Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

-

Changjiang Liu

, Fulian Chen

, Zhoulian Zheng

, Jingwei Yang

, Bo Yang

Abstract

Poor crack resistance, high brittleness, and poor toughness are inherent limitations of traditional cement-based materials. Besides, cement-based materials have certain shortcomings in energy consumption and environmental protection. Therefore, improving the performance of cement-based materials becomes a hot topic in related research. At the same time, the development of nanomaterials and technologies provides researchers with a new research idea: to enhance the performance of cement-based materials at the nanoscale level. Graphene oxide (GO) is one of the most representative nano-reinforcements. Due to its high surface area and excellent physical properties, GO has a surprising effect on improving the performance of cement-based materials. In addition, nanosilica (NS) and carbon nanotubes (CNTs) have excellent improvement on cement-based materials, and people also hope to further improve the performance of cement-based materials through the interaction of various nanomaterials. In this paper, the influence of GO on cement-based materials is reviewed by consulting a lot of correlative literature, mainly focusing on the following aspects: (i) The dispersion of GO in cement paste. (ii) The influence of GO on the properties of cement-based materials, including working performance, mechanical strength, microstructural characteristics, and durability. (iii) The effect of nanohybrid materials of GO, NS, and CNTs on cement-based materials, and the synergistic effects of various nanomaterials are reviewed for the first time. (iv) Evaluation of current progress. This paper aims to provide guidance for the study and application of GO-modified cement-based materials and nanohybrid materials.

1 Introduction

In the past few decades, the construction industry has developed rapidly. Cement-based materials have played a vital role in infrastructure construction and become the most widely used materials in civil engineering due to their rich resources, low cost, and convenient construction. However, the traditional cement-based materials have high brittleness and poor toughness, which are prone to cracks in the use process, thereby affecting the performance and life of the materials [1,2]. On the other hand, people notice that the production of cement is accompanied by the destruction of the environment. The production of ordinary Portland cement needs to consume limited natural resources, and 0.8 tons of carbon dioxide emissions per ton of cement clinker will pollute the environment [3]. It can be predicted that traditional cement-based materials have become increasingly difficult to adapt to the requirements of modern civil structures [4]. Therefore, the key challenge of sustainable development in the next few decades is to develop and produce less clinker concrete and ensure the same or better reliability and durability under the premise of lower carbon dioxide emissions [5,6]. The most direct and feasible way to face this challenge is to enhance the performance of cement-based materials. The improvement of cement-based materials by traditional reinforcement methods is not satisfactory. Based on the top 10% highly cited papers determined using the co-citation clustering method, nano-modification of cement-based materials has been identified as one of the top 10 engineering research fronts [7,8,9]. The development of nanomaterials and technologies will bring a new generation of building materials with expected performance.

The size of nanomaterials is 1–100 nm, and the efficient characterization at the nanoscale makes them develop rapidly in the fields of medicine, chemistry, biotechnology, and environmental energy [10,11]. The report of the 197th Building Materials Nanotechnology Committee clarified the application of nanoparticles in improving the performance of cement-based composites [5,11]. Studies have shown that the addition of nanosilica, nano-alumina, nano calcium carbonate, nano titanium dioxide, nano ferric oxide, carbon nanofiber, and carbon nanotubes (CNTs) has improved the mechanical and durability of cement composites to varying degrees [12,13,14,15,16,17,18,19]. Its mechanism is mainly nucleation effect and filling effect. First, nanomaterials have high specific surface area (Figure 1), which can provide additional nucleation sites for hydration products and accelerate cement hydration. At the same time, C–S–H gel changed from loose structure to dense, uniform, and stable state [20,21]. Second, the addition of nanomaterials can reduce the orientation and size of CH crystals, especially the CH crystals in the interfacial transition zone [22]. Third, nanomaterials can fill pores to optimize pore size distribution and provide more compact microstructure for cement matrix [23,24]. In addition, the high pozzolanic activity of nanosilica [25] and the crack-bridging effect of CNTs [6] are also important reasons for the improvement of cement matrix properties. It should be noted that nanomaterials can be divided into zero-dimensional (0D) particles, one-dimensional (1D) fillers, and two-dimensional (2D) sheets. 0D nanomaterials lack the ability to prevent the development of microcracks, and the reinforcement effect is low [27]. 1D and 2D nanomaterials can produce more interactions and stronger bonding [28]. Among them, graphene oxide (GO) has become one of the research hotspots in recent years due to its unique layered structure and high active functional groups.

![Figure 1

Particle size and specific surface area related to concrete materials [20].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_001.jpg)

Particle size and specific surface area related to concrete materials [20].

GO is an essential derivative of graphene, which can be seen as a layer of graphene grafted with oxygen functional groups. Its properties and structure are similar to graphene, as shown in Figure 2. The commonly used GO preparation methods [3] include Brodie method, Staudemnaier method, and Hummers method. Compared with graphene, the grafted oxygen-containing functional groups can reduce the van der Waals force of GO sheets and improve the hydrophilicity of GO sheets. In addition, oxygen-containing functional groups can participate in chemical or physical interactions, thus providing a large number of active sites for connecting other functional groups and organic molecules [26,29]. Due to these advantages, GO is widely used in various matrices, such as ceramic and polymer composites [29]. At the same time, GO is also one of the key research directions of cement-based nano modification. Figure 3 shows the number of SCI papers on GO-modified cement-based materials. It can be seen that the research on GO-modified cement-based materials has continued to increase since 2014; this confirms the high research potential of GO in cement composites on the other hand. It can also be seen from the existing research results that GO effectively solves the inherent defects of cement-based materials and shows unexpected results in terms of performance improvement.

![Figure 2

Representation of (a) grapheme and (b) graphene oxide (GO) [3].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_002.jpg)

Representation of (a) grapheme and (b) graphene oxide (GO) [3].

Annual number of SCI papers on GO-modified cement-based materials.

Although the research on GO-modified cement-based materials has made great progress in the past decade, there are still many problems as follows: (1) Due to the differences in materials and production methods in some literature, the results obtained are also different or contradictory. (2) There are many repetitive studies in some literature, and there is no new theoretical supplement. In this paper, the improvement effect and mechanism of GO on cement-based materials in recent years are reviewed. At the same time, the synergistic effect of GO and other nanomaterials on cement-based materials is summarized for the first time. Finally, further research directions are discussed. This review hopes to help engineers and researchers further understand the role of GO in cement-based materials and provide guidance for the research of nanohybrid materials.

2 Dispersion of graphene oxide

In the ideal state, the mechanical properties and durability of cement-based materials will increase with the increase of GO content. However, due to the large specific surface area of GO and the strong van der Waals force between layers, GO is prone to agglomeration in the preparation and use process. Higher content of GO does not provide higher performance for cement composites and even has a negative impact. Therefore, good dispersion is the key to the successful application of GO.

2.1 Aggregation of graphene oxide

First of all, it should be pointed out that the GO sheet contains a large number of oxygen-containing functional groups. Due to its electrostatic repulsion and high hydrophilicity, the dispersion in water is good [31,32]. However, unlike aqueous solution, cement pore solution is a strong alkaline solution containing a large number of metal cations (Ca2+, K+, Na+, etc.) [33]. Numerous studies [34–36] have shown that GO is prone to agglomeration in cement paste, and the main reason for agglomeration is the high calcium ion concentration and high alkaline of cement paste. When the concentration of Ca2+ is too high, GO will agglomerate by bridging Ca2+ due to the limited tolerance of GO to Ca2+ [37,38]. In high alkaline solution with pH value of 12–13, GO is easy to deoxygenate rapidly, and the loss of oxygen-containing functional groups will lead to the decrease of electrostatic repulsion and hydrophilicity of GO, thus leading to agglomeration [34,39]. Literatures [40,41] pointed out that “face-to-face” agglomeration of GO sheets occurred preferentially under high alkaline conditions, and “side-by-side” agglomeration occurred preferentially under high calcium conditions. In addition, monovalent cations such as K+, Na+ can reduce the electrostatic repulsion between GO, thus promoting agglomeration [41]. Since agglomeration is inevitable, how to improve the dispersion of GO in cement-based materials becomes crucial. The commonly used dispersion methods include physical dispersion method and chemical modification method.

2.2 Physical dispersion method

The commonly used physical dispersion methods include high-shear stirring, electromagnetic stirring, and ultrasonic dispersion [11]. The principle of physical dispersion is to output mechanical energy through high-speed shear or ultrasonic. The additional input energy can destroy the chemical bonds between nanomaterials, reduce van der Waals force, and improve the dispersion of materials [11,42]. The working parameters of the equipment and the use method of researchers will affect the physical dispersion. Liu et al. [43] pointed out that when the ultrasonic power was too small, the extension of ultrasonic time could not increase the dispersion effect of GO, while too large ultrasonic power was not conducive to the dispersion of GO, and it might destroy the lamellar structure of GO. Lu et al. [36] also observe similar results. It should be pointed out that the physical dispersion method has great limitations, which can only improve the dispersion of GO in water. Because it cannot work continuously, GO will also reaggregate after the physical effect is eliminated, especially in alkaline cement paste [40]. Therefore, the physical dispersion method often needs to be combined with chemical modification method.

2.3 Chemical modification method

The chemical modification method has high flexibility, which means that GO can be modified according to its own structure and application direction [40]. Chemical modification method mainly has two forms, one is using surfactants to adsorb GO surface, reduce surface energy, and disperse GO through electrostatic repulsion or steric hindrance. Second, new functional groups were connected to GO surface by grafting or copolymerization to improve its hydrophilicity.

In the first method, the type of surfactant and the compatibility between surfactant and cement are important factors affecting the dispersion effect. Yuan et al., Long et al., and Li et al. [44–46] used several different types of superplasticizers such as aminosulfonic acid series, aliphatic series, naphthalene series, and polycarboxylic series to disperse GO. The results showed that each type of superplasticizer had a good improvement effect on the dispersion of GO in cement-based materials. Among them, polycarboxylate superplasticizer (PC/PCE) had the best dispersion in alkaline environment and showed good compatibility with cement. Lv et al. [47] explained that the acidic group contained in PC could reduce the alkalinity of cement paste. At the same time, it could be used as a dispersant to increase the repulsion and steric hindrance between cement particles, between GO, and between cement particles and GO particles, reduce the concentration of calcium ions, and make GO uniformly dispersed. Luo et al. [48] established the PC–GO dispersion mechanism model (Figure 4), and its explanation was similar to that of Lv et al. [47]. Wang et al. [49] pointed out that the successful adsorption of PCE on GO surface is a necessary condition to improve the dispersion of GO. He believed that the agglomeration of Ca2+ complexed by GO is effectively hindered by steric hindrance due to the side chains. Second, the carboxyl groups of the PCE main chain complex with Ca2+ reduce the free Ca2+ concentration near the GO sheets. The dispersion mechanism model established in the study is shown in Figure 5. However, Sam et al. [39] found that PCE was ineffective in preventing the aggregation of GO in Portland cement paste. This inconsistency may be related to the molecular structure of PCE and the characteristics of GO (oxygen content, size, etc.). In addition, the ratio of PC to GO is also a factor affecting dispersion. In the study of Li et al. [50], when PC:GO = 10, GO can maintain the best dispersion state in cement pore solution for 24 h. Lu et al. [36] believed that PC:GO = 15 was the optimal proportion of dispersion stability.

![Figure 4

Dispersion mechanism of PC–GO [48]: (a) dispersion mechanism in water, (b) dispersion mechanism in cement paste, and (c) simulated structures of the GO, PC, negative charge, and Ca2+.](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_004.jpg)

Dispersion mechanism of PC–GO [48]: (a) dispersion mechanism in water, (b) dispersion mechanism in cement paste, and (c) simulated structures of the GO, PC, negative charge, and Ca2+.

![Figure 5

Mechanism of improved dispersion by GO–PCE in the cement pore solution [49].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_005.jpg)

Mechanism of improved dispersion by GO–PCE in the cement pore solution [49].

The second chemical modification method is also a research hotspot. Hu et al. [51] synthesized triethanolamine-graphene oxide (TEA-GO). The reduction of –C–O–C group on GO reduced the intercalation complexation between GO and Ca2+, and the additional −OH group in TEA avoided the deoxidation in high alkaline solution, thus improving the dispersion of GO in the cement matrix. Wang et al. [52] prepared silane and copolymerized-modified graphene oxide (P–S–GO). The dispersion results showed that P–S–GO only had insignificant agglomeration in high alkaline solution with pH = 13. Zhang [53] prepared the intercalation compound (GO/(PAA-AM)) by free radical polymerization using GO, acrylic acid, and acrylamide as monomers, which significantly reduced the size of GO nanosheets and realized the effective dispersion of GO nanosheets. PC/GO copolymers prepared by Lv et al. [54] also have higher dispersion than GO.

The effect of physical dispersion method is not ideal, the chemical covalent modification method has high process requirements and high cost, and the compatibility with cement materials is often considered in the adsorption method of surfactant, so people are looking for cost-effective ways to disperse. Jing et al. [55] adopted a ball milling strategy to improve the dispersion of GO in cement matrix. The ball milling method makes the cement particles smaller and the specific surface area larger, which improves the contact between cement particles and GO and thus improves the dispersion efficiency of GO (Figure 6). This method can avoid the incompatibility between surfactant and cement. Literature [30] pointed out that the combination of ultrasonic dispersion and surfactant (PC) is the most commonly used method in current research, because this method has low time and economic cost and can ensure the uniform dispersion of GO.

![Figure 6

Schematic illustration of reinforced cement paste [55].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_006.jpg)

Schematic illustration of reinforced cement paste [55].

It can be seen from the above research results that most of the current decentralized research is limited to the laboratory stage and lacks practical engineering application practice. There are also some problems in previous studies: (1) The dispersion method has high economic and time costs, and the operation process is relatively complex. Both ultrasonic dispersion and chemical surface modification are difficult to be applied to practical engineering. (2) The best scheme of ultrasonic dispersion and the best ratio of PC/GO are different in the study. (3) At present, it has not been able to summarize which method can obtain the best dispersion in cement hydration through research and comparison. Therefore, more and deeper studies are needed to ensure the uniform dispersion of GO in cement.

3 Research progress of graphene oxide-modified cement-based materials

3.1 Effect of graphene oxide on the workability of cement-based materials

Working performance refers to the fluidity and consolidation of fresh cement paste [30]. In order to facilitate the compaction of cement-based materials and ensure the uniform distribution of engineering properties in concrete, high fluidity, medium viscosity, and cohesive stability are necessary conditions. Good working performance is the guarantee for the mechanical properties and durability of cement-based materials [27]. Current research results show that the addition of GO reduces the fluidity of cement paste. The mini-slump results in refs [37,56–60] showed that the incorporation of 0.03–0.08 wt% GO reduced the slump diameter of cement paste by 18.8–41.7%. It can be seen from Figure 7 that with the increase of GO content, the mini-slump flow of cement paste gradually decreases. When the GO content is 0.1 wt%, the mini-slump flow decreases by 27.8%. Lu and Dong [61] also pointed out that 0.03 wt% GO reduced the slump and slump flow of ultra-high strength concrete by 8.3 and 15.6%, respectively. In addition, Wang et al. [62] indicated that the plastic viscosity and yield stress of cement paste increased sharply with the increase of GO content, especially when the GO content was greater than 0.01 wt% (Figure 8). Fang [63] pointed out that when the content of GO was 0.09 wt%, the yield stress and plastic viscosity of cement paste reached the maximum, and then the yield stress and plastic viscosity decreased with the increase of GO.

![Figure 7

Effect of GONSs contents on the fluidity of cement mortars [61].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_007.jpg)

Effect of GONSs contents on the fluidity of cement mortars [61].

![Figure 8

Effect of GO addition on yield stress and plastic viscosity of fresh cement pastes [62].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_008.jpg)

Effect of GO addition on yield stress and plastic viscosity of fresh cement pastes [62].

According to many research results [37,58,60,62,64,65], the following mechanisms can be summarized about the influence of GO on the working performance of cement paste: (1) GO and cement particles will form a flocculation structure through electrostatic interaction, and free water is intercepted by flocculation. With the increase of GO content, the number of flocs will increase and GO reacts with a high concentration of Ca2+ to form additional aggregates with high water retention, resulting in a sharp increase in yield stress and plastic viscosity and a decrease in fluidity. (2) Hydrophilic functional groups and large specific surface area of GO can absorb a large amount of water, resulting in the decrease of lubricating water for cement particles. In addition, the strong van der Waals force between GO sheets makes cement particles attract each other and increase the friction resistance between cement particles, thereby decreasing the fluidity of cement paste and increasing viscosity and yield stress. (3) GO can promote the hydration of cement, accelerate the aggregation of cement particles, reduce the free water content in the cement paste, and thus reduce the fluidity of cement paste.

To eliminate the negative impact of GO on the working performance, researchers have proposed many methods as follows: the working performance of GO-cement composites can be adjusted to different degrees by using superplasticizers, mixing with silica fume or modifying with silica fume [60], mixing with fly ash [66,67], or synthesizing chemical copolymers by using polyether amine and carboxymethyl chitosan [68,69]. Among them, adding superplasticizers is the simplest and most effective method with low economic cost. The electrostatic repulsion and steric hindrance of PCE superplasticizers [30] can effectively disperse cement particles, release free water of flocs, and then make up for the water absorbed by the large specific surface area of GO. Lv et al. [54] also proved the regulation of PCE superplasticizers (Figure 9); the study showed that GO dosage increased by 0.01 wt% and PCE dosage increased by 0.03 wt% almost can make up for the loss of liquidity. Birenboim et al. [70] reported that the fluidity of cement paste containing 0.2 wt% PCE was 34% higher than that of cement paste without PCE. Liu et al. [43] maintained the consistency of fluidity of cement mortar by changing the amount of PCE. This treatment can ensure the good working performance of mortar and eliminate the influence of different fluidity on the final results.

![Figure 9

Effects of GONs and PCs on initial fluidity [54].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_009.jpg)

Effects of GONs and PCs on initial fluidity [54].

In summary, the research on the influence of GO on the working performance has made great progress, but there are still some limitations in improving the working performance. For example, the increase of PC content will affect the early mechanical properties of cement while regulating the working performance, and even cause the segregation and drenching of cement. Hence, more studies are needed to improve the workability and rheological properties of GO-modified cement paste.

3.2 Effect of graphene oxide on mechanical properties of cement-based materials

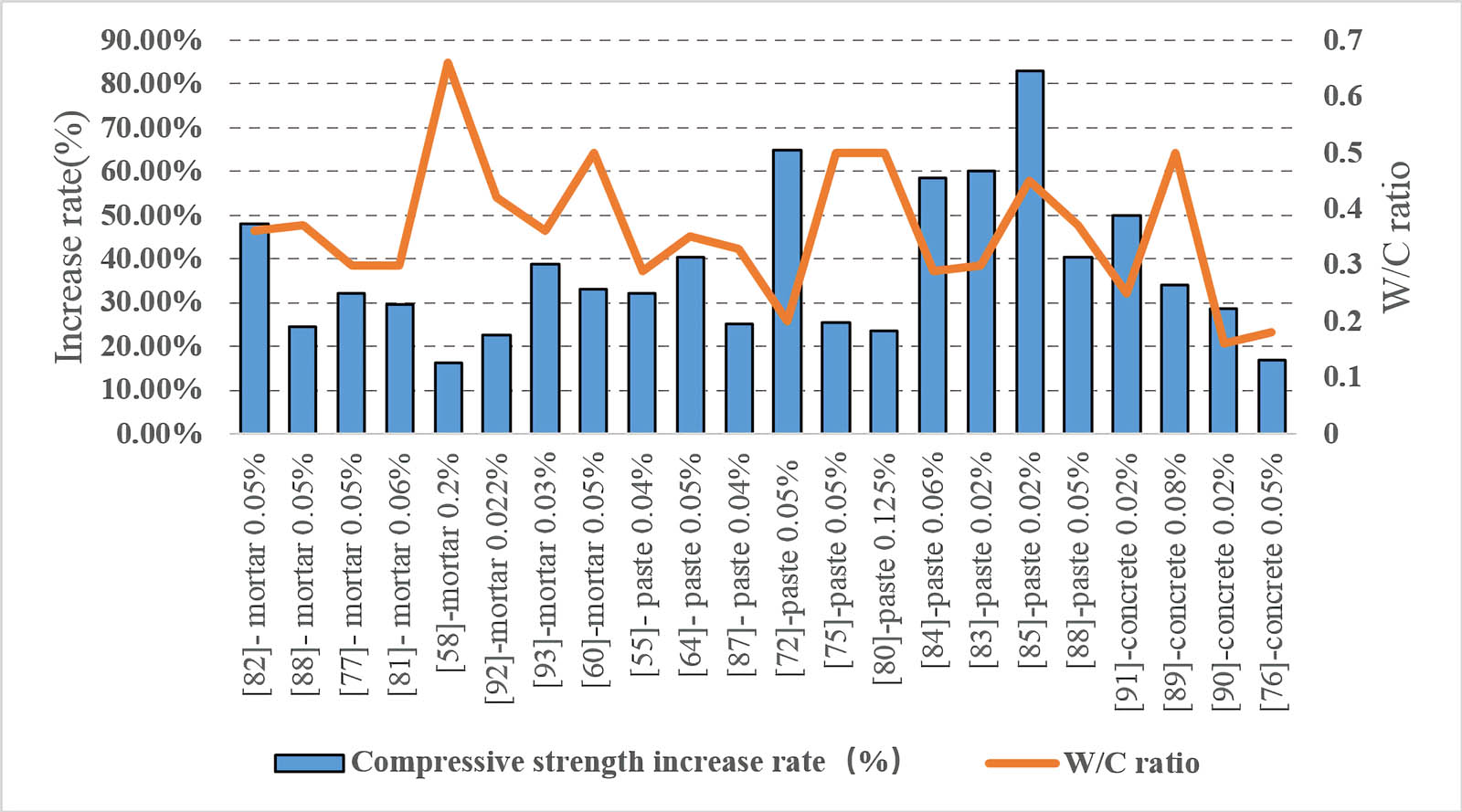

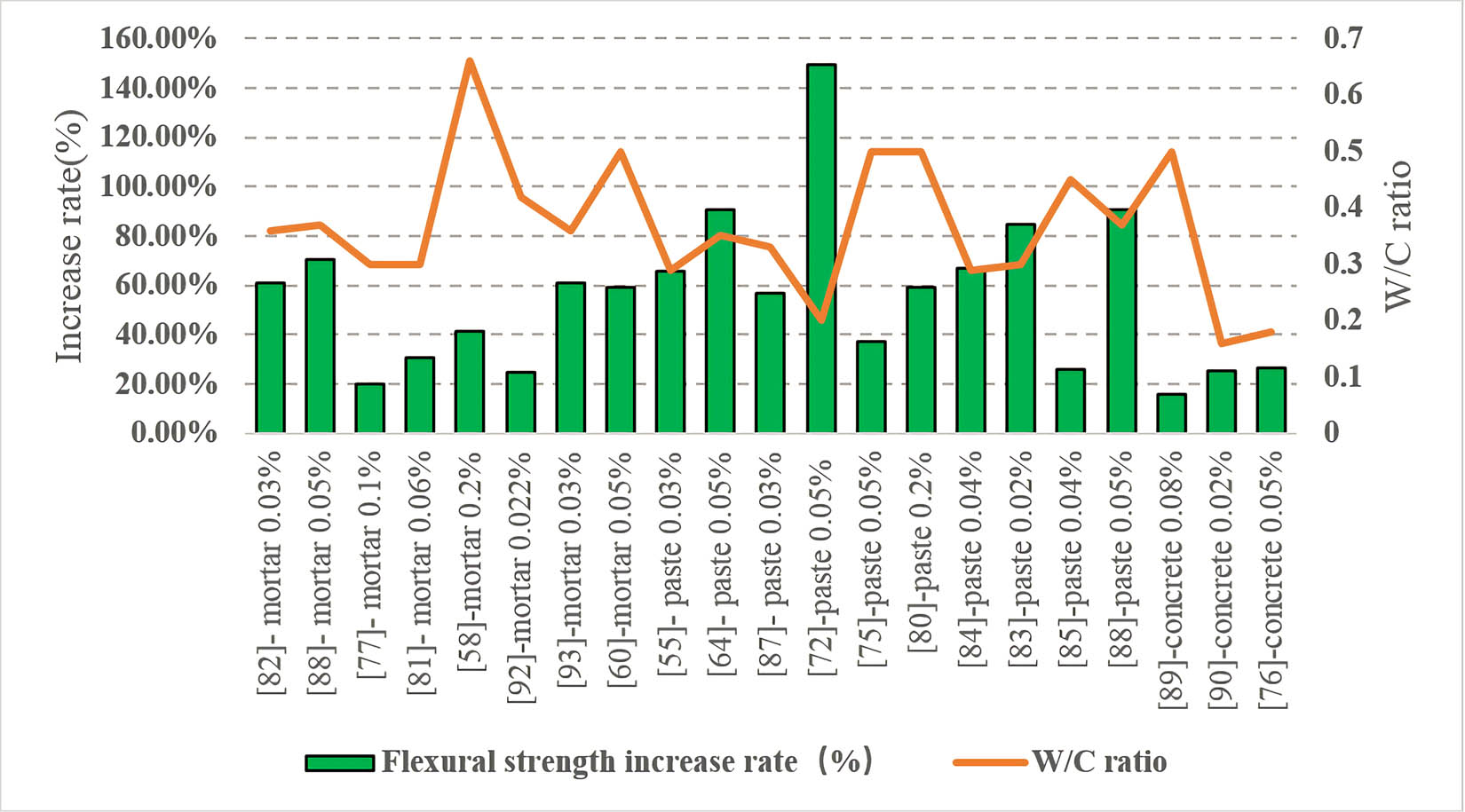

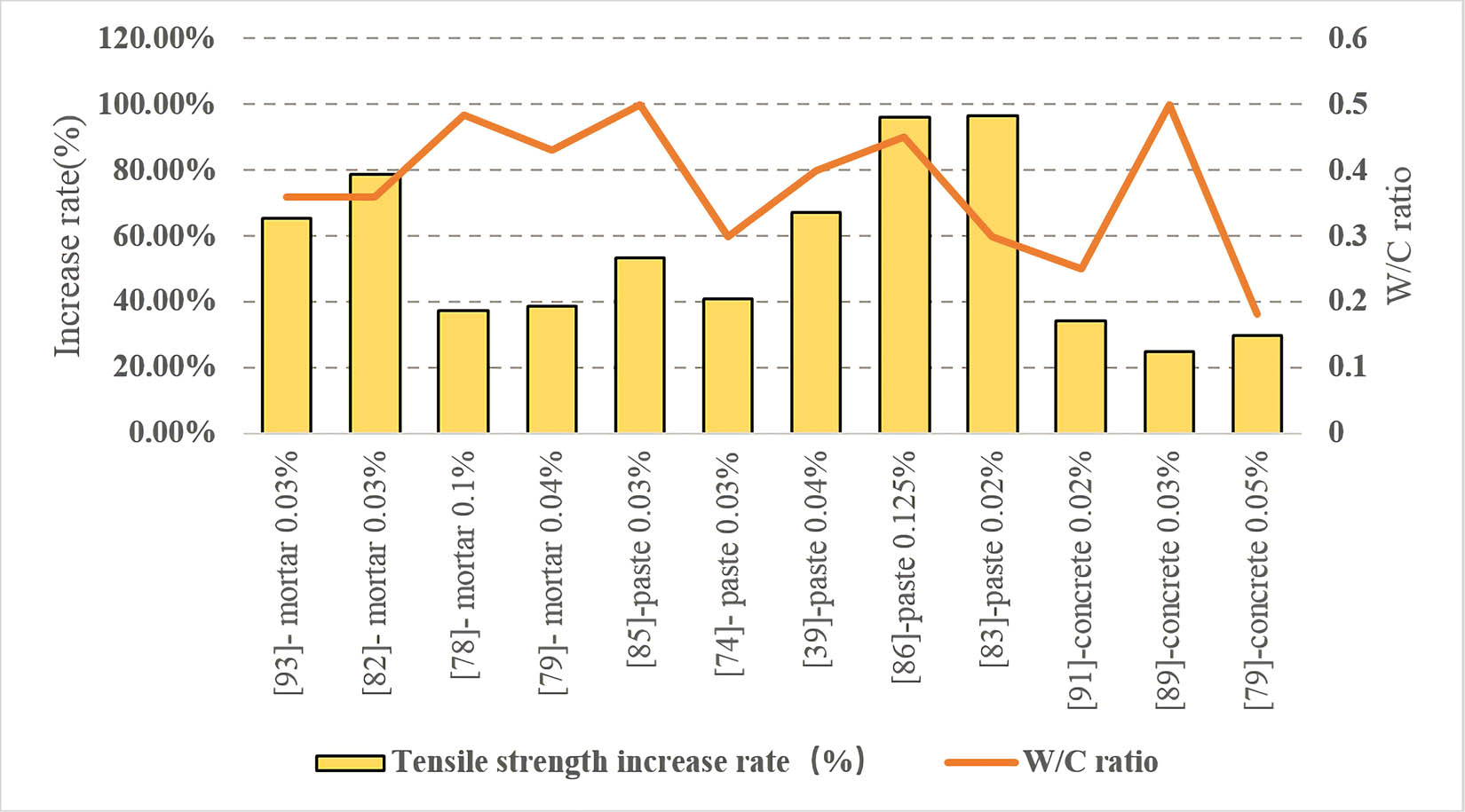

The mechanical properties of cement composites are the key factor in engineering application, and their quality directly affects the quality and service life of the project. Previous studies have shown that GO has a good enhancement effect on the mechanical properties of cement-based materials in the appropriate dosage range. Figures 10–12 [38,54,57,59,62,64,69,71–90] summarize the strengthening effect of GO on compressive, flexural, and tensile strength of cement-based materials, respectively. It can be seen that adding a small amount of GO has an unexpected effect on strengthening mechanical properties. The optimal dosage and maximum increase of different studies are different. Even under the same W/C ratio and GO dosage, the increase of mechanical strength is not similar. The difference in these data may be related to the nature of GO (oxygen content, size, etc.), the dispersion degree of GO, the type of cement, the production process, and the curing conditions. It is worth mentioning that although the optimal content of GO does not have a fixed value, in the existing studies, the optimal content range of GO is mostly concentrated in 0.02–0.06 wt%. Figure 13 [75] shows the general law of the effect of GO content on mechanical properties: the strength of cement mortar increases first and then decreases with the amount of GO, and there is an optimal amount of GO to make the mechanical properties reach the optimal. This rule is also confirmed in refs [50,71,84,91]. Saafi et al. [92] explained that with the increase of GO sheet concentration, they were more likely to overlap with each other, rather than to separate randomly. The current research mainly focuses on the influence of GO content, oxidation degree (oxygen content), dispersion degree, and lamellar size on the mechanical performance enhancement efficiency of cement-based materials.

Compressive strength enhancement of GO reinforced cement composite specimens.

Flexural strength enhancement of GO reinforced cement composite specimens.

Tensile strength enhancement of GO reinforced cement composite specimens.

![Figure 13

Variation of 7 and 28 days tensile and compressive strength of GO-cement mortar with different GO contents [75].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_013.jpg)

Variation of 7 and 28 days tensile and compressive strength of GO-cement mortar with different GO contents [75].

Gholampour et al. [75] added eight different dosages of GO to cement mortar and found that the best GO content was 0.1 wt% and the compressive strength and tensile strength of 28 days were increased by 77.7 and 37.5%, respectively. The content exceeded 0.01 wt%, and the growth rate of strength began to decline. In the study of Lv et al. [93], 0.03 wt% GO made the tensile strength and flexural strength of 28 days reach the peak (78.6 and 70.0%, respectively), and 0.05 wt% GO made the compressive strength improvement reach the maximum (47.9%). In addition, the results also pointed out that the growth rate of the strength of 3 days was generally higher than that of 28 days, which indicated that the effect of GO on early strength was more significant, and similar trends were observed in [94]. Devi and Khan [95] studied the effect of GO content on the mechanical properties of concrete at 7, 28, 56, and 90 days. It was found that the compressive strength and splitting tensile strength of concrete increased with the increase of GO concentration at each age, and the optimum GO content was 0.08 wt%. It was also found that the increase rate of compressive strength reached the maximum at 56 days, which also indicated that the toughening effect of GO could continue to the later stage of curing. Lv et al. [80] studied the influence of oxygen content of GO on mechanical properties. The results showed that when the oxygen content of GO increased from 12.36 to 25.45%, the increase rate of tensile strength, flexural strength, and compressive strength increased from 23.0, 26.3, and 14.5% to 97.2, 84.5, and 60.1%, respectively. However, the strength did not increase further when the oxygen content increased to 29.33%. In some studies [37,38,96], GO with poor dispersion can also improve the mechanical strength of cement paste, because GO aggregates themselves have high intrinsic strength. Lu et al. [97] found that the larger the size of GO aggregates, the lower the compressive strength growth efficiency of cement composites. However, the dispersion degree of GO directly affects the mechanical properties of cement-based materials. The experimental results of Lu et al. [98] show that compared with the post-addition of PCE in GO-cement composites, PCE-pre-stabilized GO contributes the most to cement paste. Long et al. [99] also showed that the compressive and flexural strength of cement paste mixed with PCE-modified GO was higher than that of cement paste with PCE added at the end. In ref. [78], the average thickness of GO decreased from 27.6 to 3.1 nm, and the average size decreased from 430 to 72 nm. The growth rates of flexural and compressive strength of cement paste increased from 30.8 and 29.5% to 52.9 and 38.2%, respectively. However, in ref. [100], GO sheets with a thickness of 3.5 nm and sizes of 5–140, 5–260, and 5–410 nm were prepared by hummers method and control of ultrasonic dispersion time. The increase of compressive and flexural strength of cement composites was the highest in the GO group of 5–410 nm, which was 77.6 and 88.5%, respectively. Tong et al. [101] observed similar trends and explained that more functional groups tended to adhere to larger GO to provide more nucleation sites for hydration products, thereby enhancing their mechanical properties.

In addition to compressive, flexural, and tensile strength, GO can also improve the elastic modulus and fracture performance of cement paste. Horszczaruk et al. [102] showed that the addition of 0.03 wt% GO can significantly improve the elastic modulus of cement paste from 1–10 to 5–20 GPa. Pan et al. [59] observed that adding 0.05 wt% GO increased the elastic modulus of cement from 3.48 to 3.70 GPa. Zhao et al. [103] studied the fracture properties of GO-modified cement mortar and found that the fracture energy, critical stress intensity factor, and other fracture parameters of GO-modified mortar increased with the increase of GO content. In addition, some studies have used mineral admixtures [66] and chemical modification methods [68,104] to improve the toughening effect of GO on cement composites.

In summary, GO has great potential in enhancing the mechanical properties of cement-based materials. Although great progress has been made in the research, there are still some problems. (1) Most types of cement studied are limited to Portland cement, and most types of concrete studied are limited to ordinary concrete, and the range of W/C ratio studied is also limited. (2) The research is still limited to the laboratory stage, limited to the test of test cube, lack of component test, and lack of engineering application practice. So the research still needs efforts.

3.3 Microstructural characteristics of graphene oxide-modified cement-based materials

Numerous studies have shown that the change of microstructure of cement-based materials caused by GO is the most important factor for the enhancement of macro-performance. Pore characteristics, microstructure of hydration products, and microstructure of interface transition zone are three main aspects of microstructural characteristics of cement-based materials.

Most studies have shown that GO can reduce the porosity of cement matrix, optimize the pore distribution, and thus make the microstructure of the matrix more compact, reflecting the enhancement of mechanical strength and the improvement of durability. In the study of Gong et al. [56], 0.03 wt% GO was added to reduce the total porosity of cement composites by 13.5%. He also pointed out that the number of capillary pores (10 nm < d < 10 µm) of GO-modified samples decreased by 27.7%, the number of gel pores increased significantly, and the average pore size was 36.7% smaller than that of blank samples. These results confirmed the potential of GO in refining pore structure. The research results of Gong can also be observed in refs [105–107]. References [54,81] also pointed out that GO can significantly reduce the total pore area, median pore diameter, average pore diameter, and porosity of hardened cement paste and make the pore diameter uniform (with median pore diameter close to the average diameter). Sharma and Kothiyal [108] observed that small-size GO could better reduce porosity. Wang et al. [85] showed that the role of GO became more important with the increase of hardening time. In the early stage of hardening, GO has an important influence on the gel pores. With the increase of age, the addition of GO not only affects the volume of small pore size, but also the volume of large pore size.

Many studies used scanning electron microscopy (SEM) to observe the changes in the microstructure of hydration products. Figure 14 [79] shows the SEM images of cement paste reinforced by different proportions of GO. When there is no GO, the hydration products are mostly needle-like and rod-like crystals (Figure 14a), and the hydration products are stacked disorderly. After adding 0.01–0.03 wt% GO (Figure 14b–d), flower-like crystals began to form and gradually become dense, and hydration products interweave with each other. After adding 0.04–0.05 wt% GO (Figure 14e and f), the hydration products gradually become regular polyhedron crystals, and the overall structure of hydration products is further dense. One of the reasons for the higher compressive strength of cement mortar with high GO content is that the hydration products of polyhedron crystals have greater compressive strength than flower-like crystals. Lv et al. [81] also studied the microstructure of cement mortar with different GO contents at different ages (Figure 15). The results showed that the hydration products of specimens with low GO content (0.01–0.04 wt%) became more dense with the increase of age, and the rod-like crystals almost disappeared. The hydration products of GO samples with high content (0.05–0.06 wt%) showed dense accumulation after 7 days of curing, and larger polyhedral crystals with interlaced structure appeared after 28 days of curing. These results can reflect the compressive strength changes of cement-based materials under different GO contents and different curing ages.

![Figure 14

SEM images of cement composites at 28 days mixed with GO: (a) no GO; (b) GO 0.01%; (c) 0.02%; (d) 0.03%; (e) 0.04%; and (f) 0.05% [79].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_014.jpg)

SEM images of cement composites at 28 days mixed with GO: (a) no GO; (b) GO 0.01%; (c) 0.02%; (d) 0.03%; (e) 0.04%; and (f) 0.05% [79].

![Figure 15

SEM images of the fracture surfaces of the hardened cement pastes with different GO contents at 7 days, 15 days and 28 days. GO contents: (a) 0.01%; (b) 0.02%; (c) 0.03%; (d) 0.04%; (e) 0.05%; and (f) 0.06% bwoc [81].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_015.jpg)

SEM images of the fracture surfaces of the hardened cement pastes with different GO contents at 7 days, 15 days and 28 days. GO contents: (a) 0.01%; (b) 0.02%; (c) 0.03%; (d) 0.04%; (e) 0.05%; and (f) 0.06% bwoc [81].

The interfacial transition zone between cement paste and aggregate is the weak link of cement-based materials, which has the characteristics of high porosity, low strength, and Ca(OH)2 enrichment, and is easy to become the generation and expansion zone of cracks. It has an important influence on the strength and permeability of cement-based materials [109]. In the study of Yan et al. [110], the matrix and interface of pure mortar are rough and porous, and there are many defects. The cement matrix with 0.02 wt% GO becomes uniform and dense, but the transition zone is still weak. When the content is increased to 0.04 wt%, the density of the interface transition zone increases significantly. Figure 16 shows the SEM images of RFA (recycled fine aggregates) mortar at 7 days [111]. It can be seen that in mortar without GO addition (Figure 16a and b), the interface between RFA and mortar is characterized by inhomogeneity, weak bonding, and high porosity, and only a small amount of hydration products are filled in the interface transition zone. In mortar with GO addition (Figure 16c and d), the interface density between REF and mortar is larger, and the interface is filled by GO itself and more high-density hydration products. The authors also point out that the hydroxyl on the surface of GO forms a strong covalent bond between GO and C–S–H gel, which further strengthens the interface bonding.

![Figure 16

SEM images of crystal morphology at different magnifications in RFA mortar sample (a and b) and in RFA mortar containing GO sample (c and d) after 7 days curing [111].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_016.jpg)

SEM images of crystal morphology at different magnifications in RFA mortar sample (a and b) and in RFA mortar containing GO sample (c and d) after 7 days curing [111].

The above studies have proved the improvement effect of GO on the microstructure of cement-based materials, including reducing the porosity of the matrix, refining the pore structure, densification of the hydration products, and strengthening the interfacial transition zone. The microscopic optimization has significantly improved the macroscopic properties (mechanical strength and durability) of GO-modified cement-based materials. However, some results were inconsistent. Yang et al. [94] said that GO had no effect on the structure of C–S–H. The XRD and FTIR results of Lin et al. [112] showed that the functional groups of GO did not change, indicating that GO was a catalyst rather than a reactant in the hydration process of cement. Cui et al. [113] indicate that the essence of flower-like crystals is calcium carbonate rather than cement hydration products. The characterization tools and methods, the characteristics of GO itself, the preparation methods of cement, and the curing methods may all lead to these inconsistencies. Therefore, the influence of GO on the microscopic characteristics of cement composites still needs further research.

3.4 Effect of graphene oxide on the durability of cement-based materials

Durability refers to the ability of cement-based materials to resist environmental media and maintain their good performance and complete appearance for a long time, thereby maintaining the safety and normal use of structural components. On the one hand, improving durability can ensure the safety and stability of the structure; on the other hand, it can increase the service life and reduce maintenance cost. Previous studies have shown that GO can significantly improve the durability of cement-based materials. The improvement of porosity and pore characteristics of cement matrix by GO is the key factor to improve the durability. The study of GO on improving the durability of cement-based materials mainly focuses on chloride ion resistance and impermeability, frost resistance, carbonation resistance, and corrosion resistance.

It is generally recognized that GO can improve the resistance to chloride ions and impermeability of cement-based composites. From Figure 17 [114], it can be seen that the addition of GO significantly reduces the penetration depth of chloride ions in the cement matrix. The research results of Zhang et al. [115] showed that the chloride diffusion coefficient of the self-leveling mortar specimen containing 0.04 wt% GO was 98.5% lower than that of the control group for 28 days. Chu et al. [73] showed that the chloride ion migration coefficient of recycled sand ultra-high performance concrete decreased by 6.90–12.07% after adding GO. The chloride resistance of recycled concrete studied by Guo et al. [116] also shows a similar trend. Mohammed et al. [114] explained that GO had the structural characteristics of layered cross-linking, and it could form a sponge structure after mixing with cement mortar. Chloride ions were trapped in this structure, thus limiting its entry into the cement matrix. Zhang et al. and Guo et al. [115,116] explained that the improvement of chloride resistance was attributed to the decrease of the proportion of harmful pores and the effective improvement of total porosity and pore size distribution by adding GO. References [43,117] pointed out that GO could improve the impermeability of cement mortar by 72.1 and 80%, and the research of Indukuri et al. [118] also had a similar trend. It was explained that GO could fill the pores or holes in cement composites, thus forming a more compact interlocking network of cement hydration crystals, reducing the permeability of water into the capillary pores or pore space of cement composites, and playing a barrier role in water permeability.

![Figure 17

Chloride front of the control mix comparison to GO mix [114].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_017.jpg)

Chloride front of the control mix comparison to GO mix [114].

Most studies mainly measure the improvement effect of GO on frost resistance from the surface damage degree, strength, and mass loss. In the study of Mohammed et al. [107], the mass loss of specimens containing 0.06 wt% GO after 540 freeze-thaw cycles was only 0.25% (the mass loss of the control group was 0.8%). Figure 18 shows the surface damage of the mortar specimen after 378 cycles. Compared with the control group, the surface of the sample containing GO has less scaling damage. Tong et al. [101] compared the effect of GNP and GO on frost resistance of mortar, indicating that GO improves the frost resistance of mortar but GNP plays a negative role. In Lu et al. [91], the mass loss rate after 300 freeze-thaw cycles was only 0.44–0.79%. Xu and Fan [119] studied the frost resistance of GO-modified concrete under the combined action of chlorine salt and freeze-thaw. The results showed that after 200 cycles of salt freezing, the surface damage of concrete containing 0.03 wt% GO was less, and the shedding blocks at the edge were less. The compressive strength of concrete increased by 34.83% compared with the reference specimen, and the strength loss and mass loss were the smallest. The improvement of frost resistance is mainly because GO promotes the hydration of cement, enhances the pore structure (the decrease of mesopore volume), and effectively slows down the initiation and propagation of internal microcracks. Besides, the water transport in cement materials is blocked during the freeze-thaw cycle, thereby enhancing the ability to resist freeze-thaw cycles.

![Figure 18

Freeze-thaw damages of different cement mixes [107].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_018.jpg)

Freeze-thaw damages of different cement mixes [107].

In the study of anti-carbonization ability, Long et al. [120] used thermogravimetric analysis (TG) to study the carbonization kinetics and found that GO can improve the stability of C–S–H in early carbonization. In Lv et al. [117], the carbonation depths of 7 days and 28 days of specimens containing GO were 78.57 and 65.71% lower than those of the control group, respectively. Devi and Khan [121] observed that the carbonation depth of concrete containing recycled concrete aggregate (RCA) decreases with the increase of GO concentration and the increase of curing time. In ref. [122], compared with the control group, the carbonization depth of GO mixture group decreased by 60, 71.4, 77.7, 72.7, and 81.3% at 3, 6, 12, 15, and 18 months, respectively. From Figure 19, we can intuitively see the improvement of GO against carbonization performance. Mohammed [122] explained that GO limited the movement of carbon dioxide molecules to cementitious materials by enhancing microstructure and reducing porosity, thereby slowing down the carbonation rate.

![Figure 19

Images for cementitious mixes after carbonation [122].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_019.jpg)

Images for cementitious mixes after carbonation [122].

At present, many studies have proved that GO can improve corrosion resistance. Liu et al. [43] pointed out that the strength retention rate of 0.03 wt% GO mortar under sulfate corrosion was the highest, which was 11.3 and 6.7% higher than the compressive strength and flexural strength of the reference sample corroded for three months, respectively. Devi and Khan [121] showed that the residual compressive strength and mass loss of 0.1 wt% GO mixture after sulfate attack were significantly higher than those of the control mixture. Li and Yang [123,124] also put the mortar specimens in different solutions (Na2SO4, NaCl, NaHCO3) for long-term immersion and dry-wet cycles. The results show that GO can effectively reduce the mass loss and the degree of mechanical properties attenuation and has a significant positive effect on preventing ion erosion and improving the salt erosion resistance of cement mortar composites. The reason is that GO improves the porosity inside the cement mortar and the weak area of interface transition, which forms a regular and orderly microstructure, slows down and hinders the erosion of corrosive ions, and thus achieves the purpose of optimizing the salt resistance.

In addition, studies have shown that GO can reduce water absorption [95,114,125] and calcium leaching [126] and improve wear resistance [115]. From the results, GO is of great significance to improve the durability of cement-based materials. However, the study of durability is also limited to laboratory and there is lack of systematic practical engineering evaluation. Durability affects the life of the structure. Therefore, to better apply GO in future construction practice, more in-depth research on durability is needed, such as steel corrosion, alkali-aggregate reaction, etc.

4 Effect of graphene oxide combined with other nanomaterials on cement-based materials

In recent years, there have been many studies on using one kind of nanoparticles alone to enhance cement-based materials. However, the research on using two different nanoparticles to improve the performance of cement matrix through different mechanisms is very limited, and most of them are in the initial stage. Nanohybrid materials have been widely studied in other fields, and people also hope to further improve the mechanical properties and operability of cement-based materials through the additional synergistic effect of various nanomaterials. Nanosilica (NS) and CNTs are the most studied nanoparticles. This section summarizes the synergistic effect of GO and these two materials.

4.1 GO/NS hybrid

The nanohybrid materials of GO and NS have been used to develop multifunctional materials, such as superhydrophilic surface [127] and epoxy resin composite [128]. This nanohybrid material has been proved to improve the corrosion resistance [129], wear resistance [130], flame retardancy, thermal stability, and low power consumption of functional materials [131]. At present, there are also a few studies on cementitious materials.

There are four main methods for preparing hybrid nanomaterials of GO and NS: (1) NS@PCE was synthesized by the “grafting to” method, and then GO and NS@PCE were dispersed in mixed water for ultrasonic dispersion [132]. (2) GO@PCE was prepared by stirring and ultrasonic dispersion, and then mixed with NS for ultrasonic dispersion [133,134]. (3) Dispersion of GO, NS, and PC in mixed water by agitation followed by ultrasonic dispersion [135]. (4) Nanohybrids were synthesized by gel–sol method. In a typical procedure, NS particles were deposited on GO nanosheets by in situ hydrolysis and condensation of TEOS [136–138]. The results also showed that the dispersion of the prepared nanohybrid materials in cement pore solution was better than that of single GO or NS. The improvement of dispersion can be attributed to the following two points (Figure 20): (1) NS particles on GO form a physical barrier, which can effectively reduce the reduction rate in a high alkaline medium and prevent the complexation between GO and Ca2+ [133,134,136,137]. (2) The covalent bonds between the Si–OH on the NS surface and the active functional groups (−COOH, −OH, etc.) of GO are easy to deionize to form negative charges, resulting in electrostatic repulsion between GO sheets [133,134].

![Figure 20

Scheme showing the dispersion mechanism of SiO2NPs on GO surface: (a) the surface structure of SiO2NPs; (b) the covalent interaction between Si–OH and functional groups of GO nanosheets; (c) the uniformly dispersed SiO2NPs on GO nanosheets and (d) the electrostatic repulsion between GO nanosheets covered with negatively charged SiO2NPs [134].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_020.jpg)

Scheme showing the dispersion mechanism of SiO2NPs on GO surface: (a) the surface structure of SiO2NPs; (b) the covalent interaction between Si–OH and functional groups of GO nanosheets; (c) the uniformly dispersed SiO2NPs on GO nanosheets and (d) the electrostatic repulsion between GO nanosheets covered with negatively charged SiO2NPs [134].

The mechanical properties of nanohybrid materials prepared by different methods are different. Hu et al. [136] introduced GO/NS nanocomposites prepared by the sol–gel method into cement composites. Compared with the blank group, the compressive strength of the specimens containing GO/NS increased by 20.6–33%, while the improvement effect of the specimens containing GO was 6–13.6%. Liu et al. [133] prepared nanohybrid materials by mixing GO, NS, and PC and ultrasonic dispersion. After curing for 3, 7, and 28 days, the compressive strength of hybrid cement increased by 50.0, 45.4, and 43.2%, respectively, which was much higher than that of single nanomaterial doping. Li et al. [134] also showed the same trend in the hybrid materials prepared by modifying PC@GO with NS particles. Lin et al. [137] studied the influence of two hybrid materials (GOS prepared by sol–gel method and simple hybrid GO + NS) on the strength of cement. The compressive strengthening effect of specimens containing GOS and GO + NS was better than that of the GO group, but the optimization effect of the GOS group was the largest. Mowlaei et al. [138] showed that the increase of compressive strength of GOS hybrid cement was proportional to the increase of thickness of NS coating. It can be seen from the above studies that GO and NS have a synergistic effect in enhancing the mechanical properties of cement. The fundamental reason for the enhancement of mechanical properties is the change of microstructure. In the study of Hu et al. [136], the addition of GO/NS can promote the formation of more dense C–S–H gels (Figure 21). The cumulative porosity of hybrid cement at 10–100 nm is also much lower than that of blank cement and GO cement. The results of Lin et al. [112] showed that the average pore size of the hybrid cement decreased by 16.9%, and the total porosity decreased by 25.5%. Moreover, a large number of obvious columnar and flower-like hydration products could be seen in the hybrid cement (Figure 22). Excellent pore structure and special microstructure were the keys to better mechanical properties.

![Figure 21

SEM images of hydration products in cement composites at 7 days: (a) plain, (b) GO, and (c) GO–NS [136].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_021.jpg)

SEM images of hydration products in cement composites at 7 days: (a) plain, (b) GO, and (c) GO–NS [136].

![Figure 22

Fractured surface morphology of four kinds of hardened cement pastes [133]: (a) blank constant, (b) graphene oxide cement, (c) nano-silica cement, and (d) hybrid nano-materials cement.](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_022.jpg)

Fractured surface morphology of four kinds of hardened cement pastes [133]: (a) blank constant, (b) graphene oxide cement, (c) nano-silica cement, and (d) hybrid nano-materials cement.

For the enhancement mechanism of GO and NS hybrid nanomaterials on cement-based materials, the following points can be summarized: (1) NS coating is uniformly and stably covered on the surface of GO, thus forming a barrier to prevent GO agglomeration. GO/NS with better dispersion is more effective as the core of hydrate formation [133,134,136]. (2) GO/NS can provide more nucleation sites in the hydration process and reduce the orientation index of CH crystal. At the same time, the volcanic ash NS coating also accelerated the transformation of CH to C–S–H, providing a template for the growth of C–S–H [133]. (3) The hybrid structure of GO/NS makes the ion transfer in the hydration system more efficient, so the C–S–H gel formed around GO is easy to combine with secondary C–S–H gel to form a network structure (Figure 23) [134,136]. (4) The [SiO2–GO–CSH] cross-linked structure formed by hybrid materials can alleviate the stress concentration, facilitate the uniform transmission of load in the cement matrix, and improve mechanical strength (Figure 24) [134].

![Figure 23

The sketch map of hybrid nanomaterials effect on cement hydration process [133].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_023.jpg)

The sketch map of hybrid nanomaterials effect on cement hydration process [133].

![Figure 24

Schematic diagram of chemical bonding structure of [SiO2–GO–CSH]: (a) covalent bonding between SiO2 NPs and GO nanosheets; (b) development of chemical reaction between the functional groups and hydration products; and (c) cross-linking structure is formed using GO as the bridge [134].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_024.jpg)

Schematic diagram of chemical bonding structure of [SiO2–GO–CSH]: (a) covalent bonding between SiO2 NPs and GO nanosheets; (b) development of chemical reaction between the functional groups and hydration products; and (c) cross-linking structure is formed using GO as the bridge [134].

In addition, some studies also show that GO/NS hybrid nanomaterials can reduce the working performance [135,137,138] and water absorption [132,135] of cement-based materials, but it can balance the decrease of working performance and further reduce the water absorption by increasing the amount of superplasticizer [135]. Xie et al. [132] studied the effects of GO and NS nanohybrid materials on fly ash-doped cement systems and found that 1% NS@PCE incorporation and 0.01% GO incorporation were sufficient to compensate for the early strength loss caused by FA incorporation. However, there are still contradictory and inconsistent views on the synergistic effect of GO/NS. In the study of Newell and Garcia-Taengua [135], the improvement of compressive strength of cement composites by GO/NS hybrid materials is slightly lower than that by using NS alone. This inconsistency may be related to the preparation method of hybrid materials, the properties of hybrid materials (properties of GO or NS), and the preparation process of cement paste. Moreover, the synergistic effect of GO/NS hybrid materials on other properties (durability, volume stability, etc.) of cement-based materials is lacking. Besides, there are still some defects in the current methods for the preparation of hybrid materials. For example, the number and distribution of NS cannot be controlled accurately, and the critical concentration of GO/NS hybrid materials has not been determined. Therefore, the influence of GO/NS nanohybrid materials on cement-based materials needs more and more in-depth research.

4.2 GO/CNTs hybrid

Compared with the GO/NS nanocomposite, the influence of GO/CNTs nanocomposite on cement-based materials has been studied more and more deeply. As early as 2010, Zhang et al. [139] reported the π–π stacking interaction between CNTs and GO sheets, which made the original CNTs dispersed and graded stably in water medium. The mixed GO/CNTs have also been widely studied in other fields [140,141]. Therefore, it is recognized that GO can be used as both a dispersant for CNTs and a reinforcing agent for CNTs-modified cement composite. Hence, the influence of GO/CNTs on the mechanical properties and durability of cementitious materials has been studied more.

In previous studies, simple methods are often used to prepare GO/CNTs hybrid materials, as shown in Figure 25 [142]: GO, CNTs, and superplasticizer are put into distilled water to prepare different hybrid suspensions under different ultrasonic dispersion schemes. The results show that GO/CNTs hybrid materials exhibit better dispersion and stability in an aqueous solution and alkaline environment. The presence of superplasticizer [143,144], ultrasonic time and power [145,146], and the ratio between GO and CNTs [143,145,147] all affect the dispersion of hybrid materials. In the study of Kaur et al. [145], when only containing FCNT/GO, the dispersion effect of nanohybrid materials with the ratio of 1:9 (GO: FCNT) was the best, and the optimal proportion of FCNT/GO stabilized by superplasticizer was 5:5. Gao et al. [146] pointed out that the increase of ultrasonic time and power can effectively improve the dispersion of GO/CNTs powder in the solution until it reaches dispersion stability. Since then, the extension of ultrasonic time has had little effect on dispersion, and excessive ultrasonic power will lead to the deterioration of dispersion. The improvement of dispersion was attributed to the π–π stacking interaction between GO and CNTs, which prevented the reaggregation of CNTs and the restacking of GO sheets. This inherent dispersion mechanism shows strong electrostatic repulsion, reducing the particle size of hybrid GO/CNTs, and the main contributor to this electrostatic repulsion is the C═O ester group formed in the hybrid material [147]. Besides, due to the effect of the superplasticizer side chain, the steric hindrance is stable, and the dispersion is further increased by the addition of the superplasticizer [148]. The dispersion diagram of hybrid GO/CNTs is shown in Figure 26 [149].

![Figure 25

Preparation processes of dispersed GO/MWCNT suspensions [142].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_025.jpg)

Preparation processes of dispersed GO/MWCNT suspensions [142].

![Figure 26

Schematic of dispersion of GO and CNTs [149].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_026.jpg)

Schematic of dispersion of GO and CNTs [149].

Current research shows that GO/CNTs hybrid materials have a synergistic effect on the compressive strength of cement composites. In refs [143,147–152], the enhancement effect of hybrid nanomaterials on the compressive strength of cement was much higher than that of single nanomaterials, and the increased range was 23.8–83.6%. Gao et al. [146] showed that different ultrasonic energy could make the mechanical properties of GO/CNTs hybrid cement change by 11.7–78.8%, and the optimal ultrasonic time and power were 15 min and 81–94 W. Du et al. [153] and Ramanjit et al. [144,145] studied the adaptability of GO/CNTs hybrid materials in potassium magnesium phosphate cement and fly ash cement, respectively. It was also found that the compressive strength of the specimens containing hybrid materials increased greatly. Gong et al. [154] pointed out that GO/CNTs had a more significant strengthening effect on the composites at the initial curing stage. Besides, literature [148] pointed out that adding superplasticizer can further improve the mechanical strength of hybrid cement. However, it is controversial whether GO/CNTs materials have a synergistic effect on the flexural strength of cement. The synergistic effect can be observed in the study of refs [143,144,151,152]. However, Du et al. [147] pointed out that the flexural strength is significantly negatively correlated with the ratio of GO and CNTs, and the increment of flexural strength is attributed to CNTs. This inconsistency may be related to the properties of GO or CNTs and the preparation process of cement paste.

The improvement of the mechanical strength of hybrid cement can be attributed to the optimization of pore structure. References [149] pointed out that the addition of GO/CNTs promoted the refinement of pores in cement paste and the transformation of harmful macropores (>1,000 nm) to micropores. Several studies by Ramanjit et al. [143–145] also supported this view and explained that the three-dimensional network of hybrid materials acted as the crystallization center of hydration products so that the hydration products were uniformly grown to the spaces between water-filled pores and hydrates, thereby refining the pores of cementitious matrix. Du et al. [147] observed that the porosity and average pore size of cement pastes with different GO/CNTs ratios were quite different (Figure 27). The inappropriate GO/CNTs ratio-added nanomaterials did not improve the pore structure of cement pastes, but damaged their pore structure. Gao et al. [155] results show that ultrasonic power plays a major role in enhancing pore characteristics. Ultrasonic time only affects mesopores, but has little effect on large pores. His other study [142] pointed out that longer multi-walled CNTs and some GO sheets adsorbed on the surface connect the ends of the crack and act as crack-bridging materials to suppress crack propagation (Figure 28). In the potassium magnesium phosphate cement studied by Du et al. [153], the hybrid nanomaterials greatly reduced the median pore size of the paste, with a minimum of 121 nm. He found that the addition of hybrid nanomaterials promoted the development of Struvite-k crystals, reduced the number of unreacted MgO particles, and improved the microstructure of the paste. Zhou et al. [149] pointed out that in the GO/CNTs paste containing PC, partial well-dispersed CNTs with a longer effective length could be anchored by the hydration products and, without adding PC or higher concentration of GO/CNTs, will lead to serious entanglement and aggregation of CNTs in the hydration products. Du et al. [147] proposed the strengthening mechanism of GO/CNTs on cement materials (Figure 29): First, the interlocking between hydroxyl and carboxyl groups grafted on the CNTs and GO interface ensured the stability of the three-dimensional GO/CNTs structure at the microscale. Second, hybrid GO/CNTs, GO individuals, or CNTs individuals can be connected to CSH and calcium hydroxide (two main phases in cement matrix), thereby improving the load transfer in all aspects.

![Figure 27

Porosity and average pore diameter of pastes with various GO: CNTs ratios [147].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_027.jpg)

Porosity and average pore diameter of pastes with various GO: CNTs ratios [147].

![Figure 28

SEM images of specimens: (a and b) Sample G/C-0, (c and d) Sample G/C-2, and (e and f) Sample G/C-4 [142].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_028.jpg)

SEM images of specimens: (a and b) Sample G/C-0, (c and d) Sample G/C-2, and (e and f) Sample G/C-4 [142].

![Figure 29

Mechanism of hybrid GO/CNTs reinforcement for cement pastes [147].](/document/doi/10.1515/ntrev-2021-0080/asset/graphic/j_ntrev-2021-0080_fig_029.jpg)

Mechanism of hybrid GO/CNTs reinforcement for cement pastes [147].

Impermeability and frost resistance are the main research directions of durability of GO/CNTs hybrid cement. Gao et al. [156] showed that the incorporation of GO/MWCNTs improved the impermeability of cement composites by 63.6%, but the enhancement rate of impermeability decreased linearly with the increase of the water-cement ratio. Gong et al. and Lin [154,157] pointed out that with the increase of the concentration of hybrid materials, the specimen changed from large porosity and high permeability to small porosity and low permeability, and then to large porosity and low permeability. Their freeze-thaw cycle results also proved the improvement of frost resistance of GO/CNTs hybrid cement. The mass loss of 300 freeze-thaw cycles in the experiment was only 0.2–0.8%, and the strength loss was only 11.5%. In addition, some studies [144,150,158] also proved that hybrid nanomaterials can make cement have lower resistivity.

In summary, GO and CNTs have a good synergistic effect on improving the performance of cement-based materials. However, the study still has some limitations: (1) The influence of hybrid materials on cement hydration has not been clarified, and the research on other properties of cement-based materials (corrosion resistance, volume stability, water absorption, etc.) is still lacking. (2) Ultrasonic dispersion is an important step in the preparation of hybrid materials. The influence of different ultrasonic dispersion methods on the properties and microstructure of hybrid cement is still unclear. (3) There is no systematic study to determine the optimal mass ratio of mixed GO/CNTs. Therefore, the research still needs to be carried out.

5 Evaluation of current progress

From the above research results, we can know that GO gives cement-based materials more excellent macroscopic properties and more uniform and dense microstructure. The current research has a certain breadth and depth, and the research covers most of the mechanical properties and durability. For the enhancement mechanism of GO, it is different to propose the mechanism through different means (test and molecular dynamics simulation), which indicates that the analysis of the mechanism is still imperfect. It should be pointed out that the research on GO-modified cement-based materials is still in the preliminary stage, and there are many problems and challenges in the test and practical application.

First, achieving uniform dispersion of GO in cement-based materials is the primary challenge. In the second chapter of the article, it is clear that the agglomeration of GO will make the superiority of nanomaterials unable to be fully played, and even weaken the performance of cement-based materials. The current decentralized method has high time and economic cost, which cannot be applied to practical engineering. Therefore, it is necessary to simplify and improve the dispersion method.

Second, GO will have a negative impact on the working performance of cement-based materials, and the current projects often have high requirements for the working performance of concrete. Although the existing research involves improving the rheological properties of cement-based materials, the research on the flow time loss is blank. Therefore, it is urgent to strengthen the research in this area to ensure the service performance of modern concrete.

Third, in previous studies cement, composite materials, and curing methods have great limitations, and the durability research is not comprehensive. Therefore, it is necessary to further study the compatibility of GO with other types of cement such as sulphoaluminate cement, explore the improvement effect of GO in concrete such as foam concrete and ultra-high performance concrete, explore the influence of different curing temperatures and different curing environments on GO-modified cement-based materials, and study the influence of GO on the volume stability and early crack resistance of cement composites. In addition, the research should be gradually closer to the direction of engineering practice.

Fourth, it is worth extending the combination of GO and other materials (other nanoparticles, mineral admixtures, fibers, etc.), so that cement-based materials have better performance and longer service life.

Fifth, the preparation methods of GO generally have pollution problems, the quality of GO in the market is uneven, and the cost is higher than other admixtures. These problems restrict the development of GO nanotechnology. Reducing cost, ensuring quality, and improving environmental adaptability will be major challenges for the development of GO.

6 Conclusion

In this paper, the application of GO in cement-based materials in recent years is reviewed in detail. Reviewing previous studies, we can draw the following conclusions:

Due to the alkaline environment and high concentration of Ca2+, GO will agglomerate in the cement paste. The dispersion of GO mainly includes physical dispersion and chemical modification. The dispersion effect of mechanical stirring and ultrasonic dispersion is not stable. The dispersion of GO after chemical modification is generally good, but the cost is high. Besides, the combined use of polycarboxylate superplasticizer and ultrasonic dispersion is the most studied and the best dispersion effect.

Due to the large specific surface area and strong van der Waals force between layers, GO will reduce the working performance of cement-based materials. The addition of PCE can eliminate the negative impact of GO on the working performance, because PCE has electrostatic repulsion and steric hindrance.

A small amount of GO significantly improves the compressive, tensile, and flexural strength of cement-based materials and also has a good improvement effect on the elastic modulus and fracture performance. The incorporation of GO, oxidation degree (oxygen content), dispersion degree, lamellar size, and superplasticizers are the factors affecting the enhancement efficiency.

The improvement of GO on the microstructure of cement-based composites mainly includes: (i) Reducing porosity and refining pore structure. (ii) Regulating the morphology of hydration products to make the microstructure more uniform and dense. (iii) Filling interface transition zone, strengthening the bonding between paste and aggregate. It should be noted that the reinforcement mechanism of GO on cement composites is still not fully elucidated.

The synergistic effect of GO, NS, and CNTs in cement-based materials has been preliminarily understood. Nanohybrid materials are superior to single nanomaterials in improving mechanical properties and durability. On the one hand, it is due to the better dispersion of nanohybrid materials. On the other hand, it is due to the interaction between different nanoparticles and the formation of a stable network structure with hydration products, which is conducive to the uniform transfer of load in the cement matrix.

The influence of GO on cement composites is still a hot research topic in the construction field. On May 25, 2021, Construction firm Nationwide Engineering completes the laying of the world’s first graphene concrete slab engineered for sustainability in a commercial setting. The project can improve the strength of concrete by 30% and reduce carbon emissions by 2%. It is a typical application of nanomaterials in the construction field. It is believed that shortly, as a derivative of graphene, GO can also make great contributions to practical engineering.

-

Funding information: This research was supported by Natural Science Foundation of China (52078079), Chongqing Technology Innovation and Application Development Special General Project (cstc2020jscx-msxmX0084), Guangzhou Science and Technology Project (Project number 202102010455), Cement Reducing Agent project of GT New Materials and Infrastructure Technology Co., Ltd (Project number GTRD202001), and Chengdu University of Technology Public Health Emergency Management Special Project (XGZ2020-ZD009).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: David Hui, who is the coauthor of this article, is a current Editorial Board member of Nanotechnology Reviews. This fact did not affect the peer-review process. The authors declare no other conflict of interest.

References

[1] Liu CJ, Huang XC, Wu YY, Deng XW, Zheng ZL, Xu Z, et al. Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials. Nanotechnol Rev. 2021;10(1):34–49.10.1515/ntrev-2021-0003Suche in Google Scholar

[2] Tiberti G, Minelli F, Plizzari GA, Vecchio FJ. Influence of concrete strength on crack development in SFRC members. Cem Concr Compos. 2014;45:176–85.10.1016/j.cemconcomp.2013.10.004Suche in Google Scholar

[3] Liu CJ, Huang XC, Wu YY, Deng XW, Liu J, Zheng ZL. Review on the research progress of cement-based and geopolymer materials modified by graphene and graphene oxide. Nanotechnol Rev. 2020;9(1):155–69.10.1515/ntrev-2020-0014Suche in Google Scholar

[4] Zhou F, Sun WB, Shao JL, Kong LJ, Geng XY. Experimental study on nano silica modified cement base grouting reinforcement materials. Geomech Eng. 2020;20:67–73.Suche in Google Scholar

[5] Abhilash PP, Nayak DK, Sangoju B, Kumar R, Kumar V. Effect of nano-silica in concrete; a review. Constr Build Mater. 2021;278(7):122347.10.1016/j.conbuildmat.2021.122347Suche in Google Scholar

[6] Yu R, Spiesz P, Brouwers H. Effect of nano-silica on the hydration and microstructure development of Ultra-High Performance Concrete (UHPC) with a low binder amount. Constr Build Mater. 2014;65(9):140–50.10.1016/j.conbuildmat.2014.04.063Suche in Google Scholar

[7] Du H, Gao HJ, Pang SD. Improvement in concrete resistance against water and chloride ingress by adding graphene nanoplatelet. Cem Concr Res. 2016;83:114–23.10.1016/j.cemconres.2016.02.005Suche in Google Scholar

[8] Gong HW, Jiang SY, Chen J, Tao S. Study on bending performance and mechanism of fiber reinforced cementitious composites. Compos Sci Eng. 2019;10:19–25 (In Chinese).Suche in Google Scholar

[9] Xiao J, Han N, Li Y, Zhang ZH, Shah SP. Review of recent developments in cement composites reinforced with fibers and nanomaterials. Front Struct Civ Eng. 2021;15(1):1–19.10.1007/s11709-021-0723-ySuche in Google Scholar

[10] Zhang P, Wan J, Wang K, Li QF. Influence of nano-SiO2 on properties of fresh and hardened high performance concrete: a state-of-the-art review. Constr Build Mater. 2017;148:648–58.10.1016/j.conbuildmat.2017.05.059Suche in Google Scholar

[11] Zhao ZF, Qi T, Zhou W, Hui D, Xiao C, Qi JY. A review on the properties, reinforcing effects, and commercialization of nanomaterials for cement-based materials. Nanotechnol Rev. 2020;9(1):303–22.10.1515/ntrev-2020-0023Suche in Google Scholar

[12] Wu Z, Shi C, Khayat KH, Wan S. Effects of different nanomaterials on hardening and performance of ultra-high strength concrete (UHSC). Cem Concr Compos. 2016;70:24–34.10.1016/j.cemconcomp.2016.03.003Suche in Google Scholar

[13] Han BG, Zhang LQ, Zeng SZ, Dong SF, Yu X, Yang RW, et al. Nano-core effect in nano-engineered cementitious composites. Compos Part A-Appl S. 2017;95:100–9.10.1016/j.compositesa.2017.01.008Suche in Google Scholar

[14] Khoshakhlagh A, Nazari A, Khalaj G. Effects of Fe2O3 nanoparticles on water permeability and strength assessments of high strength self-compacting concrete. J Iron Steel Res Int. 2012;1:73–82.10.1016/S1005-0302(12)60026-7Suche in Google Scholar

[15] Nazari A, Riahi S. Abrasion resistance of concrete containing SiO2 and Al2O3 nanoparticles in different curing media. Energ Build. 2011;43(10):2939–46.10.1016/j.enbuild.2011.07.022Suche in Google Scholar

[16] Sun JF, Xu K, Shi CQ, Ma J, Li WF, Shen XD. Influence of core/shell TiO2@SiO2 nanoparticles on cement hydration. Constr Build Mater. 2017;156:114–22.10.1016/j.conbuildmat.2017.08.124Suche in Google Scholar

[17] Tyson BM, Abu ARK, Yazdanbakhsh A, Grasley Z. Carbon nanotubes and carbon nanofibers for enhancing the mechanical properties of nanocomposite cementitious materials. J Mater Civ Eng. 2011;23(7):1028–35.10.1061/(ASCE)MT.1943-5533.0000266Suche in Google Scholar

[18] Oltulu M, Sahin R. Effect of nano-SiO2, nano-Al2O3 and nano-Fe2O3 powders on compressive strengths and capillary water absorption of cement mortar containing fly ash: a comparative study. Energy Build. 2013;58:292–301.10.1016/j.enbuild.2012.12.014Suche in Google Scholar

[19] Oltulu M, Sahin R. Single and combined effects of nano-SiO2, nano-Al2O3 and nano-Fe2O3 powders on compressive strengths and capillary permeability of cement mortar containing silica fume. Mat Sci Eng A. 2011;528:7012–9.10.1016/j.msea.2011.05.054Suche in Google Scholar

[20] Sobolev K, Gutiérrez MF. How nanotechnology can change the concrete world. Am Ceram Soc Bull. 2005;84(10):14–8.Suche in Google Scholar

[21] Monasterio M, Gaitero JJ, Erkizia E, Bustos AMG, Miccio LA, Dolado JS, et al. Effect of addition of silica- and amine functionalized silica-nanoparticles on the microstructure of calcium silicate hydrate (C–S–H) gel. J Colloid Interf Sci. 2015;450:109–18.10.1016/j.jcis.2015.02.066Suche in Google Scholar PubMed

[22] Sato T, Diallo F. Seeding effect of nano-CaCO3 on the hydration of tricalcium silicate. Transp Res Rec. 2010;2141:61–7.10.3141/2141-11Suche in Google Scholar

[23] Heikal M, Ismail MN, Ibrahim, NS. Physico-mechanical, microstructure characteristics and fire resistance of cement pastes containing Al2O3 nano-particles. Constr Build Mater. 2015;91:232–42.10.1016/j.conbuildmat.2015.05.036Suche in Google Scholar

[24] Joshaghani A, Balapour M, Mashhadian M, Ozbakkaloglu T. Effects of nano-TiO2, nano-Al2O3, and nano-Fe2O3 on rheology, mechanical and durability properties of self-consolidating concrete (SCC): an experimental study. Constr Build Mater. 2020;245:118444.10.1016/j.conbuildmat.2020.118444Suche in Google Scholar

[25] Madandoust R, Mohseni E, Mousavi SY, Mousavi SY, Namnevis M. An experimental investigation on the durability of self-compacting mortar containing nano-SiO2, nano-Fe2O3 and nano-CuO. Constr Build Mater. 2015;86:44–50.10.1016/j.conbuildmat.2015.03.100Suche in Google Scholar

[26] Parveen S, Rana S, Fangueiro R, Paiva MC. Microstructure and mechanical properties of carbon nanotube reinforced cementitious composites developed using a novel dispersion technique. Cem Concr Res. 2015;73:215–27.10.1016/j.cemconres.2015.03.006Suche in Google Scholar

[27] Chintalapudi K, Pannem RMR. An intense review on the performance of graphene oxide and reduced graphene oxide in an admixed cement system. Constr Build Mater. 2020;259:120598.10.1016/j.conbuildmat.2020.120598Suche in Google Scholar

[28] Li H, Xiao HG, Ou JP. Effect of compressive strain on electrical resistivity of carbon black-filled cement-based composites. Cem Concr Compos. 2006;28(9):824–8.10.1016/j.cemconcomp.2006.05.004Suche in Google Scholar

[29] Du MR, Jing HW, Gao Y, Su HJ, Fang HY. Carbon nanomaterials enhanced cement-based composites: advances and challenges. Nanotechnol Rev. 2020;9(1):115–35.10.1515/ntrev-2020-0011Suche in Google Scholar

[30] Zhao L, Guo XL, Song LG, Song Y, Dai GZ, Liu JP, et al. An intensive review on the role of graphene oxide in cement-based materials. Constr Build Mater. 2020;241:117939.10.1016/j.conbuildmat.2019.117939Suche in Google Scholar

[31] Shao GL, Lu YG, Wu FF, Yang CL, Zheng FL, Wu QL. Graphene oxide: the mechanisms of oxidation and exfoliation. J Mater Sci. 2012;47(10):4400–9.10.1007/s10853-012-6294-5Suche in Google Scholar