Abstract

In this paper, an experimental and numerical investigation of thermoelectric generator for energy harvesting performance of screw compressors has been studied. The sources of heat recovery from compressors are recognized and a heat exchanger to mount the Thermoelectric Generator (TEG) module assembly is designed to adapt for implementation in this work. Computational fluid dynamics (CFD) is used to find out the temperature distribution in the heat exchanger and experimental work is carried out to validate CFD results. The heat exchangers, consisting of five TEG modules, temperature profile and voltage value have been studied numerically and experimentally. The parametric study has been studied to understand the influence of various system parameters on energy harvesting performance TEG based heat exchanger. An average of 1.6 V is generated by each TEG module and heat exchanger consists of five TEG and an average of 8 V is generated continuously by the heat exchanger. Also, it is proved that the usages of steel foam with 90 % porosity in heat exchanger improves the heat transfer rate and maximize the output from 8 V to 24 V in heat exchanger.

1 Introduction

Screw compressors are being used across the various industries to compress the air for low and medium pressure applications. The amount of heat energy generated in compression of air is approximately equal to the input energy supplied. Especially in diesel powered screw air compressors, almost 75 % of the input energy is converted as heat which is dissipated to atmosphere without utilization. The paper proposes a realistic approach to thermoelectric energy harvesting from the waste heat produced by industrial screw compressor. Energy harvesting by utilization of this waste heat from these screw compressors using thermoelectric generator systems is considered to have huge potential and being researched. Diesel powered screw air compressor (DPSAC) are used to compress air for low and medium pressure applications for water well drilling, construction and mining application. The total energy supplied by the diesel fuel to the engine for compressing the air is almost converted into heat. Only 14 % of the energy supplied by fuel is carried away by the air to the application. Remaining 86 % of heat is dissipated into the atmosphere by inter-coolers, oil coolers and silencers without any utilization. To improve the efficiency of these compressors, recovering the utilized waste heat from compressors sources and converting them into useful energy is significant. Further this conversion will reduce the thermal pollution and reduce the global warming.

Thermoelectric generators can harness heat, provided that a temperature difference exists between the semiconductor module’s hot and cold sides. The TEGs generate electric power relying on the Seebeck effect by directly converting temperature differences into electric energy. Song et al. (2018) mainly focused on the thermoelectric performance study under there different types of cooling methods on the cold side of TE modules. A mathematical model capable of simulating the thermoelectric generations and the heat exchangers has been developed and an experimental realization of the three typical heat exchanger with TEGs was presented and discussed. Champier (2017) reviewed the state of the art of thermoelectric generators and introduced latest thermoelectric modules introduced and different materials used in TEGs are discussed. Zhang et al. (2015) fabricated TEG using nanostructured half-heusler materials and the devices produce superior power density above 5 W/cm2 and a TEG system with over 1 kW power output is demonstrated by recovering automotive waste heat. Kim, Kwak, and Kim (2018) designed hexagonal thermoelectric generator for waste heat recovery from passenger vehicle and maximum output power of 98.8W and maximum efficiency of 2.6 % were achieved. Nithyanandam and Mahajan (2018) studied the performance for metal foam based thermoelectric energy generator for automobile waste recovery and proved that net electric power output from TEG module with metal foam is 6–8 times higher that TEG without metal foam and optimal mass flow rates that maximize the net electric power output are reported.

Wang et al. (2014) proposed an open-cell metal foam-filled plate heat exchanger based thermoelectric generator system to utilize low grade waste heat and proved that the heat exchange efficiency of the metal foam-filled plate heat exchanger is tested as 83.56 % performance has been increased. Patil, Arakerimath, and Walke (2018) reviewed the various thermoelectric materials and heat exchangers for power generations. It is seen that in the thermoelectric generator, semiconductors are used to generate the power. Heavily doped semiconductors show high thermal resistance and low electric resistance properties and are suitable for TEG. Gou, Xiao, and Yang (2010) studied the performance of TEG system and optimized the thermoelectric generator system for low waste heat application analytically and experimentally. Hsu et al. (2011) studied a system to recover waste heat comprised 24 thermoelectric generators to convert heat from the exhaust pipe of an automobile to electrical energy has been constructed. Simulations and experiments for the thermoelectric module in this system are undertaken to assess the feasibility of these applications. Hsiao, Chang, and Chen (2010) presented a mathematical model of thermoelectric module with applications on waste heat recovery from automobile engine.

Weng and Huang (2013) analysed energy-harvesting system from the automotive exhaust pipe using thermoelectric power generators (TEGs) and found that The efficiency is enhanced by keeping some downstream part of the heat exchanger uncovered by TEGs. Meng et al. (2013) proposed a complete three-dimensional thermoelectric cooler (TEC) transient model was proposed and dynamic behaviors are studied at extensive operating conditions, and found that Temperature-dependent material properties have strong effect on dynamic behaviors. Liu et al. (2015) the automotive thermoelectric generator system was constructed and studied and Road test and revolving drum test were used to measure the output power, and found that a performance of 201.7 V (open circuit voltage)/944 W obtained. Niu et al. (2014) developed a 3-D model for exhaust-based thermoelectric waste heat recovery for internal combustion engine and also various heats, mass and electric transfer characteristics are elucidated. Tian et al. (2015) presented a novel segmented TEG, which could recover waste heat of diesel engine’s exhaust and detailed performance effects were analysed and optimal parameters were obtained.

He et al. (2016) new thermolelectric performances were studied considering temperature gradient and different cooling methods for a thermoelectric generator (TEG) system were compared, and proved that it had a higher power output per module area for coflow than counterflow method. Du et al. (2015) developed a 3-D model of TEG coupled with exhaust and cooling channels for internal combustion engine and studied the effect cooling type, flow rate, baffler and flow arrangement on waste heat recovery, and found that counter is better than co-flow by keeping temperature difference for all TEGs. Liu et al. (2014) different internal structures and thickness of heat exchangers were proposed and power output testing system of the two heat exchangers was characterized, and chaos-shaped heat exchanger (5 mm thickness) shows better performance. Shen, Tian, and Liu (2019) prepared a comprehensive review on automotive exhaust thermoelectric generators (AETEGs) and pointed out major challenges faced by AETEGs. Wang et al. (2018) a virtual platform to assess the performance of an on board TEG is constructed and the back pressure could be reduced by 20.57 % in the ATEG with dimpled surface. The net power output of the ATEG with dimpled surface could be improved by 173.60 % and the efficiency of the ATEG with dimpled surface is 0.68 %.

Luo et al. (2020) proposed a novel thermoelectric module structure optimization approach for fluid waste heat recovery and ann fluid-thermal-electric multi-physics model is developed to conduct the optimization, and found that the output power between the novel module and the corresponding base module is compared. He et al. (2020) a non-isothermal thermoelectric model is developed using the finite element method and temperature gradient at different work conditions is shown by fitting correlations, and the thermoelectric material properties temperature dependence is considered. Miao et al. (2020) the stress and deformation of TE module are analyzed under stable heat and the basic TE module is designed for comparative analysis, and the effect of TE legs on stress and deformation was studied, and Optimize the structure of TE module to reduce the stress and deformation. Araiz et al. (2020) analysed the thermoelectric generators for waste-heat recovery in a real industry and used two computational models to design a thermoelectric generation system, and found that optimized design could generate up to 45 kW from a hot gas flow. Elghool et al. (2020) Multi-objective optimisation on heat pipe-heat sinks with TEG is investigated and the heat pipe-heat sinks optimized parameters are obtained, and the contribution of each factor on TEG performance is achieved. The TEG efficiency is improved by 36.7 % compared with previous results.

Converting the waste heat from the screw compressors into electricity is not being popularly researched. Moreover, thermoelectric generators having the merit of direct conversion of thermal energy into electrical energy are not being frequently studied in the literature. In particular the DPSAC compressors, having the need of electricity to operate accessories during their operation, employing the thermoelectric generator systems for harvesting the energy and utilize them to operate the accessories will be beneficial for the customers. Exhaust gas has an elevated temperature from the heat rejection sources of DPSAC compressor, a better outcome will be harvested by recovering the waste energy from this source in a compressor. In this work, a TEG module is directly attached to exhaust part of the DPSAC one and converted into electrical energy. The numerical and experimental setup is implemented to harvest energy and the power almost is harvested at 1.8 W with eight TEG modules.

This paper is organized as follows: The system description includes experimental model is given in Section 2. The numerical model and validation are given in Section 3. The complete results and discussion are given in Section 4. Finally, the important conclusions are drawn in Section 5.

2 Experimental setup

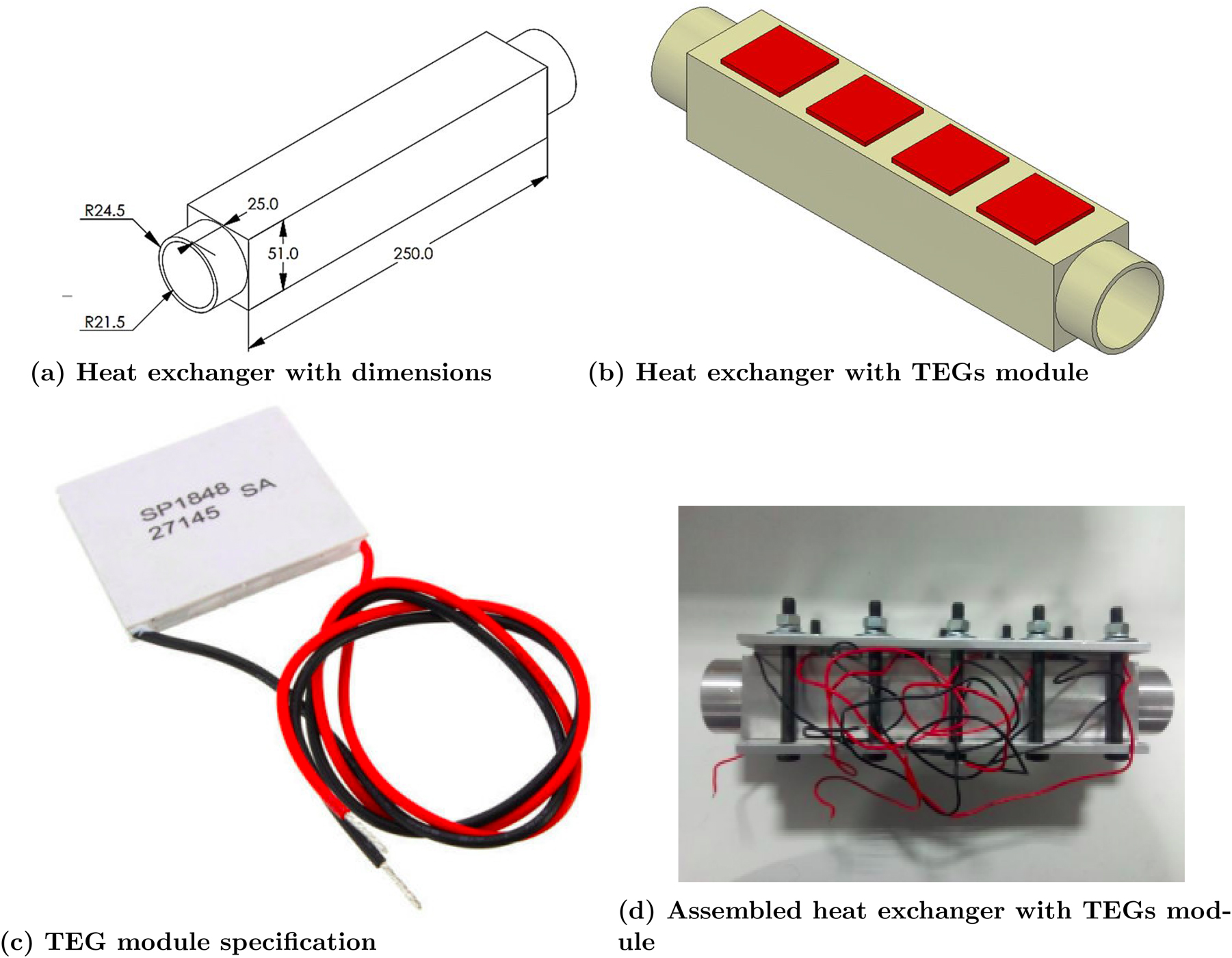

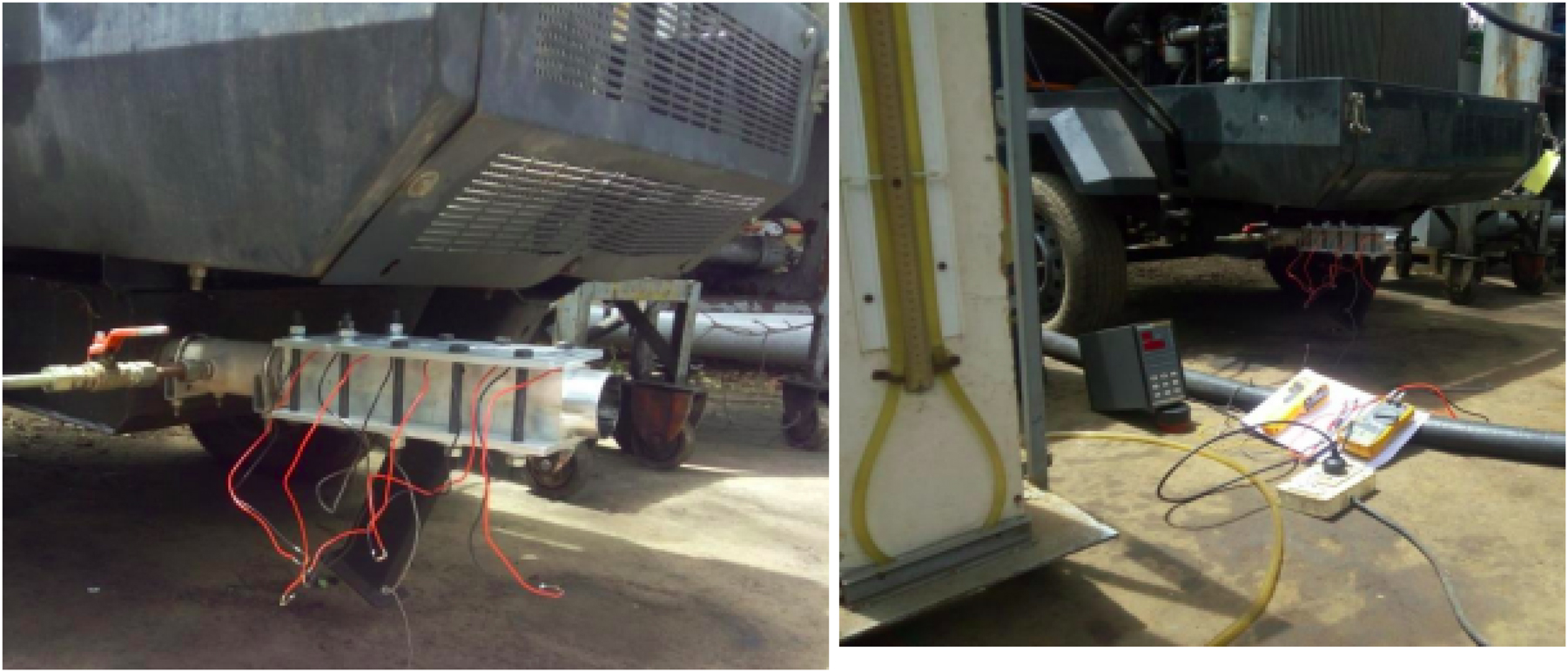

To verify the thermoelectric generators suitability for the system and to validate the numerical results, an experimental facility is developed. Test set up is created and experimented with the screw compressor as shown in Figure 2. The outlet of the engine exhaust system is connected to the heat exchanger by an adapter to analyse the actual temperature profile. This heat exchanger is made from aluminium grade 6063 which is widely used to make various types of heat exchangers. The adapter has a provision to measure the pressure drop and temperature. The exhaust back pressure is measured with the U-tube manometer with uncertainty of ±10 Pa and the temperature is measured using k-type Thermocouple and scanner with uncertainty of ±1 °C. Commercially available TEG SP1848-27145 SA shown in Figure 1c and it is mounted in the heat exchanger as shown in Figure 1d. This TEG module has a Seebeck coefficient, S = 0.0485V − K 1 and electrical resistance R = 3.23 Ω. This TEG module is able to generate an open circuit voltage of 4.8 V and a maximum current of 0.669 mA. The maximum operating temperature is limited to 150 °C. Overall size of the TEG module is 40mm × 40mm × 3.6 mm. A load resistance of 2.2 KΩ is connected in series with the TEG output. The hot side TEG surface is placed over the heat exchanger and clamped using aluminium 6063 plates. A multi-meter has uncertainty of ±0.001V is used to measures an open circuit voltage developed in the experimental setup. Two tests were conducted for the validation of CFD results. In the first test, the TEG modules are not mounted over the heat exchanger surface to achieve the temperature profile over the heat exchanger surface. The compressor is operated at a speed of 1800 rpm and allowed to stabilize. After the stabilization period of 20 min, the inlet temperature, pressure drop and temperature profile upon the heat exchanger is measured.The outer wall surface temperature of the heat exchanger is measured before the TEG is getting mounted by using infrared thermometers with uncertainty range of ±1.5 °C. The temperature measurements are made at 13 points axially in the outer surface from inlet port to plot the temperature profile and compare with the CFD results. Figure 2 shows heat exchanger connected with the compressor exhaust part.After obtaining the temperature profile without the TEG in the first test, the second test is conducted after mounting the TEG modules to the heat exchanger. The five TEG modules were mounted over the top side of the heat exchanger throughout its length. After the stabilization of the temperature in heat exchanger open circuit voltage is measured in individual modules by using multi-meter.

Thermoelectric generators assembled in heat exchanger.

Experiment test set up.

3 Numerical model and validation

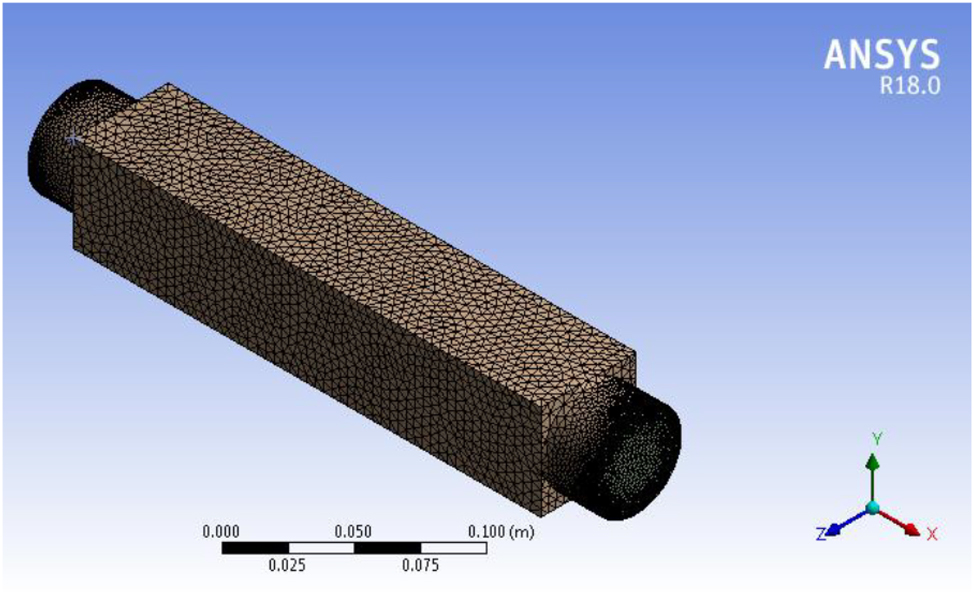

A heat exchanger with TEG module is designed to connect the outlet of the existing exhaust silencer in the compressor. The 3D model is created using SolidWorks 2013 and the dimension of the heat exchanger model is shown in Figure 1a. The 3D model of the heat exchanger which is to be integrated in the experiment set up is done using the SolidWorks package. The specifications of are as follows, the length of the heat exchanger = 0.3 m, inner diameter = 0.043 m, outer square = 0.051 m and mounting length = 0.25 m. Preliminary analysis to estimate the heat transfer and pressure drop in the heat exchanger is performed using CFD approach which is quite familiar to solve complex flows without an experiment. The solid model is imported through the design modeller into ANSYS FLUENT. The fluid and solid bodies are defined in the geometry information interface. The solid and fluid bodies formed as a single part to avoid contact regions and then meshing is done. After making a fine mesh model, an edge sizing is performed to make the improved mesh as shown in Figure 3. The tetrahedron elements are used in meshing and the total number of nodes is 21388 and elements are 106030. The inlet, outlet, outer wall and wall sections are selected and named in the meshing interface. The mesh convergence study has been performed and the temperature in °C is measured at 0.275 m from inlet and it is listed in Table 1.

Meshed model.

Mesh convergence study.

| Mesh convergence study | ||

|---|---|---|

| Nodes | Elements | Temperature |

| 21388 | 106030 | 67.14 |

| 24755 | 120700 | 67.39 |

| 27012 | 130581 | 67.57 |

| 36292 | 185748 | 67.15 |

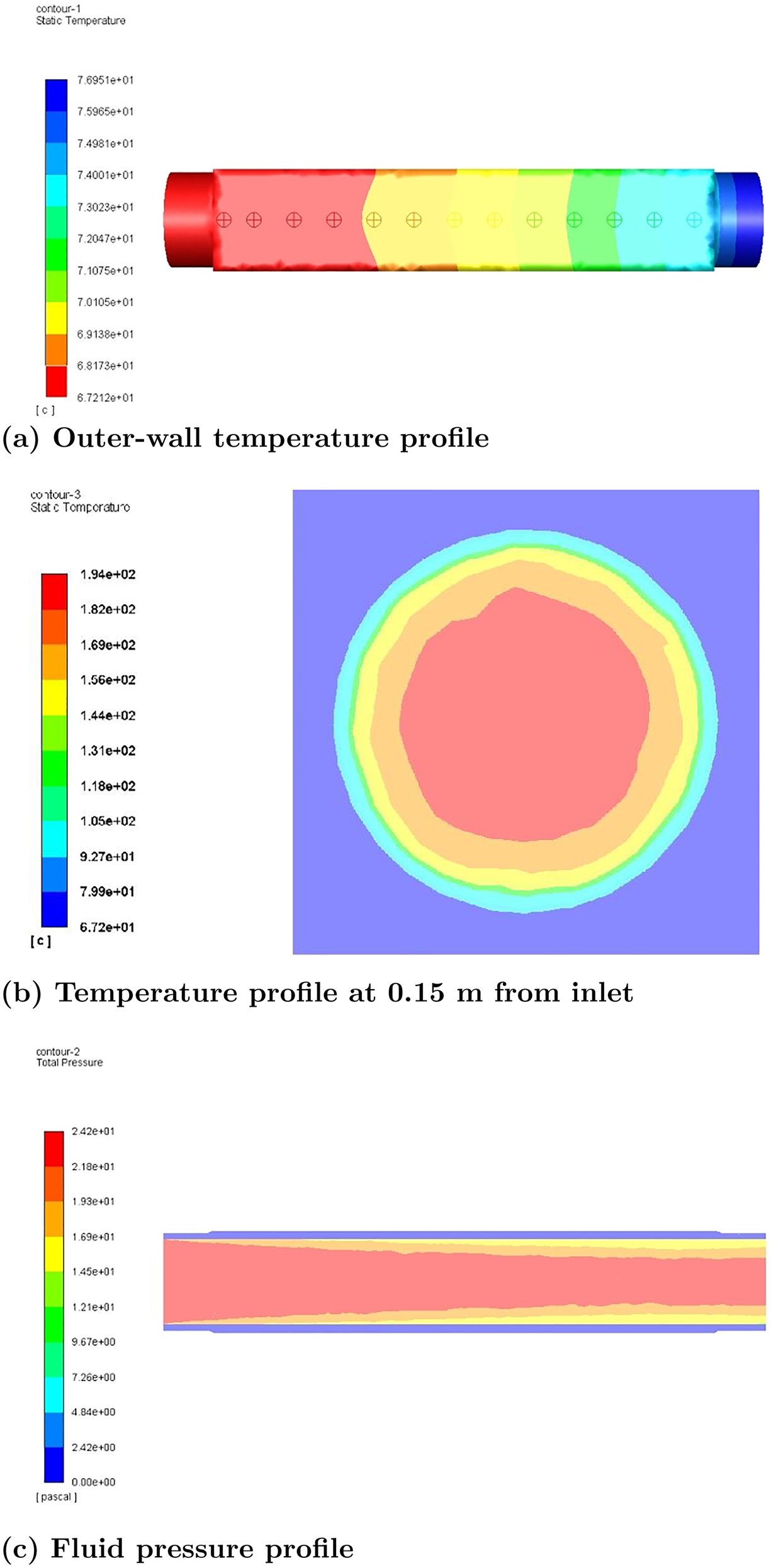

The governing equations used for the CFD simulations to solve the heat transfer and pressure drop in fluid flow mathematically are based on the principle of conservation of mass, momentum and energy equations. The k-ϵ model which is widely used for turbulent flows analysis is followed to solve the problem. Boundary conditions arrived based on the experimental test results and the same was applied in fluent package. Since the flow has the Reynolds number 7.64 × 104 the turbulent model, standard k-ϵ model with enhanced wall treatment was selected for the computation of heat transfer and pressure drop in the flow model. The properties used for the calculation is taken from the experiment test data. The inlet is considered as velocity-inlet and the outlet is considered as mass flow outlet with the target mass flow rate of 0.0664 kg/s. The turbulence is specified as 5 % intensity and the hydraulic diameter is set to 0.043 in inlet and outlet. The inlet temperature of the exhaust gas is considered as 194 °C. The density of air at hot gas is taken as 0.749 kg/m3. Thermal Conductivity of Aluminium is considered as 200 W/m K. The residuals for convergence of energy is kept as 10–6, the continuity, velocities, k and ϵ is kept as 10−4. After the solution convergence, the outer wall temperature profile contour shown in Figure 4a and its cross section view as shown in Figure 4b and pressure drop contour shown in Figure 4c is analysed for further studies.

Computational fluid dynamics numerical results (a) outer-wall temperature profile (b) temperature profile at 0.15 m from inlet and (c) fluid pressure profile.

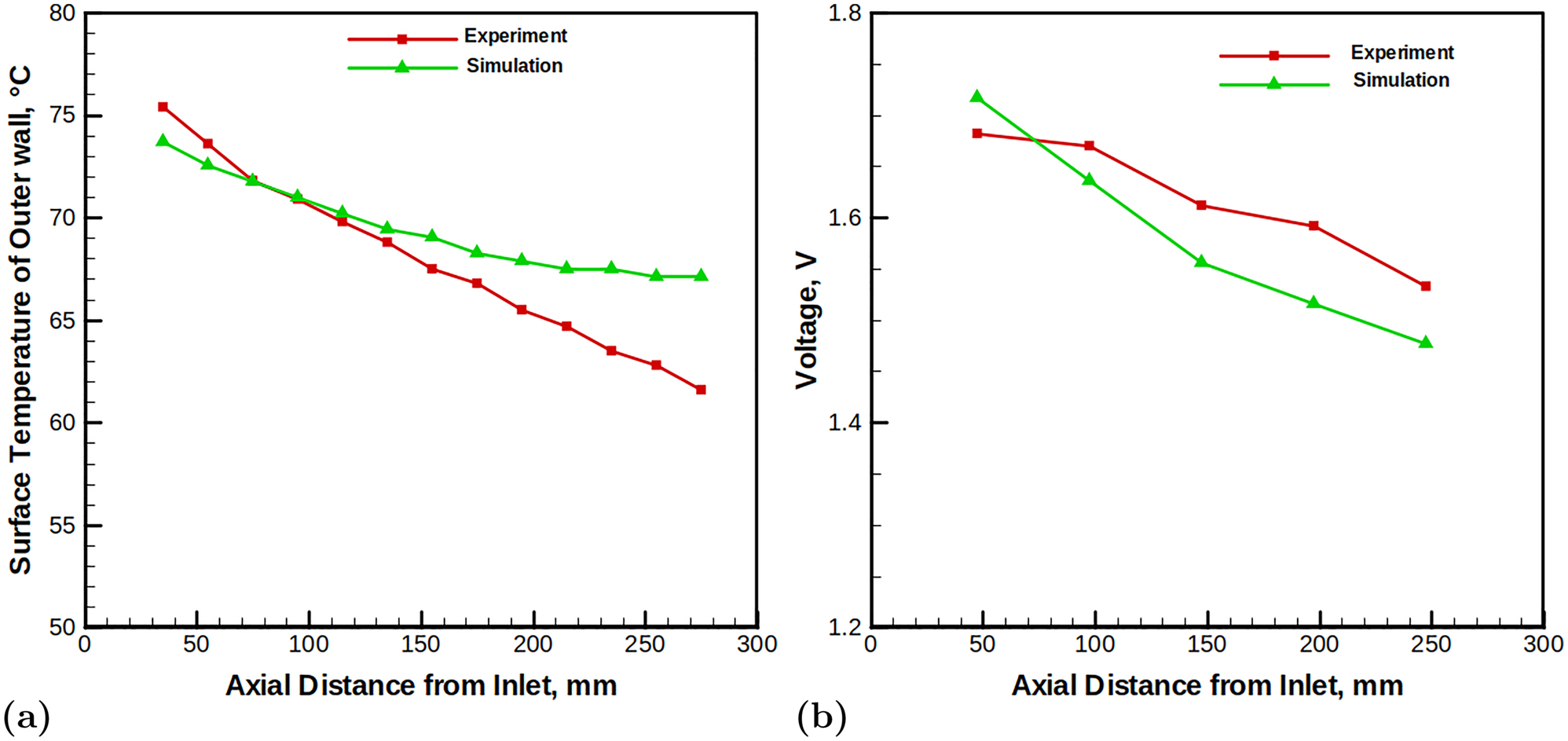

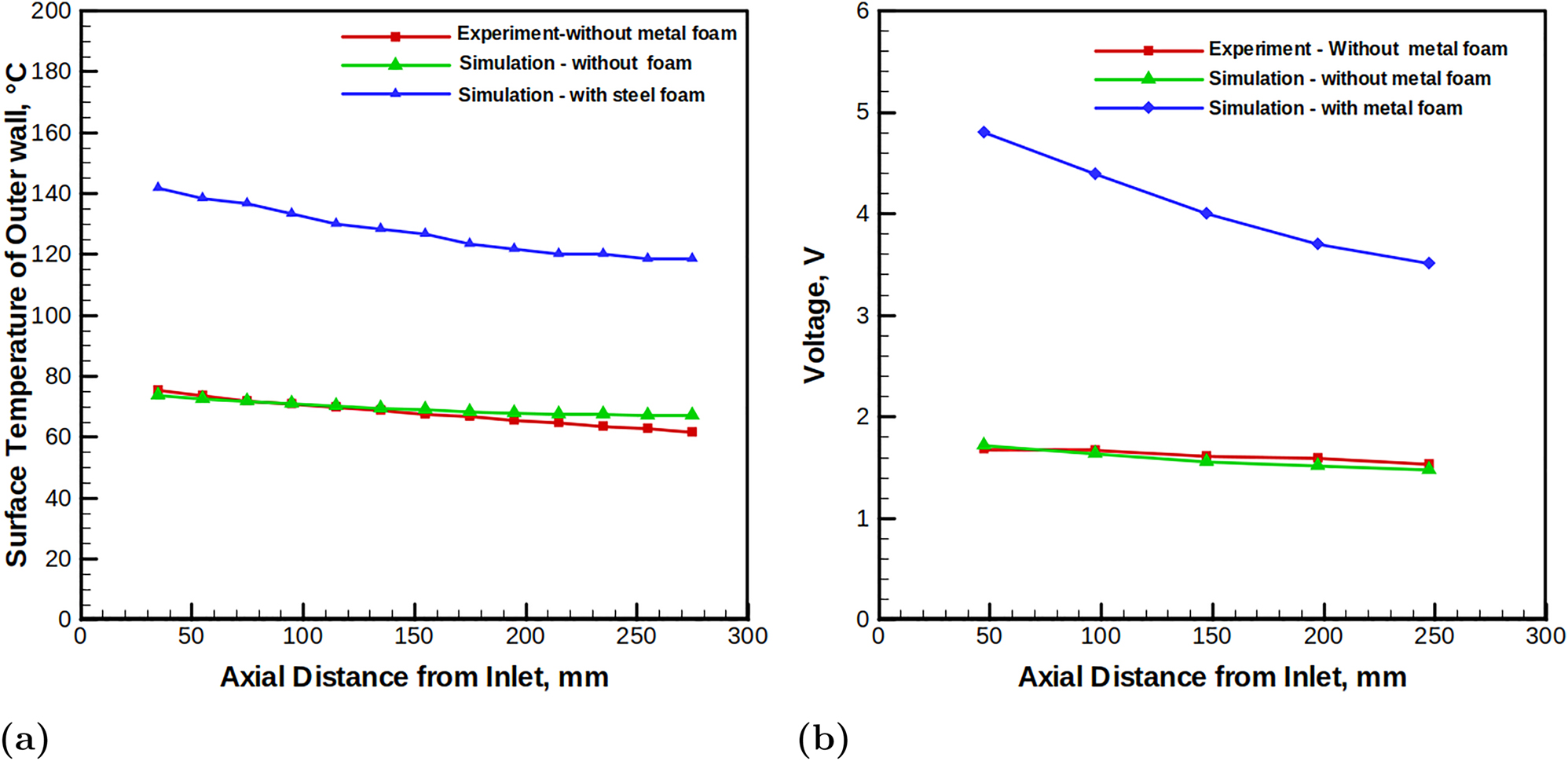

The actual temperature profile of the surface is observed with aluminium heat exchanger and compared against the CFD simulation results. The maximum error in temperature profiles between experiments and CFD is less than 8.96 %. Figure 5 shows the temperature profiles in experiment and CFD results. The voltage is developed in the range of 1.6 V–1.5 V in the experiment. From the temperature data with simulation results the output voltage is calculated considering the cold side temperature TEG.

Comparison of experimental and numerical results (a) temperature distribution comparison and (b) open circuit voltage comparisons.

4 Results and discussions

In this section, the effect of heat exchanger materials, hot side fluids and metal foam and its porosity on temperature distribution and power generation numerically and analytically. Finally, the total power can be harvested from the proposed heat exchanger also calculated.

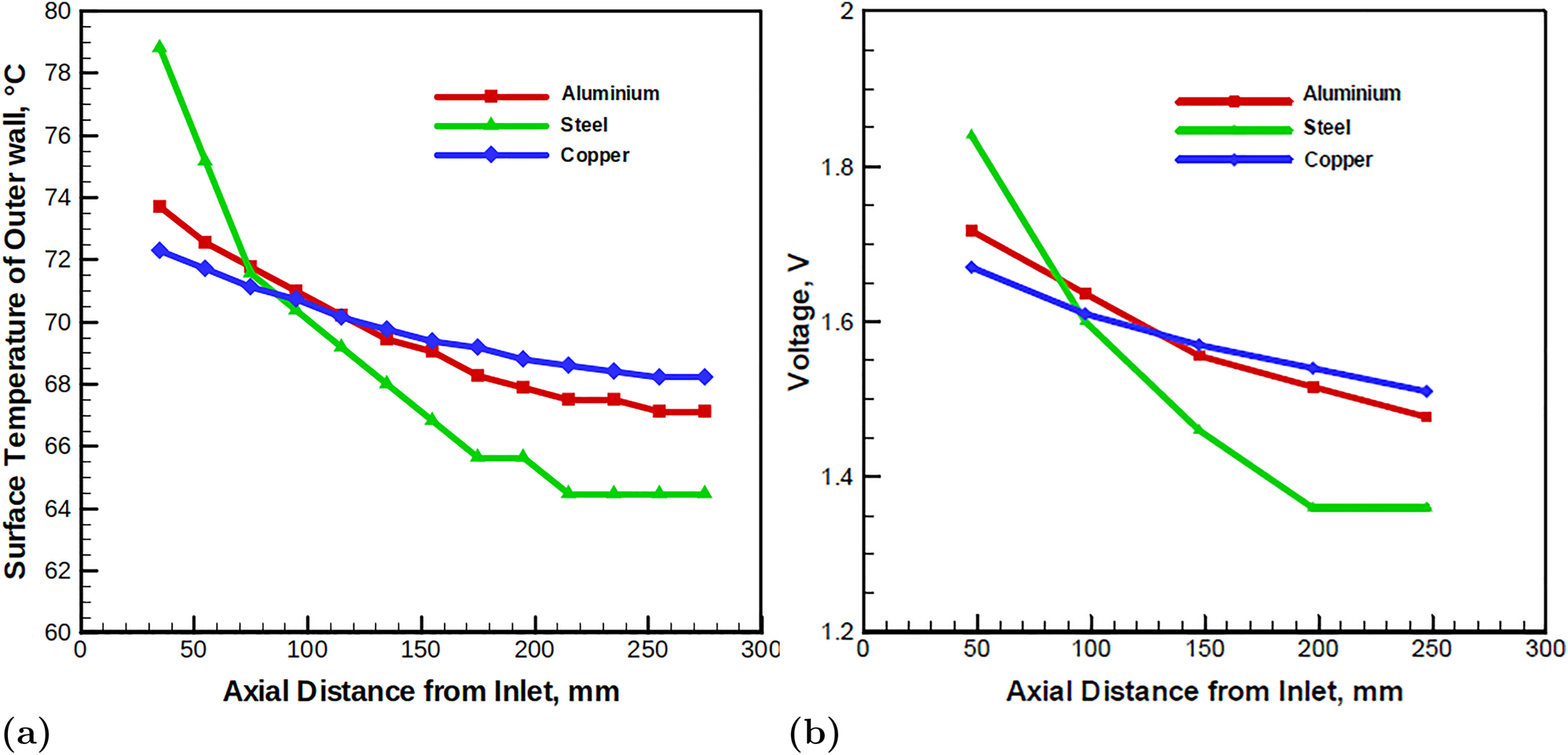

4.1 Effect of heat exchanger materials

The effect of hot side heat exchanger material which predominantly contributes to the heat transfer in the heat exchanger is studied using CFD simulations for commonly used heat exchanger materials aluminium, steel and copper. The variation in temperature profile suggests that copper has a minimum drop in temperature from inlet to the outlet in the heat exchanger as shown in Figure 6.

Numerical simulation results (a) temperature and (b) voltage distribution for different materials.

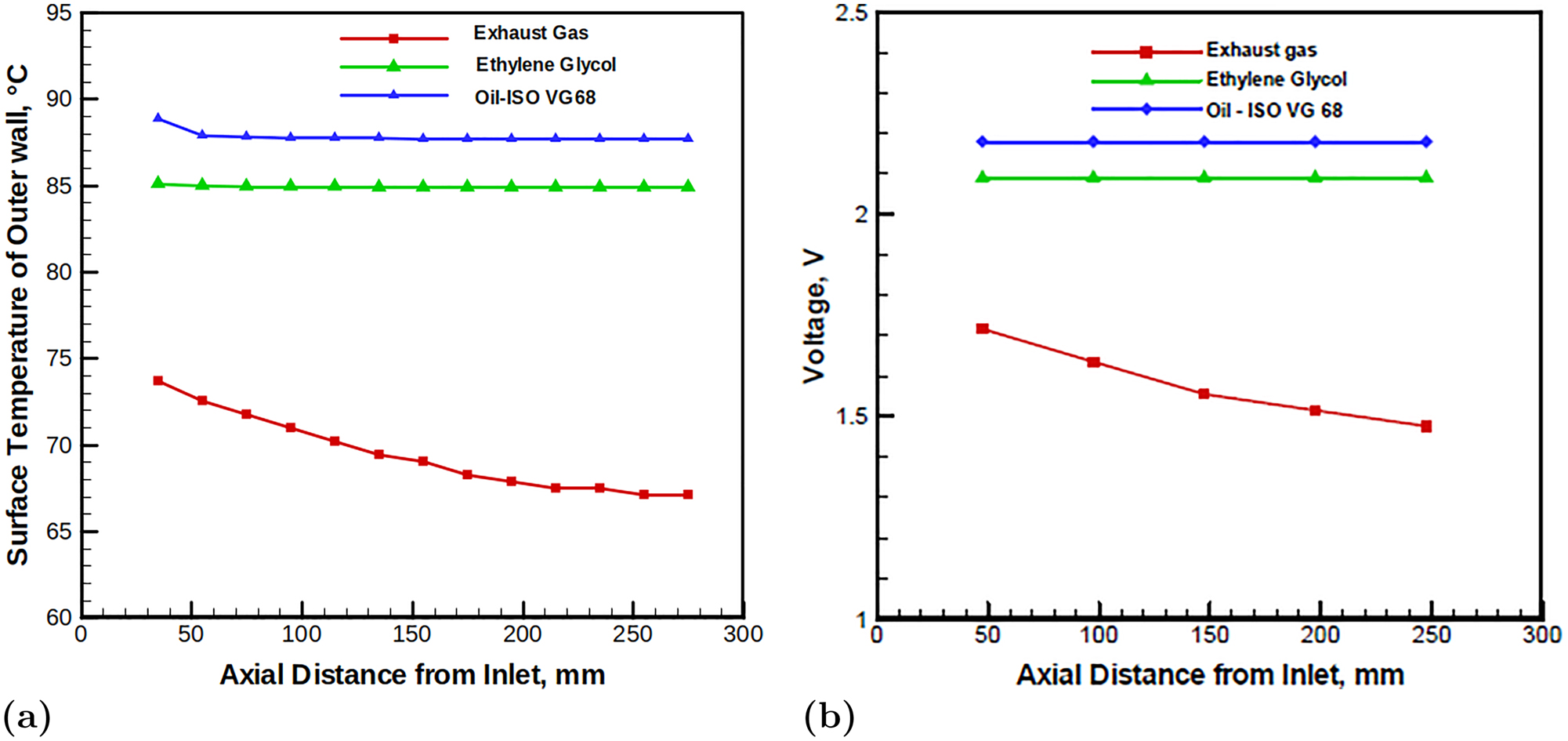

4.2 Effect of hot side fluids

In a portable diesel powered screw air compressor, the heat is dissipated from exhaust gas, compressor oil and engine radiator coolant. This simulation provides information about the temperature distribution for different application media’s used in compressors. Figure 7 shows the temperature profiles with different media’s. The input flow parameters for different fluids were kept same expect for the material properties and input temperature. For the available heat sources in the compressor, the heat transfer from the compressor oil has a better potential than ethylene glycol and exhaust gas.

Numerical simulation results (a) temperature and (b) voltage distribution for different medium.

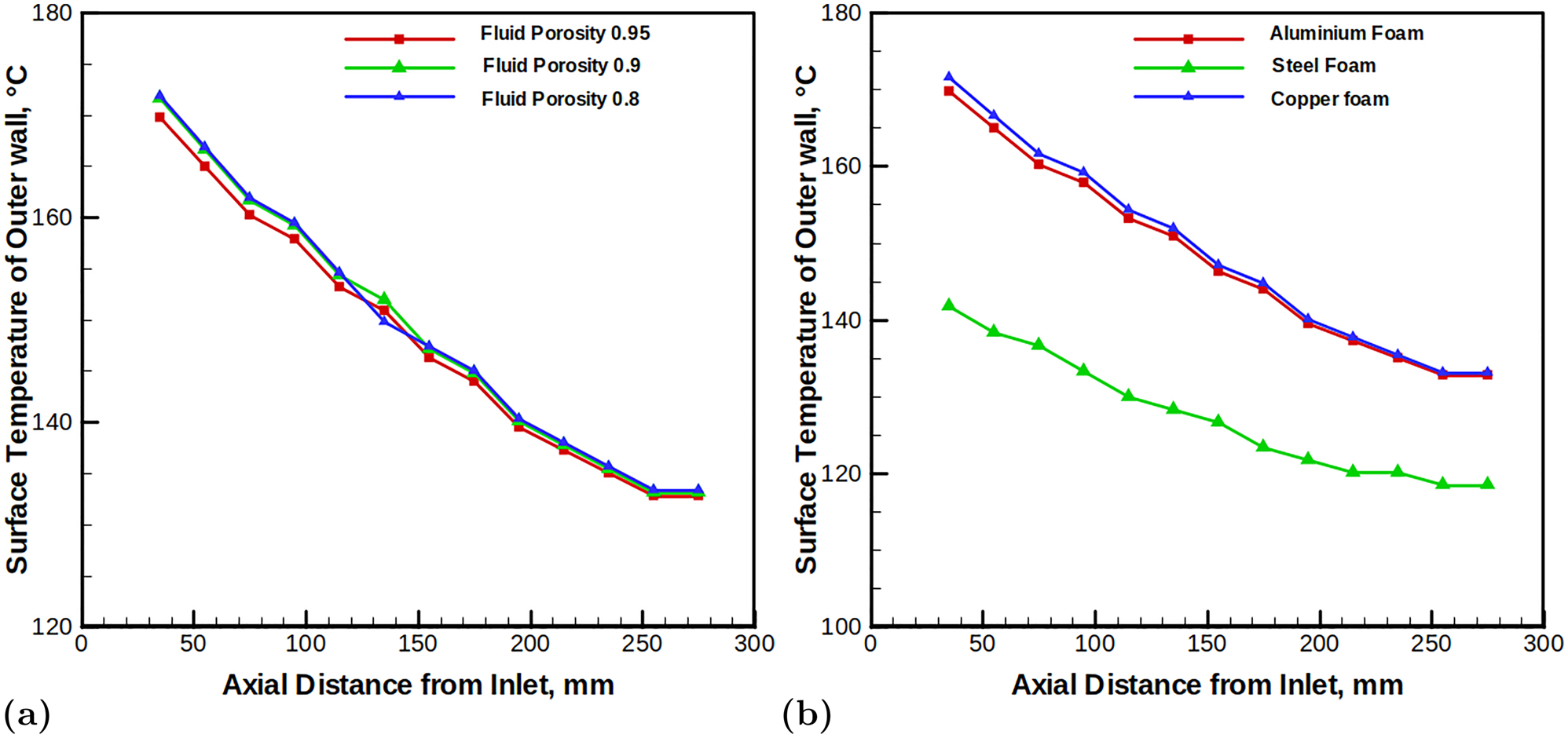

4.3 Effect of metal foams materials and its porosity

Metal foams used in heat exchanger have a significant impact on the heat transfer due to the improvement in surface area of foams. Metal foams improve the convection heat transfer to the hot side heat exchanger. The foam porosity is included in the cell zone conditions during the simulations. The porosity of fluid flow is varied as 0.95, 0.90 and 0.80 respectively and its effect of the temperature distribution on the outer wall by considering aluminium metal foam as shown in Figure 8a. The heat transfer to the outer wall surface is increased to a larger extent by the inclusion of aluminium metal foam as shown in Figure 8b. However, this temperature observed is above the manufacturer specification of 150 °C and however operating at this temperature will degrade the power output of the TEG. Due to TEG module requirements, copper and aluminium foams cannot be adopted for our system. However, there is also a significant improvement in the outer surface temperature with the steel foam. With the steel foam the hot side temperature is around 142 °C which is highly recommended to use with the selected TEG.

Numerical simulation results (a) temperature and (b) voltage distribution for various metal foam porosity’s and materials.

To identify the configuration of heat exchanger for exhaust gas application, a comparison is made between the simulation and experimental results. The temperature output obtained from the experiment and fluent simulation is reasonably accurate with an error of less than 9 % as shown in Figure 9. The steel foam with 95 % porosity is simulated and the results are plotted. The output voltage from the TEG is improved by the usage of metal foam form 1.6 V in the experiment to that of 4.8 V which is shown in Figure 9. The output power of the metal foam TEG heat exchanger generates power of about 3.2 W against that of 0.36 W in a plain heat exchanger. In present experiment, the power output from the TEG (without foam) is about 1.82 W by 5 TEG modules.

Experimental results (a) temperature and (b) voltage distribution for various metal foam porosity’s and materials.

In general, the portable diesel powered screw air compressor’s predominantly operates in remote locations where there is little or no access to electrical power lines. At present, in case of power requirements to operate the tripod lamps, portable drill bit grinder, mobile charging etc. the power is taken from the alternators of the engine. A lot of energy is wasted in the current practice. Energy harvested from the waste heat sources of the compressor by proposed thermoelectric generators can be utilized for work lamp and tripod mounted lamps. These lamps operate with a 30W input, which could be harvested in this method. This energy harvesting method will make the compressor system more efficient and also reduce the carbon footprint. The power generated from the heat exchanger with TEG module is 1.820W with 5 number of TEG module. The maximum power can be obtained with surface available in the silencer is 64.152W with 180 TEG modules as shown in Table 2.

Power Generation from TEG module.

| Power generation from TEG module | |||

|---|---|---|---|

| Configuration | No of modules | Heat exchanger area | Output power |

| Present TEG model | 5 | 0.01275 | 1.820 |

| By utilizing the surface area available in silencer | 180 | 0.48 | 64.152 |

5 Conclusions

In this work, an experimental and numerical investigation of thermoelectric generator for energy harvesting performance of screw compressors has been studied. Thermoelectric generators being the potential option for heat recovery in compressors, the design of thermoelectric heat recovery system for compressor is carried out to mount 5 modules of TEG to understand the recovery of waste heat from DPSAC compressors engine exhaust. From the experiment results, there is a power output of 1.82 W from present configuration. Computational fluid dynamics simulations results were compared against experiment results for temperature profiles in the heat exchanger within the error of 9 %. From the simulation, the parametric study has been carried out in order to improve the heat exchanger efficiency. The study comprises of different heat exchanger materials, potential hot fluids of compressor, metal foams in hot flow regions with different porosity’s and different metal foam materials. From the simulation results the heat exchanger with steel foam of porosity 5 % (fluid porosity 95 %) suits the application requirements and it is capable to deliver 4.8 V without degradation of the thermoelectric generator. To further improve the heat recovery the number of modules can be increased depending upon the available surface area. In future, upon increasing the thermoelectric material efficiency by advanced technologies, this system has a great potential to improve the efficiency in the compressors. This work can be extended to oil coolers of compressors, where the heat can be recovered from hot oil and from radiators of DPSAC compressor to recover energy from engine coolant.

-

Author contributions: The author has accepted responsibility for the entire content of this submitted manuscript and approved submission.

-

Research funding: None declared.

-

Conflict of interest statement: The author declares no conflicts of interest regarding this article.

References

Araiz, M., Á. Casi, L. Catalán, Á. Martínez, and D. Astrain. 2020. “Prospects of Waste-Heat Recovery from a Real Industry Using Thermoelectric Generators: Economic and Power Output Analysis.” Energy Conversion and Management 205: 112376.10.1016/j.enconman.2019.112376Search in Google Scholar

Champier, D. 2017. “Thermoelectric Generators: A Review of Applications.” Energy Conversion and Management 140: 167–81. https://doi.org/10.1016/j.enconman.2017.02.070.Search in Google Scholar

Du, Q., H. Diao, Z. Niu, G. Zhang, G. Shu, and K. Jiao. 2015. “Effect of Cooling Design on the Characteristics and Performance of Thermoelectric Generator Used for Internal Combustion Engine.” Energy Conversion and Management 101: 9–18. https://doi.org/10.1016/j.enconman.2015.05.036.Search in Google Scholar

Elghool, A., F. Basrawi, H. Ibrahim, T. K. Ibrahim, M. Ishak, T. M. Yusof, and S. A. Bagaber. 2020. “Enhancing the Performance of a Thermo-Electric Generator through Multi-Objective Optimisation of Heat Pipes-Heat Sink under Natural Convection.” Energy Conversion and Management 209: 112626. https://doi.org/10.1016/j.enconman.2020.112626.Search in Google Scholar

Gou, X., H. Xiao, and S. Yang. 2010. “Modeling, Experimental Study and Optimization on Low-Temperature Waste Heat Thermoelectric Generator System.” Applied Energy 87 (10): 3131–6. https://doi.org/10.1016/j.apenergy.2010.02.013.Search in Google Scholar

He, W., S. Wang, C. Lu, X. Zhang, and Y. Li. 2016. “Influence of Different Cooling Methods on Thermoelectric Performance of an Engine Exhaust Gas Waste Heat Recovery System.” Applied Energy 162: 1251–8. https://doi.org/10.1016/j.apenergy.2015.03.036.Search in Google Scholar

He, W., R. Guo, S. Liu, K. Zhu, and S. Wang. 2020. “Temperature Gradient Characteristics and Effect on Optimal Thermoelectric Performance in Exhaust Power-Generation Systems.” Applied Energy 261: 114366. https://doi.org/10.1016/j.apenergy.2019.114366.Search in Google Scholar

Hsiao, C.C., W. Chang, and S. Chen. 2010. “A Mathematic Model of Thermoelectric Module with Applications on Waste Heat Recovery from Automobile Engine.” Energy 35 (3): 1447–54. https://doi.org/10.1016/j.energy.2009.11.030.Search in Google Scholar

Hsu, C.-T., G.-Y. Huang, H.-S. Chu, B. Yu, and D.-J. Yao. 2011. “Experiments and Simulations on Low-Temperature Waste Heat Harvesting System by Thermoelectric Power Generators.” Applied Energy 88 (4): 1291–7. https://doi.org/10.1016/j.apenergy.2010.10.005.Search in Google Scholar

Kim, T. Y., J. Kwak, and B.-W. Kim. 2018. “Energy Harvesting Performance of Hexagonal Shaped Thermoelectric Generator for Passenger Vehicle Applications: An Experimental Approach.” Energy Conversion and Management 160: 14–21. https://doi.org/10.1016/j.enconman.2018.01.032.Search in Google Scholar

Liu, X., Y. D. Deng, K. Zhang, M. Xu, Y. Xu, and C. Q. Su. 2014. “Experiments and Simulations on Heat Exchangers in Thermoelectric Generator for Automotive Application.” Applied Thermal Engineering 71 (1): 364–70. https://doi.org/10.1016/j.applthermaleng.2014.07.022.Search in Google Scholar

Liu, X., Y. D. Deng, Z. Li, and C. Q Su. 2015. “Performance Analysis of a Waste Heat Recovery Thermoelectric Generation System for Automotive Application.” Energy Conversion and Management 90: 121–7. https://doi.org/10.1016/j.enconman.2014.11.015.Search in Google Scholar

Luo, D., R. Wang, W. Yu, and W. Zhou. 2020. “A Novel Optimization Method for Thermoelectric Module Used in Waste Heat Recovery.” Energy Conversion and Management 209: 112645. https://doi.org/10.1016/j.enconman.2020.112645.Search in Google Scholar

Meng, J.-H., and X.-D. Wang, X.-X. Zhang. 2013. “Transient Modeling and Dynamic Characteristics of Thermoelectric Cooler.” Applied Energy 108: 340–8. https://doi.org/10.1016/j.apenergy.2013.03.051.Search in Google Scholar

Miao, Z., X. Meng, S. Zhou, and M. Zhu. 2020. “Thermo-mechanical Analysis on Thermoelectric Legs Arrangement of Thermoelectric Modules.” Renewable Energy 147 (1): 2272–8. https://doi.org/10.1016/j.renene.2019.10.016.Search in Google Scholar

Nithyanandam, M., and R. Mahajan. 2018. “Evaluation of Metal Foam Based Thermoelectric Generators for Automobile Waste Heat Recovery.” International Journal of Heat and Mass Transfer 122: 877–83. https://doi.org/10.1016/j.ijheatmasstransfer.2018.02.029.Search in Google Scholar

Niu, Z., H. Diao, S. Yu, K. Jiao, Q. Du, and G. Shu. 2014. “Investigation and Design Optimization of Exhaust-Based Thermoelectric Generator System for Internal Combustion Engine.” Energy Conversion and Management 85: 85–101. https://doi.org/10.1016/j.enconman.2014.05.061.Search in Google Scholar

Patil, D.S., R.R. Arakerimath, and P. V. Walke. 2018. “Thermoelectric Materials and Heat Exchangers for Power Generation – A Review.” Renewable and Sustainable Energy Reviews 95: 1–22. https://doi.org/10.1016/j.rser.2018.07.003.Search in Google Scholar

Shen, Z.-G., L.-Li. Tian, and X. Liu. 2019. “Automotive Exhaust Thermoelectric Generators: Current Status, Challenges and Future Prospects.” Energy Conversion and Management 195: 1138–73. https://doi.org/10.1016/j.enconman.2019.05.087.Search in Google Scholar

Song, L. V., W. He, Q. Jiang, Z. Hu, X. Liu, H. Chen, and M. Liu. 2018. “Study of Different Heat Exchange Technologies Influence on the Performance of Thermoelectric Generators.” Energy Conversion and Management 156: 167–77. https://doi.org/10.1016/j.enconman.2017.11.011.Search in Google Scholar

Tian, H., X. Sun, J. Qi, X. Liang, G. Shu, and Xu. Wang. 2015. “Comparison and Parameter Optimization of a Segmented Thermoelectric Generator by Using the High Temperature Exhaust of a Diesel Engine.” Energy 84: 121–30. https://doi.org/10.1016/j.energy.2015.02.063.Search in Google Scholar

Wang, T., W. Luan, W. Wang, and S.-T. Tu. 2014. “Waste Heat Recovery through Plate Heat Exchanger Based Thermoelectric Generator System.” Applied Energy 136: 860–5. https://doi.org/10.1016/j.apenergy.2014.07.083.Search in Google Scholar

Wang, Y., S. Li, Xu. Xie, Y. Deng, X. Liu, and C. Su. 2018. “Performance Evaluation of an Automotive Thermoelectric Generator with Inserted Fins or Dimpled-Surface Hot Heat Exchanger.” Applied Energy 218: 391–401. https://doi.org/10.1016/j.apenergy.2018.02.176.Search in Google Scholar

Weng, C.-C., and M.-J. Huan. 2013. “A Simulation Study of Automotive Waste Heat Recovery Using a Thermoelectric Power Generator.” International Journal of Thermal Sciences 71: 302–9. https://doi.org/10.1016/j.ijthermalsci.2013.04.008.Search in Google Scholar

Zhang, Y., M. Cleary, X. Wang, N. Kempf, L. Schoensee, J. Yang, G. Joshi, and L. Meda. 2015. “High-temperature and High-Power-Density Nanostructured Thermoelectric Generator for Automotive Waste Heat Recovery.” Energy Conversion and Management 105: 946–50. https://doi.org/10.1016/j.enconman.2015.08.051.Search in Google Scholar

© 2024 the author(s), published by De Gruyter, Berlin/Boston

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Solar photovoltaic-integrated energy storage system with a power electronic interface for operating a brushless DC drive-coupled agricultural load

- Analysis of 1-year energy data of a 5 kW and a 122 kW rooftop photovoltaic installation in Dhaka

- Reviews

- Real yields and PVSYST simulations: comparative analysis based on four photovoltaic installations at Ibn Tofail University

- A comprehensive approach of evolving electric vehicles (EVs) to attribute “green self-generation” – a review

- Exploring the piezoelectric porous polymers for energy harvesting: a review

- A strategic review: the role of commercially available tools for planning, modelling, optimization, and performance measurement of photovoltaic systems

- Comparative assessment of high gain boost converters for renewable energy sources and electrical vehicle applications

- A review of green hydrogen production based on solar energy; techniques and methods

- A review of green hydrogen production by renewable resources

- A review of hydrogen production from bio-energy, technologies and assessments

- A systematic review of recent developments in IoT-based demand side management for PV power generation

- Research Articles

- Hybrid optimization strategy for water cooling system: enhancement of photovoltaic panels performance

- Solar energy harvesting-based built-in backpack charger

- A power source for E-devices based on green energy

- Theoretical and experimental investigation of electricity generation through footstep tiles

- Experimental investigations on heat transfer enhancement in a double pipe heat exchanger using hybrid nanofluids

- Comparative energy and exergy analysis of a CPV/T system based on linear Fresnel reflectors

- Investigating the effect of green composite back sheet materials on solar panel output voltage harvesting for better sustainable energy performance

- Electrical and thermal modeling of battery cell grouping for analyzing battery pack efficiency and temperature

- Intelligent techno-economical optimization with demand side management in microgrid using improved sandpiper optimization algorithm

- Investigation of KAPTON–PDMS triboelectric nanogenerator considering the edge-effect capacitor

- Design of a novel hybrid soft computing model for passive components selection in multiple load Zeta converter topologies of solar PV energy system

- A novel mechatronic absorber of vibration energy in the chimney

- An IoT-based intelligent smart energy monitoring system for solar PV power generation

- Large-scale green hydrogen production using alkaline water electrolysis based on seasonal solar radiation

- Evaluation of performances in DI Diesel engine with different split injection timings

- Optimized power flow management based on Harris Hawks optimization for an islanded DC microgrid

- Experimental investigation of heat transfer characteristics for a shell and tube heat exchanger

- Fuzzy induced controller for optimal power quality improvement with PVA connected UPQC

- Impact of using a predictive neural network of multi-term zenith angle function on energy management of solar-harvesting sensor nodes

- An analytical study of wireless power transmission system with metamaterials

- Hydrogen energy horizon: balancing opportunities and challenges

- Development of renewable energy-based power system for the irrigation support: case studies

- Maximum power point tracking techniques using improved incremental conductance and particle swarm optimizer for solar power generation systems

- Experimental and numerical study on energy harvesting performance thermoelectric generator applied to a screw compressor

- Study on the effectiveness of a solar cell with a holographic concentrator

- Non-transient optimum design of nonlinear electromagnetic vibration-based energy harvester using homotopy perturbation method

- Industrial gas turbine performance prediction and improvement – a case study

- An electric-field high energy harvester from medium or high voltage power line with parallel line

- FPGA based telecommand system for balloon-borne scientific payloads

- Improved design of advanced controller for a step up converter used in photovoltaic system

- Techno-economic assessment of battery storage with photovoltaics for maximum self-consumption

- Analysis of 1-year energy data of a 5 kW and a 122 kW rooftop photovoltaic installation in Dhaka

- Shading impact on the electricity generated by a photovoltaic installation using “Solar Shadow-Mask”

- Investigations on the performance of bottle blade overshot water wheel in very low head resources for pico hydropower

- Solar photovoltaic-integrated energy storage system with a power electronic interface for operating a brushless DC drive-coupled agricultural load

- Numerical investigation of smart material-based structures for vibration energy-harvesting applications

- A system-level study of indoor light energy harvesting integrating commercially available power management circuitry

- Enhancing the wireless power transfer system performance and output voltage of electric scooters

- Harvesting energy from a soldier's gait using the piezoelectric effect

- Study of technical means for heat generation, its application, flow control, and conversion of other types of energy into thermal energy

- Theoretical analysis of piezoceramic ultrasonic energy harvester applicable in biomedical implanted devices

- Corrigendum

- Corrigendum to: A numerical investigation of optimum angles for solar energy receivers in the eastern part of Algeria

- Special Issue: Recent Trends in Renewable Energy Conversion and Storage Materials for Hybrid Transportation Systems

- Typical fault prediction method for wind turbines based on an improved stacked autoencoder network

- Power data integrity verification method based on chameleon authentication tree algorithm and missing tendency value

- Fault diagnosis of automobile drive based on a novel deep neural network

- Research on the development and intelligent application of power environmental protection platform based on big data

- Diffusion induced thermal effect and stress in layered Li(Ni0.6Mn0.2Co0.2)O2 cathode materials for button lithium-ion battery electrode plates

- Improving power plant technology to increase energy efficiency of autonomous consumers using geothermal sources

- Energy-saving analysis of desalination equipment based on a machine-learning sequence modeling

Articles in the same Issue

- Solar photovoltaic-integrated energy storage system with a power electronic interface for operating a brushless DC drive-coupled agricultural load

- Analysis of 1-year energy data of a 5 kW and a 122 kW rooftop photovoltaic installation in Dhaka

- Reviews

- Real yields and PVSYST simulations: comparative analysis based on four photovoltaic installations at Ibn Tofail University

- A comprehensive approach of evolving electric vehicles (EVs) to attribute “green self-generation” – a review

- Exploring the piezoelectric porous polymers for energy harvesting: a review

- A strategic review: the role of commercially available tools for planning, modelling, optimization, and performance measurement of photovoltaic systems

- Comparative assessment of high gain boost converters for renewable energy sources and electrical vehicle applications

- A review of green hydrogen production based on solar energy; techniques and methods

- A review of green hydrogen production by renewable resources

- A review of hydrogen production from bio-energy, technologies and assessments

- A systematic review of recent developments in IoT-based demand side management for PV power generation

- Research Articles

- Hybrid optimization strategy for water cooling system: enhancement of photovoltaic panels performance

- Solar energy harvesting-based built-in backpack charger

- A power source for E-devices based on green energy

- Theoretical and experimental investigation of electricity generation through footstep tiles

- Experimental investigations on heat transfer enhancement in a double pipe heat exchanger using hybrid nanofluids

- Comparative energy and exergy analysis of a CPV/T system based on linear Fresnel reflectors

- Investigating the effect of green composite back sheet materials on solar panel output voltage harvesting for better sustainable energy performance

- Electrical and thermal modeling of battery cell grouping for analyzing battery pack efficiency and temperature

- Intelligent techno-economical optimization with demand side management in microgrid using improved sandpiper optimization algorithm

- Investigation of KAPTON–PDMS triboelectric nanogenerator considering the edge-effect capacitor

- Design of a novel hybrid soft computing model for passive components selection in multiple load Zeta converter topologies of solar PV energy system

- A novel mechatronic absorber of vibration energy in the chimney

- An IoT-based intelligent smart energy monitoring system for solar PV power generation

- Large-scale green hydrogen production using alkaline water electrolysis based on seasonal solar radiation

- Evaluation of performances in DI Diesel engine with different split injection timings

- Optimized power flow management based on Harris Hawks optimization for an islanded DC microgrid

- Experimental investigation of heat transfer characteristics for a shell and tube heat exchanger

- Fuzzy induced controller for optimal power quality improvement with PVA connected UPQC

- Impact of using a predictive neural network of multi-term zenith angle function on energy management of solar-harvesting sensor nodes

- An analytical study of wireless power transmission system with metamaterials

- Hydrogen energy horizon: balancing opportunities and challenges

- Development of renewable energy-based power system for the irrigation support: case studies

- Maximum power point tracking techniques using improved incremental conductance and particle swarm optimizer for solar power generation systems

- Experimental and numerical study on energy harvesting performance thermoelectric generator applied to a screw compressor

- Study on the effectiveness of a solar cell with a holographic concentrator

- Non-transient optimum design of nonlinear electromagnetic vibration-based energy harvester using homotopy perturbation method

- Industrial gas turbine performance prediction and improvement – a case study

- An electric-field high energy harvester from medium or high voltage power line with parallel line

- FPGA based telecommand system for balloon-borne scientific payloads

- Improved design of advanced controller for a step up converter used in photovoltaic system

- Techno-economic assessment of battery storage with photovoltaics for maximum self-consumption

- Analysis of 1-year energy data of a 5 kW and a 122 kW rooftop photovoltaic installation in Dhaka

- Shading impact on the electricity generated by a photovoltaic installation using “Solar Shadow-Mask”

- Investigations on the performance of bottle blade overshot water wheel in very low head resources for pico hydropower

- Solar photovoltaic-integrated energy storage system with a power electronic interface for operating a brushless DC drive-coupled agricultural load

- Numerical investigation of smart material-based structures for vibration energy-harvesting applications

- A system-level study of indoor light energy harvesting integrating commercially available power management circuitry

- Enhancing the wireless power transfer system performance and output voltage of electric scooters

- Harvesting energy from a soldier's gait using the piezoelectric effect

- Study of technical means for heat generation, its application, flow control, and conversion of other types of energy into thermal energy

- Theoretical analysis of piezoceramic ultrasonic energy harvester applicable in biomedical implanted devices

- Corrigendum

- Corrigendum to: A numerical investigation of optimum angles for solar energy receivers in the eastern part of Algeria

- Special Issue: Recent Trends in Renewable Energy Conversion and Storage Materials for Hybrid Transportation Systems

- Typical fault prediction method for wind turbines based on an improved stacked autoencoder network

- Power data integrity verification method based on chameleon authentication tree algorithm and missing tendency value

- Fault diagnosis of automobile drive based on a novel deep neural network

- Research on the development and intelligent application of power environmental protection platform based on big data

- Diffusion induced thermal effect and stress in layered Li(Ni0.6Mn0.2Co0.2)O2 cathode materials for button lithium-ion battery electrode plates

- Improving power plant technology to increase energy efficiency of autonomous consumers using geothermal sources

- Energy-saving analysis of desalination equipment based on a machine-learning sequence modeling