Abstract

Helical carbon nanotubes (HCNTs) are a kind of potential microwave absorption (MA) material due to their chiral and dielectric properties. However, the inert surface property makes HCNTs with poor polarization loss ability and impedance matching characteristic, which impedes its ability in attenuating microwaves. Herein, the HCNTs were modified with defects and functional groups on the surface to optimize their electromagnetic response characteristics and achieve an enhanced MA performance. The experimental results show that the modified HCNTs (F-HCNTs) exhibit a significant enhancement in MA performance when compared with HCNTs. The minimum reflection (RLmin) loss of F-HCNTs reaches −45.4 dB at 17.5 GHz at a thickness of 2.4 mm and the bandwidth of RL < −10 dB is 3.6 GHz (from 14.4 to 18.0 GHz). Further analysis demonstrates that proper modification of HCNTs leads to enhanced dielectric loss ability and optimized impedance matching characteristics, both of which are beneficial to the MA performance of HCNTs.

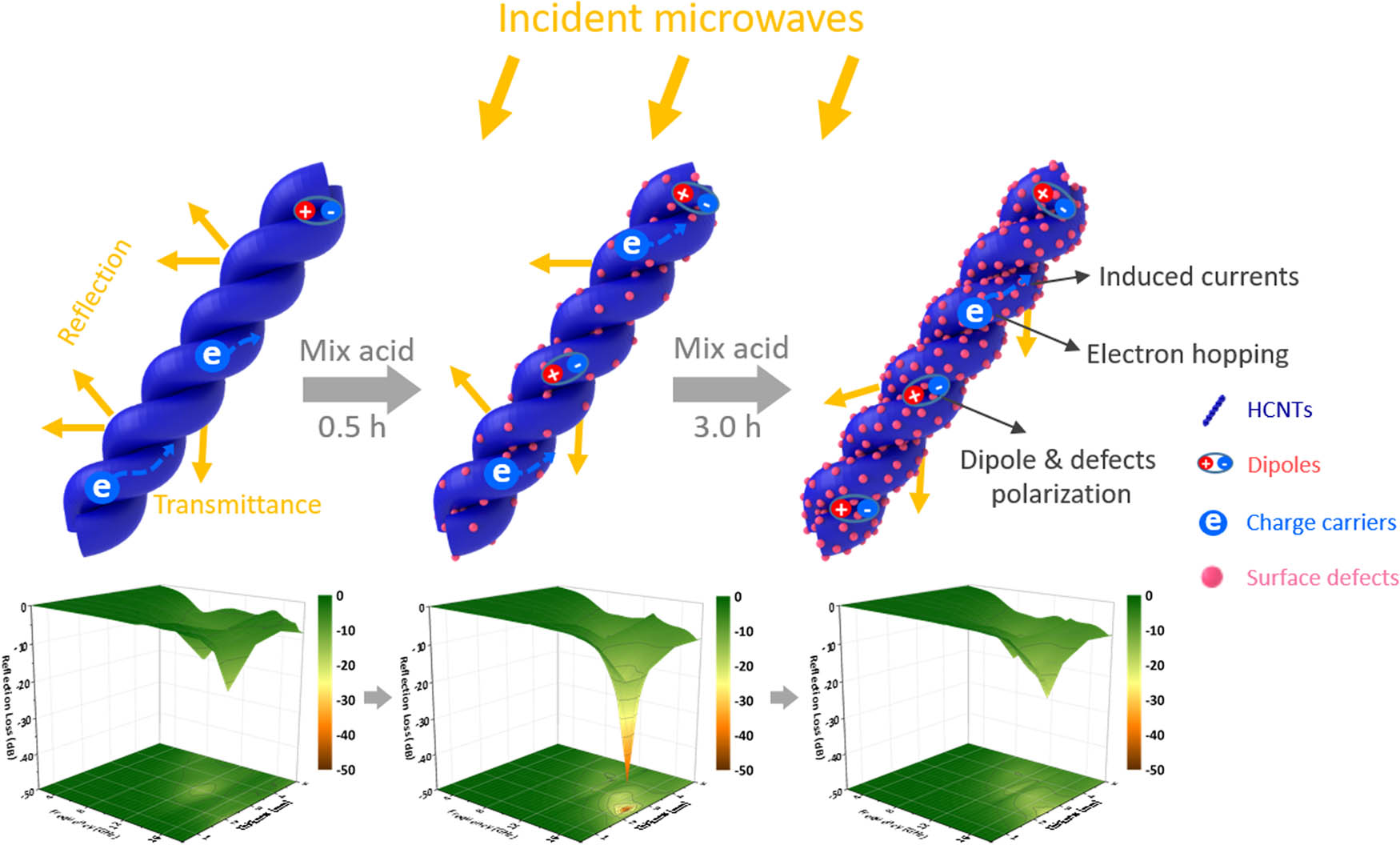

Graphical abstract

1 Introduction

Chiral structures have been proved to be capable of attenuating microwaves, and many investigations have demonstrated that helical carbon nanotubes (HCNTs) exhibit good microwave absorption (MA) performance because of their chiral structure and dielectric properties [1,2,3,4]. Except for the resistance loss and polarization loss brought by the carbon component and polarization centers including defects edges and interfaces, the helical nanostructures can induce cross-polarization under continuous microwave irradiation that leads to resonance losses, which also contributes to attenuate the electromagnetic waves [5,6]. In addition, the HCNTs had the advantages of low density and small size, which makes it feasible to be applied in electromagnetic protection coatings. However, the inert surface property makes HCNTs with poor polarization loss ability and impedance matching characteristics [7,8], which impedes its MA performance. Based on the electromagnetic interference shielding and the relevant theories, the main mechanisms for attenuating microwaves are dielectric loss and magnetic loss, wherein the polarization loss plays a key role. The polarization centers include the dipoles, heterogeneous interfaces, and polarizable structures. At GHz frequency band, polarization centers including electric dipoles and interfaces absorb greatly microwaves because these cause the electric polarization centers to execute damped oscillations, and magnetic dipoles precess with damping under the torques produced by the microwave’s magnetic field [9,10]. For HCNTs, the hexagonal rings are the main structure that offer resistance loss, the defects including pentagonal rings and heptagonal rings, and the edges that offer polarization loss are minority [11,12].

The mainstream approach to enhance the MA polarization loss and optimize the impedance matching characteristics is to form hybrid materials that incorporate magnetic or dielectric materials, such as ferrites, nickels, and polymers [13,14,15]. For example, Li et al. successfully fabricated porous nickel ferrite hollow nanospheres/helical carbon nanowires composites, where the minimal reflection loss (RLmin) and bandwidth (RL < −10 dB) were −33.94 dB at a thickness of 2.1 mm and 3.22 GHz (from 9.18 to 12.4 GHz), respectively [13]. Tian et al. introduced polyaniline to modify HCNTs and prepared a dual-chirality hierarchical structure. The experimental results show that the hierarchical hybrids exhibit significantly enhanced MA performance when compared with those of either pure polyaniline or HCNTs [16]. The polarization centers relax in the alternating electromagnetic field to transform the electromagnetic energy into other forms; thus, the newly formed hybrid structure and heterogeneous interfaces offer more sites to attenuate microwaves. In addition, by incorporating with other materials, the spatial structure can be designed to optimize the impedance characteristics and further enhance the MA performance [17,18]. To fabricate the HCNTs into composites or hybrids, a process of activating the HCNTs’ surface to increase the surface activity is necessary [19]. During the process, some vacancies or functional groups are created on the HCNTs, and their dielectric properties are simultaneously changed. It can be predicted that the MA performance of HCNTs would change simultaneously, and this is a feasible way to tune and enhance the MA performance. However, the study about the effect of these processes on the MA performance and the potential microwave loss mechanism remains vacant. Here in this paper, the evaluation of the effect of the surface modification process on HCNTs’ structure and properties was performed. The authors strongly believe that this study not only reveals the relationship between the surface structure and MA performance but also offers guidance for the researchers who work on HCNTs and the relative materials.

2 Experiments

2.1 Materials and methods

HCNTs were synthesized through the chemical vapor deposition method by acetylene decomposition over the as-obtained precursor that was prepared by the novel precipitation/sol-gel/reduction technique [20]. The obtained products were annealed and washed to remove the amorphous carbon and excessive precursors before using and noted as O-HCNTs. The F-HCNTs were prepared by immersing O-HCNTs in a bottle filled with an acid mixture (HNO3/H2SO4 = 1/3 in volume) for a set time (0.5, 1.0, and 3.0 h). During this process, the bottle was put in ice bath (sonication with a power of 100 W). The F-HCNTs modified at different times were noted as F-HCNTs-X h.

2.2 Characterization and testing

X-ray diffraction patterns were recorded with an X-ray diffractometer (XRD, Philips X-30) with Cu Kα radiation (λ = 1.54056 Å). Scanning electron microscope (SEM, JEOL JSM-7800F) and transmission electron microscope (TEM, JEOL JEM-2100) were used to characterize the morphologies. Raman spectra were conducted on Renishaw InVia Reflex with an excitation wavelength of 532 nm. Fourier transform infrared spectroscopy (FTIR, Bruker Tensor II) was conducted with a spectral resolution of 2/cm. The electromagnetic parameters of the frequency range of 2–18 GHz were collected by the vector network analyzer (VNA, Agilent 15071C) by the coaxial-line method. The testing samples were prepared by blending the aerogel microspheres with a paraffin matrix in a weight ratio of 1:9 toroidal-shaped samples ϕ out = 7.00 mm and ϕ in = 3.04 mm.

3 Results and discussion

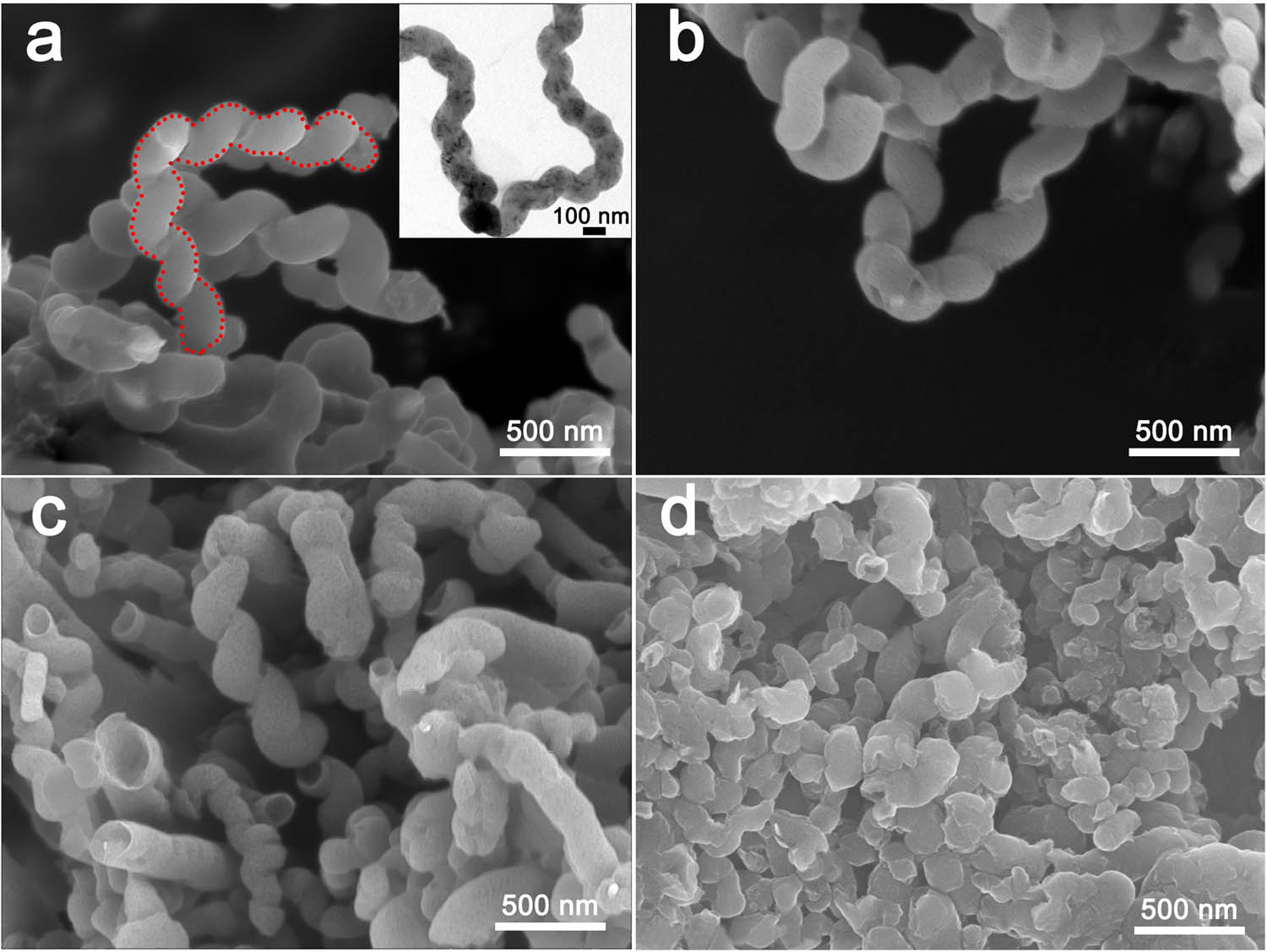

First, the morphological analysis was conducted to evaluate the effect of modification time. The HCNTs were synthesized using Fe-bearing compounds [20], and the morphology exhibits typical features: chirality and helicity. As shown in Figure 1a and inset, the single carbon nanotubes show a kink-like structure with a tube diameter of about 200 nm. It has been proved that the diameter is determined by the grain size of the catalysts [21,22]; thus, the uneven tube diameter should be ascribed to the grain size difference of the catalysts. Two coiled nanotubes growing from Fe catalyst particle can be observed from the inset image, demonstrating a typical symmetrical growth mode that causes a mirror image of the two nanotubes. After 0.5 h of mixed acid treating, the helical structure remains relatively intact (Figure 1b), while exhibits remarkable change after more than 1 h of treating. As shown in Figure 1c, the morphologies of F-HCNTs are destroyed, and almost all the symmetrical nanotubes were broken and hollow nozzles of HCNTs can be observed clearly. When extending the treating time to 3 h, the helical structure was destroyed. Excessive treating causes severe morphological destroy of F-HCNTs, and the structure is simultaneously changed.

Morphological analysis of HCNTs. The SEM images of (a) O-HCNTs and (b–d) F-HCNTs treated for 0.5, 1, and 3 h.

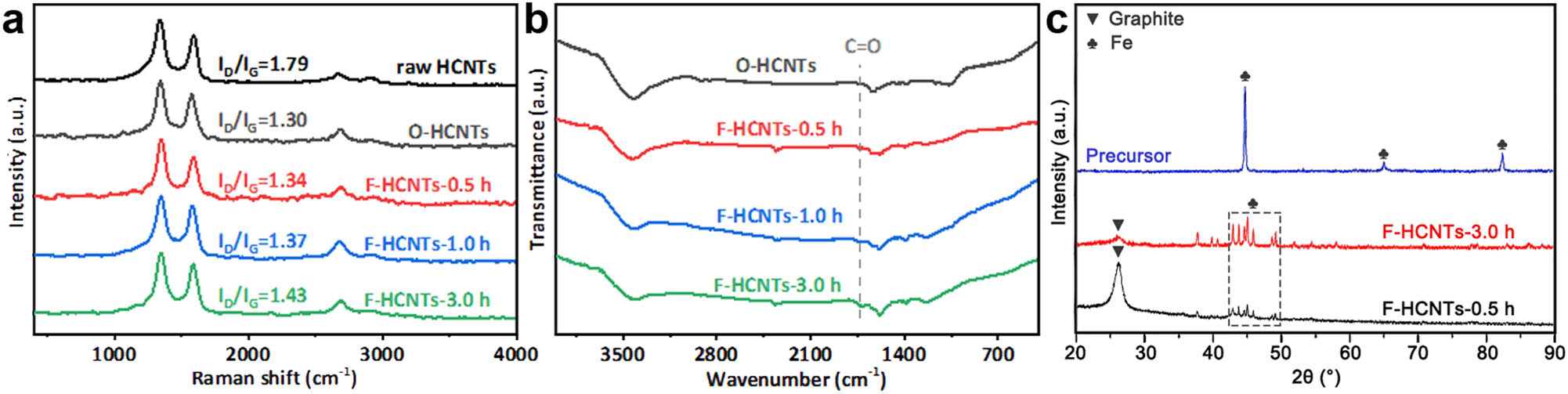

Then, the Raman and FTIR spectra were performed to further analyze the structural information. It can be observed from the Raman spectra that the annealing treatment is effective to remove the amorphous carbon due to the I D/I G value of HCNTs drops from 1.79 to 1.30 after annealing (Figure 2a) [23,24]. It further confirmed the destructive effect of the mixed acid treatment on HCNTs for the I D/I G value gradually increases from 1.30 to 1.43. In addition, the mixed acid treating is also capable of oxidizing the carbon structure. The FTIR spectra show no significant change of HCNTs after annealing, while a new peak belonging to carboxyl groups appears around the 1,722/cm when treated by mixed acid for 0.5 h, implying the carboxyl groups has been grafted on the surface of F-HCNTs (Figure 2b) [25]. Except for the helical structures, the precursors inside HCNTs’ tubes also offer electromagnetic loss mechanisms in MA performance. Thus, the XRD was applied to detect the existence of Fe. As shown in Figure 2c, there exhibits an obvious pattern of Fe after 3 h of treating, indicating the magnetic component is reserved [26].

Structural analysis of HCNTs: (a) the Raman spectra, (b) the FT-IR spectra, and (c) the XRD patterns of O-HCNTs, F-HCNTs treated for 0.5, 1, and 3 h.

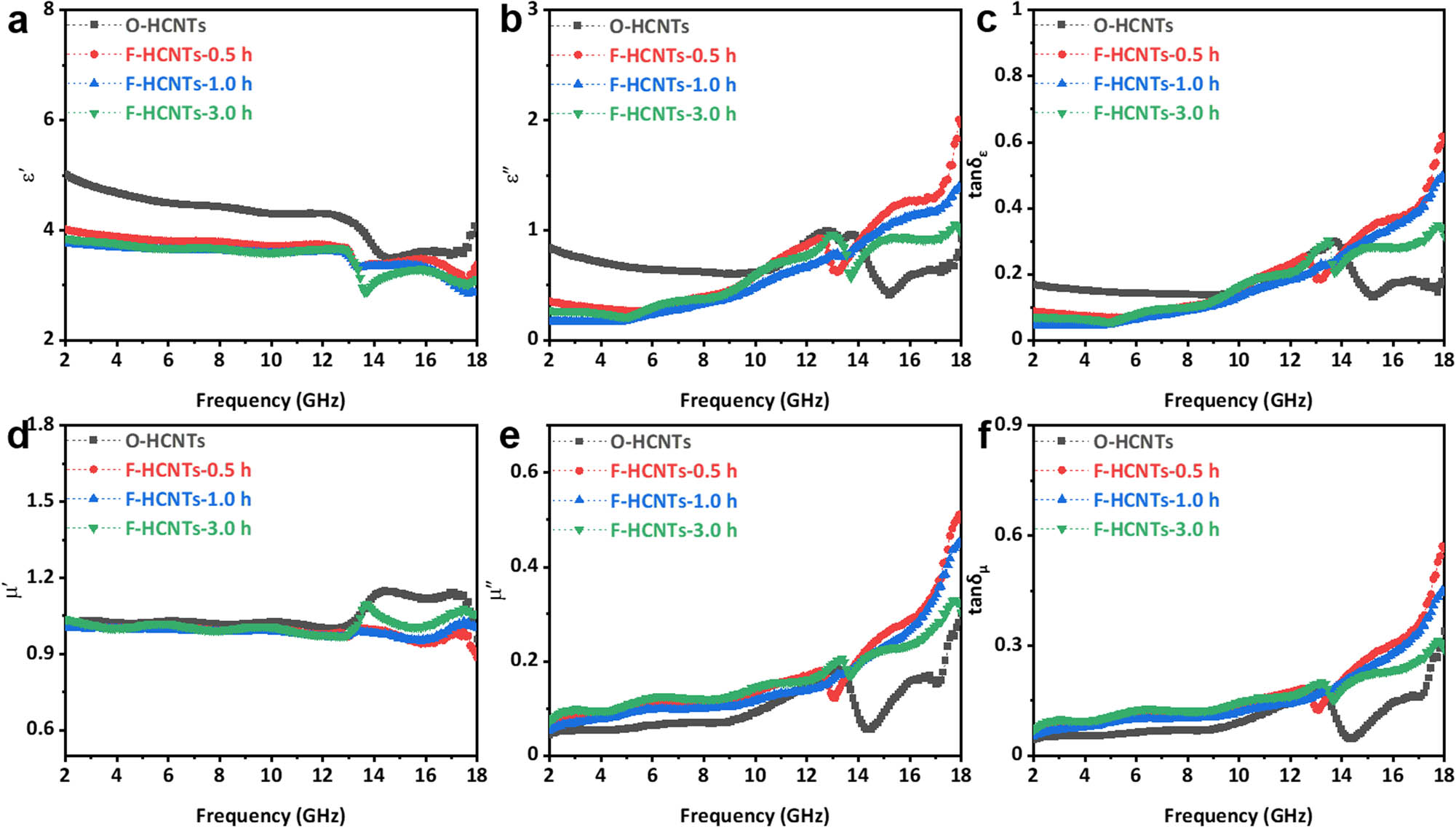

Taking the magnetic component of HCNTs into account, it can be deduced that both dielectric loss and magnetic loss play key roles in electromagnetic absorption [27]. Along with the chemical treatment, the structural evolution leads to changes in dielectric and magnetic properties that relate to the MA performance. Therefore, the complex permittivity including real part (ε′) and imaginary part (ε″) and the complex permeability including real part (μ′) and imaginary part (μ″) of HCNTs in the frequency range of 2.0–18.0 GHz was collected by the vector network analyzer through the coaxial-line method. ε′ represents absorbers’ capacity of storing electromagnetic energy, and an increase indicates that the material is easier to be polarized under an external magnetic/electrical field and to store the energy [28,29]. As shown in Figure 3a, the ε′ of F-HCHTs is lower than O-HCNTs, which indicates a weakened energy storage ability. The ε′ shows a downward trend with the increase of frequency, which can be comprehended by the increased lagging of polarization with respect to electric-field change at higher frequency [30]. The ε″ stands for the dissipation ability of absorbers [31]. As depicted in Figure 3b, ε″ of F-HCNTs shows a small decrease in 2.0–14.4 GHz and an increase in 14.4–18.0 GHz when compared with O-HCNTs. For ε″ in the lower frequency band is mainly related to the resistance loss and in higher frequency band relates to the dielectric loss, which indicates that the modification process weakens the resistance loss ability of F-HCNTs due to the destroyed carbon structure [32,33]. However, the newly formed surface groups and defects on F-HCNTs are beneficial to enhance the dielectric loss ability that attenuates the electromagnetic waves at a higher frequency band. Benefits from the surface groups and defects that offers polarization centers, the F-HCNTs show an improvement in the capacity of converting electromagnetic wave energy to other forms in the range of 14–18 GHz as described by dielectric dissipation factors (tan δ ε = ε″/ε′) (Figure 3c) [34]. Except for the dielectric loss part, the HCNTs also exhibit the ability in magnetic loss due to the helical structure and the existence of magnetical precursor. The complex permeability versus frequency curves exhibits several fluctuations in the 13–18 GHz as the complex permittivity does, which implies multiple magnetic loss behaviors and the capacity in storing and converting electromagnetic energy of the HCNTs (Figure 3d–f). Although the helical structure of F-HCNTs was certainly destroyed, the uncovered precursor inside the nanotubes simultaneously forms enhanced hysteresis including the multiple resonance effect, nature, and exchange resonance that attributes to the magnetic loss. It can be seen that the fluctuations appear at the high-frequency band, indicating a stronger attenuation ability at the high-frequency band.

Measured frequency dependence of (a) ε′, (b) ε″, (c) tan δ ε , (d) μ′, (e) μ″, and (f) tan δ μ of O-HCNTs and F-HCNTs.

The MA performance is closely related to the electromagnetic parameters; thus, the MA performance was evaluated to further verify the above speculation. Based on parameters, the reflection loss (RL) was calculated by equations (1) and (2), where Z in is the input characteristic impendence, Z 0 is the free space impendence, μ and ε are the measured complex permeability and complex permittivity, respectively, d is the thickness of the tested sample, c is the propagation velocity of microwave in free space, and f is the frequency of microwave [35].

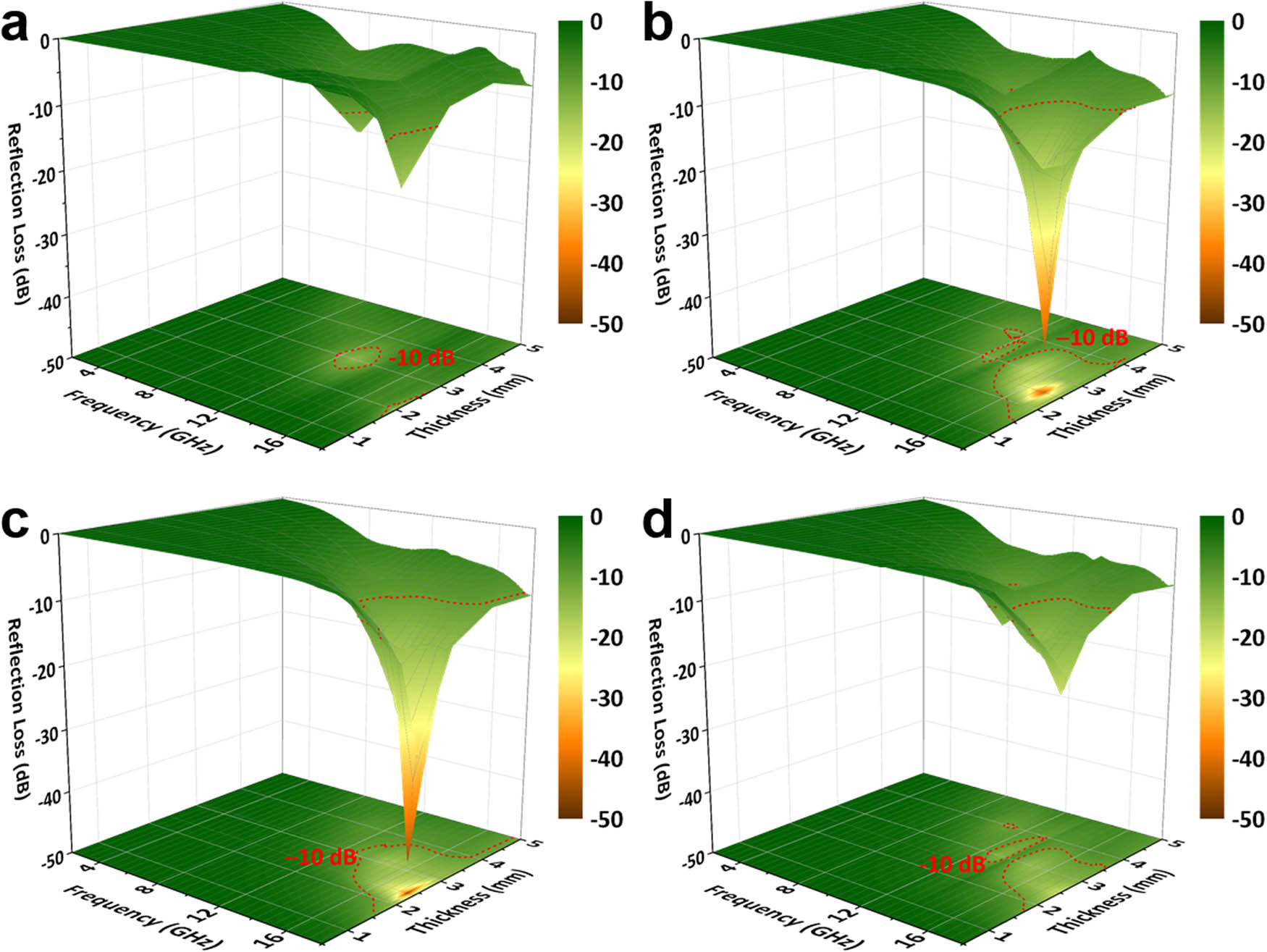

As shown in Figure 4a, the pristine O-HCNTs barely meet the practical requirement of −10.0 dB [36], while undergoing the functionalization processing the F-HCNTs exhibits significantly enhanced MA capacity. When treated for 0.5 h, the minimal RL (RLmin) reaches −43.0 dB at 17.0 GHz with a thickness of 2.5 mm and a bandwidth of RL < −10 dB is 4.0 GHz (from 14.0 to 18.0 GHz) (Figure 4b). When further elongating the treating time for 1 h, the MA performance has a slight increase that the RLmin reaches −45.4 dB at 17.5 GHz with a thickness of 2.4 mm and a bandwidth of RL < −10 dB is 3.6 GHz (from 14.4 to 18.0 GHz) (Figure 4c). These results are consistent with the testing electromagnetic parameters, which will be further analyzed later. However, when increasing the treating time to 3.0 h, the RL significantly decreases. As illustrated in Figure 4d, the optimized RLmin reaches −20.2 dB at 17.7 GHz with a thickness of 2.5 mm and a bandwidth of RL < −10 dB is 3.4 GHz (from 14.6 to 18.0 GHz).

The calculated reflection loss of HCNTs. (a) A-HCNTs, (b–d) F-HCNTs-0.5 h, F-HCNTs-1.0 h, and F-HCNTs-3.0 h, respectively.

The MA performance is closely affected by the loss characteristics. To explain why the MA performance of HCNTs changes with the treating time, further analysis on the electromagnetic parameters is performed. First, the loss mechanism is studied based on the Debye theory, which is described as the following equations [37]:

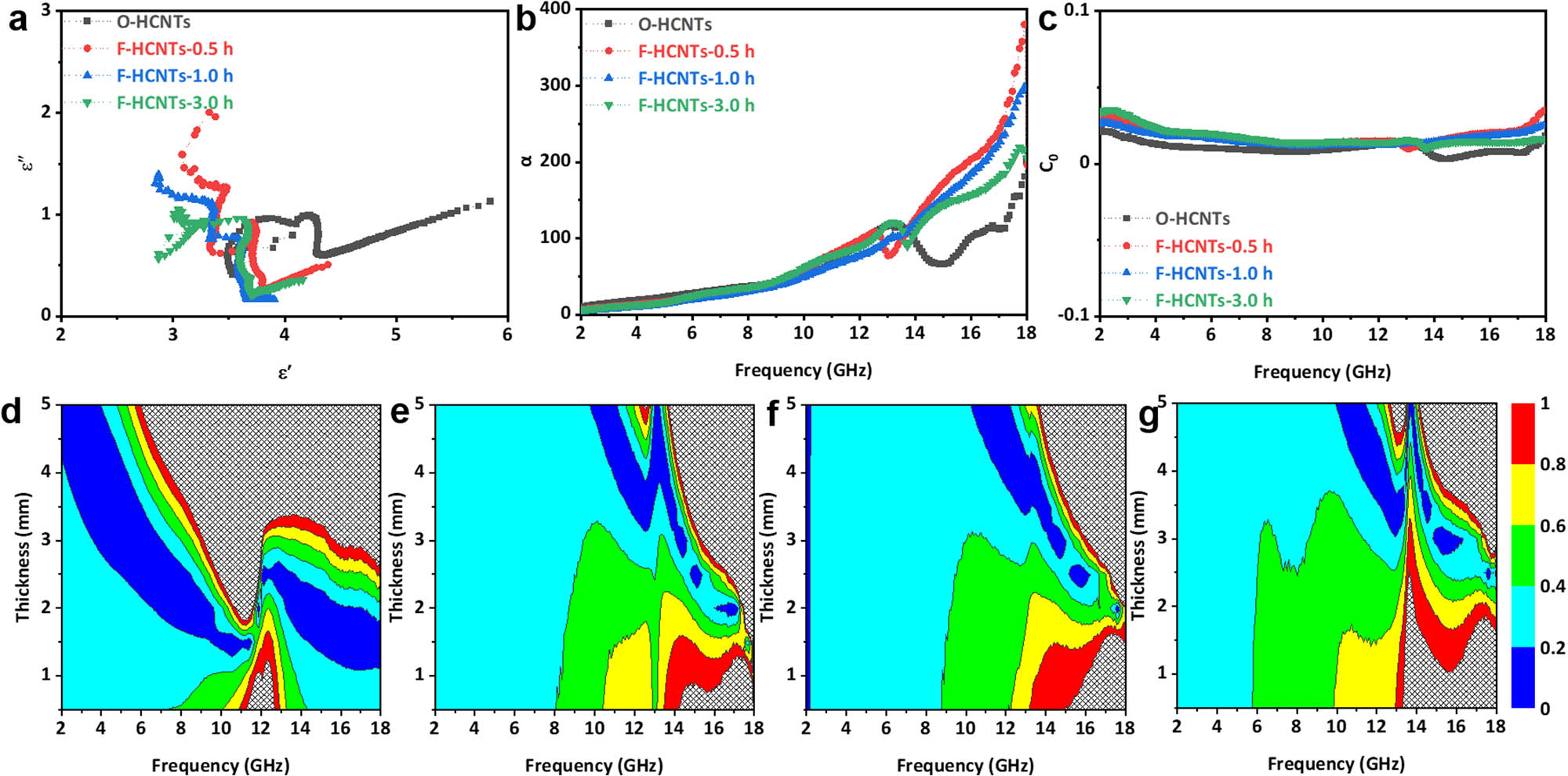

where ε s is the static dielectric constant, ε ∞ refers to the dielectric constant at infinite frequency, and τ indicates polarization relaxation time, respectively. The ε′ and ε″ can be expressed by formulas (4) and (5) [38]

Figure 5a depicts the Cole–Cole semicircles. Every semicircle represents a relaxation process; thus, the multiple semicircles for all the F-HCNTs imply the presence of multi-dielectric relaxations [39,40]. Meanwhile, the number of semicircles increases as treating time increases, indicating there exists more newly formed loss mechanisms on F-HCNTs. In addition, the more multiple semicircles of F-HCNTs indicate more loss mechanisms over O-HCNTs. For carbon nanotubes, the main mechanism of dielectric loss includes resistance loss at lower frequency band, polarization relaxation loss, interfaces polarization loss, and dielectric structural loss and resonance loss at higher frequency band. From Figure 3c, it can be concluded that the loss mechanism transfer from dielectric loss to polarization loss as the increasing frequency of all the F-HCNTs. The special spatial conformation of the HCNTs and the surface modification process that brings more defects and polarization centers leads to enhanced dielectric loss mechanisms at high-frequency bands. While for O-HCNTs, the tan δ ε at lower frequency band is higher than F-HCNTs, which means O-HCNTs possess stronger resistance loss ability. This explains the phenomenon of O-HCNTs that exist a longer tail at the curve end. An excellent MA performance should be obtained only when the material has both loss characterization and impedance matching at the same time [32,41,42]. To explain the superior MA performance of F-HCNTs-1.0 h to the others, first, the loss characterization (attenuation constant, α) is evaluated by equation (6) (Figure 5b) [43]. It can be found that α of F-HCNTs shows an enhanced trend over O-HCNTs at the higher frequency band (about 14–18 GHz) and a slightly weaken trend at the lower frequency band. This indicates that surface modification is beneficial to enhance the dielectric loss ability. Eddy currents exist in the material that permeates in the alternate electromagnetic field, and it would be detrimental to the material’s attenuating ability. Thus, the eddy currents should be avoided [14,44]. The C 0 value is calculated based on equation (7) to evaluate the effect of eddy currents [45]. As shown in Figure 5c, F-HCNTs show almost a constant in the measured frequency, indicating a negligible eddy current effect. Second, the impedance matching degree (delta, Δ) is further evaluated by equation (8), in which the K and M can be calculated from the relative permittivity and relative permeability by equations (9) and (10), respectively [46]. According to the impedance matching theory, the impedance matching degree should be equal or close to that of free space at the interface between MA absorbers and free space. Impedance mismatching would cause reflection or transmission of most electromagnetic waves, a Δ value smaller than 0.4 is considered acceptable for MA performance [47]. As presented in Figure 5d–g, the F-HCNTs possess larger area than O-HCNTs, indicating an enhanced impedance matching degree over the O-HCNTs. This further explains why the F-HCNTs exhibit better MA performance over O-HCNTs.

Analysis of the electromagnetic parameters: (a) Cole–Cole curves, (b) attenuation factors, (c) C 0, and (d–f) the impedance matching degree of O-HCNTs, F-HCNTs-0.5 h, F-HCNTs-1.0 h, and F-HCNTs-3.0 h, respectively.

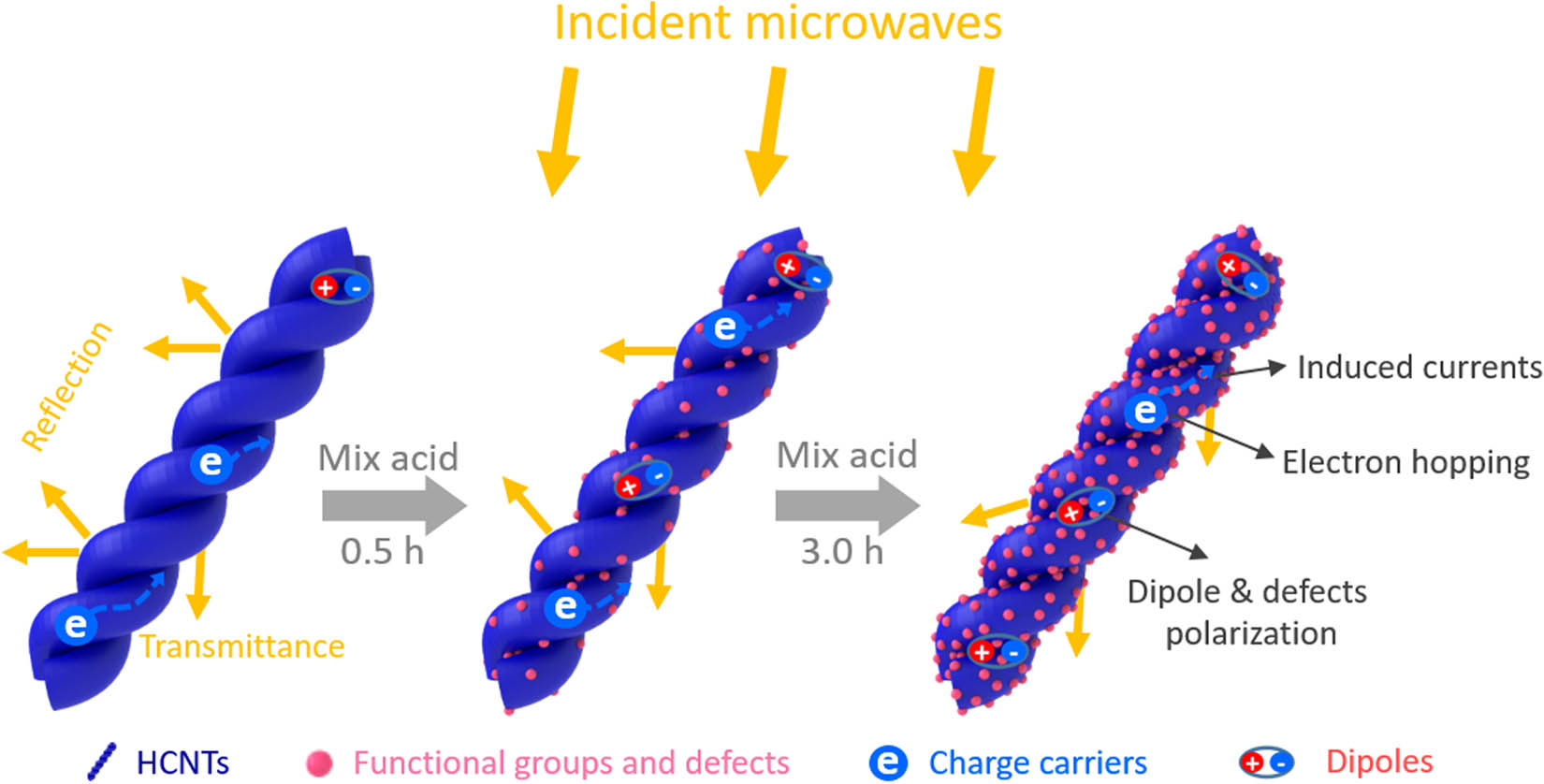

Based on the above analysis, the difference in MA performance among HCNTs can be explained. O-HCNTs have relatively higher resistance loss ability than the F-HCNTs, while their polarization loss ability is weak due to the fewer polarization centers. Besides, the impedance matching degree of O-HCNTs is poor, these factors make O-HCNTs exhibit relatively poor MA performance than F-HCNTs. For F-HCNTs-0.5 h whose surface is covered by functional groups and defects, the newly formed heterogeneous structure offers polarization centers to attenuate microwaves. In addition, the treating process changes the dielectric properties of HCNTs, reserves its resistance loss ability, and optimizes its impedance matching degree to enhance the MA performance. When elongating the treating time to 1 h, more functional groups and defects appear on the surface of HCNTs, resulting in enhanced polarization loss ability and optimized impedance matching degree. However, 3 h of treating seriously destroys the structure of HCNTs and the dielectric loss ability drops obviously, leading to poor MA performance. In conclusion, the excellent MA performance of F-HCNTs should be attributed to its optimized impedance matching and high attenuation constant, mainly due to the outstanding dielectric loss generated from the defects, surface groups, residue precursors, and resistance loss and interfacial polarization of HCNTs. A possible MA mechanism of HCNTs is presented in Figure 6.

Schematic illustration of the potential MA mechanisms for HCNTs.

4 Conclusion

In summary, this paper synthesized functional helical carbon nanotubes (F-HCNTs) and evaluated their ability and mechanism of attenuating microwaves. The F-HCNTs show an enhanced microwave absorption (MA) performance compared to HCNTs. The optimized minimal reflection loss (RLmin) of F-HCNTs reaches −45.4 dB at 17.5 GHz with a thickness of 2.4 mm and bandwidth of RL < −10 dB is 3.6 GHz (from 14.4 to 18.0 GHz). Structural characterization demonstrated that functional groups and defects were formed on HCNTs’ surface when treated by an acid mixture. Enhanced MA performance can be ascribed to the newly formed polarization centers and optimized impedance matching characteristics. The cooperation of the relaxations from functional groups and defects synergistically enhances the dielectric loss ability. In addition, the MA performance could simply be controlled by tuning the treating time of the HCNTs. The authors believe that this article will provide a new pathway toward the controllable design of high-performance or multifunctional devices based on helical carbon nanostructures and their hybrids.

-

Funding information: This work was financially supported by the Opening Foundation of Sichuan Province Engineering Research Center for Powder Metallurgy (SC-FMYJ2020-04), Applied Basic Research Programs of Sichuan province (2018JY0062), and Chengdu Technology Innovation Research and Development Project (2019-YFYF-00013-SN).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Li KY, Sun H, Zhang X, Zhang S, Dong HW, Zhu CL, et al. Micro-nanospheres assembled with helically coiled nitrogen-doped carbon nanotubes: fabrication and microwave absorption properties. Mater Design. 2020;186:108290.10.1016/j.matdes.2019.108290Suche in Google Scholar

[2] Qi X, Yang E, Cai H, Xie R, Bai Z, Jiang Y, et al. Water-assisted and controllable synthesis of core/shell/shell structured carbon-based nanohybrids, and their magnetic and microwave absorption properties. Sci Rep. 2017;7(1):9851.10.1038/s41598-017-10352-8Suche in Google Scholar PubMed PubMed Central

[3] Barathi Dassan EG, Anjang Ab Rahman A, Abidin MSZ, Akil HM. Carbon nanotube–reinforced polymer composite for electromagnetic interference application: a review. Nanotechnol Rev. 2020;9(1):768–88.10.1515/ntrev-2020-0064Suche in Google Scholar

[4] Lau KT, Lu M, Hui D. Coiled carbon nanotubes: synthesis and their potential applications in advanced composite structures. Compos Part B Eng. 2006;37(6):437–48.10.1016/j.compositesb.2006.02.008Suche in Google Scholar

[5] Wu F, Yang K, Li Q, Shah T, Ahmad M, Zhang Q, et al. Biomass-derived 3D magnetic porous carbon fibers with a helical/chiral structure toward superior microwave absorption. Carbon. 2021;173:918–31.10.1016/j.carbon.2020.11.088Suche in Google Scholar

[6] Wu F, Liu Z, Xiu T, Zhu B, Khan I, Liu P, et al. Fabrication of ultralight helical porous carbon fibers with CNTs-confined Ni nanoparticles for enhanced microwave absorption. Compos Part B Eng. 2021;215:108814.10.1016/j.compositesb.2021.108814Suche in Google Scholar

[7] Selim MM, El-Safty SA. Vibrational analysis of an irregular single-walled carbon nanotube incorporating initial stress effects. Nanotechnol Rev. 2020;9(1):1481–90.10.1515/ntrev-2020-0114Suche in Google Scholar

[8] Dong M, Peng M, Wei W, Xu H, Liu C, Shen C. Improved microwave absorption performance of double helical C/Co@CNT nanocomposite with hierarchical structures. J Mater Chem C. 2021;9(6):2178–89.10.1039/D0TC05811DSuche in Google Scholar

[9] Ulloa RZ, Santiago MGH, Rueda VLV. The interaction of microwaves with materials of different properties. London: IntechOpen; 2019.Suche in Google Scholar

[10] Wang C, Murugadoss V, Kong J, He ZF, Mai XM, Shao Q, et al. Overview of carbon nanostructures and nanocomposites for electromagnetic wave shielding. Carbon. 2018;140:696–733.10.1016/j.carbon.2018.09.006Suche in Google Scholar

[11] Xu HL, Yin XW, Fan XM, Tang ZM, Hou ZX, Li MH, et al. Constructing a tunable heterogeneous interface in bimetallic metal-organic frameworks derived porous carbon for excellent microwave absorption performance. Carbon. 2019;148:421–9.10.1016/j.carbon.2019.03.091Suche in Google Scholar

[12] Zhang D, Hao Z, Qian Y, Huang Y, Bizeng, Yang Z, et al. Simulation and measurement of optimized microwave reflectivity for carbon nanotube absorber by controlling electromagnetic factors. Sci Rep. 2017;7(1):479.10.1038/s41598-017-00372-9Suche in Google Scholar PubMed PubMed Central

[13] Li LD, Lu LF, Qi SH. Preparation, characterization and microwave absorption properties of porous nickel ferrite hollow nanospheres/helical carbon nanotubes/polypyrrole nanowires composites. J Mater Sci-Mater El. 2018;29(10):8513–22.10.1007/s10854-018-8865-ySuche in Google Scholar

[14] Zhao B, Li Y, Zeng Q, Wang L, Ding J, Zhang R, et al. Galvanic replacement reaction involving core-shell magnetic chains and orientation-tunable microwave absorption properties. Small. 2020;16(40):e2003502.10.1002/smll.202003502Suche in Google Scholar PubMed

[15] Zhao Y, Zhang H, Yang X, Huang H, Zhao G, Cong T, et al. In situ construction of hierarchical core–shell Fe3O4@C nanoparticles–helical carbon nanocoil hybrid composites for highly efficient electromagnetic wave absorption. Carbon. 2021;171:395–408.10.1016/j.carbon.2020.09.036Suche in Google Scholar

[16] Tian X, Meng F, Meng F, Chen X, Guo Y, Wang Y, et al. Synergistic enhancement of microwave absorption using hybridized polyaniline@helical CNTs with dual chirality. ACS Appl Mater Interfaces. 2017;9(18):15711–8.10.1021/acsami.7b02607Suche in Google Scholar PubMed

[17] Singh SK, Akhtar MJ, Kar KK. Hierarchical carbon nanotube-coated carbon fiber: ultra lightweight, thin, and highly efficient microwave absorber. ACS Appl Mater Interfaces. 2018;10(29):24816–28.10.1021/acsami.8b06673Suche in Google Scholar PubMed

[18] Wang T, Shi M, Fang D, He J, Zhang M, Zhang S, et al. Novel spiro[fluorene-9,9′-xanthene]-based hole transport layers for red and green PHOLED devices with high efficiency and low efficiency roll-off. J Mater Chem C. 2021;9(9):3247–56.10.1039/D0TC04676KSuche in Google Scholar

[19] Yang X, Peng Y, Hou J, Liu Y, Jian X. A review for modified Li composite anode: principle, preparation and challenge. Nanotechnol Rev. 2020;9(1):1610–24.10.1515/ntrev-2020-0120Suche in Google Scholar

[20] Meng FB, Wang Y, Wang Q, Xu XL, Jiang M, Zhou XS, et al. High-purity helical carbon nanotubes by trace-water-assisted chemical vapor deposition: large-scale synthesis and growth mechanism. Nano Res. 2018;11(6):3327–39.10.1007/s12274-017-1897-4Suche in Google Scholar

[21] Tang N, Wen J, Zhang Y, Liu F, Lin K, Du Y. Helical carbon nanotubes: catalytic particle size-dependent growth and magnetic properties. Acs Nano. 2010;4(1):241–50.10.1021/nn901425rSuche in Google Scholar PubMed

[22] Pant M, Singh R, Negi P, Tiwari K, Singh Y. A comprehensive review on carbon nano-tube synthesis using chemical vapor deposition. Mater Today Proc. 2021. 10.1016/j.matpr.2021.02.646.Suche in Google Scholar

[23] Fang B, Chang D, Xu Z, Gao C. A review on graphene fibers: expectations, advances, and prospects. Adv Mater. 2020;32(5):e1902664.10.1002/adma.201902664Suche in Google Scholar PubMed

[24] Tian W, Zhang X, Guo Y, Mu C, Zhou P, Yin L, et al. Hybrid silica-carbon bilayers anchoring on FeSiAl surface with bifunctions of enhanced anti-corrosion and microwave absorption. Carbon. 2021;173:185–93.10.1016/j.carbon.2020.11.002Suche in Google Scholar

[25] Yengejeh SI, Kazemi SA, Ochsner A. Carbon nanotubes as reinforcement in composites: a review of the analytical, numerical and experimental approaches. Comp Mater Sci. 2017;136:85–101.10.1016/j.commatsci.2017.04.023Suche in Google Scholar

[26] Almessiere MA, Slimani Y, Trukhanov AV, Sadaqat A, Korkmaz AD, Algarou NA, et al. Review on functional bi-component nanocomposites based on hard/soft ferrites: structural, magnetic, electrical and microwave absorption properties. Nano-Struct Nano-Objects. 2021;26:100728.10.1016/j.nanoso.2021.100728Suche in Google Scholar

[27] Zhang Z, Cai Z, Wang Z, Peng Y, Xia L, Ma S, et al. A review on metal–organic framework-derived porous carbon-based novel microwave absorption materials. Nano-Micro Let. 2021;13:1.10.1007/s40820-020-00582-3Suche in Google Scholar PubMed PubMed Central

[28] Li Y, Meng F, Mei Y, Wang H, Guo Y, Wang Y, et al. Electrospun generation of Ti3C2Tx MXene@graphene oxide hybrid aerogel microspheres for tunable high-performance microwave absorption. Chem Eng J. 2020;391:123512.10.1016/j.cej.2019.123512Suche in Google Scholar

[29] Gu WH, Sheng JQ, Huang QQ, Wang GH, Chen JB, Ji GB. Environmentally friendly and multifunctional shaddock peel-based carbon aerogel for thermal-insulation and microwave absorption. Nano-Micro Let. 2021;13(1):1–14.10.1007/s40820-021-00635-1Suche in Google Scholar PubMed PubMed Central

[30] Quan B, Liang X, Ji G, Ma J, Ouyang P, Gong H, et al. Strong electromagnetic wave response derived from the construction of dielectric/magnetic media heterostructure and multiple interfaces. ACS Appl Mater Interfaces. 2017;9(11):9964–74.10.1021/acsami.6b15788Suche in Google Scholar PubMed

[31] Wu N, Hu Q, Wei R, Mai X, Naik N, Pan D, et al. Review on the electromagnetic interference shielding properties of carbon based materials and their novel composites: Recent progress, challenges and prospects. Carbon. 2021;176:88–105.10.1016/j.carbon.2021.01.124Suche in Google Scholar

[32] Liu Y, Jiang L, Wang H, Wang H, Jiao W, Chen G, et al. A brief review for fluorinated carbon: synthesis, properties and applications. Nanotechnol Rev. 2019;8(1):573–86.10.1515/ntrev-2019-0051Suche in Google Scholar

[33] Li XL, Yin XW, Han MK, Song CQ, Xu HL, Hou ZX, et al. Ti3C2 MXenes modified with in situ grown carbon nanotubes for enhanced electromagnetic wave absorption properties. J Mater Chem C. 2017;5(16):4068–74.10.1039/C6TC05226FSuche in Google Scholar

[34] Zhou J, Chen Y, Li H, Dugnani R, Du Q, UrRehman H, et al. Facile synthesis of three-dimensional lightweight nitrogen-doped graphene aerogel with excellent electromagnetic wave absorption properties. J Mater Sci. 2017;53(6):4067–77.10.1007/s10853-017-1838-3Suche in Google Scholar

[35] Wang C, Wang B, Cao X, Zhao J, Chen L, Shan L, et al. 3D flower-like Co-based oxide composites with excellent wideband electromagnetic microwave absorption. Compos Part B Eng. 2021;205(30):108529.10.1016/j.compositesb.2020.108529Suche in Google Scholar

[36] Wei HJ, Yin XW, Li X, Li MH, Dang XL, Zhang LT, et al. Controllable synthesis of defective carbon nanotubes/Sc2Si2O7 ceramic with adjustable dielectric properties for broadband high-performance microwave absorption. Carbon. 2019;147:276–83.10.1016/j.carbon.2019.03.008Suche in Google Scholar

[37] Xu HL, Yin XW, Li MH, Ye F, Han MK, Hou ZX, et al. Mesoporous carbon hollow microspheres with red blood cell like morphology for efficient microwave absorption at elevated temperature. Carbon. 2018;132:343–51.10.1016/j.carbon.2018.02.040Suche in Google Scholar

[38] Wang H, Meng F, Huang F, Jing C, Li Y, Wei W, et al. Interface modulating CNTs@PANi hybrids by controlled unzipping of the walls of CNTs to achieve tunable high-performance microwave absorption. ACS Appl Mater Interfaces. 2019;11(12):12142–53.10.1021/acsami.9b01122Suche in Google Scholar PubMed

[39] Jia Z, Zhang M, Liu B, Wang F, Wei G, Su Z. Graphene foams for electromagnetic interference shielding: a review. ACS Appl Nano Mater. 2020;3(7):6140–55.10.1021/acsanm.0c00835Suche in Google Scholar

[40] Green M, Chen XB. Recent progress of nanomaterials for microwave absorption. J Mater. 2019;5(4):503–41.10.1016/j.jmat.2019.07.003Suche in Google Scholar

[41] Quan B, Liang XH, Ji GB, Cheng Y, Liu W, Ma JN, et al. Dielectric polarization in electromagnetic wave absorption: review and perspective. J Alloys Compd. 2017;728:1065–75.10.1016/j.jallcom.2017.09.082Suche in Google Scholar

[42] Xie J, Jiang H, Li J, Huang F, Zaman A, Chen X, et al. Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption. Nanotechnol Rev. 2021;10(1):1–9.10.1515/ntrev-2021-0001Suche in Google Scholar

[43] Li T, Zhi DD, Chen Y, Li B, Zhou ZW, Meng FB. Multiaxial electrospun generation of hollow graphene aerogel spheres for broadband high-performance microwave absorption. Nano Res. 2020;13(2):477–84.10.1007/s12274-020-2632-0Suche in Google Scholar

[44] Lv H, Zhang H, Ji G, Xu ZJ. Interface strategy to achieve tunable high frequency attenuation. ACS Appl Mater Interfaces. 2016;8(10):6529–38.10.1021/acsami.5b12662Suche in Google Scholar PubMed

[45] Du S, Chen H, Hong R. Preparation and electromagnetic properties characterization of reduced graphene oxide/strontium hexaferrite nanocomposites. Nanotechnol Rev. 2020;9(1):105–14.10.1515/ntrev-2020-0010Suche in Google Scholar

[46] Zhi D, Li T, Li J, Ren H, Meng F. A review of three-dimensional graphene-based aerogels: synthesis, structure and application for microwave absorption. Compos Part B Eng. 2021;211:108642.10.1016/j.compositesb.2021.108642Suche in Google Scholar

[47] Xu X, Shi S, Tang Y, Wang G, Zhou M, Zhao G, et al. Growth of NiAl-layered double hydroxide on graphene toward excellent anticorrosive microwave absorption application. Adv Sci (Weinh). 2021;8(5):2002658.10.1002/advs.202002658Suche in Google Scholar PubMed PubMed Central

© 2021 Ying Li et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions

Artikel in diesem Heft

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions