Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

-

Jinlong Xie

, David Hui

Abstract

Microwave-absorbing materials with good microwave absorption performance are of great interest for military applications and human health, which is threatened by electromagnetic radiation pollution. Herein, the design and synthesis of multi-componential metal-hybridized graphene composites via freeze drying and pyrolysis of ferrocene hydrazone complex precursor are reported. Various magnetic nanoparticles are loaded on reduced graphene oxide (rGO) via controlling their pyrolysis temperature. The complex electromagnetic parameters of these hybrids are therefore regulated by the hybrid components. Among them, rGO hybridized by the sea-island-like Fe2O3/Fe3O4/FeNi3 multi-componential metals shows a good balance of dielectric and magnetic constants. Thus, the improved impedance matching with free space brings about a superior electromagnetic wave absorption performance, especially on the effective absorption bandwidth. The minimum reflection loss (RL) of the hybrids is as low as −40.3 dB at 11 GHz with the RL bandwidth of −10 dB being 4.55 GHz (from 9.25 to 13.8 GHz).

1 Introduction

The rapid growth of modern technologies promotes the applications of electronic devices, providing convenience to human lives or military equipment. However, electronic equipment leads to serious electromagnetic wave pollution [1,2,3,4,5]. Therefore, the development of absorbing materials seems to be necessary. Generally, the microwave absorption (MA) performances of materials are determined by their impedance matching and attenuation behaviors. The former decides the incident electromagnetic wave into the interior of materials that are subsequently consumed by dielectric and magnetic loss as described by the latter [6,7,8,9]. But the mismatched dielectric constant and permeability, namely, impedance mismatching that exists in most materials, always lead to a narrow absorbing bandwidth. In this regard, the componential and structural design of materials has aroused the enthusiasm toward good MA performance with broad absorption bandwidth.

Among these research studies, constructing pores in carbon-based materials has been proved to be a meaningful strategy for improving the impedance matching. The air existing in the porous ensures the impedance value of materials close to that of free space. Thus, the porous structure allows a broad absorption bandwidth [10,11,12,13,14,15]. However, porous materials always possess poor strength [16,17] and are easy to be saturated by adsorbed molecules or clusters due to their high specific surface area [18]. Incorporation of magnetic metal particles with dielectric carbon materials, such as graphene, is another important method for designing absorbing materials. The balanced dielectric constant and permeability achieve a good impedance matching. Graphene layers hybridized with a series of single magnetic metal particles, including Fe, Ni, and their oxides, are synthesized. For example, Co/rGO is simply synthesized by hydrothermal method [19], and Fe-hybridized rGO is achieved through primitive chemical reduction [20]. However, these hybrids exhibit improved but uncontrollable MA performances due to the single component of magnetic particles [21,22]. Subsequently, multi-component metal (McM) compounds are used for constructing graphene-based nanostructures, achieving a tunable MA performance [23,24]. But the limited methods for the componential and structural regulations of McM compounds restrict the development of related graphene nanostructures.

In this work, ferrocene hydrazone condensation bimetallic complex is captured by graphene oxide (GO) sheets. The following freeze drying and pyrolysis of the complex precursor form varieties of magnetic particles depended on the pyrolysis temperature. Compared with the existing methods, pyrolyzing bimetallic precursor is able to achieve a controllable McM@rGO hybrid by simply tuning the annealing temperature. The relationships between their MA performances and structure are systematically studied, which provides a meaningful perspective for the componential and structural design of McM-hybridized graphene toward high MA performances.

2 Experiment

2.1 Materials

GO was synthesized by a modified Hummers method [25]. Nitrilotriacetic acid, hydrazine hydrate, 1,1′-diacetylferrocen, and nickel acetate tetrahydrate were purchased from KeLong Chemistry Company. All the reagents involved in the experiment are analytical reagent without any further purification.

2.2 Synthesis of ferrocene hydrazone condensates

A volume of 100 mL of ethanol was mixed with 100 mL of deionized (DI) water, followed by the addition of nitrilotriacetic acid (3.9 g) and hydrazine hydrate (6 mL). The solution was heated to 85°C and stirred for 0.5 h. Then, 8.1 g of 1,1′-diacetylferrocen was added into the solution together with 10 mL of acetic acid. The mixture was maintained for another 2 h. The separated red precipitate was filtered, washed with ethanol, and then dried at 60°C under vacuum for 12 h to obtain the ferrocene hydrazone condensates (Fc).

2.3 Synthesis of Fc–Ni derivatives

A total of 5.6 g of Fc and 5.6 g of nickel acetate tetrahydrate were added to N,N-dimethylformamide (150 mL). The mixture was heated to 160°C and kept stirring for 1 h. The precipitate was filtered, washed with ethanol, and then dried at 60°C under vacuum for 12 h to obtain the brown Fc–Ni derivatives.

2.4 Synthesis of multi-componential metal-hybridized rGO

The preparation of McM@rGO is diagrammatically illustrated in Figure S1. In brief, 100 mg of GO was first dissolved in 100 mL of DI water, and the mixture was mildly sonicated (70 W) for 0.5 h to obtain a GO dispersion (1 mg/mL). A total of 180 mg of Fc–Ni derivatives was then added into 20 mL of GO dispersion, followed by the demulsification for 3 min (2,000 rpm) using a demulsified machine. The suspensions were freeze-dried to get the precursors and then annealed at different temperatures for 2 h under the argon atmosphere. The final product was referred to as McM@rGO.

2.5 Characterization

The SEM images were characterized by a field-emission scanning electron microscope (JSM-7001F; JEOL). TEM and high-resolution TEM (HR-TEM) were performed on a transmission electron microscope (Zeiss Libra200). The element distribution was discriminated by the energy-dispersive spectrometer (EDS) mapping (Oxford 8118). XRD patterns were obtained on an X-ray diffractometer (D8 ADVANCE; Bruker) with a Cu Kα radiation (λ = 1.54056 Å). The composition of samples was characterized by the XPS (Escalab Xi+; Thermo Fisher Scientific). Hysteresis loops were tested on a vibrating sample magnetometer (PPMS-9; Quantum Design). The electromagnetic parameters of samples were measured using a vector network analyzer (E5071C, Agilent) in the frequency range of 2–18 GHz. The samples were mixed with wax with a ratio of 20 wt% and then pressed into cyclic annular with an outer diameter of 7.0 mm and an inner diameter of 3.04 mm for further test.

3 Results and discussion

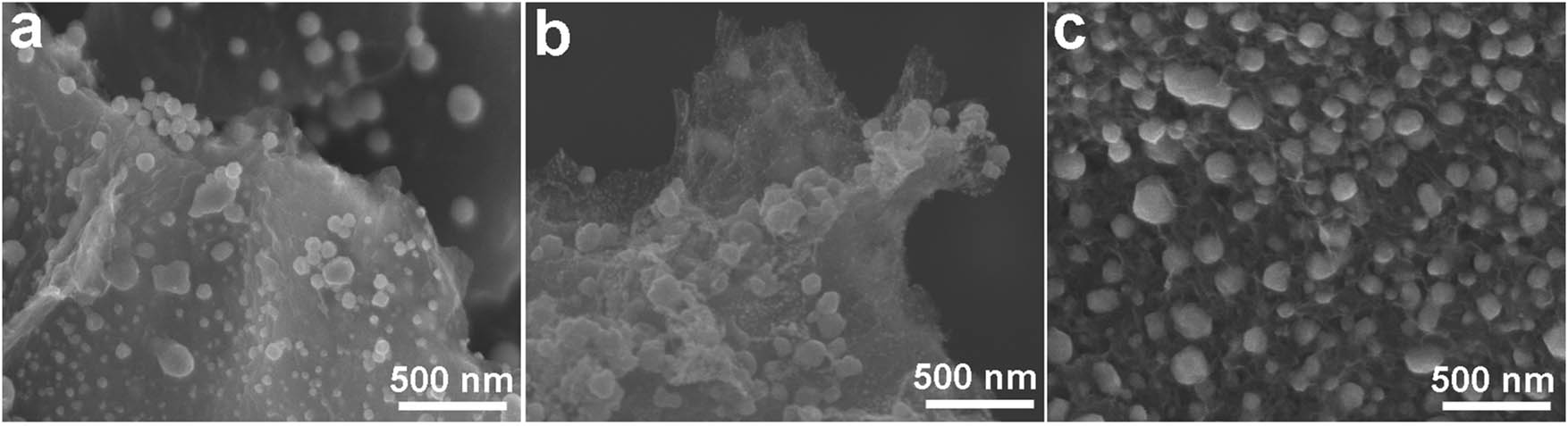

The annealing process of the precursors always involves the reduction of graphene layers as well as the decomposition of Fc–Ni. The structures of the obtained McM@rGO are significantly dependent on the annealing temperature. Thus, a series of McM@rGO annealed at different temperatures are synthesized to recognize their structural differences. These samples are recorded as McM@rGO-x, where x refers to the annealing temperatures. The morphologies of the synthesized McM@rGO are first investigated by SEM as depicted in Figure 1. At high temperature, the Fc–Ni attached on the surface of GO decomposes into nanoparticles and annealing temperatures remarkably influence the structures of decomposed particles. It is clear that a higher annealing temperature benefits the uniformity of particle size. But the annealing temperature of 800°C results in submicron particles as shown in Figure 1(c). We notice that an appropriate annealing temperature is important for controlling the particle size. At 600°C, decomposed nanoparticles disperse on the graphene layers uniformly with a size of about 10 nm.

SEM images of McM@rGO synthesized at different annealing temperatures: (a) McM@rGO-400, (b) McM@rGO-600, and (c) McM@rGO-800.

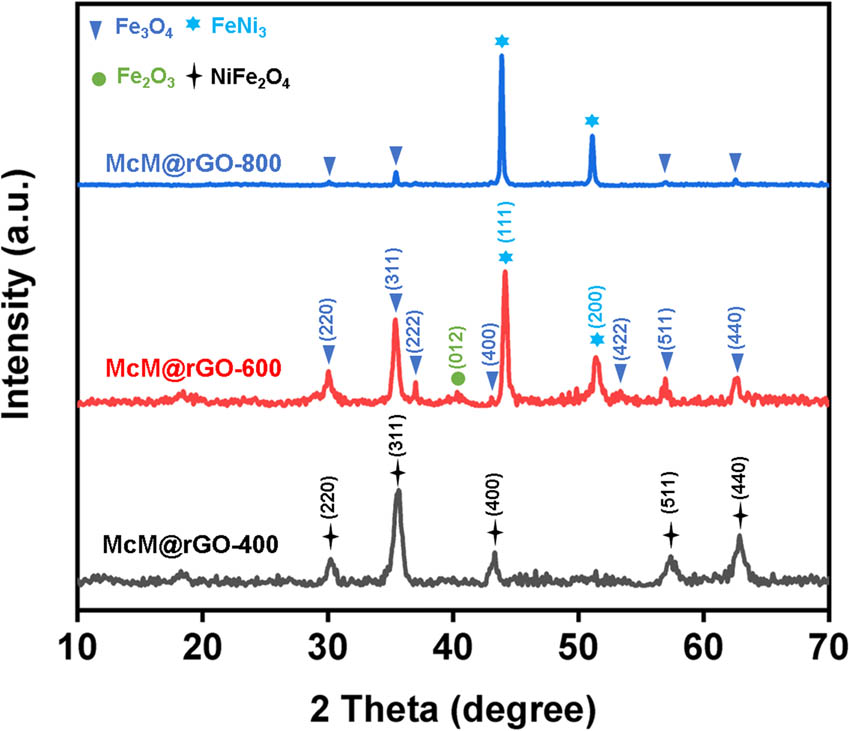

As the annealing process may influence the decomposition of precursors, the XRD patterns of McM@rGO synthesized at different annealing temperatures are tested to recognize their crystalline structures. As shown in Figure 2, the McM@rGO-400 exhibits strong diffraction peaks at 2θ = 30.1, 35.7, 43.1, 57.4, and 62.6°, attributing to the (220), (311), (400), (511), and (440) planes of NiFe2O4 [26] (Figure S2). Thus, the particles attached on the surface of rGO are supposed to be NiFe2O4. But the McM@rGO prepared at 600 and 800°C present different peaks at 2θ = 44.2 and 51.8°, which indicates the generation of FeNi3 [27]. Besides, the (220), (511), and (440) planes of Fe3O4, and the (012) plane of Fe2O3 are distinguished especially in McM@rGO-600, implying the formation of iron oxides [28,29].

XRD patterns of McM@rGO synthesized at different annealing temperatures.

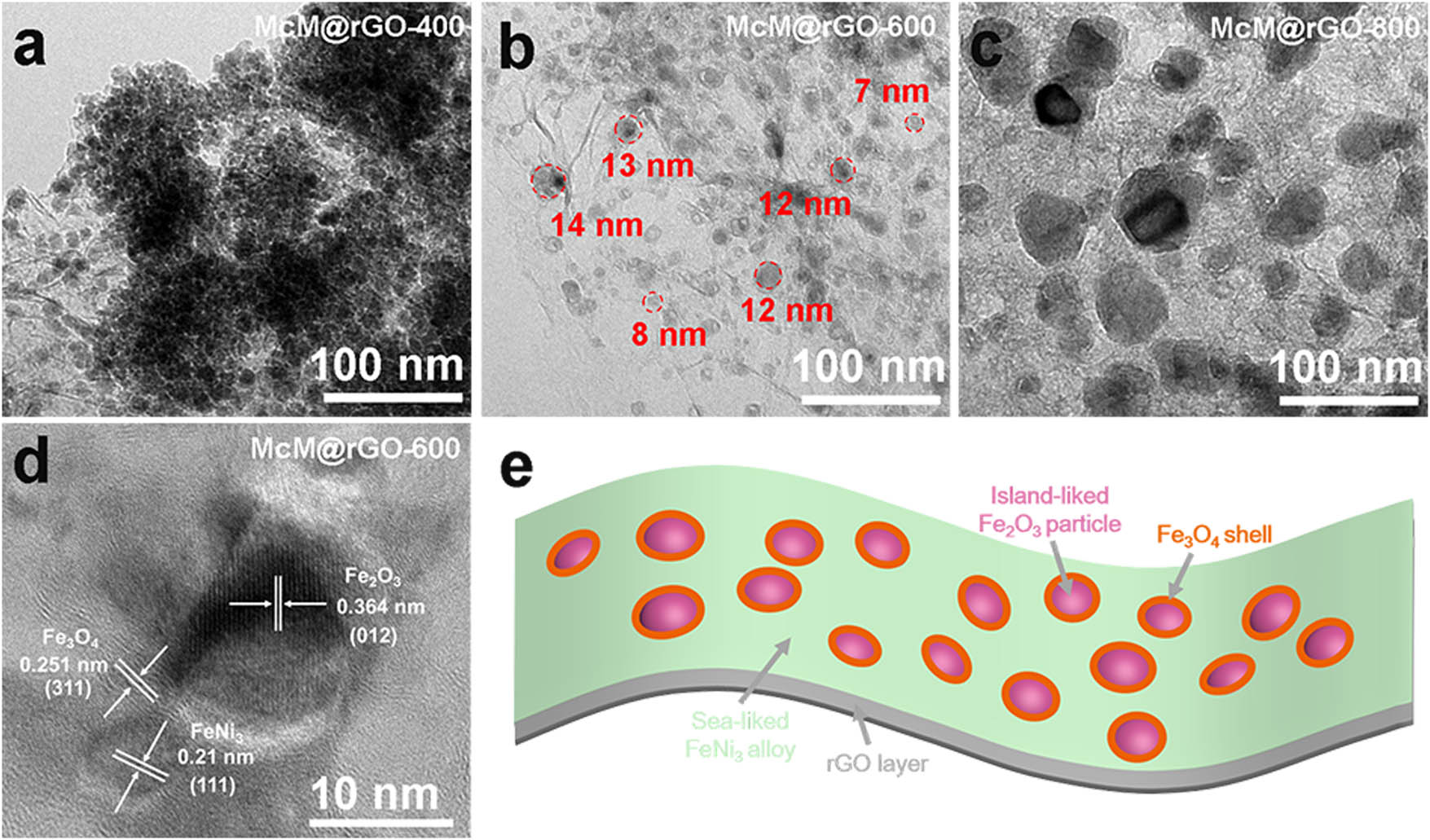

TEM characterizations are applied for further investigations of the nanoparticle-hybridized rGO. As shown in Figure 3(a), NiFe2O4 densely aggregated on rGO. The particle size of this sample is in the range of 20–100 nm with a wide size distribution. For the McM@rGO annealed at 800℃, the nanoparticles display a narrow size distribution in 40–50 nm. But the TEM image of McM@rGO-600 in Figure 3(b) reveals the uniform distribution of nanoparticles on the surfaces of graphene layers. The size of these particles is about 10 nm, coinciding with the results of SEM characterizations in Figure 1(b). The EDS mapping in Figure S3 identifies the elementary composition of nanoparticles, majorly involving Fe, Ni, and O. This result is in accordance with the XPS as shown in Figure S4. The HR-TEM images exhibited in Figure 3(d) clearly demonstrates the multi-componential metals in McM@rGO-600. The well-resolved lattice of 0.364 nm is attributed to the interplanar spacing of (012) in Fe2O3 [30]. The particle is surrounded by Fe3O4 and FeNi3 as recognized by the marked lattices in the image [31,32]. Thus, the HR-TEM, along with the aforementioned XRD patterns, proves convincing proofs about the multi-componential sea-island structure comprising the island-like Fe2O3 nanoparticle as well as the sea-like Fe3O4 and FeNi3 alloy as illustrated in Figure 3(e).

TEM characterizations of McM@rGO synthesized at different temperatures. TEM images of (a) McM@rGO-400, (b) McM@rGO-600, (c) McM@rGO-800, and (d) HR-TEM image of McM@rGO-600. (e) The diagram of the sea-island structure comprised of McMs on the surface of rGO.

Therefore, the structural regulation of McM@rGO is achieved by controlling the annealing temperatures. Fc–Ni attached on the graphene fully transforms into NiFe2O4 at a relatively low temperature of about 400℃. But with increasing temperature, they are decomposed into Fe2O3 nanoparticles with a size of several nanometers. The precursors, meanwhile, are partly reduced by graphene into Fe3O4 and FeNi3, forming a continuous phase around the Fe2O3 particles. Thus, a coating contrasted by the multi-componential metals is achieved on the rGO layer. With a higher annealing temperature, the precursors are mostly transformed into FeNi3, resulting in the significantly enhanced diffraction peaks as identified in McM@rGO-800.

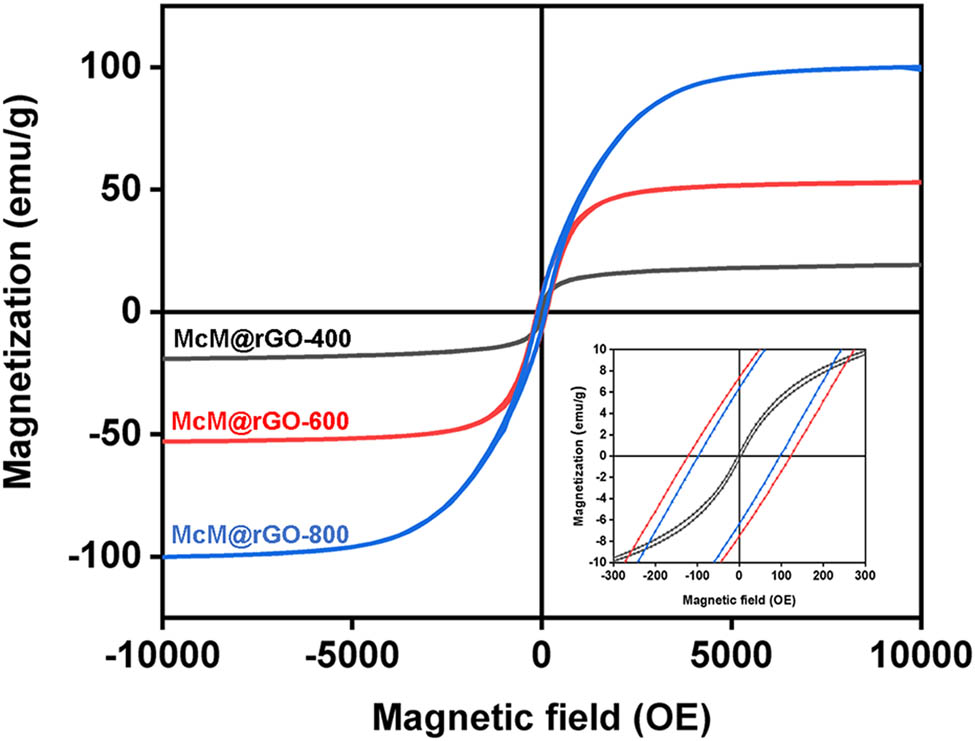

Considering the intrinsic ferromagnetism of NiFe2O4, FeNi3 Fe3O4, and Fe2O3, the magnetic behaviors of McM@rGO hybrids are measured by vibrating sample magnetometer (VSM) at room temperature. The hysteresis loops of these samples are shown in Figure 4. Generally, saturation magnetization and coercivity are regarded as the most important parameters for a magnetic material [33]. As shown in the inset, the magnified curves demonstrate the ferromagnetic of all McM@rGO. Normally, the saturation magnetic intensity is sequenced as follows: Fe3O4 [34], FeNi3 [35], NiFe2O4 [36], and α-Fe2O3 [37]. The saturation magnetization (Ms) of McM@rGO-400 is only 18.91 emu/g due to the relatively weak ferromagnetism of NiFe2O4. But the Ms of McM@rGO-800 is much larger than that of McM@rGO-600, perhaps due to the increased ratio of FeNi3 to Fe3O4 as proved by the structural characterization. We notice that McM@rGO-600 possesses the largest remanent magnetization (Mr) and coercivity (Hc) among these samples, which might owe to its refined grains and good dispersion among all samples [38]. Thus, the area enclosed by the hysteresis loop, which represents the magnetic loss capability, is thought to be higher for McM@rGO-600.

Hysteresis loops of the McM@rGO synthesized at different annealing temperatures. The inset provides an enlarged view of the loops in the range of −300 to 300 OE.

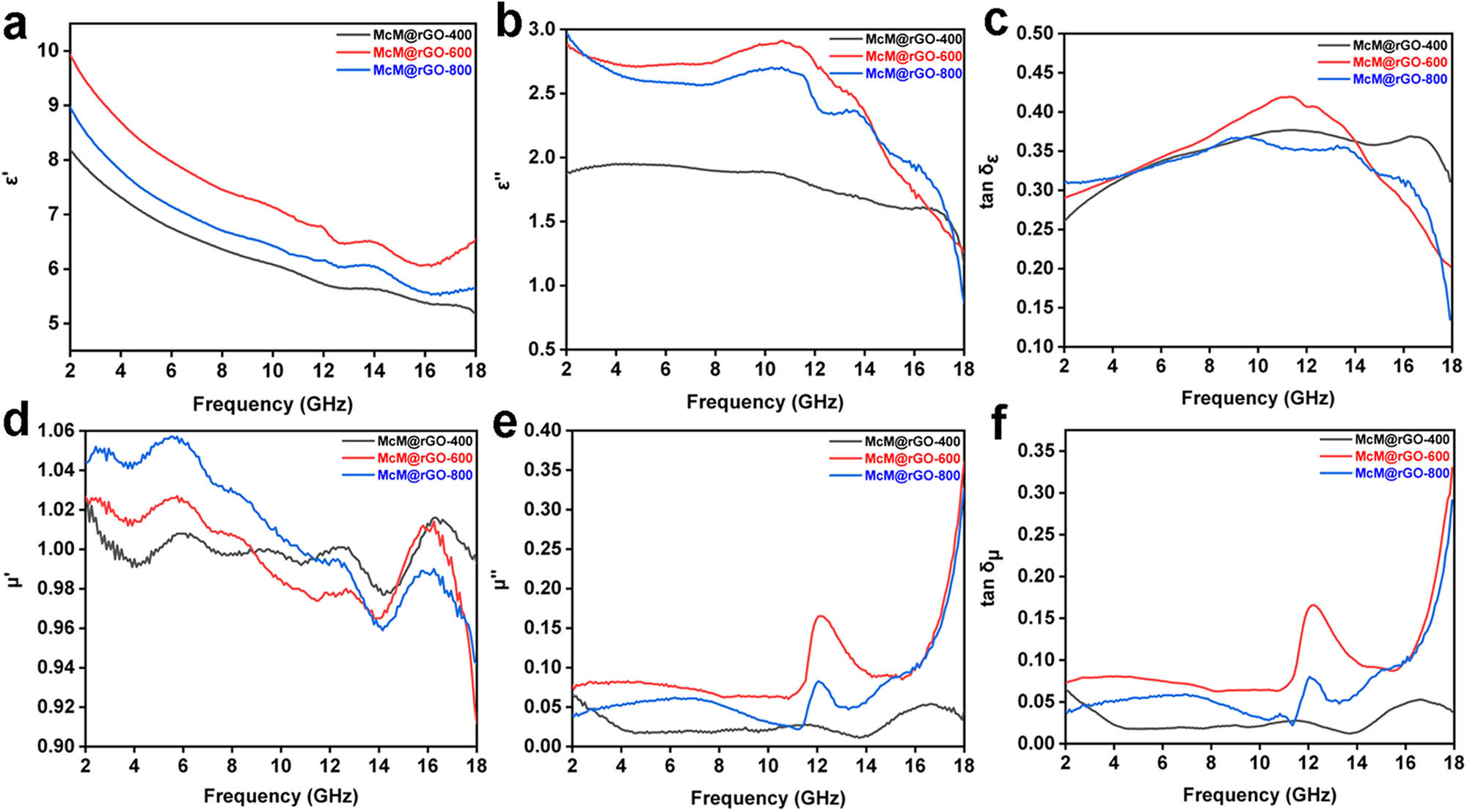

The cooperation between dielectric rGO and magnetic McM leads to the changes in complex permittivity (ε r = ε′ – jε′′) and permeability (μ r = μ′ – jμ′′), which is closely related to the MA [39,40,41]. To investigate the MA performance of the McM@rGO hybrids, frequency-dependent electromagnetic parameters are measured. The real parts of permittivity (ε′) and permeability (μ′) represent the storage ability of field energy, whereas the imaginary parts of permittivity (ε″) and permeability (μ″) indicate the dissipation capacity [42,43,44,45]. The complex permittivities of these synthesized hybrids are given in Figure 5(a and b). Both the real and imaginary parts decrease with an increase in frequency, indicating a frequency dispersion behavior induced by the enhanced polarization lagging in the high frequency [46,47]. The dielectric behaviors of McM@rGO majorly originate from the interfaces between nanoparticles and graphene layers as well as the polarization of residual functional groups [48]. Benefitting from the uniform hybridization between sea-island-like McM and rGO layers, McM@rGO-600 displays an improvement in dielectric dissipation in the range of 9–14 GHz as described by dielectrical dissipation factors (tan δε) in Figure 5(c). For the situation of complex permeabilities (Figure 5d and e), McM@rGO-400 presents a comparable permeability but few abilities in magnetic loss due to the lossless NiFe2O4 [49]. The magnetic loss factor (tan δμ) in Figure 5(f) demonstrates a strong magnetic loss in the range of 11–14 GHz, especially for McM@rGO-600. The relative low magnetic loss peak for McM@rGO-800 might be due to the decreased contents of Fe3O4 and Fe2O3 as proved by XRD patterns.

Frequency-dependent electromagnetic parameters of McM@rGO synthesized at different annealing temperatures. (a) ε′, (b) ε″, (c) tan δε, (d) μ′, (e) μ″, and (f) tan δμ.

Reflection loss (RL) is an important index that directly reflects the microwave absorption performance of materials. According to the transmission line theory, the RL is calculated by the following equations (1) and (2) [50,51].

where d, f, and c are the thickness of absorber, frequency of incident microwave, and velocity of light.

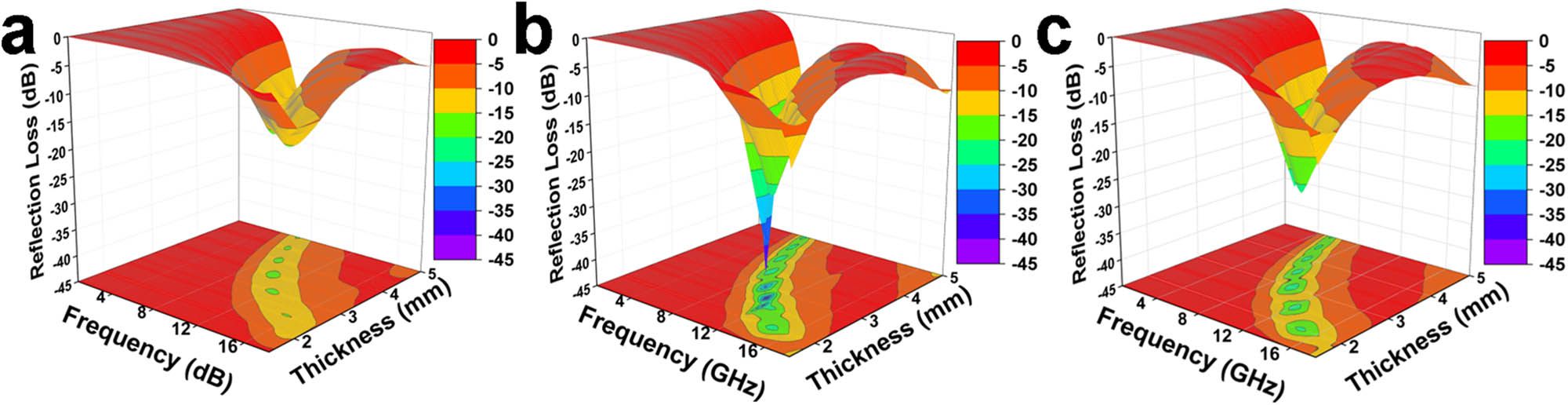

In Figure 6(a), McM@rGO-400 demonstrates a weak RL peak, majorly owing to its poor magnetic loss. We notice that the McM@rGO-600 holds a superior MA ability even better than McM@rGO-800. The minimum RL value is down to −40.3 dB at 11 GHz with the effective absorption bandwidth (RL < −10 dB) of 4.55 GHz (from 9.25 to 13.8 GHz) at 2.7 mm. Moreover, the widest effective absorption bandwidth is calculated to be 5.25 GHz with a thickness of only 2.0 mm.

RL curves of McM@rGO at different thicknesses (1.5–5.0 mm) from 2.0 to 18.0 GHz: (a) McM@rGO-400, (b) McM@rGO-600, and (c) McM@rGO-800.

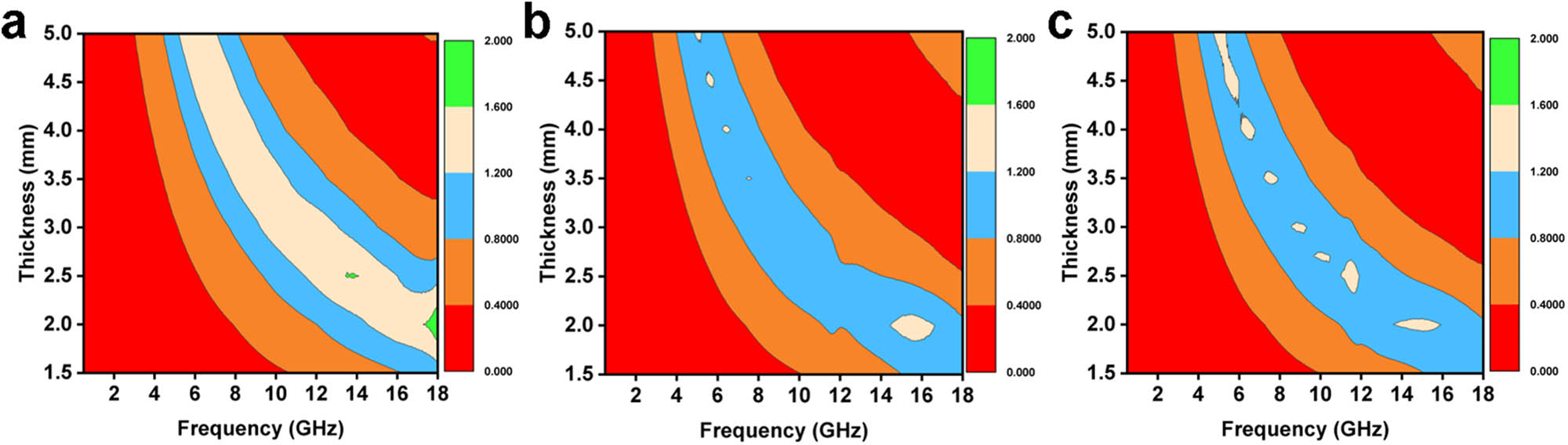

The superior MA performance of McM@rGO-600 is closely related to the improved impedance matching and increased dissipation. The impedance matching values (|Z in/Z 0|) of McM@rGO are derived from electromagnetic parameters and shown in Figure 7. |Z in/Z 0| illustrates the proximity between the input impedance (Z in) of the absorber and the impedance (Z 0) of the free space. The |Z in/Z 0| value of hybrids is expected to be 1 to achieve the maximum incident wave into the interior of the absorber [52]. The blue area represents a good impedance matching (0.8–1.2) as the other colors indicate a mismatching. Benefitting from the matching between permittivity and permeability, McM@rGO-600 possesses the best impedance matching as recognized by the maximum blue area in Figure 7, profiting the incident of microwave for further dissipation.

The impedance matching of McM@rGO. |Z in/Z 0| maps of (a) McM@rGO-400, (b) McM@rGO-600, and (c) McM@rGO-800.

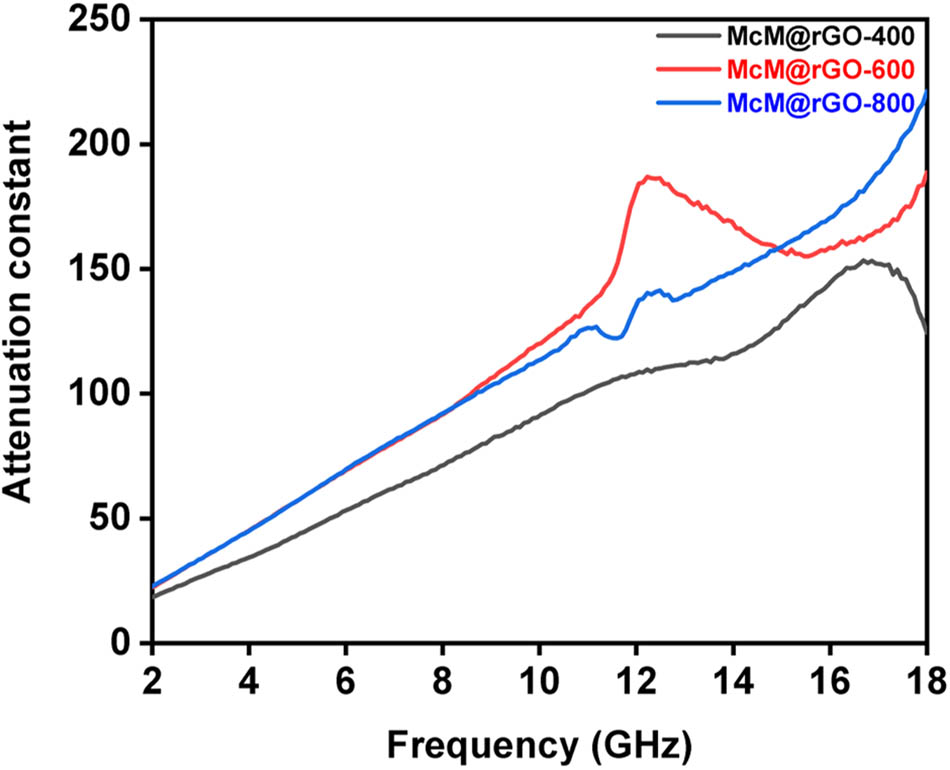

On the other hand, the attenuation value (α) is used to evaluate the dissipation of incident wave in absorbers [53,54]. The α values of samples are calculated using equation (3), and the results are shown in Figure 8. The increased α, especially in the range of 10–14 GHz for McM@rGO-600, originates from the synergistic enhancements of dielectric and magnetic loss. Moreover, the tiny but uniformly dispersed nanoparticles may also benefit to their MA performance [55].

The attenuation constant curves of McM@rGO.

4 Conclusions

In conclusion, this work achieves the compositional and structural regulations of McM-hybridized rGO by controlling the decomposition and reduction of Fc–Ni precursors. The rGO hybridized by the sea-island-like Fe2O3/Fe3O4/FeNi3 McM displays a good balance of dielectric and magnetic constants, significantly improving the impedance matching with free space. Therefore, a superior MA performance is realized for the McM@rGO hybrids. The minimum RL of the hybrids is as low as −40.3 dB at 11 GHz with the RL bandwidth of −10 dB being 4.55 GHz (from 9.25 to 13.8 GHz), which seems to be an ideal candidate for high-performance EM wave absorption.

-

Funding information: The authors gratefully acknowledge the financial support of the National Natural Science Foundation of China (No. 52002338) and the Key R & D Projects in Sichuan Province (No. 2020ZDZX0005 and No. 2020ZDZX0008).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Zhang XJ, Zhu JQ, Yin PG, Guo AP, Huang AP, Guo L, et al. Tunable high-performance microwave absorption of Co1−xS hollow spheres constructed by nanosheets within ultralow filler loading. Adv Funct Mater. 2018;28(49):1800761.10.1002/adfm.201800761Search in Google Scholar

[2] Ye F, Song Q, Zhang Z, Li W, Zhang S, Yin X, et al. Direct growth of edge-rich graphene with tunable dielectric properties in porous Si3N4 ceramic for broadband high-performance microwave absorption. Adv Funct Mater. 2018;28(17):1707205.10.1002/adfm.201707205Search in Google Scholar

[3] Zhao S, Yan L, Tian X, Liu Y, Chen C, Li Y, et al. Flexible design of gradient multilayer nanofilms coated on carbon nanofibers by atomic layer deposition for enhanced microwave absorption performance. Nano Res. 2018;11(1):530–41.10.1007/s12274-017-1664-6Search in Google Scholar

[4] Wang H, Meng F, Li J, Li T, Chen Z, Luo H, et al. Carbonized design of hierarchical porous carbon/Fe3O4@Fe derived from loofah sponge to achieve tunable high-performance microwave absorption. ACS Sustain Chem Eng. 2018;6(9):11801–10.10.1021/acssuschemeng.8b02089Search in Google Scholar

[5] Liu Y, Jiang L, Wang H, Wang H, Jiao W, Chen G, et al. A brief review for fluorinated carbon: synthesis, properties and applications. Nanotechnol Rev. 2019;8(1):573–86.10.1515/ntrev-2019-0051Search in Google Scholar

[6] Han M, Yin X, Hou Z, Song C, Li X, Zhang L, et al. Flexible and thermostable graphene/SiC nanowire foam composites with tunable electromagnetic wave absorption properties. ACS Appl Mater Interfaces. 2017;9(13):11803–10.10.1021/acsami.7b00951Search in Google Scholar PubMed

[7] Zhao B, Guo X, Zhao W, Deng J, Fan B, Shao G, et al. Facile synthesis of yolk-shell Ni@void@SnO2(Ni3Sn2) ternary composites via galvanic replacement/Kirkendall effect and their enhanced microwave absorption properties. Nano Res. 2017;10(1):331–43.10.1007/s12274-016-1295-3Search in Google Scholar

[8] Barathi Dassan EG, Anjang Ab Rahman A, Abidin MSZ, Akil HM. Carbon nanotube-reinforced polymer composite for electromagnetic interference application: a review. Nanotechnol Rev. 2020;9(1):768–88.10.1515/ntrev-2020-0064Search in Google Scholar

[9] Ovid’ko IA. Enhanced mechanical properties of polymer-matrix nanocomposites reinforced by graphene inclusions: a review. Rev Adv Mater Sci. 2013;34(1):19–25.Search in Google Scholar

[10] Cui X, Liang X, Chen J, Gu W, Ji G, Du Y. Customized unique core-shell Fe2N@N-doped carbon with tunable void space for microwave response. Carbon. 2020;156:49–57.10.1016/j.carbon.2019.09.041Search in Google Scholar

[11] Wang L, Zhou P, Guo Y, Zhang J, Qiu X, Guan Y, et al. The effect of ZnCl2 activation on microwave absorbing performance in walnut shell-derived nano-porous carbon. Rsc Adv. 2019;9(17):9718–28.10.1039/C8RA09932DSearch in Google Scholar

[12] Xu H, Yin X, Li M, Li X, Li X, Dang X, et al. Ultralight cellular foam from cellulose nanofiber/carbon nanotube self-assemblies for ultrabroad-band microwave absorption. ACS Appl Mater Interfaces. 2019;11(25):22628–36.10.1021/acsami.9b03731Search in Google Scholar PubMed

[13] Zhao H, Yeow Seow JZ, Cheng Y, Xu ZJ, Ji G. Green synthesis of hierarchically porous carbons with tunable dielectric response for microwave absorption. Ceram Int. 2020;46(10):15447–55.10.1016/j.ceramint.2020.03.089Search in Google Scholar

[14] Wu Z, Tian K, Huang T, Hu W, Xie F, Wang J, et al. Hierarchically porous carbons derived from biomasses with excellent microwave absorption performance. ACS Appl Mater Interfaces. 2018;10(13):11108–15.10.1021/acsami.7b17264Search in Google Scholar PubMed

[15] Gou G, Meng F, Wang H, Jiang M, Wei W, Zhou Z. Wheat straw-derived magnetic carbon foams: in situ preparation and tunable high-performance microwave absorption. Nano Res. 2019;12(6):1423–9.10.1007/s12274-019-2376-xSearch in Google Scholar

[16] Liu F, Seo TS. A controllable self-assembly method for large-scale synthesis of graphene sponges and free-standing graphene films. Adv Funct Mater. 2010;20(12):1930–6.10.1002/adfm.201000287Search in Google Scholar

[17] Ovid’ko IA. Mechanical properties of graphene. Rev Adv Mater Sci. 2013;34(1):1–11.Search in Google Scholar

[18] Yang F, Fan X, Wang C, Yang W, Hou L, Xu X, et al. P-doped nanomesh graphene with high-surface-area as an efficient metal-free catalyst for aerobic oxidative coupling of amines. Carbon. 2017;121:443–51.10.1016/j.carbon.2017.05.101Search in Google Scholar

[19] Zhang C, Wang B, Xiang J, Su C, Mu C, Wen F, et al. Microwave absorption properties of CoS2 nanocrystals embedded into reduced graphene oxide. ACS Appl Mater Interfaces. 2017;9(34):28868–75.10.1021/acsami.7b06982Search in Google Scholar PubMed

[20] Li Y, Yu M, Yang P, Fu J. Enhanced microwave absorption property of Fe nanoparticles encapsulated within reduced graphene oxide with different thicknesses. Ind Eng Chem Res. 2017;56(31):8872–9.10.1021/acs.iecr.7b01732Search in Google Scholar

[21] Xu W, Wang GS, Yin PG. Designed fabrication of reduced graphene oxides/Ni hybrids for effective electromagnetic absorption and shielding. Carbon. 2018;139:759–67.10.1016/j.carbon.2018.07.044Search in Google Scholar

[22] Du SM, Chen HY, Hong RY. Preparation and electromagnetic properties characterization of reduced graphene oxide/strontium hexaferrite nanocomposites. Nanotechnol Rev. 2020;9(1):105–14.10.1515/ntrev-2020-0010Search in Google Scholar

[23] Wang Y, Wu X, Zhang W, Luo C, Li J, Wang Q. 3D heterostructure of graphene@Fe3O4@WO3@PANI: preparation and excellent microwave absorption performance. Synth Met. 2017;231:7–14.10.1016/j.synthmet.2017.06.013Search in Google Scholar

[24] Wang L, Huang Y, Sun X, Huang H, Liu P, Zong M, et al. Synthesis and microwave absorption enhancement of graphene@Fe3O4@SiO2@NiO nanosheet hierarchical structures. Nanoscale. 2014;6(6):3157–64.10.1039/C3NR05313JSearch in Google Scholar

[25] Zahed M, Parsamehr PS, Tofighy MA, Mohammadi T. Synthesis and functionalization of graphene oxide (GO) for salty water desalination as adsorbent. Chem Eng Res Des. 2018;138:358–65.10.1016/j.cherd.2018.08.022Search in Google Scholar

[26] Kooti M, Sedeh AN. Synthesis and characterization of NiFe2O4 magnetic nanoparticles by combustion method. J Mater Sci Technol. 2013;29(1):34–8.10.1016/j.jmst.2012.11.016Search in Google Scholar

[27] Tahernejad Javazmi F, Shabani Nooshabadi M, Karimi Maleh H. 3D reduced graphene oxide/FeNi3-ionic liquid nanocomposite modified sensor; an electrical synergic effect for development of tert-butylhydroquinone and folic acid sensor. Compos Part B-Eng. 2019;172:666–70.10.1016/j.compositesb.2019.05.065Search in Google Scholar

[28] Moon JY, Jeon YT. Characterization of superlattices of monodisperse Fe3O4 nanoparticles in a polystyrene matrix with TEM and XRD. Superlattices Microstruct. 2008;43(2):141–5.10.1016/j.spmi.2007.06.006Search in Google Scholar

[29] Liu XQ, Tao SW, Shen YS. Preparation and characterization of nanocrystalline alpha-Fe2O3 by a sol-gel process. Sens Actuators B-Chem. 1997;40(2–3):161–5.10.1016/S0925-4005(97)80256-0Search in Google Scholar

[30] Wang YL, Li YH, Wang XL, Hou Y, Chen AP, Yang HG. Effects of redox mediators on alpha-Fe2O3 exposed by {012} and {104} facets for photocatalytic water oxidation. Appl Catal B-Environ. 2017;206:216–20.10.1016/j.apcatb.2016.11.028Search in Google Scholar

[31] Lv H, Lin L, Zhang X, Gao D, Song Y, Zhou Y, et al. In situ exsolved FeNi3 nanoparticles on nickel doped Sr2Fe1.5Mo0.5O6- perovskite for efficient electrochemical CO2 reduction reaction. J Mater Chem A. 2019;7(19):11967–75.10.1039/C9TA03065DSearch in Google Scholar

[32] Martínez-Mera I, Espinosa Pesqueira ME, Pérez-Hernández R, Arenas-Alatorre J. Synthesis of magnetite (Fe3O4) nanoparticles without surfactants at room temperature. Mater Lett. 2007;61(23–24):4447–51.10.1016/j.matlet.2007.02.018Search in Google Scholar

[33] Wang J, Cui Y, Wu F, Shah T, Ahmad M, Zhang A, et al. Core-shell structured Fe/Fe3O4 @TCNFs@TiO2 magnetic hybrid nanofibers: preparation and electromagnetic parameters regulation for enhanced microwave absorption. Carbon. 2020;165:275–85.10.1016/j.carbon.2020.04.090Search in Google Scholar

[34] Han DH, Wang JP, Luo HL. Crystallite size effect on saturation magnetization of fine ferrimagnetic particles. J Magn Magn Mater. 1994;136(1):176–82.10.1016/0304-8853(94)90462-6Search in Google Scholar

[35] Nasseh N, Taghavi L, Barikbin B, Nasseri MA, Allahresani A. FeNi3/SiO2 magnetic nanocomposite as an efficient and recyclable heterogeneous fenton-like catalyst for the oxidation of metronidazole in neutral environments: adsorption and degradation studies. Compos Part B Eng. 2019;166:328–40.10.1016/j.compositesb.2018.11.112Search in Google Scholar

[36] Salavati Niasari M, Davar F, Mahmoudi T. A simple route to synthesize nanocrystalline nickel ferrite (NiFe2O4) in the presence of octanoic acid as a surfactant. Polyhedron. 2009;28(8):1455–8.10.1016/j.poly.2009.03.020Search in Google Scholar

[37] Zolghadr S, Kimiagar S, Davarpanah AM. Magnetic property of α-Fe2O3–GO nanocomposite. IEEE Trans Magn. 2017;53(12):1–6.10.1109/TMAG.2017.2733503Search in Google Scholar

[38] Sun L, Chien CL, Searson PC. Fabrication of nanoporous nickel by electrochemical dealloying. Chem Mater. 2004;16(16):3125–9.10.1021/cm0497881Search in Google Scholar

[39] Shu R, Li W, Wu Y, Zhang J, Zhang G. Nitrogen-doped Co-C/MWCNTs nanocomposites derived from bimetallic metal-organic frameworks for electromagnetic wave absorption in the X-band. Chem Eng J. 2019;362:513–24.10.1016/j.cej.2019.01.090Search in Google Scholar

[40] Shu R, Zhang G, Wang X, Gao X, Wang M, Gan Y, et al. Fabrication of 3D net-like MWCNTs/ZnFe2O4 hybrid composites as high-performance electromagnetic wave absorbers. Chem Eng J. 2018;337:242–55.10.1016/j.cej.2017.12.106Search in Google Scholar

[41] Shu R, Zhang G, Zhang J, Wang X, Wang M, Gan Y, et al. Fabrication of reduced graphene oxide/multi-walled carbon nanotubes/zinc ferrite hybrid composites as high-performance microwave absorbers. J Alloy Compd. 2018;736:1–11.10.1016/j.jallcom.2017.11.084Search in Google Scholar

[42] Cheng Y, Zhao H, Lv H, Shi T, Ji G, Hou Y. Lightweight and flexible cotton aerogel composites for electromagnetic absorption and shielding applications. Adv Electron Mater. 2020;6(1):1900796.10.1002/aelm.201900796Search in Google Scholar

[43] Wu Y, Shu R, Zhang J, Wan Z, Shi J, Liu Y, et al. Oxygen vacancies regulated microwave absorption properties of reduced graphene oxide/multi-walled carbon nanotubes/cerium oxide ternary nanocomposite. J Alloy Compd. 2020;819:152944.10.1016/j.jallcom.2019.152944Search in Google Scholar

[44] Agarwal K, Prasad M, Katiyar M, Jaiswal R, Kumar S, Prasad NE. Study of electromagnetic properties of fabricated NiFe2O4/polyurethane nanocomposites. J Appl Polym Sci. 2020;137(27):48645.10.1002/app.48645Search in Google Scholar

[45] Wang H, Meng F, Huang F, Jing C, Li Y, Wei W, et al. Interface modulating CNTs@PANi hybrids by controlled unzipping of the walls of CNTs to achieve tunable high-performance microwave absorption. ACS Appl Mater Interfaces. 2019;11(12):12142–53.10.1021/acsami.9b01122Search in Google Scholar PubMed

[46] Guo Y, Li J, Meng F, Wei W, Yang Q, Li Y, et al. Hybridization-induced polarization of graphene sheets by intercalation-polymerized polyaniline toward high performance of microwave absorption. ACS Appl Mater Interfaces. 2019;11(18):17100–7.10.1021/acsami.9b04498Search in Google Scholar PubMed

[47] Yang Y, Xia L, Zhang T, Shi B, Huang L, Zhong B, et al. Fe3O4@LAS/RGO composites with a multiple transmission-absorption mechanism and enhanced electromagnetic wave absorption performance. Chem Eng J. 2018;352:510–8.10.1016/j.cej.2018.07.064Search in Google Scholar

[48] Jia Z, Gao Z, Feng A, Zhang Y, Zhang C, Nie G, et al. Laminated microwave absorbers of A-site cation deficiency perovskite La0.8FeO3 doped at hybrid RGO carbon. Compos Part B Eng. 2019;176:107246.10.1016/j.compositesb.2019.107246Search in Google Scholar

[49] Wang Y, Gao X, Wu X, Zhang W, Luo C, Liu P. Facile design of 3D hierarchical NiFe2O4/N-GN/ZnO composite as a high performance electromagnetic wave absorber. Chem Eng J. 2019;375:121942.10.1016/j.cej.2019.121942Search in Google Scholar

[50] Li K, Zhao R, Xia J, Zhao GL. Reinforcing microwave absorption multiwalled carbon nanotube-epoxy composites using glass fibers for multifunctional applications. Adv Eng Mater. 2020;22(3):1900780.10.1002/adem.201900780Search in Google Scholar

[51] Wu Z, Huang T, Li T, Li L. Facile preparation of a hierarchical C/rGO/FeOx composite with superior microwave absorption performance. Langmuir. 2019;35(10):3688–93.10.1021/acs.langmuir.8b04276Search in Google Scholar PubMed

[52] Shu R, Wu Y, Li Z, Zhang J, Wan Z, Liu Y, et al. Facile synthesis of cobalt-zinc ferrite microspheres decorated nitrogen-doped multi-walled carbon nanotubes hybrid composites with excellent microwave absorption in the X-band. Compos Sci Technol. 2019;184:107839.10.1016/j.compscitech.2019.107839Search in Google Scholar

[53] Song WL, Cao MS, Wen B, Hou ZL, Cheng J, Yuan J. Synthesis of zinc oxide particles coated multiwalled carbon nanotubes: dielectric properties, electromagnetic interference shielding and microwave absorption. Mater Res Bull. 2012;47(7):1747–54.10.1016/j.materresbull.2012.03.045Search in Google Scholar

[54] Liu Y, Chen Z, Zhang Y, Feng R, Chen X, Xiong C, et al. Broadband and lightweight microwave absorber constructed by in situ growth of hierarchical CoFe2O4/reduced graphene oxide porous nanocomposites. ACS Appl Mater Interfaces. 2018;10(16):13860–8.10.1021/acsami.8b02137Search in Google Scholar PubMed

[55] Wu N, Liu X, Zhao C, Cui C, Xia A. Effects of particle size on the magnetic and microwave absorption properties of carbon-coated nickel nanocapsules. J Alloy Compd. 2016;656:628–34.10.1016/j.jallcom.2015.10.027Search in Google Scholar

© 2021 Jinlong Xie et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions