Abstract

The paper presents the continuation of work devoted to the analysis of a brush seal with thermo-regulating bimetal elements aimed at thermal protection of a brush seal. This paper presents a method of determining the operating temperature of such a seal using the finite element method. It has been shown that building the seal according to the idea allows a significant reduction of its working temperature.

1 Introduction

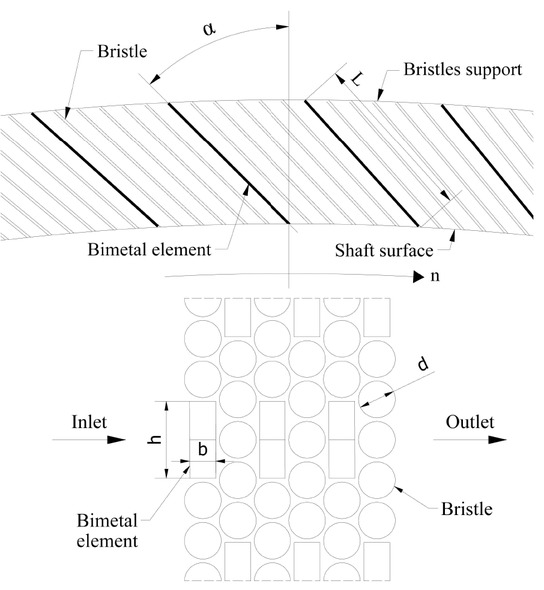

Brush seals in recent years have been an interest to many researchers, this being due to a relatively good sealing and a large potential for their development. They are becoming a viable alternative to labyrinth seals currently used in gas and steam turbines. These seals according to various sources are characterized by 5-20 times smaller leakage compared with labyrinth seals with the same operating parameters [1, 2, 3, 4]. A characteristic feature distinguishing the brush seal is its susceptibility to small radial displacement of the shaft. These seals belong to a contact sealing group, therefore, it is inevitable for the seal and the shaft to wear out due to friction phenomena. Rubbing, besides the outwearing, causes a formation of large quantities of heat which, in extreme cases, can cause the bristles to melt their ends. A completely new design solution for this type of the seal is a one with thermo-regulating bimetal elements [4], whose construction is shown in Figure 1.

Scheme of the brush seal with bimetal elements

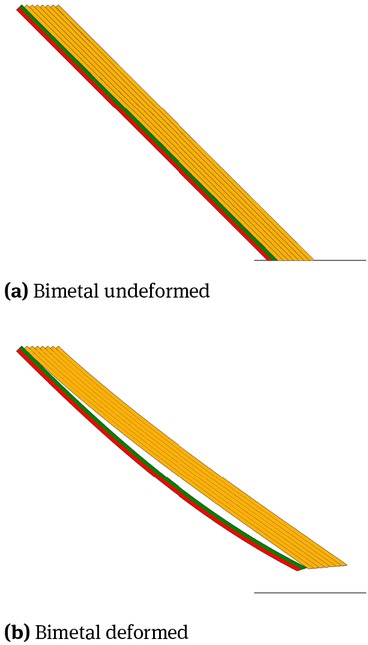

The structure and the principle of operation of such a seal are described in detail in [5]. In this seal, bimetallic elements are used which, while deforming, reduce the pressure of the seal on the surface of the shaft which subsequently leads to decrease of the friction heat flux, and thus, drop in temperature (Figure 2).

The idea of using bimetal in brush seal

The most important criterion for assessing the work of such a seal besides tightness, the author plans to analyze in the near future, is the effect of this solution on the working temperature of the seal. This paper presents the method of determining the working temperature of the seal built according to the idea. As an additional goal, a modification of the standard seal supplied for the testing whose measured operating temperature during the test was about 125∘C, in such a way that after adding bimetal elements its working temperature was for example, about 80∘C.

2 FEM model for calculating the temperature of the seal with thermo-regulating bimetal elements

In the seal constructed according to the idea the pressure force of bristles on the surface of the shaft depends on the deformation of the bimetallic elements, which in turn, depends on the temperature. On the other hand, the temperature depends on the frictional heat flux generated in the contact zone of the seal with the shaft, and the heat depends on the pressure. There is a kind of feedback between the temperature, the frictional heat flux, and the deformation of the bimetal. To determine the equilibrium temperature during the operation of such a seal, it is necessary to carry out a coupled thermal-mechanical analysis.

The thermo-mechanical 3D analysis of the seal consisting of a large number of bristles conducting heat, which is subsequently dissipated on the outer surface by convection is not of great use [6, 7] due to a high degree of complexity. The bristles arranged at the circumferance of the seal come into contact with one another in many places creating between themselves randomly located pores filled with fluid. The position of the bristles, and thus the shape and distribution of the pores, is variable and depends on the interference and working conditions of the seal. In case of embedding additional bimetal elements in the seal to reduce the pressure of the bristles on the shaft the problem becomes even more complicated.

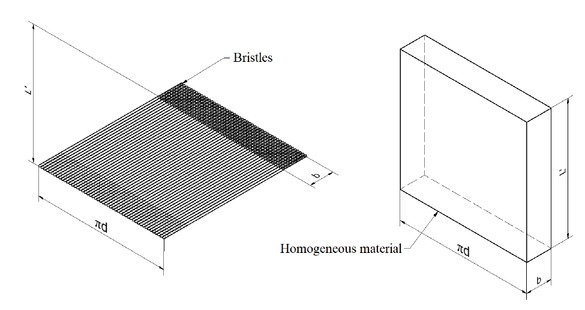

In order to simplify the issue it was decided to treat the palisade of bristles as a homogeneous material with substitute heat conductivity and stiffness. It significantly simplifies the analysis, thus, speeds up numerical calculations.

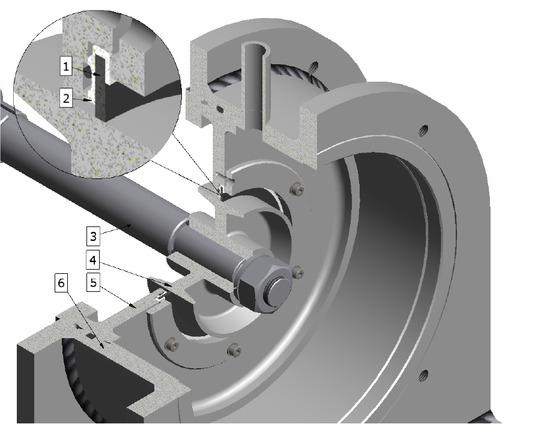

Utilizing the ANSYS software a combined thermal and mechanical analysis of the brush seal mounted in the test rig was carried out (Figure 3), the problem was solved as axial symmetry.

The CAD geometry used in analysis: 1. bristles palisade, 2. seal housing, 3. test rig shaft, 4. conical disk, 5. seal support, 6. test rig chamber.

The finite element method matrix equation while solving the steady state coupled thermal-structural analysis is described by the equation (1) [8].

where:

[K] - structural stiffness matrix,

[Kut] - thermal contraction matrix,

[Kt] - thermal conductivity matrix,

{u} - displacement vector,

{T} - temperature,

{F} - nodal force vector,

{Q} - heat flux vector.

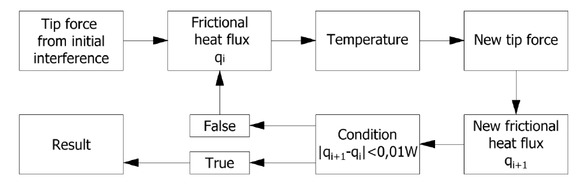

The order of solving the problem by means of the finite element method is presented in Figure 4. In the first iteration the pressure force resulting from the initial interference at ambient temperature is calculated. Then, for the calculated pressure force, the friction heat flux is calculated according to the equation 2.

Block diagram of coupled thermal-structural analysis

where:

μ - friction coefficient,

v - sliding speed, [m/s]

F - pressure force, [N]

In the equation 2 a constant value of friction coefficient μ = 0.28 in pair Haynes 25 - 1.4301 Stainless Steel [9] is assumed. In the next step, the temperature distribution is calculated under the determined heat flux load. In the end, a new pressure force is determined due to the change in the seal temperature. The second iteration starts where the convergence condition is checked after calculating the new heat flux. If the convergence is greater than 0.01W the next iteration is performed, if it is smaller, the calculations are completed.

To solve this problem a rectangular 20-node PLANE223 was applied. It is a 2D element for solving the coupled thermal-structural analyses,where the degrees of freedom are displacements and temperature.

To reduce the number of shafts with different diameters to implement different interference values, a conical disk with a very small cone angle was used. The interference adjustment was made by changing the position of the test rig chamber with the seal in it through sliding it in an axial direction.

3 Stiffness of the seal

If we simplify the geometry of the seal by replacing the bristles palisade with a homogeneous material (Figure 5), then at the same sliding speed and friction coefficient the friction heat flux will be the same, provided that the pressure force is the same. If the dimensions of the seal made of a homogeneous material are the same as those made of bristles, then, the temperature distribution will also be the same, providing the heat load and thermal conductivity are the same.

The idea of a brush seal treated as a homogeneous material

For this purpose, it is necessary to determine the stiffness of a homogeneous material as a function of temperature. In that way, after compression of the homogeneous material which is related to the interference, the pressure characteristics as a function of temperature will be the same as in the case of the previously determined characteristics of the segment of the seal made of bimetal and bristles [5].

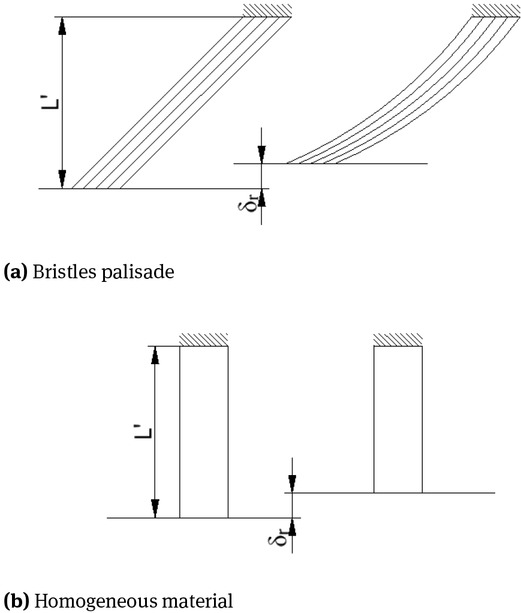

Assuming that the material meets Hooke’s law, we can calculate the stiffness modulus of a homogeneous material. For this purpose, we change bended bristles palisade into the compressed homogeneous material (Figure 6).

Scheme of the deformation due to radial interference δr of the real brush seal and the seal treated as a homogeneous material

It should be noted that the introduction of such a simplification is intended only to achieve the same pressure force, since in both cases there are different stress states. Hooke’s law follows:

the modulus of elasticity of the homogeneous material will be described by equation (3).

where:

| E(T) | - homogeneous material modulus of elasticity, | [MPa] |

| F(T) | - the pressure of seal with bimetal element [5], | [N] |

| A | - Contoured contact surface, | [mm2] |

| δr | - radial interference, | [mm] |

| L′ | - initial bristles palisade hight, | [mm] |

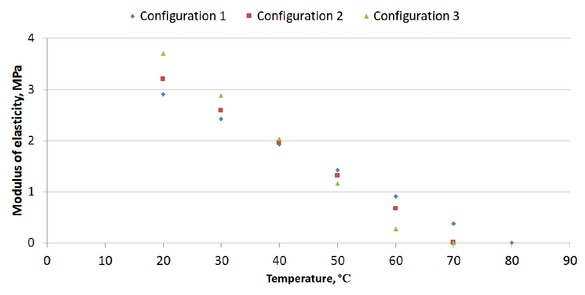

The values of the modulus of elasticity of the homogeneous material obtained in this way are shown in Figure 7. It was calculated for three design configuration

The modulus of elasticity of the brush seal with thermo-regulating bimetal elements treated as a homogeneous body as a function of temperature

where the bimetal element is working with 5,7 or 9 bristles respectively.

4 Thermal conductivity of the seal

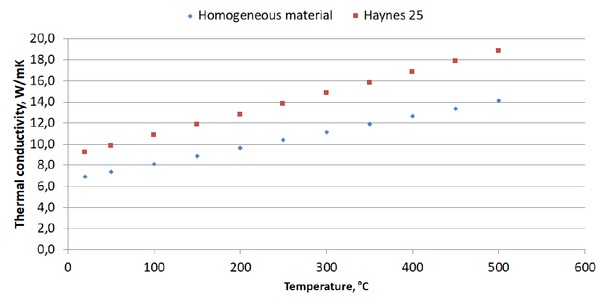

The substitute thermal conductivity coefficient of the brush seal treated as a homogeneous body was determined by taking into account the presence of fluid filling the spaces between bristles [10,11] according to the equation 4.

where:

λ - substitute thermal conductivity coefficient of the homogeneous material, [W/mK]

λAir - thermal conductivity coefficient of air, [W/mK]

λH25 - thermal conductivity coefficient of Haynes-25 alloy the seal is made of, [W/mK]

ϵ - porosity,

The substitute thermal conductivity coefficient calculated according to the equation 4 is shown in Figure 8. It is also compared with the basic brush seal material Haynes-25 alloy. As it can be seen the substitute thermal conductivity of homogeneous material is approximately 20% lower than that of Haynes-25.

Substitute thermal conductivity coefficient of homogeneous material

5 Heat exchange conditions

A precise determination of the temperature distribution in the seal requires an accurate determination of convective heat exchange conditions in the analyzed system. The heat flux flowing between the surface of the solid body and the surrounding fluid is determined by Newton equation (5)

where:

q - heat flux, [W/m2]

α - film coefficient, [W/m2K]

Ts - surface temperature of a solid body, [K]

Tf - fluid temperature, [K]

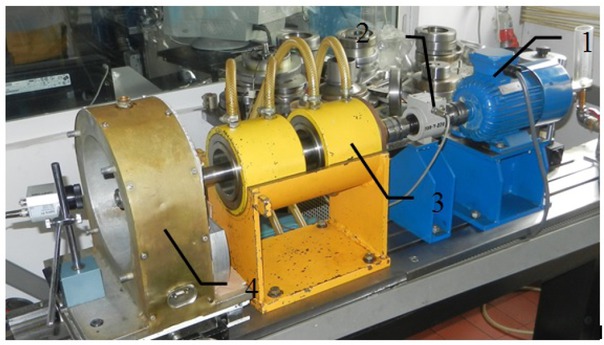

The greatest difficulty while using the equation (5) is to determine the value of the film coefficient α. Due to the complicated convection mechanism, this coefficient depends on many factors. Therefore, the initial value of α for the analyzed geometry was determined based on the literature [12, 13]. In order to verify the choosen teoretical values of α, experimental tests were carried out at the test rig intended for sealings tests (Figure 9).

The test rig

It consisted of a motor (1), torque meter (2), shaft supported in aerostatical bearings with minimal frictional moment (3) and the test rig chamber (4). All tests were performed by means of only one standard brush seal with a nominal diameter of 88 mm. During the test, the following data were recorded: the frictional moment of the seal, the rotational speed and the temperature. The temperature of bristles was measured by a thermocouple sensor with a diameter of 0.075 mm located inside the bristles pack and the temperature of the entire system by a thermal imaging camera. The tests were carried out until the temperature stabilized.

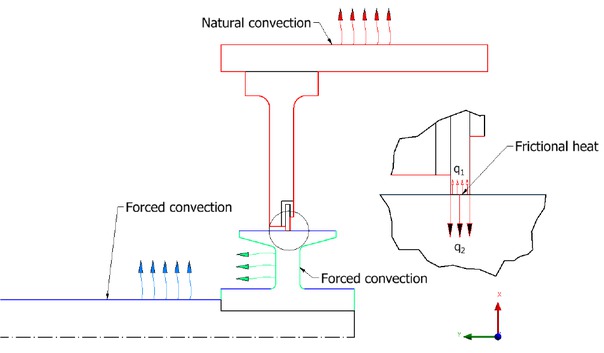

After dozens of tests at different rotational speeds (n = 500 ÷ 4000RPM every 500RPM) and interference (σ = 0 ÷ 0, 5 mm every 0,05 mm) a few results were selected for which a numerical model was built. The problem was solved as axial symmetry using the ANSYS software. The palisade of the brush seal was treated as the homogeneous body. Heat analysis was carried out for part of the sealing test stand, taking into account only those parts whose temperature during the tests significantly exceeded ambient temperature. As heat load in the FEM model the experimentally determined friction heat flux was assumed. In order to simplify the analyzed geometry some construction elements, i.e. nuts, bolts and construction details like chamfering, rounding, etc. were omitted. The analyzed geometry in an axisymmetrical form with respect to the Y axis together with boundary conditions and load is presented in Figure 10.

FEM model boundary conditions and load

The assumptions of the numerical model:

load and boundary conditions are symmetrical with respect to the Y axis,

all energy lost to overcome friction resistance is converted into heat,

heat is dissipated only by convection, radiation is omitted,

no thermal resistance at the element boundary,

ambient temperature t = 22∘C.

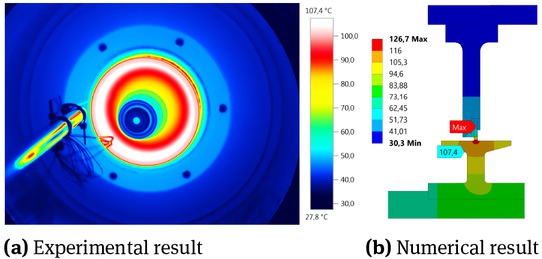

Then, the initial heat exchange conditions in the numerical model were corrected until the numerical results matched the experimental results. Examplary results comparison of the temperature distribution for n = 4000RPM and Mf = 0, 39Nm at frictional heat flux of Q ≈ 164W and the result obtained in a numerical way is shown in Figure 12.

Temperature distibution in brush seal

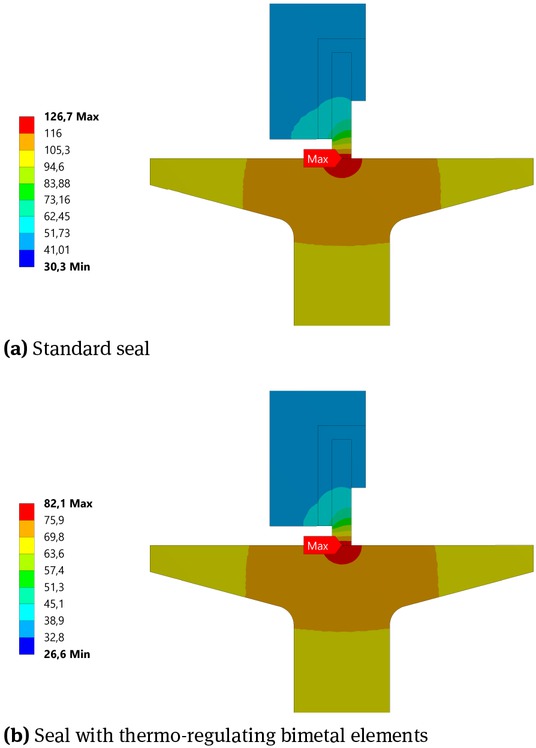

Comparison of temperature distributions in the seal before and after modification

In all cases the only visible difference in the temperature between the numerical results and the experimental ones is the temperature of a fixing nut on the shaft. In the numerical model it was omitted. Its much lower temperature results from a different emissivity factor of the surface. This coefficient for the nut is smaller than the rest of the elements included in the thermovision, which gives the impression of a much lower temperature. A higher temperature value in the numerical model in relation to the measurement results from the fact that a thermovision camera measures temperature only on the surface, whereas in the numerical model we determine the temperature also in the middle of the seal, where it is slightly higher. Such convergence of the results obtained numerically and experimentally allows to assume that the heat exchange conditions in the numerical model have been correctly selected.

6 Results

Using the presented numerical model, the characteristics of the stiffness of the seal, the thermal properties of the seal as well as the heat exchange conditions, the equilibrium temperature during the operation of the seal with thermo-regulating bimetal elements was determined. Three constructional solutions were analyzed in which the bimetal cooperates with 5, 7 or 9 ordinary seal bristles. The Figure compares the temperature distribution for the same operating conditions (rotation speed 4000RPM and interference 0.5mm) in a standard seal and the one built according to the idea.

Table 1 summarizes the results obtained for other seal construction configurations, working under the same conditions. As can be seen in every analyzed configuration the use of a bimetallic element reduces the friction heat flux, which translates into a drop in the seal operating temperature. This effect is the greater the smaller the number of ordinary seal bristles per one bimetallic element.

The equilibrium temperature of the seal for different design configuration

| Temperature, ∘C | Frictional heat flux,W | |

|---|---|---|

| Configuration 1 | 100 | 135 |

| Configuration 2 | 90 | 117 |

| Configuration 3 | 82 | 103 |

7 Summary

The article presents the method and results of determining the working temperature of the brush seal with thermo-regulating bimetal elements aimed at its thermal protection. Using the experimental data the stiffness characteristic of the seal and the heat exchange conditions in the analyzed geometry were determined. Next, by means of the finite element method, the working temperature in the seal made according to the idea was determined and compared with the values obtained during the measurement of a regular seal. The tests confirmed the author’s thesis that it is possible to reduce the working temperature of the brush seal by means of of bimetallic elements. By an appropriate selection of the material and a number of bimetallic elements, the maximum working temperature of the seal can be determined at the construction stage. This enables the design of a seal with an increased durability resulting from the reduction of thermal load. In this particular case, the ordinary brush seal during operation was heating up to an equilibrium temperature of approximately 126∘C. The modification of the construction of the seal by using the TB208 / 110 bimetallic element cooperating with 5 ordinary seal bristles enables reduction of the friction heat flux by ~60 W, which allows to reduce the operating temperature by almost 45∘C.

References

[1] Aslan-zada F.,Mammadov V., Dohnal F., Brush seals and labyrinth seals in gas turbine applications, Journal of Power and Energy, 2013, 227, 216-23010.1177/0957650912464922Search in Google Scholar

[2] Saber E., Abdou K. M., Advanced seal design for rotating machinery, American Journal of Scientific and Industrial Research, 2011, 2, 58-6810.5251/ajsir.2011.2.1.58.68Search in Google Scholar

[3] Flitney R. K., Seals and sealing handbook, Elsevier, 201110.1016/S1350-4789(11)70372-5Search in Google Scholar

[4] Gawliński M., Stanclik M., Thermal protection of the brush seal, European patent application PL222951, 2012Search in Google Scholar

[5] Stanclik M., Brush seal with thermo-regulating bimetal element, Open Engineering 2018, 8, 307-31310.1515/eng-2018-0037Search in Google Scholar

[6] Dogu Y., Aksit M, Brush seal temperature distribution analysis, Journal of engineering for gas turbines and power, 2006,128, 599-60910.1115/GT2005-69120Search in Google Scholar

[7] Chew J., Guardino C., Simulation of flow and heat transfer in the tip region of a brush seal, International journal of heat and fluid flow, 2004, 25, 649-65810.1016/j.ijheatfluidflow.2003.12.001Search in Google Scholar

[8] ANSYS Inc., Theory reference for the mechanical APDL and mechanical applications, 2009, Release 12.0, 368-383Search in Google Scholar

[9] Crudgington P., Bowsher A., Brush seal pack hysteresis, Paper No. AIAA-2002-3794, 200210.2514/6.2002-3794Search in Google Scholar

[10] Qiu B., Li J., Numerical Investigations on the Heat Transfer Behavior of Brush Seals Using Combined Computational Fluid Dynamics and Finite Element Method, Journal of Heat Transfer 2013, 135, 79-8910.1115/1.4024556Search in Google Scholar

[11] Demiroglu M., Tichy J., An Investigation of Heat Generation Characteristics of Brush Seals, ASME Turbo Expo 2007: Power for Land, Sea, and Air, 2007, 1261-127010.1115/GT2007-28043Search in Google Scholar

[12] Lienhard IV J.H, Lienhard V J.H, A Heat Transfer Textbook, Knovel, 2011Search in Google Scholar

[13] Owen J. M., Rogers R. H., Flow and heat transfer in rotating disk systems, John Wiley and Sons, 1989Search in Google Scholar

© 2019 M. Stanclik, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.