Abstract

An injection mechanism which is split injection was found to reduce emissions in Diesel engines. In this mechanism, split injection proportion and split injection timing was varied and analyzed to reduce engine emissions. Injection proportion was varied at 25% of the pilot and 75% of the fuel as main injection and timing as 54° ATDC (after top dead center) and 40° ATDC for split injection. Since a homogeneous mixture occurs in this pilot injection, combustion is becoming complete for Diesel Engine. Hence, BTE was increased by 1.5% for timing 40° ATDC and 12° BTDC (before top dead center) and reduced by 1.4% for timing 54° ATDC and 12° BTDC. The reduction in BTE for 54° ATDC is because the increase in timing increases cooling effect of air and combustion rating was reduced. Also, combustion takes place at low temperature itself due to homogeneous mixture. So, NOx emission was also reduced by 8.4% and 18.6% for 40° ATDC and 54° ATDC injection timing respectively. The other emissions like HC and CO were also observed to be reduced upto 35% and 11% respectively due to increase in homogeneous mixture in Diesel Engine.

1 Introduction

In Diesel engines, the thermal efficiency is higher compared to Gasoline engines due to high compression ratio. But engine emissions are very high since the heterogeneous mixture of fuel and air happens in diesel. Since Diesel is injected at the end of the compression stroke, it does not have sufficient time to mix with air so that homogeneous mixture cannot happen (Edara et al. 2018). Diesel fuel is thicker and less volatile than gasoline, making it more difficult to mix with air. In a diesel engine, the fuel is injected into the combustion chamber at high pressure and temperature, which causes it to vaporize and mix with the air quickly. However, the mixing process is not as thorough as in a gasoline engine, where the fuel and air are mixed before entering the combustion chamber. Due to this design difference, diesel engines do not allow as much time for fuel-air mixing as gasoline engines do. Due to this heterogeneous mixture, combustion cannot be completed. So, HC, CO and smoke emissions are increased in the Diesel engine. Moreover, due to the in-cylinder temperature which is increased, NOx emission also increased (Sindhu, Prasad Rao, and Murthy 2018).

For reducing emissions, emission control mechanisms such as catalytic converters are not efficient. Generally, two methods can be adapted as Homogeneous charged compression ignition (HCCI) and premixed charged compression ignition (PCCI) for reducing emissions and increasing efficiency. HCCI cannot be used for this technique since control mechanisms of engine is not proper for HCCI. HCCI engines have a limited operating range, where at high loads and speeds, the rates of heat release and pressure rise increase, result in knocks, and at low loads, malfunction may occur. Therefore, PCCI method can be adapted. In HCCI combustion, well-mixed air and fuel enter the combustion chamber and are compressed to the point of auto-ignition. HCCI and diesel combustion are combined in PCCI, which introduces fuel during the compression phase. EGR may be used more in PCCI combustion than HCCI (Edara et al. 2019).

The premixed charged compression ignition can be implemented by splitting the diesel injection as: pilot & main injection. Pilot injection is first injection where some part of diesel (around 20%–25%) was injected first and in main injection, remaining part of diesel was injected (Gogulothu and Chandra Reddy 2015). Pilot injection may be used for a wide range of purposes; however its major uses are to reduce emissions and noise. In order to speed up engine starters, cylinder pressure can be increased using a pre-injection or early pilot, which increases cylinder pressure toward the end of the compression stroke. Hence, heterogeneous mixture of diesel and fuel can be converted to a homogeneous mixture. Due to homogeneous mixture, combustion may be complete. And, emissions like HC, CO can also be reduced. Since the homogeneous mixture happens, temperature may also be less compared to conventional concept (Biffiger and Soltic 2015). Hence, NOx emission can also be reduced.

Various researchers analyzed the concept of split injection mechanism in diesel engine. With DI and IDI diesel engines, split injection has been demonstrated to be an effective technique for simultaneously reducing particulate and NOx emissions when the injection timing is optimized. It is described as the process of dividing the primary single injection profile into two or more injection pulses with a specified period of time between each injection. (Zheng, Tian, and Zhang 2015) finalized that 25% of pilot injection is optimum for split injection concept in diesel engine to reduce engine emissions and improve efficiency by analyzing various split injection proportion.

Before Top Dead Center, or BTDC, refers to the location of the crankshaft and pistons where the initiation of engine combustion takes place. Because BTDC is a bit of a tongue twister, it is most frequently referred to as the “Advance” timing position. ATDC, also known as after top dead center, is the opposite of BTDC. This defines an igniting process that starts once the piston has already descended into the cylinder bore and reached TDC.

Another parameter, split injection timing can also be an important factor in improving performances. Pilot injection timing can be varied from 40° ATDC to 54° ATDC for improving efficiency based on many researchers. (How et al. 2018) analysed and adopted 54° ATDC for pilot injection and 12° BTDC for main injection as timings to improve efficiency. Finalized that 40° ATDC is optimum for pilot injection timing to reduce emissions.

Nanotechnology may be used in a variety of automobile parts, including paint, batteries, fuel cells, tires, mirrors, and windows. The performance of existing tech for the automotive sector is improved by the introduction of nanotechnologies. The primary benefits of implementing nanotechnology in automobiles are the requirement of lighter and stronger body parts to improve safety and fuel efficiency, as well as the improvement of fuel consumption efficiency and, subsequently, the achievement of better performance over a longer period of time. Moreover, nanoparticle fuel additives can significantly improve the efficiency of combustion fuels and reduce carbon dioxide emissions (Shafique and Luo 2019).

Hence, in this research, CRDI diesel engine was split into pilot injection and main injection with varying split injection proportion from 5% to 45% pilot injection proportions. Split injection involves dividing the total fuel injection into smaller injections, with the first injection igniting the air in the combustion chamber and the second injection providing the bulk of the power. The timing and quantity of fuel injected in each stage is adjusted to achieve split injection proportions ranging from 5% to 45% pilot injection proportions. These experiments can help determine the optimal split injection proportion for a particular engine and operating conditions, leading to more efficient and cleaner combustion and improved fuel efficiency and lower emissions. Also, split injection timing was varied into: 40° ATDC pilot and 54° ATDC for pilot injection timing and main injection timing as 12° BTDC (Breda et al. 2019; Costa et al. 2016). By adopting these data, engine emissions were reduced by 8.4% in 40° ATDC pilot and 18.6% in 54° ATDC pilot.

2 Experimental setup

The test was conducted in single cylinder CRDI diesel engine to determine emissions and efficiency. The Common Rail Direct Injection (CRDi) method uses a single, common line called the common rail to directly inject fuel into the cylinders of a diesel engine. All of the fuel injectors are interconnected to an identical rail. An engine that is controlled electronically stores its fuel under variable pressure in a cylinder or “rail” that is connected to each of the engine’s fuel injectors through a separate pipe, forming a “common rail” for all of the injectors. The components that are presented in the CRDI engine is fuel injection pump, high-pressure pipe, injection nozzle, feed pump, fuel filter and engine control unit. The specifications of Kirloskar single cylinder diesel engine were mentioned in the following Table 1.

Engine specifications.

| Type | Four stroke, single cylinder CRDI vertical water cooled diesel engine (VCR) |

|---|---|

| Rated power | 3.5 kW |

| Rated speed | 1500 rpm |

| Bore Dia (D) | 87.5 mm |

| Stroke (L) | 110 mm |

| Compression ratio | 17.5:1 |

| C.V. of fuel for diesel | 42,500 kj/kg |

| Density of diesel | 840 kg/m3 |

Several steps are taken to measure the emissions and efficiency from a single CRDI diesel engine. Firstly, fuel consumption must be determined by measuring the fuel flow rate or the amount of fuel used over a set time. Secondly, the engine’s power output can be determined either through a dynamometer or by measuring the torque and speed of the engine. To calculate the engine’s efficiency, divide the power output by the fuel consumption. Thirdly, emissions can be measured by analyzing the engine’s exhaust gases with an exhaust gas analyzer for various pollutants such as CO, NOx, and PM. Lastly, to assess the engine’s performance, compare the emissions and efficiency measurements with industry standards or previous measurements. The reduced emissions and improved efficiency were determined by optimizing the engine into split injection in the following method (Figure 1).

Methodology – experimental set-up.

Eddy Current Dynamometer was used to determine the performances. Eddy current dynamometers operate on the basis of Faraday’s Law of electromagnetic induction. According to the law, an emf is produced on a set of conductors every time there is a relative displacement between the conductors and the magnetic field. It is known as dynamically induced emf. Eddy current dynamometers produce eddy currents in order to measure an engine’s torque. They are often utilized to generate braking torque in the automobile industries. These instruments, commonly referred to as eddy current dynos, have the benefits of inexpensive maintenance, high levels of control, and simple design. It was connected to 5 Gas Analyser for finding engine emissions and AVL smoke meter for smoke emissions. The AVL Smoke Meter utilizes the filter paper technique to calculate the filter smoke number (FSN, as defined by ISO 10054), and the soot concentration in mg/m3. A wide range of applications are made possible by the variable sample volume and thermal conditioning of the exhaust gas. Moreover, users can utilize shop air to completely purge the whole fuel line from the input through the measurement block and back to the sample probe. When compared to diaphragm pump purging, it delivers an increasing pressure. The main benefit of this is that particle deposits in the device and sample lines are eliminated. 5 Gas Analyser can measure HC and NOx for range from 0 to 4000 ppm and CO for range 0–10% by volume. AVL smoke meter can measure smoke range of 0–100 Hatridge smoke unit (HSU).

3 Results and discussion

The split injection proportion was varied as 25% pilot and 75% main in injection process. The injection timing was varied for 54° ATDC and 40° ATDC for pilot injection and 12° BTDC for main injection based on (How et al. 2018). The results were found out and discussed here.

3.1 Performance characteristics

3.1.1 Brake thermal efficiency

From the Figure 2, it is to be noted that the brake thermal efficiency for Diesel with single injection is comparatively higher than that of split injection by 1.5%. This is because of the high compression ratio and high pressure in single injection (Li et al. 2016a).

Brake thermal efficiencies for comparison of single injection and split injection timings of 40° ATDC and 54° ATDC.

In split injection mechanism, the premixed charge was introduced and required less temperature to be burnt for complete combustion. Premixed charge is an advanced low-temperature combustion technique in which the injected fuel is premixed with the induction charge and then combusted by compression-induced auto-ignition. Premixed fires produce fewer polluting species, particularly less coal and CO. Nevertheless, it has stability issues and can emit more NO in conditions of higher flame temperatures. Hence, the brake thermal efficiency is slightly less than single injection (Li et al. 2016b, 2019; Wang et al. 2015).

The thermal efficiency is different for two different injection timings (40° ATDC and 54° ATDC). For 40° ATDC, Diesel was injected earlier compared to 54° ATDC so that the fuel for 40° ATDC will get more time to mix with air. A pilot injection timing of 40° ATDC is more effective in reducing engine emissions compared to a single injection with an injection timing of 54° ATDC, because a pilot injection with a 40° ATDC timing reduces the ignition delay period, leading to more controlled and complete combustion, resulting in lower emissions of pollutants like NOx and particulate matter. The reason why fuel injected at 40° ATDC has more time to mix with air compared to 12° BTDC is due to the different stages of the combustion process. During engine operation, fuel is injected into the cylinder at specific positions in the engine cycle. At 40° ATDC, the piston has moved further away from the spark plug, allowing the fuel more time to mix with the air as it enters the combustion chamber. This longer mixing time results in a more homogeneous air-fuel mixture that burns more efficiently. However, when fuel is injected at 12° BTDC, the piston is closer to the spark plug, which reduces the time available for the fuel to mix with the air. As a result, the mixture may not be as uniform, which can lead to incomplete combustion and increased emissions. Thus, the timing of fuel injection in the engine cycle plays a crucial role in determining the mixing time available for fuel and air, which can affect combustion efficiency. Hence, the thermal efficiency for 40° ATDC and 12° BTDC has higher thermal efficiency than 54° ATDC by 0.5%.

3.1.2 Brake power

Figure 3 shows that Brake power for Diesel in single injection is comparatively higher than split injection by 1.45%. The pressure in the single injection is higher than split injection and hence increases power.

Brake power for comparison of single injection and split injection timings of 40° ATDC and 54° ATDC.

In particular, split injection with injection timing of 40° ATDC is higher brake power while comparing with 54° ATDC. The premixing charge in the gap of this 14° ATDC provided increase in pressure to attain 0.58% more power than 54° ATDC.

The more pressure and higher compression ratio in single injection created impact in thermal efficiency and power in high amount than for split injection. But high pressure also increases NOx emission which could be reduced by split injection.

3.2 Emission characteristics

Split injection plays a major role in reducing emissions such as HC, CO, NOx and smoke. In single injection, Diesel is injected at the end of compression stroke and creates heterogeneous mixture due to which air and diesel cannot be mixed properly. Hence, emissions like HC and CO are increased. These emissions can be reduced by adopting split injection concept in Diesel engine (Yang and Zeng 2018).

3.2.1 Hydrocarbon and carbon monoxide

It is evident from Figures 4 and 5 that hydrocarbon and carbon monoxide emissions were reduced for split injection compared to single injection for Diesel engine. Since premixed charge in Diesel for 25% of fuel in pilot injection converts heterogeneous mixture into homogeneous mixture, combustion could be complete in split injection. To improve engine performance and efficiency in split injection, the fuel in the pilot injection undergoes a transformation from a heterogeneous mixture to a homogeneous mixture. This is achieved by injecting the fuel at high pressure and velocity, which atomizes the fuel and creates small fuel droplets that mix more thoroughly with the air. The resulting homogeneous mixture promotes more even combustion and stabilizes the flame kernel created by the pilot injection, improving the ignition and combustion of the main injection. Hence, hydrocarbon and carbon monoxide emissions were reduced by 7.1% and 6.8% respectively.

HC emission for comparison of single injection and split injection timings of 40° ATDC and 54° ATDC.

CO emission for comparison of single injection and split injection timings of 40° ATDC and 54° ATDC.

While comparing pilot injection timings of 54° ATDC and 40° ATDC, the early injection of Diesel in 40° ATDC has sufficient time for mixing with air compared with 54° ATDC. Hence, hydrocarbon and carbon monoxide emissions are less in 40° ATDC by 2.9% and 3.1% respectively.

Hydrocarbon emissions can support various industrial operations, to reduce waste. Moreover, it indicates incomplete combustion. Hydrocarbon emissions cause ground-level ozone, which harms humans and the environment. Carbon monoxide may be utilized as a fuel in some industrial operations, decreasing waste. Carbon monoxide is a key contributor to air pollution and can harm the ecosystem, particularly in cities. Hydrocarbon and carbon monoxide emissions are hazardous to humans and the environment but have certain advantages. Internal combustion engine efficiency and sustainability depends on reducing these emissions.

3.2.2 Nitrogen oxide

From the Figure 6, it is shown that NOx emission for split injection with 40° ATDC is having lesser than that of single injection. NOx emission occurs due to high peak cycle temperature. Since the split injection of Diesel has homogeneous mixture with air, it required less temperature to combust. Split injection is a technique used in diesel engines that involves dividing the total fuel injection into two or more smaller injections, with the first injection being the pilot injection and the second injection being the main injection. The pilot injection is responsible for igniting the air in the combustion chamber, while the main injection provides the majority of the power. One of the benefits of split injection is that it creates a more uniform mixture of fuel and air in the combustion chamber, resulting in more complete combustion and improved fuel efficiency. Furthermore, split injection requires less temperature to combust compared to single injection. Consequently, less temperature is required to ignite the fuel, which reduces the occurrence of engine knock and lowers the amount of nitrogen oxides (NOx) emissions produced. Due to low peak cycle temperature in the premixed charge of Diesel in split injection, NOx emission is lesser in amount by 2.3%.

NOx emission for comparison of single injection and split injection timings of 40° ATDC and 54° ATDC.

Comparing 40° ATDC and 54° ATDC injection timing of pilot injection, NOx emission for injection timing of 40° ATDC has lesser amount than for 54° ATDC since 40° ATDC has sufficient time to mix with air. Hence, it required even less temperature involved in combustion and NOx is also reduced by 1.2%. Due to the increasing pressure and temperature, the NOx and CO2 emissions increase with higher compression ratios. On the other hand, at higher compression ratios, the specific PM emission and smoke opacity are less. It has been observed that CO emission lowers when compression ratio increases. This is so that more air and, consequently, more oxygen are accessible inside the cylinder for efficient combustion as the compression ratio improves. It has been established that when the compression ratio increases, the engine’s intake capacity also increases.

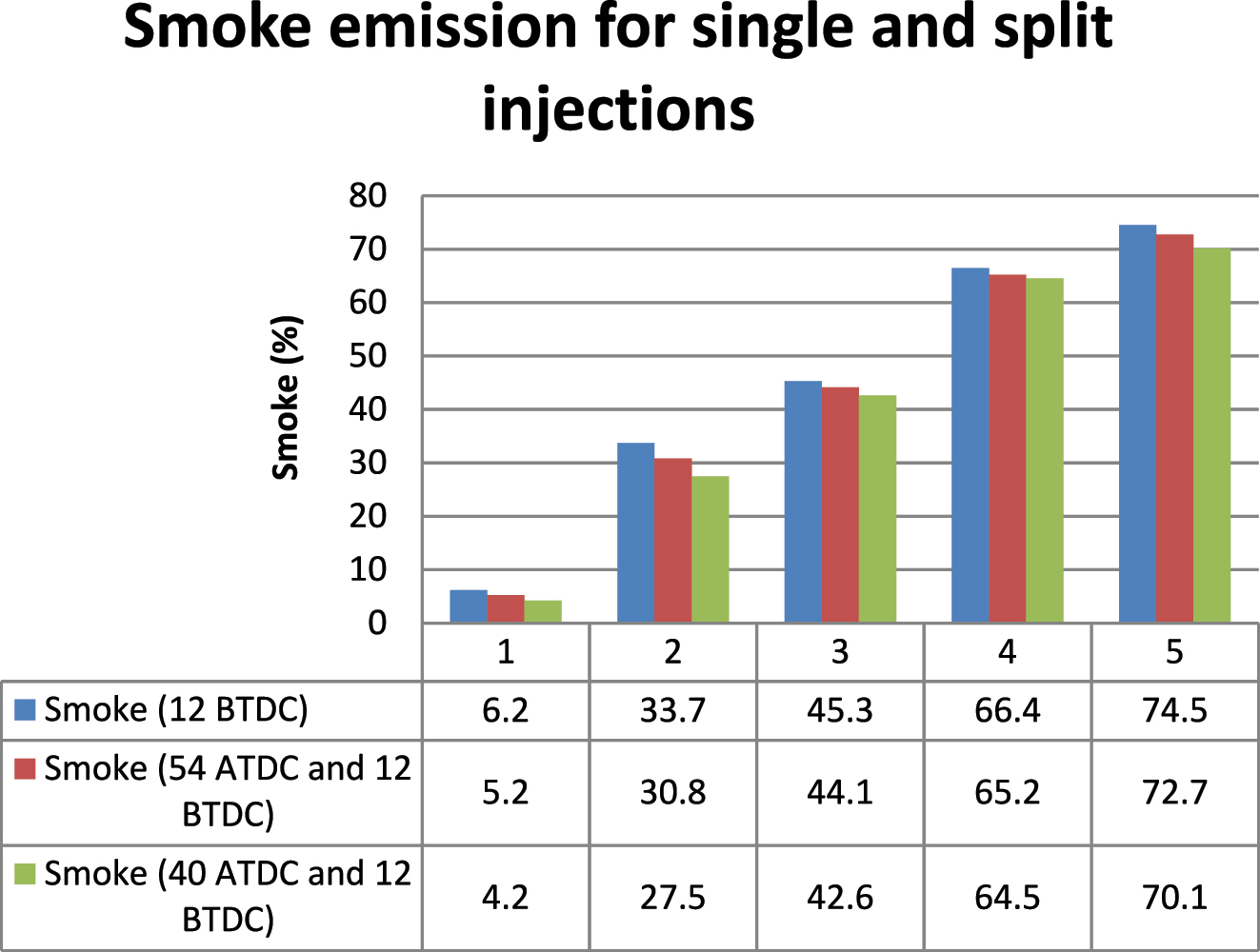

3.2.3 Smoke emission

Smoke emission occurs due to incomplete combustion of fuel. In single injection of Diesel, it is not having sufficient time to mix with air and smoke increases while comparing with split injection (Premixed charge of Diesel mixes with air efficiently and thus reduces smoke) (Figure 7). When diesel fuel is injected into a combustion chamber in a single injection, it may not have enough time to mix with air before combustion, which can lead to incomplete combustion and increased smoke. In contrast, split injection, which divides the fuel injection into multiple smaller injections, provides more time for the fuel to mix with air before combustion, resulting in better combustion efficiency and reduced smoke. Insufficient residence time, inadequate temperature, poor air-fuel mixing, and little overall extra air are the main causes of incomplete combustion. Dust or carbon monoxide are produced when a portion of the carbon during incomplete combustion is not totally oxidized (CO). Complete combustion utilizes fuel inefficiently and produces harmful levels of carbon monoxide.

Smoke emission for comparison of single injection and split injection timings of 40° ATDC and 54° ATDC.

In split injection mechanism, the injection timing of Diesel in pilot injection varies smoke emission as per Figure 7. Since 40° ATDC injection timing has more time to mix with air, it has lesser emission of smoke compared with 54° ATDC (Yousefi, Guo, and Birouk 2018; Yousefia et al. 2019; Zhang, Yu, and Bai 2015).

Hence, smoke is less in amount for split injection for pilot injection 40° ATDC compared with single injection and split injection for pilot injection of 54° ATDC by 5.9% and 3.5% respectively.

3.3 Combustion characteristics

From the Figures 8 –10, it is evident that the pressure for single injection is maximum (66.47 bar). It is because that the compression ratio for single injection is more than split injection for Diesel combustion (Zhou et al. 2018).

P–θ Diagram for single injection of diesel.

P–θ Diagram for pilot injection (split injection) of 54° ATDC.

P–θ Diagram for pilot injection (split injection) of 40° ATDC.

Comparatively, pilot injection of 40° ATDC required less compression ratio with respect to 54° ATDC for complete combustion. Hence, pressure required for 40° ATDC is less in amount (64.54 bar) compared with 54° ATDC (65.57 bar). Split injection is a fuel injection mechanism that utilizes two separate injections of fuel to promote complete combustion in an engine. By initiating combustion early through a small pilot injection, reducing nitrogen oxide emissions through cooling, providing precise control of the fuel injection process, and reducing noise and vibration, split injection effectively enables the engine to burn fuel more completely and efficiently.

Since high compression ratio and high pressure directly impacts knocking characteristics and NOx emission, the pilot injection timing of 40° ATDC have less knocking characteristics compared with pilot injection timing of 54° ATDC and single injection of Diesel (it has less peak pressure of 1.57% and 2.9% compared with 54° ATDC and single injection of Diesel respectively). The most suitable timing for pilot injection in diesel engines to decrease emissions depends on several factors, including engine load, speed, fuel injection pressure, fuel properties, and combustion chamber geometry. However, a pilot injection timing of 40° ATDC is more effective in reducing engine emissions compared to a single injection with an injection timing of 54° ATDC, because a pilot injection with a 40° ATDC timing reduces the ignition delay period, leading to more controlled and complete combustion, resulting in lower emissions of pollutants like NOx and particulate matter. Moreover, the early introduction of fuel into the combustion chamber with a 40° ATDC pilot injection timing allows for more comprehensive mixing with air before the main injection occurs, resulting in more complete combustion and fewer emissions. On the other hand, a single injection with a 54° ATDC injection timing may lead to incomplete mixing of fuel and air, longer ignition delay period, and incomplete combustion, which results in higher emissions.

4 Conclusions

The split injection was introduced by pilot injection and main injection where pilot injection timing was varied as 54° ATDC and 40° ATDC based on (How et al. 2018). The findings are discussed here:

Brake Thermal Efficiency is higher for single injection by 1.5% than for split injection since there is high pressure for single injection.

Brake Power is high for single injection by 1.45% than for premixed charge due to high compression ratio in single injection.

When compared to single injection and pilot injection timing of 54° ATDC, hydrocarbon emission was reduced by 7.1% and 2.9% for pilot injection timing of 40° ATDC due to more time to mix with air for pilot injection timing of 40° ATDC and it was compared to pilot injection timing of 54° ATDC.

Carbon monoxide emission was reduced by 6.8% and 3.1% for split injection varying timing of 40° ATDC while comparing with single injection and pilot injection timing of 54° ATDC since the combustion is nearly complete as the mixing of air is better for 40° ATDC.

Nitrogen oxide emission was also reduced by 2.3% and 1.2% for 40° ATDC pilot injection timing with respect to single injection and split injection timing of 54° ATDC due to low peak cycle temperature and pressure for 40° ATDC since the compression ratio for 40° ATDC is less.

Smoke emission is lesser for 40° ATDC injection timing of pilot injection compared with single injection and pilot injection timing of 54° ATDC by 5.9% and 3.5% due to combustion is nearly complete in 40° ATDC pilot injection.

Peak pressure is less in 40° ATDC by 2.9% and 1.57% in comparison with single injection and pilot injection timing of 54° ATDC due to which NOx and knocking are less in 40° ATDC pilot injection timing.

From the results, we could find that the pilot injection timing of 40° ATDC for Diesel injection is optimum for reducing engine emissions than single injection of Diesel and injection timing of 54° ATDC. But the power output is comparatively less than single injection. Hence, the 40° ATDC injection timing can be adopted with varying injection pressures also since the injection pressure variation can improve power output.

-

Author contribution: G. Balamurugana and S. Gowthaman contributed to the design and methodology of this study, the assessment of the outcomes and the writing of the manuscript.

-

Research funding: No funds, grants were received by any of the authors.

-

Conflict of interest statement: There is no conflict of interest among the authors.

-

Data availability: All data generated or analysed during this study are included in the manuscript.

-

Code availability: Not applicable.

References

Biffiger, H., and P. Soltic. 2015. “Effects of Split Port/Direct Injection of Methane and Hydrogen in a Spark Ignition Engine.” International Journal of Hydrogen Journal 40: 1994–2003. https://doi.org/10.1016/j.ijhydene.2014.11.122.Suche in Google Scholar

Breda, S., F. D. Orrico, F. Berni, A. d’Adamo, S. Fontanesi, A. Irimescu, and S. S. Merola. 2019. “Experimental and Numerical Study on the Adoption of Split Injection Strategies to Improve Air-Butanol Mixture Formation in a DISI Optical Engine.” Fuel 243: 104–24. https://doi.org/10.1016/j.fuel.2019.01.111.Suche in Google Scholar

Costa, M., U. Sorge, S. Merola, A. Irimescu, M. LaVilletta, and V. Rocco. 2016. “Split Injection in a Homogeneous Stratified Gasoline Direct Injection Engine for High Combustion Efficiency and Low Pollutants Emission.” Energy 117: 1–11. https://doi.org/10.1016/j.energy.2016.03.065.Suche in Google Scholar

Edara, G., Y. V. V. S. N. Murthy, P. Srinivas, J. Nayar, and M. Ramesh. 2018. “Effect of Cooled EGR on Modified Light Duty Diesel Engine for Combustion, Performance and Emissions under High Pressure Split Injection Strategies.” Case Studies in Thermal Engineering 12: 188–202. https://doi.org/10.1016/j.csite.2018.03.004.Suche in Google Scholar

Edara, G., Y. V. V. S. N. Murthy, J. Nayar, M. Ramesh, and P. Srinivas. 2019. “Combustion Analysis of Modified Light Duty Diesel Engine under High Pressure Split Injections with Cooled EGR, Engineering Science and Technology.” International Journal 22: 966–78. https://doi.org/10.1016/j.jestch.2019.01.013.Suche in Google Scholar

Gogulothu, S. K., and K. H. Chandra Reddy. 2015. “Effect of Injection Timing and Split Injection on Different Piston Bowl Configuration in a DI Diesel Engine.” Procedia Engineering 127: 924–31. https://doi.org/10.1016/j.proeng.2015.11.435.Suche in Google Scholar

How, H. G., H. H. Masjuki, M. A. Kalam, and Y. H. Teoh. 2018. “Influence of Injection Timing and Split Injection Strategies on Performance, Emissions, and Combustion Characteristics of Diesel Engine Fueled with Biodiesel Blended Fuels.” Fuel 213: 106–14. https://doi.org/10.1016/j.fuel.2017.10.102.Suche in Google Scholar

Li, X., H. Gao, L. Zhao, Z. Zhang, X. He, and F. Liu. 2016. “Combustion and Emission Performance of a Split Injection Diesel Engine in a Double Swirl Combustion System.” Energy 114: 1135–46. https://doi.org/10.1016/j.energy.2016.08.092.Suche in Google Scholar

Li, X., H. Zhou, L. Zhao, L. Su, H. Xu, and F. Liu. 2016. “Effect of Split Injections Coupled with Swirl on Combustion Performance in DI Diesel Engines.” Energy Conversion and Management 129: 180–8. https://doi.org/10.1016/j.enconman.2016.09.011.Suche in Google Scholar

Li, G., X. Yu, W. Shi, C. Yao, S. Wang, and Q. Shen. 2019. “Effects of Split Injection Proportion and the Second Injection Timings on the Combustion and Emissions of a Dual Fuel SI Engine with Split Hydrogen Direct Injection.” International Journal of Hydrogen Journal 44: 11194–204. https://doi.org/10.1016/j.ijhydene.2019.02.222.Suche in Google Scholar

Sindhu, R., G. A. Prasad Rao, and K. M. Murthy. 2018. “Effective Reduction of NOx Emissions from Diesel Engine Using Split Injections.” Alexandria Engineering Journal 57: 1379–92. https://doi.org/10.1016/j.aej.2017.06.009.Suche in Google Scholar

Shafique, M., and X. Luo. 2019. “Nanotechnology in Transportation Vehicles: An Overview of its Applications, Environmental, Health and Safety Concerns.” Materials 12 (15): 2493. https://doi.org/10.3390/ma12152493.Suche in Google Scholar PubMed PubMed Central

Wang, Z., H. Ding, M. L. Wyszynski, J. Tian, H. Xu, and H. Xu. 2015. “Experimental Study on Diesel Fuel Injection Characteristics under Cold Start Conditions with Single and Split Injection Strategies.” Fuel Processing Technology 131: 213–22. https://doi.org/10.1016/j.fuproc.2014.10.003.Suche in Google Scholar

Yang, B., and K. Zeng. 2018. “Effects of Natural Gas Injection Timing and Split Pilot Fuel Injection Strategy on the Combustion Performance and Emissions in a Dual-Fuel Engine Fueled with Diesel and Natural Gas.” Energy Conversion and Management 168: 162–9. https://doi.org/10.1016/j.enconman.2018.04.091.Suche in Google Scholar

Yousefi, A., H. Guo, and M. Birouk. 2018. “An Experimental and Numerical Study on Diesel Injection Split of a Natural Gas/diesel Dual-Fuel Engine at a Low Engine Load.” Fuel 212: 332–46. https://doi.org/10.1016/j.fuel.2017.10.053.Suche in Google Scholar

Yousefia, A., H. Guo, M. Birouk, and B. Liko. 2019. “On Greenhouse Gas Emissions and Thermal Efficiency of Natural Gas/Dieseldual-Fuel Engine at Low Load Conditions: Coupled Effect of Injector Railpressure and Split Injection.” Applied Energy 242: 216–31. https://doi.org/10.1016/j.apenergy.2019.03.093.Suche in Google Scholar

Zhang, F., R. Yu, and X. S. Bai. 2015. “Effect of Split Fuel Injection on Heat Release and Pollutant Emissions in Partially Premixed Combustion of PRF70/air/EGR Mixtures.” Applied Energy 149: 283–96. https://doi.org/10.1016/j.apenergy.2015.03.058.Suche in Google Scholar

Zheng, Z., X. Tian, and X. Zhang. 2015. “Effects of Split Injection Proportion and the Second Injection Time on the Mixture Formation in a GDI Engine under Catalyst Heating Mode Using Stratified Charge Strategy.” Applied Thermal Engineering 84: 237–45. https://doi.org/10.1016/j.applthermaleng.2015.03.041.Suche in Google Scholar

Zhou, L., K. Dong, J. Hua, H. Wei, R. Chen, and Y. Han. 2018. “Effects of Applying EGR with Split Injection Strategy on Combustion Performance and Knock Resistance in a Spark Assisted Compression Ignition (SACI) Engine.” Applied Thermal Engineering 145: 98–109. https://doi.org/10.1016/j.applthermaleng.2018.09.001.Suche in Google Scholar

© 2024 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Solar photovoltaic-integrated energy storage system with a power electronic interface for operating a brushless DC drive-coupled agricultural load

- Analysis of 1-year energy data of a 5 kW and a 122 kW rooftop photovoltaic installation in Dhaka

- Reviews

- Real yields and PVSYST simulations: comparative analysis based on four photovoltaic installations at Ibn Tofail University

- A comprehensive approach of evolving electric vehicles (EVs) to attribute “green self-generation” – a review

- Exploring the piezoelectric porous polymers for energy harvesting: a review

- A strategic review: the role of commercially available tools for planning, modelling, optimization, and performance measurement of photovoltaic systems

- Comparative assessment of high gain boost converters for renewable energy sources and electrical vehicle applications

- A review of green hydrogen production based on solar energy; techniques and methods

- A review of green hydrogen production by renewable resources

- A review of hydrogen production from bio-energy, technologies and assessments

- A systematic review of recent developments in IoT-based demand side management for PV power generation

- Research Articles

- Hybrid optimization strategy for water cooling system: enhancement of photovoltaic panels performance

- Solar energy harvesting-based built-in backpack charger

- A power source for E-devices based on green energy

- Theoretical and experimental investigation of electricity generation through footstep tiles

- Experimental investigations on heat transfer enhancement in a double pipe heat exchanger using hybrid nanofluids

- Comparative energy and exergy analysis of a CPV/T system based on linear Fresnel reflectors

- Investigating the effect of green composite back sheet materials on solar panel output voltage harvesting for better sustainable energy performance

- Electrical and thermal modeling of battery cell grouping for analyzing battery pack efficiency and temperature

- Intelligent techno-economical optimization with demand side management in microgrid using improved sandpiper optimization algorithm

- Investigation of KAPTON–PDMS triboelectric nanogenerator considering the edge-effect capacitor

- Design of a novel hybrid soft computing model for passive components selection in multiple load Zeta converter topologies of solar PV energy system

- A novel mechatronic absorber of vibration energy in the chimney

- An IoT-based intelligent smart energy monitoring system for solar PV power generation

- Large-scale green hydrogen production using alkaline water electrolysis based on seasonal solar radiation

- Evaluation of performances in DI Diesel engine with different split injection timings

- Optimized power flow management based on Harris Hawks optimization for an islanded DC microgrid

- Experimental investigation of heat transfer characteristics for a shell and tube heat exchanger

- Fuzzy induced controller for optimal power quality improvement with PVA connected UPQC

- Impact of using a predictive neural network of multi-term zenith angle function on energy management of solar-harvesting sensor nodes

- An analytical study of wireless power transmission system with metamaterials

- Hydrogen energy horizon: balancing opportunities and challenges

- Development of renewable energy-based power system for the irrigation support: case studies

- Maximum power point tracking techniques using improved incremental conductance and particle swarm optimizer for solar power generation systems

- Experimental and numerical study on energy harvesting performance thermoelectric generator applied to a screw compressor

- Study on the effectiveness of a solar cell with a holographic concentrator

- Non-transient optimum design of nonlinear electromagnetic vibration-based energy harvester using homotopy perturbation method

- Industrial gas turbine performance prediction and improvement – a case study

- An electric-field high energy harvester from medium or high voltage power line with parallel line

- FPGA based telecommand system for balloon-borne scientific payloads

- Improved design of advanced controller for a step up converter used in photovoltaic system

- Techno-economic assessment of battery storage with photovoltaics for maximum self-consumption

- Analysis of 1-year energy data of a 5 kW and a 122 kW rooftop photovoltaic installation in Dhaka

- Shading impact on the electricity generated by a photovoltaic installation using “Solar Shadow-Mask”

- Investigations on the performance of bottle blade overshot water wheel in very low head resources for pico hydropower

- Solar photovoltaic-integrated energy storage system with a power electronic interface for operating a brushless DC drive-coupled agricultural load

- Numerical investigation of smart material-based structures for vibration energy-harvesting applications

- A system-level study of indoor light energy harvesting integrating commercially available power management circuitry

- Enhancing the wireless power transfer system performance and output voltage of electric scooters

- Harvesting energy from a soldier's gait using the piezoelectric effect

- Study of technical means for heat generation, its application, flow control, and conversion of other types of energy into thermal energy

- Theoretical analysis of piezoceramic ultrasonic energy harvester applicable in biomedical implanted devices

- Corrigendum

- Corrigendum to: A numerical investigation of optimum angles for solar energy receivers in the eastern part of Algeria

- Special Issue: Recent Trends in Renewable Energy Conversion and Storage Materials for Hybrid Transportation Systems

- Typical fault prediction method for wind turbines based on an improved stacked autoencoder network

- Power data integrity verification method based on chameleon authentication tree algorithm and missing tendency value

- Fault diagnosis of automobile drive based on a novel deep neural network

- Research on the development and intelligent application of power environmental protection platform based on big data

- Diffusion induced thermal effect and stress in layered Li(Ni0.6Mn0.2Co0.2)O2 cathode materials for button lithium-ion battery electrode plates

- Improving power plant technology to increase energy efficiency of autonomous consumers using geothermal sources

- Energy-saving analysis of desalination equipment based on a machine-learning sequence modeling

Artikel in diesem Heft

- Solar photovoltaic-integrated energy storage system with a power electronic interface for operating a brushless DC drive-coupled agricultural load

- Analysis of 1-year energy data of a 5 kW and a 122 kW rooftop photovoltaic installation in Dhaka

- Reviews

- Real yields and PVSYST simulations: comparative analysis based on four photovoltaic installations at Ibn Tofail University

- A comprehensive approach of evolving electric vehicles (EVs) to attribute “green self-generation” – a review

- Exploring the piezoelectric porous polymers for energy harvesting: a review

- A strategic review: the role of commercially available tools for planning, modelling, optimization, and performance measurement of photovoltaic systems

- Comparative assessment of high gain boost converters for renewable energy sources and electrical vehicle applications

- A review of green hydrogen production based on solar energy; techniques and methods

- A review of green hydrogen production by renewable resources

- A review of hydrogen production from bio-energy, technologies and assessments

- A systematic review of recent developments in IoT-based demand side management for PV power generation

- Research Articles

- Hybrid optimization strategy for water cooling system: enhancement of photovoltaic panels performance

- Solar energy harvesting-based built-in backpack charger

- A power source for E-devices based on green energy

- Theoretical and experimental investigation of electricity generation through footstep tiles

- Experimental investigations on heat transfer enhancement in a double pipe heat exchanger using hybrid nanofluids

- Comparative energy and exergy analysis of a CPV/T system based on linear Fresnel reflectors

- Investigating the effect of green composite back sheet materials on solar panel output voltage harvesting for better sustainable energy performance

- Electrical and thermal modeling of battery cell grouping for analyzing battery pack efficiency and temperature

- Intelligent techno-economical optimization with demand side management in microgrid using improved sandpiper optimization algorithm

- Investigation of KAPTON–PDMS triboelectric nanogenerator considering the edge-effect capacitor

- Design of a novel hybrid soft computing model for passive components selection in multiple load Zeta converter topologies of solar PV energy system

- A novel mechatronic absorber of vibration energy in the chimney

- An IoT-based intelligent smart energy monitoring system for solar PV power generation

- Large-scale green hydrogen production using alkaline water electrolysis based on seasonal solar radiation

- Evaluation of performances in DI Diesel engine with different split injection timings

- Optimized power flow management based on Harris Hawks optimization for an islanded DC microgrid

- Experimental investigation of heat transfer characteristics for a shell and tube heat exchanger

- Fuzzy induced controller for optimal power quality improvement with PVA connected UPQC

- Impact of using a predictive neural network of multi-term zenith angle function on energy management of solar-harvesting sensor nodes

- An analytical study of wireless power transmission system with metamaterials

- Hydrogen energy horizon: balancing opportunities and challenges

- Development of renewable energy-based power system for the irrigation support: case studies

- Maximum power point tracking techniques using improved incremental conductance and particle swarm optimizer for solar power generation systems

- Experimental and numerical study on energy harvesting performance thermoelectric generator applied to a screw compressor

- Study on the effectiveness of a solar cell with a holographic concentrator

- Non-transient optimum design of nonlinear electromagnetic vibration-based energy harvester using homotopy perturbation method

- Industrial gas turbine performance prediction and improvement – a case study

- An electric-field high energy harvester from medium or high voltage power line with parallel line

- FPGA based telecommand system for balloon-borne scientific payloads

- Improved design of advanced controller for a step up converter used in photovoltaic system

- Techno-economic assessment of battery storage with photovoltaics for maximum self-consumption

- Analysis of 1-year energy data of a 5 kW and a 122 kW rooftop photovoltaic installation in Dhaka

- Shading impact on the electricity generated by a photovoltaic installation using “Solar Shadow-Mask”

- Investigations on the performance of bottle blade overshot water wheel in very low head resources for pico hydropower

- Solar photovoltaic-integrated energy storage system with a power electronic interface for operating a brushless DC drive-coupled agricultural load

- Numerical investigation of smart material-based structures for vibration energy-harvesting applications

- A system-level study of indoor light energy harvesting integrating commercially available power management circuitry

- Enhancing the wireless power transfer system performance and output voltage of electric scooters

- Harvesting energy from a soldier's gait using the piezoelectric effect

- Study of technical means for heat generation, its application, flow control, and conversion of other types of energy into thermal energy

- Theoretical analysis of piezoceramic ultrasonic energy harvester applicable in biomedical implanted devices

- Corrigendum

- Corrigendum to: A numerical investigation of optimum angles for solar energy receivers in the eastern part of Algeria

- Special Issue: Recent Trends in Renewable Energy Conversion and Storage Materials for Hybrid Transportation Systems

- Typical fault prediction method for wind turbines based on an improved stacked autoencoder network

- Power data integrity verification method based on chameleon authentication tree algorithm and missing tendency value

- Fault diagnosis of automobile drive based on a novel deep neural network

- Research on the development and intelligent application of power environmental protection platform based on big data

- Diffusion induced thermal effect and stress in layered Li(Ni0.6Mn0.2Co0.2)O2 cathode materials for button lithium-ion battery electrode plates

- Improving power plant technology to increase energy efficiency of autonomous consumers using geothermal sources

- Energy-saving analysis of desalination equipment based on a machine-learning sequence modeling