Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

-

Tummala Srinag

, Sudhir Kumar Singh

Abstract

In order to achieve total biodegradability in polymer materials, researchers are looking into natural polymer matrices and fillers to replace the existing partially biodegradable polymers and particle-filled composites. This work focuses on using a natural polymer matrix derived from neem shells as a hosting medium and walnut shell powder as a particle filler. Mechanical characterization is carried out, which includes an examination of tensile strength, modulus, thermal conductivity, and impact strength. The composite specimens, which contain varied weight fractions of walnut shell powder, are tested. The results show that increasing weight fractions leads to significant improvements in mechanical qualities. At a 25% weight fraction, the tensile strength increases by 57.5%, while the flexural strength improves by 59.09%. Additionally, at a 30% weight fraction, the impact strength shows a remarkable increase of 282%, whereas thermal conductivity decreases by 36.36%. These findings highlight the potential of natural reinforcements in biodegradable polymer composites, demonstrating their ability to enhance mechanical performance while reducing thermal conductivity and find applications in the automotive industry, construction, packaging goods, and biocompatible materials for prosthetics and implants.

1 Introduction

With the increasing awareness of global warming, there has been a shift toward biodegradable polymer matrices to mitigate environmental degradation. Conventional polymer matrices significantly contribute to pollution, making it crucial to either minimize their usage or replace them with biodegradable alternatives [1,2,3].

Efforts have been made to introduce fully or partially biodegradable polymer matrices to reduce environmental impact [4,5,6,7]. This is achieved by reducing the polymer content by incorporating biodegradable agricultural waste [8,9,10] and by replacing synthetic polymers with bio-based alternatives such as polysaccharides, natural rubbers, starch blends, and PHA-based biopolymers [11,12,13,14,15].

One option for mitigating this impact is to minimize the use of polymer matrices, hence lowering their environmental impact [4,5,6,7]. Furthermore, substituting non-biodegradable polymer matrices with fully or partially biodegradable alternatives is critical to increasing total biodegradability [8,9,10]. Numerous researchers have explored natural polymer matrices derived from plant-based sources, evaluating their mechanical properties.

Partial biodegradability can be accomplished by lowering the polymer content and introducing biodegradable agricultural waste [11,12,13]. Another aim is to completely replace synthetic polymers with biodegradable, non-synthetic alternatives [14]. Natural polymers originating from various plant-based sources are currently being identified. Many researchers have shed light on many natural matrix materials, including polysaccharides [15], natural rubbers and oils [16], starch-blended biodegradable polymers [17], and starch-PHA blend-based biopolymers [18].

Once various sources for producing natural polymer matrices have been identified, the next step is their characterization to assess their mechanical properties. In this study, luffa natural fiber is used as reinforcement, while natural rubber serves as the matrix in composite fabrication. The tensile strength of these composites is predicted [19,20]. Furthermore, efforts are being made to enhance the mechanical properties of natural polymers while preserving their biodegradability. This includes improving the strength, durability, and other mechanical attributes to ensure that biodegradable materials remain viable alternatives to synthetic polymers while reducing environmental impact.

Du et al. [21] used high-yield pulp from hardwood and softwood, and fibers from bleached kraft softwood pulp, and the mechanical and thermal characteristics of the composite were described.

A thermomechanical analysis has been conducted on a few new, fully bioactive, three-component composite systems meant for bone augmentation and repair by Nazhat et al. [22]. Using direct injection molding, new Himalaya calamus falconeri fiber-reinforced polylactic acid bio composites were created, and mechanical characterization was performed [23]. The leftover fruit from tamarind was studied as a potential polymer composite filler for dashboard applications in cars, as suggested [24]. It was found that a greater tensile strength of 27 MPa, particularly for the composite with 80% matrix, 14% flax, and 6% pine cone fibers, was observed [25]. Research has been done on the physio-chemical properties, thermal properties, and other features of Careya Arborea (CA) fiber [26] and particulate composites are clearly studied [27].

Most research has focused on identifying naturally occurring biodegradable fillers and PLA-based matrices for the development of biodegradable composites. Additionally, extensive material characterization has been conducted to ensure their suitability for various applications. However, until now, there has been no discussion on the mechanical characterization supporting finite element analysis (FEA) of neem shell liquid as a matrix material combined with a natural filler. In this study, efforts are made to develop a biodegradable composite using neem shell liquid as the matrix and walnut shell powder as the filler. Furthermore, the thermal behavior of the fabricated composites is analyzed using the finite element approach.

This study aims to develop a biodegradable composite using neem shell liquid as the matrix and walnut shell powder as the filler. The mechanical properties of the composite were investigated to assess its suitability for practical applications. Additionally, FEA was used to study the thermal behavior of the composite, addressing a gap in current research. This approach introduces a novel biodegradable matrix, reducing reliance on synthetic polymers while maintaining structural integrity and eco-friendliness. While most studies are limited to predicting tensile and flexural modulus, this research extends beyond these properties by also identifying thermal conductivity and performing impact analysis using finite element methods.

2 Materials and methods

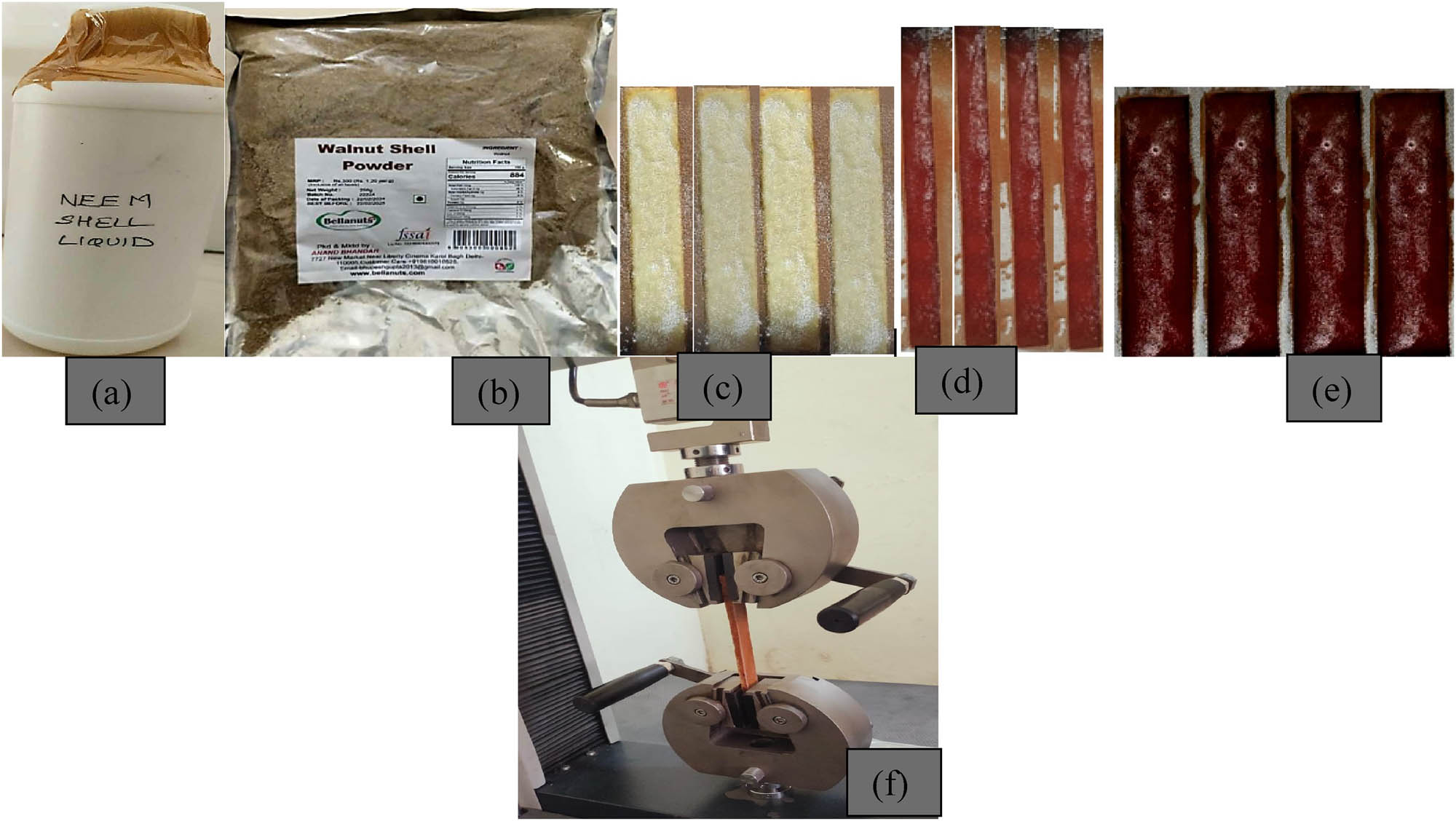

To prepare the natural composite material, two natural components are used: a natural matrix made from neem shell liquid (Figure 1a) and walnut shell powder (Figure 1b) as another natural constituent. The hand layup method is used to create full composite specimens that include a natural filler and a natural matrix (Figure 1c–e). This procedure entails manually pouring the walnut shell powder into the neem shell liquid matrix to create the required composite specimen, which is then tested using the universal tensile testing machine (Figure 1f).

Neem shell and walnut shell powder along with the pure and filler mixed specimens: (a) neem shell liquid, (b) wall nut shell powder, (c) pure neem shell specimens, (d) tensile specimens of neem shell and wall nut powder, (e) flexural specimens of neem shell and wall nut powder, and (f) tensile testing of composite specimen.

Neem shell liquid matrix is the liquid component recovered from neem shells. When treated, these shells produce a liquid fluid that can be used as a natural matrix material in composite manufacturing. Neem shell liquid is purchased from Vriksha Agencies, along with appropriate hardeners and catalysts. Additionally, walnut shell powder, obtained from Bellanuts, is mixed with the neem shell liquid, along with the hardener and catalyst. The mixing ratio for walnut shell powder ranges from 5 to 30% by weight, with 5% interval.

A sonication procedure is used to verify that the walnut shell powder and neem shell liquid are properly mixed at the considered weight fractions. Ultrasonication aids in the homogeneous blending of walnut shell powder with neem shell liquid, resulting in inhomogeneity in the composite material. This facility is located at Prasad V Potluri Siddhartha Institute of Technology (Kanuru, Vijayawada, Andhra Pradesh, India).

This liquid matrix, when mixed with additional natural reinforcements like walnut shell powder, can be used to prepare composite materials with specific weight fractions. In the context of natural composite production, the neem shell liquid matrix functions as a binder or adhesive, binding the filler particles together to form a cohesive structure. A particle filter mesh collects uniformly sized walnut shell powder particles. The diameter of the green waste powder particles is maintained at 0.3 mm.

To prepare the specimen with a weight fraction of 5% walnut shell powder, 1.2 g of dry walnut shell powder is suspended in 60.2 mL of neem shell liquid. Initially, the mixture is mechanically agitated at 150 rpm for 1 h. This stirring operation ensures that the walnut shell powder is thoroughly mixed with the neem shell liquid, resulting in a uniform product.

Following mechanical swirling, the mixture is subjected to ultrasonication for additional processing. The ultrasonicator runs at 600 rpm for 2 h. During this period, ultrasonic waves are applied to the mixture, promoting the dispersion of walnut shell powder particles and improving the mixture’s homogeneity. This ultrasonication technique helps to remove any leftover agglomerates, resulting in a well-dispersed composite material with consistent characteristics throughout the specimen.

After sonication, the material is poured into molds to form composite specimens. These specimens are prepared for tensile, flexural, impact, and thermal conductivity testing to evaluate the mechanical properties of the walnut shell-reinforced neem shell matrix composite. All specimens undergo a 24-h curing process before testing. To ensure measurement repeatability, four specimens are prepared for each weight fraction examined in the investigation.

The weight fraction examined for the study is limited to 30% based on open literature, as many studies have demonstrated that the optimum concentration lies between 20 and 30% [20,21].

Tensile specimens are prepared using the ASTM D3039 procedure, whereas flexural specimens are prepared using the dimensions recommended by ASTM D790. ASTM D256 guidelines are used to produce impact specimens, while ASTM Designation E1530 is used to prepare the thermal conductivity specimens.

Tensile and flexural tests are carried out using a digital universal tensile testing machine. The testing speed is kept at 2 mm/min, and a 20 kN load cell is used for both tests. For the Izod impact test, all prepared natural composites are evaluated using the Izod Charpy Impact Tester Touch Screen model with an H1 impactor. When the H1 impactor strikes the specimen, it generates 2.71 J of potential energy. Tensile, flexural, impact, and thermal conductivity testing is carried out at Prasad V Potluri Siddhartha Institute of Technology (Kanuru, Vijayawada, India).

2.1 Finite element modeling of the wall nut powder mixed with neem shell matrix composite

The performance of a unique natural composite material made of powdered walnut shell mixed with a matrix of neem shell is assessed in this study using a thorough thermal analysis. The main goal is to evaluate this environmentally friendly composite material’s capacity for thermal insulation under heat loading conditions, which is essential for uses in packaging, thermal barrier systems, and sustainable building.

ANSYS Workbench, a popular engineering simulation program, is utilized to carry out the study through finite element-based simulation. Based on actual fabrication considerations for insulating panels, the composite sample is modeled as a rectangular plate with dimensions of 100 mm × 100 mm in length and width and a thickness of 5 mm. In order to provide a standard test specimen appropriate for comparing thermal performance, certain geometrical parameters were carefully selected (Figure 2a).

![Figure 2

(a) Composite plate dimension and applied loading conditions. (b) Presents the finite element contours of Uz in the composite plate used for validation [28].](/document/doi/10.1515/jmbm-2025-0078/asset/graphic/j_jmbm-2025-0078_fig_002.jpg)

(a) Composite plate dimension and applied loading conditions. (b) Presents the finite element contours of Uz in the composite plate used for validation [28].

The ANSYS Workbench environment’s Design Modeler module is used to create the geometrical model of the composite plate. This entails establishing the 3D geometry, allocating suitable material attributes based on the walnut–neem composite’s experimental characterization, and getting the model ready for meshing. After that, the finite element mesh is produced with enough accuracy to precisely depict temperature gradients throughout the plate’s thickness and surface.

In order to apply thermal boundary conditions, one face of the plate is simulated to be exposed to a constant heat flow or temperature source, while the other face is kept at room temperature or insulated. This configuration replicates the actual circumstances used to assess thermal insulation performance (Figure 2a), which depicts the 3D structure of the composite plate, serves as a visual reference for the analysis scenario, and displays the resultant geometrical model and simulation setup. The simulation’s findings on temperature distribution and thermal deformation provide important information on how well the composite withstands heat flow, strengthening the recommendation for thermal insulation applications.

To evaluate the thermal insulation capabilities of the proposed natural composite, a steady-state thermal analysis is conducted using ANSYS Workbench. Table 1 lists the material properties considered in the analysis, such as density, specific heat capacity, and thermal conductivity. Both the pure neem shell matrix material and the walnut shell powder–neem shell matrix composite have these characteristics and have been shown experimentally.

Material properties

| S.I. no | Type of material | Thermal conductivity (W/mm°C) |

|---|---|---|

| 1. | Neem shell matrix | 0.0012235 |

| 2. | Walnut-filled matrix at 25% weight fraction | 0.77861 |

In order to simulate a warm environment, a thermal boundary condition is applied, exposing one surface of the composite plate to a continuous heat source of 50°C. To represent actual operating conditions, the opposite surface is kept at room temperature (22°C). This configuration makes it possible to examine heat flux and temperature distribution through the thickness of the composite, which are the two important markers of the material’s ability to insulate against heat. The geometrical model of the composite plate (100 mm × 100 mm × 5 mm) is discretized using the SOLID186 element, a 20-node higher-order 3D solid element with quadratic displacement behavior, in order to carry out the FEA. SOLID186 is appropriate for precisely recording the temperature gradients and structural responses in composite materials because each node has three degrees of freedom, or translations in the x, y, and z axes.

To represent the real behavior of the material under thermal loading, the finite element model is built from the geometric model, as shown in Figure 2. Heat transfer through the composite is shown graphically and quantitatively by the temperature distribution and heat flux vectors that were derived from the simulation. A comparative investigation is carried out to demonstrate the benefits of adding walnut shell powder to the neem shell matrix. A plate composed of a pure neem shell matrix is subjected to the same loads and boundary conditions, and the thermal responses are contrasted. The temperature distribution over the thickness of the plate varies noticeably due to the different thermal conductivity of the two materials. This comparison successfully illustrates the blended composite’s improved thermal insulation properties, bolstering its possible applicability in applications needing increased thermal resistance while preserving sustainability and biodegradability.

2.2 Validation of the finite element method

In order to verify the precision of the FEA, the outcomes of the simulation were compared to the conclusions presented in Jameel and Yousuf [28]. The identical geometry, material properties, boundary conditions, and thermal loading conditions were used to model the same problem in ANSYS for the current investigation.

Thermal loads of 60 and −15°C were used to assess the static deflections in the X and Y directions. The projected deflections are in good agreement with the experimental and simulation results described in the reference publication, according to a thorough comparison of the simulated results and the published data. This uniformity attests to the correctness and dependability of the finite element method used in this investigation.

At 60 and −15°C thermal loading, with a volume fraction of 25.076%, the deformation in the Z-direction is simulated. The finite element contours showing the Z-direction deformation under 60°C loading conditions are presented in Figure 2(b). The percentage variation between the present simulation results and the published results is 3.52% at 60°C and 3.26% at −15°C, respectively. Table 2 presents the simulation results along with the corresponding percentage errors compared to the published data.

3 Results and discussion

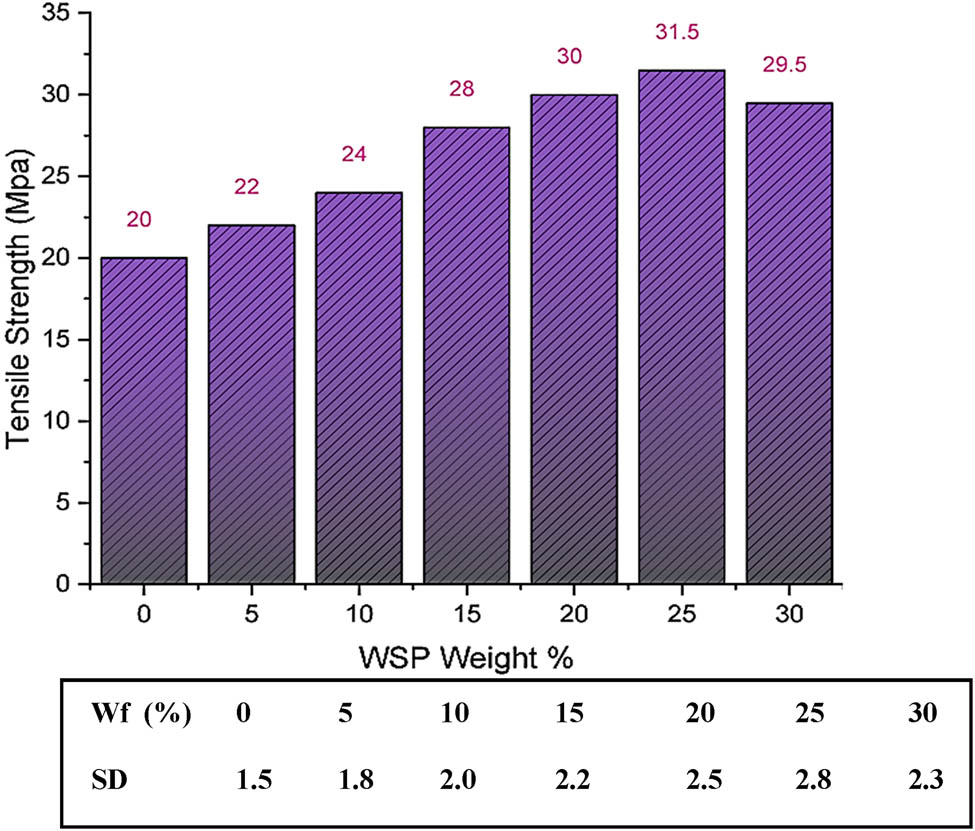

Figure 3 displays the tensile strength of a composite material made of a natural matrix filled with walnut shell powder. The filler amount of walnut powder varies from 5 to 30%. For comparison, specimens without walnut filler, i.e., pure neem shell matrix specimens, are evaluated and compared to identify the improvement.

Variation of tensile strength with WSP%.

The infusion of walnut shell powder increases the tensile strength by 10% above the prior percentage. For example, when comparing 0 and 5% walnut shell powder, the tensile modulus improves by 10%. Similarly, comparing 10–5% yields a 10% improvement. The maximum strength of 31.5 MPa is achieved for a 25% walnut shell powder concentration. However, the characteristic decreases beyond this limit due to particle aggregation in the neem shell matrix. At this concentration, the walnut shell powder effectively reinforces the neem shell matrix, enhancing load-bearing capacity and mechanical performance. However, beyond this threshold, the mechanical properties begin to decline. This reduction is primarily attributed to particle aggregation, where excessive filler content leads to clustering and uneven dispersion within the matrix. These agglomerates act as stress concentrators, disrupting the uniform stress transfer between the matrix and the filler. Additionally, higher filler loading may reduce the matrix’s ability to adequately wet and bond with the walnut shell powder, leading to weak interfacial adhesion and increased void formation. Consequently, instead of enhancing the composite’s mechanical properties, excessive filler content compromises its structural integrity, leading to a decline in strength. This agglomeration reduces dispersion and interfacial adhesion between the walnut shell powder and the neem shell matrix, resulting in a reduction in tensile strength [29,30,31].

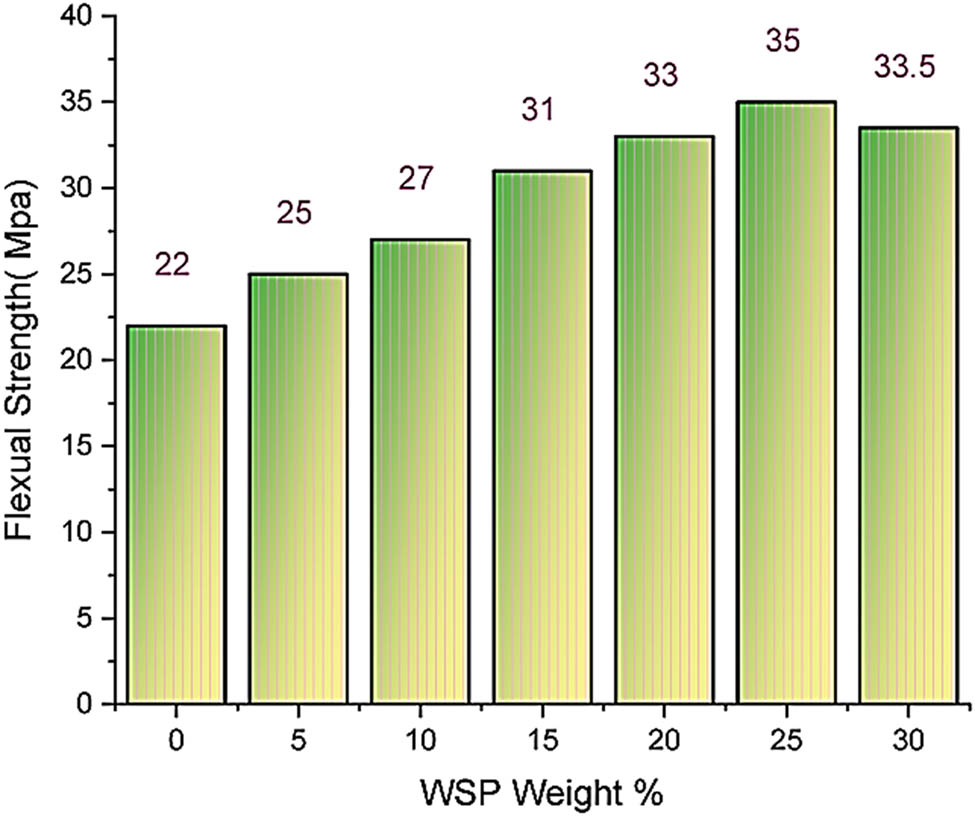

Figure 4 depicts the flexural strength of a composite material made of walnut shell blended with neem shell matrix. Flexural strength improves with the addition of 5% walnut shell powder to the neem shell matrix. This pattern continues until 25%, at which point the characteristic decreases by 4.28% [32].

Variation of flexural strength with WSP%.

The decrease in the property after adding 25% walnut shell powder can be attributed to restrictions in effective transformation within the neem shell matrix liquid due to the increasing amount of the filler material [33]. When the concentration of walnut shell powder surpasses the recommended range, it becomes difficult for the neem shell matrix to accommodate and distribute the filler evenly. This uneven distribution can cause localized stress concentrations and discontinuities within the composite structure, resulting in lower flexural strength.

Consequently, localized stress concentrations form, increasing the likelihood of microcracks and structural discontinuities under applied loads; additionally, an excessive amount of filler weakens the interfacial adhesion between the two phases by reducing the matrix’s ability to fully encapsulate and bond with the walnut shell powder, which results in premature failure when subjected to bending forces, lowering the composite’s flexural strength; additionally, an excessive amount of filler can introduce voids and defects within the material, further jeopardizing its overall mechanical integrity; therefore, maintaining an ideal filler concentration is essential to the composite’s balance between reinforcement and structural stability.

Thus, while the inclusion of filler material initially improves mechanical qualities, surpassing the appropriate concentration might result in diminishing returns and a decrease in the overall performance [34].

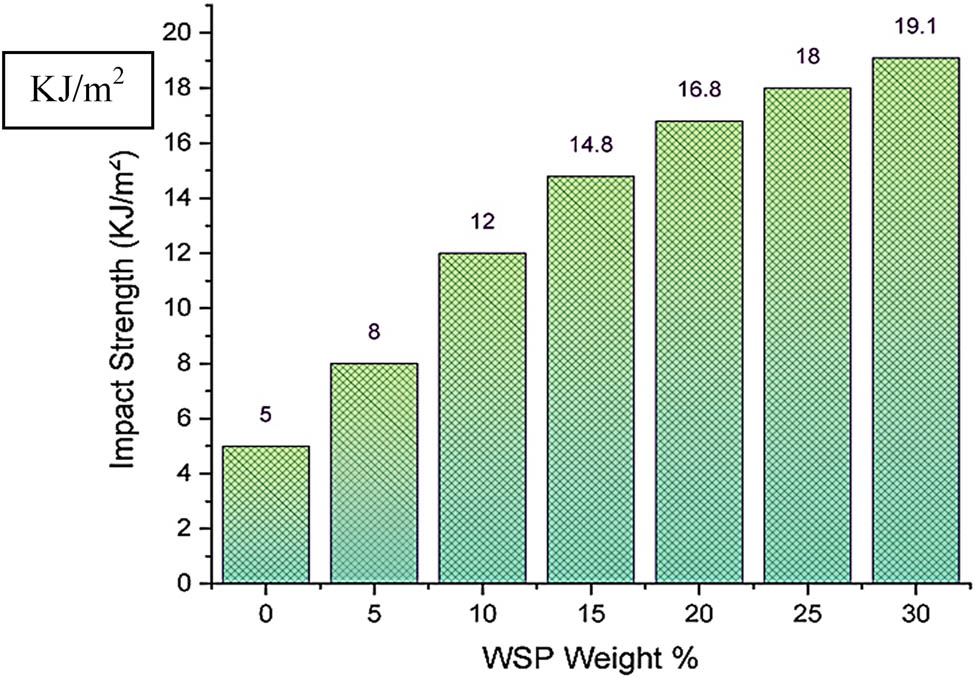

The impact strength of the constructed composite is shown in Figure 5. Unlike tensile and flexural strength, which might vary with the addition of filler, impact strength improves continuously with the addition of the filler material [35].

Variation of impact strength with WSP%.

The addition of walnut filler significantly increased the impact strength as compared to the pure neem shell matrix. For example, adding 5% walnut shell powder to neem shell resin increases the impact strength from 5 to 8 kJ/m2. This suggests that the natural matrix may struggle to absorb abrupt loads. However, by including natural biodegradable fillers in the matrix, the impact strength can be greatly enhanced [36].

Toughening mechanisms include crack deflection, energy dissipation through filler–matrix interactions, and enhanced stress distribution introduced by the filler. Because of its increased fracture resistance, the composite is a more practical material for applications that need increased impact durability without sacrificing its biodegradable and environmentally benign qualities.

The continual improvement in impact strength with increasing filler content shows that the addition of walnut shell powder improves the composite material’s capacity to sustain rapid impacts or dynamic loading conditions. This increased impact resistance may make the composite appropriate for applications in which structures are subjected to impact loads within the prescribed range [37].

The decrease in tensile and flexural strength at 30% walnut shell reinforcement is likely due to the excessive filler content, which can lead to poor interfacial bonding between the matrix and filler, resulting in stress concentration points and reduced load transfer efficiency. However, the impact strength increases with higher filler content because walnut shell particles act as energy-absorbing elements, enhancing toughness and resistance to sudden loads. This trade-off highlights the importance of optimizing filler content to balance the mechanical properties.

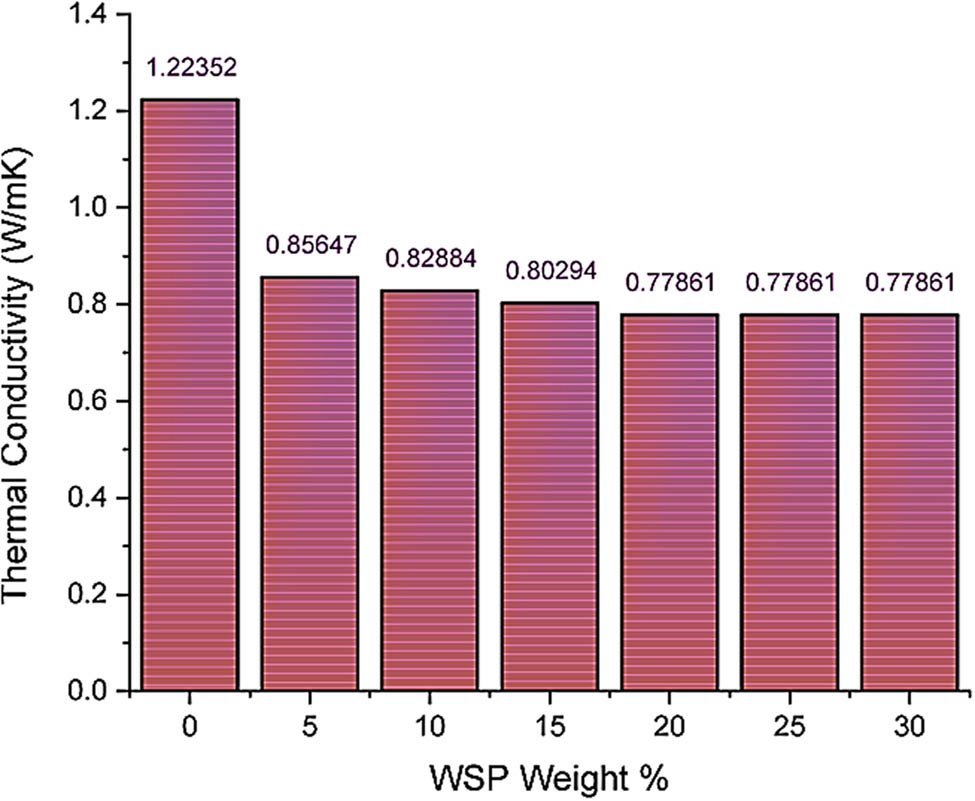

Figure 6 shows the thermal conductivity of the created natural composite. The thermal conductivity of the pure matrix was measured to be 1.22352 W/m K. Interestingly, the incorporation of walnut shell powder within the matrix reduces thermal conductivity [38]. This means that adding walnut shell powder to the neem-shell matrix boosts its insulating ability significantly. The addition of walnut shell powder improves the thermal insulating capacity of the pure neem shell resin by up to 36%. This suggests that the presence of walnut shell powder improves the composite’s ability to resist heat transfer, resulting in better thermal insulation qualities.

Variation of thermal conductivity with WSP%.

However, after adding a 20% weight fraction of walnut powder, the heat conductivity levels off. This implies that adding walnut shell powder at higher concentrations does not result in significant improvements in the thermal insulating capacity. As a result, adding walnut shell powder into the resin at this concentration yields the highest thermal insulating capacity [39].

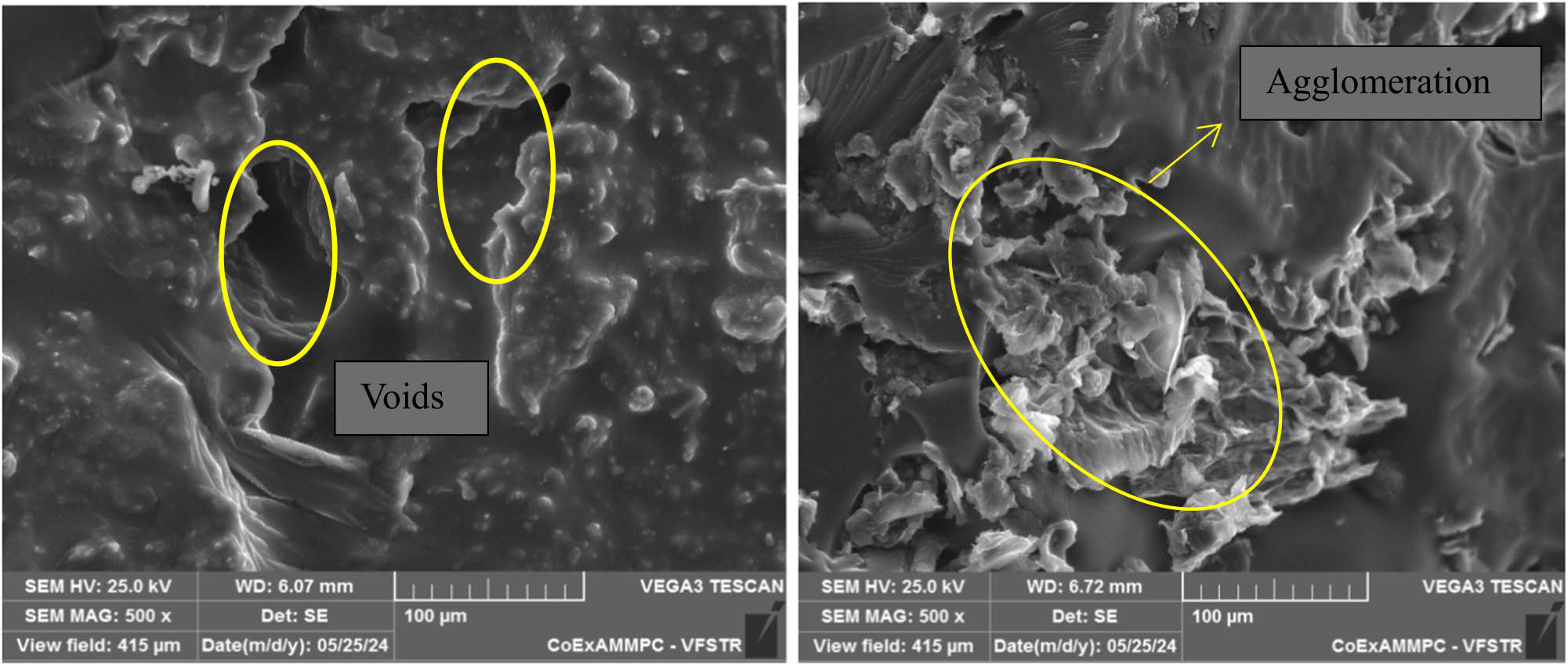

Scanning electron microscopy (SEM) images were created utilizing the VEGA3 Tescan SEM with a 10 kV voltage. Scanning electronic images of the walnut powder blended neem shell matrix composite are shown in Figure 7. These images were captured at 30% wall nutshell powder mixed with a neem shell matrix composite. The formation of voids and agglomeration is responsible for the decrease in tensile strength at a 30% weight fraction of walnut powder in the neem shell matrix.

SEM images of walnut powder mixed with a neem shell matrix composite.

3.1 FEA of the walnut powder mixed with a neem shell matrix composite

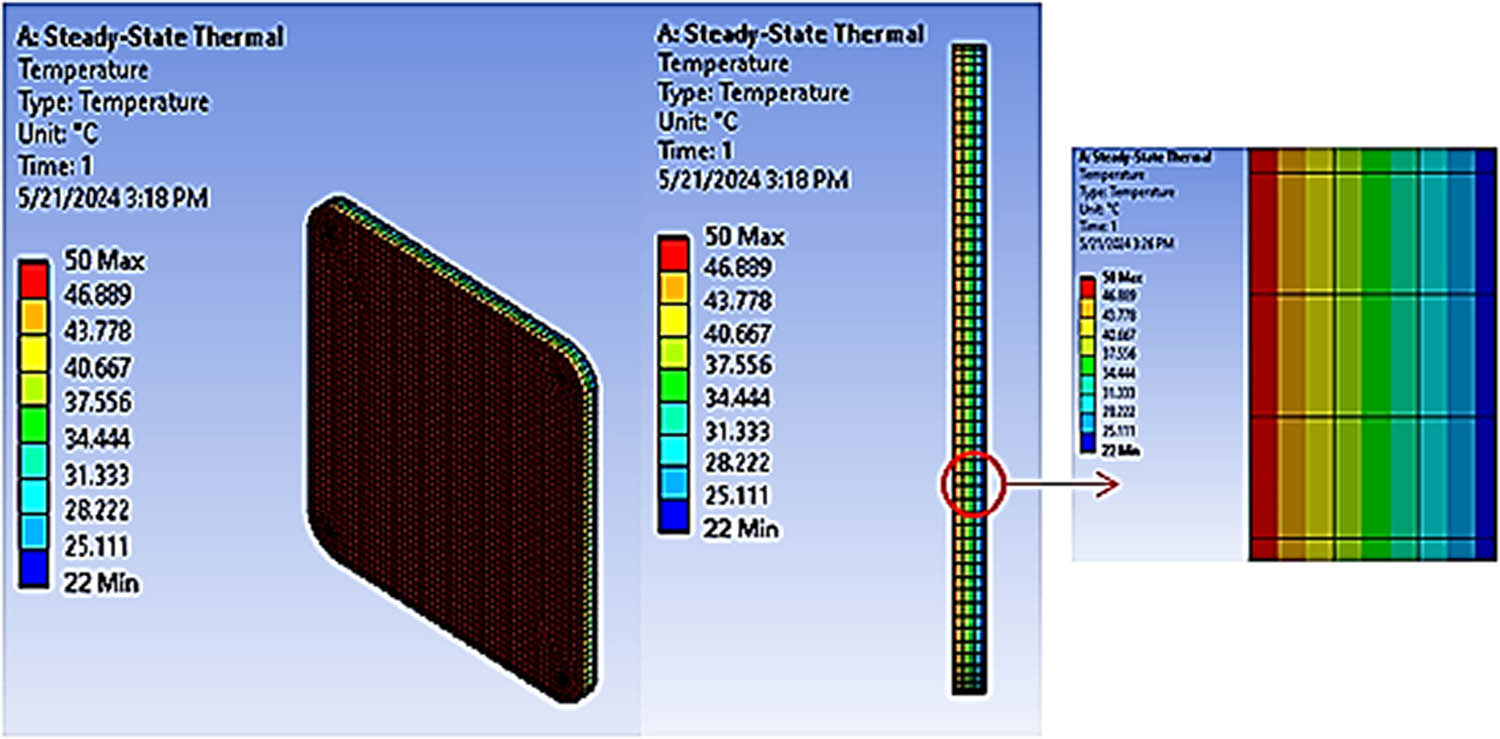

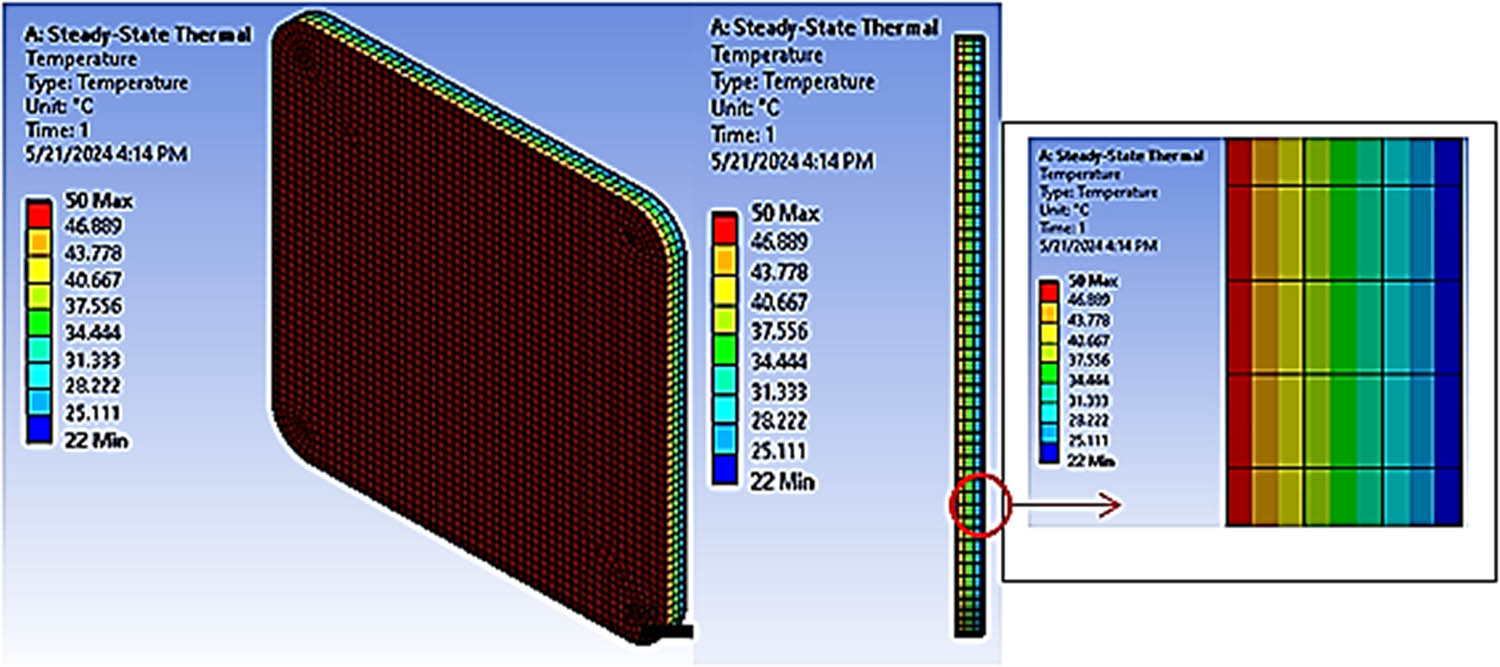

Figure 8 depicts the temperature distribution within the pure neem shell matrix, demonstrating how the temperature changes over the plate’s thickness when the temperature difference is between 22 and 50°C.

Temperature distribution of the plate made with the neem shell matrix.

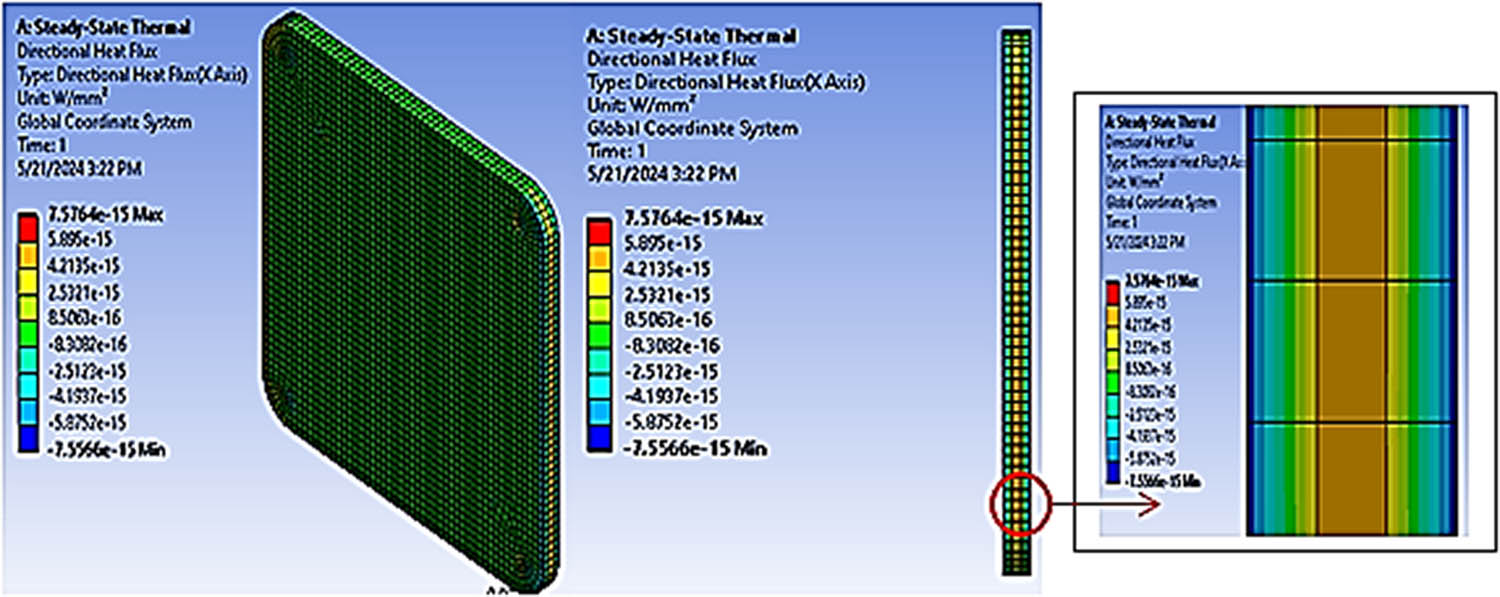

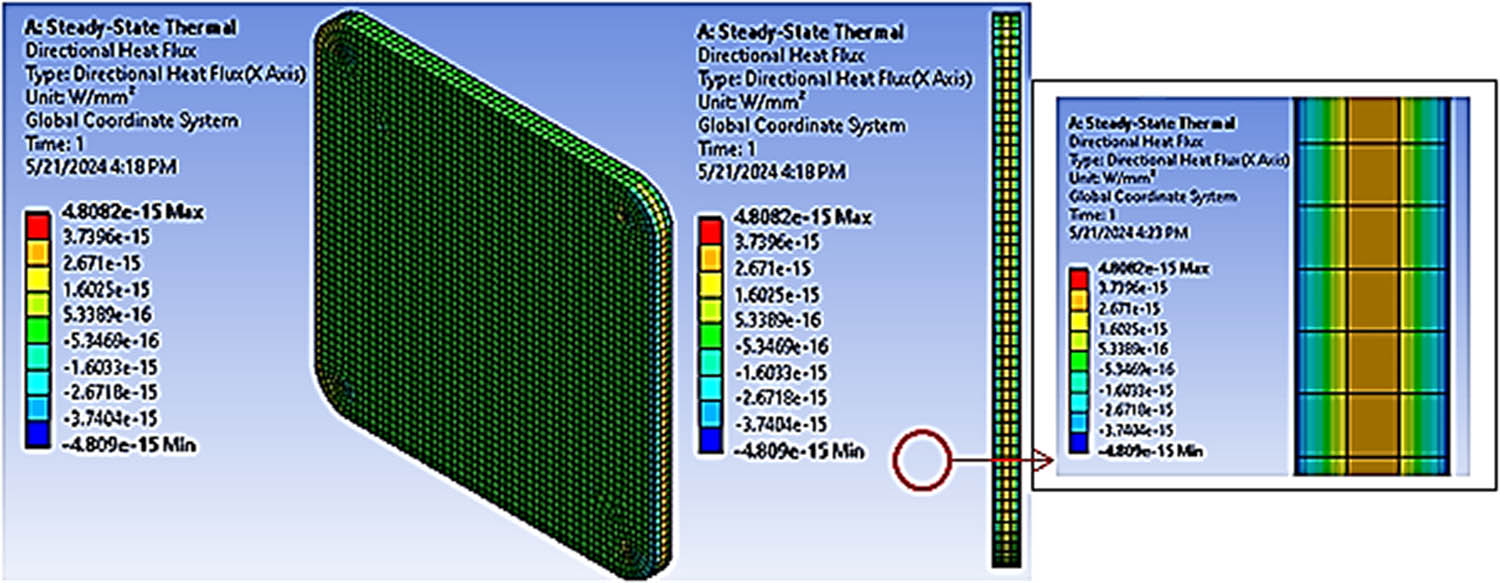

Figure 9 shows the heat flux in the x-direction, demonstrating how it varies across the plate’s thickness. Under the specified parameters, the total heat flow for the pure matrix is determined as 0.0068517 W/mm2.

Heat flux in the X-direction of the plate made with the neem shell matrix.

In this work, the analysis was conducted by replacing the pure resin plate with a walnut-filled neem shell composite. It is observed that while changes in the temperature distribution (Figure 10) may not be significantly impacted by changes in thermal conductivity, significant differences are observed in the total heat flux and directional heat flux of the composite plate. The total heat flux of the composite plate is 4.3574 × 10−003, which is 36.4% less than that of the pure matrix used in the study. This reduction in heat flux shows that the walnut shell powder mixed with a neem shell composite material has better thermal insulation qualities than the pure matrix [40].

Temperature distribution of the plate made with the walnut-filled neem shell composite.

The addition of walnut shell powder to the neem shell matrix modifies the thermal characteristics of the composite, resulting in decreased heat transport through the material. This is due to the natural insulating qualities of walnut shell powder, which form barriers to heat conduction inside the composite structure.

Furthermore, the directional heat flow study shows changes in heat transport patterns within the composite plate (Figure 11). These changes show that the composite material effectively reduces heat transmission in specific directions, which contributes to its better thermal insulation ability.

Heat flux in the X-direction of the plate made with the walnut-filled neem shell composite.

The findings indicate that the walnut-filled neem shell composite has better thermal insulation properties than the pure matrix, making it a potential material for applications requiring effective heat management and insulation. This analysis sheds light on how changes in the thermal conductivity of the plate material influence temperature distribution and heat flux within the composite plate. By comparing these findings to variations in material properties, engineers may improve the design for thermal insulation applications, assuring efficient heat transfer management and improving composite performance in real-world settings.

4 Conclusions

In order to create high-performing, eco-friendly composite materials, this study offers a thorough assessment of the incorporation of walnut shell powder as a reinforcing filler into a biodegradable resin matrix based on neem shells. The study demonstrates the promise of such natural materials for sustainable engineering applications by highlighting notable improvements in the composite’s mechanical and thermal characteristics.

The neem shell-based composite’s tensile modulus is significantly increased by the addition of walnut shell powder. When compared to the pure neem shell resin without any filler, the composite showed a significant 57.5% increase in tensile modulus with a filler loading of 25% by weight. This notable improvement emphasizes how the stiff lignocellulosic structure of walnut shell particles, which serve as efficient stress transfer sites within the polymer matrix, provides a stiffening effect.

Additionally, the flexural strength is significantly increased by the use of walnut shell powder. The tensile performance is in line with the ideal filler proportion that produces this improvement; a 25% weight fraction of powdered walnut shell results in an improvement of roughly 59% over the pure matrix material. Better load-bearing capability and enhanced interfacial adhesion between the filler and matrix at this concentration are responsible for this.

The gradual improvement in impact strength with increasing filler content is among the study’s most striking findings. The addition of powdered walnut shell greatly enhances the material’s capacity to absorb and release energy under conditions of abrupt loading. The composite was shown to have an impact strength enhancement of up to 282%, which makes it ideal for applications requiring great toughness and resistance to dynamic loads.

The inclusion of walnut shell filler shows encouraging outcomes in terms of thermal insulation. Thermal conductivity is decreased by about 36% when 30% walnut shell powder is added to the neem shell resin, suggesting improved insulating qualities. This conclusion is supported by complementary FEA, which demonstrates a 36.4% decrease in heat flux, confirming the composite’s improved thermal barrier performance.

These results highlight the potential of neem shell-based composites with walnut shell powder for sustainable, biodegradable applications requiring enhanced mechanical strength and thermal insulation.

Acknowledgments

The authors gratefully acknowledge the support of AICTE for funding the RPS project and Prasad V. Potluri Siddhartha Institute of Technology, under which the tensile, bending, and thermal conductivity tests were conducted.

-

Funding information: Authors state no funding involved.

-

Author contributions: Tummala Srinag: methodology, experimental investigation, and writing – original draft; Chennupati Lakshmi Srinivas: experimental investigation, validation, and resources. C. H. Sandeep: software and formal analysis; Parvathaneni Phani Prasanthi: methodology, supervision, and review & editing; Vallabhaneni Venkata Venu Madhav: validation, formal analysis, and supervision; Ashish Kumar: software, simulation, and visualization; Rakesh Chandrashekar: data curation and fund acquisition; Din Bandhu: conceptualization and writing – review & editing; Sudhir Kumar Singh: resources and supervision. Akkireddy Anitha Lakshmi: resources and proofreading. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article.

References

[1] Taib NA, Rahman MR, Huda D, Kuok KK, Hamdan S, Bakri MK, et al. A review on poly lactic acid (PLA) as a biodegradable polymer. Polym Bull. 2023;80(2):1179–213.10.1007/s00289-022-04160-ySuche in Google Scholar

[2] Kumar R, Sadeghi K, Jang J, Seo J. Mechanical, chemical, and bio-recycling of biodegradable plastics: A review. Sci Total Environ. 2023 Jul 15;882:163446.10.1016/j.scitotenv.2023.163446Suche in Google Scholar PubMed

[3] Zadafiya K, Bandhu D, Kumari S, Chatterjee S, Abhishek K. Recent trends in drilling of carbon fiber reinforced polymers (CFRPs): A state-of-the-art review. J Manuf Process. 2021;69:47–68.10.1016/j.jmapro.2021.07.029Suche in Google Scholar

[4] Lazăr S, Dobrotă D, Breaz RE, Racz SG. Eco-design of polymer matrix composite parts: a review. Polymers. 2023;15(17):3634.10.3390/polym15173634Suche in Google Scholar PubMed PubMed Central

[5] Chen L, Yang M, Chen Z, Xie Z, Huang L, Osman AI, et al. Conversion of waste into sustainable construction materials: A review of recent developments and prospects. Mater Today Sustainability. 2024;27:100930.10.1016/j.mtsust.2024.100930Suche in Google Scholar

[6] Simelane NP, Olatunji OS, John MJ, Andrew J. Engineered transparent wood with cellulose matrix for glass applications: A review. Carbohydr Polym Technol Appl. 2024;7:100487.10.1016/j.carpta.2024.100487Suche in Google Scholar

[7] Phani Prasanthi P, Raghavender V, Venu Madhav VV, Sonia P, Sri Chaitanya C, Bandhu D, et al. Experimental and simulation study for mechanical properties characterisation of green natural reinforced composites. Int J Interact Des Manuf (IJIDeM). 2024;18(5):3459–71.10.1007/s12008-023-01695-wSuche in Google Scholar

[8] Mangal M, Rao CV, Banerjee T. Bioplastic: an eco-friendly alternative to non-biodegradable plastic. Polym Int. 2023;72(11):984–96.10.1002/pi.6555Suche in Google Scholar

[9] Mukherjee C, Varghese D, Krishna JS, Boominathan T, Rakeshkumar R, Dineshkumar S, et al. Recent advances in biodegradable polymers–properties, applications and future prospects. Eur Polym J. 2023;192:112068.10.1016/j.eurpolymj.2023.112068Suche in Google Scholar

[10] Mohan MM, Bandhu D, Mahesh PV, Thakur A, Deka U, Saxena A, et al. Machining performance optimization of graphene carbon fiber hybrid composite using TOPSIS-Taguchi approach. Int J Interact Des Manuf (IJIDeM). 2025;19(5):3171–82.10.1007/s12008-024-01768-4Suche in Google Scholar

[11] Goswami R, Khosla A, Alam A, Varshney P. Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene. J Mech Behav Mater. 2025;34(1):20240031.10.1515/jmbm-2024-0031Suche in Google Scholar

[12] Sri Ram Vikas K, Rahul, Venkata Ramana V, Morampudi P, Bhavani K, Madhusudhan Reddy G. Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics. J Mech Behav Mater. 2025;34(1):20250054.10.1515/jmbm-2025-0054Suche in Google Scholar

[13] Prabhanjan N, Kumar K. Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute. J Mech Behav Mater. 2025;34(1):20250064.10.1515/jmbm-2025-0064Suche in Google Scholar

[14] Ali Z, Abdullah M, Yasin MT, Amanat K, Ahmad K, Ahmed I, et al. Organic waste-to-bioplastics: Conversion with eco-friendly technologies and approaches for sustainable environment. Environ Res. 2024;244:117949.10.1016/j.envres.2023.117949Suche in Google Scholar PubMed

[15] Jabeen N, Atif M. Polysaccharides based biopolymers for biomedical applications: A review. Polym Adv Technol. 2024;35(1):e6203.10.1002/pat.6203Suche in Google Scholar

[16] Luo X, Muttaqin F, Zhang Y. Investigating non-petroleum-based biodegradable polymers as eco-friendly and sustainable materials in asphalt modification: A review on natural rubbers and natural oils. J Clean Prod. 2024;436:140483.10.1016/j.jclepro.2023.140483Suche in Google Scholar

[17] Singh P, Pandey VK, Singh R, Singh K, Dash KK, Malik S. Unveiling the potential of starch-blended biodegradable polymers for substantializing the eco-friendly innovations. J Agric Food Res. 2024;15:101065.10.1016/j.jafr.2024.101065Suche in Google Scholar

[18] Paul V, Rai S, Vikranta U, Nandan A, Agarwal A, Tripathi AD. Starch-PHA blend-based biopolymers with potential food applications. Starch-Stärke. 2024;76(11–12):2300131.10.1002/star.202300131Suche in Google Scholar

[19] Gurjar AK, Kulkarni SM, Joladarashi S, Doddamani S. Investigation of mechanical properties of luffa fibre reinforced natural rubber composites: implications of process parameters. J Mater Res Technol. 2024;29:4232–44.10.1016/j.jmrt.2024.02.133Suche in Google Scholar

[20] Bhadauria A, Bajpai S, Tiwari A, Mishra SK, Nisar A, Dubey S, et al. Bimodal microstructure toughens plasma sprayed Al2O3-8YSZ-CNT coatings. Ceram Int. 2023;49(8):12348–59.10.1016/j.ceramint.2022.12.092Suche in Google Scholar

[21] Du Y, Wu T, Yan N, Kortschot MT, Farnood R. Fabrication and characterization of fully biodegradable natural fiber-reinforced poly (lactic acid) composites. Compos Part B: Eng. 2014;56:717–23.10.1016/j.compositesb.2013.09.012Suche in Google Scholar

[22] Nazhat SN, Kellomäki M, Törmälä P, Tanner KE, Bonfield W. Dynamic mechanical characterization of biodegradable composites of hydroxyapatite and polylactides. J Biomed Mater Res. 2001;58(4):335–43.10.1002/jbm.1026.absSuche in Google Scholar

[23] Mousa G, Basha M, Moustafa E. Evaluation of the mechanical and dynamic properties of scrimber wood produced from date palm fronds. J Mech Behav Mater. 2024;33(1):20220305. 10.1515/jmbm-2022-0305.Suche in Google Scholar

[24] Janyakunmongkol K, Nhuapeng W, Thamjaree W. Effect of alkaline treatment on mechanical properties of composites between vetiver fibers and epoxy resin. J Mech Behav Mater. 2024;33(1):20220310. 10.1515/jmbm-2022-0310.Suche in Google Scholar

[25] Abass R, Ausama Al-Sarraf M, Bachtiar D, Rejab M. Eco-friendly mechanical performance of date palm Khestawi-type fiber-reinforced polypropylene composites. J Mech Behav Mater. 2024;33(1):20240019. 10.1515/jmbm-2024-0019.Suche in Google Scholar

[26] Kuan HT, Tan MY, Shen Y, Yahya MY. Mechanical properties of particulate organic natural filler-reinforced polymer composite: A review. Compos Adv Mater. 2021;30:26349833211007502.10.1177/26349833211007502Suche in Google Scholar

[27] Battegazzore D, Noori A, Frache A. Natural wastes as particle filler for poly (lactic acid)-based composites. J Compos Mater. 2019;53(6):783–97.10.1177/0021998318791316Suche in Google Scholar

[28] Jameel AN, Yousuf LS. Temperature distribution on rectangular composite plate under thermal gradient loading environment: experiment and simulation. In IOP Conference Series: Materials Science and Engineering 2021 Feb 1 (Vol. 1094, No. 1, p. 012016). IOP Publishing.10.1088/1757-899X/1094/1/012016Suche in Google Scholar

[29] Mohan Kumar K, Naik V, Kaup V, Waddar S, Santhosh N, Harish HV. Nontraditional Natural Filler‐Based Biocomposites for Sustainable Structures. Adv Polym Technol. 2023;2023(1):8838766.10.1155/2023/8838766Suche in Google Scholar

[30] Sudha P, Jamali PV, Sudagar IP. Emerging improvements in the characterization and advanced utilization of woodland fibres and its hybrid composites. Ric Int J Multidiscip Res Innov. 2023;2(10):1–49.Suche in Google Scholar

[31] Bhadauria A, Singh LK, Laha T. Nanoindentation and nanoscratch properties of graphene nanoplatelets reinforced spark plasma sintered aluminium-based nanocomposite. Adv Mater Process Technol. 2019;5(2):295–302.10.1080/2374068X.2019.1578554Suche in Google Scholar

[32] Cruz T, Maranon A, Hernandez C, Alvarez O, Ayala-García C, Porras A. Exploring the potential of cashew nutshells: A critical review of alternative applications. BioResources. 2024;19(3):6768.10.15376/biores.19.3.CruzSuche in Google Scholar

[33] Bhowmik S, Kumar S, Mahakur VK. Various factors affecting the fatigue performance of natural fiber-reinforced polymer composites: a systematic review. Iran Polym J. 2024;33(2):249–71.10.1007/s13726-023-01243-zSuche in Google Scholar

[34] Singh LK, Bhadauria A, Laha T. Understanding the effect of bimodal microstructure on the strength–ductility synergy of Al–CNT nanocomposites. J Mater Sci. 2021;56(2):1730–48.10.1007/s10853-020-05302-1Suche in Google Scholar

[35] Jagadeesh P, Puttegowda M, Thyavihalli Girijappa YG, Rangappa SM, Siengchin S. Effect of natural filler materials on fiber reinforced hybrid polymer composites: An Overview. J Nat Fibers. 2022;19(11):4132–47.10.1080/15440478.2020.1854145Suche in Google Scholar

[36] Khan F, Hossain N, Mim JJ, Rahman SM, Iqbal MJ, Billah M, et al. Advances of composite materials in automobile applications–A review. J Eng Res. 2025;13(2):1001–23.10.1016/j.jer.2024.02.017Suche in Google Scholar

[37] Sutherland LS. A review of impact testing on marine composite materials: Part I–Marine impacts on marine composites. Compos Struct. 2018;188:197–208.10.1016/j.compstruct.2017.12.073Suche in Google Scholar

[38] Miedzińska K, Członka S, Strąkowska A, Strzelec K. Vermiculite filler modified with casein, chitosan, and potato protein as a flame retardant for polyurethane foams. Int J Mol Sci. 2021;22(19):10825.10.3390/ijms221910825Suche in Google Scholar PubMed PubMed Central

[39] Pradhan P, Satapathy A. Physico-mechanical characterization and thermal property evaluation of polyester composites filled with walnut shell powder. Polym Polym Compos. 2022;30:09673911221077808.10.1177/09673911221077808Suche in Google Scholar

[40] Mohan N, Dash SP, Boby NM, Shetty D. Study of bamboo as a building material–Construction & preservation techniques and its sustainability. Mater Today: Proc. 2022;60:100–14.10.1016/j.matpr.2021.12.263Suche in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite

Artikel in diesem Heft

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite