Abstract

For use in additive manufacturing (AM), powders that have a spherical shape, high fluidity, and packing density are required. One of the methods for producing spherical powders is spheroidization using inductively coupled plasma. In this work, the powder of steel grade EI961 was used. To obtain the powder for subsequent use in 3D printing, the selection of modes was carried out with the change in various parameters of the unit: different power, powder feed rate to the plasma as well as the height of feed rate. The optimal spheroidization mode is as follows: power of 15 kW, pressure of 1 atm, feed rate height of 0 mm, and powder feed rate of 28 g·min−1. The temperature distribution over the plasma torch cross section was calculated and the maximum plasma temperature was also determined. In addition, the effect of plasma treatment on the granulometric composition, phase composition, and chemical composition was studied.

1 Introduction

Additive manufacturing (AM) is based on the additive principle of manufacturing parts i.e., on the creation of physical spatial products by sequentially adding material. The main technologies that use metal powder as a raw material are powder bed fusion and directed energy deposition. For the production of high-quality products, certain requirements for powders are required. To produce a high-density part, the powders must have high sphericity, fluidity, and the absence of nanoparticles [1]. There are also certain requirements for the size of the powder particles which are in the range of 15–60 µm.

There are several methods for producing spherical powders for additive technologies: gas atomization, plasma atomization with a rotating electrode, and plasma spheroidization [2]. In a plasma process with a rotating electrode, resulting powders have a spherical shape and high flowability, but have a significant drawback i.e., the size range is 100–300 microns and 50% of the powder has a size of about 175 microns [3]. In the process of gas atomization, resulting powders have a near-spherical shape but have many satellite particles. It is mainly used to produce a large amount of powder with a small particle diameter (∼40 microns). After the plasma atomization process, spherical powders are obtained without satellite particles. Powders have a narrow particle size distribution with an average value of 40 μm [4]. It is used to obtain a large amount of powder. In the process of plasma spheroidization, spherical powders are obtained with a size distribution like that of initial powder. It can be used both in a laboratory and industrial conditions [5,6,7,8,9].

Plasma spheroidization is remelting process of initial powder composition in the flow of highly ionized gas heated to high temperatures (3,500–12,000 K). Falling into the plasma flow, the powder particles when moving in a high-temperature gas flow are heated to the melting point and are cooled in free fall under the action of surface tension forces and turn into spherical particles (Figure 1). Plasma spheroidization allows improving the following characteristics of powders: fluidity, reduction in porosity, increase in bulk density, reduction in toughness, and improving the purity of the powder. In this case, the effect of plasma can lead to overheating and evaporation of powder particles, followed by condensation in the form of submicron particles on the surface, which degrades the properties of the powder. To remove these particles, the sedimentation method is used as well as processing in a centrifugal classifier. By controlling parameters, such as the feed rate, the power of the plasma, and the point at which the powder enters the plasma, it is possible to determine the optimal mode for obtaining spherical particles of compounds of a given composition.

Schematic representation of the TEKNA Tek-15 system and spheroidization process.

Chromium-nickel steels of the ferritic/martensitic class are used in power engineering for the production of parts of gas turbines that operate for a long time at temperatures up to 600°C. Steels with a chromium content of about 9–12% are the structural material of nuclear and thermonuclear reactors. It is also known that one of the main elements of stationary gas turbine installations are low-pressure compressor blades made of EI961 steel (steel EUVROFER-97 and 9Cr-2WVTa grades are similar in chemical composition) which is a typical representative of ferritic/martensitic class steels. Because the blade complex determines the service life of gas turbine installations, improving the properties of ferritic/martensitic class steels is important and relevant for increasing the service life of such installations, as well as meeting the needs of modern mechanical engineering. Reduced activation ferritic/martensitic steels have been recognized as the primary candidate for structural materials for Test Blanket Module of fusion reactors because of their good mechanical and thermophysical properties as well as mature industrial bases [10,11]. Some articles describe the manufacture of components for breeding-blanket and the first wall (typical applications of nuclear fusion) using the technology of selective laser melting from steels of this class [12,13,14,15]

The purpose of this work is to select the modes and optimize the process of spheroidization of the EI961 powder, as well as to study the influence of various parameters on the properties of the powder. The novelty consists in obtaining a suitable powder of the EI961 brand by the method of plasma spheroidization for additive technologies from metalworking waste, as well as obtaining results on the effect of plasma treatment on the properties of the powder.

2 Materials and methods

The simulation was carried out in the framework of the FLUENT©. The problem was solved in a 2D axisymmetric setting. The computational region includes the plasma jet area and the region of existence of the electromagnetic field around the induction coupled plasma torch.

The heat power N G during plasma exposure to the powder is spent on heating the solid particle, melting, heating the liquid particle, evaporation, and vapor ionization. Based on the ongoing processes, the following equation was presented for calculating the thermal power of the installation:

where G p – the weight flow of powder, T m – the melting point of the material, c pm – specific heat of the material in the solid-state, Q m – specific heat of fusion, c pl – the specific heat of the material in the liquid condition, T b – boiling point of the material, Q v – specific heat vaporization of the material, c pv – specific material in the vapor condition, T v – temperature ionization of the material, J – the degree of ionization, and Q + – specific heat of education singly ionized vapor [16].

The results of heat power calculations for various spheroidization modes are presented in Table 1.

Plasma spheroidization parameters

| Mode no. | Power (kW) | Feed rate height (mm) | Feed rate (g·min−1) | Heat power N G (kW) |

|---|---|---|---|---|

| 1 | 15 | 0 | 28 | 2.25 |

| 2 | 14 | 0 | 28 | 2.1 |

| 3 | 13 | 0 | 28 | 1.95 |

| 4 | 12 | 0 | 28 | 1.8 |

| 5 | 11 | 0 | 28 | 1.65 |

| 6 | 10 | 0 | 28 | 1.5 |

| 7 | 15 | +10 | 28 | 2.25 |

| 8 | 15 | −10 | 28 | 2.25 |

| 9 | 15 | 0 | 33 | 2.25 |

| 10 | 15 | 0 | 37 | 2.25 |

| 11 | 15 | 0 | 22 | 2.25 |

| 12 | 15 | 0 | 25 | 2.25 |

Experimental studies on induction plasma spheroidization of powders were carried out on the Tek-15 unit manufactured by Tekna Plasma Systems Inc. (Canada). TekSphero 15 plasma spheroidization unit is equipped with a high-frequency generator with a maximum power of 15 kW. Operating frequency is in the range from 2 to 4 MHz. The induction plasma powder spheroidization process, as shown schematically in Figure 1, consists basically of the inflight heating and melting of individual particles of the powder feed material. The latter could be constituted from sintered or crushed solids. The thus-formed molten spherical droplets are gradually cooled under “free fall” projection conditions. Depending on the particle size and apparent density of the treated powder, the time of flight is controlled such that the molten droplets have sufficient time for complete solidification before reaching the base of the primary reactor chamber. Finer particles, still entrained in the plasma gases, are recovered downstream of the primary reactor chamber by means of a cyclone and filter collector arrangements.

The initial powder of steel EI961 (high-alloy heat-resistant steel) was obtained by grinding the chips remaining after processing the workpieces in an industrial ball mill (Figure 2). Powder EI961 was shaken for fraction 45–63 µm by using the shaking machine Fritsch Analysette 3. For each experiment using 170 g EI961 powder, the power of the unit was 10–15 kW, the pressure was 1 atm, the feed rate was 20–40 g·min−1, and the feed rate height was −10, 0, and +10 mm. The various modes with variable parameters are presented in Table 1.

Morphology of initial EI961 powder.

The morphology of the powder was studied using a scanning electron microscope (SEM, Tescan Mira 3) with a fluorescent radiation detector (Bruker X-Flash 6/10). The cross-sectional image of the powder was used to study the chemical composition. The carbon content was determined by the absorption method using the CS-230 analyzer from LECO (USA, ISO 9556-1989). Determination of the oxygen and nitrogen content was carried out by the method of reducing melting in the flow of an inert carrier gas (helium) using a TC-500 analyzer from LECO (USA, ISO 17053-2005 and ISO 15351-1999). Using a laser diffractometer (Fritsch Analysette 22), the granulometric composition of the obtained powder was investigated (ISO 8130-13). X-ray diffractometer Bruker D8 Advance was used for x-ray analysis using Cu Kα (1.5406 Å) radiation in the 2θ.

The particle projection dimensions were measured using a Leica DIM 5000 light optical microscope. Image processing and calculation of the ratio of the maximum linear size to the minimum was carried out in the image editor “IMAGE J.” At least 100 particles of each sample were analyzed to determine the percentage of sphericity. Sphericity was defined as the ratio of the larger side to the smaller one. The particles are spherical with a size ratio from 1 to 1.2, from 1.2 to 2 for rounded, from 2 to 5 for angular, and more than 5 for irregular.

The fluidity of the powder was measured using a Hall funnel according to the ISO 4490-2018 standard.

3 Results and discussion

As can be seen from Figure 3, when working on a mixture of hydrogen–argon gases (1:10), the maximum plasma temperature reaches 10,764 K in the center of the torch where the powder injector is located. The ratio H2:Ar is optimal for this type of plasma. Further, increasing the percentage of hydrogen content (over 10%) will lead to a change in the plasma properties i.e., the electrical conductivity will increase slightly (because ionization energies of argon atom and hydrogen atom are close to each other, 15.76 eV for argon and 13.6 eV for hydrogen), but the enthalpy of such mixture will increase significantly (due to high value of the dissociation energy of hydrogen molecules) [17,18].

Calculated plasma temperature field and plasma temperature distribution in the output section of a 15 kW plasma torch and a hydrogen–argon mixture (1:10).

Based on the calculated and experimental data, the energy transfer efficiency according to equation (1) was estimated at 60%, which means that only 9 kW of plasma torch power is supplied to the discharge. The thermal power transmitted to the powder during the flight through the plasma torch reaches 25% of the effective transmitted power of 2.25 kW. The remaining part is spent on heating the reactor chamber which can be estimated by changing the temperature of the coolant or is dispersed.

The first part of the experiment is devoted to determining the optimal power of the unit accordingly with different heat energies with the same powder feed rate to the reactor (mode 1–6). According to the calculated data, with a decrease in the power of the installation, the specific heat capacity decreases. After the experiments, the powder was investigated using an SEM. The morphology of the powder is shown in Figure 4.

Morphology of the powder in the modes 1–6: (a) 15 kW, (b) 14 kW, (c) 13 kW, (d) 12 kW, (e) 11 kW, and (f) 10 kW; feed rate of 28 g·min−1.

Based on the obtained images it can be concluded that with a decrease in the power of the unit and accordingly the supplied specific heat energy, the percentage of sphericity of the powder decreases (Figure 4a–f). This is because the applied power is not enough to melt the largest particles in the powder. In addition, with a decrease in power, the number of nanoparticles on the surface of the powder decreases, which appears as a result of evaporation and rapid desublimation. The percentage of nanoparticles in the studied powders was measured by a laser diffractometer.

Figure 5 shows the results of calculating the shape factor after plasma spheroidization. The highest value of sphericity is achieved at a power of 15 kW and with a decrease in power, the yield of the usable fraction increases slightly. The optimal power of the unit for obtaining the maximum number of spherical particles is 15 kW.

The dependence of the sphericity and the percentage yield of the powder on the power (left) and feed rate (right).

The second part of the experiment is to determine the optimal feed rate of the powder into the plasma. After a series of experiments (mode 1, 9–12), the sphericity, the percentage of yield of powder as well as the content of nanoparticles were analyzed. Changing the feed rate of powder into the plasma revealed the following: an increase in feed rate higher than 28 g·min−1 leads to a reduction in sphericity of the powder and the reduction in speed leads to an increase in the number of nanoparticles on the surface of the powder, as well as lowers the yield of the powder (Figure 5 right). The optimal feed rate of the powder for obtaining the maximum number of spherical particles is 28 g·min−1.

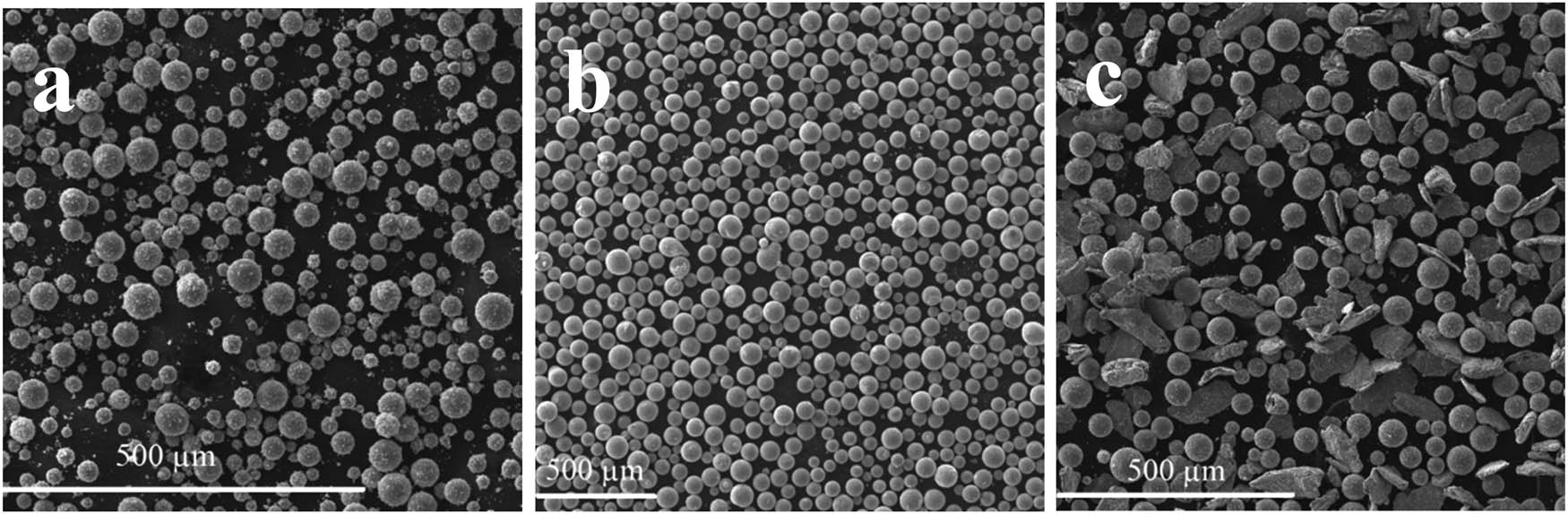

The third part of the experiment (mode 1, 7, and 8) was devoted to studying the influence of the powder feed rate height in the plasma jet. Changing the entry point allows you to increase (decrease) the time of flight of the powder. In this experiment, 3 feed rate heights were examined, 0, −10, and +10 mm with the same heat energy. To select the optimal insertion point, the obtained powder was examined using the SEM. To select the optimal feed rate height, the resulting powder was examined using the SEM (Figure 6) and the percentage of powder yield was estimated (Figure 7).

Morphology of the powder in the modes 1, 7, and 8; feed rate height of 0 (a), +10 (b), and −10(c).

The dependence of the sphericity and the percentage yield of the powder from the feed rate height.

According to the obtained images, the following conclusions can be drawn: when the time spent in the plasma increases, the powder turns out to be spherical but smaller than at the zero point and with a large number of submicron particles on its surface; when the time spent in the plasma decreases, not all particles have time to heat up to the melting point and hence do not take a spherical shape.

After a series of experiments, the optimal mode of plasma spheroidization of the EI961 powder was selected. According to the evaluation of microphotographs obtained from the SEM, the maximum sphericity is achieved in the following mode: the power of the unit is 15 kW, zero feed rate height, and powder feed rate is 28 g·min−1. But for the subsequent use of this powder, it is necessary to remove the submicron particles from its surface. The presence of submicron particles in the powder negatively affects the technological characteristics of the powder such as fluidity and bulk density. For this purpose, a sedimentation method is used based on different deposition rates of particles of different sizes in a liquid medium after ultrasonic exposure. Figure 8 shows the microphotographs obtained from SEM after the sedimentation process.

Microphotographs obtained from SEM after sedimentation process.

Figure 9 shows the results of comparing the granulometric composition of the initial powder, the powder after plasma spheroidization, and the powder after the sedimentation process. A study of the granulometric composition of the powder showed that after spheroidization there is a narrowing and shifting of the peak of the distribution of powder particles to a region of smaller size due to the partial evaporation of materials from the surface. From the presented graph it follows that during the sedimentation process, particles smaller than 10 microns are almost completely removed from the powder. The granulometric composition of the powder after the sedimentation process coincides with the original one.

Granulometric composition of EI961 powder.

As can be seen from Figure 10, the fluidity of the powder changes as a result of processing. The initial powder has a low fluidity, but after processing in plasma and, accordingly, changing the shape of the particles, it increases. But due to the presence of submicron particles, it doesn’t reach the maximum possible value. After the removal of submicron particles, the fluidity increases significantly.

Flowability of the powder: (1) initial, (2) after spheroidization, and (3) after sedimentation.

To analyze the crystal structure of the powders before and after spheroidization, XRD analysis was carried out and the results are shown in Figure 11. Only α ferrite phase with a body-centered cubic structure is present (Im3m and parameter a = 0.2866 nm). When analyzing the diffractograms, it can be seen that there was no change in the phase composition after spheroidization. There is also a noticeable narrowing of the peaks and an increase in their intensity which indicates an increase in the size of the crystallites, since the half-width of the diffraction maxima depends on their size. The change in the size of the crystallite can be explained by the fact that during plasma spheroidization, a complete melt of the particles occurs and then crystallization occurs at a high cooling rate (∼106 K·s−1), which also contributes to a change in the magnitude of the microstresses in the particles of the powder (Figure 12).

XRD patterns of initial and spherical powder after spheroidization.

Example of determining the chemical composition of a powder after spheroidization.

The chemical composition of the powders before and after spheroidization is presented in Table 2.

Chemical composition of the powder (wt%)

| Powder | Fe | Cr | Ni | V | W | Si | Mo | O | N | C |

|---|---|---|---|---|---|---|---|---|---|---|

| Initial | Basic | 11.80 | 1.57 | 0.20 | 2.02 | 0.37 | 0.34 | 0.2 | 0.03 | 0.11 |

| After spheroidization | Basic | 10.70 | 1.69 | 0.27 | 2.00 | 0.34 | 0.44 | 0.1 | 0.03 | 0.1 |

After plasma spheroidization, the chemical composition of the steel remained virtually unchanged, with the exception of chromium and oxygen. The decrease in the oxygen content is explained by the presence of hydrogen in the plasma-forming gas. The hydrogen in the plasma not only increases its thermal conductivity but also creates a reducing atmosphere. During the spheroidization process of the powder in the flow of argon-hydrogen plasma, it was possible to reduce the oxygen content by two times. The decrease in Cr content would be due to the higher evaporation rate of Cr than other elements in the high-temperature plasma process. The evaporation rate of the element is proportional to the vapor pressure [19,20]. Elements with high vapor pressure have a high evaporation rate, so when exposed to a high-temperature environment, they evaporate quickly and their concentration decreases. The vapor pressure of a pure element

4 Conclusion

In this article, the temperature field of the plasma was calculated using mathematical modeling. It was found that the maximum plasma temperature is 1,074 K at these parameters of the unit. It was also calculated that heat power accounts for only 15% of the unit’s power.

The influence of various parameters (power, feed rate, and feed rate height) of the plasma installation on the properties of the obtained powders were studied i.e., the percentage of powder yield, the percentage of sphericity, and the percentage of the content of the nanoscale fraction. Based on the analyzed data, the optimal mode of obtaining spherical powder of the EI961 brand was selected. The optimal mode is power of 15 kW, pressure of 1 atm, 0 mm feed rate height, and feed rate of 28 g·h−1. To select the optimal mode, two changeable parameters with a third unchanged parameter are sufficient. Also, the use of this experimental scheme was influenced by the rationality of using a plasma spheroidization unit. After the experiments, the following conclusions were made: with a decrease in the optimal power (15 kW), to achieve maximum sphericity, it is necessary either to reduce the feed rate, which leads to a decrease in efficiency, or to increase the height of the powder feed point, which, in turn, will lead to an increase in the number of nanoparticles on its surface. An increase in the feed rate (more than 28 g·h−1) leads to a decrease in sphericity, as well as a decrease in productivity. To ensure maximum sphericity, it is necessary to increase the height of the powder entry point, which, in turn, will lead to an increase in the content of nanoparticles. Reducing the feed rate requires reducing the height of the powder entry point, which will lead to low sphericity. Reducing the height of the powder entry point will reduce the number of spherical particles. To avoid this, it is necessary to reduce the feed rate, which leads to a decrease in efficiency. The powder obtained by the selected mode, as well as the sedimentation process, is suitable for use in powder bed fusion and directed energy deposition technologies.

The effect of plasma spheroidization on the granulometric composition, phase composition, and chemical composition was also studied. The granulometric composition corresponds to the original powder, except for the presence of a larger number of submicron particles which were later removed. After plasma spheroidization, the phase composition did not change, but the size of the crystallites and the magnitude of the microstresses changed. Compared to the original powder, the percentage of chromium in the steel was changed due to a higher evaporation rate. The change in the chromium content is still within the standard composition for this steel grade.

-

Funding information: The research is partially funded by the Ministry of Science and Higher Education of the Russian Federation: Advanced Digital Technologies (contract No. 075-15-2020-934 dated 17.11.2020).

-

Author contributions: The author's contribution lies in the development of spheroidization modes, conducting experiments, analyzing the results obtained, writing an article.

-

Conflict of interest: Authors state no conflict of interest.

References

[1] ASTM B213 – Standard test methods for flow rate of metal powders using the Hall flowmeter funnel.Search in Google Scholar

[2] Yolton, C. F. and F. H. Froes . Conventional titanium powder production. Titanium powder metallurgy: science, technology and applications, Elsevier, Waltham, MA, 2015, pp. 51–67.10.1016/B978-0-12-800054-0.00002-2Search in Google Scholar

[3] Nachtrab, W. T. , P. R. Roberts , and H. A. Newborn. Powder metallurgy of advanced titanium alloys. Key Engineering Materials, Vol. 77–78, 1993, pp. 115–140.10.4028/www.scientific.net/KEM.77-78.115Search in Google Scholar

[4] Entezarian, M. , F. Allaire , P. Tsantrizos , and R. A. L. Drew . Plasma atomization: a new process for the production of fine, spherical powders. JOM, Vol. 48, No. 6, pp. 53–55.10.1007/BF03222969Search in Google Scholar

[5] Tekna Plasma Systems Inc. http://tekna.com/equipment-spheroidizationnanosynthesis-deposition/spheroidization-equipment/ (access date 03/03/2021).Search in Google Scholar

[6] Popovich, A. A. , N. G. Razumov , A. V. Grigoriev , A. V. Samokhin , V. S. H Sufiiarov , I. S. Goncharov , et al. Fabrication of the Nb–16Si alloy powder for additive technologies by mechanical alloying and spheroidization in electric-arc discharge thermal plasma. Russian Journal of Non-Ferrous Metals, Vol. 59, No. 6, 2018, pp. 671–676.10.3103/S1067821218060160Search in Google Scholar

[7] Razumov, N. G. , Q.-S. Wang , A. A. Popovich , and A. I. Shamshurin . Fabrication of spherical high-nitrogen stainless steel powder alloys by mechanical alloying and thermal plasma spheroidization. AIP Conference Proceedings, Vol. 1946, 2018, id. 020001. 10.1063/1.5030305.Search in Google Scholar

[8] Razumov, N. G. , A. A. Popovich , and Q.-S. Wang . Thermal plasma spheroidization of high-nitrogen stainless steel powder alloys synthesized by mechanical alloying. Metals And Materials International, Vol. 24, No. 2, 2018, pp. 363–370.10.1007/s12540-018-0040-8Search in Google Scholar

[9] Polozov, I. , V. Sufiiarov , A. Kantyukov , N. Razumov , I. Goncharov , T. Makhmutov , et al. Microstructure, densification, and mechanical properties of titanium intermetallic alloy manufactured by laser powder bed fusion additive manufacturing with high-temperature preheating using gas atomized and mechanically alloyed plasma spheroidized powders. Additive Manufacturing, Vol. 34, 2020, id. 101374. 10.1016/j.addma.2020.101374.Search in Google Scholar

[10] lueh, R. L. and A. T. Nelson . Ferritic/martensitic steels for next generation reactors. Journal of Nuclear Materials, Vol. 371, No. 1–3, 2007, pp. 37–52.10.1016/j.jnucmat.2007.05.005Search in Google Scholar

[11] Zmitko, M. , Y. Carin , N. Thomas , M. Simon-Perret , A. LiPuma , L. Forest , et al. The European ITER test blanket modules: EUROFER97 material and TBM’s fabrication technologies development and qualification. Fusion Engineering and Design, Vol. 124, 2017, pp. 767–773.10.1016/j.fusengdes.2017.04.051Search in Google Scholar

[12] Neuberger, H. , J. Rey , M. Hees , E. Materna-Morris , D. Bolich , J. Aktaa , et al. Selective laser sintering as manufacturing process for the realization of complex nuclear fusion and high heat flux components. Fusion Science and Technology, Vol. 72, 2017, pp. 667–672.10.1080/15361055.2017.1350521Search in Google Scholar

[13] Koehly, C. , H. Neuberger , and L. Bühler . Fabrication of thin-walled fusion blanket components like flow channel inserts by selective laser melting. Fusion Engineering and Design, Vol. 143, 2019, pp. 171–179.10.1016/j.fusengdes.2019.03.184Search in Google Scholar

[14] Bonk, S. , H. Neuberger , D. Beckers , J. Koch , S. Antusch , and M. Rieth . Additive manufacturing technologies for EUROFER97 components. Journal of Nuclear Materials, Vol. 548, May 2021, id. 152859. 10.1016/j.jnucmat.2021.152859.Search in Google Scholar

[15] Jiang, M. G. , Z. W. Chen , J. D. Tong , C. Y. Liu , G. Xu , H. B. Liao , et al. Strong and ductile reduced activation ferritic/martensitic steel additively manufactured by selective laser melting. Materials Research Letters, Vol. 7, No. 10, 2019, pp. 426–432.10.1080/21663831.2019.1631224Search in Google Scholar

[16] Boulos, M. I. The role of transport phenomena and modeling in the development of thermal plasma technology. Plasma Chemistry and Plasma Processing, Vol. 36, No. 1, 2016, pp. 3–28.10.1007/s11090-015-9660-7Search in Google Scholar

[17] Ivanov, D. V. and S. G. Zverev . Mathematical simulation of processes in ICP/RF plasma torch for plasma chemical reactions. IEEE Transactions on Plasma Science, Vol. 45, No. 12, 2017, pp. 3125–3129.10.1109/TPS.2017.2773140Search in Google Scholar

[18] Ivanov, D. V. and S. G. Zverev . Mathematical simulation of processes in Air ICP/RF plasma torch for high-power applications. IEEE Transactions on Plasma Science, Vol. 48, No. 2, 2019, pp. 338–342.10.1109/TPS.2019.2957676Search in Google Scholar

[19] Chakrabarti, O. , L. Weisensel , and H. Sieber . Reactive melt infiltration processing of biomorphic Si-Mo-C ceramics from wood. Journal of the American Ceramic Society, Vol. 88, 2005, pp. 1792–1798.10.1111/j.1551-2916.2005.00366.xSearch in Google Scholar

[20] Tong, J. B. , X. Lu , C. C. Liu , Z. Q. Pi , R. J. Zhang , and X. H. Qu . Numerical simulation and prediction of radio frequency inductively coupled plasma spheroidization. Applied Thermal Engineering, Vol. 100, 2016, pp. 1198–1206.10.1016/j.applthermaleng.2016.02.108Search in Google Scholar

[21] Yanqing, S. , G. Jingjie , J. Jun , L. Guizhong , and L. Yuan . Composition control of a TiAl melt during the induction skull melting (ISM) process. Journal of Alloys and Compounds, Vol. 334, 2002, pp. 261–266.10.1016/S0925-8388(01)01766-2Search in Google Scholar

[22] Park, J. Y. , K. B. Park , J. W. Kang , H. G. Kim , N. M. Hwang , and H. K. Park . Spheroidization behavior of water-atomized 316 stainless steel powder by inductively-coupled thermal plasma. Materials Today Communications, Vol. 25, 2020, id. 101488. 10.1016/j.mtcomm.2020.101488.Search in Google Scholar

© 2021 Nikolai Ozerskoi et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- A review on filler materials for brazing of carbon-carbon composites

- Nanotechnology-based materials as emerging trends for dental applications

- A review on allotropes of carbon and natural filler-reinforced thermomechanical properties of upgraded epoxy hybrid composite

- High-temperature tribological properties of diamond-like carbon films: A review

- A review of current physical techniques for dispersion of cellulose nanomaterials in polymer matrices

- Review on structural damage rehabilitation and performance assessment of asphalt pavements

- Recent development in graphene-reinforced aluminium matrix composite: A review

- Mechanical behaviour of precast prestressed reinforced concrete beam–column joints in elevated station platforms subjected to vertical cyclic loading

- Effect of polythiophene thickness on hybrid sensor sensitivity

- Investigation on the relationship between CT numbers and marble failure under different confining pressures

- Finite element analysis on the bond behavior of steel bar in salt–frost-damaged recycled coarse aggregate concrete

- From passive to active sorting in microfluidics: A review

- Research Articles

- Revealing grain coarsening and detwinning in bimodal Cu under tension

- Mesoporous silica nanoparticles functionalized with folic acid for targeted release Cis-Pt to glioblastoma cells

- Magnetic behavior of Fe-doped of multicomponent bismuth niobate pyrochlore

- Study of surfaces, produced with the use of granite and titanium, for applications with solar thermal collectors

- Magnetic moment centers in titanium dioxide photocatalysts loaded on reduced graphene oxide flakes

- Mechanical model and contact properties of double row slewing ball bearing for wind turbine

- Sandwich panel with in-plane honeycombs in different Poisson's ratio under low to medium impact loads

- Effects of load types and critical molar ratios on strength properties and geopolymerization mechanism

- Nanoparticles in enhancing microwave imaging and microwave Hyperthermia effect for liver cancer treatment

- FEM micromechanical modeling of nanocomposites with carbon nanotubes

- Effect of fiber breakage position on the mechanical performance of unidirectional carbon fiber/epoxy composites

- Removal of cadmium and lead from aqueous solutions using iron phosphate-modified pollen microspheres as adsorbents

- Load identification and fatigue evaluation via wind-induced attitude decoupling of railway catenary

- Residual compression property and response of honeycomb sandwich structures subjected to single and repeated quasi-static indentation

- Experimental and modeling investigations of the behaviors of syntactic foam sandwich panels with lattice webs under crushing loads

- Effect of storage time and temperature on dissolved state of cellulose in TBAH-based solvents and mechanical property of regenerated films

- Thermal analysis of postcured aramid fiber/epoxy composites

- The energy absorption behavior of novel composite sandwich structures reinforced with trapezoidal latticed webs

- Experimental study on square hollow stainless steel tube trusses with three joint types and different brace widths under vertical loads

- Thermally stimulated artificial muscles: Bio-inspired approach to reduce thermal deformation of ball screws based on inner-embedded CFRP

- Abnormal structure and properties of copper–silver bar billet by cold casting

- Dynamic characteristics of tailings dam with geotextile tubes under seismic load

- Study on impact resistance of composite rocket launcher

- Effects of TVSR process on the dimensional stability and residual stress of 7075 aluminum alloy parts

- Dynamics of a rotating hollow FGM beam in the temperature field

- Development and characterization of bioglass incorporated plasma electrolytic oxidation layer on titanium substrate for biomedical application

- Effect of laser-assisted ultrasonic vibration dressing parameters of a cubic boron nitride grinding wheel on grinding force, surface quality, and particle morphology

- Vibration characteristics analysis of composite floating rafts for marine structure based on modal superposition theory

- Trajectory planning of the nursing robot based on the center of gravity for aluminum alloy structure

- Effect of scan speed on grain and microstructural morphology for laser additive manufacturing of 304 stainless steel

- Influence of coupling effects on analytical solutions of functionally graded (FG) spherical shells of revolution

- Improving the precision of micro-EDM for blind holes in titanium alloy by fixed reference axial compensation

- Electrolytic production and characterization of nickel–rhenium alloy coatings

- DC magnetization of titania supported on reduced graphene oxide flakes

- Analytical bond behavior of cold drawn SMA crimped fibers considering embedded length and fiber wave depth

- Structural and hydrogen storage characterization of nanocrystalline magnesium synthesized by ECAP and catalyzed by different nanotube additives

- Mechanical property of octahedron Ti6Al4V fabricated by selective laser melting

- Physical analysis of TiO2 and bentonite nanocomposite as adsorbent materials

- The optimization of friction disc gear-shaping process aiming at residual stress and machining deformation

- Optimization of EI961 steel spheroidization process for subsequent use in additive manufacturing: Effect of plasma treatment on the properties of EI961 powder

- Effect of ultrasonic field on the microstructure and mechanical properties of sand-casting AlSi7Mg0.3 alloy

- Influence of different material parameters on nonlinear vibration of the cylindrical skeleton supported prestressed fabric composite membrane

- Investigations of polyamide nano-composites containing bentonite and organo-modified clays: Mechanical, thermal, structural and processing performances

- Conductive thermoplastic vulcanizates based on carbon black-filled bromo-isobutylene-isoprene rubber (BIIR)/polypropylene (PP)

- Effect of bonding time on the microstructure and mechanical properties of graphite/Cu-bonded joints

- Study on underwater vibro-acoustic characteristics of carbon/glass hybrid composite laminates

- A numerical study on the low-velocity impact behavior of the Twaron® fabric subjected to oblique impact

- Erratum

- Erratum to “Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete”

- Topical Issue on Advances in Infrastructure or Construction Materials – Recycled Materials, Wood, and Concrete

- Structural performance of textile reinforced concrete sandwich panels under axial and transverse load

- An overview of bond behavior of recycled coarse aggregate concrete with steel bar

- Development of an innovative composite sandwich matting with GFRP facesheets and wood core

- Relationship between percolation mechanism and pore characteristics of recycled permeable bricks based on X-ray computed tomography

- Feasibility study of cement-stabilized materials using 100% mixed recycled aggregates from perspectives of mechanical properties and microstructure

- Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete

- Research on nano-concrete-filled steel tubular columns with end plates after lateral impact

- Dynamic analysis of multilayer-reinforced concrete frame structures based on NewMark-β method

- Experimental study on mechanical properties and microstructures of steel fiber-reinforced fly ash-metakaolin geopolymer-recycled concrete

- Fractal characteristic of recycled aggregate and its influence on physical property of recycled aggregate concrete

- Properties of wood-based composites manufactured from densified beech wood in viscoelastic and plastic region of the force-deflection diagram (FDD)

- Durability of geopolymers and geopolymer concretes: A review

- Research progress on mechanical properties of geopolymer recycled aggregate concrete

Articles in the same Issue

- Review Articles

- A review on filler materials for brazing of carbon-carbon composites

- Nanotechnology-based materials as emerging trends for dental applications

- A review on allotropes of carbon and natural filler-reinforced thermomechanical properties of upgraded epoxy hybrid composite

- High-temperature tribological properties of diamond-like carbon films: A review

- A review of current physical techniques for dispersion of cellulose nanomaterials in polymer matrices

- Review on structural damage rehabilitation and performance assessment of asphalt pavements

- Recent development in graphene-reinforced aluminium matrix composite: A review

- Mechanical behaviour of precast prestressed reinforced concrete beam–column joints in elevated station platforms subjected to vertical cyclic loading

- Effect of polythiophene thickness on hybrid sensor sensitivity

- Investigation on the relationship between CT numbers and marble failure under different confining pressures

- Finite element analysis on the bond behavior of steel bar in salt–frost-damaged recycled coarse aggregate concrete

- From passive to active sorting in microfluidics: A review

- Research Articles

- Revealing grain coarsening and detwinning in bimodal Cu under tension

- Mesoporous silica nanoparticles functionalized with folic acid for targeted release Cis-Pt to glioblastoma cells

- Magnetic behavior of Fe-doped of multicomponent bismuth niobate pyrochlore

- Study of surfaces, produced with the use of granite and titanium, for applications with solar thermal collectors

- Magnetic moment centers in titanium dioxide photocatalysts loaded on reduced graphene oxide flakes

- Mechanical model and contact properties of double row slewing ball bearing for wind turbine

- Sandwich panel with in-plane honeycombs in different Poisson's ratio under low to medium impact loads

- Effects of load types and critical molar ratios on strength properties and geopolymerization mechanism

- Nanoparticles in enhancing microwave imaging and microwave Hyperthermia effect for liver cancer treatment

- FEM micromechanical modeling of nanocomposites with carbon nanotubes

- Effect of fiber breakage position on the mechanical performance of unidirectional carbon fiber/epoxy composites

- Removal of cadmium and lead from aqueous solutions using iron phosphate-modified pollen microspheres as adsorbents

- Load identification and fatigue evaluation via wind-induced attitude decoupling of railway catenary

- Residual compression property and response of honeycomb sandwich structures subjected to single and repeated quasi-static indentation

- Experimental and modeling investigations of the behaviors of syntactic foam sandwich panels with lattice webs under crushing loads

- Effect of storage time and temperature on dissolved state of cellulose in TBAH-based solvents and mechanical property of regenerated films

- Thermal analysis of postcured aramid fiber/epoxy composites

- The energy absorption behavior of novel composite sandwich structures reinforced with trapezoidal latticed webs

- Experimental study on square hollow stainless steel tube trusses with three joint types and different brace widths under vertical loads

- Thermally stimulated artificial muscles: Bio-inspired approach to reduce thermal deformation of ball screws based on inner-embedded CFRP

- Abnormal structure and properties of copper–silver bar billet by cold casting

- Dynamic characteristics of tailings dam with geotextile tubes under seismic load

- Study on impact resistance of composite rocket launcher

- Effects of TVSR process on the dimensional stability and residual stress of 7075 aluminum alloy parts

- Dynamics of a rotating hollow FGM beam in the temperature field

- Development and characterization of bioglass incorporated plasma electrolytic oxidation layer on titanium substrate for biomedical application

- Effect of laser-assisted ultrasonic vibration dressing parameters of a cubic boron nitride grinding wheel on grinding force, surface quality, and particle morphology

- Vibration characteristics analysis of composite floating rafts for marine structure based on modal superposition theory

- Trajectory planning of the nursing robot based on the center of gravity for aluminum alloy structure

- Effect of scan speed on grain and microstructural morphology for laser additive manufacturing of 304 stainless steel

- Influence of coupling effects on analytical solutions of functionally graded (FG) spherical shells of revolution

- Improving the precision of micro-EDM for blind holes in titanium alloy by fixed reference axial compensation

- Electrolytic production and characterization of nickel–rhenium alloy coatings

- DC magnetization of titania supported on reduced graphene oxide flakes

- Analytical bond behavior of cold drawn SMA crimped fibers considering embedded length and fiber wave depth

- Structural and hydrogen storage characterization of nanocrystalline magnesium synthesized by ECAP and catalyzed by different nanotube additives

- Mechanical property of octahedron Ti6Al4V fabricated by selective laser melting

- Physical analysis of TiO2 and bentonite nanocomposite as adsorbent materials

- The optimization of friction disc gear-shaping process aiming at residual stress and machining deformation

- Optimization of EI961 steel spheroidization process for subsequent use in additive manufacturing: Effect of plasma treatment on the properties of EI961 powder

- Effect of ultrasonic field on the microstructure and mechanical properties of sand-casting AlSi7Mg0.3 alloy

- Influence of different material parameters on nonlinear vibration of the cylindrical skeleton supported prestressed fabric composite membrane

- Investigations of polyamide nano-composites containing bentonite and organo-modified clays: Mechanical, thermal, structural and processing performances

- Conductive thermoplastic vulcanizates based on carbon black-filled bromo-isobutylene-isoprene rubber (BIIR)/polypropylene (PP)

- Effect of bonding time on the microstructure and mechanical properties of graphite/Cu-bonded joints

- Study on underwater vibro-acoustic characteristics of carbon/glass hybrid composite laminates

- A numerical study on the low-velocity impact behavior of the Twaron® fabric subjected to oblique impact

- Erratum

- Erratum to “Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete”

- Topical Issue on Advances in Infrastructure or Construction Materials – Recycled Materials, Wood, and Concrete

- Structural performance of textile reinforced concrete sandwich panels under axial and transverse load

- An overview of bond behavior of recycled coarse aggregate concrete with steel bar

- Development of an innovative composite sandwich matting with GFRP facesheets and wood core

- Relationship between percolation mechanism and pore characteristics of recycled permeable bricks based on X-ray computed tomography

- Feasibility study of cement-stabilized materials using 100% mixed recycled aggregates from perspectives of mechanical properties and microstructure

- Effect of PVA fiber on mechanical properties of fly ash-based geopolymer concrete

- Research on nano-concrete-filled steel tubular columns with end plates after lateral impact

- Dynamic analysis of multilayer-reinforced concrete frame structures based on NewMark-β method

- Experimental study on mechanical properties and microstructures of steel fiber-reinforced fly ash-metakaolin geopolymer-recycled concrete

- Fractal characteristic of recycled aggregate and its influence on physical property of recycled aggregate concrete

- Properties of wood-based composites manufactured from densified beech wood in viscoelastic and plastic region of the force-deflection diagram (FDD)

- Durability of geopolymers and geopolymer concretes: A review

- Research progress on mechanical properties of geopolymer recycled aggregate concrete