Abstract

Bioactive compounds are highly susceptible to oxidation and degradation, limiting their stability, bioavailability, and effectiveness, particularly in food applications where preservation is critical. Microencapsulation presents a promising strategy to protect these compounds and enhance their functional performance. This review explores key factors influencing microencapsulation efficiency, including extraction methods, encapsulation techniques – such as fluidized-bed spray coating, emulsification, emulsion solidification, liposomal entrapment, coacervation, and ionic gelation – and their effects on capsule structure, controlled release, and bioaccessibility. Findings from in vitro and in vivo studies are synthesized to evaluate the outcomes of microencapsulated compounds. The results show that optimizing the entire microencapsulation process – from extraction and formulation to production techniques – can enhance stability and bioavailability, ultimately supporting the development of functional foods with protective and health-promoting properties. The review highlights microencapsulation as a valuable tool for the food industry, offering broad potential for innovation and application.

1 Introduction

Bioactive constituents, such as vitamins, bioactive lipids (e.g., ω −3 and ω −6 fatty acids), bioactive peptides, essential oils, and probiotics, are widely acknowledged for their potential health benefits. However, these bioactive compounds in their free form are prone to autooxidation and other forms of degradation [1]. The observed susceptibility results in constraints on bioavailability, physical characteristics (such as color), applications in industry, and contributes to instability during the storage of products that incorporate these compounds. Microencapsulation technology demonstrates efficacy in regulating the release characteristics of active compounds, thus improving the bioavailability of administered active components [2]. In addition to microencapsulation, several other innovative systems have been developed for delivering bioactive compounds in food applications. These include gelled systems (such as oleogels, bigels, emulgels, and hydrogels), intelligent carriers, and stimuli-responsive delivery systems. While these alternatives offer promising benefits – such as improved stability, controlled release, and targeted delivery – they also present notable limitations. For instance, the release behavior of gelled systems depends heavily on the type and concentration of gelators, making formulation more complex [3]. Intelligent carriers and stimuli-responsive systems can enhance bioavailability and enable site-specific release by responding to physiological conditions, but they often require sophisticated design and face challenges in maintaining consistency and stability under variable conditions [4,5]. Due to these challenges, microencapsulation remains a more practical and widely adopted strategy in the food and nutraceutical industries, offering a balance of effectiveness, scalability, and formulation flexibility.

In the food industry, microencapsulation involves encapsulating various food materials within microscopic shells or coatings for protection and potential later release. This technology is employed to safeguard ingredients from degradation caused by environmental factors like water, oxygen, heat, and light, ultimately extending the shelf life of active materials [6]. Additionally, this technique enables controlled delivery and release of active food components. Driven by rising health consciousness, aging populations, and advances in food technology, the functional food sector continues to experience robust global growth. Consumers, particularly in developed regions with higher disposable incomes, are increasingly seeking products that offer health benefits beyond basic nutrition [7]. Older adults, in particular, are fueling demand for functional foods aimed at preventing age-related diseases and supporting long-term wellness [8]. Alongside these demographic drivers, economic and technological advancements – such as agricultural diversification and the development of bioactive-rich formulations – are accelerating the innovation and availability of functional products [7,9]. However, to ensure widespread adoption, industry stakeholders must navigate regulatory frameworks and safeguard consumer trust through responsible health claims and transparent labeling [10]. Microencapsulation offers a strategic platform for addressing these demands, positioning it as a key enabler in the evolution of next-generation functional foods.

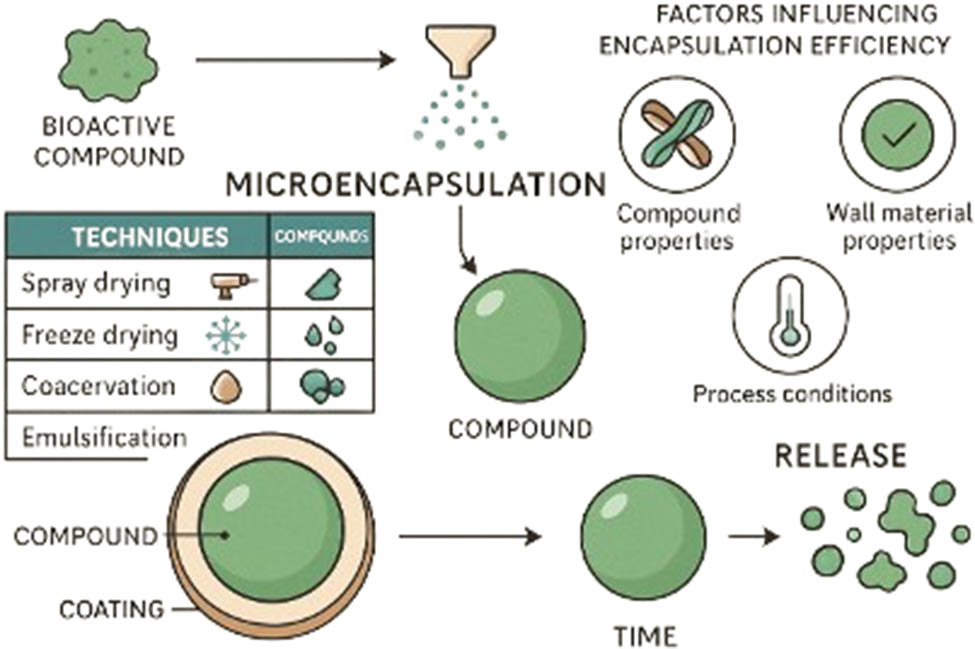

Microencapsulation is a process that involves enclosing a substance (core or sensitive material) within another substance, known as the encapsulant, coating agent, or wall material. The resulting product is referred to as the encapsulate or microcapsule. The encapsulation efficiency represents the ratio of the core material that is successfully contained within the encapsulate to the initial amount introduced into the encapsulation system. Various factors during the initial stage of microencapsulation can affect the yield of microcapsules. Microcapsules may exhibit different internal or external microstructures, depending on the extraction and microencapsulation methodologies employed. The internal microstructure refers to the composition and organization of components inside the microcapsule, such as the core composition (solid or liquid), core morphology, which may be mononuclear (single core), polynuclear (multiple cores), or even in matrix form where the active ingredient spreads throughout the shell material, as well as the pore structure [11–13]. The external microstructure pertains to the shell or coating that encases the core, such as shell composition, wall thickness, and surface morphology, which includes texture and porosity [12,13]. Both internal and external microstructures play a significant role in determining the encapsulation efficiency, retention of core material, and controlled release behavior. Microencapsulation systems characterized by lower core loads generally demonstrate greater encapsulation efficiency. This is attributed to enhanced wall coverage, improved process yields, stable morphology, optimized diffusion dynamics, and advantageous stability properties [14–16]. Therefore, the microencapsulation structure affects the encapsulation efficiency and the control release of the core material, ultimately impacting its bioavailability.

Recently, there has been an increasing focus on investigating and comprehending the processes through which bioactive substances are metabolized and made available within the human body. The bioavailability, bioaccessibility, and bioactivity of bioactive substances are currently significant topics of investigation owing to the existing uncertainties in this field [17]. Despite the common misconceptions, these phrases convey distinct meanings. The concept of “bioavailability” pertains to the extent to which a substance is accessible and utilized by the organism, encompassing processes such as digestion, absorption, metabolism, distribution within tissues, potential biotransformation, and physiological responses [18]. The challenges associated with impracticality and ethical considerations in research limit the precise evaluation of the bioavailability of particular active compounds in food products. The study of bioaccessibility, which refers to the quantity of active compounds that are liberated from food into the digestive system and may be available for absorption or bioactivity, is currently a significant area of research in contemporary science.

Despite the noted observations, comprehensive information on the factors influencing encapsulation structure and efficiency, and how this structure impacts the bioavailability of the encapsulated compound, is currently scattered, lacking a comprehensive review. The purpose of this review is to offer a thorough summary of the influence of various extraction and encapsulation methods and conditions on the controlled release and bioavailability of encapsulated compounds. Key factors influencing microstructures are highlighted, and potential solutions to achieve desirable microstructures for higher encapsulation efficiency, improved retention, and better-controlled release behavior of encapsulated materials are also discussed.

2 Factors influencing encapsulation structure and efficiency

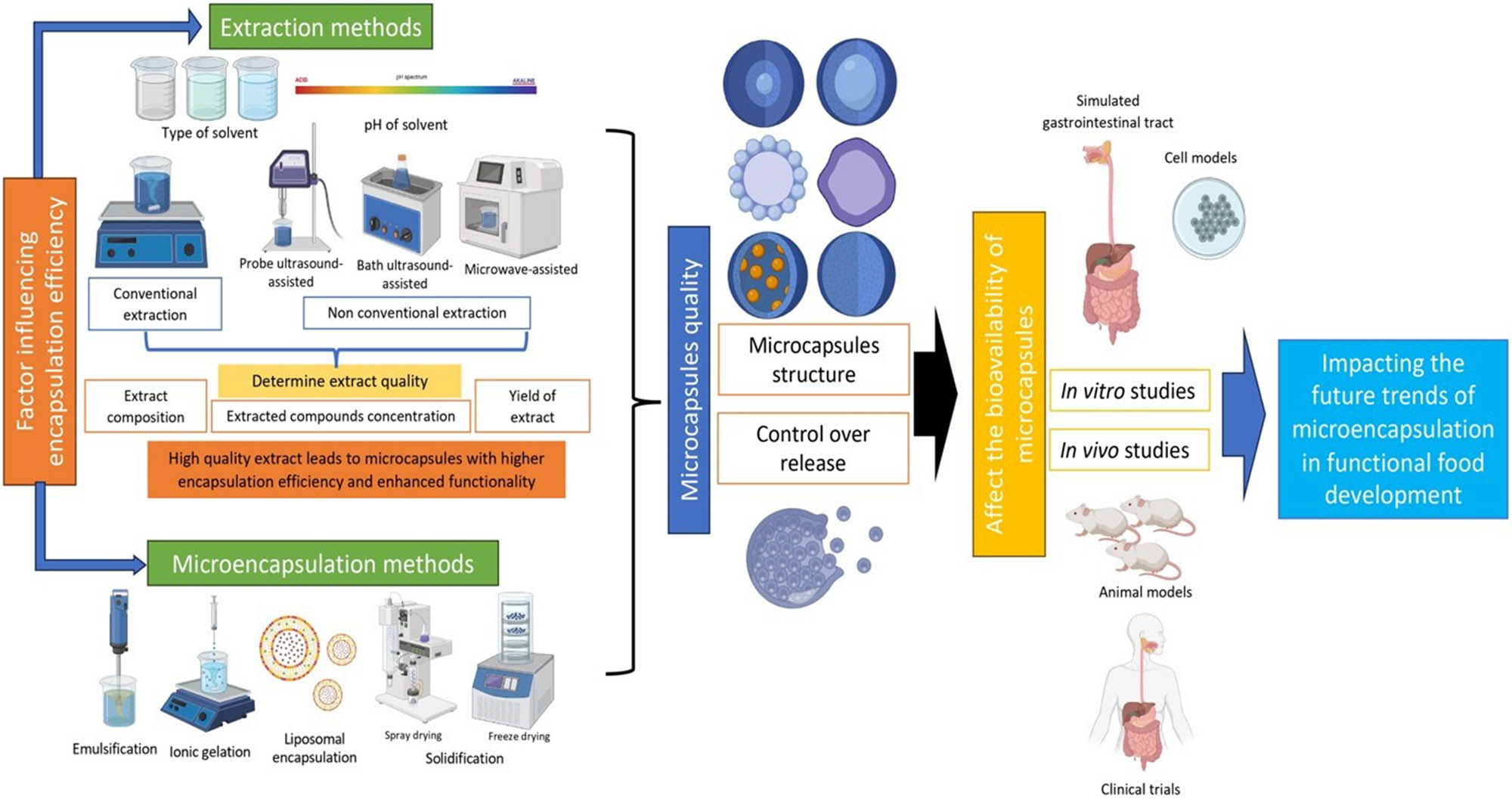

In the realm of encapsulation technology, there are several key elements that play a crucial role in shaping the structure and efficiency of the encapsulation process. Factors influencing encapsulation structure and efficiency include the choice of encapsulation method or system, the microstructure of the encapsulates, the properties of the encapsulants, the load of core materials, and the solidification conditions. It is essential to recognize that the factors influencing encapsulation efficiency are not limited solely to the details of the encapsulation process itself. Even the specific steps of the initial stages, such as how bioactive compounds are extracted, can significantly impact the overall efficiency of microencapsulation [19]. For instance, residual solvents from extraction processes may interfere with matrix formation by altering interactions between core and wall materials [20]. Additionally, a mismatch in polarity between the extracted bioactive compounds and the encapsulant can hinder the formation of table encapsulation systems, ultimately lowering encapsulation efficiency and stability [20,21]. Core material or bioactive compound characteristics, such as the molecular structure, interaction between natural components and coating material, molecular weight, polarity, and solubility, impact encapsulation efficiency, stability, and release kinetics [16]. Several parameters in forming a microencapsulation system, as illustrated in Figure 1, significantly affect the microencapsulation efficiency.

Factors affecting the structure and bioavailability of microcapsules.

2.1 Extraction methods and their impact on microencapsulation

Several parameters within the chosen extraction methodology can significantly influence the microencapsulation efficiency. These parameters encompass the classification of the extraction method, whether it is conventional or unconventional, the selection of the solvent, as well as the precise application of time and temperature conditions. The precise application of time and temperature conditions during extraction is critical to optimizing yield and preserving the bioactivity of compounds. Optimal temperature ranges vary depending on the source material: for example, garlic husk (Allium sativum) extraction is most effective between 60 and 70°C [22], and carrot (Daucus carota) compounds are efficiently extracted within 30–70°C [23]. Chamaenerion angustifolium extracts best at 58°C [24], while Levisticum officinale shows maximum extraction efficiency between 75 and 95°C [25]. Fucus vesiculosus significant yields are observed at temperatures of 75°C and above, with peak yields around 120°C [26].

Extraction time also plays a vital role, with optimal durations differing across materials. Chamaenerion angustifolium extraction times range from 20 to 60 min, peaking at around 35 min [24]. Levisticum officinale requires 20–40 min, optimally near 35.7 min [25], whereas garlic husk extractions are best sustained for 60–90 min [22]. Carrot extraction time appears less critical but has been tested between 17 and 57 min [23]. For Fucus vesiculosus, longer durations of 1–4 h, especially at higher temperatures, yield the best results [26].

Different extraction methods, such as microwave extraction (ME), ultrasound extraction (UE), and solvent ethanol–water extraction (SEWE), have been shown to have varying extraction efficiencies and yield different bioactive compounds [27]. The quality of bioactive extracts obtained through various extraction methods plays a crucial role in determining the efficiency and stability of the subsequent microencapsulation process. Parameters such as the solvent type, extraction temperature, and duration influence not only the yield but also the composition of the extract, particularly the concentration and types of bioactive compounds present. Extracts with higher purity and concentration of desired compounds tend to produce microcapsules with improved encapsulation efficiency, better retention, and enhanced functional performance [27]. For instance, overly high extraction temperatures may degrade sensitive compounds, reducing the effectiveness of encapsulation. Conversely, optimized extraction conditions can preserve compound integrity and improve interaction with encapsulating materials, resulting in microcapsules with favorable morphology, release characteristics, and bioavailability. Previous studies reported how the extraction methods, as one of the stages of microencapsulation preparation, influence the final microcapsules' properties physicochemically and biologically, as presented in Table 1.

A combination of the extraction methods and extract encapsulation

| Sample | Extraction | Optimal conditions of microencapsulation | Encapsulation efficiency (%) | Particle size (μm/nm) | Findings | Ref. | ||

|---|---|---|---|---|---|---|---|---|

| Optimal method | Extracted compounds | Coating material (s) | Method | |||||

| Prickly pear | Sample was extracted by aqueous glycerol (23.15%). Sample to solvent ratio 1:10 at 31.15°C for 10.43 min | Betalain (betaxanthin and betacyanin) | Glycerol 23.15%, core material concentration was 10% | UAE combined with glycerol as the encapsulating agent | 93.76% | Not available | UAE followed by encapsulation using glycerol as a green agent was highlighted as an effective method. The optimization achieved high encapsulation efficiency and high betalain content | [28] |

| Grape pomace | Two steps extraction with gliadin-rich hydroalcoholic solution | Phenolics | Wheat gliadin as the core material and Arabic gum ratio 1:1 | Solvent evaporation | 62.9% in terms of epicatechin | 506.6 nm | Using gliadin-rich hydroalcoholic solution to extract polyphenol from gape pomace significantly enhanced the yield and composition of extract as well as improved the encapsulating ability | [29] |

| Pomegranate peel | SEWE, pomegranate peel was combined with acidified ethanol (0.01% citric acid) and a mixture of acidified ethanol and water (1:1) for 5 min with electric mixer soaked at a maximum speed | Phenolics and anthocyanins | Mixture of 0.5 g of indigeneous gum and 4.5 g of 15% maltodextrin in water. Anthocyanin extract and coating materials ratio was 1:2 (w/w) | Freeze drying | 86.57% | 112 nm | The average size distribution of nanoencapsulated particles and the effectiveness of nanoencapsulation are significantly influenced by the type and quantity of extractive chemicals present in the extract. Because of this, PPP extract has a high concentration of antioxidant chemicals, which can be found out by closely examining the optimal extraction | [27] |

| Cocoa shell | UAE at 55°C for 45 min with 60% ethanol | Phenolics and flavonoids | Ratio between the extract and mixture of Arabic gum and maltodextrin (40% w/v) was 2:1 (w/w) | Spray drying | 59.92% | 34.4 μm | The optimized extraction of bioactive compounds from cocoa shell using UAE resulted in microcapsules that exhibited antioxidant and antibacterial activities | [30] |

| Date pit | Conventional extraction with water–ethanol solvent (25%:75%) at 25° stirred for 5 h in an incubator with shaker at 280 rpm | Phenolics | Three-layercoating consists of 20% (w/v) of maltodextrin, 15% (w/w) medium-chain triglycerides (MCT oil), and 20% (w/v) Alhagi maurorum gum | Fluidized-bed dryer | Specific numerical values are not available | Specific numerical values are not available | The combination of ethanol and water demonstrated a superior capacity for extracting phenolic compounds compared to individual solvents, which may affect the microcapsules’ physicochemical properties | [31] |

| Rosemary | Optimized high-voltage electrical discharge (HVED parameters were of frequency of 100 Hz, high- voltage current of 30 mA, pulse width of 0.4 μs, and voltage of 25 kV using nitrogen as a reaction gas, with the gap between electrodes of 15 mm, 9 min, and ratio mass to solvent of 1:50 (w/v) | Phenolics and flavonoids | All coating materials were dissolved in the rosemary extract, 1.0% sodium alginate + 0.2% zein + 0.3% hydroxypropyl methylcellulose (HPMC) and CaCl2 | Ionic gelation | 120.59% | 651.29 to 1,087.37 μm | Rosemary extract obtained through HVED has demonstrated significant potential as a source of bioactive compounds, particularly polyphenols, which facilitated the successful microencapsulation of the aqueous extract. This microencapsulation was achieved using the ionic gelation method, employing calcium alginate, zein, and HPMC as coating materials | [32] |

| Lemon | High-hydrostaticpressure and UAE with 80% methanol | Phenolics and flavonoids | The ratio between lemon extract and 30% maltodextrin solution (w/v) was 1:2 (w/w) | Freeze drying | 93.2% | 48.9 μm | High-hydrostatic-pressure and UAE affected the relative bio-accessibility and total phenolic content as well as total flavonoid content in microencapsulated lemon extract, which were higher than those obtained by the conventional methods. Additionally, the choice of solvent in the extraction process can impact the solubility and stability of the encapsulated material, which can, in turn, affect its release properties and bioavailability | [19] |

| Herbal plant leaves (Cannabis sativa L., Cannabis indica L., and Mitragyna speiosa K.) | Microwave extraction with deionized water at 100 W for 35 min (final temperature ≤ 60°C) | Phenolic and flavonoid | 2% chitosan (w/v) was dissolved in 1% (v/v) acetic acid combined with surfactant (2% (v/v) Tween 80). Wall material and extract ratio was 1:1 (v/v) | Spray drying | Cannabis sativa L. was 54.6%, Cannabis indica L. was 84.3%, and Mitragyna speiosa K. was 99.7% | 1.45 to 11 μm | The application of microwave treatment prior to chitosan encapsulation of leaf extracts led to an increased recovery of bioactive compounds within the encapsulation process | [33] |

| Blueberry pomace | Conventional extraction with acidic water (pH 2.0) at 60°C for 100 min, and the liquid to solid ratio was 10 mL/g | Anthocyanins | Volume to weight ratios between the extract and maltodextrin was 50:60 (mL/g) | Spray drying | 98.98% | 5.5 μm | The choice of the extraction method can impact the solubility of the microencapsulated compounds. The water extracts showed a high encapsulation yield and encapsulation efficiency | [34] |

| Red cabbage | Conventional extraction with acidic 70% ethanol (pH 3.3–3.5) in continuous agitation for 4 h, and the liquid to solid ratio was 1:1 | Polyphenols | CAPSUL modified starch at a final concentration of 15% (w/v) | Spray drying | 79% | 1 – 30 μm | Different solvents used for extraction affected the stability and color properties of polyphenols in red cabbage extract and microencapsulated extract. The ethanolic extract showed the highest thermal stability compared to methanolic and water extract | [35] |

The papers collectively suggest that the extraction methods used for microencapsulated bioactive compound extracts may exhibit a significant impact on the properties and bioaccessibility of the extracts. Giovagnoli-Vicuña et al. [19] found that high hydrostatic pressure and ultrasound-assisted extraction (UAE) methods resulted in lemon extracts with higher levels of bioactive compounds and improved bioaccessibility and total phenolic content as well as total flavonoid content in microencapsulated lemon extract, which were higher than those found using the conventional method. A previous study discussed the advantages of emergent non-thermal extraction technologies, such as high hydrostatic pressure, ultrasounds, pulsed electric fields, and supercritical fluids, in enhancing extraction yields and preserving the structure of bioactive compounds [36]. The choice of solvent in the extraction process can impact the solubility and stability of the encapsulated material, which can, in turn, affect its release. Moreover, the extraction method also affects the physical properties of microcapsules such as the particle size [19].

For example, Jafari et al. [30] optimized the extraction of bioactive compounds from cocoa shell using UAE and found that the resulting microcapsules exhibited antioxidant and antibacterial activities. Similarly, Zahed et al. [27] extracted pomegranate residues, which are peels and seeds, with supercritical CO2 extraction and microencapsulated the extract and reported that the extraction process influences the encapsulation efficiency by affecting the concentration and composition of the core material to be encapsulated. In summary, the extraction methods employed for microencapsulated bioactive compound extracts can influence the composition, bioaccessibility, and functional properties of the microcapsules.

2.1.1 Influence of solvent polarity

The varying polarities of bioactive compounds within intricate food matrices may hinder their concurrent extraction. The choice of solvent affected the morphology of the microparticles and microcapsules [37]. Mehta et al. [38] found that drug incorporation, matrix porosity, and solvent residues are some of the microparticle features that are impacted by the polymers’ solubilities in organic solvents, which in turn influence the pace of polymer solidification during microparticle formation (Figure 2). The influence of solvent polarity on the structure of microcapsules has been investigated in several studies. A study reported that the polarity of solvent can significantly impact the crystallinity and physicochemical properties of microcapsules. For instance, reducing solvent polarity may enhance the crystallinity of specific components within the microcapsules, potentially influencing their digestibility and functionality in various applications [39]. Moreover, in the encapsulation of gallic acid using yeast cells revealed a notable influence of the solvent type in the encapsulation media (H2O or EtOH:H2O) on both the encapsulation efficiency and bioactive properties of the resulting microcapsules. At higher concentrations, the effectiveness of yeast cell encapsulation was greatly improved by the solvent choice. The gallic acid loading and bioactive performance of distilled water were better than those of the ethanol–water mixture (EtOH:H2O) [40]. Similarly, in the preparation of bovine hemoglobin-loaded nanoparticles, an aqueous system with surfactants achieved encapsulation efficiencies exceeding 97%, demonstrating the suitability of aqueous media for hydrophilic compounds [41]. A separate investigation examined alginate microcapsules for yeast in sparkling winemaking, utilizing an aqueous system with calcium chloride as the crosslinker, resulting in a high encapsulation efficiency (∼97%) and excellent structural stability, thereby illustrating the efficacy of aqueous alginate systems for hydrophilic or biologically active agents [42]. In contrast, alcohol-based solvents exhibited improvement in solubility and encapsulation of hydrophobic compounds, such as risperidone, and allowed greater control over the particle size and porosity. Due to their greater solubility in alcohol-based solvents, the encapsulation efficiency increased from 62 to 78% or 69 to 80% [43]. A study on propolis-alginate microcapsules indicated low encapsulation efficiency when sodium alginate was dissolved in water; however, altering the solvent solution to incorporate alcohol markedly enhanced encapsulation efficiency to ∼99% [44]. This indicated that alcohol-based solvents may enhance the incorporation of hydrophobic substances such as propolis in alginate microcapsules, possibly owing to greater solubility and interaction with the active chemicals in comparison to only aqueous systems [44]. These findings suggest that solvent polarity plays a significant role in determining the structure and properties of microcapsules. Quantitative comparisons demonstrate that aqueous solvents are generally more advantageous for hydrophilic and biologically active compounds, particularly when stability and gelation through ionic crosslinking are necessary, whereas alcohol-based systems are more efficacious for hydrophobic bioactives due to enhanced solubility and diminished polarity mismatch.

![Figure 2

Factors influencing encapsulation efficiency (redrawn from Yeo and Park [20]).](/document/doi/10.1515/ntrev-2025-0222/asset/graphic/j_ntrev-2025-0222_fig_002.jpg)

Factors influencing encapsulation efficiency (redrawn from Yeo and Park [20]).

2.1.2 Effect of solvent pH

The pH of the solvent can significantly impact the structure and properties of microcapsules. Besides its influence on the yield of bioactive compounds during extraction, it also impacts the pH in the microencapsulation system. Guo et al. [45] reported how pH levels impact the microstructure and characteristics of self-assembled graphene microcapsules and revealed the presence of core material in the shells, with the pH values significantly affecting the deposition of the core material onto the shells, which leads to changes in the morphology, size, and shell thickness. The surface morphologies and core–shell structures of microcapsules are affected by the pH of the reaction medium. A different study indicated that the characteristics and degree of interactions among microcapsule components, affected by pH, affect the overall stability of the structure [46].

In addition, pH plays a crucial role in determining the charge characteristics of encapsulating polymers such as alginate, chitosan, and proteins, which in turn impact their interactions with bioactive compounds. The changes in pH influence the ionization states of functional groups, such as carboxyl or amino groups, which in turn affect electrostatic interactions and the formation of complexes. For example, alginate shows larger pores and diminished mechanical strength in acidic environments (such as pH 2.5), which may enhance the release rate of encapsulated bioactives. At a neutral pH of approximately 6.0, alginate microspheres exhibit enhanced structural stability and decreased porosity, leading to improved retention of bioactive compounds [47].

Chitosan, as a polycation, possesses a positive charge under acidic conditions, which promotes electrostatic interactions with negatively charged polymers such as alginate, leading to the creation of polyelectrolyte complexes [48]. The encapsulation efficiency of chitosan–alginate systems reaches its peak when chitosan is introduced initially at lower pH levels [49]. In a similar way, wall materials derived from proteins exhibit responses to changes in pH relative to their isoelectric point, influencing their solubility, surface activity, and capacity to interact with active compounds.

Additionally, pH-responsive synthetic polymers, like poly(acrylic acid), demonstrate charge-switching behavior that can be adjusted for controlled encapsulation and release. For instance, carboxyl-containing polymers that exhibit weak ionization may shift from extended to globular conformations in response to pH changes, thereby improving their interaction with membranes and encapsulation capabilities [50–52]. Although research regarding the influence of the pH solvent on the microcapsule structures and properties is still limited, existing studies clearly demonstrate that the solvent pH influences polymer ionization, molecular interactions, and ultimately the structural integrity and release behavior of encapsulated bioactives (Figure 3).

General factors that affect microencapsulation efficiency.

2.2 Microencapsulation techniques

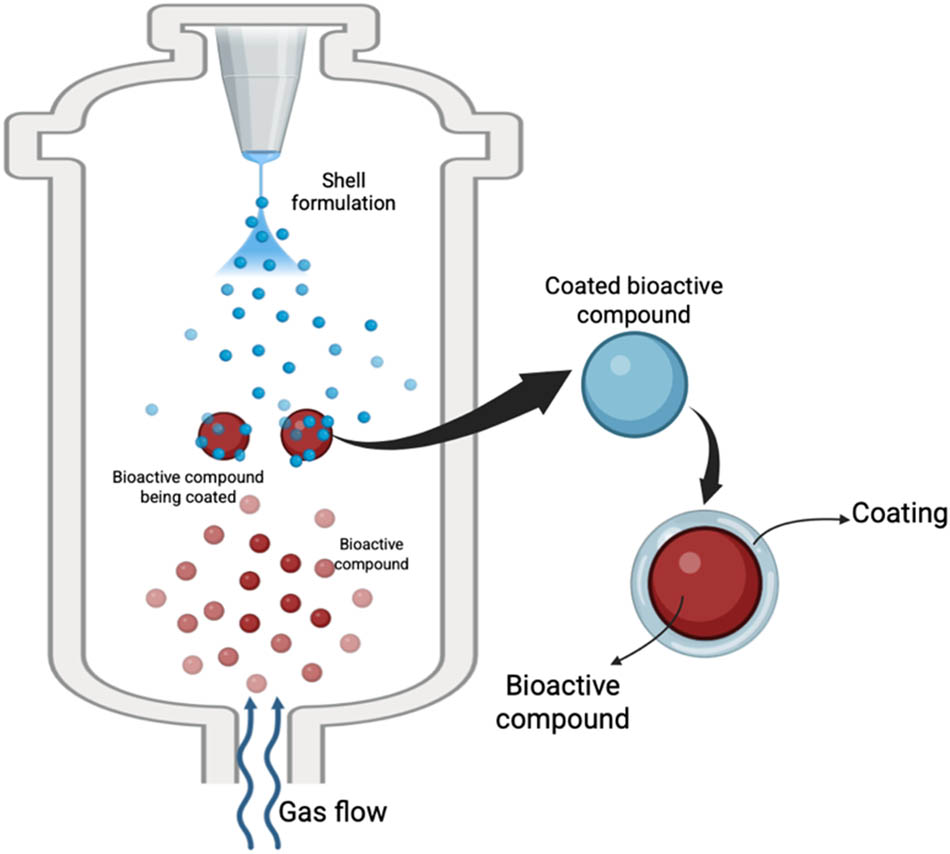

2.2.1 Encapsulation through fluidized-bed spray coating

Fluidization and spray techniques can be combined to agglomerate particles into larger granules or apply coatings to agglomerate particles or apply coatings, a process often referred to as fluid bed coating or granulation (Figure 4). This includes spray drying, cooling, and chilling, where the process air both fluidizes the particles and promotes solidification, either by congealing molten materials (e.g., waxes, hydrogenated oils) or evaporating solvents. In fluidized-bed spray coating, core particles are suspended and sprayed with an encapsulating solution or molten material. The encapsulating material may adhere to the core surface through various mechanisms, which vary based on the material used and specific encapsulation techniques, including physical adsorption such as electrostatic forces and van der Waals forces in cases where the surface is rough or irregular, chemical bonding such as covalent bonds and hydrogen bonding, coating techniques such as coacervation and in situ polymerization, mechanical interlocking, and capillary forces [11,13,53]. Since it is a coating process, the resulting encapsulation typically showcases a core–shell or mononuclear microstructure [54]. In the process of encapsulation using fluidized-bed spray coating, solidification takes place through a complex combination of fluidization, droplet spraying, adhesion, and the swift drying facilitated by circulating hot air. The interplay of these processes results in the formation of uniform microcapsules that exhibit controlled release characteristics, while effectively reducing the risks of agglomeration [55,56].

Illustration of the fluidized-bed spray coating process.

The physical properties of microcapsules produced via fluidized-bed spray coating are strongly influenced by process parameters and have a direct impact on the coating performance and final product stability. Particle sizes typically range from 0.1 mm to several millimeters, with specific applications reporting size distributions between 20 and 120 μm, and about 80% of the particles below 100 μm [57,58]. Sphericity is critical for uniform coating – systems like polyamide powders used in fluidized-bed sintering exhibit at least 75% spherical particles, enhancing coating adhesion and flow behavior [59,60]. Density and porosity also vary depending on particle size and coating materials. For example, smaller particles (50–75 μm) generally result in lower porosity, but may compromise the mechanical strength and hardness [61]. These characteristics must be carefully optimized to ensure functional encapsulation tailored to specific applications (Figure 3).

An encapsulant solution is characterized by two critical properties: surface tension and viscosity. The efficiency of encapsulation can be considerably impacted if the viscosity is either too low or too high, resulting in imperfect microstructures such as pores, cracks, or uneven thickness[62]. The atomization of coating solutions may be limited by high viscosity. The production of uniformly coated particles in fluidized-bed systems requires effective atomization of fine droplets. An excessively viscous solution may lead to inadequate dispersion and uneven coating on the substrate, preventing it from forming small droplets [63]. To attain more refined structures, uniform wall thickness, and improved encapsulation efficiency, various studies indicate the utilization of encapsulants characterized by reduced viscosity. In general, encapsulation efficiency for fluidized-bed spray coating ranges from 75 to 95%, depending on the coating thickness and substrate type. When applied to sensitive materials such as biocontrol bacteria (e.g., Collimonas arenae), this method achieved about 6 log[CFU/g coated solids], which is slightly lower than spray drying under similar conditions (7 log[CFU/g solids]) [64]. Compared to other encapsulation methods, spray drying often yields higher encapsulation efficiency for hydrophilic ingredients, typically in the 85–99% range. Extrusion and emulsion techniques using alginate systems show efficiencies of 80–97%, especially for probiotics like Lactiplantibacillus plantarum [65].

To achieve the desired microstructure and increased encapsulation efficiency in spray coating, careful selection of the encapsulant solution's concentration, surface tension, and viscosity, as well as the temperature during the drying process, is essential. Lowering the inlet drying air temperatures below 75°C has been observed to yield high encapsulation efficiencies, reaching up to 99%. It is recommended to use a material with lower viscosity for improved results [63]. The most frequently utilized coating agents for achieving the desired microstructure of capsules include polymer-based components, specifically acrylic polymers, cellulose esters, and copolymers. Enhanced solubility, decreased viscosity and permeability, along with the ability to generate more compact films, represent some of the recognized advantages of these coating agents [66].

In terms of release profiles, fluidized-bed spray coatings offer controlled release times ranging from less than 1 h to more than 22 h, depending on the coating thickness and material properties [67]. Thicker and uniform coatings favor slower, sustained release, whereas thinner or porous coatings may lead to faster “burst” release. In contrast, spray-dried capsules typically have thinner walls and higher porosity, resulting in faster release, often within minutes to a few hours [64]. Extrusion-based alginate beads also allow for prolonged release depending on the crosslinking density and bead size, with smaller beads releasing faster due to higher surface area, and multilayered beads mimicking the slow-release behavior of fluidized-bed capsules [64,68].

It is important to note that adjusting the flow rate of the coating solution, along with factors such as glass transition temperature, atomization pressure, core/encapsulant ratio, and fluidizing air velocity, is crucial for optimal results.

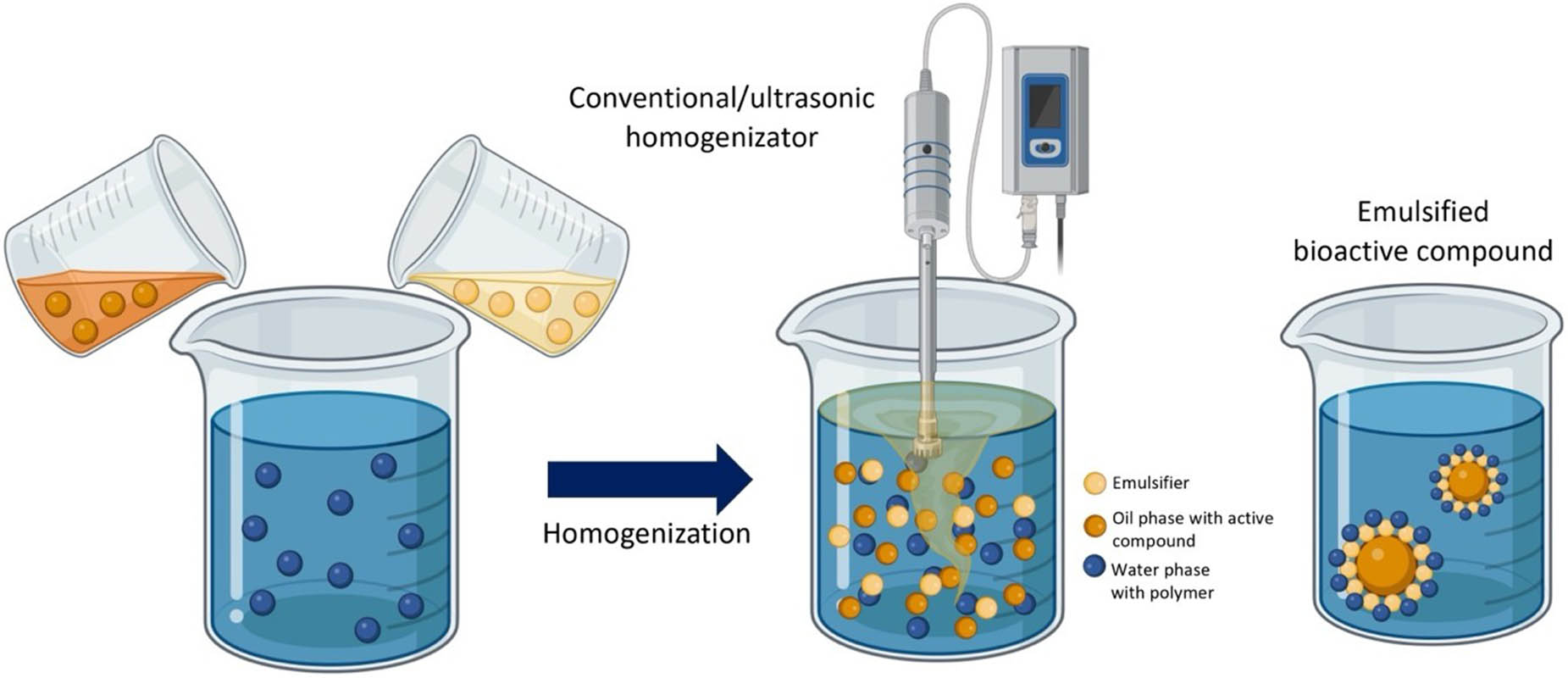

2.2.2 Emulsion technique encapsulation

An emulsion is a mixture of at least two immiscible liquids – liquids that do not dissolve into each other. One of these liquids makes up the dispersed phase, which is distributed as tiny droplets within the other liquid, referred to as the continuous phase (Figure 5). The continuous phase may consist of an organic solvent, oil, a meltable solid, or any substance that is soluble in a solvent. The polymer functioning as the encapsulant is typically dissolved in the solution or within the continuous phase of a suspension or emulsion, such as sorbitans, polysorbates, sucrose esters, sodium caseinate, sodium carboxymethyl cellulose, gelatine, or natural surfactants such as soybean lecithin and saponins [69–71]. After being homogenized, the liquid core forms small droplets in the continuous phase [72].

Illustration of the emulsion technique encapsulation.

Commonly, oil and water are used as the two immiscible liquids to create an emulsion. Emulsions are categorized into two primary forms: single emulsions and double emulsions. Single emulsions, particularly oil-in-water (O/W) emulsions, are widely used for oil-soluble core materials [73]. In practical food applications, O/W emulsions are employed to encapsulate flavor oils, enhancing sensory properties and masking undesirable tastes [74]. They are also used to deliver nutraceuticals – such as essential vitamins and minerals – to improve the health value of food products [75], and can contribute to novel textures through gel formation, improving the overall eating experience [76].

Particles produced through emulsion encapsulation techniques exhibit a wide range of sizes and morphologies, depending on the formulation and processing parameters. Colloidosomes, for example, vary from 5 nm to several microns and often show broad size distributions due to the use of polydisperse emulsions [77]. Chitosan-based microcapsules typically display uniform spherical shapes with micron-sized, monomodal distributions, as confirmed by laser diffraction [78]. Polymeric nanoparticles produced for pharmaceutical use are generally smaller than 500 nm, offering advantages for controlled drug release [79]. The mechanical strength, permeability, and encapsulation efficiency of these particles depend heavily on the emulsion type, stabilizers, and polymer matrix, with challenges such as size uniformity and structural integrity during processing remaining critical for optimized performance.

Double emulsions (W1/O/W2), on the other hand, may be employed for specific purposes, referring to emulsions in which oil globules (O) containing small aqueous droplets (W1) are dispersed in a continuous aqueous phase (W2) [70]. In the process of incorporation, cores that are either oil-soluble or water-soluble may first be dissolved in their respective mediums – oil or water – prior to the introduction of an encapsulant or emulsifier, followed by the homogenization of the resultant mixture. Homogenization is essential in the production of emulsions, as it adeptly minimizes droplet size, amplifies surface area, boosts stability, and ensures an even distribution of core materials throughout the solution [80]. In the process of emulsion production, small droplets are effectively coated by emulsifiers, utilizing a blend of electrostatic forces, hydrogen bonding, steric stabilization, and the intricate dance of hydrophobic and hydrophilic interactions. The interplay of these mechanisms promotes a stable emulsion, effectively inhibiting droplet coalescence and ensuring a consistent dispersion throughout the continuous phase [81].

Various types of emulsions, including conventional, layer-by-layer or multilayer, microemulsions, nanoemulsions, emulsion gel, and pickering emulsion, have been developed to enhance their performance [69,82–84]. The process of creating multilayer emulsions typically commences with the creation of a main emulsion with a charged emulsifier. This comprises the homogenization of an oil and aqueous phase, wherein the ionized hydrophilic emulsifier rapidly adsorbs to the surface of the droplets generated during homogenization, yielding small charged droplets [85]. The addition of a biopolymer, electrolyte, or another oppositely charged polymer to the mixture leads to adsorption onto the surfaces of the droplets, which facilitates the formation of a secondary emulsion. This technique can be employed repeatedly to construct multiple layers. The pH of an emulsion requires meticulous regulation, as the charged state of the biopolymer may fluctuate with changes in pH [86].

The zeta potential (ζ-potential) is a critical factor in predicting emulsion stability, as it reflects the net surface charge of dispersed droplets. Stable emulsions are characterized by zeta potential values exceeding 30 mV, irrespective of whether the charge is positive or negative. The stability of these emulsions is primarily maintained through electrostatic repulsions within the colloidal system [87]. While high ζ-potential generally promotes stability, excessively high values can lead to emulsion instability due to over-repulsion, causing droplet breakup or flocculation [88–90]. On the other hand, flocculation can occur when the δ-potential is close to zero since there is not enough repulsive force within the system. Therefore, maintaining a balanced zeta potential is key to ensuring long-term emulsion stability, especially in functional food formulations.

2.2.3 Emulsion solidification process

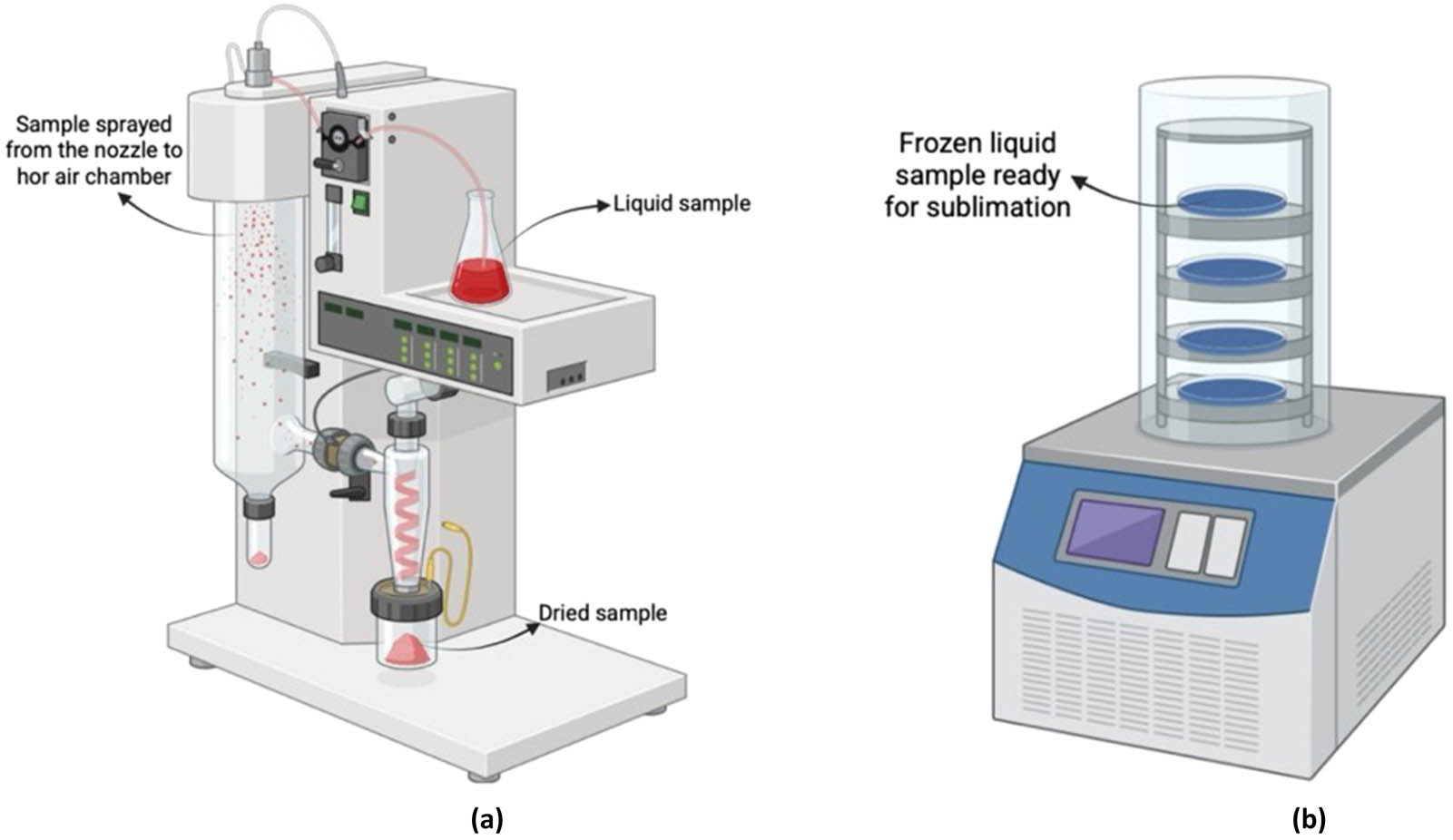

Various atomization techniques, including spray drying, spray cooling, spray chilling, and spray-freeze drying, are frequently employed to solidify emulsions. The most common technique of this process is spray drying, which employs hot air to facilitate the evaporation of water from atomized droplets [91]. Spray cooling and chilling, on the other hand, use temperatures below the encapsulant material's melting point to solidify atomized droplets. Spray–freeze drying is a method that utilizes the properties of spray drying, which entails the atomization of a liquid to produce smaller particles, alongside freeze-drying, which is particularly beneficial for drying thermally sensitive materials, to generate dry powders with controlled size and improved stability [92].

The physical characteristics of particles produced by solidification of emulsion encapsulation techniques – such as spray drying, spray cooling, spray chilling, and freeze drying – are highly dependent on the processing method and encapsulating materials (Figure 6). Spray-dried powders typically have particle sizes ranging from 20 to 120 μm, with approximately 80% of particles measuring less than 100 μm in diameter [57]. Spray-freeze drying tends to yield spherical particles, although some aggregation may occur depending on the properties of the encapsulation agents [93]. The morphology of spray-dried particles generally falls into three categories: crystalline structures, skin-forming shells, and loose agglomerates [94]. In particular, spray-dried flavor encapsulates are known for their low surface area to volume ratio, resulting in high bulk density and good flowability [95]. Bulk density is significantly influenced by the composition of the encapsulant; for instance, milk fat with higher lipid content tends to produce powders with lower bulk density [57]. Flowability, as indicated by the angle of repose, ranges between 37 and 46° and is closely linked to the particle size and morphology. While spray drying often provides powders with desirable flow and encapsulation characteristics, freeze-drying techniques can be more effective in preserving the solubility and stability of thermally sensitive bioactive compounds, highlighting the need to carefully balance physical attributes with functional requirements [96].

Illustration of the emulsion technique encapsulation. (a) Spray drying illustration and (b) freeze drying illustration.

The microstructure of matrix encapsulates can exhibit considerable variation in characteristics such as surface morphology, which refers to the external structure; it may be rough, porous, hollow, fractured, or shrinking [16]. The shape may be spherical, but it can also exhibit heterogeneity in size and form based on the encapsulants employed [97]. This can be influenced by variables such as the inlet temperature, the encapsulant's properties (such as molecular weight), and the drying medium's characteristics [54]. Encapsulates with a compact microstructure, often referred to as perfect-microstructure encapsulates, are reported to have the highest encapsulation efficiency according to several studies. Conversely, encapsulates with microstructures such as holes, dents, or shrinkage may result in reduced encapsulation efficiency. This is because these features have the ability to push the core material beyond the outer surface [98]. Additionally, hollow encapsulates are prone to breakage during handling, resulting in the loss of volatile core materials. Microcapsules with structural defects such as cracks or blow holes exhibit reduced encapsulation efficiency [99]. This is primarily because these defects create pathways that allow environmental factors, such as moisture and oxygen, to penetrate and interact with the core material. Consequently, the protective function of the microcapsule is compromised, leading to a more rapid release of the encapsulated substance and diminished stability. Consequently, these types of microstructures generally lead to lower encapsulation efficiencies.

Encapsulates with a porous structure are typically achieved through processes such as spray–freeze drying or freeze drying [100]. While spray–freeze or freeze-dried encapsulates exhibit elevated encapsulation efficiencies initially, which is related to reduced drying temperatures [101], the pronounced porosity associated with these structures becomes a drawback when considering the abilities to preserve and promote sustained release of a core material. Increased porosity also implies a larger surface area, making them more susceptible to oxidative degradation for oxygen-sensitive core materials.

Incorporating high-molecular-weight encapsulants such as maltodextrin into an emulsion prior to spray drying is advisable to enhance both the efficiency of the process and the quality of the resultant powder. Low-molecular-weight sugars in food powders can induce stickiness during spray drying, which can be reduced by employing high-molecular-weight encapsulants [102]. Employing suitable coating materials, such as carbohydrates and proteins, is crucial for food-grade applications and preserves the core materials from external influences [103]. To prevent the occurrence of cracks, blow holes, and hollow structures, it is essential to meticulously regulate the temperature of the drying process. Moreover, regulating the exit air temperature can indirectly control the moisture levels, hence affecting the final particle output [104]. The inclusion of substances with a high molecular weight can result in smaller droplet sizes in emulsions [105]. Smaller droplets generally yield reduced pore diameters in the final dried products, as they facilitate a more uniform structure during the drying process. Subsequently, it is advisable for the drying process to be conducted at a temperature lower than the glass transition temperature of the resultant emulsion.

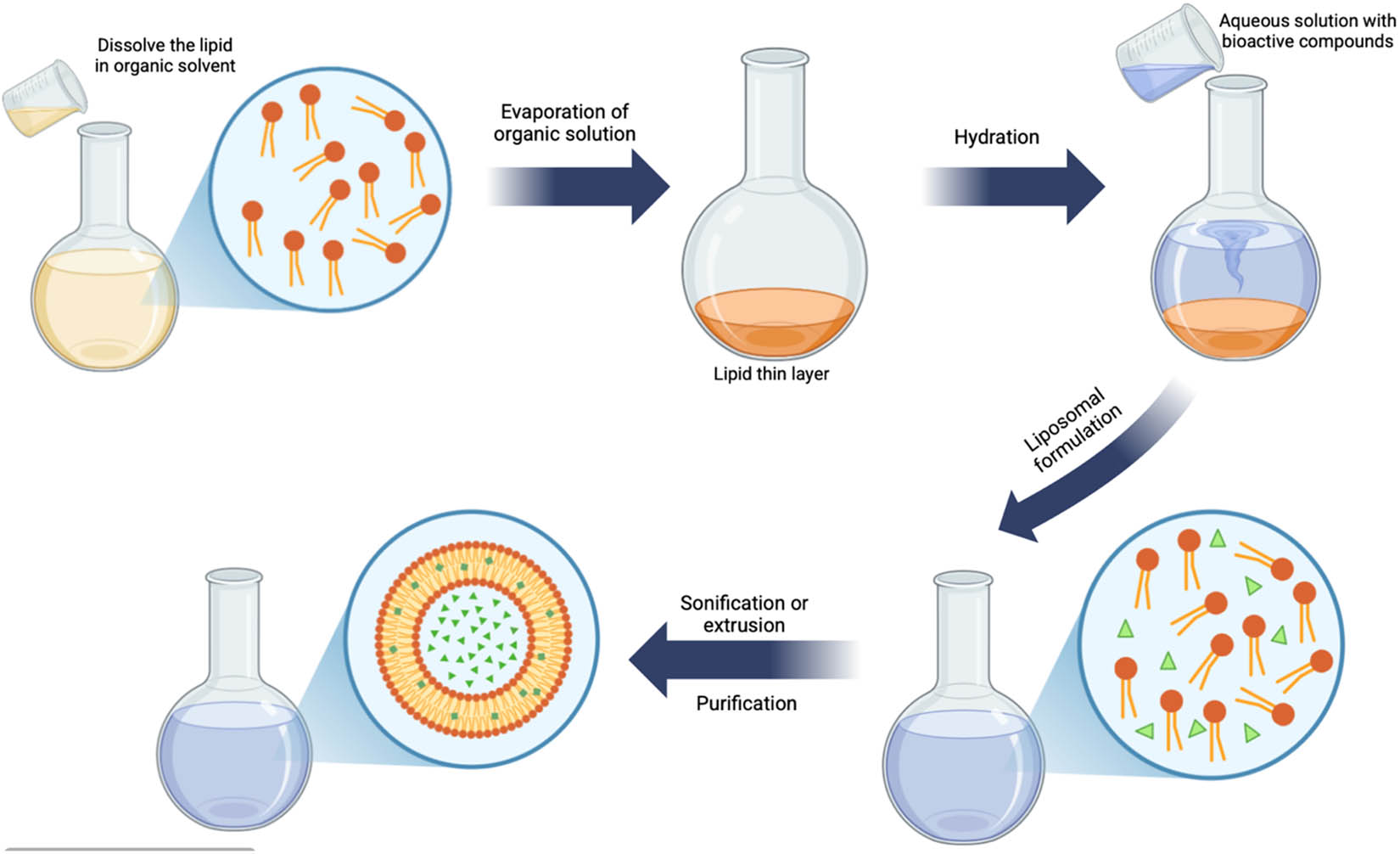

2.2.4 Liposome encapsulation technique

Liposomes are colloidal carriers characterized by their spherical structure composed of lipid bilayers that encapsulate an aqueous core (Figure 7). This structural versatility makes them highly effective in food technology applications, particularly for improving the stability, solubility, and bioavailability of sensitive bioactive compounds [106]. The ability of liposomes to encapsulate both hydrophilic and hydrophobic drugs allows for versatile therapeutic applications, including in pharmaceuticals, cosmetics, and food industries [107]. In the food industry, liposomes are used for nutrient enrichment (e.g., vitamins and antioxidants), controlled delivery of flavors and natural colorants, and protection of volatile or oxidation-prone ingredients. By shielding encapsulated materials from environmental stressors such as heat, oxygen, and light, liposomes help preserve sensory quality and extend shelf life [108,109]. Their biocompatibility and ability to target delivery make them a valuable encapsulation method in functional and fortified food products [110].

Illustration of the liposome encapsulation technique.

The primary classifications of liposomes structures are small unilamellar vesicles (SUVs), characterized by a single lipid bilayer and a size typically under 100 nm; large unilamellar vesicles (LUVs), which possess a single bilayer exceeding 100 nm; multilamellar vesicles (MLVs), consisting of several lipid bilayers arranged in an onion-like configuration; and multivesicular vesicles (MVVs), which feature a multilamellar structure with concentric phospholipid spheres formed by multiple unilamellar vesicles within larger liposomes [111]. MLVs generally vary in size from 500 nm to 5 μm. MLVs possess an onion-like architecture, consisting of concentric bilayer membranes [112]. MLVs and MVVs demonstrate enhanced stability compared to unilamellar liposomes [113]. MLVs and UVs, despite being similar in size, exhibit distinct physicochemical characteristics such as permeability, stability, elasticity, and toughness, resulting in varied applications [114]. LUV, possessing an extensive hydrophilic zone, adeptly encapsulates a substantial quantity of hydrophilic substances, whereas MLV successfully entraps hydrophobic materials owing to its lipophilic region. Liposomes can concurrently encapsulate both hydrophilic and hydrophobic core substances.

The internal microstructure of liposomes is determined by their composition and can be classified according to their size and the quantity of bilayers present [111], such as phospholipids, cholesterol molecules, position, and vesicle types. Phospholipids act as the primary structural element of liposomes, characterized by a hydrophilic head and a hydrophobic tail, which facilitates the development of an amphiphilic architecture. Cholesterol plays a key role in liposome formation by positioning its hydroxyl group toward the aqueous core and its hydrophobic part in the bilayer's hydrocarbon region. It enhances bilayer rigidity, strengthening its mechanical stability [115].

Liposomes' internal microstructure is predominantly determined by their distinctive composition and organization. The internal microstructures are unique and do not include mononuclear, polynuclear, or matrix components. Liposomes typically demonstrate a significant capacity for encapsulating hydrophobic core materials effectively. The encapsulation efficiency of liposomes for hydrophilic substances improves with liposome size and decreases with the number of bilayers [111]. The application of biopolymers like chitosan, pectin, and alginate to coat liposomes has demonstrated enhancements in their stability and encapsulation efficiency. The application of these coatings serves to protect the liposomes against environmental degradation while minimizing the leakage of active components [116].

Nevertheless, previous studies have suggested that liposomes generally demonstrate a lower encapsulation efficiency for hydrophilic core materials than for hydrophobic ones. Many studies have reported that encapsulation efficiencies of hydrophilic materials, e.g., Gonzalez Gomez et al. [117] have reported that the ability of liposomes to integrate hydrophobic drugs into their lipid bilayer offers them an optimal encapsulant for such drugs. Conversely, hydrophilic drugs are typically less effectively retained due to their propensity to diffuse from the liposomal aqueous core. Substances that are challenging to encapsulate in liposomes include hydrophilic antibiotics such as vancomycin, which has an encapsulation effectiveness of 33.4%. One possible explanation is that the twisted structure of liposomes acts as a barrier for certain water-soluble core components with molecular weights below 500 Da [117]. Liposome encapsulation efficiency varies based on core material properties. While larger molecules like peptides and proteins may encapsulate more effectively, high core loading can compromise liposome stability, leading to leakage. Hydrophobic cores with lower molecular weights achieve high encapsulation efficiency, whereas hydrophilic cores below 500 Da exhibit reduced efficiency.

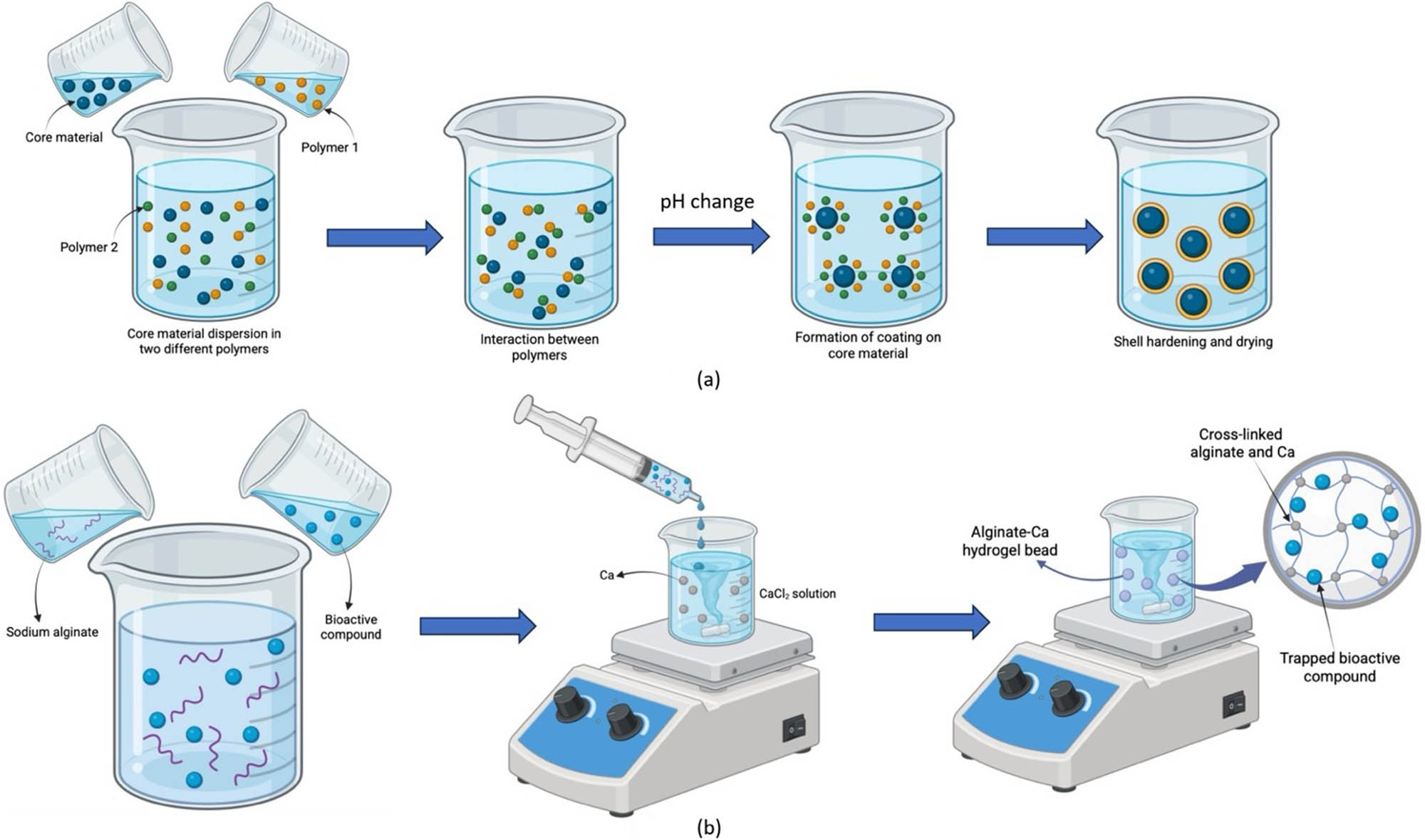

2.2.5 Encapsulation by coacervation and ionic gelation

Two significant techniques for microencapsulation are coacervation and ionic gelation, commonly employed across multiple domains, including pharmaceuticals, food technology, and cosmetics (Figure 8). Both techniques leverage the physicochemical properties of polymers to encapsulate bioactive compounds, enhancing their stability and bioavailability.

Illustration of coacervation (a) and ionic gelation (b) encapsulation.

Coacervation is a microencapsulation technique that involves the separation of a colloidal solution into two liquid phases: one rich in colloid (coacervate) and the other poor in colloid. This process can be categorized into two types: simple and complex coacervation [118]. In simple coacervation, a single polymer, such as sodium alginate, is dissolved in water, and upon the addition of a core material, droplets form. Introducing these droplets into a gel-forming medium (e.g., calcium chloride) leads to the creation of calcium alginate microcapsules [118,119]. This method is particularly effective for encapsulating lipophobic molecules but has limitations due to its sensitivity to pH and electrolyte concentrations. Complex coacervation involves two or more polymers, such as alginate and gelatine, which are solubilized in water at different pH levels [118,119].

Electrostatic interactions between the polymers promote coacervate formation around the core material. This method provides improved stability for sensitive compounds like anthocyanins but requires careful control of pH and charge conditions. When the ζ-potential between biopolymers approaches zero, charge neutralization facilitates coacervation and the formation of compact microcapsules [120,121]. However, a near-neutral ζ-potential alone does not guarantee full interaction or efficient encapsulation – maintaining electrostatic balance and suitable environmental conditions is essential for stable capsule formation [122].

Ionic gelation is another encapsulation technique that has gained attention for its simplicity and effectiveness. This method relies on the ability of ionic polymers to crosslink with counter ions to form hydrogels. The mechanism of ionic gelation entails the establishment of complexes between anionic salts and charged biopolymers [118]. Ionotropic gelation typically occurs when two molecules possessing opposing charges interact with each other. In a chemical reaction, negatively charged divalent or multivalent ions interact with positively charged polymer chains. The creation of microstructured particles featuring interconnected nanofibrillar networks results from the electrostatic response. This can be achieved through one of three techniques: internal, external, or inverse gelation (Table 2) [123].

Comparison of three ionic gelation techniques

| Gelation type | Mechanism | Pros | Cons | Common applications |

|---|---|---|---|---|

| External gelation | Crosslinking ions (e.g., Ca²⁺) diffuse from outside into polymer droplets (dropwise addition) | Simple to control | Heterogeneous structure | Probiotic alginate beads [127], enzyme delivery [128], antioxidant [129]. |

| Rapid bead formation | Higher porosity at the core | |||

| Internal gelation | Insoluble salts (e.g., CaCO₃) inside polymer matrix dissolve in acid bath, releasing ions gradually | More uniform gelation | Requires optimization of acid–salt ratio | Vitamin delivery [130], antioxidant [129] |

| Improved core retention | Larger pores, lower density | |||

| Inverse gelation | Gelling ions are added to polymer in oil-based emulsion (W/O or O/W) | Soft, thin-shelled capsules | Fragile structure | Antioxidant [131], flavor oil encapsulation [132,133] |

| Minimal polymer required | Less suited for harsh conditions |

The external method is the most prevalent method employed in ionotropic gelation. This technique is also referred to as controlled diffusion [124]. The crosslinking solution is administered incrementally, dropwise, in conjunction with the polysaccharide solution. The formation of the bead matrix occurs as crosslinking agents migrate from the external continuous phase of the polymer into its internal structure. The droplets conducting the sol–gel transition are located within the outermost layer of the produced hydrogel bead. The outer layer of the produced hydrogel bead exhibits a rapid sol–gel transition, resulting in immediate gel formation. Rapidly, counter-ions start forming in the subsequent phases, and the process of gel formation initiates immediately. The subsequent steps entail the penetration of counter-ions into the particle, leading to a heterogeneous gelation profile. This profile indicates that the interaction between the ions and polymer functional groups is maximized at the surface and diminishes to zero at the core [125].

Internal and in situ gelling are interchangeable. An alternative to this procedure is polymer particle preparation. An insoluble calcium salt (CaCO3 or CaSO4) is incorporated into the polymer solution and extruded into an acidic crosslinking bath. Various conditions enhance the solubility of the calcium salt, facilitating its release and the formation of a gel network with the polymer. This regulates the gelling mechanism and uniformly exposes the polymer to cations, resulting in the formation of a gel network. The primary disadvantage of this strategy is significant, which generates matrices with larger pore sizes and reduced densities compared to external gelling, enhancing permeability but diminishing entrapment efficiency and elevating release rates [125,126].

The third method is reverse gelation, which involves the gradual addition of a medium containing gelling agents to the polymer solution. This approach is commonly employed for the production of polymer-based soft-shell microcapsules containing oil-in-emulsions. This technique employs minimal quantities of biopolymer, leading to the formation of a soft molecular shell. The unique characteristics of the produced microcapsules, such as mechanical qualities and pharmaceutical active compounds release, may differ based on the emulsion type employed (water-in-oil or oil-in-water) [123,125].

The outcomes of inverse gelation, internal gelation, and external gelation consistently yield equivalent levels of encapsulation efficiency. The final product's microstructures can exhibit compact, rough, or cracked characteristics, influenced by the concentrations of biopolymers and anionic salts, the degree of cross-linkage, and the specific drying processes and conditions employed. Sufficient concentrations and effective complexation between biopolymers and anionic salts yield compact complexes. Insufficient concentrations, complex formation, or cross-linking may result in diminished, uneven, or porous structures, hence decreasing encapsulation efficiency [54]. Encapsulation efficiency improves with reduced core loads. Consequently, an optimally optimized ionic gelation technique utilizing a reduced core load, adequate charged biopolymers and anionic salts, along with enhanced cross-linking, can attain very high encapsulation efficiencies.

The physical characteristics of particles formed through coacervation and ionic gelation encapsulation techniques are significantly shaped by the composition and process parameters. In ionic gelation, particles such as chitosan-based nanoparticles generally exhibit sizes in the nanometer range, with their dimensions governed by the concentrations of chitosan and crosslinking agents like tripolyphosphate, as well as by the reaction time [134,135]. The morphology is typically spherical, as confirmed by scanning electron microscopy, and remains stable even with the addition of substances like sodium fluoride, unless used at high concentrations [136]. These nanoparticles also exhibit positive zeta potential values that increase with higher chitosan concentrations, contributing to their colloidal stability, which is essential for pharmaceutical and food delivery systems [135]. In contrast, coacervation produces larger particles, generally below 1,000 μm, with morphologies ranging from spherical to elongated ellipsoids. These particles are typically mononuclear in structure and maintain integrity without aggregation, even when encapsulating heat-sensitive compounds [137]. Structural analyses using gas chromatography–mass spectrometry and infrared spectroscopy confirm their stable architecture. While both methods allow for the encapsulation of sensitive bioactive materials, ionic gelation offers enhanced control over particle stability, whereas coacervation is particularly suited for producing larger, structurally robust particles for applications requiring thermal protection.

3 Impact of microcapsule structures on the bioavailability of bioactive compounds

Microcapsule structures play a crucial role in determining the bioavailability of encapsulated compounds. The behavior of microcapsules within the body can be influenced by various aspects of their structures, encompassing the size, shape, and wall composition [13]. The properties such as permeability, porosity, and the existence of multiple concentric coatings may play a role in determining the release of the encapsulated substance and subsequently affect its bioavailability.

In conjunction with the microcapsule structure, the concept of bioaccessibility adds a crucial dimension to understanding ingredient bioavailability. Bioaccessibility, defined as the release of components or their fractions during digestion in the gastrointestinal tract (GIT) to make them available for absorption, marks the initial stage in releasing an ingredient bioavailable. Nutritionally speaking, bioaccessibility is the fraction of substances that are released from the food matrix during the digestive process and are subsequently available for tissue distribution [138]. Besides bioaccessibility, the concept of bioavailability encompasses the utilization of ingredients and their ensuing bioactivity, which pertains to the impact exerted by the absorbed components [17]. To elaborate, bioavailability includes processes such as gastrointestinal digestion, absorption, entry into the bloodstream, distribution within tissues, and, finally, the bioactivity. While these terms are closely linked, they are not always directly correlated, and improving one does not guarantee enhancement of the other.

Microencapsulation has been shown to improve both parameters in various applications. For instance, liposoluble vitamin B1 microcapsules prepared with β-cyclodextrin demonstrated a high bioaccessibility of 82.81% in oil-based systems, indicating enhanced solubility and stability (Tian et al., 2023). Similarly, iron-peptide microparticles showed bioaccessibility and bioavailability of 49% and 56%, respectively, outperforming traditional iron salts [139]. However, despite these successes, the relationship between bioaccessibility and bioavailability remains complex. For instance, high bioaccessibility may not translate into high bioavailability if the compound is poorly absorbed or rapidly metabolized after release. Factors such as the physicochemical properties of the core material (e.g., hydrophobicity), the type of encapsulating polymer, gastrointestinal transit time, and interactions with food matrices significantly affect this relationship [133,140]. Furthermore, the release profile of microcapsules under varying pH or enzyme conditions can be inconsistent, leading to partial or premature release before absorption. Thus, while microencapsulation is a promising tool to enhance the delivery of functional compounds, it requires careful design and optimization to align release kinetics with the absorption window of the target bioactive.

3.1 Microcapsule structures and their influence on release mechanisms

The design of microcapsules, particularly their structural features, significantly influences the mechanisms governing the release of encapsulated compounds. The microcapsule matrix may not change throughout the release, but it occasionally occurs because of fragmentation, shrinkage, or swelling behaviors. Apart from the microcapsules’ structural characteristics, other factors may influence the release of the bioactive material. These include the composition of the bioactive compounds and the physicochemical characteristics of the encapsulating material, such as the degree of solubility of the compound in the microcapsules’ internal core, the rheological characteristics of the material inside the polymer capsule, the size of the pores in biopolymer microcapsules, the potential interaction between the microcapsule network and properties of the encapsulated substance in microcapsules (like shape, size, and structure), and the gradient of bioactive material concentration between the microcapsules’ wall and the surrounding environment [141].

A study emphasized the significance of food microstructure in influencing the bioavailability of nutrients. It is suggested that encapsulating bioactive molecules in carefully designed matrices can provide protection during the process of digestion [142]. Yang et al. [143] discussed the relationship between protein encapsulation in microcapsules and the bioavailability of astaxanthin esters. They stated that protein encapsulation, especially with whey protein, improves the stability, water solubility, and bioavailability of astaxanthin esters. Differently, previous studies discussed in the study of Lin et al. [144] indicated that the bioaccessibility of β-carotene is influenced by both simulated digestive conditions and the features (composition and structure) of lipid-based microcapsules. These factors affect the structural stability of delivery systems, the digestion of lipids, and the transfer of β-carotene to mixed micelles. Building on these insights, the ability to adjust microcapsule composition and structure presents a significant approach to regulating the release kinetics of encapsulated substances, which is essential for enhancing bioavailability and functional efficacy in food systems.

3.1.1 Control over release rates

One of the key factors influencing release mechanisms is the composition of the microcapsule shell. Shell materials such as alginate, chitosan, and lipids contribute to the mechanical strength and permeability of the microcapsule, thus dictating the controlled diffusion and release rates of encapsulated substances [141]. The morphology of microcapsules, including regular or irregular shapes, mononuclear, polynuclear, and matrix types, also affects the release properties. Different microstructures resulting from encapsulation methods or systems, such as spray coating, co-extrusion, emulsion-based, and ionic gelation encapsulation, influence the encapsulation efficiency and retention of core materials [145]. The size of the pores in the microcapsule shell determines the release mechanism, with smaller pores leading to slower release rates [54]. Additionally, the thickness and permeability of the microcapsule shell can be adjusted to control the release kinetics of the encapsulated compounds [146]. In one study, it was observed that the size of the pores in the Ca-alginate network has an impact on the release of encapsulated bioactive compounds. The release kinetics of encapsulated compounds within the core of Ca-alginate microcapsules were noticeably influenced by the structure and physicochemical properties of the bioactive substance [141]. Jurić et al. [147] further demonstrated that the surface morphology and structure of alginate microparticles, influenced by factors such as calcium concentration and the presence of Trichoderma viride spores, can impact the release behavior of bioactive agents.

Another study stated that spray-coated encapsulates are recognized as a slow-release system, primarily attributed to the presence of additional layer(s) covering the core particles [72]. The outer layer(s) plays a crucial role in regulating the release of the encapsulated core. In order to extend the release duration of encapsulated cores, low-solubility materials are frequently employed in conjunction with fluidized-bed coating. As an illustration, ethylcellulose has been observed to significantly prolong the release of a coated drug for up to 10 h in demineralized water at 37°C [148]. Hence, the outer layer's role is crucial in determining the duration and pace of the release process. Incorporating low-solubility materials in the formulations can be a consideration to achieve desired controlled-release characteristics for various drugs.

3.1.2 pH-responsive system

The pH of the microencapsulation matrix has a significant impact on the release of the encapsulated material. In one study, pectin matrices were used to encapsulate gallic acid (GA) via spray drying. The pH-responsive release mechanism was monitored, and optimal results were obtained at a pH value of 7, indicating that the release of GA was influenced by the pH of the matrix [149]. Similarly, Baghi et al. [150] examined the ability of pea protein isolate and soybean lecithin to encapsulate trans-cinnamaldehyde (TC) at pH 3 and 7. Better thermal stability was demonstrated by the powders generated at pH 3, indicating that the matrix's pH had an impact on the TC release properties. Furthermore, one study found that the pH of the coacervation and crosslinking processes influenced the size, morphology, and release properties of geraniol-containing microcapsules. Optimal conditions for pH resulted in longer-lasting retention of geraniol, indicating that pH affected the release of the encapsulated material [151]. Moreover, Lavelli and Sri Harsha [152] also stated that the pH of the microencapsulation matrix affects the release of the encapsulated material. At pH 1.4, only 13% of the total phenolic compounds were released, while at pH 7.4, the microbeads dissolved and released the encapsulated material. By controlling the rate at which the microcapsule shells dissolve, the pH of the microencapsulation matrix influences the release of the substance that has been encapsulated. Microcapsules that react to either basic or acidic conditions are made using various polymers with varying pH values. Once exposed to a trigger pH, the shells dissolve steadily, releasing the contents in the process. By adjusting the ratios of pH-responsive and pH-unresponsive polymers in the shell composition, the rate of release can be independently adjusted [153].

3.2 Impact of coating materials

The substances that are enclosed are often referred to as active, core, payload, internal phase, encapsulate, or filling, whereas the materials that surround the core are typically termed the outer layer, protective shell, coating, external phase, supportive layer, or barrier. The coating materials can create a protective and unified layer around the core, ensuring its stability and enhancing the capsules’ durability. It is typically unable to dissolve and is unreactive with the core, inert, and does not impart any distinct flavor to the product [17]. Moreover, it is impermeable and able to release the core under specific conditions at a predetermined time and place [6,154,155]. In the context of application within the food sector, it is imperative that the coating material employed for encapsulation attains the status of generally recognized as safe. The critical first step in the encapsulation process is the identification of the suitable material to coat the substance to be microencapsulated. The choice of this coating material is contingent upon the specific properties of the active ingredient and the desired attributes of the final product. The final microcapsule properties are influenced by the structure and composition of the coating material [156]. The chemical as well as physical properties of the final microcapsules or microspheres are determined by the choice of a suitable coating material. The needs of the product, such as stability, decreased volatility, release characteristics, environmental factors, bioavailability, etc., should be taken into account while determining a coating material [6,11]. Previous studies have investigated how the coating material influences the biological activity and bioavailability of the bioactive compounds after microencapsulation, as depicted in Table 3.

List of studies reporting the impact of coating agent(s) on bioavailability

| Coating agent(s) | Microencapsulation method | Bioactive compound(s) | Core to wall concentration/ratio | Encapsulation efficiency (%) | Bioaccessibility/ bioavailability gain (%) | Findings | Ref. |

|---|---|---|---|---|---|---|---|

| Pectin, chitosan, and alginate | Emulsification and ionic gelation | Microalgae Haematococcus pluvialis (H.p.) astaxanthin | Astaxhantin concentration to be 1.3 mg g−1 in oleoresin soybean oil and combined with the polymer solutions at a polymer:oleoresin ratio of 6:1 (w:w). | 87% | Alginate: 58%, Pectin: 46–48% (compared by payload) | By the time the beads with alginate finished digesting, 58% of the astaxanthin had been released, compared to 46–48% for the beads made of pectin. The higher the concentration of pectin, the greater the stability of the carotenoid, but the lower its bioaccessibility | [157] |

| Polyvinylpyrrolidone K30 (PVP) and phospholipid | Electrospray | Capsaicin | Ratio of capsaicin/PVP/phospholipid is 1:6:0.5 | 97.3% | 219.8% increase in oral bioavailability vs free capsaicin (AUC) >80% release in 24 h vs 24–37% from control in vitro | Electrosprayed microcapsules were significantly enhanced both in vitro release and in vivo absorption; excellent IVIVC (r ≥ 0.981) confirmed the predictive power of dissolution data | [158] |

| β-Cyclodextrin, maltodextrin, and Arabic gum | Spray drying | Polyphenols | Leaf extract:carrier ratio was 1:2, with carrier composition β-cyclodextrin/maltodextrin 50:50 | 80.43% | Bioaccessibility in gastric: ∼150%; intestinal: ∼80% vs extract ∼60% | Spray drying microencapsulation with carrier mixtures increased the bioaccessibility of laurel flavonols by approximately 50% in the gastric phase and 10% in the intestinal phase, compared to the non-encapsulated extract | [159] |

| Sodium alginate and soluble potato starch | Ionic gelation | Iron | Alginate, starch, ferrous bisglycinate powder, and water in a ratio of 2:1:2:100 (w:w:w:v) | 82.3% | At the end of simulated oral-gastric-intestinal digestion, the beads heated to 180°C released 1.22-fold more bioaccessible ferrous ions than the corresponding bisglycinate powder | The alginate-starch-iron beads have potential as carriers for oral delivery of iron, as they can enhance the bioaccessibility of ferrous ions during digestion | [160] |

| Sodium carboxymethyl and maltodextrin | Freeze drying and spray drying | Phenolic acids and flavonols | Maltodextrin 10% and 12% in extract, and carboxymethyl 0.70 and 0.75% in extract | N.A | All treatments lost flavonols: 16.58–28.90%; GABA: 34.91–51.14%; 1-deoxynojirimycin: 17.56–20.42%; Phenolic acids: 0.53–0.67% (during the gastric phase) | Encapsulation was found to enhance bioaccessibility but had negative effects on bioefficiency and bioavailability. Carriers had a major effect on the digestibility and antioxidative activity of the compounds. Sodium carboxymethyl cellulose was found to reduce the losses of biocompounds during intestinal digestion, and spray-drying resulted in lesser losses of biomolecules compared to freeze-drying | [161] |

| High methyl pectin (HMP), whey protein isolates (WPI), and soy protein isolates (SPI) | Spray drying | Anthocyanins | Blueberry anthocyanin powder/wall materials (4% SPI + 2% HMP) ratio was 1:4 | 93.5% | Microencapsulated blueberry anthocyanin powder <50% anthocyanins vs. blueberry anthocyanin powders alone (control) ∼100%, indicating controlled release and increased bioaccessibility | Microcapsules created with a combination of 4% SPI and 2% HMP (MBAPc) showed superior anthocyanin release behavior and antioxidant stability compared to those produced with 4% SPI alone (MBAPs). Both MBAPc and MBAPs exhibited continuous release of anthocyanins throughout simulated gastrointestinal digestion and followed two first-order kinetics | [162] |

| Enzymatic cyclodextrin synthesis product, maltodextrin, and β-cyclodextrin | Spray drying | Tributyrin | Tributyrin/maltodextrin ratio was 1:1 | 90.90% | 69.06% released in stomach (SGF); 100% release within 1 h in the intestine. Moderate to low protection; reduced bioavailability | Tributyrin microcapsules prepared using the method of encapsulating tributyrin during enzymatic cyclodextrin synthesis (CGT) showed superior controlled release of their tributyrin content in a model of the mammalian intestine, indicating improved bioavailability | [163] |

| Maillard reaction products (MRP) and OSA starch | Spray drying | Docosahexaenoic acid (DHA) | Not available | Not available | Significant increase in blood DHA and Omega-3 index by week 2; low fecal DHA; superior bioavailability vs non-encapsulated oil | The results demonstrated enhanced bioavailability with significantly greater concentrations of blood DHA levels in formulas with microencapsulated powders. The bioavailability of DHA was assessed through blood and fecal fatty acid levels, and the results indicated improved bioavailability with the use of microencapsulated powders | [164] |

3.2.1 Hydrophilic coating agents

The application of hydrophilic encapsulants facilitates the effective encapsulation of micro- or nanosized hydrophilic compounds. The utilization of the internal aqueous pockets within the capsules enhances encapsulation efficiency by maintaining the stability of the active components and inhibiting their premature release into the surrounding environment [165]. The encapsulation effectiveness of hydrophilic substances can be improved using hydrophilic encapsulants such as chitosan and alginate. Microcapsules containing alginate-coated chitosan, produced from poly (dl-lactide-co-glycolide) (PLGA), exhibited superior encapsulation rates and reduced early burst release compared to conventional methods, facilitating a more regulated and extended-release profile [166]. The choice of coating material has a significant impact on the kinetics of chemical release. As an example, chitosan coatings allow hydrophilic drugs to be released slowly, reducing the initial burst release significantly [166]. This is crucial for reaching and maintaining therapeutic levels in the bloodstream while minimizing the risk of undesirable effects caused by rapid drug release. The ability of various hydrophilic encapsulants to respond to pH variations renders them optimal for application in biological contexts as drug delivery systems. Certain tissues or pathological conditions may lead to the degradation of biodegradable nanocarriers made from poly(thiourethane-urethane). Encapsulated hydrophilic compounds can be selectively released upon reaching certain regions of the body [167].

A different study found that eugenol, an antimicrobial compound that has been encapsulated and dried by spray-drying, demonstrated a significant reduction in the populations of both Gram-negative (Escherichia coli) and Gram-positive (Listeria innocua) bacteria, decreasing from 5 to 6 log CFU/mL to 0 log CFU/mL within a time frame of just 30 min [86]. The implementation of low-solubility encapsulants facilitates the achievement of a slower, controlled release over a duration ranging from hours to days from spray-dried encapsulates. When combined with suitable encapsulation technology, this approach leads to extended-release periods. In such cases, an initial rapid release may occur, attributed to the presence of some core droplets on the surface of the encapsulates, followed by a slower and sustained release. Additionally, manipulating the release rate of the encapsulated material can be achieved by varying the core-encapsulant ratio. Decreasing the core load, for instance, contributes to a reduced release rate due to the resulting larger shell thickness of the encapsulates.

3.2.2 Hydrophobic coating agents