Abstract

The relevance of the study of technical means for the production, management, application, and conversion of heat is conditioned by the rapid development of the energy sector, the global challenges of climate change, and the need for sustainable and efficient solutions for providing thermal energy, in connection with the need for energy efficiency, optimization of resource use, sustainability, and environmental compatibility, as well as technological progress and innovation. The purpose of this study is to investigate the problems associated with technical means for heat generation, identify shortcomings related to the production, use, and management of thermal energy flows, and consider technical devices for converting alternative types of energy into thermal energy to identify recommendations that would allow them to be used more efficiently. The main results of the study were the analysis of technical means and devices in the field of thermal power engineering and alternative energy, the main problems and shortcomings that lead to a decrease in the efficiency of the operation of technical means, heat loss, reduced comfort, and emissions of harmful substances into the environment, which can lead to a negative impact on human health, a decrease in quality, and other environmental problems.

1 Introduction

The study of technical means in the field of thermal energy is important, as it allows for increased energy efficiency and reduction of energy losses, as well as contributing to energy security, a variety of energy sources, and a lower negative impact on the environment. Research in this field contributes to technological progress, innovation, and the creation of sustainable, environmentally friendly energy systems, as well as the desire for energy independence, which is important for the development of energy infrastructure and ensuring sustainable use of resources. The problems of technical means for the production of heat include several aspects, one of which is energy efficiency. There is a need to find and develop more efficient methods of heat production and use since many existing systems and technologies have low energy efficiency and high energy losses. Improving efficiency can reduce resource consumption and harmful emissions and increase energy independence. Optimal control of heat flows is also important for the efficient use of energy and maintaining the stability of systems. There is also a need to integrate various systems and technologies for more efficient production and use of heat. For example, the integration of renewable energy sources, energy-saving technologies, and control systems can lead to optimal use of resources and increase the overall efficiency of the system.

The global energy context is characterized by a rapidly increasing demand for energy, driven by growing populations, industrialization, and the proliferation of modern technologies. This escalating demand underscores the critical need for efficient heat production technologies. As countries around the world strive to meet their energy needs, the focus has shifted towards optimizing existing energy systems and exploring innovative solutions for heat generation and distribution. Efficient heat production is not only a matter of meeting demand but also a significant factor in addressing the environmental challenges associated with energy generation. Traditional methods of heat production, primarily based on the combustion of fossil fuels, are significant contributors to greenhouse gas emissions, which exacerbate global warming and climate change. Therefore, the development and implementation of more efficient and environmentally sustainable heat production technologies are crucial. In this scenario, the pursuit of advanced thermal energy systems becomes highly relevant. These systems need to be more efficient, reliable, and capable of integrating renewable energy sources to reduce dependence on fossil fuels. The transition to such systems is imperative for achieving the dual goals of fulfilling the growing energy demand and minimizing the environmental impact of energy production.

According to Aliyeva (2020), the importance of energy efficiency in thermal systems cannot be overstated in the current global energy landscape. Efficient thermal systems are paramount for reducing energy consumption, which is a critical factor in meeting both environmental goals and economic objectives. Inefficient heat production not only leads to increased energy usage but also exacerbates the release of greenhouse gases and harmful pollutants. This inefficiency thus has a two-fold negative impact: it strains our energy resources and significantly harms the environment. High energy consumption in inefficient systems often results from outdated technologies, poor heat transfer mechanisms, and energy losses through heat dissipation and system leakages. These inefficiencies necessitate the consumption of more fuel to achieve the desired level of heating or cooling, leading to increased operational costs and resource depletion. Furthermore, the environmental implications of inefficient thermal systems are profound (Fialko et al. 1993).

The burning of fossil fuels in these systems contributes substantially to the emission of greenhouse gases, such as carbon dioxide (CO2), a major driver of global warming and climate change. In addition, the release of nitrogen oxides (NOx) and sulphur oxides (SOx) from these processes exacerbates air pollution, leading to smog formation, acid rain, and significant health hazards to human populations. Therefore, improving energy efficiency in heat production is not just a matter of reducing energy bills or conserving energy; it is also about mitigating the environmental impact. This encompasses reducing the carbon footprint of energy systems and curbing the emissions of noxious gases. Efficient thermal systems, with optimized heat transfer and minimal losses, represent a vital step towards sustainable energy use (Ali et al. 2019). They also align with global initiatives and regulations aimed at reducing emissions and combating climate change, thereby supporting environmental stewardship while fulfilling energy demands more effectively.

As stated by Aliyev (2018), outdated and inefficient heat production systems pose significant problems in terms of energy efficiency. Such systems often suffer from significant heat losses caused by insufficient insulation, leaks, or poor heat distribution. For example, old boilers may have low fuel combustion efficiency, which leads to incomplete use of their energy potential. Heat losses can also occur in pipelines, distribution systems, and heat exchangers, which further reduces the efficiency of the system. Huseynov (2017) notes that the development and implementation of efficient combustion and heat generation systems allow increasing the degree of energy use from fuel and reducing heat loss. The development of innovative heat exchange devices and heat flow control systems also contributes to improving the energy efficiency of systems. In addition, the use of renewable energy sources, such as solar and wind energy, reduces dependence on fossil fuels and lowers the negative impact on the environment.

According to Naziyev (2019), one of the important aspects of heat flow management is to ensure optimal distribution and redistribution of heat within the system. For example, in heating and air conditioning systems, it is necessary to control heat flows in different areas of the room to maintain a comfortable temperature. Industrial processes also require precise control of heat flows to ensure optimal production conditions and prevent energy losses. According to Mamedov and Mamedov (2014), efficient management of heat flows minimizes energy losses and increases the energy efficiency of systems. For example, the use of thermal insulation materials and devices can reduce heat loss in heat supply systems and heat exchangers. The use of automated control and regulation systems also allows accurately controlling heat flows and adapting to changing conditions. According to Aliyev and Aliyev (2014), the integration of various systems and technologies facilitates optimal use of heat resources. For example, cogeneration systems, combined generation of electricity and heat, integrate the processes of electricity and heat production, allowing the use of heat, which usually goes to waste in the production of electricity alone. This allows increasing the energy efficiency of the system and reducing resource consumption.

This study is dedicated to formulating actionable recommendations aimed at enhancing thermal energy efficiency and reducing operational losses in heat production systems. The focus will be on integrating cutting-edge technologies and materials to improve heat transfer and reduce waste, exploring the potential of renewable energy sources for more sustainable operations, and optimizing system design for better performance. In addition, the study advocates for the implementation of advanced control systems to fine-tune energy use, regular maintenance protocols to sustain efficiency, and policy frameworks to support the adoption of energy-efficient practices. Emphasizing education and training, the study also recognizes the need for skill enhancement among professionals to effectively implement these technological advancements. Collectively, these recommendations are geared towards creating more efficient, cost-effective, and environmentally friendly thermal energy systems.

The significance of this study lies in its potential to drive technological progress and innovation in the realm of thermal energy systems, marking a pivotal step towards the creation of sustainable and environmentally friendly energy solutions. By addressing the pressing issues of energy efficiency and operational losses in heat production, this research contributes directly to the global endeavour for energy independence and the sustainable use of resources. It underscores a commitment to reducing environmental impact through improved system designs and the integration of renewable energy sources, aligning with broader global initiatives aimed at combating climate change and fostering a more sustainable energy future. The research aims to address these crucial needs by exploring and enhancing technical means in the field of thermal energy, contributing significantly to the broader goal of sustainable and efficient energy use worldwide. In general, the purpose of the study is to investigate the problems associated with the production and use of heat, the operation of alternative energy in the thermal power industry, and develop recommendations that can improve the efficiency of the use of thermal energy and reduce losses during its operation.

2 Materials and methods

The study’s approach to exploring technical means for the generation, management, and operation of heat is multifaceted, employing a blend of analytical research, materials and technology investigations, and comprehensive comparative analysis and economic research. This amalgamation of methods enables a detailed exploration of both the capabilities and limitations of current heat production technologies.

2.1 Analytical research in heat production technologies

This phase of the research delves deep into the operational principles of various heat generation devices, facilitating a nuanced understanding of their functionality and potential constraints. The analysis extends to evaluating the energy consumption patterns, system efficiency levels, and the broader environmental impacts of these technologies. The data for this segment are primarily sourced from technical specifications, operational data from existing systems, and industry benchmarks. This ensures a balanced view that combines theoretical knowledge with practical insights.

2.2 Comparative analysis methodology

The comparative analysis relied on gathering technical specifications, efficiency ratings, cost data, and environmental impact assessments for various heat production technologies from trusted industry sources. These included white papers from technology manufacturers, industry research reports, and government databases. The data were compiled into tables to allow side-by-side comparisons of key parameters. Quantitative metrics like efficiency ratings, costs, and emissions data enabled numerical comparisons. Qualitative factors like maturity of technology, ease of operation, and sustainability were also compared based on a literature review and expert opinions. The reliability of data sources was ensured by cross-verification and using only reputable sources. The main limitation of this methodology is that real-world performance may differ somewhat from technical specifications.

2.3 Comparative analysis and economic research

Comparative analysis forms the backbone of this study, wherein various technical means of heat generation are juxtaposed based on their efficiency, cost, availability of resources, and environmental footprint. This methodical comparison is instrumental in pinpointing the most sustainable and economically viable technologies. Economic research complements this analysis by examining the long-term economic feasibility and sustainability of these systems. Key parameters modelled included capital costs, fuel costs, operations and maintenance costs, usable heat production, and plant lifetime. The modelling was used to calculate metrics like the levelized cost of heat production, payback periods, and net present costs for different technologies. The financial models were validated through expert reviews. The main data limitation was that real-world costs can vary depending on local factors like labour and resource pricing. However, the economic analysis still provides a reasonable basis for comparison between different heat production technologies.

Based on comparative analysis, economic research, and consideration of sustainability factors, optimal solutions in the field of heat production were identified, and systems and methods that combine high efficiency, economic feasibility, and low environmental impact were identified. Furthermore, a literature review and analysis of existing solutions in the field of materials and technologies for heat production were carried out, which provided an understanding of the current state of ideas and technologies, identifying their advantages and disadvantages, and problems that require further research. Then, the research of new materials and technologies was carried out; the analysis of the physical and chemical properties of materials, the analysis of prototypes, and the determination of their production and energy efficiency were carried out. The data obtained helped assess the potential of new solutions and identify possible improvements. Furthermore, the properties and characteristics of new materials and technologies were analysed and compared to existing solutions, and their potential for use in heat production systems was evaluated. Based on all the data obtained, strategies and recommendations were developed to improve the efficiency of technical means for heat production, reduce the percentage of heat loss during operation, and reduce the cost of operating these systems.

3 Results

In the modern world, the study of technical means related to thermal energy is an important topic for research, as it contributes to the search for sustainable and environmentally friendly solutions to meet the needs of society and the creation of a sustainable energy system. First, energy efficiency and the sustainability of heat supplies are key factors for ensuring comfort and stable development. The use of effective technical means and systems allows optimizing heat production, reducing the consumption of resources and energy, and lowering the negative impact on the environment, including greenhouse gas emissions. Moreover, increasing the share of alternative energy sources, such as solar, wind, geothermal, and biomass, is an important area to reduce dependence on fossil fuels and lower the impact on the climate. The study of technical means capable of converting energy from these sources into heat enables efficient use of renewable resources while also reducing environmental pollution.

The development and application of new technical solutions in the field of heat production and management contribute to the development of various innovations, such as the development of energy-efficient heating and cooling systems, intelligent devices, and device systems that improve people’s lives and contribute to economic growth (Ismayil-Zada 2022). Technical means in the field of thermal power engineering can be different and include various heat generators, heat pumps, heat exchangers, control valves and dampers, thermoregulators, heating networks, power supply devices, and other technical solutions. One of the main technical means for the production of heat is heat generators. These are devices that generate thermal energy by burning fuel or using electrical energy. Different types of heat generators are used in various fields, including industry, residential, and commercial construction, and in domestic conditions (Figure 1).

Types of heat generators. Source: compiled by the authors.

Boilers are one of the most common types of heat generators. There are several types of boilers used for heat generation, including gas, oil, coal, biomass, and electric boilers. Each type has its own characteristics, advantages, and disadvantages, and the choice depends on the availability of fuel, power requirements, and energy efficiency. Gas boilers are one of the most common and more environmentally friendly options, with low emissions of greenhouse gases and pollutants. However, coal-fired boilers and oil-fired boilers may have higher emission levels. Boilers for heat generation strive for high energy efficiency for optimal fuel use and reduction of energy costs. Modernization of boilers using technologies such as condensing boilers can achieve high levels of energy efficiency exceeding 90%. The power of boilers can vary significantly depending on the requirements of a particular application. It can be expressed in kilowatts (kW) or megawatts (MW). For example, boilers in private homes often have a capacity of 10–50 kW, whereas boilers in industrial complexes can have a capacity of several MW. Boilers are subject to strict safety and regulatory requirements to protect against potential accidents and hazardous situations. This includes checking for compliance with safety standards, regular maintenance and testing, and the installation of safety systems, such as safety valves and sensors (Shadek 2016).

Electrical systems for heat generation, such as electric radiators and infrared heaters, are also widely used. Infrared heaters use infrared radiation to heat objects and surfaces, not air. They are effective in transferring heat directly to objects, which reduces heat loss due to convection and conduction. Infrared heaters have a high coefficient of performance (COP), reaching up to 95%. This means that almost all the electrical energy consumed by the heater is converted into thermal energy, minimizing losses. They begin to transfer heat almost instantly after switching on, without requiring a long time to warm up the heater itself, and are often controlled by temperature and operating time. Infrared heaters can be installed for zone heating, allowing users to choose specific areas or rooms to maintain a comfortable temperature, which reduces energy consumption and increases efficiency (Li et al. 2021). The main factors are as follows:

COP: 0.95–0.98;

Efficiency: Infrared heaters convert 80–85% of input energy into radiant heat. They are generally more efficient than convection heaters;

Cost: $100–$500 depending on power rating. Operating costs are lower compared to forced air systems;

Capacity: 1,000–5,000 W. Sufficient for heating small-to-medium-sized rooms;

Applications: Spot heating of indoor spaces like bedrooms, bathrooms, and offices. Best for localized heating needs.

Electric radiators, in turn, operate based on the heating principle of the heating element, which is located inside the radiator casing. When an electric current is applied, the heating element begins to emit heat, which is transmitted to the environment. Electric radiators have the ability to accurately control the temperature. They can be equipped with thermoregulators that allow adjusting the desired temperature and automatically maintaining it in the room. They also have high efficiency and precise temperature control, which saves energy (Prokopov et al. 1992). Some models are equipped with a programming function that allows adjusting the operating modes and operating time to optimize power consumption. In general, this type of heat generator is an effective and convenient solution for heating residential and commercial premises. The main factors are as follows:

COP: 1;

Efficiency: Close to 100% efficient in converting input electricity into heat;

Cost: $50–$300 depending on power rating. Operating costs depend on electricity rates;

Capacity: 400–2,500 W. Can heat small-to-large-sized rooms;

Applications: Whole room heating. Popular for supplementing central heating systems. Different types are available, including oil-filled radiators and ceramic radiators.

In summary, infrared heaters provide efficient localized heating, while electric radiators can efficiently heat entire rooms. Infrared heaters have higher upfront costs but can have lower operating costs. Electric radiators are more affordable initially but have higher energy costs for whole-room heating. The choice depends on specific heating requirements. There are quite a large number of different residential and commercial heat pump models in the world. Each of them has its own different advantages and disadvantages:

Residential heat pumps:

Daikin Fit Heat Pump – A ductless mini-split heat pump often used in homes to heat and cool individual rooms. Provides up to 17 seasonal energy efficiency ratio (SEER) efficiency.

Goodman DSZC18 Air-to-Air Heat Pump – An affordable packaged heat pump for whole-home heating and cooling. Provides up to 18 SEER efficiency.

Commercial heat pumps:

WaterFurnace Envision Series – A geothermal water-to-air heat pump used in office buildings, schools, etc. Provides up to 49 energy efficiency ratio (EER) efficiency.

ClimateMaster Tranquillity Large Water-to-Water Heat Pump – A water-source heat pump for hotels, factories, hospitals, etc. Provides up to 21 EER efficiency.

These are just a few examples of the many heat pump models available for residential and commercial use. The specific heat pump chosen depends on factors like required heating/cooling capacity, efficiency targets, available space, budget, and more. But heat pumps are a proven, highly efficient heating, ventilation, and air conditioning (HVAC) technology for various applications (Antypov et al. 2022).

It is worth noting that electric heat generation systems are limited by the power of the electrical network to which they are connected. Some systems may have limitations on the maximum power they can provide, which may limit their applicability in large industrial facilities or buildings where high thermal power is required. The operation of electric heat generators depends entirely on a reliable power supply. In case of power outages, the system stops functioning and stops the supply of heat, which can be problematic, especially in cold times when reliable heating is critical. Unlike some other heat generators, electrical systems usually do not have the ability to efficiently dispose of waste heat. This means that part of the electricity produced may be lost in the form of unused heat, which, as a result, reduces the overall energy efficiency of the system. In turn, conventional heat generators, such as boilers that burn fuel, can lead to emissions of harmful substances and environmental pollution. Uncontrolled emissions can negatively affect air quality and human health. Moreover, some types of heat generators have low efficiency and inefficient use of fuel, which can lead to high energy costs and the loss of resources. The use of new technologies, such as systems with low emissions of nitrogen oxides (NOx), plays an important role in reducing atmospheric pollution. NOx emissions are one of the main sources of air pollution and can have a negative impact on human health and the environment (Cai et al. 2021).

New systems with low NOx emissions used in gas boilers and other heat generators are based on the use of special combustion methods. They reduce the formation of nitrogen oxides during the combustion of fuel. These systems may include separate combustion zones with controlled conditions where optimized fuel combustion takes place in order to reduce NOx formation. In addition, low-emission systems can use the addition of reagents or catalysts that help convert nitrogen oxides into less harmful substances. For example, some systems use the injection of ammonia or urea, which react with nitrogen oxides and turn them into safe compounds. The effectiveness of such emission reduction systems is demonstrated in practice. For example, gas boilers with low NOx emission systems can reduce nitrogen oxide emissions by 40–50% compared to conventional boilers not equipped with such systems. This significant reduction in emissions has a positive effect on air quality and reduces the negative impact on human health and the environment (Cai et al. 2021).

Table 1 shows a comparative analysis of three major heat generation technologies: gas boilers, electric heaters, and solar thermal systems. The comparison is based on several key parameters, including efficiency range, heat output range, fuel types, emissions, and other technical specifications. This comparison provides a comprehensive overview of these technologies, assisting in informed decision-making for individuals and businesses considering different heating solutions.

Comparison table for the three main heat generation technologies: gas boilers, electric heaters, and solar thermal systems

| Specification | Gas boilers | Electric heaters | Solar thermal systems |

|---|---|---|---|

| Efficiency range | 89–98% | Nearly 100% | 20–80% |

| Heat output range | 10–100 kW | 0.5–3 kW | Depends on collector size and sunlight availability |

| Fuel types | Natural gas, propane, and oil | Electricity | Solar energy |

| Emissions | CO2, NOx, and SO2 (lower with high-efficiency models) | None (but depends on electricity source) | None (direct emissions) |

| Initial cost | Moderate to high | Low to moderate | High (due to installation of solar panels/collectors) |

| Operational cost | Dependent on gas prices | Dependent on electricity prices | Low (after initial setup costs) |

| Lifespan | 15–20 years | 10–15 years | 20–25 years |

| Other specifications | – Requires ventilation | – Easy to install | – Requires solar collectors and storage |

| – Needs regular maintenance | – No ventilation needed | – Weather-dependent | |

| – Risk of carbon monoxide | – Quick response time | – Low operational cost |

Note: The values and specifications in the table are approximations and can vary based on specific models, brands, and advancements in technology. Efficiency range, in particular, can be influenced by installation quality and maintenance. In addition, the environmental impact of electric heaters is dependent on the source of the electricity; if the electricity comes from renewable sources, the environmental impact is significantly lower.

The comparative analysis of gas boilers, electric heaters, and solar thermal systems reveals distinct characteristics for each heat generation technology. Gas boilers are highly efficient (89–98%) and suitable for large-scale heating needs (10–100 kW), but they emit greenhouse gases and require regular maintenance. Electric heaters are extremely efficient (nearly 100%), ideal for smaller spaces or supplemental heating with outputs ranging from 0.5 to 3 kW, and have no direct emissions, although their environmental impact is tied to the source of electricity. Solar thermal systems, while dependent on climatic conditions, offer a variable efficiency (20–80%) and a heat output contingent on collector size and sunlight exposure, standing out for their eco-friendliness with no direct emissions and low operational costs after the initial high setup expense. The choice among these systems hinges on factors like desired heat output, environmental considerations, installation space, and budget constraints, with gas boilers fitting high-demand scenarios, electric heaters for targeted heating needs, and solar systems for sustainable, long-term solutions (Trokhaniak and Gorobets 2023).

Increasing the efficiency of electric heat generators can be achieved using several methods. First, it is important to ensure good insulation of the heating system and premises in order to minimize heat loss. The less heat is lost, the more efficiently the heat generator works. Another way to increase efficiency is to programme the temperature. Adjustable thermostats and control systems allow optimizing the operation of the heat generator by adjusting the temperature depending on the time of day or the needs of the premises. Regular maintenance and cleaning of heat generators will help reduce the risk of emissions and increase their efficiency. Regular descaling, cleaning of chimneys, and replacement of filters will maintain optimal operating conditions for the generator. The chimneys of heat generators can be filled with soot and other contaminants over time, which can lead to a deterioration in the draft and increased generation of harmful emissions. Regular cleaning of chimneys helps maintain optimal working conditions and reduces the risk of environmental pollution.

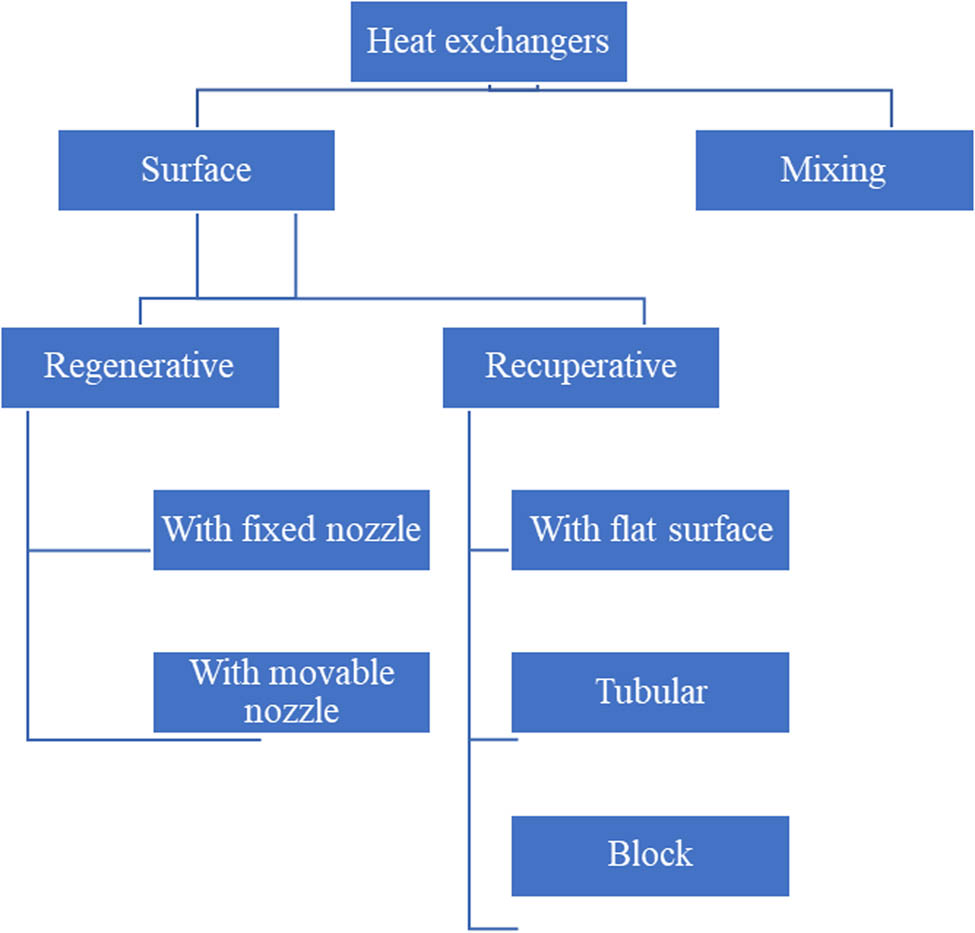

The key components of the heat flow control system are heat exchangers. They provide efficient heat transfer between two different media without mixing them. Heat exchangers are widely used in various fields, including heating, ventilation, air conditioning systems, industrial processes, and other areas where control and regulation of heat flows are required. Heat exchangers can be divided into two main categories: surface and mixing. Surface heat exchangers are based on the principle of heat transfer through the contact surface between two media. They work by creating a large contact surface between hot and cold media to exchange heat. Mixing heat exchangers are based on mixing hot and cold media to transfer heat. They work by creating a turbulent flow and mixing media. Typically, mixing heat exchangers are a system of pipes in which hot and cold media are mixed and heat is exchanged (Figure 2).

Types of heat exchangers depending on the principle of operation.

Plate recuperative heat exchangers are one of the most common types of heat exchangers due to their efficiency and wide range of applications. They consist of several parallel plates, usually made of materials with good thermal conductivity, such as stainless steel or titanium. The plates have ribs that create channels for the flow of hot and cold media between them. The main advantage of plate heat exchangers is their large contact surface between the media (Martynova and Rogacheva 2022). Due to the parallel configuration of the plates and fins on them, the total contact surface becomes much higher than that of other types of heat exchangers. For example, plate heat exchangers can provide a heat transfer coefficient in the range from 5,000 to 20,000 W/m² ℃, which is a very high value. In addition, this type of heat exchanger provides an efficiency of up to 95% or even higher, which makes it one of the most efficient types of heat exchangers on the market (Pandya et al. 2020).

An important factor is that, in comparison with some other types, plate heat exchangers may have limitations in working with media having high viscosity. With the high viscosity of the medium, there may be a problem with the flow through narrow channels between the plates, which will lead to a decrease in the efficiency of heat transfer. Plate heat exchangers can also be relatively expensive compared to some other types of heat exchangers, especially if a special configuration or plate materials are required. This may be a factor to consider when choosing a heat exchanger, depending on the project budget. In case of damage to the plates in the plate heat exchanger, their replacement or repair can be a complex process. Since they have a modular structure, it is necessary to remove and disassemble the modules to access the damaged plates. This can lead to significant time and financial costs for repairs or replacements, which should also be considered when choosing them. Plate heat exchangers have found application in a variety of industries and systems. They are widely used in HVAC systems for heat exchange between hot water and air, as well as finding wide application in industrial processes, including cooling and heating various liquids and gases. The main aspects of heat exchangers are as follows:

Technical aspects: These consist of multiple, thin, slightly separated plates that have very large surface areas and fluid flow passages for heat transfer. This stacked-plate arrangement can be more effective, in a given space, than the shell and tube heat exchanger;

Heat transfer coefficients: They are generally very high due to the large surface area in contact with the fluids. The corrugations in the plates induce turbulence in the fluids, which enhances heat transfer;

Materials: Typically made from stainless steel or titanium, the plates are often brazed or gasketed depending on the application’s temperature and pressure requirements;

Applications: Commonly used in space heating, refrigeration, air conditioning, the wine industry, and for heating swimming pools;

Problems: The main issue is the potential for leakage, especially in gasketed models. Scaling and fouling can also reduce efficiency;

Solutions: Regular inspection and maintenance, as well as proper material selection and fluid treatment, can help prevent leaks and scaling.

Tubular heat exchangers are another important type of heat exchanger widely used in various industries. They consist of a system of tubes where one medium flows inside these tubes, surrounded by another medium that flows along the outer surface of the tubes. Tubes can be made of a variety of materials, including metals, plastics, and glass, depending on the requirements of the process. One of the advantages of tubular heat exchangers is their large tube surface, which ensures efficient heat exchange. The larger the surface of the tubes, the greater the possibility for heat transfer between the media. The shape and design of the tubes can help increase the efficiency of heat exchange. To ensure efficient heat exchange in tubular heat exchangers, a turbulent flow of media is used. Turbulence creates a mixture of media and provides better contact between heat carriers, which contributes to more efficient heat transfer. Tubular heat exchangers provide high heat transfer efficiency depending on factors such as the material of the tubes, the surface area of the tubes, the turbulence of the media flow, and the temperature difference between the media. They can provide a heat transfer coefficient in the range from 1,000 to 10,000 W/m² °C (Khoshvaght-Aliabadi and Feizabadi 2020). The main aspects of heat exchangers:

Technical aspects: These heat exchangers consist of a series of tubes. One set of these tubes contains the fluid that must be either heated or cooled. The second fluid runs over the tubes that are being heated or cooled so that it can either provide the heat or absorb the heat required. A set of tubes is called the tube bundle and can be made up of several types of tubes: plain, longitudinally finned, etc.;

Heat transfer coefficients: They generally offer a good heat transfer coefficient, but this can vary based on the design and the fluids involved. The flow arrangement and the turbulence induced by the design also affect the coefficient;

Materials: They are typically made from thermally conductive metals. Common materials include stainless steel, copper alloys, and titanium, which are chosen based on factors like thermal conductivity, corrosion resistance, and cost;

Applications: Widely used in oil refineries and other large chemical processes, and also used in heating and cooling in large industrial processes;

Problems: One common issue is fouling, which reduces efficiency over time. Corrosion can also be a problem depending on the fluids involved and the materials used;

Solutions: Regular cleaning and maintenance are essential. Using corrosion-resistant materials or coatings can mitigate corrosion issues.

In summary, both tubular and plate heat exchangers have their own unique advantages and challenges. Shell and tube exchangers are versatile and robust, suitable for high-pressure applications, but can suffer from fouling and are generally larger. Plate exchangers, on the other hand, are compact and have high heat transfer efficiency but require careful maintenance to prevent leaks and are less suitable for high-pressure applications. Selection between the two types depends largely on the specific requirements of the application, including the nature of the fluids involved, temperature and pressure conditions, space constraints, and maintenance capabilities (Ostanin 2022).

In comparison with some other types of heat exchangers, tubular heat exchangers may have a limited surface area for heat exchange. This means that they may require more installation space compared to more compact types of heat exchangers. In addition, when the medium flow through the heat exchanger tubes is low, there may be a problem with non-uniform heat exchange, which may lead to insufficient use of the surface area and a decrease in the efficiency of heat transfer. However, despite these features, tubular heat exchangers are widely used in various industrial processes. They are used for cooling or heating various media, including liquids and gases. They are also effectively used in cooling systems where the hot medium transfers heat to the cooling medium through tubes (Trokhaniak et al. 2023). Examples of applications include the chemical industry, the food industry, power plants, the oil and gas industry, and air conditioning systems. All types of heat exchangers have some common problems and disadvantages. Deposits and contaminants such as scale, corrosion, or mechanical particles may form during the operation of heat exchangers. This can reduce the efficiency of heat transfer and require regular maintenance and cleaning of heat exchangers. For example, scale on the surface of the heat exchanger can lead to an increase in energy loss by 25–30%. This means that untimely cleaning and maintenance can lead to significant energy losses and additional heating or cooling costs. Moreover, choosing the right type and size of heat exchanger for a particular application can be challenging. The wrong choice of heat exchanger can lead to a loss of energy by 10–20%. This is due to the discrepancy between the needs of the system and the capabilities of the selected heat exchanger, which leads to inefficient heat transfer and additional energy costs (Klemeš et al. 2020).

To increase the efficiency of heat exchangers, it is worth performing preventive maintenance. Regular maintenance of heat exchangers prevents the formation of deposits, contamination, and corrosion. It is recommended to periodically clean and flush the heat exchangers using special solutions or methods that can effectively remove scale and dirt. One of the solutions may be the use of anticorrosive materials. When choosing materials for heat exchangers, their corrosion resistance should be considered. Uncontrolled corrosion can lead to the destruction of the material, deterioration of the efficiency of heat exchange, and an increase in the cost of repair or replacement of equipment. One example of anticorrosive materials is stainless steel. This material has a high degree of corrosion resistance due to the presence of chromium and other special alloys. Stainless steel is widely used in heat exchangers, especially in systems where aggressive environments or high temperatures are present. Various polymers and ceramic materials are also used as anticorrosive coatings. These coatings form a protective layer on the surface of the heat exchanger, preventing metal contact with an aggressive environment and thereby protecting it from corrosion. For example, polymer coatings based on epoxy resins or polyurethane coatings are widely used to protect heat exchange surfaces from corrosion in heating and cooling systems (Panahi et al. 2020).

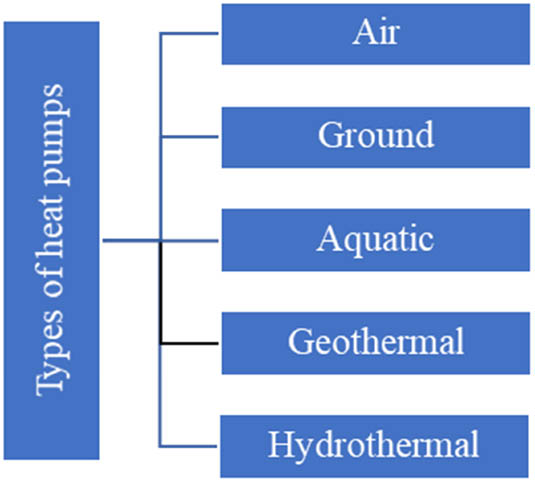

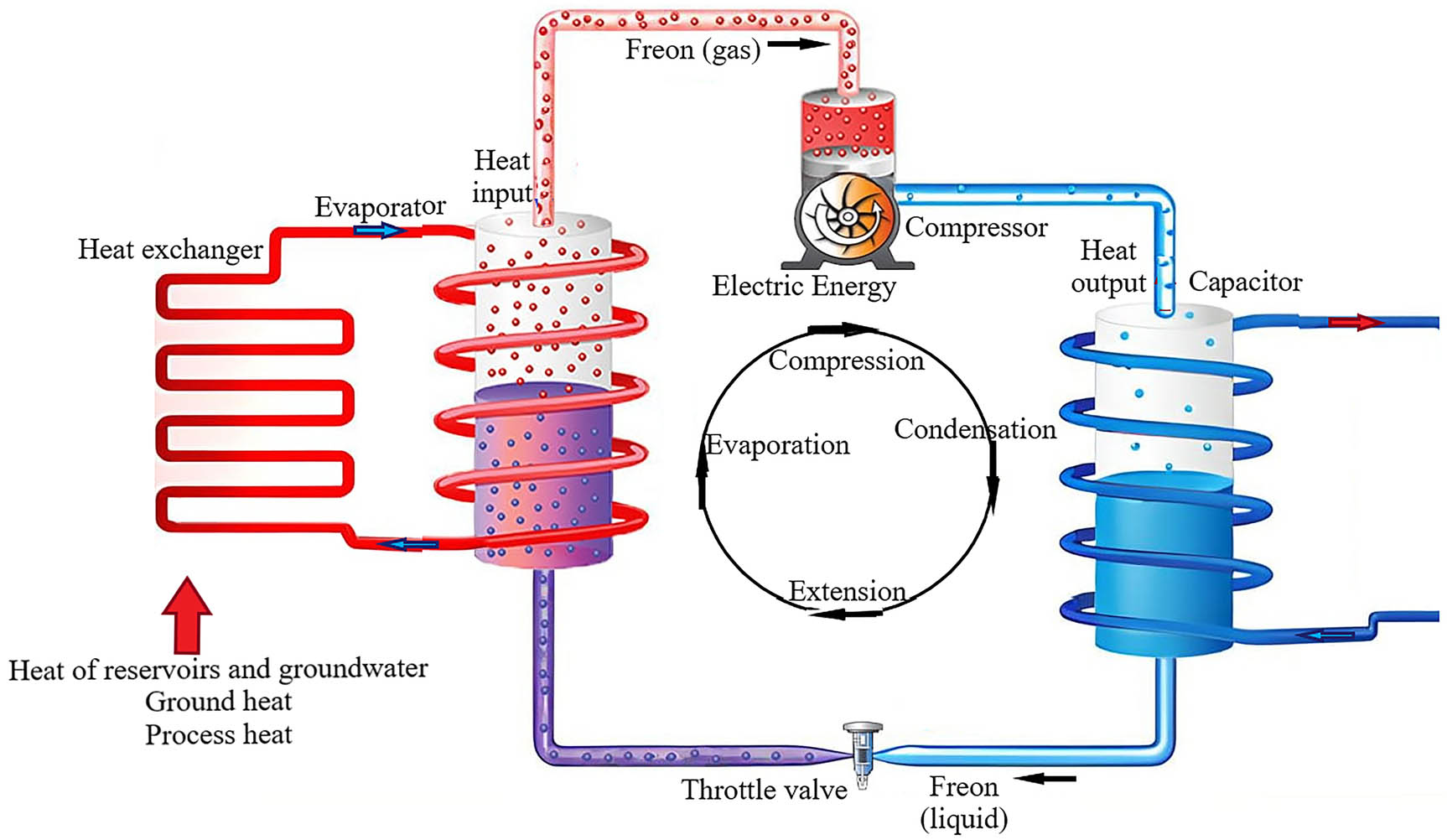

Heat pumps can be used to transfer heat from the environment into the room or to produce hot water. These are efficient and environmentally friendly devices that are based on the principle of a heat pump, which transfers heat from a cold source to a warm one using a minimum amount of electrical energy (Figure 3).

Types of heat pumps. Source: compiled by the authors.

One type of heat pump is geothermal heat pump. It uses thermal energy stored in the soil or soil to heat rooms or produce hot water. Geothermal systems require the laying of earth collectors or the installation of geothermal borehole equipment, but they ensure stable and efficient operation throughout the year. Another type of heat pump is air heat pump. It uses energy from the air by compressing and expanding the working medium (usually a refrigerant) to raise the temperature and transfer heat to the heating system or to heat the water. Air heat pumps are a popular choice for heating residential buildings, as they can be installed without the need for complex earthworks or the installation of a well (Figure 4).

Operation principle of a heat pump. Source: Economic Energy (2023).

Heat pumps can also operate in reverse mode and be used to cool the premises in the summer. In this case, they extract heat from inside the room and release it into the environment, which creates a cool atmosphere inside the premises. Such systems are called reverse heat pumps or air conditioners with a heat pump. The advantages of heat pumps include high efficiency and economical operation. They can produce a significant amount of heat with minimal electricity consumption. For example, the energy efficiency of air heat pumps can reach a heat transfer coefficient of 2.5–4, which means that they can produce 2.5–4 units of heat for each unit of electricity consumed (Long et al. 2021).

Heat pumps also have their own problems. The operation of the heat pump may be limited by extreme weather conditions, such as very low temperatures. In such cases, the efficiency of the heat pump is reduced, which affects its ability to provide sufficient heating or hot water. For example, an air–water heat pump can provide high efficiency at ambient temperatures above −15℃, but at lower temperatures, its efficiency will be lower. In addition, heat pumps require a certain level of investment to install and configure the system. Depending on the size and type of pump, the cost of this can be quite significant. However, despite these limitations, heat pumps still offer many advantages. For example, they have high efficiency, which allows them to use less energy to produce heat. Studies show that heat pumps can provide an efficiency of more than 300%, which means that every kW of electricity consumed is converted into more than 3 kW of thermal energy (Wu et al. 2020).

One of the ways to increase the efficiency of this equipment is through the use of hybrid systems. Hybrid systems combine several heat sources, such as a heat pump and a conventional boiler. This allows improving the operation of the system in extreme weather conditions when the efficiency of the heat pump is reduced. When the temperature is too low, the system can automatically switch to using the boiler, ensuring reliable heating. Another solution to improve the efficiency of pumps is to improve insulation and sealing. A good one will help to minimize heat loss and reduce energy consumption for heating by 20–30%. Heat losses through pipelines can also be significant. To improve efficiency, it is recommended to isolate pipelines, especially those that pass through unheated rooms or outdoor spaces. Choosing the right materials for insulation is another important factor. Popular insulation materials include mineral wool, expanded polystyrene, polyurethane foam, and silicon-based sealants, as these materials have a high thermal insulation ability and can significantly reduce heat loss (Chesser et al. 2021).

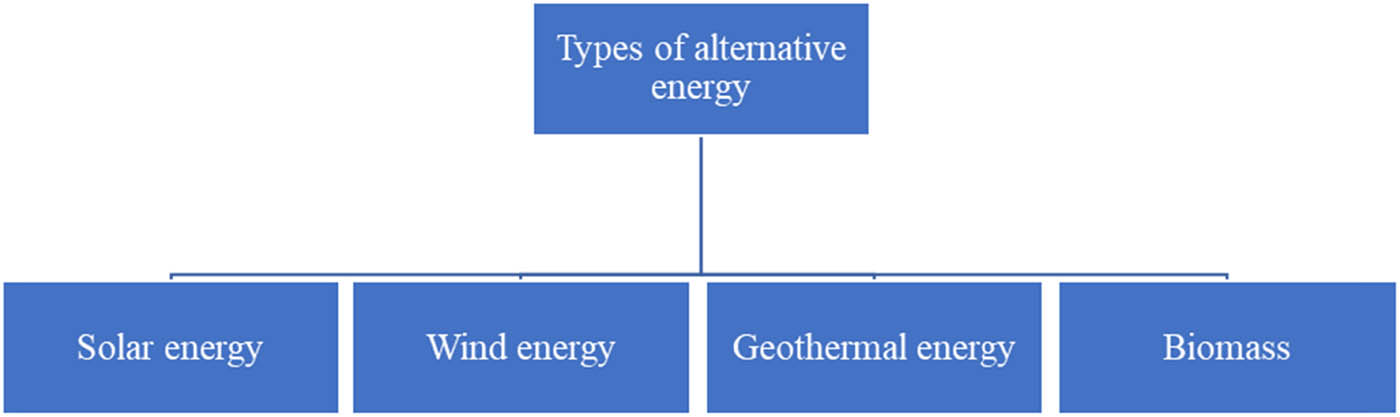

The use of renewable resources to convert them into thermal energy is becoming an increasingly popular solution in the field of thermal energy. These types of alternative resources include:

Solar energy: The International Space Station uses solar panels to generate power, showcasing solar energy’s versatility.

Wind energy: The Gansu Wind Farm in China is one of the largest wind farms in the world, with a planned capacity of 20,000 MW.

Geothermal energy: Iceland uses geothermal energy for about 85% of its heating;

Biomass energy: Sweden utilizes biomass to produce about 32% of its total energy consumption, one of the highest rates in the world.

Alternative energy systems like solar, wind, geothermal, and biomass offer promising solutions for sustainable and decentralized energy production. Each system has unique advantages and limitations, but collectively, they significantly contribute to reducing carbon emissions and dependence on non-renewable energy sources. Incorporating real-world examples and numerical data highlights the practical applications and efficiencies of these technologies, reinforcing their importance in the transition to cleaner energy solutions. An important aspect of the conversion of alternative energy into heat is decentralization and independence. The installation of energy generation systems at the place of use reduces losses in the process of energy transmission over networks and ensures independence from centralized power supply systems, which allows creating more stable and flexible energy systems. The variety and combination of sources are also advantageous in converting alternative energy into heat. Depending on local conditions and needs, various energy sources can be used (Figure 5).

Types of alternative energy. Source: compiled by the authors.

Solar collectors are one of the most popular technologies for converting alternative energy into heat, using solar radiation to produce heat. There are several different types of solar collectors, each of which has its own design and ability to collect and use solar energy. Some of the most common types include flat panels, vacuum tubes, and concentrating systems. Flat panels are the most common type of solar collector. They consist of black absorbent panels that absorb solar radiation and tubes or channels through which the coolant passes to collect and transfer heat. The panels are usually covered with a special glass or film that allows solar radiation to pass through but reduces heat loss from the system. After absorbing solar energy, heat is transferred to a heat carrier, usually a glycolic solution or water, which circulates inside the collector and delivers heat to the designated place of use. Vacuum tubes, in turn, represent a more complex design of solar collectors. They consist of glass tubes filled with vacuum to reduce heat loss. Inside each pipe are metal absorbers, usually in the form of aluminium-coated rods or tubes. Absorbers absorb solar radiation and convert it into heat. Vacuum pipes have better thermal insulation, which helps preserve the resulting heat and increase the efficiency of the system.

Concentrating systems use mirrors or lenses to concentrate solar radiation on a small area where the absorber is located. Mirrors reflect solar radiation onto the absorber, increasing its intensity and allowing very high temperatures to be reached. The absorber can be either a solid material capable of withstanding high temperatures or a working medium that transfers heat to generate steam or electricity. Concentrating systems are usually used in large industrial installations or solar power plants where high energy density and efficient use of solar energy are required. The efficiency of solar collectors directly depends on solar activity and weather conditions. Cloud cover, fog, or poor illumination can reduce their performance. Another important factor in their use is the need for energy storage. Solar energy should be used directly or stored for use during periods of lack of solar radiation. To ensure the continuity of heat supply, efficient energy storage systems are required, such as thermal accumulators and batteries that can be used to ensure the stability and continuity of heat supply (Gurung and Qiao 2018).

Solar collectors do not use fossil fuels, do not produce harmful emissions, and can be installed almost anywhere where there is access to sunlight. The use of solar energy helps reduce dependence on unstable energy markets and reduce greenhouse gas emissions, contributing to the fight against climate change. They have flexibility and modularity in terms of installation and scaling. They can be installed on the roofs of buildings, facades, ground, or other accessible surfaces. Due to their modular design, solar collector systems can be easily expanded or reduced depending on their needs. This allows flexibly adapting to different conditions and volumes of heat consumption. They also have a long service life and require minimal maintenance in operation. Collectors are made of durable materials that are resistant to solar radiation, moisture, and atmospheric conditions. In many cases, solar collectors are guaranteed for 20–25 years, and the service life can reach 30 years. This makes them reliable and cost-effective in the long run (Rashidov et al. 2021).

A good option would be to use wind energy with wind generators. The principle of their operation is to use the kinetic energy of the wind to drive the rotor blades. When the wind passes through the blades, they start to rotate, which leads to the conversion of the wind’s kinetic energy into mechanical rotational energy of the rotor. Wind turbines can be of various sizes, ranging from small installations for use in individual homes to huge wind farms with high wind turbines. The size and power of the wind generator are selected depending on the energy needs and availability of wind in a particular area. The main disadvantage of wind turbines is their dependence on the availability of sufficient wind speed. Wind generators cannot operate efficiently with too little or too much wind. This limitation requires careful selection of the installation location in order to maximize the wind potential. It should also be borne in mind that large wind turbines can have a significant visual effect on the landscape. This is due to their size and height, as well as the fact that they are usually installed in open spaces. Modern technologies for the design and placement of wind turbines tend to minimize their visual impact. This is achieved by selecting optimal installation locations, considering local landscape features, or integrating into the environment, such as offshore wind turbines that can be placed away from the coastline. In addition, new wind turbine concepts are being researched and developed, which may be more compact, aesthetically appealing, or be able to integrate into existing infrastructure such as buildings or bridges. This helps to soften the visual effect and consider various aspects when installing wind turbines (Amano 2017).

Wind turbines can be installed both on the scale of individual houses or small communities and in large-scale projects involving wind farms with dozens or hundreds of turbines, which allows wind generation to be used in various conditions and scales, from the micro level to large energy systems. Wind energy is a clean energy source that does not emit greenhouse gases or other harmful substances. Wind turbines do not require the burning of fossil fuels, which reduces environmental pollution and reduces the negative impact on the climate. Wind turbines also have relatively low operating costs after installation. The main costs are maintenance and regular system checks. They do not require expensive fuels or constant purchases of resources, which makes them economically attractive in the long term (Ruhnau et al. 2020). Another type of alternative energy that can be used in thermal power engineering is geothermal energy. Geothermal systems are based on the use of hot water or steam, which are located deep in the Earth. These are heat sources that can be used to produce heat or electricity. Geothermal energy requires the drilling of geothermal wells that allow access to hot water or steam reservoirs. In some geothermal systems, heat pumps are used, which use low-temperature heat from the ground or groundwater to heat or cool rooms (Beckers et al. 2022).

One of the disadvantages of geothermal systems is the limited location. Geothermal systems require certain geological conditions to be effective. High investment costs should be considered when using such systems. Initial investments for the construction of geothermal systems can be quite high; drilling geothermal wells and installing the necessary equipment also require significant financial resources. In addition, the exploitation of geothermal resources can lead to a decrease in the level of hot water or steam in geothermal reservoirs, which can cause problems related to the sustainability of ecosystems and damage to natural resources. There are several approaches that can help to cope with some of the disadvantages of geothermal systems. First, the development of new technologies can help reduce the investment costs of geothermal systems and improve their efficiency. The development of new materials and drilling methods can reduce costs and increase the availability of geothermal resources. Proper management of geothermal resources can help prevent their depletion. This includes the control of heat production and the establishment of a sustainable mode of use of geothermal reservoirs. It is also possible to monitor and assess the impact of geothermal systems on the environment to minimize possible negative consequences. Low-temperature geothermal systems can be more affordable and less costly compared to high-temperature systems. The use of low-temperature systems for heating and cooling rooms can be more cost-effective and reduce the impact on geothermal reservoirs.

Combining geothermal systems with other renewable energy sources, such as solar or wind, can increase the overall sustainability and efficiency of the energy system. The use of hybrid systems can help to smooth out the possible disadvantages of each individual energy source and make them more attractive for operation. Geothermal energy is an environmentally friendly source of energy, since its production does not emit greenhouse gases and other harmful substances. It is available throughout the year because it does not depend on weather conditions or time of day, which makes geothermal systems reliable and stable sources of energy. In the long term, geothermal systems can be economically advantageous, since they have low operating costs compared to fossil energy sources (Lund and Toth 2021).

Biomass systems can also be used efficiently to convert biomass to produce heat. The principle of operation of biomass systems is based on the process of burning or decomposition of organic materials, such as plant matter, wood, agricultural waste, or animal manure. In combustion systems, biomass is burned in special boilers or burners, releasing heat. In systems with decomposition, biomass decomposes under anaerobic or aerobic conditions, releasing gases such as methane, which can be used for energy production. The heat can be transferred directly to the heating or cooling system, which is used for industrial processes or to drive engines. The advantages of using biomass for heat production include its renewability. Biomass is a product of living organisms and can be reproduced by agriculture or forestry. This distinguishes it from fossil fuels such as oil or coal, which are limited resources. In addition, the use of biomass has the potential to reduce greenhouse gas emissions, since the burning of biomass releases only the carbon that was captured during photosynthesis by plants during their growth. Biomass can also use existing infrastructure for heat supply, such as heating systems and distribution networks, which makes it relatively affordable to implement (Zhang et al. 2020). These technical means are promising solutions in the field of thermal energy, and with proper implementation, they can significantly reduce the level of emissions of toxic substances into the environment, help switch to more independent energy sources, and make the heat supply system much more stable and autonomous (Selvakumar et al. 2023).

Economically, evaluating thermal energy systems such as boilers, heat pumps, and renewable energy solutions requires a detailed understanding of their financial viability. This assessment typically includes factors like payback period, return on investment (ROI), and net present value (NPV). These metrics provide a comprehensive view of the economic attractiveness of different heating technologies.

3.1 Payback period

This is the time it takes for an investment to repay its initial cost through savings or earnings. For instance, high-efficiency boilers or advanced heat pump systems may have higher upfront costs compared to traditional systems. However, their lower operational costs, due to energy efficiency, can lead to faster payback. In the case of renewable energy solutions like solar thermal systems, the payback period can be longer due to higher installation costs, but government incentives and decreasing equipment costs are shortening these periods.

3.2 ROI

ROI measures the profitability of an investment and is crucial in comparing different heating technologies. High-efficiency heating systems often exhibit a higher ROI in the long term, despite their higher initial costs. This is due to significant savings in energy costs over the lifespan of the system. Renewable energy installations like wind or solar power may require substantial capital investment but can offer high ROIs, especially in regions with favourable climatic conditions and where energy prices are high.

3.3 NPV

NPV calculates the value of an investment by discounting future cash flows to the present. A positive NPV indicates that the projected earnings (in terms of saved energy costs and possible incentives) from an investment exceed the anticipated costs, adjusted for the time value of money. This is particularly relevant for long-term investments like geothermal systems, where initial costs are offset by very low operational costs over many years. The economic analysis of thermal systems also depends on external factors such as energy prices, government subsidies, and technological advancements. For example, in regions with high electricity costs, electric heat pumps might have a lower economic appeal compared to areas with lower electricity prices. Similarly, advancements in technology can lead to more cost-effective and efficient solutions over time, altering economic calculations.

In summary, understanding the financial viability of different thermal energy systems requires a multifaceted approach, considering payback periods, ROI, and NPV. These analyses help in making informed decisions, especially when considering long-term benefits and costs and in scenarios where initial investments are significant. As the global energy landscape evolves, these economic considerations become crucial in steering towards sustainable and cost-effective energy solutions.

4 Discussion

In the modern world, technical means for energy production and heat power engineering in general is an extremely important topic for study, since it has a number of problems that can lead to losses in the efficiency of heat exchange systems and environmental pollution. This study showed that many factors can affect losses in the process of using thermal energy and provided an understanding of the technical means for the production of energy and ways to convert other types of energy into heat. Among the considered problems related to the operation of technical means for production, flow control, and heat conversion, it is possible to single out insufficiently high efficiency, increased cost of use, and the presence of emissions into the atmosphere, which creates the need to search for improved technologies and technical means.

This study, which focused on the technical means for energy production and heat power engineering, shed light on several key aspects, such as the inefficiencies in heat exchange systems and the environmental impact of various energy production methods. For instance, the notable heat loss in boilers, particularly in traditional solid fuel boilers, aligns with the existing body of research, underscoring the need for more efficient and environmentally friendly heating solutions. This points to an ongoing industry trend of transitioning towards more sustainable energy sources, as seen in recent advancements in heat pump technologies and renewable energy integration. The study’s exploration of electrical systems, like infrared heaters and electric radiators, also contributes to the broader discourse on sustainable heating solutions. While these systems offer benefits such as ease of installation and operation, and a higher level of safety, our findings regarding their long-term cost implications resonate with the broader challenges faced in the field. This highlights a crucial trade-off in energy solutions: balancing upfront costs with long-term efficiency and sustainability.

According to Zadravec et al. (2021), heat loss is an unavoidable aspect of boiler operation. Part of the heat generated by the boiler is lost through the flue gases. Depending on the type of boiler and the fuel used, these losses can range from 10 to 30% of the total heat generated. For example, traditional solid fuel boilers have higher flue gas losses than modern gas or electric boilers. Heat loss directly affects the energy consumption of the boiler. The greater the heat loss, the more fuel or electricity is required to maintain the required temperature in the room. For example, each percentage of heat loss through flue gases leads to an increase in energy consumption by about 2–3%. To reduce heat loss and improve boiler efficiency, it is important to ensure optimal insulation and tightness of the system. The use of high-quality insulation materials for the boiler and pipelines and the proper installation and tightness of the connections will help reduce heat loss. In addition, measures such as cleaning the chimney, checking seals, and adjusting the heating system will reduce heat loss and ensure optimal operation of the boiler.

According to the results obtained by Radhi et al. (2022), infrared heaters, electric radiators, and other electrical systems can be a modern choice as a heat generation device. They are easy to install and use and do not require complex pipelines or circulation systems, which makes them convenient to install and connect. In addition, they are usually equipped with temperature controls that allow the user to easily control and maintain the desired heat level. Infrared heaters and electric radiators have a high level of safety, do not work on an open fire, do not produce waste or harmful emissions, and do not require gas supply. This makes them safe for use in various premises, including homes, offices, and commercial facilities. Nevertheless, despite these advantages, in comparison with some other heating systems, the operation of infrared heaters and electric radiators may be costlier in the long term. The high cost of electricity consumed can lead to an increase in electricity bills, especially when using these systems on an ongoing basis. In addition, in the case of infrared heaters, directional radiation can lead to a non-uniform distribution of heat in the room. In some cases, proximity to heated objects may cause overheating, while remote areas may remain less heated.

In terms of heat exchangers, our study adds to the growing literature on their diverse applications across industries. The challenges in selecting the optimal type and configuration for specific processes echo the complexities in this field, emphasizing the need for specialized knowledge and experience in heat exchanger design. However, the study is not without its limitations. One significant limitation is the potential variability in the operational context of different energy systems. The efficiency and effectiveness of these systems can vary widely based on geographical location, climate, and specific usage scenarios, which might not have been fully captured in our analysis. In addition, the study primarily focuses on the technical and environmental aspects, with less emphasis on the socio-economic factors that influence the adoption and implementation of these technologies. Future research could address these limitations by conducting more localized studies that account for specific operational contexts and by incorporating a more holistic approach that includes socio-economic factors. Further exploration into emerging technologies in heat exchange and energy production, as well as in-depth cost–benefit analyses of various energy systems, could also provide valuable insights for the field. This would foster a more comprehensive understanding and facilitate the development of tailored, sustainable solutions in thermal energy and heat power engineering.

Based on the statements of Olabi et al. (2021), heat exchangers have a wide range of applications in various industries, which makes them an integral element of many processes and systems. They are used not only in the heating and cooling systems of buildings but also in industry for processing and cooling liquids and gases. For example, in the oil and gas industry, heat exchangers are used to cool petroleum products and gas streams during their processing. They are also used in the food industry to heat or cool products. However, it should be borne in mind that, due to the wide range of applications of heat exchangers, choosing the optimal type and configuration can be difficult. Different industries require specific requirements for heat exchangers, and it is not always easy to determine the most effective solution for a particular process. It requires in-depth knowledge and experience in the field of heat exchanger design to choose the right type, materials, and parameters. Depending on the specific application, heat exchangers can consume energy for their operation, e.g. for the operation of pumps or fans that circulate the medium in the heat exchanger. This may entail additional energy costs, which should be considered when choosing and operating a heat exchanger.

According to Yang et al. (2020), heat exchangers made of high-quality materials are usually supplied in the form of ready-made structures with predefined dimensions, shapes, and characteristics. They are designed and manufactured considering specific requirements and standards, but they do not always provide for the possibility of modification after installation. The limited options for modifying heat exchangers may restrict the possibilities of potential system upgrades in the future. If the user plans to make changes or improvements to the heating or cooling system, such as adding new components, integrating additional functions, or scaling up the system, then the limited modifiability of the heat exchanger may become an obstacle to the implementation of these plans.

Wu et al. (2021) noted that heat pumps operate on the basis of a reverse refrigeration cycle, where they extract heat from a low-temperature source (e.g. soil, air, or water) and transfer it to a heating or hot water supply system. In this process, a low-temperature medium is cooled, which must be returned back to the source for reuse. To provide reverse current and return the cooled medium to the source, an additional system is required, which may vary depending on the type of heat pump and its installation. The installation of an additional reverse current system may require additional work, including laying pipelines, installing pumps, laying cables, and connecting to appropriate sources. In addition, it may entail additional costs for materials, equipment, and labour. It is important to consider this feature when planning and installing a heat pump, since the absence of a reverse current system can lead to improper operation of the pump and reduce its efficiency.

Yang et al. (2012) have shown that the introduction of alternative energy sources for heat production can reduce energy costs in the long term, since the costs of such systems are much lower compared to conventional systems using fossil fuels. For example, installing a solar system to produce heat can save up to 70% of energy costs in 20 years. Nevertheless, despite this, the high cost of the initial installation of the system can create some financial barriers for users, especially for those who cannot afford high costs or do not have access to financing and subsidies. As a result, the introduction of alternative systems may be more limited or delayed due to financial problems.

In general, the study of technical means for energy production and heat power engineering reveals a complex landscape with various challenges and opportunities. While heat loss in boilers and the costliness of electrical systems like infrared heaters and radiators present significant efficiency and economic challenges, advancements in heat exchangers and the incorporation of renewable energy sources offer promising solutions. The trade-offs between initial installation costs and long-term savings, especially in alternative energy systems, highlight the need for careful financial planning and consideration of environmental impacts. Overall, the ongoing search for improved technologies and technical means in heat power engineering is essential for achieving more efficient, cost-effective, and environmentally sustainable energy production and management systems. The use of alternative types of energy, such as solar, wind, geothermal, and biomass energy, is an important condition for improving the environmental situation, reducing emissions into the environment, and generating heat, which will allow them to be used as a resource for indoor heating, water heating, and other methods and will create a more stable heat supply, regardless of the central heating system.

5 Conclusions

This article has conducted an extensive examination of the key technical means related to thermal energy. The importance of this topic stems from the need to enhance efficiency, reduce losses, and increase sustainability in heat production systems. The analysis reveals several crucial findings that highlight the need for continued innovation and the adoption of advanced thermal technologies.

A major takeaway is that improving energy efficiency in heat generation processes is imperative for curbing resource consumption, lowering costs, and minimizing environmental footprints. The study shows that new technical systems can enable better fuel utilization through optimized combustion, integration of waste heat recovery, and adoption of smart control mechanisms. This allows reducing harmful emissions and increasing energy independence. In addition, the research highlights the significance of effective heat transfer and management. The use of high-performance heat exchangers coupled with intelligent control of heat flows minimizes losses across production and distribution networks, thereby boosting overall system efficiency.

The analysis also underscores the potential of emerging clean energy technologies to transform heat production paradigms. Solar collectors, wind turbines, geothermal wells, and biomass systems allow harnessing renewable alternative resources in a decentralized and eco-friendly manner. Their integration with conventional solutions promotes flexibility and sustainability across micro and macro scales. At the same time, the study indicates that each method has its own blend of advantages and limitations pertaining to parameters like efficiency, capacity, scalability, fuel use, and costs. A key inference is that hybrid systems that synergistically combine multiple technologies provide optimized performance.

Moreover, the research emphasizes that regular maintenance and adoption of robust, anticorrosive materials are imperative for maintaining efficiency and preventing issues like corrosion or fouling in heat transfer equipment over prolonged operational lifetimes. The article concludes that a transition to next-generation thermal energy systems necessitates investments in R&D, skill enhancement, and supportive policy frameworks prioritizing sustainability, energy independence, and environmental stewardship. In summary, this study establishes a firm analytical foundation to steer the future development of efficient, clean, and smart heat production technologies, propelling global energy and climate goals. Further efforts should concentrate on techno-economic evaluations of emerging techniques and the demonstration of integrated thermal energy solutions.

Further research in the field is crucial for practical advancements, potentially leading to the development of more efficient heating technologies. These innovations could optimize resource usage and improve the distribution of heat energy across different zones and rooms, enhancing overall energy efficiency. Research in the field of converting other types of energy into heat will help develop more environmentally friendly energy sources. All this contributes to technological progress, economic development, improvement of air quality, reduction of climate change, decrease of heat losses, and optimization of energy costs. The findings and recommendations of this study are expected to serve as a vital resource for policymakers, engineers, and industry leaders in shaping a more efficient, resilient, and eco-conscious energy landscape.

-

Funding information: Authors state no funding involved.

-

Author contributions: Matanat Ismayilzada: Project administration, Conceptualization, Formal analysis, Investigation, Data Curation, Writing - Original Draft, Writing - Review & Editing, Supervision. Sevda Abbasova: Conceptualization, Methodology, Software, Validation, Resources, Writing - Original Draft, Writing - Review & Editing, Visualization. Ulduza Novruzova: Methodology, Validation, Formal analysis, Investigation, Resources, Data Curation, Writing - Original Draft, Writing - Review & Editing. Tarana Safarova: Methodology, Software, Validation, Formal analysis, Investigation, Writing - Original Draft, Writing - Review & Editing, Visualization.

-

Conflict of interest: The authors declare no conflicts of interest regarding this article.

-

Data availability statement: The authors confirm that the data supporting the findings of this study are available in the article.

References

Ali M., Alkaabi A. K., Alameri S. A., and Alrwashdeh M. (2019). “Effect of thermal energy storage integration on overall nuclear power plant efficiency,” Trans. Am. Nucl. Soc., vol. 121, pp. 1097–1098.10.13182/T30837Search in Google Scholar

Aliyev R. A. (2018). “Prospects for the development of the heat supply system in the Republic of Azerbaijan as one of the strategic objectives,” Glob. Sci. Capabilities, vol. 3, no. 84, pp. 102–104.Search in Google Scholar

Aliyev R. N. and Aliyev A. R. (2014). “Prospects for the development of ecological clean alternative energy generating infrastructures in Azerbaijan,” Environ. Prot. Oil Gas. Complex., vol. 8, pp. 29–31.Search in Google Scholar

Aliyeva O. (2020). “Types of alternative energy and its application in Azerbaijan,” Int. Indep. Sci. J., vol. 20, no. 1, pp. 20–23.10.29228/edu.104Search in Google Scholar

Amano R. S. (2017). “Review of wind turbine research in 21st century,” J. Energy Resour. Technol., vol. 139, no. 5, p. 050801. 10.1115/1.4037757.Search in Google Scholar

Antypov I., Mishchenko A., Shelimanova O., and Tarasenko S. (2022). “Analysis of the influence of the internal heat capacity of a public building on the thermal comfort parameters of the premises during the operation of the heating system in alternating mode,” Machinery Energetics, vol. 13, no. 2, pp. 20–31. 10.31548/machenergy.13(2).2022.20-31.Search in Google Scholar

Beckers K. F., Rangel-Jurado N., Chandrasekar H., Hawkins A. J., Fulton P. M., and Tester J. W. (2022). “Techno-economic performance of closed-loop geothermal systems for heat production and electricity generation,” Geothermics, vol. 100, p. 102318. 10.1016/j.geothermics.2021.102318.Search in Google Scholar

Cai T., Zhao D., Sun Y., Ni S., Li W., Guan D., and Wang B. (2021). “Evaluation of NOx emissions characteristics in a CO2 – Free micro-power system by implementing a perforated plate,” Renew. Sustain. Energy Rev., vol. 145, p. 111150. 10.1016/j.rser.2021.111150.Search in Google Scholar

Chesser M., Lyons P., O’Reilly P., and Carroll P. (2021). “Air source heat pump in-situ performance,” Energy Build, vol. 251, p. 111365. 10.1016/j.enbuild.2021.111365.Search in Google Scholar

Economic Energy, Energy savings systems. Heat pumps – energy saving heating equipment, 2023, http://www.economic-energy.com.ua/article/article18.html (accessed August 20, 2023).Search in Google Scholar

Fialko N. M., Prokopov V. G., Meranova N. O., Borisov Y. S., Korzhik V. N., and Sherenkovskaya G. P. (1993). “Thermal physics of gasothermal coatings formation processes. State of investigations,” Fiz. i Khimiya Obrabotki Materialov, vol. 4, pp. 83–93.Search in Google Scholar

Gurung A. and Qiao Q. (2018). “Solar charging batteries: Advances, challenges, and opportunities,” Joule, vol. 2, no. 7, pp. 1217–1230. 10.1016/j.joule.2018.04.006.Search in Google Scholar

Huseynov D. R. (2017). “Prospects for the development of renewable energy sources in the Republic of Azerbaijan,” Topical Issues Economic. Sci., vol. 56, pp. 203–206.Search in Google Scholar

Ismayil-Zada M. (2022). “The new economic theory is the main branch of the new physics,” Astra Salvensis, vol. 2022, no. 1, pp. 13–36.Search in Google Scholar