Abstract

The effect of different cinnamon essential oil (CEO) contents on flammability, thermal stability and morphological characteristics of nanocellulose fibre–reinforced starch biopolymer composites was studied. This sugar palm nanocellulose reinforced with sugar palm starch, containing 0–2% CEO, was prepared through solution casting technique. From scanning electron microscopy analysis, the cross-sections of the CEO-containing films showed appearance of micro-porous spots as micro-porous holes because of the occurrence of partial evaporation on the cryo-fractured surface as a result of the vacuum condition. Increment in CEO concentration resulted in increasing trend of the number and size of the micro-porous holes. Significant increase was observed in the thermal stability with the CEO loading when compared with neat composites. Besides that, increasing CEO loading also resulted in decrement of linear burning rate of the composites.

1 Introduction

Conventional packaging from petroleum-based plastics, such as polypropylene, polyethylene, polyvinyl chloride, polyamide, polyethylene terephthalate and high density polyethylene, is being extensively used in food and beverage industries considering their ease of processing, strength, cost effectiveness and durability [1,2]. Food packaging requires a considerable consumption of various materials, where utilization of plastics has exponentially increased over the last two decades, with approximately 5% annual growth. Plastics, after paper and cardboard, are also the second most regularly used materials in food packaging applications. According to Sanyang et al. [3], the lack of biodegradability of conventional packaging materials that are petroleum based is known to contribute to many environmental hazards, e.g. emitting dangerous toxins into the air and destroying ocean habitats from the coral reefs to thousands of other species. This will lead to loss of revenue for fishing and tourism industries. Moreover, restoring it is costly as the cities, states and country need to spend millions of their revenues to clear-out littered plastics as well as to build and sustain landfills.

In recent years, biodegradable polymers, particularly agro-based polymers, have been widely explored as alternatives to non-degradable polymers that are now primarily used in the production of food packaging films [4,5,6,7]. Starch is one of the widest packaging biopolymers available as it is easily available, biodegradable, renewable and of low cost [8,9]. Therefore, starch has drawn considerable interests as an alternative to non-biodegradable plastics, hence a promising new green material in the industry [10]. However, starch-based films for packaging applications have reportedly shown that they have poor antimicrobial properties [11,12]. These disadvantages limit their broad uses, particularly for the purposes of food packaging. Therefore, to cater this problem, materials scientists conducted several studies to enhance the antimicrobial properties without affecting their biodegradability.

Natural fibres such as cotton [13], rice husk [14,15], kenaf [16], water hyacinth [17], flax [18], jute [18], ginger [19,20] and sugar palm [21] from plants have attracted the attention of many researchers in the past, and they are used because of their important properties such as low cost of materials, ease of availability and biodegradability [22]. For example, cotton fibres were used by Boufi et al. [13] with plasmonic nanoparticles for the destruction of harmful molecules. Rice husk fibres were also used in the development of aluminium-based green metal composites to reduce soil pollution [14]. Jain et al. [15] used agricultural waste rice husk–reinforced epoxy for coating, electronic implements, aerospace and automotive structures. Besides that, many scientists have made an effort on cellulose fibre as conducting composites (i.e. activated carbon) using binder [22]. Thompson et al. [23] reported research on cellulose nanocrystals made from woods. The cellulose crystals were made into composites to produce transparent films, which have good mechanical properties. Bukit et al. [24] represented the work on nanoparticles made from oil palm boiler ash from a palm oil mill. The materials were characterized by X-ray diffraction (XRD) and Fourier transforms infrared (FTIR), and the materials showed great potential in nanocomposite industry. Similar work was represented by Chu et al. [25] on fly ashes and was also characterized using XRD, FTIR and scanning electron microscopy (SEM), which showed promising results. This shows that natural fibre had many advantages to be used in various applications. In the current research sugar palm fibres (SPMs) are used as reinforcement in starch composites in the form of nanocelluloses. One important advantage of using bio-nanocellulose in composites in food packaging is its use does not pose any health hazard unlike nanoparticles made from synthetic materials [26]. In food packaging, nanocellulose composite had better antibacterial activity than its individual constituent (starch and fibre) [27].

The natural fibre–reinforced natural polymer had good advantages over synthetic fibre in terms of biodegradability, recyclability and low cost per weight to resist tensile load [28]. Therefore, selection of the right packaging technologies and materials is a vital aspect in preserving food freshness and quality as well as reducing environmental pollutants. One possibility that is being researched extensively is the inclusion of active substances, e.g. essential oil (EO) in the packaging contents as biopolymer starch-based films. [29]. To help improving and preserving the food safety, scientists have developed a novel packaging, known as active packaging (AP). It might also be a beneficial alternative for both conventional and modified packaging, in terms of preservatives’ usage, because it provides microbial protection to the food by decreasing and inhibiting the growth of microorganisms, which subsequently extends the shelf-life of the packed food [30]. Natural antimicrobial ingredients have acquired rising demand as customers are more conscious of possible health hazards associated with the use of preservatives as well as aware of the effectiveness of AP [31,32,33,34]. Natural ingredients with antimicrobial activity include lemon oil [35], lemongrass [36,37], peppermint oil [37,38,39], cinnamon [29,37,39,40,41,42], lavender [43], Mexican oregano [44], neem [45], tea tree [39,46], Lavandula angustifolia [47], Mentha pulegium [47], turmeric [48], lime [49], Origanum vulgare L. [50], Ziziphora clinopodioides [51], grape seed [51] and Zataria multiflora Boiss [52].

Sugar palm starch (SPS) is being extensively used in the manufacturing of bio-based starch films and yielded promising results [3,21,61,53,54,55,56,57,58,59,60]. SPS films are defined as non-toxic, colourless, biodegradable, tasteless, odourless and isotropic. In a previous study performed by Ilyas et al. [21], SPS films that were plasticized with glycerol and sorbitol and reinforced with sugar palm nanocellulose (SPN) were developed [62,63,64,65]. The reported findings were significant as they provided information on an ideal formulation to manufacture composite film with enhanced mechanical, thermal and water barrier characteristics. Therefore, authors are currently attempting to incorporate the SPS films’ formulation with antimicrobial agents as the carrier of natural additives that might in the foreseeable future be seen as new tendencies in the functional food packaging. AP provides the customer with microbial protection by reducing or inhibiting the growth of microorganisms, which could then prolong the shelf-life of the food.

A research conducted by Kechichian et al. [66] on cassava starch had incorporated clove and cinnamon essential oils (CEOs) and showed reduction in tensile properties, whereas water vapour permeability showed increment compared to control. These EOs were chosen as raw materials in the continuation of their research, which was performed by the same researchers as the present study. Besides that, other authors who presented antimicrobial effectiveness of cinnamon agents in literature include Souza et al. [29], Iamareerat et al. [40], Utami et al. [41], Liakos et al. [39], Rojas-Graü et al. [37] and Nazari et al. [42]. The main constituent of cinnamon oils is cinnamaldehyde, a well-known agent because of its antimicrobial activities.

EOs are plant based having volatile, natural and complex compounds. Besides having strong odour, they become interesting additives in food industry for having good medicinal and antimicrobial properties, as well as providing health benefits. EOs are dissolved with a surfactant because it is insoluble in water (hydrophobic). Tween 80 and Span 80 are two commonly used surfactants in hydrophile–lipophile balance [67]. Cinnamon was mainly used as spice for a long time, which contains main constituents like cinnamaldehyde and eugenol that are two important agents in antimicrobial activities [68]. Cinnamon EOs were reported to have good antimicrobial activity against meat-isolated Pseudomonas putida strain [30]. It was also reported that they had high activity on preventing the spoilage of fungi on bread. Oussalah et al. [69] revealed that cinnamon EOs were among the most active EOs, as screened for four pathogenic bacteria. In the current research, SPS films were developed via solution casting technique and were incorporated with cinnamon EOs.

None of the preceding studies, based on a literature survey, has discussed the effects of CEO on the flammability and thermal stability as well as morphology of biopolymer composites of SPN reinforced with SPS. It is well known in composites that the use of nanofillers such as nanocelluloses is important in influencing the composite properties such as thermal performances [70]. Lapčík et al. [70] reported that nanofillers are commonly used for structural and non-structural components, and packaging as well as advanced coating applications. Therefore, this study aimed to investigate the possible effects of using EO as fillers on the flammability, thermal stability and morphological properties of SPN/SPS biopolymer composites at different loadings.

2 Materials and methods

2.1 Materials

There are several places in Malaysia that are planted with sugar palm, hence becoming the sources for SPS and SPF. In this study, SPF and SPS were obtained from a village in Kuala Jempol, Negeri Sembilan, Malaysia. Chemicals used, e.g. sodium hydroxide (NaOH), ethanoic acid (CH3COOH), Sodium chlorite (NaClO2), sorbitol, glycerol and Tween 80, were purchased from Sue Evergreen Sdn. Bhd., Semenyih, Selangor, Malaysia.

2.2 SPS extraction and preparation

SPS was removed from inside the stem of a matured sugar palm tree using a chainsaw. The starch powder then underwent washing process by adding water to the mixture and followed by using a special designed extractor machine for sugar palm to extract the starch from the mixture. The mixture was then filtered using a sieve (<300

2.3 SPF extraction and preparation

SPF is located on the stem of sugar palm tree as natural woven shape fibre. SPF wraps up the tree trunk and worker used an axe to cut and remove it from the tree. Then SPF was ground and filtered to 2 mm size.

2.4 Cellulose extraction

The two main processes carried out to extract the cellulose fibres from the SPF were delignification and mercerization. Lignin was removed from SPF to get the holocellulose through chlorination and bleaching processes according to ASTM D1104-56 (1978). According to ASTM D1103-60 (1977), α-cellulose is produced through further treatment of holocellulose [72].

2.5 Separation of sugar palm nanocrystalline celluloses

Acid hydrolysis method was used to prepare sugar palm nanocrystalline celluloses (SPNCCs). Cellulose was mixed with the aqueous H2SO4 (60 wt%) at 5:100 ratio (wt%) and was stirred at 45°C for 45 min at a rotation speed of 1,200 rpm using a mechanical stirrer. Then, washing process took place for the hydrolysed cellulose for four repetitions through centrifugation (6,000 rpm, 20 min and 20°C) to remove all the leftover H2SO4. Next, the cellulose was dialysed using distilled water until neutral pH (6.5–7) was reached. Sonication process was performed to the cellulose using a sonicator for 30 min. The final cellulose was freeze dried and kept in cool place before further analysis and application as starch film’s reinforcement.

2.6 Preparation of SPS/SPNCCs-incorporated CEO nanocomposite films

Composite films from SPNCCs were prepared by solution casting technique. Firstly, all materials and solutions such as sorbitol, glycerol, starch (10 g), SPNCCs (0.05 g), cinnamon EOs, tween 80 and distilled water (190 mL) were prepared. All the solutions were mixed together by simple stirring, and the mixture was put into the sonicator to produce a homogenous nanocomposite film. About 190 mL of distilled water was added to the prepared solution with different concentrations of cinnamon EOs, as presented in Table 1, and the solutions were sonicated for 30 min. After sonication process, 10 g of SPS solution was poured and stirred for 20 min at 1,000 rpm at 85°C in a disperser to gelatinize the starch. This process is vital to assure that homogenous dispersion happened simultaneously and the starch granules were uniformly degraded. The ratio of plasticizers used was 1:1, which was about 1.5 wt% of the plasticizers in this experiment. The film-forming process was performed under vacuum condition so that the air bubbles were removed. Then, the solution-casting process was performed by pouring 45 g of the suspension into a 15 cm diameter petri dish. The setup was then kept in an oven for overnight drying at 40°C. Next, the film was removed from the petri dish and kept in a controlled room at 23 ± 2°C and relative humidity of 53 ± 1% for 7 days.

Denotations of SPS/SPNCC-incorporated CEO nanocomposite films

| Denotation of the films | Formulation | ||

|---|---|---|---|

| Sorbitol (wt%) | Glycerol (wt%) | CEO (wt%) | |

| 1 | 1.5 | 1.5 | 0 |

| 2 | 1.5 | 1.5 | 0.8 |

| 3 | 1.5 | 1.5 | 1.2 |

| 4 | 1.5 | 1.5 | 1.6 |

| 5 | 1.5 | 1.5 | 2.0 |

2.7 Scanning electron microscopy

A field emission electron microscope (FEI NOVA NanoSEM 230, Czech Republic) was used to investigate the morphology of the films. All the samples were gold-coated by using a plasma argon (sputter coater K575X; Edwards Limited, Crawley, United Kingdom) to prevent unwanted charging. The SEM testing was conducted at a 3 kV acceleration voltage.

2.8 Thermogravimetric analysis

The thermal stability of the samples was investigated using a Q series thermal analysis machine (TA Instruments, New Castle, DE, USA). The process was conducted in an aluminium vessel in dynamic nitrogen environment. The heating rate was fixed at 10°C/min to heat the samples in a temperature range of 25–800°C. About 5–15 mg of the sample was put in the metallic vessel and was made ready for the heating process. Then, the temperature was increased for strong heating. The weight loss determination was analysed from the plot of per cent of mass loss against temperature (thermogravimetric analysis [TGA] curve).

2.9 Flammability test

Flammability test was carried out for all samples via horizontal burning test according to ASTM D635 with slight modification. Samples having dimensions of 120 mm × 10 mm × 0.2 mm were prepared and two lines at 25 and 100 mm from one end of the sample were drawn as the reference marks. Then, fire was ignited with natural gas on one end of the sample. The overall burnt length and the time taken for the flame to spread to the 25 and 100 mm reference marks were noted. The linear rate of the burning samples was calculated using equation (1).

where V is the linear burning rate (mm/min), L is the burnt length (mm) and t is the time (minutes).

3 Results and discussion

3.1 Microscopy analysis

SPS-based films that are homogeneous, flexible and thin (0.25 mm) were obtained. After drying, they were easily peeled off the petri dish plates. From the observation, all films were yellowish in colour and slightly opaque (Figure 1). The microstructure test was performed to determine the appearance and presence of EO on the morphological surface of the biofilms. Microscopic film analysis is closely linked to the physical properties of the final materials of biofilms, including the visual, mechanical and barrier properties. Figure 2 displays the scanning electron microscopy (SEM) micrographs corresponding to the biofilm surfaces and also the SEM micrographs of active SPS films surface with remarkable changes. The control film surface without CEO exhibited a smooth and uniform texture without traces of starch granular or cracks (Figure 2a). The finding is similar to Ilyas et al. [21,53,60] who also reported the appearance of continuous and smooth microstructure for SPS film. Meanwhile, Acosta et al. [73], who studied the microstructure of starch–gelatin (SG) blend films, revealed that neat SG composite films (without EO) showed heterogeneous structures on their surface. Formation of circles was detected on the surface of the SG films because of the incomplete miscibility of starch and gelatin. It was also associated with the polymer separation phase that gave rise to starch-rich phase that was interpenetrated with a gelatin-rich phase. The incorporation of CEO in SPN/SPS biofilms affected the SPS matrix microstructure, as presented in Figure 2b–e. Adding 0.8, 1.2, 1.6% and 2.0% CEO to the SPN/SPS biofilm yielded uneven surface structures with the increasing surface coarseness with CEO concentration (Figure 2b–f), similar to the findings reported by Choi et al. [74]. Since the surface of the pure film had no micro-porous holes, these phenomena may be caused by the evaporation of essential oils after the drying process [29]. In Figure 2b–f, irregularities were exhibited in cross-section images of the control film that looked like a network of fibres. Homogenous and smooth surface was observed in Figure 2a, without the presence of micro-porous holes. The formation of this microstructure might be associated with the incomplete dissolution/gelatinization of starch granules that are held together by the solubilized-gelatinized starch fraction [29]. Similar results were obtained for different starch-based films as reported in ref. [4,29,43] and other authors. The crosssection of the films revealed the micro-porous spots that emerged as micro-porous holes under the micrographs (Figure 2b–e). The number and size of the microporous holes were found to increase with concentrations of CEO. The appearance of abundant holes corresponded to the position of the oil droplets, where these droplets could partially vaporize on the cryo-fractured surface during SEM analysis because of the high vacuum condition. They were elongated, which, as previously noted, could be explained by their distortion during drying of the film and consecutive packaging of the polymer chains [29]. Similar results were obtained by Peng and Li [75] and Sánchez-González et al. [76], who worked with lion oil and tea tree EO that were added to chitosan films and hydroxypropyl methylcellulose films, respectively.

Transparent film of CEO-reinforced SPN/SPS biocomposite film.

SPN/SPS biocomposite film incorporated with (a) 0%, (b) 0.8%, (c) 1.2%, (d) 1.6 and (e) 2.0% of CEO.

3.2 FTIR spectroscopy analysis

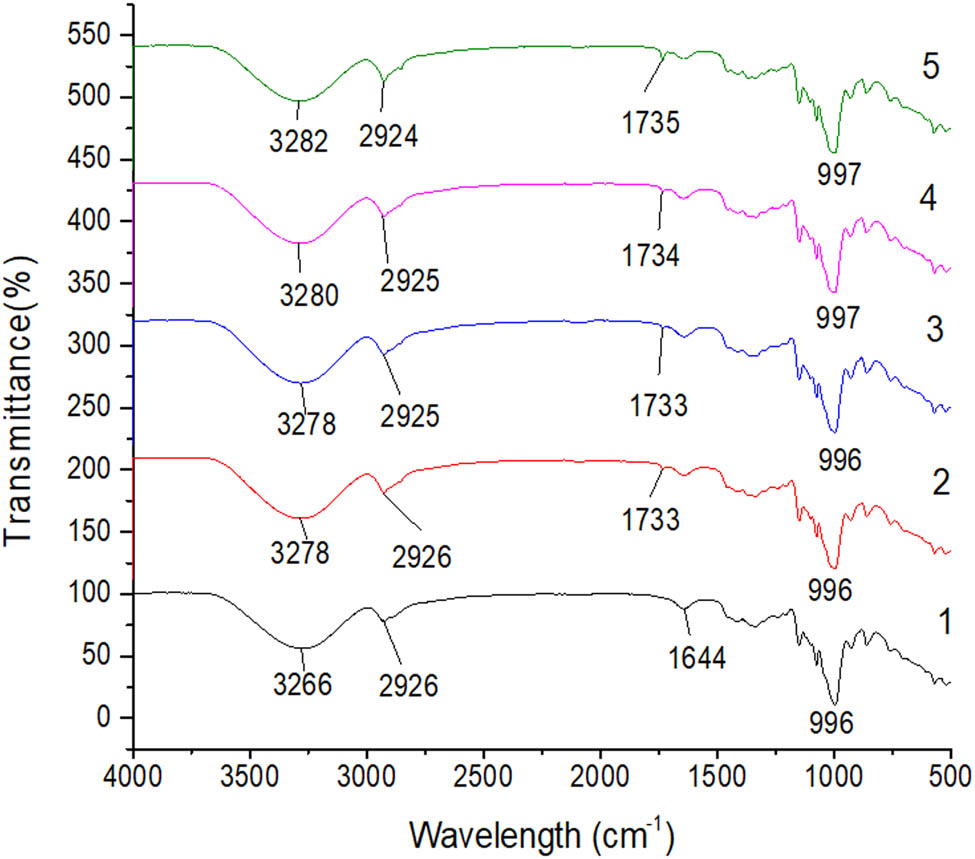

The FTIR spectra of the control SPS/SPNCC nanocomposite film and SPS/SPNCC nanocomposite films incorporated with various concentration of cinnamon EO are shown in Figure 3. The purpose of this analysis was to identify the changes occurred in the chemical structures of the films. Intermolecular rearrangement of polysaccharide chain orientation can be recognized by analysing the spectral differences between the films. The peak at 996 cm−1 was associated with C–O bond of C–O–C groups. The high peak that displayed at 2,926 cm−1 was assigned to C–H stretching, whereas the low peak at 1,644 cm−1 corresponded to C–O stretching. O–H group assigned at the broad peak of the film, which was observed from 3,000 to 3,700 cm−1, is an indicator of hydrophilic properties because of the presence of hydroxyl group in nanofibre. These findings reflect those of Ilyas et al. [77]. The peak at 1,735 cm−1 was associated with aldehyde groups [78,79]. According to Salzer et al. [78] and Shankaranarayana et al. [79], CEO contains a high amount of aldehyde. An absorbance peak at 1,733 cm−1 appeared in cinnamon EO-incorporated films, and this peak shifted from 1,733 to 1,735 cm−1 as the concentration increased [79].

FTIR spectra of cinnamon EO-incorporated SPS/SPNCC nanocomposite films.

The broad peaks at 3,000–3,500 cm−1 were because of the relative peak strength of stretching vibrations for O–H groups in the films. Films incorporated with cinnamon EO had higher amplitude of peaks near 3,266 cm−1. This indicates the presence of EO that contains hydrocarbons in the matrix. As the EO concentrations in the films increased, the peak at wavenumber 3,266 cm−1 shifted to 3,282 cm−1. The peak shifting can be attributed to the fact that hydrogen bonding between molecules was partially destroyed [62]. The differences in absorption peaks for films incorporated with cinnamon EO indicated that the molecular structure had been altered [80]. It is probably because of the formation of hydrogen bonding between hydroxyl group and cinnamon EO compounds. The peak shifting from lower to higher wavenumber was largely attributed to different conformations of molecular structures induced by the addition of cinnamon EO.

Furthermore, the peak at 996 cm−1 was shifted to 997 cm−1 probably because of new interaction between C–O stretching vibrations for EOs and the starch molecules. The changes in wavenumber were probably caused by the electron jumps between orbitals with well-defined energy differences, and the bonds in the given molecules may bend, rotate or stretch with certain frequencies [81]. The result also showed a similar IR spectrum compared to control film. The increase in EO concentration caused the inter/intra-molecular interaction existed between the starch and the EO via hydrogen bonding or the van der walls force [77]. The band greater than 996 cm−1 was attributed to C–O stretching vibrations of polysaccharide compound of starch and glycerol [55]. The results suggested that the addition of cinnamon EO influenced the molecular interaction of polymer chain in the film matrix [43]. As the substances were mixed, physical blends against chemical reactions caused changes in the spectral peak [82]. It is generally known that hydrogen bonding will increase the wavenumber of bending vibrations but decrease the wavenumber of stretching vibrations [81]. The FTIR results indicate the existence of the interaction between SPS and cinnamon EO.

3.3 Thermogravimetric analysis

The effect of the CEO on the thermal stability of the composites was examined by TGA and derivative thermogravimetry (DTG) curves, and the results are presented in Figure 4. Thermal analysis test allows food manufacturers to optimize production, storage, transportation, cooking and consumption quality of the food. TGA techniques continually examined the mass of a sample as it is heated or cooled at a regulated rate or is held at a selected temperature for a set length of time. TGA is useful for tracking processes that involve a shift in the mass of a food packaging materials, and applications typically involve evaporation, desorption and vaporization behaviour, as well as thermal stability, decomposition and compositional investigation. Besides that, the TGA indicates maximum temperature for the food packaging to package food. From the thermograms, it can be observed that both the SPN/SPS and the CEO/SPN/SPS biocomposite films degraded in similar steps, as shown in Figure 4. In the TGA and DTG curves of control SPS, multi-step thermal decomposition events have been observed. Similar results with two-step thermal decompositions in majority of starch-based films were obtained and reported in the literatures [21,54]. Apart from that, the mass loss of the sample was decreased with the increment of CEO loading, as stated in Table 2. The first degradation step represented by small peak DTG curve occurred below 100°C, approximately at T max ≈ 69–90°C. This was because of the evaporation of the broken inter- and intra-molecular hydrogen bonds followed by loss of water. Besides that, mass loss at this temperature range might also be because of the removal of water or evaporation of low molecular weight compounds and loosely bonded water in the sample. As more CEO added in the film solution, the amount of water decreased. The same phenomenon was observed to occur for the other film samples, including control SPS, as can be clearly seen in their DTG curves.

TGA and DTG curves of SPN/SPS and CEO/SPN/SPS biocomposite films in different concentrations.

Maximum weight loss rate degradation temperature (T max), weight loss (W L) and char yield for SPN/SPS and CEO/SPN/SPS biocomposite films for different concentrations obtained from the TG and DTG curves

| Samples | 1st thermal degradation | 2nd thermal degradation | Char yield | ||

|---|---|---|---|---|---|

| T max (°C) | W L (%) | T max (°C) | W L (%) | W (%) | |

| 1 | 89.51 | 14.93 | 289.18 | 77.76 | 6.752 |

| 2 | 69.95 | 13.16 | 292.72 | 81.17 | 5.668 |

| 3 | 69.75 | 12.23 | 295.36 | 79.93 | 7.088 |

| 4 | 69.54 | 12.67 | 295.67 | 80.11 | 6.704 |

| 5 | 69.13 | 10.84 | 296.25 | 81.36 | 6.074 |

A prolonged pyrolysis process took place at 200–370°C and reached maximum mass loss at 296.25°C. From Figure 4, it was obvious that control film was less stable compared to other films, having the lowest decomposition temperature of 289°C compared to CEO-reinforced SPN/SPS biocomposites. The weight loss might be associated with the vaporization and decomposition (oxidative and thermal) of bio-polymers and elimination of glycerol and volatile products [54,83]. In the TGA thermogram of CEO/SPN/SPS, the weight loss was initiated at around 40°C, showing an onset point at around 80°C, indicating that CEO has volatile nature. The flash point of cinnamon oils is between 38 and 60°C.

The thermal stability of polymer networks was shown to be improved by the CEO, as control films displayed lower weight loss temperature (T max ≈ 289.18°C) than CEO films. The thermal stability of the films increased with the loading of CEO. The lowest loading (CEO sample 1) resulted in lower thermal stability and was increased with increased loading (CEO samples 2 and 3). This phenomenon could be associated with polymer structure rearrangement following the addition of higher CEO concentrations. It was observed that the polymer structure changed with the smallest quantity of CEO, but upon adding more CEO, the thermal stability increased. This was related to the rise in crystallinity indexes when the CEO concentration increased, as described by Noshirvani et al. [84]. Ma et al. [85], who observed the same pattern, concluded that the use of olive oil in the film matrix has led to an increased gelatine transition helix–coil temperature. They decided that olive oil created non-miscible emulsified phases in the films. The thermal stability is also parallel to the degree of crystallinity. Higher degree of crystallinity resulted in higher thermal stability [21,54,86]. This was ascribed to lower neat SPS values similar to the findings also observed in other works [87,88].

3.4 Flammability analysis

Plastics have become one of the most useful materials known to humankind. Because of their chemical composition, plastics can easily ignite when exposed to sufficient heat in the presence of oxygen. Because of the rate of burning for plastics, considerable work has been directed to study and minimize the flammability issues of these materials, like the addition of flame retardant chemicals to prevent or minimize the combustion of these materials. This test is done to classify and measure burning characteristics of plastics. Figure 5 shows the effect of varying CEO loadings on the flammability of SPN/SPS composites, as indicated by the linear burning rate. The burning rate was increased with CEO concentration. With 2% CEO, the SPN/SPS biocomposite displayed the shortest burnout time compared to the unfilled composites and then had the highest linear burning rate. Most EOs, including CEO, are extremely flammable [89,90,91]. CEO possesses complex mixture comprising over 300 different compounds [92,93]. CEO consists of volatile organic compounds, typically having molecular weight below 300 [94,95]. The volatile compounds are from different chemical classes, such as ethers and oxide, ketones, alcohols, amines, aldehydes, phenols, esters and amides. The flash point for CEO is 71°C, which explained the flammability characteristic of the film composites. During the burning process, the CEO formed a non-protective oil layer on the surface of the matrix, serving as an oxygen conductor and permitting heat to penetrate the matrix [96,97]. Therefore, the quantity of decomposed volatiles that escaped the interior polymer matrix was increased, resulting in a shorter burning time and thus increasing the linear burning rate.

The effect of different CEO loadings on the flammability of SPN/SPS biocomposite film.

4 Conclusions

The thermal stability of the CEO/SPN/SPS biopolymer composites was remarkably improved with increasing CEO loadings (sample 5, T max = 296.25°C) compared to the thermal stability of the unfilled compound (sample 1, T max = 289.18°C). The control film surface without CEO displayed a uniform and smooth texture with no traces of starch granular or crack. The presence of the CEO in the SPN/SPS biofilms affected the microstructures of the SPS matrix, resulting in rough surface structures and increased surface coarseness with CEO concentrations. The appearance of numerous holes was consistent with the position of oil droplets, where the number of holes rose as EO loading increased. Because of the high vacuum situation, this can partially evaporate on the cryo-fractured surface during SEM study. The linear burning rate was increased with the CEO concentration. The SPN/SPS biocomposite with 2% CEO showed the shortest burnout time compared to the unfilled composites and hence had the fastest linear burning rate.

Acknowledgements

The authors are thankful to Universiti Putra Malaysia (UPM) for the financial support via the Graduate Research Assistantship (GRA), Ministry of Higher Education Malaysia Grant scheme HiCOE (6369107), Fundamental Research Grant Scheme (FRGS): FRGS/1/2017/TK05/UPM/01/1 (5540048) and Geran Putra Berimpak (GPB), UPM/800-3/3/1/GPB/2019/9679800.

-

Conflict of interest: The authors declare no conflict of interest regarding the publication of this paper.

References

[1] Ilyas RA, Sapuan SM, Kadier A, Kalil MS, Ibrahim R, Atikah MSN, et al. Properties and characterization of PLA, PHA, and other types of biopolymer composites. In: Al-Oqla F, Sapuan SM, editors. Advanced Processing, Properties, and Applications of Starch and Other Bio-Based Polymers. 1st ed Elsevier; 2020. p. 111–38.10.1016/B978-0-12-819661-8.00008-1Search in Google Scholar

[2] Lee CH, Sapuan SM, Ilyas RA, Lee SH, Khalina A. Development and processing of PLA, PHA, and other biopolymers. In: Al-Oqla F, Sapuan SM, editors. Advanced processing, properties, and applications of starch and other bio-based polymers. 1st ed Elsevier; 2020. p. 47–63.10.1016/B978-0-12-819661-8.00005-6Search in Google Scholar

[3] Sanyang ML, Ilyas RA, Sapuan SM, Jumaidin R. Sugar palm starch-based composites for packaging applications. Bionanocomposites for Packaging Applications [Internet]. Cham: Springer International Publishing; 2018. p. 125–47. Available from: http://link.springer.com/10.1007/978-3-319-67319-6_7.10.1007/978-3-319-67319-6_7Search in Google Scholar

[4] Song X, Zuo G, Chen F. Effect of essential oil and surfactant on the physical and antimicrobial properties of corn and wheat starch films. Int J Biol Macromol [Internet]. 2018 Feb;107:1302–9. Available from: https://linkinghub.elsevier.com/retrieve/pii/S0141813017320378.10.1016/j.ijbiomac.2017.09.114Search in Google Scholar PubMed

[5] Ilyas RA, Sapuan SM. Biopolymers and biocomposites: Chemistry and technology. Curr Anal Chem. 2020 Jul;16(5):500–3.10.2174/157341101605200603095311Search in Google Scholar

[6] Ilyas RA, Sapuan SM. The preparation methods and processing of natural fibre bio-polymer composites. Curr Org Synth. 2020 Jan;16(8):1068–70.10.2174/157017941608200120105616Search in Google Scholar PubMed

[7] Ilyas RA, Sapuan SM, Sanyang ML, Ishak MR, Zainudin ES. Nanocrystalline cellulose as reinforcement for polymeric matrix nanocomposites and its potential applications: A review. Curr Anal Chem [Internet]. 2018 May 7;14(3):203–25. Available from: http://www.eurekaselect.com/156148/article.10.2174/1573411013666171003155624Search in Google Scholar

[8] Ayu RS, Khalina A, Harmaen AS, Zaman K, Isma T, Liu Q, et al. Characterization study of empty fruit bunch (EFB) fibers reinforcement in poly(Butylene) succinate (PBS)/starch/glycerol composite sheet. Polymers. 2020 Jul;12(7):1571.10.3390/polym12071571Search in Google Scholar PubMed PubMed Central

[9] Jumaidin R, Khiruddin MAA, Asyul Sutan Saidi Z, Salit MS, Ilyas RA. Effect of cogon grass fibre on the thermal, mechanical and biodegradation properties of thermoplastic cassava starch biocomposite. Int J Biol Macromol. 2019;146:746–55.10.1016/j.ijbiomac.2019.11.011Search in Google Scholar PubMed

[10] Abral H, Basri A, Muhammad F, Fernando Y, Hafizulhaq F, Mahardika M, et al. A simple method for improving the properties of the sago starch films prepared by using ultrasonication treatment. Food Hydrocoll. 2019 Aug;93:276–83.10.1016/j.foodhyd.2019.02.012Search in Google Scholar

[11] do Evangelho JA, da Silva Dannenberg G, Biduski B, el Halal SLM, Kringel DH, Gularte MA, et al. Antibacterial activity, optical, mechanical, and barrier properties of corn starch films containing orange essential oil. Carbohydr Polym. 2019 Oct;222:114981.10.1016/j.carbpol.2019.114981Search in Google Scholar PubMed

[12] Pirouzifard M, Yorghanlu RA, Pirsa S. Production of active film based on potato starch containing Zedo gum and essential oil of Salvia officinalis and study of physical, mechanical, and antioxidant properties. J Thermoplast Compos Mater. 2020;33(7):915–37.10.1177/0892705718815541Search in Google Scholar

[13] Boufi S, Bouattour S, Ferraria AM, Ferreira LFV, Rego AMB D, Chehimi MM, et al. Cotton fibres functionalized with plasmonic nanoparticles to promote the destruction of harmful molecules: An overview. Nanotechnol Rev. 2020;8(1):671–80.10.1515/ntrev-2019-0058Search in Google Scholar

[14] Dwivedi SP, Dwivedi G. Utilization of RHA in development of hybrid composite by electromagnetic stir casting technique using RSM. J Mech Behav Mater. 2019;29(4):45–54.10.55713/jmmm.v29i4.538Search in Google Scholar

[15] Jain N, Somvanshi KS, Gope PC, Singh VK. Mechanical characterization and machining performance evaluation of rice husk/epoxy an agricultural waste based composite material. J Mech Behav Mater. 2019;28(1):29–38.10.1515/jmbm-2019-0005Search in Google Scholar

[16] Mazani N, Sapuan SM, Sanyang ML, Atiqah A, Ilyas RA. Design and fabrication of a shoe shelf from kenaf fiber reinforced unsaturated polyester composites. Lignocellulose for Future Bioeconomy. Elsevier; 2019. p. 315–32.10.1016/B978-0-12-816354-2.00017-7Search in Google Scholar

[17] Syafri E, Mashadi S, Yulianti E, Mochamad Asrofi D, Abral H, Sapuan SM, et al. Effect of sonication time on the thermal stability, moisture absorption, and biodegradation of water hyacinth (Eichhornia crassipes) nanocellulose-filled bengkuang (Pachyrhizus erosus) starch biocomposites. J Mater Res Technol. 2019 Nov;8(6):6223–31.10.1016/j.jmrt.2019.10.016Search in Google Scholar

[18] Chen C, Yang Y, Zhou Y, Xue C, Chen X, Wu H, et al. Comparative analysis of natural fiber reinforced polymer and carbon fiber reinforced polymer in strengthening of reinforced concrete beams. J Clean Prod [Internet]. 2020;263:121572. Available from: https://doi.org/10.1016/j.jclepro.2020.121572.10.1016/j.jclepro.2020.121572Search in Google Scholar

[19] Abral H, Ariksa J, Mahardika M, Handayani D, Aminah I, Sandrawati N, et al. Highly transparent and antimicrobial PVA based bionanocomposites reinforced by ginger nanofiber. Polym Test. 2019 Oct;(October):106186.10.1016/j.polymertesting.2019.106186Search in Google Scholar

[20] Abral H, Ariksa J, Mahardika M, Handayani D, Aminah I, Sandrawati N, et al. Transparent and antimicrobial cellulose film from ginger nanofiber. Food Hydrocoll. 2020 Jan;98:105266.10.1016/j.foodhyd.2019.105266Search in Google Scholar

[21] Ilyas RA, Sapuan SM, Ishak MR, Zainudin ES. Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bionanocomposites. Carbohydr Polym. 2018;202:186–202.10.1016/j.carbpol.2018.09.002Search in Google Scholar PubMed

[22] Ventrapragada LK, Creager SE, Rao AM, Podila R. Carbon nanotubes coated paper as current collectors for secondary li-ion batteries. Nanotechnol Rev. 2019;8(1):18–23.10.1515/ntrev-2019-0002Search in Google Scholar

[23] Thompson L, Azadmanjiri J, Nikzad M, Sbarski I, Wang J, Yu A. Cellulose nanocrystals: Production, functionalization and advanced applications. Rev Adv Mater Sci. 2019;58(1):1–16.10.1515/rams-2019-0001Search in Google Scholar

[24] Bukit N, Ginting EM, Hutagalung EA, Sidebang E, Frida E, Bukit BF. Preparation and characterization of oil palm ash from boiler to nanoparticle. Rev Adv Mater Sci. 2019;58(1):195–200.10.1515/rams-2019-0023Search in Google Scholar

[25] Chu YS, Davaabal B, Kim DS, Seo SK, Kim Y, Ruescher C, et al. Reactivity of fly ashes milled in different milling devices. Rev Adv Mater Sci. 2019;58(1):179–88.10.1515/rams-2019-0028Search in Google Scholar

[26] Naseer B, Srivastava G, Qadri OS, Faridi SA, Islam RU, Younis K. Importance and health hazards of nanoparticles used in the food industry. Nanotechnol Rev. 2018;7(6):623–41.10.1515/ntrev-2018-0076Search in Google Scholar

[27] Das S, Srivastava VC. An overview of the synthesis of CuO-ZnO nanocomposite for environmental and other applications. Nanotechnol Rev. 2018;7(3):267–82.10.1515/ntrev-2017-0144Search in Google Scholar

[28] Chen C, Yang Y, Yu J, Yu J, Tan H, Sui L, et al. Eco-friendly and mechanically reliable alternative to synthetic FRP in externally bonded strengthening of RC beams: Natural FRP. Compos Struct [Internet]. 2020;241(February):112081. Available from: https://doi.org/10.1016/j.compstruct.2020.112081.10.1016/j.compstruct.2020.112081Search in Google Scholar

[29] Souza AC, Goto GEO, Mainardi JA, Coelho ACV, Tadini CC. Cassava starch composite films incorporated with cinnamon essential oil: Antimicrobial activity, microstructure, mechanical and barrier properties. LWT - Food Sci Technol [Internet]. 2013 Dec;54(2):346–52. Available from: https://linkinghub.elsevier.com/retrieve/pii/S002364381300234X.10.1016/j.lwt.2013.06.017Search in Google Scholar

[30] Nielsen PV, Rios R. Inhibition of fungal growth on bread by volatile components from spices and herbs, and the possible application in active packaging, with special emphasis on mustard essential oil. Int J Food Microbiol. 2000;60(2–3):219–29.10.1016/S0168-1605(00)00343-3Search in Google Scholar

[31] Ju J, Chen X, Xie Y, Yu H, Guo Y, Cheng Y, et al. Application of essential oil as a sustained release preparation in food packaging. Trends Food Sci Technol. 2019 Oct;92:22–32.10.1016/j.tifs.2019.08.005Search in Google Scholar

[32] Bhavaniramya S, Vishnupriya S, Al-Aboody MS, Vijayakumar R, Baskaran D. Role of essential oils in food safety: Antimicrobial and antioxidant applications. Grain Oil. Sci Technol. 2019;49–55.10.1016/j.gaost.2019.03.001Search in Google Scholar

[33] Atarés L, Chiralt A. Essential oils as additives in biodegradable films and coatings for active food packaging. Trends Food Sci Technol. 2016;48:51–62.10.1016/j.tifs.2015.12.001Search in Google Scholar

[34] Donsì F, Ferrari G. Essential oil nanoemulsions as antimicrobial agents in food. J Biotechnol. 2016;233:106–20.10.1016/j.jbiotec.2016.07.005Search in Google Scholar PubMed

[35] Song X, Zuo G, Chen F. Effect of essential oil and surfactant on the physical and antimicrobial properties of corn and wheat starch films. Int J Biol Macromol. 2018;107(PartA):1302–9.10.1016/j.ijbiomac.2017.09.114Search in Google Scholar PubMed

[36] Resianingrum R, Atmaka W, Khasanah LU, Kawiji, Utami RPD. Characterization of cassava starch-based edible film enriched with lemongrass oil (Cymbopogon citratus). Nusant Biosci [Internet]. 2016 Dec 1;8(2):278–82. Available from: http://biosains.mipa.uns.ac.id/N/N0802/N080223.pdf.10.13057/nusbiosci/n080223Search in Google Scholar

[37] Rojas-Graü MA, Avena-Bustillos RJ, Olsen C, Friedman M, Henika PR, Martín-Belloso O, et al. Effects of plant essential oils and oil compounds on mechanical, barrier and antimicrobial properties of alginate-apple puree edible films. J Food Eng. 2007;81(3):634–41.10.1016/j.jfoodeng.2007.01.007Search in Google Scholar

[38] Liang R, Xu S, Shoemaker CF, Li Y, Zhong F, Huang Q. Physical and antimicrobial properties of peppermint oil nanoemulsions. J Agric Food Chem. 2012;60:7548–55.10.1021/jf301129kSearch in Google Scholar PubMed

[39] Liakos I, Rizzello L, Scurr DJ, Pompa PP, Bayer IS, Athanassiou A. All-natural composite wound dressing films of essential oils encapsulated in sodium alginate with antimicrobial properties. Int J Pharm [Internet]. 2014;463(2):137–45. Available from: http://dx.doi.org/10.1016/j.ijpharm.2013.10.046.10.1016/j.ijpharm.2013.10.046Search in Google Scholar PubMed

[40] Iamareerat B, Singh M, Sadiq MB, Anal AK. Reinforced cassava starch based edible film incorporated with essential oil and sodium bentonite nanoclay as food packaging material. J Food Sci Technol [Internet]. 2018 May 5;55(5):1953–9. Available from: http://link.springer.com/10.1007/s13197-018-3100-7.10.1007/s13197-018-3100-7Search in Google Scholar PubMed PubMed Central

[41] Utami R, Khasanah LU, Manuhara GJ, Ayuningrum ZK. Effects of cinnamon bark essential oil (cinnamomum burmannii) on characteristics of edible film and quality of fresh beef. Pertanika J Trop Agric Sci. 2019;42(4):1173–84.Search in Google Scholar

[42] Nazari M, Majdi H, Milani M, Abbaspour-Ravasjani S, Hamishehkar H, Lim LT. Cinnamon nanophytosomes embedded electrospun nanofiber: Its effects on microbial quality and shelf-life of shrimp as a novel packaging. Food Packag Shelf. Life [Internet]. 2019;21(June):100349. Available from: https://doi.org/10.1016/j.fpsl.2019.100349.10.1016/j.fpsl.2019.100349Search in Google Scholar

[43] Jamróz E, Juszczak L, Kucharek M. Investigation of the physical properties, antioxidant and antimicrobial activity of ternary potato starch-furcellaran-gelatin films incorporated with lavender essential oil. Int J Biol Macromol [Internet]. 2018;114(2017):1094–101. Available from: https://doi.org/10.1016/j.ijbiomac.2018.04.014.10.1016/j.ijbiomac.2018.04.014Search in Google Scholar PubMed

[44] Avila-Sosa R, Hernández-Zamoran E, López-Mendoza I, Palou E, Munguía MTJ, Nevárez-Moorillón GV, et al. Fungal inactivation by Mexican oregano (lippia berlandieri schauer) essential oil added to amaranth, chitosan, or starch edible films. J Food Sci [Internet]. 2010 Apr;75:M127–33. Available from: http://doi.wiley.com/10.1111/j.1750-3841.2010.01524.x3.10.1111/j.1750-3841.2010.01524.xSearch in Google Scholar PubMed

[45] Cano A, Cháfer M, Chiralt A. González-Martínez C. Physical and antimicrobial properties of starch-PVA blend films as affected by the incorporation of natural antimicrobial agents. Foods [Internet]. 2015;5(1):3. Available from: http://www.mdpi.com/2304-8158/5/1/3.10.3390/foods5010003Search in Google Scholar PubMed PubMed Central

[46] Silveira MP, Silva HC, Pimentel IC, Poitevin CG, da Costa Stuart AK, Carpiné D, et al. Development of active cassava starch cellulose nanofiber-based films incorporated with natural antimicrobial tea tree essential oil. J Appl Polym Sci. 2020;137(21):1–11.10.1002/app.48726Search in Google Scholar

[47] Aitboulahsen M, El Galiou O, Laglaoui A, Bakkali M, Hassani, Zerrouk M. Effect of plasticizer type and essential oils on mechanical, physicochemical, and antimicrobial characteristics of gelatin, starch, and pectin-based films. J Food Process Preserv. 2020;44(6):1–10.10.1111/jfpp.14480Search in Google Scholar

[48] Mustapha FA, Jai J, Nik Raikhan NH, Sharif ZIM, Yusof NM. Response surface methodology analysis towards biodegradability and antimicrobial activity of biopolymer film containing turmeric oil against Aspergillus niger. Food Control [Internet]. 2019;99(December 2018):106–13. Available from: https://doi.org/10.1016/j.foodcont.2018.12.042.10.1016/j.foodcont.2018.12.042Search in Google Scholar

[49] Sánchez Aldana D, Andrade-Ochoa S, Aguilar CN, Contreras-Esquivel JC, Nevárez-Moorillón GV. Antibacterial activity of pectic-based edible films incorporated with Mexican lime essential oil. Food Control [Internet]. 2015;50:907–12. Available from: http://dx.doi.org/10.1016/j.foodcont.2014.10.044.10.1016/j.foodcont.2014.10.044Search in Google Scholar

[50] Hosseini SF, Rezaei M, Zandi M, Farahmandghavi F. Development of bioactive fish gelatin/chitosan nanoparticles composite films with antimicrobial properties. Food Chem [Internet]. 2016;194:1266–74. Available from: http://dx.doi.org/10.1016/j.foodchem.2015.09.004.10.1016/j.foodchem.2015.09.004Search in Google Scholar PubMed

[51] Shahbazi Y. The properties of chitosan and gelatin films incorporated with ethanolic red grape seed extract and Ziziphora clinopodioides essential oil as biodegradable materials for active food packaging. Int J Biol Macromol [Internet]. 2017;99:746–53. Available from: http://dx.doi.org/10.1016/j.ijbiomac.2017.03.065.10.1016/j.ijbiomac.2017.03.065Search in Google Scholar PubMed

[52] Dashipour A, Razavilar V, Hosseini H, Shojaee-Aliabadi S, German JB, Ghanati K, et al. Antioxidant and antimicrobial carboxymethyl cellulose films containing Zataria multiflora essential oil. Int J Biol Macromol [Internet]. 2015;72:606–13. Available from: http://dx.doi.org/10.1016/j.ijbiomac.2014.09.006.10.1016/j.ijbiomac.2014.09.006Search in Google Scholar PubMed

[53] Ilyas RA, Sapuan SM, Ibrahim R, Abral H, Ishak MR, Zainudin ES, et al. Effect of sugar palm nanofibrillated cellulose concentrations on morphological, mechanical and physical properties of biodegradable films based on agro-waste sugar palm (Arenga pinnata (Wurmb.) Merr) starch. J Mater Res Technol [Internet]. 2019 Sep;8(5):4819–30. Available from: https://linkinghub.elsevier.com/retrieve/pii/S2238785419308828.10.1016/j.jmrt.2019.08.028Search in Google Scholar

[54] Ilyas RA, Sapuan SM, Ibrahim R, Abral H, Ishak MR, Zainudin ES, et al. Thermal, biodegradability and water barrier properties of bio-nanocomposites based on plasticised sugar palm starch and nanofibrillated celluloses from sugar palm fibres. J Biobased Mater Bioenergy. 2020;14:1–13.10.1166/jbmb.2020.1951Search in Google Scholar

[55] Ilyas RA, Sapuan SM, Ibrahim R, Abral H, Ishak MR, Zainudin ES, et al. Effect of sugar palm nanofibrillated cellulose concentrations on morphological, mechanical and physical properties of biodegradable films based on agro-waste sugar palm (Arenga pinnata(Wurmb.) Merr) starch. J Mater Res Technol [Internet]. 2019;8(5):4819–30. Available from: https://doi.org/10.1016/j.jmrt.2019.08.028.10.1016/j.jmrt.2019.08.028Search in Google Scholar

[56] Ilyas RA, Sapuan SM, Ishak MR, Zainudin ES, Atikah MSN. Characterization of sugar palm nanocellulose and its potential for reinforcement with a starch-based composite. Sugar Palm Biofibers, Biopolymers, & Biocomposites. 1st ed. Boca Raton: CRC Press/Taylor & Francis Group; 2018. p. 190–212.10.1201/9780429443923-10Search in Google Scholar

[57] Ilyas RA, Sapuan SM, Kadier A, Krishnan S, Atikah MSN, Ibrahim R, et al. Mechanical testing of sugar palm fiber reinforced sugar palm biopolymer composites. In: Al-Oqla F, Sapuan SM, editors. Advanced processing, properties, and applications of starch and other bio-based polymers. 1st ed. Elsevier; 2020. p. 89–110.10.1016/B978-0-12-819661-8.00007-XSearch in Google Scholar

[58] Hazrol MD, Sapuan SM, Ilyas RA, Othman ML, Sherwani SFK. Electrical properties of sugar palm nanocrystalline cellulose reinforced sugar palm starch nanocomposites. Polimery. 2020 May;65(5):363–70.10.14314/polimery.2020.5.4Search in Google Scholar

[59] Ilyas RA, Sapuan SM, Atiqah A, Ibrahim R, Abral H, Ishak MR, et al. Sugar palm (Arenga pinnata [Wurmb.] Merr) starch films containing sugar palm nanofibrillated cellulose as reinforcement: Water barrier properties. Polym Compos. 2020 Feb;41(2):459–67.10.1002/pc.25379Search in Google Scholar

[60] Atikah MSN, Ilyas RA, Sapuan SM, Ishak MR, Zainudin ES, Ibrahim R, et al. Degradation and physical properties of sugar palm starch/sugar palm nanofibrillated cellulose bionanocomposite. Polimery. 2019;64(10):27–36.10.14314/polimery.2019.10.5Search in Google Scholar

[61] Ilyas RA, Sapuan SM, Ishak MR, Zainudin ES. Water transport properties of bio-nanocomposites reinforced by sugar palm (Arenga Pinnata) nanofibrillated cellulose. J Adv Res Fluid Mech Therm Sci J. 2018;51(2):234–46.Search in Google Scholar

[62] Ilyas RA, Sapuan SM, Ishak MR. Isolation and characterization of nanocrystalline cellulose from sugar palm fibres (Arenga Pinnata). Carbohydr Polym. 2018;181(November 2017):1038–51.10.1016/j.carbpol.2017.11.045Search in Google Scholar PubMed

[63] Ilyas RA, Sapuan SM, Ishak MR, Zainudin ES. Sugar palm nanofibrillated cellulose (Arenga pinnata (Wurmb.) Merr): Effect of cycles on their yield, physic-chemical, morphological and thermal behavior. Int J Biol Macromol [Internet]. 2018;123:379–88. Available from: https://linkinghub.elsevier.com/retrieve/pii/S0141813018331477.10.1016/j.ijbiomac.2018.11.124Search in Google Scholar PubMed

[64] Ilyas RA, Sapuan SM, Ibrahim R, Abral H, Ishak MR, Zainudin ES, et al. Sugar palm (Arenga pinnata (Wurmb.) Merr) cellulosic fibre hierarchy: A comprehensive approach from macro to nano scale. J Mater Res Technol. 2019 May;8(3):2753–66.10.1016/j.jmrt.2019.04.011Search in Google Scholar

[65] Ilyas RA, Sapuan SM, Atikah MSN, Asyraf MRM, Ayu Rafiqah S, Aisyah HA, et al. Effect of hydrolysis time on the morphological, physical, chemical, and thermal behavior of sugar palm nanocrystalline cellulose (Arenga pinnata (Wurmb.) Merr). Text Res J. 2020 Jun. 004051752093239.10.1177/0040517520932393Search in Google Scholar

[66] Kechichian V, Ditchfield C, Veiga-Santos P, Tadini CC. Natural antimicrobial ingredients incorporated in biodegradable films based on cassava starch. LWT - Food Sci Technol. 2010 Sep;43(7):1088–94.10.1016/j.lwt.2010.02.014Search in Google Scholar

[67] Ojagh SM, Rezaei M, Razavi SH, Hosseini SMH. Development and evaluation of a novel biodegradable film made from chitosan and cinnamon essential oil with low affinity toward water. Food Chem [Internet]. 2010;122(1):161–6. Available from: http://dx.doi.org/10.1016/j.foodchem.2010.02.033.10.1016/j.foodchem.2010.02.033Search in Google Scholar

[68] Oussalah M, Caillet S, Saucier L, Lacroix M. Antimicrobial effects of selected plant essential oils on the growth of a Pseudomonas putida strain isolated from meat. Meat Sci. 2006;73(2):236–44.10.1016/j.meatsci.2005.11.019Search in Google Scholar PubMed

[69] Oussalah M, Caillet S, Saucier L, Lacroix M. Inhibitory effects of selected plant essential oils on the growth of four pathogenic bacteria: E. coli O157:H7, Salmonella Typhimurium, Staphylococcus aureus and Listeria monocytogenes. Food Control. 2007;18(5):414–20.10.1016/j.foodcont.2005.11.009Search in Google Scholar

[70] Lapčík L, Vašina M, Lapčíková B, Hui D, Otyepková E, Greenwood RW, et al. Materials characterization of advanced fillers for composites engineering applications. Nanotechnol Rev. 2019;8(1):503–12.10.1515/ntrev-2019-0045Search in Google Scholar

[71] Sahari J, Sapuan SM, Zainudin ES, Maleque MA. Thermo-mechanical behaviors of thermoplastic starch derived from sugar palm tree (Arenga pinnata). Carbohydr Polym. 2013 Feb;92(2):1711–6.10.1016/j.carbpol.2012.11.031Search in Google Scholar PubMed

[72] Sanyang ML, Sapuan SM, Jawaid M, Ishak MR, Sahari J. Effect of sugar palm-derived cellulose reinforcement on the mechanical and water barrier properties of sugar palm starch biocomposite films. BioResources. 2016;11(2):4134–45.10.15376/biores.11.2.4134-4145Search in Google Scholar

[73] Acosta S, Jiménez A, Cháfer M, González-Martínez C, Chiralt A. Physical properties and stability of starch-gelatin based films as affected by the addition of esters of fatty acids. Food Hydrocoll. 2015;49:135–43.10.1016/j.foodhyd.2015.03.015Search in Google Scholar

[74] Choi WS, Singh S, Lee YS. Characterization of edible film containing essential oils in hydroxypropyl methylcellulose and its effect on quality attributes of ‘Formosa’ plum (Prunus salicina L.). LWT. 2016 Jul;70:213–22.10.1016/j.lwt.2016.02.036Search in Google Scholar

[75] Peng Y, Li Y. Combined effects of two kinds of essential oils on physical, mechanical and structural properties of chitosan films. Food Hydrocoll. 2014 May;36:287–93.10.1016/j.foodhyd.2013.10.013Search in Google Scholar

[76] Sánchez-González L, Pastor C, Vargas M, Chiralt A, Gonzalez-Martinez C, Chafer M. Effect of hydroxypropylmethylcellulose and chitosan coatings with and without bergamot essential oil on quality and safety of cold-stored grapes. Postharvest Biol Technol. 2011;60(1):57–63.10.1016/j.postharvbio.2010.11.004Search in Google Scholar

[77] Ilyas RA, Sapuan SM, Ishak MR, Zainudin ES, Products F. Sugar palm nanofibrillated cellulose fibre reinforced sugar palm starch nanocomposite. Part 1: Morphological. Mechanical and physical properties. 2018 September:1–30.10.20944/preprints201809.0140.v1Search in Google Scholar

[78] Salzer UJ, Furia TE. The analysis of essential oils and extracts (oleoresins) from seasonings – A critical review. C R C Crit Rev Food Sci Nutr. 1977;9(4):345–73.10.1080/10408397709527239Search in Google Scholar PubMed

[79] Shankaranarayana ML, Raghavan B, Abraham KO, Natarajan CP. Titrimetric determination of total aldehydes in cinnamon bark and leaf oils using chloramine‐T reagent. J Food Qual. 1981;4(1):35–41.10.1111/j.1745-4557.1981.tb00710.xSearch in Google Scholar

[80] Liu X, Xu Y, Zhan X, Xie W, Yang X, Cui SW, et al. Development and properties of new kojic acid and chitosan composite biodegradable films for active packaging materials. Int J Biol Macromol [Internet]. 2020;144:483–90. Available from: https://doi.org/10.1016/j.ijbiomac.2019.12.126.10.1016/j.ijbiomac.2019.12.126Search in Google Scholar PubMed

[81] Ahmad M, Hani NM, Nirmal NP, Fazial FF, Mohtar NF, Romli SR. Optical and thermo-mechanical properties of composite films based on fish gelatin/rice flour fabricated by casting technique. Prog Org Coatings [Internet]. 2015;84:115–27. Available from: http://dx.doi.org/10.1016/j.porgcoat.2015.02.016.10.1016/j.porgcoat.2015.02.016Search in Google Scholar

[82] Xu YX, Kim KM, Hanna MA, Nag D. Chitosan-starch composite film: Preparation and characterization. Ind Crops Prod. 2005;21(2):185–92.10.1016/j.indcrop.2004.03.002Search in Google Scholar

[83] Ilyas RA, Sapuan SM, Ishak MR, Zainudin ES. Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bionanocomposites. Carbohydr Polym [Internet]. 2018;202(September):186–202. Available from: https://doi.org/10.1016/j.carbpol.2018.09.002.10.1016/j.carbpol.2018.09.002Search in Google Scholar PubMed

[84] Noshirvani N, Ghanbarzadeh B, Gardrat C, Rezaei MR, Hashemi M, Le Coz C, et al. Cinnamon and ginger essential oils to improve antifungal, physical and mechanical properties of chitosan-carboxymethyl cellulose films. Food Hydrocoll. 2017 Sep;70:36–45.10.1016/j.foodhyd.2017.03.015Search in Google Scholar

[85] Ma W, Tang C-H, Yin S-W, Yang X-Q, Wang Q, Liu F, et al. Characterization of gelatin-based edible films incorporated with olive oil. Food Res Int. 2012 Nov;49(1):572–9.10.1016/j.foodres.2012.07.037Search in Google Scholar

[86] Sun L, Sun J, Chen L, Niu P, Yang X, Guo Y. Preparation and characterization of chitosan film incorporated with thinned young apple polyphenols as an active packaging material. Carbohydr Polym. 2017 May;163:81–91.10.1016/j.carbpol.2017.01.016Search in Google Scholar PubMed

[87] Hosseini SF, Rezaei M, Zandi M, Farahmandghavi F. Bio-based composite edible films containing origanum vulgare L. essential oil. Ind Crops Prod. 2015 May;67:403–13.10.1016/j.indcrop.2015.01.062Search in Google Scholar

[88] Tongnuanchan P, Benjakul S, Prodpran T, Pisuchpen S, Osako K. Mechanical, thermal and heat sealing properties of fish skin gelatin film containing palm oil and basil essential oil with different surfactants. Food Hydrocoll. 2016 May;56:93–107.10.1016/j.foodhyd.2015.12.005Search in Google Scholar

[89] Turek C, Stintzing FC. Stability of essential oils: A review. Compr Rev Food Sci Food Saf. 2013;12(1):40–53.10.1111/1541-4337.12006Search in Google Scholar

[90] Wong Y, Ahmad-Mudzaqqir M, Wan-Nurdiyana W. Extraction of essential oil from cinnamon (cinnamomum zeylanicum). Orient J Chem. 2014 Mar;30(1):37–47.10.13005/ojc/300105Search in Google Scholar

[91] Murbach Teles Andrade BF, Nunes Barbosa L, da Silva Probst I, Fernandes Júnior A. Antimicrobial activity of essential oils. J Essent Oil Res. 2014 Jan;26(1):34–40.10.1080/10412905.2013.860409Search in Google Scholar

[92] Cardoso-Ugarte GA, López-Malo A, Sosa-Morales ME. Cinnamon (Cinnamomum zeylanicum) essential oils. Essent Oils Food Preserv Flavor Saf. 2016;339–47.10.1016/B978-0-12-416641-7.00038-9Search in Google Scholar

[93] Khalid H, Lêda RAF, EEO. Cinnamon oil. Green Pestic Handb Essent Oils Pest Control [Internet]. 2017 Feb 7. 117–50. Available from: https://www.qeios.com/read/definition/70017.10.1201/9781315153131-7Search in Google Scholar

[94] El Atki Y, Aouam I, El Kamari F, Taroq A, Nayme K, Timinouni M, et al. Antibacterial activity of cinnamon essential oils and their synergistic potential with antibiotics. J Adv Pharm Technol Res. 2019;10(2):63–7.10.4103/japtr.JAPTR_366_18Search in Google Scholar PubMed PubMed Central

[95] Kamaliroosta L. Extraction of cinnamon essential oil and identification of its chemical compounds. J Med Plants Res [Internet]. 2012 Jan 30;6(4):609–14. Available from: http://www.academicjournals.org/jmpr/abstracts/abstracts/abstracts2012/30Jan/Kamaliroosta et al.htm.10.5897/JMPR11.1215Search in Google Scholar

[96] Dierking Jim. Material safety data sheet cinnamomum essential oil [Internet]. Liberty natural products. 2020 [cited 2020 Oct 8]. p. 1–2. Available from: https://www.libertynatural.com/msd/19.htm.Search in Google Scholar

[97] Young C. Is cinnamon flammable? [Internet]. chefsteps. 2019 [cited 2020 Oct 8]. p. 1. Available from: https://www.chefsteps.com/activities/is-cinnamon-flammableSearch in Google Scholar

© 2020 Razali M. O. Syafiq et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Generalized locally-exact homogenization theory for evaluation of electric conductivity and resistance of multiphase materials

- Enhancing ultra-early strength of sulphoaluminate cement-based materials by incorporating graphene oxide

- Characterization of mechanical properties of epoxy/nanohybrid composites by nanoindentation

- Graphene and CNT impact on heat transfer response of nanocomposite cylinders

- A facile and simple approach to synthesis and characterization of methacrylated graphene oxide nanostructured polyaniline nanocomposites

- Ultrasmall Fe3O4 nanoparticles induce S-phase arrest and inhibit cancer cells proliferation

- Effect of aging on properties and nanoscale precipitates of Cu-Ag-Cr alloy

- Effect of nano-strengthening on the properties and microstructure of recycled concrete

- Stabilizing effect of methylcellulose on the dispersion of multi-walled carbon nanotubes in cementitious composites

- Preparation and electromagnetic properties characterization of reduced graphene oxide/strontium hexaferrite nanocomposites

- Interfacial characteristics of a carbon nanotube-polyimide nanocomposite by molecular dynamics simulation

- Preparation and properties of 3D interconnected CNTs/Cu composites

- On factors affecting surface free energy of carbon black for reinforcing rubber

- Nano-silica modified phenolic resin film: manufacturing and properties

- Experimental study on photocatalytic degradation efficiency of mixed crystal nano-TiO2 concrete

- Halloysite nanotubes in polymer science: purification, characterization, modification and applications

- Cellulose hydrogel skeleton by extrusion 3D printing of solution

- Crack closure and flexural tensile capacity with SMA fibers randomly embedded on tensile side of mortar beams

- An experimental study on one-step and two-step foaming of natural rubber/silica nanocomposites

- Utilization of red mud for producing a high strength binder by composition optimization and nano strengthening

- One-pot synthesis of nano titanium dioxide in supercritical water

- Printability of photo-sensitive nanocomposites using two-photon polymerization

- In situ synthesis of expanded graphite embedded with amorphous carbon-coated aluminum particles as anode materials for lithium-ion batteries

- Effect of nano and micro conductive materials on conductive properties of carbon fiber reinforced concrete

- Tribological performance of nano-diamond composites-dispersed lubricants on commercial cylinder liner mating with CrN piston ring

- Supramolecular ionic polymer/carbon nanotube composite hydrogels with enhanced electromechanical performance

- Genetic mechanisms of deep-water massive sandstones in continental lake basins and their significance in micro–nano reservoir storage systems: A case study of the Yanchang formation in the Ordos Basin

- Effects of nanoparticles on engineering performance of cementitious composites reinforced with PVA fibers

- Band gap manipulation of viscoelastic functionally graded phononic crystal

- Pyrolysis kinetics and mechanical properties of poly(lactic acid)/bamboo particle biocomposites: Effect of particle size distribution

- Manipulating conductive network formation via 3D T-ZnO: A facile approach for a CNT-reinforced nanocomposite

- Microstructure and mechanical properties of WC–Ni multiphase ceramic materials with NiCl2·6H2O as a binder

- Effect of ball milling process on the photocatalytic performance of CdS/TiO2 composite

- Berberine/Ag nanoparticle embedded biomimetic calcium phosphate scaffolds for enhancing antibacterial function

- Effect of annealing heat treatment on microstructure and mechanical properties of nonequiatomic CoCrFeNiMo medium-entropy alloys prepared by hot isostatic pressing

- Corrosion behaviour of multilayer CrN coatings deposited by hybrid HIPIMS after oxidation treatment

- Surface hydrophobicity and oleophilicity of hierarchical metal structures fabricated using ink-based selective laser melting of micro/nanoparticles

- Research on bond–slip performance between pultruded glass fiber-reinforced polymer tube and nano-CaCO3 concrete

- Antibacterial polymer nanofiber-coated and high elastin protein-expressing BMSCs incorporated polypropylene mesh for accelerating healing of female pelvic floor dysfunction

- Effects of Ag contents on the microstructure and SERS performance of self-grown Ag nanoparticles/Mo–Ag alloy films

- A highly sensitive biosensor based on methacrylated graphene oxide-grafted polyaniline for ascorbic acid determination

- Arrangement structure of carbon nanofiber with excellent spectral radiation characteristics

- Effect of different particle sizes of nano-SiO2 on the properties and microstructure of cement paste

- Superior Fe x N electrocatalyst derived from 1,1′-diacetylferrocene for oxygen reduction reaction in alkaline and acidic media

- Facile growth of aluminum oxide thin film by chemical liquid deposition and its application in devices

- Liquid crystallinity and thermal properties of polyhedral oligomeric silsesquioxane/side-chain azobenzene hybrid copolymer

- Laboratory experiment on the nano-TiO2 photocatalytic degradation effect of road surface oil pollution

- Binary carbon-based additives in LiFePO4 cathode with favorable lithium storage

- Conversion of sub-µm calcium carbonate (calcite) particles to hollow hydroxyapatite agglomerates in K2HPO4 solutions

- Exact solutions of bending deflection for single-walled BNNTs based on the classical Euler–Bernoulli beam theory

- Effects of substrate properties and sputtering methods on self-formation of Ag particles on the Ag–Mo(Zr) alloy films

- Enhancing carbonation and chloride resistance of autoclaved concrete by incorporating nano-CaCO3

- Effect of SiO2 aerogels loading on photocatalytic degradation of nitrobenzene using composites with tetrapod-like ZnO

- Radiation-modified wool for adsorption of redox metals and potentially for nanoparticles

- Hydration activity, crystal structural, and electronic properties studies of Ba-doped dicalcium silicate

- Microstructure and mechanical properties of brazing joint of silver-based composite filler metal

- Polymer nanocomposite sunlight spectrum down-converters made by open-air PLD

- Cryogenic milling and formation of nanostructured machined surface of AISI 4340

- Braided composite stent for peripheral vascular applications

- Effect of cinnamon essential oil on morphological, flammability and thermal properties of nanocellulose fibre–reinforced starch biopolymer composites

- Study on influencing factors of photocatalytic performance of CdS/TiO2 nanocomposite concrete

- Improving flexural and dielectric properties of carbon fiber epoxy composite laminates reinforced with carbon nanotubes interlayer using electrospray deposition

- Scalable fabrication of carbon materials based silicon rubber for highly stretchable e-textile sensor

- Degradation modeling of poly-l-lactide acid (PLLA) bioresorbable vascular scaffold within a coronary artery

- Combining Zn0.76Co0.24S with S-doped graphene as high-performance anode materials for lithium- and sodium-ion batteries

- Synthesis of functionalized carbon nanotubes for fluorescent biosensors

- Effect of nano-silica slurry on engineering, X-ray, and γ-ray attenuation characteristics of steel slag high-strength heavyweight concrete

- Incorporation of redox-active polyimide binder into LiFePO4 cathode for high-rate electrochemical energy storage

- Microstructural evolution and properties of Cu–20 wt% Ag alloy wire by multi-pass continuous drawing

- Transparent ultraviolet-shielding composite films made from dispersing pristine zinc oxide nanoparticles in low-density polyethylene

- Microfluidic-assisted synthesis and modelling of monodispersed magnetic nanocomposites for biomedical applications

- Preparation and piezoresistivity of carbon nanotube-coated sand reinforced cement mortar

- Vibrational analysis of an irregular single-walled carbon nanotube incorporating initial stress effects

- Study of the material engineering properties of high-density poly(ethylene)/perlite nanocomposite materials

- Single pulse laser removal of indium tin oxide film on glass and polyethylene terephthalate by nanosecond and femtosecond laser

- Mechanical reinforcement with enhanced electrical and heat conduction of epoxy resin by polyaniline and graphene nanoplatelets

- High-efficiency method for recycling lithium from spent LiFePO4 cathode

- Degradable tough chitosan dressing for skin wound recovery

- Static and dynamic analyses of auxetic hybrid FRC/CNTRC laminated plates

- Review articles

- Carbon nanomaterials enhanced cement-based composites: advances and challenges

- Review on the research progress of cement-based and geopolymer materials modified by graphene and graphene oxide

- Review on modeling and application of chemical mechanical polishing

- Research on the interface properties and strengthening–toughening mechanism of nanocarbon-toughened ceramic matrix composites

- Advances in modelling and analysis of nano structures: a review

- Mechanical properties of nanomaterials: A review

- New generation of oxide-based nanoparticles for the applications in early cancer detection and diagnostics

- A review on the properties, reinforcing effects, and commercialization of nanomaterials for cement-based materials

- Recent development and applications of nanomaterials for cancer immunotherapy

- Advances in biomaterials for adipose tissue reconstruction in plastic surgery

- Advances of graphene- and graphene oxide-modified cementitious materials

- Theories for triboelectric nanogenerators: A comprehensive review

- Nanotechnology of diamondoids for the fabrication of nanostructured systems

- Material advancement in technological development for the 5G wireless communications

- Nanoengineering in biomedicine: Current development and future perspectives

- Recent advances in ocean wave energy harvesting by triboelectric nanogenerator: An overview

- Application of nanoscale zero-valent iron in hexavalent chromium-contaminated soil: A review

- Carbon nanotube–reinforced polymer composite for electromagnetic interference application: A review

- Functionalized layered double hydroxide applied to heavy metal ions absorption: A review

- A new classification method of nanotechnology for design integration in biomaterials

- Finite element analysis of natural fibers composites: A review

- Phase change materials for building construction: An overview of nano-/micro-encapsulation

- Recent advance in surface modification for regulating cell adhesion and behaviors

- Hyaluronic acid as a bioactive component for bone tissue regeneration: Fabrication, modification, properties, and biological functions

- Theoretical calculation of a TiO2-based photocatalyst in the field of water splitting: A review

- Two-photon polymerization nanolithography technology for fabrication of stimulus-responsive micro/nano-structures for biomedical applications

- A review of passive methods in microchannel heat sink application through advanced geometric structure and nanofluids: Current advancements and challenges

- Stress effect on 3D culturing of MC3T3-E1 cells on microporous bovine bone slices

- Progress in magnetic Fe3O4 nanomaterials in magnetic resonance imaging

- Synthesis of graphene: Potential carbon precursors and approaches

- A comprehensive review of the influences of nanoparticles as a fuel additive in an internal combustion engine (ICE)

- Advances in layered double hydroxide-based ternary nanocomposites for photocatalysis of contaminants in water

- Analysis of functionally graded carbon nanotube-reinforced composite structures: A review

- Application of nanomaterials in ultra-high performance concrete: A review

- Therapeutic strategies and potential implications of silver nanoparticles in the management of skin cancer

- Advanced nickel nanoparticles technology: From synthesis to applications

- Cobalt magnetic nanoparticles as theranostics: Conceivable or forgettable?

- Progress in construction of bio-inspired physico-antimicrobial surfaces

- From materials to devices using fused deposition modeling: A state-of-art review

- A review for modified Li composite anode: Principle, preparation and challenge

- Naturally or artificially constructed nanocellulose architectures for epoxy composites: A review

Articles in the same Issue

- Research Articles

- Generalized locally-exact homogenization theory for evaluation of electric conductivity and resistance of multiphase materials

- Enhancing ultra-early strength of sulphoaluminate cement-based materials by incorporating graphene oxide

- Characterization of mechanical properties of epoxy/nanohybrid composites by nanoindentation

- Graphene and CNT impact on heat transfer response of nanocomposite cylinders

- A facile and simple approach to synthesis and characterization of methacrylated graphene oxide nanostructured polyaniline nanocomposites

- Ultrasmall Fe3O4 nanoparticles induce S-phase arrest and inhibit cancer cells proliferation

- Effect of aging on properties and nanoscale precipitates of Cu-Ag-Cr alloy

- Effect of nano-strengthening on the properties and microstructure of recycled concrete

- Stabilizing effect of methylcellulose on the dispersion of multi-walled carbon nanotubes in cementitious composites

- Preparation and electromagnetic properties characterization of reduced graphene oxide/strontium hexaferrite nanocomposites

- Interfacial characteristics of a carbon nanotube-polyimide nanocomposite by molecular dynamics simulation

- Preparation and properties of 3D interconnected CNTs/Cu composites

- On factors affecting surface free energy of carbon black for reinforcing rubber

- Nano-silica modified phenolic resin film: manufacturing and properties

- Experimental study on photocatalytic degradation efficiency of mixed crystal nano-TiO2 concrete

- Halloysite nanotubes in polymer science: purification, characterization, modification and applications

- Cellulose hydrogel skeleton by extrusion 3D printing of solution

- Crack closure and flexural tensile capacity with SMA fibers randomly embedded on tensile side of mortar beams

- An experimental study on one-step and two-step foaming of natural rubber/silica nanocomposites

- Utilization of red mud for producing a high strength binder by composition optimization and nano strengthening

- One-pot synthesis of nano titanium dioxide in supercritical water

- Printability of photo-sensitive nanocomposites using two-photon polymerization

- In situ synthesis of expanded graphite embedded with amorphous carbon-coated aluminum particles as anode materials for lithium-ion batteries

- Effect of nano and micro conductive materials on conductive properties of carbon fiber reinforced concrete

- Tribological performance of nano-diamond composites-dispersed lubricants on commercial cylinder liner mating with CrN piston ring

- Supramolecular ionic polymer/carbon nanotube composite hydrogels with enhanced electromechanical performance

- Genetic mechanisms of deep-water massive sandstones in continental lake basins and their significance in micro–nano reservoir storage systems: A case study of the Yanchang formation in the Ordos Basin

- Effects of nanoparticles on engineering performance of cementitious composites reinforced with PVA fibers

- Band gap manipulation of viscoelastic functionally graded phononic crystal

- Pyrolysis kinetics and mechanical properties of poly(lactic acid)/bamboo particle biocomposites: Effect of particle size distribution

- Manipulating conductive network formation via 3D T-ZnO: A facile approach for a CNT-reinforced nanocomposite

- Microstructure and mechanical properties of WC–Ni multiphase ceramic materials with NiCl2·6H2O as a binder

- Effect of ball milling process on the photocatalytic performance of CdS/TiO2 composite

- Berberine/Ag nanoparticle embedded biomimetic calcium phosphate scaffolds for enhancing antibacterial function

- Effect of annealing heat treatment on microstructure and mechanical properties of nonequiatomic CoCrFeNiMo medium-entropy alloys prepared by hot isostatic pressing

- Corrosion behaviour of multilayer CrN coatings deposited by hybrid HIPIMS after oxidation treatment

- Surface hydrophobicity and oleophilicity of hierarchical metal structures fabricated using ink-based selective laser melting of micro/nanoparticles

- Research on bond–slip performance between pultruded glass fiber-reinforced polymer tube and nano-CaCO3 concrete

- Antibacterial polymer nanofiber-coated and high elastin protein-expressing BMSCs incorporated polypropylene mesh for accelerating healing of female pelvic floor dysfunction

- Effects of Ag contents on the microstructure and SERS performance of self-grown Ag nanoparticles/Mo–Ag alloy films

- A highly sensitive biosensor based on methacrylated graphene oxide-grafted polyaniline for ascorbic acid determination

- Arrangement structure of carbon nanofiber with excellent spectral radiation characteristics

- Effect of different particle sizes of nano-SiO2 on the properties and microstructure of cement paste

- Superior Fe x N electrocatalyst derived from 1,1′-diacetylferrocene for oxygen reduction reaction in alkaline and acidic media

- Facile growth of aluminum oxide thin film by chemical liquid deposition and its application in devices

- Liquid crystallinity and thermal properties of polyhedral oligomeric silsesquioxane/side-chain azobenzene hybrid copolymer

- Laboratory experiment on the nano-TiO2 photocatalytic degradation effect of road surface oil pollution

- Binary carbon-based additives in LiFePO4 cathode with favorable lithium storage

- Conversion of sub-µm calcium carbonate (calcite) particles to hollow hydroxyapatite agglomerates in K2HPO4 solutions

- Exact solutions of bending deflection for single-walled BNNTs based on the classical Euler–Bernoulli beam theory

- Effects of substrate properties and sputtering methods on self-formation of Ag particles on the Ag–Mo(Zr) alloy films

- Enhancing carbonation and chloride resistance of autoclaved concrete by incorporating nano-CaCO3

- Effect of SiO2 aerogels loading on photocatalytic degradation of nitrobenzene using composites with tetrapod-like ZnO

- Radiation-modified wool for adsorption of redox metals and potentially for nanoparticles

- Hydration activity, crystal structural, and electronic properties studies of Ba-doped dicalcium silicate