Abstract

This paper investigated the response and residual compression properties of honeycomb sandwich structures subjected to single quasi-static indentation (QSI) and repeated QSI (RQSI). The damage depth after repeated low-velocity impact (LVI) was considered as the governing parameter during the QSI experiments. Three-dimensional digital image correlation method was applied to determine deformation of the front panels after LVI and QSI to describe damage to honeycomb structures. For specimens with the same depth, it is found that the residual strength of QSI was less than that of LVI and close to that of RQSI. Results indicated that it is more reasonable to describe the damage by volume than by depth.

1 Introduction

Honeycomb sandwich structures have extensively been used in engineering applications, such as aerospace, automotives, and ships because of their remarkable properties like high strength/stiffness-to-weight ratio, excellent heat resistance, and favorable energy absorption capability [1]. Typically, a honeycomb sandwich structure consists of a low-density honeycomb core and two face sheets [2]. The face sheets are used to bear the bending and stretching loads, while the honeycomb core is used to reduce the total weight, provide shear stress transmission, absorb energy, and mitigate the shock [3]. During establishment or in service in an engineering context, a sandwich structure is prone to impact because of various reasons, such as propulsion of debris, dropped tools, and bird strikes [4]. Impact damage can cause significant failure due to the reduction in stiffness and strength of structures [5]. Thus, it is necessary to understand the mechanical behavior of the honeycomb sandwich structures during and after impacts [6].

Numerous studies have focused on experimental and analytical investigations on the dynamic response of sandwich structures subjected to low-velocity impact (LVI) [7]. And some research were often accompanied by numerical simulation [8]. The response/energy absorption has been discussed in different ways [9]. Results indicated that the absorbed energy/impact energy ratio and contact duration decrease with the face-sheet thickness [10]. The perforation force was strongly dependent on the shear strength of the core [11]. There was a reduction in impact strength after impact at elevated temperatures [12]. Further, various models have also been developed to investigate the mechanical behavior of sandwich structures under LVI [13]. For example, refined numerical models were applied to provide sufficient detailed information of failure mechanism and damage evolution [14]. Three-dimensional models with detailed cell walls were used to reveal accurate deformation damage progression [15]. The energy-balance model was proposed to predict the damage mechanisms and failure [16].

In addition to single impact, another important real case of impact is the repeated impact [17]. In recent years, repeated LVIs have rendered honeycomb sandwich structures attractive for researchers [18]. Some interesting experiments have been performed [19]. The results showed that matrix cracking, delamination, and fiber failure propagated with the number of impacts [20]. Both energy absorption and energy absorption efficiency increased initially, then decreased rapidly after repeated impacts with each impact energy level [21]. The deflections of front and back face sheets demonstrated differing responses with the increment of impact numbers when low and high impact energy was applied [22].

Valuable conclusions have been obtained from these kinds of research with regard to impact damage and residual mechanical properties. However, the impact duration is quite short, and the propagation of impact damage is difficult to detect accurately. Furthermore, the experimental results show great dispersion, and sometimes they show a lack of agreement between experimental data and simulation methods. Then, researchers tried to find another equivalent type of loading condition. Fortunately, it has been found experimentally that the failure mode of sandwich structures subjected to LVI was similar to that of quasi-static indentation (QSI) [23].

Based on the above finding, quasi-static loading is considered prevalent and important in studying the mechanical behaviors of sandwich structures [24]. QSI was chosen in this study to consider localized contact analogous to LVI [25]. It was also applied to represent the impact response due to the negligible strain-rate and wave propagation for LVI [26]. Furthermore, quasi-static tests are more accessible, easier to conduct, and provide consistent and controlled data acquisition of damaged and undamaged structures, which are unavailable or inaccessible in impact tests [27]. Thus, various studies have been conducted on the response of honeycomb structures under QSI. It was found that the indenter nose shape influenced the indentation resistance [28] and failure mechanism of the sandwich panels [29]. Further, the indentation behaviors depended on governing parameters, such as the cell size and shape, and foil thickness [30].

As outlined above, most investigations on the quasi-static response of sandwich panels were limited to a single QSI (SQSI). In this study, an extensive experimental investigation was undertaken to determine the response and residual compression properties of honeycomb sandwich structures subjected to SQSI and repeated QSIs (RQSIs) as well as the LVI. Unlike previous traditional experiments, the damage depth, rather than peak loading, was considered as the governing parameter. All tests were carried out on sandwich panels with aluminum alloy honeycomb cores and aluminum alloy face sheets. Three-dimensional digital image correlation (3D-DIC), a nondestructive optical technique with a wide range of sensitivities and resolutions [31], was employed in this research to determine the 3D profile and full-field deformation distributions. The residual compressive properties were also investigated based on compression after impact (CAI) tests. The onset of damage processing and failure modes were obtained from the strain distributions and digital images.

2 Materials

Figure 1 shows the image and structure of the honeycomb sandwich specimen tested in this study. The specimen was designed and manufactured as a square with a length of 100 mm. The total thickness of the sample was 8 mm, and the thicknesses of the top and bottom face sheets were 0.8 mm. The wall thickness and cell size of the hexagonal cell are 0.05 and 12 mm, respectively. The face sheets and honeycomb core were glued with adhesive layers of epoxy resin. The material used for fabricating the panels and the honeycomb core was an aluminum alloy. The mechanical properties of the aluminum alloy are given in Table 1.

(a) Image of honeycomb sandwich plate and (b) schematic diagram of structure.

Mechanical properties of the aluminum alloy

| Density (

|

Young’s modulus (GPa) | Poisson’s ratio | Compressive strength (MPa) | Shear strength (MPa) |

|---|---|---|---|---|

| 2.71 | 70 | 0.34 | 110 | 63 |

3 Experiments

It has been reported that the similar failure modes can be produced in impact and quasi-static tests under certain conditions. Generally speaking, the so-called “certain conditions” refer to the “large-mass, low-velocity” regime, provided the peak load is the same (with all other parameters constant) during the impact and quasi-static tests [27]. Various experimental and numerical investigations were conducted to elucidate the damage mechanism [32,33] and the relationships between mechanical performance and geometric parameters [34]. However, most of the literature studies were focused on SQSI. Two issues need to be addressed more comprehensively: (1) ongoing deformation process during the SQSI and RQSI and (2) residual compression properties of honeycomb sandwich structures subjected to the SQSI and RQSI.

Regarding the problems mentioned above, two basic response characteristics were used to compare the impact and quasi-static responses of honeycomb sandwich structures in this investigation: loading response (force displacement histories) and residual strength. It is well known that the damage degree is always evaluated based on the damage depth. Then, the latter comparison was based on damage depth being the same in both test types in this research. A brief description of the experimental methods is discussed in the following sections.

3.1 QSI

QSI tests were conducted on a universal testing machine (Shimadzu Suzhou Instruments Mfg. Co. Ltd, Suzhou, China) with a maximum loading of 10 kN, as shown in Figure 2a. The loading speed could be adjusted in the range of 0.5–500 mm/min. The loading speed was set at 1.0 mm/min in the present study. The loading was recorded and displayed on a computer in real time. As shown in Figure 2b, the rectangular specimen was clamped between two aluminum alloy frames with an opening area of 50 × 50 mm. A hemispherical indenter with a 6 mm radius was used to indent the sample. A micrometer was applied to monitor the movement of the indenter in the vertical direction with an accuracy of 0.01 mm. A mirror tilted at 45° was placed under the honeycomb plate to reflect the deformation of the lower surface. Figure 2c presents the image obtained by reflection.

(a) Experimental set-up for QSI test, (b) clamping fixture, and (c) specimen.

3D-DIC method, which has low environmental vulnerability and can obtain full-field deformation [35], was employed to determine the displacement and strain distributions of the lower surface. A conventional 3D-DIC system consists of two cameras and light source [36]. CCD cameras (UI-1540LE-M-GL, IDS Co., Ltd, Germany) with a resolution of 2,048 × 1,088 pixels at 256 Gy levels were used to capture the deformation images during the testing.

During the experiment, the micrometer was fixed to the compression head, and the drop distance of the head was measured with a micrometer. The drop distance was considered as the indentation depth because the stiffness of the head was much greater than that of the specimen. There was a rebound phenomenon in the indentation process. To indent the honeycomb plate to the desired depth as soon as possible, it is necessary to determine the rebound distance of the honeycomb plate. The rebound distance of the honeycomb plate can be obtained by subtracting the data 20 min after loading from the data at the end of the loading obtained from the micrometer. The distance can also be determined using 3D-DIC [37]. Figure 3a and b show the out-of-plane displacements of the rear surface at the end of the load and rebound, respectively, when the drop distance was 14 mm. The comparison between the displacements of the corresponding center lines is shown in Figure 3c. It was found that the rebound distance was approximately 1.8 mm, which was 0.2 mm smaller than that obtained by micrometer. This was because the honeycomb core attached to the top face-sheet was not compacted, and the rebound distance was larger than that on the lower panel.

Out-of plane displacements of two moments when drop distance was 14 mm: (a) contours at the end of loading, (b) contours at the end of rebound, and (c) comparison between the displacements of center lines.

3.2 LVI test and CAI test

LVI tests were carried out in order to examine the single and repeated impact responses of the sandwich composites [38]. Both single and repeated LVI tests were performed using a pressure-assisted Instron-Dynatup 9250 HV instrumented drop-weight impact machine with a 6 mm radius hemispherical indentor according to the ASTM-D7136/D7136M standard [39]. Three impact energy levels (5, 10, and 20 J) were selected for the LVI tests.

In order to quantitatively establish the loss of the sandwich mechanical strength after an impact, the experimental program of CAI tests was often carried out [40]. In this study, CAI tests were performed on specimens after QSI and LVI using a CAI test system, which consists of a loading equipment and a set of support fixtures, as shown in Figure 4. The loading speed of the universal testing machine was set at 1.25 mm/min for the CAI tests. The support fixture was designed according to the ASTM-D7137/D7137M standard [41].

CAI test system.

4 Results and discussion

4.1 Contact force–displacement curves

To verify the reproducibility of the experimental results, three indentation tests on identical specimens were conducted under QSI at a velocity of 1.0 mm/min. Figure 5 shows the typical contact force–displacement curves for honeycomb sandwich panels with the same dimension under an SQSI. The curve change trends were notable close to each other, which indicate that the experimental results were consistent. Furthermore, the stiffness of the three specimens was almost the same, and the loading stiffness was larger at the initial stage of loading. Good repeatability was presented for identical sandwich structures in terms of the load–displacement response. The scatter in the experimental data was attributed to the indentor position over the core. The maximum load capacity of all specimens was approximately 1.62 kN. The average drop displacement was 7.75 mm at the time of damage. The image of damaged specimen 2 is also shown in Figure 5. It can be seen that the indentation was hemispherical. There was a localized crescent-shaped damage area on the edge. Moreover, the fracture energy can be calculated by integrating the contact force–displacement curve. The average fracture energy was 6.8 J.

Force–displacement curves of specimens subjected to SQSI.

Figure 6 shows the contact force–displacement curves of the repeated impact structures with an energy of 5 J. The slope of the ascending sections in these curves represents the bending stiffness, while the enclosed area under the curves shows the absorbed energy. It can be observed that the stiffness and maximum contact force increased with the impact number. The values of the second and third impacts were close to each other but larger than that of the first impact. The maximum contact forces were 1.53, 2.20, and 2.48 kN, respectively. In contrast, the displacement decreased with the impact number. The final displacements were 5.71, 3.50, and 3.72 mm, respectively. The reason for this was that the honeycomb core was compacted and provided a harder surface along with the panels during the previous impacts [21]. Additionally, with the increasing number of repeats, the mechanical properties were reduced gradually as the damage expanded along the depth [42].

Force–displacement curves of specimens subjected to repeated LVI.

To compare the effect of loading mode on the residual compression strength, RQSI experiments were carried out according to the depth after repeated LVI. The indentation depths at various impact energy levels and impact numbers are listed in Table 2.

Indentation depth for LVI

| Impact energy (J)/impact number | 5 J/1st | 5 J/2nd | 5 J/3rd | 10 J/1st | 10 J/2nd | 20 J/1st |

| Indentation depth (mm) | 4.5 | 6.1 | 7.8 | 7.2 | 12.2 | — |

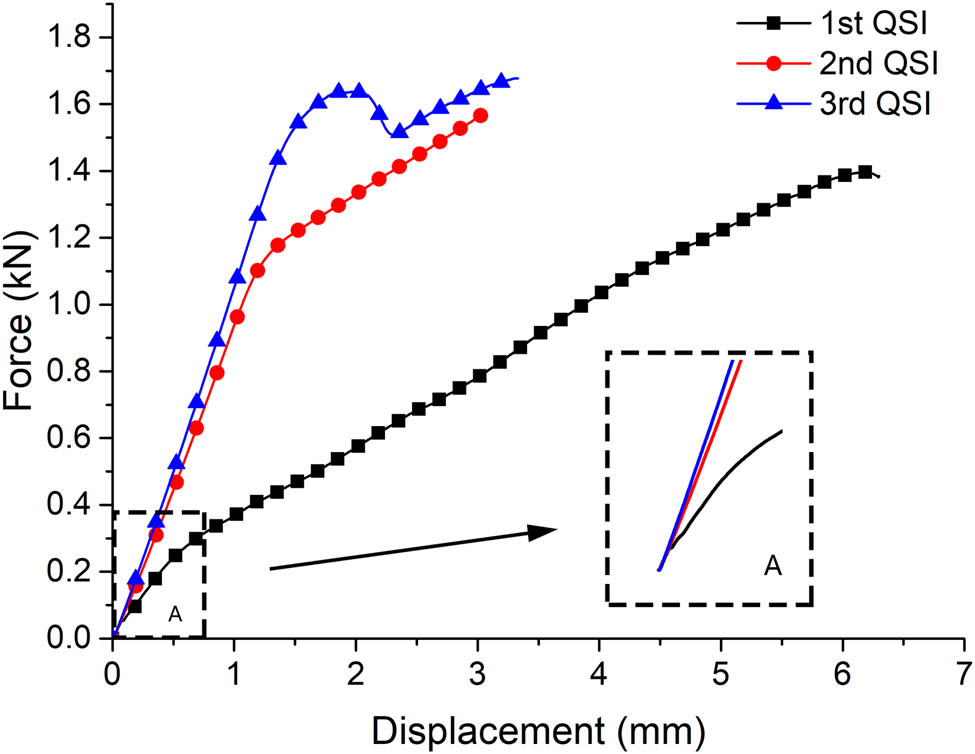

The experiment ended when the desired depth was reached. Figure 7 shows the force–displacement curves of the specimen subjected to RQSI. It can be seen that the bending stiffness of the second and third times was obviously greater than that of the first time, which was the same as the repeated LVI. However, in contrast to the repeated LVI, the stiffness of the second and third times was close to each other over a long period after loading. The maximum contact forces of RQSI increased with loading numbers, which were 1.40, 1.57, and 1.68 kN, respectively. It can also be found from the comparison of experimental results that the load difference increased with depth.

Force–displacement curves of specimen subjected to RQSI.

Figure 8 presents a comparison of the force–displacement curves of the specimens at the same depth when the specimens were subjected to QSI and LVI, respectively. For the first QSI and LVI at 10 J, it can be seen from Figure 8a that the honeycomb structure damage was initiated when they reached almost the same displacement in both cases. However, the damage force and energy of LVI were larger than those of QSI. The energies of QSI and LVI were 9.3 and 6.8 J, respectively. As for the second QSI and LVI at 10 J, the loading stiffness and the curve change trends of the force–displacement curves were almost the same.

Comparison of force–displacement curves of specimen at same depth: (a) 7.2 mm and (b) 12.2 mm.

4.2 Deformation of face-sheets

Figure 9 shows the damage images of three specimens with a depth of 7.8 mm, which were subjected to QSI. It can be seen that the three damages of the honeycomb panel were very similar, as were the damage range and size of the crescent shape. At both ends of the crescent, the same pattern of cracks appeared. This indicates that the discreteness of the QSI experiment was very small, which further validates the good reproducibility of the QSI method.

Damage of specimens with depth of 7.8 mm after QSI: (a) specimen 1, (b) specimen 2, and (c) specimen 3.

Figure 10 shows four typical damage images of honeycomb sandwich structures subjected to SQSI and LVI. It can be seen that when the dent depth was 6.1 mm, there was large plastic deformation but no damage occurred to the top panel of impacted plate, while the top panel of the SQSI-subjected structure was damaged. Top panels of structures after SQSI and LVI were both damaged when the depth was 7.8 mm, and the SQSI-subjected structure displayed worse damage than that of the LVI-subjected structure. As for the indent depth of 12.2 mm, the damage on the top panel of SQSI-subjected sample was similar to that of the LVI-subjected one. However, the crack forms on the bottom panels were different. The cracks of SQSI- and LVI-subjected samples were petal-shaped and crescent-shaped, respectively, as shown in rectangles A and B. When the specimens were penetrated, the damage forms were almost the same. Moreover, the cracks on the bottom panels were presented as a petal-shape. The damage to the honeycomb structure caused by SQSI was greater than that caused by LVI when the depth was the same. To quantitatively describe the damage to honeycomb structures, the 3D-DIC method was applied to determine the front panels of the specimens after LVI and QSI. The volumes of the pit areas can be calculated based on the obtained data [20]. The front panel was flat before deformation and became uneven after deformation. The volume of the uneven region around the pit was the damage volume. Table 3 lists the measurement damage volumes of specimens with the same depths. It can be observed from the comparison that when the depth was the same, the volume caused by SQSI was the greatest, while that caused by LVI was the smallest. When the specimen was subjected to RQSI, the corresponding damage volume was smaller than that of SQSI, but greater than that of LVI. The reason was that the SQSI duration was long and the deformation around the pressure head area continued to accumulate, which will eventually produce large plastic deformation. As for the RQSI, owing to the time interval between each indentation, part of the elastic deformation could be recovered in the time interval, and the final damage volume was less than that from SQSI. When the specimen was subjected to LVI, the experiment was conducted before the far region experienced large deformation.

Comparison of damage after LVI and QSI.

Depth and volume obtained by DIC

| Sample | Depth (mm) | Volume (mm3) |

|---|---|---|

| LVI-E5-f1 | 4.5 | 173.87 |

| SQSI-E5-f1 | 4.5 | 193.12 |

| LVI-E5-f2 | 6.1 | 761.01 |

| SQSI-E5-f2 | 6.1 | 801.66 |

| RQSI-E5-f2 | 6.1 | 782.25 |

| LVI-E10-f1 | 7.2 | 763.12 |

| SQSI-E10-f1 | 7.2 | 877.58 |

| LVI-E5-f3 | 7.8 | 879.09 |

| SQSI-E5-f3 | 7.8 | 1104.79 |

| RQSI-E5-f3 | 7.8 | 1030.65 |

| LVI-E10-f2 | 12.2 | 1620.23 |

| SQSI-E10-f2 | 12.2 | 1960.57 |

| RQSI-E10-f2 | 12.2 | 1883.27 |

Figure 11 shows four typical out-of plane displacement distributions of the rear face-sheet when the honeycomb structure is subjected to SQSI. It can be seen that the contour lines are concentric circles with centers at the loading points. The maximum displacement was at the center. The farther away from the center, the smaller the displacement [43]. A center line was selected to present the plastic deformation propagation in the x direction. The pattern of deflections along width direction is shown in Figure 12. The curves indicate that the out-of-plane displacements of the near and far fields increased with an increase in the drop displacement. Furthermore, the indentation also became deeper and wider.

Out-of plane displacement of rear face-sheet: (a) 8.5 mm, (b) 10 mm, (c) 11.5 mm, and (d) 13 mm.

Out-of plane displacement distribution along x axis.

3D-DIC was also used to determine the in-plane strain fields of the rear face sheet. Figure 13 shows the normal strain distributions when the drop displacements were 8.5, 10, 11.5, and 13 mm. Figure 13(a-1) to (d-1) illustrate the normal strain fields in the x direction, and Figure 13(a-2) to (d-2) show the normal strain fields in the y direction. The figures indicate that the normal strains in the x direction are distributed as butterfly-like shapes, while strain distributions in the y direction appeared bulbous. Strains in these two directions were symmetrical along the x- and y-axes, respectively. For the strain in the x direction, the left and right areas of the central line were under compression and in a state of tension, respectively. As for the strain in the y direction, the local central region was under tension while the above and below areas were under compression [23].

Strain distributions of rear face-sheet: (a-1) to (d-1) normal strain in x direction, (a-2) to (d-2) normal strain in y direction.

Two profiles, named

Strain distributions along center line: (a)

4.3 Residual strength

The residual strength of compression is defined as follows:

where

The normalized residual strength is defined as follows:

where

The maximum compression load is 8,050

The main purpose of CAI tests was to quantitatively describe the decrease of compression strength of an impacted specimen compared with a pristine specimen [44]. Table 4 presents the maximum load and the residual compressive strength of honeycomb structures with and without different indentation depths subjected to LVI and QSI. For LVI, the results indicates that the maximum load and residual strength decreased with an increase in the impact energy level and impact numbers. For specimens with the same depth, the residual strength of QSI was less than that of LVI. The residual strength of an SQSI was close to that of RQSI. The reason was that the specimen subjected to SQSI damaged more seriously than the one subjected to LVI when the depth of the specimens was the same. The greater the damage, the smaller the bearing capacity of the honeycomb plate during the residual strength experiment. As for the honeycomb plate penetrated once, the residual strength of LVI was slightly larger than that of an SQSI. The residual strength of the penetrated specimens subjected to LVI and SQSI was appropriately 27 and 25% of that of undamaged specimens, respectively. Considering the damage volumes given in Table 3, it can be found that the residual strength showed a slow downward trend with a decrease in the damage volume. That is to say, the residual strength decreased with the increment of damage volume, even when the damage depth was the same. Moreover, the residual strength could be similar to each other when the damage volume was close, even if the damage depth varied greatly. It can be concluded that it is more reasonable to describe the damage by volume than by depth.

Comparison of maximum load and residual strength

| Depth (mm) | Maximum load (kN) | Residual strength (MPa) | Normalized residual strength |

|---|---|---|---|

| Non-damaged | 8.05 | 50.31 | 1 |

| 4.5 (1st 5 J LVI) | 7.15 | 44.69 | 0.89 |

| 4.5 (SQSI) | 6.85 | 42.81 | 0.85 |

| 6.1 (2nd 5 J LVI) | 6.55 | 40.94 | 0.81 |

| 6.1 (SQSI) | 5.95 | 37.19 | 0.74 |

| 6.1 (RQSI) | 5.85 | 36.56 | 0.73 |

| 7.2 (1st 10 J LVI) | 6.05 | 37.81 | 0.75 |

| 7.2 (SQSI) | 5.45 | 34.06 | 0.68 |

| 7.8 (3rd 5 J LVI) | 5.90 | 36.88 | 0.73 |

| 7.8 (SQSI) | 4.95 | 30.94 | 0.61 |

| 7.8 (RQSI) | 5.00 | 31.25 | 0.62 |

| 12.2 (2nd 10 J LVI) | 4.30 | 26.88 | 0.53 |

| 12.2 (SQSI) | 3.00 | 18.75 | 0.37 |

| 12.2(RQSI) | 3.20 | 20.00 | 0.40 |

| Penetration (1st 20 J LVI) | 2.20 | 13.75 | 0.27 |

| Penetration (SQSI) | 2.05 | 12.81 | 0.25 |

5 Conclusion

In this study, the residual compression properties and responses of honeycomb sandwich structures subjected to S QSI and RQSIs were investigated based on 3D-DIC method. Detailed results and conclusions are as follows:

The damage to the honeycomb structure caused by SQSI was greater than that caused by LVI when the depth was the same.

It is more reasonable to describe the damage by volume than by depth. The residual strength decreased with the increase in damage volume, even when the damage depth was the same. The residual strength could be similar to each other when the damage volume was close, even if the damage depth varied greatly.

When the depth was the same, the volume caused by SQSI was the greatest, and that caused by LVI was the smallest. Moreover, the residual strength of QSI was close to that of RQSI and less than that of LVI for the specimens with the same damage depth.

Although the change trend was obtained and described in detail, the quantitative relationship between the damage volume and residual strength should also be given. Furthermore, measurement on the deformation of top face sheet, especially the region near the indentor, could be expected in the future.

-

Funding information: This work was supported by the National Natural Science Foundation of China (No. 11672167), the Youth Science and Technology Innovation Program in Higher Education of Shandong Province, China (2019KJB033), and the Natural Science Foundation of Shandong Province (Nos. ZR2020MA060 and ZR2020QA041).

-

Author contributions: H. Ye: Experimental investigation, Simulation. X. Dai: Investigation, Methodology, Supervision, Writing. T. Yuan: Data analysis. J. Zhou: Repeated quasi-static indentation experiment investigation. J. Zhang: Single quasi-static indentation experiment investigation. S. Shao: Simulation.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

[1] Gibson, L. J. and M. F. Ashby. Cellular solids: structure and properties, Cambridge University Press, Cambridge, 1997.10.1017/CBO9781139878326Search in Google Scholar

[2] Abrate, S. Impact on composite structures, Cambridge University Press, Cambridge, 1998.10.1017/CBO9780511574504Search in Google Scholar

[3] Dai, X., X. Shao, C. Ma, H. Yun, F. Yang, and D. Zhang. Experimental and numerical investigation on vibration of sandwich plates with honeycomb cores based on radial basis function. Experimental Techniques, Vol. 42, 2018, pp. 79–92.10.1007/s40799-017-0220-3Search in Google Scholar

[4] Ahmad, S. I., H. Hamoudi, A. Abdala, Z. K. Ghouri, and K. M. Youssef. Graphene-reinforced bulk metal matrix composites: synthesis, microstructure, and properties. Reviews on Advanced Materials Science, Vol. 59, No. 1, 2020, pp. 67–114.10.1515/rams-2020-0007Search in Google Scholar

[5] Ude, A. U., A. K. Ariffin, and C. H. Azhari. Impact damage characteristics in reinforced woven natural silk/epoxy composite face-sheet and sandwich foam, coremat and honeycomb materials. International Journal of Impact Engineering, Vol. 58, 2013, pp. 31–38.10.1016/j.ijimpeng.2013.03.003Search in Google Scholar

[6] Bhaskar, S., M. Kumar, and A. Patnaik. Mechanical and tribological overview of ceramic particulates reinforced aluminium alloy composites. Reviews on Advanced Materials Science, Vol. 58, No. 1, 2019, pp. 280–294.10.1515/rams-2019-0033Search in Google Scholar

[7] Ivañez, I., E. Barbero, and S. Sanchez-Saez. Analytical study of the low-velocity impact response of composite sandwich beams. Composite Structures, Vol. 111, 2014, pp. 459–467.10.1016/j.compstruct.2014.01.028Search in Google Scholar

[8] Alhijazi, M., Q. Zeeshan, Z. Qin, B. Safaei, and M. Asmael. Finite element analysis of natural fibers composites: a review. Nanotechnology Reviews, Vol. 9, No. 1, 2020, pp. 853–875.10.1515/ntrev-2020-0069Search in Google Scholar

[9] Susainathan, J., F. Eyma, E. D. Luycker, A. Cantarel, C. Bouvet, and B. Castanie. Experimental investigation of compression and compression after impact of woodbased sandwich structures. Composite Structures, Vol. 220, 2019, pp. 236–249.10.1016/j.compstruct.2019.03.095Search in Google Scholar

[10] Wang, J., A. M. Waas, and H. Wang. Experimental and numerical study on the low-velocity impact behavior of foam-core sandwich panels. Composite Structures, Vol. 96, 2013, pp. 298–311.10.1016/j.compstruct.2012.09.002Search in Google Scholar

[11] Hassan, M. Z. and W. J. Cantwell. The influence of core properties on the perforation resistance of sandwich structures – an experimental study. Composites Part B: Engineering, Vol. 43, No. 8, 2012, pp. 3231–3238.10.1016/j.compositesb.2012.03.012Search in Google Scholar

[12] Kumar, C. S., V. Arumugam, H. N. Dhakal, and R. John. Effect of temperature and hybridisation on the low velocity impact behavior of hemp-basalt/epoxy composites. Composite Structures, Vol. 125, 2015, pp. 407–416.10.1016/j.compstruct.2015.01.037Search in Google Scholar

[13] Chen, Y., S. Hou, K. Fu, X. Han, and L. Ye. Low-velocity impact response of composite sandwich structures: modelling and experiment. Composite Structures, Vol. 168, 2017, pp. 322–34.10.1016/j.compstruct.2017.02.064Search in Google Scholar

[14] Zhang, X., F. Xu, Y. Zang, and W. Feng. Experimental and numerical investigation on damage behavior of honeycomb sandwich panel subjected to low-velocity impact. Composite Structures, Vol. 236, 2020, id. 111882.10.1016/j.compstruct.2020.111882Search in Google Scholar

[15] Sun, G., X. Huo, D. Chen, and Q. Li. Experimental and numerical study on honeycomb sandwich panels under bending and in-panel compression. Materials and Design, Vol. 133, 2017, pp. 154–168.10.1016/j.matdes.2017.07.057Search in Google Scholar

[16] Foo, C. C., G. B. Chai, and L. K. Seah. A model to predict low-velocity impact response and damage in sandwich composites. Composites Science and Technology, Vol. 68, 2008, pp. 1348–1356.10.1016/j.compscitech.2007.12.007Search in Google Scholar

[17] Akatay, A., M. Ö. Bora, O. Çoban, S. Fidan, and V. Tuna. The influence of low velocity repeated impacts on residual compressive properties of honeycomb sandwich structures. Composite Structures, Vol. 125, 2015, pp. 425–433.10.1016/j.compstruct.2015.02.057Search in Google Scholar

[18] Lin, N., R. Xie, J. Zou, J. Qin, and B. Tang. Surface damage mitigation of titanium and its alloys via thermal oxidation: a brief review. Reviews on Advanced Materials Science, Vol. 58, No. 1, 2019, pp. 132–146.10.1515/rams-2019-0012Search in Google Scholar

[19] Balci, O., O. Çoban, M. Ö. Bora, E. Akagündüz, and E. B. Yalçin. Experimental investigation of single and repeated impacts for repaired honeycomb sandwich structures. Materials Science & Engineering, A: Structural Materials: Properties, Microstructure and Processing, Vol. 682, 2017, pp. 23–30.10.1016/j.msea.2016.11.030Search in Google Scholar

[20] Moriniere, F. D., R. C. Alderliesten, M. Yarmohammad Tooski, and R. Benedictus. Damage evolution in Glare fiber-metal laminate under repeated low velocity impact tests. Central European Journal of Engineering, Vol. 2, No. 4, 2012, pp. 603–611.10.2478/s13531-012-0019-zSearch in Google Scholar

[21] Dai, X., T. Yuan, Z. Zu, H. Ye, X. Cheng, and F. Yang. Experimental investigation on the response and residual compressive property of honeycomb sandwich structures under single and repeated low velocity impacts. Materials Today Communications, Vol. 25, 2020, id. 101309.10.1016/j.mtcomm.2020.101309Search in Google Scholar

[22] Guo, K., L. Zhu, Y. Li, T. Yu, A. Shenoi, and Q. Zhou. Experimental investigation on the dynamic behaviour of aluminum foam sandwich plate under repeated impacts. Composite Structures, Vol. 200, 2018, pp. 298–305.10.1016/j.compstruct.2018.05.148Search in Google Scholar

[23] Zhu, S. and G. B. Chai. Damage and failure mode maps of composite sandwich panel subjected to quasi-static indentation and low velocity impact. Composite Structures, Vol. 101, 2013, pp. 204–214.10.1016/j.compstruct.2013.02.010Search in Google Scholar

[24] Mahmoudabadi, M. Z. and M. Sadighi. Experimental investigation on the energy absorption characteristics of honeycomb sandwich panels under quasi-static punch loading. Aerospace Science and Technology, Vol. 88, 2019, pp. 273–286.10.1016/j.ast.2019.02.035Search in Google Scholar

[25] Huang, X., J. Yang, I. Azim, X. Ren, and X. Wang. Static and dynamic analyses of auxetic hybrid FRC/CNTRC laminated plates. Nanotechnology Reviews, Vol. 9, No. 1, 2020, pp. 1625–1642.10.1515/ntrev-2020-0106Search in Google Scholar

[26] Nettles, A. T. and M. J. Douglas. A comparison of quasi-static testing to low velocity impact testing. Composites materials: testing, design, and acceptance criteria, ASTM STP 1416, A. Zureick, A. T. Nettles, editors., American Society for Testing and Materials International, West Conshohocken, PA, 2002, pp. 116–130.10.1520/STP10634SSearch in Google Scholar

[27] Weirdie, B. L. and P. A. Lagace. On the use of quasi-static testing to assess impact damage resistance of composite shell structures. Mechanics of Composite Materials and Structures, Vol. 5, 1998, pp. 103–121.10.1080/10759419808945895Search in Google Scholar

[28] Wen, H. M., T. Y. Reddy, S. R. Reid, and P. D. Soden. Indentation, penetration and perforation of composite laminate and sandwich panels under quasi-static and projectile loading. Key Engineering Materials, Vol. 141–143, 1998, pp. 501–552.10.4028/www.scientific.net/KEM.141-143.501Search in Google Scholar

[29] Zhou, G., M. Hill, J. Loughlan, and N. Hookham. Damage characteristics of composite honeycomb sandwich panels in bending under quasi-static loading. Journal of Sandwich Structures and Materials, Vol. 8, No. 1, 2006, pp. 55–90.10.1177/1099636206056888Search in Google Scholar

[30] Seah, L. K., G. B. Chai, and C. C. Foo. Quasi-static and low-velocity impact failure of aluminium honeycomb sandwich panels, Proceedings of the institution of mechanical engineers. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, Vol. 220, No. 2, 2006, pp. 53–66.10.1243/14644207JMDA98Search in Google Scholar

[31] Dai, X., H. Ye, T. Yuan, X. Shao, Z. Zu, X. Cheng, et al. Strain determination based on strain gauge-guided radial basis function and digital image correlation. Optics and Lasers in Engineering, Vol. 126, 2020, id. 105894.10.1016/j.optlaseng.2019.105894Search in Google Scholar

[32] Gunes, R. and K. Arslan. Development of numerical realistic model for predicting low velocity impact response of aluminium honeycomb sandwich structures. Journal of Sandwich Structures and Materials, Vol. 18, No. 1, 2015, pp. 95–112.10.1177/1099636215603047Search in Google Scholar

[33] Ma, J., G. Chen, L. Ji, L. Qian, and S. Dong. A general methodology to establish the contact force model for complex contacting surfaces. Mechanical Systems and Signal Processing, Vol. 140, 2020, id. 106678.10.1016/j.ymssp.2020.106678Search in Google Scholar

[34] Chai, G. B. and S. Zhu. A review of low-velocity impact on sandwich structures. Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, Vol. 225, No. 4, 2011, pp. 207–230.10.1177/1464420711409985Search in Google Scholar

[35] Shao, X., X. Dai, Z. Chen, and X. He. Real-time 3D digital image correlation method and its application in human pulse monitoring. Applied Optics, Vol. 55, No. 4, 2016, id. 696.10.1364/AO.55.000696Search in Google Scholar PubMed

[36] Zhang, X., Y. Wang, N. Guo, Y. Wang, R. Li, C. Zhang, et al. Effect of ferrite/pearlite banded structure on the local deformation and crack initiation at notches in pipeline steel. Engineering Fracture Mechanics, Vol. 237, 2020, id. 107244.10.1016/j.engfracmech.2020.107244Search in Google Scholar

[37] Yuan, T., X. Dai, X. Shao, Z. Zu, X. Cheng, F. Yang, et al. Dual-biprism-based digital image correlation for defect detection of pipelines. Optical Engineering, Vol. 58, No. 1, 2019, id. 014107.10.1117/1.OE.58.1.014107Search in Google Scholar

[38] Ozdemir, O., N. Oztoprak, and H. Kandas. Single and repeated impact behaviors of bio-sandwich structures consisting of thermoplastic face sheets and different balsa core thicknesses. Composites Part B: Engineering, Vol. 149, 2018, pp. 49–57.10.1016/j.compositesb.2018.05.016Search in Google Scholar

[39] ASTM D 7136. Test method for measuring the damage resistance of a fiber-reinforced polymer matrix composite to a drop-weight impact event, ASTM International, W. Conshohocken, PA, 2005.Search in Google Scholar

[40] Gilioli, A., C. Sbarufatti, A. Manes, and M. Giglio. Compression after impact test (CAI) on NOMEX™ honeycomb sandwich panels with thin aluminum skins. Composites Part B: Engineering, Vol. 67, 2014, pp. 313–325.10.1016/j.compositesb.2014.07.015Search in Google Scholar

[41] ASTM D 7137. Test method for compressive residual strength properties of damaged polymer matrix composite plates, ASTM International, W. Conshohocken, PA, 2005.Search in Google Scholar

[42] Sevkat, E., B. Liaw, F. Delale, and B. B. Raju. Effect of repeated impacts on the response of plain-woven hybrid composites. Composites Part B: Engineering, Vol. 41, No. 5, 2010, pp. 403–413.10.1016/j.compositesb.2010.01.001Search in Google Scholar

[43] Ruan, D., G. Lu, and Y. C. Wong. Quasi-static indentation tests on aluminium foam sandwich panels. Composite Structures, Vol. 92, No. 9, 2010, pp. 2039–2046.10.1016/j.compstruct.2009.11.014Search in Google Scholar

[44] Susainathan, J., F. Eyma, E. D. Luycker, A. Cantarel, C. Bouvet, and B. Castanie. Experimental investigation of compression and compression after impact of wood-based sandwich structures. Composite Structures, Vol. 220, 2019, pp. 236–249.10.1016/j.compstruct.2019.03.095Search in Google Scholar

© 2021 Hangyu Ye et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- A review on filler materials for brazing of carbon-carbon composites

- Nanotechnology-based materials as emerging trends for dental applications

- A review on allotropes of carbon and natural filler-reinforced thermomechanical properties of upgraded epoxy hybrid composite

- High-temperature tribological properties of diamond-like carbon films: A review

- A review of current physical techniques for dispersion of cellulose nanomaterials in polymer matrices

- Review on structural damage rehabilitation and performance assessment of asphalt pavements

- Recent development in graphene-reinforced aluminium matrix composite: A review

- Mechanical behaviour of precast prestressed reinforced concrete beam–column joints in elevated station platforms subjected to vertical cyclic loading

- Effect of polythiophene thickness on hybrid sensor sensitivity

- Investigation on the relationship between CT numbers and marble failure under different confining pressures

- Finite element analysis on the bond behavior of steel bar in salt–frost-damaged recycled coarse aggregate concrete

- From passive to active sorting in microfluidics: A review

- Research Articles

- Revealing grain coarsening and detwinning in bimodal Cu under tension

- Mesoporous silica nanoparticles functionalized with folic acid for targeted release Cis-Pt to glioblastoma cells

- Magnetic behavior of Fe-doped of multicomponent bismuth niobate pyrochlore

- Study of surfaces, produced with the use of granite and titanium, for applications with solar thermal collectors

- Magnetic moment centers in titanium dioxide photocatalysts loaded on reduced graphene oxide flakes

- Mechanical model and contact properties of double row slewing ball bearing for wind turbine

- Sandwich panel with in-plane honeycombs in different Poisson's ratio under low to medium impact loads

- Effects of load types and critical molar ratios on strength properties and geopolymerization mechanism

- Nanoparticles in enhancing microwave imaging and microwave Hyperthermia effect for liver cancer treatment

- FEM micromechanical modeling of nanocomposites with carbon nanotubes

- Effect of fiber breakage position on the mechanical performance of unidirectional carbon fiber/epoxy composites

- Removal of cadmium and lead from aqueous solutions using iron phosphate-modified pollen microspheres as adsorbents

- Load identification and fatigue evaluation via wind-induced attitude decoupling of railway catenary

- Residual compression property and response of honeycomb sandwich structures subjected to single and repeated quasi-static indentation

- Experimental and modeling investigations of the behaviors of syntactic foam sandwich panels with lattice webs under crushing loads

- Effect of storage time and temperature on dissolved state of cellulose in TBAH-based solvents and mechanical property of regenerated films

- Thermal analysis of postcured aramid fiber/epoxy composites

- The energy absorption behavior of novel composite sandwich structures reinforced with trapezoidal latticed webs

- Experimental study on square hollow stainless steel tube trusses with three joint types and different brace widths under vertical loads

- Thermally stimulated artificial muscles: Bio-inspired approach to reduce thermal deformation of ball screws based on inner-embedded CFRP

- Abnormal structure and properties of copper–silver bar billet by cold casting

- Dynamic characteristics of tailings dam with geotextile tubes under seismic load

- Study on impact resistance of composite rocket launcher

- Effects of TVSR process on the dimensional stability and residual stress of 7075 aluminum alloy parts

- Dynamics of a rotating hollow FGM beam in the temperature field

- Development and characterization of bioglass incorporated plasma electrolytic oxidation layer on titanium substrate for biomedical application

- Effect of laser-assisted ultrasonic vibration dressing parameters of a cubic boron nitride grinding wheel on grinding force, surface quality, and particle morphology

- Vibration characteristics analysis of composite floating rafts for marine structure based on modal superposition theory

- Trajectory planning of the nursing robot based on the center of gravity for aluminum alloy structure

- Effect of scan speed on grain and microstructural morphology for laser additive manufacturing of 304 stainless steel

- Influence of coupling effects on analytical solutions of functionally graded (FG) spherical shells of revolution

- Improving the precision of micro-EDM for blind holes in titanium alloy by fixed reference axial compensation

- Electrolytic production and characterization of nickel–rhenium alloy coatings

- DC magnetization of titania supported on reduced graphene oxide flakes

- Analytical bond behavior of cold drawn SMA crimped fibers considering embedded length and fiber wave depth

- Structural and hydrogen storage characterization of nanocrystalline magnesium synthesized by ECAP and catalyzed by different nanotube additives

- Mechanical property of octahedron Ti6Al4V fabricated by selective laser melting

- Physical analysis of TiO2 and bentonite nanocomposite as adsorbent materials

- The optimization of friction disc gear-shaping process aiming at residual stress and machining deformation

- Optimization of EI961 steel spheroidization process for subsequent use in additive manufacturing: Effect of plasma treatment on the properties of EI961 powder

- Effect of ultrasonic field on the microstructure and mechanical properties of sand-casting AlSi7Mg0.3 alloy

- Influence of different material parameters on nonlinear vibration of the cylindrical skeleton supported prestressed fabric composite membrane

- Investigations of polyamide nano-composites containing bentonite and organo-modified clays: Mechanical, thermal, structural and processing performances

- Conductive thermoplastic vulcanizates based on carbon black-filled bromo-isobutylene-isoprene rubber (BIIR)/polypropylene (PP)

- Effect of bonding time on the microstructure and mechanical properties of graphite/Cu-bonded joints

- Study on underwater vibro-acoustic characteristics of carbon/glass hybrid composite laminates

- A numerical study on the low-velocity impact behavior of the Twaron® fabric subjected to oblique impact

- Erratum

- Erratum to “Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete”

- Topical Issue on Advances in Infrastructure or Construction Materials – Recycled Materials, Wood, and Concrete

- Structural performance of textile reinforced concrete sandwich panels under axial and transverse load

- An overview of bond behavior of recycled coarse aggregate concrete with steel bar

- Development of an innovative composite sandwich matting with GFRP facesheets and wood core

- Relationship between percolation mechanism and pore characteristics of recycled permeable bricks based on X-ray computed tomography

- Feasibility study of cement-stabilized materials using 100% mixed recycled aggregates from perspectives of mechanical properties and microstructure

- Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete

- Research on nano-concrete-filled steel tubular columns with end plates after lateral impact

- Dynamic analysis of multilayer-reinforced concrete frame structures based on NewMark-β method

- Experimental study on mechanical properties and microstructures of steel fiber-reinforced fly ash-metakaolin geopolymer-recycled concrete

- Fractal characteristic of recycled aggregate and its influence on physical property of recycled aggregate concrete

- Properties of wood-based composites manufactured from densified beech wood in viscoelastic and plastic region of the force-deflection diagram (FDD)

- Durability of geopolymers and geopolymer concretes: A review

- Research progress on mechanical properties of geopolymer recycled aggregate concrete

Articles in the same Issue

- Review Articles

- A review on filler materials for brazing of carbon-carbon composites

- Nanotechnology-based materials as emerging trends for dental applications

- A review on allotropes of carbon and natural filler-reinforced thermomechanical properties of upgraded epoxy hybrid composite

- High-temperature tribological properties of diamond-like carbon films: A review

- A review of current physical techniques for dispersion of cellulose nanomaterials in polymer matrices

- Review on structural damage rehabilitation and performance assessment of asphalt pavements

- Recent development in graphene-reinforced aluminium matrix composite: A review

- Mechanical behaviour of precast prestressed reinforced concrete beam–column joints in elevated station platforms subjected to vertical cyclic loading

- Effect of polythiophene thickness on hybrid sensor sensitivity

- Investigation on the relationship between CT numbers and marble failure under different confining pressures

- Finite element analysis on the bond behavior of steel bar in salt–frost-damaged recycled coarse aggregate concrete

- From passive to active sorting in microfluidics: A review

- Research Articles

- Revealing grain coarsening and detwinning in bimodal Cu under tension

- Mesoporous silica nanoparticles functionalized with folic acid for targeted release Cis-Pt to glioblastoma cells

- Magnetic behavior of Fe-doped of multicomponent bismuth niobate pyrochlore

- Study of surfaces, produced with the use of granite and titanium, for applications with solar thermal collectors

- Magnetic moment centers in titanium dioxide photocatalysts loaded on reduced graphene oxide flakes

- Mechanical model and contact properties of double row slewing ball bearing for wind turbine

- Sandwich panel with in-plane honeycombs in different Poisson's ratio under low to medium impact loads

- Effects of load types and critical molar ratios on strength properties and geopolymerization mechanism

- Nanoparticles in enhancing microwave imaging and microwave Hyperthermia effect for liver cancer treatment

- FEM micromechanical modeling of nanocomposites with carbon nanotubes

- Effect of fiber breakage position on the mechanical performance of unidirectional carbon fiber/epoxy composites

- Removal of cadmium and lead from aqueous solutions using iron phosphate-modified pollen microspheres as adsorbents

- Load identification and fatigue evaluation via wind-induced attitude decoupling of railway catenary

- Residual compression property and response of honeycomb sandwich structures subjected to single and repeated quasi-static indentation

- Experimental and modeling investigations of the behaviors of syntactic foam sandwich panels with lattice webs under crushing loads

- Effect of storage time and temperature on dissolved state of cellulose in TBAH-based solvents and mechanical property of regenerated films

- Thermal analysis of postcured aramid fiber/epoxy composites

- The energy absorption behavior of novel composite sandwich structures reinforced with trapezoidal latticed webs

- Experimental study on square hollow stainless steel tube trusses with three joint types and different brace widths under vertical loads

- Thermally stimulated artificial muscles: Bio-inspired approach to reduce thermal deformation of ball screws based on inner-embedded CFRP

- Abnormal structure and properties of copper–silver bar billet by cold casting

- Dynamic characteristics of tailings dam with geotextile tubes under seismic load

- Study on impact resistance of composite rocket launcher

- Effects of TVSR process on the dimensional stability and residual stress of 7075 aluminum alloy parts

- Dynamics of a rotating hollow FGM beam in the temperature field

- Development and characterization of bioglass incorporated plasma electrolytic oxidation layer on titanium substrate for biomedical application

- Effect of laser-assisted ultrasonic vibration dressing parameters of a cubic boron nitride grinding wheel on grinding force, surface quality, and particle morphology

- Vibration characteristics analysis of composite floating rafts for marine structure based on modal superposition theory

- Trajectory planning of the nursing robot based on the center of gravity for aluminum alloy structure

- Effect of scan speed on grain and microstructural morphology for laser additive manufacturing of 304 stainless steel

- Influence of coupling effects on analytical solutions of functionally graded (FG) spherical shells of revolution

- Improving the precision of micro-EDM for blind holes in titanium alloy by fixed reference axial compensation

- Electrolytic production and characterization of nickel–rhenium alloy coatings

- DC magnetization of titania supported on reduced graphene oxide flakes

- Analytical bond behavior of cold drawn SMA crimped fibers considering embedded length and fiber wave depth

- Structural and hydrogen storage characterization of nanocrystalline magnesium synthesized by ECAP and catalyzed by different nanotube additives

- Mechanical property of octahedron Ti6Al4V fabricated by selective laser melting

- Physical analysis of TiO2 and bentonite nanocomposite as adsorbent materials

- The optimization of friction disc gear-shaping process aiming at residual stress and machining deformation

- Optimization of EI961 steel spheroidization process for subsequent use in additive manufacturing: Effect of plasma treatment on the properties of EI961 powder

- Effect of ultrasonic field on the microstructure and mechanical properties of sand-casting AlSi7Mg0.3 alloy

- Influence of different material parameters on nonlinear vibration of the cylindrical skeleton supported prestressed fabric composite membrane

- Investigations of polyamide nano-composites containing bentonite and organo-modified clays: Mechanical, thermal, structural and processing performances

- Conductive thermoplastic vulcanizates based on carbon black-filled bromo-isobutylene-isoprene rubber (BIIR)/polypropylene (PP)

- Effect of bonding time on the microstructure and mechanical properties of graphite/Cu-bonded joints

- Study on underwater vibro-acoustic characteristics of carbon/glass hybrid composite laminates

- A numerical study on the low-velocity impact behavior of the Twaron® fabric subjected to oblique impact

- Erratum

- Erratum to “Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete”

- Topical Issue on Advances in Infrastructure or Construction Materials – Recycled Materials, Wood, and Concrete

- Structural performance of textile reinforced concrete sandwich panels under axial and transverse load

- An overview of bond behavior of recycled coarse aggregate concrete with steel bar

- Development of an innovative composite sandwich matting with GFRP facesheets and wood core

- Relationship between percolation mechanism and pore characteristics of recycled permeable bricks based on X-ray computed tomography

- Feasibility study of cement-stabilized materials using 100% mixed recycled aggregates from perspectives of mechanical properties and microstructure

- Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete

- Research on nano-concrete-filled steel tubular columns with end plates after lateral impact

- Dynamic analysis of multilayer-reinforced concrete frame structures based on NewMark-β method

- Experimental study on mechanical properties and microstructures of steel fiber-reinforced fly ash-metakaolin geopolymer-recycled concrete

- Fractal characteristic of recycled aggregate and its influence on physical property of recycled aggregate concrete

- Properties of wood-based composites manufactured from densified beech wood in viscoelastic and plastic region of the force-deflection diagram (FDD)

- Durability of geopolymers and geopolymer concretes: A review

- Research progress on mechanical properties of geopolymer recycled aggregate concrete