Abstract

Titanium dioxide (TiO2) is the most effective photocatalysts for low-cost degradation of organic pollutant; however, the wide band gap and the high recombination rate of the charge carriers are drawbacks that hinders it practical application. In this study, TiO2 and titanium mixed metal oxides ternary (V/Ag/TiO2) nanocatalyst was synthesized through a microwave-assisted sol–gel route using Ti(C4H9O)4, NH4VO3, and AgNO3 as precursors. The XRD analysis of the synthesized TiO2 and V/Ag/TiO2 depicts lattice fringes for rutile and anatase crystalline phases. Raman spectra indicate the formation of a mesoporous multiphase sample mixture of rutile and anatase phases. The spectrum shift to the visible light region was demonstrated by the UV-visible spectroscopy analysis. Diffuse reflectance spectroscopy (DRS) reveals a reduced band gap of 2.9 eV for TiO2 and 2.65 eV for V/Ag/TiO2. Brunauer–Emmett–Teller (BET) indicates a large surface area of 92.8 and 84.8 m2 g−1 for TiO2 and V/Ag/TiO2, respectively. Nitrogen adsorption–desorption isotherm exhibits type IV isotherm, signifying the presence of the mesoporous structure. SEM portrays a cluster of rod-like aggregate particles, while the HRTEM analysis illustrates nanoparticles of rod-like cylindrical shape with a homogeneous size diameter. The synthesized nanocatalyst demonstrated a significant photocatalytic ability in the degradation of methyl orange (MO) and methylene blue (MB). V/Ag/TiO2 shows higher activity in the visible region. Thus, the present report suggests efficient, suitable, and economical microwave-assisted sol–gel techniques to yield V/Ag/TiO2 nanocatalysts with harnessed photocatalytic performance for the degradation of toxic organic pollutants in the presence of visible light irradiation.

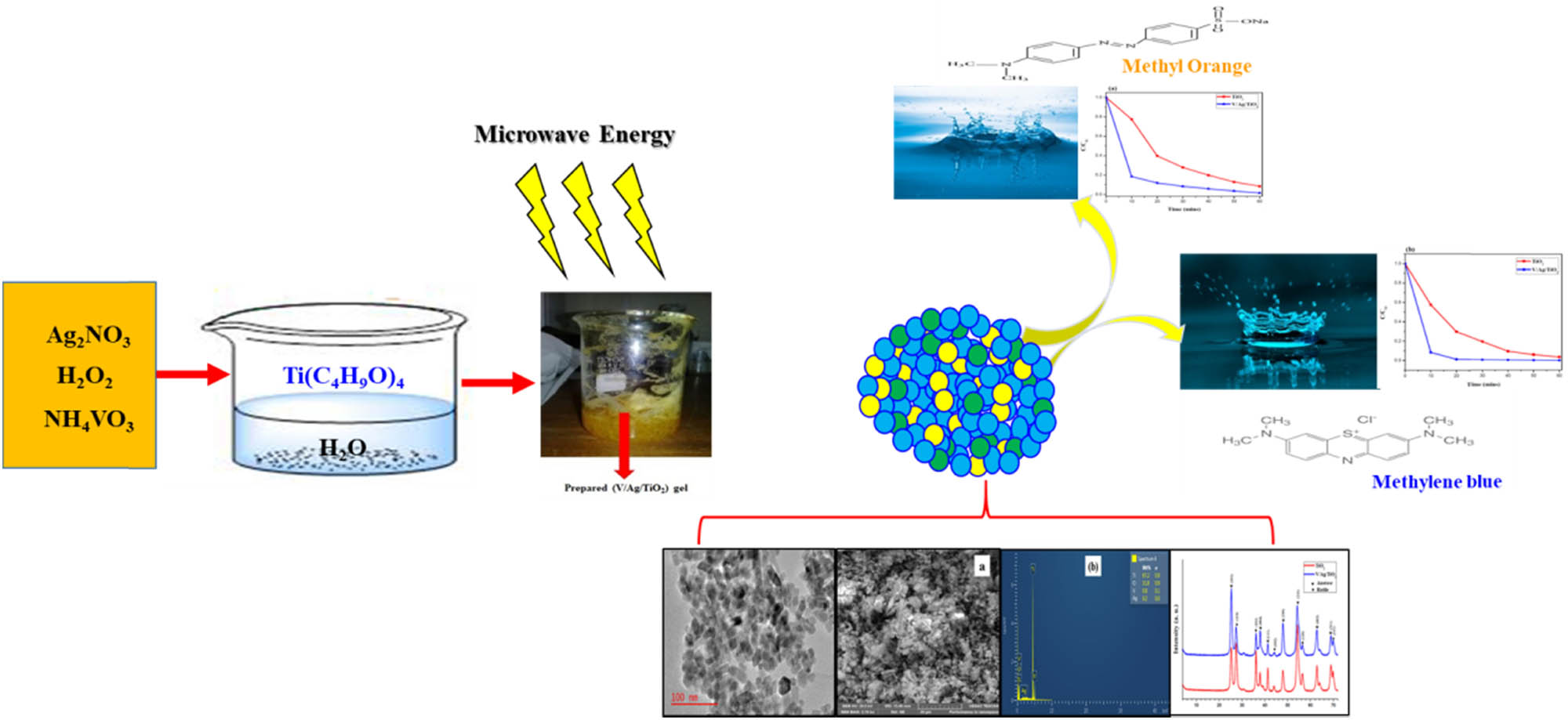

Graphical abstract

1 Introduction

Up till now, a lot of researchers worked on nanostructures, and the use of the nanostructures has been growing rapidly [1]. Nanoscaled adsorbents such as nanofibers, carbon nanotubes, graphene, and metal oxides are extensively employed to improve wastewater and water treatment [2]. Szczepanik et al. [3] showed that the photodegradation of aniline and its chloro derivatives shows the existence of Hal-Fe2O3. The performance of Hal-TiO2 nanocomposite is higher than the commercially available photocatalyst P25. Shafey [4] showed that the manufactured biological nanostructures and nanomaterials have a great application in the pharmaceutical industry, such as drug delivery, novel pharmaceuticals preparation, and production of functional nanodevices. The reason for this is that these nanomaterials are assumed to possess better adsorptive performance compared to common adsorbents. Nanosized metal oxides, such as titanium oxide [5] and zinc oxide (ZnO) [6], have shown high adsorption to inorganic and organic pollutant materials. The discovery of photocatalysis has opened up new fields in the world of wastewater treatment [7]. The photocatalysis technology is used as an alternative to environmental protection, detoxification of contaminants, and photodegradation of organic contaminants [8]. The utilization of TiO2 as a photocatalyst has gained momentum owing to its resistance to photocorrosion [9], chemical stability [10], biological activity [11], and low cost [12]. Still, TiO2 has three big disadvantages [13]: a high band gap value of 3.2 eV; UV-only photocatalytic response with a fast recombination photo-generated pairs of electron–hole; and low photocatalytic reaction quantity in the aqueous phase [14]. Ni et al. [15] by considering cold-rolling deformation investigated microhardness and microstructural evolution of two types of electrodeposited gradient nanostructured nickel samples with a symmetric structure.

Titanium dioxide (TiO2) has been proven to be the most commonly used by different oxide semiconductor photocatalysts [16] because of its good oxidizing strength, long-term photostability, and nontoxicity [17]. Guo et al. [18] deposited ultrathin SiO2 layers by using atomic layer deposition (ALD) on nanoparticles to fabricate core/shell nanostructures. However, the photocatalytic efficiency of TiO2 to degrade dyes decreases substantially due to the high recombination ratio of photo-induced electrons (e−) [19] and holes (h+) produced when irradiated under the ultraviolet (UV) light (λ < 380 nm) [20]. With nanoscaled external dimensions, TiO2, a semiconductor photocatalyst, has extensive applications in different industries [21] such as decontamination or mineralization of pollutants in water to harmless inorganic anions [3] and cosmetic materials [22]. Therefore, TiO2 nanoparticles (T-NPs) have attracted the attention of many researchers because of their extraordinary properties [23]. It is well known that TiO2 powder in the anatase phase has strong catalytic activity because of its redox properties, surface chemistry, and high surface area. Typek et al. [24] studied the magnetic characteristics of several TiO2/graphitic carbon nanocomposites fabricated at various temperatures (300–850°C) in the presence of benzene vapor. In another study, the effect of hexylamine on the morphology of nano-TiO2 was investigated by Sun et al. [25]. Li et al. [26] reviewed theoretical calculations of TiO2-based commercial photocatalysts in water splitting. Wang et al. [27] developed an experimental test method to determine the photocatalytic degradation effect of nano-TiO2 on oil pollution of road surfaces. Guo et al. [28] explored the physicochemical properties of the mixed crystal nano-TiO2 using the X-ray diffraction (XRD) technique. MgO-modified TiO2 thin films were characterized using different techniques of instrumental analysis such as SEM-EDS, AFM, XRD, and UV-visible absorption spectrometry. The photoactivity of these structures was also studied using photo-voltammetry followed by splitting water in a twin-cell reactor, where oxygen and hydrogen gases were generated separately [29]. Mahshid et al. [30] studied the preparation of titanium oxide with two different polymorphs and reported that the water/titanium molar ratio (r) has been employed to control the hydrolysis and condensation of titanium isopropoxide in solution.

Nanostructures can make a lot of impact on material, and hence, researchers carried out many studies on composites [31] and their photocatalytic activity [32]. In another study, bulk nanocrystalline graphite has been studied for piezoresistive sensors by Simionescu et al. [33]. Naghdi et al. [34] reviewed different conductive metal nanomaterials and the challenges facing methods of applications and deposition of thin films. Liu et al. [35] studied a “cross-relaxation effect” model to investigate the water-induced shape memory effect, relaxation, and strain recovery of amorphous shape memory polymer. Sharma et al. [36] shown that the porous Co–Mo–ON alloy nanodendrites supported on nitrogen-doped graphene combines the advantages of oxygen reduction active pyridinic-N or graphitic-N contents and the high kinetic resistance of the graphitic carbon of nitrogen-doped graphene in the acidic medium. To optimize its photocatalytic performance, modification of TiO2 nanoparticles by noble metals is increasing enormously [37]. The results exerted depend on the noble metal and material chosen, the form of TiO2 used, the quality of organic dyes, and the medium of photoreaction [38]. Doping modifications, therefore, are perhaps the most popular methods introduced to improve the photocatalytic efficiency of TiO2 [17]. Therefore, the TiO2 hybridization with V2O5 can expand the absorption spectrum to the area of visible light [39]. It may expand the volume of excitable radiations in the region of visible light, which could as well change the surface and grain morphologies [40], leading to higher absorption of visible light together with an increase in the number of reactive sites that are surface active [41]. But alternatively, deposition of noble metals such as Ag could achieve high absorption within the region of visible light and efficiently isolate the electron–hole pairs attributed to plasmon resonance at the surface [42].

Microwave-assisted sol–gel synthesis is a relatively novel method to produce materials since microwave heating is an in situ mode of energy conversion and is radically different from traditional heating processes [43]. The microwave-assisted sol–gel method has sparked tremendous interest due to its numerous advantages, including the ability to generate small, uniform particles, high crystallinity, regulated morphology, and high purity due to the short reaction time. Microwave treatment has a number of advantages, including ease of use, energy savings, and high yield [44]. Since microwave heating is an in situ mode of energy conversion that is radically different from traditional heating processes, microwave-assisted sol–gel synthesis is a relatively new method of producing materials.

Metal oxide hybridization refers to a technique, whereby for a synergistic effect, two separate semiconductors are hybridized. In addition to photocatalytic improvement, the noble metal modification allows TiO2 nanoparticles to be involved in the visible light energy spectrum [45]. The photo-generated electron–hole pairs undertake rotational transport of the two semiconductors, thus lengthening the carrier’s lifespan, broadening the absorption spectrum, and using the solar energy. For instance, V2O5 is an oxide semiconductor possessing a small band gap of 2.80 eV. Hence, the excellent stability and reproducibility were present in the noble metal-modified TiO2. Ag+-modified TiO2 prepared by Gupta et al. [46] was noted to be used in mixed dye (CV and MR) degradation for the second time with 90% effectiveness. Tripathi et al. [47] prepared a mixed metal oxides of silver and vanadium-sensitized titanium, using titanium isopropoxide (C12H28O4Ti) as a TiO2 precursor, vanadium pentoxide (V2O5) as a vanadium precursor, and silver chloride (AgCl) as a silver precursor and reported that the metal oxide hybrid catalyst exhibited a superior photocatalytic performance and attributed it to the narrow band gap and reduced electron–hole recombination of the compound. In another study, Zhu et al. [39] used tetrabutyl orthotitanate (C16H40O4Ti), as a precursor for titanium, silver nitrate (AgNO3) as silver sources, triisopropoxyvandium (V) oxide (C9H21O4V) as a precursor for vanadium in synthesizing Ag/V2O5/TiO2 ternary nanostructured compound. They systematically studied the relationship between the composition and the morphology of the compound and reported a superior photocatalytic performance of the overneat TiO2. In one of our recent works, a sol–gel/hydrothermal route was used to prepare a V and Ag mixed-TiO2 nanocatalyst. We reported enhanced photocatalytic performance and selective degradation of organic pollutants from the river surface water [48]. Improvement of TiO2 photocatalytic performance with silver and vanadium doping was reported by all previous studies [49].

For this investigation, we aim to synthesized a ternary nanocatalyst and obtain small particles with a narrow size distribution in a short period of reaction time and high purity. Thus, a ternary nanocatalyst using titanium(iv) butoxide [Ti(C4H9O)4] as the titanium precursor and, ammonium metavanadate (NH4VO3) as the precursor of vanadium, and silver nitrate (Ag2NO3) as the silver precursor was synthesized using the microwave-assisted sol–gel method. The microstructural, chemical, photocatalytic, and optical features of the doped photocatalyst were investigated. For evaluation of the photocatalytic performance in degradation of organic pollutant, degradation of methyl orange (MO) and methylene blue (MB) as model pollutant with the use of visible light was examined. This innovation for microwave-assisted sol–gel synthesis of mixed metal hybrid nanocatalyst is for the development of a co-doped TiO2, with high purity, a short period of reaction time, and small particles with a narrow size distribution. This method will contribute to a faster, simplistic, environmentally friendly, and highly efficient method for the fabrication of high-performance next-generation nanocatalyst.

2 Materials and methods

2.1 Synthesis of materials

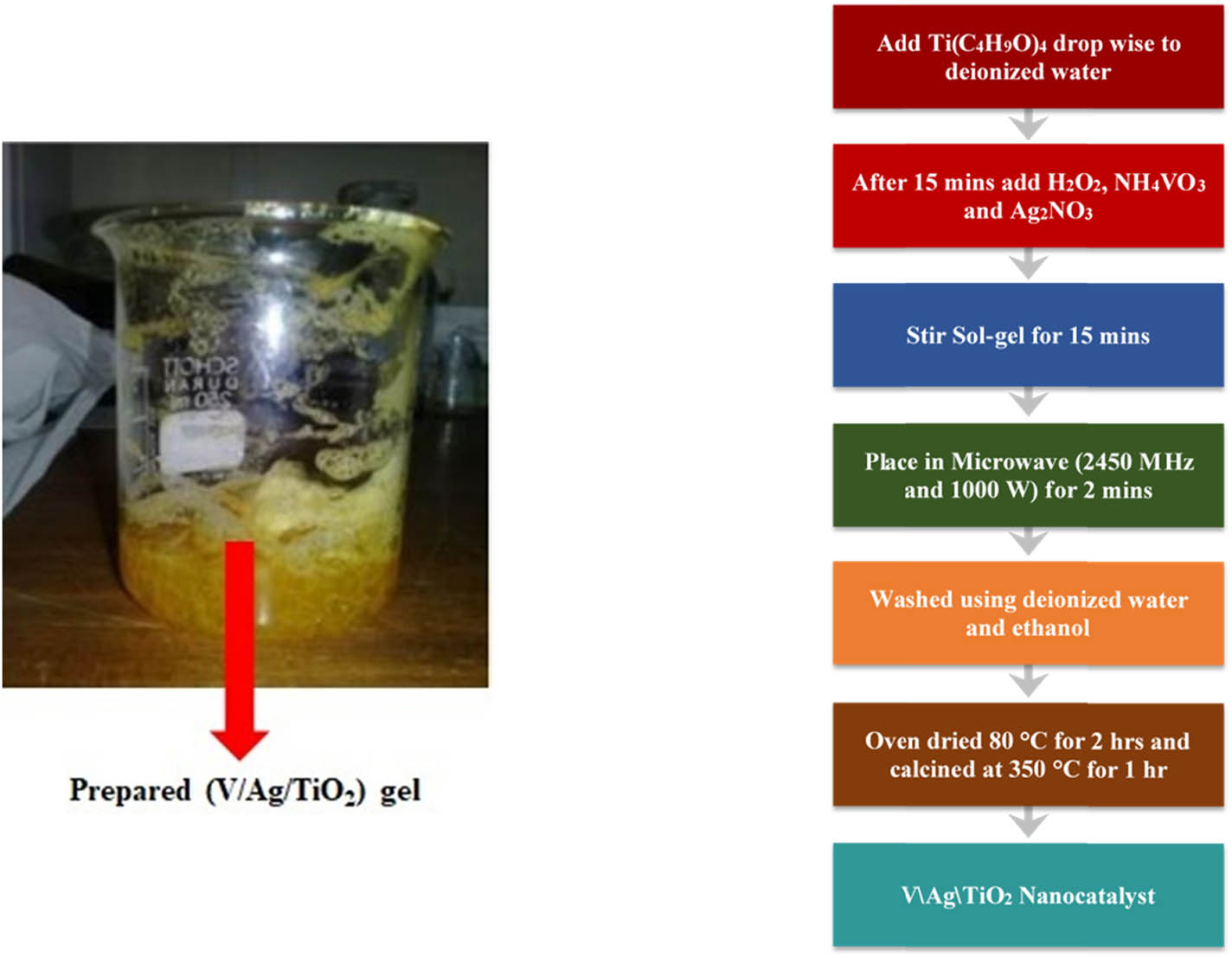

To prepare the ternary nanocatalyst, 2 mL titanium(iv) butoxide (97% Sigma-Aldrich) was added dropwise to 50 mL deionized water in a beaker. After 15 min, 5 mL H2O2 (35% Sigma-Aldrich), 5 mL AgNO3 (10 mg/L; 99% Sigma-Aldrich), and 5 mL NH4VO3 (0.4 mg/L; 99% Sigma-Aldrich) were included in the mixture. Continuous stirring of the yellowish sol mixture was carried out for 15 min. Then, the solution was microwaved with a microwave oven (LG Electronics Model No. MS2596OB) for 2 min at a frequency of 2,450 MHz and 1,000 W. This equipment was programmed at a temperature of 80°C with on–off cycle (20 s on – 40 s off). Unlike conventional heating, the microwave energy directly interacts with the material via molecular interaction with the electromagnetic field, and the material itself generates the heat, which subsequently generates fast homogeneous nucleation and easy gel dissolution. The sample was allowed to cool at room temperature and washed using deionized water and ethanol. The resulting precipitate was dried in oven at 80°C for 2 hours and calcined at 350°C for 1 h [47]. The weight ratio of Ag, V, and TiO2 was 1:2:6. For the comparative purpose, TiO2 was also prepared without the addition of vanadium (V) and silver (Ag). This microwave-assisted sol–gel technique is inexpensive, clean, and eco-friendly; reduces energy consumption; fast compared to the conventional sol–gel hydrothermal method. The schematic illustrations of the fabrication procedure are shown in Figure 1.

The schematic illustrations and sample preparation for the fabrication procedure.

3 Result and discussion

3.1 Nanocatalyst characterization

The crystal structure was analyzed with XRD using X-Pert Philips at 40 kV acceleration voltage as well as a 40 mA current from 2θ 4° to 75° using powdered samples. The chemical structure was examined by Raman spectroscopy using a Reinshaw Raman microscope. SEM was carried out using a TESCAN VEGA3. The samples were first place on a carbon substrate in the sample holder, and then sputter coated with car. TEM was performed using a JEM-2100 JEOL electron microscope. The samples for the TEM analysis were first sonicated in ethanol for 5 min, and few drops of the solution were placed on a carbon-coated cropper grid (Sample holder) and used for the analysis. The surface area was studied by Brunauer–Emmett–Teller (BET) using a micrometrics ASAP 2460. UV-Vis analysis was carried out using a UV-Vis-NIR spectra-photometer with a DRA inserter. VG ESCALAB MKII XPS system was employed for the XPS analysis.

3.2 Photocatalytic activity test

In the experiment, MO and MB solutions were prepared and then put to use as a pollutant for the model. A total of 0.2 g of the prepared nanocatalyst was made soluble in 500 mL of 5 × 10−5 MO solution. The MO solution of 10 mg/L of was prepared and used as a model pollutant. A total of 0.2 g of the prepared nanocatalyst was dissolved in 50 mL of the MB solution and then irradiated using a lamp as a visible illumination source (λ = 254 nm, compact fluorescent integrated lamp 9 W, 50–60 Hz, 220–240 V, Philips, Holland). The solution was stirred mechanically, with exposure to the illumination of visible light. Aliquots of 2 mL were retrieved from the solution and passed through filtration of a PTFE syringe at 30 min time intervals for 3 h. The resultant solution was analyzed by the UV-visible spectrophotometer.

3.3 Photocatalytic evaluation

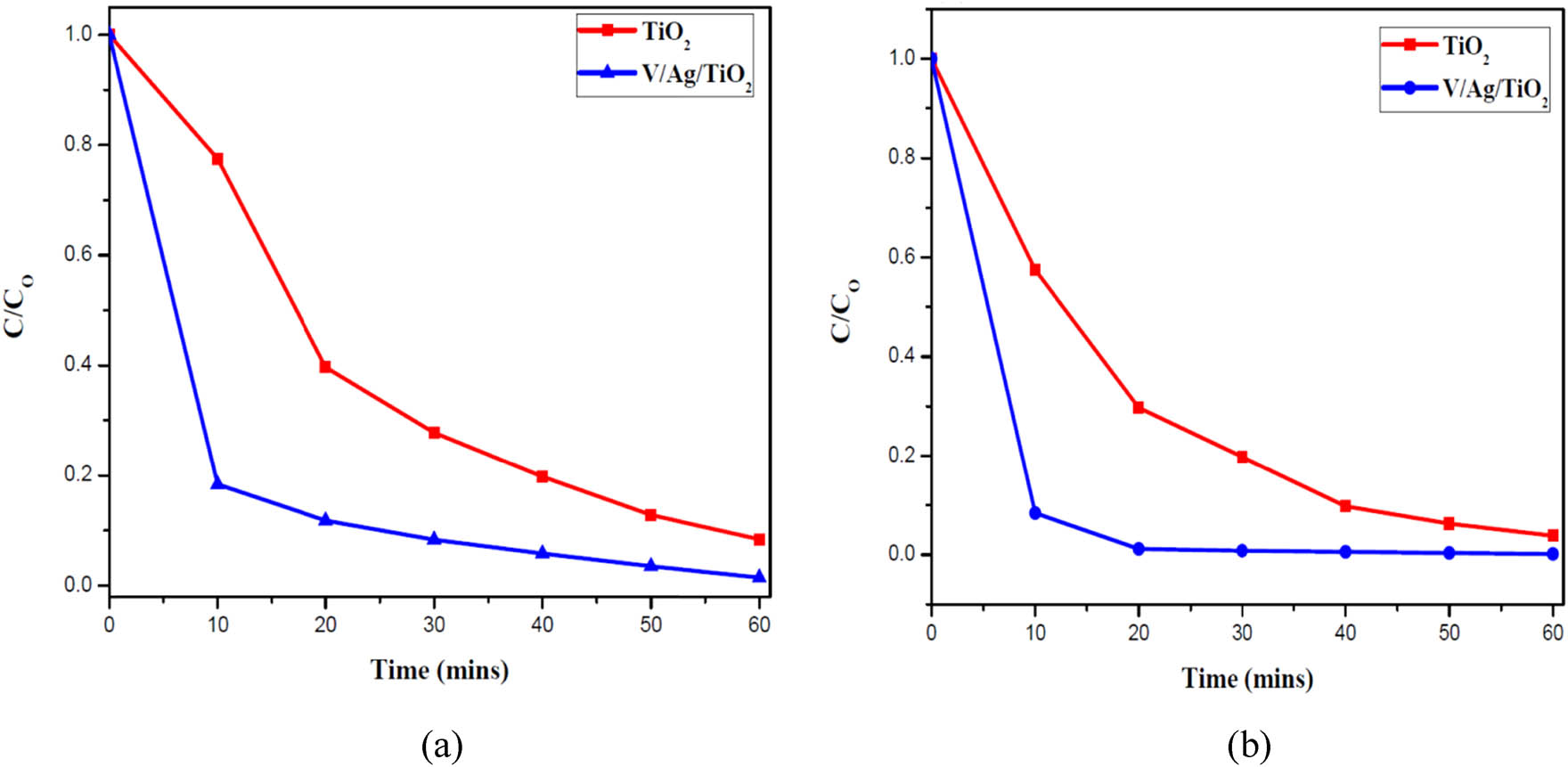

The supernatant absorbance was determined at 464 nm for MO and 473 nm for MB using applicable blanks. To compare the photocatalytic behavior of the prepared TiO2 and V/Ag/TiO2 nanocatalyst, the C/Co was plotted as shown in Figure 2. As observed, the synthesized TiO2 degradation of MO and MB exhibits poor photocatalytic effects with an average removal rate of 72.6% for MO and 73.86% for MB after 60 min compare to V/Ag/TiO2 removal of 98.55% for MO and 99.24% for MB under visible light irradiation. Similar results for TiO2 degradation of MO and MB have been previously reported [27,38,46]. The improved photocatalytic performance of the V/Ag/TiO2 nanocatalyst can be attributed to an efficient photo-induced structure [46,47,48,49,50]. This structure can be seen as the electron–hole pair separation in the reaction system. The shift of light absorption to the visible region helps in utilizing visible light for the activity of photocatalyst. In addition, the larger surface area contributes to the higher light harvesting, which effectively increases the photocatalytic activity of the nanocatalyst.

Degradation of (a) methyl orange (b) methylene blue under visible light.

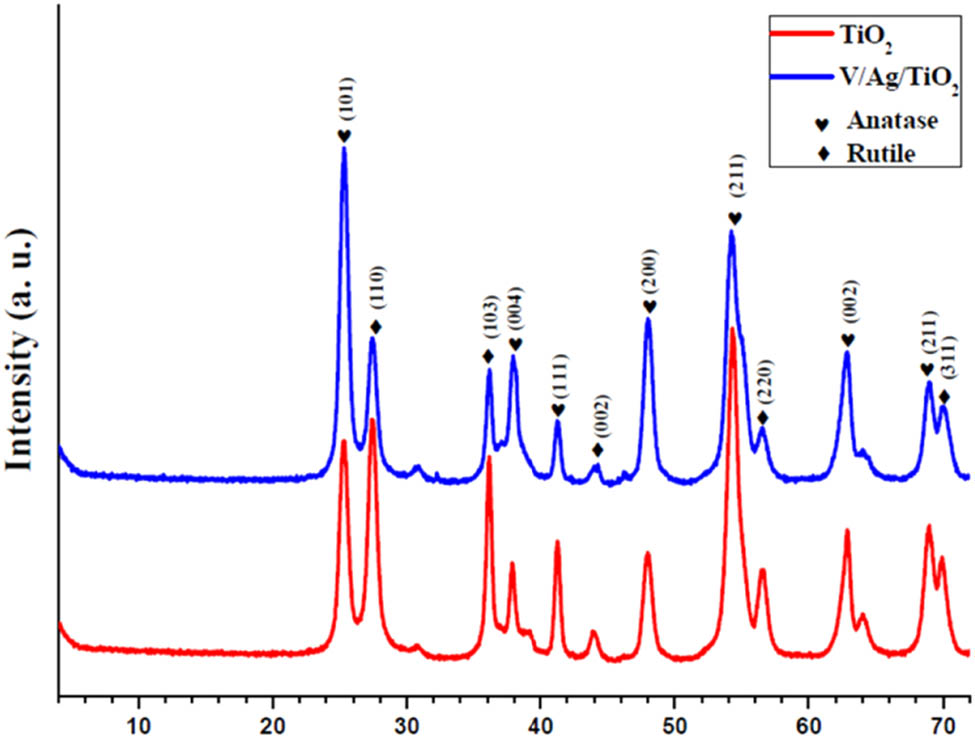

Figure 3 demonstrates the diffraction phase peaks of TiO2 and V/Ag/TiO2. The diffraction peaks reveal the combined crystal phases of both anatase and rutile. The intense peak was observed at a 2θ value of 25.4°. This corresponds to (101) anatase crystal plane for TiO2 and had consistency with the JCPDS database # 89-4921. Peaks at 37.4°, 42.4°, and 48.2° of (004), (002), and (200) plane are also attributed to the anatase phase of TiO2 [47]. Peaks at 27.3°, 35.9°, 44.3°, and 55.2° may be attributed to the rutile phase [49]. The addition of the V and Ag dopants resulted in an increase in the anatase phase in the ternary nanocatalyst, and this was in agreement with the previous studies that the addition of dopant increases the anatase phase of TiO2 [51,52].

XRD patterns of synthesized TiO2 and V/Ag/TiO2 nanostructure photocatalysts.

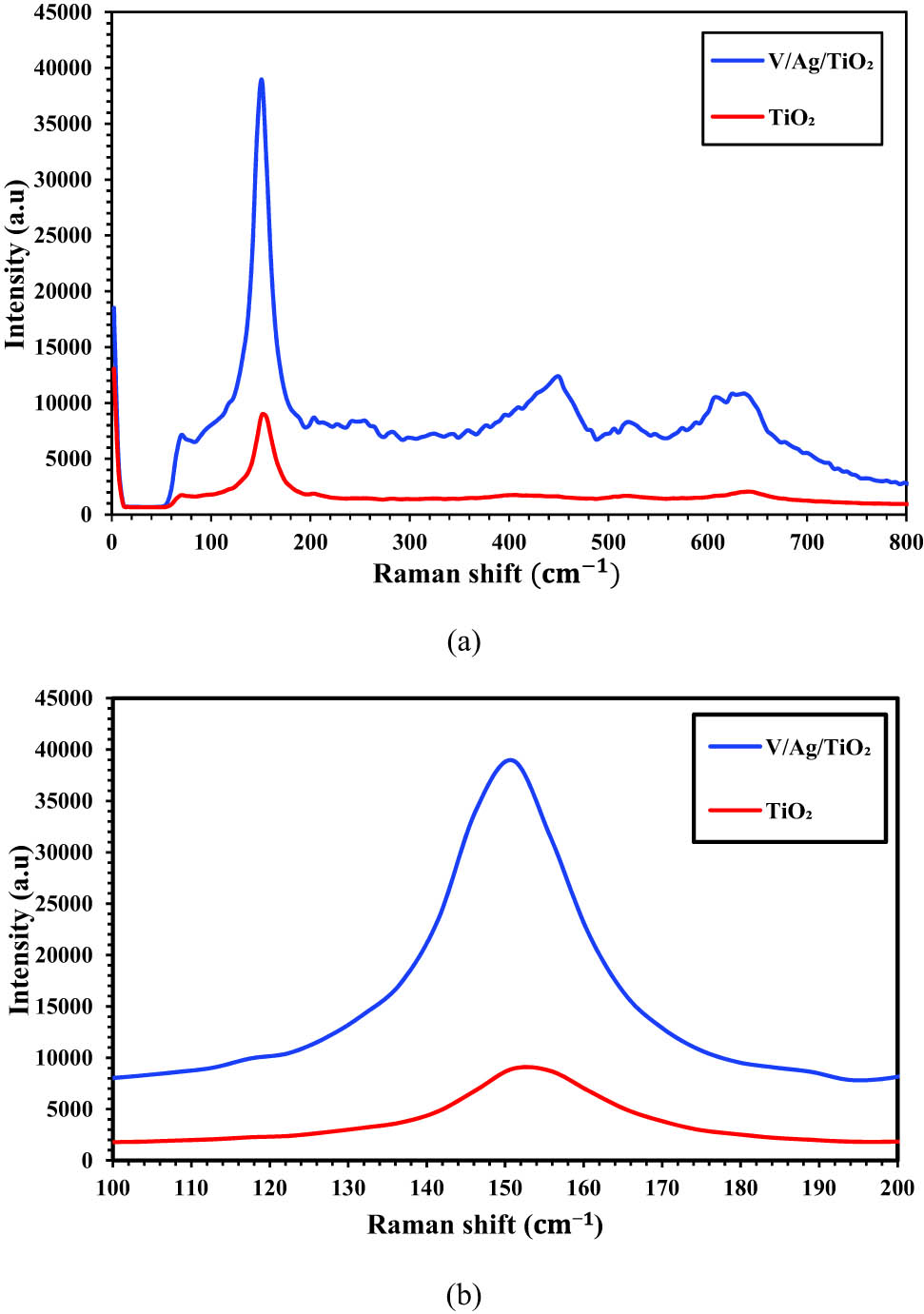

As shown in Figure 4(a), Raman spectra were measured for further investigation toward the phase structures of distinct samples. Raman bands at 150, 515, and 637 cm−1 could be attributed to the crystal phase of anatase, and that of 243, 449, and 615 cm−1 were allocated the rutile phase, which indicated the formation of a multiphase mesoporous combined samples of both anatase and rutile crystal phases, indicating consistency with the XRD study [49]. As illustrated in Figure 4(b), in comparison to the prepared TiO2 sample, the major band at 150 cm−1 for V/Ag/TiO2 was widened and then slightly shifted, which can be attributed to the disorganization of the TiO2 crystals, which resulted from the effects of the phonon confinement or the crystal size [53,54,55].

Raman spectral of synthesized TiO2 and V/Ag/TiO2 nanostructure photocatalysts.

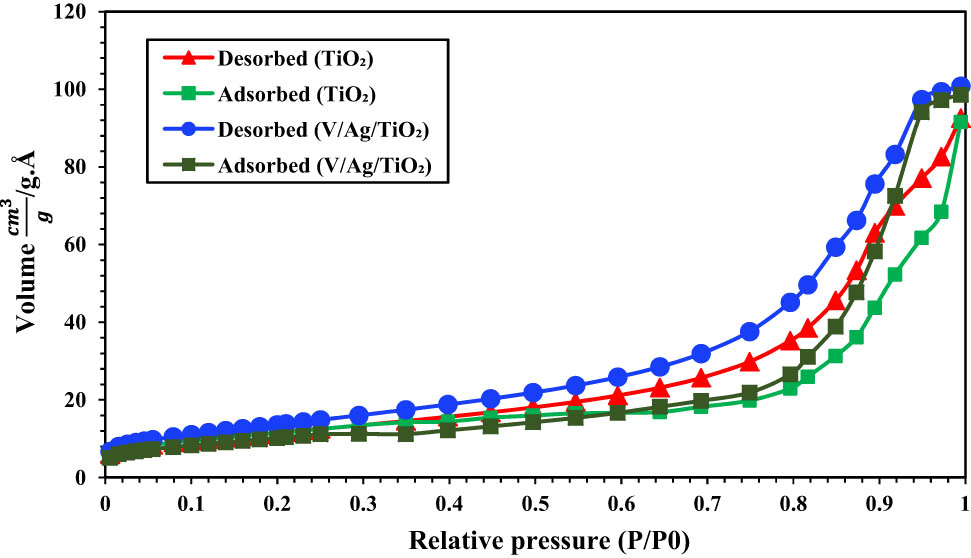

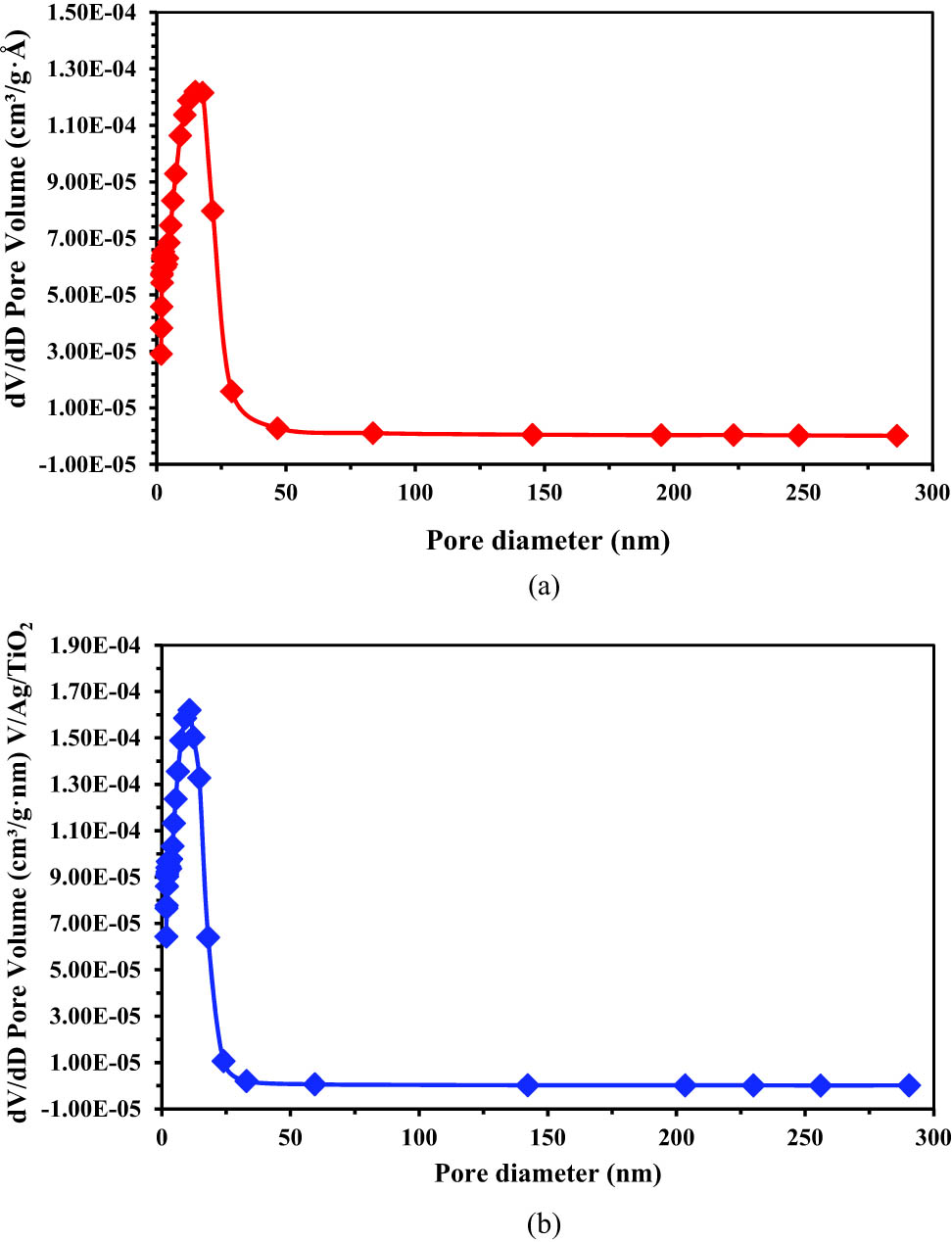

S BET results for TiO2 and V-Ag/TiO2, were 104.8 and 122.8 m2 g−1, respectively. Also, V/Ag/TiO2 nanocatalyst possesses the higher surface area due to the miniature crystallite sizes of the sample. It has been reported from the previous research that with higher specific surface areas, there is an increase in photocatalyst activities since it provides additional sites for the absorption of light. As such, the high surface area of the synthesized nanocrystal contributed to the effective degradation of MO and MB [48,50,56]. Figure 5 displays the nitrogen adsorption–desorption isotherm, which exhibits a type IV isotherm, indicating the existence of the mesoporous structure in association with the absorbent capillary condensation [57]. Figure 6 shows the pore size distribution of the synthesized (a) TiO2 and (b) V/Ag/TiO2. There was a minimal distribution of the mesoporous pores of uniform sizes ranging from 2 to 28 nm.

The nitrogen adsorption–desorption isotherms of the synthesized TiO2 and V/Ag/TiO2.

Pore size distribution of the synthesized (a) TiO2 and (b) V/Ag/TiO2.

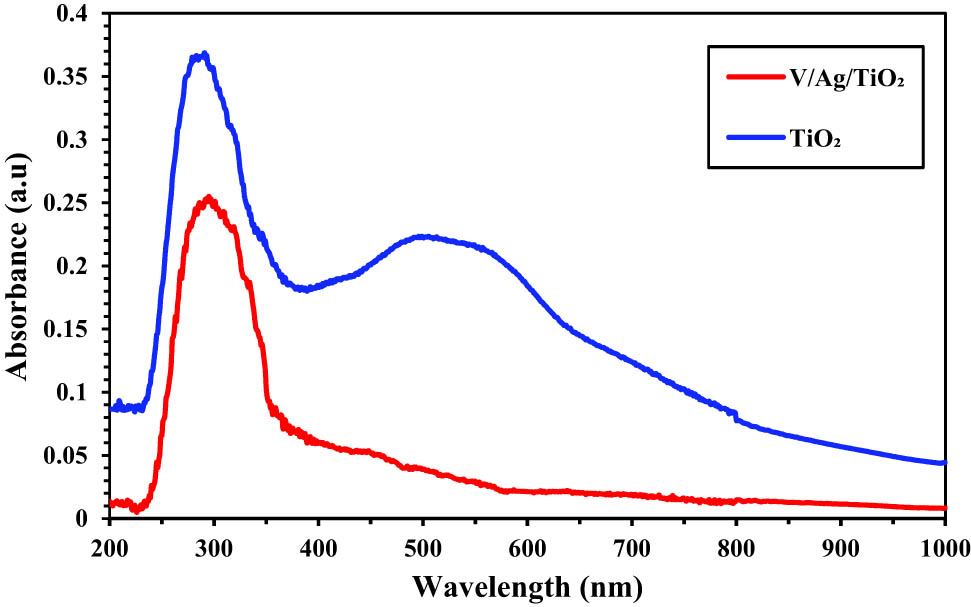

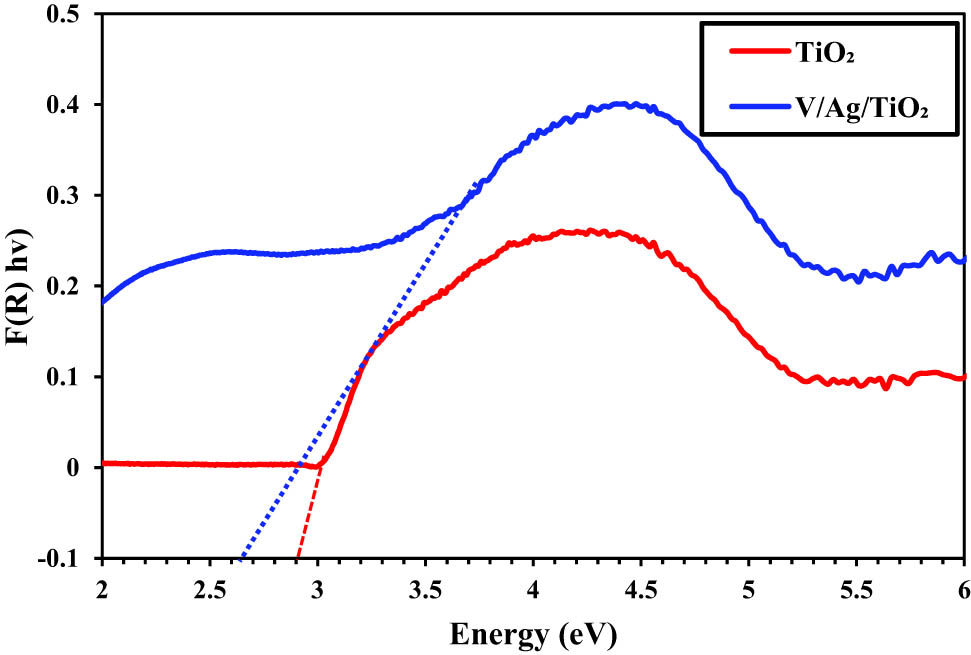

Figure 7 demonstrates the spectrum absorbance of the synthesized nanocatalyst. The absorption edges of TiO2 were observed at 404 nm and was similar to the previous studies by Khutso et al. [49] and Liu et al. [58]. Doping of TiO2 with silver and vanadium shows a remarkable increase in photocatalytic activities at the irradiation of visible light [47]. Emphasizing the synergistic impact of vanadium and silver, their influence has brought about an increased kinetic reaction as a result of moving the light absorption toward the region of visible light, hence gathering increased energy quantity. V/Ag/TiO2 absorption edge moved to the increased wavelength with an added peak around the shoulder close to 580 nm. This suggested that the V/Ag/TiO2 nanocatalyst can be successfully utilized in the visible light spectrum [47,49]. The doping effects of V and Ag significantly improve the light absorption at extended wavelengths (>400 nm) which is in the existence of the visible light regions [49]. The calculation of the energy band gap (eV) was employed for the evaluation of the energy needed for activating the nanocatalyst. Each nanocatalyst’s energy band gap (eV) was determined using the Tauc equation [59]. As illustrated in Figure 8, the band gap energies of TiO2 and V/Ag/TiO2 were interpolated to be 2.9, and 2.65 eV, respectively. The nanocatalyst V/Ag/TiO2 has achieved the desired minimal band energy value. The reduced band gap allows activation of the nanocatalyst with lower energy within the visible light region.

Absorbance spectrum of the synthesized TiO2 and V/Ag/TiO2.

Energy band gap of the synthesized TiO2 and V/Ag/TiO2.

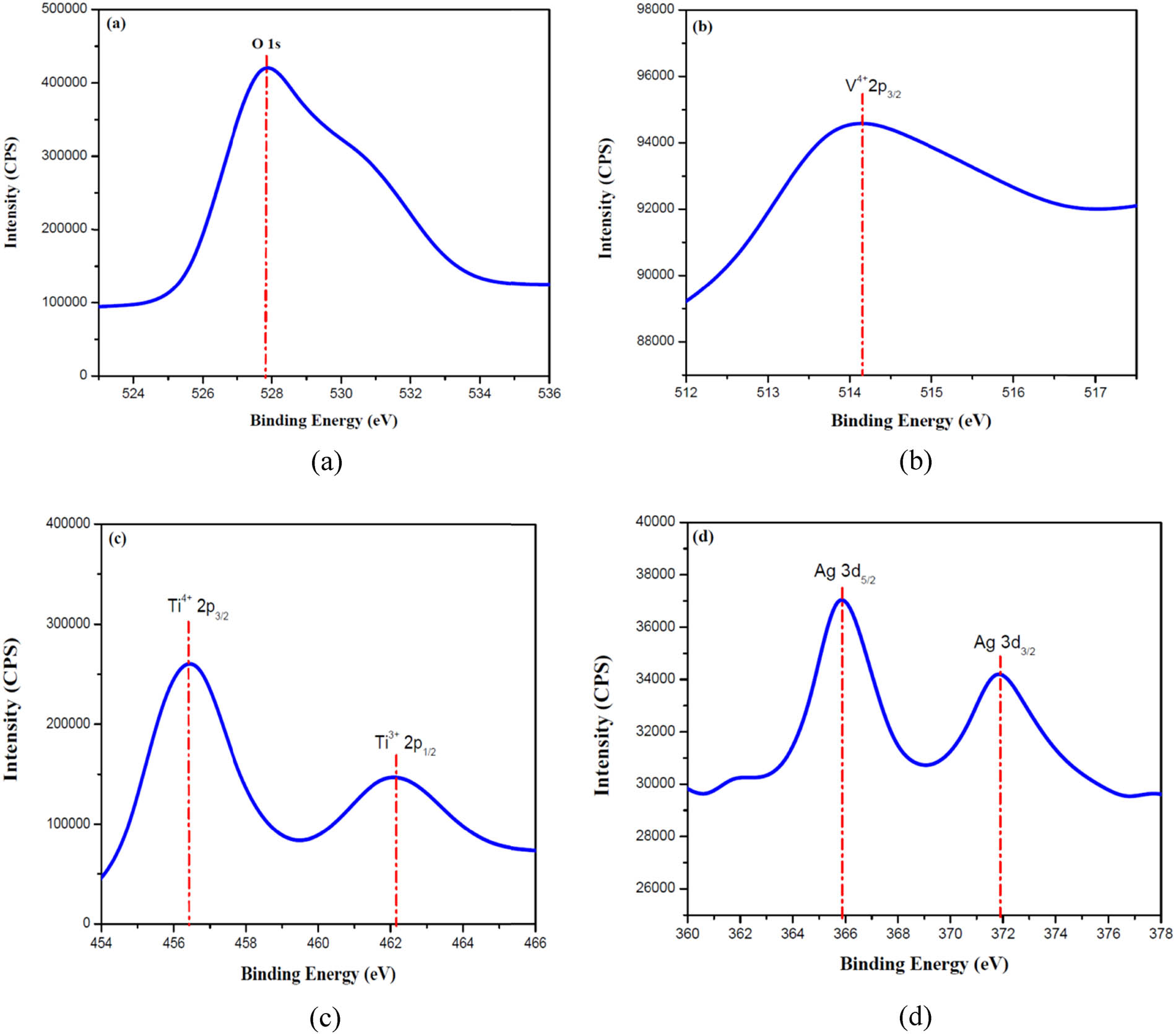

The XPS examination (Figure 9) reveals binding states of oxygen in the synthesized V/Ag/TiO2 nanocatalyst sample. O 1s spectral was observed at a 527.8 eV binding energy, which could be allotted to oxygen lattice in TiO2 [55]. V 2p3/2 binding energy was observed at a peak value of 514.1 eV, demonstrating the existence of V3+ at the surface of the catalyst in the IV state [48,58]. Binding energy peaks of Ti 2p1/2 and Ti 2p3/2 occur at 462.3 and 456.75 eV, respectively, indicating the formation of Ti4+ and Ti3+ in TiO2, and these results were similar to that obtained by other researchers [55,57]. Low binding energies of Ag 3d3/2 and Ag 3d5/2 were observed at 371. 90 and 365.85 eV, respectively [60].

XPS spectra of (a) O 1s, (b) V 2p, (c) Ti 2p, and (d) Ag 3d of the synthesized V/Ag/TiO2.

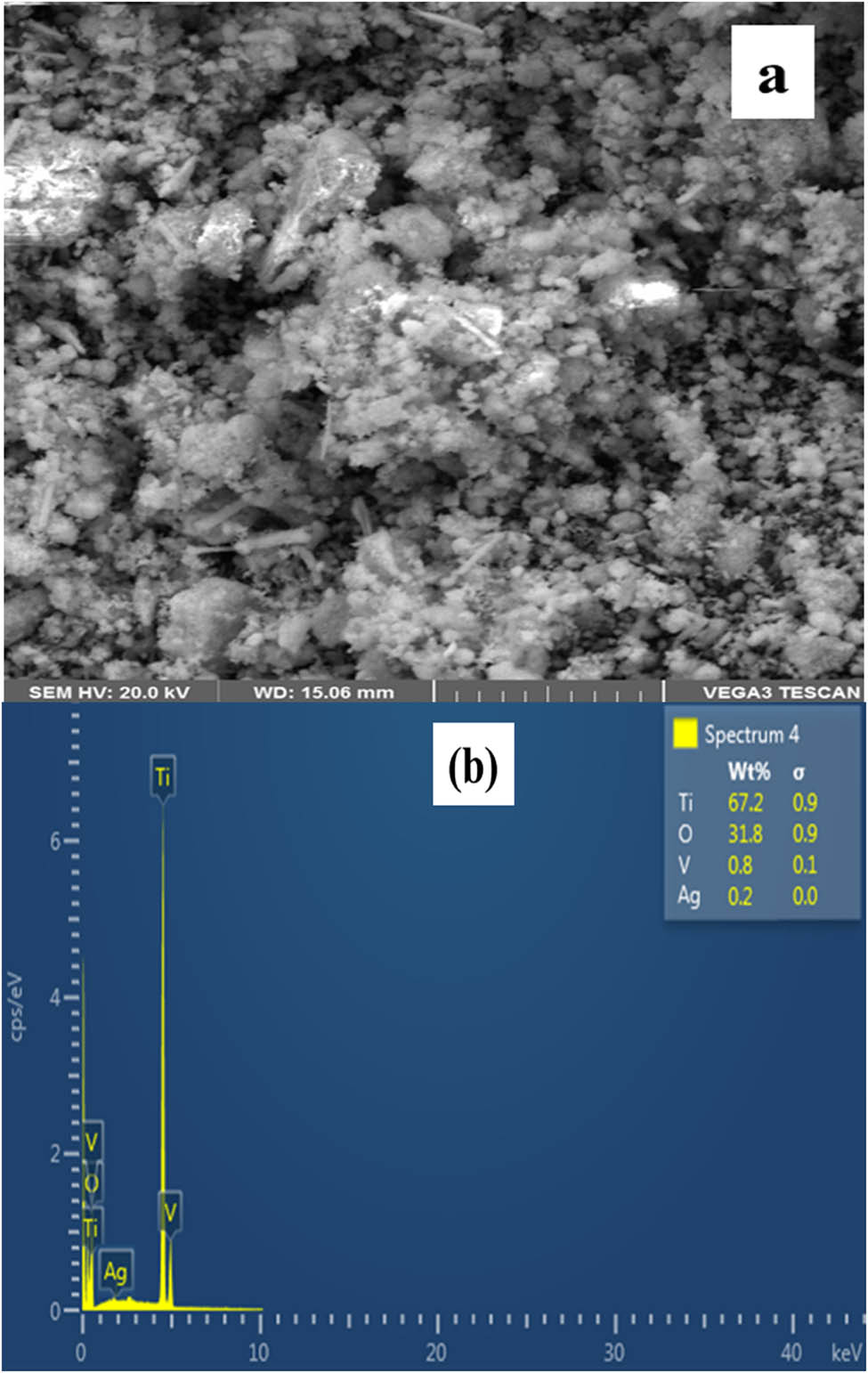

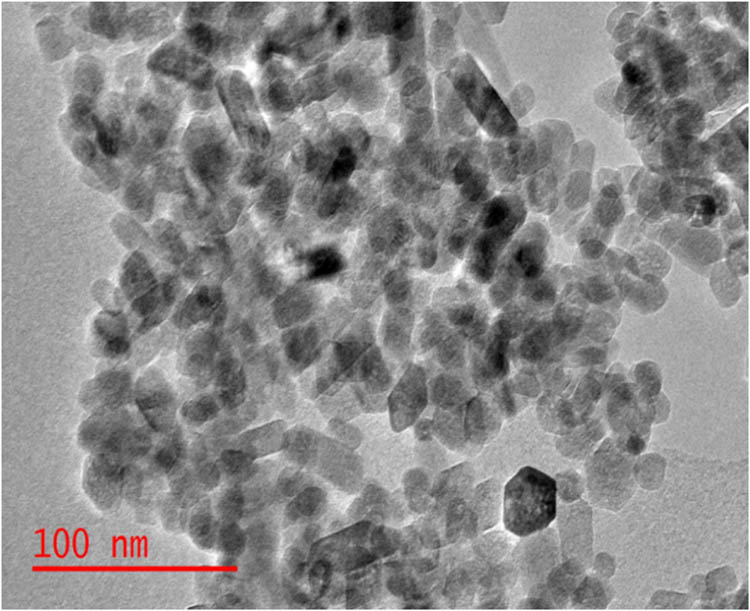

As shown in Figure 10(a), the SEM image for V/Ag/TiO2 describes the creation of a closely stacked cluster comprising rod-like aggregated particles of diameters of nonuniform sizes, while Figure 10(b) displays the EDX mapping showing the composition of the nanocatalyst. HRTEM images for the prepared nanocatalyst are shown in Figure 11. The synthesized V/Ag/TiO2 nanocatalyst was rod-like cylinder with a homogeneous size diameter ranging between 15 and 45 nm. This rod-like shape can be attributed to the type of synthesis method and precursor employed as this differs from the rectangular shape reported by Zhu et al. [39]. The photocatalyst with a rod-like shape has been reported to be very effective in organic dye degradation [49].

Morphology of V/Ag/TiO2 nanocatalyst: (a) SEM image (b) EDX mapping.

HRTEM images of V/Ag/TiO2.

4 Conclusion

Vanadium and silver co-doped titanium oxide ternary nanocatalyst was successfully synthesized using a microwave-assisted sol–gel method. The co-doped photocatalyst shows the reduced band gap of 2.65 eV, the large surface area of 84.8 m2 g−1, and the particle size between 15 and 45 nm. The synthesized V/Ag/TiO2 demonstrated the ability of these photocatalysts in successfull degradation of MO and MB, indicating the prevention of recombination of the electron hole. The synthesis of a microwave-assisted sol–gel ternary nanocatalyst is easier and faster, and nanoparticles with a larger surface area are produced. Generally, this article presents a framework for the development of microwave-assisted sol–gel synthesis of a co-doped TiO2, with high purity, a short period of reaction time, and small particles with a narrow size distribution. This method is facile, environmentally friendly, and highly efficient for the fabrication of high-performance next-generation nanocatalyst.

-

Funding information: The authors would like to appreciate the funding from URC of University of Johannesburg. T. C. Jen would like to acknowledge the financial support from NRF, as well.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Wu Q, Miao WS, Zhang YD, Gao HJ, Hui D. Mechanical properties of nanomaterials: a review. Nanotechnol Rev. 2020;9:259–73. 10.1515/ntrev-2020-0021.Search in Google Scholar

[2] Nasirian M, Mehrvar M. Modification of TiO2 to enhance photocatalytic degradation of organics in aqueous solutions. J Environ Chem Eng. 2016;4:4072–82. 10.1016/j.jece.2016.08.008.Search in Google Scholar

[3] Szczepanik B, Rogala P, Słomkiewicz PM, Banaś D, Kubala-Kukuś A, Stabrawa I. Synthesis, characterization and photocatalytic activity of TiO2-halloysite and Fe2O3-halloysite nanocomposites for photodegradation of chloroanilines in water. Appl Clay Sci. 2017;149:118–26. 10.1016/j.clay.2017.08.016.Search in Google Scholar

[4] Shafey AMEL. Green synthesis of metal and metal oxide nanoparticles from plant leaf extracts and their applications: a review. Green Process Synth. 2020;9:304–39. 10.1515/gps-2020-0031.Search in Google Scholar

[5] Syngouna VI, Chrysikopoulos CV, Kokkinos P, Tselepi MA, Vantarakis A. Cotransport of human adenoviruses with clay colloids and TiO2 nanoparticles in saturated porous media: effect of flow velocity. Sci Total Environ. 2017;598:160–7. 10.1016/j.scitotenv.2017.04.082.Search in Google Scholar PubMed

[6] Chouchene B, Chaabane TBen, Mozet K, Girot E, Corbel S, Balan L, et al. Porous Al-doped ZnO rods with selective adsorption properties. Appl Surf Sci. 2017;409:102. 10. 10.1016/j.apsusc.2017.03.018.Search in Google Scholar

[7] Mustapha S, Ndamitso MM, Abdulkareem AS, Tijani JO, Shuaib DT, Ajala AO, et al. Application of TiO2 and ZnO nanoparticles immobilized on clay in wastewater treatment: a review. Appl Water Sci. 2020;10:49. 10.1007/s13201-019-1138-y.Search in Google Scholar

[8] Pawar M, Sendoǧdular ST, Gouma P. A brief overview of TiO2 photocatalyst for organic dye remediation: case study of reaction mechanisms involved in Ce–TiO2 photocatalysts system. J Nanomater. 2018:2018. 10.1155/2018/5953609.Search in Google Scholar

[9] Ramesh S, Devred F, Debecker DP. NaAlO2 supported on titanium dioxide as solid base catalyst for the carboxymethylation of allyl alcohol with DMC. Appl Catal A Gen. 2019;581:31–6. 10.1016/j.apcata.2019.05.017.Search in Google Scholar

[10] Sun X, Sun B, Gong Q, Gao T, Zhou G. Double-shell structural polyaniline-derived TiO2 hollow spheres for enhanced photocatalytic activity. Transit Met Chem. 2019;44(555–64):8. 10.1007/s11243-019-00312.Search in Google Scholar

[11] Bourezgui A, Kacem I, Daoudi M, Al-Hossainy AF. Influence of gamma-irradiation on structural, optical and photocatalytic performance of TiO2 nanoparticles under controlled atmospheres. J Electron Mater. 2020;49:1904–21. 10.1007/s11664-019-07887-z.Search in Google Scholar

[12] Li C, Zhu N, Dong X, Zhang X, Chen T, Zheng S, et al. Tuning and controlling photocatalytic performance of TiO2/kaolinite composite towards ciprofloxacin: role of 0D/2D structural assembly. Adv Powder Technol. 2020;31:1241–52. 10.1016/j.apt.2020.01.007.Search in Google Scholar

[13] Al Zoubi W, Salih Al-Hamdani AA, Sunghun B, Ko YG. A review on TiO2-based composites for superior photocatalytic activity. Rev Inorg Chem. 2021. 10.1515/revic-2020-0025.Search in Google Scholar

[14] Bakbolat B, Daulbayev C, Sultanov F, Beissenov R, Umirzakov A, Mereke A, et al. Recent developments of TiO2-based photocatalysis in the hydrogen evolution and photodegradation: a review. Nanomaterials. 2020;10:1790. 10.3390/nano10091790.Search in Google Scholar PubMed PubMed Central

[15] Ni H, Wang L, Wang Z, Zhu J. Grain orientation induced softening in electrodeposited gradient nanostructured nickel during cold rolling deformation. Rev Adv Mater Sci. 2020;59:144–50. 10.1515/rams-2020-0105.Search in Google Scholar

[16] Yan Z, He Z, Li M, Zhang L, Luo Y, He J, et al. Curcumin doped SiO2/TiO2 nanocomposites for enhanced photocatalytic reduction of Cr(vi) under visible light. Catalysts. 2020;10:942. 10.3390/catal10080942.Search in Google Scholar

[17] Shi W, Duan D, Wang H, Ma C, Sun Z, Song X. Improving the photocatalytic performance of a sea-cucumber-like nanoporous TiO2 loaded with Pt[sbnd]Ag for water splitting. Int J Hydrogen Energy. 2019;44:13040–51. 10.1016/j.ijhydene.2019.03.196.Search in Google Scholar

[18] Guo J, Benz D, Doan Nguyen TT, Nguyen PH, Thi Le TL, Nguyen HH, et al. Tuning the photocatalytic activity of TiO2 nanoparticles by ultrathin SiO2 films grown by low-temperature atmospheric pressure atomic layer deposition. Appl Surf Sci. 2020;530:147244. 10.1016/j.apsusc.2020.147244.Search in Google Scholar

[19] Ariyanti D, Maillot M, Gao W. TiO2 used as photocatalyst for rhodamine B degradation under solar radiation. Int J Mod Phys B (World Scientific Publishing Co. Pte Ltd). 2017;31:16–9. 10.1142/S0217979217440957.Search in Google Scholar

[20] Allen NS, Vishnyakov V, Kelly PJ, Kriek RJ, Mahdjoub N, Hill C. Characterisation and photocatalytic assessment of TiO2 nano-polymorphs: Influence of crystallite size and influence of thermal treatment on paint coatings and dye fading kinetics. J Phys Chem Solids. 2019;126:131–42. 10.1016/j.jpcs.2018.11.004.Search in Google Scholar

[21] Bayal N, Jeevanandam P. Synthesis of TiO2–MgO mixed metal oxide nanoparticles via a sol–gel method and studies on their optical properties. Ceram Int. 2014;40:15463–77. 10.1016/j.ceramint.2014.06.122.Search in Google Scholar

[22] Ghafoori S, Nasirian M, Al-Jamal R, Mallouh FA, Mehrvar M. Statistical parameter optimization and modeling of photodegradation of methyl orange using a composite photocatalyst prepared by thermal synthesis. Environ Sci Pollut Res. 2020;27:45650–60. 10.1007/s11356-020-10301-5.Search in Google Scholar PubMed

[23] Dariani RS, Esmaeili A, Mortezaali A, Dehghanpour S. Photocatalytic reaction and degradation of methylene blue on TiO2 nano-sized particles. Optik (Stuttg). 2016;127:7143–54. 10.1016/j.ijleo.2016.04.026.Search in Google Scholar

[24] Typek J, Guskos N, Zolnierkiewicz G, Pilarska M, Guskos A, Kusiak-Nejman E, et al. Magnetic properties of TiO2/graphitic carbon nanocomposites. Rev Adv Mater Sci. 2019;58:107–22. 10.1515/rams-2019-0009.Search in Google Scholar

[25] Sun P, Wang S, Li Y, Zhang T, Wang D, Zhang B, et al. One-pot synthesis of nano titanium dioxide in supercritical water. Nanotechnol Rev. 2020;9:410–7. 10.1515/ntrev-2020-0030.Search in Google Scholar

[26] Li B, Wu S, Gao X. Theoretical calculation of a TiO2-based photocatalyst in the field of water splitting: a review. Nanotechnol Rev. 2020;9:1080–103. 10.1515/ntrev-2020-0085.Search in Google Scholar

[27] Wang Q, Zheng K, Yu H, Zhao L, Zhu X, Zhang J. Laboratory experiment on the nano-TiO2 photocatalytic degradation effect of road surface oil pollution. Nanotechnol Rev. 2020;9:922–33. 10.1515/ntrev-2020-0072.Search in Google Scholar

[28] Guo Z, Huang C, Chen Y. Experimental study on photocatalytic degradation efficiency of mixed crystal nano-TiO2 concrete. Nanotechnol Rev. 2020;9:219–29. 10.1515/ntrev-2020-0019.Search in Google Scholar

[29] Huang CW, Liao CH, Wu JCS. Photocatalytic water splitting using hygroscopic MgO modified TiO2/WO3 dual-layer photocatalysts. Korean J Chem Eng. 2020;37:1352–9. 10.1007/s11814-020-0603-5.Search in Google Scholar

[30] Mahshid S, Askari M, Sasani Ghamsari M, Afshar N, Lahuti S. Mixed-phase TiO2 nanoparticles preparation usingsol–gel method. J Alloy Compd. 2009;478:586. http://dx.doi.org/10.1016/j.jallcom.2008.11.094.Search in Google Scholar

[31] Tomar SS, Zafar S, Talha M, Gao W, Hui D. State of the art of composite structures in non-deterministic framework: a review. Thin-Walled Struct. 2018;132:700–16. 10.1016/j.tws.2018.09.016.Search in Google Scholar

[32] Aman N, Satapathy PK, Mishra T, Mahato M, Das NN. Synthesis and photocatalytic activity of mesoporous cerium doped TiO2 as visible light sensitive photocatalyst. Mater Res Bull. 2012;47:179–83. 10.1016/j.materresbull.2011.11.049.Search in Google Scholar

[33] Simionescu OG, Pachiu C, Ionescu O, Dumbravescu N, Buiu O, Popa RC, et al. Nanocrystalline graphite thin layers for low-strain, high-sensitivity piezoresistive sensing. Rev Adv Mater Sci. 2020;59:306–13. 10.1515/rams-2020-0031.Search in Google Scholar

[34] Naghdi S, Rhee K, Hui D, Park S. A review of conductive metal nanomaterials as conductive, transparent, and flexible coatings, thin films, and conductive fillers: different deposition methods and applications. Coatings. 2018;8:278. 10.3390/coatings8080278.Search in Google Scholar

[35] Liu C, Lu H, Li G, Hui D, Fu YQA. “cross-relaxation effects” model for dynamic exchange of water in amorphous polymer with thermochemical shape memory effect. J Phys D Appl Phys. 2019;52:345305. 10.1088/1361-6463/ab2860.Search in Google Scholar

[36] Sharma K, Hui D, Kim NH, Lee JH. Facile synthesis of N-doped graphene supported porous cobalt molybdenum oxynitride nanodendrites for the oxygen reduction reaction. Nanoscale. 2019;11:1205–16. 10.1039/c8nr06780e.Search in Google Scholar PubMed

[37] Basavarajappa PS, Patil SB, Ganganagappa N, Reddy KR, Raghu AV, Reddy CV. Recent progress in metal-doped TiO2, non-metal doped/codoped TiO2 and TiO2 nanostructured hybrids for enhanced photocatalysis. Int J Hydrogen Energy. 2020;45:7764–78. 10.1016/j.ijhydene.2019.07.241.Search in Google Scholar

[38] Feizpoor S, Habibi-Yangjeh A. Ternary TiO2/Fe3O4/CoWO4 nanocomposites: novel magnetic visible-light-driven photocatalysts with substantially enhanced activity through p-n heterojunction. J Colloid Interface Sci. 2018;524:325–36. 10.1016/j.jcis.2018.03.069.Search in Google Scholar PubMed

[39] Zhu XD, Zheng YL, Feng YJ, Sun KN. Delicate Ag/V2O5/TiO2 ternary nanostructures as a high-performance photocatalyst. J Solid State Chem. 2018;258:691–4. 10.1016/j.jssc.2017.12.001.Search in Google Scholar

[40] Hwang SH, Kim C, Jang J. SnO2 nanoparticle embedded TiO2 nanofibers – Highly efficient photocatalyst for the degradation of rhodamine B. Catal Commun. 2011;12:1037–41. 10.1016/j.catcom.2011.02.024.Search in Google Scholar

[41] Shi W, Ma C, Wang H, Duan D, Sun Z, Yang S. A sea cucumber-like nanoporous TiO2 modified by bimetal Pt–Au through the dealloying for water splitting. Int J Hydrogen Energy. 2018;43:18850–62. 10.1016/j.ijhydene.2018.08.180.Search in Google Scholar

[42] Bumajdad A, Madkour M. Understanding the superior photocatalytic activity of noble metals modified titania under UV and visible light irradiation. Phys Chem Chem Phys. 2014;16:7146–58. 10.1039/c3cp54411g.Search in Google Scholar PubMed

[43] Rahimi N, Pax RA, Gray EMA. Review of functional titanium oxides. I: TiO2 and its modifications. Prog Solid State Chem. 2016;44:86–105. 10.1016/j.progsolidstchem.2016.07.002.Search in Google Scholar

[44] Wang Z, Zhu J, Xu W, Sui J, Peng H, Tang X. Microwave hydrothermal synthesis of perovskite BiFeO3 nanoparticles: an insight into the phase purity during the microwave heating process. Mater Chem Phys. 2012;135:330–3. 10.1016/j.matchemphys.2012.04.053.Search in Google Scholar

[45] Kadam AN, Dhabbe RS, Kokate MR, Gaikwad YB, Garadkar KM. Preparation of N doped TiO2 via microwave-assisted method and its photocatalytic activity for degradation of Malathion. Spectrochim Acta A. 2014;133:669–76. 10.1016/j.saa.2014.06.020.Search in Google Scholar PubMed

[46] Gupta AK, Pal A, Sahoo C. Photocatalytic degradation of a mixture of crystal violet (basic violet 3) and methyl red dye in aqueous suspensions using Ag+ doped TiO2. Dye Pigment. 2006;69:224–32. 10.1016/j.dyepig.2005.04.001.Search in Google Scholar

[47] Tripathi AM, Nair RG, Samdarshi SK. Visible active silver sensitized vanadium titanium mixed metal oxide photocatalyst nanoparticles through sol–gel technique. Sol Energy Mater Sol Cells. 2010;94:2379–85. 10.1016/j.solmat.2010.08.022.Search in Google Scholar

[48] Ntobeng MK, Imoisili PE, Jen TC. Facile fabrication of vanadium sensitized silver titanium oxides (V–Ag/TiO2) photocatalyst nanocomposite for pollutants removal in river water. Mater Sci Semicond Process. 2021;123:105569. 10.1016/j.mssp.2020.105569.Search in Google Scholar

[49] Khutso Ntobeng M, Ehi Imoisili P, Jen TC. Synthesis and photocatalytic performance of Ag-TiVOX nanocomposite. J King Saud Univ Sci. 2020;32:3103. 10. 10.1016/j.jksus.2020.08.021.Search in Google Scholar

[50] Liu G, Qin J, Zhou Z, Liu C, Li F, Wu W. Mesoporous V‐TiO2 catalysts with crystalline anatase‐rutile mixed phases for naphthalene degradation. ChemistrySelect. 2019;4:12955–62. 10.1002/slct.201902487.Search in Google Scholar

[51] Ren J, Wang W, Sun S, Zhang L, Chang J. Enhanced photocatalytic activity of Bi2WO6 loaded with Ag nanoparticles under visible light irradiation. Appl Catal B Environ. 2009;92:50–5. 10.1016/j.apcatb.2009.07.022.Search in Google Scholar

[52] Sangpour P, Hashemi F, Moshfegh AZ. Photoenhanced degradation of methylene blue on cosputtered M:TiO2 (M = Au, Ag, Cu) nanocomposite systems: A comparative study. J Phys Chem C. 2010;114:13955–61. 10.1021/jp910454r.Search in Google Scholar

[53] Saito K, Tominaka S, Yoshihara S, Ohara K, Sugahara Y, Ide Y. Room-temperature rutile TiO2 nanoparticle formation on protonated layered titanate for high-performance heterojunction creation. ACS Appl Mater Interfaces. 2017;9:24538–44. 10.1021/acsami.7b04051.Search in Google Scholar PubMed

[54] Leshuk T, Parviz R, Everett P, Krishnakumar H, Varin RA, Gu F. Photocatalytic activity of hydrogenated TiO2. ACS Appl Mater Interfaces. 2013;5:1892–5. 10.1021/am302903n.Search in Google Scholar PubMed

[55] Chen S, Li D, Liu Y, Huang W. Morphology-dependent defect structures and photocatalytic performance of hydrogenated anatase TiO2 nanocrystals. J Catal. 2016;341:126–35. 10.1016/j.jcat.2016.06.016.Search in Google Scholar

[56] Reddy BM, Chowdhury B, Ganesh I, Reddy EP, Rojas TC, Fernández A. Characterization of V2O5/TiO2-ZrO2 catalysts by XPS and other techniques. J Phys Chem B. 1998;102:10176–82. 10.1021/jp9826165.Search in Google Scholar

[57] Dolgonos A, Mason TO, Poeppelmeier KR. Direct optical band gap measurement in polycrystalline semiconductors: a critical look at the tauc method. J Solid State Chem. 2016;240:43–8. 10.1016/j.jssc.2016.05.010.Search in Google Scholar

[58] Liu J, Han R, Zhao Y, Wang H, Lu W, Yu T, et al. Enhanced photoactivity of V–N codoped TiO2 derived from a two-step hydrothermal procedure for the degradation of PCP-Na under visible light irradiation. J Phys Chem C. 2011;115:4507–15. 10.1021/jp110814b.Search in Google Scholar

[59] Xiang Q, Yu J, Wang W, Jaroniec M. Nitrogen self-doped nanosized TiO2 sheets with exposed {001} facets for enhanced visible-light photocatalytic activity. Chem Commun. 2011;47:6906–8. 10.1039/c1cc11740h.Search in Google Scholar PubMed

[60] Zhang H, Wang G, Chen D, Lv X, Li J. Tuning photoelectrochemical performances of Ag–TiO2 nanocomposites via reduction/oxidation of Ag. Chem Mater. 2008;20:6543–9. 10.1021/cm801796q.Search in Google Scholar

© 2021 Patrick Ehi Imoisili et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions