Abstract

Graphene is a single-atom-thick sheet of sp2 hybridized carbon atoms that are packed in a hexagonal honeycomb crystalline structure. This promising structure has endowed graphene with advantages in electrical, thermal, and mechanical properties such as room-temperature quantum Hall effect, long-range ballistic transport with around 10 times higher electron mobility than in Si and thermal conductivity in the order of 5,000 W/mK, and high electron mobility at room temperature (250,000 cm2/V s). Another promising characteristic of graphene is large surface area (2,630 m2/g) which has emerged so far with its utilization as novel electronic devices especially for ultrasensitive chemical sensor and reinforcement for the structural component applications. The application of graphene is challenged by concerns of synthesis techniques, and the modifications involved to improve the usability of graphene have attracted extensive attention. Therefore, in this review, the research progress conducted in the previous decades with graphene and its derivatives for chemical detection and the novelty in performance enhancement of the chemical sensor towards the specific gases and their mechanism have been reviewed. The challenges faced by the current graphene-based sensors along with some of the probable solutions and their future improvements are also being included.

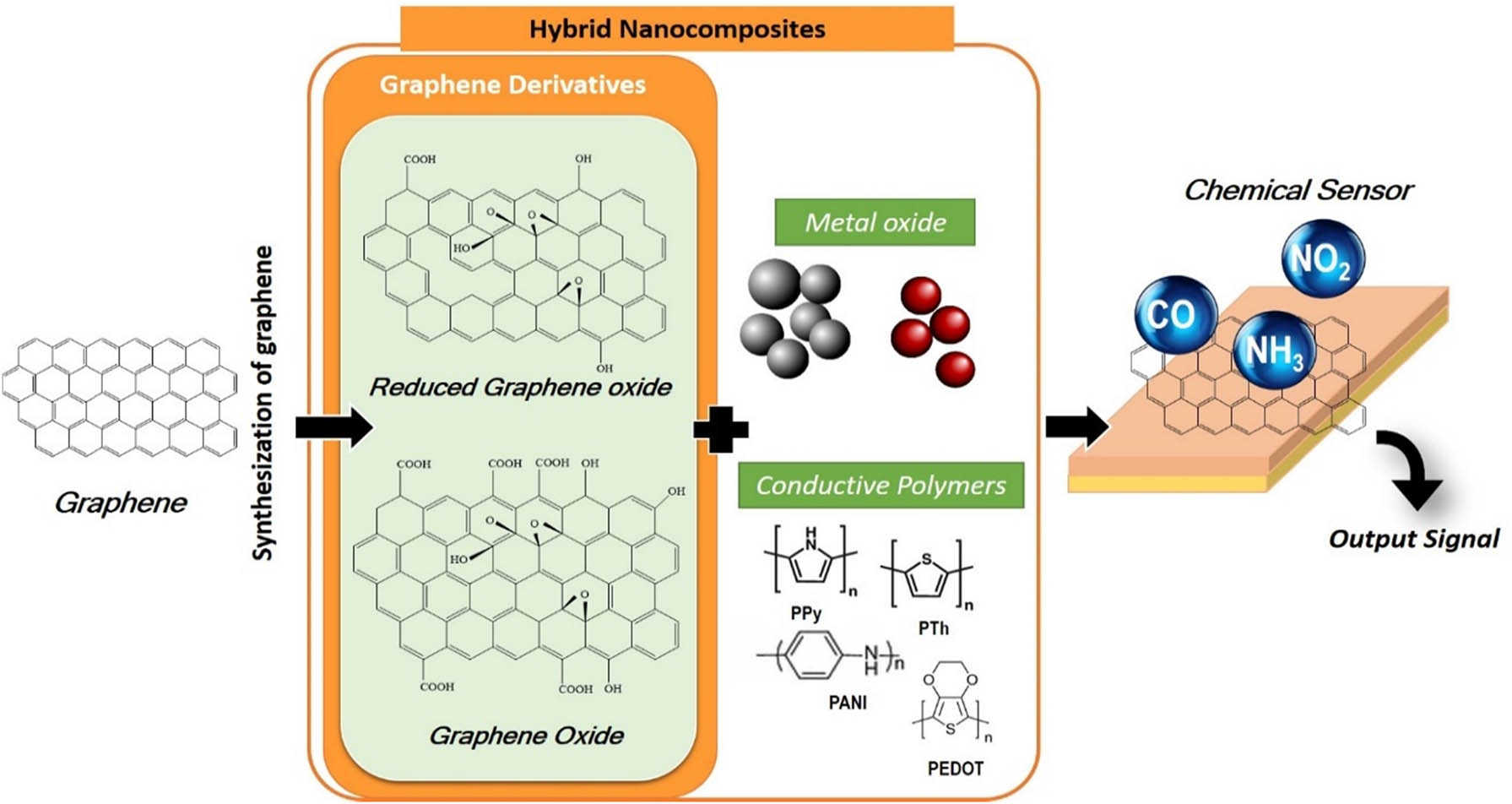

Graphical abstract

1 Introduction

Graphene and its derivatives have been emerging materials for modern chemistry and physics owing to its fascinating properties profile since Andre Geim and Konstantin Novoselov (Nobel Prize winners for Physics in 2010) achieved groundbreaking experiments regarding the two-dimensional (2D) material graphene in 2004 [1]. Since its first isolation, the scientific development involving its synthesis methodologies and related applications has been inspiringly progressive, suggesting that graphene would revolutionize the industry with its superlative and promising properties [2,3]. Graphene has a high basal plane elastic modulus with 1 TPa, ultimate strength about 130 GPa, and room temperature charge carrier mobility by 10,000 cm2/V s [3]. Graphene could be defined as a single layer of carbon atoms that are tightly packed to form a 2D honeycomb structure of sp2 hybridized carbon [4]. Further extension of honeycomb network is the basic building block of other important allotropes, such as it can be stacked to form 3D graphite, rolled to form one-dimensional (1D) nanotubes, and wrapped to form 0D fullerenes [5]. The use of three π-electrons in carbon-carbon bonding results in a system of delocalized π-electrons perpendicular to the honeycomb plane giving rise to graphene’s exceptional electrical properties.

Long-range of π-conjugation in graphene produces extraordinary thermal, mechanical, and electrical properties, which have long been the interest of many theoretical studies and more recently became an exciting area for wide range of applications [6,7]. In the applied field of research, among its wide range of applications, graphene has been largely used in batteries and cells as anodes and in supercapacitors due to its low charging time, high strength to weight ratio, and large surface area. Due to its unique properties which include a distinctive nano-porous structure, high mechanical strength, and high electrical and thermal conductivity, it has also found a large number of applications in areas like sensors, biomedical engineering, nano and flexible electronics, catalysis, and cement-based and geopolymer materials [8]. Besides that, a single atomic sheet of graphite has ignited intense research activities to clarify the electronic properties of this novel 2D electronic system [9]. However, charge transport in graphene is substantially different from that of conventional 2D electronic systems as a consequence of the linear energy dispersion relation near the charge neutrality point (Dirac point) in the electronic band gap structure [10,11]. This unique band gap structure is fundamentally responsible for the distinct electronic properties of carbon nanotubular graphene and carbon nanotubes (CNTs) [12].

Referring to Yavari and Koratkar (2012), the development of graphene-based chemical sensors presents the possibility of ultrahigh sensitivity detection of a range of gas species in air at room temperature and atmospheric pressure [13]. Before the beginning of graphene, there had been an extensive research on the starts of CNTs-based chemical sensors [14,15,16]. Graphene offers some important advantages compared to CNTs which is (1) a free-standing or suspended graphene sheet has both of its sides exposed to the chemical environment, thereby maximizing its sensitivity towards the analytes. Like multiwalled nanotubes, the inner cylinders are shielded from the chemical environment and even for single-walled nanotubes (SWCNTs), the ends may be closed (e.g. for tubes grown by chemical vapour deposition (CVD)), or the metal contact pads might cap the tubes and prevent the inside of the tube from participating in gas adsorption. (2) graphene exhibits inherently low electrical noise at room temperature [17], which arises from its unique 2D crystal lattice and high electron mobility. For these reasons, the sensitivity of graphene-based devices for molecular sensing is superior to that of CNTs. In truth, Schedin et al. (2007) have revealed that even the adsorption of single molecules could be detected using graphene [17].

This article provides a state-of-the-art review on performance of graphene’s, graphene oxide (GO), and reduced graphene oxide (rGO) for chemical detection hybridized with metal oxide and conductive polymers have been reviewed. Their mechanism towards the specific gases also has been highlighted. The graphical abstract of the paper.

1.1 Graphene’s characteristic

Cao et al. (2018) reported that arranging two layers of atom-thick graphene so that the pattern of their carbon atoms is offset by an angle of 1.1° makes the material a superconductor [18]. And although the system still needed to be cooled to 1.7° above absolute zero, the results suggest that it may conduct electricity much like known high-temperature superconductors [19]. Graphene already has impressive properties. It has shown superconductivity before, but it occurred when in contact with other materials, and the behaviour could be explained by conventional superconductivity [20]. Figure 1 shows a hexagon made up of two layers of graphene, twisted at an angle of 1.1°, had shown superconducting properties. Although graphene shows superconductivity at a very low temperature, it does so with just one-ten-thousandth of the electron density of conventional superconductors that gain the ability at the same temperature [21]. In conventional superconductors, the phenomenon is thought to arise when vibrations allow electrons to form pairs, which stabilize their path and allow them to flow without resistance. But with so few available electrons in graphene, it can somehow pair up which suggests that the interaction at play in this system should be much stronger than what happens in conventional superconductors like niobium-titanium alloy (type-II) with a superconducting critical material of 11 K [22].

In a global market, there are several types of graphene in a powder form material, such as GO, graphene nanoplatelets, graphene nanoribbons, and graphene quantum dots as well as graphene enabled products such as graphene ink or graphene masterbatches. Referring to Hernaez et al. (2017), the development of a method for the production of high-quality graphene in large quantities is essential to further exploit its full potential [23]. Hence, the use of GO and rGO has gained widespread consideration, as a compromise between the interesting properties of pristine graphene, the synthesization complexity, and cost. Figure 2 shows the schematic illustration of routes for preparation of GO and rGO from graphene flakes [24], whereas Table 1 shows the physical, mechanical, and electrical properties of the graphene materials [25,26,27,28,29,30].

![Figure 2

Schematic illustration of routes for preparation of GO and rGO. Adapted from ref. [24].](/document/doi/10.1515/ntrev-2021-0030/asset/graphic/j_ntrev-2021-0030_fig_002.jpg)

Schematic illustration of routes for preparation of GO and rGO. Adapted from ref. [24].

Physical, mechanical, and electrical properties of graphene

| Properties | Graphene | GO | rGO |

|---|---|---|---|

| Carbon (C), Oxygen (O) elemental ratio (%) | C (99) | C (62–65) | C (77–87) |

| O (–) | O (35–48) | O (13–22) | |

| Crystal size (nm) | 175.49 | 21.14 | 15.13–15.95 |

| d spacing (nm) | 0.33 | 0.93 | 0.36 |

| Plane size (μm) | 0.5–5 | 1–2 | 1–7 |

| Number of layers | 3–5 | 1–3 | 1–3 |

| Layer thickness (nm) | 0.34 | 0.76–0.84 | 0.35–0.36 |

| Stack thickness in water dispersion (nm) | 180–230 | 1.00–1.20 | 125–175 |

| Raman intensity ratio | 0.25 | 0.79 | 1.10–1.16 |

| Dispersibility in water | Not dispersible | Highly dispersible | Moderately dispersible |

| Tensile strength(GPa) | 130 | ∼0.13 | — |

| Elastic modulus (GPa) | 1,000 | 23–42 | 3.0–9.5 |

| Elongation at break (%) | 80 | 0.6 | — |

| Electrical conductivity (S/m) | ∼1,000 | Non conductive | ∼667 |

GO can be synthesized by functionalizing with hydroxyl (−OH) or carboxyl (C═O) groups covalently bonded to a planar carbon network of graphite, via treatment with oxidizing agents such as sulphuric acid (H2SO4) and nitric acid (HNO3). It is then exfoliated into few-layer or even monolayer GO, which nevertheless contains a high density of defects [31]. Small size of graphene sheets can be obtained by subsequent reduction of GO, which can eliminate most of its oxygen-containing functional groups and partially recover its sp2-bonded carbon network [32,33]. The abundance of functional groups in GO results in a hydrophilic behaviour which is strongly dependant on the level of oxidation. GO sheets show good dispersibility as a result of their strongly charged nature and hydrophilicity and form stable aqueous dispersions in a wide range of concentrations from 0.0125 to 0.05 wt% [34]. Additionally, GO are well-dispersed in organic solvents such as ethylene glycol, dimethylformamide, n-methyl-2-pyrrolidone (NMP), and tetrahydrofuran (THF) by forming hydrogen bonds between the surface and solvent interface.

1.2 rGO characteristic

In comparison to non-oxidized graphene nanoflakes, rGO is highly disordered with a relatively inferior quality due to the presence of many vacancy defects and Stone-Wales defects. Field emission electron microscope (FESEM) image presented at Figure 3 captured by Sharma et al. (2017) shows highly wrinkled and corrugated structure of rGO compared with GO, but shows liner (exhibit ohmic) I–V result for both GO and rGO. This outcomes present hint that both GO and rGO have the potential of being good gas sensing materials [35]. From FESEM in Figure 3(a) and (b), it is evident that surface of the sample gets corrugated upon reduction from GO to rGO due to reduction of oxygen-containing groups from the surface, while Figure 3(c) and (d) shows GO and rGO under high resolution transmission electron microscope (HRTEM) [36].

![Figure 3

(a and b) FESEM images and (c and d) HRTEM image of GO and rGO–Au. Adapted from ref. [36].](/document/doi/10.1515/ntrev-2021-0030/asset/graphic/j_ntrev-2021-0030_fig_003.jpg)

(a and b) FESEM images and (c and d) HRTEM image of GO and rGO–Au. Adapted from ref. [36].

Furthermore, hydrogenated, fluorinated, and oxidized graphenes which are called fluorinated graphene or fluorographene are expected to have remarkable applications in coating, batteries, separation technologies, and electrochemical sensing. In another theoretical study, porous fluorinated graphene is suggested to modulate the heat of adsorption of molecules, enhancing the binding of dipolar ones (H2O, SO2, H2S, and CO2) over N2, O2, and CH4 [37]. Therefore, applications are projected on separation of CO2 and SO2 from flue gases, purification of natural gas, and removal of H2O from air. A significant benefit is expected for porous fluorinated graphene, related to the fact that gas molecule separation is not dependent on size-exclusion mechanism, but on interaction strengths.

The introduction of either acetylenic or diacetylenic chains between carbon hexagons is experimentally shown to give a layer of single-atom thickness, which is flat like graphene and is predicted to have interesting properties like graphene; the former is named graphyne and the latter graphdiyne [38]. Graphyne and graphdiyne cannot be prepared directly from graphene, but they are compared and discussed with graphene with respect to their structure and properties. Therefore, they are classified as graphene derivatives, together with graphane, fluorographene, and GO. Graphene-related nanomaterials, including doped graphene, graphene nanoribbons, and porous graphene, in addition to five nanomaterials, are classified as graphene derivatives. Figure 4 proposed by Inagaki and Kang (2014) shows the development of graphyne and graphdiyne which suggests us a new carbon family composed of two kinds of C–C bonds, sp2 and sp1. However, graphane, fluorographene, and GO have to be included as new members of the sp3 system. These carbon materials described in the present review can be derived by chemical reactions or theoretical considerations from graphene [38].

![Figure 4

Schematic diagram of the development of graphene and its derivatives. Adapted from ref. [38].](/document/doi/10.1515/ntrev-2021-0030/asset/graphic/j_ntrev-2021-0030_fig_004.jpg)

Schematic diagram of the development of graphene and its derivatives. Adapted from ref. [38].

1.3 The discovery of graphenes as chemical sensors

These days, emissions of harmful by-products and pollutants, such as nitrogen oxides (NO x ), carbon oxides (CO x ), sulfur oxides (SO x ), and ammonia (NH3), had increased significantly and endangered our health and environment over the long term. To monitor the chemical materials that are harmful to human health and the environment, chemical sensing devices have been extensively developed and explored. Improvement and optimization of present chemical sensors, including gas sensors as well as the development of new sensors that possess higher sensing performance with higher sensitivity but lower cost, are still necessary for not only industrial sectors but also indoor health and safety, environmental monitoring, and beyond.

The nanostructures of metal oxides like titanium oxide (TiO2), Iron(iii) oxide (Fe2O3), zinc oxide (ZnO), stannous oxide (SnO2), tungsten oxide (WO3), cuprous oxide (Cu2O), etc. have been intensively explored for sensing applications. This is mainly due to their proven characteristics such as large specific surface area, excellent mechanical flexibility, good chemical stability, and better sensitivity [39,40,41,42]. However, metal oxide-based sensor materials hold certain limitations of high operating temperature (100–500°C), resulting in high power consumption, which in turn adversely affects the integration and long-term stability. In addition, metal oxide gas sensors are used since many decades to detect a gas species at high working temperature that is needed to promote gas reaction with the oxygen ionosorbed over the semiconductor, inducing a variation in the resistance of the material. As a matter of fact, high-temperature operation could raise the problem of ignition of fuels when detecting high explosive gases. Hydrogen, for example, can explode when mixed with atmospheric oxygen at concentration of 4% of lower explosive limit. Thus, room temperature detection is very important [43].

Besides that, common commercial gas sensors are based on semiconductor, polymer materials, and the methods used for sensing are optical methods, chemiresistive, calorimetric methods, gas chromatography, and acoustic methods, etc. [44]. The limitations of these gas sensors can be one or more of the following: costly, rare sensitivity in parts per billion (ppb), poor selectivity, limited life time, poor repeatability, difficult in miniaturization, and high power consumption [45,46].

As an alternative, nanomaterial-based gas sensing materials have gained significant momentum due to many promising electrical, optical, and thermal properties combined with high surface to volume ratio, short response and recovery times, high sensitivity, selectivity, reversibility, and stability [47,48]. Other than metal oxide, different carbonaceous materials, such as CNT, charcoal, and carbon black, have been shown to be useful as chemical and biosensors due to the ease in tailoring their sensitivity through functionalization. Chatterjee et al. (2015) [49] had highlighted the other sides of graphene that can be considered the limitations. The problems related to intrinsic graphene are: (1) it is not producible in large scale, (2) it has no functional groups (required for gas/vapour adsorption), and (3) it has no band gap. The main performance enhancement techniques in graphene-based sensors are found to be doping [50], hybridization [51], functionalization [52], nano mesh formation [53], and field-effect transistor modulation [54]. In the context of rGO, a form of graphene, produced by reduction of GO which contains many functional groups and defects, has offered great potential as it is easy and cheap to produce in large scale. In addition, it can be easily functionalized, thereby generating and tuning the band gap energy. It is therefore no wonder that researchers have shown a great deal of interest in exploring rGO as a gas sensor candidate [55,56].

It was reported that the first graphene-based gas sensor was pioneering in 2007 by Schedin’s and team [17]; demonstrated micrometre size sensors made from graphene are capable of detecting individual gas molecules that attach to or detach from the graphene surface. They showed that the adsorbed molecules change the local carrier concentration in graphene one electron by one electron, which leads to step-like changes in resistance. The achieved sensitivity is due to the fact that graphene is remarkably low-noise material electronically, which makes it a promising material not only for chemical detectors but also for other applications where local probes sensitive to external charge, magnetic field, or mechanical strain are required [17]. The gas-induced changes in resistivity had different magnitudes for different gases, and the sign of the change indicated whether the gas was an electron acceptor (e.g. NO, NO2, O3,) or an electron donor (e.g. CO, NH3, C2H5OH). This research has created new possibilities for researchers to develop graphene-based gas sensors [57]. The interaction between graphene sheets and gas could vary from weak van der Waals to strong covalent bonding. All these interactions transform the electronic structure of graphene, which can be readily monitored by convenient electronic methods. Booth et al. (2008) and Hill (2011) indicated that the presence of interaction between target gas/vapour molecules could reach the lower limit of even a single molecule, i.e. high sensitivity even at low gas concentrations [58,59].

Recently, the use of graphene and its derivatives like GO, rGO, etc. [60,61,62,63] has been reported to show a promising sensing characteristic application due to its countless exceptional properties such as good thermal stability, ballistic conductivity, high carrier mobility at room temperature, low electrical noise due to its unique 2D honeycomb lattice as well as large surface area (theoretical surface area of 2,630 m2/g) [17]. In addition, 2D materials can screen charge fluctuations better than 1D materials like CNT, etc. [64]. Referring to Ratinac et al. (2010), the most important reason graphene has been considered as a promising gas sensing material is that its electronic properties are strongly affected by the adsorption of gas molecules. Based on their discoveries, the planar structure of graphene eases Hall pattern fabrication and four probe measurements, limiting the contact resistance impact, and helps to focus only on the active area compared to its 1D counterpart, CNT [65,66].

Lu et al. (2011) reported that under a positive gate potential (n-type conductance), rGO exhibits sudden response and fast recovery for ammonia (NH3) detection, far superior to the performance in p-mode at zero or negative gate potential [67]. In order to enhance the gas sensing performance of graphene, researchers have further explored chemical and physical functionalization of graphene with nanomaterials and in particular, conducting polymers, metals, and metal oxides such that a sizable energy gap can be opened up in graphene through the quantum confinement effect [68,69]. Russo et al. (2012) reported fabrication of room temperature hydrogen gas sensor from rGO, tin oxide (SnO₂), and platinum (Pt) with fast response and recovery times [70]. Paul et al. (2012) fabricated a sensor based on a nano mesh patterned from a CVD-grown large area graphene which exhibits sensitivities of about 4.32%/ppm of nitrogen dioxide (NO2) and 0.71%/ppm of NH3 with limits of detection of 15 and 160 ppb, respectively [71].

Furthermore, the involvement of graphene as GO and rGO in the developed sensors is attributed to some of the distinct advantages like the large surface-to-volume ratio, unique optical properties, excellent carrier mobility, and exceptional electrical and thermal properties compared to the other allotropes of carbon [72]. These properties are constant for the double and multilayered graphene structures. Apart from the difference in the structure and working conditions, the use of these advantages in graphene sensors lies mainly in their capability to adjust according to the application. For example, in strain sensors, properties like the detection limit, maximum sensing range, signal response, and reproducibility of the response hold a pivotal role to determine the quality of the sensor. These characteristics are attributed to the electrical and mechanical properties of graphene. In electrochemical sensors, its large surface area helps the loading of the desired biomolecules, resulting in the interaction between the analyte molecule and electrode surface due to the high ballistic transport capability and the very small band gap. Another advantage of graphene materials is its low environmental impact, making it more popular for sensing purposes than other nanostructured metal oxides [49].

Chemical sensor is particularly interesting as it hybridizes the nanostructure of graphene with metal oxides to form hybrid nanostructures. This is because not only do they display the individual properties of the nanoparticles and of graphene, but may also exhibit additional synergistic properties that are desirable and advantageous for gas sensing applications; in other word, compliment the limitations on each for the desired detection and applications. One of the major advantages of such nanocomposite sensor is that graphene has near metallic conductivity with a possible inherent-amplified sensing configuration [49]. The high specific surface area of graphene may cause synergetic effects in achieving good gas response at room temperature when blended with metal oxides, especially on sensitivity and selectivity. Table 2 shows the structural and electrical properties of various types of carbonaceous materials.

The structural and electrical properties of various carbonaceous materials including graphene

| Carbon materials | Advantages | Limitations | Structural | Electrical | Reference |

|---|---|---|---|---|---|

| Amorphous porous carbon | High surface area, advanced porous system, abundant defective sites, superior chemical inertness | Relative low conductivity, poor adhesion with fluorine-doped tin oxide (FTO) | Consists of an outer spherical shell with porous interior structure | High electronic conductivity and high surface area | [74] |

| A covalent random network composed of sp3 and sp2 hybridized carbons without grain boundaries | Electronic conductivity and ionic conductivity, with specific capacities of 212 mA h g−1 and 162 mA h g−1 at 0.5C and 1C, respectively. | ||||

| Non-crystalline | |||||

| Graphene | Excellent conductivity, fast charged carrier mobility, good mechanical strength, high optical transparency, good mechanical inertness, large surface area | Low surface area arising from the easy aggregation, low quantities of defective sites, high-quality thin film still lacking reproducibility, difficult to control bi-layer, tri-layer graphene, sheet resistance of tens or hundreds of nm thick layer is quite high | Crystalline carbon materials | Conducts both electricity and heat | [75] |

| Monolayers of carbon atoms arranged in a honeycomb network | Thermal conductivity and mechanical stiffness (3,000 W m−1 K−1 and 1,060 GPa, respectively) | ||||

| Giant aromatic macromolecule | |||||

| Graphite | Good conductivity, corrosion resistance, excellent thermal stability | Poor porous system, low surface area | Stacks of graphene layers | High electrical and thermal conductivity | [76,77] |

| Weak interactions that hold the graphene sheets together | Thermal conductivity 25–470 W m−1 K−1 | ||||

| Electrical resistivity 5 × 10−4–30 × 10−4 Ωcm | |||||

| Carbon black | Plentiful defective sites, good chemical inertness | Low surface area, inappropriate pore size, inadequate conductivity | Typical particle sizes range from around 8–100 nm for furnace blacks | Highly structured carbon blacks provide higher viscosity | [78] |

| Greater electrical conductivity and easier dispersion for specialty carbon blacks | |||||

| Electrical volume resistivity between 1 and 106 Ω cm | |||||

| Carbon nanofibre | Excellent mechanical strength, high thermal conductivity, good chemical inertness | Insufficient conductivity, low surface area, inferior porous system | Cylindrical nanostructures with graphene layers arranged as stacked cones, cups, or plates | High electrical conductivity, and high thermal conductivity | [79,80] |

| Diameters from 50 to 200 nm | Intrinsic conductivity, at room temperature to be 5 × 10−5 Ωcm | ||||

| Carbon nanotube | Large surface area, high electrical conductivity, good chemical inertness, shorter response and recovery times, reversibility and stability for raw CNT, ageing and thermal process increase the sensitivity of the sensors | Low quantities of defective sites, additional purifications and functionalizations required, lack of selectivity for raw CNT | Crystalline carbon materials | High electrical conductivity | [80,81] |

| Most of the physical properties of carbon nanotubes derived from graphene | High thermal conductivity | ||||

| Carbon atoms are densely organized in a regular sp2-bonded atomic-scale honeycomb (hexagonal) pattern | Resistivity of the SWCNT is 10−4 Ωcm at 27°C | ||||

| sp2 hybridization of carbon builds a layered construction with weak out-of-plane bonding of the van der Waals form and strong in-plane bounds | The SWCNT ropes able to sustain much higher stable current densities, as high as 1013 A/cm2 |

While graphene and rGO exhibit ambipolar and almost symmetric behaviour in the electron and hole doping regions, they show p (hole)-dominant conducting properties because of the adsorbed water and oxygen molecules [73]. The strategy of hybridization of graphene with metal oxide will be discussed in the last part. To date, the unique optical, chemical, and morphological properties of graphene functionalized with conductive polymers, metal oxides, etc. are attracting a growing interest in the scholar’s league. A closer look at Figure 5 in the number of publications reveals the rapid progress on the research of graphene and graphene composite-based gas sensors in the last decade. For the past ten years, about 886,000 number of publications related to the keyword “graphene” and about 41,700 number of publications related to the keyword “graphene chemical sensor” were found in Google Scholar (28th November 2020). In addition, about 25,500 number of publications related to “graphene composite chemical sensor” were found. These number indicate that graphene is becoming an interesting subject to be studied, and many more explorations can be done that could lead to huge impacts to the nation. This paper discussed the fundamentals of graphene and derivatives, the synthesization of graphene involved, the chemical modification of graphene involved, chemical sensor characteristics, and the performance of functionalized graphene for chemical sensor which includes hybrid of graphene with metal oxide and conductive polymers. This review ends with a conclusion and future perspectives of graphene materials in chemical sensors.

Progress of graphene-based chemical sensor in the last decade.

2 Chemical sensor characteristics and the basic mechanism

Chemical sensors are attracting tremendous interest because of the demand of sensitive, fast response, reversibility, and stable at low temperature sensor for public safety, space exploration, biomedicine, pharmaceuticals, for leakage detections of explosive gases such as hydrogen, for a real-time detection of toxic or carcinogenic gases in industries, and for the military purposes especially at the airport or at public area. Recently, extensive interest in improving reliable graphene-based chemical sensors has been rising as innumerable fields have been expanding. The key aspects expected for the development of a chemical sensor include sensitivity in the parts per million (ppm) to billion (ppb) range where the trace levels are involved, absolute discrimination, mild operation temperature, low power consumption, practical size, volume and mass, and low cost for large-scale applications [82,83]. Figure 6 explains a brief description of the four major important aspects for chemical sensor [84]. To satisfy these critical aspects and enhance the sensing performance, miscellaneous detection techniques for gas sensing have been explored and studied in the following section. This review begins with the sensing mechanism and working principles of the most prevalent gas sensing methods.

Four major important aspects for chemical sensor.

Sensor response traits of n-type and p-type gas sensors to different gases are summarized in Table 3 [85]. Because of these different characteristics, sensor response is defined according to resistivity of the active layer and in different ways depending on the type of measurements. Nevertheless, it is easily and commonly described as the ratio of resistance in air (R a) to resistance in the presence of analyte (R g) (R a/R g) for an n-type material with a reducing analyte. The response is expressed otherwise (R g/R a) for a n-type material with an oxidizing analyte [86,87]. It is vice versa for p-type sensors [88,89]. Although several compiled sensors make up a p–n heterojunction, they are decidedly sorted into their single dominant charge carrier trait of either n-type or p-type behaviour based on how resistivity decreases or increases in the augmentations of analyte concentration. This is to guarantee a straightforward understanding and an effective assessment of analyte sensing characteristics for both n-type and p-type gas sensors. The sensing response of p-type graphene-based chemical sensor over the chemical or analytes detection was determined using equation (1).

Where R o and R g are the electrical resistance of graphene-based sensor before and after the exposure to analytes (e.g. NH3) at specific time and temperatures, respectively.

Sensing response behaviour of p-type and n-type sensors to reducing and oxidizing analytes

| Sensing response behaviour | Examples of analytes | p-type sensor | n-type sensor |

|---|---|---|---|

| Reducing analytes | CO, NH3, C2H5OH, SO2 | Resistance increases | Resistance decreases |

| Oxidizing analytes | NO2, H2O, F2, Cl2, Br2, I2, and O2 | Resistance decreases | Resistance increases |

| Dominant charge carrier | — | Holes (h+) | Electrons (e−) |

Pristine graphene, GO and rGO, have presented a distinct gas sensing capability based on its structural characteristics. The 2D structure of graphene makes the electron transport through the graphene highly sensitive to the adsorption of gas molecules [90]. The adsorption of gas molecules on graphene’s surface leads to changes in its electrical conductivity attributed to the change in the local carrier concentration. That change in the local carrier concentration is induced by the surface adsorbates which act as electron donors or acceptors [91]. All these materials have different electrical conductivity and surface functional groups, which play an important role in the gas sensing mechanism. For example, due to absence of functional groups in pristine graphene, the interaction occurs through the defects, and it possesses low intrinsic noise and high electrical conductivity even in absence of charge carriers; few charge carriers induced by the gas adsorbates lead to notable changes in charge carrier density resulting in detectable changes in electrical conductivity. In the following sections, we summarized the theoretical aspects of the sensing performance and related mechanisms on the detected gas of graphene-based materials followed by a detailed discussion on the state of the novel research work on applications of pristine graphene, GO, rGO, and functionalized graphene for gas sensing.

Referring to Jeevitha et al. (2019), the vapour sensing mechanism of rGO/metal oxide nanocomposites is governed by several factors like sensor porosity, specific surface area, and heterojunction formation. Metal oxide semiconductor-based sensors work on the principle of the change in resistance owing to the reaction among gas molecules and the sensitive surface. In the case of rGO/WO3 nanocomposites, WO3 is an n-type semiconductor and rGO behaves like p-type. It is well-known that the n and p type materials are dominated by electrons and holes, respectively. Once they come into contact with each other, a depletion layer is formed at the interface which is a p–n heterojunction. The rGO/WO3 sensor shows p-type behaviour towards NH3 detection. rGO possesses a higher work function and defects in the prepared nanocomposite surface, which will provide many adsorption centers for NH3. Therefore, when the sensor surface is exposed to NH3, the NH3 molecules are adsorbed on the composite surface, and the interaction between adsorbed

The sensing behaviour of the polypyrrole (PPy)/rGO sensor is attributed to the electron transfer between NH3 molecule and the rGO/PPy nanocomposite. As described at the equations (2) and (3), the PPy behaves like a p-type semiconductor. When the electron-donating NH3 molecules adsorb onto the PPy surface, electrons transfer from NH3 to the π backbone of the PPy [93]. This neutralizes holes in the PPy, thereby increasing the PPy resistance. For desorption of analytes, the electrons come back from the PPy to NH3 and then the neutralized PPy becomes p-type, recovering the PPy resistance to its original value. The resistance changes from the electron transfer occurring on the surface of the PPy can be effectively transferred to the interdigitated electrodes (IDEs) through the rGO. It is worth noting that the electron transfers between the PPy and rGO is feasible due to the good interfacial affinity

Besides that, the rGO includes a high density of sp2-bonded carbons, vacancies, structural defects, and residual oxygen groups for a hole-transporting matrix, which behaves as a p-type semiconductor. The adsorbed NH3 may transfer to the rGO matrix through the PPy layer and donating electrons to the rGO. The electrons transfer depletes holes in the matrix, also increased the rGO resistance [94]. The synergistic effect of the PPy and rGO explains that the PPy/rGO sensor exhibits significantly higher sensitivity than the pristine rGO sensor. Although pristine PPy is a sensing material for NH3 at room temperature, the response and recovery time is very long. The PPy layer allows electrons to quickly transfer between NH3 molecules and the PPy/rGO nanocomposite. Besides, the presence of the PPy molecules on the surface of the rGO allows the complete interaction between NH3 and the binding sites; the adsorbed NH3 molecules can bind on the rGO through the PPy layer for the electron transfer. Therefore, the ultrathin PPy layer plays an important role in the PPy/rGO sensor response [95].

3 Performance of functionalized graphene in chemical sensor

3.1 Performance of graphene nanocomposite-based sensor

Graphene is highly sensitive towards changing chemical environment. This is because the suspended graphene has extremely high electron mobility at room temperature, and the electron transport in graphene remains increasing up to 0.3 μm at 300 K. Besides, in every carbon atom in graphene, there is a surface atom that provides the highest possible surface area per unit volume which leads the electron transport through the graphene and is highly sensitive to the adsorbed molecular species. The other factor is graphene has characteristically low electrical noise due to the quality of its crystal lattice and its high electron mobility [13]. These properties make graphene the best candidate for the ultrahigh sensitivity detection of different gases existing in various environments. High levels of sensitivity in detection processes are important for different industrial, environmental, public safety, and military applications [96].

The working principle for most of the graphene-based gas sensor is based on changes in their electrical conductivity due to the adsorption of gas molecules on the graphene’s surface. These gas molecules act as donors or acceptors on graphene, similar to other solid-state sensors [97]. In 2007, Schedin and team were the first researchers team who fabricated a microscopic sensor made from graphene that is capable of detecting individual gas molecules such as NO2, NH3, H2O, and CO. From the experiment, their sensor is able to respond as soon as a gas molecule attaches to or detaches from graphene’s surface and the adsorbed molecules change the local carrier concentration in graphene. This leads to step-like changes in resistance.

The device shows concentration-dependent changes in electrical resistivity by adsorption of gases after which the sensor is regenerated by annealing at 150°C under vacuum. This ultrahigh sensitivity stems from the fact that pristine graphene is an exceptionally low-noise material. The detection limit for solid-state gas sensors is usually defined as the minimal concentration that causes a signal exceeding sensors’ intrinsic noise. In Schedin et al. (2007) graphene sensor, a typical noise level in their devices is ∆ρ/ρ ≈ 10−4 that translates into the detection limit of the order of 1 ppb. As a result, this places graphene on parity with other materials used for most sensitive gas sensors [98]. The lowest level of noise was found in their devices with the highest mobility (>10,000 cm2/V s) and the lowest contact resistance. Sensors made from few-layer graphene (3 to 5 layers) were most electrically quiet, probably because their contact resistance could be as low as 50 Ω, as compared with typically 1,000 Ω for single-layer of graphene devices.

Different gases have different effects on the resistivity. The magnitudes and the sign of the change in the resistivity indicate whether the gas is an electron acceptor (e.g. NO2, H2O, and I2) or an electron donor (e.g. CO, ethanol, and NH3) [99]. Since conductivity is proportional to the product of number of charge carriers and mobility, the change in conductivity must be due to changes in the number density or mobility of carriers, or both. From the results, Hall effect measurement showed extra charge carriers being formed during gas adsorption on their device. That means that gas adsorption can increase the number of holes if the gas is an acceptor or increase the number of electrons if the gas is a donor. This change in the carrier concentration is the basic mechanism that governs the operation of all electrical conductivity-based graphene gas sensor devices towards the increased or decreased of resistance.

Graphene-based chemical sensors offer the possibility of ultrahigh sensitivity detection of a range of gas type in mixtures with air at room temperature and atmospheric pressure. Referring to Yavari and Koratkar (2012), comparing graphene to CNTs, it is concluded that a free-standing or suspended graphene sheet has both of its sides exposed to the chemical environment, thereby maximizing its sensitivity. But, for the multiwalled CNTs, the inner cylinders are shielded from the chemical environment. Even for SWCNTs, the ends may be closed (e.g. for tubes grown by CVD), or the metal contact pads might cap the tubes and prevent the inside of the tube from participating in gas adsorption. Graphene also exhibits inherently low electrical noise at room temperature, which arises from its unique 2D crystal lattice and high electron mobility [100].

Chu et al. (2011) investigated the characteristics of hydrogen detection using epitaxial graphene covered with a thin layer of platinum as a catalyst. The multilayered graphene was grown by CVD on a Si-polar 4H-SiC substrate. Graphene covered with a thin film of Pt showed reduced resistance in response to exposure to 1% hydrogen at various temperatures. This sensor works based on splitting of the H2 molecule in the presence of the catalytic metal. Dissociated hydrogen atoms will accumulate at the surface of Pt and diffuse into the graphene/Pt boundary, causing the hydrogen atoms to form covalent bonds with graphene. This hydrogenated form of graphene will have an increased work function and the separation distance increase between graphene and Pt can also cause the Fermi-level shift to become larger. Thus, the free carrier concentrations will increase and raise the conductance of the graphene/Pt device [101].

Chen et al. (2011) investigated the electrical resistivity of monolayer CVD-grown graphene that exhibits significant changes upon exposure to oxygen (O2) at room temperature. Results showed that O2 can be detected at concentrations of around 1.25% in volume ratio. When O2 molecules are attached to the surface of graphene, they form epoxide and carboxylic groups that are electron-withdrawing and increase hole concentration of the conduction band which generates a significant decrease in resistance [102].

Unlike graphene with zero band gap, which greatly hinders its applications, penta-graphene (PG), a new 2D allotrope of carbon based on Cairo pentagonal tiling pattern, is a material with individual atomic layer exclusively consisting of pentagons (a mixture of sp2- and sp3-coordinated carbon atoms) in a planar sheet geometry [103]. The sensing capabilities of monolayer of PG using first-principles and non-equilibrium Green’s function (NEGF) calculations towards small gas molecules, such as CO, CO2, NH3, NO, and NO2, have been conducted by Cheng et al. (2019) [104]. The results proved that monolayer PG is most preferred for the NO x (x = 1, 2) molecules with suitable adsorption strength and apparent charge transfer. Moreover, the current–voltage (I–V) curves of PG display a tremendous reduction of 88% (90%) in current after NO2 (NO) adsorption. The superior sensing performance of PG rivals or even surpasses that of other 2D materials such as graphene and phosphorene. The ultrahigh sensitivity and selectivity to nitrogen oxides make PG a superior gas sensor that promises wide-ranging applications. Figure 7(a) shows that the a 3 × 3 PG supercell with and without gas adsorption is used for each of the left and right electrodes and the centre scattering region, respectively, and Figure 7(b) and (c) shows the I–V curves of PG with and without the NO x gas adsorption.

![Figure 7

(a) Illustration of the two-probe systems of semi-infinite left and right electrode regions (red shaded region) which are in contact with the central scattering region of PG (b) and (c) display the I–V curves of PG and PG with the NO and NO2 adsorption. Reproduced from ref. [104].](/document/doi/10.1515/ntrev-2021-0030/asset/graphic/j_ntrev-2021-0030_fig_007.jpg)

(a) Illustration of the two-probe systems of semi-infinite left and right electrode regions (red shaded region) which are in contact with the central scattering region of PG (b) and (c) display the I–V curves of PG and PG with the NO and NO2 adsorption. Reproduced from ref. [104].

Lee et al. (2016) investigated the characteristic of defect-engineered graphene chemical sensors on NO2 and NH3 detection using commercial graphene [105]. Theoretically, a graphene defect engineering strategy was proposed to tailor the interface and mechanical properties of graphene nanocomposites. From the study, the defects were formed from the reaction of oxygen radicals and graphene via diffusion because the direct ion bombardment was blocked by the silicon wafer. During oxidation, oxygen radicals react with the carbon atoms in the graphene, forming sp3-type defects and vacancies formed by the detachment of carbon atoms in the form of CO or CO2. In this work, defects were created in graphene using oxygen plasma, with a conventional reactive ion etching system. The graphene was grown on copper foil by the CVD technique and the monolayered graphene (0.5 × 0.5 cm2) on the copper foil was wet-transferred to the (11 cm2) SiO2/Si substrate. Result shows that the defect-engineered graphene chemical sensors exhibited optimized sensitivities of 53 and 25% to 200 ppm of NO2 and NH3, respectively. The density functional theory simulations showed that the graphene sensors can be activated and enhanced by the presence of defects. Besides that, vacancy defect, whose density can be precisely controlled by defect engineering, is the main factor contributing to sensitivity. From the experiment, the pristine graphene exhibited sensitivity towards NH3 molecules, suggesting that vacancies are already present even in pristine graphene. The lower adsorption strength of NH3 compared with NO2 can explain a higher sensitivity of the latter than the former. However, the increase in the sensitivity of NH3 due to defect engineering was much higher than that in the sensitivity of NO2 (increases of sensitivity for NO2 and NH3 gases were 33 and 614%, respectively) because there was no charge transfer between defect-free graphene and NH3 molecules. Figures 8 and 9 show the molecular adsorption on defective graphene which has higher adsorption strength than pristine graphene for NO2 and NH3.

![Figure 8

Optimized structures of the NO2 molecule adsorbed on (a) pristine graphene, (b) sp3-type defect (epoxy group)-graphene, (c) sp3-type defect (carbonyl group)-graphene, (d) sp3-type defect (ether group)-graphene, and (e) single vacancy of graphene. The red, brown, and grey colours represent O, C, and N atoms, respectively. Reproduced from ref. [105].](/document/doi/10.1515/ntrev-2021-0030/asset/graphic/j_ntrev-2021-0030_fig_008.jpg)

Optimized structures of the NO2 molecule adsorbed on (a) pristine graphene, (b) sp3-type defect (epoxy group)-graphene, (c) sp3-type defect (carbonyl group)-graphene, (d) sp3-type defect (ether group)-graphene, and (e) single vacancy of graphene. The red, brown, and grey colours represent O, C, and N atoms, respectively. Reproduced from ref. [105].

![Figure 9

Optimized structure of the NH3 molecule adsorbed on (a) pristine graphene, (b) sp3-type defect (epoxy group)-graphene, (c) sp3-type defect (carbonyl group)-graphene, (d) sp3-type defect (ether group)-graphene, and (e) single vacancy of graphene. The red, brown, grey, and light pink colours represent O, C, N, and H atoms, respectively. Reproduced from ref. [105].](/document/doi/10.1515/ntrev-2021-0030/asset/graphic/j_ntrev-2021-0030_fig_009.jpg)

Optimized structure of the NH3 molecule adsorbed on (a) pristine graphene, (b) sp3-type defect (epoxy group)-graphene, (c) sp3-type defect (carbonyl group)-graphene, (d) sp3-type defect (ether group)-graphene, and (e) single vacancy of graphene. The red, brown, grey, and light pink colours represent O, C, N, and H atoms, respectively. Reproduced from ref. [105].

A developed graphene-based resistive gas sensor fabricated by transfer of CVD-grown graphene on a smooth paper showed low detection limit of 300 parts per trillion (ppt) for NO2 at room temperature which is comparable to or better than those from other paper-based sensors [106]. The overall sensor response of the graphene paper sensor was around 118% ppm−1 of NO2 and by ultraviolet exposure for 10 min, and the response is increased by a factor of 2.5. Referring to Kumar et al. (2015), large strain can generate cracks in graphene paper and results in large effect on its electrical and sensing properties. When graphene paper is subjected with different values of strain, the conductance (S) increased by a factor of 2 over the unstrained sample [106]. For large strains applied here (radius of curvature about 12 mm or lower), the resistance of the sample changes irreversibly to higher value of strains. Large strains can produce cracks and other defects in graphene layer, so this behaviour is expected. The cracks and defects formation provides more sites for adsorption of test gas, as well as bear large effect on resistance when they are bridged. As a result, the response improves as presented in the inset of Figure 11(c). Figure 10(a) and (b) shows the schematic diagram of preparation of graphene paper and the transfer process on the paper. Figure 11(a) shows the conductance change of graphene paper strips when 2.5 ppm of NO2 exposure, while Figure 11(b) shows the change in conductance of a graphene paper as concentration of NO2 increases from 0.5 pm up to 2.5 ppm.

![Figure 10

(a) and (b) Schematic diagram of graphene transfer process on to the paper. Starting with (1) graphene on Cu foil, (2) a layer of poly(methyl methacrylate) (PMMA) is spin-coated and Cu is etched to get graphene supported by PMMA in water, (3) PMMA-graphene film is then dredged on to paper and PMMA is dissolved with acetone and (4) normal paper yields patchy coverage compared to transfer on smooth paper (5). The smooth paper at (5) shows two layers of graphene transferred on smooth paper. (b) Schematic of a G-paper strip in action as a gas sensor. The circuit had sufficient current to make an LED glow ((bottom left). Reproduced from ref. [106].](/document/doi/10.1515/ntrev-2021-0030/asset/graphic/j_ntrev-2021-0030_fig_010.jpg)

(a) and (b) Schematic diagram of graphene transfer process on to the paper. Starting with (1) graphene on Cu foil, (2) a layer of poly(methyl methacrylate) (PMMA) is spin-coated and Cu is etched to get graphene supported by PMMA in water, (3) PMMA-graphene film is then dredged on to paper and PMMA is dissolved with acetone and (4) normal paper yields patchy coverage compared to transfer on smooth paper (5). The smooth paper at (5) shows two layers of graphene transferred on smooth paper. (b) Schematic of a G-paper strip in action as a gas sensor. The circuit had sufficient current to make an LED glow ((bottom left). Reproduced from ref. [106].

![Figure 11

(a) Change in conductance of a graphene paper strip to 2.5 ppm of NO2. The inset shows a fit of double exponential function to the temporal response for 2.5 ppm of NO2, (b) change in conductance of a graphene paper as concentration of NO2 increases starts from 0.5 to 2.5 ppm. The inset shows the plot of response at t = 1,000 s vs the concentration of NO2, which has a slope of 167 ppm−1 at the start (indicated by dashed line) and (c) change in conductance of a graphene paper as strain is applied at 2.5 ppm of N NO2 flow. The inset shows that both the baseline resistance and response of the strip increase with increasing strain. Reproduced from ref. [106].](/document/doi/10.1515/ntrev-2021-0030/asset/graphic/j_ntrev-2021-0030_fig_011.jpg)

(a) Change in conductance of a graphene paper strip to 2.5 ppm of NO2. The inset shows a fit of double exponential function to the temporal response for 2.5 ppm of NO2, (b) change in conductance of a graphene paper as concentration of NO2 increases starts from 0.5 to 2.5 ppm. The inset shows the plot of response at t = 1,000 s vs the concentration of NO2, which has a slope of 167 ppm−1 at the start (indicated by dashed line) and (c) change in conductance of a graphene paper as strain is applied at 2.5 ppm of N NO2 flow. The inset shows that both the baseline resistance and response of the strip increase with increasing strain. Reproduced from ref. [106].

Graphene gas sensors with different number of graphene layers were successfully fabricated by the facile transfer of monolayer CVD graphene sheets grown on Cu foil for NO2 sensing detection [107]. Results on gas sensing show that all graphene sensors demonstrated the p-type sensing behaviours under the adsorption of NO2 molecules. The highest response and the highest sensitivity towards NO2 at room temperature were shown by the bilayer graphene gas sensor. The increase is linearly with NO2 concentration over the range of 1 to 25 ppm and had a high linear sensitivity of 1.409 ppm−1. The bilayer graphene gas sensor also exhibited high selectivity to NO2 against CO, CO2, NH3, C2H5OH, and H2 at room temperature.

For the NO2 sensing mechanism, p-type gas sensing characteristics and bilayer graphene display considerably higher NO2 response than monolayer, 3-layer, and 4-layer of graphene. The NO2 sensing mechanism of graphene at low temperature may generally be explained based on (1) reducing reaction and (2) direct change transfer processes. In the case of the reducing reaction process, chemisorbed oxygen species (

Before the NO2 gas adsorption, the monolayer of graphene at Figure 12(a) exhibits the unique massless conical band electronic structure, while bilayer and multilayer graphene structures have typical parabolic bands associated with the finite charge carrier effective mass, which increases with increasing number of graphene layers [107]. In air,

![Figure 12

Schematic diagram of band diagrams of NO2-sensing mechanism of (a) monolayer, (b) bilayer, and (c) multilayer of graphene gas sensors proposed by Seekaew et al. Reproduced from ref. [107].](/document/doi/10.1515/ntrev-2021-0030/asset/graphic/j_ntrev-2021-0030_fig_012.jpg)

Schematic diagram of band diagrams of NO2-sensing mechanism of (a) monolayer, (b) bilayer, and (c) multilayer of graphene gas sensors proposed by Seekaew et al. Reproduced from ref. [107].

For monolayer graphene at Figure 12(a), the amount of charge transfer to NO2 molecules may be quite limited due to less available electronic state at high energy in valence band compared with bilayer one. Thus, the bilayer graphene, which has comparable accessible active surface area as monolayer one, could exhibit more charge transfer due to N

3.2 Performance of GO nanocomposite-based sensor

As discussed in synthesis of graphene in Section 2, the chemical oxidation of graphene and simultaneous reduction of resulting GO is one of the popular approaches used for graphene synthesis. GO has a layered structure parallel to graphene, but it is functionalized with oxygen-containing groups such as hydroxyls, epoxies, carboxyl, and lactones. These functional groups not only expand the interlayer spacing, but also make the atomic-thick layers more hydrophilic, enabling these oxidized layers to exfoliate in water under ultra-sonication or mechanical stirring [110]. Choi et al. (2015) studied the role of oxygen functional groups in GO for reversible room-temperature NO2 sensing [111]. Based on the results, graphene-based materials defects such as oxygen functional groups, Stone-Wales defects, and holes from the basal plane can act as active sites for interaction with molecules [112]. Owing to its oxygen-rich functional groups, GO could be considered as an ideal material for gas sensing. But the numerous oxygen functional groups of GO make it too electrically insulating for use as an active material for chemiresistive sensors. Choi et al. (2015) also stated that the major drawback of rGO-based sensors is the extremely sluggish and irreversible recovery to the initial state after a sensing event, which makes them incapable of producing repeatable and reliable sensing signals.

Based on study by Peng and Li (2013), GO shows better detection of NH3 than pristine graphene, since the active surface of defective sites of GO such as the epoxy and hydroxyl groups promotes the interactions between the NH3 molecules and GO [113]. Based on ab initio studies [114], the presence of hydroxyl and carbonyl groups attached on the carbon atoms on GO surface results in large binding energies and enhanced charge transfers from nitrogen oxides NO x (x = 1, 2, 3). This leads to chemisorption of gas molecules on GO surface [115]. Alam et al. (2018) have studied the development of GO-gold nanocrystals (AuNCs) nanocomposite-modified glassy carbon electrode (GCE) for the sensitive detection of dopamine (DA), uric acid (UA), and 4-aminophenol (4-AP) [116]. The GO was synthesized through modified Hummer’s method, which was utilized to prepare GO-AuNCs nanocomposites by in situ synthesis method using sodium L(−) malate as a reducing agent. It was observed that the sensor showed interference-free and selective detection of DA and UA with sensitivities of ca. 30.3 and 17.28 μA/cm2/μM, respectively, and detection limits of ca. 28 and 50 nM, respectively, with wider dynamic ranges, measured by differential pulse voltammetry (DPV) technique. It also shows a sensitivity and detection limit of ca. 5.70 μA/cm2/mM and 0.017 nM, respectively, for the detection of 4-AP, using current density (J)-voltage (V) measurement method. The sensor revealed an excellent stability, reproducibility, and recoveries of DA, UA, and 4-AP in real samples.

Yu et al. (2018) had fabricated Pt nanoparticle-incorporated GO nanocomposite-based microfiber sensor with high sensitivity for NH3 sensing [117]. The Pt-decorated sensor displayed a sensitivity of 10.2 pm/ppm, 3 times higher than the sensitivity without Pt-decorated nanoparticles. These results indicate the sensor has the optimal sensing sensitivity when the Pt nanoparticle concentration is 185.2 mg/L and exhibits a linear response with NH3 gas concentration below 80 ppm. This nanocomposite film-based passive optical fibre sensor provides an approach for highly sensitive NH3 sensing in a limited space, flammable or in explosive environment.

An excellent gas sensing characteristic of GO is contributed by the dangling bonds attached on its surface, which are essential for detecting the gas molecules. Yu and team (2018) made GO sheets that have higher adsorption efficiency of gas molecules by the presence of Pt nanoparticles. More NH3 gas molecules absorb to the surface of GO because the NH3 gas molecule can bind strongly to the bulk surfaces of platinum [118]. This incidentally improves the absorption ability of GO to NH3 gas molecules, resulting in the improvement in sensitivity for NH3 sensing. From their experiment, the different concentrations of Pt with the same GO content were tested for NH3 sensing. The result shows that the sensitivity for NH3 sensing is raised as the Pt concentration increases in the range from 0 mg/L to 185.2 mg/L. The sensing sensitivity was not improved significantly when the Pt concentration exceeds 185.2 mg/L. This could be because the refractive index change of GO is saturated with more gas molecules absorbed onto the surface of GO.

NH3 gas sensor characteristics based on fluorinated-GO (f-GO) have been investigated by Park et al. (2016) [119]. Gas sensor was fabricated by dropping dispersion solution (5 μL) of f-GO onto SiO2/Si wafers patterned with Pt electrodes. The fluorination treatment was carried out at partial fluorine gas (98%) pressures of 0.1 (GO-F1N9), 0.3 (GO-F3N7), and 0.5 (GO-F5N5) bar with an injection time of 5 min. The total pressure was adjusted to 1 bar with nitrogen gas, and the reaction time was 10 min. After the reaction, the residual gas was expelled and then purged 2 times with nitrogen gas. The gas sensor fabricated using f-GO (GO-F1N9) shows an approximately 7% change in the resistive response, whereas the non-treated GO does not exhibit any sensing ability to NH3 gas [119]. This change in the response is attributed to the lower Fermi level of GO and the increased number of holes in the GO after fluorination, which is helpful for effectively attracting NH3 gas. However, all samples do not exhibit recovery at room temperature and the presence of a higher number of fluorine-carbon bonds caused a decrease in the electrical resistance change.

For these reasons, fluorine bonded to GO surface leads to change in the electronic structure of GO. In Park et al. (2016) study, f-GO acts as an electron acceptor showing an increase of resistance when the reducing gas like NH3 is detected (Figure 13). GO decorated with fluorine functional group has a lower Fermi level than raw GO and makes electrons in the valence band move to the lowest unoccupied molecular orbital (LUMO) due to high electronegativity of fluorine. This fluorine doped on the GO surface creates a higher number of holes in the valence band. The absorption of NH3 gas on f-GO results in the electron lone pair of the NH3 molecules being transferred to LUMO of f-GO, leading to increases of Fermi level. Holes are not created in the valence band any more, thus the current flow is limited by the increase of resistance due to the decreased number of hole carriers. However, the GO-F5N5 (the higher fluorine gas pressure bar) showed a lower sensitivity to NH3 relative to those of GO-F1N9 and GO-F3N7. This result is supported by the loss of sp2 bonds by excess fluorination in GO. Figure 14 shows the sensing behaviour of f-GO under 100 ppm of NH3 gas at room temperature.

Adsorption phenomenon of NH3 with increase of resistance when the reducing gas like NH3 is detected.

![Figure 14

Sensing behaviour of f-GO under 100 ppm of NH3 gas at room temperature. Reproduced from ref. [119].](/document/doi/10.1515/ntrev-2021-0030/asset/graphic/j_ntrev-2021-0030_fig_014.jpg)

Sensing behaviour of f-GO under 100 ppm of NH3 gas at room temperature. Reproduced from ref. [119].

Prezioso et al. (2013) had investigated a number of forms of GO to optimize the sensing sensitivity and efficiency [120]. The fabricated sensing device by drop-casting water-dispersed single-layer GO flakes on standard 30 µm spaced interdigitated Pt electrodes. A practical p-type gas sensor using GO drop-casted shows a stable operating conditions, has a lifetime larger than 1,000s h, and exhibits a very low detection limit (20ppb). This excellent performance is due to the high quality of GO which have large and highly oxidized flakes. With correspondence to other carbonaceous materials such as rGO and CNTs, GO has the advantage to have a much larger number of active sites but the limitation being poorly conductive. Because of this, GO is considered as a good choice for applications that do not require fast responses, but require high sensitivities.

Dielectrophoresis (DEP) process for GO nanostructures for hydrogen gas sensor at room temperature was investigated by Wang et al. (2014) [121]. The GO nanostructures synthesized using Hummer’s method was assembled into gold electrodes using DEP process by varying parameters such as frequency, peak-to-peak voltage (Vpp), and processing time (t). Results show that an optimum DEP parameter required for hydrogen gas sensing using GO nanostructures is observed to be Vpp = 10 V, frequency = 500 kHz, and t = 30 s. The optimized device was found more effective and better hydrogen sensor with a good sensing response of 5%, fast response time (<90 s), and fast recovery time (<60 s) for 100 ppm hydrogen gas concentration at room temperature.

Some et al. (2013) had studied the highly sensitive and selective gas sensor using hydrophilic and hydrophobic graphenes coated on polymer optical fibre (POF) [122]. The high oxygenated functionalities on GO surface were observed to maintain the high sensitivity in highly unfavourable environments (extremely high humidity, strong acidic or basic). The GO-based sensor displayed faster sensing and higher sensitivity when compared to rGO even under extreme environments of over 90% humidity, making it the best choice for an environmentally friendly gas sensor. Furthermore, according to the experimental results, the sensitivity of GO to VOCs (mainly nitro and amine containing compounds) is much higher than that of rGO due to the presence of numerous polar functional groups like hydroxyl and carboxylic acid [122].

Shown in Figure 15 are the comparison of sensing responses for GO and rGO to eight different chemicals (hydrazine, ethanol, methanol, dichloromethane, acetone, THF, nitromethane, and diethylamine) at a 500 ppb of concentration level. The result shows that only GO and only rGO-coated POF sensors showed different sensitivities toward the various vapours. The intensity of the reflected optical response for the only GO and only rGO POF sensor was highest for hydrazine, diethylamine, and nitromethane vapours at the same concentration, respectively and was lowest for methanol and dichloromethane vapours, respectively. The experimental result shows the sensitivity of GO to VOCs (mainly nitro and amine containing compounds) is much higher than that of rGO due to the presence of numerous polar functional groups.

![Figure 15

Comparative of sensing behaviour towards the different chemical gas by GO and rGO coated on POF. Reproduced from ref. [122].](/document/doi/10.1515/ntrev-2021-0030/asset/graphic/j_ntrev-2021-0030_fig_015.jpg)

Comparative of sensing behaviour towards the different chemical gas by GO and rGO coated on POF. Reproduced from ref. [122].

3.3 Performance rGO nanocomposite-based sensor

Referring to Yavari and Koratkar (2012), even though GO is electrically insulating due to plentiful oxygen functional groups, the conductivity can be restored to several orders of magnitude. This is by the removal of oxygen groups using chemical or thermal reduction or can be partially reduced to graphene-like sheets. By removing the oxygen-containing groups with the recovery of a conjugated structure termed as rGO, the conductivity can be possessing up to several orders of magnitude. Even so, this process does not lead to pure graphene, and some residual oxygen groups remain even after the reduction process. Consequently, rGO has both high electrical conductivity and chemically active defect sites, making it a promising candidate for gas sensing. This sensor is able to reversibly and selectively detect chemically aggressive vapors such as NO2, Cl2, and so forth down to concentrations ranging from 100 to 500 ppb [13].

Exploitation of a new concept for enhancing the performance of rGO gas sensors by combining the structural engineering techniques of 3D microstructuring has been explored by Duy et al. (2015) [123]. From that, a high performance of three-dimensional chemical sensor platform using rGO for NH3 and NO2 detection was achieved. The performance of a chemical sensing device was enhanced from a simple three-dimensional (3D) chemiresistor-based gas sensor platform with an increased surface area by forming networked, self‐assembled rGO nanosheets on 3D SU8 micro‐pillar arrays. The 3D rGO sensor is highly responsive at low concentration of NH3 and NO2 diluted at room temperature. Compared to the two-dimensional (2D) planar rGO sensor structure, as the result of the increase in sensing area and interaction cross‐section of R‐GO on the same device area, the 3D rGO gas sensors show improved sensing performance with faster response (about 2%/s exposure), higher sensitivity, and even a possibly lower limit of detection towards NH3 at room temperature. Figure 16 shows the schematic diagram of structure for 2D and 3D devices and sensing response of rGO sensors towards 5 ppm of NO2 and 40 ppm of NH3.

![Figure 16

(a) Schematic diagram of structure for 2D and 3D devices of SU8 micro‐pillar arrays with different heights of 40 and 70 μm for 3D devices, (b) sensing response of rGO sensors towards a) 5 ppm NO2 (exposure time about 15 min) and (c) 40 ppm NH3 (exposure time about 30 min). Adapted from ref. [123].](/document/doi/10.1515/ntrev-2021-0030/asset/graphic/j_ntrev-2021-0030_fig_016.jpg)

(a) Schematic diagram of structure for 2D and 3D devices of SU8 micro‐pillar arrays with different heights of 40 and 70 μm for 3D devices, (b) sensing response of rGO sensors towards a) 5 ppm NO2 (exposure time about 15 min) and (c) 40 ppm NH3 (exposure time about 30 min). Adapted from ref. [123].

A sono-synthesis method to produce rGO nanosheets for NH3 vapour detection at room temperature was studied by Veluswamy et al. (2015). From their study, the polyethylenimine (PEI) was used as reducing agent to reduce the GO, which increases the conducting nature of the GO. The synthesis of GO and reduced rGO was prepared by Hummer’s method and sonication method with low-frequency ultrasound under ambient condition, respectively. The rGO-based chemiresistive sensors showed a good sensing response (3,500%), high sensitivity (38.85 kΩ/ppm), low level detection (1 ppm), wide range of detection (1 –100 ppm), quick response (6 s), recovery time (75 s), good reparability, better selectivity, and stability to be operated at room temperature for NH3 detection. Figure 17(a) shows the sensing response of various test vapours, and Figure 17(b) and (c) shows the sensing response of rGO film towards 1–5 ppm, and 10–100 ppm range of NH3 vapour [124].

![Figure 17

(a) Sensing response of various test vapours, (b) and (c) show the sensing response of rGO film towards 1–5 ppm and 10–100 ppm range of NH3 vapour. Adapted from ref. [124].](/document/doi/10.1515/ntrev-2021-0030/asset/graphic/j_ntrev-2021-0030_fig_017.jpg)

(a) Sensing response of various test vapours, (b) and (c) show the sensing response of rGO film towards 1–5 ppm and 10–100 ppm range of NH3 vapour. Adapted from ref. [124].

The NH3 sensing response of GO and rGO also has been investigated by Veluswamy et al. (2018) and shown in Figure 18. The result indicates that the NH3 response increases for rGO drastically (nearly 3–9 times), increases from 16 to 45% for 10 ppm, and from 403 to 3,400% for 100 ppm for rGO. The oxidation process from graphene to the highly oxygenated GO depends on various factors such as the size of GO sheets, the content of oxygen functional groups, and thus greater defect intensity of GO, which is confirmed by Raman results [125]. The electrical resistance of GO is high because of the disturbance of the conjugated electronic structure by these oxygen-containing groups. However, chemical reduction of GO can effectively bring back its conductivity; meanwhile, a fewer amount of oxygen-containing functional groups still remain in rGO, because of its incomplete reduction. The reduction process may introduce some vacancies and structural defects which can also act as adsorption sites. From that, the interaction of chemical molecules with high-energy defects in graphene differed dramatically from those with conjugated carbon structure. Therefore, optimization of defect density and its kind may be an effective way to manage the response, sensitivity, and selectivity of rGO-based chemical sensor [125].

![Figure 18

Comparative ammonia sensing response of GO and rGO film. Adapted from ref. [124].](/document/doi/10.1515/ntrev-2021-0030/asset/graphic/j_ntrev-2021-0030_fig_018.jpg)

Comparative ammonia sensing response of GO and rGO film. Adapted from ref. [124].

A highly selective detection of carbon monoxide (CO) gas by rGO-based chemical sensor at room temperature has been investigated by Panda et al. (2016) [126]. The sensing performances of rGO-based chemical sensor against CO were studied in terms of percent sensitivity (sensor response), response and recovery times, and I/V characteristics at room temperature. Gas sensing experiments exhibit about 71% sensitivity at room temperature at 30 ppm of CO. The selectivity of the sensor using different n-type reducing gases was negligible cross-sensitivity against NH3, CH4, and H2 at different concentrations. Thus, the rGO is shown as highly potential material for development of CO gas sensor with high degree of sensitivity, selectivity, and reliability, proving it selective to CO gas at room temperature within permissible exposure limits.

The research on rGO-based gas sensor functionalized with a peptide receptor to detect explosives, dinitrotoluene (DNT), which is a by-product of trinitrotoluene (TNT) was investigated by Lee et al. (2019) [127]. The rGO-based sensor was fabricated using DNT-specific binding peptide functionalized rGO. The sensitivity was calculated by measuring the resistance change using the differential signals between DNT-BP (binding peptide) and DNT-NBP (non-binding peptide) to function as highly specific and highly non-specific (for the control experiment) peptide receptors.

The rGO-based sensor showed an excellent linear sensitivity of (0.27 ± 0.02) × 10−4 ppb with an approximate limit of detection (LOD) of 2.43 ppb. The multi-arrayed rGO sensor was fabricated using spin coating and a standard microfabrication technique. The result was sensitivity of 27 ± 2 × 10−6 part per billion (ppb) for the slope of resistance change versus DNT gas concentration of 80, 160, 240, 320, and 480 ppm, respectively. By sequentially flowing DNT vapour (320 ppb), acetone (100 ppm), toluene (1 ppm), and ethanol (100 ppm) onto the rGO sensors, the change in the signal of rGO in the presence of DNT gas is 6,400 × 10−6 per ppb (Figure 19(c)). However, the signals from the other gases show no changes and represent highly selective performance. Figure 19(a) and (b) shows the rGO-based sensor for DNT detection and location of the rGO sensor patterns (200 μm × 100 μm) between the Au electrodes, respectively.

![Figure 19

(a) Enlarged rGO chemical sensor with eight multiple arrays for DNT detection, (b) location of the rGO sensor patterns (200 μm × 100 μm) between the Au electrodes, and (c) resistance change on five different gases: the differential values (black bar) of DNT-BP and DNT-NBP confirm the high selectivity. Adapted from ref. [127].](/document/doi/10.1515/ntrev-2021-0030/asset/graphic/j_ntrev-2021-0030_fig_019.jpg)

(a) Enlarged rGO chemical sensor with eight multiple arrays for DNT detection, (b) location of the rGO sensor patterns (200 μm × 100 μm) between the Au electrodes, and (c) resistance change on five different gases: the differential values (black bar) of DNT-BP and DNT-NBP confirm the high selectivity. Adapted from ref. [127].

A rGO-based sensor was synthesized and fabricated under H2/Ar treatment 100 to 900°C for H2 detection [128]. Before that, the GO samples were prepared according to a modified Hummers’ method. The prepared GO was then treated at different temperature to obtain a series rGO samples (rGO-100 to rGO-900); numbers denote the treating temperature. From the results obtained, the rGO-100 and rGO-200 showed very weak responses. Further responses of rGO-300 to rGO-900 against 500 ppm of H2 at room temperature were presented in Figure 20(a). From that, rGO-300 had exhibited the best sensitivity towards the H2 detection. Other than that, CO and CH4 also produced signals on rGO-300-based sensors. The balance between the chemical adsorption capacity and electronic conductivity and the dominance of either electrons or holes are the key factors of the high sensitivity from the rGO-300.

![Figure 20

(a) rGO structure with the attached carbonyl, carboxylic, hydroxyl, and epoxide groups considered as defective sites and (b) oxygen content, conductivity, and sensitivity of rGO samples with different treatment temperature. Adapted from ref. [128].](/document/doi/10.1515/ntrev-2021-0030/asset/graphic/j_ntrev-2021-0030_fig_020.jpg)

(a) rGO structure with the attached carbonyl, carboxylic, hydroxyl, and epoxide groups considered as defective sites and (b) oxygen content, conductivity, and sensitivity of rGO samples with different treatment temperature. Adapted from ref. [128].

Zhang et al. (2011) stated that in order to generate a strong sensing signals, adsorption of target gas molecules was necessary. It required relatively strong binding force between the sensing materials and the target gas molecules. As example, it was reported that the hydrogen molecules tended to be adsorbed on the defect site of the rGO (Figure 20(a)). Thus, the binding force between H2 and the sidewall of rGO was rather weak. This was the same for rGO-700 and rGO-900 samples because these two samples had few defect sites. For rGO, the oxygenate groups could be considered as the defect sites on the graphene sheets. The relationship among sensing properties, conductivity, and the oxygen content could be further described in Figure 20(b). The oxygen content decreased from GO to rGO-900 as determined from XPS, leading to increased conductivity. During the sensing process, the gas molecule is adsorbed on the rGO surface with the oxygenated groups through hydrogen-bonding, then electron is transferred to the rGO resulting in a change of the resistance. In order to generate a sufficient sensing signal, a sufficient amount of functional groups is needed to act as an adsorption site. However, too many functional groups also would significantly reduce the conductivity of the rGO sample as observed on rGO-100 and rGO-200. The amount of hydrogen adsorption may also affect the response pattern of rGO-300 and rGO-900. Therefore, a delicate balance between chemical adsorption capacity and the conductivity of the rGO samples was the key factor for good sensing responses’ properties realized on rGO-300.