Abstract

In the global construction industry, with the growth of population, two important construction problems have to be faced, namely, the excessive consumption of non-renewable resources and the massive accumulation of construction waste. In order to solve these problems, geopolymer recycled aggregate concrete (GRAC) arises at the historic moment. On the one hand, using geopolymers produced by industrial wastes to completely or partially replace cement can reduce cement consumption, thus reducing CO2 emissions. On the other hand, recycled concrete made of recycled aggregate can consume accumulated construction waste and save non-renewable materials and land resources. The combination of the two materials can protect the environment to the greatest extent and save resources. This article reviews the current research on the mechanical properties of GRAC, makes a systematic analysis of GRAC materials, reaction mechanisms, and evaluation indicators, and also discusses the application prospects of GRAC, and strives to make contributions to the field and industry.

1 Introduction

With the increasingly acute problem of environmental pollution, the world pays more and more attention to environmental protection, and various fields are actively responding to the environmental protection concept of green economy. In the construction industry, due to the rapid growth of the demand for energy-saving and environmentally friendly building technology, the concept of green building is becoming more and more popular. As the most needed building material, the nature of concrete is also the most prominent in the building. With the growth of population, statistics show that the annual output of global cement unit will increase to 6.1 billion tons by 2050. Among them, developing countries account for a high proportion, such as China accounts for about half of the world's cement production in 2019. At the same time, the mass production of ordinary Portland concrete (OPC) also means ultra-high CO2 emissions (7% of global carbon emissions) [1, 2]. On the other hand, in addition to cement and other cementitious materials, sand and stones are also the main raw materials for concrete. For a long time, due to a wide range of sources of sand and gravel aggregates, relatively low prices and other reasons, they have been arbitrarily mined, which has caused a large number of landslides, river flooding and other serious environmental problems [3,4,5,6]. At the same time, due to the high energy consumption of aggregate mining, this will also cause a lot of energy waste. Moreover, with the continuous construction of a large number of buildings, the replacement of new and old buildings has become more frequent. It's very easy to generate a large amount of construction waste disposal, and cause irreversible damage to the environment. Therefore, it is urgent to effectively solve these problems to ensure the sustainable development of the construction industry. Coincidentally, GRAC can solve these problems very well. It is necessary to study the geopolymer recycled aggregate concrete in a comprehensive and systematic way. The first thing is to solve the problems of its research foundation and current situation. It is of great value to summarize this aspect.

On the one hand, the use of geopolymer produced from industrial waste to replace cement can greatly reduce CO2 emissions [7,8,9,10]. Geopolymer is made by combining raw materials rich in silica and alumina, such as fly ash (FA), ground granulated blast furnace slag (GGBFS), with strong alkali solutions, such as potassium hydroxide (KOH), sodium hydroxide (NaOH), a cementing material synthesized by mixing sodium hydroxide and sodium silicate (Na2O·nSiO2) solution. After geopolymerization, a three-dimensional amorphous aluminosilicate network with strength similar to or higher than that of OPC is formed. Geoaggregation can be divided into three steps: (1) Dissolve the oxide minerals of raw materials under high alkaline conditions; (2) The dissolved oxide mineral condenses into a gel; (3) Condensation to form a 3D network of aluminosilicate structure [11]. According to the type of chemical bond produced, three types of structures can be derived from the 3D aluminosilicate network: Polysialic acid (–Si–O–Al–O–), Polysialic acid-siloxane (Si–O–Al–O–Si–O) and polysialic acid disiloxy potassium salt (Si–O–Al–O–Si–O–Si–O–).

On the other hand, the emergence of recycled aggregate concrete can well solve the problem of construction waste disposal. Usually the test blocks of waste concrete are crushed, cleaned, graded and mixed in a certain proportion to make “recycled aggregate”, and the concrete made from these recycled aggregates is called recycled aggregate concrete. Waste concrete usually comes from several aspects: (1) buildings reach their useful life or aging demolition; (2) infrastructure transformation, laboratory waste test blocks, etc.; (3) construction of excess concrete in new buildings. In addition, some scholars use waste glass [12], corncob ash [13], and waste marble slag [14] to make recycled aggregate concrete. All in all, recycled aggregate concrete has a wide range of sources, which can effectively solve the problems of urban construction waste accumulation and pollution. It can also efficiently recycle resources and contribute to the conservation of non-renewable resources.

At this stage, with the continuous development of research, there have been researches on the combination of geopolymer and recycled concrete. Luhar et al. reviewed the combination of glass ballast and geopolymer [15]. He introduced the characteristics, strength, and microscopic aspects of this kind of GRAC using materials as the starting point, and proposed new development directions. Some scholars also use chromium coarse aggregate and silica fume (SF), to study the modification effect of chromium coarse aggregate and silica fume in fly ash geopolymer concrete(GPC) with machinability, strength, water absorption and other indexes. It was found that the machinability and water absorption of GPC decreased and the strength increased with the increase of SF content [16]. There are also studies on the properties of geopolymers prepared from zeolite tuff and marble waste. This study uses the modulus of NaOH as a variable to study the influence of 5M and 10M on the strength of GPC. The results show that the geopolymer prepared with 10 M NaOH exhibits higher compressive strength [14]. The combination of geopolymer and recycled concrete can not only be greener and environmentally friendly, save resources, but also have better durability and mechanical properties than OPC [12, 13]. To a certain extent, this is an epoch-making research that has completely changed the materials used in ordinary Portland concrete (OPC) and solved the disadvantages of traditional concrete to the greatest extent. However, the research on GRAC is still not systematic, and there is no article to make a comprehensive summary of the current research situation of GRAC.

Because the combination of geopolymer and recycled concrete can solve the problems of high CO2 emissions and construction waste stacking. Based on the above point of view, this article mainly summarizes the current research on the mechanical properties of GRAC, hoping to summarize the various research directions of GRAC and make a contribution to the research of GRAC.

2 Overview of materials

2.1 Recycled aggregate

Since the main difference between recycled aggregate concrete (RAC) and OPC is in aggregate, recycled aggregate (RCA) determines the performance of recycled concrete to a great extent [17, 18]. In this context, a large amount of construction waste is recycled, such as waste concrete, masonry, etc. Crush construction waste and mix it in a certain proportion, and then use it as RCA to completely or partially replace natural aggregates (NA) to produce recycled concrete [19,20,21]. The study shows that the use of RCA in the preparation of concrete can not only meet the performance requirements of natural structural concrete, but also solve the problem of shortage of landfills, which is consistent with the essence of sustainable development, that is, environmental protection and effective treatment of environmental pollution [21,22,23]. On the other hand, recycled aggregate contains a large number of residual cementitious materials, which have larger pores, lower strength, high water absorption and crushing index than natural aggregates. At the same time, due to the existence of residual mortar, the interface transition zone (ITZ) of recycled aggregate concrete will make the combination of new with old mortar unstable and incompact, and it is easy to destroy the interface transition zone, which is the main reason why the strength of recycled concrete is lower than that of natural concrete [24].

In this section, the microscopic characterization and compression resistance of RCA will be mainly introduced, so that readers have an overall understanding of recycled aggregate.

2.1.1 Microscopic characterization of recycled aggregate

The study of the microscopic characterization of aggregates should start with the interface conditions around the aggregates. Traditional concrete usually uses the interface transition zone (ITZ) to indicate the surrounding interface of NA [25]. The ITZ of NA is usually between the aggregate and the cementing material, and there is also the ITZ between the aggregate and the fiber in fiber concrete. Recycled aggregate is essentially composed of old natural aggregate and residual mortar, and the two are integral to each other. Therefore, recycled aggregates usually have the following three types of ITZ [26, 27]:

ITZ between NA and newly added cementitious material

ITZ between NA and old residual cementitious material

ITZ between old and new mortar

These three ITZ types are illustrated vividly in Figure 1 [26]. The type of ITZ is named ITZ 1, ITZ 2 and ITZ3.

![Figure 1 Various types of ITZ in recycled aggregate concrete [26]](/document/doi/10.1515/rams-2021-0021/asset/graphic/j_rams-2021-0021_fig_001.jpg)

Various types of ITZ in recycled aggregate concrete [26]

When the RAC is stressed, the cracks start from the fragile area near the ITZ and gradually spread to the aggregate and cementitious materials, resulting in the destruction of the entire concrete [24, 28]. It has been found that ITZ is composed of pores, Ca(OH)2, C-S-H gel, ettringite and cement particles [29]. At the same time, it can be found that the volume ratio of C-S-H in the ITZ between the aggregate and the new cementitious material is greater than that of the old cementitious material, as shown in Figure 2 [29]. Studies have shown that the characteristics of ITZ in RAC are related to the quality of the attached mortar and have nothing to do with the quantity of mortar [30]. Because RCA is attached to more residual gelling materials, the thickness of ITZ in NAC is usually 9–51 μm, and the thickness of ITZ in RAC is 30–60 μm [31, 32].

![Figure 2 Difference in thickness between new and old ITZ [29]](/document/doi/10.1515/rams-2021-0021/asset/graphic/j_rams-2021-0021_fig_002.jpg)

Difference in thickness between new and old ITZ [29]

On this basis, some scholars continue to deepen the study of the microstructure of RAC and found that the strength of ITZ is more affected by the water-to-binder ratio. In the lower water-binder ratio concrete, its strength is mainly affected by the ITZ between the residual cementitious materials, and the new ITZ mainly affects the high water-binder ratio concrete components. Therefore, in the high water-binder ratio concrete, even if the residual cementitious material strength is higher than the newly added cementitious material strength, the strength of RAC is still equal to the strength of NAC. In low water-binder ratio concrete components, the strength of residual cementitious material is lower than that of newly added cementitious material, so the strength of RAC will be lower than that of NAC [33].

Therefore, most scholars believe that the strength of RAC is directly affected by the strength of ITZ [34]. However, there are two views on the results of the ITZ impact. Spaeth and Tegguer [24], Wong et al. [35] and others believe that when concrete is damaged under compression, cracks first originate from ITZ and gradually spread to other areas. Therefore, ITZ reduces the strength and impermeability of concrete. On the contrary, Diamond and Huang [36] and others believe that the porosity of ITZ in RAC is only slightly higher than that of the surrounding cementitious materials, because the voids in ITZ will be filled by Ca(OH)2, C-S-H gel, etc. Therefore, the ITZ in RAC does not necessarily have a negative impact on concrete. In summary, the microscopic characterization of recycled aggregate is mainly determined by the characteristics of ITZ, and ITZ has a major effect on the strength of concrete.

2.1.2 Compressive ability of recycled aggregate

In the unit cubic volume of concrete, aggregate volume usually accounts for 70%–80%. The compressive strength of aggregate can often directly affect the strength of concrete [37]. Usually, the crushing index (%) is used to judge the compressive strength of aggregate, and its expression is as follows:

Qg: Crushing index (%); G1: The quality of the sample (g); G2: The quality of the sieve residue after the crush test (g)

The strength of aggregate is one of the main factors affecting the strength of concrete, which mainly affects the transfer of stress and the ability of compression [37, 38].

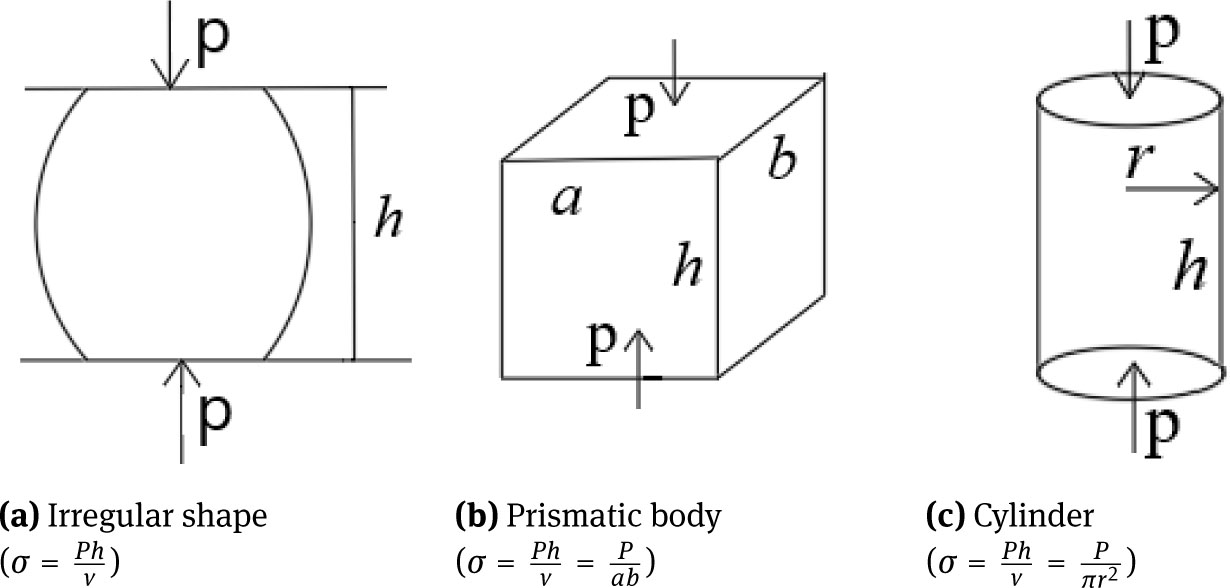

The compressive strength of recycled aggregate usually refers to the compressive strength of coarse aggregate, because the volume of coarse aggregate accounts for 60% and 70% of all aggregate [39]. Due to the complex composition of recycled aggregates, it has high porosity and high water absorption. At the same time, the waste construction waste will often produce cracks when it is destroyed, which will further affect the strength of aggregate. On the other hand, due to the high porosity of RCA, it tends to absorb surrounding moisture. When RCA is saturated with water absorption or has high water content, it will significantly reduce the compressive strength [40]. The influence of water on the strength of NCA is usually negligible, but it cannot be ignored for RCA. Under the influence of these factors, the strength of RCA is often lower than that of NCA. In the case of the same mix ratio, if the strength of the aggregate is not up to the standard, it is still difficult to increase the strength, or even decrease it, even if the water-binder ratio is reduced. For the compressive strength of RCA, the prediction formula method can be adopted. The basic principle and formula are shown in Figure 3. It is proved that the strength of RCA can be calculated accurately by the prediction of aggregate strength [41].

Different types of shape estimation methods (V is the volume of geometry)

The compressive strength of recycled aggregate is usually characterized by crushing index. Because the residual cementitious material is attached to the surface of recycled aggregate, it is weak and easy to fall off and crush under the condition of external force. Therefore, in general, the crushing index of RCA is higher than that of NCA. Moreover, the RCA crushing index in the saturated surface dry state is higher than that in the air-dry state, which is due to the decrease of the strength of the surrounding residual cementitious materials due to water absorption saturation. At the same time, because the test concrete components were tested under 28d conditions, the RCA has been saturated with water at this time. Therefore, it is unscientific to use the crushing index of RCA in air-dry state to measure the strength of RCA. At present, there is a lack of research in this area, which has the value of continuing in-depth research.

Due to the low compressive strength of RCA, there are many modification methods at this stage to help RCA reduce its crushing index. Impregnation with pozzolanic mortar, accelerated carbonization and solidification, and polymer impregnation are the main methods, as shown in Figure 4 [42]. The negative value in the graph shows that the amount of crushing index is reduced.

![Figure 4 The influence of different processing methods on crushing index [42].](/document/doi/10.1515/rams-2021-0021/asset/graphic/j_rams-2021-0021_fig_004.jpg)

The influence of different processing methods on crushing index [42].

Pandurangan et al. [43] proved that the use of physical means to remove the residual mortar on the surface of the RCA (the crushing index was reduced from 36% to 22.1%) was better than the use of 0.1 mol HCl solution and H2SO4 solution to soak RCA (both reduced 8.3%). At the same time, Saravanakumar et al. [44] studied the difference between HCL (reduced by 7.0%), HNO3 (reduced by 3.0%), and H2SO4 (reduced by 2.0%). The reason why the effect of acid solution to remove residual mortar on the surface is not obvious is that too high acid solution concentration or too long immersion time will reduce the performance of RCA. Ismail and Ramli [45] found that the optimal concentration of HCl solution is 0.1 mol (average decrease of 3.6%), higher than 0.5 mol (average decrease of 2.4%) and 0.8 mol (average decrease of 2.5%). Their results also showed that the average crushing index (ACD) dropped the most after 3d soaking (an average drop of 4.5%) compared with 1d and 5d soaking.

Weng [46] found that the crush value of RCA treated with 6% Poly-Vinyl-Alcohol (PVA) solution was reduced by 24.1%. The crushing index of RCA decreased to 28.8% as the concentration of PVA gradually increased to 12%. However, when the concentration of PVA solution exceeds 12%, the crushing index for reducing RCA will no longer become obvious.

As shown in Figure 4, the effect of CO2 accelerated carbonization is the most significant, and the modification effect is (−44, −1.6). Li et al. [47] found that the carbonization treatment not only strengthened the residual cementitious material in RCA, but also strengthened the old ITZ, and the average hardness of the residual cementitious material increased by 17.4%.

In summary, the hardness of recycled aggregate has a direct effect on the strength of RAC, and increasing the hardness of RCA has a significant effect on the strength of RAC. There are a variety of methods to improve the treatment of RCA, but at present, most of the methods only stay at the physical level, and the chemical composition of the residual cementitious materials has not been studied, so as to make improvements from the chemical level.

2.2 Geopolymer cementing material

Geopolymer is a common substitute for Portland cement at present. Its main source is processed from industrial waste, such as: fly ash, metakaolin, slag powder, coal gangue, etc. [48]. Geopolymer often need alkali solution to activate, which has the characteristics of early strength, high strength and so on. Inorganic organic polymers are formed by polycondensation of certain waste materials containing aluminosilicate with alkali solution. Geopolymer is an amorphous to semi-crystalline three-dimensional aluminosilicate framework formed by the combination of SiO4 and Al2O3. In the process of geopolymerization, the raw materials containing aluminosilicate are dissolved in alkaline solvents to form aluminate and silicate monomers, which are then converted into geopolymers [49]. Water is consumed in the process of dissolution and release polymerization, which is shown in Figure 5 [50]. The molecular reaction of the geopolymerization process is shown in Figure 6 [50]. The process of geopolymerization includes dissolution and reorganization, condensation and polymerization. The dissolution and recombination of aluminum silicate form several types of geopolymers; geopolymers connect and form large polymers. When a local polymer is connected, the OH-group at its end meets by sharing an oxygen atom and releases water [51].

![Figure 5 Schematic diagram of the formation of geopolymer materials [50].](/document/doi/10.1515/rams-2021-0021/asset/graphic/j_rams-2021-0021_fig_005.jpg)

Schematic diagram of the formation of geopolymer materials [50].

![Figure 6 (a) Recombination of aluminosilicate (b) Polymerization to form gel (c) Polymerization [50].](/document/doi/10.1515/rams-2021-0021/asset/graphic/j_rams-2021-0021_fig_006.jpg)

(a) Recombination of aluminosilicate (b) Polymerization to form gel (c) Polymerization [50].

Geopolymers have very high environmental benefits and are very ideal cement substitutes [52,53,54]. In the polymerization process, there are mainly two kinds of materials, one is cementing materials such as: fly ash (FA), silica fume (SF), metakaolin (MK), red mud (RM), etc., and the other is various alkali stimulators [55]. Generally, the alkali activator is composed of NaOH solution or NaOH and Na2SiO3 aqueous solution, and the modulus should be between 1.0–1.5 [56]. The mixing process of these two types of materials is shown in Figure 7 [49].

![Figure 7 Geopolymer mixing process [49]](/document/doi/10.1515/rams-2021-0021/asset/graphic/j_rams-2021-0021_fig_007.jpg)

Geopolymer mixing process [49]

By studying the geopolymer model, people can more intuitively understand the principle of molecular movement, cluster formation and reaction in the polymerization process [57, 58]. Barbosa et al. [59] proposed a model concept, and the whole reaction is divided into (a) oligomerization, (b) polymerization, (c) concentration. See Figure 8 [50].

![Figure 8 Geopolymer molecular model [50].](/document/doi/10.1515/rams-2021-0021/asset/graphic/j_rams-2021-0021_fig_008.jpg)

Geopolymer molecular model [50].

Fly ash and metakaolin are currently more widely used geopolymer materials [60]. The combination of fly ash and calcined paper sludge has also been used as a cementitious material. Pulp sludge improves the reactivity of bottom coal ash during the polymerization process [61]. Waste paper sludge-based geopolymer mortar can be used for masonry applications, and has achieved considerable results [62]. The blending of recycled sludge and RM has been used to prepare lightweight geopolymers [63].

In general, although geopolymers have a wide range of sources, they are all Si and Al compounds in nature. A proper Si/Al ratio can significantly improve the performance of the geopolymer. Due to the environmental protection and sustainable development of geopolymer materials, in the future, it should gradually replace cement and be used as the main cementing material for concrete. But at present, the research on geopolymers is still not thorough, and there are still many problems to be solved, such as: the constitutive relationship of geopolymer concrete, the difference between different regions, etc.

3 Research progress of GRAC mechanical properties

Compared with other concrete, there is still a lack of research on GRAC, and the research in this field is still in its infancy. Panizza et al. [64] use construction waste to make coarse aggregate, combined with MK-FA cementitious material to make recycled geopolymer concrete. Tan et al. [65] use waste bricks to make recycled aggregates and make GRAC with slag powder. Mesgari et al. [66] directly used geopolymer waste blocks to make aggregates, and newly added geopolymer cementing materials to make GRAC. However, geopolymers are more sensitive to the modulus of the alkali activator. Directly using geopolymers as aggregates will have an uncontrollable effect on the overall GRAC strength. Therefore, the research on this aspect should be more careful to clean the residual cementing materials on the aggregate surface. On the other hand, Ren and Zhang [67] and Liu et al. [68] also found that geopolymer cementitious materials and recycled aggregates are tightly bonded, and the strength of ITZ between geopolymer colloids and recycled aggregates is higher than that of OPC base recycled aggregate concrete.

This section will introduce the research on the mechanical properties of GRAC at this stage, and hope to expand the scope of research and advance the depth of research.

3.1 Compressive strength research

Compressive strength is one of the basic judgment values of concrete mechanical properties. Geopolymer concrete has the characteristics of early strength and high strength, but the compressive strength of GRAC is more difficult to predict and control due to the inclusion of RCA. This section summarizes the research on the compressive strength of GRAC, summarizes the current research on this aspect, and explains and analyzes it.

To study the effect of RCA on concrete often requires studying the effect of substitution rate. Mesgari et al. [66] studied the performance of OPC and GRAC made of different proportions of geopolymer RCA (0%, 20%, 50% and 100%) instead of NA. The results show that the use of recycled geopolymer concrete aggregates to replace rough natural aggregates by up to 20% will significantly reduce the elastic modulus, flexural strength and compressive strength of OPC. At this time, the compressive strength is 50 MPa, which is 10% lower than the standard group, shown in Figure 9 [86]. Moreover, the negative impact of geopolymer recycled aggregate on OPC is more significant than that of silicate recycled aggregate. Experiments have found that the impact of recycled geopolymer coarse aggregate on OPC is slightly more significant than that of geopolymer concrete. This is because the residual mortar on the surface of the geopolymer recycled aggregate is relatively alkaline and has a significant impact on the silicate concrete.

![Figure 9 Percentage of Coarse NA Replaced with RCA (%) [66]](/document/doi/10.1515/rams-2021-0021/asset/graphic/j_rams-2021-0021_fig_009.jpg)

Percentage of Coarse NA Replaced with RCA (%) [66]

The curing temperature has a significant effect on the strength of geopolymer concrete [69, 70]. But for GRAC, the curing temperature and curing time are still controversial [71]. When the curing temperature exceeds a certain optimal temperature or the curing time exceeds a certain curing time, the physical properties of GRAC will not be further changed or even reduced. Based on this, Wang et al. [72] conducted research on the curing temperature and curing time of GRAC. Use construction waste as aggregate and use fly ash-slag base polymer instead of ordinary Portland cement to prepare GRAC. The compressive strength, elastic modulus, toughness and microstructure of different initial curing temperature (20°C, 40°C, 60°C, 80°C and 100°C) and curing time (6 h, 12 h and 24 h) were studied. It is found that the best curing condition is curing at 80°C for 12–24 h. Under these conditions, GRAC has the highest compressive strength, elastic modulus and toughness, and its 7-day compressive strength can reach 45 MPa. The microstructure is shown in Figure 10 [72].

![Figure 10 Microstructure at 80°C curing temperature [72].](/document/doi/10.1515/rams-2021-0021/asset/graphic/j_rams-2021-0021_fig_010.jpg)

Microstructure at 80°C curing temperature [72].

The essence of geopolymers is Si and Al compounds, so Si/Al is a very important factor to study the chemical effects of geopolymers. Tan et al. [65] focused on the influence of Si/Al on the chemical level. They extracted regenerated cementitious materials from the waste materials from the demolition of the masonry structure, and used a ball mill to grind them into powder and slag powder as cementitious materials to make geopolymer recycled mortar test blocks. Through the experiment, it is found that the compressive strength can reach the highest when Si/Al is 3, and the compressive strength of 7 days is close to 70 MPa. At the same time, it is also found that the increase of slag content has a significant effect on the compressive strength of geopolymers when the alkali concentration is lower than 10 mol/L. When the alkali concentration reaches 12 mol/l, the replacement rate of slag powder should be controlled below 25%. Moreover, under this condition, the ratio of compressive strength to tensile strength is 1.02, which is much higher than that of OPC. This proves that the concrete has good shaping and is not easy to have brittle failure.

On this basis, Zhu et al. [73] and others used 12 mol/L NaOH solution to make GRAC. This experiment studies the recycling of waste geopolymer concrete blocks, which are ground and used to make recycled fine aggregates to replace river sand. Then 5 kinds of RCA replacement rates (0%, 20%, 50%, 80% and 100%) were used to prepare GRAC mortar test blocks. After testing, it has been found to have a lower apparent density (1.85) and a higher water absorption rate (15.04). When the RCA share is less than 50%, its compressive and flexural strength decreases only slightly (less than 10%). As the RCA replacement rate increases to 100%, the compressive strength of the GRAC mortar has dropped significantly, but it is still greater than 35 MPa. This experiment on the same side proves that the modulus of the alkali activator is a very important influencing factor, and its degree of influence is greater than that of the replacement rate of fine aggregate.

In summary, the compressive strength of GRAC is similar to that of GPC, and both are affected by the modulus of the alkali activator, curing temperature, and Si/Al. Within an appropriate range, it can be ensured that the strength of the two concretes is not much different, which proves that GRAC can effectively replace the use of GPC in terms of compression resistance.

3.2 Tensile strength research

Hayrullah and Yasin [12] used waste glass mill powder and fly ash as cementitious material, sodium silicate solution (SS) and sodium hydroxide (SH) solution together as alkali activator, the substitution rate was 5%, 15%, 20%, 25% and 50%. The tensile strength was studied at 85°C curing temperature. Through the experiment, it is found that: The 50% replacement rate of glass powder can increase the tensile strength by 67%, and when the modulus of the alkali activator solution is 12M and 14 mol/L, the strength can be increased by 25% and 15%. This is because the content of SiO2 in primary fly ash is 22.73%, but with the use of high siliceous materials, the total silica content in the polymerization reaction increases significantly, and the number of C-S-H gels therefore increases. Similarly, related studies [74, 75] also proved that under alkaline conditions, glass is partially dissolved, and a silicone gel is formed on the surface of the glass particles to further prevent its complete dissolution. This can also be understood as a higher replacement rate of waste glass powder will reduce the strength of concrete. On the other hand, the solubility of waste glass in the lower alkali modulus solution is relatively low, so the compressive strength value of the concrete is 2.5–5.6 MPa at a concentration of 10 mol/L, and 8.1–12.7 MPa at a concentration of 12 mol/L. It is 9.4–15.3 MPa at a concentration of 14 mol/L.

The research of Peem et al. [76] went further. Because the internal structure of geopolymer concrete made of recycled aggregates is usually weaker than that of natural aggregates, SiO2-rich materials are used to improve strength properties, one of which is the well-known nano-SiO2 [77]. But SiO2 is not environmentally friendly, so it is often more feasible to use other green substances rich in SiO2, such as rice husk ash. The experimental results show that the addition of rice husk ash can effectively increase the strength of GRAC, especially when the Si/Al ratio is increased to 4.17. The 28-day compressive strength of GMRC containing rice husk ash is between 36.0 and 38.1 MPa, which is due to the improved microstructure that makes the entire structure more compact. However, the addition of rice husk ash did not significantly improve the tensile strength of GRAC, only 8%. Because of the high bond strength of geopolymer cementitious materials [78], the ITZ strength of geopolymer cementitious materials is higher than that of OPC, and most of the tensile cracks do not pass through the aggregate. Therefore, even if you use NA, the strength will not change much. This may explain why the addition of silicon-rich materials has little improvement in tensile strength.

Avinash and Lokesh [79] make GRAC with high fly ash (FA-MK) base polymer concrete and recycled aggregate. But the difference is that this study also carried out a comparative study of the effects of recycled aggregate on OPC and GPC, and also set up a comparative study between GPC and GRAC. The experiment shows that the average strength, compressive strength and splitting strength of concrete prepared with natural coarse aggregate are 30.3 MPa and 3.4 MPa, respectively. For conventional recycled aggregate concrete, it is 28.2 MPa and 2.8 MPa respectively. The average compressive strength of geopolymer concrete mixed with natural coarse aggregate is 28.8 MPa, and the splitting strength is 3.1 MPa. The compressive strength and splitting strength of recycled aggregate geopolymer concrete are 26.4 MPa and 2.24 MPa, respectively, as shown in Table 1 [79]. This experiment compares and analyzes the influence of the difference of aggregate and the difference of cementitious materials.

Test results of conventional concrete (M-25) and geopolymer concrete (GC-25) with natural and recycled coarse aggregates [79].

| Test group | Characteristics | Conventional Concrete Type | Geopolymer Concrete Type | ||

|---|---|---|---|---|---|

| With Natural aggregates (CC) (MPa) | With Recycled aggregates (CCR) (Mpa) | With Natural aggregates (GC) (MPa) | With Recycled aggregates (GCR) (MPa) | ||

| 1 | Average compressive strength | 30.30 | 28.20 | 28.80 | 26.40 |

| 2 | Split tensile strength | 3.4 | 2.92 | 3.10 | 2.24 |

The source of most recycled aggregates is construction waste [79,80,81,82,83]. However, Zhou et al. [84] used waste mud-stone as aggregate to make GRAC with slag-red mud. Experiments have found that the phosphorus content in waste mudstone has a more significant impact on tensile strength than compressive strength. When the replacement rate of waste mud is 10% and 20%, as the modulus of the alkali activator increases, the tensile strength gradually decreases. At the same time, when the replacement rate is 15%, the maximum tensile strength is 2.98 MPa. As shown in Figure 11 [84].

![Figure 11 P is the content of waste mudstone and Q is the content of alkali activator [84].](/document/doi/10.1515/rams-2021-0021/asset/graphic/j_rams-2021-0021_fig_011.jpg)

P is the content of waste mudstone and Q is the content of alkali activator [84].

In summary, although the research on tensile strength is not as adequate as compressive strength, it can still be seen that the negative impact of recycled aggregates on the tensile strength of GPC is more extensive, although not as significant as the compressive strength. At present, the research on the tension-compression ratio of GRAC is relatively rare, and there are few studies involving the effect of modification and strengthening of RCA on the tensile strength of GRAC, so the research in this area should be continuously deepened.

3.3 Flexural strength study

The research on the flexural strength of concrete is of great significance. Flexural strength can directly reflect the load-bearing capacity of concrete. Maheshbabu et al. [85] and others used recycled aggregates and alkali to activate fly ash to make recycled asphalt, and used recycled geopolymer asphalt to make components. Through the experimental study, it is found that the 28-day bending strength of the unreinforced test block is 2.26 MPa, that of the double-reinforced test block is 2.43 MPa, and that of the three-way grid test block is 2.67 MPa. Just like ordinary concrete, the addition of steel bar can effectively improve the bending strength of members. And the formula of fracture energy dissipation is deduced:

GD = flexural energy dissipation (J/m2); WD = loaded area-displacement curve (work) (KN-mm); L = beam span length (mm); H = specimen thickness (mm).

As mentioned earlier, there are many sources of recycled aggregates. Aly et al. [86] collect waste rubber from tires to make aggregates, and use slag-based GPC to make GRAC. The substitution rates of 10%, 20% and 30% were used to replace coarse aggregate and fine aggregate with rubber particles, respectively. The results show that when the percentage of aggregates replaced by rubber particles is 10%, the bending strength can be reduced by 20%. But on the other hand, if the replacement rate increases to 20% and 30%, the flexural strength drops by 30%, as shown in Figure 12 [86]. This is due to the high elastic modulus comparison between concrete aggregate and rubber. Therefore, rubber particles with low stiffness are not good for bearing the load in the concrete matrix. This effect of rubber is called the reduction of the effective surface of concrete. On the other hand, the weak bond between the rubber particles and the cementitious material results in the formation of weaker ITZ between the rubber particles and the cement matrix. The formation of weak adhesion reduces the mechanical properties of concrete. Some scholars also explain this phenomenon as the uneven distribution of rubber particles in the concrete cementitious material, which leads to the decrease of concrete strength.

![Figure 12 Flexure tensile strength for replacement of both fine and coarse aggregates of slag based geopolymer concrete with crumb rubber [86].](/document/doi/10.1515/rams-2021-0021/asset/graphic/j_rams-2021-0021_fig_012.jpg)

Flexure tensile strength for replacement of both fine and coarse aggregates of slag based geopolymer concrete with crumb rubber [86].

Ferrochrome slag (FS) is a waste produced in the stainless steel industrial production process. Jena and Panigrahi [87] used iron chromium slag as coarse aggregate with fly ash to make GRAC. In his experiment, the 28d flexural strength of 9 different mixtures including FS0, FS5, FS10, FS15, FS20, FS25, FS30, FS35 and FS40 (the number is the substitution rate) were tested. Compared with the control group, as the FS content increased from 0 to 30%, the bending strength showed an upward trend, and the maximum strength of FS30 was 5.83 MPa. As the content of FS in GRAC increases, the content of lead and chromium in concrete continues to increase, the strength of FS35 and FS40 concrete is reduced by about 4% and 14%, respectively, compared with FS30.

To sum up, the research on flexural strength of GRAC is the same as that of tensile strength. The main reason is that the characteristics of concrete are determined by its own characteristics [88,89,90,91,92]. Most studies focus on the compressive strength, but the flexural strength often determines the shaping ability of concrete itself, which has a significant impact on the failure mode of concrete, so the research in this area should be continuously strengthened.

4 Summary and prospect

The geopolymer in GRAC is an ideal substitute for cement. The use of cement instead of cement can reduce CO2 emissions. Recycled aggregate can solve the problem of stacking construction waste and reduce the consumption of non-renewable resources such as sand and stone. The research progress on materials and mechanical properties of GRAC is reviewed in this paper. The research on GRAC is still lacking, it still strives to be detailed and accurate. The main contents of this paper are summarized and the future prospects are as follows:

The microscopic characterization of recycled aggregate is mainly determined by the characteristics of ITZ. And the characteristic of ITZ in RAC is related to the quality of attached mortar and has nothing to do with the quantity of mortar. At the same time, it is also found that the strength of ITZ is more affected by the water-binder ratio of concrete. At present, there is no final conclusion on whether the strength of ITZ directly affects the strength of concrete, so the research on this aspect should be continuously strengthened.

The strength of RCA can directly affect the strength of concrete, which is well known. However, there is still some controversy about the manifestation of aggregate strength. The strength of RCA in the airdry state is often higher than the strength of water saturation. Is it unreasonable to use the crushing index of the air-dry state to characterize the strength of RCA? This point still needs to be further studied. At the same time, most of the enhancement methods of RCA are limited to reinforced aggregate, and there is a lack of research on the enhancement of construction waste treatment. Making a big breakthrough in this area can save a lot of costs.

The strength of GRAC depends on many aspects, such as curing temperature, alkali activator modulus, aggregate strength, etc. The strength influencing factors of GRAC are very similar to GPC, so the constitutive characteristics of the two are also very similar. The research on fiber-modified GPC is now more mature, so you can consider using fiber-modified GPC. The current research on this aspect is very lacking and should be continuously strengthened.

At present, the research on the strength of GRAC is mainly focused on the compressive strength, but there is a lack of research on tensile strength and flexural strength. Therefore, it is necessary to deepen the comprehensive analysis of various strength of GRAC.

The research and development on GRAC is in its infancy, but on the other hand the research on GPC and RAC is relatively mature. Although there is a lack of research on the application of GRAC at present, scholars can combine the application research progress of GPC and RAC, combine with each other, and put it into practical production as soon as possible.

Funding information: This study was financially supported by the Open Project of Chongqing groundwater Resources Utilization and Environmental Protection Laboratory (DXS20191029), Sichuan Science and Technology Program (2020JDR0266, 2019YFG0460) and Innovation and Application Development Special General Project (Project number cstc2020jscx-msxmX0084).

Author contribution: Zhong Xu, Zhenpu Huang, Changjiang Liu wrote the article, Xiaowei Deng, David Hui, and Shujin Deng checked the manuscript.

Conflict of Interests: The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Data availability statement: All data generated or analyzed during this study are included in this published article or are available from the corresponding author on reasonable request.

References

[1] Navid, R. and M. Z. Zhang. Fiber-reinforced geopolymer composites: A review. Cement and Concrete Composites, Vol. 107, 2020, id. 103498.10.1016/j.cemconcomp.2019.103498Search in Google Scholar

[2] Sun, Y. F., Y. Y. Peng, T. S. Zhou, H. W. Liu, and P. W. Gao. Study of the mechanical-electrical-magnetic properties and the microstructure of three-layered cement-based absorbing boards. Reviews on Advanced Materials Science, Vol. 59, No. 1, 2020, pp. 160–169.10.1515/rams-2020-0014Search in Google Scholar

[3] Ken, P. W., R. Mahyuddin, and C. C. Ban. An overview on the influence of various factors on the properties of geopolymer concrete derived from industrial by-products. Construction & Building Materials, Vol. 77, 2015, pp. 370–395.10.1016/j.conbuildmat.2014.12.065Search in Google Scholar

[4] Reiter, M. P., O. Holčapek, O. Zobal, and M. Keppert. Freeze-Thaw Resistance of Cement Screed with Various Supplementary Cementitious Materials. Reviews on Advanced Materials Science, Vol. 58, No. 1, 2019, pp. 66–74.10.1515/rams-2019-0006Search in Google Scholar

[5] Liu, Y. S., M. J. Jia, C. Z. Song, S. Lu, H. Wang, G. H. Zhang, et al. Enhancing ultra-early strength of sulphoaluminate cement-based materials by incorporating graphene oxide. Nanotechnology Reviews, Vol. 9, No. 1, 2020, pp. 17–27.10.1515/ntrev-2020-0002Search in Google Scholar

[6] Jung, C. Y. and J. H. Lee. Crack closure and flexural tensile capacity with SMA fibers randomly embedded on tensile side of mortar beams. Nanotechnology Reviews, Vol. 9, No. 1, 2020, pp. 354–356.10.1515/ntrev-2020-0026Search in Google Scholar

[7] He, J., Y. X. Jie, J. H. Zhang, and G. P. Zhang. Synthesis and characterization of red mud and rice husk ash-based geopolymer composites. Cement and Concrete Composites, Vol. 37, 2013, pp. 18–28.10.1016/j.cemconcomp.2012.11.010Search in Google Scholar

[8] Lv, P. Z., L. J. Zhu, Y. M. Yu, and H. G. Lu. Effect of NaOH concentration on antibacterial activities of Cu nanoparticles and the antibacterial mechanism. Materials Science and Engineering C, Vol. 55, 2014, pp. 58–65.10.1016/j.msec.2020.110669Search in Google Scholar PubMed

[9] Bukit, N., E. M. Ginting, E. A. Hutagalung, E. Sidebang, E. Frida, and B. F. Bukit. Preparation and characterization of oil palm ash from boiler to nanoparticle. Reviews on Advanced Materials Science, Vol. 58, No. 1, 2019, pp. 195–200.10.1515/rams-2019-0023Search in Google Scholar

[10] Chu, Y. S., B. Davaabal, D. S. Kim, S. K. Seo, Y. Kim, C. Ruescher, et al. Reactivity of fly ashes milled in different milling devices. Reviews on Advanced Materials Science, Vol. 58, No. 1, 2019, pp. 179–188.10.1515/rams-2019-0028Search in Google Scholar

[11] Silva, P. D., K. C. Sagoe, and V. Sirivivatnanon. Kinetics of geopolymerization: Role of Al2O3 and SiO2. Cement and Concrete Research, Vol. 37, No. 4, 2007, pp. 512–518.10.1016/j.cemconres.2007.01.003Search in Google Scholar

[12] Hayrullah, S. A. and D. M. Yasin. Properties of high-calcium fly ash-based geopolymer concretes improved with high-silica sources. Construction & Building Materials, Vol. 261, 2007, id. 120014.10.1016/j.conbuildmat.2020.120014Search in Google Scholar

[13] Solomon, O., E. Anthony, and O. Festus. Geopolymer concrete incorporating agro-industrial wastes: Effects on mechanical properties, microstructural behavior and mineralogical phases. Construction & Building Materials, Vol. 256, 2020, id. 119390.10.1016/j.conbuildmat.2020.119390Search in Google Scholar

[14] Ilker, T., G. Osman, and G. Aliakbar. Recycling zeolitic tuff and marble waste in the production of eco-friendly geopolymer concretes. Journal of Cleaner Production, Vol. 268, 2020, id. 122298.10.1016/j.jclepro.2020.122298Search in Google Scholar

[15] Luhar, S., T.W. Cheng, D. Nicolaides, and I. Luhar. Valorization of glass waste for development of Geopolymer composites – Mechanical properties and rheological characteristics: A review. Construction and Building Materials, Vol. 220, 2020, pp.547–564.10.1016/j.conbuildmat.2019.06.041Search in Google Scholar

[16] Sanghamitra, J., and P. Ramakanta. Feasibility study of the properties of geopolymer concrete with ferrochrome slag and silica fume. Materials Today: Proceedings, August 2020. (In press). DOI: https://doi.org/10.1016/j.matpr.2020.07.510.10.1016/j.matpr.2020.07.510Search in Google Scholar

[17] Paranavithana, S. and A. Mohajerani. Effects of recycled concrete aggregates on properties of asphalt concrete. Resources, Conservation and Recycling, Vol. 48, No. 1, 2006, pp. 1–12.10.1016/j.resconrec.2005.12.009Search in Google Scholar

[18] Meng, T., J. L. Zhang, H. D. Wei, and J. J. Shen. Effect of nano-strengthening on the properties and microstructure of recycled concrete. Nanotechnology Reviews, Vol.9, No.1,2020, pp.79–92.10.1515/ntrev-2020-0008Search in Google Scholar

[19] Kisku, N., H. Joshi, M. Ansari, S. K. Panda, S. Nayak, and S. C. Dutta. A critical review and assessment for usage of recycled aggregate as sustainable construction material. Construction & Building Materials, Vol. 131, 2017, pp. 721–740.10.1016/j.conbuildmat.2016.11.029Search in Google Scholar

[20] Etxeberria, M., E. Vázquez, A. Marí, and M. Barra. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cement and Concrete Research, Vol. 37, No. 5, 2007, pp. 735–742.10.1016/j.cemconres.2007.02.002Search in Google Scholar

[21] Rao, A., K. N. Jha, and S. Misra. Use of aggregates from recycled construction and demolition waste in concrete. Resources, Conservation and Recycling, Vol. 50, No.1, 2007, pp. 71–81.10.1016/j.resconrec.2006.05.010Search in Google Scholar

[22] Lu, W., and H. Yuan. A framework for understanding waste management studies in construction. Waste Management (New York, N.Y.), Vol. 31, No. 6, 2011, pp. 1252–1260.10.1016/j.wasman.2011.01.018Search in Google Scholar

[23] Limbachiya, M., M. S. Meddah, and Y. Ouchagour. Use of recycled concrete aggregate in fly-ash concrete. Construction & Building Materials, Vol. 27, 2012, pp. 439–449.10.1016/j.conbuildmat.2011.07.023Search in Google Scholar

[24] Spaeth, V., and A. D. Tegguer. Improvement of recycled concrete aggregate properties by polymer treatments. International Journal of Sustainable Built Environment, Vol. 2, No. 2, 2013, pp. 143–152.10.1016/j.ijsbe.2014.03.003Search in Google Scholar

[25] Wang, R. J., N. G. Yu, and Y. Li. Methods for improving the microstructure of recycled concrete aggregate: A review. Construction & Building Materials, Vol. 242, 2020, pp. 1–18.10.1016/j.conbuildmat.2020.118164Search in Google Scholar

[26] Zhang, H. R., T. Ji, X. P. Zeng, Z. X. Yang, X. J. Lin, and Y. N. Liang. Mechanical behavior of ultra-high performance concrete (UHPC) using recycled fine aggregate cured under different conditions and the mechanism based on integrated microstructural parameters. Construction & Building Materials, Vol. 192, 2018, pp. 489–507.10.1016/j.conbuildmat.2018.10.117Search in Google Scholar

[27] Kim, J. H., R. E. Robertson, and A. E. Naaman. Structure and properties of poly (vinyl alcohol)-modified mortar and concrete. Cement and Concrete Research, Vol. 29, No. 3, 1998, pp. 407–415.10.1016/S0008-8846(98)00246-4Search in Google Scholar

[28] Lee, G. C. and H. B. Choi. Study on interfacial transition zone properties of recycled aggregate by micro-hardness test. Construction & Building Materials, Vol. 40, 2013, pp. 455–460.10.1016/j.conbuildmat.2012.09.114Search in Google Scholar

[29] Bravo, M., A. Santos Silva, J. de Brito, and L. Evangelista. Microstructure of concrete with aggregates from construction and demolition waste recycling plants. Microscopy and Microanalysis, Vol. 22, No. 1, Feb. 2016, pp. 149–167.10.1017/S1431927615015512Search in Google Scholar PubMed

[30] Posi, P., C. Teerachanwit, C. Tanutong, S. Limkamoltip, S. Lertnimoolchai, V. Sata, et al. Lightweight geopolymer concrete containing aggregate from recycle lightweight block. Materials & Design, Vol. 52, 2013, pp. 580–586.10.1016/j.matdes.2013.06.001Search in Google Scholar

[31] Li, J., H. Xiao, and Y. Zhou. Influence of coating recycled aggregate surface with pozzolanic powder on properties of recycled aggregate concrete. Construction & Building Materials, Vol. 23, No. 3, 2009, pp. 1287–1291.10.1016/j.conbuildmat.2008.07.019Search in Google Scholar

[32] Li, Y., S. Zhang, R. J. Wang, Y. Zhao, and C. S. Men. Effects of carbonation treatment on the crushing characteristics of recycled coarse aggregates. Construction and Building Materials, Vol. 201, 2019, pp. 408–420.10.1016/j.conbuildmat.2018.12.158Search in Google Scholar

[33] Otsuki, N., S. Miyazato, and W. Yodsudjai. Influence of recycled aggregate on interfacial transition zone, strength, chloride penetration and carbonation of concrete. Journal of Materials in Civil Engineering, Vol. 15, No. 5, 2003, pp. 443–451.10.1061/(ASCE)0899-1561(2003)15:5(443)Search in Google Scholar

[34] Xiao, J., W. Li, Z. Sin, D. A. Lange, and S. P. Shah. Properties of interfacial transition zones in RAC tested by Nano indentation. Cement and Concrete Composites, Vol. 37, 2013, pp. 276–292.10.1016/j.cemconcomp.2013.01.006Search in Google Scholar

[35] Wong, H. S., M. Zobel, N. R. Buenfield, and R. W. Zimmerman. Influence of the interfacial transition zone and micro cracking on the diffusivity, permeability and sorptivity of cement-based materials after drying. Magazine of Concrete Research, Vol. 61, No. 8, 2009, pp. 571–589.10.1680/macr.2008.61.8.571Search in Google Scholar

[36] Diamond, S. and J. Huang. The ITZ in concrete – a different view based on image analysis and SEM observations. Cement and Concrete Composites, Vol. 23, No. 2, 2001, pp. 179–188.10.1016/S0958-9465(00)00065-2Search in Google Scholar

[37] Kou, S., B. Zhan, and C. Poon. Feasibility study of using recycled fresh concrete waste as coarse aggregates in concrete. Construction & Building Materials, Vol. 28, No. 1, 2012, pp. 549–556.10.1016/j.conbuildmat.2011.08.027Search in Google Scholar

[38] Geng, Y., Y. Wang, and J. Chen. Creep behavior of concrete using recycled coarse aggregates obtained from source concrete with different strengths. Construction & Building Materials, Vol. 128, 2016, pp. 199–213.10.1016/j.conbuildmat.2016.10.086Search in Google Scholar

[39] Topcu, L. B. and N. F. Guncan. Using waste concrete as aggregate. Cement and Concrete Research, Vol. 25, No. 27, 1995, pp. 1385–1390.10.1016/0008-8846(95)00131-USearch in Google Scholar

[40] Muttashar, H. L., M. A. M. Arifln, M. N. Hussein, M. W. Hussin, and S. B. Ishaq. Self-compacting geopolymer concrete with spend garnet as sand replacement. Journal of Building Engineering, Vol. 15, 2018, pp. 85–94.10.1016/j.jobe.2017.10.007Search in Google Scholar

[41] Kikuchi, T., and Y. Kuroda. Carbon dioxide uptake in demolished and crushed concrete. Journal of Advanced Concrete Technology, Vol. 9, No. 1, 2011, pp. 115–124.10.3151/jact.9.115Search in Google Scholar

[42] Ouyang, K., C. J. Shi, H. Q. Chu, H. Guo, B. Song, Y. Ding, et al. An overview on the eflciency of different pretreatment techniques for recycled concrete aggregate. Journal of Cleaner Production, Vol. 263, 2020, id. 121264.10.1016/j.jclepro.2020.121264Search in Google Scholar

[43] Pandurangan, K., A. Dayanithy, and S. O. Prakash. Influence of treatment methods on the bond strength of recycled aggregate concrete. Construction & Building Materials, Vol. 120, 2016, pp. 212–221.10.1016/j.conbuildmat.2016.05.093Search in Google Scholar

[44] Saravanakumar, P., K. Abhiram, and B. Manoj. Properties of treated recycled aggregates and its influence on concrete strength characteristics. Construction & Building Materials, Vol. 111, 2016, pp. 611–617.10.1016/j.conbuildmat.2016.02.064Search in Google Scholar

[45] Ismail, S. and M. Ramli. Engineering properties of treated recycled concrete aggregate (RCA) for structural applications. Construction & Building Materials, Vol. 44, No. 7, 2013, pp. 464–476.10.1016/j.conbuildmat.2013.03.014Search in Google Scholar

[46] Weng, Z. Experimental Study on Microstructure of Recycled High Performance Concrete Affected by Intensified Test. Fuzhou University, Fuzhou, 2018.Search in Google Scholar

[47] Li, L. P., C. S. Xiao, and J. Xuan. Effect of carbonated recycled coarse aggregate on the dynamic compressive behavior of recycled aggregate concrete. Construction & Building Materials, Vol. 151, 2017, pp. 52–62.10.1016/j.conbuildmat.2017.06.043Search in Google Scholar

[48] Singh, B., G. Ishwarya, M. Gupta, and S. K. Bhattacharyya. Geopolymer concrete: A review of some recent developments. Construction & Building Materials, Vol. 85, 2015, pp. 78–90.10.1016/j.conbuildmat.2015.03.036Search in Google Scholar

[49] Singh, N. B., and B. Middendorf. Geopolymers as an alternative to Portland cement: An overview. Construction & Building Materials, Vol. 237, 2020, pp. 1–15.10.1016/j.conbuildmat.2019.117455Search in Google Scholar

[50] Zhang, M., N. A. Deskins, G. Zhang, R. T. Cygan, and M. Tao. Modeling the Polymerization Process for Geopolymer Synthesis through Reactive Molcular Dynamics Simulations. Journal of Physical Chemistry C, Vol. 122, No. 12, 2018, pp. 6760–6773.10.1021/acs.jpcc.8b00697Search in Google Scholar

[51] Farhan, K. Z., M. A. M. Joharia, and R. Demirboğa. Assessment of important parameters involved in the synthesis of geopolymer composites: A review. Construction & Building Materials, Vol. 264, 2020, id. 120276.10.1016/j.conbuildmat.2020.120276Search in Google Scholar

[52] Pham, T. M., J. Liu, P. Tran, V.-L. Pang, F. Shi, W. Chen, et al. Tran. Dynamic compressive properties of lightweight rubberized geopolymer concrete. Construction & Building Materials, Vol. 265, 2020, pp. 1–12.10.1016/j.conbuildmat.2020.120753Search in Google Scholar

[53] Peyne, J., J. Gautron, J. Doudeau, and S. Rossignol. Development of low temperature lightweight geopolymer aggregate from industrial Waste in comparison with high temperature processed aggregates. Journal of Cleaner Production, Vol. 189, 2018, pp. 47–58.10.1016/j.jclepro.2018.04.038Search in Google Scholar

[54] Nuaklong, P., V. Sata, and P. Chindaprasirt. Properties of metakaolin-high calcium fly ash geopolymer concrete containing recycled aggregate from crushed concrete specimens. Construction & Building Materials, Vol. 161, 2018, pp. 365–373.10.1016/j.conbuildmat.2017.11.152Search in Google Scholar

[55] Zhang, Z., J. L. Provis, A. Reid, and H. Wang. Geopolymer foam concrete: An emerging material for sustainable construction. Construction & Building Materials, Vol. 56, 2014, pp. 113–127.10.1016/j.conbuildmat.2014.01.081Search in Google Scholar

[56] Jones, M. R. and A. Mccarthy. Heat of hydration in foamed concrete: Effect of mix constituents and plastic density. Cement and Concrete Research, Vol. 36, No. 6, 2006, pp. 1032–1041.10.1016/j.cemconres.2006.01.011Search in Google Scholar

[57] Yang, C. S., J. M. M. Fonz, and R. R. A. Catlow. Modeling the Polymerization of Aluminosilicate Clusters. Journal of Physical Chemistry C, Vol. 116, No. 42, 2012, pp. 22121–22128.10.1021/jp3049197Search in Google Scholar

[58] Yamahara, K. and K. Okazaki. Molcular Dynamics Simulation of the Structural Development in Sol-Gel Process for Silica Systems. Fluid Phase Equilibria, Vol. 144, No. 1, 1998, pp. 449–459.10.1016/S0378-3812(97)00289-6Search in Google Scholar

[59] Barbosa, V. F. F., K. J. D. Mackenzie, and C. Thaumaturgy. Synthesis and Characterization of Materials Based on Inorganic Polymers of Alumina and Silica: Sodium Polysialate Polymers. International Journal of Inorganic Materials, Vol. 2, No. 4, 2000, pp. 309–317.10.1016/S1466-6049(00)00041-6Search in Google Scholar

[60] Part, W. K., M. Ramli, and C. B. Cheah. An overview on the influence of various factors on the properties of geopolymer concrete derived from industrial by-products. Construction & Building Materials, Vol. 77, 2015, pp. 370–395.10.1016/j.conbuildmat.2014.12.065Search in Google Scholar

[61] Antunes Boca Santa, R. A., A. M. Bernardin, H. G. Riella, and N. C. Kuhnen. Geopolymer synthetized from bottom coal ash and calcined paper sludge. Journal of Cleaner Production, Vol. 57, 2013, pp. 302–307.10.1016/j.jclepro.2013.05.017Search in Google Scholar

[62] Yan, S. and K. Sagoe-Crentsil. Properties of wastepaper sludge in geopolymer mortars for masonry applications. Journal of Environmental Management, Vol. 112, Dec. 15, 2012, pp. 27–32.10.1016/j.jenvman.2012.07.008Search in Google Scholar

[63] Nimwinya, E., W. Arjharn, S. Horpibulsuk, T. Phoo-ngernkham, and A. Poowancum. A sustainable calcined water treatment sludge and rice husk ash Geopolymer. Journal of Cleaner Production, Vol. 119, No. 4, 2016, pp. 128–134.10.1016/j.jclepro.2016.01.060Search in Google Scholar

[64] Panizza, M., M. Natali, E. Garbin, V. Ducman, and S. Tamburini. Optimization and mechanical-physical characterization of geopolymers with Construction and Demolition Waste (CDW) aggregates for construction products. Construction & Building Materials, Vol. 264, 2020, pp. 120–158.10.1016/j.conbuildmat.2020.120158Search in Google Scholar

[65] Tan, J. W., J. M. Cai, X. P. Li, J. L. Pan, and J. Li. Development of eco-friendly geopolymers with ground mixed recycled aggregates and slag. Journal of Cleaner Production, Vol. 256, 2020, id. 120369.10.1016/j.jclepro.2020.120369Search in Google Scholar

[66] Mesgari, S., A. Akbarnezhad, and J. Z. Xiao. Recycled geopolymer aggregates as coarse aggregates for Portland cement concrete and geopolymer concrete: Effects on mechanical properties. Construction and Building Materials. Vol. 236, 2020, id. 117571.10.1016/j.conbuildmat.2019.117571Search in Google Scholar

[67] Ren, X. and L. Zhang. Experimental study of interfacial transition zones between geopolymer binder and recycled aggregate. Construction & Building Materials, Vol. 167, 2018, pp. 749–756.10.1016/j.conbuildmat.2018.02.111Search in Google Scholar

[68] Liu, Z., C. Cai, and H. Peng. Experimental study of the geopolymeric recycled aggregate concrete. Journal of Materials in Civil Engineering, Vol. 28, No. 9, 2016, id. 04016077.10.1061/(ASCE)MT.1943-5533.0001584Search in Google Scholar

[69] Noushini, A. and A. Castel. The effect of heat-curing on transport properties of low-calcium fly ash-based geopolymer concrete. Construction & Building Materials, Vol. 112, 2016, pp. 464–477.10.1016/j.conbuildmat.2016.02.210Search in Google Scholar

[70] Rovnaník, P. Effect of curing temperature on the development of hard structure of met kaolin-based geopolymer. Construction & Building Materials, Vol. 24, No. 7, 2010, pp. 1176–1183.10.1016/j.conbuildmat.2009.12.023Search in Google Scholar

[71] Nasvi, M. M., R. P. Gamage, and S. Jay. Geopolymer as well cement and the variation of its mechanical behavior with curing temperature. Greenhouse Gases (Chichester, UK), Vol. 2, No. 1, 2012, pp. 46–58.10.1002/ghg.39Search in Google Scholar

[72] Wang, J. J., J. H. Xie, C. Wang, J. Zhao, F. Liu, and C. Fang. C.H. Wang. Study on the optimum initial curing condition for fly ash and GGBS based geopolymer recycled aggregate concrete. Construction & Building Materials, Vol. 247, 2020, id. 118540.10.1016/j.conbuildmat.2020.118540Search in Google Scholar

[73] Zhu, P. H., M. Q. Hua, H. Liu, X. Wang, and C. Chen. Interfacial evaluation of geopolymer mortar prepared with recycled geopolymer fine aggregates. Construction & Building Materials, Vol. 259, 2020, id. 119849.10.1016/j.conbuildmat.2020.119849Search in Google Scholar

[74] Toniolo, N., A. Rincon, J. A. Roether, P. Ercole, E. Bernardo, and A. R. Boccaccini. Extensive reuse of soda-lime waste glass in fly-ash based geopolymers. Construction & Building Materials, Vol. 188, 2018, pp. 1077–1084.10.1016/j.conbuildmat.2018.08.096Search in Google Scholar

[75] Toniolo, N. and A. R. Boccaccini. Fly ash-based geopolymer containing added silica waste. A review. Ceramics International, Vol. 43, No. 17, 2017, pp. 14545–14551.10.1016/j.ceramint.2017.07.221Search in Google Scholar

[76] Peem, N., J. V. Pitcha, and P. Thanyawat. Influence of rice husk ash on mechanical properties and fire resistance of recycled aggregate high-calcium fly ash geopolymer concrete. Journal of Cleaner Production, Vol. 252, 2020, id. 119797.10.1016/j.jclepro.2019.119797Search in Google Scholar

[77] Yue, Y.C., Y. W. Zhou, F. Xing, G. Q. Gong, B. Hu, and M. H. Guo. An industrial applicable method to improve the properties of recycled aggregate concrete by incorporating nano-silica and micro-CaCO3. Journal of Cleaner Production, Vol. 259, 2020, id.120920.10.1016/j.jclepro.2020.120920Search in Google Scholar

[78] Duan, P., C. Yan, and W. Zhou. Compressive strength and microstructure of fly ash based geopolymer blended with silica fume under thermal cycle. Cement and Concrete Composites, Vol. 78, 2017, pp. 108–119.10.1016/j.cemconcomp.2017.01.009Search in Google Scholar

[79] Avinash, O. and G. Lokesh. Comparative study on mechanical properties of conventional and geo-polymer concrete with recycled coarse aggregate. Materials Today: Proceedings, Vol. 28, No. Part 3, 2020, pp. 1403–1406.10.1016/j.matpr.2020.04.811Search in Google Scholar

[80] Jämstorp, E., J. Forsgren, S. Bredenberg, H. Engqvist, and M. Strømme. Mechanically strong geopolymers offer new possibilities in treatment of chronic pain. Journal of Controlled Release, Vol. 146, No. 3, 2010, pp. 370–377.10.1016/j.jconrel.2010.05.029Search in Google Scholar PubMed

[81] Chen, Z., J. S. Li, B. J. Zhan, U. Sharma, and C. S. Poon. Compressive strength and microstructural properties of dry-mixed geopolymer pastes synthesized from GGBS and sewage sludge ash. Construction & Building Materials, Vol. 182, 2018, pp. 597–607.10.1016/j.conbuildmat.2018.06.159Search in Google Scholar

[82] Rashad, A. M. and D. M. Sadek. An investigation on Portland cement replaced by high-volume GGBS pastes modified with micro-sized met kaolin subjected to elevated temperatures. International Journal of Sustainable Built Environment, Vol. 6, No. 1, 2017, pp. 91–101.10.1016/j.ijsbe.2016.10.002Search in Google Scholar

[83] Barbosa, V. F. F. and K. J. D. MacKenzie. Thermal behavior of inorganic geopolymers and composites derived from sodium polysialate. Materials Research Bulletin, Vol. 38, No. 2, 2003, pp. 319–331.10.1016/S0025-5408(02)01022-XSearch in Google Scholar

[84] Wei, Z., X. Y. Shi, X. Lu, C. C. Qi, B. Luan, and F. Liu. The mechanical and microstructural properties of refuse mudstone-GGBS-red mud based geopolymer composites made with sand. Construction & Building Materials, Vol. 253, 2020, id. 119193.10.1016/j.conbuildmat.2020.119193Search in Google Scholar

[85] Maheshbabu, J., A. Arulrajah, and S. Saride. Flexural fatigue behavior of fly ash geopolymer stabilized-geogrid reinforced RAP bases. Construction & Building Materials, Vol. 254, 2020, id. 119263.10.1016/j.conbuildmat.2020.119263Search in Google Scholar

[86] Aly, M. A., M. S. Elfeky, M. Kohail, and E.-S. A. R. Nasr. K. Mohamed. Performance of geopolymer concrete containing recycled rubber. Construction & Building Materials, Vol. 207, 2019, pp. 136–144.10.1016/j.conbuildmat.2019.02.121Search in Google Scholar

[87] Jena, S. G. and R. Panigrahi. Performance assessment of geopolymer concrete with partial replacement of ferrochrome slag as coarse aggregate. Construction & Building Materials, Vol. 220, 2019, pp. 525–537.10.1016/j.conbuildmat.2019.06.045Search in Google Scholar

[88] Pavithra, P., M. S. Reddy, B. P. Dinakar, B. K. H. Rao, and A. N. M. Satpathy. A mix design procedure for geopolymer concrete with fly ash. Journal of Cleaner Production, Vol. 133, 2016, pp. 117–125.10.1016/j.jclepro.2016.05.041Search in Google Scholar

[89] Abhijit, A. W., and Y. M. Nigade. Technical Assessment on Performance of Partial Replacement of Coarse Aggregate by Steel Slag in Concrete. International Journal of Engineering Trends and Technology, Vol. 30, No. 1, 2016, pp. 37–41.10.14445/22315381/IJETT-V30P208Search in Google Scholar

[90] Haddad, R. H., and O. Alshbuol. Production of geopolymer concrete using natural pozzolan: A parametric study. Construction & Building Materials, Vol. 114, 2016, pp. 699–707.10.1016/j.conbuildmat.2016.04.011Search in Google Scholar

[91] Cong, X. Y., S. Lu, Y. Yao, and Z. Wang. Fabrication and characterization of self-ignition coal gangue autoclaved aerated concrete. Materials & Design, Vol. 97, 2016, pp. 155–162.10.1016/j.matdes.2016.02.068Search in Google Scholar

[92] Zhou, Y. W., H. Gao, Z. H. Hu, Y. D. Qiu, M. H. Guo, X. X. Huang, et al. Ductile, durable, and reliable alternative to FRP bars for reinforcing seawater sea-sand recycled concrete beams: steel/FRP composite bars. Construction and Building Materials, Vol. 269, 2021, id. 121264.10.1016/j.conbuildmat.2020.121264Search in Google Scholar

© 2021 Zhong Xu et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- A review on filler materials for brazing of carbon-carbon composites

- Nanotechnology-based materials as emerging trends for dental applications

- A review on allotropes of carbon and natural filler-reinforced thermomechanical properties of upgraded epoxy hybrid composite

- High-temperature tribological properties of diamond-like carbon films: A review

- A review of current physical techniques for dispersion of cellulose nanomaterials in polymer matrices

- Review on structural damage rehabilitation and performance assessment of asphalt pavements

- Recent development in graphene-reinforced aluminium matrix composite: A review

- Mechanical behaviour of precast prestressed reinforced concrete beam–column joints in elevated station platforms subjected to vertical cyclic loading

- Effect of polythiophene thickness on hybrid sensor sensitivity

- Investigation on the relationship between CT numbers and marble failure under different confining pressures

- Finite element analysis on the bond behavior of steel bar in salt–frost-damaged recycled coarse aggregate concrete

- From passive to active sorting in microfluidics: A review

- Research Articles

- Revealing grain coarsening and detwinning in bimodal Cu under tension

- Mesoporous silica nanoparticles functionalized with folic acid for targeted release Cis-Pt to glioblastoma cells

- Magnetic behavior of Fe-doped of multicomponent bismuth niobate pyrochlore

- Study of surfaces, produced with the use of granite and titanium, for applications with solar thermal collectors

- Magnetic moment centers in titanium dioxide photocatalysts loaded on reduced graphene oxide flakes

- Mechanical model and contact properties of double row slewing ball bearing for wind turbine

- Sandwich panel with in-plane honeycombs in different Poisson's ratio under low to medium impact loads

- Effects of load types and critical molar ratios on strength properties and geopolymerization mechanism

- Nanoparticles in enhancing microwave imaging and microwave Hyperthermia effect for liver cancer treatment

- FEM micromechanical modeling of nanocomposites with carbon nanotubes

- Effect of fiber breakage position on the mechanical performance of unidirectional carbon fiber/epoxy composites

- Removal of cadmium and lead from aqueous solutions using iron phosphate-modified pollen microspheres as adsorbents

- Load identification and fatigue evaluation via wind-induced attitude decoupling of railway catenary

- Residual compression property and response of honeycomb sandwich structures subjected to single and repeated quasi-static indentation

- Experimental and modeling investigations of the behaviors of syntactic foam sandwich panels with lattice webs under crushing loads

- Effect of storage time and temperature on dissolved state of cellulose in TBAH-based solvents and mechanical property of regenerated films

- Thermal analysis of postcured aramid fiber/epoxy composites

- The energy absorption behavior of novel composite sandwich structures reinforced with trapezoidal latticed webs

- Experimental study on square hollow stainless steel tube trusses with three joint types and different brace widths under vertical loads

- Thermally stimulated artificial muscles: Bio-inspired approach to reduce thermal deformation of ball screws based on inner-embedded CFRP

- Abnormal structure and properties of copper–silver bar billet by cold casting

- Dynamic characteristics of tailings dam with geotextile tubes under seismic load

- Study on impact resistance of composite rocket launcher

- Effects of TVSR process on the dimensional stability and residual stress of 7075 aluminum alloy parts

- Dynamics of a rotating hollow FGM beam in the temperature field

- Development and characterization of bioglass incorporated plasma electrolytic oxidation layer on titanium substrate for biomedical application

- Effect of laser-assisted ultrasonic vibration dressing parameters of a cubic boron nitride grinding wheel on grinding force, surface quality, and particle morphology

- Vibration characteristics analysis of composite floating rafts for marine structure based on modal superposition theory

- Trajectory planning of the nursing robot based on the center of gravity for aluminum alloy structure

- Effect of scan speed on grain and microstructural morphology for laser additive manufacturing of 304 stainless steel

- Influence of coupling effects on analytical solutions of functionally graded (FG) spherical shells of revolution

- Improving the precision of micro-EDM for blind holes in titanium alloy by fixed reference axial compensation

- Electrolytic production and characterization of nickel–rhenium alloy coatings

- DC magnetization of titania supported on reduced graphene oxide flakes

- Analytical bond behavior of cold drawn SMA crimped fibers considering embedded length and fiber wave depth

- Structural and hydrogen storage characterization of nanocrystalline magnesium synthesized by ECAP and catalyzed by different nanotube additives

- Mechanical property of octahedron Ti6Al4V fabricated by selective laser melting

- Physical analysis of TiO2 and bentonite nanocomposite as adsorbent materials

- The optimization of friction disc gear-shaping process aiming at residual stress and machining deformation

- Optimization of EI961 steel spheroidization process for subsequent use in additive manufacturing: Effect of plasma treatment on the properties of EI961 powder

- Effect of ultrasonic field on the microstructure and mechanical properties of sand-casting AlSi7Mg0.3 alloy

- Influence of different material parameters on nonlinear vibration of the cylindrical skeleton supported prestressed fabric composite membrane

- Investigations of polyamide nano-composites containing bentonite and organo-modified clays: Mechanical, thermal, structural and processing performances

- Conductive thermoplastic vulcanizates based on carbon black-filled bromo-isobutylene-isoprene rubber (BIIR)/polypropylene (PP)

- Effect of bonding time on the microstructure and mechanical properties of graphite/Cu-bonded joints

- Study on underwater vibro-acoustic characteristics of carbon/glass hybrid composite laminates

- A numerical study on the low-velocity impact behavior of the Twaron® fabric subjected to oblique impact

- Erratum

- Erratum to “Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete”

- Topical Issue on Advances in Infrastructure or Construction Materials – Recycled Materials, Wood, and Concrete

- Structural performance of textile reinforced concrete sandwich panels under axial and transverse load

- An overview of bond behavior of recycled coarse aggregate concrete with steel bar

- Development of an innovative composite sandwich matting with GFRP facesheets and wood core

- Relationship between percolation mechanism and pore characteristics of recycled permeable bricks based on X-ray computed tomography

- Feasibility study of cement-stabilized materials using 100% mixed recycled aggregates from perspectives of mechanical properties and microstructure

- Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete

- Research on nano-concrete-filled steel tubular columns with end plates after lateral impact

- Dynamic analysis of multilayer-reinforced concrete frame structures based on NewMark-β method

- Experimental study on mechanical properties and microstructures of steel fiber-reinforced fly ash-metakaolin geopolymer-recycled concrete

- Fractal characteristic of recycled aggregate and its influence on physical property of recycled aggregate concrete

- Properties of wood-based composites manufactured from densified beech wood in viscoelastic and plastic region of the force-deflection diagram (FDD)

- Durability of geopolymers and geopolymer concretes: A review

- Research progress on mechanical properties of geopolymer recycled aggregate concrete

Articles in the same Issue

- Review Articles

- A review on filler materials for brazing of carbon-carbon composites

- Nanotechnology-based materials as emerging trends for dental applications

- A review on allotropes of carbon and natural filler-reinforced thermomechanical properties of upgraded epoxy hybrid composite

- High-temperature tribological properties of diamond-like carbon films: A review

- A review of current physical techniques for dispersion of cellulose nanomaterials in polymer matrices

- Review on structural damage rehabilitation and performance assessment of asphalt pavements

- Recent development in graphene-reinforced aluminium matrix composite: A review

- Mechanical behaviour of precast prestressed reinforced concrete beam–column joints in elevated station platforms subjected to vertical cyclic loading

- Effect of polythiophene thickness on hybrid sensor sensitivity

- Investigation on the relationship between CT numbers and marble failure under different confining pressures

- Finite element analysis on the bond behavior of steel bar in salt–frost-damaged recycled coarse aggregate concrete

- From passive to active sorting in microfluidics: A review

- Research Articles

- Revealing grain coarsening and detwinning in bimodal Cu under tension

- Mesoporous silica nanoparticles functionalized with folic acid for targeted release Cis-Pt to glioblastoma cells

- Magnetic behavior of Fe-doped of multicomponent bismuth niobate pyrochlore

- Study of surfaces, produced with the use of granite and titanium, for applications with solar thermal collectors

- Magnetic moment centers in titanium dioxide photocatalysts loaded on reduced graphene oxide flakes

- Mechanical model and contact properties of double row slewing ball bearing for wind turbine

- Sandwich panel with in-plane honeycombs in different Poisson's ratio under low to medium impact loads

- Effects of load types and critical molar ratios on strength properties and geopolymerization mechanism

- Nanoparticles in enhancing microwave imaging and microwave Hyperthermia effect for liver cancer treatment

- FEM micromechanical modeling of nanocomposites with carbon nanotubes

- Effect of fiber breakage position on the mechanical performance of unidirectional carbon fiber/epoxy composites

- Removal of cadmium and lead from aqueous solutions using iron phosphate-modified pollen microspheres as adsorbents

- Load identification and fatigue evaluation via wind-induced attitude decoupling of railway catenary