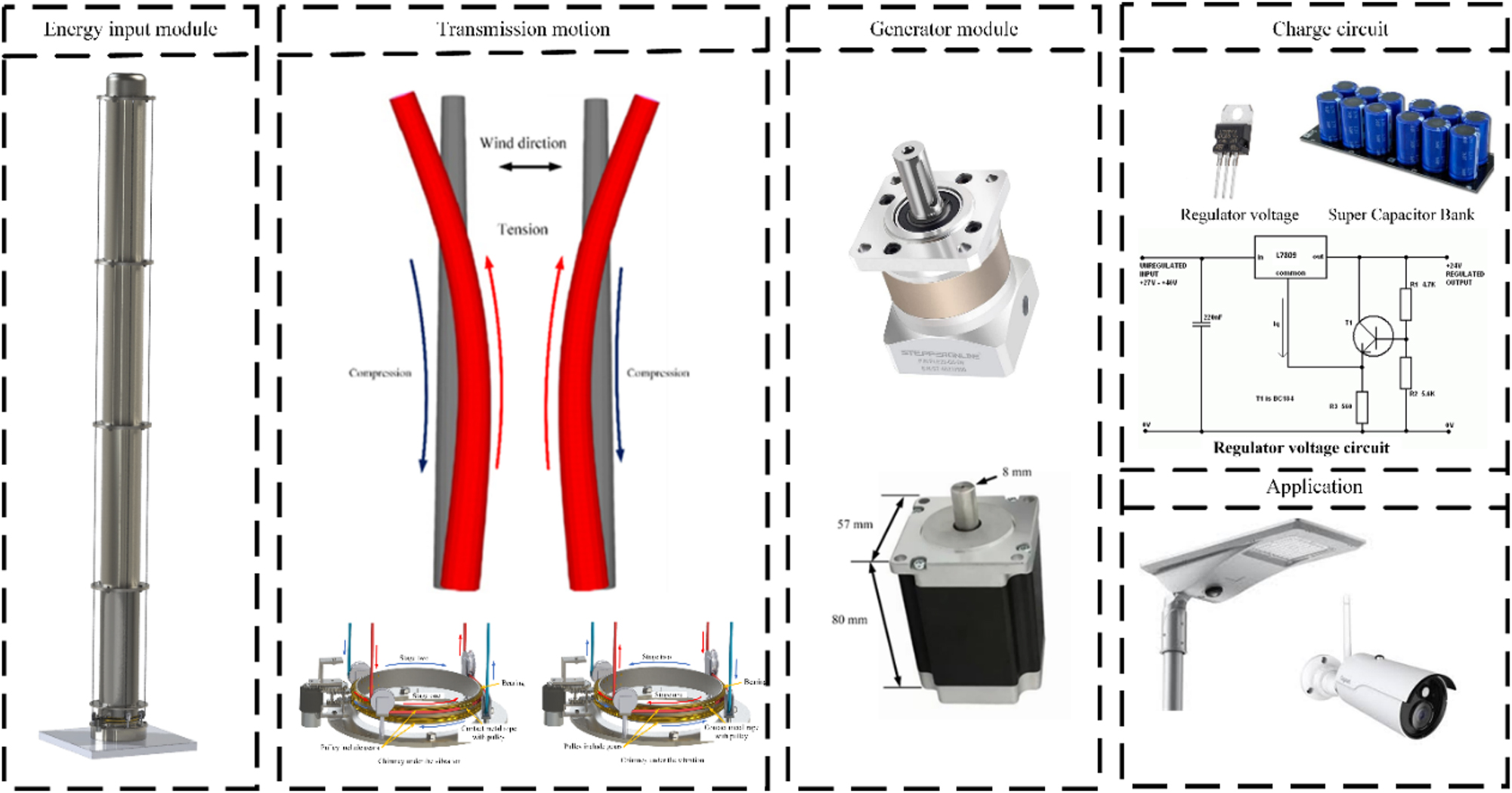

Wind energy is not only derived from the kinetic energy of the wind using wind turbines to generate electrical energy but is also considered a form of electromechanical energy. It is a widely utilized type of renewable energy that serves as an alternative to fossil fuels. Wind energy is abundant and renewable, although its availability varies from one location to another. It is a clean source of energy that does not emit greenhouse gases during operation. The required land area for wind energy installations varies depending on the size of the plant and the type of towers utilized. The first electric windmill was constructed in Scotland in July 1887 by Professor James Blyth of Anderson College in Glasgow. These windmills were employed to charge batteries developed by Frenchman Camille Alphonse Faure, enabling the lighting of a hut through wind-powered electricity. This milestone marked the first instance of a house being illuminated using wind energy (Price 2005). In this paper, the mechatronic energy-absorber comprises five main components. The first component is the energy input module, followed by the transmission motion module, which utilizes pulleys, belts, and a gearbox to convert linear motion into rotational motion. This rotation then activates the electric generator, harnessing the kinetic energy from wind-induced vibrations. The third component is the generator module, consisting of a pair of three-phase generators. These generators are integrated into the new design of the wind chimney device, allowing for increased power output. The fourth component is the charge circuit, which includes a circuit for charging a battery along with a capacitor. This circuit incorporates a power supply that can be connected to both the capacitor and the battery. It is designed to capture a voltage of 180 V, but can be easily scaled up to higher voltages and currents by using suitable components. Lastly, the application of this energy is explored in various areas, such as battery charging and the operation of surveillance cameras. It can also be utilized for night lights. The system includes an electronic switch connected to the power supply, as depicted in Figure 1.

Details of the chimney and its surrounding environment.

3 System design

3.1 Design of the kinetic wind energy

The Regenerative Damping Chimney (RDC) is a novel concept that can be implemented in companies with chimneys. Based on research conducted using SolidWorks and MATLAB, the proposed design has the potential to be highly effective in supplying energy for various applications. These applications include battery charging, operating surveillance cameras, powering night lights, and even enabling remote monitoring systems for weather stations and earthquakes. The idea for this research was born out of the importance of energy production in addressing fuel shortages caused by high fuel prices, high temperatures, and environmental pollution. The energy harvesting process in this study relies on converting the linear motion generated by the wind into rotational motion to activate the generator, utilizing the kinetic energy. This function is distinct from other components, as depicted in Figure 2. The transmission motion relies on the use of pulleys, metal ropes, and a gearbox.

Regenerative damping chimney.

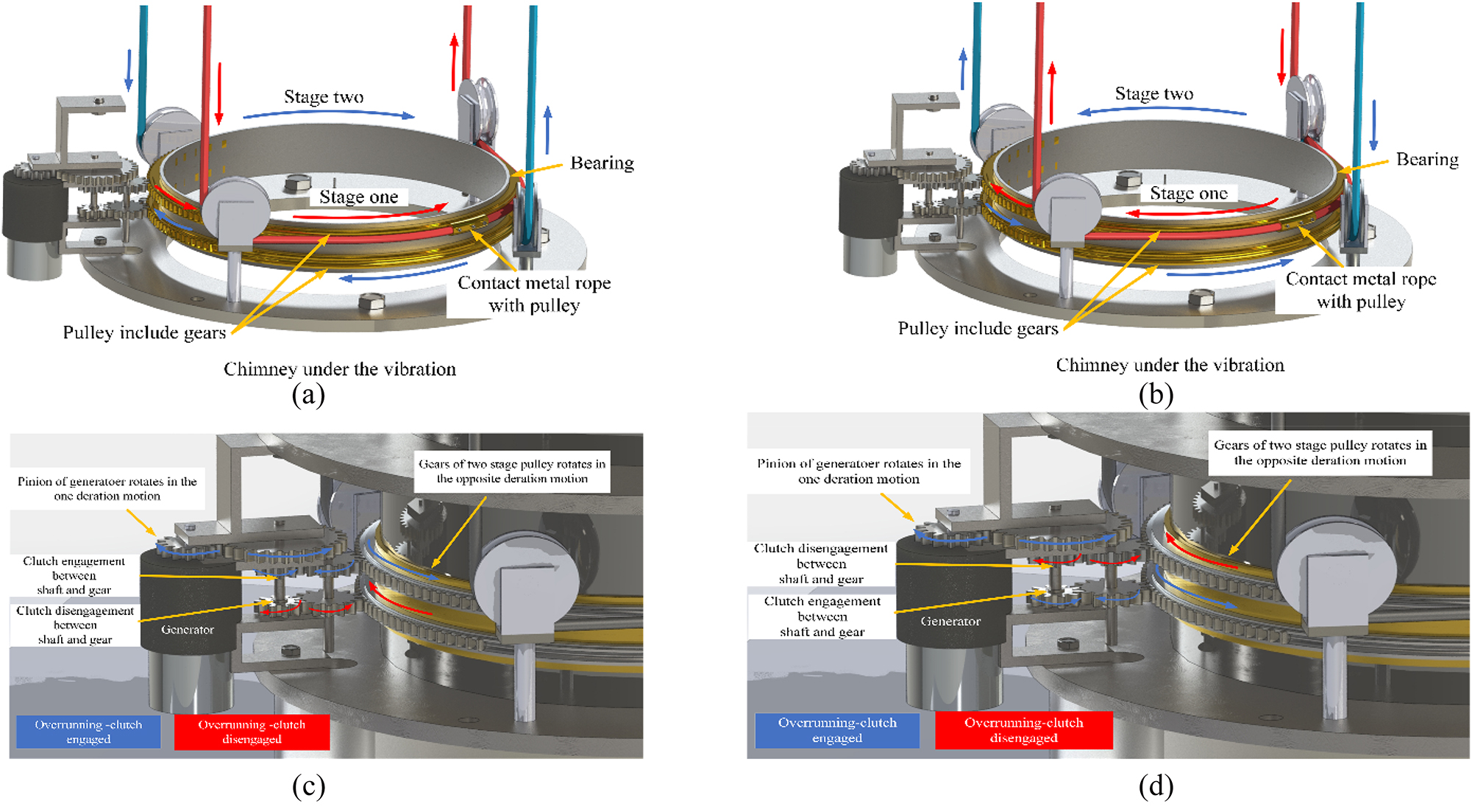

3.2 Transmission module

The working mechanism of this system is unique as it employs a new design of pulleys. One side of the pulley is connected to metal ropes, while the other side features a half gear. The pulleys are utilized to transmit movement along the perimeter of the chimney, diagonally from the bottom. When subjected to wind force, the chimney bends in the opposite direction, resulting in a change in the length of the ropes. This change in rope length is leveraged to rotate the generator. Metal ropes are installed on the chimney’s wall perimeter to ensure that they remain parallel to the chimney wall and follow a path opposite to the rollers, extending from the bottom of the chimney to the upper surface. Please refer to Figure 3(a and b) for visual representation. Then the resulting reciprocating then we used the gearbox to unify the move to only one direction and then to the generator, as shown in Figure 3(c and d).

Transmission module.

3.3 Wind-induced vibrations

The wind force has a significant impact on the height of the chimney. Therefore, damping is crucial to ensure the structural integrity and prevent bending or collapse. In this study, measurements were taken and analyzed for a 60-m-high steel chimney. The system was installed and fine-tuned to control vibrations. Specifically, the guidance system was adjusted to restrict movement in a single direction. The maximum displacement recorded for the chimney was more than 60 mm in both positive and negative directions. These observations were made for a chimney with a length of 28 m, under varying wind speeds and directions (Kuras et al. 2016). Wind-induced vibration refers to the dynamic response of engineering structures when subjected to vibrations caused by fluctuating wind forces For chimney engineering structures, the fundamental natural vibration period is longer due to their lower stiffness.

4 Dynamic analysis of RDCs

4.1 Dynamic analysis of chimney

This part will explain the dynamic analysis of the chimney when it undergoes wind or seismic effects. The proposed generator technique divides the outer circumstance of the chimney into four quarters; at the end of each quarter, there is a fastened rope point at the top of the chimney. At each time, there is one rope (at least, or two at most according to wind direction) in tension and the opposite direction rope in looseness. So, a dynamic analysis will explore one side rope located on the bending side of the chimney. Related to Newton’s second low ΣF = ma, the combination of the forces that affect the tip of the chimney can be elaborated in the following equation (Cai 2021; Liu et al. 2022):

where F is the component of wind force that is perpendicular on the chimney and robe movement direction which dependent on wind velocity, m is the vibrated mass of the total chimney mass M, c the damping coefficient of the structure, k the stiffness, x is the displacement of the chimney top. Figure 4 describes the effect of the wind on the chimney and the changes that be happened on the rob in the bending side. The solution of the second-order Equation (1) relative to the displacement of vibration x is as follows:

where X is the oscillation amplitude, ω is the oscillation frequency, and φ is the phase difference of the displacement with respect to the exciting force.

The chimney under different wind conditions. (a) The chimney without wind effect, (b) the chimney undergoes wind effect.

The amplitude is as follows:

and

where ω is natural frequency of chimney and equals to

where y is the rob displacement, as shown in Figure 5, l is the rob length at the stillness of wind, and L is the rope length undergoes the wind blows. The L is calculated as follows:

System of pulley.

The velocity of rope drawing can be calculated form the deriving Equation (5), as following:

Due to the possibility that the chimney’s high vibration would result in rope slack, we installed a spiral spring tension-type to stop it. As shown in Figure 5.

4.2 Analysis of the generator

The power generation design includes a generator fixed in the lower cylinder of the regenerative damping chimney using a fixture rope, metal rope, and flange. It undergoes reciprocating up and down motion, converting the two different rotations into a unidirectional rotary motion. Figure 6 illustrates the power generator design, which utilizes this unidirectional rotation to generate power. For power generation, a DC brushless motor was chosen for its small size, lighter weight, high reliability, and low maintenance. It has no brushes, a simple construction, and low rotor inertia. The specific generator model selected for this study is 57BL75S10-230TF9. The parameters of the regenerative damping chimney are provided in Table 1.

Circuit diagram for the rectifier with DC generators.

The parameters for the AR series AC hybrid servo motor | oriental motor.

| Parameter | Value |

|---|---|

| Rated voltage | 24–80 V |

| Rated speed | 2000 rpm |

| Rated torque | 4 N m |

| Internal inductance | 4 mH |

| Rotor inertia | 0.4 kg cm2 |

| Rated power | 200 W |

| Max current per phase | 4 A |

| Internal resistor | 1.2 Ω |

| Product size | 54 × 54 × 82 mm |

| Back electromotive voltage constant | 0.12 V s/rad |

| Steps/rev | 200 |

The power generation design includes a generator fixed in the lower cylinder of the regenerative damping chimney using a fixture rope, metal rope, and flange. It undergoes reciprocating up and down motion, converting the two different rotations into a unidirectional rotary motion. Figure 6 illustrates the power generator design, which utilizes this unidirectional rotation to generate power. For power generation, a DC brushless motor was chosen for its small size, lighter weight, high reliability, and low maintenance. It has no brushes, a simple construction, and low rotor inertia. The specific generator model selected for this study is 57BL75S10-230TF9. The parameters of the regenerative damping chimney are provided in Table 1.

where I and R are the internal and external resistance of the generator, respectively.

Equation (8) describes the rotary damping coefficient of a generator connected to a charging circuit based on the parameters of the generator.

4.3 Linear modeling

To define the linear damping coefficient (L

d

), the proposed shock absorber is subjected to a displacement x, where

where

where P f is the friction power loss in the rack pinion, and P g is the generator power.

where ω g is the angular velocity of the generator, and P g is the generator power, which is given by,

where η p is the efficiency of pulley, and η sg is the efficiency of the spur gears, and η pg is the efficiency of planetary gears, and η g is the efficiency of the generator.

(RDCs) subjected to a general input excitation.

Substituting Equation (9) and Equation (11) into Equation (12), we arrive at:

The rotational motion converted from linear motion from the pulley include half gear is expressed as:

where ω

p

is the angular velocity of the rack pinion,

As shown in Figure 8, there is an input excitation acting on the proposed absorber. The exciting force is defined using the Lagrange formulation as:

where x is the displacement, D is the damping energy, and T is the kinetic effect, which is determined from:

where m rope is the mass of rope, and J p , J s , J sg , J pg , J g are the inertias of the pulley, shaft, spur gears, planetary gears, and generator, respectively.

Where the chimney head moves with a distance of 1–100 mm and a frequency from 5.5 Hz to 165 Hz.

Substituting Equations (15) into Equation (18), T can be expressed as:

However, the damping effect D can be expressed as:

Therefore, substituting Equations (19) and (20) in Equation (17):

According to Newton’s third law, the damping force F D is equal to the exciting force F:

5 SIMULINK

5.1 Data input

The wind significantly impacts the strength of the chimney, causing it to bend in the direction of the wind force. This bending results in high-frequency vibrations and displacements of over 200 mm in the natural atmosphere. The analysis of the wind effects on the chimney under normal conditions, as shown in Figure 4(a and b), revealed frequency values ranging from 5.5 Hz to 165 Hz and displacements ranging from 1 to 100 mm in natural wind conditions. For more detailed information, refer to the source. Focusing on Figure 4(b), we observe the variable effect of wind force on the chimney, starting from 20 mm, then decreasing to 18 mm, and finally increasing to 60 mm. The optimal location for damping is at the highest point of the chimney, as depicted in Figure 6, as this area is more prone to vibrations. It is worth noting that multiple dampers can be installed if the chimney is exceptionally long, thereby increasing the energy harvest for the innovative device.

5.2 Realest

After using the actual data from the source, where variable distances and frequencies were selected and the results were when using the distance 18 mm and the frequency was 5.5 Hz, we obtained a voltage of 14.5 V as in the diagram (3, a). And we used a Figure 10(a) of 20 mm and a frequency of 10 Hz, we got a voltage of 26 V, as in the Figure 10(b) (3, b). We used a distance of 25 mm and a frequency of 15 Hz, and we got 180 V as in the Figure 10(c) (3, c). On the other hand, we will fix the distance and change the frequency, as a distance of 25 mm was taken with a number of frequencies (5.5, 10, 15) Hz as in Figure 8. We notice an increase in the potential difference as a result of the frequency change, even if the distance is proven, evidence that the speed of Wind is a direct relationship with the potential difference.

On the other hand, tests were conducted about the damping of the wind force and speed as a result of generating energy. An impedance will be generated that reverses the speed and direction of the wind, which maintains the life of the chimney, and this was proven by the system that was built in MATLAB SIMULINK. From the input relationship to distance and frequency, the damping force was calculated through which the speed resistance Wind and storms, and making the chimney more stable, as a fixed distance of 25 mm and variable frequencies (5.5, 10, 15) Hz were introduced, and we obtained a variable damping force where the value of the damping force was (10 kN) at a frequency of 5.5 Hz. And the value of the damping force (20 kN) at a frequency of 10 Hz. And the value of the wind damping force (40 kN) at a frequency of 15 Hz. According to the results we obtained in Table 2, the relationship between wind speeds and damping force is direct, and this is what we need in order to maintain the strength of the chimney at any increase in wind speed, storms and earthquakes, as shown in Figure 9a–c (Figure 10, Tables 2 and 3).

The relationship between the force and time from the simulation of 10 Hz, 5.5 Hz, 0.15 Hz and distance of 25 mm.

Output voltage of the wind chimney in: (a) frequency 5.5 Hz; (b) frequency 10 Hz; (c) frequency 15 Hz, and distance is 25 mm.

The deferent between frequencies and the power with 18 mm, 20 mm, and 25 mm of displacement.

| Displacement | Frequencies | Power |

|---|---|---|

| 18 mm | 5.5 Hz | 14.5 V 3a |

| 20 mm | 10 Hz | 26 V 3b |

| 25 mm | 15 Hz | 50 V 3c |

Comparison of the traditional damping chimney and (RDC).

| No. | Regenerative damping chimney | Traditional damping chimney |

|---|---|---|

| 1 | Dual function | One function |

| 2 | Damping and harvest energy | Damping |

| 3 | Used kinetic energy for damping | Using materials for damping |

| 4 | Good for steel chimney | Used for all |

| 5 | Damping dependent on load | Damping is constant |

| 6 | Use mechanism movement for example Gears and generators |

There are more types of materials, for example, water and rubber |

5.3 Applications of the regenerative damping chimney

The purpose of this paper, as depicted in Figure 2, is to address the significance of energy production in mitigating fuel shortages caused by high prices and environmental pollution. The focus of the study is on harnessing vibrational energy, presenting a novel approach to dampen the effects of wind forces and harness the energy that otherwise leads to chimney collapse during storms and earthquakes. The research involved the design and analysis of power output using software programs such as Solidworks and Matlab. The design of the regenerative damping chimney primarily aims to convert vibrations into rotational movement, which is induced by wind forces. This is achieved through the utilization of metal ropes and pulleys for transmitting motion. The opposite-direction rotation is facilitated by employing bevel gears and clutches. Additionally, the use of a planetary gearbox increases the generator’s rotational speed, resulting in a DC 24 V 400 W power output.

5.4 Comparison of the traditional damping chimney and (RDC)

We can assess the significance of our work through the comparison made between the traditional damper and the energy harvesting damper in Table 3.

6 Conclusions

The concept of regenerative damping chimney is a novel idea that can be implemented in chimneys. It has been discovered that sustainable energy can be obtained for applications such as night lighting or powering sensors and monitoring cameras. This paper not only emphasizes the significance of damping chimneys in relation to wind speed and earthquakes but also introduces a new model for energy harvesting in chimneys, employing innovative methods and technologies. The designed model was subjected to testing using the SolidWorks program, and energy and efficiency equations were calculated, resulting in an efficiency rating of 55 %. The system’s harvesting capacity reached an impressive 750 W. Based on the experiment, it was concluded that the amount of captured energy is directly influenced by wind speed. There are opportunities for further research and the exploration of new approaches in this field. The presented idea holds great promise for researchers in the realm of energy harvesting in chimney damping. Overall, this groundbreaking concept opens up exciting possibilities for harnessing renewable energy and demonstrates the potential of chimneys as a valuable source of sustainable power.

This concept represents a novel approach to mitigate the impact of wind forces and harness the energy that can lead to chimney collapse during storms and earthquakes. The power output of the designed system was analyzed and calculated using programs such as Solidworks and Matlab. The regenerative damping chimney design primarily focuses on converting vibrations caused by wind forces into rotational movement using metal ropes, pulleys, bevel gears, and clutches. Furthermore, the incorporation of a planetary gearbox increases the rotational speed of the DC 24 V 400 W generator. The use of a high-watt generator serves two purposes: it enhances the energy generation capacity and improves the damping factor, thereby ensuring the stability of the chimney during storms and vortex winds. By effectively converting vibrations into rotational motion and generating electrical energy, this innovative design aims to prevent chimney damage and promote sustainable energy utilization.

Acknowledgments

The Iraqi Ministry of Education, Iraqia University, the Iraqi railway station.

-

Research ethics: We declare that declare the manuscript has not been published before not submitted to another journal for the consideration of publication.

-

Author contributions: Waleed Salman: Conceptualization, Methodology, Software, Writing – Original Draft; Ayad M. Kwad: Conceptualization, Methodology, Software; Al-othmani Abdulwasea: Writing - Review & Editing; Ahmed S Abdulghafour: Writing - Review & Editing, Visualization.

-

Competing interests: The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported in this paper.

References

Abdulwasea, A. O., L. Li, W. S. Mohammed, and A. S. Abdulghafour. 2022. “Regenerative Shock Absorber Using Cylindrical Cam and Slot Motion Conversion.” Energy Harvesting and Systems 9 (2): 1–13, https://doi.org/10.1515/EHS-2021-0074/MACHINEREADABLECITATION/RIS.Search in Google Scholar

Andersen, K. T. 1995. “Theoretical Considerations on Natural Ventilation by Thermal Buoyancy.” ASHRAE Transactions 38 (11): 56–87, https://doi.org/10.2172/814402.Search in Google Scholar

Ali, A., L. Qi, T. Zhang, H. Li, and A. Azam. 2021. “Design of Novel Energy-Harvesting Regenerative Shock Absorber Using Barrel Cam Follower Mechanism to Power the Auxiliaries of a Driverless Electric Bus.” Sustainable Energy Technologies and Assessments 48. https://doi.org/10.1016/j.seta.2021.101565.Search in Google Scholar

Cai, Q. 2021. “The Nexus between Vibration-Based Energy Harvesting and Structural Vibration Control.” A Comprehensive Review 155. https://doi.org/10.1016/j.rser.2021.111920.Search in Google Scholar

Elias, S., V. Matsagar, and T. K. Datta. 2016. “Effectiveness of Distributed Tuned Mass Dampers for Multi-Mode Control of Chimney under Earthquakes.” Engineering Structures 124: 1–16. https://doi.org/10.1016/J.ENGSTRUCT.2016.06.006.Search in Google Scholar

Fan, C. 2022. “An H-Shaped Coupler Energy Harvester for Application in Heavy Railways.” Energy 270. https://doi.org/10.1016/j.energy.2023.126854.Search in Google Scholar

Habibollahzade, A., E. Houshfar, M. Ashjaee, A. Behzadi, E. Gholamian, and H. Mehdizadeh. 2018. “Enhanced Power Generation through Integrated Renewable Energy Plants: Solar Chimney and Waste-To-Energy.” Energy Conversion and Management 166: 48–63. https://doi.org/10.1016/J.ENCONMAN.2018.04.010.Search in Google Scholar

Jianliu, X., and L. Weihua. 2013. “Study on Solar Chimney Used for Room Natural Ventilation in Nanjing.” Energy and Buildings 66: 467–9. https://doi.org/10.1016/J.ENBUILD.2013.07.036.Search in Google Scholar

Jia, D., J. Liu, and Y. Zhou. 2009. “Harvesting Human Kinematical Energy Based on Liquid Metal Magnetohydrodynamics.” Physics Letters A 15 (373): 1305–9. https://doi.org/10.1016/J.PHYSLETA.2009.02.028.Search in Google Scholar

John, A. D., A. Gairola, E. Ganju, and A. Gupta. 2011. “Design Wind Loads on Reinforced Concrete Chimney – An Experimental Case Study.” Procedia Engineering 14: 1252–7. https://doi.org/10.1016/J.PROENG.2011.07.157.Search in Google Scholar

Kuras, P., Ł. Ortyl, T. Owerko, R. Kocierz, M. Kędzierski, and P. Podstolak. 2016. “Analysis of Effectiveness of Steel Chimneys Vibration Dampers Using Surveying Methods.” JISDM: 1–8.Search in Google Scholar

Lupi, F., H. J. Niemann, and R. Höffer. 2017. “A Novel Spectral Method for Cross-Wind Vibrations: Application to 27 Full-Scale Chimneys.” Journal of Wind Engineering and Industrial Aerodynamics 171: 353–65. https://doi.org/10.1016/J.JWEIA.2017.10.014.Search in Google Scholar

Li, Y., S. Liu, and A. Shukla. 2016. “Experimental Analysis on Use of Thermal Conductivity Enhancers (TCEs) for Solar Chimney Applications with Energy Storage Layer.” Energy and Buildings 116: 35–44. https://doi.org/10.1016/J.ENBUILD.2015.12.049.Search in Google Scholar

Liang, S., W. Yang, J. Song, L. Wang, and G. Hu. 2018. “Wind-induced Responses of a Tall Chimney by Aeroelastic Wind Tunnel Test Using a Continuous Model.” Engineering Structures 176: 871–80. https://doi.org/10.1016/J.ENGSTRUCT.2018.09.015.Search in Google Scholar

Liu, G., Z. Fang, Z. Zhang, X. Tan, C. Dai, X. Wu, Z. Jin, and D. Li. 2022. “A Vibration Energy Harvester for Freight Train Track Self.” iScience 25: 105155. https://doi.org/10.1016/j.isci.2022.105155.Search in Google Scholar PubMed PubMed Central

Mann, H. S., and P. K. Singh. 2020. “Energy Recovery Ducted Turbine (ERDT) System for Chimney Flue Gases – A CFD Based Analysis to Study the Effect of Number of Blade and Diffuser Angle.” Energy 213: 118501. https://doi.org/10.1016/J.ENERGY.2020.118501.Search in Google Scholar

Maia, C. B., J. O. Castro Silva, L. Cabezas-Gómez, S. M. Hanriot, and A. G. Ferreira. 2013. “Energy and Exergy Analysis of the Airflow Inside a Solar Chimney.” Renewable and Sustainable Energy Reviews 27: 350–61. https://doi.org/10.1016/J.RSER.2013.06.020.Search in Google Scholar

Menon, D., and P. S. Rao. 1997. “Estimation of Along-Wind Moments in RC Chimneys.” Engineering Structures 19 (1): 71–8. https://doi.org/10.1016/S0141-0296(96)00041-7.Search in Google Scholar

Oró, E., A. de Gracia, A. Castell, M. M. Farid, and L. F. Cabeza. 2012. “Review on Phase Change Materials (PCMs) for Cold Thermal Energy Storage Applications.” Applied Energy 99: 513–33. https://doi.org/10.1016/J.APENERGY.2012.03.058.Search in Google Scholar

Price, T. J. 2005. “James Blyth — Britain’s First Modern Wind Power Pioneer.” Wind Engineering 29 (3): 1–10, https://doi.org/10.1260/030952405774354921.Search in Google Scholar

Ruscheweyh, H., W. Langer, and C. Verwiebe. 1998. “Long-term Full-Scale Measurements of Wind Induced Vibrations of Steel Stacks.” Journal of Wind Engineering and Industrial Aerodynamics 74–76: 777–83. https://doi.org/10.1016/S0167-6105(98)00070-1.Search in Google Scholar

Salman, W., X. Zhang, H. Li, X. Wu, A. Azam, and Z. Zhang. 2022. “A Novel Energy Regenerative Shock Absorber for In-Wheel Motors in Electric Vehicles.” Mechanical Systems and Signal Processing 181: 109488. https://doi.org/10.1016/J.YMSSP.2022.109488.Search in Google Scholar

Salman, W., L. Qi, X. Zhu, H. Pan, X. Zhang, S. Bano, Z. Zhang, and Y. Yuan. 2018. “A High-Efficiency Energy Regenerative Shock Absorber Using Helical Gears for Powering Low-Wattage Electrical Device of Electric Vehicles.” Energy 159: 361–72. https://doi.org/10.1016/J.ENERGY.2018.06.152.Search in Google Scholar

Suda, Y., and T. Shiiba. 2007. “A New Hybrid Suspension System with Active Control and Energy Regeneration.” Vehicle System Dynamics 25 (Suppl.): 641–54, https://doi.org/10.1080/00423119608969226.Search in Google Scholar

Sangi, R. 2012. “Performance Evaluation of Solar Chimney Power Plants in Iran.” Renewable and Sustainable Energy Reviews 16 (1): 704–10. https://doi.org/10.1016/J.RSER.2011.08.035.Search in Google Scholar

Shi, Y., M. Guo, H. Zhong, X. Ji, D. Xia, X. Luo, and Y. Yang. 2022. “Kinetic Walking Energy Harvester Design for a Wearable Bowden Cable-Actuated Exoskeleton Robot.” Micromachines 13 (4): 571, https://doi.org/10.3390/MI13040571.Search in Google Scholar

Sun, Y. 2020. “Rail Corrugation Inspection by a Self-Contained Triple-Repellent Electromagnetic Energy Harvesting System.” Applied Energy 286: 116512. https://doi.org/10.1016/j.apenergy.2021.116512.Search in Google Scholar

Wang, H., C. He, S. Lv, and H. Sun. 2018. “A New Electromagnetic Vibrational Energy Harvesting Device for Swaying Cables.” Applied Energy 228: 2448–61, https://doi.org/10.1016/J.APENERGY.2018.07.059.Search in Google Scholar

Wang, J., Z. Shi, H. Xiang, and G. Song. 2015. “Modeling on Energy Harvesting from a Railway System Using Piezoelectric Transducers.” Smart Materials and Structures 24: 105017. https://doi.org/10.1088/0964-1726/24/10/105017.Search in Google Scholar

Wang, S., J. Zhang, J. Li, F. Kong, and J. Fan. 2020. “Analysis of Vibration Attenuation and Energy Consumption of Blasting Demolition Chimney: A Case Study.” Technical Gazette 27: 826–34. https://doi.org/10.17559/TV-20200225022727.Search in Google Scholar

Xu, G., T. Ming, Y. Pan, F. Meng, and C. Zhou. 2011. “Numerical Analysis on the Performance of Solar Chimney Power Plant System.” Energy Conversion and Management 52 (2): 876–83. https://doi.org/10.1016/J.ENCONMAN.2010.08.014.Search in Google Scholar

Zhang, Z., X. Zhang, W. Chen, Y. Rasim, W. Salman, H. Pan, Y. Yuan, and C. Wang. 2016. “A High-Efficiency Energy Regenerative Shock Absorber Using Supercapacitors for Renewable Energy Applications in Range Extended Electric Vehicle.” Applied Energy 178: 177–88. https://doi.org/10.1016/J.APENERGY.2016.06.054.Search in Google Scholar

Zhang, G., J. Cao, and F. Yu. 2012. “Design of Active and Energy-Regenerative Controllers for DC-Motor-Based Suspension.” Mechatronics 22 (8): 1124–34. https://doi.org/10.1016/J.MECHATRONICS.2012.09.007.Search in Google Scholar

Zha, X., J. Zhang, and M. Qin. 2017. “Experimental and Numerical Studies of Solar Chimney for Ventilation in Low Energy Buildings.” Procedia Engineering 205: 1612–9. https://doi.org/10.1016/J.PROENG.2017.10.294.Search in Google Scholar

Zuo, J. 2022. “Energy Harvesting Solutions for Railway Transportation: A Comprehensive Review.” Renewable Energy 202: 56–87.10.1016/j.renene.2022.11.008Search in Google Scholar

© 2024 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Solar photovoltaic-integrated energy storage system with a power electronic interface for operating a brushless DC drive-coupled agricultural load

- Analysis of 1-year energy data of a 5 kW and a 122 kW rooftop photovoltaic installation in Dhaka

- Reviews

- Real yields and PVSYST simulations: comparative analysis based on four photovoltaic installations at Ibn Tofail University

- A comprehensive approach of evolving electric vehicles (EVs) to attribute “green self-generation” – a review

- Exploring the piezoelectric porous polymers for energy harvesting: a review

- A strategic review: the role of commercially available tools for planning, modelling, optimization, and performance measurement of photovoltaic systems

- Comparative assessment of high gain boost converters for renewable energy sources and electrical vehicle applications

- A review of green hydrogen production based on solar energy; techniques and methods

- A review of green hydrogen production by renewable resources

- A review of hydrogen production from bio-energy, technologies and assessments

- A systematic review of recent developments in IoT-based demand side management for PV power generation

- Research Articles

- Hybrid optimization strategy for water cooling system: enhancement of photovoltaic panels performance

- Solar energy harvesting-based built-in backpack charger

- A power source for E-devices based on green energy

- Theoretical and experimental investigation of electricity generation through footstep tiles

- Experimental investigations on heat transfer enhancement in a double pipe heat exchanger using hybrid nanofluids

- Comparative energy and exergy analysis of a CPV/T system based on linear Fresnel reflectors

- Investigating the effect of green composite back sheet materials on solar panel output voltage harvesting for better sustainable energy performance

- Electrical and thermal modeling of battery cell grouping for analyzing battery pack efficiency and temperature

- Intelligent techno-economical optimization with demand side management in microgrid using improved sandpiper optimization algorithm

- Investigation of KAPTON–PDMS triboelectric nanogenerator considering the edge-effect capacitor

- Design of a novel hybrid soft computing model for passive components selection in multiple load Zeta converter topologies of solar PV energy system

- A novel mechatronic absorber of vibration energy in the chimney

- An IoT-based intelligent smart energy monitoring system for solar PV power generation

- Large-scale green hydrogen production using alkaline water electrolysis based on seasonal solar radiation

- Evaluation of performances in DI Diesel engine with different split injection timings

- Optimized power flow management based on Harris Hawks optimization for an islanded DC microgrid

- Experimental investigation of heat transfer characteristics for a shell and tube heat exchanger

- Fuzzy induced controller for optimal power quality improvement with PVA connected UPQC

- Impact of using a predictive neural network of multi-term zenith angle function on energy management of solar-harvesting sensor nodes

- An analytical study of wireless power transmission system with metamaterials

- Hydrogen energy horizon: balancing opportunities and challenges

- Development of renewable energy-based power system for the irrigation support: case studies

- Maximum power point tracking techniques using improved incremental conductance and particle swarm optimizer for solar power generation systems

- Experimental and numerical study on energy harvesting performance thermoelectric generator applied to a screw compressor

- Study on the effectiveness of a solar cell with a holographic concentrator

- Non-transient optimum design of nonlinear electromagnetic vibration-based energy harvester using homotopy perturbation method

- Industrial gas turbine performance prediction and improvement – a case study

- An electric-field high energy harvester from medium or high voltage power line with parallel line

- FPGA based telecommand system for balloon-borne scientific payloads

- Improved design of advanced controller for a step up converter used in photovoltaic system

- Techno-economic assessment of battery storage with photovoltaics for maximum self-consumption

- Analysis of 1-year energy data of a 5 kW and a 122 kW rooftop photovoltaic installation in Dhaka

- Shading impact on the electricity generated by a photovoltaic installation using “Solar Shadow-Mask”

- Investigations on the performance of bottle blade overshot water wheel in very low head resources for pico hydropower

- Solar photovoltaic-integrated energy storage system with a power electronic interface for operating a brushless DC drive-coupled agricultural load

- Numerical investigation of smart material-based structures for vibration energy-harvesting applications

- A system-level study of indoor light energy harvesting integrating commercially available power management circuitry

- Enhancing the wireless power transfer system performance and output voltage of electric scooters

- Harvesting energy from a soldier's gait using the piezoelectric effect

- Study of technical means for heat generation, its application, flow control, and conversion of other types of energy into thermal energy

- Theoretical analysis of piezoceramic ultrasonic energy harvester applicable in biomedical implanted devices

- Corrigendum

- Corrigendum to: A numerical investigation of optimum angles for solar energy receivers in the eastern part of Algeria

- Special Issue: Recent Trends in Renewable Energy Conversion and Storage Materials for Hybrid Transportation Systems

- Typical fault prediction method for wind turbines based on an improved stacked autoencoder network

- Power data integrity verification method based on chameleon authentication tree algorithm and missing tendency value

- Fault diagnosis of automobile drive based on a novel deep neural network

- Research on the development and intelligent application of power environmental protection platform based on big data

- Diffusion induced thermal effect and stress in layered Li(Ni0.6Mn0.2Co0.2)O2 cathode materials for button lithium-ion battery electrode plates

- Improving power plant technology to increase energy efficiency of autonomous consumers using geothermal sources

- Energy-saving analysis of desalination equipment based on a machine-learning sequence modeling

Articles in the same Issue

- Solar photovoltaic-integrated energy storage system with a power electronic interface for operating a brushless DC drive-coupled agricultural load

- Analysis of 1-year energy data of a 5 kW and a 122 kW rooftop photovoltaic installation in Dhaka

- Reviews

- Real yields and PVSYST simulations: comparative analysis based on four photovoltaic installations at Ibn Tofail University

- A comprehensive approach of evolving electric vehicles (EVs) to attribute “green self-generation” – a review

- Exploring the piezoelectric porous polymers for energy harvesting: a review

- A strategic review: the role of commercially available tools for planning, modelling, optimization, and performance measurement of photovoltaic systems

- Comparative assessment of high gain boost converters for renewable energy sources and electrical vehicle applications

- A review of green hydrogen production based on solar energy; techniques and methods

- A review of green hydrogen production by renewable resources

- A review of hydrogen production from bio-energy, technologies and assessments

- A systematic review of recent developments in IoT-based demand side management for PV power generation

- Research Articles

- Hybrid optimization strategy for water cooling system: enhancement of photovoltaic panels performance

- Solar energy harvesting-based built-in backpack charger

- A power source for E-devices based on green energy

- Theoretical and experimental investigation of electricity generation through footstep tiles

- Experimental investigations on heat transfer enhancement in a double pipe heat exchanger using hybrid nanofluids

- Comparative energy and exergy analysis of a CPV/T system based on linear Fresnel reflectors

- Investigating the effect of green composite back sheet materials on solar panel output voltage harvesting for better sustainable energy performance

- Electrical and thermal modeling of battery cell grouping for analyzing battery pack efficiency and temperature

- Intelligent techno-economical optimization with demand side management in microgrid using improved sandpiper optimization algorithm

- Investigation of KAPTON–PDMS triboelectric nanogenerator considering the edge-effect capacitor

- Design of a novel hybrid soft computing model for passive components selection in multiple load Zeta converter topologies of solar PV energy system

- A novel mechatronic absorber of vibration energy in the chimney

- An IoT-based intelligent smart energy monitoring system for solar PV power generation

- Large-scale green hydrogen production using alkaline water electrolysis based on seasonal solar radiation

- Evaluation of performances in DI Diesel engine with different split injection timings

- Optimized power flow management based on Harris Hawks optimization for an islanded DC microgrid

- Experimental investigation of heat transfer characteristics for a shell and tube heat exchanger

- Fuzzy induced controller for optimal power quality improvement with PVA connected UPQC

- Impact of using a predictive neural network of multi-term zenith angle function on energy management of solar-harvesting sensor nodes

- An analytical study of wireless power transmission system with metamaterials

- Hydrogen energy horizon: balancing opportunities and challenges

- Development of renewable energy-based power system for the irrigation support: case studies

- Maximum power point tracking techniques using improved incremental conductance and particle swarm optimizer for solar power generation systems

- Experimental and numerical study on energy harvesting performance thermoelectric generator applied to a screw compressor

- Study on the effectiveness of a solar cell with a holographic concentrator

- Non-transient optimum design of nonlinear electromagnetic vibration-based energy harvester using homotopy perturbation method

- Industrial gas turbine performance prediction and improvement – a case study

- An electric-field high energy harvester from medium or high voltage power line with parallel line

- FPGA based telecommand system for balloon-borne scientific payloads

- Improved design of advanced controller for a step up converter used in photovoltaic system

- Techno-economic assessment of battery storage with photovoltaics for maximum self-consumption

- Analysis of 1-year energy data of a 5 kW and a 122 kW rooftop photovoltaic installation in Dhaka

- Shading impact on the electricity generated by a photovoltaic installation using “Solar Shadow-Mask”

- Investigations on the performance of bottle blade overshot water wheel in very low head resources for pico hydropower

- Solar photovoltaic-integrated energy storage system with a power electronic interface for operating a brushless DC drive-coupled agricultural load

- Numerical investigation of smart material-based structures for vibration energy-harvesting applications

- A system-level study of indoor light energy harvesting integrating commercially available power management circuitry

- Enhancing the wireless power transfer system performance and output voltage of electric scooters

- Harvesting energy from a soldier's gait using the piezoelectric effect

- Study of technical means for heat generation, its application, flow control, and conversion of other types of energy into thermal energy

- Theoretical analysis of piezoceramic ultrasonic energy harvester applicable in biomedical implanted devices

- Corrigendum

- Corrigendum to: A numerical investigation of optimum angles for solar energy receivers in the eastern part of Algeria

- Special Issue: Recent Trends in Renewable Energy Conversion and Storage Materials for Hybrid Transportation Systems

- Typical fault prediction method for wind turbines based on an improved stacked autoencoder network

- Power data integrity verification method based on chameleon authentication tree algorithm and missing tendency value

- Fault diagnosis of automobile drive based on a novel deep neural network

- Research on the development and intelligent application of power environmental protection platform based on big data

- Diffusion induced thermal effect and stress in layered Li(Ni0.6Mn0.2Co0.2)O2 cathode materials for button lithium-ion battery electrode plates

- Improving power plant technology to increase energy efficiency of autonomous consumers using geothermal sources

- Energy-saving analysis of desalination equipment based on a machine-learning sequence modeling