Abstract

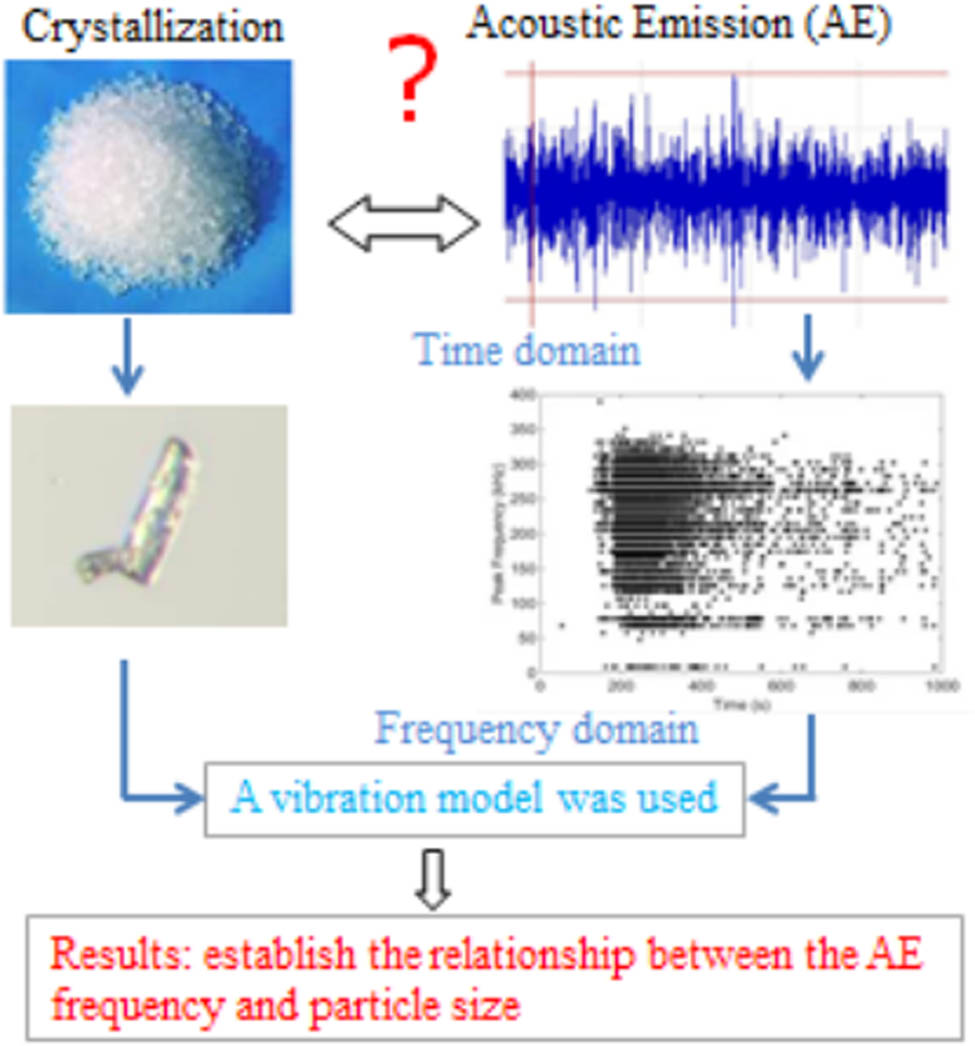

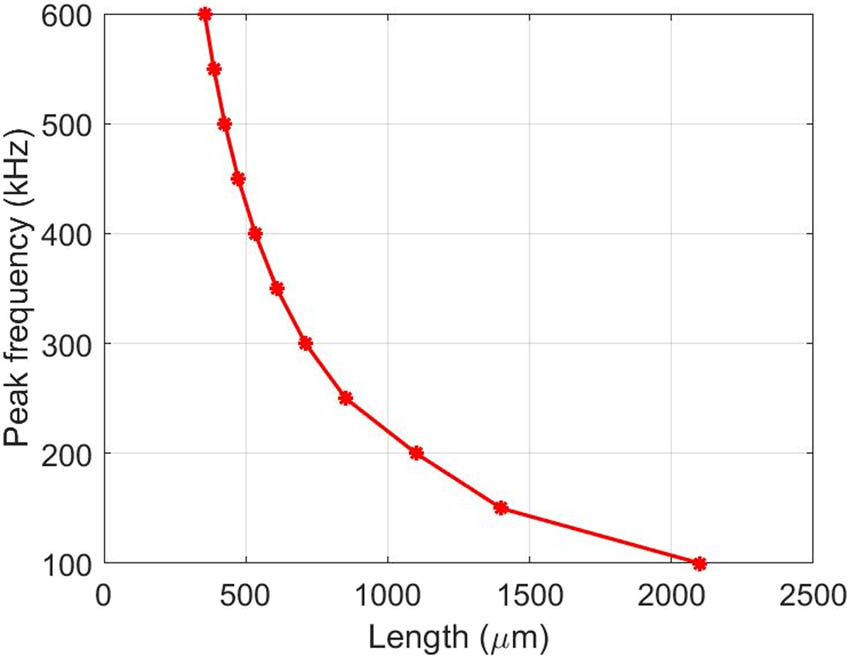

Based on the results of the previous experiment, this article studied the acoustic emission (AE) signals released during the crystallization of salicylic acid to establish the relationship between the AE signal and the particle size. A tremendous amount of acoustic data was analyzed using time–frequency domain analysis methods in order to extract the valuable contents. Based on the diffusion theory, the vibratory model between the AE signal and the crystal particle size was established. This article mainly studies the process of small particles diffusing to the growth point by impact, adding to the lattice, and the crystal releases energy. The impact of the growth unit on particle aggregate is equivalent to a linear elastic vibration system with one end fixed and the other end free. The vibration frequency is 200–355 kHz when the particle size is between 600 and 1,100 µm. The calculated vibration frequency is in good agreement with the measured frequency.

Graphical abstract

1 Introduction

Crystallization is an important step significantly affecting the final product characteristics, such as particle size and its distributions [1], shape, and purity [2,3]. Crystalline particle size is usually the key requirement of the drug crystallization process, which not only affects the performance of the final product but also affects the operation and product characteristics of downstream products [4]. Some factors (temperature, stirring, impurities, and external field) affect the size of nucleation by affecting the metastable state of the solution. On the one hand, with the increase of temperature, the interaction process between particles is accelerated; on the other hand, the process slows down with the decrease of saturation. Therefore, it is a complex process. Vibration and stirring increase all kinds of collisions and impact a supersaturated solution resulting in a high supersaturated area, which accelerates the fine crystal nucleus in the solution. In addition, magnetic field, radioactive ray, and roentgen ray have influences on the nucleation rate of the solution. The anisotropic growth was studied [5]. The effect of ultrasound on supersaturated solutions mainly depends on the power and intensity of radiation. X-ray, infrared spectroscopy, and electron diffraction methods were used to analyze the crystal structures [6]. The microstructure and the thermal behavior of the deformed disks have been studied by differential scanning calorimetry [7,8]. Different particle sizes could change the properties of microstructure [9]. Some traditional methods of measuring particle size, such as focused beam reflectance measurement (FBRM) [10,11,12], laser diffraction [13,14], mass spectrometry [15], and pressure fluctuations [16], need clean test environment. Subero-Couroyer et al. used the reaction crystallization method to generate SA microparticles (5 μm) in the suspension and then controlled agglomeration to increase its size to improve downstream solid processing operations [17]. Hatkar and Gogate studied the effect of additives on the crystallization process at a given supersaturation level. They considered that the change of particle size is due to the change in supersaturation [18]. Seidel and Martins studied the effect of the change of antisolvent crystallization conditions on the size and shape of SA crystal under thermal gradient [19,20]. Caro et al. studied the effects of process conditions (i.e., stirring speed, feeding point, reactant concentration, and vessel diameter) on the size of SA crystal after reactive crystallization [21]. However, many chemical production processes are often carried out under hard process conditions, such as high pressure, high temperature, corrosive medium, dust content, and non-real-time technique.

Wang et al. used acoustic emission (AE) monitoring to explain the relationship between AE variables and the development of crystallization mechanism from a new perspective so as to better understand crystallization phenomena (such as nucleation, growth, and agglomeration) [22,23]. In addition, by monitoring the vibration signal released during the crystallization of salicylic acid, the effect of the injection rates on the particle size distribution was studied [24]. AE method has some advantages compared with these methods. One of the main advantages of AE technology is that its sensor does not need to be placed inside the reaction equipment (e.g., reactor, dryer, grinder, grinder, and crystallizer). Because of its nonintrusive and nondestructive features and due to the possibility of real-time information collections, AE might be a very attractive technique for the development of online monitoring and control systems. It has been applied in various areas of research and industrial process monitoring, such as plastic strain mechanisms [25], tablets [26], slurries [27], powder blending [28], heterogeneous reactions [29,30], various fluidized bed processes [31,32,33,34], ice-melting [35], fiber fracture [36], end-point detection in high shear granulation [37,38,39,40], and phase transition [41]. However, few studies deal with the AE monitoring of crystallization processes [42,43,44].

In recent times, the AE technology and its vibration model in the process of crystal nucleation are the research hot spot in related fields, which has significant research value for the development of online monitoring system. The novelty of this study is to use a physical model to set up the corresponding relationship between AE frequency and particle size by analyzing the collected AE signals. Previous studies showed the presence of AE signals during crystallization [22]. As the relation between the AE frequencies and particle sizes has not yet been explicated in the literature for this phenomenon, the vibration behavior of laminated composite plates was studied [45,46,47,48,49]. Thanks to Landau Lifchitz, Theory of Elasticity: Volume 7 (Theoretical Physics) Chapter: 25, this research is to set up the relation between the fundamental (lowest) natural frequency in function of the size of the crystals. The result can use the parameters of AE frequencies to measure the mode of crystallization growth. Generally, the crystal structure grows from nanosize to micrometers. The results of this research give a new method to study nanocrystallization [50,51,52,53] molecular dynamics simulation [54].

The rest of this article is organized as follows. Section 2 briefly introduces the main features of hits and defines the AE signal parameters in the specification. Section 3 presents the crystallization device and signal acquisition equipment used in this study, as well as the parameter setting and working principle of the equipment. The mechanical model is used to calculate the frequency of the AE signal released during the growth of the salicylic acid crystal in Section 4. Such calculation is based on the elastic theory of theoretical physics course. To obtain further information and views on the crystallization process, the experimental results are further explained in Section 5. Finally, the article concludes with a discussion of further research direction.

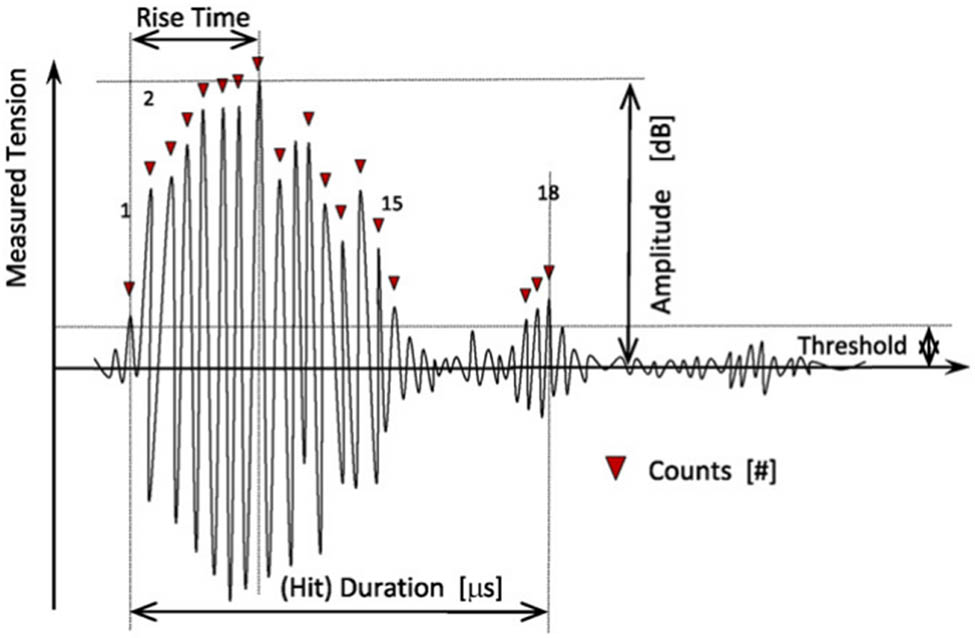

2 Introduction to AE

As shown in Figure 1, the AE parameters can be measured to avoid recording too large number of data. For example, a threshold power ratio value (40 dB) has to be used from “blank” measurements to evaluate the level of insignificant signals emitted by the stirring system, the electromagnetic environment, and the flow of the liquid in the crystallizer. In this study, the counts and the peak frequencies of AE signal were used. The counts are defined as the number of times the emission acoustic signal crosses the detection threshold. There are 18 counts in Figure 1. The peak frequency is defined as the point in the power spectrum at which the peak magnitude occurs. The real-time fast Fourier transform is performed on the waveform. The peak frequency contains the largest magnitude of AE hit.

The characteristic parameters of a emission acoustic signal.

3 Experiment

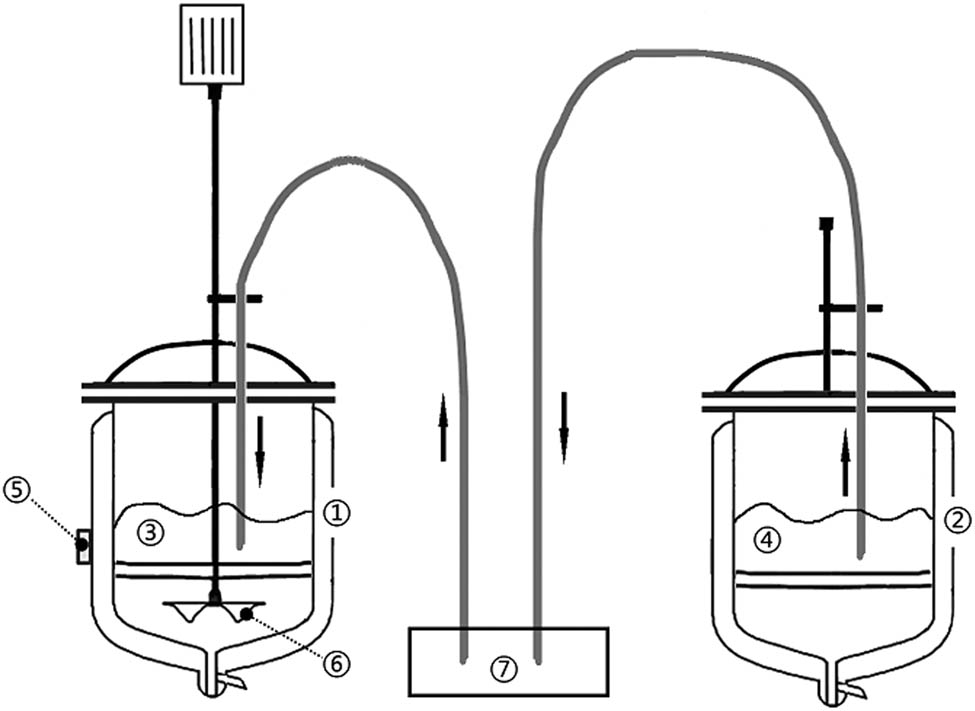

Figure 2 shows the schematic diagram of the crystallization device used in this study. Two flat-bottom jacketed 1 L glass containers are connected by a peristaltic pump (Watson 313S), and sulfuric acid solution (H2SO4) in No. 1 glass is added into the reactor (No. 2 glass). A high-efficiency propeller (mix TT TM) is set in the mold, with a rotating speed of 200 rpm. The reactor is a cylindrical vessel with a diameter of 0.11 m and a maximum height of 0.2 m. The gap between the agitator and the bottom of the reactor is 0.03 m. The injection point is located in the liquid midpoint between the agitator position in the center of the reactor and the reactor wall.

Experimental setup for the semi-continuous precipitation of salicylic acid. (1) 1 L glass 2 reactor, (2) 1 L glass 1, (3) R_Na, (4) H2SO4, (5) acoustic emission sensor, (6) stirrer, and (7) pumper.

The AE signal is detected by the piezoelectric sensor (physical acoustics company, wd-fs62), which is fixed on the outer wall of the reactor. To improve the transmission efficiency of AE signal, coupling grease is used between the glass wall and the sensor. Then, the data acquisition system (DAS of European physical acoustics company) is used to adjust, amplify, filter, and process the signals collected by the detection equipment. To avoid the interference of the background signal, the detection threshold is set higher than 40 dB. Please refer to the author’s previous articles [24] for the parameter setting of our experimental AE equipment.

The whole experimental process is continuously monitored by AE equipment, which starts to work before sulfuric acid is introduced. At the end of the intermittent process, SA suspension samples are extracted from two sampling points of the crystallizer for offline size measurement. During the whole experiment, the temperature of the reactor is controlled at 20°C by manipulating the set-point temperature of the heating tank. The sulfuric acid solution is prepared in reactor 1 and added to the sodium salicylate solution at an injection rate of 20 mL/min. The concentration of the latter is 0.2 mol/L, which was initially prepared in No. 2 glass reactor.

4 Experimental results and discussion

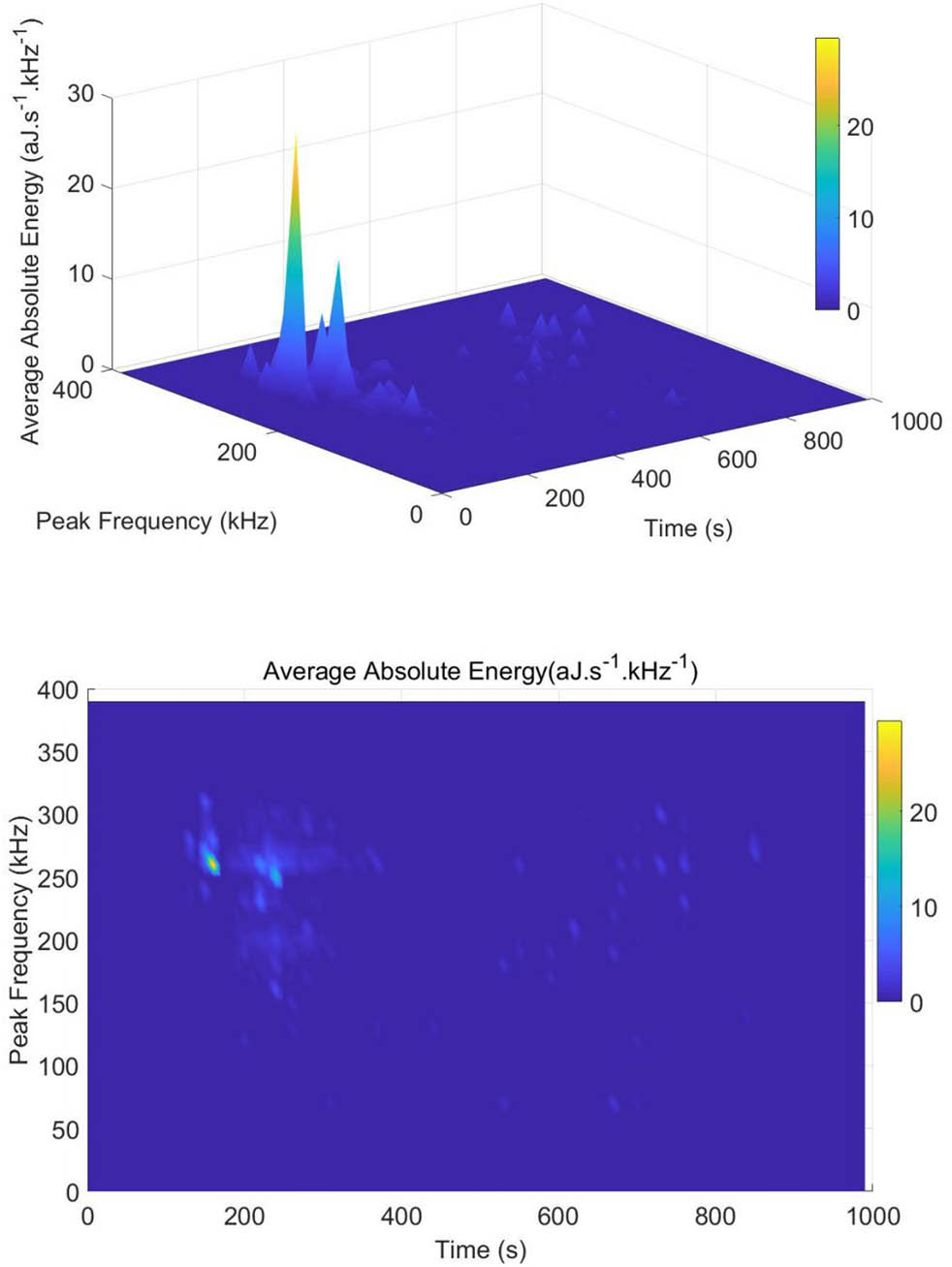

The AE signal emitted by developing slurries consists of a mixture of many waves, spread over several orders of magnitude. This is why the recorded AEs frequency spectra are generally complex. The time–domain analysis is used to grasp the macro distribution of the data, but the small changes in the data are not easy to observe. To evaluate these parameters as a function of the basic mechanism of crystallization, the time–frequency analysis method is used. This technique studies a two-dimensional signal in both the time and the frequency domains simultaneously.

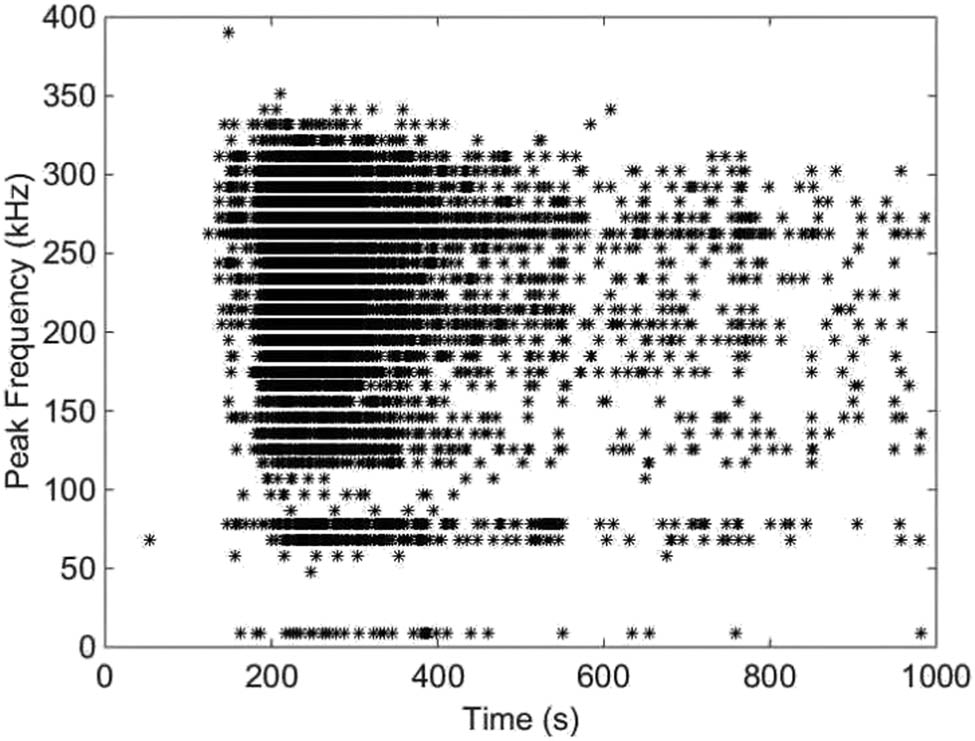

The results of the previous experiment are reviewed to reveal the relationship between the AE signal and the corresponding crystallization phenomenon. For example, as shown in Figure 3, the first time period, from 0 to 200 s, the sulfuric acid solution (H2SO4) is added into the reactor. No crystallization is observed, and the count of emission acoustic is almost zero. In the second time period, from 200 to 600 s, crystallization is observed and the count increases. In the third time period, from 600 to 1,000 s, the AE become less, because of collision and friction between the crystals.

Time variations of the individual peak frequencies during the crystallization of salicylic acid.

As shown in Figure 3, from about 150 s, several frequency signals are observed. This observation means that there is crystal nucleation. From about 200 to 400 s, huge amounts of emission acoustic signals are observed. There are lots of crystals nucleation and growth. After 600 s, the emission acoustic signal tends to several frequencies. Crystal growth is indeed the basic permanent crystal phenomenon in the process from about 150 s to the end.

In the following sections, a mechanics model is used to calculate the frequency of the AE signal released during the crystal growth stage of salicylic acid. According to the diffusion theory of Noyes, Whitney, and Nernst [53,54], the matter is deposited on the crystal surface continuously at a rate proportional to the concentration difference between the surface and the bulk solution.

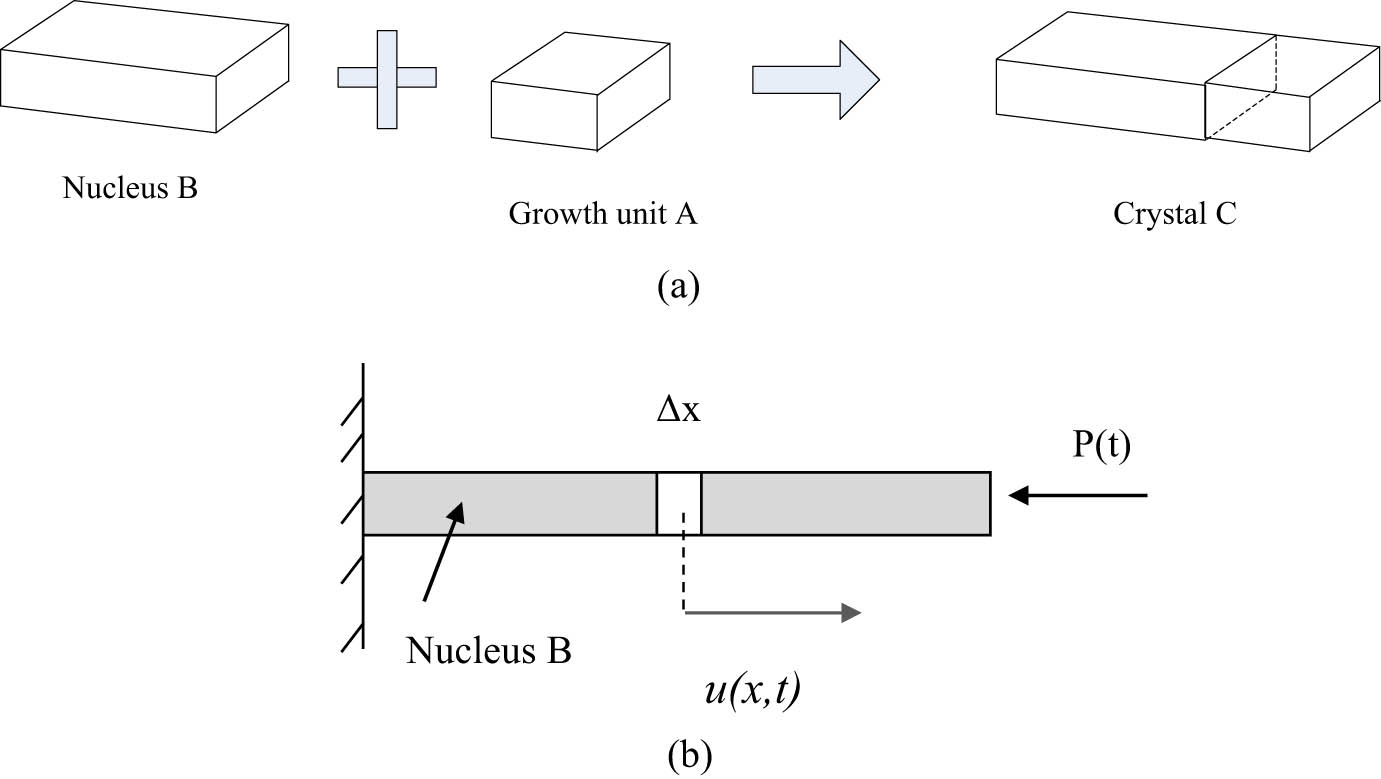

Thanks to Landau Lifchitz, Theory of Elasticity: Volume 7 (Theoretical Physics), Chapter: 25, this section sets up the relation between emission acoustic frequency and crystallization. The vibration of crystals leads to the emission of acoustic signals. As shown in Figure 4, a particle is fixed on the left end side, and the right end is free. A force is applied to the right side. It is assumed that the elastic displacement of u(x,t) is produced by the force P(t) acting on the free end of particle a. Considering the basic strength of particles, we assume that the cross-section of particles is perpendicular to the x-axis of the spindle and the cross-sectional area is A. The particle is linear elastic and its properties (ρ, E) are homogeneous at any given cross-section. When a force is applied to the right side of the particle, the particle will begin vibrating. This vibration leads to the AE signal. During crystallization (nucleation, growth), when the growth unit A joins the nucleus B, as shown in Figure 4a, the two particles grow to crystal C. This phenomenon is similar to that in Figure 4b, growth unit A gives a force to the nucleus B. Nucleus B begins to vibrate. The three-dimensional structure diagram of the process of growth unit A combining with nucleus B is approximately represented in Figure 4a, and a schematic view of elastic nucleus B undergoing axial motions is represented in Figure 4b. Vibration frequencies of crystal growth will be calculated in the following section.

(a) Three-dimensional schematic diagram of crystal C is obtained by combining growth unit A and nucleus B; (b) schematic view of elastic nucleus B undergoing axial motions.

Consider the free body diagram of an infinitesimally small piece of a particle with length Δx, P(x,t) is the axial force at a cross-section of the particle.

Applying Newton’s second law of motion on the growth unit differential element gives

where the left side of the equation is the sum of all forces acting on the infinitesimally small piece of a particle along the x-direction, Δm is the mass of the infinitesimally small piece of a particle along the x-direction,

In the present case, the unique force acting at the free end of the particle is P. Therefore, equation (1) can be written as follows:

By the definition of limit, as

The solution of partial differential equation (PED) (3) is of the form:

Substitution of the product solution equation (4) into PDE (3) gives

The above formula is based on the assumption that all points on the particle move synchronously. By using the method of separating variables, u(x,t) is decomposed into the product of two functions

With the definitions

Above, the left-hand side is only a function of time, while the right-hand side is only a function of spatial coordinate x. This is possible only if both sides equal to a constant. It can be written as follows:

Hence, the PDE is converted into two ordinary differential equations (ODEs):

The solution of the ODEs (8) and (9) is

where

where L is the length of the particle.

Hence, from the characteristic equation

Note that

Hence, the roots of equation (12) are

And since

Hence, we obtained the formula for calculating the vibration frequencies generated by the combination of particles and crystallization nucleation [55].

The particle size with the injection rate of 20.8 mL/min is about 600 to 1,100 µm [24]. The density and Young’s modulus of salicylic acid are

The particle length corresponding to vibration frequencies.

5 Further discussion

A time and frequency domain analysis was performed to get an additional point of view on the crystallization process. As shown in Figure 6, the frequency range was divided into samples of width 10 kHz, (0–10 kHz, 10–20 kHz, 390–400 kHz). In order to reduce the amount of acoustic data and to compute a smooth (

Average absolute energy E abs, as a function of the peak frequency and time.

where E k is the value of the absolute energy of hit n 0 k located inside the cell [i, j], N i,j is the total number of hits inside the same cell, and Δf and Δt are the frequency and time intervals defining the size of the [i, j] grid, respectively.

Figure 6 shows the 3D plot of the average absolute acoustic energy recorded in the frequency domain (0–400 kHz). A significant level of energy can be observed at 150 to 180 s and the corresponding peak frequency related to the maximum AE energy is located around 260 kHz. Figure 6 also shows that the energy becomes negligible after 400 s. As shown in Figure 6, the AE signals vary from 250 to 300 kHz and the crystal size corresponds to 852–710 μm.

The beginning of the AE activity in the frequency domain 260 kHz could be expected to correspond to the beginning of nucleation and crystal growth. The outbreak of AE activity at time 200 s precedes the two-dimensional nucleus and three-dimensional nucleation [57]. It seems again reasonable to conclude that AE allows detecting the onset of nucleation much before the solids generation process becomes significant. One can therefore assume that the absolute energy recorded in the frequency domain investigation is related to the rate of crystal nucleation and growth. The end of the AE activity under investigation could be expected to be the end of the chemical reaction. More details of physical explanation could be found in previous research [24].

The final grain of salicylic acid is shown in Figure 7. The shape of the salicylic acid could be considered as a cylinder. Although there are several components of the wave traveling in a solid, this article uses a simple 1D analysis to set up the relationship between AE frequency and particle size. Future work is focused on different waves corresponding to the AE frequency.

Grain size of salicylic acid.

6 Conclusion

In this article, the corresponding relationship between AE frequency and particle size has been set up by analyzing the collected AE signals.

The vibration frequencies of particles (600–1,100 µm) calculated by the proposed formula are in good agreement with the experimental results (200–355 KHz).

Once the relationship between AE frequency and crystal particle size is established, the formula can be used to predict the particle size.

This method can be used to monitor the crystallization process to obtain the required crystal size and particle distribution, to achieve the desired final product quality. AE signal during the process of crystal nucleation and its vibration model are further studied in future work.

-

Funding information: The presented work was supported by the National Natural Science Foundation of China (grant nos. 51808554).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Zhang S, Liang Y, Qian X, Hui D, Sheng K. Pyrolysis kinetics and mechanical properties of poly(lactic acid)/bamboo particle biocomposites: effect of particle size distribution. Nanotechnol Rev. 2020;9:524–33.10.1515/ntrev-2020-0037Search in Google Scholar

[2] Variankaval N, Cote AS, Doherty MF. From form to function: crystallization of active pharmaceutical ingredients. AIChE J. 2008;54:1682–8.10.1002/aic.11555Search in Google Scholar

[3] Cheng C, Song W, Zhao Q, Zhang H. Halloysite nanotubes in polymer science:purification, characterization, modification and applications. Nanotechnol Rev. 2020;9:323–44.10.1515/ntrev-2020-0024Search in Google Scholar

[4] Takiyama, H. Supersaturation operation for quality control of crystalline particles in solution crystallization. Adv Powder Technol. 2012;23:273–8.10.1016/j.apt.2012.04.009Search in Google Scholar

[5] Przybyłek M, Cysewski P, Pawelec M, Ziółkowska D, Kobierski M. On the origin of surface imposed anisotropic growth of salicylic and acetylsalicylic acids crystals during droplet evaporation. J Mol Modeling. 2015;(21):49–61.10.1007/s00894-015-2599-zSearch in Google Scholar PubMed PubMed Central

[6] Oku T. Crystal structures of perovskite halide compounds used for solar cells. Rev Adv Mater Sci. 2020;59:264–305.10.1515/rams-2020-0015Search in Google Scholar

[7] Révész D, Horváth A, Ribárik G, Schafler E, Kovács Z. Crystallization of Cu60Zr20Ti20 bulk metallic glass by high pressure torsion. Rev Adv Mater Sci. 2019;58:304–12.10.1515/rams-2019-0037Search in Google Scholar

[8] Jahangir A, Malik F, Muhammad N, Fayyaz R, Abbasi JN, Nazir A. Reflection phenomena of waves through rotating elastic medium with micro-temperature effect. Rev Adv Mater Sci. 2020;59:455–63.10.1515/rams-2020-0036Search in Google Scholar

[9] Ment T, Ying K, Hong Y, Xu Q. Effect of different particle sizes on nano-SiO2 on the properties and microstructure of cement paste. Nanotechnol Rev. 2020;9:833–42.10.1515/ntrev-2020-0066Search in Google Scholar

[10] Greaves D, Boxall J, Mulligan J, Montesi A, Creek J, Sloan ED, et al. Measuring the particle size of a known distribution using the focused beam reflectance measurement technique. Chem Eng Sci. 2008;63:5410–9.10.1016/j.ces.2008.07.023Search in Google Scholar

[11] Yu W, Erickson K. Chord length characterization using focused beam reflectance measurement probe – methodologies and pitfalls. Powder Technol. 2008;185:24–30.10.1016/j.powtec.2007.09.011Search in Google Scholar

[12] Wynn EJW. Relationship between particle-size and chord-length distributions in focused beam reflectance measurement: stability of direct inversion and weighting. Powder Technol. 2003;133:125–33.10.1016/S0032-5910(03)00084-6Search in Google Scholar

[13] Nishioka Y, Ohsawa T, Kobayashi M, Noda K. Laser diffraction estimation of particle size distribution of slightly water-soluble drugs coexisting with additives: application to solid dosage forms. Chem Pharm Bull. 1992;40:1563–8.10.1248/cpb.40.1563Search in Google Scholar

[14] Ma Z, Merkus HG, Smet J, Heffels C, Scarlett B. New developments in particle characterization by laser diffraction: size and shape. Powder Technol. 2000;111:66–78.10.1016/S0032-5910(00)00242-4Search in Google Scholar

[15] Linton RW, Williams P, Evans CA. Determination of the surface predominance of toxic elements in airborne particles by ion microprobe mass spectrometry and Auger electron spectrometry. Anal Chem. 1997;49:1514–21.10.1021/ac50019a015Search in Google Scholar

[16] Dhodapkar SV, Klinzing GE. Pressure fluctuations in pneumatic conveying systems. Powder Technol. 1993;74:179–95.10.1016/0032-5910(93)87010-LSearch in Google Scholar

[17] Subero-Couroyer C, Mangin D, Rivoire A, Blandin AF, Klein JP. Agglomeration in suspension of salicylic acid fine particles: analysis of the wetting period and effect of the binder injection mode on the final agglomerate size. Powder Technol. 2006;161:98–109.10.1016/j.powtec.2005.08.014Search in Google Scholar

[18] Hatkar UN, Gogate PR. Process intensification of anti-solvent crystallization of salicylic acid using ultrasonic irradiations. Chem Eng Process Process Intensif. 2012;57–58:16–24.10.1016/j.cep.2012.04.005Search in Google Scholar

[19] Seidel J, Ulrich J. Generation of crystalline microcontainers of salicylic acid. Chem Eng & Technol. 2015;38:984–90.10.1002/ceat.201400716Search in Google Scholar

[20] Martins D, Stelzer T, Ulrich J, Coquerel, G. Formation of crystalline hollow whiskers as relics of organic dissipative structures. Cryst Growth Des. 2011;11:3020–6.10.1021/cg2002892Search in Google Scholar

[21] Caro JA, Woldehaimanot M, Rasmuson ÅC. Semibatch reaction crystallization of salicylic acid. Chem Eng Res Des. 2014;92:522–33.10.1016/j.cherd.2013.09.009Search in Google Scholar

[22] Wang XJ, Févotte G, Huang Y, Michelitsch TM. Acoustic emission during the solvent mediated cooling crystallization of citric acid. Powder Technol. 2016;301:70–7.10.1016/j.powtec.2016.05.057Search in Google Scholar

[23] Wang XJ, Huang Y, Michelitsch TM. Acoustic emission detection of crystallization in two forms: monohydrate and anhydrous citric acid. Pharm Dev Technol. 2019;24:419–26.10.1080/10837450.2018.1507037Search in Google Scholar PubMed

[24] Wang XJ, Huang Y. An investigation of the acoustic emission generated during crystallization process of salicylic acid. Powder Technol. 2017;311:350–5.10.1016/j.powtec.2016.12.066Search in Google Scholar

[25] Kusnierz J, Pawelek A, Ranachowski Z, Piatkowski A, Jasienski Z, Kudela S. Mechanical and acoustic emission behaviour induced by channel-die compression of Mg-Li nanocrystalline alloys obtained by ecap technique. Rev Adv Mater Sci. 2008;12:583–9.Search in Google Scholar

[26] Albion K, Briens L, Briens C, Berruti F. Detection of the breakage of pharmaceutical tablets in pneumatic transport. Int J Pharma. 2006;322:119–29.10.1016/j.ijpharm.2006.05.039Search in Google Scholar PubMed

[27] Albion K, Briens L, Briens C, Berruti F, McDougall S. Detection of oversized material in a hydrotransport slurry pipe using a non-invasive acoustic method. Powder Technol. 2009;190:361–71.10.1016/j.powtec.2008.08.020Search in Google Scholar

[28] Allan P, Bellamy LJ, Nordon A, Littlejohn D. Non-invasive monitoring of the mixing of pharmaceutical powders by broadband acoustic emission. Analyst. 2010;135:518–24.10.1039/b922446gSearch in Google Scholar PubMed

[29] Nordon A, Waddell RJH, Bellamy LJ, Gachagan A, McNab D, Littlejohn D, et al. Monitoring of a heterogeneous reaction by acoustic emission. Analyst. 2004;129:463–7.10.1039/b402875aSearch in Google Scholar PubMed

[30] Nordon A, Carella Y, Gachagan A, Littlejohn D, Hayward G. Factors affecting broadband acoustic emission measurements of a heterogeneous reaction. Analyst. 2006;131:323–30.10.1039/B510922ASearch in Google Scholar

[31] Vervloet D, Nijenhuis J, van Ommen JR. Monitoring a lab-scale fluidized bed dryer: a comparison between pressure transducers, passive acoustic emissions and vibration measurements. Powder Technol. 2010;197:36–48.10.1016/j.powtec.2009.08.015Search in Google Scholar

[32] Wang JD, Ren CJ, Yang YR. Characterization of flow regime transition and particle motion using acoustic emission measurement in a gas–solid fluidized bed. AIChE. 2010;56:1173–83.10.1002/aic.12071Search in Google Scholar

[33] Zhou YF, Dong KZ, Zhengliang H, Wang JD, Yang YR. Fault detection based on acoustic emission-early agglomeration recognition system in fluidized bed reactor. Ind Eng Chem Res. 2011;50:8476–84.10.1021/ie200260tSearch in Google Scholar

[34] Matero S, Poutiainen S, Leskinen J, Järvinen K, Ketolainen J, Reinikainen SP, et al. The feasibility of using acoustic emissions for monitoring of fluidized bed granulation. Chemom Intell Lab Syst. 2009;97:75–81.10.1016/j.chemolab.2008.11.001Search in Google Scholar

[35] Stamm M, Pfeiffer H, Reynaert J, Wevers M. Using acoustic emission measurements for Ice-melting detection. Appl Sci. 2019;9:5387.10.3390/app9245387Search in Google Scholar

[36] Zhang X, Xin BJ, Zheng YS, Shi MW, Lin LT, Gao C, et al. Study on fiber fracture sequence during yarn tensile fracture via acoustic emission method. J Text Inst. 2021;112:417–28.10.1080/00405000.2020.1761671Search in Google Scholar

[37] Daniher D, Briens L, Tallevi A. End-point detection in high-shear granulation using sound and vibration signal analysis. Powder Technol. 2008;181:130–6.10.1016/j.powtec.2006.12.003Search in Google Scholar

[38] Gamble JF, Dennis AB, Tobyn M. Monitoring and end-point prediction of a small scale wet granulation process using acoustic emission. Pharm Dev Technol. 2009;14:299–304.10.1080/10837450802603618Search in Google Scholar PubMed

[39] Briens L, Daniher D, Tallevi A. Monitoring high-shear granulations using sound and vibration measurements. Int J Pharma. 2007;331:54–60.10.1016/j.ijpharm.2006.09.012Search in Google Scholar PubMed

[40] Hansuld EM, Briens L, McCann JAB, Sayani A. Audible acoustics in high-shear wet granulation: application of frequency filtering. Int J Pharma. 2009;378:37–44.10.1016/j.ijpharm.2009.05.042Search in Google Scholar PubMed

[41] Sawada T, Gohsi Y, Abe C, Furuya K. Acoustic emission from phase transition of some chemicals. Anal Chem. 1985;57:1743–5.10.1021/ac00285a054Search in Google Scholar

[42] Ersen A, Smith A, Chotard T. Effect of malic and citric acid on the crystallization of gypsum investigated by coupled acoustic emission and electrical conductivity techniques. J Mater Sci. 2006;41:7210–7.10.1007/s10853-006-0918-6Search in Google Scholar

[43] Lube EL, Zlatkin AT. In-process monitoring of crystal perfection during melt growth. J Cryst Growth. 1989;98:817–26.10.1016/0022-0248(89)90322-9Search in Google Scholar

[44] Yaroslavkina E, Tyurin E, Zobnin P, Melnikov E. Acoustic emission system for studing the effect of AlTi5Bi modifier on the crystallization of aluminum. International Conference Complex Systems: Control and Modeling Problems (CSCMP). Samara, Russia: IEEE; 2019.10.1109/CSCMP45713.2019.8976683Search in Google Scholar

[45] Safaei B. The effect of embedding a porous core on the free vibration behavior of laminated composite plates. Steel Comp Struct. 2020;35:659–70.Search in Google Scholar

[46] Li H, Lv H, Sun H, Qin Z, Xiong J, Han Q, et al. Nonlinear vibrations of fiber-reinforced composite cylindrical shells with bolt loosening boundary conditions. J Sound Vib. 2021;496:115935.10.1016/j.jsv.2021.115935Search in Google Scholar

[47] Moradi-Dastjerdi R, Behdinan K, Safaei B, Qin Z. Static performance of agglomerated CNT-reinforced porous plates bonded with piezoceramic faces. Int J Mech Sci. 2020;188:105966.10.1016/j.ijmecsci.2020.105966Search in Google Scholar

[48] Moradi-Dastjerdi R, Behdinan K, Safaei B, Qin Z. Buckling behavior of porous CNT-reinforced plates integrated between active piezoelectric layers. Eng Struct. 2020;222:111141.10.1016/j.engstruct.2020.111141Search in Google Scholar

[49] Sahmani S, Safaei B. Large-amplitude oscillations of composite conical nanoshells with in-plane heterogeneity including surface stress effect. Appl Math Model. 2021;89:1792–1813.10.1016/j.apm.2020.08.039Search in Google Scholar

[50] Ying L, Li L. Understanding the corrosion resistance of nanocrystalline materials: electrochemical influences. Corrosion protection and control using nanomaterials. Woodhead Publishing; 2012. p. 59–85.10.1533/9780857095800.1.59Search in Google Scholar

[51] Bloch L, Kauffmann Y, Pokroy B. Size effect on the short range order and the crystallization of nanosized amorphous alumina. Cryst Growth Des. 2014;14:3983–9.10.1021/cg500580cSearch in Google Scholar

[52] Mosivan S, Kazeminezhad I. Magnetite nanoparticles functionalized with polypyrrole by pulsed sono-electrocrystallization and their applications for water treatment. J Mater Sci Mater Electron. 2018;29:12466–76.10.1007/s10854-018-9365-9Search in Google Scholar

[53] Jiang Q, Tallury S, Qiu Y. Interfacial characteristics of a carbon nanotube-polyimide nanocomposite by molecular dynamics simulation. Nanotechnol Rev. 2020;9:136–45.10.1515/ntrev-2020-0012Search in Google Scholar

[54] Thompson L, Azadmanjiri J, Nikzad M, Sbarski I, Wang J, Yu A. Cellulose nanocrystals: production, functionalization and advanced applications. Rev Adv Mater Sci. 2019;58:1–16.10.1515/rams-2019-0001Search in Google Scholar

[55] Lifchitz EM, Kossevitch A, Pitayevski LP. Transl, theoretical physics. Vol. 7. Theory of elasticity. From the Russian by V. kolimeev. 2nd ed. Moscow: Editions Mir. 264 P; 1990.Search in Google Scholar

[56] Roberts RJ, Rowe RC, York P. The relationship between young modulus of elasticity of organic-solids and their molecular-structure. Powder Technol. 1991;65:139–46.10.1016/0032-5910(91)80176-JSearch in Google Scholar

[57] Mullin JW. Crystallization. 3rd ed. Oxford: Butterworth-Heinemann; 1993. p. 205Search in Google Scholar

© 2021 Xingjun Wang et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions