Abstract

This article studies the functional properties of a self-carrying metal inflatable shell structure. The design scheme of a rigid multi-sectional inflatable shell with high compactness should provide resistance to the action of outer operational loads under the condition of minimizing its own mass. The structure with a metal shell of stainless steel AISI321, which provides the required load-carrying capacity compared to known synthetic materials and does not require additional methods of rigidization, is considered. A brief comparative analysis of acceptable types of permanent joints of a multi-sectional inflatable shell is provided. A computational evaluation of the degree of their influence on the load-carrying capacity of a cantilevered fixed metal inflatable boom was carried out. The kinetics of maximum stresses in the zone of circumferential joints of the shell in the process of deployment was investigated, and numeric simulation of the stress–strain state in them under the action of inertial loads was performed. It was determined that the type of circumferential joint of conical sections of inflatable shell structure has a significant influence on its load-carrying capacity. In case of using glue and solder joints, the level of deploying pressure cannot exceed 30 kPa and the shell thickness should not exceed 0.15 mm. When using the welded type of a joint, a significant safety margin is noted, the level of stresses does not exceed 70 MPa. The load-carrying capacity of the considered metal deployable boom in space conditions when using welded joints can be increased approximately twice due to the reduction in the mass of such a joint.

1 Introduction

Inflatable shell structures are increasingly being used in aerospace engineering due to their ability of compact folding for saving usable space during a space launch, which is critically important. The main functional qualities of this class of structures are high compactness, low mass, and load-carrying abilities at sufficient sealing, and the best combination of these qualities is a relevant field of research [1]. The ability to combine sufficient rigidity in deployable state with the flexibility to allow compact folding in a single shell structure is always controversial. The folded surfaces of such shells allow achieving exceptional mechanical characteristics [2], but their ability to perceive loads at sufficient rigidity is in the vast majority of cases limited by the use of soft sheet materials and should be supported by additional means (e.g., a shell of stabilized Nylon with rubber latex [3]). Conventional synthetic inflatable shells [4] can be inflated effectively using overpressure, but require constant pressure maintenance to ensure self-supporting properties, which can be critical for long missions. Indeed, they also have the advantage of a low coefficient of thermal expansion compared to metals. On the other hand, various complex methods of rigidization of synthetic shells of laminated Kapton [5], carbon/epoxy prepreg [6], and a wider range of composite shells [7] have limited effectiveness, and one of the rational approaches to solving this contradiction is the use of materials with sufficient rigidity and the search for technological solutions for their repeated bending without loss of tightness.

Load-carrying capacity is particularly important for inflatable booms, which is a variant of using inflatable shells as carrying-out or joining elements of space structures [8,9,10], more often having cantilevered fixation and payload at the free end. The classification of soft synthetic materials previously used in inflatable booms considered in the study by Block et al. [8] (thermosetting resins, stretched metal laminates, shape memory polymers, etc.) is based precisely on their grouping according to strengthening methods; however, the required load-carrying capacity of structures is more rationally obtained by selecting the suitable material. Metal shell can be used to give them sufficient rigidity, which allows eliminating complex and limitedly effective methods of rigidization [11] of easy-to-fold synthetic materials. On the other hand, when using a thin metal shell, restrictions on the type of geometric surface and its proportions appear, since the processes of folding and the next unfolding should be carried out with the least possible tension and compression of the sheet material median surface. For long-length metal inflatable booms based on zero Gaussian curvature surfaces, such as conical and cylindrical surfaces, partitioning of the shell into sections is required. A comparative analysis of the two main types of such multi-sectional structures is presented, for example, in the study by Lobanov et al. [12], where the advantages of the folding and deploying process for the conical-type shell are described along with its lower resistance to non-axisymmetric loads. Furthermore, Li et al. [13] emphasized on the advantages of the cylindrical-type shell, which, nevertheless, is significantly inferior to the multi-conical version in compactness and ability to compensate for large values of inertial loads without buckling [11]. This article presents a brief analysis of the capabilities that allow levelling the disadvantages of inflatable conical-type shell structures by increasing the rigidity of their shell without changing their mass and compactness.

The improvement of such functional qualities of metal inflatable booms as rigidity and stability was previously investigated from the point of view of optimization of geometrical parameters of their structural elements [12,14] or shell surface engineering [15]. Nevertheless, dividing a lengthy structure into sections requires focusing on their joining elements, which play an important role in ensuring its rigidity and sealing. The work identifies the advantages and disadvantages of such alternative types of ring connections of load-carrying shell cones as soldered and adhesive. Their influence on the integrity of the structure both during deployment and under operating conditions is considered.

2 Methods

Creation of metal inflatable boom is realized using a method of successive transformation of a smooth truncated conical shell, where its section Q 1 is transformed into concentric circumferential folds of a compact disc with a wavy cross-section (Figure 1a). Furthermore, compact discs with closed-end sections united in a single structure along the contours of equal bases can be deployed by creating overpressure in the inner cavity. The shell transformation ratio K T , i.e., the ratio of its height in the unfolded and compact state (Figure 1b), is directly proportional to the quantity of circumferential folds n and is related to the geometrical parameters of the conical billet and its thickness. Thus, the approximate relationship between the fold pitch b and the ѕhell thickness δ is b = (26…29) × δ [12], and the transformation ratio can be evaluated through the length of the side conical generatrix S and the taper angle α:

Scheme of the transformation of a truncated conical shell to a compact state (a), process of deployment of a multi-sectional inflatable boom (b), and general view of an unfolded shell (c).

As is seen from (1), the desire to create a long-length boom with high compactness and sufficient rigidity, which implies the use of a metal shell of sufficient thickness, entails the necessity of partitioning of the shell into sections of equal geometry forming a structure with a periodic profile. The choice of a structural material with the best physical and mechanical properties is not a universal solution, as it can stimulate restrictions on the geometrical parameters of the folded surface, which leads to a decrease in the compactness of a shell and the reliability of its deformable joints. This study considers the possibility of increasing the rigidity of a shell made of conical sections by optimizing circumferential joints of its structural elements. In this case, the computational example considers its compactness at the level of К T = 10 to compare, for example, with the compactness of a cylindrical inflatable boom at the level of К T = 3…4 [13]. It should be noted that К T value is related to the thickness of the shell material [14]. However, it can be significantly increased by increasing the ratio of diameters of the bases of truncated conical sections and can reach К T = 50 and more.

A wide enough range of metal materials can be used in the manufacture of shells, for example, aluminium and titanium alloys widely used in the aerospace industry. However, in the process of folding and deployment of the shell, the level of equivalent plastic deformations in local zones can reach 20–30%, which makes it impossible to use metals with a low level of relative elongation as a structural material. On the other hand, the high ductility of the structural material generates significant displacements in the apices of already formed folds and, as a consequence, buckling of the shell during deployment. The most acceptable material in terms of mechanical properties to ensure the successful process of shaping a metal inflatable shell is mild austenitic stainless steel, with the ratio of yield strength R p0.2 to tensile strength σu within the range of values 0.3:0.8 [12], which also has a number of advantages in creating reliable permanent joints of different types. Stainless steel AISI 321 selected as shell material with values R p0.2 = 229 MPa, σ u = 651 MPa, and R p0.2/σ u ≈ 0.35 also provides lower deformability of the structure due to 1.5–2 times higher modulus of elasticity compared to titanium and aluminium. Finally, the possibility of effective modification of thermal radiation properties of its surface by vacuum deposition of thin protective coatings has been investigated for thin sheet steel of this grade [15], which provides the resistance of the metal inflatable boom to extreme temperature differences in space conditions.

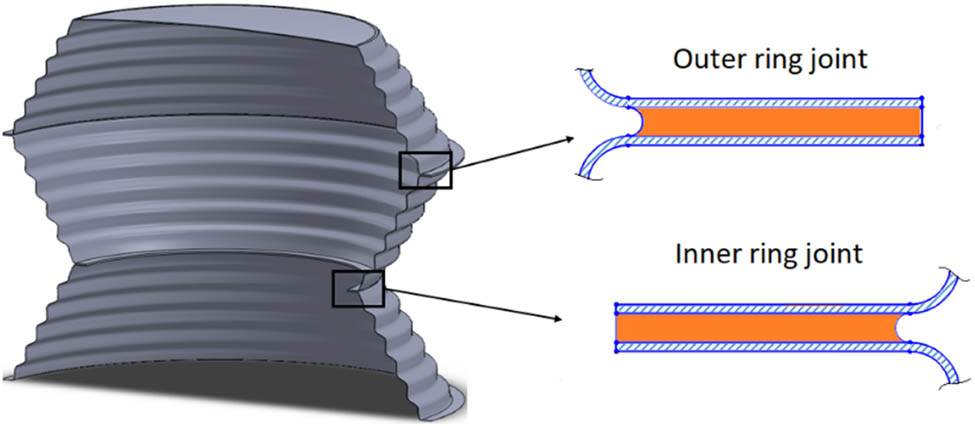

In capacity of butt circumferential joints uniting conical sections into a single structure, either glue, solder, or welded joints can be used. Each of these methods of joining metallic materials is applied in the aerospace industry, including various methods of welding alloy steels [16,17], their soldering [18], and gluing [19]. The layout of outer and inner circumferential joints is shown in Figure 2.

Layout of circumferential joints of deployable shell.

The tensile strength of glue (TEROSON EP 5055) and solder (Castolin 157 PA Solder paste) joint is relatively low, within 18…22 and 58 MPa, respectively, whereas welded joint exhibits mechanical properties close to those of base material, which makes it possible to use higher pressure values in the process of shell deployment. On the other hand, in some cases, the functional application of inflatable boom allows limiting its maximum degree of deployment while reconfiguring the circumferential joints. Possible combinations of these approaches are discussed below.

3 Results

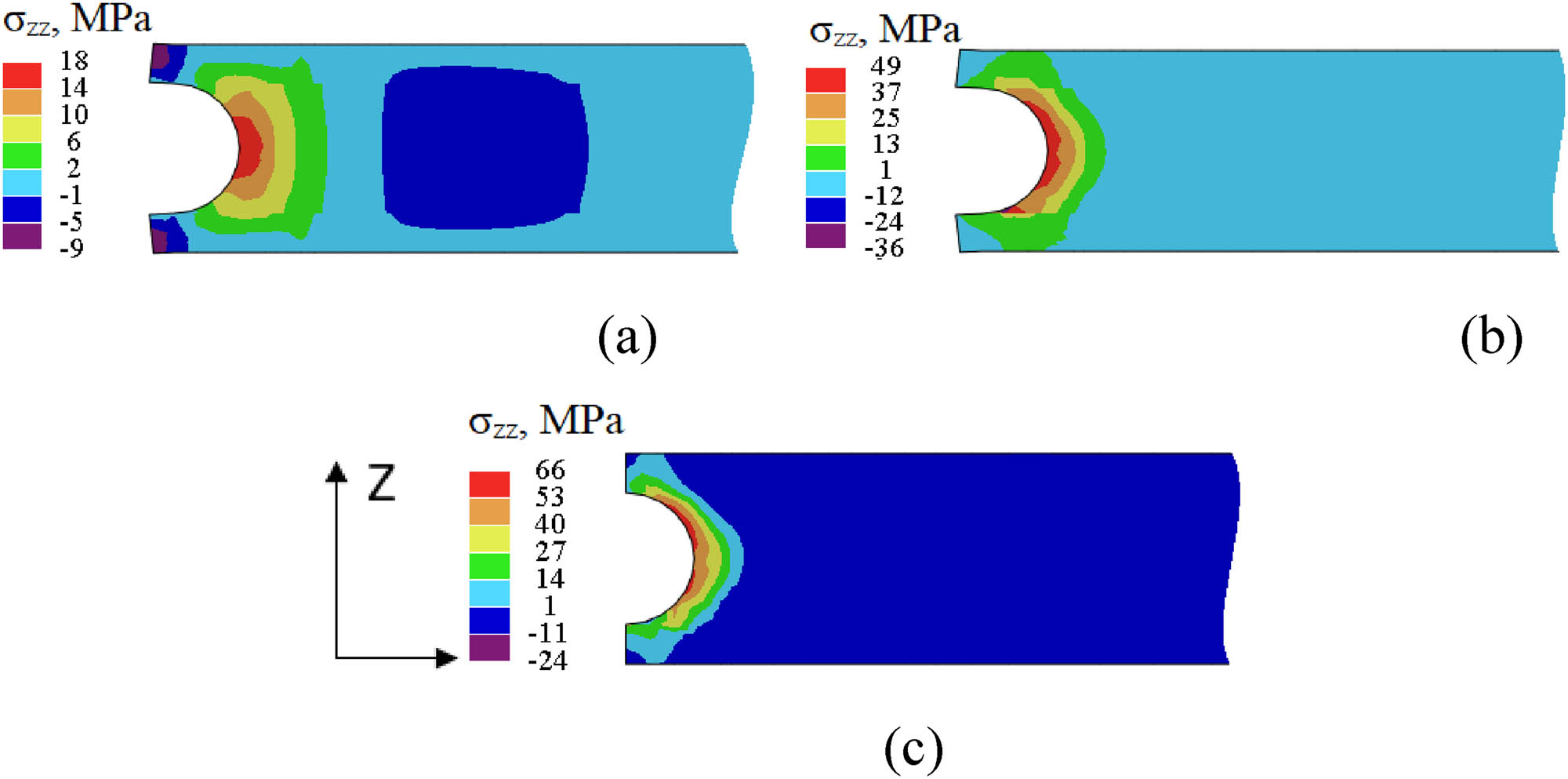

In order to substantiate the choice of technology for joining conical sections of the structure, the design stresses were analysed arising in the process of deployment in the zone of circumferential glue, solder, and welded joints in the region of a large-diameter butt of the shell on its outer surface. The shell thickness is 0.15 mm, which is the minimum possible one from the point of view of folding and joining processes; it is made of stainless AISI 321 steel; the ratio of the maximum diameter to the length of the shell is 1:5, which is characteristic for the booms class. For each type of a joint, the same model (idealized) geometry of a joint (Figure 3) and the corresponding value of the elastic modulus of the material were specified: for glue E = 1.5 GPa, for solder E = 40 GPa, and for weld metal E = 200 GPa. The process was carried out at a pressure of 30 kPa. The results of mathematical modelling were obtained using software PrePoMax (v.2.0.0, 2024) [20].

Distribution of maximum stresses σ zz, (MPa) in the transverse direction relative to the plane of the joint in the process of the structure deployment: (a) glue, (b) solder, and (c) welded joint.

In the work, a traditional algorithm of designing aerospace structural elements was used, in which the main results of numerical modelling of the characteristic process are compared with the obtained experimental data (see, for example, [21]). The problem of inflatable boom deployment is solved in an axisymmetric formulation. The finite element model consists of 5,485 nodes and predominantly 4,530 4-node bilinear axisymmetric quadrilateral elements. The mesh of the finite element model has four elements across the thickness of the shell wall and is thickened in the region of stress concentrators – in the zone of a circumferential joint and corrugations’ folds, the minimum size of an element is 0.04 × 0.1 mm.

The mathematical model of a three-section inflatable boom deployment at each increment over time (≈1,500 increments depending on the type of a joint) allows determining determined stress–strain state (SSS) in all its nodes and directions. The problem was solved in an elastic–plastic formulation, which allowed analysing the kinetics of inflatable boom stresses in the process of its deployment, taking into account elastic and plastic deformations. We have considered axial, circumferential, and radial stresses in the region of circumferential joints and determined that the highest stress level in the process of deployment corresponds to the axial direction at the joint of large (outer) inflatable boom diameters.

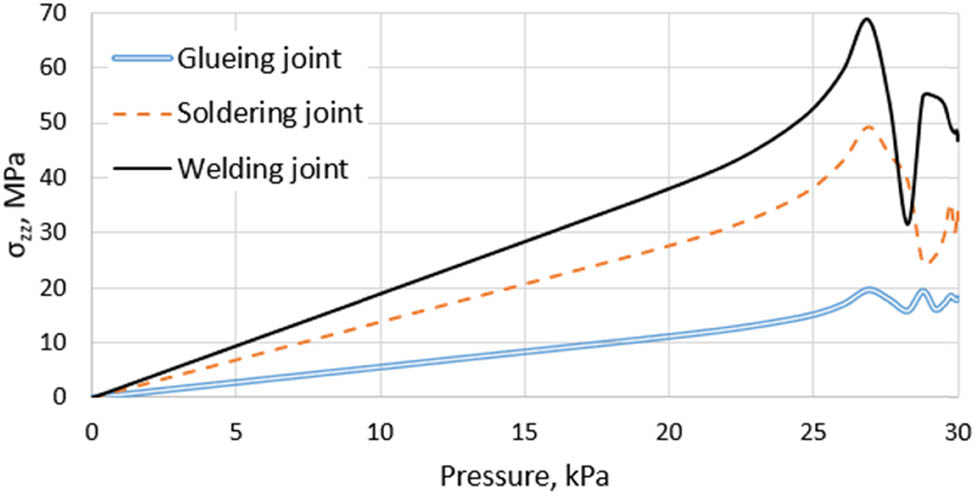

The computational results showed that higher stresses during the deployment process occur in the zone of outer circumferential joints. In this case, the material of joint (glue, solder, weld metal) and its deformability affect the stress state in the shell itself. As is seen from Figure 3a and b, during the deployment process, the axial stresses in the case of glue and solder joints reach the values of tensile strength for the material under study, and increasing the deployment pressure (Figure 4) can lead to depressurization of the shell. In the case of welded joint (Figure 3c), the maximum design stresses (at the level of 66 MPa) during the deployment process are significantly lower than the yield strength and tensile strength characteristics of the austenitic filler material.

Kinetics of maximum stresses in the butt joint zone in the process of the structure deployment.

The thickness of the structure wall of 0.15 mm and the deployment pressure of 30 kPa are ultimate for alternative methods of a circumferential joining (glued/soldered), and an increase in the value of each of these parameters can lead to a violation of the structural integrity in the process of deployment as well as to its incomplete deployment.

Therefore, it is appropriate to use welded joints in the structure. The structure of glue and solder joints requires modification, e.g., the introduction of additional edge turning to ensure higher strength characteristics and reliability during deployment of the shell.

Mechanical tests to determine the strength of the joints are part of a study of the kinetics of the process of deploying a multi-section inflatable boom presented in Figure 1(b). According to the results of mathematical modelling, when the inner overpressure is increased to the value of 30 kPa, the stresses in the axial direction in glue and solder joints reach their tensile strength σ zz = 20 MPa and σ zz = 50 MPa, respectively. The stresses in the welded joint do not exceed σ zz = 70 MPa, which is significantly lower than the yield/tensile strength of the welded joint material. Thus, to test the deployment process, the inflatable boom structure was manufactured with welded circumferential joints.

During mechanical tests of the inflatable boom deployment process at an increase in the inner pressure (up to 100 kPa), irreversible deformations in the circumferential welded joints are observed, the beginning of which was determined by distortions (the so-called snap-throw behaviour) of the adjacent shell surface. Here, the integrity of the structure is preserved, which is also confirmed by the results of computational evaluations. Furthermore, at an inner pressure over 100 kPa, the violation of monolithicity of the circumferential joint is developing, which leads to the further loss of its sealing in the zones of distortions of the adjacent shell surface.

3.1 Determination of the SSS of inflatable boom under the action of inertial loads

The load-carrying capacity of the inflatable boom with glued and soldered circumferential joints is quite limited due to the inability of the structure to maintain its integrity at a high deployment pressure.

As an example of a potential application, we considered the case of using inflatable boom with circumferential joints as a cantilever-fixed load-carrying element, which are subjected to inertial loads specified in the form of linear accelerations.

According to Lobanov et al. [12], the recommended rigidity of fixing the mounted load-carrying elements and equipment at space stations should correspond to the frequencies of natural oscillations not lower than 20 Hz. Here, the values of linear accelerations, taking into account the safety factor η = 2, are a X = 12 m/s2, a Y = 12 m/s2, and a Z = 9 m/s2, where the Z axis corresponds to the axial direction of the structure and X and Y axes are orthogonal to the radial directions. Additionally, as a payload, a payload was applied on the free end, remote from the rigidly fixed end of the shell.

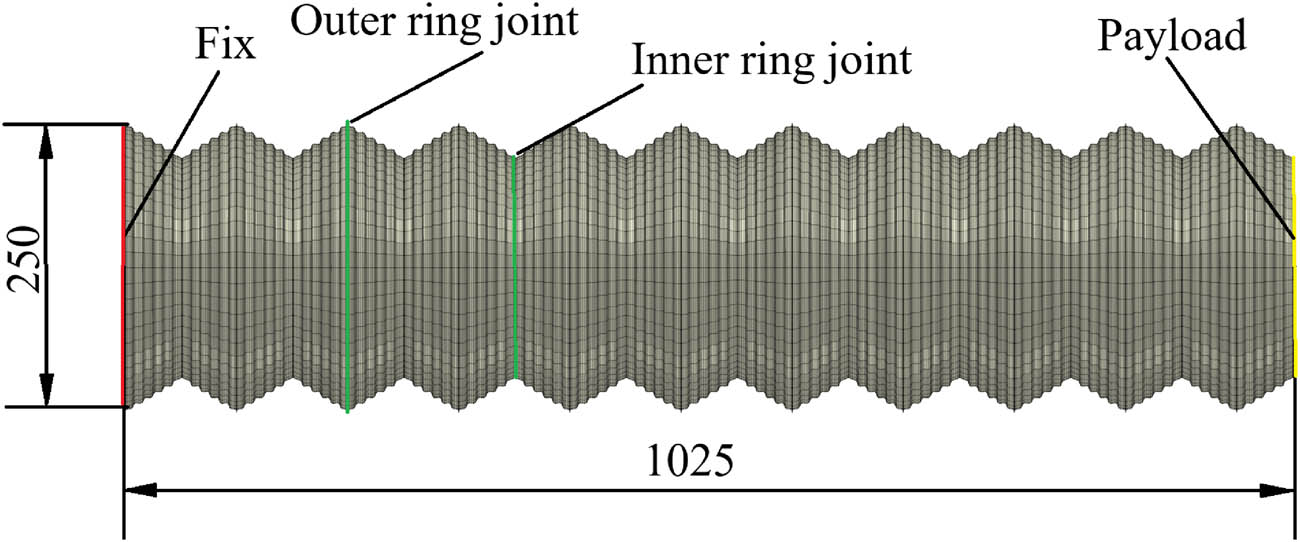

To ensure a sufficient level of rigidity of inflatable boom under conditions of high level of loading in the form of linear accelerations, the thickness of the shell, other geometrical parameters being equal (Figure 5), was determined at the level of 0.15 mm, and the weight of this deployable structure depending on the type of a joint varies from 1.2 to 2 kg.

Basic geometrical parameters, boundary conditions, and loads of inflatable boom.

The strength of the structure is considered to be ensured if the following condition is met:

where

where

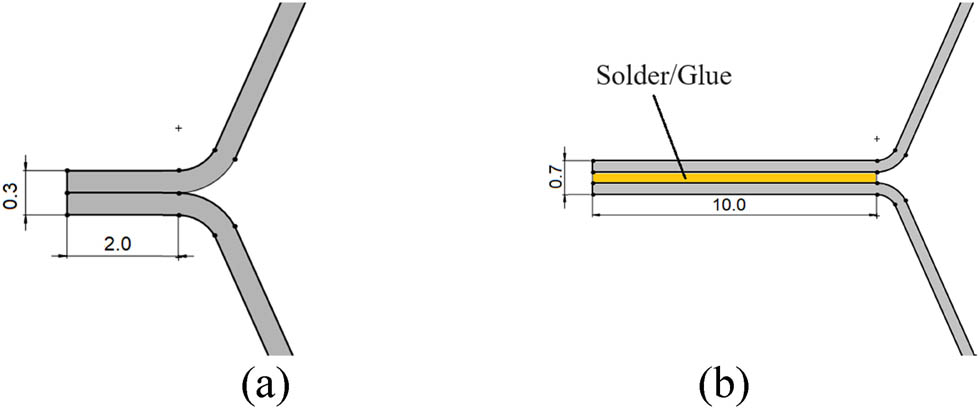

Two different types of circumferential joints of truncated conical sections are considered. The first type of joints is characteristic for welded joints, and the second one for solder/glue joints due to its technological features (Figure 6).

Types of circumferential joints: welded (a) and solder/glue (b) joint.

The technology of uniting adjacent circumferential flanges of the shells into a common rigid frame ring by welding (Figure 6a) limits its width to the value of 2 mm and its thickness to two shell thicknesses (0.3 mm). The width of solder/glue circumferential joint is practically unlimited and is assumed to be 10 mm, while the thickness due to the solder/glue layer is ≈ 0.7 mm. According to the previously determined SSS fields of the structure under characteristic loading conditions, the most loaded zones are the regions of inner welded circumferential joints [12]. Increasing the width and thickness of such a joint by replacing it with a solder/glue joint makes it possible to increase its rigidity and, consequently, the load-carrying capacity of inflatable boom.

The problem of determining SSS of inflatable boom under space loading conditions was solved in a three-dimensional formulation using a shell geometric model. The finite element model consists of 60,916 nodes and predominantly 60,903 4-node double-curved thin shell elements. The size of a finite element is 2 × 12 mm. It was determined to be the most optimal in terms of the quality of convergence of the computational results.

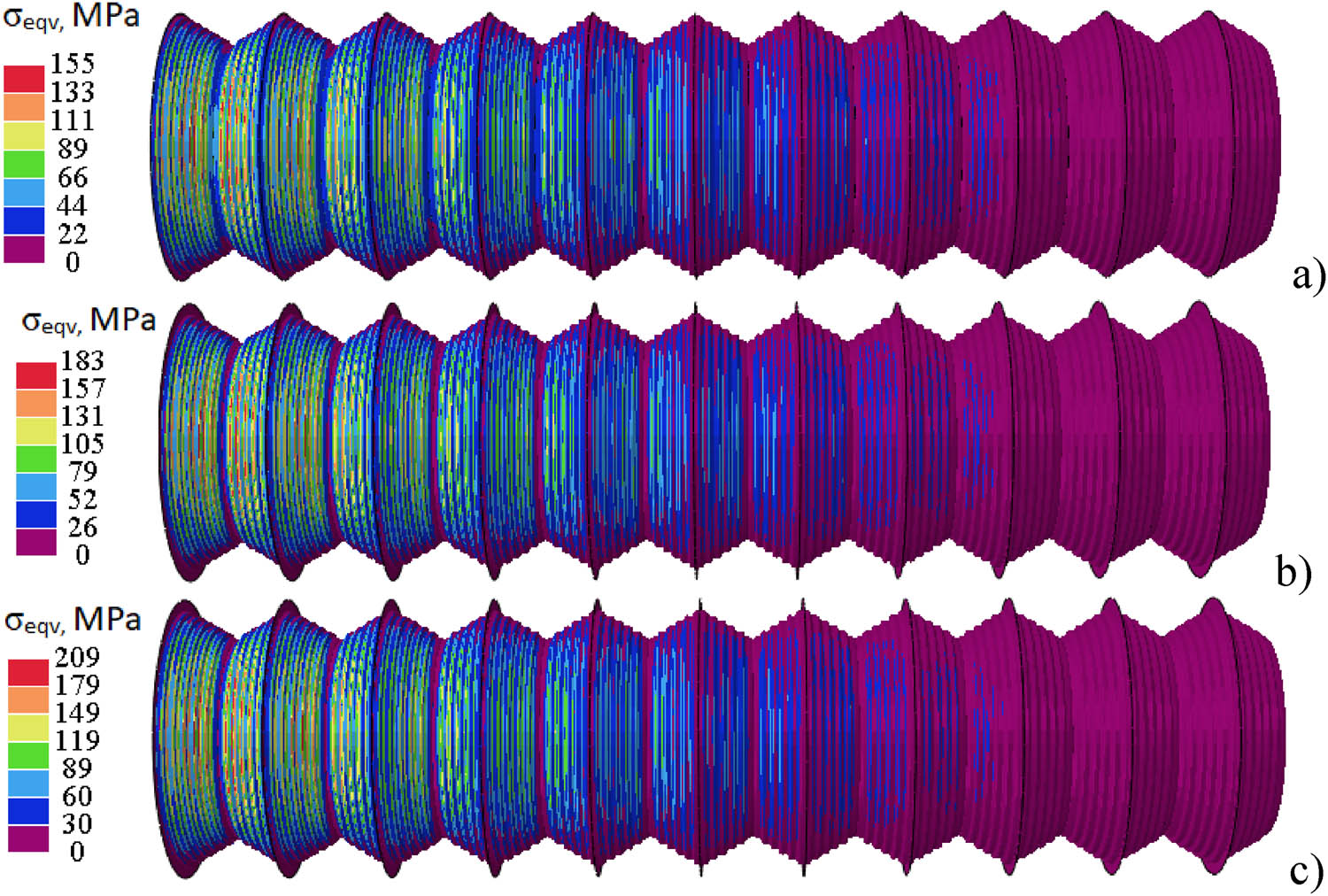

In the course of mathematical simulation of SSS of the structure for three different types of circumferential joints, a significant influence of a joint type on the maximum equivalent stress level was determined (Figure 7).

Stress fields in the structure shell–welded joint (a), glued joint (b), and soldered joint (c).

The results of computation of the SSS for the case of loading with additional payload of 0.5 kg have shown that when using welded circumferential joints, the maximum equivalent stresses of the structure reach 155 MPa of the material, and the stress concentrators are concentrated in the region of corrugations folds with predominance of axial tensile stresses (Figure 7). In the case of using alternative glued and soldered types of a joint, the level of maximum equivalent stresses is 183 and 209 MPa, respectively, and their peak was also shifted to the region of corrugation folds (Figure 7).

For the considered structure in the case of weld circumferential joints, the critical value of the payload is 1 kg, at which the maximum level of equivalent stresses is close to the yield strength and is 229 MPa. In the case of a soldered/glued joint with the same value of the payload (1 kg), the initiation of plastic deformations (Table 1) was determined, which is not desirable for critical elements of engineering structures. A comparison of the main characteristics affecting the structural integrity depending on the type of a circumferential joint is presented in Table 1.

Deformation characteristics of inflatable booms of the considered types at different payloads

| Welded circumferential joint | Glue circumferential joint | Solder circumferential joint | ||||

|---|---|---|---|---|---|---|

| Payload, kg | 0 | 0.5 | 0 | 0.5 | 0 | 0.5 |

| m, kg | 1.18 | 1.56 | 1.96 | |||

| σ eq, MPa | 86 | 155 | 111 | 183 | 137 | 209 |

| Free end deviation of, mm | 10.43 | 21.24 | 12.73 | 23.29 | 15.76 | 26.36 |

From Table 1, it is seen that the load-carrying capacity of the inflatable boom decreases when using glue and solder as an element of the circumferential joint – the stress level and the value of deviation of the free end of the structure grow, regardless of the payload value.

A decrease in the load-carrying capacity of the inflatable boom is associated with an increase in the section area of the structure in the zone of the circumferential joint. The mass of the shell without taking into account the joining elements is approximately 1.1 kg. In alternative methods of a circumferential joining, the mass of the entire structure grows due to the weight of the glue (by 0.46 kg) and solder (by 0.86 kg).

4 Conclusions

Lightweight self-carrying multi-conical inflatable booms are a competitive solution in the field of inflatable shells for space applications due to a significant compactness combined with a low mass and the ability to compensate for characteristic loads without buckling.

When choosing the method of producing butt circumferential joining of the shell (glue, solder, welded), it was determined that in the case of using glue and solder joints, the level of deployment pressure cannot exceed the value of 30 kPa, and the shell thickness should not exceed 0.15 mm. The stress values in the case of using welded joint under equivalent conditions of shell deployment do not exceed 70 MPa (Rp0.2 = 229 MPa), which allows performing the process of deployment under higher pressure while achieving a higher degree of shell deployment. A similar conclusion was also obtained during simulation of the behaviour of a lightweight multi-conical inflatable boom with a payload fixed on the free end under the action of inertial loads specified in the form of linear accelerations.

So, the type of circumferential joint of conical sections of inflatable shell structure has a significant influence on its load-carrying capacity. Thus, due to technological peculiarities of the welding process, the width and thickness of welded circumferential joint are limited, which affects the rigidity of this zone of the structure in the process of loading by inertial loads. The use of the alternative method of a circumferential joining (solder/glue) allows increasing the cross-sectional area of the shell structure in the zone of circumferential joint and, consequently, reducing the stress level. In such a way, the load-carrying capacity of the considered inflatable boom can be twice increased.

When using an alternative method of a circumferential joint (soldering/glue), the cross-sectional area of the shell structure in the zone of the circumferential joint grows and entails an increase in the mass of the structure, which subsequently reduces its load-carrying capacity.

-

Funding information: The authors state no funding involved.

-

Author contributions: Lobanov L.M. and Volkov V.S.: supervision, conceptualization, designed the experiments; Borovyk Y.V.: carried them out; Kandala S.M. and Makhnenko O.V.: developed the model code and analysed the results; Kandala S.M.: performed the simulations. All co-authors made an equal contribution to the preparation of the manuscript for publication. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: All data generated or analysed during this study are included in this published article.

References

[1] Schenk M, Viquerat AD, Seffen KA, Guest SD. Review of inflatable booms for deployable space structures: Packing and rigidization. J Spacecr Rocket. 2014 May;51(3):762–78.10.2514/1.A32598Search in Google Scholar

[2] Xiang XM, Lu G, You Z. Energy absorption of origami inspired structures and materials. Thin-Walled Struct. 2020 Dec;157:107130.10.1016/j.tws.2020.107130Search in Google Scholar

[3] Cook AJ, Walker SJ. Experimental research on tape spring supported space inflatable structures. Acta Astronautica. 2016 Jan;118:316–28.10.1016/j.actaastro.2015.10.016Search in Google Scholar

[4] Kezerashvili VY, Kezerashvili RY, Starinova OL. Solar sail with inflatable toroidal shell. Acta Astronautica. 2023 Jan;202:17–25.10.1016/j.actaastro.2022.09.039Search in Google Scholar

[5] Rastogi V, Upadhyay SH, Singh KS. Self-rigidizable Kapton-SMA conical booms: A comprehensive numerical and experimental study. Adv Space Res. 2024 Jan;73(8):3936–62.10.1016/j.asr.2024.01.004Search in Google Scholar

[6] Liu TW, Bai JB, Xi HT, Fantuzzi N, Bu GY, Shi Y. Experimental and numerical investigation on folding stable state of bistable deployable composite boom. Compos Struct. 2023 May;320:117178.10.1016/j.compstruct.2023.117178Search in Google Scholar

[7] Liu TW, Bai JB, Fantuzzi N, Zhang X. Thin-walled deployable composite structures: A review. Prog Aerosp Sci. 2024 Apr;146:100985.10.1016/j.paerosci.2024.100985Search in Google Scholar

[8] Block J, Straubel M, Wiedemann M. Ultralight deployable booms for solar sails and other large gossamer structures in space. Acta Astronaut. 2011 Apr;68(7–8):984–92.10.1016/j.actaastro.2010.09.005Search in Google Scholar

[9] Chu Z, Lei Y, Li D. Dynamics and robust adaptive control of a deployable boom for a space probe. Acta Astronaut. 2014 Jan 23;97:138–50.10.1016/j.actaastro.2014.01.009Search in Google Scholar

[10] Chen T, Wen H, Jin D, Hu H. New design and dynamic analysis for deploying rolled booms with thin wall. J Spacecr Rocket. 2015 Dec [cited 2025 Mar 14];53(1):225–30, https://www.researchgate.net/publication/287249111_New_Design_and_Dynamic_Analysis_for_Deploying_Rolled_Booms_with_Thin_Wall.10.2514/1.A33184Search in Google Scholar

[11] Mahias R, Defoort B, Mille M, Coqueret X, Langlois S. Polymerization of composite materials in free space environment. Proceedings of the 11th International Symposium on Materials in Space Environment. Aix en Provence, France: 2009 Sep 15–18.Search in Google Scholar

[12] Lobanov L, Volkov V, Yakimkin A. Construction methods and comparative evaluation of metal deployable load-carrying shell structures. J Aerosp Technol Manag. 2018 Aug;10:e3818.10.5028/jatm.v10.959Search in Google Scholar

[13] Li M, Zhou Z, Hao B, Yu C, Chen Y, Ma J. Design and deformation analysis of an inflatable metallic cylinder based on the Kresling origami pattern. Thin-Walled Struct. 2023 Jul;188:110859, https://www.sciencedirect.com/science/article/abs/pii/S0263823123003373.10.1016/j.tws.2023.110859Search in Google Scholar

[14] Volkov VS, Makhnenko OV, Kandala SM, Volkova OA, Borovyk YV. Compactness variability of metal deployable load-carrying shell structures. Mater Today Proc. 2021 Jan;46:170–5.10.1016/j.matpr.2020.07.227Search in Google Scholar

[15] Lobanov LM, Ustinov AI, Volkov VS, Mokhniuk AA, Telichko VA, Demchenkov SA. Al/TiO2 bilayer coatings for space applications: Mechanical and thermoradiation properties. Thin Solid Films. 2018 Oct;668:30–7.10.1016/j.tsf.2018.10.017Search in Google Scholar

[16] Thirumalaikkannan D, Paramasivam S, Visvalingam B, Sonar T, Ivanov M, Murugaesan S. Microstructural characteristics and mechanical properties of rotary friction-welded dissimilar AISI 431 steel/AISI 1018 steel joints. J Mech Behav Mater. 2023 Jan;32(1):20220273.10.1515/jmbm-2022-0273Search in Google Scholar

[17] Dhanya MS, Manwatkar SK, Gupta RK, Murty SVSN. Metallurgical investigation of leakage observed in welded interface of Pilot pressure distributor of liquid stage for aerospace application. Eng Fail Anal. 2023 Jul;152:107510.10.1016/j.engfailanal.2023.107510Search in Google Scholar

[18] Elrefaey A. High-temperature brazing in aerospace engineering. In: Chaturvedi M, editor. Welding and Joining of Aerospace Materials. Woodhead Publishing; 2011. p. 329–62.10.1016/B978-0-12-819140-8.00011-0Search in Google Scholar

[19] Bishopp J. Chapter 5 Aerospace: A pioneer in structural adhesive bonding. Handb Adhes Sealants. 2005 Jan;1:215–347.10.1016/S1874-5695(02)80006-9Search in Google Scholar

[20] PrePoMax [Internet] 2025 [cited 2025 Mar 14]. https://prepomax.fs.um.si.Search in Google Scholar

[21] Sakkampang K, Sakkampang C, Sakkampang D. An experimental study and finite element analysis of the parametric of circular honeycomb core. J Mech Behav Mater. 2022 Jan;31(1):98–111.10.1515/jmbm-2022-0011Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite

Articles in the same Issue

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite