Abstract

Intra-plant transport systems within their operation directly impact on the performance of production systems. For their effective operation, it is, therefore, necessary to realize evaluation of operational performance and effectivity. For the realization of this type of evaluation, in addition to a wide range of sensors that can be difficult for installation and operation, we can also use indirect methods that are equally able to provide reliable operational characteristics. Indirect analytical methods are presented above all by the approach which is based on the use of simulation methods. The method of computer simulation provides a wide range of options for the evaluation of efficiency and performance. The paper describes the use of a simulation model created in the program Tecnomatix Plant Simulation for analyzing the supply of production workplaces within the MilkRun system.

1 Introduction

The process of workplaces supplying within different types of production processes can be realized by a wide range of transport technologies. The choice of suitable transport technologies depends on the particular production, the final product, production capacity and other factors. In the context of the present time, with the philosophy of the Industry 4.0, automatization of enterprise processes gains ground, and automatized logistics systems are preferred within intra-plant transport, which is capable of self-navigation and moving within the production areas [1]. They are most often named as AGV or FTS.

In both cases, it is the same type of transport system. This system most often consists of autonomous vehicles or it is presented by vehicle combination with towing vehicle and transporters, i.e. peripherals [2]. Within production units, the route can be guided to meet different criteria [4]. Various methods and approaches are used by the implementation of these transport systems to the systems of intra-logistics. Their aim is to adapt to the transport system as much as possible to the operating conditions. One of the possible solutions is described for example by Johnson and Brandeau [5].

For their reliable operation, it is also important a navigation system, which is used by AGV systems [6]. The system of vehicles control is also depended on the choice of the type of navigation [7]. AGV vehicles are in most cases applied in a continuous operating mode, moving on predetermined fixed transport routes and providing a continuous flow of material for workplaces and production lines. The system MilkRun is the most often used system for this process [8, 9, 10, 11, 12, 13].

2 Characteristics of the system MilkRun

“The system MilkRun is delivery of material from the store on precisely defined logistics routes with a precise delivery schedule. It is a set of several transporters pulled by one vehicle that runs on the planned route with specified stopping places” [14]. The use of the system MilkRun is common in lean production. It allows more frequent supplies of material and supplies to more than one mounting area. Supply by the system MilkRun is increasingly used in firms.

“The principle is to distribute material from a store according to a pre-agreed schedule and unload material at precisely defined locations. At the same time, empty transport units are transported back to the store. They are more expensive, but the difference between them and a forklift is about the same as between taxi and public transport. The taxi goes in one direction loaded and the other empty, as well as a forklift, so it is filled only to 50%.” Handling devices which are the most often used are so-called trains [15].

Set with AGV towing vehicle within the system MilkRun

3 Simulation model

Measuring of the AGV system performance within MilkRun is a challenging process that needs to reflect a large set of operational indicators and helps to understand the functioning of the transport system. One of the tools we can use is a computer simulation. The application of this method for the need of the system of MilkRun will be presented by an example that will describe the creation and use of a simulation model of AGV transport system.

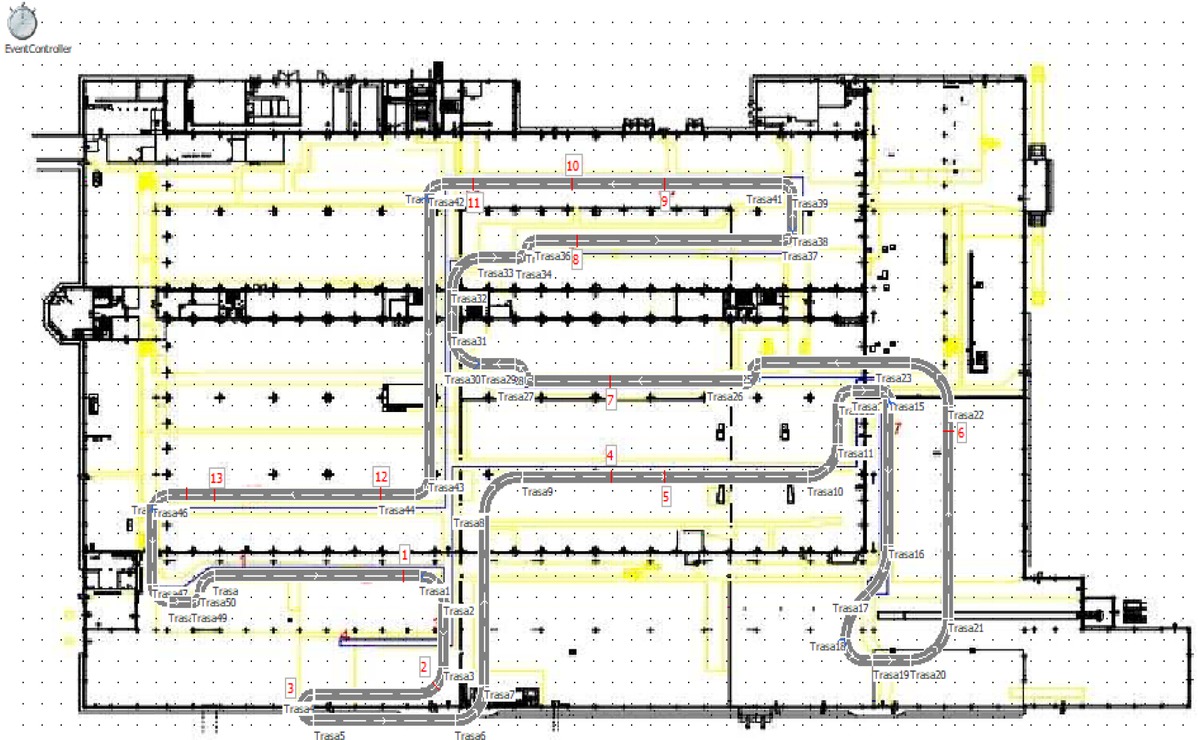

The simulation model was created with the intention of using it to supply of workplaces within the existing MilkRun system. The creation of this system was based on the analysis of the current state of the transport route (Figure 2). Each section of the route was created separately for a better change of details, for example by changing directions. The individual part of the route has its length that was divided into several smaller parts due to the variability of changes. Within the route, the locations of stops were defined for loading and unloading of material. For this purpose the function of sensors was used, where the AGV set is due to stop and load, or unload metal extrusions 1, metal extrusions 2 or EURO Kanban crates.

Layout with the definition of MilkRun route and stopping places

Further, within the simulation model, five types of handling units MUs of the type “Transporter” were created, specifically the first transporter with the title “AGV”, the second transporter with the title “transporter 1”, the third transport with the title “transporter 2”, the fourth transporter with the title “transporter 3” and the last fifth transporter with the title “transporter 4”. In addition, two “Entity” were created, the first with the title “metal extrusion 1” and the second with the title “metal extrusion2”, to which colour was assigned for recognizing them. As the last MUs was used the “Container” and named as “EURO-container”.

For the simulation of the process of material loading and unloading on the individual stops within the system MilkRun, the method of additional programming was used. Individual statements created by the programming language SimTalk were used in the block “Method”. AGV set circulated along a predefined route among the first and thirteenth stop.

There was a store of containers beyond the thirteenth stop in the simulation model, and all EURO containers, that were collected by the set during the AGV ride, were unloaded. Subsequently, the set continued to the place of loading of transported components and after its realization continued in the ride along the circuit and supplying workplaces.

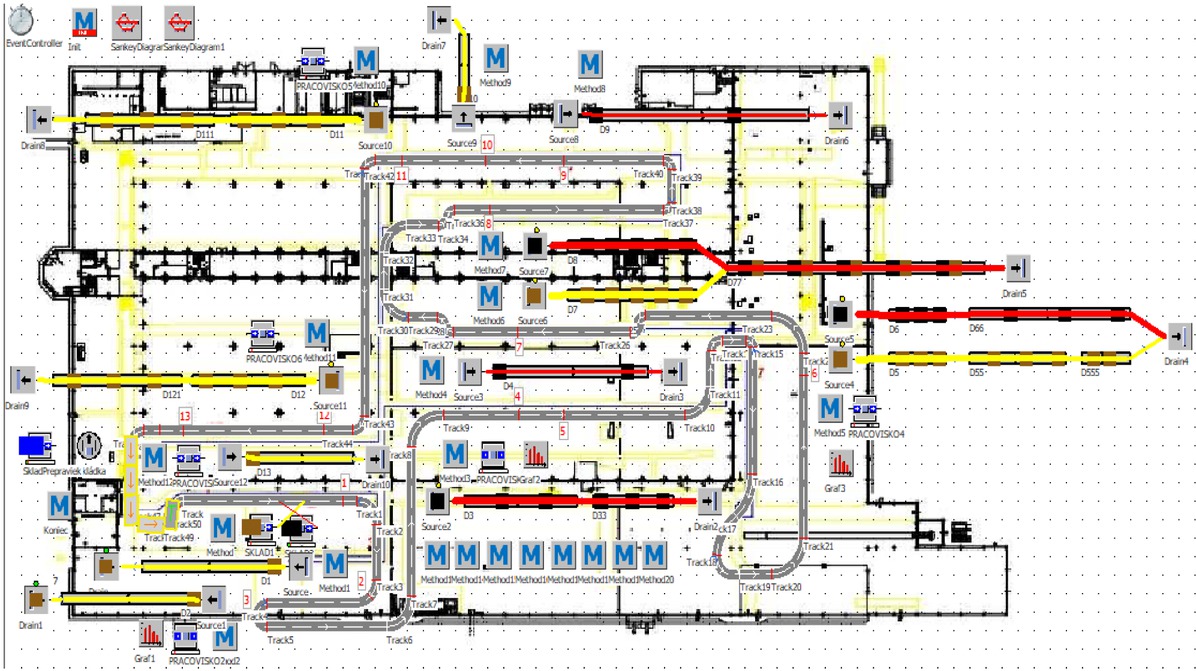

Two Sankey diagrams were inserted into the model, which allowed to monitor the material flow of metal extrusions (Figure 3).

Demonstration of material flow for metal extrusions 1 and also metal extractions 2

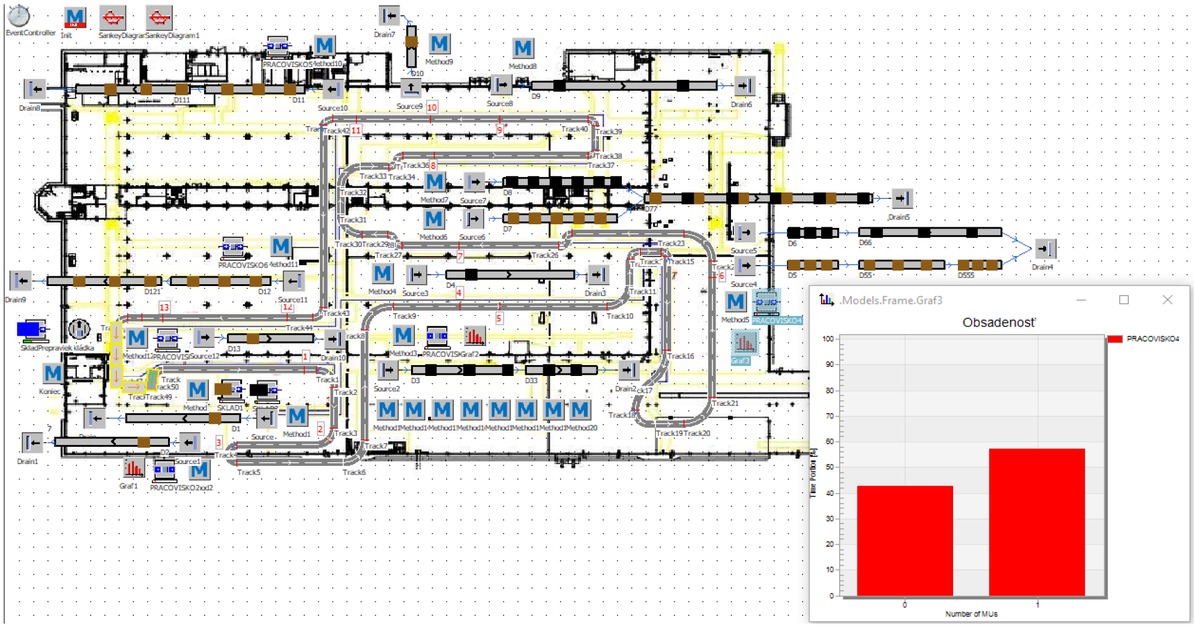

Within the workplaces, the possibility of utilization evaluation was implemented in the simulation model. The results are presented as histograms (Figure 4).

Demonstration of visualization of the results of workplace occupancy

4 Results

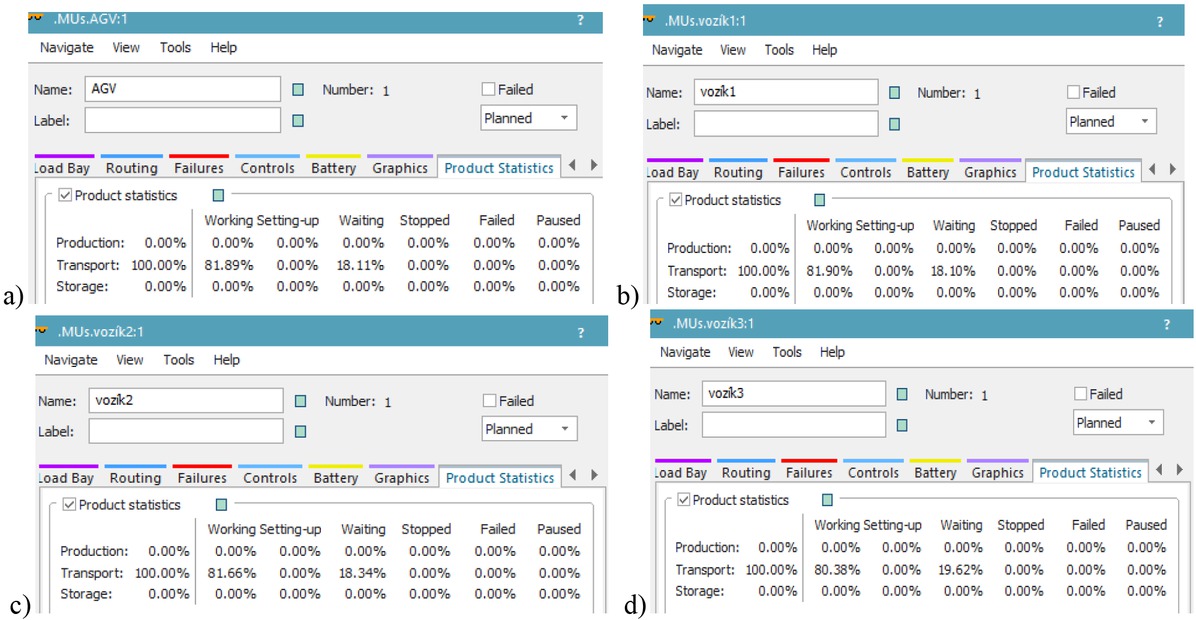

The created simulation model was used for the analysis of changes of MilkRun system performance in the case that the number of transporters in the set towed by AGV vehicle is reduced from four to three. From the simulation model, with the cancelled transporter 4 (Figure 5), it is evident that after this change the vehicle “AGV” worked at 81,89% and its waiting is 18,11%- The “transporter 1” worked at 81,90% and waiting of the transporter 1 is 18,10%, the “transporter 2” worked at 81,66% and waiting is 18,34% and the “t transporter 3” worked at 80,38% and waiting was 19,62%. The average occupancy of the vehicle “AGV” and three transporters was 81,46%.

Statistical occupancy of the “AGV” vehicle and “transporter s” by cancelling of the transporter 4

The second experiment with the applied simulation model was based on reducing the number of stops on the transport route, while the number of transporters in the tandem vehicle was original. Specifically, stops number 6, 9 and 10 were cancelled. The reduction was within the simulation model realized by simply removing the corresponding sensors.

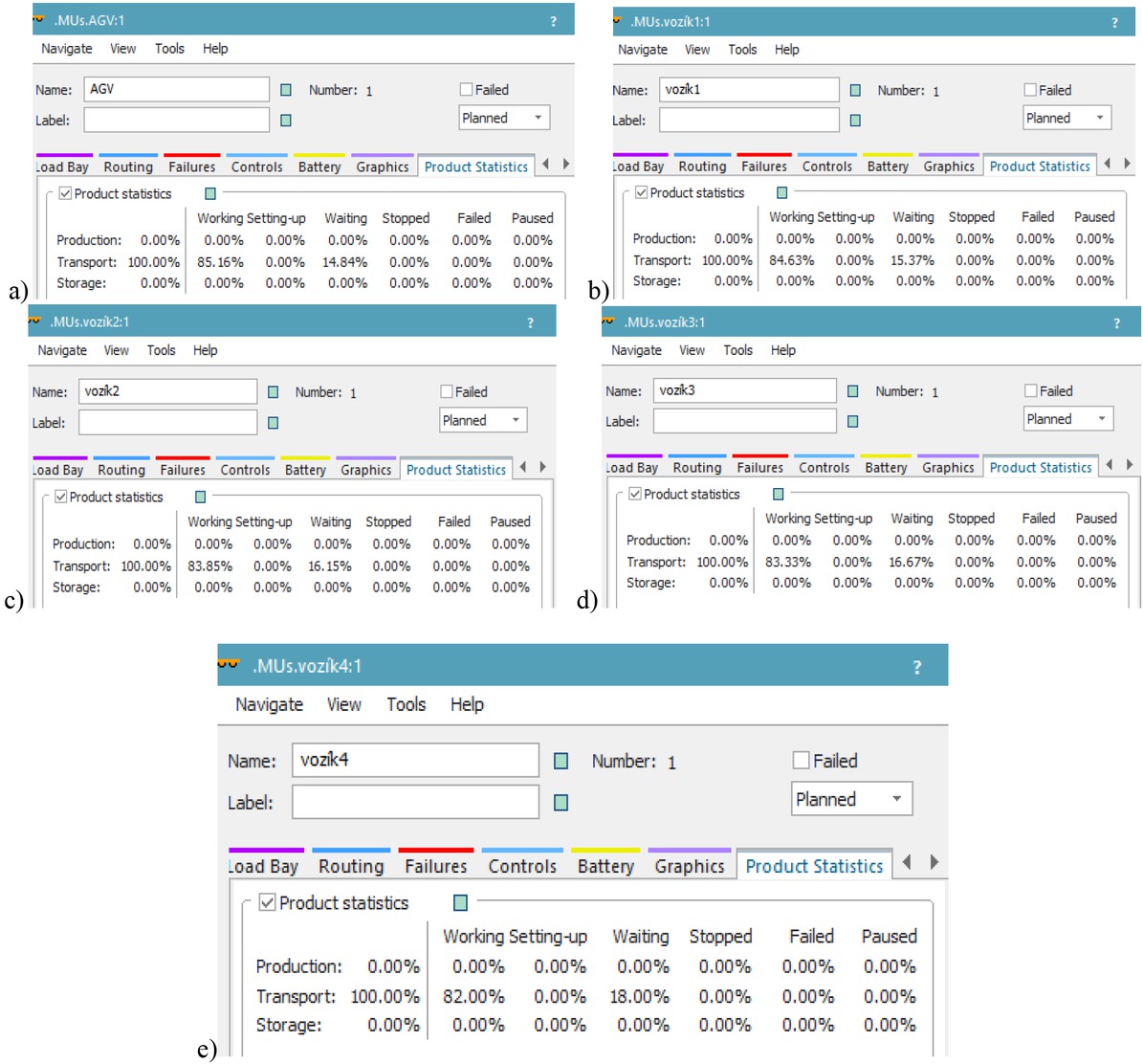

From the simulation model with cancelled three stops (Figure 6), it is evident that the vehicle “AGV” worked at 85,16% and its waiting was 14,86%. The ”transporter 1” worked at 84,63% and its waiting was 15,3%, “transporter 2” worked at 83,85% and waiting was 16,15%, “transporter 3” worked at 83,33% and its waiting was 16,67% and the “transporter 4” worked at 82% and its waiting was 18%. The average occupancy of the AGV vehicle and its four transporters with three cancelled stops was 83,79%. In comparison with the simulation model with thirteen stops, the occupancy of the AGV vehicle and transporters with three cancelled stops was higher by 1,52%.

Statistical occupancy of the “AGV” vehicle and “transporters” by cancelling of three stops

5 Conclusion

Measuring of transport systems performance within individual logistics processes has great importance for their effective operation and reduction of operating costs. Their operators must have sufficient information providing them with a real state about applied vehicles, the volume of transported material and other operational indicators. In this way, it is possible from time to time to debug these systems and effectively operate. Computer simulation is currently a robust and powerful tool for a meeting of these requirements, which do not demand costly investments after the creation of the simulation model and it can be used within different types of engineering analysis.

Acknowledgement

This work is a part of these projects VEGA 1/0063/16, VEGA 1/0638/19, KEGA 012TUKE-4/2019 and APVV SK-SRB-18-0053.

References

[1] Cheong H-W & Lee H.. (2018). Concept Design of AGV (Automated Guided Vehicle) Based on Image Detection and Positioning. In 6th International conference on information technology and quantitative management, 20-21 October 2018 (pp. 104-107). Omaha, Nevada, USA: Elsevier science BV, Amsterdam, Netherlands.10.1016/j.procs.2018.10.224Search in Google Scholar

[2] Bandyopadhyay, S. (2018). Intelligent Vehicles and Materials Transportation in the Manufacturing Sector: Emerging Research and Opportunities. 701 E CHOCOLATE AVE, STE 200, HERSEY, PA 17033-1240 USA: IGI GLOBAL.10.4018/978-1-5225-3064-0Search in Google Scholar

[3] Kumbhar, S., Thombare, R. & Salunkhe, A.. (2018). Automated Guided Vehicles for Small Manufacturing Enterprises: A Review. 11 (3), 253-258. DOI: 10.4271/05-11-03-0024.10.4271/05-11-03-0024Search in Google Scholar

[4] Huang, C.. (1997). Design of material transportation system for tandem automated guided vehicle systems. International Journal of Production Research. 35 (4), 943-953. DOI: 10.1080/002075497195461.10.1080/002075497195461Search in Google Scholar

[5] Johnson, ME. & Brandeau, ML. (1993). An Analytic Model for Design of a Multivehicle Automated Guided Vehicle System. Management Science. 39 (12), 1477-1489. DOI: 10.1287/mnsc.39.12.1477.10.1287/mnsc.39.12.1477Search in Google Scholar

[6] Makela, H. & von Numers, T. (2001). Development of a navigation and control system for an autonomous outdoor vehicle in a steel plant. Control Engineering Practice. 9 (5), 573-583. DOI: 10.1016/S0967-0661(01)00014-4.10.1016/S0967-0661(01)00014-4Search in Google Scholar

[7] Martinez-Barbera, H. & Herrero-Perez, D. (2010). Autonomous Navigation of an Automated Guided Vehicle in Industrial Environments. Robotics and Computer-Integrated Manufacturing. 26 (4), 296-311. DOI: 10.1016/j.rcim.2009.10.003.10.1016/j.rcim.2009.10.003Search in Google Scholar

[8] Gyulai, D., Pfeffer, A., Sobottka, T., & Vancza, J. (2013). Milkrun vehicle routing approach for shop-floor logistics. In 46th CIRP Conference on Manufacturing Systems, CIRP CMS 2013, 29-30 May 2013 (pp. 59-64). Setubal, Portugal: Elsevier science BV, Amsterdam, Netherlands.Search in Google Scholar

[9] Stopka, O. (2019). Approach technique of specifying a proper autonomous cart type for its service in the logistics center. The Archives of Automotive Engineering, 84(2), 23-31. DOI: 10.14669/AM.VOL84.ART2.10.14669/AM.VOL84.ART2Search in Google Scholar

[10] Brumerčík, F. (2011). Discrete event simulation of logistic and transport systems. In: Logi - Scientific Journal on Transport and Logistics, 2011, Vol. 2, No. 1, pp. 5 - 10, ISSN 1804-3216.Search in Google Scholar

[11] Mikusova, N. Cujan, Z. Tomkova, E. (2017). Robotization of logistics processes. In 18th International scientific conference-LOGI 2017, 19 October 2017 (pp. 1-8). Ceske Budejovice, Czech republic: EDP Sciences.Search in Google Scholar

[12] Molnar, V. & Pacutova, K. (2001). Assessing the possibilities of reducing the transport company costs. In Proceedings of the third international conference on trafflc and transport engineering (ICTTE), 24-25 November 2016 (pp. 570-575). Belgrade, Serbia: Scientific research center LTD Belgrade.Search in Google Scholar

[13] Janekova, J. Fabianova, J. Izarikova, G. Onofrejova, D. & Kovac, J. (2018). Product mix optimization based on monte carlo simulation: a case study. Int J Simul Model. 17(2), 295–307. DOI: 10.2507/IJSIMM17(2)436.10.2507/IJSIMM17(2)436Search in Google Scholar

[14] Meyer, A.. (2017). Milk run Design, Definitions, Concepts and Solution approaches. Karlsruhe: Karlsruher institut für technologie.Search in Google Scholar

[15] Cigáneková, M. (2017) Milkrun. Retrieved February 13, 2019, from https://www.ipaslovakia.sk/sk/ipa-slovnik/milk-runSearch in Google Scholar

© 2019 G. Fedorko et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Article

- Exploring conditions and usefulness of UAVs in the BRAIN Massive Inspections Protocol

- A hybrid approach for solving multi-mode resource-constrained project scheduling problem in construction

- Identification of geodetic risk factors occurring at the construction project preparation stage

- Multicriteria comparative analysis of pillars strengthening of the historic building

- Methods of habitat reports’ evaluation

- Effect of material and technological factors on the properties of cement-lime mortars and mortars with plasticizing admixture

- Management of Innovation Ecosystems Based on Six Sigma Business Scorecard

- On a Stochastic Regularization Technique for Ill-Conditioned Linear Systems

- Dynamic safety system for collaboration of operators and industrial robots

- Assessment of Decentralized Electricity Production from Hybrid Renewable Energy Sources for Sustainable Energy Development in Nigeria

- Seasonal evaluation of surface water quality at the Tamanduá stream watershed (Aparecida de Goiânia, Goiás, Brazil) using the Water Quality Index

- EFQM model implementation in a Portuguese Higher Education Institution

- Assessment of direct and indirect effects of building developments on the environment

- Accelerated Aging of WPCs Based on Polypropylene and Plywood Production Residues

- Analysis of the Cost of a Building’s Life Cycle in a Probabilistic Approach

- Implementation of Web Services for Data Integration to Improve Performance in The Processing Loan Approval

- Rehabilitation of buildings as an alternative to sustainability in Brazilian constructions

- Synthesis Conditions for LPV Controller with Input Covariance Constraints

- Procurement management in construction: study of Czech municipalities

- Contractor’s bid pricing strategy: a model with correlation among competitors’ prices

- Control of construction projects using the Earned Value Method - case study

- Model supporting decisions on renovation and modernization of public utility buildings

- Cements with calcareous fly ash as component of low clinker eco-self compacting concrete

- Failure Analysis of Super Hard End Mill HSS-Co

- Simulation model for resource-constrained construction project

- Getting efficient choices in buildings by using Genetic Algorithms: Assessment & validation

- Analysis of renewable energy use in single-family housing

- Modeling of the harmonization method for executing a multi-unit construction project

- Effect of foam glass granules fillers modification of lime-sand products on their microstructure

- Volume Optimization of Solid Waste Landfill Using Voronoi Diagram Geometry

- Analysis of occupational accidents in the construction industry with regards to selected time parameters

- Bill of quantities and quantity survey of construction works of renovated buildings - case study

- Cooperation of the PTFE sealing ring with the steel ball of the valve subjected to durability test

- Analytical model assessing the effect of increased traffic flow intensities on the road administration, maintenance and lifetime

- Quartz bentonite sandmix in sand-lime products

- The Issue of a Transport Mode Choice from the Perspective of Enterprise Logistics

- Analysis of workplace injuries in Slovakian state forestry enterprises

- Research into Customer Preferences of Potential Buyers of Simple Wood-based Houses for the Purpose of Using the Target Costing

- Proposal of the Inventory Management Automatic Identification System in the Manufacturing Enterprise Applying the Multi-criteria Analysis Methods

- Hyperboloid offset surface in the architecture and construction industry

- Analysis of the preparatory phase of a construction investment in the area covered by revitalization

- The selection of sealing technologies of the subsoil and hydrotechnical structures and quality assurance

- Impact of high temperature drying process on beech wood containing tension wood

- Prediction of Strength of Remixed Concrete by Application of Orthogonal Decomposition, Neural Analysis and Regression Analysis

- Modelling a production process using a Sankey diagram and Computerized Relative Allocation of Facilities Technique (CRAFT)

- The feasibility of using a low-cost depth camera for 3D scanning in mass customization

- Urban Water Infrastructure Asset Management Plan: Case Study

- Evaluation the effect of lime on the plastic and hardened properties of cement mortar and quantified using Vipulanandan model

- Uplift and Settlement Prediction Model of Marine Clay Soil e Integrated with Polyurethane Foam

- IoT Applications in Wind Energy Conversion Systems

- A new method for graph stream summarization based on both the structure and concepts

- “Zhores” — Petaflops supercomputer for data-driven modeling, machine learning and artificial intelligence installed in Skolkovo Institute of Science and Technology

- Economic Disposal Quantity of Leftovers kept in storage: a Monte Carlo simulation method

- Computer technology of the thermal stress state and fatigue life analysis of turbine engine exhaust support frames

- Statistical model used to assessment the sulphate resistance of mortars with fly ashes

- Application of organization goal-oriented requirement engineering (OGORE) methods in erp-based company business processes

- Influence of Sand Size on Mechanical Properties of Fiber Reinforced Polymer Concrete

- Architecture For Automation System Metrics Collection, Visualization and Data Engineering – HAMK Sheet Metal Center Building Automation Case Study

- Optimization of shape memory alloy braces for concentrically braced steel braced frames

- Topical Issue Modern Manufacturing Technologies

- Feasibility Study of Microneedle Fabrication from a thin Nitinol Wire Using a CW Single-Mode Fiber Laser

- Topical Issue: Progress in area of the flow machines and devices

- Analysis of the influence of a stator type modification on the performance of a pump with a hole impeller

- Investigations of drilled and multi-piped impellers cavitation performance

- The novel solution of ball valve with replaceable orifice. Numerical and field tests

- The flow deteriorations in course of the partial load operation of the middle specific speed Francis turbine

- Numerical analysis of temperature distribution in a brush seal with thermo-regulating bimetal elements

- A new solution of the semi-metallic gasket increasing tightness level

- Design and analysis of the flange-bolted joint with respect to required tightness and strength

- Special Issue: Actual trends in logistics and industrial engineering

- Intelligent programming of robotic flange production by means of CAM programming

- Static testing evaluation of pipe conveyor belt for different tensioning forces

- Design of clamping structure for material flow monitor of pipe conveyors

- Risk Minimisation in Integrated Supply Chains

- Use of simulation model for measurement of MilkRun system performance

- A simulation model for the need for intra-plant transport operation planning by AGV

- Operative production planning utilising quantitative forecasting and Monte Carlo simulations

- Monitoring bulk material pressure on bottom of storage using DEM

- Calibration of Transducers and of a Coil Compression Spring Constant on the Testing Equipment Simulating the Process of a Pallet Positioning in a Rack Cell

- Design of evaluation tool used to improve the production process

- Planning of Optimal Capacity for the Middle-Sized Storage Using a Mathematical Model

- Experimental assessment of the static stiffness of machine parts and structures by changing the magnitude of the hysteresis as a function of loading

- The evaluation of the production of the shaped part using the workshop programming method on the two-spindle multi-axis CTX alpha 500 lathe

- Numerical Modeling of p-v-T Rheological Equation Coefficients for Polypropylene with Variable Chalk Content

- Current options in the life cycle assessment of additive manufacturing products

- Ideal mathematical model of shock compression and shock expansion

- Use of simulation by modelling of conveyor belt contact forces

Articles in the same Issue

- Regular Article

- Exploring conditions and usefulness of UAVs in the BRAIN Massive Inspections Protocol

- A hybrid approach for solving multi-mode resource-constrained project scheduling problem in construction

- Identification of geodetic risk factors occurring at the construction project preparation stage

- Multicriteria comparative analysis of pillars strengthening of the historic building

- Methods of habitat reports’ evaluation

- Effect of material and technological factors on the properties of cement-lime mortars and mortars with plasticizing admixture

- Management of Innovation Ecosystems Based on Six Sigma Business Scorecard

- On a Stochastic Regularization Technique for Ill-Conditioned Linear Systems

- Dynamic safety system for collaboration of operators and industrial robots

- Assessment of Decentralized Electricity Production from Hybrid Renewable Energy Sources for Sustainable Energy Development in Nigeria

- Seasonal evaluation of surface water quality at the Tamanduá stream watershed (Aparecida de Goiânia, Goiás, Brazil) using the Water Quality Index

- EFQM model implementation in a Portuguese Higher Education Institution

- Assessment of direct and indirect effects of building developments on the environment

- Accelerated Aging of WPCs Based on Polypropylene and Plywood Production Residues

- Analysis of the Cost of a Building’s Life Cycle in a Probabilistic Approach

- Implementation of Web Services for Data Integration to Improve Performance in The Processing Loan Approval

- Rehabilitation of buildings as an alternative to sustainability in Brazilian constructions

- Synthesis Conditions for LPV Controller with Input Covariance Constraints

- Procurement management in construction: study of Czech municipalities

- Contractor’s bid pricing strategy: a model with correlation among competitors’ prices

- Control of construction projects using the Earned Value Method - case study

- Model supporting decisions on renovation and modernization of public utility buildings

- Cements with calcareous fly ash as component of low clinker eco-self compacting concrete

- Failure Analysis of Super Hard End Mill HSS-Co

- Simulation model for resource-constrained construction project

- Getting efficient choices in buildings by using Genetic Algorithms: Assessment & validation

- Analysis of renewable energy use in single-family housing

- Modeling of the harmonization method for executing a multi-unit construction project

- Effect of foam glass granules fillers modification of lime-sand products on their microstructure

- Volume Optimization of Solid Waste Landfill Using Voronoi Diagram Geometry

- Analysis of occupational accidents in the construction industry with regards to selected time parameters

- Bill of quantities and quantity survey of construction works of renovated buildings - case study

- Cooperation of the PTFE sealing ring with the steel ball of the valve subjected to durability test

- Analytical model assessing the effect of increased traffic flow intensities on the road administration, maintenance and lifetime

- Quartz bentonite sandmix in sand-lime products

- The Issue of a Transport Mode Choice from the Perspective of Enterprise Logistics

- Analysis of workplace injuries in Slovakian state forestry enterprises

- Research into Customer Preferences of Potential Buyers of Simple Wood-based Houses for the Purpose of Using the Target Costing

- Proposal of the Inventory Management Automatic Identification System in the Manufacturing Enterprise Applying the Multi-criteria Analysis Methods

- Hyperboloid offset surface in the architecture and construction industry

- Analysis of the preparatory phase of a construction investment in the area covered by revitalization

- The selection of sealing technologies of the subsoil and hydrotechnical structures and quality assurance

- Impact of high temperature drying process on beech wood containing tension wood

- Prediction of Strength of Remixed Concrete by Application of Orthogonal Decomposition, Neural Analysis and Regression Analysis

- Modelling a production process using a Sankey diagram and Computerized Relative Allocation of Facilities Technique (CRAFT)

- The feasibility of using a low-cost depth camera for 3D scanning in mass customization

- Urban Water Infrastructure Asset Management Plan: Case Study

- Evaluation the effect of lime on the plastic and hardened properties of cement mortar and quantified using Vipulanandan model

- Uplift and Settlement Prediction Model of Marine Clay Soil e Integrated with Polyurethane Foam

- IoT Applications in Wind Energy Conversion Systems

- A new method for graph stream summarization based on both the structure and concepts

- “Zhores” — Petaflops supercomputer for data-driven modeling, machine learning and artificial intelligence installed in Skolkovo Institute of Science and Technology

- Economic Disposal Quantity of Leftovers kept in storage: a Monte Carlo simulation method

- Computer technology of the thermal stress state and fatigue life analysis of turbine engine exhaust support frames

- Statistical model used to assessment the sulphate resistance of mortars with fly ashes

- Application of organization goal-oriented requirement engineering (OGORE) methods in erp-based company business processes

- Influence of Sand Size on Mechanical Properties of Fiber Reinforced Polymer Concrete

- Architecture For Automation System Metrics Collection, Visualization and Data Engineering – HAMK Sheet Metal Center Building Automation Case Study

- Optimization of shape memory alloy braces for concentrically braced steel braced frames

- Topical Issue Modern Manufacturing Technologies

- Feasibility Study of Microneedle Fabrication from a thin Nitinol Wire Using a CW Single-Mode Fiber Laser

- Topical Issue: Progress in area of the flow machines and devices

- Analysis of the influence of a stator type modification on the performance of a pump with a hole impeller

- Investigations of drilled and multi-piped impellers cavitation performance

- The novel solution of ball valve with replaceable orifice. Numerical and field tests

- The flow deteriorations in course of the partial load operation of the middle specific speed Francis turbine

- Numerical analysis of temperature distribution in a brush seal with thermo-regulating bimetal elements

- A new solution of the semi-metallic gasket increasing tightness level

- Design and analysis of the flange-bolted joint with respect to required tightness and strength

- Special Issue: Actual trends in logistics and industrial engineering

- Intelligent programming of robotic flange production by means of CAM programming

- Static testing evaluation of pipe conveyor belt for different tensioning forces

- Design of clamping structure for material flow monitor of pipe conveyors

- Risk Minimisation in Integrated Supply Chains

- Use of simulation model for measurement of MilkRun system performance

- A simulation model for the need for intra-plant transport operation planning by AGV

- Operative production planning utilising quantitative forecasting and Monte Carlo simulations

- Monitoring bulk material pressure on bottom of storage using DEM

- Calibration of Transducers and of a Coil Compression Spring Constant on the Testing Equipment Simulating the Process of a Pallet Positioning in a Rack Cell

- Design of evaluation tool used to improve the production process

- Planning of Optimal Capacity for the Middle-Sized Storage Using a Mathematical Model

- Experimental assessment of the static stiffness of machine parts and structures by changing the magnitude of the hysteresis as a function of loading

- The evaluation of the production of the shaped part using the workshop programming method on the two-spindle multi-axis CTX alpha 500 lathe

- Numerical Modeling of p-v-T Rheological Equation Coefficients for Polypropylene with Variable Chalk Content

- Current options in the life cycle assessment of additive manufacturing products

- Ideal mathematical model of shock compression and shock expansion

- Use of simulation by modelling of conveyor belt contact forces