Abstract

The recent past witnessed rapid strides in the development of lithium-based rechargeable batteries. Here, some key technological developments in intercalation, conversion, and alloy-type anode and cathode materials are reviewed. Beyond the active electrode materials, we also discuss strategies for improving electrolytes and current collectors. An outlook with remarks on easily misleading battery characteristics reported in the literature, impending challenges, and future directions in lithium-based rechargeable batteries is provided. Lastly, the authors also emphasize the need for lab-based research at the pouch cell level with practical energy densities, in addition to discussing scalability and economic viability of different battery materials and their architectures.

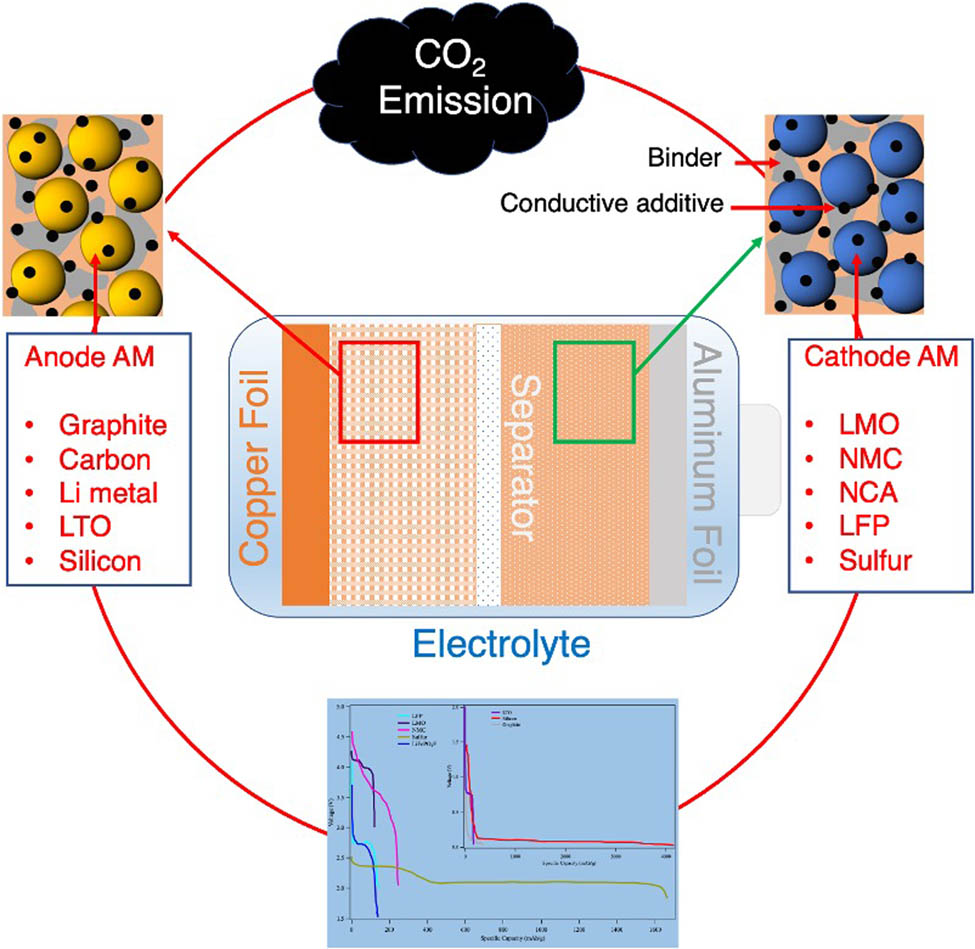

Graphical abstract

1 Introduction

Alternative vehicle technologies, such as battery electric vehicles (BEVs), are being developed to reduce our dependence on oil for transportation and mitigate CO2 emissions [1,2,3,4]. Unlike low-efficiency gasoline or diesel-based internal combustion engines that power most present-day vehicles, a BEV is fully powered by the energy stored in a large onboard battery pack with projected efficiencies up to 70%. The performance of a BEV ultimately hinges on the power and energy capacity of its battery pack. An automotive battery pack typically consists of a large number of cells (few hundreds to thousands) to meet the required energy and power needs of a BEV. The wide deployment of BEVs for maximizing the electrification of the road transportation system demands drastic improvements in the performance of today’s battery packs. Specifically, the U.S. Advanced Battery Consortium developed a set of goals for BEV battery packs, which require that the specific energy be increased beyond 235 W h/kg at the pack level (with a concomitant volumetric energy density of 500 W h/L) at power densities as high as 2,000 W/kg while reducing the cost to <$125 per kW h [5].

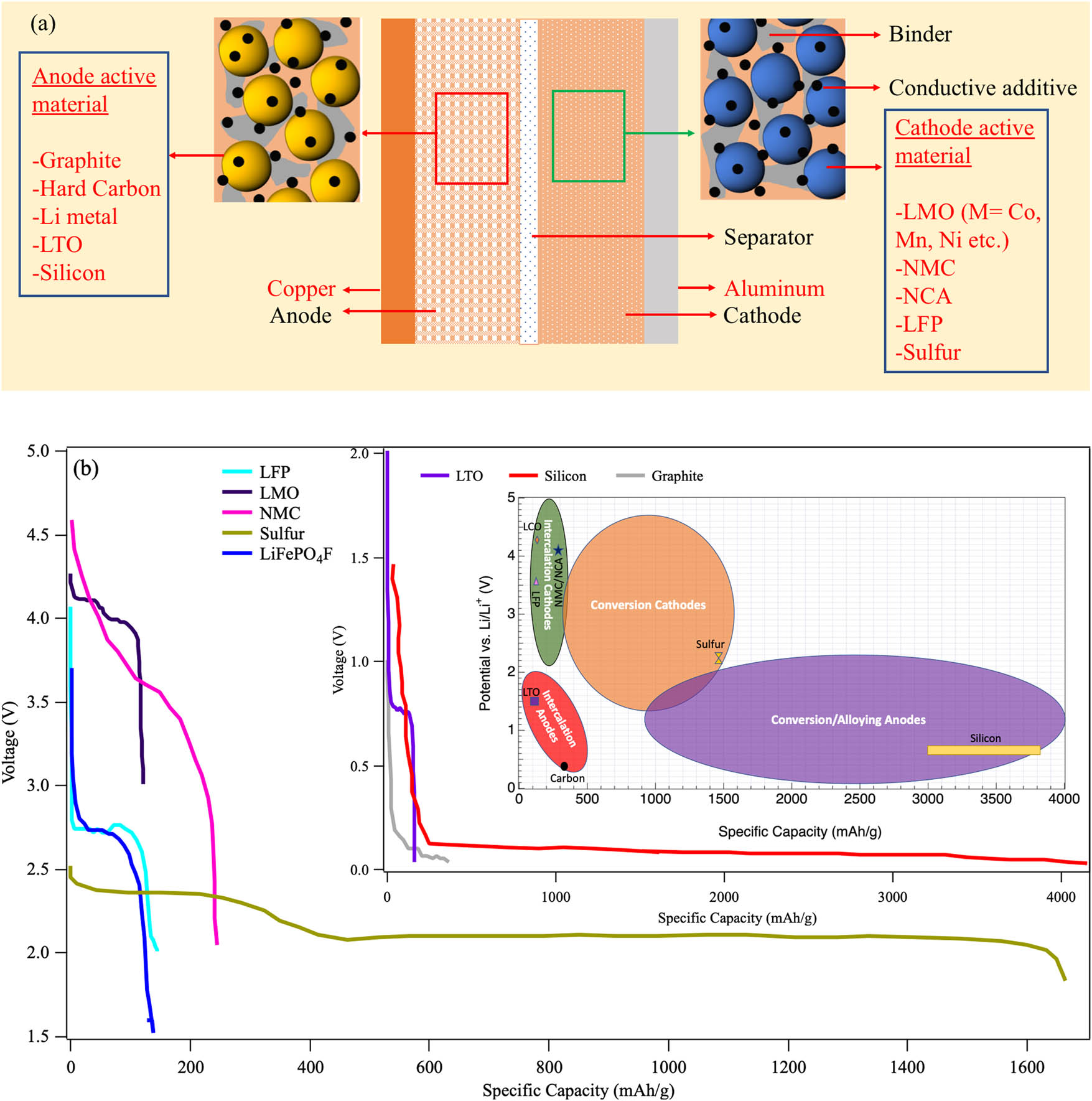

The automotive and electronic industries have embraced rechargeable lithium-ion battery (LIB; Figure 1a) as “the component” for battery packs because it provides the highest energy density of all commercially available battery chemistries [1,6,7]. Although presently used 85 kW h LIB-based packs allow up to ∼250 miles driving range on a single charge, their cost is twice the price of a standard economy car. The high cost and limited mileage of present LIB-powered cars are due to the intrinsically limited capacities of the Li-ion insertion cathodes, which are nearing their practical limits. While much progress is being made to improve LIBs, other battery chemistries such as lithium–sulfur batteries (LSBs), Al-ion, Na-ion, and K-ion are also being explored [8,9,10,11,12,13,14]. In this short review, recent progress in improving the electrochemical performance and cycle life of lithium batteries is presented.

(a) A schematic showing the components of Li-ion batteries. Novel strategies to improve LIB performance by optimizing different components of LIB (red text) will be discussed in this review. (b) Approximate behavior of theoretical discharge curves for selected cathode (inset-anode) materials. The inner inset shows the approximate ranges for average discharge potentials and specific/gravimetric capacities for intercalation and conversion/alloy type electrodes. Some widely used or promising electrode materials that are highlighted in this review are also shown (Li4Ti5O12 (LTO): Li4Ti5O12; LiFePO4 (LFP): LiFePO4; LiCoO2 (LCO): LiCoO2; nickel manganese cobalt oxide (NMC): LiNi0.33Co0.33Mn0.33O2; NCA: LiNi0.8Co0.15Al0.05O2).

Given that lithium batteries can deliver higher energy and power densities, they were the obvious choice for portable electrochemical energy storage. In the recent past, much research has been devoted to realizing LIB electrodes with higher rate capability and charge capacity. For LIB cathodes, achieving sufficiently high voltage can drastically improve their energy and power densities and make them smaller and cheaper. Figure 1b shows the general range of different intercalation and conversion/alloying-type cathodes and anodes for LIBs. This review discusses efforts to improve lithium battery electrodes at various levels via: (1) the identification of the optimal chemical composition of active materials (AMs), (2) tailoring physical properties of AMs such as size and surface, and (3) integrating AMs with binders, conductive additives, and current collectors. More importantly, this review will also discuss how different interfaces such as the solid electrolyte interface (SEI) and current collector active material interface (CCAMI) impact the LIB performance and highlight strategies to overcome adverse interfacial effects.

2 Intercalation cathodes

The LIB intercalation cathodes can be categorized into four different crystal structures, viz., layered, spinel, olivine, and tavorite [15,16]. Although many materials can be used as intercalation cathodes, much attention has been paid to transition metal oxide and polyanion compounds because of their higher operating voltages [17]. These oxide cathodes can deliver specific capacities ∼150–200 mA h/g at the cathode level. To increase the specific capacity and cycling stability, much research has been devoted to identifying the optimal chemical composition for achieving high specific capacity in intercalating AMs.

2.1 Layered intercalation cathodes

The first intercalation cathode (LiTiS2) was developed by Whittingham and Gamble in 1975 [18], but due to a lower voltage (∼2 V), these cathodes were replaced by layered intercalation metal oxide cathodes (LiMO2, M is either bulk transition metal or a mixture of different transition metals) [18]. These cathodes have high operating voltage (3.0–4.8 V) and high theoretical specific capacity (∼250–280 mA h/g). Goodenough, the 2019 Nobel Laureate in Chemistry, introduced LCO as an alternative cathode that was eventually commercialized by SONY [19]. Although it exhibited high capacity (∼275 mA h/g), the cost of Co is high. Also, at higher voltages, LCO suffers from a fast capacity fade due to the structural changes within the material [20,21,22]. Additionally, its thermal instability limits its use in EVs [17,23]. The use of other isostructural oxides has also been explored, for example, LiNiO2 (LNO) is a cheaper alternative to LCO with a comparable theoretical specific capacity. However, LNO is difficult to synthesize [24,25] and is thermally unstable [26]. Another cheaper and environmentally friendly alternative to both LCO and LNO is LiMnO2 (specific capacity ∼285 mA h/g), which too is difficult to synthesize and suffers from high capacity fading due to a change in its crystal structure from layered to spinel (LiMn2O4) with cycling [17,27,28,29,30,31,32,33]. Subsequent studies found that the presence of dopants in LiMnO2 helped reduce the thermal runaway and enhance structural stability and cycling stability at higher voltages [34,35,36,37,38]. Consequently, ternary materials such as LiNi x Co y Mn z O2 (often referred to as NCM or NMC) and LiNi0.8Co0.15Al0.05O2 (NCA) were developed, which proved attractive for commercial use. For example, NMC proved as a cheaper alternative compared to LCO as it contained a minimal amount of Co and exhibited a relatively superior thermal stability and a similar or higher specific capacity compared to LCO at the same operating voltage [39]. LiNi0.33Co0.33Mn0.33O2 (also known as NMC 111) is the common form of NMC that is widely used in today’s battery market. Beyond the NMC 111 composition, higher specific capacities were achieved in Ni-rich NMC cathode materials; however, they suffered from poor thermal stability and cycle life [40,41]. Similar to NMC, NCA is another cathode AM in which Ni is substituted with small amounts of Co and Al, and Al is known to improve the thermal stability of NCA [42]. The theoretical capacity of NCA is ∼280 mA h/g [42], and both Panasonic and Tesla have embraced NCA over LCO as the cathode material for their LIBs. Lastly, a small amount of ion doping (Cl, Mg, Na, F, etc.) has also been shown to improve the thermal stability of NCA [24,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60].

Recently, another family of Li-rich layered oxide composite has been synthesized by structurally incorporating a Li2MnO3 stabilizer into an electrochemically active LiXO2 host (X = Mn, Ni, Co). The excess lithium in such Li-rich oxide composites boosts the specific capacity of the cell up to ∼460 mA h/g (for Li2MnO3) by activating Li2MnO3 at >4.5 V [68]. Such activation releases Li2O initially and facilitates better Li diffusion by acting as a Li reservoir. LiXO2 are cost effective and environmentally friendly [69], and although they exhibit a relatively higher capacity they are considered to be electrochemically inactive (Table 1). Accordingly, much effort has been devoted to increase their electrochemical performance through ion doping (Ni, Mg, Ru, Cr, Mo etc.) [63,64,65,66,67,68,69,70,71,72,73,74,75,17].

Representative layered intercalation cathode materials along with their operating voltage, cycle capacity, and C rate

| Material | Operating voltage (V) | Initial/final capacity (mA h/g) | Cycle/C rate | Year/Ref. |

|---|---|---|---|---|

| LCO | 2.7–4.3 | 145/140 | 20/1C | 2003 [83] |

| NMC 111 | 3.0–4.3 | 150/150 | 10/0.5C | 2013 [84] |

| NCA | 3.0–4.3 | 184.5/172.3 | 110/1C | 2018 [85] |

| NMC 622 | 3.0–4.2 | 155.4/147.3 | 400/0.1C | 2017 [86] |

| NMC 811 | 3.0–4.2 | 172.5/114.7 | 400/0.1C | 2017 [86] |

| LiNi0.8(1−x)Co0.1Mn0.1Ca0.8x O2 | 2.5–4.5 | 195/130 | 100/0.2C | 2017 [64] |

| Li(Ni0.5Co0.2Mn0.3)1−x Zr x O2 | 3.0–4.6 | 190/166 | 100/1C | 2016 [54] |

| Li2MnO3 | 2.0–4.8 | 180/NA | NA | 2013 [87] |

| Li1.98Mg0.01MnO3 | 2.0–4.6 | 307.5/259.8 | 30/0.1C | 2016 [79] |

| Li1.23Fe0.15Ni0.15Mn0.46O2 | 1.5–4.5 | 255/211 | 50/NA | 2017 [78] |

2.2 Spinel intercalation cathodes

In 1983, Thackeray et al. proposed that LiMn2O4 (LMO) [88] (specific capacity ∼150 mA h/g) could be used as an intercalating cathode. LMO exhibits a cubic “spinel” structure in which Li is present at tetrahedral sites and Mn at the octahedral sites. LMO is relatively cheaper and environmentally friendly; however, its cycling stability is poor because Mn tends to dissolve in electrolytes such as LiPF6 [89,90] and LiAsF6 [89,90]. Surface coating [91,92,93,94,95,96], tuning morphology and size [97,98,99], and doping [100,101,102,103,104] have been found to increase the cycling stability of LMO. Particularly, Ni-substituted (LiMn2−x Ni x O4) and (Li x (MnNi)1−x O4) spinels have emerged as promising cathode materials (Table 2) as they exhibit excellent cycling stability even at a high potential (∼4.8–5.0 V) [105,106,107].

Representative spinel intercalation cathode materials along with their operating voltage, cycle capacity, and C rate

| Material/condition | Operating voltage (V) | Initial/final capacity (mA h/g) | Cycle/C rate | Year/Ref. |

|---|---|---|---|---|

| LiMn2O4/pure | 3.0–4.5 | 96.00/85.15 | 100/1C | 2019 [97] |

| LiMn2O4/LaF3 coated | 0–1.1 | 109.5/107.9 | 100/10C | 2016 [108] |

| LiMn2O4 nanorods/Li4Ti5O12 coated | 3.2–4.2 | 98.4/80.9 | 500/1C | 2019 [98] |

| LiMn2O4/mesoporous | 3.0–4.5 | 100.51/96.42 | 100/1C | 2019 [97] |

| LiMn2O4/Al doped | 3.2–4.2 | 100.7/94.6 | 400/0.5C | 2020 [104] |

| LiMn1.5Ni0.5O4 | 3.5–5.0 | 111.4/102.3 | 50/5C | 2010 [106] |

| Li1.2Mn0.6Ni0.2O2 | 2.0–4.8 | >200/200 | 50/NA | 2016 [107] |

2.3 Olivine intercalation cathodes

Olivine phosphates (LiMPO4) [109] and olivine silicates (Li2MSiO4) [110], where M = Fe, Mn, Mg, and Co, have also been evaluated as cathode materials [42,111]. Unlike the layered LCO and LNO cathodes, olivine electrodes are significantly more stable and exhibit better power capability [17]. Although LFP has been used in commercial LIBs, it exhibits a relatively low open circuit potential (3.5 V) and low electrical/ionic conductivity [111]. As such, surface coatings and dopants have been used to increase the conductivity of the LFP [112,113,114,115]. Notably, as discussed later in Section 2.6, a new approach involving Al current collector with vertically aligned carbon nanotubes (VACNTs) could resolve the CCAMI issue and improve conductivity across the interface between LFP and the Al current collector [116]. Other olivine-like materials such as LiNiPO4, LiMnPO4, LiMgPO4, and LiCoPO4 also have a higher potential (4.1–4.8 V) but they exhibit a high intrinsic resistance which results in lower electrochemical activity and capacity [117,118,119]. Similar CCAMI approaches as in the case of LFP were used to improve the electrochemical activity and capacity [117,120,121]. Olivine silicates are more thermally stable than phosphates as all four oxygen atoms of tetrahedron SiO4 contribute to connect the structural framework, whereas in phosphate only three oxygen atoms contribute [122]. Also, the theoretical capacity of silicates is almost double (∼330 mA h/g) that of LFP [123,124,125]; however, the practical cycling performance of these silicates is not comparable to that of LFP because of its structural instability/phase change during charging [126,127,128]. Excess lithium was found to improve structural stability [129], specifically Li x MSiO4 (where x = 2), which was modified using approaches similar to those used for LFP to increase the overall electrochemical performance (Table 3) [122,130,131,132].

Representative olivine intercalation cathode materials along with their operating voltage, cycle capacity, and C rate

| Material/condition | Operating voltage (V) | Initial/final capacity (mA h/g) | Cycle/C rate | Year/Ref. |

|---|---|---|---|---|

| LiFePO4 | 2.0–4.0 | 117/113 | 50/0.1C | 2019 [115] |

| LiFePO4/GdPO4 and C coating | 2.0–4.0 | 158/157 | 50/0.1C | 2019 [115] |

| LiFePO4/Ti doped | 2.3–4.2 | 155/150 | 500/1C | 2020 [112] |

| LiMnPO4/C | 2.5–4.5 | 105/100 | 50/0.05C | 2017 [120] |

| LiMn0.99Y0.01PO4/C | 2.5–4.5 | 153.6/148.1 | 50/0.05C | 2017 [120] |

| Li2FeSiO4/C | 1.5/4.5 | 134/155 | 190/0.2C | 2010 [129] |

| Li2MnSiO4/C | 1.5–4.8 | 280/120 | 16/NA | 2020 [130] |

2.4 Tavorite intercalation cathodes

Considering their exceptional thermal stability and ionic conductivity, tavorite intercalation cathodes (LiMPO4F) are a suitable replacement for olivine cathodes. Tavorite cathodes allow 3D ion transport unlike 1D transport in olivine cathodes [12,133]. Materials with an open structure, such as LiFeSO4F/LiVPO4F/LiVPO4O (specific capacity ∼150 mA h/g) have been considered as promising cathodes as they exhibit an open circuit potential (>4 V) in addition to a stable structure that supports fast Li-ion diffusion (Table 4) [52,133–137]. Although the stability is better, the synthesis of these materials in their pure form remains challenging [135,138].

Representative tavorite intercalation cathode materials along with their operating voltage, cycle capacity, and C rate

| Material/condition | Operating voltage (V) | Initial/final capacity (mA h/g) | Cycle/C rate | Year/Ref. |

|---|---|---|---|---|

| LiFePO4F | 1.5–4.0 | 110.2/91.5 | 300/0.5C | 2018 [138] |

| LiFePO4F/Ag decorated | 1.5–4.0 | 120.3/115.5 | 300/0.5C | 2018 [138] |

| LiFePO4F nanospheres | 1.5–4.0 | 110/104 | 200/0.5C | 2018 [12] |

| LiVPO4F/C | 2.5–4.6 | 126.6/116.7 | 125/1C | 2018 [139] |

| Li0.99K0.01VPO4F/C | 2.5–4.6 | 131.9/126.8 | 125/1C | 2018 [139] |

2.5 Nanostructured intercalating AMs for cathodes

The recent progress in lithium batteries has largely benefited from the development of nanostructured electrodes in comparison to conventional electrodes because of their unique morphology, significantly enhanced kinetics, and large surface area (Table 5) [3,6,17,140–151]. Nanostructured electrodes shorten the diffusion length and facilitate a higher contact area between the electrolyte and AMs leading to more exposed redox sites, which deliver higher power and energy densities [144,152–154]. Fick’s correlation between the diffusion length L and its diffusion coefficient D can be expressed as τ = L 2/D [144], where τ is the diffusion time.

Representative performance of nanostructured AMs

| Material | Operating voltage (V) | Initial/final capacity (mA h/g) | Cycle/C rate | Particle size or morphology | Year/Ref. |

|---|---|---|---|---|---|

| LiFePO4 | 2.5–4.0 | 163/163 | 1/1C | 30 nm | 2006 [194] |

| LiFePO4 | 2.8–4.2 | 130/130 | 1/1C | 150 nm | 2006 [195] |

| LiFePO4 | 2.0–4.5 | 115/115 | 1/1C | 500 nm | 2003 [196] |

| LiFePO4 | 2.1–4.5 | 82/82 | 1/1C | 800 nm | 2006 [197] |

| Li1.2Mn0.54Ni0.13Co0.13O2 | 2.0–4.8 | 153.9/136.7 | 300/3C | Nanotubes | 2016 [177] |

| LiMnPO4/C | 2.5–4.5 | 123/120 | 100/1C | Nanorods | 2018 [163] |

| Li1.2Mn0.54Ni0.13Co0.13O2 | 2.0–4.8 | 138/121 | 100/10C | Nanowires | 2019 [171] |

| LiCoPO4 | 2.5–4.8 | 180/147 | 300/0.1C | Nanoplates | 2016 [179] |

| LiNi0.5Mn1.5O4 | 3.5–4.8 | 136/126 | 100/1C | Nanosheets | 2019 [183] |

| Li1.2Mn0.6Ni0.2O2 | 2.0–4.8 | 197.3/174.6 | 200/1C | 3D micro/nano | 2019 [185] |

| Li1.16Mn0.6Ni0.12Co0.12O2 | 2.0–4.8 | 227/213 | 50/5C | 3D micro/nano | 2017 [187] |

Based on the Li-ion diffusion coefficient D = 2.5 × 10−12 cm2/s, a complete discharge occurs within ∼40 s when the particle size is L = 100 nm while it takes ∼1 h for L = 2 µm. Many physicochemical characteristics such as crystallinity, phase purity, particle morphology, grain size, and surface area depend largely on the AM synthesis methods. Thus, different fabrication methods such as grinding, ball milling, and sol–gel method have been used to synthesize nanostructured intercalating AMs. A detailed review on the synthesis methods can be found in ref. [155].

Okubo et al. [156] demonstrated excellent high-rate capability for nanosized LCO (average particle size ∼17 nm), that is, 65% of the 1C-rate capability retention. However, they also found that extreme reductions in the crystallite size below 15 nm drastically decreased the overall capacity plausibly due to defects. In the case of LFP, the capacity increased linearly with decreasing particle size [152]. In the case of LMO, though the initial capacity was higher, increased capacity fading was observed due to the dissolution of Mn into electrolyte via disproportionation reaction on the larger surface area nanostructured LMO [157–160]. Although nanostructuring can reduce Li+ diffusion length ensuring an improved rate capability, it increases the oxidation of nanoparticles (NPs) leading to a thicker SEI layer on the surface of the electrode and results in capacity fading [153,154]. As discussed in the previous section, both size and structure of AM play a critical role in improving the electrode performance. Recent efforts have focused on 1D morphologies such as nanorods [161–167], nanowires [168–174], and nanotubes [175–178] as they can effectively accommodate volume changes during lithiation/delithiation in addition to promoting diffusion and structural stability [152,174].

Two-dimensional cathode materials with high specific areas are of interest because they provide open 2D channels for Li-ion transport and show better stability than that of the 0D and 1D particles. Although most of the research on 2D electrodes has focused on anode materials, a few reports focused on LMPO4 [117,179–183] 2D cathodes, mostly plausibly due to the unavailability of simple and cost-effective ways of synthesizing 2D cathode materials [181]. Zhao et al. [183] prepared flower-like LiNi0.5Mn1.5O4 nanosheets, which delivered a capacity of 142 mA h/g at 1-C-rate after 100 cycles at 55°C. The LMO microsheets synthesized using a simple carbon gel-combustion synthesis method delivered 91 mA h/g after 300 cycles at 10C [184]. Many challenges such as high preparation cost, low packing density, and inevitable particle aggregation have hampered the use of nanomaterials. Novel 3D hierarchical micro/nanoarchitectures have also been used to improve cell performance [184–193]. Such structures are micron-scale assemblies comprising nanoscale building blocks that enable better electrochemical performance and structural stability [185]. A detailed review of such architectures could be found elsewhere [152].

2.6 Integrating AMs with conductive additives

Most AMs used in LIB electrodes (both anodes and cathodes) are poor electrical conductors and are often mixed with conductive additives (e.g., conductive carbon black often referred to as Super P) [142,198]. In a typical LIB cathode (/anode) manufacturing line, the Al (/Cu) current collector is coated with a slurry containing AM and conductive additives and a binder such as polyvinylidene fluoride or PVDF in N-methyl-2-pyrrolidone (NMP) [199]. Although carbon black (e.g., Super P) is widely used as a conductive additive, other carbon nanomaterials such as graphene, CNTs, and reduced graphene oxide (rGO) have shown great promise in improving the specific capacity (Table 6) [200–216]. When carbon-based additives are used, one should be aware of the fact that such additives could reduce the tap density and affect Li-ion transport. Thus, the use of the minimum amount of additives is suggested [217,218].

Representative electrochemical performance of intercalating AM cathodes made by integrating conductive additives

| Material | Conductive carbon additive | Operating voltage (V) | Initial/final capacity (mA h/g) | Cycle/C rate | Year/Ref. |

|---|---|---|---|---|---|

| LiFePO4 | Carbon | 2.5–4.2 | 144/138 | 100/0.5C | 2017 [207] |

| LiFePO4 | N-carbon and rGO | 2.0–4.2 | 116/112 | 700/10C | 2017 [219] |

| LiFePO4 | 3D graphene | 2.4–4.2 | 141.1/139.8 | 600/10C | 2018 [220] |

| NCA | Carbon nanotubes | 2.8–4.5 | 187/181 | 60/0.25C | 2017 [200] |

| Li2MnO3 | rGO | 2.0–4.6 | 290/250 | 45/0.1C | 2017 [221] |

| LiMn2O4 | Carbon and carbon nanofibers | 3.0–4.3 | 120/92 | 1,000/1C | 2020 [222] |

| NMC | Graphene | 2.7–4.2 | 140/103 | 500/1C | 2017 [223] |

| LiMn0.8Fe0.2PO4 | Carbon/N-rGO | 2.0–4.6 | 156.9/145.5 | 100/0.2C | 2019 [224] |

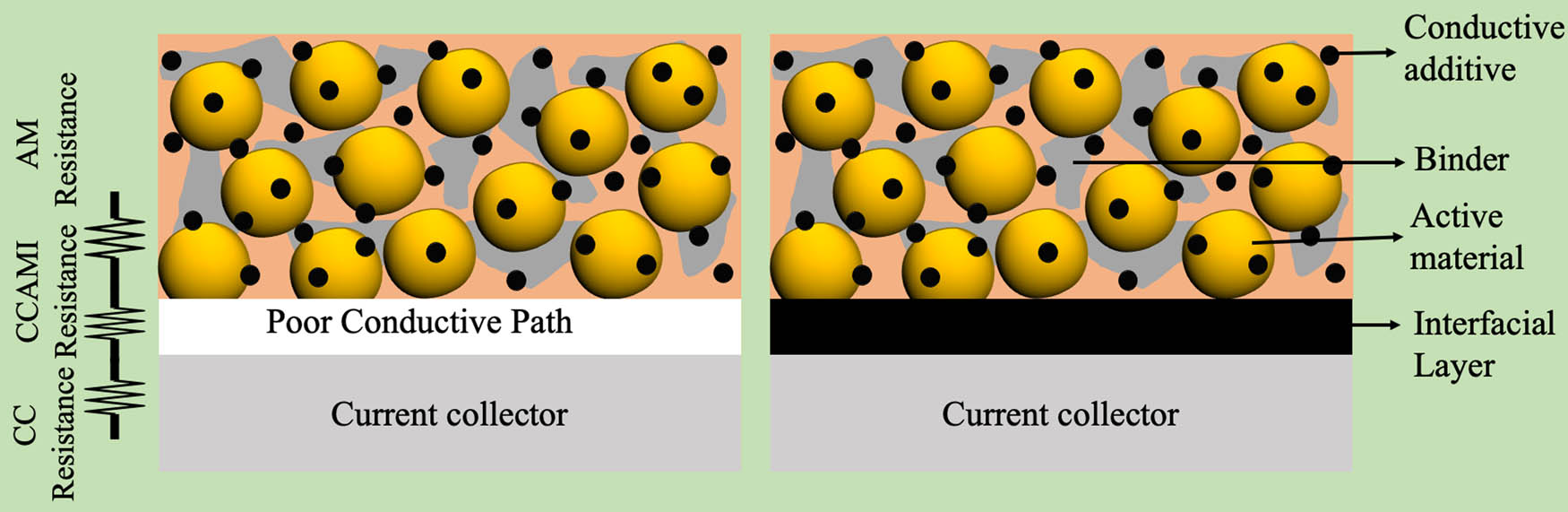

2.7 Modifying/replacing traditional Al current collectors for cathodes

Although Al foils are widely used as the cathode current collector, there are several drawbacks such as localized corrosion due to electrolyte, weak adhesion to AMs, and limited contact area [225,226], which adversely affect the electrochemical performance of cells. To improve AM adhesion to Al-foils, the surface is often treated chemically or modified [227–231]. As shown in Figure 2, the total internal resistance of LIBs arises due to the existence of the interfaces between AM, binder, conductive additives, and the current collector. An increase in the internal resistance could decrease the overall electrochemical activity [232]. As described in Sections 2.1–2.5, the present LIB literature is replete with different procedures for improving the interfaces within the active materials using nano/micro-structuring or adding novel conductive additives such as carbon black, graphene, and rGO [2,233]. While conductive carbon additives decrease the resistance of interfaces within the cathode/anode active material, they are ineffective in decreasing the current collector active material interface or CCAMI resistance (see Figure 2) – a key driving factor for increasing energy and power densities that has largely been ignored in LIBs [234].

Various resistances in a cathode/anode electrode (left – traditional electrode, right – CCAMI engineered electrode). An interfacial layer of carbon, CNTs, and VACNTs enables better electrical contact between the AM and the current collector (CC), which improves the electrochemical performance of the electrode.

Ventrapragada et al. [116] extensively investigated the role of CCAMI resistance by using VACNTs, either directly grown or spray coated on Al foils. The CCAMI resistance of traditional LFP and NMC electrodes coated on Al/VACNT current collector was reduced by a factor of 3 in comparison to bare Al foil. Moreover, the capillary channels provided by the VACNTs grown on the Al foil promotes the wettability of aqueous slurry due to an increase in surface roughness, thus alleviating the need for toxic organic solvents (e.g., NMP) to prepare the AM slurry. CNT-coated electrodes displayed energy densities as high as follows: ∼500 W h/kg at 170 W/kg for LFP and ∼760 W h/kg at ∼570 W/kg for NMC. The CCAMI engineered LIBs exhibited an initial capacity of ∼103 mA h/g with a capacity retention of ∼80% at 4C after 500 cycles, unlike the commercial electrodes that could not withstand such a high C-rate. By using the carbon black and graphene-modified Al-foil (CG-Al) for the LFP electrode, Wang et al. [228] also demonstrated superior performance over the bare Al-foil (B–Al). The capacity retention at 1C-rate after 500 cycles of CG–Al–LFP battery was ∼94% with initial capacity ∼154 mA h/g, whereas, for B-Al-LFP, the capacity retention was ∼90% with initial capacity ∼120 mA h/g. Interestingly, Loghavi et al. treated the Al surface with a combination of three acids and observed an increase in capacity over the untreated Al foil [229].

There has been a growing interest in displacing relatively heavy metallic current collectors in LIBs with lightweight, low cost, and highly conductive materials that can satisfy the robustness as well as high utility requirement of LIBs (Table 7) [226]. Lightweight and flexible carbon-based current collectors have been researched because of their wide electrochemical window. Using graphene foil as a current collector for NMC523 cathode, Xu et al. [226] reported a ∼45% increase in gravimetric capacity at the electrode level compared to bare Al foil current collector at 0.5C after 200 cycles. The energy density of graphene foil was ∼350 W h/kg after 200 cycles at 0.5C higher than the bare Al foil that showed ∼240 W h/kg. The use of carbon paper [235], carbon fiber [236], and carbon cloth [237] in place of the Al foil have resulted in higher gravimetric and higher energy density. Another alternative for Al-based cathodes is paper/cellulose-based current collectors. Low cost of raw materials, ease of availability, and biodegradability of cellulose-based current collectors have attracted much attention. However, unlike Al foil, these current collectors are not highly conducting. In this regard, many researchers have endeavored to make cellulose fiber-based conducting composites or coat papers with different conducting materials (e.g., activated carbon) using additives, which affects the gravimetric capacity as the amount of inactive material is increased [238–245]. Ventrapragada et al. [246] prepared additive-free paper-CNT current collectors by spray coating CNTs on cellulose paper. Cells assembled using this current collector with LFP coating showed a high energy density of 460 W h/kg at a power density of 250 W/kg. These batteries were able to withstand a high current rate (4C) and showed cycling stability up to 450 cycles at 1C-rate. Wang et al. [237] developed a carbon cloth-based Li1.2Mn0.6Ni0.2O2 electrode, which performed better than commercial Al-foil at a high C-rate (5C).

Representative electrochemical performance of cathodes depending on current collector

| Material | Current collector | Operating voltage (V) | Initial/final capacity (mA h/g) | Cycle/C rate | Year/Ref. |

|---|---|---|---|---|---|

| LiMnO4 | Bare Al | 3.0–4.4 | 101/76 | 360/0.5C | 2017 [231] |

| LiMn2O4 | Graphene/Al | 3.0–4.4 | 100/91 | 360/0.5C | 2017 [231] |

| LFP | CNT/Al | 2.0–4.2 | 103/79 | 500/4C | 2018 [116] |

| NCA | Acid treated Al | 2.8–4.2 | 187/170 | 80/0.5C | 2019 [229] |

| NMC523 | Graphene foil | 2.8–4.5 | 112.4/42.0 | 200/5C | 2020 [226] |

| Li1.2Mn0.6Ni0.2O2 | Carbon cloth | 2.0–4.8 | 78/78 | 100/5C | 2017 [237] |

| LFP | CNT/printing paper | 2.0–4.2 | 135/90 | 450/1C | 2019 [246] |

3 Conversion-type cathodes

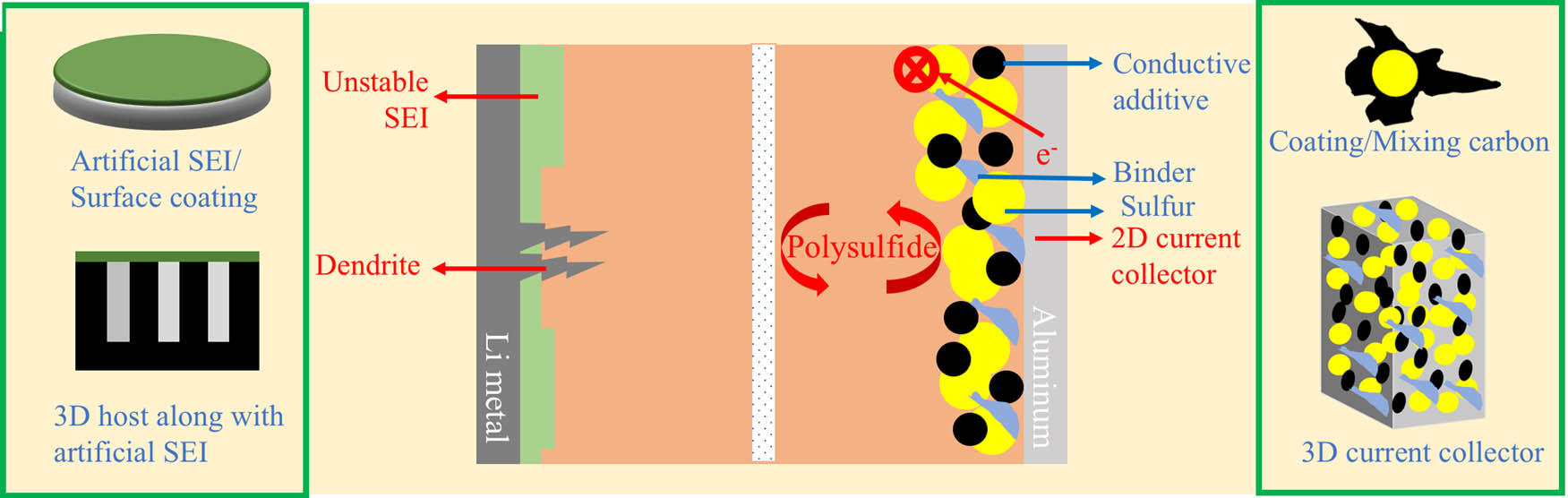

Since SONY’s launch of the first commercial LIBs in 1991, researchers have endeavored to improve the performance of LIBs [6,247–250]. As the gravimetric energy densities of the state-of-the-art LIBs based on intercalating AMs (such as LFP [251], NCA [252], and NMC [86]) reached their practical limits, alternative conversion-type AMs have attracted much attention. Among all the existing conversion-type AMs, sulfur is one of the most promising candidates for the next-generation portable electronic devices owing to its high theoretical gravimetric capacity (1,675 mA h/g) and gravimetric energy density of 2,500 W h/kg (practical energy densities of 400–600 W h/kg at the cell level for lithium-sulfur batteries, or LSBs) in addition to low cost and abundance of sulfur [253]. However, there are many challenges impeding the practical applications of LSBs such as the following: (1) insulating nature of sulfur (S8) and its discharge product (Li2S), (2) polysulfide intermediates resulting in a loss of active material, (3) dendrite formation and unstable SEI leading to the consumption of electrolyte and lithium, (4) low areal capacity of the LSBs due to low sulfur-loadings; and (5) usage of binder, carbon additives and heavy current collector leading to low gravimetric capacity. To overcome these challenges, many efforts have been made as evident from the number of published review articles. From Google scholar search of keyword “lithium-sulfur review” and adjusting the timeline to “since 2019,” we were able to find at least 20 review articles on LSBs, which address challenges presented earlier individually or collectively [254–274].

Although sulfur has a high theoretical capacity, its low electric conductivity ∼5 × 10−30 S/cm (at 25°C) leads to its low utilization as an AM. In the past two decades, carbon-based conductive frameworks have been used for increasing the electrical conductivity of elemental sulfur-based cathodes. These hosts include materials such as carbon black [275–277] carbon fibers [278,279], carbon/graphene sheets [280–282], carbon nanotubes [281,283,284], and hollow porous carbon materials [285–289] The highly soluble polysulfide intermediates (LiS x , 4 ≤ x ≤ 8) generated during the reversible redox reaction between sulfur and its discharge product Li2S (the so-called shuttle effect) lead to the continuous loss of the cathode AMs and degradation of the Li metal anode (Figure 3). Consequently, such elemental sulfur-based cathodes exhibit poor cycling stability and low Coulombic efficiency. These challenges have been addressed in two ways: (i) designing better carbon frameworks and (ii) replacing elemental sulfur with a sulfur-based polymer. Indeed, different carbon framework designs aimed toward suppressing the diffusion of polysulfide intermediates have been developed. Such designs include 1D permeable hollow porous carbon shell cathode [290–296] and 2D conductive polymers or reduced graphene oxide nanosheets wrapped cathode [281,297–301]. Although physically confining sulfur could effectively reduce the outward diffusion of the polysulfides, the weak interaction between the nonpolar carbon and polar polysulfides prohibits the complete immobilization of polysulfides. Zhong et al. [275] prepared the popcorn-inspired macrocelluar carbon interconnected porous network that exhibited high electrical conductivity and was capable of blocking the polysulfide formation. N-doped carbon nanoflakes/carbon nanotubes can also decrease the polysulfide formation by decreasing the active sites for Li2S decomposition [297,302,303]. Also, metal-organic frameworks in combination with carbon can increase the electrical conductivity and enable polysulfide immobilization [292,302,304–308].

A schematic of a typical LSB battery is shown in middle. The red text corresponds to the challenges that are commonly reported in LSBs. The common solutions are shown in green boxes.

Alternatively, polysulfide formation can be eliminated by using sulfurized polymers. Polyacrylonitrile (PAN) has been widely used as a carbon precursor for synthesizing porous carbon materials mainly due to its ease of dehydrogenation and cyclization into conjugated carbon backbones. The one-pot reaction of PAN with elemental sulfur provides a facile approach for the preparation of sulfurized PAN or SPAN. SPAN is a conductive sulfur-containing compound in which S atoms are covalently bonded to the polymer carbon matrix through a pyrolytic process. During sulfurization, sulfur acts as a mild oxidant to dehydrogenate PAN [309]. The structure and S content in SPAN depend on the pyrolysis temperature and duration. Based on extensive spectroscopic and theoretical studies, a few possible structures have been proposed as shown in Figure 4 [309]. Clearly, all possible SPAN structures do not exhibit the octagonal S8 structure. Indeed, based on thermogravimetric analysis-mass spectrometry data, Zhang [309] proposed that Figure 4a is the most likely structure for SPAN obtained through pyrolysis at relatively lower temperatures (<600°C). In such structures, the lithiation of SPAN is expected to occur without the formation of any higher-order polysulfides, as shown in Figure 4d.

![Figure 4

(a–c) Proposed chemical structures for SPAN based on pyrolysis temperature and duration [310]. (d) Lithiation of SPAN with the chemical structure shown in (a) does not result in the formation of higher-order polysulfides.](/document/doi/10.1515/ntrev-2021-0114/asset/graphic/j_ntrev-2021-0114_fig_004.jpg)

(a–c) Proposed chemical structures for SPAN based on pyrolysis temperature and duration [310]. (d) Lithiation of SPAN with the chemical structure shown in (a) does not result in the formation of higher-order polysulfides.

SPAN-based LSBs were first reported by Wang et al. [310], which was followed by He et al. [311,312] Beyond the one-pot reaction, Lai et al. [313] synthesized SPAN using a two-step technique by first pyrolyzing PAN and then reacting it with elemental sulfur. Their Li/SPAN cell with a 1 M LiPF6 electrolyte showed a single discharge voltage plateau and a stable capacity of 770 mA h/g for 110 cycles at 40 mA/g. Similarly, Guo et al. [314] first pyrolyzed PAN into disordered amorphous carbon nanotubes and subsequently reacted them with sulfur at 500°C for 3 h. Their resulting SPAN tubes contained 40 wt% sulfur and were thermally stable up to 700°C suggesting that sulfur was covalently bonded to carbon as shown in Figure 4a–c. Moreover, their Li/SPAN cell showed stable capacities of nearly 700 mA h/g for 100 cycles at 10 mA/g. Ahn et al. and Ming et al. [315,316] also reported that the polysulfide intermediates could be eliminated by using SPAN as the cathode material. Although SPAN provides a stable conversion-type sulfur cathode, its use is limited by its poor ionic and electronic conductivities, which can be improved using carbon-based additives [317–322].

To increase the cycling stability with Li metal anode in LSBs, an electrolyte that is capable of forming a stable SEI layer is needed. The SEI layer forms on the electrode from the decomposition of electrolytes and solutes. A stable SEI layer passivates the electrode and mitigates dendrite formation, which could short-circuit the battery. Fan et al. [323] developed novel mixed electrolytes for LSB that enable the simultaneous formation of SEIs on both electrodes. Their SPAN-based LSBs with mixed electrolytes showed a high utilization of sulfur (over 80% at 0.15C), superior rate performance, excellent coulombic efficiency (≈100%), and long cycling life (1,000 cycles at 1C and 2,400 cycles at 7.5 C with capacity retention of 86.6 and 82.3%, respectively). Indeed, they were able to achieve high mass loadings and capacities as high as ∼1,250 mA h/g at 0.75 C with no capacity fade up to 200 cycles. Liu et al. developed a gel polymer electrolyte, which showed stable performance even at high temperatures (55°C) compared to traditional liquid electrolytes [324]. A recently published mini-review about electrolyte regulation in lithium metal–SPAN battery can be found in ref. [325].

According to statistical analysis in ref. [253], 57% of >100 publications (in 2015–2016) reported areal sulfur loadings below 2 mg/cm and 49% corresponding areal capacities below 2 mA h/cm. Such electrodes are reasonable to use in reaction mechanism studies but unsuitable for practical application despite their high specific capacities (normalized by the amount of sulfur) because they deliver much lower gravimetric energy densities than commercial lithium-ion batteries [326]. An areal capacity of at least 6 mA h/cm is needed for LSBs to displace commercial LIBs because of the low operating voltage of LSBs (∼2.1 V) [253]. Although there have been advances in the LSBs research, the commercialization is still lagging. This could be due to the fact that there is a vast difference on how research is conducted in academia and industry [327]. For example, usually coin cell is used in academia whereas pouch cell is generally used in industry. The advanced structures of the C/S that are used in academia are hard to produce in larger quantities [327]. Recently published article from Bhargav et al. have outlined some critical metrics, viz., “Five 5s” (S-loading >5 mg/cm2, C-content <5%, E/S ratio <5 µL/mg, N/P ratio <5, E/C ratio <5 µL/(mA h)) to achieve high energy density, which could be helpful to translate to industry [328]. Although “Five 5s” seems attractive, there are several issues that need to be addressed first. While increasing the loading might increase the energy density, it will adversely increase the electrochemical polarization, decrease the utilization and increase thermal instability [327,329,330].

Lastly, most studies report the gravimetric capacities of cathodes calculated based on the mass of sulfur. Unfortunately, although the sulfur content of some reported cathode materials can reach up to 70 wt%, the use of polymer binder (usually 10% of the slurry) and carbon black (usually ∼10–20% of the slurry) in the slurry coating procedure (especially coating on the widely used aluminum foil current collector) results in a low-rate capacity on the electrode level in addition to a low gravimetric energy density [253]. High sulfur loading cathodes with high sulfur utilization and lightweight current collectors are essential for realizing high-energy-density LSBs. Recently, more efforts have been focused on self-supporting cathode electrodes [331–337]. Manthiram et al. [338] developed graphene-wrapped double-shelled hollow carbon sphere cathode with sulfur loading of 3.9 mg/cm2, which exhibited a stable areal capacity of ∼2 mA h/cm2 at a current density of 3.3 mA/cm2. Zheng et al. [339] fabricated a two-dimensional carbon yolk-shell nanosheets cathode with sulfur loading of 10 mg/cm2 that delivered an areal capacity of ∼11.4 mA h/cm2 after 50 cycles at a current density of 1.68 mA/cm2. Lou et al. [300] designed a freestanding pie-like cathode by sulfurizing the electrospun PAN/polystyrene paper and wrapping the carbon–sulfur composite film with a thin layer of functionalized rGO. The pie-like cathode with a sulfur loading of 10.8 mg/cm2 showed an areal capacity of ∼10.7 mA h/cm2 at a current density of 1.2 mA/cm2. Liu et al. [335] developed a continuous core-shell structure of boron-doped carbon–sulfur aerogel (S-loading ∼13.5 mg/cm2) and achieved an areal capacity of 12.3 mA h/cm2. Zhang et al. [332] showed dense monolithic metal-organic framework (MOF) and CNT can be used for sulfur electrode, which exhibited high areal (10.7 mA h/cm2) and volumetric (676 mA h/mL) capacity. Sulfur can be infiltrated inside the VACNTs to get high areal capacity LSBs [331,340]. In this regard, we fabricated LSB cathodes by vacuum filtrating aqueous SPAN slurry through chemical vapor deposition grown freestanding graphene foam. More importantly, porous 3D graphene foams allowed S loadings as high as ∼26 mg/cm2 without any delamination or increased electrical resistance unlike Al foils that could only support a maximum S loading of 0.2–0.4 mg/cm2 (Al–SPAN) without the binders (Figure 5). The graphene foam–SPAN (GF–SPAN) cathodes outperformed conventional Al–SPAN cathodes at the electrode level with areal capacity ∼20 mA h/cm2 at the current density of 3 mA/cm2 (Table 8) [341].

![Figure 5

Top panel: A schematic showing the fabrication steps of a GF/SPAN cathode: GF is grown on a 3D-Ni mesh using the chemical vapor deposition technique. The GF/SPAN cathode electrode was prepared by vacuum filtrating a slurry of SPAN, carboxymethyl cellulose, and carbon black (mass ratio of 70:15:15) onto the GF current collector (with Ni mesh). The as-prepared cathode electrode was air-dried overnight followed by drying in an oven ∼130°C for 12 h. Next, 5 wt% poly(methyl methacrylate) thin layer was coated on the cathode before it was submerged in a 6 M HCl solution for 6 h at 70°C to completely remove the nickel. The resulted cathode electrode was cleaned in KOH solution and washed in DI H2O and dried [341]. Bottom panel: Weight comparison of different components inside the electrode for same S-loadings [341].](/document/doi/10.1515/ntrev-2021-0114/asset/graphic/j_ntrev-2021-0114_fig_005.jpg)

Top panel: A schematic showing the fabrication steps of a GF/SPAN cathode: GF is grown on a 3D-Ni mesh using the chemical vapor deposition technique. The GF/SPAN cathode electrode was prepared by vacuum filtrating a slurry of SPAN, carboxymethyl cellulose, and carbon black (mass ratio of 70:15:15) onto the GF current collector (with Ni mesh). The as-prepared cathode electrode was air-dried overnight followed by drying in an oven ∼130°C for 12 h. Next, 5 wt% poly(methyl methacrylate) thin layer was coated on the cathode before it was submerged in a 6 M HCl solution for 6 h at 70°C to completely remove the nickel. The resulted cathode electrode was cleaned in KOH solution and washed in DI H2O and dried [341]. Bottom panel: Weight comparison of different components inside the electrode for same S-loadings [341].

Representative electrochemical performance of sulfur cathodes

| Material | Operating voltage (V) | Initial/final capacity (mA h/g) | Cycle/C rate | Year/Ref. |

|---|---|---|---|---|

| Puffed rice derived carbon/Ni/S | 1.7–2.8 | 1,257/821 | 500/0.2C | 2018 [275] |

| Macro porous carbon nanotubes/S | 1.5–2.8 | 1,544/901 | 100/0.5C | 2018 [283] |

| Porous carbon fibers/vanadium nitride/S | 1.7–2.8 | 1310.8/1052.5 | 250/0.1C | 2018 [278] |

| N, O, and P-doped carbon/S | 1.7–3.0 | 921/489 | 300/0.2C | 2019 [287] |

| rGO–carbon composite–S paper | 1.8–2.6 | 997/670 | 400/0.2C | 2019 [298] |

| S/superP@SPAN | 1.0–3.0 | 1,500/1,251 | 100/0.1C | 2019 [322] |

| Porous SPAN fiber | 1.0–3.0 | 903/903 | 150/1C | 2019 [320] |

| Carbon–cotton/S | 1.5–3.0 | 1,173/788 | 100/0.1C | 2016 [301] |

| SPAN–carbon fiber current collector | 1.0–3.5 | 1,640/1,250 | 100/NA | 2017 [319] |

| Boron-doped carbon/S aerogel | 1.8–3.0 | 1,120/836 | 500/1C | 2019 [335] |

| Functionalized super aligned CNT/S | 1.6–2.8 | 1,079/741 | 400/1C | 2019 [334] |

| Dense monolithic MOF and CNT/S | 1.5–3.0 | 580/470 | 300/1C | 2019 [332] |

| Sulfur sandwiched between CeO2–CNT@C membrane | 1.7–2.8 | 1,300/847 | 100/0.2C | 2020 [342] |

| S@LiAlO2 on aluminum foil | 1.8–2.6 | 989/842 | 100/0.2C | 2020 [343] |

| Sulfur infused porous carbon | 1.7–2.8 | 1,143/950 | 200/0.2C | 2020 [336] |

| Graphene foam–SPAN | 1.0–3.0 | 800/728 | 500/1C | 2021 [341] |

4 Anodes

4.1 Li metal

Li metal is the ideal anode for LIBs due to its low density (0.59 g/cm3) and negative electrochemical potential (−3.04 V) and high theoretical gravimetric capacity (3,860 mA h/g) [344,345]. Li-metal anodes are prone to dendrite formation, which can cause short circuits, thermal runaway reactions on the cathode, and could also cause the battery to catch fire. Indeed, in 1976, Exxon tried to commercialize Li metal batteries (anode Li metal, cathode TiS2); however, the task was unsuccessful due to safety concerns that resulted from short circuiting [6,346]. Furthermore, Li-metal anodes also suffer from poor cycle life due to volume changes and subsequent formation of unstable SEI during cycling [345,347–353]. In the past 7 years, many research groups have been trying to revive the Li metal as a stable anode using different strategies such as optimization of solid/liquid electrolytes and additives [354–359], protective surface coatings (/artificial SEI layer) [353,360–363], modified separator [364,365], and the design of 3D conductive Li host [351,366–373]. Although such strategies improve the lifespan of the Li-metal anode, commercial applications of such batteries are still far away as they still have many disadvantages. Although surface coatings and solid electrolyte combination can increase the ionic concentration, it inevitably increases internal interfacial impedance that adversely affects the cycling stability [358,362,374]. Nanostructures such as MOFs [375], carbon materials [376,377], and 3D current collectors [375,378,379], which have pre-stored lithium, along with artificial SEI layer are promising alternatives [375]. This kind of structure can simultaneously address the volume change and unstable SEI formation. In this review, anodes beyond Li are discussed. A detailed review focused on Li-metal batteries can be found in refs [345,358]. Lastly, it should be noted that lithium-air batteries (specific energy ∼5,200 W h/kg) wherein air is used as a cathode, have also been researched extensively in an effort to enhance the specific energy of the battery [380,381]. However, the practical application of such batteries is still far fetched due to the side reaction with electrolytes, poor cycling stability, and elimination of water and CO2 [382]. The recent efforts that are focused on developing the electrolytes and porous cathode materials can be found in the review articles [380–383].

4.2 Intercalating anodes

Graphitic anodes (theoretical capacity ∼372 mA h/g) initially enabled LIBs to become commercially viable and are still used widely due to their low cost and excellent stability [6]. In graphitic anodes, Li ions intercalate between the graphene planes, which offers good 2D mechanical stability, electrical conductivity, and Li+ transport. Different forms of carbon such as graphite, CNTs, carbon fibers, exfoliated graphene, and rGO have been used as anodes [151]. The demand for new anode materials with higher capacity has increased as the theoretical limit of graphitic anodes has already been achieved commercially [384].

Titanium-based oxides (e.g., LTO) also have received much attention despite having low intrinsic conductivity and low theoretical capacity (175 mA h/g) because they show low volume change (2–3%) upon Li insertion/de-insertion. Additionally, they also exhibit excellent cycling life [385–388]. LTO is relatively safer due to its high open-circuit voltage (∼1.55 V), which prevents dendrite formation [384,389–392]. To improve the low intrinsic conductivity, similar approaches as in the case of the spinel layered cathodes have been suggested. For example, many strategies such as doping [393–396], change in size and morphology [397–399], and combining/coating with conducting carbon additives [392,400–403] either individually or in combination have been used (Table 9) [393,404–407].

Representative electrochemical performance of Li metal anode and intercalating anode

| Material | Operating voltage (V) | Initial/final capacity (mA h/g) | Cycle/C rate | Year/Ref. |

|---|---|---|---|---|

| LiF and Li–Al alloy protected layer–Li metal/LFP | 0.01–4.2 | 120.4/94.2 | 300/3C | 2020 [354] |

| Organophosphate-derived dual-layered Li metal/sulfur | 1.7–2.7 | 800/735 | 100/1C | 2020 [353] |

| Polyacrylic acid-coated Li/Cu matrix//LCO | 3.0–4.2 | 127/103 | 1,000/2C | 2020 [375] |

| Pure LTO | 1.0–2.5 | 55.6/39.5 | 500/10C | 2019 [402] |

| N-doped LTO/carbon | 1.0–2.5 | 121.8/117.1 | 500/10C | 2019 [402] |

| Mesoporous carbon/LTO nanoflakes | 0.01–3.0 | 1,000/300 | 100/1C | 2019 [403] |

| LTO microspheres@C | 1.0–2.5 | 212/201 | 500/1C | 2018 [392] |

| Al3+ and Mn4+ co-doped LTO/CNT | 1.0–3.0 | 286.2/259.5 | 100/0.1C | 2020 [393] |

| Necklace-type LTO/VACNT nanocomposites | 1.0–2.5 | 170/165 | 500/10C | 2016 [401] |

| Nanostructured LTO/crystallite size-7 nm | 1.0–2.5 | 143/129 | 800/10C | 2018 [408] |

5 Alloying-type AMs for anodes

Based on their high specific capacity, low delithiation potential, low cost, and safety, alloying type materials such Sn, Ge, and Si have garnered much attention as promising candidates for anode [409,410]. Although gravimetric capacity (Sn: 994 mA h/g, Ge: 1,625 mA h/g, Si: 4,200 mA h/g) of these materials is different, their volumetric capacity (Sn: 7,216 mA h/cm3, Ge: 8,645 mA h/cm3, Si: 9,786 mA h/cm3) is almost the same. These anode materials suffer from a volume change during cycling and most of the approaches to mitigate volume change are similar to those used for Si. In this review, we will focus on Si as recent reviews on Sn and Ge can be found in refs. [52,411], respectively.

Si has both the highest gravimetric capacity (4,200 mA h/g, Li22Si5) and volumetric capacity (9,786 mA h/cm3) among the anode material candidates (see Figure 1b). The practical application of Si anodes is, however, impeded by its lower conductivity, large volume expansion upon lithiation (∼400%) during first discharge, pulverization during subsequent cycling, delamination from current collector, and unstable SEI layer [52,409,412–414]. Companies such as Sila Nanotechnology, Advano, and NanoGraf are leading the commercialization efforts for Si anodes, but none of them penetrated the market with their Si anode-based batteries yet.

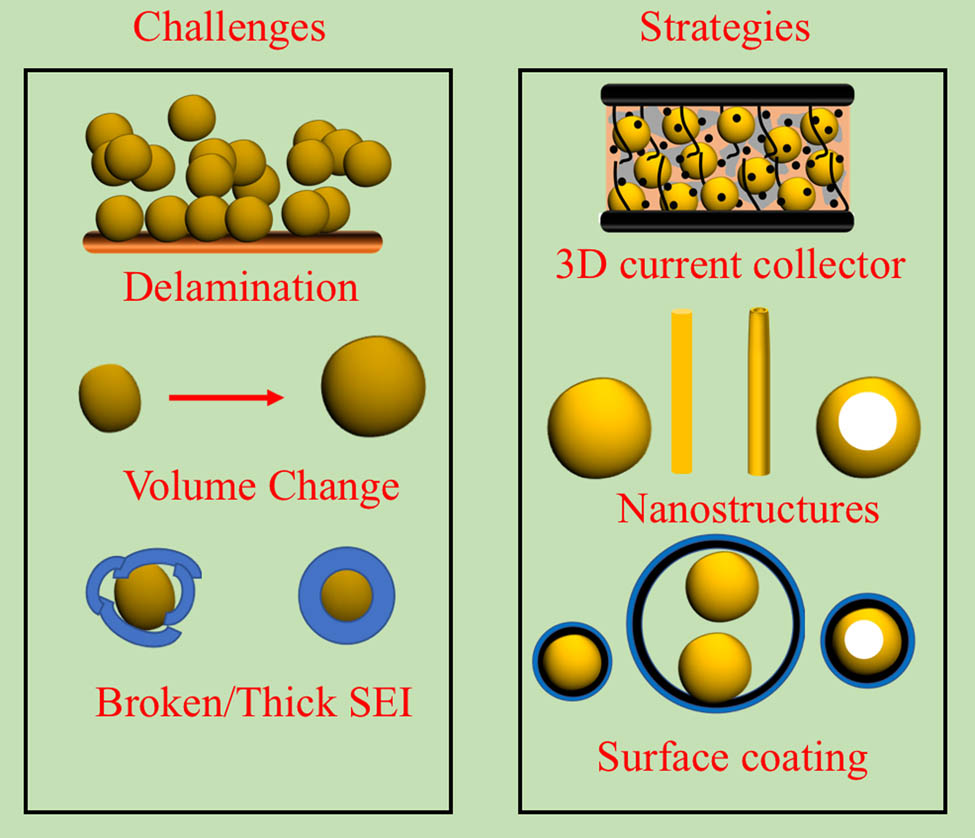

Several strategies have been suggested to overcome the challenges mentioned above (Figure 6). These include change in size/morphology of Si (nanotube, nanorods, nanowires, and porous particles) [52,415–420], coating/mixing with carbon/carbon composite [412,421–426], 3D Si host/conductive framework [427–432], and optimization of electrolyte, binders, and additives [433]. These strategies have also been combined with one another to get better electrochemical performance [422,423,434]. A detailed review of the design/optimization of electrolytes and binders can be found in ref. [433]. Also, limiting the discharge voltage and avoiding the re-crystallization voltage (>80 mV) can mitigate the pulverization issue to some extent [428].

Schematic showing the challenges and strategies commonly found in the literature for Si anodes.

The particle’s ability to resist mechanical degradation increases with tailoring its size from the bulk to the nanometer scale. Many studies have suggested that the stress generation and subsequent cracking/fracture of the particle is size dependent [415–420]. Above 150 nm, Si particles are susceptible to fracture [419]. Although nanostructuring reduces pulverization issues, it also increases side reaction with electrolyte, internal resistance of the electrode, and agglomeration of NPs [433]. Also, the volumetric capacity of the NPs is often lower because of the low density. Nanostructures such as nanorods and nanowires were regarded as better alternatives; however, large capacity fading was observed in such structures due to an unstable SEI and delamination from the current collector [435,436]. Similar problems were observed with thin-film Si anodes with increasing thickness of the films [436]. Porous particles such as porous nanotubes and porous spheres can minimize the mechanical stress by providing the internal space for volumetric expansion and can shorten the Li-diffusion pathways [436,437]. Based on these findings, the development of innovative Si structures has gained momentum in recent years (Table 10) [438]. But, problems such as side reaction at the surface and growth of SEI still exist [437].

Representative electrochemical performance of Si anode (1C = 4.2 A/g)

| Material | Operating voltage (V) | Initial/final capacity (mA h/g) | Cycle/C rate | Year/Ref. |

|---|---|---|---|---|

| Micro-sized Si particle | 0.001–1.5 | 2,100/275 | 20/0.25C | 2019 [458] |

| Micro-sized branched Si particle | 0.001–1.5 | 1,600/1,133 | 100/0.25C | 2019 [458] |

| Si (<100 nm) NPs | 0.01–1.2 | 193.2/68.5 | 100/0.05C | 2019 [459] |

| Si (<100 nm)@mesoporous carbon | 0.01–1.2 | 1,340/1,330 | 100/0.05C | 2019 [459] |

| Si/CNT | 0.001–2.0 | 1,537/246 | 100/0.25C | 2018 [452] |

| Si/CNT/C microsphere | 0.001–2.0 | 1,989/1,392 | 100/0.25C | 2018 [452] |

| Double core-shell porous Si–Ag/C | 0.01–1.5 | 1566.7/1,000 | 100/0.5C | 2018 [450] |

| 3D graphdiyne–Si | 0.01–2.0 | 1,770/1,250 | 100/0.25C | 2018 [430] |

| Si@N-doped carbon | 0.01–2.0 | 2,385/2,003 | 500/0.2C | 2020 [460] |

| Si@graphene | 0.01–1.5 | 3,578/1,909 | 100/0.05C | 2019 [461] |

| Hollow Si@void@C microspheres | 0.01–1.5 | 3,000/1,040 | 500/0.5C | 2019 [447] |

| Si@MOF derived C | 0.005–3.0 | 2,709/1,978 | 350/0.25C | 2020 [462] |

| MXene–Si–CNT | 0.01–1.5 | 1,050/841 | 200/0.5C | 2019 [463] |

| Si@CNT/C-microscroll | 0.01–2.0 | 2,710/2,056 | 300/0.05C | 2020 [464] |

| Amorphous Si@SiO x thin film | 0.01–1.0 | 2,173/2,116 | 100/0.5C | 2019 [465] |

| Si – carbon coaxial nanotube as CC | 0.05–1.0 | 2,750/2,200 | 50/0.2C | 2011 [428] |

| Si – 3D Cu foil/Cu nanowires/CNT as CC | 0.01–2.0 | 2,168/1,845 | 180/0.8C | 2019 [434] |

| Bucky paper/Si/Bucky paper sandwich | 0.01–1.0 | 2,900/1,635 | 100/0.1C | 2020 [457] |

Carbon-based materials such as activated carbon, graphene, CNTs, and graphene oxide have been used to improve the conductivity of the electrode as well as the overall electrochemical activity of Si/C composite [409,439–442]. The electrochemical performance of such composite depends mostly upon the types of carbon matrix used. Pyrolytic carbon-coated Si NPs provide void space for volume change ensuing in excellent performance. Carbon coating can also reduce side reactions of electrolytes with Si and also prevent the growth of SEI [443–448]. Liu et al. [449] first showed the Si/C (yolk/shell) structure can be used. Subsequently, such C shells were replaced by other stable/porous metal/metal oxide as C cannot accommodate the volume change during long cycling [446,450]. 2D carbon forms such as graphene were also used to wrap SiNPs [422–425,439]. Luo et al. [421] showed that crumpled graphene/Si NPs have better cycle performance than bare Si NPs. Si/CNT have also shown promising performance [451,452]. Using CNTs alone may not be enough to mitigate volume change, and therefore CNTs are often used in conjunction with C [437,452]. A detailed review on surface coatings can be found in ref. [453].

Although several efforts have been made to accommodate volume changes by focusing on the AM alone, a key factor for the better electrode performance, that is, the current collector has been overlooked. Mostly, planar current collectors such as Cu-foils have been used in most studies. However, such Cu foil current collectors do not accommodate volume changes in the AM. However, 3D current collectors that can (i) provide better electrical connection between AM and CC reduce the CCAMI resistance, (ii) accommodate the volume change, and (iii) decrease the diffusion time are needed [428,434,454–456]. As an alternative approach to mixing Si NPs with other nanomaterials, we sandwiched SiNPs between freestanding CNT Bucky papers. This method alleviates the need for the traditional Cu current collector due to the high electrically conductive CNTs. Based on exhaustive electrochemical impedance spectroscopy studies, we found that the diffusion time constant for the sandwiched structures is ∼150 times smaller than that of Cu foil [457].

6 CO2 emissions

Although BEVs are touted as cleaner cars based on a comparison of their CO2 emissions with respect to that of gasoline-powered vehicles, there are several factors ranging from mining/manufacturing to driving to disposal or recycling which might have a larger effect on the CO2 emission from BEVs. Despite their low operation (driving) emissions, the CO2 emission from the BEV manufacturing is more because of the added emissions during battery manufacturing, which is negligible during the manufacturing of gasoline-powered vehicles (pink bars in Figure 7a). Overall, present analyses suggest that mid-size BEVs will have a 51% reduction in CO2 emission during operation compared to gasoline-powered vehicles (Figure 7a) [466]. In reality, this percent reduction is highly dependent on how the electricity used during manufacturing was produced. If the electricity grids were not cleaner and used non-renewable sources like coal, then the overall manufacturing CO2 emissions are higher. Therefore, in our analysis of the overall emissions, a key factor that has been overlooked (gray bars in Figure 7a) and must be considered is whether or not clean energy was used during manufacturing. In addition, the battery chemistry also contributes to the CO2 emission (Figure 7b). For mid-size BEV with LCO (hydrothermal process), the CO2 emission is increased by ∼45%, whereas for the LCO (solid-state process) the emission is increased by only ∼9% [466]. If instead LMO is used, then the CO2 emission will be decreased by ∼18% and ∼43% for mid-size and full-size BEVs, respectively (Table 11) [466,467].

Representative battery chemistry and global warming emission change. This table is obtained from ref. [466]

| Battery | Process | Mid-size BEV (%) | Full-size BEV (%) |

|---|---|---|---|

| LCO | Solid state | 9 | −25 |

| LFP | Solid state | −14 | −41 |

| LCO | Hydrothermal | 45 | NA |

| LFP | Hydrothermal | −7 | −36 |

| LMO | NA | −18 | −43 |

In general, the total emissions (T e) from an automobile could be expressed as a sum of emissions from manufacturing (E m), operation (E o), and disposal/recycling (E d).

In equation (1), T e and E o are time dependent as ∼65% emissions of an automobile come from its operation over a period of time [466]. In the case of a BEV, the total manufacturing and disposal emissions contribute up to 30–35% of lifetime global warming emissions [466]. Thus, for BEVs, E m could be decoupled into manufacturing emissions from batteries (E bm) and emissions from other car parts and assembly (E cm).

In a typical mid- or full-size BEVs, E bm contributes ∼15–35% (for present-day LIBs) to E m while E cm contributes ∼65–85%.

The offset in total emissions by using BEVs ΔT e(t) in place of gasoline vehicles would be

In equation (3), (E bm − E gasoline) is the difference between emissions for battery manufacturing and well-to-tank emissions for gasoline or diesel production. The total E bm for LIBs ranges from 123 to 1,090 lbs of CO2 per kW h [468] while E gasoline is 0.16 lbs per kW h of gasoline [469]. Given that well-to-tank emissions of gasoline are at least several magnitudes lower than battery emissions, we approximate E bm − E gasoline ≅ E bm. From the available data on BEV and gasoline car manufacturing [466], ΔE cm could be neglected due to its minimal contribution (i.e., no significant difference in emissions from the car body parts such as tires and metal frame; see Figure 7a). The difference in emissions from battery disposal (ΔE d) is significantly low (<5% of E m for present-day LIBs). Thus, following the earlier approximations, we may express

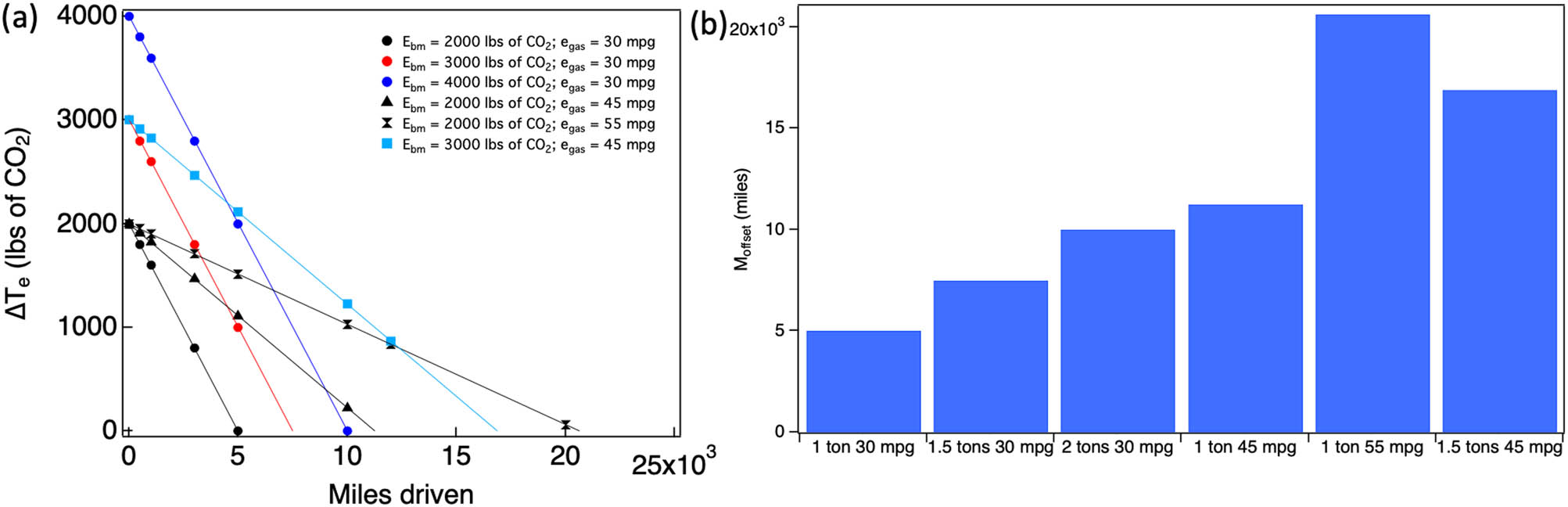

It is important to note that the term ΔE o(t) is a highly dependent electricity grid mix representative of where BEVs are used. By explicitly including gasoline efficiency (e gas in miles per gallon or mpg), BEV efficiency (e BEV in miles per kW h), and electricity mix (C em, lbs of CO2 emitted per kW h of electricity produced), one obtains

In equation (5), M y stands for average annual miles per car (∼13,500 miles per year in the United States) and t is expressed in years. Factor 20 comes from the fact that one gallon of gasoline results in ∼20 lbs of CO2 emissions. We used lbs of CO2 emission instead of traditional metric tons as ΔT e(t) and ΔE o(t) pertain to a single BEV/gasoline car. Here, we assumed constant automobile efficiency during the lifetime of a car. Using equation (5) and converting all time-dependence into miles driven (M d), the total offset in emissions becomes

In equation (6), E bm depends upon the size of the car. For example, for a mid-size 84-mile-range BEV (/full-size 265-mile-range BEV), manufacturing emissions are approximately 15% (/68%), or 1 ton or 2,000 lbs (/6 tons or 12,000 lbs) of CO2 higher than those of a comparable conventional gasoline vehicle. Accordingly, considering that E bm > 0, ΔT e is offset (i.e., ΔT e = 0) only after BEV is driven for M offset miles, which is given by

Clearly, M

offset directly depends upon emissions from battery manufacturing E

bm in addition to C

em and

Building on the data from Figure 8, Figure 9a shows different ΔT e for different scenarios of E bm and e gas for mid-size vehicles used in the United States. It can be noticed that different lines (corresponding to different E bm and e gas combinations) intersect the x-axis (corresponding to ΔT e = 0) at different points (i.e., each line has a different M offset). In Figure 9b, differences in M offset for various scenarios with different E bm and e gas are shown. It is evident that the increase in M offset is significantly impacted by increases in emissions from battery manufacturing. A 50% increase in battery manufacturing emissions (from the present estimate 2,000 lbs of CO2 to 3,000 lbs) increases M offset from ∼5,000 to 7,500 miles while a 100% increase leads to a higher M offset of 10,000 miles. In other words, as the emission from battery manufacturing increases, it takes longer BEV driving time to offset the emissions (which is the primary goal of BEVs). More importantly, as seen from Figure 8b, e gas increased non-linearly in the last two decades. Further expected increase in e gas to 45 and 55 mpg for passenger vehicles (see Figure 9a and b) increases M offset to ∼11,250 and 20,650 miles, respectively. Lastly, in the developing world, C em is much higher than the United States/Europe. For example, India (C em = 1.63 lbs of CO2 per kW h) and China (C em = 1.35 lbs of CO2 per kW h) have C em, which is ∼100% greater compared to the United States (∼0.8 lbs of CO2 per kW h) with lower average miles per year. In India, the average annual miles for a passenger car is ∼7,500 miles much lower than the US value of ∼13,500 miles. With combined effects of higher C em and lower miles driven per year, a typical mid-size BEVs will take ∼2 years (/3–4 years) to offset emissions that would have come from a gasoline car in the United States (/India). Given that C em is dependent on geographical location, batteries produced in the developing world with higher C em produce more E bm per kW h [468].

(a) The difference in total emissions (ΔT e) between mid-size BEV and gasoline vehicles for different scenarios of battery manufacturing emissions (E bm) and mileage (e gas). Different scenarios require a different number of miles to be driven (M offset) before total emissions could be offset (ΔT e = 0). (b) The values of M offse for scenarios shown in (a). It should be noted that a conversion factor of 2,000 is used to convert lbs of CO2 into tons.

The primary goal of road electrification is to offset CO2 emissions from gasoline cars. While increasing power and energy density are necessary for ensuring that BEVs provide the same level of comfort as a gasoline car, newer battery chemistries should not significantly increase E bm, E bd, and M offset. Concerted efforts have been focused on discovering new materials, novel architectures, and better chemistries (e.g., Li–S batteries, Na–S batteries) with little or no attention paid to % increase in battery manufacturing emissions for new chemistries. Life cycle analyses (LCA) of present LIB-based BEV batteries suggest that significant emissions result from battery manufacturing. These emissions have been identified to directly depend upon the choice of cathode and anode materials in addition to other components [474–477]. For example, cathode material lithium NMC and anode material graphite together contribute 74% of the total carbon footprint of raw materials needed to make NCM LIBs [477]. Dunn et al. published a series of articles through Argonne National Labs with detailed LCA analysis for five LIB cathode materials [474–476]. Based on their analysis, for at-capacity battery assembly plants, battery materials dominate the carbon footprint of emissions, with cathode materials representing 10–50% of that energy, depending on cathode type. Similarly, based on the LIB LCA analysis from various publications presented in ref. [468], studies indicate that battery production is associated with significant emissions of up to 125 to 1,000 lbs of CO2 per kW h for BEVs. In other words, a 24 kW h battery pack in Nissan Leaf results in E bm = 2,480 lbs of CO2 while a 100 kW h pack in Tesla Model S Long Range Plus leads to E bm = 12,500 lbs of CO2. As described in the mathematical framework earlier (cf. Figure 9), such high emissions imply that a higher M offset (i.e., significantly more miles need to be driven) is needed to offset ΔT e.

Considering that the CO2 emissions are dependent on materials chemistry (Table 11), current collectors, and manufacturing methods, we recommend that researchers use simple LCA based on existing battery chemistries (e.g., GREET™ model from Argonne National Labs) to estimate % change in CO2 emissions for any new active materials, composites, and electrode configurations (including changes in current collector or changes in manufacturing/assembly methods). For example, replacing traditional Al foil current collector with a nano-carbon matrix (e.g., graphene foam, Bucky paper) could possibly lead to a significant increase in CO2 emissions in battery production based on the method used for graphene production (e.g., chemical vapor deposition of graphene from CH4 at 1,000°C produces significantly more emissions than exfoliation). In addition to complete electrochemical characterization, it is important for battery researchers to report % changes in CO2 emissions per kW h that would be caused by their battery chemistry and assembly processes. Ignoring a net increase in CO2 emissions for new materials or manufacturing processes while focusing exclusively on better electrochemical performance will eventually delay our efforts to mitigate the effects of climate change. Furthermore, one should also consider the recyclability of cell components, which ultimately could reduce the net CO2 emissions at the materials production level.

7 Outlook and conclusions

Although AM chemical compositions and physical characteristics have been optimized, many studies are still focused on improving the gravimetric capacity of AMs and largely ignore the need to enhance areal capacity and volumetric capacity beyond existing commercial electrodes. Beyond these incremental studies, future research should also focus on improving the mass loading and tap density of the electrodes while maintaining a high areal capacity. It should be mentioned that there are important issues with how battery parameters are reported or compared in the literature. For example, (i) it is important to report gravimetric capacities at the electrode level and not just the AM level. Inactive binders and additives increase the total weight of the electrode and must be included in normalizing the total capacity to assess the practical usability of the electrodes and (ii) the C rate was developed to compare and evaluate similar electrodes that have similar cross-sectional area [478]. As a result, based on high gravimetric C rates obtained at the coin-cell level (with a small electrode area), it would be incorrect to claim that batteries in BEVs (with relatively higher electrode area) can be charged at a very high C rate within a few minutes. It is easy to maintain a high current density (a high C rate) in coin cells with a very small capacity per unit area for a short time. In larger cells, it may not be possible to maintain such high current densities for longer times because the Li+ ion transport is limited by the diffusivity and the available cross-sectional area of the electrode. Furthermore, gravimetric C rates (calculated per gram of AM) should be converted to appropriate areal C rates (per cm2 of the electrode) while assessing practical applications.

Although a lot of research has been focusing on alternative paper or carbon-based 2D/3D porous or nonporous electrodes, scaling up these techniques using current commercialized manufacturing systems is tricky. For example, to scale up from coin cells level to pouch cells, additional challenges such as gas evolution, placing tabs, or coating the slurry in a cost-effective manner must be addressed. A detailed discussion on gas evolution can be found in ref. [479]. While nano-structuring of AM has shown better results, most of the synthesis approaches reported in the literature are not cost effective because of the low product yield. For example, graphite is still used as the anode even though silicon has been known as an attractive alternative, and commercial silicon batteries remain implausible at this time. Several reports have appeared in the literature in which modified silicon (NPs, porous, core/shell) was used to obtain capacity as close as to its theoretical gravimetric capacity of 4,200 mA h/g. While such studies advance our understanding of battery chemistry, they fall short of commercializing the silicon battery technology. Replacing thermally and structurally stable layered oxides cathodes with sulfur-based cathodes pose a lot of challenges, mainly because of the lower open-circuit voltage (∼2.1 V) in the latter that yields a lower energy density. Therefore, the areal capacity must be increased to 6 mA h/cm2 by overcoming the insulating nature of sulfur and the polysulfide shuttle.

While this review is based on the experimental work reported in the literature, we also acknowledge the fact that extensive modeling of the electrochemical processes has helped advance LIBs [480,481]. Many approaches have been used to understand the electro-chemo mechanics [482], SEI formation [483], development of different components of the battery and its aging [484] as well as the safety [485,486]. Tools such as density functional theory (DFT) and molecular dynamics are used for computation and simulations for Li-ion batteries [323,480,487]. For example, Fan et al. [323] used DFT calculations to investigate the merit of using either ether-based or carbonate-based electrolyte solvents or a mixture of them in their LSBs. Specifically, they demonstrated that 1 M LiTFSI in EC0.5DME0.25DOL0.25 yielded the best battery performance as the mixed electrolyte could promote the formation of a bilateral SEI. In this regard, machine learning is used extensively to identify optimal electrode materials, battery degradation patterns, state of charge, etc. [488–493]. As machine learning requires a significant amount of verified data as input, either experimental or computational data on hand or a combination of both is expected to accelerate new materials discovery for advanced LIBs. Additionally, in-depth knowledge of electrode materials and their electrochemical properties deduced from advanced in situ/operando tools constitutes an important set of inputs for machine learning [494–496]. As such, in situ/operando characterization tools such as imaging (SEM, TEM, AFM), optical (Raman, UV/Vis, FTIR), X-ray, and neutron scattering have been extensively used in recent years. A detailed review on these techniques can be found in ref. [497]. Lastly, more importance must be given to explore environmentally friendly and facile routes that can displace the use of toxic solvents in nanomaterials synthesis and lithium battery manufacturing.

-

Funding information: This work was financially supported by NASA-EPSCoR award under #NNH17ZHA002C and South Carolina EPSCoR/IDeA Program under Award #18-SR03. The authors also thank all the members of Clemson Nanomaterials Institute for their inputs.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Omar N, Daowd M, van den Bossche P, Hegazy O, Smekens J, Coosemans T, et al. Rechargeable energy storage systems for plug-in hybrid electric vehicles – assessment of electrical characteristics. Energies. 2012;5:2952–88.10.3390/en5082952Suche in Google Scholar

[2] Lu J, Chen Z, Ma Z, Pan F, Curtiss LA, Amine K. The role of nanotechnology in the development of battery materials for electric vehicles. Nat Nanotechnol. 2016;11:1031–8.10.1038/nnano.2016.207Suche in Google Scholar PubMed

[3] Zaghib K, Mauger A, Groult H, Goodenough JB, Julien CM. Advanced electrodes for high power Li-ion batteries. Mater (Basel). 2013;6:1028–49.10.3390/ma6031028Suche in Google Scholar PubMed PubMed Central

[4] Brownson DAC, Kampouris DK, Banks CE. An overview of graphene in energy production and storage applications. J Power Sources. 2011;196:4873–85.10.1016/j.jpowsour.2011.02.022Suche in Google Scholar

[5] Auston D, Samuelsen S, Brouwer J, DenBaars S, Glassley W, Jenkins B, et al. Chapter 5. assessing the need for high impact technology research, development & deployment for mitigating climate change. Collabra. 2016;2:1–24.10.1525/collabra.64Suche in Google Scholar

[6] Deng D. Li-ion batteries: basics, progress, and challenges. Energy Sci Eng. 2015;3:385–418.10.1002/ese3.95Suche in Google Scholar

[7] Cairns EJ, Albertus P. Batteries for electric and hybrid-electric vehicles. Annu Rev Chem Biomol Eng. 2010;1:299–320.10.1146/annurev-chembioeng-073009-100942Suche in Google Scholar PubMed

[8] Childress AS, Parajuli P, Zhu J, Podila R, Rao AM. A Raman spectroscopic study of graphene cathodes in high-performance aluminum ion batteries. Nano Energy. 2017;39:69–76.10.1016/j.nanoen.2017.06.038Suche in Google Scholar

[9] Lin MC, Gong M, Lu B, Wu Y, Wang DY, Guan M, et al. An ultrafast rechargeable aluminium-ion battery. Nature. 2015;520:325–8.10.1038/nature14340Suche in Google Scholar PubMed

[10] Bommier C, Ji X. Electrolytes, SEI formation, and binders: a review of nonelectrode factors for sodium-ion battery anodes. Small. 2018;14:1703576.10.1002/smll.201703576Suche in Google Scholar PubMed

[11] Wu C, Tong X, Ai Y, Liu DS, Yu P, Wu J, et al. The surface coating of commercial LiFePO4 by utilizing ZIF-8 for high electrochemical performance lithium ion battery. Nano-Micro Lett. 2018;10:1–18.10.1007/s40820-017-0154-4Suche in Google Scholar

[12] Zhang Y, Liang Q, Huang C, Gao P, Shu H, Zhang X, et al. Nearly monodispersed LiFePO4F nanospheres as cathode material for lithium ion batteries. J Solid State Electrochem. 2018;22:1995–2002.10.1007/s10008-018-3905-3Suche in Google Scholar

[13] Liu Y, Sun Q, Li W, Adair KR, Li J, Sun X. A comprehensive review on recent progress in aluminum–air batteries. Green Energy Env. 2017;2:246–77.10.1016/j.gee.2017.06.006Suche in Google Scholar

[14] Zhang W, Mao J, Li S, Chen Z, Guo Z. Phosphorus-based alloy materials for advanced potassium-ion battery anode. J Am Chem Soc. 2017;139:3316–9.10.1021/jacs.6b12185Suche in Google Scholar

[15] Meng YS, Arroyo-De Dompablo ME. Recent advances in first principles computational research of cathode materials for lithium-ion batteries. Acc Chem Res. 2013;46:1171–80.10.1021/ar2002396Suche in Google Scholar

[16] Islam MS, Fisher CAJ. Lithium and sodium battery cathode materials: computational insights into voltage, diffusion and nanostructural properties. Chem Soc Rev. 2014;43:185–204.10.1039/C3CS60199DSuche in Google Scholar

[17] Nitta N, Wu F, Lee JT, Yushin G. Li-ion battery materials: present and future. Mater Today. 2015;18:252–64.10.1016/j.mattod.2014.10.040Suche in Google Scholar

[18] Whittingham MS, Gamble FR. The lithium intercalates of the transition metal dichalcogenides. Mater Res Bull. 1975;10:363–71.10.1016/0025-5408(75)90006-9Suche in Google Scholar

[19] Mizushima K, Jones PC, Wiseman PJ, Goodenough JB. LixCoO2 (0 < x < −1): a new cathode material for batteries of high energy density. Mater Res Bull. 1980;15:783–9.10.1016/0025-5408(80)90012-4Suche in Google Scholar

[20] Jung YS, Cavanagh AS, Dillon AC, Groner MD, George SM, Lee S-H. Enhanced stability of LiCoO2 cathodes in lithium-ion batteries using surface modification by atomic layer deposition. J Electrochem Soc. 2010;157:A75.10.1149/1.3258274Suche in Google Scholar

[21] Chen Z, Dahn JR. Methods to obtain excellent capacity retention in LiCoO2 cycled to 4.5 V. Electrochim Acta. 2004;49:1079–90.10.1016/j.electacta.2003.10.019Suche in Google Scholar

[22] Cho J, Kim YJ, Kim TJ, Park B. Zero-strain intercalation cathode for rechargeable Li-ion cell. Angew Chem - Int Ed. 2001;40:3367–9.10.1002/1521-3773(20010917)40:18<3367::AID-ANIE3367>3.0.CO;2-ASuche in Google Scholar

[23] MacNeil DD, Dahn JR. The reaction of charged cathodes with nonaqueous solvents and electrolytes: II. LiMn2O4 charged to 4.2 V. J Electrochem Soc. 2001;148:A1211.10.1149/1.1407246Suche in Google Scholar

[24] Ohzuku T. Electrochemistry and structural chemistry of LiNiO2 (R3m) for 4 volt secondary lithium cells. J Electrochem Soc. 1993;140:1862–70.10.1149/1.2220730Suche in Google Scholar

[25] Rougier A, Gravereau P, Delmas C. Optimization of the composition of the Li1 − zNi1+zO2 electrode materials: structural, magnetic, and electrochemical studies. J Electrochem Soc. 1996;143:1168–75.10.1149/1.1836614Suche in Google Scholar

[26] Arai H, Okada S, Sakurai Y, Yamaki JI. Thermal behavior of Li1−yNiO2 and the decomposition mechanism. Solid State Ion. 1998;109:295–302.10.1016/S0167-2738(98)00075-7Suche in Google Scholar

[27] Armstrong AR, Bruce PG. Synthesis of layered LiMnO2 as an electrode for rechargeable lithium batteries. Nature. 1996;381:499–500.10.1038/381499a0Suche in Google Scholar

[28] Davidson IJ, McMillan RS, Murray JJ, Greedan JE. Lithium-ion cell based on orthorhombic LiMnO2. J Power Sources. 1995;54:232–5.10.1016/0378-7753(94)02074-DSuche in Google Scholar

[29] Croguennec L, Deniard P, Brec R. Electrochemical cyclability of orthorhombic LiMnO2: characterization of cycled materials. J Electrochem Soc. 1997;144:3323–30.10.1149/1.1838013Suche in Google Scholar

[30] Mishra SK, Ceder G. Structural stability of lithium manganese oxides. Phys Rev B - Condens Matter Mater Phys. 1999;59:6120–30.10.1103/PhysRevB.59.6120Suche in Google Scholar