Abstract

The mechanical properties of basalt fiber-reinforced epoxy composites (BFRPs) are significantly dependent on the interfacial adhesion between basalt fibers (BFs) and the epoxy matrix. In this study, we proposed a simple and efficient method for deep and stable penetration of BFs into the epoxy matrix through dry-ozone treatments. To confirm the efficiency of the proposed method, BFRPs were fabricated using two types of composites: untreated BFs and dry-ozonized BFs in varying amounts, and the optimum amount of BFs for all the composites fabricated in this work was 60 wt%. With the addition of this amount of dry-ozonized BFs, the interlaminar shear strength and fracture toughness of the composites were enhanced by 21.2 and 23.2%, respectively, as compared with untreated BFs. The related reinforcing mechanisms were also analyzed, and the enhanced interfacial adhesion was mainly attributed to the mechanical interlocking effect. This approach shows that the dry-ozone treatment of BFs is a simple and efficient method for the preparation of BFRPs with excellent interfacial adhesion, which can be a potential application in the auto parts industry.

1 Introduction

Currently, carbon fiber-reinforced polymer composites (CFRPs) are being extensively studied owing to their superior mechanical properties [1,2,3,4,5,6]. However, while CFRPs can reduce vehicle weight by 30–60%, the cost of the overall process is not currently economically viable [7,8]. Recently, basalt fibers (BFs) have attracted considerable attention as reinforcement in polymer-based composites and auto parts industry because it is eco-friendly, nontoxic, easy to process, and costs less than carbon fibers (CFs) [9,10,11,12].

However, poor interfacial interaction of the fiber surfaces, particularly for BFs with chemically inert surfaces, makes incorporation within a polymer matrix difficult due to low wettability, resulting in poor interfacial adhesion [13,14]. Several recent studies have confirmed that surface modification was utilized to overcome these challenges in basalt fiber-reinforced polymer composites (BFRPs) [15,16,17]. In this regard, Lee et al. [18] demonstrated that acid treatment can promote the chemical reaction of BFs with an epoxy matrix. In addition, Kim et al. [19] demonstrated that plasma-treated BFs enhance the interlaminar shear strength (ILSS) of BFRPs. As is well known, high concentration acid and plasma treatment has shown promising results to improve interfacial adhesions onto BFRPs. However, it has been reported that defects/damage are unavoidably introduced onto the fiber surfaces when exposing fibers to plasma irradiation [20]. In addition, the high concentration acid requires strong acids or harmful chemicals, and consequently, fibers contain traces of undesirable chemicals and thus require further purification [21]. While both of these methods have demonstrated to be efficacious, they still have some drawbacks when applied to practical applications.

Dry-ozone treatment is an eco-friendly and straightforward process as compared with the other surface functionalization techniques [22,23]. This treatment method can be performed in an atmospheric condition and can enhance the interfacial adhesions by inducing oxygen-containing functional groups through the O3 oxidation process [24,25]. In this respect, Downey and Drzal [26] modified CF surfaces using ozone treatment and found the enhanced interface and mechanical properties of CFRPs. Considering the above facts, not only do various functional groups on the dry-ozonized BFs enhance wettability with the epoxy matrix, but they can also act as reactive sites for further promotion of interfacial adhesion between the BFs and the epoxy matrix.

The aim of the present research is to explore the potential of BFRPs fabricated from dry-ozonized BFs, which provides new types of economical and eco-friendly composites. Herein, the chemical and morphological changes of dry-ozonized BFs were investigated, and the effects of dry-ozonized BFs on the interfacial adhesion and fracture toughness of the composites are evaluated. Such an effort could result in the conversion of auto parts into fiber-reinforced polymer composites (FRPs) and provide a rational solution toward determining the theoretical limits of composite interfaces.

2 Experimental

2.1 Materials

Unless otherwise stated, chemicals were obtained from a commercial company and were used without further purification. BFs (chopped-type, a diameter of 0.5 mm and length of 4.0 mm, F260 grade) were purchased from Secotech Co., Korea. Epoxy resin (density: ∼1.16 g cm−3 at 25°C and epoxide equivalent weight: 185–190 g eq−1) was purchased from Kukdo Co., Korea. A 4,4′-diaminodiphenylmethane (DDM) curing agent was purchased from Tokyo Chemical Co., Japan.

2.2 Dry-ozone treatment of BFs

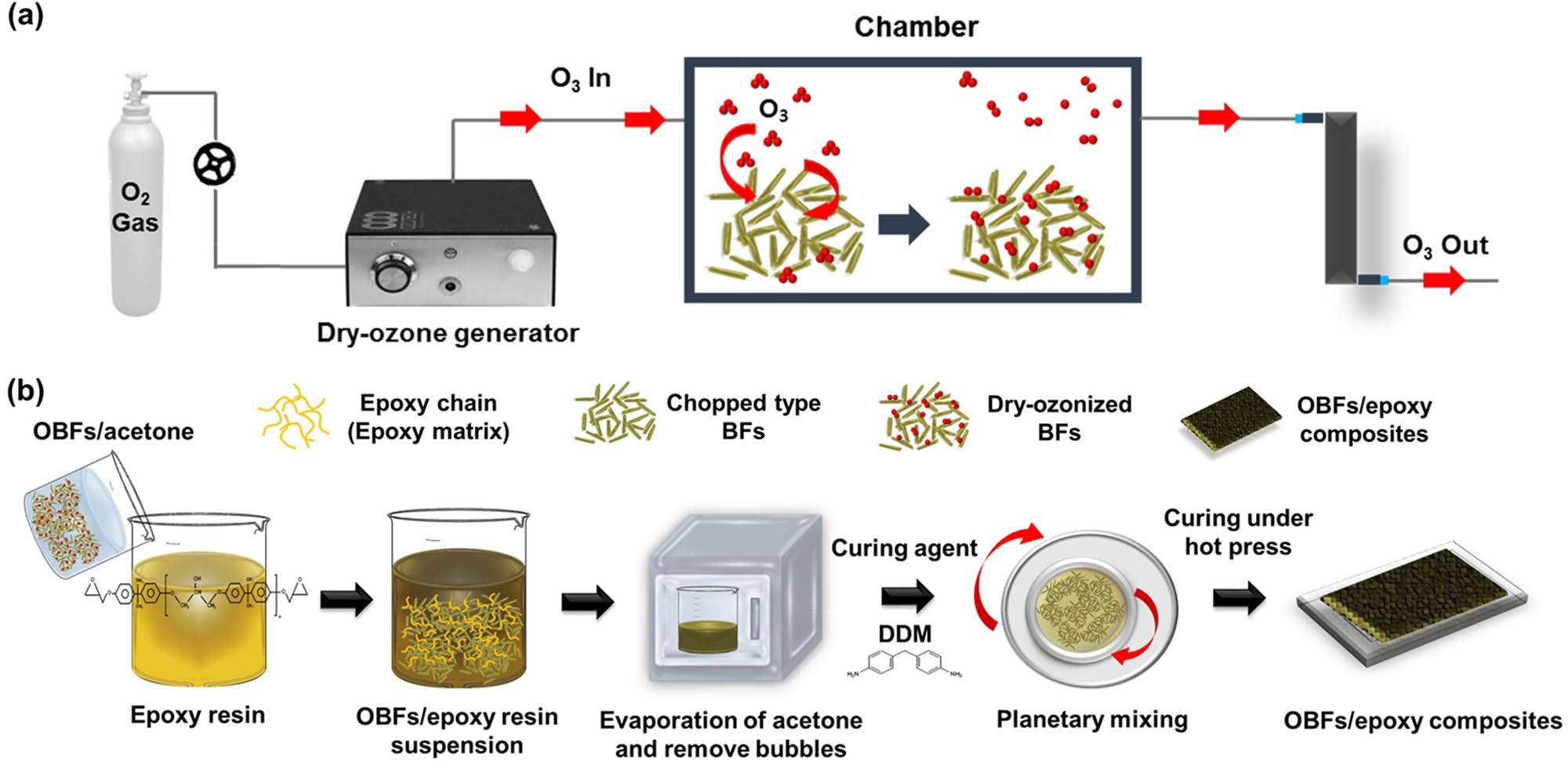

Figure 1(a) illustrates the dry-ozone treatment process. An Ozonetech Lab-Series ozone generator was used for the production of ozone from dry and pure O2 as the gas source. The oxygen flow rate to the generator was maintained at 0.8 L min−1 and monitored with a rotameter incorporated into the ozone generator. The diffusion rate of the O3 gas, introduced from the bottom of the ozone chamber through a sintered metal diffusing plate, was 8 g h−1 and was measured at room temperature for 4 h [20]. The dry-ozonized BFs were denoted as OBFs.

Schematic representation of OBFs/epoxy composites: (a) dry-ozone treatment of BFs and (b) composite preparation process.

2.3 Fabrication of OBFs/epoxy composites

Figure 1(b) illustrates the OBF/epoxy composite preparation process. First, different concentrations of BFs or OBFs (20, 40, 60, or 80 wt%) were added to an acetone/epoxy resin suspension and sonicated for 50 min at a power of 600 W (maximum temperature: 45°C). Thereafter, the mixture was heated in a vacuum oven at 100°C for 24 h to evaporate acetone. The curing agent (DDM) was added to the OBF/epoxy mixture and planetary mixed for approximately 5 min (planetary mixing is an efficient method to fabricate bubble-free composites). When the curing agent was dissolved, the resultant suspension was degassed at 70°C in the vacuum oven for 1 h to eliminate bubbles. After the bubble removal, the resulting mixture was continuously impregnated by BFs or OBFs using a three-roll milling machine for manufacturing the prepregs. Finally, the BF or OBF prepregs were cured at 80°C for 30 min, 110°C for 1 h, and 140°C for 2 h, and post-cured at 170°C for 2 h.

2.4 Characterization

X-ray diffraction (XRD, D2 Phaser, Bruker Co) was performed using the Cu-Kα radiation at 40 kV 40 mA−1 at scan steps of 0.02° from 10° to 80° to obtain XRD patterns of OBFs. Fourier-transform infrared vacuum spectroscopy (FT-IR, VERTEX 80 V, Bruker Co) was performed to evaluate the chemical states using KBr (radiation ranging from 500 to 4,000 cm−1). X-ray photoelectron spectroscopy (XPS, K-alpha, Thermo Co) was performed to study the surface elements of OBFs using a monochromated Mg-Kα source (1486.6 eV). High-resolution scanning electron microscopy (HR-SEM, SU8010, Hitachi Co) was performed at an operating voltage of 20 kV to characterize the fracture surface of the composites after coating with platinum. Dynamic contact angles (DCAs) were tested using the sessile drop method on a dynamic contact angle meter (Phoenix 300 Plus/Touch, SEO Co). As proposed by Fowkes [27], Owens and Wendt [28], and Kaelble [29], the surface free energy can be calculated using equations (1) and (2):

where γ is the total surface free energy, γ L is the London dispersion component, γ SP is the specific polar components, L represents a liquid, S represents a solid, and θ represents the DCAs [30]. The basic three-liquid data of surface free energy are provided in Table S1.

The universal testing machine (UTM, Lloyd LR5k, Lloyd-Instruments Co) was used to determine the fracture toughness (K IC) of the composites in terms of the critical stress intensity factor, satisfying the requirements of ASTM E399. A span-to-depth ratio of 4:1 and a crosshead speed of 1 mm min−1 were considered. The fracture toughness of the specimens was calculated as follows [31,32]:

where F is the critical load; L is the span between the supports; b and d are the specimen thickness and characteristic length, respectively; and Y is the shape factor given by

where a is the crack length. The precrack was cut to approximately half the specimen depth using a diamond razor blade (LSDC, DY Co).

The interlaminar shear strength (ILSS) of the specimens was evaluated using the UTM in three-point bending tests in accordance with ASTM D-2344 [33]. A span-to-depth ratio of 5:1 and a crosshead speed of 2 mm min−1 were considered. The ILSS determined from the specimens was calculated as (5)

where the parameters are the same as those for K IC.

3 Results and discussion

3.1 Characteristics of OBFs

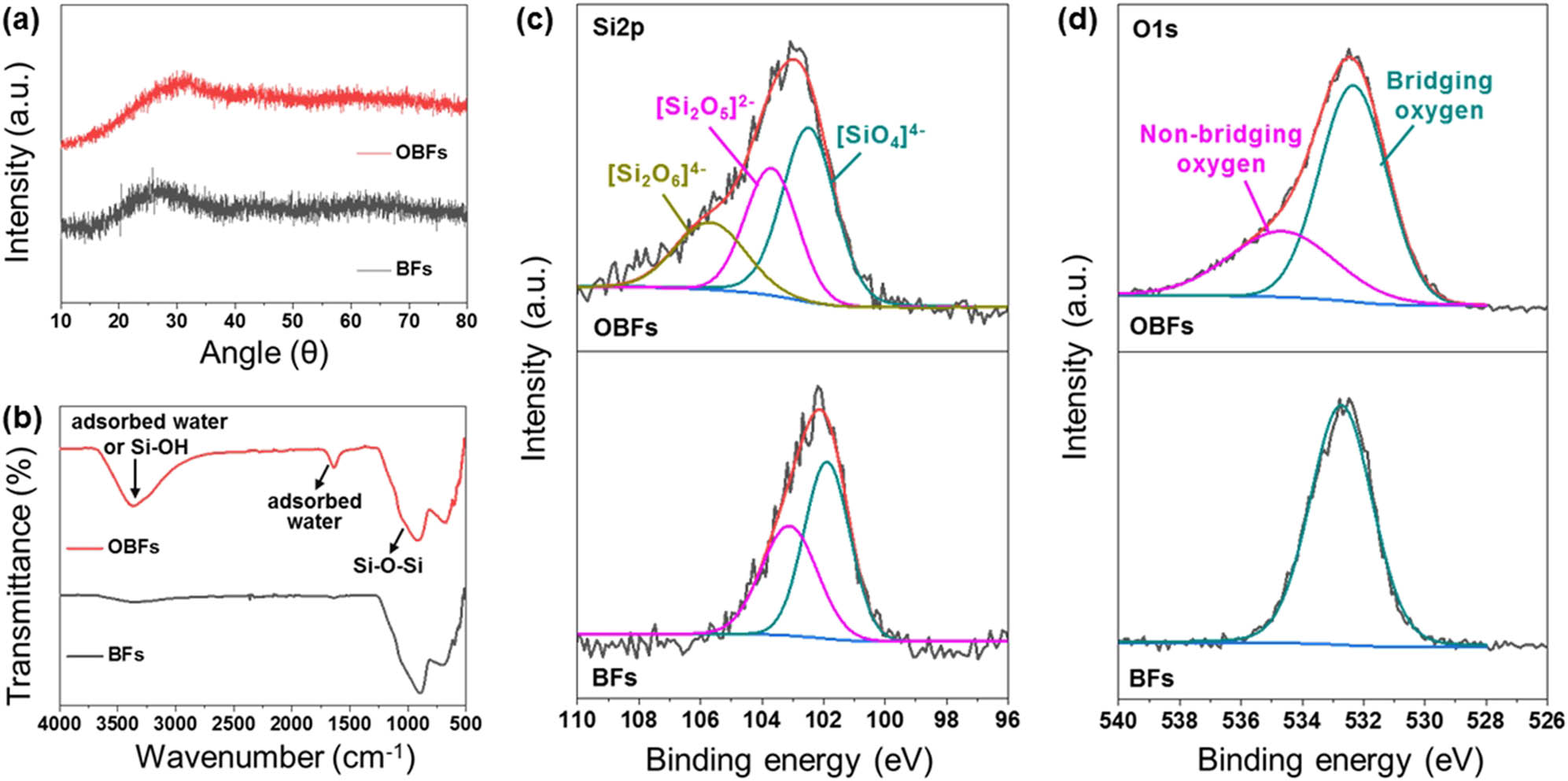

XRD analysis was performed to investigate the crystallographic nature of BFs and OBFs, the results of which are shown in Figure 2(a). The XRD pattern indicates that a major portion of BFs has an amorphous structure [34,35]. The XRD pattern of the OBFs was similar to that of BFs, indicating that the amorphous structure and the interplanar spacing were the same. This indicates that the dry-ozonization process did not change the amorphous structure of BFs.

Characterization of BFs and OBFs: (a) XRD, (b) FT-IR spectra, (c) Si2p core level of XPS spectra, and (d) O1s core level of XPS spectra.

Figure 2(b) shows the FT-IR spectra of BFs before and after the dry-ozone treatment. After dry ozonization, the FT-IR spectra of OBFs exhibited a decrease in the peak at 914.6 cm−1 (corresponding to the Si–O–Si stretching vibrations) while new peaks appeared at 1636.7 and 3379.3 cm−1, corresponding to the adsorbed water and Si–OH stretching vibrations, respectively refs. [36,37,38]. In dry-ozone treatment, the Si–O–Si network is attacked by OH− and H+. The reactions are explained by the following equations (6) and (7):

The OBF surfaces have a uniform structure because the OH− and H+ ions attack at ozonization.

In addition, for a detailed investigation on the surface elemental composition and chemical states of OBFs, the Si2p and O1s XPS spectra were deconvoluted, and the results are shown in Figure 2(c) and (d). There were mainly three silicate groups present in the Si2p core level spectrum (Figure 2(c)), and the corresponding binding energies were determined to be 102.5, 103.7, and 105.8 eV [19,38,39]. The peak at the binding energy, centered at 102.5 eV, can be attributed to [SiO4]4− (tetrahedron structure). The peak at lower binding energy at 103.7 eV can be attributed to [Si2O5]2− of the layer shape structure. Similar to the FT-IR spectrum, a new peak corresponding to [Si2O6]4− (chain shape structure), derived from the oxygen end radicals, appeared at 105.8 eV [40,41]. To support this claim, direct evidence for the oxygen end radicals introduced on the surface of BFs can be obtained from the O1s peak deconvolution of OBFs shown in Figure 2(d). For the O1s core level spectra of BFs, only one peak was observed at 532.6 eV, corresponding to the bridging oxygen. However, the O1s core level spectra of OBFs divided into two peaks at 532.2 and 534.3 eV corresponded to the bridging oxygen and non-bridging oxygen, respectively. From the results for O1s spectra, the OBFs demonstrate the presence of non-bridging oxygen groups on the surface, which could enhance the interfacial adhesion between the fibers and the epoxy matrix. Thus, the FT-IR and XPS spectra demonstrate the presence of oxygen-containing functional groups on the surface of OBFs, which could affect the curing reaction of the epoxy resin.

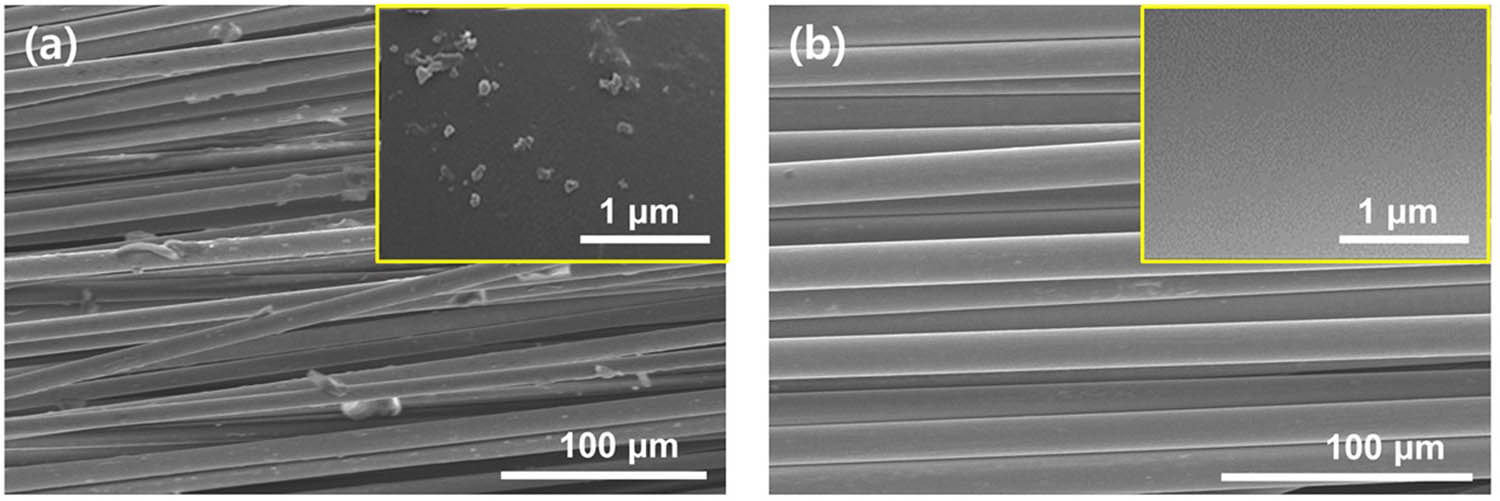

3.2 Morphologies of OBFs

The microstructures of BFs and OBFs were observed by SEM, as shown in Figure 3(a and b). As evident in Figure 3(a), the BFs were fairly straight and highly ordered structures, and the outer surface was partially covered with a layer of metal oxide and starch. As shown in Figure 3(b), after dry ozonization, the surface of OBFs was very smooth with a few pits and grooves. This is because dry ozonization begins at the outer surface of BFs and progressively removes some of the metal oxide and starch by continuous O3 oxidation. However, the fact that the highly ordered structure of OBFs is relatively clear proves that dry ozonization does not significantly disrupt the fiber structures.

Surface morphology of BFs and OBFs: (a) SEM images of BFs and (b) OBFs.

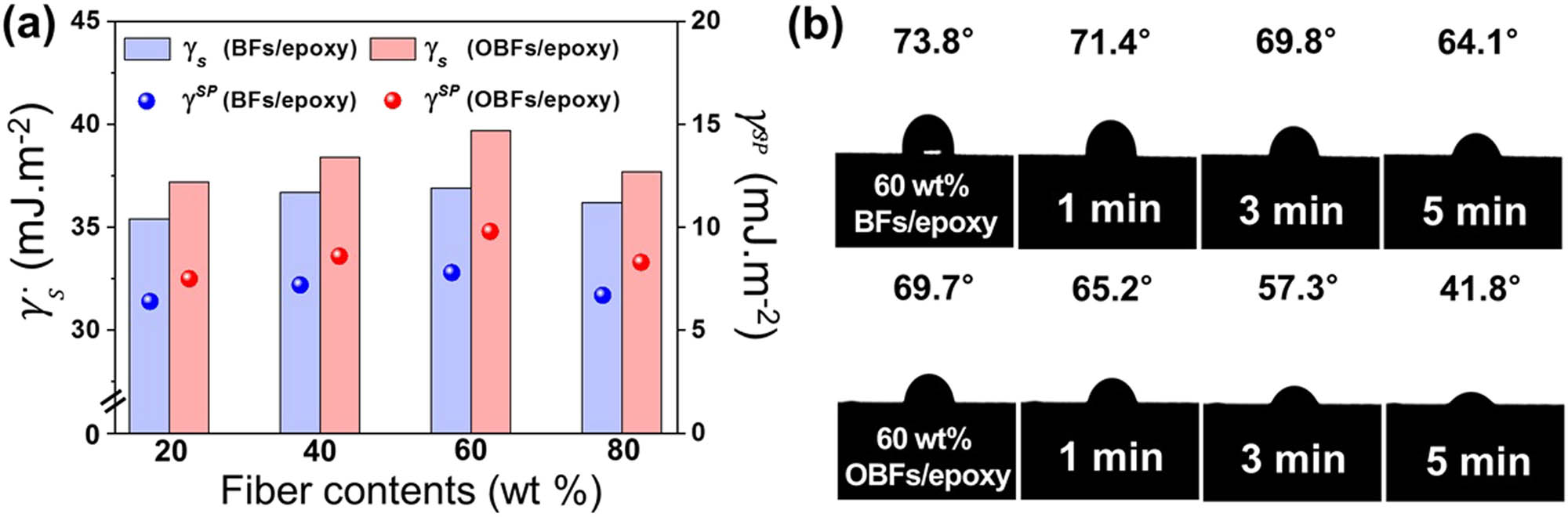

3.3 Interfacial properties of OBF/epoxy composites

The surface free energy of the composites was closely related to the wettability between the fibers and epoxy matrix [42,43]. A high surface free energy can lead to better wettability and strong interfacial adhesion. The total surface free energy results for the OBF/epoxy composites are listed in Table S2 and shown in Figure 4(a). As expected, the BF/epoxy composites exhibited a low surface free energy due to the chemically inert BF surfaces. In contrast, the surface free energy of the OBF/epoxy composites was enhanced significantly compared to that of the BF/epoxy composites. Compared to the 20 wt% BF/epoxy composites (35.4 mJ m−2), the surface free energy values for the 20 wt% OBF/epoxy composites (37.2 mJ m−2) increased by 5.1%. Moreover, the measured highest surface free energy value was 39.7 mJ m−2 in the 60 wt% OBF/epoxy composites, leading to a 7.6% increase compared to that of the OBF/epoxy composites (36.9 mJ m−2). In particular, the polar components of the OBF/epoxy composites exerted a greater influence on the surface free energy than the London dispersion components. The polar component of the BFs/epoxy composites reached roughly from ∼6.4 to a maximum of ∼7.8 mJ m−2. In contrast, for the OBF/epoxy composites, the polar component increased significantly, ranging from ∼7.5 to ∼9.8 mJ m−2, indicating that OBFs are more compatible with the polar epoxy matrixes. As demonstrated via FT-IR and XPS, the OBFs showed an increase in the oxygen-containing groups, which could be an important contributing factor for the improvement in the polar components [44,45].

Interfacial interaction of BFs/epoxy and OBFs/epoxy composites: (a) surface free energy and (b) optical images of the DCA of distilled water over time.

To support this explanation, we performed a detailed study on the wetting behavior of distilled water (at 27°C for 5 min) acting on the composites. It can be seen from Figure 4(b) that the wetting behavior of the 60 wt% BF/epoxy composite indicates low wettability due to the chemically inactive surface of BFs, and the DCA is maintained at roughly 64.1°. In contrast, the wetting behavior of the 60 wt% OBF/epoxy composites decreased the DCAs rapidly and became saturated at approximately 41.8°. This decrease is due to the oxygen-containing groups with a large number of hydrophilic surfaces on the OBFs from which water droplets could rapidly diffuse, thereby indicating enhanced wettability within the composites.

3.4 Mechanical properties of OBF/epoxy composites

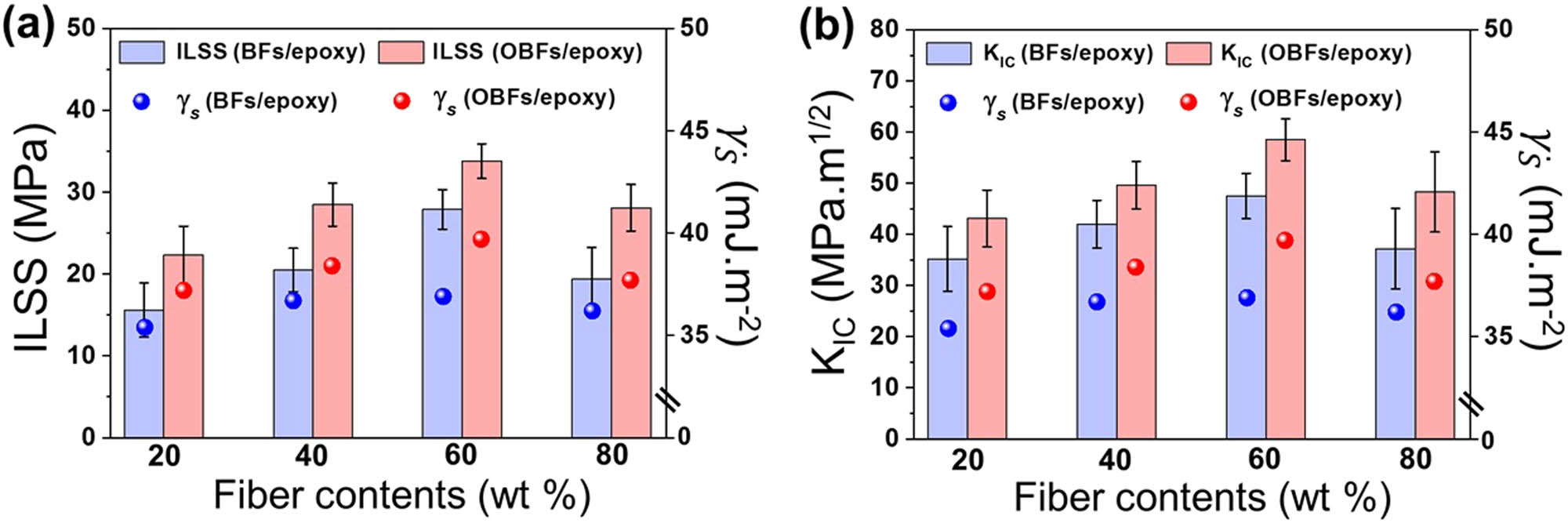

The ILSS and K IC can lay a solid foundation for the shear and fracture properties depending on the interfacial adhesion of the fibers within the epoxy matrix [46,47,48]. Therefore, the mechanical properties, including ILSS and K IC, were studied for the OBF/epoxy composites to evaluate their efficiency. As shown in Figure 5, the OBF/epoxy composites revealed good linearity in the relationship between the mechanical properties and surface free energy. In addition, the OBF/epoxy composites showed significant improvements in the ILSS and K IC values as compared to those of the BF/epoxy composites. Compared to the 20 wt% BF/epoxy composites, the ILSS and K IC values of the 20 wt% OBF/epoxy composites increased by 43.0 and 22.5%, respectively. Moreover, the measured highest ILSS and K IC values reached 33.8 MPa and 58.5 MPa m1/2 in the 60 wt% OBF/epoxy composites, leading to a 21.2 and 23.2% increase compared to those in the 60 wt% BF/epoxy composites, respectively. These results indicate that the additional interfacial interlocking was active when OBFs were included within the epoxy matrix, and this enhanced the mechanical properties of the composites.

Mechanical properties of BFs/epoxy and OBFs/epoxy composites: (a) ILSS and (b) fracture toughness.

3.5 Interfacial mechanism of OBFs/epoxy composites

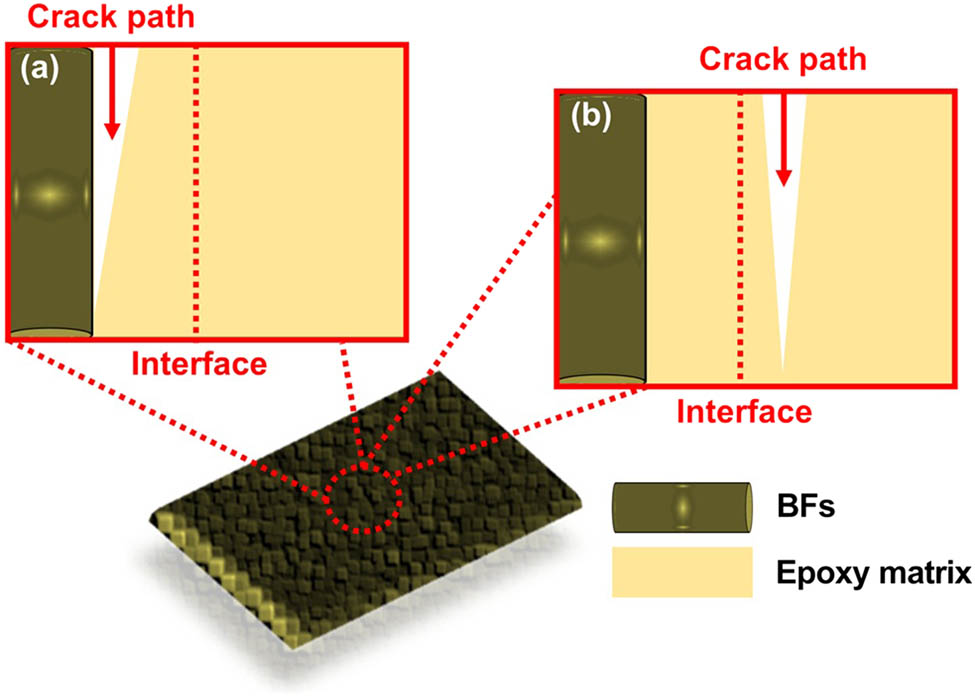

The schematic in Figure 6 depicts the interfacial mechanisms explaining the interfacial interlocking. As the crack opens, the cracks as shown in Figure 6(a) and (b) can occur, depending on the interfacial adhesion of the composites. For the BF/epoxy composites (Figure 6(a)), the crack paths can immediately extend to the fiber surface due to poor adhesion at the interface. Consequently, the composites could crack easily under a low load. In contrast, the OBF/epoxy composites (Figure 6(b)) prevented the cracks from contacting directly with the fiber surface, and crack paths could deviate into the interface area. This interface acted as a crack pinning that reduced the internal stress concentration and enhanced the energy dissipation during deformation.

Schematic description of interfacial mechanism: (a) BFs/epoxy composite and, (b) OBFs/epoxy composites.

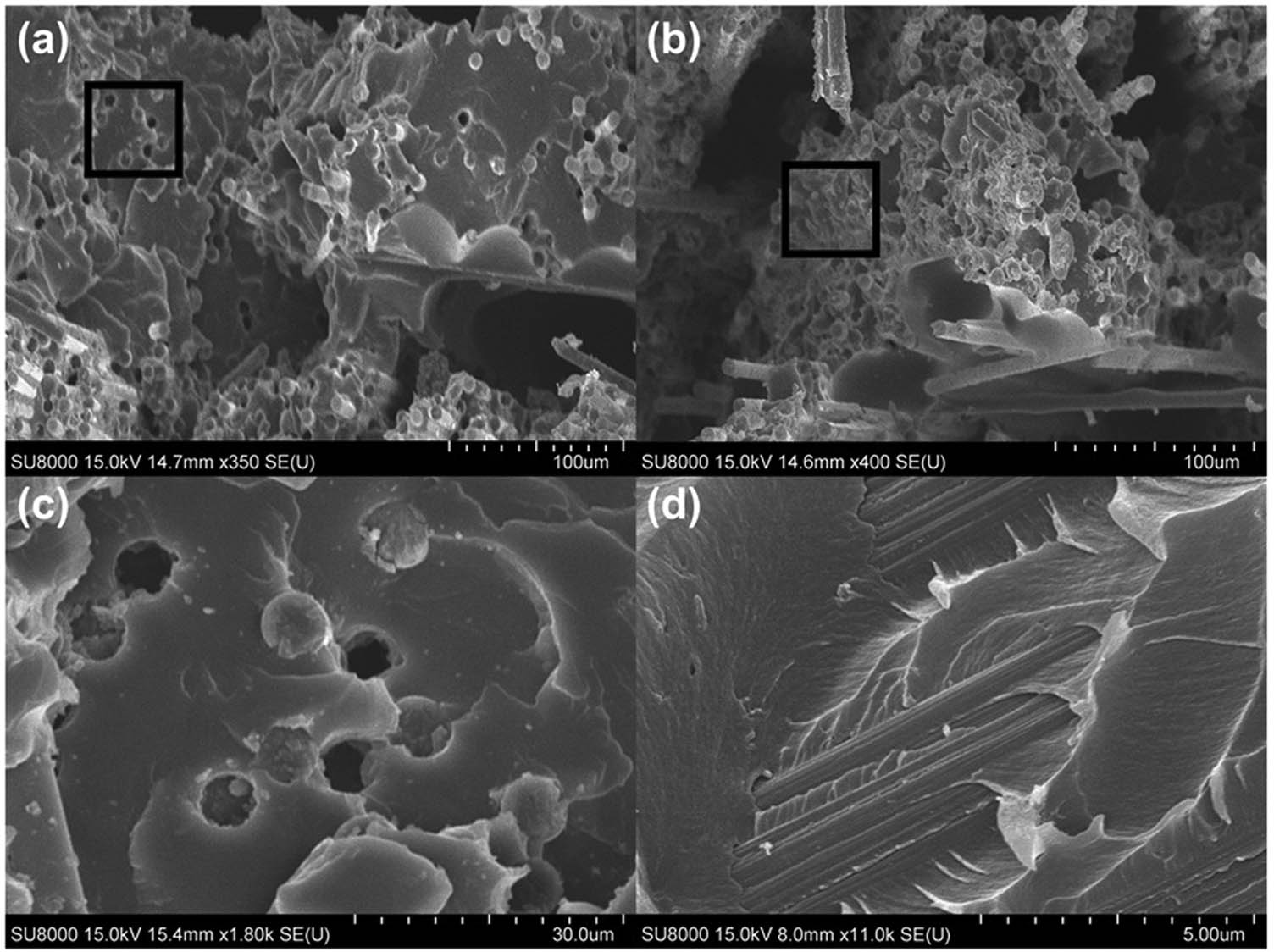

Some evidence for these interfacial mechanisms could be demonstrated on the presented fractured surfaces. Figure 7(a–d) displays SEM images of the fractured surfaces of the BF/epoxy and OBFs/epoxy composites. For the 60 wt% BF/epoxy composites (Figure 7(a) and (c)), there are distinct cracks between the BFs and the epoxy matrix. Consequently, the interfacial debonding occurred on the BF surfaces; the BFs were totally detached from the resin, and a large number of holes remained in the epoxy matrix. In contrast, the 60 wt% OBF/epoxy composites exhibited crack progression almost proprietarily along the rich interfaces and were tightly embedded within an epoxy matrix without de-bonding (Figure 7(b) and (d)). This inhibits propagation through the epoxy matrix as a crack must pass either through or fiber regions with epoxy-rich interfaces, resulting in enhanced mechanical properties.

Fracture surfaces of BFs/epoxy and OBFs/epoxy composites: (a) 60 wt% BFs/epoxy composites, (b) 60 wt% OBFs/epoxy composites, (c) and (d) the magnified fractured surface of the closed regions in (a) and (b), respectively.

4 Conclusion

In summary, OBFs were effectively utilized as reinforcements to enhance the interfacial adhesion of composites. The results show that OBFs can enhance the interfacial adhesion of composites, thereby leading to a significant enhancement in both ILSS and K IC. The enhanced interfacial adhesion was attributed to the oxygen end radicals introduced to the OBF surfaces, which can penetrate deep and stably into the epoxy matrix. In this regard, the measured highest ILSS and K IC values reached 33.8 MPa and 58.5 MPa m1/2 with 60 wt% OBF/epoxy composites, indicating 21.2 and 23.2% enhancement compared to the 60 wt% BF/epoxy composites. Our results demonstrate that the hierarchical OBF/epoxy composites with outstanding interfacial adhesions and mechanical properties obtained through simple and commercial manufacturing are attractive candidates for fabricating new types of structural-functional integrated composites.

-

Funding information: This work was supported by the “Policy R&D program KPP20002-2” funded by the Korea Institute of Ceramic Engineering and Technology, Republic of Korea, and the Technological Innovation R&D Program (S2829590) funded by the Small and Medium Business Administration (SMBA, Korea).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The datasets generated during and/or analysed during the current study are available in the Supplementary material on the journal website.

References

[1] Robertson ID, Yourdkhani M, Centellas PJ, Aw JE, Ivanoff DG, Goli E, et al. Rapid energy-efficient manufacturing of polymers and composites via frontal polymerization. Nature. 2018;557(7704):223–7.10.1038/s41586-018-0054-xSuche in Google Scholar PubMed

[2] Yang K, Guan J, Numata K, Wu C, Wu S, Shao Z, et al. Integrating tough Antheraea pernyi silk and strong carbon fibres for impact-critical structural composites. Nat Commum. 2019;10(1):1–12.10.1038/s41467-019-11520-2Suche in Google Scholar PubMed PubMed Central

[3] Taynton P, Ni H, Zhu C, Yu K, Loob S, Jin Y, et al. Repairable woven carbon fiber composites with full recyclability enabled by malleable polyimine networks. Adv Mater. 2016;28(15):2904–9.10.1002/adma.201505245Suche in Google Scholar PubMed

[4] Yao Z, Wang C, Qin J, Su S, Wang Y, Wang Q, et al. Interfacial improvement of carbon fiber/epoxy composites using one-step method for grafting carbon nanotubes on the fibers at ultra-low temperatures. Carbon. 2020;164:133–42.10.1016/j.carbon.2020.03.060Suche in Google Scholar

[5] Wu Q, Zhao R, Xi T, Yang X, Zhu J. Comparative study on effects of epoxy sizing involving ZrO2 and GO on interfacial shear strength of carbon fiber/epoxy composites through one and two steps dipping routes. Compos Pt A-Appl Sci Manuf. 2020;134:105909.10.1016/j.compositesa.2020.105909Suche in Google Scholar

[6] Han J, Wang D, Zhang P. Effect of nano and micro conductive materials on conductive properties of carbon fiber reinforced concrete. Nanotechnol Rev. 2020;9(1):445–54.10.1515/ntrev-2020-0034Suche in Google Scholar

[7] Tapper RJ, Longana ML, Norton A, Potter KD, Hamerton I. An evaluation of life cycle assessment and its application to the closed-loop recycling of carbon fibre reinforced polymers. Compos Pt B-Eng. 2020;184:107665.10.1016/j.compositesb.2019.107665Suche in Google Scholar

[8] Zakaria MR, Akil HM, Omar MF. Abdullah MMAB, Ab Rahman AA, Othman MBH. Improving flexural and dielectric properties of carbon fiber epoxy composite laminates reinforced with carbon nanotubes interlayer using electrospray deposition. Nanotechnol Rev. 2020;9(1):1170–82.10.1515/ntrev-2020-0090Suche in Google Scholar

[9] Dhand V, Mittal G, Rhee KY, Park SJ, Hui D. A short review on basalt fiber reinforced polymer composites. Compos Pt B-Eng. 2015;73:166–80.10.1016/j.compositesb.2014.12.011Suche in Google Scholar

[10] Kim SH, Park SJ, Rhee KY, Park SJ. Effects of ozonized carbon black on fracture and post-cracking toughness of carbon fiber-reinforced epoxy composites. Compos Pt B-Eng. 2019;177:107379.10.1016/j.compositesb.2019.107379Suche in Google Scholar

[11] Zhang Y, Yu C, Chu PK, Lv F, Zhang C, Ji J, et al. Mechanical and thermal properties of basalt fiber reinforced poly (butylene succinate) composites. Mater Chem Phys. 2012;133(2–3):845–9.10.1016/j.matchemphys.2012.01.105Suche in Google Scholar

[12] Ying Z, Wu D, Zhang M, Qiu Y. Polylactide/basalt fiber composites with tailorable mechanical properties: effect of surface treatment of fibers and annealing. Compos Struct. 2017;176:1020–7.10.1016/j.compstruct.2017.06.042Suche in Google Scholar

[13] Zhou S, Wang J, Wang S, Ma X, Huang J, Zhao G, et al. Facile preparation of multiscale graphene-basalt fiber reinforcements and their enhanced mechanical and tribological properties for polyamide 6 composites. Mater Chem Phys. 2018;217:315–22.10.1016/j.matchemphys.2018.06.080Suche in Google Scholar

[14] Seghini MC, Touchard F, Sarasini F, Cech V, Chocinski-Arnault L, Mellier D, et al. Engineering the interfacial adhesion in basalt/epoxy composites by plasma polymerization. Compos Pt A-Appl Sci Manuf. 2019;122:67–76.10.1016/j.compositesa.2019.04.013Suche in Google Scholar

[15] Zhu H, Wu G, Zhang L, Zhang J, Hui D. Experimental study on the fire resistance of RC beams strengthened with near-surface-mounted high-Tg BFRP bars. Compos Pt B-Eng. 2014;60:680–7.10.1016/j.compositesb.2014.01.011Suche in Google Scholar

[16] Xie J, Yao L, Xu F, Li Y, Shan Z, Hui D, et al. Fabrication and characterization of three-dimensional PMR polyimide composites reinforced with woven basalt fabric. Compos Pt B-Eng. 2014;66:268–75.10.1016/j.compositesb.2014.05.028Suche in Google Scholar

[17] Balaji KV, Shirvanimoghaddam K, Rajan GS, Ellis AV, Naebe M. Surface treatment of Basalt fiber for use in automotive composites. Mater Today Chem. 2020;17:100334.10.1016/j.mtchem.2020.100334Suche in Google Scholar

[18] Lee SO, Rhee KY, Park SJ. Influence of chemical surface treatment of basalt fibers on interlaminar shear strength and fracture toughness of epoxy-based composites. J Ind Eng Chem. 2015;32:153–6.10.1016/j.jiec.2015.08.009Suche in Google Scholar

[19] Kim MT, Kim MH, Rhee KY, Park SJ. Study on an oxygen plasma treatment of a basalt fiber and its effect on the interlaminar fracture property of basalt/epoxy woven composites. Compos Pt B-Eng. 2011;42(3):499–504.10.1016/j.compositesb.2010.12.001Suche in Google Scholar

[20] Kim SH, Heo YJ, Park SJ. Ozonization of SWCNTs on thermal/mechanical properties of basalt fiber-reinforced composites. Steel Compos Struct. 2019;31(5):517–27.Suche in Google Scholar

[21] Sun X, Liu X, Shen X, Wu Y, Wang Z, Kim JK. Reprint of Graphene foam/carbon nanotube/poly (dimethyl siloxane) composites for exceptional microwave shielding. Compos Pt A-Appl Sci Manuf. 2017;92:190–7.10.1016/j.compositesa.2016.10.030Suche in Google Scholar

[22] Luo J, Liu Y, Wei H, Wang B, Wu KH, Zhang B, et al. A green and economical vapor-assisted ozone treatment process for surface functionalization of carbon nanotubes. Green Chem. 2017;19(4):1052–62.10.1039/C6GC02806CSuche in Google Scholar

[23] Gong J, Liu Y, Sun X. O3 and UV/O3 oxidation of organic constituents of biotreated municipal wastewater. Water Res. 2008;42(4–5):1238–44.10.1016/j.watres.2007.09.020Suche in Google Scholar

[24] Alaton IA, Balcioglu IA, Bahnemann DW. Advanced oxidation of a reactive dyebath effluent: comparison of O3, H2O2/UV-C and TiO2/UV-A processes. Water Res. 2002;36(5):1143–54.10.1016/S0043-1354(01)00335-9Suche in Google Scholar

[25] Wang Q, Shi W, Zhu B, Su DS. An effective and green H2O2/H2O/O3 oxidation method for carbon nanotube to reinforce epoxy resin. J Mater Sci Technol. 2020;40:24–30.10.1016/j.jmst.2019.08.038Suche in Google Scholar

[26] Downey MA, Drzal LT. Toughening of carbon fiber-reinforced epoxy polymer composites utilizing fiber surface treatment and sizing. Compos Pt A-Appl Sci Manuf. 2016;90:687–98.10.1016/j.compositesa.2016.09.005Suche in Google Scholar

[27] Fowkes FM. Determination of interfacial tensions, contact angles, and dispersion forces in surfaces by assuming additivity of intermolecular interactions in surfaces. J Phys Chem. 1962;66(2):382–2.10.1021/j100808a524Suche in Google Scholar

[28] Owens DK, Wendt RC. Estimation of the surface free energy of polymers. J Appl Polym Sci. 1969;13(8):1741–7.10.1002/app.1969.070130815Suche in Google Scholar

[29] Kaelble DH. Dispersion-polar surface tension properties of organic solids. J Adhes. 1970;2:66–81.10.1080/0021846708544582Suche in Google Scholar

[30] Park SJ, Brendle M. London dispersive component of the surface free energy and surface enthalpy. J Colloid Interface Sci. 1997;188(2):336–9.10.1006/jcis.1997.4763Suche in Google Scholar

[31] Cha J, Jun GH, Park JK, Kim JC, Ryu HJ, Hong SH. Improvement of modulus, strength and fracture toughness of CNT/Epoxy nanocomposites through the functionalization of carbon nanotubes. Compos Pt B-Eng. 2017;129:169–79.10.1016/j.compositesb.2017.07.070Suche in Google Scholar

[32] Kim SH, Rhee KY, Park SJ. Amine-terminated chain-grafted nanodiamond/epoxy nanocomposites as interfacial materials: thermal conductivity and fracture resistance. Compos Pt B-Eng. 2020;192:107983.10.1016/j.compositesb.2020.107983Suche in Google Scholar

[33] Bisht A, Dasgupta K, Lahiri D. Investigating the role of 3D network of carbon nanofillers in improving the mechanical properties of carbon fiber epoxy laminated composite. Compos Pt A-Appl Sci Manuf. 2019;126:105601.10.1016/j.compositesa.2019.105601Suche in Google Scholar

[34] Kwak BS, Kim KM, Park SM, Kang M. Synthesis of basalt fiber@ Zn1-xMgxO core/shell nanostructures for selective photoreduction of CO2 to CO. Appl Surf Sci. 2017;407:109–16.10.1016/j.apsusc.2017.02.178Suche in Google Scholar

[35] Zhao X, Ouyang J, Yang H, Tan Q. Effect of Basalt fibers for reinforcing resin-based brake composites. Minerals. 2020;10(6):490.10.3390/min10060490Suche in Google Scholar

[36] Arslan C, Dogan M. The effects of silane coupling agents on the mechanical properties of basalt fiber reinforced poly butylene terephthalate) composites. Compos Pt B-Eng. 2018;146:145–54.10.1016/j.compositesb.2018.04.023Suche in Google Scholar

[37] Wei B, Song S, Cao H. Strengthening of basalt fibers with nano-SiO2-epoxy composite coating. Mater Des. 2011;32(8–9):4180–6.10.1016/j.matdes.2011.04.041Suche in Google Scholar

[38] Paukshtis EA, Yaranova MA, Batueva IS, Bal’zhinimaev BSA. FTIR study of silanol nests over mesoporous silicate materials. Microporous Mesoporous Mat. 2019;288:109582.10.1016/j.micromeso.2019.109582Suche in Google Scholar

[39] Zhang X, Zhou X, Ni H, Rong X, Zhang Q, Xiao X, et al. Surface modification of basalt fiber with organic/inorganic composites for biofilm carrier used in wastewater treatment. ACS Sustain Chem Eng. 2018;6(2):2596–602.10.1021/acssuschemeng.7b04089Suche in Google Scholar

[40] Wang ZT, Luo HJ, Zhang L, Zhang J, Chen HW, Jiang H. Mechanical properties of basalt fiber improved by starch phosphates sizing agent. Applied Surface Science. 2020;521:146196.10.1016/j.apsusc.2020.146196Suche in Google Scholar

[41] Wang J, Zhou S, Huang J, Zhao G, Liu Y. Interfacial modification of basalt fiber filling composites with graphene oxide and polydopamine for enhanced mechanical and tribological properties. RSC Adv. 2018;8(22):12222–31.10.1039/C8RA00106ESuche in Google Scholar PubMed PubMed Central

[42] Jiang Q, Tallury SS, Qiu Y, Pasquinelli MA. Interfacial characteristics of a carbon nanotube-polyimide nanocomposite by molecular dynamics simulation. Nanotechnol Rev. 2020;9(1):136–45.10.1515/ntrev-2020-0012Suche in Google Scholar

[43] Park JM, Kim DS, Kim SR. Improvement of interfacial adhesion and nondestructive damage evaluation for plasma-treated PBO and Kevlar fibers/epoxy composites using micromechanical techniques and surface wettability. J Colloid Interface Sci. 2003;264(2):431–45.10.1016/S0021-9797(03)00419-3Suche in Google Scholar

[44] Liu Y, Jiang X, Shi J, Luo Y, Tang Y, Wu Q, et al. Research on the interface properties and strengthening–toughening mechanism of nanocarbon-toughened ceramic matrix composites. Nanotechnol Rev. 2020;9(1):190–208.10.1515/ntrev-2020-0017Suche in Google Scholar

[45] Zakaria MR, Akil HM, Omar MF, Abdullah MMAB, Ab Rahman AA, Othman MBH. Improving flexural and dielectric properties of carbon fiber epoxy composite laminates reinforced with carbon nanotubes interlayer using electrospray deposition. Nanotechnol Rev. 2020;9(1):1170–82.10.1515/ntrev-2020-0090Suche in Google Scholar

[46] Khandelwal S, Rhee KY. Recent advances in basalt-fiber-reinforced composites: tailoring the fiber-matrix interface. Compos Pt B-Eng. 2020;192:108011.10.1016/j.compositesb.2020.108011Suche in Google Scholar

[47] Golewski GL. Estimation of the optimum content of fly ash in concrete composite based on the analysis of fracture toughness tests using various measuring systems. Constr Build Mater. 2019;213:142–55.10.1016/j.conbuildmat.2019.04.071Suche in Google Scholar

[48] Adak NC, Chhetri S, Kuila T, Murmu NC, Samanta P, Lee JH. Effects of hydrazine reduced graphene oxide on the inter-laminar fracture toughness of woven carbon fiber/epoxy composite. Compos Pt B-Eng. 2018;149:22–30.10.1016/j.compositesb.2018.05.009Suche in Google Scholar

© 2021 Seong-Hwang Kim et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions

Artikel in diesem Heft

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions