Abstract

Computed tomography (CT) scanning technology is helpful in investigating rock materials as it can demonstrate the micro structure of rock clearly. Conventional triaxial compression tests and the corresponding graded triaxial loading tests were carried out to investigate the complex failure mechanism of the marble at the Jinping Hydropower Station. After that CT-scanning tests were done on the loaded marble specimens. The test results show that (1) the CT numbers of the specimens have a certain statistical regularity, that is, the CT numbers of the specimens under different confining pressures satisfy the Weibull distribution, as the confining pressure increases, the mean values rise while variances decrease; (2) in the two groups of tests, the average CT numbers corresponding to the conventional triaxial tests are higher than those corresponding to the graded loading tests, but the CT number variances are lower than those of the graded loading tests; and (3) according to meso-damage mechanics, the damage variables of the rock specimens were established based on the definition of CT numbers. The calculation results show that the damage variables decrease with the increase in confining pressure, the damage variables of the rock specimens in the graded loading tests are higher than those in the conventional triaxial test, and the differences between the two loading tests have grown with the increase in confining pressure.

1 Introduction

With the development of science and technology, more advanced scientific and technological methods have been applied in studying rock materials. In recent years, computed tomography (CT) technology has been widely used to study the mesoscopic mechanical behavior of geotechnical engineering materials and has achieved abundant results.

Teng et al. carried out CT scanning of brittle rock masses, analyzed internal crack development before and after the fracture of the specimens, and have used the fractal theory to analyze the damage degree of CT images in different parts of the fractured specimens [1]. Nasseri et al. conducted the fracture toughness test on granites. They used the micro-CT scanner to measure the fracture morphology of granite cracks and analyzed the characteristics of their structure [2]. Yang et al. found that the CT number is closely related to rock damage, and defined the damage variable based on the CT number [3]. Zhu et al. used mortar to simulate rock materials to study the evolution law of its fractures, and found that the gray frequency curves of CT images can reflect the different evolution effects of microcracks [4]. Li et al. conducted a CT-scan test on the rock under cyclic loading and found that the CT number and its standard deviation can reflect the distribution of rock cracks [5]. Zhu et al. established a set of analysis procedures based on the gray-level co-occurrence matrix theory to study the initial meso-damage distribution of concrete specimens, and quantitatively characterized the meso-damage through statistical eigenvalues [6]. Based on the damage partition theory, Fang et al. proposed a probability statistical method to determine the threshold, and partitioned the concrete CT-scan image to study the crack distribution [7]. Song et al. combined CT image processing with the analysis of CT numbers, and described the damage evolution law of damaged rock samples quantitatively [8]. Lang et al. used CT scanning technology to construct a three-dimensional numerical model that can characterize the internal pore structure of the basalt [9]. Cheng et al. conducted CT-triaxial shear tests on expansive soils and proved the rationality of using the average value and variance value of CT numbers to characterize damage variables [10]. Zhong et al. conducted in situ experimental research on marble in a 2,400 m deep underground cave, and analyzed the macroscopic and microscopic morphological characteristics of the core disk fracture surface using three-dimensional optical scanning and electron microscope scanning [11]. Jiang et al. used X-ray CT technology to observe the evolution characteristics of water-induced cracks in mudstone in real time [12].

To summarize, the current research of rock failure using CT scanning has mainly focused on the microscopic characteristics of rock, while the study on the change law of CT number after rock failure is still relatively scarce. Rock materials have memory, and the CT scanning investigation on rock materials with different loading histories have practical scientific significance. In this study, based on the CT-scan data of damaged rock samples, combined with the theory and technology of digital image processing, the variation law of the CT number of marble samples under different loading paths was analyzed. The statistical law of the CT number as well as the corresponding relationship with the confining pressure were obtained. Finally, the rock physical damage variable was established based on the definition of the CT number.

2 Conventional triaxial compression test and its corresponding graded loading triaxial compression test

The marbles of Jinping II Hydropower Station were selected as the test specimens, and each rock sample was processed into a cylinder with a diameter of 50 mm and a height of 100 mm. In this study, the conventional triaxial compression tests and the corresponding graded loading tests under different confining pressures were conducted systematically. The test setup is shown in Figure 1. The confining pressures were set to 5, 10, and 15 MPa, respectively.

The image of the test setup.

The graded loading triaxial compression tests were carried out according to the peak strength (σ c) obtained from the conventional triaxial compression tests under different confining pressures. The specific implementation scheme is shown in Figure 2. Under the same confining pressure, the axial stress in the graded loading triaxial compression test was loaded to 60% of the peak strength in the conventional triaxial tests successively, and then maintained for 48 h. After 48 h, the axial stress was gradually increased to 10% of the peak strength, and the loading time of each grade was 48 h until the marble failed. We selected 60% of the peak strength as the starting point of the graded loading tests, because at this strength grade, the rock sample has entered the crack initiation stage.

Schematic of loading path in triaxial compression test with step loading.

3 CT-scan test and data analysis

3.1 CT-scan test

The CT number reflects the degree of X-ray absorption of the test material, and it has a linear relationship with the volume electron density of the material. Therefore, the ability of the object to absorb X-ray is related to its own density. The greater the density of the specimens, the stronger the ability to absorb X-rays. The following formula represents the intensity of the X-rays [13]:

where I 0 and I are the light intensity before and after the X-ray penetrates the specimens, respectively, with the unit of eV·m−2·s−1; x is the penetration length of the X-ray in the tested object, with the unit of cm.

In this study, the CT-scanning test was completed on the Zeiss X-radia 410 Versa micro-CT scanner of the Institute of Rock and Soil Mechanics in Wuhan. The sample console distances (x, y, z) are 45, 100, and 50 mm. The light source distance (z) is 190 mm, the detector distance (z) is 290 mm, the sample console (rotation angle) is 360°, the sample size limit is 300 mm, the flow rate is 0.001–107 mL·min−1, the flow accuracy is 0.5%, the sensor accuracy is 0.1%, the pump volume is 266 mL, and the pressure range is 0–52 MPa. After the rock samples of the mechanical tests were damaged, based on the size limitation of the CT scanner, the damaged rock samples were selected and cut into sectors with a thickness of 30 mm, a radius of 30 mm, and a radian of π/2, as shown in Figure 3.

CT scanning test pieces.

In the CT scanning tests, each rock sample was scanned from top to bottom. The scanning layer thickness was 0.03 mm. Approximately 1,000 CT scan images could be obtained totally but only about 800 images were valid because the images corresponding to the up and down surface were in disorder. For a single rock sample, the scanning time lasted about 3 h. The pixel at any point in the image can be represented by a numerical value, which is referred to as the CT number. It can be expressed as [14]:

where a and b are constants and μ is the absorption coefficient of X-ray.

3.2 CT number and microscopic characteristics of samples

According to the principle of CT imaging, there is a linear relationship between the CT number and the density of the specimens. The larger the CT number, the greater the density of the rock sample. In contrast, the smaller the fluctuation of the CT number, the more uniform and complete are the specimens. The presence of artifacts during the scanning process will affect the CT number. So, it will also have a significant impact on the CT number corresponding to the crack inside the specimens. Therefore, the CT image after threshold segmentation can be more useful to discover the internal microstructure of the specimen, including the uniformity of the rock and even its micro cracks. According to Figure 4, the left image is the threshold segmentation images of the same specimen at 160, 450, and 730 layers, and in the right figure the x-axis stands for the distance between the pixel and the left border of the rock sample, and the y-axis stands for the CT number corresponding to each pixel taken from a horizontal line in the same ordinate in the image. The specific location is shown by the red line in the figures. As shown in Figure 4, the fluctuation range of CT numbers on the same horizontal line is the same roughly, while at both ends of the specimen, the CT numbers dropped significantly, which was due to the “edge effect” caused by the cutting of the rock. According to the principle of the CT scanning test, the black parts in the images represent cracks or a low-density matrix. Besides, Professor Hounsfield, the inventor of CT technology, defines the CT value of air as −1,000 [15]. It can be seen from the figure that the CT numbers in the micro-fracture parts of the rock sample were all negative values, which were significantly lower than those in other parts, and the CT number of higher layers was closer to −1,000. For instance, points A, B, C, and D in Figure 4.

Distribution of the transverse CT number of the different layers of the test piece. (a) Layer 160th, (b) layer 450th, and (c) layer 730th.

3.3 Statistical analysis of CT number probability

Weibull distribution is a vital distribution in probability statistics, and its distribution function is

where α is a scale parameter, β is a shape parameter, x is a random variable, and x > 0, α, β > 0.

According to the data from the CT scanning tests, the CT numbers of all scanning sections were analyzed statistically. The CT number distribution diagrams are shown in Figure 5. Among them, specimens A-1, A-2, and A-3 are conventional triaxial tests with confining pressures of 5, 10, and 15 MPa. Specimens B-1, B-2, and B-3 are graded loading tests with confining pressures of 5, 10, and 15 MPa. The CT numbers of the specimens under conventional triaxial compression tests and graded loading tests meet the Weibull distribution.

Microelement intensity distribution of CT numbers under different experimental conditions. (a) Conventional triaxial test and (b) triaxial compression test with step loading.

Under the confining pressures of 5, 10, and 15 MPa, with the increase of the confining pressure, the probability distribution curves of CT numbers shift to the right in turn. This indicates that the overall density of the specimens and the mean values of CT numbers rise with the increase in confining pressure.

The mean values and the standard deviations of CT numbers in the two groups of tests were counted, as shown in Table 1. The average CT numbers of rock samples under the graded loading test are lower than those in the conventional triaxial test, and the standard deviations are higher than those of the conventional test.

Weibull distribution characteristics of the CT number of different rock samples

| Conventional triaxial compression test | Staged loading compression test | |||||

|---|---|---|---|---|---|---|

| A-1 | A-2 | A-3 | B-1 | B-2 | B-3 | |

| Confining pressure (MPa) | 5 | 10 | 15 | 5 | 10 | 15 |

| Mean values of CT numbers | 2,665 | 2,767 | 2,837 | 2,542 | 2,570 | 2,635 |

| Standard deviations of CT numbers | 454 | 450 | 394 | 610 | 608 | 601 |

The mean values of the CT numbers after rock failure reflect the overall characteristics of the material. In the graded loading test, after being loaded at least three grades, the rock materials under different confining pressures were destroyed, and the loading time lasted for 146 h at least. The long-term high stress level will lead to the full development of microcracks in the rock. So, the average CT numbers of the graded loading test are lower than that of the conventional triaxial test. In contrast, the standard deviation reflects the dispersion of materials. The larger the standard deviation, the stronger the heterogeneity of the material, and the more defects inside the material. In mechanical tests, the peak strengths of the graded loading tests are lower than those of the conventional triaxial tests generally. According to the mean values and the standard deviations of the CT numbers, the loaded rock samples not only have weaker material properties than conventional tests, but also have worse material homogeneity.

3.4 The relationship between CT number and confining pressure

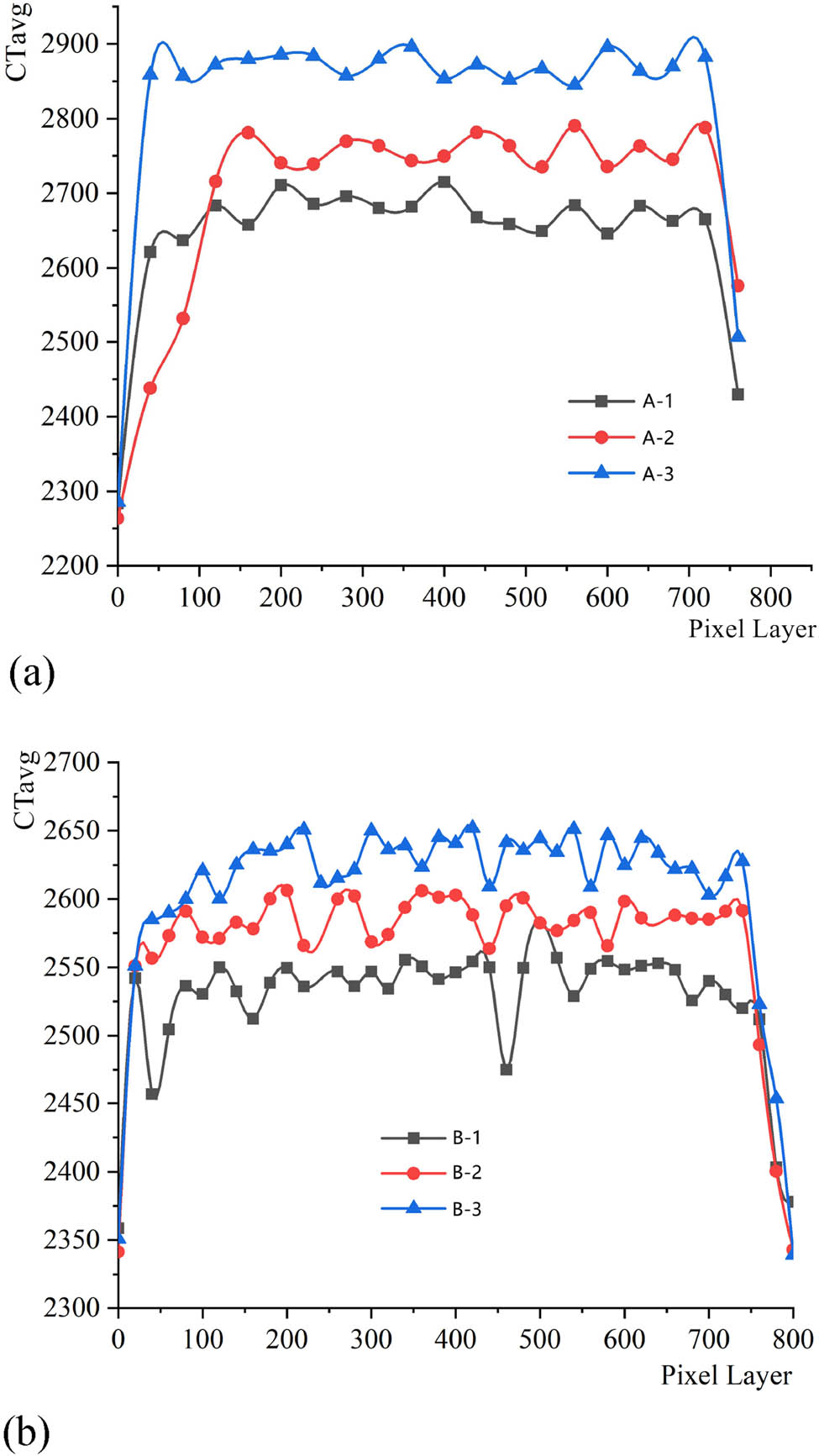

We used the CT scanning test to scan the rock samples layer by layer. Therefore, in order to understand the microscopic fracture of each specimen in detail, CTavg was defined as the average CT numbers per layer in the test. The distribution of CTavg layers is shown in Figure 6, where the abscissa is the number of layers scanned by rock samples, and the ordinate is the average CT number of rock samples at this number of layers.

CT digital scan under different experimental conditions. (a) Conventional triaxial test and (b) triaxial compression test with step loading.

At the starting point of the distribution curve, CTavgs are significantly lower than those obtained from the internal scanning of the rock sample. This is caused by the “edge effect.” In Figure 6(a) it can be observed that the CTavgs of the rock samples rise significantly with the increase in confining pressure, and the fluctuation range of the CT numbers of the samples under the same confining pressure is the same roughly. The fluctuation range of the average CT numbers under different confining pressures is distinguished clearly. The CTavgs rise gradually with the increase of the confining pressure, and the increased amplitude is approximately 100. Similarly, in Figure 6(b), the CTavgs of the graded loading tests also show an upward trend, but the increment is less than 100.

To summarize, the loading history of marble has a significant effect on the CTavgs of rock samples. The CTavgs of each layer of rock samples especially have a significant memory effect on the confining pressure level of rock samples.

4 Damage analysis of specimen based on CT number

According to the definition of damage, the calculation method of the damage variable based on the values of pixels is as follows [16]:

where n 1 is the number of pixels in the damaged area of the threshold-segmentation on image and n is the number of all pixels in the scanned image.

Table 2 shows the damage variable values of each sample at 20, 200, 400, 600, and 800 layers. Figure 7 data were acquired according to the damage variables in Table 2.

Statistical table of de-lamination damage variables of rock samples

| Layer | A-1 | A-2 | A-3 | B-1 | B-2 | B-3 |

|---|---|---|---|---|---|---|

| 20 | 0.645 | 0.549 | 0.475 | 0.664 | 0.640 | 0.633 |

| 200 | 0.673 | 0.637 | 0.538 | 0.670 | 0.657 | 0.652 |

| 400 | 0.727 | 0.646 | 0.546 | 0.732 | 0.665 | 0.635 |

| 600 | 0.734 | 0.671 | 0.570 | 0.743 | 0.717 | 0.656 |

| 800 | 0.750 | 0.684 | 0.591 | 0.757 | 0.721 | 0.660 |

Damage variables under different experimental conditions. (a) Conventional triaxial test and (b) triaxial compression test with step loading.

In the two loading tests, the damage of the specimen decreases with the increase of the confining pressure. It can be seen from Figure 7 that under the confining pressure of 5 MPa, the damage variable values between the rock samples A-1 and B-1 are in the same range roughly, that is, they are 0.70 and 0.71, respectively. Under the confining pressure of 10 MPa, comparing the damage variable values of rock samples A-2 and B-2, the damage variable values of graded loading tests are greater than those of conventional triaxial tests. When the confining pressure was 15 MPa, the difference between the damage variables of rock samples A-3 and B-3 grows further.

Based on the definition of meso-damage mechanics, the damage variable in this study is based on the physical damage of the CT number. This damage variable indicates that the strength of the rock material will continue to increase with the increase in confining pressure. It is well known that the rock material is a complex compressive material. Three-dimensional compression can improve mechanical properties greatly and can increase the strength of the materials. Therefore, in order to obtain the mathematical expression between the damage variable defined by the CT number and the material strength damage directly, further research is needed.

5 Conclusion

The CT numbers of the rock samples after the triaxial compression test meet the Weibull distribution. With the increase in confining pressure, the mean values of CT numbers increase while variances decrease gradually. The standard deviations of the graded loading tests are higher than those of conventional triaxial tests significantly, indicating that the internal heterogeneity or the degree of damage of rock samples is higher than those of the conventional triaxial tests, and this makes it easier to form macroscopic cracks and cause damage to the rock sample.

In the two groups of tests, the CTavgs corresponding to the conventional triaxial tests are higher than the CTavgs corresponding to the graded loading tests. The CTavgs of each layer of the rock sample correspond to the corresponding confining pressure roughly.

The damage variable defined based on the CT number shows that the internal damage of rock samples decreases with the increase in confining pressure. The damage variables of the rock samples in graded loading tests are higher than those in the conventional triaxial tests, and the difference grows with the increase in confining pressure.

Acknowledgements

This study was supported by the National Natural Science Foundation of China (Nos. 51609080 and 51708188). We would also like to express our sincere gratitude to the editor and reviewers for their valuable comments, which have greatly improved this article.

-

Author contributions: Yang: Conceptualization, methodology; Li, Tian and Cheng: validation, investigation; Zhou and Zhang: supervision; Kaunda: writing – reviewing.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: This data that support the findings of this study are available from the corresponding author upon the reasonable request.

References

[1] Teng, J., J. Tang, J. Wang, and Y. Zhang. The evolution law of the damage of bedded composite rock and its fractal characteristics. Chinese Journal of Rock Mechanics and Engineering, Vol. 37, No. 346(S1), 2018, pp. 3263–3278.Search in Google Scholar

[2] Nasseri, M. H., F. Rezanezhad, and R. P. Young. Analysis of fracture damage zone in anisotropic granitic rock using 3D X-ray CT scanning techniques. International Journal of Fracture, Vol. 168, No. 1, 2011, pp. 1–13.10.1007/s10704-010-9551-0Search in Google Scholar

[3] Yang, G., D. Xie, and C. Zhang. The quantitative analysis of distribution regulation of CT values of rock damage. Chinese Journal of Rock Mechanics and Engineering, Vol. 17, No. 3, 1998, pp. 279–285.Search in Google Scholar

[4] Zhu, H., H. Xie, C. Yi, Z. Liu, H. Liu, and H. Wang. CT identification of microcracks evolution for rock materials. Chinese Journal of Rock Mechanics and Engineering, Vol. 30, No. 6, 2011, pp. 1230–1238.Search in Google Scholar

[5] Li, S., J. Xu, C. Yang, Y. Pu, and W. Ma. Study of CT meso-experiment of rock damage under cyclic load. Chinese Journal of Rock Mechanics and Engineering, Vol. 28, No. 8, 2009, pp. 1604–1609.Search in Google Scholar

[6] Zhu, L., F. Dang, W. Ding, Y. Xue, and L. Zhang. Coupled X-ray computed tomography and grey level co-occurrence matrices theory as a method for detecting microscopic damage of concrete under different loads. China Civil Engineering Journal, Vol. 53, No. 8, 2020, pp. 97–107.Search in Google Scholar

[7] Fang, J., N. Li, F. Dang, Y. Pan, and X. Ren. Reconstruction of concrete numerical model based on damage zoning theory and CT number. Journal of Chang’an University (Natural Science Edition), Vol. 40, No. 2, 2020, pp. 66–73.Search in Google Scholar

[8] Song, Y., H. Yang, F. Dang, L. Zhang, and J. Ren. CT real-time monitoring on uniaxial damage of frozen red sandstone. Rock and Soil Mechanics, Vol. 40, No. S1, 2019, pp. 152–160.Search in Google Scholar

[9] Lang, Y., Z. Liang, D. Duan, and Z. Cao. Three-dimensional parallel numerical simulation of porous rocks based on CT technology and digital image processing. Rock and Soil Mechanics, Vol. 40, No. 3, 2019, pp. 1204–1212.Search in Google Scholar

[10] Cheng, M., S. Wang, Y. Zang, X. Li, S. Jiang, and Z. Chen. Experimental study of assessment of different characterization methods of expansive soil damage. Rock and Soil Mechanics, Vol. 36, No. 10, 2015, pp. 2892–2896.Search in Google Scholar

[11] Zhong, S., Q. Jiang, C. Liu, S. Li, W. Qin, J. Zhou, et al. In-site core disking phenomenon and break mechanism of hard marble: Investigation in 2400 m deep-buried underground laboratory. Journal of Central South University, Vol. 27, No. 10, 2020, pp. 2959–2970.10.1007/s11771-020-4521-9Search in Google Scholar

[12] Jiang, Q., J. Cui, X. Feng, and Y. Jiang. Application of computerized tomographic scanning to the study of water-induced weakening of mudstone. Bulletin of Engineering Geology and the Environment, Vol. 73, No. 4, 2014, pp. 1293–1301.10.1007/s10064-014-0597-5Search in Google Scholar

[13] Ba, N., H. Gao, X. Liu, X. Wu, Y. Zhang, S. Zhang, et al. The modified of the X-ray diffraction intensity formula. Journal of Jishou University, Vol. 33, No. 1, 2012, pp. 41–45.Search in Google Scholar

[14] Yang, G., J. Sun, D. Xie, and C. Zhang. Analysis of the relation between the damage variable and CT value of rock material. Mechanics in Engineering, Vol. 33, No. 1, 1998, pp. 48–50.Search in Google Scholar

[15] Yang, G., D. Xie, C. Zhang, and Y. Pu. Ct identification of rock damage properties. Chinese Journal of Rock Mechanics and Engineering, Vol. 15, No. 1, 1996, pp. 48–54.Search in Google Scholar

[16] Liu, H., G. Yang, Y. Wan, Y. Shen, H. Zhang, and L. Tang. Analysis of water and ice content and damage characteristics of the frozen rock during freezing based on the three-valued segmentation of CT images. Journey of Mining & Safety Engineering, Vol. 33, No. 6, 2016, pp. 1130–1137.Search in Google Scholar

© 2021 Yang Yan-Shuang et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- A review on filler materials for brazing of carbon-carbon composites

- Nanotechnology-based materials as emerging trends for dental applications

- A review on allotropes of carbon and natural filler-reinforced thermomechanical properties of upgraded epoxy hybrid composite

- High-temperature tribological properties of diamond-like carbon films: A review

- A review of current physical techniques for dispersion of cellulose nanomaterials in polymer matrices

- Review on structural damage rehabilitation and performance assessment of asphalt pavements

- Recent development in graphene-reinforced aluminium matrix composite: A review

- Mechanical behaviour of precast prestressed reinforced concrete beam–column joints in elevated station platforms subjected to vertical cyclic loading

- Effect of polythiophene thickness on hybrid sensor sensitivity

- Investigation on the relationship between CT numbers and marble failure under different confining pressures

- Finite element analysis on the bond behavior of steel bar in salt–frost-damaged recycled coarse aggregate concrete

- From passive to active sorting in microfluidics: A review

- Research Articles

- Revealing grain coarsening and detwinning in bimodal Cu under tension

- Mesoporous silica nanoparticles functionalized with folic acid for targeted release Cis-Pt to glioblastoma cells

- Magnetic behavior of Fe-doped of multicomponent bismuth niobate pyrochlore

- Study of surfaces, produced with the use of granite and titanium, for applications with solar thermal collectors

- Magnetic moment centers in titanium dioxide photocatalysts loaded on reduced graphene oxide flakes

- Mechanical model and contact properties of double row slewing ball bearing for wind turbine

- Sandwich panel with in-plane honeycombs in different Poisson's ratio under low to medium impact loads

- Effects of load types and critical molar ratios on strength properties and geopolymerization mechanism

- Nanoparticles in enhancing microwave imaging and microwave Hyperthermia effect for liver cancer treatment

- FEM micromechanical modeling of nanocomposites with carbon nanotubes

- Effect of fiber breakage position on the mechanical performance of unidirectional carbon fiber/epoxy composites

- Removal of cadmium and lead from aqueous solutions using iron phosphate-modified pollen microspheres as adsorbents

- Load identification and fatigue evaluation via wind-induced attitude decoupling of railway catenary

- Residual compression property and response of honeycomb sandwich structures subjected to single and repeated quasi-static indentation

- Experimental and modeling investigations of the behaviors of syntactic foam sandwich panels with lattice webs under crushing loads

- Effect of storage time and temperature on dissolved state of cellulose in TBAH-based solvents and mechanical property of regenerated films

- Thermal analysis of postcured aramid fiber/epoxy composites

- The energy absorption behavior of novel composite sandwich structures reinforced with trapezoidal latticed webs

- Experimental study on square hollow stainless steel tube trusses with three joint types and different brace widths under vertical loads

- Thermally stimulated artificial muscles: Bio-inspired approach to reduce thermal deformation of ball screws based on inner-embedded CFRP

- Abnormal structure and properties of copper–silver bar billet by cold casting

- Dynamic characteristics of tailings dam with geotextile tubes under seismic load

- Study on impact resistance of composite rocket launcher

- Effects of TVSR process on the dimensional stability and residual stress of 7075 aluminum alloy parts

- Dynamics of a rotating hollow FGM beam in the temperature field

- Development and characterization of bioglass incorporated plasma electrolytic oxidation layer on titanium substrate for biomedical application

- Effect of laser-assisted ultrasonic vibration dressing parameters of a cubic boron nitride grinding wheel on grinding force, surface quality, and particle morphology

- Vibration characteristics analysis of composite floating rafts for marine structure based on modal superposition theory

- Trajectory planning of the nursing robot based on the center of gravity for aluminum alloy structure

- Effect of scan speed on grain and microstructural morphology for laser additive manufacturing of 304 stainless steel

- Influence of coupling effects on analytical solutions of functionally graded (FG) spherical shells of revolution

- Improving the precision of micro-EDM for blind holes in titanium alloy by fixed reference axial compensation

- Electrolytic production and characterization of nickel–rhenium alloy coatings

- DC magnetization of titania supported on reduced graphene oxide flakes

- Analytical bond behavior of cold drawn SMA crimped fibers considering embedded length and fiber wave depth

- Structural and hydrogen storage characterization of nanocrystalline magnesium synthesized by ECAP and catalyzed by different nanotube additives

- Mechanical property of octahedron Ti6Al4V fabricated by selective laser melting

- Physical analysis of TiO2 and bentonite nanocomposite as adsorbent materials

- The optimization of friction disc gear-shaping process aiming at residual stress and machining deformation

- Optimization of EI961 steel spheroidization process for subsequent use in additive manufacturing: Effect of plasma treatment on the properties of EI961 powder

- Effect of ultrasonic field on the microstructure and mechanical properties of sand-casting AlSi7Mg0.3 alloy

- Influence of different material parameters on nonlinear vibration of the cylindrical skeleton supported prestressed fabric composite membrane

- Investigations of polyamide nano-composites containing bentonite and organo-modified clays: Mechanical, thermal, structural and processing performances

- Conductive thermoplastic vulcanizates based on carbon black-filled bromo-isobutylene-isoprene rubber (BIIR)/polypropylene (PP)

- Effect of bonding time on the microstructure and mechanical properties of graphite/Cu-bonded joints

- Study on underwater vibro-acoustic characteristics of carbon/glass hybrid composite laminates

- A numerical study on the low-velocity impact behavior of the Twaron® fabric subjected to oblique impact

- Erratum

- Erratum to “Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete”

- Topical Issue on Advances in Infrastructure or Construction Materials – Recycled Materials, Wood, and Concrete

- Structural performance of textile reinforced concrete sandwich panels under axial and transverse load

- An overview of bond behavior of recycled coarse aggregate concrete with steel bar

- Development of an innovative composite sandwich matting with GFRP facesheets and wood core

- Relationship between percolation mechanism and pore characteristics of recycled permeable bricks based on X-ray computed tomography

- Feasibility study of cement-stabilized materials using 100% mixed recycled aggregates from perspectives of mechanical properties and microstructure

- Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete

- Research on nano-concrete-filled steel tubular columns with end plates after lateral impact

- Dynamic analysis of multilayer-reinforced concrete frame structures based on NewMark-β method

- Experimental study on mechanical properties and microstructures of steel fiber-reinforced fly ash-metakaolin geopolymer-recycled concrete

- Fractal characteristic of recycled aggregate and its influence on physical property of recycled aggregate concrete

- Properties of wood-based composites manufactured from densified beech wood in viscoelastic and plastic region of the force-deflection diagram (FDD)

- Durability of geopolymers and geopolymer concretes: A review

- Research progress on mechanical properties of geopolymer recycled aggregate concrete

Articles in the same Issue

- Review Articles

- A review on filler materials for brazing of carbon-carbon composites

- Nanotechnology-based materials as emerging trends for dental applications

- A review on allotropes of carbon and natural filler-reinforced thermomechanical properties of upgraded epoxy hybrid composite

- High-temperature tribological properties of diamond-like carbon films: A review

- A review of current physical techniques for dispersion of cellulose nanomaterials in polymer matrices

- Review on structural damage rehabilitation and performance assessment of asphalt pavements

- Recent development in graphene-reinforced aluminium matrix composite: A review

- Mechanical behaviour of precast prestressed reinforced concrete beam–column joints in elevated station platforms subjected to vertical cyclic loading

- Effect of polythiophene thickness on hybrid sensor sensitivity

- Investigation on the relationship between CT numbers and marble failure under different confining pressures

- Finite element analysis on the bond behavior of steel bar in salt–frost-damaged recycled coarse aggregate concrete

- From passive to active sorting in microfluidics: A review

- Research Articles

- Revealing grain coarsening and detwinning in bimodal Cu under tension

- Mesoporous silica nanoparticles functionalized with folic acid for targeted release Cis-Pt to glioblastoma cells

- Magnetic behavior of Fe-doped of multicomponent bismuth niobate pyrochlore

- Study of surfaces, produced with the use of granite and titanium, for applications with solar thermal collectors

- Magnetic moment centers in titanium dioxide photocatalysts loaded on reduced graphene oxide flakes

- Mechanical model and contact properties of double row slewing ball bearing for wind turbine

- Sandwich panel with in-plane honeycombs in different Poisson's ratio under low to medium impact loads

- Effects of load types and critical molar ratios on strength properties and geopolymerization mechanism

- Nanoparticles in enhancing microwave imaging and microwave Hyperthermia effect for liver cancer treatment

- FEM micromechanical modeling of nanocomposites with carbon nanotubes

- Effect of fiber breakage position on the mechanical performance of unidirectional carbon fiber/epoxy composites

- Removal of cadmium and lead from aqueous solutions using iron phosphate-modified pollen microspheres as adsorbents

- Load identification and fatigue evaluation via wind-induced attitude decoupling of railway catenary

- Residual compression property and response of honeycomb sandwich structures subjected to single and repeated quasi-static indentation

- Experimental and modeling investigations of the behaviors of syntactic foam sandwich panels with lattice webs under crushing loads

- Effect of storage time and temperature on dissolved state of cellulose in TBAH-based solvents and mechanical property of regenerated films

- Thermal analysis of postcured aramid fiber/epoxy composites

- The energy absorption behavior of novel composite sandwich structures reinforced with trapezoidal latticed webs

- Experimental study on square hollow stainless steel tube trusses with three joint types and different brace widths under vertical loads

- Thermally stimulated artificial muscles: Bio-inspired approach to reduce thermal deformation of ball screws based on inner-embedded CFRP

- Abnormal structure and properties of copper–silver bar billet by cold casting

- Dynamic characteristics of tailings dam with geotextile tubes under seismic load

- Study on impact resistance of composite rocket launcher

- Effects of TVSR process on the dimensional stability and residual stress of 7075 aluminum alloy parts

- Dynamics of a rotating hollow FGM beam in the temperature field

- Development and characterization of bioglass incorporated plasma electrolytic oxidation layer on titanium substrate for biomedical application

- Effect of laser-assisted ultrasonic vibration dressing parameters of a cubic boron nitride grinding wheel on grinding force, surface quality, and particle morphology

- Vibration characteristics analysis of composite floating rafts for marine structure based on modal superposition theory

- Trajectory planning of the nursing robot based on the center of gravity for aluminum alloy structure

- Effect of scan speed on grain and microstructural morphology for laser additive manufacturing of 304 stainless steel

- Influence of coupling effects on analytical solutions of functionally graded (FG) spherical shells of revolution

- Improving the precision of micro-EDM for blind holes in titanium alloy by fixed reference axial compensation

- Electrolytic production and characterization of nickel–rhenium alloy coatings

- DC magnetization of titania supported on reduced graphene oxide flakes

- Analytical bond behavior of cold drawn SMA crimped fibers considering embedded length and fiber wave depth

- Structural and hydrogen storage characterization of nanocrystalline magnesium synthesized by ECAP and catalyzed by different nanotube additives

- Mechanical property of octahedron Ti6Al4V fabricated by selective laser melting

- Physical analysis of TiO2 and bentonite nanocomposite as adsorbent materials

- The optimization of friction disc gear-shaping process aiming at residual stress and machining deformation

- Optimization of EI961 steel spheroidization process for subsequent use in additive manufacturing: Effect of plasma treatment on the properties of EI961 powder

- Effect of ultrasonic field on the microstructure and mechanical properties of sand-casting AlSi7Mg0.3 alloy

- Influence of different material parameters on nonlinear vibration of the cylindrical skeleton supported prestressed fabric composite membrane

- Investigations of polyamide nano-composites containing bentonite and organo-modified clays: Mechanical, thermal, structural and processing performances

- Conductive thermoplastic vulcanizates based on carbon black-filled bromo-isobutylene-isoprene rubber (BIIR)/polypropylene (PP)

- Effect of bonding time on the microstructure and mechanical properties of graphite/Cu-bonded joints

- Study on underwater vibro-acoustic characteristics of carbon/glass hybrid composite laminates

- A numerical study on the low-velocity impact behavior of the Twaron® fabric subjected to oblique impact

- Erratum

- Erratum to “Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete”

- Topical Issue on Advances in Infrastructure or Construction Materials – Recycled Materials, Wood, and Concrete

- Structural performance of textile reinforced concrete sandwich panels under axial and transverse load

- An overview of bond behavior of recycled coarse aggregate concrete with steel bar

- Development of an innovative composite sandwich matting with GFRP facesheets and wood core

- Relationship between percolation mechanism and pore characteristics of recycled permeable bricks based on X-ray computed tomography

- Feasibility study of cement-stabilized materials using 100% mixed recycled aggregates from perspectives of mechanical properties and microstructure

- Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete

- Research on nano-concrete-filled steel tubular columns with end plates after lateral impact

- Dynamic analysis of multilayer-reinforced concrete frame structures based on NewMark-β method

- Experimental study on mechanical properties and microstructures of steel fiber-reinforced fly ash-metakaolin geopolymer-recycled concrete

- Fractal characteristic of recycled aggregate and its influence on physical property of recycled aggregate concrete

- Properties of wood-based composites manufactured from densified beech wood in viscoelastic and plastic region of the force-deflection diagram (FDD)

- Durability of geopolymers and geopolymer concretes: A review

- Research progress on mechanical properties of geopolymer recycled aggregate concrete