Abstract

It is needed to join C/C composite to other materials since its individual use is limited. Brazing is a method to join C/C composite that has been studied most, maturest and most widely used in recent decades. The quality of a brazed joint is largely determined by the intermediate layer material. It is significant to choose filler materials reasonably. C/C composite is difficult to be wetted by common brazing filler materials. Moreover, there is a large difference in the coefficient of thermal expansion between C/C composite and metals. At present, there is no brazing filler alloy exclusively recommended for commercial C/C composites and metal brazing. Usually, active elements are added into filler metals to improve the wettability of them on C/C composite surface. The existing research includes Al-based, Ag-based, Cu-based, Ti-based, Ni-based brazing filler metals, and so on. In addition, various particle reinforced composite filler materials and stress buffer metal interlayer added composite filler materials have been studied for brazing C/C composite. The summarization of the overview on the application of intermediate filler metals is made in this paper. The basic reference basis is provided for the subsequent brazing filler metals development and joint performance improvement for C/C composite brazing.

1 Introduction

Carbon fiber reinforced carbon matrix composite, also known as carbon/carbon composite (C/C composite) is a new composite material with both functional and structural properties. It is characterized by low density, high specific strength, high specific stiffness, high specific modulus, good thermal conductivity, good fracture toughness, good ablation resistance, good thermal shock resistance, excellent friction and wear resistance, good fatigue resistance and corrosion resistance, etc. [1, 2]. It is widely used in aerospace, navigation, nuclear energy, medical, military project and other high-tech fields [3]. C/C composite has been developed rapidly since its appearance, and with the rapid development of low-cost rapid preparation technology and high-temperature oxidation resistance technology, more and more attention will be paid to C/C composites.

While expanding its application fields, the individual use of C/C composite is limited to a certain extent. It is difficult and expensive to directly prepare large and complex components because of the complex preparation process and long generation cycle of C/C composites. Meanwhile, the plasticity, deformation and workability of C/C composite are poor. Generally, in order to reduce costs and improve production efficiency, the economical and feasible solution is to join C/C composites to metals or other materials without affecting the structural performance, while giving play to their own advantages, so as to meet the processing requirements of special size and shape components.

So far, the joining methods of C/C composites include mechanical joining [4, 5], adhesive joining [5, 6], brazing, diffusion bonding and high-temperature self-propagating reaction, etc. There are some limitations in both mechanical and adhesive joining. C/C composite cannot be joined by the conventional fusion welding methods since its high melting point (3600°C~3800°C). As an economical and reliable method of material joining, brazing is a kind of joining method between C/C composites and metals that has been studied most, maturest and most widely used in recent decades.

In the brazing process of C/C composite, the melted brazing filler metal can not only wet the matrix, but also disperse the joint pressure evenly at the interface. The thermal stress concentration phenomenon caused by the mismatch of the thermal expansion coefficient was alleviated. Meanwhile, the brazed parts are joined through the molten brazing filler metals. The properties of the braze joints are determined by the properties of the brazing filler metals and the interaction between them and base materials to a great extent. C/C composite should be well wetted by the brazing filler metals. Moreover, the properties of brazing joints are also related to the composition of joint products, the structure of compounds, the structure of matrix material interface, and difference of thermal expansion coefficient of brazed parts. Therefore, the quality of brazed joint is largely determined by the brazing filler metal. It is significant to choose filler materials reasonably for improving the reliability of the joint. At present, there is no brazing filler alloy exclusively recommended for commercial C/C composites and metal brazing [7]. Many experts and scholars have studied the joining of C/C composites with different filler metals. The summarization of the overview on the application of brazing filler metals is made in this paper. The basic reference basis is provided for the subsequent brazing filler metals development and joint performance improvement for C/C composite brazing.

2 Common brazing filler metals

2.1 Al-based brazing filler metals

When brazing C/C composite, it requires not only the wetting ability of brazing filler metal on the workpiece but also the chemical reaction between filler and C/C composite to form high strength metallurgical bonding [8]. Currently, the commonly used filler metals include Al-based, Ag-based, Cu-Ni-based brazing filler metals, etc.

Aluminum and aluminum alloys occupy a unique position in modern industrial materials due to their low density, high thermal conductivity and electrical conductivity. Al-based brazing filler metal is characterized by low cost, low melting point and low operating temperature. When applying in brazing of C/C composite, Al from the brazing filler metal can react with C from C/C composite to generate Al4C3 compound, so as to realize high strength joining of C/C composite. However, the existence of Al elementary substance in the joint makes it unsuitable to be used at high temperature. The applications of Al-based brazing filler metals in joining of C/C composites are shown in Table 1.

Al-based brazing filler metals used in joining of C/C composites

| Composition of brazing filler metal (wt. %) | Base materials | Brazing temperature (°C) Holding time (min) | Strength (MPa) | References |

|---|---|---|---|---|

| Al | C/C-C/C | 1000/45 | 10 (Shear) | [9] |

| Al-Ti | C/C-C/C | 1110/10 | 12.3 (Shear) | [10] |

| Al-15Ti | C/C-C/C | 1100/10 | 16 (Shear) | [11] |

| Al-14Ti | C/C-C/C | 1050/10 | 14.7 (Tensile) | [12] |

Although Al and C can react to form Al4C3 compound, Al can wet carbon materials only at high temperature. Therefore, it is generally preferred to add active element Ti to increase the wettability of the brazing filler metal on C/C composites’ surface. On the other hand, Ti can react with C to form TiC intermetallic compounds, further improving the bonding strength. However, the addition amount of Ti should not be too much to avoid the brittle TiC layer is too thick, which will affect the interface joining strength.

2.2 Ag-based brazing filler metals

Ag-based brazing filler metal has the advantages of moderate melting point, good manufacturability, good strength, good toughness, high electrical conductivity, high thermal conductivity and good corrosion resistance. It is a kind of widely used brazing filler metal. The main alloying elements of Ag-based brazing filler metal include Cu, Zn, Cd and Sn, etc. Since the addition of Cu can reduce the melting temperature of silver without forming brittle phases, Cu is the most important alloying element. Brazing filler metals with Ag-Cu alloy as the matrix, assisted adding Zn, In, Mn, Ni, Si, Sn, Ti and other metal elements possess the advantages of good brazing temperature controllability [13], good wettability with the joined parts, and strong filling gap ability, and so on. Compared with Ni-based or Ti based brazing filler metal, the brazing temperature of Ag-based brazing filler metal is lower. The applications of Ag-based brazing filler metals in joining of C/C composites are shown in Table 2.

Ag-based brazing filler metals used in joining of C/C composites

| Composition of brazing filler metal (wt. %) | Base materials | Brazing temperature (°C) Holding time (min) | Strength (MPa) | References |

|---|---|---|---|---|

| Ag28Cu | C/C-TC4 | 850/10 | 38 (Shear) | [16] |

| Ag28Cu | C/C-TC4 | 880/10 | 33 (Shear) | [17] |

| Ag-Cu-2Ti | C/C-CuCr | 850/5 | 16 (Shear) | [18] |

| Ag-Cu-2Ti | C/C-CuW | 850/5 | 13 (Shear) | [18] |

| Ag-26.4Cu-4.6Ti | C/C-C/C | 900/10 | 22 (Shear) 38 (Bending) |

[19] |

| 68.8Ag-26.7Cu-4.5Ti | C/C-Ti | 910/5 | 0.24±0.09 (Tensile) | [20,21,22] |

| Ag-26.7Cu-4.6Ti | C/C-TC4 | 910/10 | 25 (Shear) | [23,24,25] |

| 68.8Ag-26.7Cu-4.5Ti | C/C-(Cu-Mo-Cu) | (915~920)/5 | — | [26, 27] |

| 63Ag-34.3Cu-1Sn-1.75Ti | C/C-(Cu-Mo-Cu) | (821~826)/5 | — | [26] |

| 63Ag-35.3Cu-1.75Ti | C/C-(Cu-Mo-Cu) | (830~835)/5 | — | [27] |

| 63Ag-32.25Cu-1.75Ti | C/C-Graphite foam-Ti tube | 820/5 | 12.4 (Shear) 11.8 (Tensile) |

[28] |

| Ag-26.7Cu-4.6Ti | C/C-TiAl | 900/10 | 12.9 (Shear) | [29] |

| Ag26Cu2Ti | C/C-K24 (Ni-based) | 880/10 | 16 (Shear) | [30] |

| Ag-32.25Cu-1.75Ti | C/C-Pure Ti | 830/5 | 24 (Shear) | [31] |

| 70Ag28Cu2Ti | C/C-TC4 | 860/10 | 28 (Shear) | [32] |

| Ag-27Cu-3.5Ti | C/C-C/C | 900/10 | 20 (Shear) | [33] |

| Ag-26.7Cu-4.6Ti | C/C-TC4 | 900/10 | — | [34] |

| Ag-26.7Cu-4.5Ti | C/C-C/C | 850/30 | 26.7 (Shear) | [35] |

| Ag27Cu3Ti | C/C-Rene N5 | 910/10 | Shear: 18.7 (Flat), 31 (zigzag grooved) | [36] |

| 68.83Ag-26.77Cu-4.4Ti | C/C-TC17 | 860/15 | 24±1 (Shear) | [14] |

| Ag-68.8Cu-4.5Ti | C/C-Cu | 910/10 | Bending: 14 (Flat), 52 (Conical interface) | [37] |

| Cu-28Ag-2Ti | C/C-OF Cu | 850/10 | 22 (Shear) | [38] |

| Ag-(10,20, 30, 40)Ti | C/C-GH3044 | (990~1080)/(10~90) | 45.8 (Shear) (Ag-20Ti; 1020/30) | [39] |

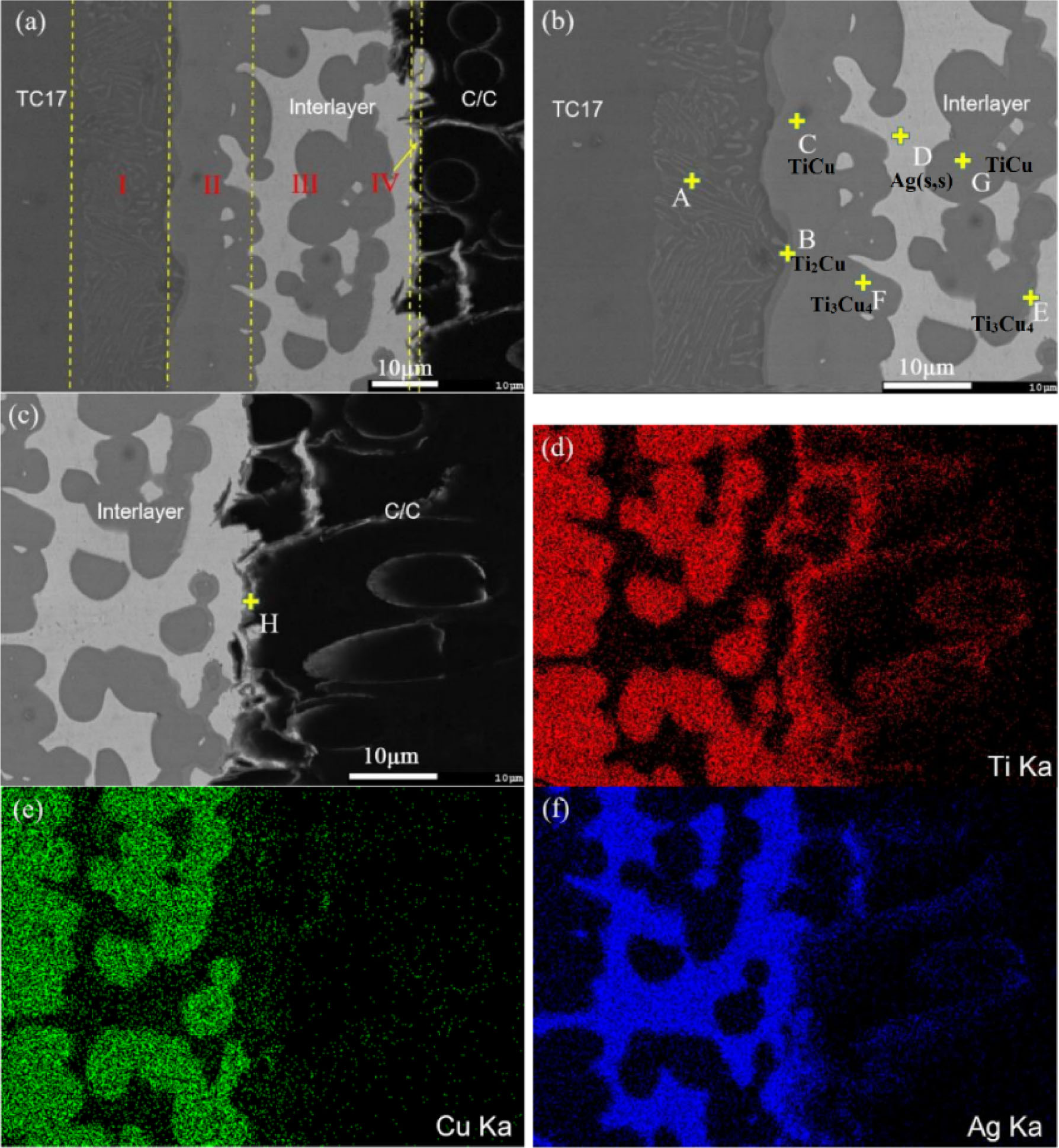

It can be seen from Table 2 that the Ag-based brazing filler metals used for brazing C/C composites are mainly Ag-Cu eutectic alloy and Ag-Cu-Ti brazing filler metals. Ag-Cu-Ti brazing filler metal is one kind of relatively mature and most important active brazing filler metals in the active brazing method. Its low melting temperature makes it is suitable for medium and low temperature. Ag-Cu-Ti used in brazing C/C composites is generally based on Ag-Cu eutectic and added trace Ti element. The content of Ti ranges from 1.75 wt.% to 4.6 wt.%. During brazing process, interfacial metallurgical bonding was formed thanks to the elements diffusion and chemical reaction (Figure 1) [14]. The content of element Ti and Cu indicates that diffusion and reactions occur between base material and brazing filler. According the thermodynamic data [15], the Gibbs free energy of TiC formation are represented as follows:

Back-scattered electron image of C/C composite/AgCuTi/TC17 joint.

The Gibbs free energy of forming TiC calculated by Equation (1) is about −172.2 kJ/mol~ −171.2 kJ/mol at 820°C~920°C. Therefore, element Ti and C can react with each other while using Ag-Cu-Ti fillers to brazing C/C composite.

Ag-based brazing filler metals are commonly used for brazes between C/C composites and Ti alloys, Cu alloys and Ni-based superalloys. The strength of brazing joint varies with different material composition and structure. Most of the shear strength of the joints was above 20 MPa, which was close to the interlaminar shear strength of C/C composites.

2.3 Cu-based brazing filler metals

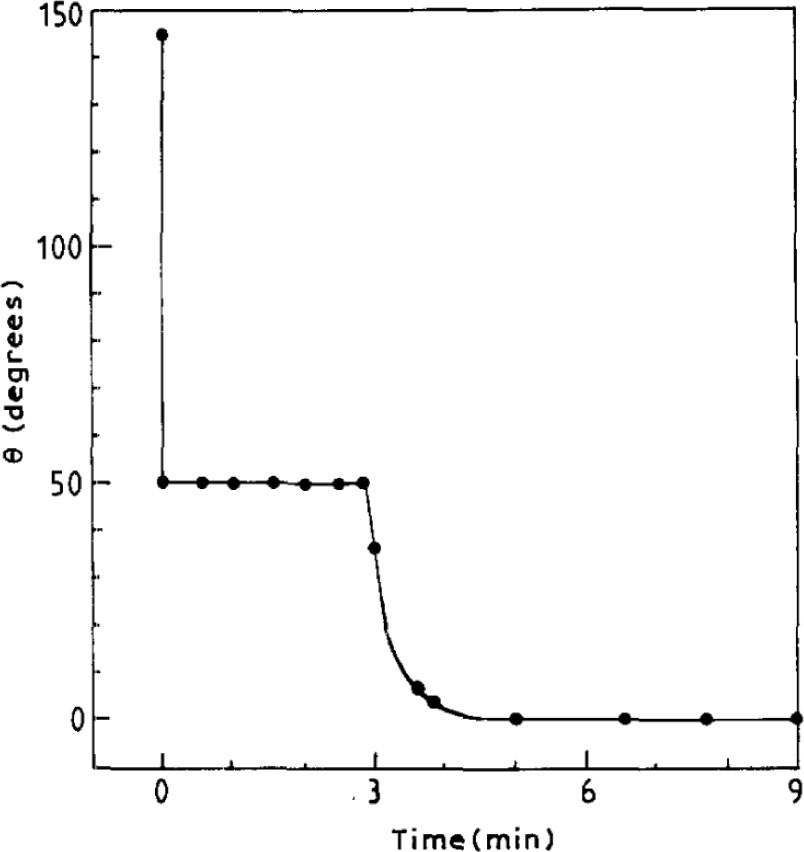

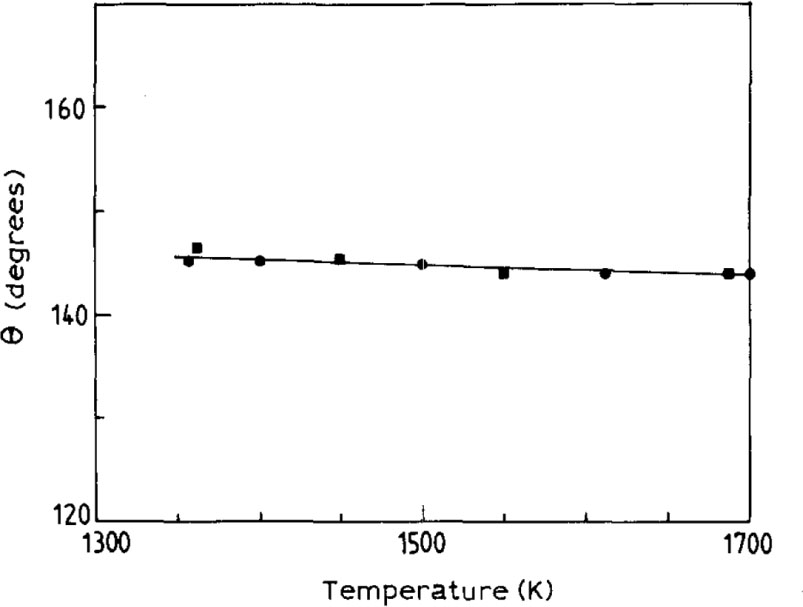

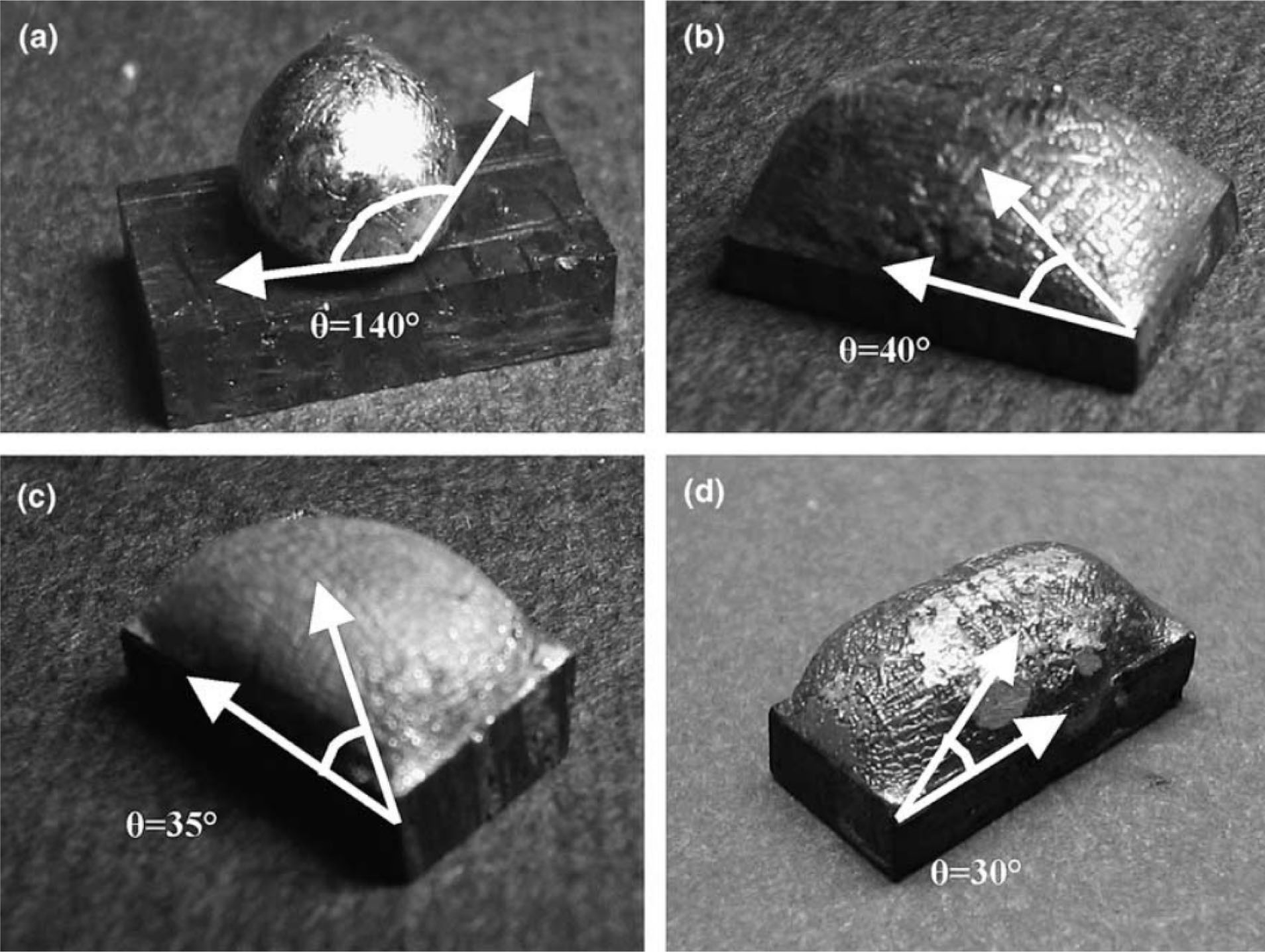

Cu-based brazing filler metal has the characteristics of relatively high high-temperature bearing capacity, good strength, good plasticity and relatively low price. Researches showed that Cu-based brazing filler metals were widely used in brazing of C/C composites, carbon-based ceramic composites and metals. Some scholars pointed out that C/C composite does not bond well with pure Cu since the wetting angle of molten copper on carbon substrates is very high, approximately 137°~140° [40, 41]. However, the surface wetting on C/C composites was greatly improved by Cu after the addition of Ti element. Li proved that the wetting angle of Cu-12.6Ti (at. %) on carbon materials was close to 0° under the condition of 1077°C heat preservation 5 min [42]. The reason is that after adding Ti element into Cu-based brazing filler metal, Ti and C will react to generate TiC, improving the wettability of the brazing filler metal on base materials (Figure 2). Between the instantaneous process of the pure copper on the same substrate (Figure 3) to 50° and the process of the reduction in θ from 50° to the stationary value of zero, which proceeds quite quickly, there is an intermediate plateau of θ at a value of 50° for about 3min, indicating the existence of an incubation period needed to initiate the chemical reactions between the absorbed titanium and carbon. The kinetics and mechanism of chemical reactions developing at interfaces are important because the reactive wetting process depends on represents the first important step towards the understanding of the reactive wetting phenomena.

Contact angle, θ, of the (Cu-12.6 at% Ti) alloy on the glassy carbon substrate as a function of time at 1350K.

Contact angle, θ, of pure copper on glassy carbon versus temperature.

The applications of Cu-based brazing filler metals in joining of C/C composites are shown in Table 3.

Cu-based brazing filler metals used in joining of C/C composites

| Composition of brazing filler metal (wt. %) | Base materials | Brazing temperature (°C) Holding time (min) | Strength (MPa) | References |

|---|---|---|---|---|

| Cu-30Ti | C/C-Cu | 930 | 7 (Shear) | [18] |

| Cu15Ti | C/C-C/C | 1050/30 | 21 (Shear) | [43, 45] |

| Cu-14Ti | C/C-C/C | 1200/10 | — | [44] |

| Cu-Ti (TLP-DB) (0.4, 0.6, 0.8, 0.9, 1.0, 1.1)mm Cu +0.1mmTi | C/C-Nb | 1050/30 | 28.6 (Shear) 0.9mmCu +0.1mmTi | [46] |

| Cu-50Pb | C/C-Cu | 1150/40 | 1.5 (Shear) | [47] |

| 99Cu-1Cr | C/C-W | 1155/5 | 24.7 (Shear) | [48] |

| Cu-(15~25)Mn- (8~14)Ti | C/C-Stainless steel | (850~950)/(2~10) | 16 (Shear) | [49, 50] |

| Cu-2Al-3Si-2.3Ti | C/C-OF Cu | 1030±2 | 20.2 (Tensile) | [51] |

| 92.8Cu-3Si-2Al-2.2Ti | C/C-Ti | 1040/5 | 0.27±0.12 (Tensile) | [20,21,22] |

| 92.8Cu-3Si-2Al-2.25Ti | C/C- (Cu-Mo-Cu) | (1040~1045)/5 | — | [26] |

| Cu75Pt25 | C/C-Nb | 1160/20 | Shear: 26.7(RT), 17.6(600°C) | [52] |

Since C and Cu can react to form solid solution, a diffusion layer with gradual composition will be formed when Cu diffuses to C/C composite and C diffuses to the brazing joint. The diffusion layer has better compatibility with C/C composite than that of the brazing filler metal with C/C composite [43]. Adding Ti in copper matrix, Ti elements will be enriched towards the interface and form TiC because of the action of chemical and physical adsorption, during which the interfacial tension decreases. Therefore, the wettability of Cu-based brazing filler metal on C/C composite will be improved by adding Ti elements. The brazing filler alloys also can penetrate into the pores of C/C composite by capillary force to form a strong interface bonding [44].

2.4 Ti-based brazing filler metals

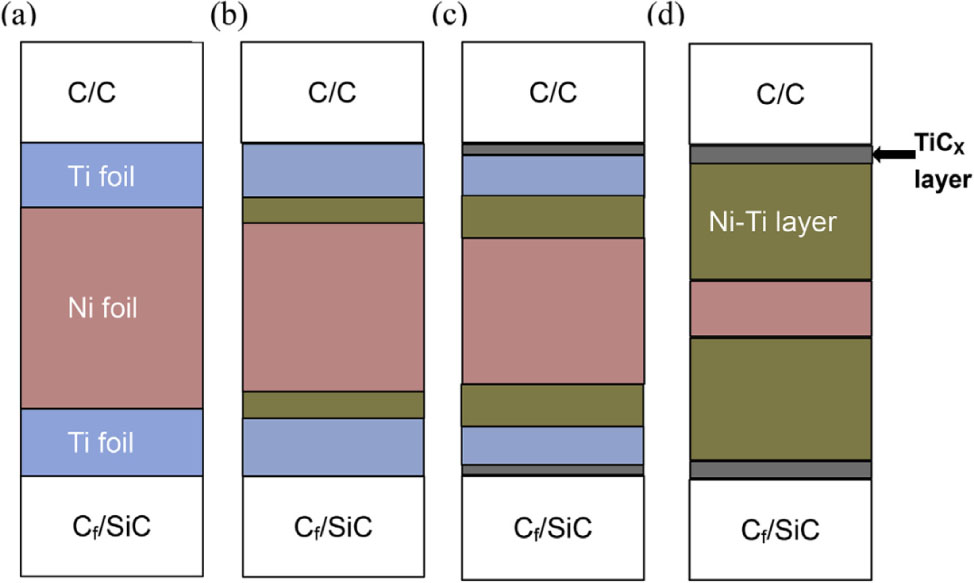

The corrosion resistance and high temperature strength of Ti-based brazing filler metals are superior compared with Al-based or Ag-based brazing filler metals. The Ti-based brazing filler metals used for brazing carbon materials are mainly binary or ternary alloys of Ti. Although pure Ti can also be used for brazing carbon materials, a very thick car-bide layer will be generated at the joint due to the strong reaction between Ti and C. Moreover, the coefficient of thermal expansion of pure Ti is high, which is easy to cause cracks in carbon materials. Adding a small amount of Cr and Ni to Ti matrix can reduce the melting point of Ti-based brazing filler metal and improve its wettability (Figure 4). In addition, 49Ti-49Cu-2Be [53], Ti-Ni-Si [54] and Ti-Si-SiC-C [55] can be used for brazing C/C composites as well. The applications of Ti-based brazing filler metals in joining of C/C composites are shown in Table 4.

The formation model of the C/C-Cf /SiC composite joint.

Ti-based brazing filler metals used in joining of C/C composites

| Composition of brazing filler metal (wt. %) | Base materials | Brazing temperature (°C) Holding time (min) | Strength (MPa) | References |

|---|---|---|---|---|

| 49Ti-49Cu-2Be | C/C-Metals (Cu, steel, etc.) | 980/5 | — | [53] |

| Ti-Ni-Si (1:1:4) PTLP | C/C-C/C | 1150/45 30MPa | 23.58 (Shear) | [54] |

| Ti-SiC-Si-C (3:1:1:1) vacuum hot pressing | C/C-C/C | 1600/6 30MPa | 38.09±5.09 (Shear) | [55] |

| 70Ti15Cu15Ni | C/C-Cu | 1000/10 | 24 (Shear) | [56, 57] |

| 70Ti15Cu15Ni | C/C-(Cu-Mo-Cu) | 975–980/5 | — | [26] |

| 70Ti15Cu15Ni | C/C-Ti | 975/5 | 0.33±0.13 (Tensile) | [20,21,22] |

| Ti35Zr10Ni15Cu | C/C-(TiBw-TC4) | 900/10 | 13.6 (Shear) | [58] |

| 50Ti50Ni | (low density) C/C -Nb | 1200/20 | Shear: 44(RT), 36 (600°C) | [59] |

| 50Ti50Ni | (high density) C/C -Nb | 1200/20 | Shear: 17 (Flat), 92 (Conical interface) | [59] |

| Ti-Ni-Cu (1:1:1) | C/C-TiAl | 980/10 | 18 (Shear) | [60] |

| TiSi2 | C/C-C/C | 1490/2 | Shear: 34.4±9.6 (1164°C) | [61] |

| Ti-Ni-Ti (1:3:1) | C/C-Cf /SiC | 960/30 0.5MPa | 44.7 ± 12.8(Shear) | [62] |

2.5 Ni-based brazing filler metals

At present, when joining C/C composites, Ag-based or Cu-based brazing filler metals are widely used. However, the service temperature of Ag-based or Cu-based brazing filler metals is lower, which cannot guarantee reliable joining strength while above 500°C. It is unable to reflect the excellent high-temperature performance of C/C composite. For example, the joint using Ag-based or Cu-based brazing filler metal cannot meet the high temperature service requirements when C/C composite is used in the engine nozzle. Therefore, it is necessary to search and develop brazing filler metals which meet the requirements of high temperature performance.

Ni-based brazing filler metal is used for brazing work-piece that works at high temperature. It has excellent corrosion resistance and heat resistance. The bearable servicing temperature of the brazing joints using Ni-based brazing filler metals can reach up to 1000°C. The brazing joints using Ni-based brazing filler metals also have satisfactory performance in liquid oxygen, liquid nitrogen and other low temperature media. Whereas, the melting point of nickel is high. The thermal strength of nickel is low. The reaction ability of nickel with carbon materials is weak. Alloying elements should be added to reduce its melting point and improve its thermal strength.

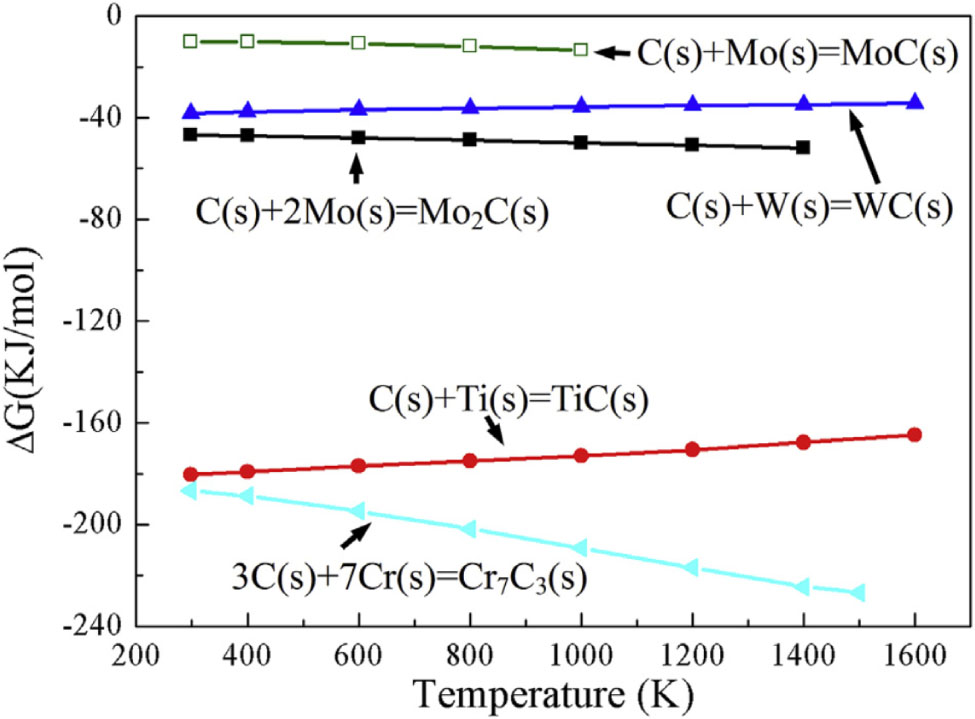

NiP and NiCrP are two kinds of Ni-based brazing filler metals with lowest melting points. They are both able to join materials tightly because of the eutectic structure and excellent fluidity. The main functions of Cr in NiCrP are solid solution strengthening by forming solid solution with Ni, and improving the antioxidant capacity of it. Cr is also used as active element to react with carbon material to form carbide layer. The Gibbs free energy for the formation of Cr-C compound is shown in Figure 5. The applications of Ni-based brazing filler metals in joining of C/C composites are shown in Table 5.

Gibbs free energy calculation results of carbides.

Ni-based brazing filler metals used in joining of C/C composites

| Composition of brazing filler metal (wt. %) | Base materials | Brazing temperature (°C) Holding time (min) | Strength (MPa) | References |

|---|---|---|---|---|

| Ni-33Cr-24Pd-4Si | C/C-Cu | 1210 | 6 (Shear) | [18] |

| Ni-11Cr-10P | C/C-Cu | 935 | 7 (Shear) | [18] |

| Ni-Zr-Cr | C/C-C/C | 1270/10 | 10 (Bending) | [63] |

| MBF-20 Amorphous (Ni-6.48Cr-3.13Fe-4.38Si-3.13B) | C/C-Ti | 1045/4 | — | [64] |

| MBF-30 Amorphous (Ni-4.61Si-2.8B-0.02Fe) | C/C-Ti | 1080/4 | — | [64] |

| BNi-2 Ni-(6~8)Cr-(2.5~3.5)Fe-(4~5)Si-(2.75~3.5)B | C/C-GH99 | 1170/60 | Shear: 35.4(RT), 15.3(800°C), 8.6(1000°C) | [65] |

| Ni-Si | C/C-GH3128 | 1160 | 12.6 (Shear) | [66] |

| 80Ni-20Ti PTLP | C/C-GH3044 | 1030/30 4.5(MPa) | 9.78 (Shear) | [67] |

| BNi-2 (Ni-7.0Cr-3.0Fe-4.5Si-3.1B) | C/C-GH3128 | 1170/60 | 24 (Shear) | [68] |

| BNi68CrWB | C/C-GH600 | 1150–1200/10 | Shear: 49.9(RT), 21.6(800°C) | [69] |

| NiCrSiBFe Amorphous | C/C-Ni-based superalloy | 1170/60 | Shear: 35 (RT), 15 (800°C), 9(1000°C) | [70] |

It can be seen from Table 5 that Ni-based brazing filler metal is mainly used for the joining between C/C composite and Ni-based superalloy. With the development of materials, amorphous active Ni-based brazing filler metals are increasingly used in brazing between C/C composites and metals. Through comparison, it is found that the strength of C/C composite joints using Ni-based brazing filler metals is generally lower than that of joints with Ag-based, Cu-based and Ti-based brazing filler metals.

3 Surface treatment of C/C composites before joining

Indirect brazing is another method that has been used to join C/C composites and other materials. Indirect brazing of C/C composites usually involves depositing a metal film on the surface or generating a thin carbide layer before brazing (Figure 6). Metals used for surface metallization generally include: Mo, W, Ni, Cu, Cr, etc. The elements commonly used to generate carbide surface layer are Cr, Ti, Mo, Ta, etc. In addition, the in-situ synthesis of carbon nanotubes on the C/C composite material surface before brazing can also improve the wettability of the filler metal on composite material surface, which is beneficial to the strength of the joint. However, indirect brazing process is complex and its application is limited. The researches on joining of C/C composites through surface treatment before joining are shown in Table 6.

Wettability of pure copper on CFC substrate (1100°C for 30 min).

Surface treatment before joining and brazing filler metals used in joining of C/C composites

| Composition of brazing filler metal (wt. %) | Surface treatment of C/C composites | Base materials | Brazing temperature (°C) Holding time (min) | Strength (MPa) | References | |

|---|---|---|---|---|---|---|

| Surface treatment | Without treatment | |||||

| Ag26.7Cu4.6Ti | Cr-C compound layer was formed | C/C-Ni-20Co-18Cr | 990/15 | Fracture occurred on C/C side. | — | [53] |

| 87.75Cu12Ge0.25Ni Gemco | Cr-C composite layer | C/C-OFHC Cu-CuCrZr | (970 980)/30 995 | 34±4 (Shear) | — | [71, 72] |

| — | carbide layer (Cr, Mo, W)-C | C/C-Cu | 1100/60 | Shear: 33±4(Cr), 11±2(Mo) | — | [73,74,75] |

| Ti23Cu11Zr9Ni foil + Cu foil 20, 40, 100 (μm) | Cr-C composite layer | C/C-TC4 | 960/20 | 39±8.5 (Shear) 40μm Cu | 15±2 (Shear) | [76] |

| Ti23Cu11Zr9Ni powder | Cr-C composite layer | C/C-TC4 | 960/20 | 52±6 (Shear) | 15±2 (Shear) | [77] |

| Ti or Ag based | 3μmNi+ 2μmTC4 | C/C-Ti alloy | (800~850)/15 | 48 (Shear) | — | [78] |

| Cu-3.5Ti 2mm OFHC Cu | Depositing TiH2 | C/C- Cu- CuCrZr | 800/30 5MPa | Shear: 44 (Flat), 79 (Conical interface) | — | [79] |

| Zr64Ni36 | Rhenium (Re) coating | C/C-Nb | 1110/20 | 19 (Shear) | — | [80] |

| Ti20Zr15Cu5Ni | SiC modification coating | C/C-Ti | 877/5 | 15.3 (Shear) | — | [12] |

| Ni-Ti | SiC surface modification coating | C/C-GH3128 | 1170 | 22.5 (Shear) | 0 (Shear) | [81] |

| Ti-SiC-Si-C | SiC surface modification coating | C/C-C/C | 1600/6 30MPa | 22.64±2.61 (Shear) | 38.09±5.09 (Shear) | [55] |

| Ni71CrSi | SiC surface modification coating | C/C-GH3044 | 1180/30 | 35.08 (Shear) | Joint failed | [82] |

| Ni71CrSi | SiC nanowires -toughed SiC coating modified | C/C-GH3044 | 1180/30 | 54.4 (Shear) | — | [83] |

| Cu-46Zr | φ15.7nm × 2μm CNT were in situ formed | C/C-Ti600 | 930/10 | Shear: 73(RT), 41(600°C) | 33(RT), 25(600°C) | [84] |

| 22Ti78Cu | φ18.9nm × 2μm CNT were in situ formed | C/C-Nb | 950/10 | 41 (Shear) | 17 (Shear) | [85] |

| Ti/Ni/Cu/Ni (1:1:20:1) | Pre micro-oxidation and partial transient liquid phase (PTLP) process | C/C-GH3044 | 1030/30 0.3MPa | 32.09 ± 1.98 (Shear) | 23.47 ± 1.15 (Shear) | [86] |

| Ti-Si eutectic alloy Ti14Si86 | Pre-infiltration Ti-Si | C/C-C/C | 1400/10 | Shear: 26(RT); 36(1200°C) | <10 (Shear) | [87] |

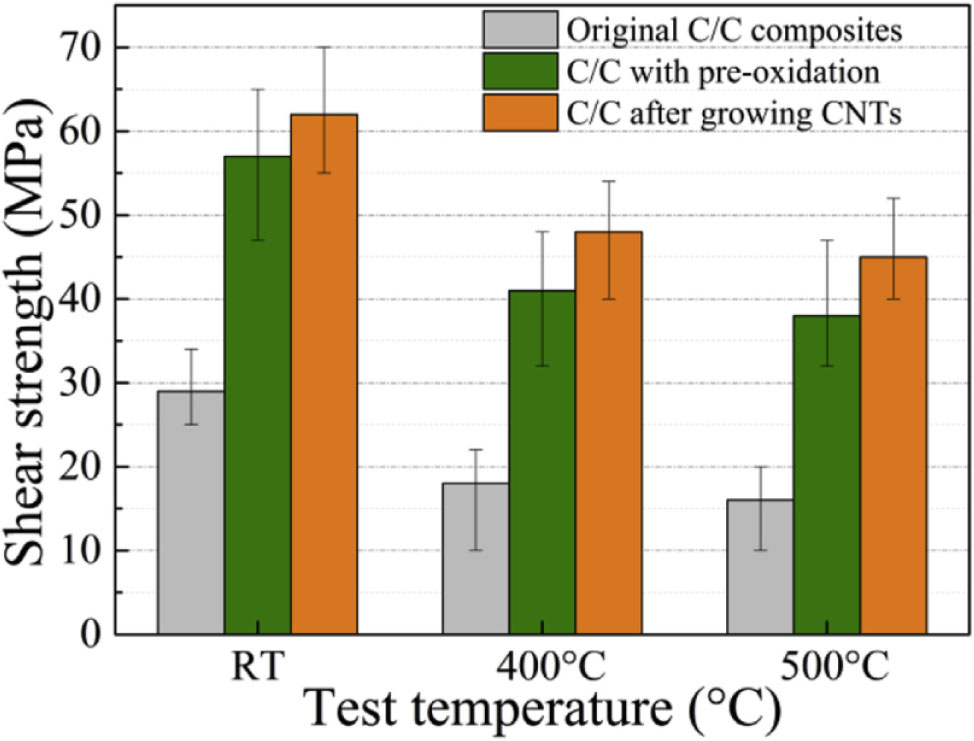

| Ag27.6Cu1.5Ti | pre-oxidation and in situ growth of CNT | C/C-Nb | 880/10 | Shear: 62(RT); 48(500°C) | 29 (Shear) | [88] |

It can be seen from Table 6 that the shear strength of joints obtained by brazing C/C composites after surface treatment is usually higher than that of joints without surface treatment (Figure 7). Nevertheless, when the connection between the surface treatment layer and C/C composites is poor, the fracture occurs in the surface treatment layer during shear test, the strength of the joint decreases instead. The strength of joints between surface treated C/C composites and other materials is related to the composition and thickness of surface coating, the bonding strength between C/C composites and coating layer, and chemical reaction between coating and the brazing filler metal.

Shear strength of Nb-C/C joint brazed at 880°C for 10 min under different surface modification conditions of C/C composites at different test temperatures.

4 Composite brazing filler metals

In recent years, the single brazing filler metals cannot meet the demand of application in some aspects. In consequence, the development of new composite brazing filler metals has been widely concerned by scholars.

4.1 Micro-nano particles reinforced composite brazing filler metals

The performance of joint is significantly affected by the thickness of intermetallic compound layer. It is necessary to control the interface structure when joining C/C composite, mainly the thickness of the brittle intermetallic carbide layer at the interface, which can be adjusted through changing the composition of the brazing filler metal.

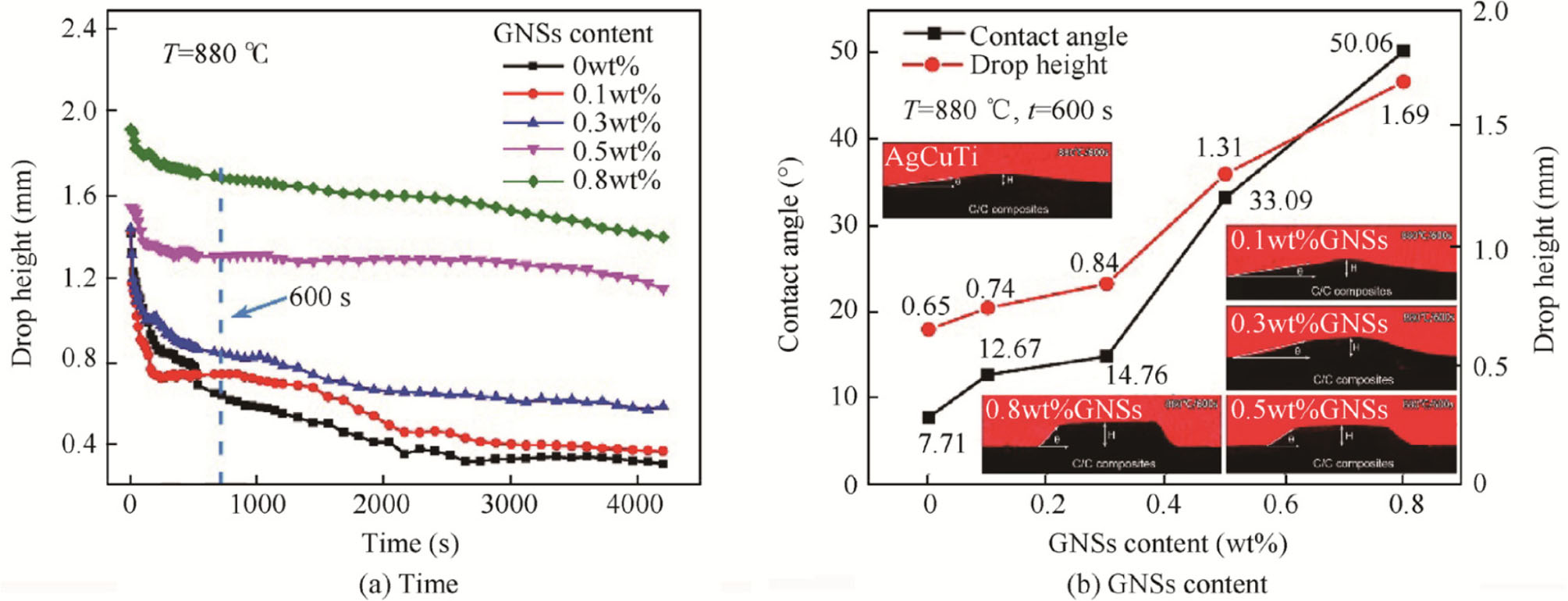

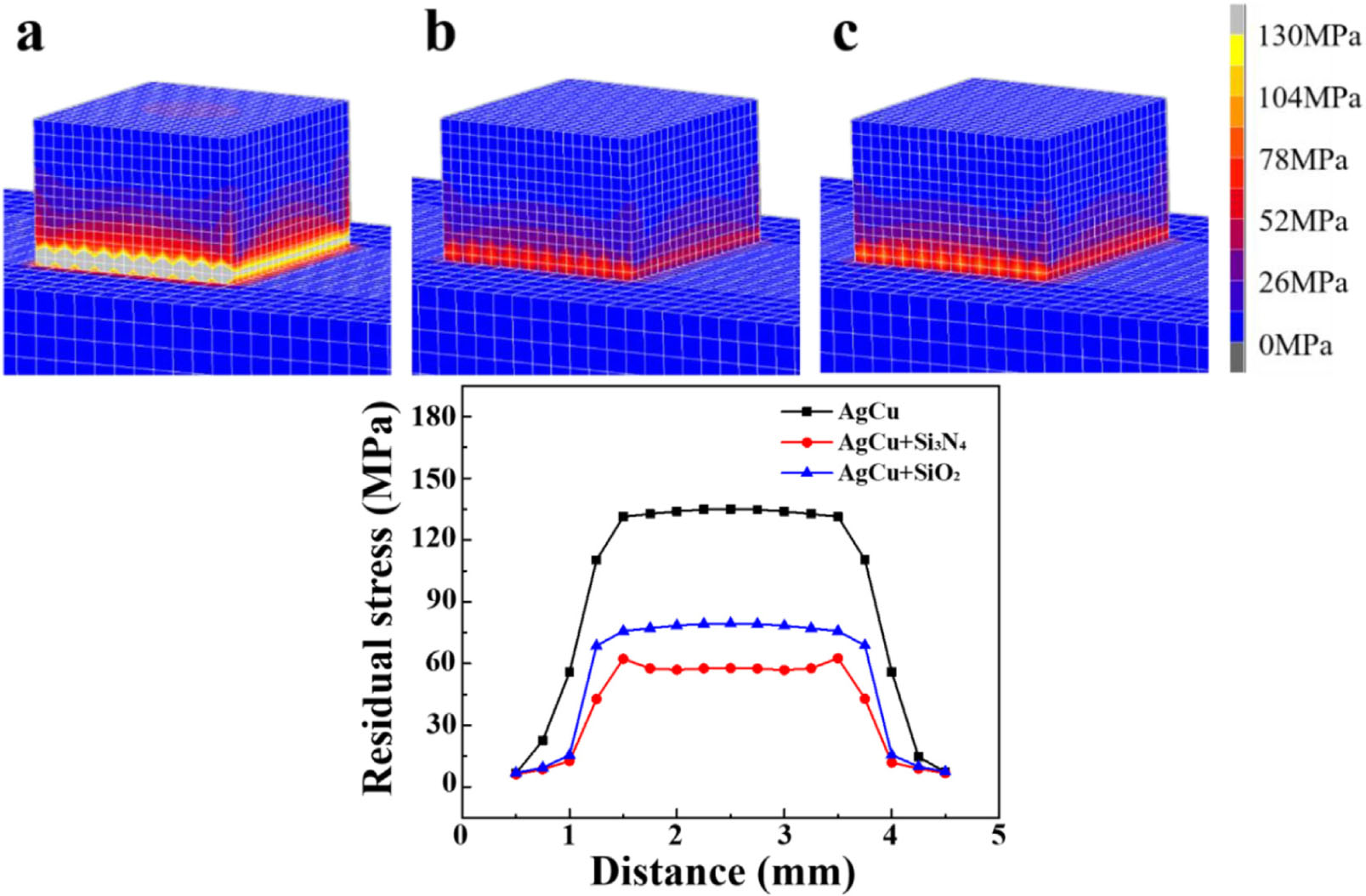

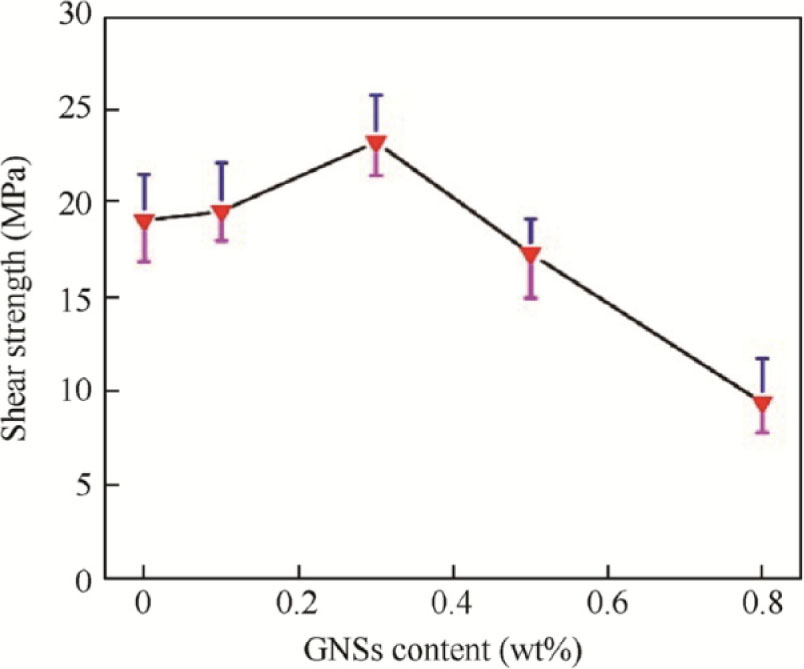

It has been found that micron-sized or nano-sized particles are beneficial to improve the wettability of filler metals on C/C composite (Figure 8) [92], inhibit the growth of the reaction layer and alleviate the mismatch of thermal expansion coefficient between the brazed seam and base material, thus reducing the residual thermal stress (Figure 9) [94] and improving the mechanical properties of the joint (Figure 10) [92]. Therefore, manufacturing composite brazing filler metal with particle dispersion enhancement through adding micro-nano ceramic particles becomes an effective method to join C/C composite. The applications of micro-nano particles reinforced composite brazing filler metals in joining of C/C composites are shown in Table 7.

Variations of drop height and contact angle with different GNS contents.

Distribution of equivalent Von Mises stress in joints brazed with (a) pure AgCu, (b) AgCu+Si3N4, and (c) AgCu+SiO2, and residual stress distribution of the middle cross-section in C/C composites.

Effect of GNS content on the shear strength of joints (T=880°C, t=10min).

Micro-nano particles reinforced composite brazing filler metals used in joining of C/C composites

| Composition of brazing filler metal (wt. %) | Composition and content of reinforced particles | Base materials | Brazing temperature (°C) Holding time (min) | Strength (MPa) | References | |

|---|---|---|---|---|---|---|

| Composite brazing filler metals | Additive free | |||||

| Ag26.7Cu4.6Ti | 4.6μm SiC (0 35) vol. % | C/C-TC4 | 910/10 | 29 (Shear) 15vol.% SiC | 25 (Shear) | [8] |

| Ag-28Cu | 2mm Al2O3 plate | C/C-Ni-based superalloy | 910/10 | Bending: 33(Flat), 73 (zigzag interface) | 16 (Bending) | [89] |

| Ag26.7Cu4.5Ti | 20nm Al2O3 0.3 (wt. %) | C/C-TC4 | 880/10 | 27.8 (Shear) 0.3wt. % Al2O3 | 19.5 (Shear) | [90] |

| Ag26.7Cu4.5Ti | GNS[a] 0, 0.1, 0.3, 0.5, 0.8(wt. %) | C/C-TC4 | 900/10 | 30.2 (Shear) 0.3wt. % GNS | 19.5 (Shear) | [91, 92] |

| Ag26.7Cu4.5Ti | 25μm diamond 5, 15, 25 vol.% | C/C-316 stainless steel | 900/10 | 53 (Shear) 15vol. % diamond | 26 (Shear) | [93] |

| Ag-28Cu | <2μm 4wt.% Si3N4 or SiO2 | C/C-TC4 | 850/5 | Shear: 45±3.1(Si3N4), 41±2.1(SiO2) | 18±2.5 (Shear) | [94] |

| AgCu eutectic+ 50μm Cu foil | 60μm TiH2 powder | C/C-Cu | 930/25 | 30 (Shear) | — | [95] |

| Cu-50Ni | 2 8μmTiB2 3wt. % | C/C-TiBw/TC4 | 950/10 | Shear: 18.5(RT[b]), 34.5(400°C), 10(700°C) | 8.4 (RT Shear) | [58, 96] |

| Cu-50Ni | 0.5 0.8μm SiC 3wt. % | C/C-TiBw/TC4 | 950/10 | Shear: 22.5(RT), 35.4(400°C), 6(700°C) | 8.4 (RT Shear) | [58] |

| Cu-50TiH2 | BN 2wt. % | C/C-CuCrZr | 950/10 | — | — | [97] |

| Ti-23Cu-11Zr-9Ni | φ(1 2)μm GNS 1wt. % | C/C-TC4 | 940/10 | 42±3 (Shear) | 22±4 (Shear) | [98] |

| Ti-23Cu-11Zr-9Ni | φ(20 30)nm × (1 2)μm CNT[c] 0.5, 1.0, 3.0 (wt. %) | C/C-TC4 | 940/10 | 38±2 (Shear) 1wt. % CNT | 22±4 (Shear) | [99] |

| BNi-2 | TiH2 1, 3, 8(wt. %) | C/C-GH99 | 1170/60 | Shear: 40(RT), 10(800°C), 10(1000°C) 5wt. % TiH2 | 35.4 (RT), 15.3(800°C); 8.6(1000°C) | [65, 100] |

| Pyrocarbon PyC | CNT/PyC interlayer | C/C-C/C | — | 19.2 (Shear) | 9.4 (Shear) | [101] |

| Ag26.7Cu4.5Ti(TiH2) | GNP[d] 0.05 0.6 wt. % | C/C-Ti3Al | 880/15 | 26.7 (Shear) 0.1wt.% GNP | 19.1 (Shear) | [102] |

- [a]

GNS: graphene nanosheets

- [b]

RT: room temperature

- [c]

CNT: carbon nanotube

- [d]

GNP: graphene nanoplatelet

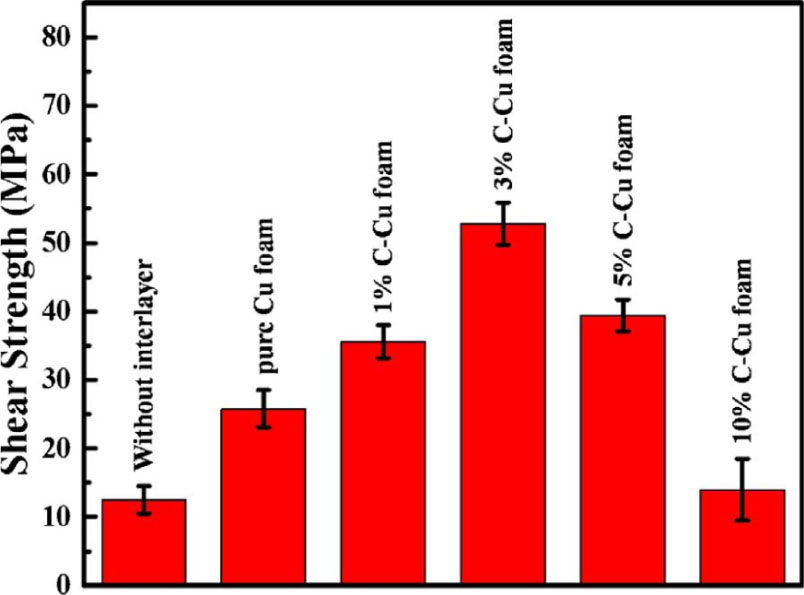

4.2 Stress buffer metal interlayer added composite brazing filler metals

While joining C/C composites to metals, one of the important factors hindering joint performance is the large difference of thermal expansion coefficient between them (Figure 11). In order to alleviate the joint thermal stress and improve the strength of the joint, the method of inserting metal interlayer into the joint is generally adopted. Depending on the different ways of stress relief, it can be divided into soft interlayer (such as copper, aluminum and nickel, etc.) and hard interlayer (such as niobium, tungsten, molybdenum, etc.). The soft interlayer generally has lower elastic modulus but better plasticity. Stress can be reduced through the elasticity, plasticity and creep deformation of the metal during the joining process [23] lastic modulus of hard interlayer is generally high, and the thermal expansion coefficient is low, which is close to that of the carbon material. When joining, the residual thermal stress in the joint can be transferred to the interlayer [103] applications of stress buffer metal interlayer added composite brazing filler metals in joining of C/C composites are shown in Table 8.

Effect of thickness of interlayer on shear strength at room temperature of the joints.

Stress buffer metal interlayer added composite brazing filler metals used in joining of C/C composites

| Composition of brazing filler metal (wt. %) | composition and specification of intermediate layer | Base materials | Brazing temperature (°C) Holding time (min) | Strength (MPa) | References | |

|---|---|---|---|---|---|---|

| With interlayer | Interlayer free | |||||

| Ag26.7Cu4.5Ti | Nb 0.1mm | C/C- 1Cr18Mn15N Stainless steel | 900/10 | 72.2 (Bending) | — | [104] |

| Ag68.8Cu4.5Ti | Nb 0.3mm, 1mm | C/C-Cu | 910/10 | Bending: 37.39 (Flat), 52(Conical interface) 1mm Nb | 14.42 (Bending(Flat)) | [105, 106] |

| Ag26.7Cu4.6Ti | 0.3mm graphene-foam Cu (G-Cu) | C/C-Nb | 880/10 | Shear: 43 (G-Cu) | 13 (Shear) | [107] |

| Ag26.7Cu4.6Ti | 0.3mm C-Cu foam; (1, 3, 5, 10) C-Cu (wt. %) | C/C-Nb | 880/10 | 52.8 (Shear) 3C-Cu (wt. %) | 12.2 (Shear) | [108] |

| 93Cu2Ti2Al3Si (Cu-ABA) 87.75Cu12Ge0.25Ni (Gemco) | Mo (1~2)mm | C/C-CuZrCr C/C-CuABA-Mo-Gemco-CuZrCr | 1035/18 | — | — | [109, 110] |

| Ti-37.5Zr-15Cu-10Ni Amorphous | Cu (0.2, 0.3, 0.5, 0.7, 0.9) mm +Mo (0.1mm) | C/C-TC4 | 900/5 | Shear: 21(RT), 27(650°C) (0.3mmCu+ 0.1mmMo) | 7 (RT Shear) | [23, 111, 112] |

| Fe-42Ni-20Cr-(10~12)(Si,P) | (100 500)μm Nb +φ100μm Mo | C/C-Inconel-600 | 1080/5 | 11.2 (Shear) 1μm Nb | — | [113] |

| 87.75Cu12Ge0.25Ni (Gemco) | The brazing foil has been coated by Cr. | C/C-Cu | 980/15 | 23 (Shear) 3μm Cr | — | [114] |

5 Glass brazing filler materials

Compared with other materials, glass has incomparable properties. The thermal expansion coefficient of glass material can be adjusted in a wide range. By adjusting the composition and content of the glass material, it is possible to prepare glass brazing filler that matches the thermal expansion coefficient of the base material. Meanwhile, glass ceramic materials have a series of advantages such as good thermal stability and good thermal shock resistance [115, 116]. Glass materials have been applied in the joining of C/C composite material itself, C/C composites and ceramics. The applications of glass brazing fillers in joining of C/C composites are shown in Table 9.

Glass brazing filler materials used in joining of C/C composites

| Composition of brazing filler metal (wt. %) | Surface treatment of C/C composites | Base materials | Brazing temperature (°C) Holding time (min) | Max Strength (MPa) | References |

|---|---|---|---|---|---|

| SB Borosilicate glass | — | C/C-C/C | 1020/45, 1200/45 | — | [9, 118, 119] |

| ZBM Glass[a] | — | C/C-C/C | 1200/45 | — | [9, 118, 119] |

| SABB Glass[b] | β-SiC surface modification coating | C/C-C/C | 1300/60 | 30 (Shear) | [117] |

| Borosilicate glass[c] | α-SiC surface modification coating | C/C-C/C | 1400/30 | 26 (Shear) | [120] |

| LMAS Glass[d] VHPT[e] | SiC surface modification coating and SiC whiskers | C/C-LAS Glass-ceramic[f] | (1200~1300)/30 (20~25)MPa | Shear: 12.17 (coating), 19.91 (whisker) | [121] |

| Y2O3-Al2O3-SiO2-TiO2 VHPT | SiC-MoSi2 surface modification coating | C/C-LAS Glass-ceramic | 1250/30 20MPa | 26.21 (Shear) | [122] |

| MAS Glass[g] VHPT | SiC-MoSi2 surface modification coating | C/C-LAS Glass-ceramic | 1200/15 20MPa | 30 (Shear) | [115] |

| MAS Glass VHPT | SiC surface modification coating | C/C-LAS Glass-ceramic | 1200/15 20MPa | 26.21 (Shear) | [116] |

| YAST glass VHPT | MWCNT[h] in-situ formed, directly added | C/C- LAS Glass-ceramic | 1150/45 20MPa | 26.07 (Shear) In-situ | [123] |

| MAS Glass VHPT | SiC nanowire reinforced SiC surface modification coating | C/C- LAS Glass-ceramic | 1250/45 30MPa | 38.16 ± 4.99 (Shear) | [124] |

| MAS Glass VHPT | CNT reinforced SiC surface modification coating | C/C- LAS Glass-ceramic | (1220~1250)/30 25MPa | 31.84 ± 3.07 (Shear) | [125] |

- [a]

SB Borosilicate glass: 80SiO2-20B2O (mol. %); ZBM Glass: 4.53SiO2-29.48B2O-4.04 Al2O3-50.46ZnO-2.37Na2O-9.12MgO (mol. %)

- [b]

SABB Glass: 70.4SiO2-2.1Al2O3-17.5 B2O3-10.0BaO (wt. %)

- [c]

Borosilicate glass: 50~75 SiO2, 10~25 Al2O3, 5~10 CaO (wt. %)

- [d]

YAST Glass: Li2O-MgO-Al2O3-SiO2

- [e]

VHPT: Vacuum hot-pressing technology

- [f]

LAS Glass-ceramic: Li2CO3-Al2O3-SiO2

- [g]

MAS Glass: MgO-Al2O3-SiO2

- [h]

MWCNT: Multi-walled carbon nanotube

However, since most glass and glass-ceramic materials are difficult to wet the surface of carbon materials [117], it is difficult to give full play to its advantages in joining. Surface treatment of C/C composites is usually required to improve wettability between brazing fillers and base materials. In consideration of good physical and chemical compatibility between SiC and C/C composites and glass materials, the surface SiC modification of C/C composites has become a research trend.

As can be seen from Table 9, when using glass brazing fillers to joining C/C composites, fillers are mainly concentrated in inorganic mixed powders composed of SiO2, B2O, Al2O3, MgO, ZnO, and other oxides. The joining systems are also mainly the joining between C/C composites themselves, and between C/C and glass-ceramic materials. A certain amount of pressure was needed during the joining process, so as to discharge the gas, which produced by glass brazing filler due to excessive temperature, from the welding seam, and reduce the occurrence of defects.

6 Other kinds of brazing filler materials

Except for the above-mentioned brazing filler materials, the Si slice and Mg2Si powder can also be used to realize the joining of C/C composite itself. The average shear strength of joints was 22 MPa and 5 MPa, respectively [9]. The shear strength at room temperature of the joints was 20~24MPa when brazing C/C composite itself using Au-23Pd-22Ni-(6~12)V or Au-8Cu-30Pd-20Ni-(6~12)V. The C/C composite itself, C/C composite and TZM, C/C composite and W, C/C composite and Nb were brazed by Cu-(22~32)Pd-(6~12)V brazing filler metal. The shear strength of the joints at room temperature can be up to 30.6MPa, 36.9MPa, 44.8MPa and 21.9 MPa, respectively [126]. The shear strength of the joint of C/C composite brazed with W-(18~22)Co-(8~15)Cr-(14~21)Ti was 30 MPa at room temperature. After conical surface designing of C/C composite, the shear strength was increased to 45 MPa [127]. When using B powder as intermediate material to join C/C composite and the brazing parameter was 1995° C/15min, the maximum shear strength (18.6±1.9 MPa) was obtained at 1600°C [61].

7 The effect of brazing parameters on joint properties

The brazing of C/C composite is mainly achieved by the chemical reaction among C element and the chemical elements in the intermediate layer material to form a metallurgical bonding. The strength of the joint depends largely on the type, size, and distribution of the compound, that is, the reaction degree in the interface. The insufficient reaction will lead to the weakening of interfacial bonding, while excessive reaction will destroy the performance of the joint by forming more brittle compounds at the interface. It is necessary to control the interface structure when joining C/C composite, mainly the thickness of the brittle intermetallic carbide layer at the interface, which can be adjusted through selecting appropriate process parameters. Therefore, the influence of brazing process parameters, such as temperature, heating/cooling rate and holding time, on joint strength should also be considered after the brazing material is selected.

The selection of brazing temperature should be based on the solidus and liquidus temperature of the chosen filler metal as the most important reference index. When brazing C/C composite, in order to form a metallurgical bonding, adequate temperature is required to melt the filler metal and cause a chemical reaction at the interface. However, when the brazing temperature is too high, large number of brittle compounds will be generated in the reaction layer, which is not good for the properties of the joint. Large temperature gradient and internal stress will be caused in the base materials and joint since excessive heating or cooling rate during brazing. Excessive residual stress can seriously reduce the strength of the joint and even cause cracks at the interface between C/C composite material and the intermediate layer materials. Adequate holding time can make sure the occurrence of metallurgical reaction and a firm joint. With the extension of holding time, the brazing joint structure tends to be homogenized. Whereas, if the holding time is too long, the thickness of the compound reaction layer will be increased and the performance of the joint will be reduced.

The formation of the braze joint is the result of the synergistic effect of various factors, such as temperature, heating or cooling rate, and holding time. Therefore, a robust joint can only be obtained under the appropriate process conditions. For the brazing of C/C composite, different process parameters are needed when the joining systems and filler materials are different. Especially for the joining of heterogeneous materials, the interfacial metallurgical behavior of different materials is significantly different, and the types and distribution of the interface phases will become more complex, and the interface structure will be more difficult to explore. Generally, a large number of experiments or finite element simulation auxiliary methods should be used to explore the best process parameters.

8 Conclusions and prospects

In order to improve the wettability of brazing filler metals on C/C composites, active metal elements such as Ti, Cr and V which can react with C to form carbide are generally added to brazing filler metals, such as Al-Ti, Ag-Cu-Ti, Cu-Ti, Cu-Cr, Ni-Ti, Ni-Cr-P, Ni-Cr-Si-B brazing filler metals mentioned above. The active metal can react with C in the brazing process to generate carbide reaction layer, and the metallurgical bonding formed at the joint improves the joint strength.

Ag-based, Cu-based and Ti-based brazing filler metals are commonly used in joining of C/C composites. They are usually used to join C/C composite itself, C/C composite and Cu alloy, C/C composite and Ti alloy, etc. However, the joints prepared by these brazing filler metals cannot bear high temperature. Therefore, the excellent high temperature performance of C/C composites cannot be reflected. The joints used Ni-based brazing filler metals are of high service temperature, so Ni-based brazing filler metals are usually used to connect C/C composites and superalloys.

The research and development of composite brazing filler metals improves the shear strength of joints on the basis of traditional brazing filler metals. Composite brazing filler metals used in joining C/C composites are mainly divided into two categories: First, adding micro-nano scale reinforcing particles, to prepare dispersion reinforced composite brazing filler metals. The second is to add a metal interlayer to cushion stress. There are three main functions of the additives, whether it is micro-nano reinforced particle or stress buffer metal interlayer. The first is to improve the wettability of brazing filler metal on the composite surface. The other is to decrease the difference of thermal expansion coefficient between materials to reduce the residual thermal stress of the joint. Moreover, the thickness of brittle carbide layer can be reduced by adding particles or inter-layer materials, which avoided the bad influence of thick reactive layer on joint strength.

At present, the joining technology of C/C composites is still in its infancy, and joining technology and process stability are not yet mature. The brazing filler metals used in C/C composite joining are not systematic. There are few studies on brazing filler metals which can be used in high temperature. Possible solutions include: (1) adjusting the composition of brazing filler metal and controlling the composition and thickness of interface reaction layer; (2) developing high-temperature resistance brazing filler metals which can reflect the excellent high-temperature performance of C/C composite; (3) experimenting and developing appropriate glass brazing fillers; (4) applying new composite brazing filler metals or stress buffer interlayers. It is believed that with the further development of C/C composites, high temperature resistance, low cost and high quality joining technologies will emerge as the times require.

Acknowledgement

This work was supported by Joint Funds of the National Natural Science Foundation of China under Grant [Nos. U1904197] and the Innovation Scientists and Technicians Troop Projects of Henan Province under Grant [Nos. ZYQR20180030].

References

[1] Savage, G. Carbon-Carbon composites. Chpman & Hall, Great Britain, UK, 1993. https://doi.org/10.1007/978-94-011-1586-5.10.1007/978-94-011-1586-5Search in Google Scholar

[2] Fitzer, E. and L. M. Manocha. Carbon reinforcements and carbon/carbon composites. Springer-Verlag, Berlin, Germany, 1998. https://doi.org/10.1007/978-3-642-58745-0.10.1007/978-3-642-58745-0Search in Google Scholar

[3] Li, H. J. Carbon/carbon composites. New Carbon Materials, Vol. 16, 2001, pp. 79–80 (in Chinese).Search in Google Scholar

[4] Chen, X. Z., Q. Y. Lu, Z. X. Zheng, W. J. Cai, K. Q. Wang, and Z. Y. Zhang. The connection mode for carbon fiber composite materials. [Natural Science Edition]. Journal of Yangzhou University, Vol. 19, 2016, pp. 33.Search in Google Scholar

[5] Sun, T. and J. Y. Zhou. Summary for the connection performance of carbon fiber composite bolt. Modern Manufacturing Engineering, Vol. 09, 2018, pp. 154–160 (in Chinese).Search in Google Scholar

[6] Yang, G. Research on high temperature adhesion process and mechanism of carbon materials. Master's thesis, Harbin Institute of Technology, 2014 (In Chinese).Search in Google Scholar

[7] Ikeshoji, T. T. Brazing of carbon–carbon (C/C) composites to metals. Advances in brazing science, technology and applications. Woodhead, Cambridge, UK, 2013.10.1533/9780857096500.2.394Search in Google Scholar

[8] Qin, Y. Q. and Z. S. Yu. Joining of C/C composite to TC4 using SiC particle-reinforced brazing alloy. Materials Characterization, Vol. 61, No. 6, 2010, pp. 635–639.10.1016/j.matchar.2010.03.008Search in Google Scholar

[9] Salvo, M., P. Lemoine, M. Ferraris, M. Montorsi, and M. Merola. Joining of carbon-carbon composites for thermonuclear fusion applications. Journal of the American Ceramic Society, Vol. 80, No. 1, 1997, pp. 206–212.10.1111/j.1151-2916.1997.tb02811.xSearch in Google Scholar

[10] Geng, H. R., H. Li, and G. L. Chen. Microstructure and strength of C/C composites joint with Al based brazing filler metal. Journal of Function Materials, Vol. 39, Supplement, 2008, pp. 362 (in Chinese).Search in Google Scholar

[11] Wang, M., X. G. Qi, M. A. Chen, and H. R. Geng. Microstructure and properties of vacuum brazing Cf /C composites using reactive Al based filler metals. Hot Working Technology, Vol. 38, 2009, pp. 180–182 (in Chinese).Search in Google Scholar

[12] L. X. Deng. Study on interface microstructure and joining mechanism of C/C composite materials active brazing joints. Master's thesis, Central South University, 2011 (in Chinese).Search in Google Scholar

[13] Wu, C. P., D. Q. Yi, C. H. Xu, J. M. Zhou, and Z. Weng. Present research situation and development trend of silver alloys. Electrical Engineering Materials., Vol. 2, 2012, pp. 1 (In Chinese).Search in Google Scholar

[14] Cao, X. J., Y. Zhu, W. Guo, P. Peng, and K. T. Ma. Microstructure and Mechanical Properties of C/C composite/TC17 Joints with Ag-Cu-Ti Brazing Alloy. Materials Science and Engineering, Vol. 275, 2017, pp. 12.10.1088/1757-899X/275/1/012040Search in Google Scholar

[15] Liu, S. Y. and Y. C. Shin. Simulation and experimental studies on microstructure evolution of resolidified dendritic TiCx in laser direct deposited Ti-TiC composite. Materials & Design, Vol. 159, 2018, pp. 212–223.10.1016/j.matdes.2018.08.053Search in Google Scholar

[16] Qin, Y. Q., J. C. Feng, and L. X. Zhang. Microstructure and fracture properties of carbon/carbon composite and TC4 titanium alloy joints. Transactions of the China Welding Institution., Vol. 03, 2007, pp. 13–16 (in Chinese).Search in Google Scholar

[17] Guo, W., L. Wang, Y. Zhu, and P. K. Chu. Microstructure and mechanical properties of C/C composite/TC4 joint with inactive AgCu filler metal. Ceramics International, Vol. 41, No. 5, 2015, pp. 7021–7027.10.1016/j.ceramint.2015.02.006Search in Google Scholar

[18] Okamura H., S. J. Kajiura, and M. Akiba. Bonding between carbon fiber/carbon composite and copper alloy. Quarterly journal of the Japan Welding Society. Vol. 14, 1996, pp. 39–46 (in Japanese).10.2207/qjjws.14.39Search in Google Scholar

[19] Ma, W. L., W. Mao, X. H. Li, and Y. Y. Cheng. The vacuum brazing of carbon/carbon composite using silver-based active filler metal. Journal of Materials Engineering, Vol. 01, 2002, pp. 9 (in Chinese).Search in Google Scholar

[20] Morscher, G. N., M. Singh, T. P. Shpargel, and R. Asthana. A simple test to determine the effectiveness of different braze compositions for joining Ti tubes to C/C composite plates. Materials Science and Engineering A, Vol. 418, No. 1-2, 2006, pp. 19–24.10.1016/j.msea.2005.10.067Search in Google Scholar

[21] Singh, M., G. N. Morscher, T. P. Shpargel, and R. Asthana. Effect of composite substrate properties on the mechanical behavior of brazed joints in metal-composite system. Abstract for 3rd International Brazing and Soldering Conference April 24–26, 2006, TX, San Antonio, USA.Search in Google Scholar

[22] Singh, M., T. P. Shpargel, G. N. Morscher, and R. Asthana. Active metal brazing and characterization of brazed joints in titanium to carbon-carbon composites. Materials Science and Engineering A, Vol. 412, No. 1-2, 2005, pp. 123–128.10.1016/j.msea.2005.08.179Search in Google Scholar

[23] Y. Q. Qin. Study on microstructure and mechanical properties of C/C composite and TC4 brazed joint. PhD thesis, Harbin Institute of Technology, 2007 (in Chinese).10.1016/j.msea.2006.11.056Search in Google Scholar

[24] Qin, Y. Q., J. C. Feng, and L. X. Zhang. Microstructure and mechanical properties of carbon/carbon composites and TC4 joints. Rare Metal Materials and Engineering, Vol. 36, 2007, pp. 1210–1214 (in Chinese).Search in Google Scholar

[25] Qin, Y. Q. and J. C. Feng. Microstructure and mechanical properties of C/C composite/TC4 joint using AgCuTi filler metal. Materials Science and Engineering A, Vol. 454, 2006, pp. 322–327.10.1016/j.msea.2006.11.056Search in Google Scholar

[26] Singh, M., R. Asthana, and T. P. Shpargel. Brazing of carbon-carbon composites to Cu-clad molybdenum for thermal management applications. Materials Science and Engineering A, Vol. 452–453, 2007, pp. 699–704.10.1016/j.msea.2006.11.031Search in Google Scholar

[27] Singh, M. and R. Asthana. Characterization of brazed joints of C-C composite to Cu-clad-Molybdenum. Composites Science and Technology, Vol. 68, No. 14, 2008, pp. 3010–3019.10.1016/j.compscitech.2008.06.012Search in Google Scholar

[28] Singh, M., G. N. Morscher, T. P. Shpargel, and R. Asthana. Active metal brazing of titanium to high-conductivity carbon-based sandwich structures. Materials Science and Engineering A, Vol. 498, No. 1-2, 2008, pp. 31–36.10.1016/j.msea.2007.11.151Search in Google Scholar

[29] Wang, H. Q., J. Cao, and J. C. Feng. Brazing mechanism and infiltration strengthening of C/C composites to TiAl alloys joint. Scripta Materialia, Vol. 63, No. 8, 2010, pp. 859–862.10.1016/j.scriptamat.2010.06.035Search in Google Scholar

[30] Wang, L., K. K. Wang, W. Guo, Y. Zhu, P. Qu, H. Kang, et al. Research on the brazing of carbon-carbon composite and Ni-based superalloy K24. Proceedings of the 16th national welding academic conference, April, 2011, Jiangsu, China (in Chinese).Search in Google Scholar

[31] Ikeshoji, T. T., T. Amanuma, A. Suzumura, and T. Yamazaki. Shear strength of brazed joint between titanium and C/C composites with various cross-ply angles. Journal of Solid Mechanics and Materials Engineering, Vol. 05, No. 12, 2011, pp. 1022–1028.10.1299/jmmp.5.1022Search in Google Scholar

[32] Li, J. K., X. Liu, and J. E. Zhou. Microstructure and mechanical performances of C/C composite and TC4 alloy brazed joints. Key Engineering Materials, Vol. 512–515, 2012, pp. 415–420.10.4028/www.scientific.net/KEM.512-515.415Search in Google Scholar

[33] Guo, W., Y. Zhu, L. Wang, P. Qu, H. Kang, and P. K. Chu. Microstructure evolution and mechanical properties of vacuum-brazed C/C composite with AgCuTi foil. Materials Science and Engineering A, Vol. 564, 2013, pp. 192–198.10.1016/j.msea.2012.11.057Search in Google Scholar

[34] Zhou, X. G., F. Q. Zhang, Q. Yu, and L. H. Xia. Microstructure analyses on joint of carbon/carbon composites and titanium ally using Ag-Cu-Ti as brazing metal. Materials Research and Application, Vol. 7, 2013, pp. 67 (in Chinese).Search in Google Scholar

[35] Yang, L. Y., M. Z. Yi, L. P. Ran, Y. C. Ge, and K. Peng. Joining of carbon/carbon composite using AgCuTi braze. Materials Science and Engineering of Powder Metallurgy, Vol. 20, 2015, pp. 765 (in Chinese).Search in Google Scholar

[36] Guo, W., T. F. Gao, X. F. Cui, Y. Zhu, and P. K. Chu. Interfacial reactions and zigzag groove strengthening of C/C composite and Rene N5 single crystal brazed joint. Ceramics International, Vol. 41, No. 9, 2015, pp. 11605–11610.10.1016/j.ceramint.2015.05.119Search in Google Scholar

[37] Zhang, K. X., L. H. Xia, F. Q. Zhang, and L. L. He. Active brazing of C/C composite to copper by AgCuTi filler metal. Metallurgical and Materials Transactions. A, Physical Metallurgy and Materials Science, Vol. 47A, No. 5, 2016, pp. 2162–2176.10.1007/s11661-016-3340-ySearch in Google Scholar

[38] Gotoh, Y., H. Okamura, S. Kajiura, M. Kumagai, T. Ando, M. Akiba, et al. Development and material testing of OF-Cu/DS-Cu/OF-Cu triplex tube and trial fabrication of a vertical target mock-up for ITER divertor. Journal of Nuclear Materials, Vol. 258–263, 1998, pp. 271–274.10.1016/S0022-3115(98)00361-4Search in Google Scholar

[39] Wang, Y. L., W. L. Wang, J. H. Huang, R. H. Yu, J. Yang, and S. H. Chen. Reactive composite brazing of C/C composite and GH3044 with Ag–Ti mixed powder filler material. Materials Science and Engineering A, Vol. 759, 2019, pp. 303–312.10.1016/j.msea.2019.05.065Search in Google Scholar

[40] Eustathopoulos, N., M. G. Nicholas, and B. Drevet. Wettability at Hightemperatures. Pergamon, Boston, USA, 1999.Search in Google Scholar

[41] Casalegno, V., M. Salvo, S. Murdaca, and M. Ferraris. One-step brazing process for CFC monoblock joints and mechanical testing. Journal of Nuclear Materials, Vol. 393, No. 2, 2009, pp. 300–305.10.1016/j.jnucmat.2009.06.015Search in Google Scholar

[42] Li, J. G. Kinetics of wetting and spreading of Cu-Ti alloys on alumina and glassy carbon substrates. Journal of Materials Science Letters, Vol. 11, No. 23, 1992, pp. 1551–1554.10.1007/BF00740830Search in Google Scholar

[43] Li, H., H. R. Geng, G. L. Chen, J. H. Chen, and M. A. Chen. Microstructure and strength of Cf /C composites joint brazed with Cu based brazing filler metal. Welding & Jioning, Vol. 01, 2008, pp. 42 (in Chinese).Search in Google Scholar

[44] Yi, Z. H., K. Z. Yang, J. Xiang, F. M. Liu, and S. Y. Zhao. Experimental research on Ti-Cu brazing filler for C/C composites. Materials Research and Application, Vol. 03, 2008, pp. 215 (in Chinese).Search in Google Scholar

[45] Chen, J. H. Microstructure and properties of brazed joint of Cf /C composite by vacuum brazing using Cu based active brazed filler. Material and Heat Treatment, Vol. 39, 2010, pp. 94 (in Chinese).Search in Google Scholar

[46] Li, J. L., J. T. Xiong, and F. S. Zhang. Transient liquid-phase diffusion bonding of two-dimensional carbon-carbon composites to niobium alloy. Materials Science and Engineering A, Vol. 483–484, 2008, pp. 698–700.10.1016/j.msea.2006.11.170Search in Google Scholar

[47] Salvo, M., P. Lemoine, M. Ferraris, M. A. Montorsi, and R. Matera. Cu-/Pb rheocast alloy as joining material for CFC composites. Journal of Nuclear Materials, Vol. 226, No. 1-2, 1995, pp. 67–71.10.1016/0022-3115(95)00107-7Search in Google Scholar

[48] Koppitz, Th., G. Pintsuk, U. Reisgen, J. Remmel, T. Hirai, R. Sievering, et al. High-temperature brazing for reliable tungsten-CFC joints. Physica Scripta, Vol. 128, 2007, pp. 175–181.10.1088/0031-8949/2007/T128/034Search in Google Scholar

[49] Liu, J. Y. Brazing of carbon-carbon composites: filler metals and techniques for brazing C-C composite to metals. PhD thesis, Auburn University, 1993.Search in Google Scholar

[50] Liu, J. Y., S. Chen, and B. A. Chin. Brazing of vanadium and carbon-carbon composites to stainless steel for fusion reactor applications. Journal of Nuclear Materials, Vol. 212, 1994, pp. 1590–1593.10.1016/0022-3115(94)91095-2Search in Google Scholar

[51] Trester, P. W., P. G. Valentine, W. R. Johnson, E. Chin, E. E. Reis, and A. P. Colleraine. Tensile fracture characterization of braze joined copper-to-CFC coupon as assemblies. Journal of Nuclear Materials, Vol. 233–237, 1996, pp. 906–912.10.1016/S0022-3115(96)00246-2Search in Google Scholar

[52] Luo, Y., H. Bian, H. W. Niu, Y. Y. Song, Z. B. Chen, X. G. Song, and M. R. Wang. Interfacial microstructure and mechanical properties of C/C composites and Nb joints brazed with Cu75Pt25 filler metal. Vacuum, Vol. 157, 2018, pp. 202–209.10.1016/j.vacuum.2018.08.036Search in Google Scholar

[53] Lauf, R. J., A. D. McMillan, and A. J. Moorhead. Method for joining carbon-carbon composites to metals. US. Patent 5648180, 1997.Search in Google Scholar

[54] Wang, J., K. Z. Li, X. R. Song, L. J. Guo, W. Li, and Z. Q. Li. The study on joining carbon/carbon composites using Ti-Ni-Si compound. Materials Science and Engineering A, Vol. 547, 2012, pp. 12–18.10.1016/j.msea.2012.03.059Search in Google Scholar

[55] Wang, J., K. Z. Li, W. Li, H. J. Li, Z. Q. Li, and L. J. Guo. The preparation and mechanical properties of carbon/carbon composite joints using Ti-Si-SiC-C filler as interlayer. Materials Science and Engineering A, Vol. 574, 2013, pp. 37–45.10.1016/j.msea.2013.03.007Search in Google Scholar

[56] Appendino, P., V. Casalegno, M. Ferraris, M. Grattarola, M. Merola, and M. Salvo. Joining of C/C composites to copper. Fusion Engineering and Design, Vol. 68, 2003, pp. 225–229.10.1016/S0920-3796(03)00218-7Search in Google Scholar

[57] Branca, V., A. Federici, and M. Grattarola. The brazing technology for high heat flux components. 10th International Workshop on Carbon Materials for Fusion Applications, September 17–19, 2003, Jülich, Germany.Search in Google Scholar

[58] Huang, C. Brazing bonding processes and interface behavior of C/C composite and TiBw/TC4 alloy. Master's thesis, Harbin Institute of Technology, 2010 (in Chinese).Search in Google Scholar

[59] Xu, L. G. Study on technology and mechanism of brazing C/C composite to niobium. Master's thesis, Harbin Institute of Technology, 2013 (in Chinese).Search in Google Scholar

[60] Cao, J., Z. J. He, J. L. Qi, H. Q. Wang, and J. C. Feng. Brazing of C/C composite to TiAl alloy using (Ti/Ni/Cu)f multi-foil filler. Jixie Gongcheng Xuebao, Vol. 54, No. 1, 2018, pp. 108–114 (in Chinese).10.3901/JME.2018.09.108Search in Google Scholar

[61] Dadras, P., T. T. Ngai, and G. M. Mehrotra. Joining of carbon-carbon composites using boron and titanium disilicide interlayers. Journal of the American Ceramic Society, Vol. 80, No. 1, 1997, pp. 125–132.10.1111/j.1151-2916.1997.tb02800.xSearch in Google Scholar

[62] Wang, J., G. Z. Yang, F. Q. Zhang, Y. L. Xiong, and Q. L. Xiong. The preparation and mechanical properties of carbon/carbon (C/C) composite and carbon fiber reinforced silicon carbide (Cf /SiC) composite joint by partial transient liquid phase (PTLP) diffusion bonding process. Vacuum, Vol. 158, 2018, pp. 113–116.10.1016/j.vacuum.2018.09.045Search in Google Scholar

[63] Ma, W. L., W. Mao, and X. H. Li. The brazing of carbon/carbon composite using Ni-based high-temperature filler metal. Proceedings of the 10th National Welding Academic Conference, March, 2001, China (in Chinese).Search in Google Scholar

[64] Singh, M., R. Asthana, and T. P. Shpargel. Brazing of ceramic-matrix composites to Ti and hastealloy using Ni-base metallic glass interlayers. Materials Science and Engineering A, Vol. 498, No. 1-2, 2008, pp. 19–30.10.1016/j.msea.2007.11.150Search in Google Scholar

[65] Tian, X. Y. Technical and mechanism study on brazing of C/C composites to GH99 nickel-base superalloy. Master's thesis, Harbin Institute of Technology, 2010 (in Chinese).Search in Google Scholar

[66] Guo, L. J., C. Guo, H. J. Li, and K. Z. Li. Mechanical properties and microstructure of the joints between carbon-carbon composites and Ni based high temperature alloys. Rare Metal Materials and Engineering, Vol. 40, 2011, pp. 111–114 (in Chinese).Search in Google Scholar

[67] Zhang, S. M., K. Z. Li, J. Wang, X. R. Song, and L. J. Guo. PTLP bonding C/C composites to super-alloy GH3044 with Ni/Ti interlayer. Journal of Solid Rocket Technology., Vol. 35, 2012, pp. 414–418 (in Chinese).Search in Google Scholar

[68] Feng, Z. W., T. F. Gao, T. W. Shao, W. Guo, Y. Zhu, and P. Qu. Brazing of C/C composite and Ni-based high temperature alloy GH3128. Transactions of the China Welding Institution., Vol. 36, 2015, pp. 105 (in Chinese).Search in Google Scholar

[69] Wu, Y. Z., H. G. Li, L. Q. Ning, J. Y. Mao, and J. X. Bi. Microstructure and property analysis of the vacuum brazed carbon-carbon composites and high temperature alloy joint. Aerospace Materials & Technology, Vol. 1, 2015, pp. 69 (in Chinese).Search in Google Scholar

[70] Shi, J. M., L. X. Zhang, X. Y. Tian, H. W. Li, and J. C. Feng. Vacuum brazing of the Cf /C composite and Ni base superalloy using MBF 20 filler. Vacuum, Vol. 156, 2018, pp. 427–433.10.1016/j.vacuum.2018.08.004Search in Google Scholar

[71] Pintsuk, G., V. Casalegno, M. Ferraris, T. Koppitz, and M. Salvo. Thermal fatigue characterization of CFC divertor modules using a one-step brazing process. Journal of Nuclear Materials, Vol. 426, No. 1-3, 2012, pp. 78–84.10.1016/j.jnucmat.2012.03.021Search in Google Scholar

[72] Salvo, M., V. Casalegno, S. Rizzo, F. Smeacetto, M. Ferraris, and M. Merola. One-step brazing process to join CFC composites to copper and copper alloy. Journal of Nuclear Materials, Vol. 374, No. 1-2, 2008, pp. 69–74.10.1016/j.jnucmat.2007.07.010Search in Google Scholar

[73] Appendino, P., M. Ferraris, V. Casalegno, M. Salvo, M. Merola, and M. Grattarola. Proposal for a new technique to join CFC composites to copper. Journal of Nuclear Materials, Vol. 348, No. 1-2, 2006, pp. 102–107.10.1016/j.jnucmat.2005.09.007Search in Google Scholar

[74] Appendino, P., M. Ferraris, V. Casalegno, M. Salvo, M. Merola, and M. Grattarola. Direct joining of CFC to copper. Journal of Nuclear Materials, Vol. 329–333, 2004, pp. 1563–1566.10.1016/j.jnucmat.2004.04.313Search in Google Scholar

[75] Casalegno, V., M. Salvo, and M. Ferraris. Surface modification of carbon/carbon composites to improve their wettability by copper. Carbon, Vol. 50, No. 6, 2012, pp. 2296–2306.10.1016/j.carbon.2012.01.049Search in Google Scholar

[76] Song, X. R., H. J. Li, V. Casalegno, M. Salvo, M. Ferraris, and X. R. Zeng. Microstructure and mechanical properties of C/C composite/Ti6Al4V joints with a Cu/TiCuZrNi composite brazing alloy. Ceramics International, Vol. 42, No. 5, 2016, pp. 6347–6354.10.1016/j.ceramint.2016.01.026Search in Google Scholar

[77] Song, X. R., H. J. Li, V. Casalegno, M. Salvo, M. Ferraris, and X. R. Zeng. In situ TiC particle reinforced TiCuZrNi brazing alloy for joining C/C composites to Ti6Al4V. International Journal of Applied Ceramic Technology, Vol. 15, No. 3, 2018, pp. 611–618.10.1111/ijac.12863Search in Google Scholar

[78] Li, Z. X., L. Zhou, Z. Xu, Y. F. Zhang, and J. H. Du. A method for joining carbon matrix composite materials with titanium alloys. China, 2002, id. 02116859.8 (in Chinese).Search in Google Scholar

[79] Shen, Y. X., Z. L. Li, C. Y. Hao, and J. S. Zhang. Joining C/C composite to copper using active Cu-3.5Si braze. Journal of Nuclear Materials, Vol. 421, No. 1-3, 2012, pp. 28–31.10.1016/j.jnucmat.2011.10.048Search in Google Scholar

[80] Zhang, L. X., C. L. Tian, X. Y. Tian, J. C. Feng, J. S. Shi, and Y. C. Liang. Research on vacuum brazing of C/C-Re composite to Nb. Transactions of the China Welding Institution., Vol. 36, 2015, pp. 47 (in Chinese).Search in Google Scholar

[81] Guo, L. J., H. J. Li, C. Guo, K. Z. Li, and T. Feng. Joining of C/C Composites and GH3128 Ni-based superalloy with Ni-Ti mixed powder as an interlayer. Rare Metal Materials and Engineering, Vol. 40, No. 12, 2011, pp. 2088–2091.10.1016/S1875-5372(12)60018-6Search in Google Scholar

[82] Zhang, X., X. H. Shi, J. Wang, H. J. Li, and K. Z. Li. Brazing of C/C composites and GH3044 Ni-based superalloy using Ni71CrSi as the interlayer. Materials China, Vol. 32, 2013, pp. 665–670 (in Chinese)Search in Google Scholar

[83] Shi, X. H., X. X. Jin, H. J. Lin, J. Y. Jing, L. Li, and C. C. Wang. Joining of SiC nanowires-toughened SiC coated C/C composites and nickel based superalloy (GH3044) using Ni71CrSi interlayer. Journal of Alloys and Compounds, Vol. 693, 2017, pp. 837–842.10.1016/j.jallcom.2016.09.245Search in Google Scholar

[84] Zhu, Y. A. Research on the growth of CNTs on C/C composite and the process and mechanism of brazing with Ti600 alloy. Master's thesis, Harbin Institute of Technology, 2016 (in Chinese).Search in Google Scholar

[85] Song, Y. H. Research on the growth of CNTs on C/C composite and the process and mechanism of brazing with Nb. Master's thesis, Harbin Institute of Technology, 2017 (in Chinese).Search in Google Scholar

[86] Shi, X. H., X. X. Jin, N. N. Yan, and L. Yang. Influence of micro-oxidation on joints of C/C composites and GH3044 for large-size aerospace parts. Acta Astronautica, Vol. 140, 2017, pp. 478–484.10.1016/j.actaastro.2017.09.015Search in Google Scholar

[87] He, Z. J., C. Li, J. L. Qi, Y. X. Huang, J. C. Feng, and J. Cao. Preinfiltration and brazing behaviors of Cf /C composites with high temperature Ti-Si eutectic alloy. Carbon, Vol. 140, 2018, pp. 57–67.10.1016/j.carbon.2018.08.021Search in Google Scholar

[88] Yang, Z. W., C. L. Wang, Y. Han, Y. T. Zhao, Y. Wang, and D. P. Wang. Design of reinforced interfacial structure in brazed joints of C/C composites and Nb by pre-oxidation surface treatment combined with in situ growth of CNTs. Carbon, Vol. 143, 2019, pp. 494–506.10.1016/j.carbon.2018.11.047Search in Google Scholar

[89] Shen, Y. X., Z. L. Li, C. Y. Hao, and J. S. Zhang. A novel approach to brazing C/C composite to Ni-based superalloy using alumina interlayer. Journal of the European Ceramic Society, Vol. 32, No. 8, 2012, pp. 1769–1774.10.1016/j.jeurceramsoc.2011.12.016Search in Google Scholar

[90] Zhou, Y. H., D. Liu, H. W. Niu, X. G. Song, X. D. Yang, and J. C. Feng. Vacuum brazing of C/C composite to TC4 alloy using nano-Al2O3 strengthened AgCuTi composite filler. Materials & Design, Vol. 93, 2016, pp. 347–356.10.1016/j.matdes.2015.12.143Search in Google Scholar

[91] Zhou, Y. H., D. Liu, X. G. Song, J. H. Liu, Y. Y. Song, Z. Wang, et al. Characterization of carbon/carbon composite/Ti6Al4V joints brazed with graphene nanosheets strengthened AgCuTi filler. Ceramics International, Vol. 43, No. 18, 2017, pp. 16600–16610.10.1016/j.ceramint.2017.09.049Search in Google Scholar

[92] Liu, D., Y. Y. Song, Y. H. Zhou, X. G. Song, W. Fu, and J. C. Feng. Brazing of C/C composite and Ti-6Al-4V with graphene strengthened AgCuTi filler: Effects of graphene on wettability, microstructure and mechanical properties. Chinese Journal of Aeronautics, Vol. 31, No. 7, 2018, pp. 1602–1608.10.1016/j.cja.2017.08.017Search in Google Scholar

[93] Zhang, S. Y., Y. Yuan, Y. Y. Su, and X. R. Song. Interfacial microstructure and mechanical properties of brazing carbon/carbon composites to stainless steel using diamond particles reinforced Ag-Cu-Ti brazing alloy. Journal of Alloys and Compounds, Vol. 719, 2017, pp. 108–115.10.1016/j.jallcom.2017.05.151Search in Google Scholar

[94] Ba, J., Y. H. Wang, Y. L. Liu, J. H. Lin, J. L. Qi, G. Wang et al. In situ consume excessive Ti element and form fine Ti based compounds as reinforcements for strengthening C/C-TC4 joints. Vacuum, Vol. 143, 2017, pp. 303–311.10.1016/j.vacuum.2017.06.035Search in Google Scholar

[95] Zhao, L., J. B. Hou, and X. H. Li. Active cement added brazing of Cf /C composites to copper. Welding Journal, Vol. 01, 2018, pp. 46 (in Chinese).Search in Google Scholar

[96] Lin, T. S., M. X. Yang, P. He, C. Huang, P. Pan, and Y. D. Huang. Effect of in situ synthesized TiB whisker on microstructure and mechanical properties of carbon-carbon composite and TiBw/Ti-6Al-4V composite joint. Materials & Design, Vol. 32, No. 8-9, 2011, pp. 4553–4558.10.1016/j.matdes.2011.04.028Search in Google Scholar

[97] Yu, S. Research on joining of carbon materials to CuCrZr alloys with Cu-based fillers. Master's thesis, Wuhan Institute of Technology, 2016 (in Chinese).Search in Google Scholar

[98] Song, X. R., H. J. Li, X. R. Zeng, and L. L. Zhang. Brazing of C/C composites to Ti6Al4V using graphene nanoplatelets reinforced TiCuZrNi brazing alloy. Materials Letters, Vol. 183, 2016, pp. 232–235.10.1016/j.matlet.2016.07.111Search in Google Scholar

[99] Song, X. R., H. J. Li, and X. R. Zeng. Brazing of C/C composites to Ti6Al4V using multiwall carbon nanotubes reinforced TiCuZrNi brazing alloy. Journal of Alloys and Compounds, Vol. 664, 2016, pp. 175–180.10.1016/j.jallcom.2015.12.242Search in Google Scholar

[100] Tian, X. Y., J. L. Qi, L. X. Zhang, Y. C. Liang, H. W. Li, and J. C. Feng. Brazing of C/C composite and GH99 superalloy using BNi2+TiH2 composite filler powder. Transactions of the China Welding Institution, Vol. 35, 2014, pp. 35–38 (in Chinese).Search in Google Scholar

[101] Feng, L., K. Z. Li, B. Xue, Q. Song, X. R. Song, and Q. G. Fu. Joining carbon/carbon composites with radially-aligned carbon nanotube reinforced pyro-carbon bonding interlayer. Materials Letters, Vol. 187, 2017, pp. 158–161.10.1016/j.matlet.2016.10.067Search in Google Scholar

[102] Guo, W., H. Q. Zhang, W. Q. Yuan, Y. Zhu, H. Zhang, P. Peng et al. The microstructure and mechanical properties of C/C composite/Ti3Al alloy brazed joint with graphene nanoplatelet strengthened Ag-Cu-Ti filler. Ceramics International, Vol. 45, No. 7, 2019, pp. 8783–8789.10.1016/j.ceramint.2019.01.203Search in Google Scholar

[103] Zhang, Y., Z. Y. He, and D. Feng. Recent progress of interlayer used to join metals and ceramics. Journal of Iron and Steel Research., Vol. 19, 2007, pp. 1–4 (in Chinese).10.1016/S1006-706X(07)60018-1Search in Google Scholar

[104] Ou, X. X., F. Q. Zhang, L. H. Xia, and S. D. Liang. Joining of carbon/carbon composite with stainless steel using AgCuTi as brazing alloy and Nb interlayer. Materials Science and Engineering of Powder Metallurgy, Vol. 16, 2011, p. 442–447 (in Chinese).Search in Google Scholar

[105] Zhang, X. Y., F. Q. Zhang, L. H. Xia, and Q. Yu. Effect of joining temperature on residual stress of C/C composites and Cu joints. Zhongguo Youse Jinshu Xuebao, Vol. 22, 2012, pp. 1298–1303 (in Chinese).Search in Google Scholar

[106] Zhang, X. Y. Interfacial stress analysis and structural design for composite and Cu joints. Master's thesis, Central South University, 2012 (in Chinese).Search in Google Scholar

[107] Wang, Z. Y., G. Wang, M. N. Li, J. H. Lin, Q. Ma, A. Zhang et al. Three-dimensional graphene-reinforced Cu foam interlayer for brazing C/C composites and Nb. Carbon, Vol. 118, 2017, pp. 723–730.10.1016/j.carbon.2017.03.099Search in Google Scholar

[108] Wang, Z. Y., M. N. Li, J. Ba, Q. Ma, Z. Q. Fan, J. H. Lin et al. In-Situ synthesized TiC nano-flakes reinforced C/C composite-Nb brazed joint. Journal of the European Ceramic Society, Vol. 38, No. 4, 2018, pp. 1059–1068.10.1016/j.jeurceramsoc.2017.11.059Search in Google Scholar

[109] Centeno, A., G. Pintsuk, J. Linke, C. Gualco, C. Blanco, R. Santamaría et al. Behaviour of Ti-doped CFCs under thermal fatigue tests. Fusion Engineering and Design, Vol. 86, No. 1, 2011, pp. 121–125.10.1016/j.fusengdes.2010.09.018Search in Google Scholar

[110] Rosales, C. G., G. Pintsuk, C. Gualco, N. Ordás, I. L. Galilea, J. M. R. Fernández et al. Manufacturing and high heat-flux testing of brazed actively cooled mock-ups with Ti-doped graphite and CFC as plasma-facing materials. Physica Scripta, Vol. T138, Dec. 2009, id. 014062.10.1088/0031-8949/2009/T138/014062Search in Google Scholar

[111] Qin, Y. Q. and Z. S. Yu. Effect of brazing parameters on microstructures of C/C composite/Cu/Mo/TC4 brazed joints. Journal of Materials Engineering, Vol. 8, 2012, pp. 78–82 (in Chinese).Search in Google Scholar

[112] Qin, Y. Q. and J. C. Feng. Brazing carbon/carbon composite to TC4 with Cu and Mo composite interlayers. Materials Science and Engineering A, Vol. 525, No. 1-2, 2009, pp. 181–185.10.1016/j.msea.2009.06.049Search in Google Scholar

[113] Ikeshoji, T. T., T. Tokunaga, A. Suzumura, and T. Yamazaki. Brazing of C/C composites and Ni-based alloy using interlayer. Materials Science and Engineering, Vol. 61, 2014, id. 012013.10.1088/1757-899X/61/1/012013Search in Google Scholar

[114] Casalegno, V., Th. Koppitz, G. Pintsuk, M. Salvo, S. Rizzo, S. Perero, et al. Proposal for a modified non-active brazing alloy for joining CFC composites to copper. Composites. Part B, Engineering, Vol. 56, 2014, pp. 882–888.10.1016/j.compositesb.2013.08.079Search in Google Scholar

[115] Lin, X. Q., K. Z. Li, H. J. Li, and F. T. Lan. Joining of surface modified carbon/carbon composites and LAS glass ceramic. Hangkong Xuebao, Vol. 30, 2009, pp. 380–384 (in Chinese).Search in Google Scholar

[116] Ren, X. B., H. J. Li, J. H. Lu, L. J. Guo, J. Wang, and X. R. Song. Influence of interlayer's thickness on strength of joints between LAS glass-ceramic and carbon/carbon composites. Journal of Inorganic Materials, Vol. 26, No. 8, 2011, pp. 847–851 (in Chinese).10.3724/SP.J.1077.2011.00847Search in Google Scholar

[117] Isola, C., M. Salvo, M. Ferraris, and M. A. Montorsi. Joining of surface modified carbon/carbon composites using a barium-aluminum-boro-silicate glass. Journal of the European Ceramic Society, Vol. 18, No. 8, 1998, pp. 1017–1024.10.1016/S0955-2219(97)00203-3Search in Google Scholar

[118] Trendway, W. K., K. M. Prewo, and C. G. Pantano. Fiber-matrix interfacial effects in carbon-fiber-reinforced glass matrix composites. Carbon, Vol. 27, No. 5, 1989, pp. 717–727.10.1016/0008-6223(89)90205-4Search in Google Scholar

[119] Pantano, C. G., G. Chen, and D. Qi. Interface reactions and wetting in carbon-fiber-reinforced glass matrix composites. Materials Science and Engineering A, Vol. 126, No. 1-2, 1990, pp. 191–201.10.1016/0921-5093(90)90125-MSearch in Google Scholar

[120] Lan, F. T., K. Z. Li, H. J. Li, Q. G. Fu, and X. Q. Lin. Vitreous joining of SiC-coated carbon/carbon composites. Materials Letters, Vol. 62, No. 15, 2008, pp. 2347–2350.10.1016/j.matlet.2007.11.100Search in Google Scholar

[121] Fu, Q. G., F. L. Zhao, H. J. Li, H. Peng, and X. Y. Nan. A multi-interlayer LMAS joint of C/C-SiC composites and LAS glass ceramics. Journal of Materials Science and Technology, Vol. 31, No. 5, 2015, pp. 467–472.10.1016/j.jmst.2014.11.024Search in Google Scholar

[122] Lin, X. Q., K. Z. Li, H. J. Li, F. T. Lan, and D. M. Zhu. Microstructure and properties of joints of carbon/carbon composites and LAS glass ceramic. Development and Application of Materials, Vol. 23, 2008, pp. 13 (in Chinese).Search in Google Scholar

[123] Qiang, Q., K. Z. Li, Q. M. Gao, Q. Song, and J. Wang. Connection between carbon-carbon composites and LAS ceramic with YAST glass-ceramic reinforced by CNTs. Journal of Solid Rocket Technology, Vol. 33, 2010, pp. 459–462 (in Chinese).Search in Google Scholar

[124] Zhao, F. L., Q. G. Fu, L. Wang, and Y. Liu. Construction of SiCnw/MAS nanocomposites to strengthen and toughen C/C-LAS joints. Materials Science and Engineering A, Vol. 703, 2017, pp. 137–143.10.1016/j.msea.2017.06.059Search in Google Scholar

[125] Zhao, F. L., Q. G. Fu, L. Feng, and Q. L. Shen. Enhancement of C/C-LAS joint using aligned carbon nanotubes prepared by injection chemical vapor deposition. Materials Science and Engineering A, Vol. 650, 2016, pp. 67–74.10.1016/j.msea.2015.10.003Search in Google Scholar

[126] Xiong, H. P. and B. Chen. High-temperature Brazing Filler Metals for Ceramic Joining and Interfacial Metallurgy. National Defence Industry Press, Beijing, China, 2014 (in Chinese).Search in Google Scholar

[127] Yu, Q. Joining C/C composite to molybdenum. Master's thesis, Central South University, 2012 (in Chinese).Search in Google Scholar

© 2021 Shengnan Li et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Review Articles

- A review on filler materials for brazing of carbon-carbon composites

- Nanotechnology-based materials as emerging trends for dental applications

- A review on allotropes of carbon and natural filler-reinforced thermomechanical properties of upgraded epoxy hybrid composite

- High-temperature tribological properties of diamond-like carbon films: A review

- A review of current physical techniques for dispersion of cellulose nanomaterials in polymer matrices

- Review on structural damage rehabilitation and performance assessment of asphalt pavements

- Recent development in graphene-reinforced aluminium matrix composite: A review

- Mechanical behaviour of precast prestressed reinforced concrete beam–column joints in elevated station platforms subjected to vertical cyclic loading

- Effect of polythiophene thickness on hybrid sensor sensitivity

- Investigation on the relationship between CT numbers and marble failure under different confining pressures

- Finite element analysis on the bond behavior of steel bar in salt–frost-damaged recycled coarse aggregate concrete

- From passive to active sorting in microfluidics: A review

- Research Articles

- Revealing grain coarsening and detwinning in bimodal Cu under tension

- Mesoporous silica nanoparticles functionalized with folic acid for targeted release Cis-Pt to glioblastoma cells

- Magnetic behavior of Fe-doped of multicomponent bismuth niobate pyrochlore

- Study of surfaces, produced with the use of granite and titanium, for applications with solar thermal collectors

- Magnetic moment centers in titanium dioxide photocatalysts loaded on reduced graphene oxide flakes

- Mechanical model and contact properties of double row slewing ball bearing for wind turbine

- Sandwich panel with in-plane honeycombs in different Poisson's ratio under low to medium impact loads

- Effects of load types and critical molar ratios on strength properties and geopolymerization mechanism

- Nanoparticles in enhancing microwave imaging and microwave Hyperthermia effect for liver cancer treatment

- FEM micromechanical modeling of nanocomposites with carbon nanotubes

- Effect of fiber breakage position on the mechanical performance of unidirectional carbon fiber/epoxy composites

- Removal of cadmium and lead from aqueous solutions using iron phosphate-modified pollen microspheres as adsorbents

- Load identification and fatigue evaluation via wind-induced attitude decoupling of railway catenary