Abstract

Unripe banana flour (UBF) is recognised as a functional ingredient because of its nutritional pattern. The influence of substituting wheat flour with unripe non-commercial banana (Luvhele and Mabonde) flours on bread’s physical and textural properties and sensory acceptability was evaluated. Wheat flour was replaced with 2.5, 5, 7.5, and 10% of UBF of Luvhele and Mabonde in bread production. Physical properties such as volume, density, weight, colour, and textural characteristics were determined. Furthermore, a sensory evaluation of the bread was performed. The inclusion of UBF of Luvhele and Mabonde cultivars significantly decreased (P ≤ 0.05) the weight, volume, and specific volume of breads, but a higher density of breads was observed. Breads containing 10% UBF had the highest hardness values (9.92, Luvhele, and 9.96 N, Mabonde). However, breads incorporated with UBF of both banana cultivars had lower chewiness, cohesiveness, and springiness than control bread. The control bread had crumbs and crust that were significantly lighter (P ≤ 0.05) than the crumb of composite breads. Sensory evaluation results showed that bread incorporated with up to 7.5% UBF of both banana cultivars was acceptable in terms of aroma, taste, and overall acceptability.

Graphical abstract

1 Introduction

Banana is one of the most popular fruits grown in the world’s tropical and subtropical regions, and production is increasing because of its export potential [1]. Different banana cultivars include plantain (AAB), desert banana (Musa spp. AA, AB, and AAA genome), and cooking banana (AAB). Luvhele (Musa ABB) and Mabonde (Musa AAA) cultivars are the most important non-commercial banana fruits grown in South Africa. They are planted for local markets or household consumption [2]. Bananas are highly perishable because of the physiological changes that occur immediately after harvest. Consequently, one method of minimising postharvest loss and perhaps increasing the variety of uses for non-commercial banana cultivars is to mill them into flour for bread making.

Unripe banana flour (UBF) is a good source of dietary fibre and resistant starch, which reduces microbial activity in the large intestine [3,4]. These characteristics make UBF a good choice as a raw material and can be classified as a functional component [5]. UBF is also particularly rich in minerals like calcium, magnesium, phosphorus, potassium, and sulphur [6]. Significantly, UBF contains high antioxidant compounds such as polyphenols, vitamins, catecholamine, and carotene, which are important for maintaining human health by preventing cardiovascular diseases, high blood pressure, ulcers, and diabetes [7]. As a result, UBF has been proposed as an ingredient for breads [8,9], biscuits [10,11], and pasta [12].

Bread is an important and widespread staple food made from wheat and contains beneficial macronutrients such as starch, protein, fibre, vitamins, and minerals [13]. Primary ingredients such as wheat flour, water, sugar, shortening, improver, salt, and yeast are required during the baking of bread [14,15]. Gluten in wheat plays an important role in bread production by endowing the dough with viscoelasticity, good gas retention capacity, and good crumb structure to the resulting baked product [16]. Wheat flour is the main component used in baked goods in Southern Africa’s baking sector. The agronomic requirements have resulted in wheat being imported since it cannot be cultivated in most parts of Southern Africa. Therefore, there is a need to reduce the overdependency of imported wheat by using flour blends from locally available fruits such as bananas. These mixtures of flours can offer greater economic and nutritional benefits [17,18].

Luvhele and Mabonde banana cultivars are underutilised because their use in South Africa is limited to a small population for different reasons. Results revealed that some of these non-commercial banana cultivars have higher levels of antioxidant properties than commercial cultivars [2,19]. The presence of polyphenols, free and bound phenols such as anthocyanins in fruit pulp, and a moderate level of antioxidant activity in UBF have led to a current trend of increased research on the use of unripe banana products for public consumption [20,21]. Therefore, the novelty of this work stems from the usage of non-commercial banana cultivars (Luvhele and Mabonde) in the production of wheat bread and reporting the results for the very first time.

On the other hand, not much research has been done on Luvhele and Mabonde banana cultivars to propose possible uses, and they are unknown to the general public. Thus, it is important to evaluate the acceptability of non-commercial banana cultivars in bread making. Matidze et al. [22] utilised the UBF of both banana cultivars to modify the nutritional quality of wheat dough. The inclusion of UBF significantly increased the ash, fibre, fat, and carbohydrate contents of the wheat dough. Therefore, this study aimed to evaluate the influence of adding UBF of non-commercial banana cultivars (Luvhele and Mabonde) on the physical properties and sensory acceptability of wheat bread. The result of this study is important since utilisation of unripe, non-commercial banana cultivars in bread making could be a valuable way to incorporate UBF into the food system.

2 Materials and methods

2.1 Materials

Five bunches of Luvhele (Musa ABB) and Mabonde (Musa AAA) bananas at unripe stages were purchased from rural households in Thohoyandou, Limpopo province, South Africa. Wheat flour (Sasko®) had a protein content of 11.4%, total fat (2.3%), dietary fibre (4.1%), and energy (1,456 kJ). Sugar (Selati®), salt (Cerebos®), margarine (Siqalo®), water, and dry yeast (Anchor yeast®) were purchased from a local supermarket.

2.2 Preparation of UBFs

The unripe banana fruits were detached from the bunch, washed, peeled manually, sliced into 5 mm width using a sharp knife, dipped in citric acid solution for 10 min to prevent enzymatic browning, spread evenly on a stainless steel tray, and dried in a conventional oven dryer (Model 278, digital oven, Labotec, Midrand, South Africa) at 60°C for 12 h. The dried slices were milled using a laboratory hammer mill (Retsch KG 5657, Retsch GmbH, Haan, Germany); the flour was passed through a 0.25 mm mesh sieve, packaged in a plastic bag, wrapped, and kept at room temperature (26 ± 2°C) for further use. Luvhele and Mabonde flours had a moisture content of 10.03 and 11.62%, and ash content of 1.57%, as determined by the AOAC method. The total soluble solids were 0.93 and 0.62% for Luvhele and Mabonde flours, respectively.

2.3 Preparation of breads

The dough was baked using the straight dough method [23], using different ratios of UBF (0–10%) in substituting part of the wheat flour. These included breads from Luvhele banana flour (LBF) and Mabonde banana flour (MBF). Prototype tests were performed to obtain the maximum amount of UBF that could be used in bread production. More than 20% of UBF in wheat flour produced bread with poor technological and sensory characteristics, limiting the utilisation of UBF by 20%. The dough was formulated with a mixture of wheat flour and four substitution levels of LBF and MBF (2.5, 5, 7.5, and 10% w/w). The ingredients were mixed manually for 3 to 4 min in a bowl. The dough was fermented at room temperature for 60 min and then punched back and scaled. The dough was manually moulded, placed in lightly greased bread pans, and proofed for 90 min at room temperature (26 ± 2°C) (Table 1).

Bread formulation incorporated with UBF

| Ingredients | 0% | Banana flour % 2.5% | 5% | 7.5% | 10% |

|---|---|---|---|---|---|

| White bread wheat flour (g) | 300 | 292.5 | 285 | 277.5 | 270 |

| Luvhele/MBF (g) | 0 | 7.5 | 15 | 22.5 | 30 |

| Salt (g) | 5 | 5 | 5 | 5 | 5 |

| Fat (g) | 9 | 9 | 9 | 9 | 9 |

| Yeast (g) | 3 | 3 | 3 | 3 | 3 |

| Sugar (g) | 10 | 10 | 10 | 10 | 10 |

| Water (mL) | 140 | 140 | 140 | 140 | 140 |

The breads were baked in a preheated oven (Defy, Model DSS700, Midrand, South Africa) for 15 min at 230°C. The 100% wheat flour bread served as a control. The physical characteristics and sensory attributes of the bread samples were determined after cooling overnight at room temperature. Three batches of bread were produced, and the experiment was repeated three times for the reliability of the results.

2.4 Physical properties of breads

The loaf volume was measured using the rapeseed displacement method [24]. The bread was placed in a container of known volume, and the basin was filled to the brim with rapeseed. The bread was removed, and a measuring cylinder was used to measure the volume of the loaf. The ratio between the apparent volume of the baked breads and their mass was used to determine the breads’ specific volume. The weight of breads was measured in a semi-weighing balance (BPS 51 plus, Boeco, Germany). The loaves were weighed in triplicate. The density of bread was evaluated using the following equation: density (g/cm3) = weight of bread/loaf volume of bread.

Texture profile analysis values (hardness, chewiness, cohesiveness, and springiness) of breads were determined using a TA-XTplus texture analyser (Stable Micro System, Surrey, UK) fitted with a 25 kg load cell and an aluminium cylindrical probe with a 50 mm diameter. The texture profile of the bread was determined within 24 h of baking. The test parameters were at a constant rate: pre-test speed: 5 mm/s, test speed: 5 mm/s, and post-test speed: 5 mm/s, compression distance: 60%, and slice thickness: 20 mm. Hardness was explained as the peak force needed for the first compression. The springiness was explained as the distance between the end of the first compression and the beginning of the second compression of the slice back to its original height. Cohesiveness was measured as the ratio of the area under the second compression curve to the area under the first compression curve. Chewiness: Hardness × cohesiveness × springiness [25].

The crust and crumb colour was measured using Hunterlab LabScan XE Spectrophotometer CIELAB. The standardisation was done in compliance with the manufacturer’s instructions. The colour was then denoted using CIE-L* a* b* coordinates, where L* indicates 100 = white; 0 = black, a* (green-red component, where negative values correspond to green and positive values to red), and b* (blue-yellow component, where negative values correspond to blue and positive values to yellow). Chroma was calculated by Chroma =

2.5 Sensory evaluation of breads

Panelists were verbally approached and recruited 72 h before sensory evaluation. Seventy semi-trained panelists (40 females and 30 males) in the age range of 19–50 collaborated in the sensory evaluation of bread samples. Panelists were selected from students and staff in the Faculty of Science, Engineering and Agriculture, University of Venda, South Africa, and were regular consumers of bread. Panelists were screened for critical conditions such as wheat allergy and they were given consent form prior to bread evaluation. The sensory evaluation was conducted in a sensory laboratory in individual panel booths using a hedonic scale sheet. The bread samples (with dimensions measuring 10 cm × 3 cm, including crumb and crust) were served in polystyrene plate at room temperature and marked with randomly selected three-digit numbers. The instructions were given to the panelists to evaluate the bread samples for the following attributes: colour, texture, taste, and overall acceptability. A sensory evaluation questionnaire with the nine-point hedonic scale (9 = extreme like, 5 = neither like or dislike, and 1 = extreme dislike), developed in English was distributed to panelists. Panelists were requested to clean their mouths with water in between bread tasting. Participation in the study was on a voluntary basis, and panelists were not given information about the bread samples. No monetary incentive was given to panelists for participating in the study. Permission to conduct a sensory evaluation was obtained from the University’s Ethics Committee, and a certificate of approval was issued.

2.6 Statistical analysis

Statistical analyses were carried out using SPSS 26.0 (Chicago, IL, USA). The data were analysed using one-way analysis of variance (ANOVA), and the mean values were compared using the Fisher least significant difference test (P ≤ 0.05). The mean and standard deviation of three replicates were reported for each analysis. The independent variable was the ratio of mixing the wheat flour with LBF and MBF. Dependent variables were the measured values such as physical properties, colour profile, texture, and sensory properties. The primary sensory evaluation data were subjected to statistical calculations, and, on their basis, a regression analysis was performed for each of the tested bread samples.

3 Results and discussion

3.1 Physical properties of breads incorporated with unripe non-commercial banana flour

The physical (volume, weight, density, and specific volume) properties of different breads are provided in Table 2. Breads showed a significant difference (P ≤ 0.05) regarding all physical properties. The loaf volume of composite breads significantly decreased as the proportion of UBF increased, ranging from 156.40 to 123.40 cm3 (LBF) and 270.00 to 249.33 cm3 (MBF), respectively. Consumers are mostly attracted to bread because of its volume, especially higher volume, and the loaf size reduction that occurs during baking is not desirable [27]. The reduced loaf volume of UBF-added breads could be attributed to less gluten in both banana cultivars, which diluted the gluten of wheat flour [28,29]. Moreover, Nwanekezi [30] reported that adding non-wheat flour to wheat flour during breadmaking reduces the number of gluten proteins, resulting in low volume. The coagulation of gluten during baking due to the impact of heat serves as a foundation for the loaf to become fairly rigid and not collapse [31]. Similar results were reported by Almoraie [32], where the inclusion of walnut flour reduced the volume of bread, ranging from 944.2 to 645.9 cm3.

Physical properties of breads incorporated with UBFs

| Breads | Parameters | |||

|---|---|---|---|---|

| Volume (cm3) | Weight (g) | Density (g/cm3) | Specific volume (cm3/g) | |

| Control | 280.00 ± 1.08a | 379.68 ± 0.59a | 0.16 ± 0.10d | 6.22 ± 0.03a |

| LBF1 | 156.00 ± 2.00f | 431.32 ± 0.36b | 0.28 ± 0.01b | 5.88 ± 0.01b |

| LBF2 | 151.67 ± 1.55g | 434.19 ± 0.25b | 0.29 ± 0.01b | 5.49 ± 0.03c |

| LBF3 | 141.70 ± 1.49h | 443.09 ± 0.10c | 0.32 ± 0.05b | 5.39 ± 0.04d |

| LBF4 | 123.40 ± 1.50i | 448.37 ± 0.32d | 0.45 ± 0.05a | 4.90 ± 0.02e |

| MBF1 | 270.00 ± 1.00b | 457.14 ± 0.62e | 0.17 ± 0.00cd | 5.91 ± 0.01b |

| MBF2 | 261.33 ± 0.97c | 463.28 ± 0.25f | 0.17 ± 0.01cd | 5.63 ± 0.01c |

| MBF3 | 242.00 ± 0.65e | 451.31 ± 0.59e | 0.18 ± 0.12c | 5.52 ± 0.01c |

| MBF4 | 249.33 ± 0.50d | 449.66 ± 0.19d | 0.19 ± 0.02c | 5.37 ± 0.04d |

Mean ± standard deviation in triplicates. Values in the same column with different letters show significant differences (p < 0.05). Control = 100% wheat flour; LBF1 to LBF4 = 2.5, 5, 7.5, and 10% LBF; and MBF1 to MBF4 = 2.5, 5, 7.5, and 10% MBF.

There was a significant increase in weight in all composite breads compared with the control, with values varying from 431.32 to 448.37 g (LBF) and 449.66 to 463.28 g (MBF), respectively. The addition of water during dough development and the capacity of UBF to hold water could be attributed to the increase in the weight of composite breads [28]. The weight of the bread was also attributed to factors such as moisture content and characteristics of the dough [33]. Comparably, Mudau et al. [26] found an increase in the weight of bread incorporated with finger millet flour, with values varying from 141.77 to 148.52 g. On the other hand, no significant difference (P ≥ 0.05) was observed between the weight of control and bread samples incorporated with prickly pear peel flour [34].

The composite breads had increased density compared to the control with values ranging from 0.28 to 0.45 g/cm3 (LBF) and from 0.17 to 0.19 g/cm3 (MBF), respectively. The increased density in composite bread samples could be due to factors such as the dilution of the gluten network, which might have resulted in a compact structure with less visible air pocket [24]. Gómez and Oliete [35] reported that the addition of fibre ingredients like UBF in bread production results in increased cell density. Amini-Khoozani et al. [25] reported similar results wherein the incorporation of UBF (Cavendish of Musa sp.) increased the density of wheat bread.

Specific volume is directly associated with the ability of the dough mass to retain gas production during proofing or fermentation, which in turn is due to the gluten that is available in the wheat flour. The composite breads had low specific volumes ranging from 5.88 to 4.90 cm3/g (LBF) and from 5.91 to 5.37 cm3/g (MBF), respectively. The low specific volume of composite breads might be attributed to the high amount of UBF in both banana cultivars, which competed with the dough for moisture, affecting the secondary structure of the dough’s gluten. Furthermore, the decrease in the specific volume of composite breads could be attributed to the reduced holding of carbon dioxide gas in the mixed dough [36]. Blandino et al. [37] argued that a high amount of dietary fibre could reduce bread volume because it interferes with the optional generation of gluten matrix during fermentation and baking, making bread less extensible. The fibre content of UBF varies from 6.77 to 65.76 g/100 g [38]. Similar results of decrease in a specific volume of wheat bread were observed by incorporation of other non-gluten flours such as Chinese yam at 25% [31] with values ranging from 4.47 to 3.80 mL/g and cassava at 30% [39] with values ranging from 2.5 to 1.5 cm3/g. However, the inclusion of prickly pear peel flour at 10% increased the specific volume of wheat bread [34].

3.2 Textural properties of breads incorporated with unripe non-commercial banana flours

Table 3 shows the textural properties of the breads incorporated with UBF. The hardness values of bread samples increased significantly as the UBF ratio increased, ranging from 8.73 to 9.92 N (LBF) and 8.68 to 9.96 N (MBF), respectively. When the amount of UBF increased in the flour, the resultant bread became harder, as shown by the higher hardness values in breads incorporated with both non-commercial banana cultivars. Modification in the texture of bread might be attributed to the low amounts of protein in UBF, which did not generate a network related to the gluten network, leading to a hard and more solid dough. The increased hardness of composite breads could have resulted from starch gel within inter-granular spaces that provided rigidity and resulted in the hardness of the breads [40]. Interconnection between gluten and fibrous materials might have increased the hardness of the composite breads. The hardness of composite breads might be due to the high amount of dietary fibre in UBF which interfered with the gluten matrix [41]. Moreover, the high density of bread correlates with a more compact and harder texture. The hardness of the breads is predominantly due to the amylopectin and amylose matrix which contribute to the texture of bread. Results are similar to a report by Amini-Khoozani et al. [25], whereby the inclusion of whole green banana flour improved the hardness of the wheat bread.

Textural properties of breads incorporated with non-commercial UBF

| Breads | Parameters | |||

|---|---|---|---|---|

| Hardness (N) | Chewiness (N) | Cohesiveness | Springiness (cm) | |

| Control | 7.50 ± 0.53e | 15.22 ± 1.38a | 0.89 ± 0.09a | 0.95 ± 0.02a |

| LBF1 | 8.73 ± 0.65d | 13.11 ± 1.17d | 0.80 ± 0.06ab | 0.88 ± 0.09ab |

| LBF2 | 9.08 ± 0.28c | 12.93 ± 0.94e | 0.75 ± 0.02c | 0.86 ± 0.02b |

| LBF3 | 9.60 ± 0.95b | 12.24 ± 0.33f | 0.72 ± 0.02cd | 0.80 ± 0.02bc |

| LBF4 | 9.92 ± 0.87a | 11.97 ± 0.48g | 0.71 ± 0.01cd | 0.77 ± 0.02c |

| MBF1 | 8.68 ± 0.60d | 14.81 ± 0.94b | 0.82 ± 0.02ab | 0.86 ± 0.02b |

| MBF2 | 9.13 ± 0.47c | 13.52 ± 0.97c | 0.71 ± 0.00cd | 0.84 ± 0.00b |

| MBF3 | 9.66 ± 0.79b | 12.94 ± 0.76e | 0.78 ± 0.02c | 0.78 ± 0.02c |

| MBF4 | 9.96 ± 0.65a | 12.02 ± 0.73g | 0.84 ± 0.01ab | 0.77 ± 0.01c |

Mean ± standard deviation in triplicates. Values with the same superscripts within a column are not significantly different (p < 0.05). Control = 100% wheat flour; LBF1 to LBF4 = 2.5, 5, 7.5, and 10% LBF; and MBF1 to MBF4 = 2.5, 5, 7.5, and 10% MBF.

The chewiness of breads was associated with increased UBF, with the control sample being the chewiest (15.22 N), and breads with 10% UBF being the least chewy with a value of 11.97 for LBF and 12.02 (MBF), respectively. The weak starch–gluten network contributed to the low chewiness of composite breads. This weakening is linked to the expansion of starch granules and the gluten network’s water absorption during dough production [42]. The results align with the report of Li et al. [31], wherein the inclusion of Chinese yam flour (5–15%) decreased the chewiness of bread ranging from 170.90 to 155.38 g.

The cohesiveness of breads significantly decreased (P ≤ 0.05) as UBF increased in the formulation, with values ranging from 0.80 to 0.71 (LBF) and 0.84 to 0.71 (MBF), respectively. The reduction in cohesiveness of the composite breads might be associated with high integration of crumb structure, as reported by Salinas et al. [43]. The decreased cohesiveness values of composite breads show that the crumb is more prone to rupture. Similar results were obtained by Thakaeng et al. [44], wherein the incorporation of UBF (Cavendish spp.) decreased the cohesiveness of the bread with values ranging from 0.55 to 0.27 g s.

The more wheat flour was replaced with UBF, the less springiness the bread crumb, with values ranging from 0.88 to 0.77 cm (LBF) and 0.86 to 0.77 cm (MBF); Feili et al. [45] mentioned that the association between gelatinised starch and gluten dough, which contributes to the springiness of the dough, can make a constant sponge structure of the bread upon heat treatment or baking. A low level of gluten in UBF of both banana cultivars contributed to the dough’s lower capacity to hold gas, resulting in the low springiness of composite breads. It is also possible that the interaction of protein and polysaccharides in the gluten network might have expedited starch entrapment, thereby building up the dough’s structure and reducing the bread’s texture [46]. It was expected that bread (control) with higher gluten content would be more elastic. The interactions between gluten dough and gelatinised starch, which can create a sponge structure due to high temperature, are thought to cause high springiness values [34]. The hydration of non-gluten flours, like UBF, has weak foaming characteristics and might have resulted in the formation of fewer pockets during the fermentation process, leading to a low springiness in the composite breads [47]. Ho et al. [48] found similar results wherein the cohesiveness and springiness of breads incorporated with banana pseudostem flour decreased.

3.3 Colour profile of breads incorporated with unripe non-commercial banana flour

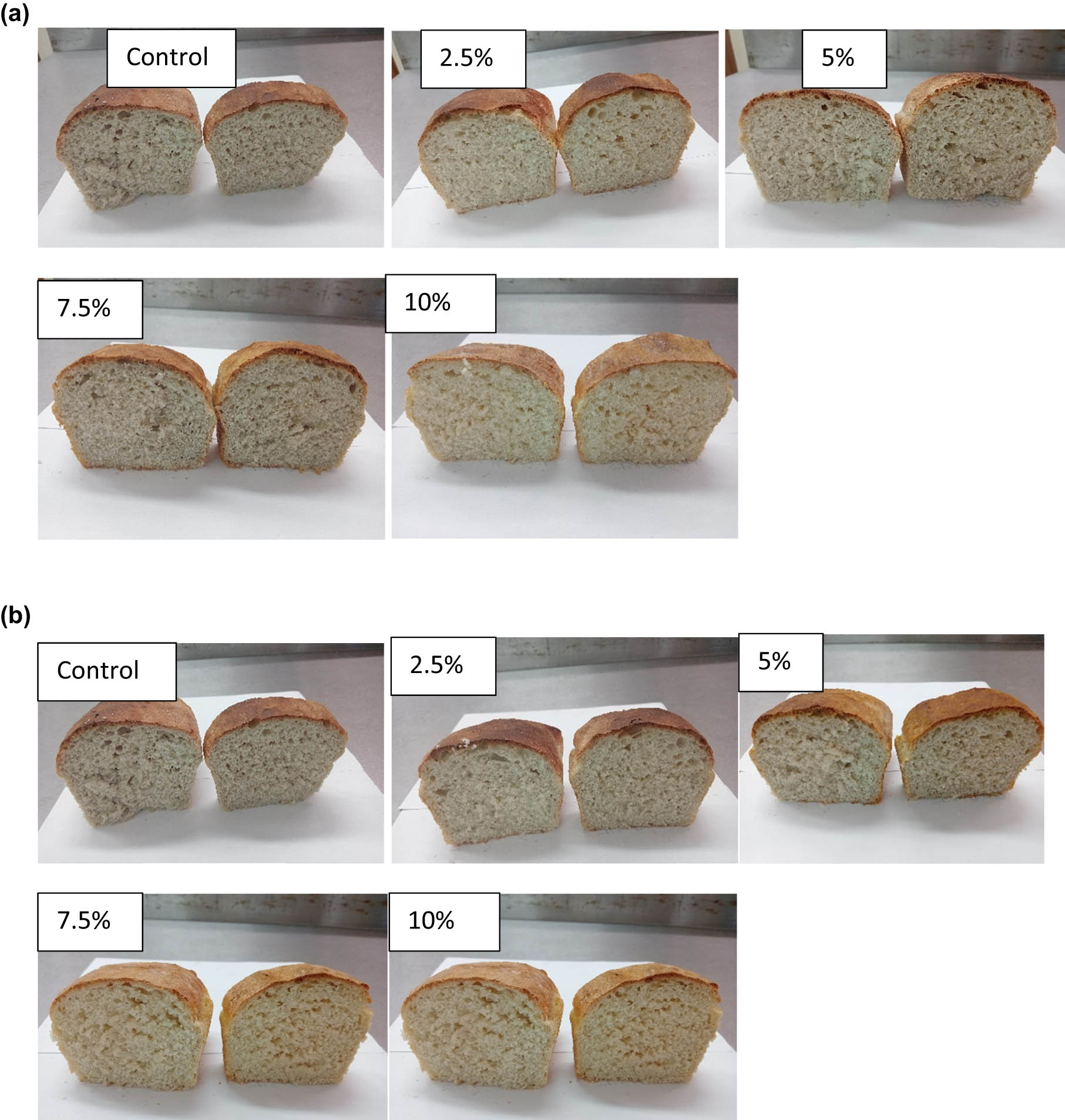

The crust and crumb colour properties of control and composite breads are depicted in Table 4, and Figure 1 shows the pictures of the formulated bread samples. The L* values of the crumb breads incorporated with UBF were significantly lower compared with the control (74.70), ranging from 61.00 to 66. 78 (LBF) and 62.62 to 65.55 (MBF), respectively. The addition of UBF significantly affected crumb lightness, as observed visually that the crumb of bread samples containing UBF was darker while the control sample had a white colour. Zuwariah and Azizh [49] reported that the crumb of bread composited with banana flour turns darker than wheat bread. Crumb lightness can be modified by the nature and particle size of the milled flour [50]. Bananas are very rich in polyphenols; nonetheless, the darkening influence might be due to the phenolase activity in the banana while milled into flour [36]. Furthermore, the decreased crust lightness of composite breads could be due to chemical reactions which occur in bread crust, such as Maillard browning caused by a reaction between wheat protein, added sugars, and caramelisation, which are influenced by the distribution of water and reaction of added sugars [51].

Colour profile of the breads incorporated with unripe non-commercial banana flour

| Breads | L* | a * | b * | Chroma | Hue | Colour difference |

|---|---|---|---|---|---|---|

| Crumb | ||||||

| Control | 74.70 ± 0.53a | 5.91a ± 0.28a | 23.12 ± 0.67a | 23.87 ± 0.71a | 75.67 ± 0.34a | 0.00 ± 0.00h |

| LBF1 | 66.78 ± 1.30b | 5.66 ± 0.67b | 20.53 ± 2.06b | 21.30 ± 2.16b | 74.61 ± 0.27a | 8.33 ± 0.03g |

| LBF2 | 64.21 ± 0.50b | 5.61 ± 0.09b | 17.58 ± 0.21d | 18.45 ± 0.22c | 72.57 ± 0.11ab | 11.87 ± 0.05e |

| LBF3 | 61.44 ± 1.34c | 5.48 ± 0.25c | 16.52 ± 0.61d | 17.41 ± 0.66c | 72.28 ± 1.70ab | 14.82 ± 0.02b |

| LBF4 | 61.00 ± 3.29c | 5.33 ± 0.29d | 15.41 ± 0.75d | 6.31 ± 0.81e | 70.32 ± 1.16c | 15.74 ± 0.02a |

| MBF1 | 65.55 ± 0.94b | 5.60 ± 0.69b | 21.25 ± 0.03b | 20.90 ± 1.80b | 74.22 ± 0.66a | 9.35 ± 0.03f |

| MBF2 | 63.05 ± 0.35bc | 5.49 ± 0.43c | 20.71 ± 0.56b | 18.38 ± 0.98c | 72.40 ± 0.58ab | 11.91 ± 0.06e |

| MBF3 | 62.20 ± 0.11c | 5.19 ± 0.69e | 19.39 ± 0.60bc | 17.20 ± 0.47c | 70.40 ± 1.10c | 13.07 ± 0.02d |

| MBF4 | 62.62 ± 0.44c | 5.10 ± 0.40ef | 16.49 ± 0.53d | 9.90 ± 0.72d | 70.25 ± 1.30c | 13.81 ± 0.05c |

| Crust | ||||||

| Control | 59.99 ± 3.88a | 18.44 ± 0.33a | 35.21 ± 0.56a | 39.75 ± 0.35a | 62.72 ± 0.08a | 0.00 ± 0.00i |

| LBF1 | 58.32 ± 1.59a | 17.55 ± 0.18a | 34.03 ± 0.24a | 38.29 ± 0.30a | 62.57 ± 0.40a | 2.23 ± 0.04h |

| LBF2 | 57.87 ± 0.34ab | 16.16 ± 0.69b | 31.56 ± 1.41cd | 34.96 ± 2.11bc | 62.03 ± 0.79ab | 4.78 ± 0.03e |

| LBF3 | 54.62 ± 1.76c | 14.99 ± 2.21c | 30.43 ± 0.69b | 34.46 ± 0.86c | 61.68 ± 2.61c | 7.97 ± 0.04c |

| LBF4 | 52.89 ± 2.10d | 13.44 ± 0.84d | 28.70 ± 0.71e | 31.69 ± 0.98c | 60.93 ± 0.90e | 10.85 ± 0.03b |

| MBF1 | 58.26 ± 0.89a | 17.49 ± 0.06a | 33.54 ± 0.39b | 38.37 ± 0.76a | 62.50 ± 0.10a | 2.59 ± 0.03g |

| MBF2 | 57.50 ± 0.28ab | 16.25 ± 0.06b | 32.61 ± 0.29c | 35.60 ± 0.69b | 61.97 ± 1.00b | 3.68 ± 0.03f |

| MBF3 | 55.59 ± 0.33c | 15.01 ± 0.08c | 30.67 ± 0.45d | 34.50 ± 0.85c | 61.18 ± 2.20d | 7.19 ± 0.04d |

| MBF4 | 53.21 ± 0.13cd | 13.51 ± 0.09d | 28.23 ± 1.02e | 32.10 ± 0.90d | 60.85 ± 2.30e | 10.91 ± 0.05a |

Mean ± standard deviation in triplicates. Values in the same column with different letters show significant differences (p < 0.05). Control = 100% wheat flour; LBF1 to LBF4 = 2.5, 5, 7.5, and 10% LBF; and MBF1 to MBF4 = 2.5, 5, 7.5, and 10% MBF.

White bread formulated with (a) Luvhele flour and (b) Mabonde flour.

Similar to crumb, the crust lightness was reduced as the percentage of UBF increased, with values varying from 58.32 to 52.89 (LBF) and 58.26 to 53.21 (MBF), respectively. No significant difference was observed between the crust of control bread and the crust of breads containing 2.5% of UBF. The decrease in the a* and b* values of composite breads characterised the colour shift from crumb to the crust. The availability of phytochemicals such as carotenoids, polyphenols, and xantophylls that are related to the colour characteristics of banana fruit might be the cause of the decrease in crust lightness of composite breads [52]. On the other hand, the majority of bread samples, except for breads incorporated with 10% UBF, were within the acceptable range of L* value for the bread crust, which is 54–62 [39]. Parafati et al. [34] also reported low L* values in bread enriched with 20% prickly pear peel flour, and values ranged from 66.6 to 47.9 for crust and 65.5 to 57.9 for crumb.

The redness (a*) and yellowness (b*) of the crumb and crust of breads decreased with the incorporation of UBF, as shown in Table 3. The low b* values of composite breads might be due to oxidation of carotenoid, which is naturally available in wheat and UBF flours. The loss of carotenoids during the production steps of bread compared to other bakery products has been reported [53]. Liu et al. [54] observed similar results wherein the inclusion of yam flour decreased the b * value of breads. Chroma (C*) and hue angle (h°) were determined to have a complete characterisation of the colour of breads. Chroma is mainly associated with colour purity. Control bread showed a significantly higher purity of yellowness in crumb and crust than breads containing UBF. It was noted that the inclusion of UBF reduced the hue value in the red quadrant. However, the obtained hue was positive, which reflected a yellow-orange hue. The decrease in hue values in the red quadrant with an increase in the ratio of UBF was notable in both crust and crumb.

The colour difference (ΔE) of the crust and crumb of composite breads increased with the increasing levels of LBF and UBF. The increase in the ΔE value of composite breads might be attributed to the composition of ingredients and generation of red pigments because of the Maillard reaction during baking [55]. The ΔE values of all composite breads were higher than three, suggesting an obvious colour difference for the human eye [56].

3.4 Sensory properties of breads incorporated with unripe non-commercial banana flours

The mean scores for sensory parameters, colour, aroma, taste, texture, and overall acceptability, were obtained from a nine-point hedonic scale and are shown in Table 5. There was no significant difference (P ≥ 0.05) between control bread and composite breads up to 7.5% UBF regarding aroma, taste, and overall acceptability. On the other hand, a significant difference was observed among breads with regard to colour and texture characteristics. Moreover, the consumer acceptance of wheat breads was affected by an increased ratio of 10% UBF in all sensory attributes. Ajala et al. [57] reported similar results wherein the addition of plantain flour at 50% resulted in bread with dark brownish colour, which was not well accepted by consumers. A high ratio of UBF resulted in a negative effect on consumer colour acceptance, as consumers showed neither like nor dislike for breads. The overall acceptability in control bread was 7.69, while in 10% UBF breads it was 7.31 (LBF) and 7.27 (MBF), respectively. This decrease in overall acceptance was due to the low score of mouth feel of breads made from a different ratio of UBF. A similar observation of consumers’ lower overall acceptance of breads was reported in breads incorporated with plantain and soybean flour [49].

Sensory evaluation of breads incorporated with unripe non-commercial banana flour

| Breads | Sensory parameters | ||||

|---|---|---|---|---|---|

| Colour | Aroma | Texture | Taste | Overall acceptability | |

| Control | 7.82 ± 1.2a | 7.39 ± 1.6a | 7.49 ± 1.3a | 7.48 ± 1.7a | 7.69 ± 1.5a |

| LBF1 | 7.61 ± 1.1b | 7.37 ± 1.4a | 7.20 ± 1.5b | 7.46 ± 1.6a | 7.65 ± 1.3a |

| LBF2 | 5.69 ± 1.8f | 7.35 ± 1.8a | 6.76 ± 1.7c | 7.43 ± 1.7a | 7.63 ± 1.5a |

| LBF3 | 5.67 ± 1.9f | 7.32 ± 1.6a | 6.56 ± 1.7d | 7.41 ± 1.7a | 7.60 ± 1.6a |

| LBF4 | 5.03 ± 2.1g | 7.11 ± 1.8b | 6.27 ± 1.7e | 7.23 ± 1.5b | 7.31 ± 1.7b |

| MBF1 | 6.60 ± 1.6c | 7.38 ± 1.6a | 7.23 ± 1.7b | 7.47 ± 1.9a | 7.66 ± 1.5a |

| MBF2 | 6.48 ± 1.9d | 7.35 ± 1.7a | 6.77 ± 1.9c | 7.44 ± 1.9a | 7.63 ± 1.5a |

| MBF3 | 6.17 ± 2.0e | 7.32 ± 1.8a | 6.50 ± 1.9d | 7.42 ± 2.0a | 7.61 ± 1.7a |

| MBF4 | 6.11 ± 2.2e | 7.15 ± 2.0b | 6.28 ± 2.0e | 7.20 ± 2.2b | 7.27 ± 1.9b |

Values with the same superscript letters within a column are not significantly different at p < 0.05. Control = 100% wheat flour; LBF1 to LBF4 = 2.5, 5, 7.5, and 10% LBF; and MBF1 to MBF4 = 2.5, 5, 7.5, and 10% MBF.

Texture attributes contribute strongly to consumer freshness perceptions. Control samples and breads with 2.5% UBF were rated best in terms of texture, and this might be due to gluten in wheat flour, which contributed to the development of the elastic dough. It is well known that wheat flour’s unique baking properties enable it to produce bread with a desirable texture [50]. The texture of bread is associated with the water-holding ability of functional components like starch, protein, and other hydrocolloids. An increase in the UBF ratio increased the hardness of breads (Table 3), which could be affected by the crumb cell’s size or structure and is also greatly influenced by the amount and characteristics of dough’s gluten protein [51]. The results suggest that overall, UBF of Luvhele and Mabonde banana cultivars at a level of 2.5 to 7.5% (w/w) might be incorporated in bread production without affecting sensory parameters such as aroma, taste, and overall acceptability.

4 Conclusion

The incorporation of UBF of non-commercial banana cultivars into wheat bread resulted in substantial modifications across various physical attributes. Notably, LBF- and MBF-incorporated bread samples showed higher weight and density at all substitution levels, while the volume and specific volume decreased. In terms of the texture, the composite breads showed an increase in the hardness with values of 1,011 and 1,015 g at a 10% substitution level for LBF and MBF, respectively. On the other hand, both types of enriched bread samples exhibited lower chewiness, cohesiveness, and springiness. However, no change was observed in cohesiveness and springiness at a 2.5% substitution level compared to the control. The inclusion of LBF and MBF affected the lightness of bread crumbs and crust, and the colour of breads decreased due to an increase in the dark brown colour. Sensory evaluation showed that up to 7.5% level of LBF and MBF can be incorporated into bread production without interfering with bread’s sensory attributes such as taste and overall acceptability. Therefore, the results demonstrated that green Luvhele and Mabonde banana cultivars could be utilised in bread and confectionery products at lower substitution levels. Further studies of the effect of these non-commercial banana cultivars on the nutritional, antioxidant, and starch digestibility of wheat bread should be explored.

-

Funding information: Authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and consented to its submission to the journal, reviewed all the results and approved the final version of the manuscript. Conceptualization, MEM; methodology, HM and NM; data analysis, MEM, HM, NM, and SER; writing – original draft preparation, MEM, HM, and NM; writing, review, and editing, MEM and SER.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Salazar D, Arancibia M, Lalaleo D, Rodríguez-Maecker R, Lopez-Caballero ME, Montero MP. Physico-chemical properties and filmogenic aptitude for edible packaging of Ecuadorian discard green banana flours (Musa acuminanta AAA). Food Hydrocoll. 2022;122:107048. 10.1016/j. foodhyd.2021.107048.Suche in Google Scholar

[2] Anyasi TA, Jideani AIO, Mchau GRA. Effect of organic acid pretreatment on some physical, functional and antioxidant properties of flour obtained from three unripe banana cultivars. Food Chem. 2015;172:515–22. 10.1016/j.foodchem.2014.09.120.Suche in Google Scholar

[3] Ahmed J, Thomas L, Khashawi R. Influence of hot-air drying and freeze drying on functional, rheological, structural and dielectric properties of green banana flour and dispersions. Food Hydrocoll. 2020;99:105331. 10.1016/j.foodhyd.2019.105331.Suche in Google Scholar

[4] Campuzano A, Rosell CM, Cornejo F. Physicochemical and nutritional characteristics of banana flour during ripening. Food Chem. 2018;256:11–7. 10.1016/j.foodchem.2018.02.113.Suche in Google Scholar

[5] Guadalupe-Moyano V, Palacios-Ponce AS, Cristina M, Rosell CM, Cornejo F. Impact of drying methods on banana flour in the gluten-free bread quality. LWT - Food Sci Technol. 2022;168:113904. 10.1016/j.lwt.2022.113904.Suche in Google Scholar

[6] Singh B, Singh JP, Kaur A, Singh N. Bioactive compounds in banana and their associated health benefits– A review. Food Chem. 2016;206:1–11. 10.1016/j.foodchem.2016.03.033.Suche in Google Scholar

[7] Kumar KS, Bhowmik D, Duraivel S, Umadevi M. Traditional and medicinal uses of banana. J Pharmacogn Phytochem. 2012;1(3):51–63.Suche in Google Scholar

[8] Amini-Khoozani AA, Kebede B, Birch J, El-Din Ahmed Bekhit A. The effect of bread fortification with whole green banana flour on its physicochemical, nutritional and in vitro digestibility. Foods. 2020;9(2):152. 10.3390/foods9020152.Suche in Google Scholar

[9] Loong CYL, Wong CYH. Chinese steamed bread fortified with green banana flour. Food Res. 2018;2(4):320–30.Suche in Google Scholar

[10] Mashau ME, Rambau FR, Kgatla TE. Influence of unripe banana flour incorporation on the physical, antioxidant properties and consumer acceptability of biscuits. J Microbiol Biotech Food Sci. 2022;12:e2632. 10.55251/jmbfs.2632.Suche in Google Scholar

[11] Mabogo FA, Mashau ME, Ramashia SE. Effect of partial replacement of wheat flour with unripe banana flour on the functional, thermal, and physicochemical characteristics of flour and biscuits. Int Food Res J. 2022;28(1):138–47.Suche in Google Scholar

[12] Cheok CY, Sulaiman R, Manan NA, Zakora AJ, Chin NL, Hussain N. Pasting and physical properties of green banana flours and pastas. Int Food Res J. 2018;25(6):2585–92.Suche in Google Scholar

[13] Bagdi A, Tóth B, Lorincz R, Szendi SZ, Gere A, Kókai Z, et al. Effect of aleurone-rich flour on composition, baking, textural, and sensory properties of bread. LWT – Food Sci Technol. 2016;65:762–9. 10.1016/j.lwt.2015.08.073.Suche in Google Scholar

[14] Mau JL, Lee CC, Yang CW, Chen RW, Zhang QF, Lin SD. Physicochemical, antioxidant and sensory characteristics of bread partially substituted with aerial parts of sweet potato. J Food Sci Technol. 2020;117:108602. 10.1016/j.lwt.2019.108602.Suche in Google Scholar

[15] Ronie ME, Mamat H, Abdul Aziz AH, Zainol MK. Proximate compositions, texture, and sensory profiles of gluten-free Bario rice bread supplemented with potato starch. Foods. 2023;12:1172. 10.3390/foods12061172.Suche in Google Scholar

[16] Odedeji JO, Ojo A, Arogundade LA, Oyeleke GO. Proximate composition and consumers acceptability of bread produced from blends of soy-cheese and wheat flour. IOSR J Environ Sci Toxicol. Food Technol. 2014;8(2):41–4. 10.10.9790/2402-08224144.Suche in Google Scholar

[17] Bolarinwa IF, Olaniyan SA, Adebayo LO, Ademola AA. Malted sorghum soy composite four: Preparation, chemical and physicochemi cal properties. J Food Process Technol. 2015;6(6):1–7. 10.4172/2157-7110.1000467.Suche in Google Scholar

[18] Kayode RMO, Chia CN, Kayode BI, Olowoseye AP, Joshua VA. Quality evaluation of chin chin produced from aerial yam (Dioscorea bulbifera) and wheat four blends. Food Prod Process Nutr. 2023;5:45. 10.1186/s43014-023-00159-8.Suche in Google Scholar

[19] Fu L, Xu BT, Xu XR, Gan RY, Zhang Y, Xia EQ, et al. Antioxidant capacities and total phenolic contents of 62 fruits. Food Chem. 2011;129(2):345–50. 10.1016/j.foodchem.2011.04.079.Suche in Google Scholar

[20] Sarawong C, Schoenlechner R, Sekiguchi K, Berghofer E, Ng PKW. Effect of extrusion cooking on the physicochemical properties, resistant starch, phenolic content and antioxidant capacities of green banana flour. Food Chem. 2014;143:33–9. 10.1016/j.foodchem.2013.07.081.Suche in Google Scholar

[21] Bennett RN, Shiga TM, Hassimotto NM, Rosa EA, Lajolo FM, Cordenunsi BR. Phenolics and antioxidant properties of fruit pulp and cell wall fractions of postharvest banana (Musa acuminata Juss.) cultivars. J Agric Food Chem. 2010;58(13):7991–8003. 10.1021/jf1008692.Suche in Google Scholar

[22] Matidze M, Kgatla TE, Mashau ME. Leavening capacity, physicochemical and textural properties of wheat dough enriched with non-commercial unripe banana flours. AIMS Agric Food. 2023;8(4):978–94. 10.3934/agrfood.2023052.Suche in Google Scholar

[23] AACCI. AACCI methods 10-10.03 (optimized straight-dough bread-making method). In: Paul ST. In Approved Methods of American Association of Cereal Chemists. 10th edn. MN, USA: AACC International; 2000.Suche in Google Scholar

[24] Ho LH, Aziz NAA, Azahari B. Physico-chemical characteristics and sensory evaluation of wheat bread partially substituted with banana (Musa acuminata X balbisiana cv. Awak) pseudo-stem flour. Food Chem. 2013;139(1–4):532–9. 10.1016/j.foodchem.2013.01.039.Suche in Google Scholar

[25] Amini-Khoozani AA, Kebede B, Birch J, El-Din Ahmed Bekhit A. Rheological, textural and structural changes in dough and bread partially substituted with whole green banana flour. LWT – Food Sci Technol. 2020;126:109252. 10.1016/j.lwt.2020.109252.Suche in Google Scholar

[26] Mudau M, Ramashia SE, Mashau ME, Silungwe H. Physicochemical characteristics of bread partially substituted with finger millet flour. Braz J Food Technol. 2021;24:e2020123. 10.1590/1981-6723.12320.Suche in Google Scholar

[27] Wronkowska M, Haros M, Soral-Śmietana M. Effect of starch substitution by buckwheat wlour on gluten-free bread quality. Food Bioprocess Technol. 2013;6:1820–7. 10.1007/s11947-012-0839-0.Suche in Google Scholar

[28] Ali RFM, El-Anany AM, Mousaa HM, Hamada EM. Nutritional and sensory characteristics of bread enriched with roasted prickly pear (Opuntia ficus-indica) seed flour. Food Funct. 2020;11:2117–25. 10.1039/c9fo02532d.Suche in Google Scholar

[29] Elleuch M, Bedigian D, Roiseux O, Besbes S, Blecker C, Attia H. Dietary fibre and fibre-rich by-products of food processing: Characterisation, technological functionality and commercial applications: A review. Food Chem. 2011;124:411–21. 10.1016/j.foodchem.2010.06.077.Suche in Google Scholar

[30] Nwanekezi EC. Composite flours for baked products and possible challenges– A review. Nigerian Food J. 2013;31(2):8–17. 10.1016/S0189-7241(15)30071-0.Suche in Google Scholar

[31] Li QM, LiY, Zou JH, Guo SY, Wang F, Yu P, et al. Influence of adding Chinese yam (Dioscorea opposita Thunb.) flour on dough rheology, gluten structure, baking performance, and antioxidant properties of bread. Foods. 2020;9(3):256–315. 10.3390/foods9030256.Suche in Google Scholar

[32] Almoraie NM. The effect of walnut flour on the physical and sensory characteristics of wheat bread. Int J Food Sci. 2019;5676205. 10.1155/2019/5676205.Suche in Google Scholar

[33] Julianti E, Rusmarilin H, Yusraini E. Functional and rheological properties of composite flour from sweet potato, maize, soybean and xanthan gum. J Saudi Soc Agric Sci. 2017;16(2):171–7. 10.1016/j.jssas.2015.05.005.Suche in Google Scholar

[34] Parafati L, Restuccia C, Palmeri R, Fallico B, Arena E. Characterization of prickly pear peel flour as a bioactive and functional ingredient in bread preparation. Foods. 2020;9(9):1189. 10.3390/foods9091189.Suche in Google Scholar

[35] Gómez M, Oliete B. Effect of fibre in enriched breads. Bread and its fortification: nutrition and health benefits. CRC Press; 2015. p. 273–305.Suche in Google Scholar

[36] Shittu TA, Raji AO, Sanni LO. Bread from composite cassava-wheat flour: Effect of baking time and temperature on some physical properties of bread loaf. Food Res Int. 2007;40:280–90. 10.1016/j.foodres.2006.10.012.Suche in Google Scholar

[37] Blandino M, Sovrani V, Marinaccio F, Reyneri A, Rolle L, Giacosa S, et al. Nutritional and technological quality of bread enriched with an intermediated pearled wheat fraction. Food Chem. 2013;141(3):2549–57. 10.1016/j.foodchem.2013.04.122.Suche in Google Scholar

[38] Falcomer AL, Riquette RFR, de Lima BR, Ginani VC, Zandonadi RP. Health benefits of green banana consumption: A systematic review. Nutrients. 2019;11(6):1222. 10.3390/nu11061222.Suche in Google Scholar

[39] Chisenga SM, Workneh TS, Bultosa G, Alimi BA, Siwela M. Dough rheology and loaf quality of wheat-cassava bread using different cassava varieties and wheat substitution levels. Food Biosci. 2020;34:100529. 10.1016/j.fbio.2020.100529.Suche in Google Scholar

[40] Eriksson E, Koch K, Tortoe C, Akonor PT, Oduro-Yeboah C. Evaluation of the physical and sensory characteristics of bread produced from three varieties of cassava and wheat composite flours. Food Public Health. 2014;4(5):214–22. 10.5923/j.fph.20140405.02.Suche in Google Scholar

[41] Gutierrez-Castillo C, Alcázar-Alay S, Vidaurre-Ruiz J, Correa MJ, Cabezas DM, Repo-Carrasco-Valencia R, et al. Effect of partial substitution of wheat flour by quinoa (Chenopodium quinoa Willd.) and tarwi (Lupinus mutabilis Sweet) flours on dough and bread quality. Food Sci Technol Int. 2023;6:619–30. 10.1177/10820132221106332.Suche in Google Scholar

[42] Ding S, Peng B, Li Y, Yang J. Evaluation of specific volume, texture, thermal features, water mobility, and inhibitory effect of staling in wheat bread affected by maltitol. Food Chem. 2019;283:123–30. 10.1016/j.foodchem.2019.01.045.Suche in Google Scholar

[43] Salinas MV, Zuleta A, Ronayne P, Puppo MC. Wheat bread enriched with organic calcium salts and inulin. A bread quality study. J Food Sci Technol. 2016;53(1):491–500. 10.1007/s13197-015-2008-8.Suche in Google Scholar

[44] Thakaeng P, Boonloom T, Rawdkuen S. Physicochemical properties of bread partially substituted with unripe green banana (Cavendish spp.) flour. Molecules. 2021;26:2070. 10.3390/molecules26072070.Suche in Google Scholar

[45] Feili R, Zzaman W, Abdullah WNW, Yang TA. Physical and sensory analysis of high fiber bread incorporated with jackfruit rind flour. Food Sci Technol. 2013;1(2):30–6. 10.13189/fst.2013.010203.Suche in Google Scholar

[46] Zhang T, Li Z, Wang Y, Xue Y, Xue C. Effects of konjac glucomannan on heat-induced changes of physicochemical and structural properties of surimi gels. Food Res Int. 2016;83:152–61. 10.1016/j.foodres.2016.03.007.Suche in Google Scholar

[47] Renzetti S, Rosell CM. Role of enzymes in improving the functionality of proteins in non-wheat dough systems. J Cereal Sci. 2016;67:35–45. 10.1016/j.jcs.2015.09.008.Suche in Google Scholar

[48] Ho LH, Abdul Aziz NA, Bhat R, Azahari B. Storage studies of bread prepared by incorporation of the banana pseudo-stem flour and the composite breads containing hydrocolloids. CyTA – J Food. 2014;12:141–9. 10.1080/19476337.2013.806597.Suche in Google Scholar

[49] Zuwariah I, Aziah AN. Physicochemical properties of wheat breads substituted with banana flour and modified banana flour. J Trop Agric Food Sci. 2009;37(1):33–42.Suche in Google Scholar

[50] Coţovanu I, Mironeasa S. Efects of molecular characteristics and microstructure of amaranth particle sizes on dough rheology and wheat bread characteristics. Sci Rep. 2022;12:7883. 10.1038/s41598-022-12017-7.Suche in Google Scholar

[51] Noorfarahzilah M, Lee JS, Sharifudin MS, Mohd Fadzelly AB, Hasmadi M. Applications of composite flour in development of food products. Int Food Res J. 2014;21(6):2061–74.Suche in Google Scholar

[52] Kurhade A, Patil S, Sonawane SK, Waghmare JS, Arya SS. Effect of banana peel powder on bioactive constituents and microstructural quality of chapatti: Unleavened Indian flat bread. J Food Meas Charact. 2016;10:32–41. 10.1007/s11694-015-9273-0.Suche in Google Scholar

[53] Hidalgo A, Brandolini A, Pompei C. Carotenoids evolution during pasta, bread and water biscuit preparation from wheat flours. Food Chem. 2010;121(3):746–75.Suche in Google Scholar

[54] Liu X, Lu K, Yu J, Copeland L, Wang S. Effect of purple yam flour substitution for wheat flour on in vitro starch digestibility of wheat bread. Food Chem. 2019;284:118–24. 10.1016/j.foodchem.2019.01.025.Suche in Google Scholar

[55] Pereira D, Correia PM, Guin´e RP. Analysis of the physical-chemical and sensorial properties of Maria type cookies. Acta Chim Slov. 2013;6(2):269–80. 10.2478/acs-2013-0040.Suche in Google Scholar

[56] Silva FDO, Miranda TG, Justo T, Frasao BDS, Conte-Junior CA, Monteiro M, et al. Soybean meal and fermented soybean meal as functional ingredients for the production of low-carb, high-protein, high-fiber and high isoflavones biscuits. LWT – Food Sci Technol. 2018;90:224–31. 10.1016/j.lwt.2017.12.035.Suche in Google Scholar

[57] Ajala AS, Ajagbe OA, Abioye AO, Bolarinwa IF. Investigating the effect of drying factors on the quality assessment of plantain flour and wheat-plantain bread. Int Food Res J. 2018;25(4):1566–73.Suche in Google Scholar

© 2024 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Regular Articles

- Supplementation of P-solubilizing purple nonsulfur bacteria, Rhodopseudomonas palustris improved soil fertility, P nutrient, growth, and yield of Cucumis melo L.

- Yield gap variation in rice cultivation in Indonesia

- Effects of co-inoculation of indole-3-acetic acid- and ammonia-producing bacteria on plant growth and nutrition, soil elements, and the relationships of soil microbiomes with soil physicochemical parameters

- Impact of mulching and planting time on spring-wheat (Triticum aestivum) growth: A combined field experiment and empirical modeling approach

- Morphological diversity, correlation studies, and multiple-traits selection for yield and yield components of local cowpea varieties

- Participatory on-farm evaluation of new orange-fleshed sweetpotato varieties in Southern Ethiopia

- Yield performance and stability analysis of three cultivars of Gayo Arabica coffee across six different environments

- Biology of Spodoptera frugiperda (Lepidoptera: Noctuidae) on different types of plants feeds: Potency as a pest on various agricultural plants

- Antidiabetic activity of methanolic extract of Hibiscus sabdariffa Linn. fruit in alloxan-induced Swiss albino diabetic mice

- Bioinformatics investigation of the effect of volatile and non-volatile compounds of rhizobacteria in inhibiting late embryogenesis abundant protein that induces drought tolerance

- Nicotinamide as a biostimulant improves soybean growth and yield

- Farmer’s willingness to accept the sustainable zoning-based organic farming development plan: A lesson from Sleman District, Indonesia

- Uncovering hidden determinants of millennial farmers’ intentions in running conservation agriculture: An application of the Norm Activation Model

- Mediating role of leadership and group capital between human capital component and sustainability of horticultural agribusiness institutions in Indonesia

- Biochar technology to increase cassava crop productivity: A study of sustainable agriculture on degraded land

- Effect of struvite on the growth of green beans on Mars and Moon regolith simulants

- UrbanAgriKG: A knowledge graph on urban agriculture and its embeddings

- Provision of loans and credit by cocoa buyers under non-price competition: Cocoa beans market in Ghana

- Effectiveness of micro-dosing of lime on selected chemical properties of soil in Banja District, North West, Ethiopia

- Effect of weather, nitrogen fertilizer, and biostimulators on the root size and yield components of Hordeum vulgare

- Effects of selected biostimulants on qualitative and quantitative parameters of nine cultivars of the genus Capsicum spp.

- Growth, yield, and secondary metabolite responses of three shallot cultivars at different watering intervals

- Design of drainage channel for effective use of land on fully mechanized sugarcane plantations: A case study at Bone Sugarcane Plantation

- Technical feasibility and economic benefit of combined shallot seedlings techniques in Indonesia

- Control of Meloidogyne javanica in banana by endophytic bacteria

- Comparison of important quality components of red-flesh kiwifruit (Actinidia chinensis) in different locations

- Efficiency of rice farming in flood-prone areas of East Java, Indonesia

- Comparative analysis of alpine agritourism in Trentino, Tyrol, and South Tyrol: Regional variations and prospects

- Detection of Fusarium spp. infection in potato (Solanum tuberosum L.) during postharvest storage through visible–near-infrared and shortwave–near-infrared reflectance spectroscopy

- Forage yield, seed, and forage qualitative traits evaluation by determining the optimal forage harvesting stage in dual-purpose cultivation in safflower varieties (Carthamus tinctorius L.)

- The influence of tourism on the development of urban space: Comparison in Hanoi, Danang, and Ho Chi Minh City

- Optimum intra-row spacing and clove size for the economical production of garlic (Allium sativum L.) in Northwestern Highlands of Ethiopia

- The role of organic rice farm income on farmer household welfare: Evidence from Yogyakarta, Indonesia

- Exploring innovative food in a developing country: Edible insects as a sustainable option

- Genotype by environment interaction and performance stability of common bean (Phaseolus vulgaris L.) cultivars grown in Dawuro zone, Southwestern Ethiopia

- Factors influencing green, environmentally-friendly consumer behaviour

- Factors affecting coffee farmers’ access to financial institutions: The case of Bandung Regency, Indonesia

- Morphological and yield trait-based evaluation and selection of chili (Capsicum annuum L.) genotypes suitable for both summer and winter seasons

- Sustainability analysis and decision-making strategy for swamp buffalo (Bubalus bubalis carabauesis) conservation in Jambi Province, Indonesia

- Understanding factors affecting rice purchasing decisions in Indonesia: Does rice brand matter?

- An implementation of an extended theory of planned behavior to investigate consumer behavior on hygiene sanitation-certified livestock food products

- Information technology adoption in Indonesia’s small-scale dairy farms

- Draft genome of a biological control agent against Bipolaris sorokiniana, the causal phytopathogen of spot blotch in wheat (Triticum turgidum L. subsp. durum): Bacillus inaquosorum TSO22

- Assessment of the recurrent mutagenesis efficacy of sesame crosses followed by isolation and evaluation of promising genetic resources for use in future breeding programs

- Fostering cocoa industry resilience: A collaborative approach to managing farm gate price fluctuations in West Sulawesi, Indonesia

- Field investigation of component failures for selected farm machinery used in small rice farming operations

- Near-infrared technology in agriculture: Rapid, simultaneous, and non-destructive determination of inner quality parameters on intact coffee beans

- The synergistic application of sucrose and various LED light exposures to enhance the in vitro growth of Stevia rebaudiana (Bertoni)

- Weather index-based agricultural insurance for flower farmers: Willingness to pay, sales, and profitability perspectives

- Meta-analysis of dietary Bacillus spp. on serum biochemical and antioxidant status and egg quality of laying hens

- Biochemical characterization of trypsin from Indonesian skipjack tuna (Katsuwonus pelamis) viscera

- Determination of C-factor for conventional cultivation and soil conservation technique used in hop gardens

- Empowering farmers: Unveiling the economic impacts of contract farming on red chilli farmers’ income in Magelang District, Indonesia

- Evaluating salt tolerance in fodder crops: A field experiment in the dry land

- Labor productivity of lowland rice (Oryza sativa L.) farmers in Central Java Province, Indonesia

- Cropping systems and production assessment in southern Myanmar: Informing strategic interventions

- The effect of biostimulants and red mud on the growth and yield of shallots in post-unlicensed gold mining soil

- Effects of dietary Adansonia digitata L. (baobab) seed meal on growth performance and carcass characteristics of broiler chickens: A systematic review and meta-analysis

- Analysis and structural characterization of the vid-pisco market

- Pseudomonas fluorescens SP007s enhances defense responses against the soybean bacterial pustule caused by Xanthomonas axonopodis pv. glycines

- A brief investigation on the prospective of co-composted biochar as a fertilizer for Zucchini plants cultivated in arid sandy soil

- Supply chain efficiency of red chilies in the production center of Sleman Indonesia based on performance measurement system

- Investment development path for developed economies: Is agriculture different?

- Power relations among actors in laying hen business in Indonesia: A MACTOR analysis

- High-throughput digital imaging and detection of morpho-physiological traits in tomato plants under drought

- Converting compression ignition engine to dual-fuel (diesel + CNG) engine and experimentally investigating its performance and emissions

- Structuration, risk management, and institutional dynamics in resolving palm oil conflicts

- Spacing strategies for enhancing drought resilience and yield in maize agriculture

- Composition and quality of winter annual agrestal and ruderal herbages of two different land-use types

- Investigating Spodoptera spp. diversity, percentage of attack, and control strategies in the West Java, Indonesia, corn cultivation

- Yield stability of biofertilizer treatments to soybean in the rainy season based on the GGE biplot

- Evaluating agricultural yield and economic implications of varied irrigation depths on maize yield in semi-arid environments, at Birfarm, Upper Blue Nile, Ethiopia

- Chemometrics for mapping the spatial nitrate distribution on the leaf lamina of fenugreek grown under varying nitrogenous fertilizer doses

- Pomegranate peel ethanolic extract: A promising natural antioxidant, antimicrobial agent, and novel approach to mitigate rancidity in used edible oils

- Transformative learning and engagement with organic farming: Lessons learned from Indonesia

- Tourism in rural areas as a broader concept: Some insights from the Portuguese reality

- Assessment enhancing drought tolerance in henna (Lawsonia inermis L.) ecotypes through sodium nitroprusside foliar application

- Edible insects: A survey about perceptions regarding possible beneficial health effects and safety concerns among adult citizens from Portugal and Romania

- Phenological stages analysis in peach trees using electronic nose

- Harvest date and salicylic acid impact on peanut (Arachis hypogaea L.) properties under different humidity conditions

- Hibiscus sabdariffa L. petal biomass: A green source of nanoparticles of multifarious potential

- Use of different vegetation indices for the evaluation of the kinetics of the cherry tomato (Solanum lycopersicum var. cerasiforme) growth based on multispectral images by UAV

- First evidence of microplastic pollution in mangrove sediments and its ingestion by coral reef fish: Case study in Biawak Island, Indonesia

- Physical and textural properties and sensory acceptability of wheat bread partially incorporated with unripe non-commercial banana cultivars

- Cereibacter sphaeroides ST16 and ST26 were used to solubilize insoluble P forms to improve P uptake, growth, and yield of rice in acidic and extreme saline soil

- Avocado peel by-product in cattle diets and supplementation with oregano oil and effects on production, carcass, and meat quality

- Optimizing inorganic blended fertilizer application for the maximum grain yield and profitability of bread wheat and food barley in Dawuro Zone, Southwest Ethiopia

- The acceptance of social media as a channel of communication and livestock information for sheep farmers

- Adaptation of rice farmers to aging in Thailand

- Combined use of improved maize hybrids and nitrogen application increases grain yield of maize, under natural Striga hermonthica infestation

- From aquatic to terrestrial: An examination of plant diversity and ecological shifts

- Statistical modelling of a tractor tractive performance during ploughing operation on a tropical Alfisol

- Participation in artisanal diamond mining and food security: A case study of Kasai Oriental in DR Congo

- Assessment and multi-scenario simulation of ecosystem service values in Southwest China’s mountainous and hilly region

- Analysis of agricultural emissions and economic growth in Europe in search of ecological balance

- Bacillus thuringiensis strains with high insecticidal activity against insect larvae of the orders Coleoptera and Lepidoptera

- Technical efficiency of sugarcane farming in East Java, Indonesia: A bootstrap data envelopment analysis

- Comparison between mycobiota diversity and fungi and mycotoxin contamination of maize and wheat

- Evaluation of cultivation technology package and corn variety based on agronomy characters and leaf green indices

- Exploring the association between the consumption of beverages, fast foods, sweets, fats, and oils and the risk of gastric and pancreatic cancers: Findings from case–control study

- Phytochemical composition and insecticidal activity of Acokanthera oblongifolia (Hochst.) Benth & Hook.f. ex B.D.Jacks. extract on life span and biological aspects of Spodoptera littoralis (Biosd.)

- Land use management solutions in response to climate change: Case study in the central coastal areas of Vietnam

- Evaluation of coffee pulp as a feed ingredient for ruminants: A meta-analysis

- Interannual variations of normalized difference vegetation index and potential evapotranspiration and their relationship in the Baghdad area

- Harnessing synthetic microbial communities with nitrogen-fixing activity to promote rice growth

- Agronomic and economic benefits of rice–sweetpotato rotation in lowland rice cropping systems in Uganda

- Response of potato tuber as an effect of the N-fertilizer and paclobutrazol application in medium altitude

- Bridging the gap: The role of geographic proximity in enhancing seed sustainability in Bandung District

- Evaluation of Abrams curve in agricultural sector using the NARDL approach

- Challenges and opportunities for young farmers in the implementation of the Rural Development Program 2014–2020 of the Republic of Croatia

- Yield stability of ten common bean (Phaseolus vulgaris L.) genotypes at different sowing dates in Lubumbashi, South-East of DR Congo

- Effects of encapsulation and combining probiotics with different nitrate forms on methane emission and in vitro rumen fermentation characteristics

- Phytochemical analysis of Bienertia sinuspersici extract and its antioxidant and antimicrobial activities

- Evaluation of relative drought tolerance of grapevines by leaf fluorescence parameters

- Yield assessment of new streak-resistant topcross maize hybrids in Benin

- Improvement of cocoa powder properties through ultrasonic- and microwave-assisted alkalization

- Potential of ecoenzymes made from nutmeg (Myristica fragrans) leaf and pulp waste as bioinsecticides for Periplaneta americana

- Analysis of farm performance to realize the sustainability of organic cabbage vegetable farming in Getasan Semarang, Indonesia

- Revealing the influences of organic amendment-derived dissolved organic matter on growth and nutrient accumulation in lettuce seedlings (Lactuca sativa L.)

- Identification of viruses infecting sweetpotato (Ipomoea batatas Lam.) in Benin

- Assessing the soil physical and chemical properties of long-term pomelo orchard based on tree growth

- Investigating access and use of digital tools for agriculture among rural farmers: A case study of Nkomazi Municipality, South Africa

- Does sex influence the impact of dietary vitD3 and UVB light on performance parameters and welfare indicators of broilers?

- Design of intelligent sprayer control for an autonomous farming drone using a multiclass support vector machine

- Deciphering salt-responsive NB-ARC genes in rice transcriptomic data: A bioinformatics approach with gene expression validation

- Review Articles

- Impact of nematode infestation in livestock production and the role of natural feed additives – A review

- Role of dietary fats in reproductive, health, and nutritional benefits in farm animals: A review

- Climate change and adaptive strategies on viticulture (Vitis spp.)

- The false tiger of almond, Monosteira unicostata (Hemiptera: Tingidae): Biology, ecology, and control methods

- A systematic review on potential analogy of phytobiomass and soil carbon evaluation methods: Ethiopia insights

- A review of storage temperature and relative humidity effects on shelf life and quality of mango (Mangifera indica L.) fruit and implications for nutrition insecurity in Ethiopia

- Green extraction of nutmeg (Myristica fragrans) phytochemicals: Prospective strategies and roadblocks

- Potential influence of nitrogen fertilizer rates on yield and yield components of carrot (Dacus carota L.) in Ethiopia: Systematic review

- Corn silk: A promising source of antimicrobial compounds for health and wellness

- State and contours of research on roselle (Hibiscus sabdariffa L.) in Africa

- The potential of phosphorus-solubilizing purple nonsulfur bacteria in agriculture: Present and future perspectives

- Minor millets: Processing techniques and their nutritional and health benefits

- Meta-analysis of reproductive performance of improved dairy cattle under Ethiopian environmental conditions

- Review on enhancing the efficiency of fertilizer utilization: Strategies for optimal nutrient management

- The nutritional, phytochemical composition, and utilisation of different parts of maize: A comparative analysis

- Motivations for farmers’ participation in agri-environmental scheme in the EU, literature review

- Evolution of climate-smart agriculture research: A science mapping exploration and network analysis

- Short Communications

- Music enrichment improves the behavior and leukocyte profile of dairy cattle

- Effect of pruning height and organic fertilization on the morphological and productive characteristics of Moringa oleifera Lam. in the Peruvian dry tropics

- Corrigendum

- Corrigendum to “Bioinformatics investigation of the effect of volatile and non-volatile compounds of rhizobacteria in inhibiting late embryogenesis abundant protein that induces drought tolerance”

- Corrigendum to “Composition and quality of winter annual agrestal and ruderal herbages of two different land-use types”

- Special issue: Smart Agriculture System for Sustainable Development: Methods and Practices

- Construction of a sustainable model to predict the moisture content of porang powder (Amorphophallus oncophyllus) based on pointed-scan visible near-infrared spectroscopy

- FruitVision: A deep learning based automatic fruit grading system

- Energy harvesting and ANFIS modeling of a PVDF/GO-ZNO piezoelectric nanogenerator on a UAV

- Effects of stress hormones on digestibility and performance in cattle: A review

- Special Issue of The 4th International Conference on Food Science and Engineering (ICFSE) 2022 - Part II

- Assessment of omega-3 and omega-6 fatty acid profiles and ratio of omega-6/omega-3 of white eggs produced by laying hens fed diets enriched with omega-3 rich vegetable oil

- Special Issue on FCEM - International Web Conference on Food Choice & Eating Motivation - Part II

- Special Issue on FCEM – International Web Conference on Food Choice & Eating Motivation: Message from the editor

- Fruit and vegetable consumption: Study involving Portuguese and French consumers

- Knowledge about consumption of milk: Study involving consumers from two European Countries – France and Portugal

Artikel in diesem Heft

- Regular Articles

- Supplementation of P-solubilizing purple nonsulfur bacteria, Rhodopseudomonas palustris improved soil fertility, P nutrient, growth, and yield of Cucumis melo L.

- Yield gap variation in rice cultivation in Indonesia

- Effects of co-inoculation of indole-3-acetic acid- and ammonia-producing bacteria on plant growth and nutrition, soil elements, and the relationships of soil microbiomes with soil physicochemical parameters

- Impact of mulching and planting time on spring-wheat (Triticum aestivum) growth: A combined field experiment and empirical modeling approach

- Morphological diversity, correlation studies, and multiple-traits selection for yield and yield components of local cowpea varieties

- Participatory on-farm evaluation of new orange-fleshed sweetpotato varieties in Southern Ethiopia

- Yield performance and stability analysis of three cultivars of Gayo Arabica coffee across six different environments

- Biology of Spodoptera frugiperda (Lepidoptera: Noctuidae) on different types of plants feeds: Potency as a pest on various agricultural plants

- Antidiabetic activity of methanolic extract of Hibiscus sabdariffa Linn. fruit in alloxan-induced Swiss albino diabetic mice

- Bioinformatics investigation of the effect of volatile and non-volatile compounds of rhizobacteria in inhibiting late embryogenesis abundant protein that induces drought tolerance

- Nicotinamide as a biostimulant improves soybean growth and yield

- Farmer’s willingness to accept the sustainable zoning-based organic farming development plan: A lesson from Sleman District, Indonesia

- Uncovering hidden determinants of millennial farmers’ intentions in running conservation agriculture: An application of the Norm Activation Model

- Mediating role of leadership and group capital between human capital component and sustainability of horticultural agribusiness institutions in Indonesia

- Biochar technology to increase cassava crop productivity: A study of sustainable agriculture on degraded land

- Effect of struvite on the growth of green beans on Mars and Moon regolith simulants

- UrbanAgriKG: A knowledge graph on urban agriculture and its embeddings

- Provision of loans and credit by cocoa buyers under non-price competition: Cocoa beans market in Ghana

- Effectiveness of micro-dosing of lime on selected chemical properties of soil in Banja District, North West, Ethiopia

- Effect of weather, nitrogen fertilizer, and biostimulators on the root size and yield components of Hordeum vulgare

- Effects of selected biostimulants on qualitative and quantitative parameters of nine cultivars of the genus Capsicum spp.

- Growth, yield, and secondary metabolite responses of three shallot cultivars at different watering intervals

- Design of drainage channel for effective use of land on fully mechanized sugarcane plantations: A case study at Bone Sugarcane Plantation

- Technical feasibility and economic benefit of combined shallot seedlings techniques in Indonesia

- Control of Meloidogyne javanica in banana by endophytic bacteria

- Comparison of important quality components of red-flesh kiwifruit (Actinidia chinensis) in different locations

- Efficiency of rice farming in flood-prone areas of East Java, Indonesia

- Comparative analysis of alpine agritourism in Trentino, Tyrol, and South Tyrol: Regional variations and prospects

- Detection of Fusarium spp. infection in potato (Solanum tuberosum L.) during postharvest storage through visible–near-infrared and shortwave–near-infrared reflectance spectroscopy

- Forage yield, seed, and forage qualitative traits evaluation by determining the optimal forage harvesting stage in dual-purpose cultivation in safflower varieties (Carthamus tinctorius L.)

- The influence of tourism on the development of urban space: Comparison in Hanoi, Danang, and Ho Chi Minh City

- Optimum intra-row spacing and clove size for the economical production of garlic (Allium sativum L.) in Northwestern Highlands of Ethiopia

- The role of organic rice farm income on farmer household welfare: Evidence from Yogyakarta, Indonesia

- Exploring innovative food in a developing country: Edible insects as a sustainable option

- Genotype by environment interaction and performance stability of common bean (Phaseolus vulgaris L.) cultivars grown in Dawuro zone, Southwestern Ethiopia

- Factors influencing green, environmentally-friendly consumer behaviour

- Factors affecting coffee farmers’ access to financial institutions: The case of Bandung Regency, Indonesia

- Morphological and yield trait-based evaluation and selection of chili (Capsicum annuum L.) genotypes suitable for both summer and winter seasons

- Sustainability analysis and decision-making strategy for swamp buffalo (Bubalus bubalis carabauesis) conservation in Jambi Province, Indonesia

- Understanding factors affecting rice purchasing decisions in Indonesia: Does rice brand matter?

- An implementation of an extended theory of planned behavior to investigate consumer behavior on hygiene sanitation-certified livestock food products

- Information technology adoption in Indonesia’s small-scale dairy farms

- Draft genome of a biological control agent against Bipolaris sorokiniana, the causal phytopathogen of spot blotch in wheat (Triticum turgidum L. subsp. durum): Bacillus inaquosorum TSO22

- Assessment of the recurrent mutagenesis efficacy of sesame crosses followed by isolation and evaluation of promising genetic resources for use in future breeding programs

- Fostering cocoa industry resilience: A collaborative approach to managing farm gate price fluctuations in West Sulawesi, Indonesia

- Field investigation of component failures for selected farm machinery used in small rice farming operations

- Near-infrared technology in agriculture: Rapid, simultaneous, and non-destructive determination of inner quality parameters on intact coffee beans

- The synergistic application of sucrose and various LED light exposures to enhance the in vitro growth of Stevia rebaudiana (Bertoni)

- Weather index-based agricultural insurance for flower farmers: Willingness to pay, sales, and profitability perspectives

- Meta-analysis of dietary Bacillus spp. on serum biochemical and antioxidant status and egg quality of laying hens

- Biochemical characterization of trypsin from Indonesian skipjack tuna (Katsuwonus pelamis) viscera

- Determination of C-factor for conventional cultivation and soil conservation technique used in hop gardens

- Empowering farmers: Unveiling the economic impacts of contract farming on red chilli farmers’ income in Magelang District, Indonesia

- Evaluating salt tolerance in fodder crops: A field experiment in the dry land

- Labor productivity of lowland rice (Oryza sativa L.) farmers in Central Java Province, Indonesia

- Cropping systems and production assessment in southern Myanmar: Informing strategic interventions

- The effect of biostimulants and red mud on the growth and yield of shallots in post-unlicensed gold mining soil

- Effects of dietary Adansonia digitata L. (baobab) seed meal on growth performance and carcass characteristics of broiler chickens: A systematic review and meta-analysis

- Analysis and structural characterization of the vid-pisco market

- Pseudomonas fluorescens SP007s enhances defense responses against the soybean bacterial pustule caused by Xanthomonas axonopodis pv. glycines

- A brief investigation on the prospective of co-composted biochar as a fertilizer for Zucchini plants cultivated in arid sandy soil

- Supply chain efficiency of red chilies in the production center of Sleman Indonesia based on performance measurement system

- Investment development path for developed economies: Is agriculture different?

- Power relations among actors in laying hen business in Indonesia: A MACTOR analysis

- High-throughput digital imaging and detection of morpho-physiological traits in tomato plants under drought

- Converting compression ignition engine to dual-fuel (diesel + CNG) engine and experimentally investigating its performance and emissions

- Structuration, risk management, and institutional dynamics in resolving palm oil conflicts

- Spacing strategies for enhancing drought resilience and yield in maize agriculture

- Composition and quality of winter annual agrestal and ruderal herbages of two different land-use types

- Investigating Spodoptera spp. diversity, percentage of attack, and control strategies in the West Java, Indonesia, corn cultivation

- Yield stability of biofertilizer treatments to soybean in the rainy season based on the GGE biplot

- Evaluating agricultural yield and economic implications of varied irrigation depths on maize yield in semi-arid environments, at Birfarm, Upper Blue Nile, Ethiopia

- Chemometrics for mapping the spatial nitrate distribution on the leaf lamina of fenugreek grown under varying nitrogenous fertilizer doses

- Pomegranate peel ethanolic extract: A promising natural antioxidant, antimicrobial agent, and novel approach to mitigate rancidity in used edible oils

- Transformative learning and engagement with organic farming: Lessons learned from Indonesia

- Tourism in rural areas as a broader concept: Some insights from the Portuguese reality

- Assessment enhancing drought tolerance in henna (Lawsonia inermis L.) ecotypes through sodium nitroprusside foliar application

- Edible insects: A survey about perceptions regarding possible beneficial health effects and safety concerns among adult citizens from Portugal and Romania

- Phenological stages analysis in peach trees using electronic nose

- Harvest date and salicylic acid impact on peanut (Arachis hypogaea L.) properties under different humidity conditions

- Hibiscus sabdariffa L. petal biomass: A green source of nanoparticles of multifarious potential