Abstract

The deterioration of concrete in places exposed to sulphate salts, chlorides and groundwater movement is a major problem. In this research, polymer concrete was produced by testing four mixtures using different sizes of aggregates with epoxy adhesive and two mixtures were reinforced with polypropylene fibers (0.5 and 1)% by weight of Epoxy in addition to the reference mix consisting of cement and sand. Compressive strength, electrical resistivity, ultrasonic pulse velocity, flexural and porosity testing were performed at ages 7, 14, 28, and 60 days. The highest compressive strength, electrical resistance, ultrasonic pulse velocity and zero porosity for mixture had a maximum size of sand less than 600 microns and more than 150 microns, where the rate of increase (272.9, 635.9, 45.9 and 57.7)% respectively compared to the reference mixture. The results showed also that the highest flexural strength was for the mix reinforced with 1% polypropylene fiber. In addition, the specimens at age 28 day submerged in the diluted solution of sulfuric acid at 5 and 10% for 11 weeks. The results showed that there were no change in the volume and weights of the specimens that were submerged.

1 Introduction

Polymer concrete is a composite material consisting of well graded inorganic aggregates bound by using a resin instead of the water and cement binder typically used in traditional cement concretes [1, 6]. Conventional concrete contains a small amount of fine aggregates or does not contain adequate amount of cement paste to encapsulate and bind the total particles together to create a system of high porosity and interconnected spaces that can quickly dispose water. In general, the content of voids in conventional concrete ranges between 15% and 25%, and water permeability is usually about 2-6 mm/s. However, strength is usually associated with porosity in concrete where strength decreases with high porosity [6, 7, 8, 9, 10]. At present, due to fast treatment, excellent bonds, reinforcing steel, high strength and durability of polymer concrete was widely used instead of ordinary concrete. Precast polymer concrete has been used to produce a variety of products such as; acid tanks, inspection rooms, drains, highway barriers and so on [11, 12].

The aggregates are usually taken as materials inert dispersed throughout the polymer molding. Usually, the aggregates are added into two groups, coarse aggregates contain material larger than 5 mm and fine aggregate size of less than 5mm.Grading is not estimated in the case of polymer concrete until the present time and varies widely from one system to another. In addition to coarse and fine aggregates, filler materials are also sometimes added to the polymer concrete system primarily to fill the micro voids. Polymer concrete can also be enhanced to improve its mechanical properties with different types of fibers used of steel fibers, polypropylene, glass and nylon [13]. One of the most important characteristics required for materials that are used in civil and construction industries are durability [14, 15]. Durability is known as the ability of material to withstand environmental loads without distorting the shape or changing the properties. Due to the high durability gained in early polymer concrete as well as high strength and chemical resistance, it is used in a wide variety of industries far beyond the construction industry [16]. The advantages of polymer concrete has low price, the possibility of controlling many of its characteristics and its ability of cold formation (setting), it also can resist chemical substances with high values [17]. These specifications made us to search more and more to know its characteristics and the possibility of using it in places that need such a type of concrete. The production of conventional concrete causes the emission of carbon dioxide (CO2) with large quantities, while the resin materials is emission less, that makes it Eco-friendly, in addition to it, the ordinary concrete deteriorates after 20 years unlike the polymer concrete that has a high durability. So, the search started about another materials more effective than conventional concrete, it is the polymeric concrete, that its main bonding material is a type of polymers (including Epoxy) with using different fillers such as; sand, with different ratios.

2 Materials

2.1 Sand

Akhaither sand was used, which is compatible with British specifications number 882, for a year 1995, listed below in Table 1.

Particle Size of Sand

| Size of sieve (mm) | Gradient area number 2 |

|---|---|

| 4.76 | 90-100 |

| 2.4 | 75-100 |

| 1.2 | 55-90 |

| 0.6 | 35-59 |

| 0.3 | 8-30 |

| 0.150 | 0-10 |

2.2 Epoxy

It is an organic particular that has the ability to combine with similar and different particulates to produce a high partial weight material (double origin compound). Specifications of Epoxy comply with ASTM D-543 and ASTM C 881-87 is listed in Table 2 below.

Specifications of Epoxy

| Density (g /cm3) | 1.05 |

| Mix ratio (by weight) | 3:1 |

| Mix ratio (by volume) | 5:2 |

| Minimum hardening temperature ∘C | 8 |

| Bone dry at 200 C (hours) | 2 |

| Thorough hardened at 20∘C (days) | 7 |

| Volume Shrinkage (%) | 3.5 |

| compressive (N/mm2) | 85 |

| Bending (N/mm2) | 45 |

| Tension force (N/mm2) | 45 |

| Flexure (%) | 4 |

| E-module (N/mm2) | 2800 |

| Storage life in months at 20∘C | 12 |

| Colour | Colourless |

2.3 Polypropylene Fibers

It is an artificial fiber that is added to concrete to increase tension resistance, impact resistance and to reduce shrinkage.

The characteristics of polypropylene are listed in Table 3 below.

The characteristics of polypropylene

| 0.91 g/cm | Specific weight |

| 18 Micron | Diameter of fibers |

| 12 mm | Length of fibers |

| 230 m2 /kg min | Surface area |

| Min 350 MPa | Tension force |

| 160∘C | Melting point |

2.4 Polyethylene

Very thin polyethylene nylon was used to ensure that the mixture won’t stick to the surfaces of molds

2.5 Proportion of Materials

This research included six mixtures in the polymer concrete reinforced or unreinforced with polypropylene fiber (0.5 and 1)% by weight of epoxy at a ratio of 1:1.3 in addition to reference mix as follows:

Used Portland cement with sand pass from sieve 4.75 mm and residual on sieve 150 micron at a ratio of 1:1.3 and water/cement ratio 0.5 (Reference) (Re)

Used epoxy + hardener with sand pass from sieve 4.75 mm and residual on sieve 150 micron at a ratio of 1:1.3 (PC1)

Used epoxy + hardener with sand pass from sieve 2.4 mm and residual on sieve 150 micron at a ratio of 1:1.3 (PC2)

Used epoxy + hardener with sand pass from sieve 1.2 mm and residual on sieve 150 micron at a ratio of 1:1.3 (PC3)

Used epoxy + hardener with sand pass from sieve 600 micron and residual on sieve 150 micron at a ratio of 1:1.3 (PC4)

Used epoxy + hardener with sand pass from sieve 600 micron and residual on sieve 150 micron at a ratio of 1:1.3 and 0.5% polypropylene fibers (PC5)

Used epoxy + hardener with sand pass from sieve 600 micron and residual on sieve 150 micron at a ratio of 1:1.3 and 1% polypropylene fibers (PC6).

Influence of Epoxy on Compressive Strength of Polymer Concrete with Age

3 Experimental Analysis and Result Discussion

3.1 Compressive Strength

The compressive strength was performed for specimens that contained sand with particle size passing from sieve 4.75 mm and residual on sieve 150 micron (PC1) and cement mortar (R). The results showed that specimens PC1 had a considerable increase in compressive strength at all ages. In spite of slight increase in strength at ages between 14 and 60 days, where the percentage of increase were (44, 307.5, 245.6, 234.1)% at ages 7, 14, 28 and 60 days respectively, compared with (R) specimens, the reason of that due to the final setting time of epoxy approximately was during 14 day.

The influence of using different particle size of sands have been revealed in Figure 2, where it was showed that, there was a little increase in the value of compressive strength. The highest value of compressive strength were for PC4 specimens which were used in passing sand from sieve 600 micron and residual on sieve 150 micron, although the percentage of increase was 4.8% at 28 days with respect to PC1 specimens which were used in passing sands from sieve 4.75 mm and residual on sieve 150 micron. The effect of progress of age on compressive strength of specimens continued increasing but very little value after 14 days, for the same reason above, and in late ages, the compressive strengths were equal because the epoxy polymer became harder. Figure 3 also showed a comparison between reinforced and non-reinforced polymer concrete as there is a slight decrease in the compressive strength of polymer concrete reinforced with polypropylene fiber compared to non-reinforced polymer concrete. This decrease is increased as the percentage of fiber increase.

Influence of Sand Size on Compressive Strength of Polymer Concrete with Age

Influence of Polypropylene Fibers on Compressive Strength of Polymer Concrete with Age

3.2 Electrical Resistance

The epoxy polymer actually has a plastic nature which gives it a high resistance to electricity,while cement mortar has a little resistance may be due to the internal combinations that consist of cement mortar. The variation of sand size in mixtures that used epoxy polymer showed variation in electrical resistance because of the fineness of sand size leads to reduce the voids in the sample and increase the bonding between components of mixture, which cause increasing in electrical resistance, as shown in Figure 4.

Influence of Sand Size on Electrical Resistance of Polymer Concrete at 28 Age

3.3 Ultrasonic Pulse Velocity

From Figure 5, it is observed that the ultrasonic pulse velocity test for the cement mortar is less than the mixtures that its bonding material is epoxy, because of the massive increasing of voids in cement mortar with respect to polymer concrete. This is due to the structure of cement mortar.

Influence of Sand Size on Ultrasonic Pulse Velocity of Polymer Concrete with Age

3.4 Absorption Test

When conducting the absorption test for cement mortar specimens and polymeric concrete specimens which consist of different sizes of sand, the results showed that the absorption rate in the cement paste was 2.978% due to the open voids in the structure of the cement paste. While the absorption rates for polymeric concrete specimens were zero for being solid and non-permeable.

3.5 Flexural Strength

The results indicated a considerable increase in flexural strength due to the usage of epoxy polymer and sand with maximum size 600μ and residual on sieve 150 micron. The percentages of increase in flexural strength with respect to reference mix were 57.7% at age 28 days, in addition, the use of polypropylene fibers has largely increased the flexural value specially, when reinforced with 1% polypropylene fibers where the percentages of increase in flexural strength with respect to reference mix were 110.77% at age 28 days as shown in Figure 6.

Influence of Sand Size on Flexural Strength of Polymer Concrete with Age

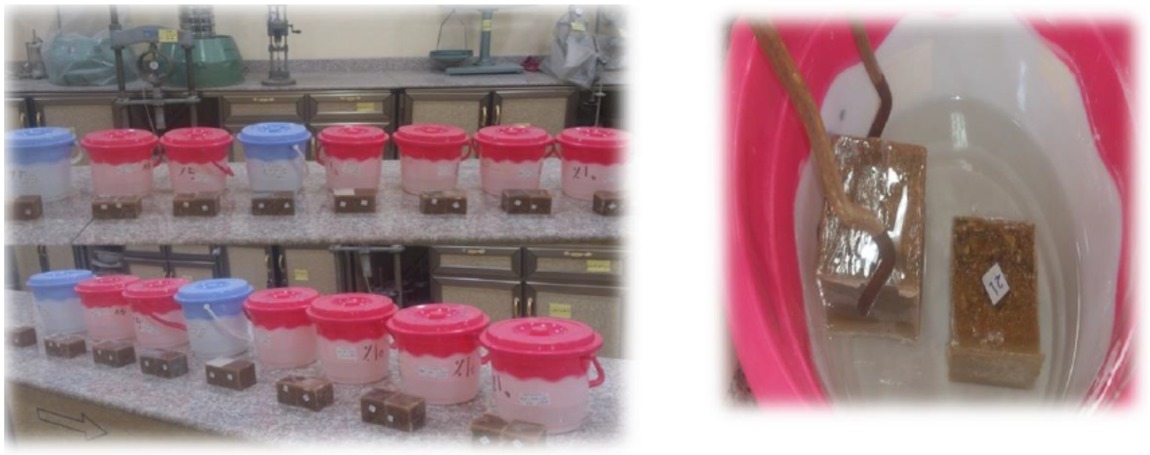

3.6 Immersion in Sulfuric Acid

Polymer concrete specimens submerged at age 28 in diluted solution (5 and 10)% of sulfuric acid for 11weeks, every weekend were weighed and measured the dimensions of the specimens after washing and cleaning it and then re-submerged in new concentrations to maintain the concentration (5 and 10)% of the acid in the submerged specimen to study the volume and weight variation of it. The results showed that there was no change in the sizes and weights of the specimens that were submerged as shown in the Figure S1. The reason was due to the small size particles of sand and the condensed interface between the surfaces of these particles and polymer making it solid and non-permeable. While reference mixes was a loss ratio by weight and volume at the concentration of 10% up to 96.43% in the fourth week.

4 Conclusions

The compressive strength of the polymer concrete is three times than that of the cement mortar. The different sizes of sand in polymer concrete has resulted in increased in compressive strength, electrical resistance and ultrasonic pulse velocity. The smaller sand size has led to increased values of these properties,

Polymer concrete has no water absorption ability and is very durable and has high resistant to sulfur acid when it is concentrated (5 -10)%,

The flexural strength of polymer concrete increases as the ratio of polypropylene fibers increases while compressive strength decreases as the ratio of these fibers increases,

Thus the use of it as an alternative of cement is necessary in many applications due to its properties of distinctive concrete.

Appendix

Specimens Submerged at Age 28 in Diluted Solution (5 and 10)% of Sulfuric Acid

References

[1] Cortés, F., and G. Castillo. "Comparison between the dynamical properties of polymer concrete and grey cast iron for machine tool applications." Materials & design 28.5 (2007): 1461-1466.10.1016/j.matdes.2006.03.012Search in Google Scholar

[2] Carrión, Francisco, et al. "Mechanical and physical properties of polyester polymer concrete using recycled aggregates from concrete sleepers." The Scientific World Journal 2014 (2014).10.1155/2014/526346Search in Google Scholar

[3] Garas, Victor Y., and C. Vipulanandan. "Review of polyester polymer concrete properties." Report for Innovative Grouting Materials and Technology (CIGMAT), Houston, TX (2003).Search in Google Scholar

[4] ACI Committee 548, Polymers in Concrete, and David W. Fowler. "Guide for the Use of Polymers in Concrete." American Concrete Institute, 1992.Search in Google Scholar

[5] Haddad H, Sbarski I (2018) Optimization of Moulding Technology of Polymer Concrete Used for Manufacture Precision Tool Machine Bases. J Material Sci Eng 7: 427. doi: 10.4172/2169-0022.100042710.4172/2169-0022.1000427Search in Google Scholar

[6] Tennis, P. D., Leming, M. L., & Akers, D. J. (2004). Pervious concrete pavements, EB302. 02. Portland cement association, skokie, illinois, and national ready mixed concrete association, Maryland, USA: Silver SpringSearch in Google Scholar

[7] Fallah, S., & Nematzadeh, M. (2017). Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Construction and building materials, 132, 170-187.10.1016/j.conbuildmat.2016.11.100Search in Google Scholar

[8] Schaefer, V. R., & Wang, K. (2006). Mix design development for pervious concrete in cold weather climates (No. 2006-01). Iowa. Dept. of Transportation. Highway DivisionSearch in Google Scholar

[9] Fowler, D. W. (1999). Polymers in concrete: a vision for the 21st century. Cement and concrete composites, 21(5-6), 449-452.10.1016/S0958-9465(99)00032-3Search in Google Scholar

[10] Huang, Baoshan, et al. "Laboratory evaluation of permeability and strength of polymer-modified pervious concrete." Construction and Building Materials 24.5 (2010): 818-823.10.1016/j.conbuildmat.2009.10.025Search in Google Scholar

[11] Muthukumar, M., and D. Mohan. "Optimization of mechanical properties of polymer concrete and mix design recommendation based on design of experiments." Journal of applied polymer science 94.3 (2004): 1107-1116.10.1002/app.21008Search in Google Scholar

[12] Mehta, P. Kumar. "Durability–Critical issues for the future." Concrete international 19.7 (1997): 27-33.Search in Google Scholar

[13] Hong, S. (2017). Influence of curing conditions on the strength properties of polysulfide polymer concrete. Applied Sciences, 7(8), 83310.3390/app7080833Search in Google Scholar

[14] Fowler, D. W. (1999). Polymers in concrete: a vision for the 21st century. Cement and concrete composites, 21(5-6), 449-45210.1016/S0958-9465(99)00032-3Search in Google Scholar

[15] Sakhakarmi, S. (2017). Cost Comparison of Cement Concrete and Polymer Concrete Manholes in Sewer Systems. UNLV Theses, Dissertations, Professional Papers, and Capstones. 3165.10.1061/9780784481301.050Search in Google Scholar

[16] Reis, J. M. L. D. (2009). Effect of textile waste on the mechanical properties of polymer concrete. Materials Research, 12(1), 63-6710.1590/S1516-14392009000100007Search in Google Scholar

[17] Abdulla, A. I., Razak, H. A., Salih, Y. A., & Ali, M. I. (2016). Mechanical properties of sand modified resins used for bonding CFRP to concrete substrates. International Journal of Sustainable Built Environment, 5(2), 517-525.10.1016/j.ijsbe.2016.06.001Search in Google Scholar

[18] Barbuta, Marinela, and Maria Harja. "Properties of fiber reinforced polymer concrete." Buletinul Institutului Politehnic din lasi. Sectia Constructii, Arhitectura 54.3 (2008): 13.Search in Google Scholar

[19] Van Gemert, D., & Cizer, Ö. (2015). Merging cement concrete, concrete-polymer composites and inorganic polymer technologies for sustainability in construction and restoration. In Advanced Materials Research (Vol. 1129, pp. 19-27). Trans Tech Publications.10.4028/www.scientific.net/AMR.1129.19Search in Google Scholar

© 2019 Z. H. Mahdil et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Regular Article

- Exploring conditions and usefulness of UAVs in the BRAIN Massive Inspections Protocol

- A hybrid approach for solving multi-mode resource-constrained project scheduling problem in construction

- Identification of geodetic risk factors occurring at the construction project preparation stage

- Multicriteria comparative analysis of pillars strengthening of the historic building

- Methods of habitat reports’ evaluation

- Effect of material and technological factors on the properties of cement-lime mortars and mortars with plasticizing admixture

- Management of Innovation Ecosystems Based on Six Sigma Business Scorecard

- On a Stochastic Regularization Technique for Ill-Conditioned Linear Systems

- Dynamic safety system for collaboration of operators and industrial robots

- Assessment of Decentralized Electricity Production from Hybrid Renewable Energy Sources for Sustainable Energy Development in Nigeria

- Seasonal evaluation of surface water quality at the Tamanduá stream watershed (Aparecida de Goiânia, Goiás, Brazil) using the Water Quality Index

- EFQM model implementation in a Portuguese Higher Education Institution

- Assessment of direct and indirect effects of building developments on the environment

- Accelerated Aging of WPCs Based on Polypropylene and Plywood Production Residues

- Analysis of the Cost of a Building’s Life Cycle in a Probabilistic Approach

- Implementation of Web Services for Data Integration to Improve Performance in The Processing Loan Approval

- Rehabilitation of buildings as an alternative to sustainability in Brazilian constructions

- Synthesis Conditions for LPV Controller with Input Covariance Constraints

- Procurement management in construction: study of Czech municipalities

- Contractor’s bid pricing strategy: a model with correlation among competitors’ prices

- Control of construction projects using the Earned Value Method - case study

- Model supporting decisions on renovation and modernization of public utility buildings

- Cements with calcareous fly ash as component of low clinker eco-self compacting concrete

- Failure Analysis of Super Hard End Mill HSS-Co

- Simulation model for resource-constrained construction project

- Getting efficient choices in buildings by using Genetic Algorithms: Assessment & validation

- Analysis of renewable energy use in single-family housing

- Modeling of the harmonization method for executing a multi-unit construction project

- Effect of foam glass granules fillers modification of lime-sand products on their microstructure

- Volume Optimization of Solid Waste Landfill Using Voronoi Diagram Geometry

- Analysis of occupational accidents in the construction industry with regards to selected time parameters

- Bill of quantities and quantity survey of construction works of renovated buildings - case study

- Cooperation of the PTFE sealing ring with the steel ball of the valve subjected to durability test

- Analytical model assessing the effect of increased traffic flow intensities on the road administration, maintenance and lifetime

- Quartz bentonite sandmix in sand-lime products

- The Issue of a Transport Mode Choice from the Perspective of Enterprise Logistics

- Analysis of workplace injuries in Slovakian state forestry enterprises

- Research into Customer Preferences of Potential Buyers of Simple Wood-based Houses for the Purpose of Using the Target Costing

- Proposal of the Inventory Management Automatic Identification System in the Manufacturing Enterprise Applying the Multi-criteria Analysis Methods

- Hyperboloid offset surface in the architecture and construction industry

- Analysis of the preparatory phase of a construction investment in the area covered by revitalization

- The selection of sealing technologies of the subsoil and hydrotechnical structures and quality assurance

- Impact of high temperature drying process on beech wood containing tension wood

- Prediction of Strength of Remixed Concrete by Application of Orthogonal Decomposition, Neural Analysis and Regression Analysis

- Modelling a production process using a Sankey diagram and Computerized Relative Allocation of Facilities Technique (CRAFT)

- The feasibility of using a low-cost depth camera for 3D scanning in mass customization

- Urban Water Infrastructure Asset Management Plan: Case Study

- Evaluation the effect of lime on the plastic and hardened properties of cement mortar and quantified using Vipulanandan model

- Uplift and Settlement Prediction Model of Marine Clay Soil e Integrated with Polyurethane Foam

- IoT Applications in Wind Energy Conversion Systems

- A new method for graph stream summarization based on both the structure and concepts

- “Zhores” — Petaflops supercomputer for data-driven modeling, machine learning and artificial intelligence installed in Skolkovo Institute of Science and Technology

- Economic Disposal Quantity of Leftovers kept in storage: a Monte Carlo simulation method

- Computer technology of the thermal stress state and fatigue life analysis of turbine engine exhaust support frames

- Statistical model used to assessment the sulphate resistance of mortars with fly ashes

- Application of organization goal-oriented requirement engineering (OGORE) methods in erp-based company business processes

- Influence of Sand Size on Mechanical Properties of Fiber Reinforced Polymer Concrete

- Architecture For Automation System Metrics Collection, Visualization and Data Engineering – HAMK Sheet Metal Center Building Automation Case Study

- Optimization of shape memory alloy braces for concentrically braced steel braced frames

- Topical Issue Modern Manufacturing Technologies

- Feasibility Study of Microneedle Fabrication from a thin Nitinol Wire Using a CW Single-Mode Fiber Laser

- Topical Issue: Progress in area of the flow machines and devices

- Analysis of the influence of a stator type modification on the performance of a pump with a hole impeller

- Investigations of drilled and multi-piped impellers cavitation performance

- The novel solution of ball valve with replaceable orifice. Numerical and field tests

- The flow deteriorations in course of the partial load operation of the middle specific speed Francis turbine

- Numerical analysis of temperature distribution in a brush seal with thermo-regulating bimetal elements

- A new solution of the semi-metallic gasket increasing tightness level

- Design and analysis of the flange-bolted joint with respect to required tightness and strength

- Special Issue: Actual trends in logistics and industrial engineering

- Intelligent programming of robotic flange production by means of CAM programming

- Static testing evaluation of pipe conveyor belt for different tensioning forces

- Design of clamping structure for material flow monitor of pipe conveyors

- Risk Minimisation in Integrated Supply Chains

- Use of simulation model for measurement of MilkRun system performance

- A simulation model for the need for intra-plant transport operation planning by AGV

- Operative production planning utilising quantitative forecasting and Monte Carlo simulations

- Monitoring bulk material pressure on bottom of storage using DEM

- Calibration of Transducers and of a Coil Compression Spring Constant on the Testing Equipment Simulating the Process of a Pallet Positioning in a Rack Cell

- Design of evaluation tool used to improve the production process

- Planning of Optimal Capacity for the Middle-Sized Storage Using a Mathematical Model

- Experimental assessment of the static stiffness of machine parts and structures by changing the magnitude of the hysteresis as a function of loading

- The evaluation of the production of the shaped part using the workshop programming method on the two-spindle multi-axis CTX alpha 500 lathe

- Numerical Modeling of p-v-T Rheological Equation Coefficients for Polypropylene with Variable Chalk Content

- Current options in the life cycle assessment of additive manufacturing products

- Ideal mathematical model of shock compression and shock expansion

- Use of simulation by modelling of conveyor belt contact forces

Articles in the same Issue

- Regular Article

- Exploring conditions and usefulness of UAVs in the BRAIN Massive Inspections Protocol

- A hybrid approach for solving multi-mode resource-constrained project scheduling problem in construction

- Identification of geodetic risk factors occurring at the construction project preparation stage

- Multicriteria comparative analysis of pillars strengthening of the historic building

- Methods of habitat reports’ evaluation

- Effect of material and technological factors on the properties of cement-lime mortars and mortars with plasticizing admixture

- Management of Innovation Ecosystems Based on Six Sigma Business Scorecard

- On a Stochastic Regularization Technique for Ill-Conditioned Linear Systems

- Dynamic safety system for collaboration of operators and industrial robots

- Assessment of Decentralized Electricity Production from Hybrid Renewable Energy Sources for Sustainable Energy Development in Nigeria

- Seasonal evaluation of surface water quality at the Tamanduá stream watershed (Aparecida de Goiânia, Goiás, Brazil) using the Water Quality Index

- EFQM model implementation in a Portuguese Higher Education Institution

- Assessment of direct and indirect effects of building developments on the environment

- Accelerated Aging of WPCs Based on Polypropylene and Plywood Production Residues

- Analysis of the Cost of a Building’s Life Cycle in a Probabilistic Approach

- Implementation of Web Services for Data Integration to Improve Performance in The Processing Loan Approval

- Rehabilitation of buildings as an alternative to sustainability in Brazilian constructions

- Synthesis Conditions for LPV Controller with Input Covariance Constraints

- Procurement management in construction: study of Czech municipalities

- Contractor’s bid pricing strategy: a model with correlation among competitors’ prices

- Control of construction projects using the Earned Value Method - case study

- Model supporting decisions on renovation and modernization of public utility buildings

- Cements with calcareous fly ash as component of low clinker eco-self compacting concrete

- Failure Analysis of Super Hard End Mill HSS-Co

- Simulation model for resource-constrained construction project

- Getting efficient choices in buildings by using Genetic Algorithms: Assessment & validation

- Analysis of renewable energy use in single-family housing

- Modeling of the harmonization method for executing a multi-unit construction project

- Effect of foam glass granules fillers modification of lime-sand products on their microstructure

- Volume Optimization of Solid Waste Landfill Using Voronoi Diagram Geometry

- Analysis of occupational accidents in the construction industry with regards to selected time parameters

- Bill of quantities and quantity survey of construction works of renovated buildings - case study

- Cooperation of the PTFE sealing ring with the steel ball of the valve subjected to durability test

- Analytical model assessing the effect of increased traffic flow intensities on the road administration, maintenance and lifetime

- Quartz bentonite sandmix in sand-lime products

- The Issue of a Transport Mode Choice from the Perspective of Enterprise Logistics

- Analysis of workplace injuries in Slovakian state forestry enterprises

- Research into Customer Preferences of Potential Buyers of Simple Wood-based Houses for the Purpose of Using the Target Costing

- Proposal of the Inventory Management Automatic Identification System in the Manufacturing Enterprise Applying the Multi-criteria Analysis Methods

- Hyperboloid offset surface in the architecture and construction industry

- Analysis of the preparatory phase of a construction investment in the area covered by revitalization

- The selection of sealing technologies of the subsoil and hydrotechnical structures and quality assurance

- Impact of high temperature drying process on beech wood containing tension wood

- Prediction of Strength of Remixed Concrete by Application of Orthogonal Decomposition, Neural Analysis and Regression Analysis

- Modelling a production process using a Sankey diagram and Computerized Relative Allocation of Facilities Technique (CRAFT)

- The feasibility of using a low-cost depth camera for 3D scanning in mass customization

- Urban Water Infrastructure Asset Management Plan: Case Study

- Evaluation the effect of lime on the plastic and hardened properties of cement mortar and quantified using Vipulanandan model

- Uplift and Settlement Prediction Model of Marine Clay Soil e Integrated with Polyurethane Foam

- IoT Applications in Wind Energy Conversion Systems

- A new method for graph stream summarization based on both the structure and concepts

- “Zhores” — Petaflops supercomputer for data-driven modeling, machine learning and artificial intelligence installed in Skolkovo Institute of Science and Technology

- Economic Disposal Quantity of Leftovers kept in storage: a Monte Carlo simulation method

- Computer technology of the thermal stress state and fatigue life analysis of turbine engine exhaust support frames

- Statistical model used to assessment the sulphate resistance of mortars with fly ashes

- Application of organization goal-oriented requirement engineering (OGORE) methods in erp-based company business processes

- Influence of Sand Size on Mechanical Properties of Fiber Reinforced Polymer Concrete

- Architecture For Automation System Metrics Collection, Visualization and Data Engineering – HAMK Sheet Metal Center Building Automation Case Study

- Optimization of shape memory alloy braces for concentrically braced steel braced frames

- Topical Issue Modern Manufacturing Technologies

- Feasibility Study of Microneedle Fabrication from a thin Nitinol Wire Using a CW Single-Mode Fiber Laser

- Topical Issue: Progress in area of the flow machines and devices

- Analysis of the influence of a stator type modification on the performance of a pump with a hole impeller

- Investigations of drilled and multi-piped impellers cavitation performance

- The novel solution of ball valve with replaceable orifice. Numerical and field tests

- The flow deteriorations in course of the partial load operation of the middle specific speed Francis turbine

- Numerical analysis of temperature distribution in a brush seal with thermo-regulating bimetal elements

- A new solution of the semi-metallic gasket increasing tightness level

- Design and analysis of the flange-bolted joint with respect to required tightness and strength

- Special Issue: Actual trends in logistics and industrial engineering

- Intelligent programming of robotic flange production by means of CAM programming

- Static testing evaluation of pipe conveyor belt for different tensioning forces

- Design of clamping structure for material flow monitor of pipe conveyors

- Risk Minimisation in Integrated Supply Chains

- Use of simulation model for measurement of MilkRun system performance

- A simulation model for the need for intra-plant transport operation planning by AGV

- Operative production planning utilising quantitative forecasting and Monte Carlo simulations

- Monitoring bulk material pressure on bottom of storage using DEM

- Calibration of Transducers and of a Coil Compression Spring Constant on the Testing Equipment Simulating the Process of a Pallet Positioning in a Rack Cell

- Design of evaluation tool used to improve the production process

- Planning of Optimal Capacity for the Middle-Sized Storage Using a Mathematical Model

- Experimental assessment of the static stiffness of machine parts and structures by changing the magnitude of the hysteresis as a function of loading

- The evaluation of the production of the shaped part using the workshop programming method on the two-spindle multi-axis CTX alpha 500 lathe

- Numerical Modeling of p-v-T Rheological Equation Coefficients for Polypropylene with Variable Chalk Content

- Current options in the life cycle assessment of additive manufacturing products

- Ideal mathematical model of shock compression and shock expansion

- Use of simulation by modelling of conveyor belt contact forces