Abstract

The most failures that occurred in the contacting surfaces were due to the wear in materials of the mechanical parts (products). The lifetime of any machine element or product will be reduced when the rate of wear increases more than the critical value. The main objective of most of the researchers and designers in the industry sectors is to improve the resistance of wear for the machine element (product) that works under heavy working conditions. It can be considered that hardfacing is one of the significant techniques used for the different elements of machines to deposit the hard layer on the contacting surfaces to improve their wear resistance. In this work, St 37 low carbon steel plate with dimensions 120 × 60 × 12.5 mm3 was hardfaced with E1-UM-450 hardfacing electrode under different hardfacing conditions. Taguchi method with L9 orthogonal array was applied to study the effect of different hardfacing parameters. Travel speed, hardfacing current, and hardfacing layers were selected as independent input parameters while impact resistance of the weld deposit was the output response. Furthermore, the optimal conditions of hardfacing process were two hardfacing layers, a current of 120 amp, and a travel speed of 200 mm/min. Microhardness profile was constructed to identify the depth of hardfacing layer(s). In addition, the chemical compositions of the hard weld deposits for nine specimens were achieved.

1 Introduction

Generally, it can be considered that the wear phenomenon is one of the most undesired disadvantages especially in the Tribology field [1]. It can be defined as the wear of material as damaging, slow removal, or deformation of surfaces of contacting bodies [2]. Surface degradation of mechanical parts is considered a significant problem in many areas of industry. This phenomenon happens because of the effect of one or more factors at the same time that has a negative impact on the wear mechanism. These factors (surrounding temperature, load, type of design, contact area, level of movement, type of lubrication, surrounding environment, material properties, status of surface, surface finishing, hardness, microstructure, etc.) increase the speed of wear mechanism, corrosion, oxidation, corrosion, corrosion, fatigue, and surface fatigue [3]. Surface properties can be considered as essential item in the design process of any product where it is linked directly to the durability and lifetime of the product. Consideration should be given to the heavy-duty working conditions that can lead to physical and chemical degradation of the surfaces of the mechanical part or product that leading to product failure before design life.

Srikarun and Muangjunburee studied the influence of the chemical composition, microstructure, welding dilution, macrostructure, hardness, and welding dilution on a plate made from low-carbon steel. A submerged arc welding procedure with one layer of hardfacing for the deposition was applied. Electrode with low carbon and different magnitudes of the chromium powder was used for the layer of hardfacing. Comparison was made between the results of the hardfacing when powder addition and when martensitic type electrode were used. The results of chemical composition and macro/microstructure for the hardfacing were analyzed using an optical emission spectrometer and optical microscope. The results proved that the microstructure of hardfacing layer contains ferrite and pearlite when the powder was used, while the microstructure of hardfacing contains ferrite and martensite phase when used the powder addition [1]. Pawar et al. investigated four Fe-based commercial hardfacing alloys, where mild steel was used as the base plate. It presented the relation between microstructural, hardness properties of hardfacing with the chemical compositions during the process. The pin-on-disc test rig was used to study the wear mechanism on the surfaces. It was found that the elements of the alloying resisted the material removal due to the action of abrasive and this led to the reduction in the rate of wear [2]. Saadat et al. applied two kinds of flux cored arc welding filler metals to achieve surface hardening. Different modes were used for the single, two, and three-pass modes on the plain carbon steel. It was found that the final properties for layers of hardfacing and the microscope metallography. Different tests were done to obtain the final properties such as X-ray diffraction, hardness, microhardness, and abrasion. It was concluded that when the molybdenum increased, the resistance of hardness and wear of the weld layers increased, and the hardness for the three layers became 62 HRC [3].

Foster et al. conducted a study to evaluate abrasive and adhesive wear on H13 tool steel dies used in the industrial hot forging process using a 160 kJ screw press. A low-cost standard test method was developed with the use of an advanced Forming Research Center. This allows for the benchmarking of new and novel coatings, lubricants, or additive layers against an established standard. Even more so, any appreciation of findings must be reproduced and executable. Due to its high machinability and good wear properties cobalt was chosen to be the hardfacing alloy. The first step in remanufacturing hot forging tools and dies with laser metal deposition using the powder was to evaluate the efficacy of this technique before coating the standard dies. The final geometry was machined from the laser metal deposition with powder coating; hot forging and wear characteristics were compared with the benchmarks. The wear of adhesives and abrasives was examined. Laser metal deposition with a powder additive layer outperformed the conventional H13 tools and steel dies in both adhesive and abrasive conditions [4]. Nanometer TiO2 particles were added to the hardfacing materials by Chen et al.; they also investigated the relationship between the inclusion of nano-TiO2 and the hardfacing material’s hardness and wear resistance. At about 1,660°C, they first converted nano-TiO2 to Ti3O5, which subsequently transformed into Ti2O3 and MnTi2O4 at roughly 600 and 550°C, respectively. Grain refining is obviously impacted by this, as the grain size slowly declines the nano-TiO2 levels grow. The results showed that at 0.6 wt% nano-TiO2 concentration, the hardness of hardfacing alloys achieved its maximum value of 56.4 HRC. Furthermore, the addition of nano-TiO2 can improve the wear resistance of the hardfacing layer for the homogeneity of the microstructure and increase in carbides [5].

Arsić et al. conducted thermal coupled analysis of 3D transient nonlinear hardfacing process with finite element method and experimental test. They compared the results with empirical formulas put forth by welding guidelines for three different carbon steels. Hardfaced plate samples were used at different usage rates and volumes in their experimental tests. After the experiments, thermocouples were used to measure temperatures and temperature cycles in a rotary-drum furnace at 800–500°C, where the maximum temperature as well as the duration of cooling between these temperatures was identified. Finite element method analysis followed after experimental testing. Simulations were carried out through the open-source platform. Second, the Gaussian double ellipsoid was selected to provide more possibilities for estimating heat source movement. Summary: the numerical results were contrasted with the available experimental and mathematical works [6]. Ebimobowei et al. reported different quantities of titanium. The mechanical behavior and microstructure of Ni–B binary alloys have been improved by Tang et al. They studied the nickel-rich region of alloys in the Ni–B–Ti system. An optical microscope and a scanning electron microscopy (SEM) equipped with energy dispersive X-ray analyzer (EDXA) was used to examine the microstructure of the alloys. Particularly the addition of titanium, after which a ternary phase was formed and multiple complex phases were created. Also, these ternary alloys’ mechanical properties were better when titanium is added to Ni–B 119, 120. Microhardness values of the alloys were found to increase from 216.2 HV in zero Ti content Ni–B alloy to those having a maximum up to that of solid solution A1-11%Ti state at 1530.7 HV (wt%). The elevated rigidity of these alloys was deduced from their elastic moduli values in the range of 513.77–1046.51 N/m2. The increase in titanium concentration allowed the Ni-based ternary alloys to exhibit some hard boride phases under solidification, as well as decrease the grain size and improve the physical properties of these materials [7].

Shrimali et al. adopted a robust Taguchi design and the analytical hierarchy process technique to obtain the appropriate welding operational parameters that ensured a good bead geometry for AISI 1023 low carbon steel weldments in submerged arc welding procedure. In designing the experiments, they employed Taguchi’s L16 orthogonal array and controlled weld condition voltage, weld speed (WS), wire feed rate (WFR), and nozzle-to-plate distance (NPD) as input process parameters. They were also able to choose bead width, reinforcement, and penetration as well as the angle of entrance and the angle of convex. The optimal welding parameters were a voltage of 44 V, WS of 4 mm/s, WFR of 28 mm/s, and NPD of 21 mm. WS was established to have the greatest influence on the remaining responses, whereas it was determined that the voltage had the greatest impact on penetration [8]. The stellite-6/TiC wear resistance and titanium carbide were studied, which was deposited on the substrate of stainless steel 316L (SS316L) by laser cladding. In order to further improve the durability the SCSM samples were clad with stellite-6 particles and titanium carbide reinforcement layer. They also tried different portions of titanium carbide (0, 10, 20, 30, 40, and 50) to modify stellite-6 until 100%. They performed a room temperature wear test with 1.6 mm cladding thickness using the pin-on-disc method. Microstructural changes in the wear samples were observed with EDAX spectrums and SEM. The results showed that the coating of stellite-6 with 10 and 20% TiC layers is a strongly preferred composition [9].

Sözeri et al. manufactured ballistic limit plates by welding S355JR steel plate with Fe–Cr–C and austenitic electrodes. An electric arc welding machine was used to form the coatings, with two coatings applied to each material’s surface. The welding voltage and current for all the coatings were set at 27 and 150 A, respectively. To analyze the phases and components of the hardfacing surfaces, and to obtain the data regarding their microstructure, hardness, and ballistic characteristics X-ray diffraction analysis and SEM were applied. The respective hardness Mc specific hardening coating layers were evaluated. They illustrated that the ballistic qualities of steel surfaces can be enhanced with hardfacing techniques, which may help in the development of protective materials for various industries [10]. There are many researchers from different countries of the world who have studied hardfacing using different techniques, due to its great importance in the industrial sectors. They have studied the most important factors affecting the hardfacing process [11–13].

The capital costs of hardfacing process is an effective method in sustaining and prolonging the durability of the hardfaced and repaired parts particularly the huge mechanical parts like large gears, conveyer screw, and parts of heavy machinery that act as vital elements in an industrial sector. Economic analyses of hardfacing expenses also examine overall cost-effectiveness, which includes initial investment and savings. Expense problems include capital costs for labor, materials, equipment, and installation; running costs, such as energy use limitations and maintenance costs. However, there may be substantial financial gains for businesses and industries if the product life expectancy rises. In addition to optimizing equipment usage with improved product reliability, these advantages include reduced maintenance costs, enhanced productivity, lowered inventory costs, and shortened lead times [14].

This research article presents the optimization process of the hardfacing parameters of St.37 low-carbon steel plate. E1-UM-450 hardfacing electrode was deposited with different hardfacing parameters to investigate their effect on the impact resistance of the weld deposit. Taguchi method with an L9 orthogonal array was adopted to analyze and optimize of the hardweld deposit. Finally, the chemical composition and hardness profile of the weld deposit were also discussed and analyzed.

2 Experimental procedure

This article presents a better understanding of the effective parameters of hardfacing-based steel plates. A low carbon steel plate is with a thickness of 12.5 mm, where the hardfacing is achieved by using the electrode with low hydrogen (E1-UM-450) and applying the welding machine (arc type) of the shielded metal.

The highest value of current of the selected welding machine is 400 amp. Table 1 lists the experimental chemical analyses and the nominal values of the base metal, while Table 2 shows the mechanical properties of the selected base metal. Table 3 illustrates the specifications and properties of the selected electrode (E1-UM-450).

Chemical composition of the selected base metal

| Steel grade | Styles | Carbon, max (%) | Manganese (%) | Phosphorus max (%) | Silicon (%) | Sulfur max (%) | Nitrogen, max (%) |

|---|---|---|---|---|---|---|---|

| ST37-2 | Steel angles | 0.2 | 0.35–0.75 | 0.05 | 0.15–0.35 | 0.05 | 0.011 |

Mechanical property of the selected base metal

| Steel grade | Styles | Tensile strength, ksi (MPa) | Yield point, min, ksi (MPa) | Elongation, min, δ (%) |

|---|---|---|---|---|

| ST37-2 | Steel angles | 52–67 (360–460) | 34 (235) | 25 |

Specifications and properties of the selected electrode

| E1-UM-450 | Specifications |

| Weld metal with a hardness of approximately 45 HRC | |

| Can be applied directly on hardenable | |

| Particularly suitable for the reclamation and fabrication of new metal cutting or forming equipment | |

| Classification | |

| DIN 8555 E1-UM-450 | |

| Typical chemical analysis (all weld metal) | |

| % Carbon (0.2), % silicon (0.3), % manganese (0.7), % chromium (4) | |

| Typical mechanical properties | |

| Hardness: 45–47 HRC | |

| Typical current values (AC or DC+/−) | |

| Diameter (mm) 3.2 | |

| Current (A) 100–140 |

The first step was cleaning the surfaces of the plate with the mechanical steel brush and then washing these surfaces with a special chemical solution. Finally, it was dried before the hardfacing process. The reason to achieve these steps is to keep the surfaces away from rusts and contaminations which negatively influence the final status of the deposit of hardfaced weld according to the quality of the final surfaces of the plate. The base of the metal plate and the deposit of weld are given in Figure 1.

Selected base metal and the deposit of weld. (a) Base metal, (b) weld deposit.

In this research article, the most effective parameters in the analysis are the number of layers, speed of travel, and current. These parameters are considered as independent variables, whereas response was considered (the value of impact) as dependent variable.

The standard range of the hardness for the electrode (D = 3.2 mm and length = 350 mm) is between 450 and 470 HV. The range of the current selected was between 100 and 140 amp based on the data of the producer, while the range of speed for travel is between 200 and 380 mm/min. The selected hardfacing layers are 1, 2, and 3. It can be seen in Table 4 the Taguchi L9 orthogonal matrix, where it has nine elements. Each element represents an experiment test under specific working conditions. It was selected by an expert in welding to achieve the tasks of the hardfacing, where the essential point is to adjust the accuracy of the input values of factors, especially for welding travel.

Experimental tests based on L9 orthogonal matrix

| New no. | Current (amp) | Layer’s number | Speed of travel (mm/min) | Impact resistance (J) |

|---|---|---|---|---|

| 1 | 100 | 1 | 200 | 35 |

| 2 | 100 | 2 | 290 | 44 |

| 3 | 100 | 3 | 380 | 36 |

| 4 | 120 | 1 | 380 | 22 |

| 5 | 120 | 2 | 200 | 64 |

| 6 | 120 | 3 | 290 | 53 |

| 7 | 140 | 1 | 290 | 21 |

| 8 | 140 | 2 | 380 | 34 |

| 9 | 140 | 3 | 200 | 55 |

3 Results and discussion

This section presents the achieved results after conducting the hardfacing process of St.37 carbon steel plate with E1-UM 450 electrodes using a shielded metal arc-welding machine.

Minitab17 and Design Expert 6 software were adopted for statistical analysis and optimization. The effect of independent input parameters will be investigated as below.

3.1 Impact results

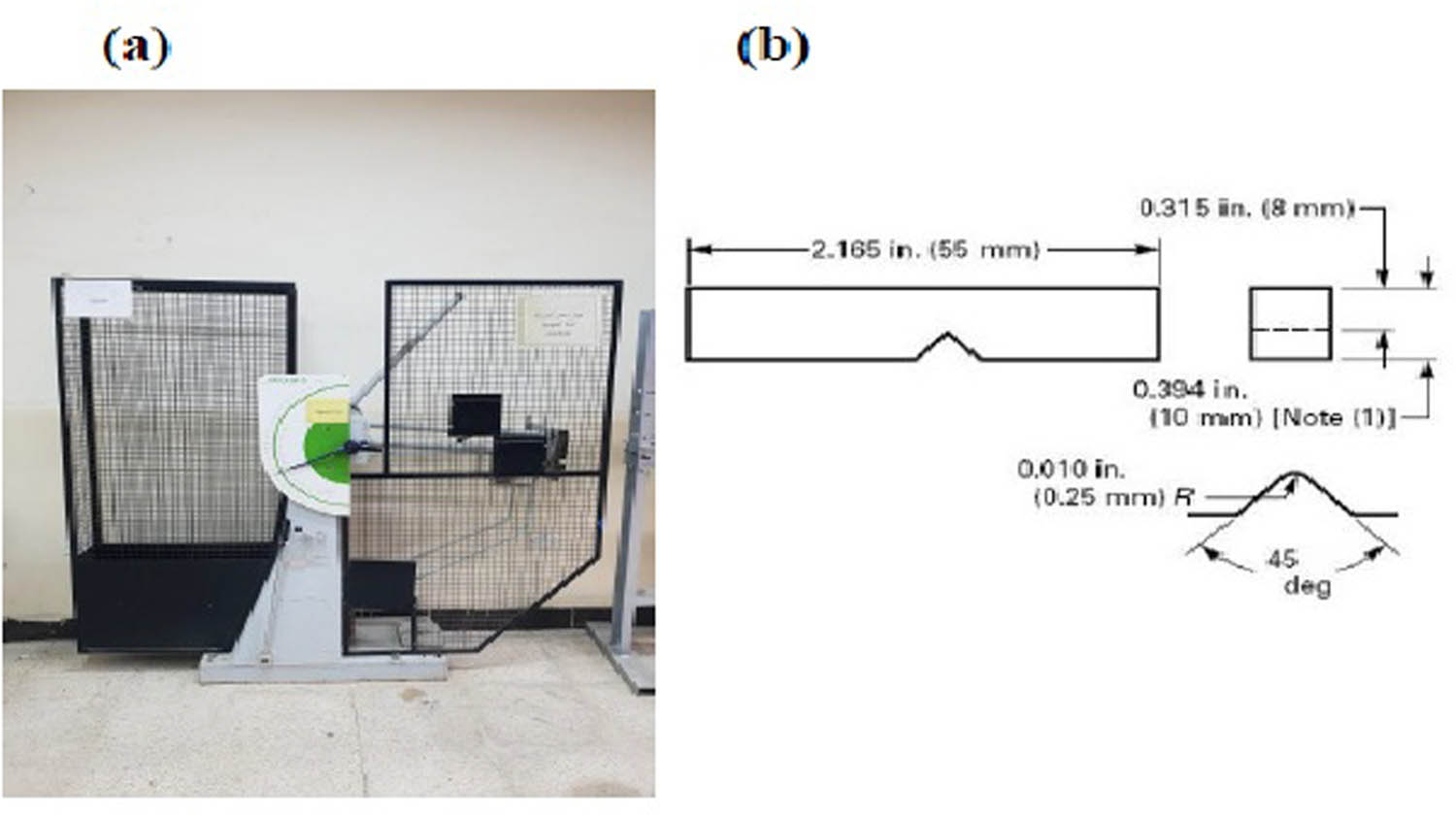

The selected hardfacing electrode is characterized by hard and tough weld deposits due to the existence of Cr and Mn. Consequently, the most appropriate tests that were carried out in this study were the Charpy impact test and Vickers microhardness. Figure 2 illustrates the Charpy impact tester and the standard dimensions of the impacted specimen.

(a) Charpy impact machine and (b) dimensions of specimen used in the test.

The results of the impact tests will be presented to show the effect, importance, and magnitude of effectiveness for each parameter using the statistical approach. Additionally, it will be presented in contour figures to show how affected is the output response by the input parameter.

Before starting with results and discussions, the results of ANOVA table should be taken into account to reveal whether the model and its terms were significant or not. Table 5 lists the outputs of ANOVA results that include the details of each parameter.

ANOVA table

| Source | Sum of squares | DF | Mean square | F value | Prop > F |

|---|---|---|---|---|---|

| Model | 1746.00 | 6 | 291.00 | 291.00 | 0.0004 |

| A | 160.22 | 2 | 80.11 | 721.00 | 0.0014 |

| B | 646.22 | 2 | 323.11 | 2908.00 | 0.0003 |

| C | 939.56 | 2 | 469.78 | 4228.00 | 0.0002 |

It can be noticed from the results of Table 5, that the proposed model is significant according to the p-value, which is less than 0.05 at 95% confidence level, and F-value of 2619.00 points is the significance of the model. There is only a 0.04% chance that in a “Model F-Value,” this large could occur due to noise. Therefore, the results of this model can be navigated and investigated.

It was also found that the model terms are significant based on the result of “Prob > F” where all are less than 0.05 at a confidence level of 95%. Under such conditions, the effective parameters (current, travel speed, and number of layers no) are significant. When the magnitude of the result is greater than 0.1, this means that the terms of the model are not significant.

The “Pred R-Squared” of 0.9974 is in reasonable agreement with the “Adj R-Squared” of 0.9995. “Adeq Precision” measures the signal-to-noise ratio. A ratio greater than 4 is desirable. A model ratio of 146.272 indicates an adequate signal. Hence, this model can be utilized to navigate the design space.

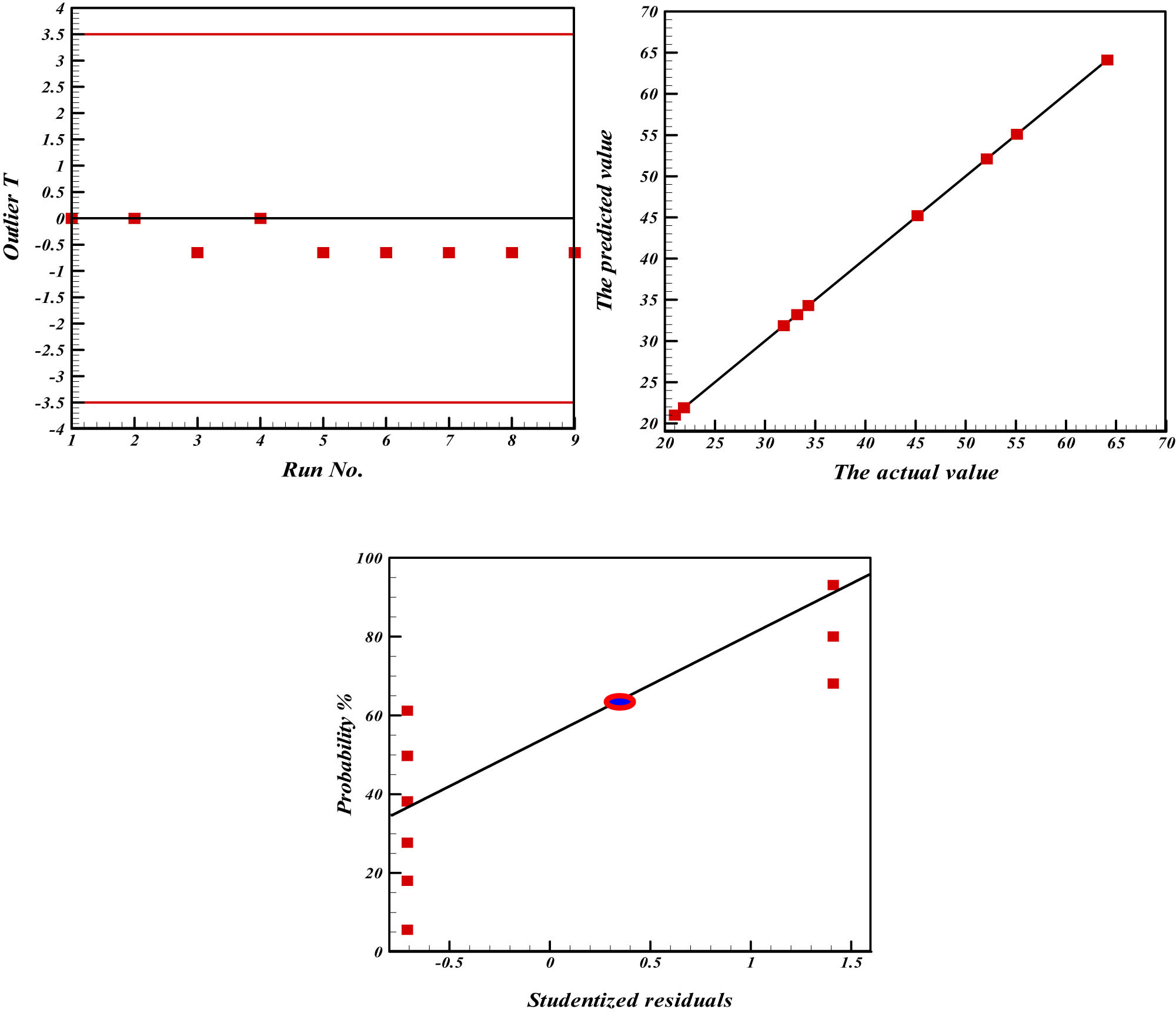

Figure 3 shows the results of the diagnostic operation. It is essential to present the normal percentage probability (predicted values against actual values) before discussing the results. The reason to present such a graph is to exhibit the distribution of data in a normal situation. It was observed that the agreement exists between the actual values and the predicted values, and there are no outlier values. It was concluded based on the obtained results; the required tasks were successfully accomplished.

Results of diagnostic process.

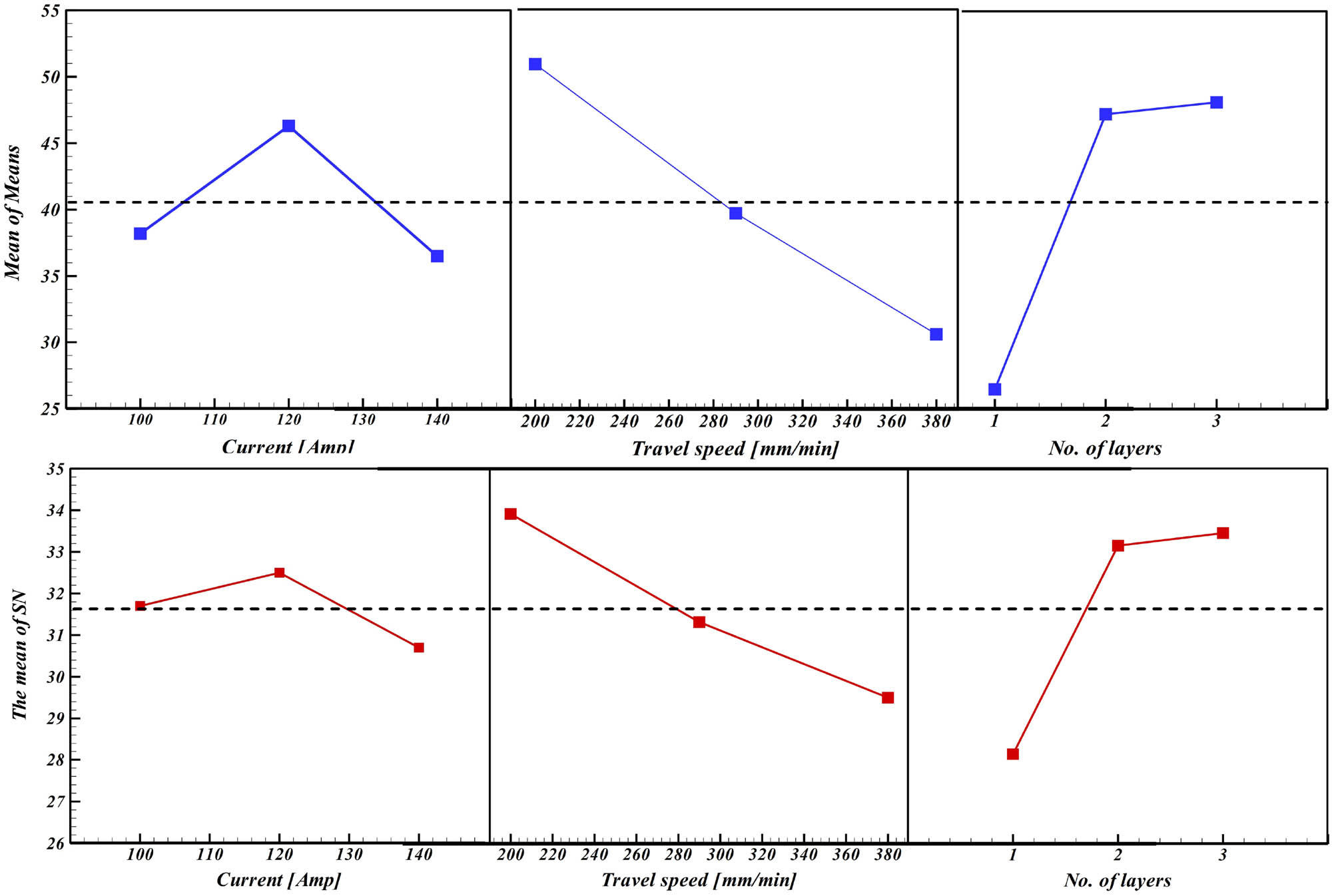

Figure 4 shows mean value and S/N plots. It is obvious that low and high levels of current are not suitable compared with medium levels where there is an increase in the average impact with an increase of current to 120 amp. Then a drop in impact occurs with an increase in current to 190 amp. On the other hand, as the travel speed increases, the impact value consequently decreases. With respect to hardfacing layer, there is a noticeable improvement when applying two hardfacing layers instead of a single layer. Based on the percentage contribution shown in Table 5, the degree of significance of input parameters can be ranked as (1) number of layers, (2) speed of travel, and (3) current.

Variation of means of variables and SN with selected range of factors.

The results shown in Table 6 proved that a low magnitude of impact value can be obtained when one layer of hardfaced was applied, while the magnitude of impact value increased when two layers of the weld deposit were applied. As a result of the heat that enters the specimen when hardfacing process was applied, the phase and microstructure changed. It was found that the temperature at the region of base metal close to the fusion line goes above Ac3 (γ phase), and this will make the structure coarse. Generally, at room temperature, the structure with fine grain has a high impact value compared to the structure with coarse grain. The magnitude of the impact values was low when one layer is applied. The impact resistance was improved when the second hardfaced layer was applied, where the second layer created what is called the self-tempering of the first layer. The resistance of impact decreased in the case when the value of travel speed is high, the current is low, and applying three layers on the specimen (see specimen No. 3). It was found that the amount of hydrogen that accumulated when three layers was applied on the specimens is higher than the other cases. Owing to the low amount of input heat and very short time, the hydrogen cannot go out (see the results of specimen No. 3). It was noticed that the resistance of impact increased when the amount of input heat increased (specimen Nos. 6 and 9).

Final chemical composition of the hard deposit of weld

| Run | C% | Si% | Mn% | S% | P% | Cr% | Ni% | V% | Mo% | Fe% |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.9359 | 0.368 | 0.4877 | 0.01144 | 0.01354 | 3.4121 | 0.06785 | 0.0204 | 0.01045 | Balance |

| 2 | 2.0105 | 0.137 | 0.6557 | 0.01661 | 0.01871 | 3.7441 | 0.01036 | 0.02173 | 0.0071 | Balance |

| 3 | 1.8803 | 0.013 | 0.6907 | 0.01751 | 0.01961 | 4.1151 | 0.01109 | 0.02076 | 0.00992 | Balance |

| 4 | 1.91 | 0.209 | 0.6337 | 0.01773 | 0.01983 | 3.7021 | 0.01184 | 0.01874 | 0.01146 | Balance |

| 5 | 1.881 | 0.028 | 0.6857 | 0.01776 | 0.01986 | 4.1041 | 0.01162 | 0.01474 | 0.01139 | Balance |

| 6 | 1.9 | 0.119 | 0.6147 | 0.01809 | 0.02019 | 3.6351 | 0.01036 | 0.02173 | 0.0071 | Balance |

| 7 | 1.8806 | 0.035 | 0.6837 | 0.01996 | 0.02206 | 4.0471 | 0.01028 | 0.01742 | 0.01269 | Balance |

| 8 | 1.9 | 0.275 | 0.5057 | 0.01996 | 0.02206 | 3.5971 | 0.01134 | 0.01923 | 0.00835 | Balance |

| 9 | 1.881 | 0.119 | 0.6837 | 0.02066 | 0.02276 | 3.9151 | 0.00748 | 0.01561 | 0.00844 | Balance |

The other important point that was found was that the tempering intensity of the primary beads and the self-heating degree of the deposited surface increased with the increase in the amount of specific energy.

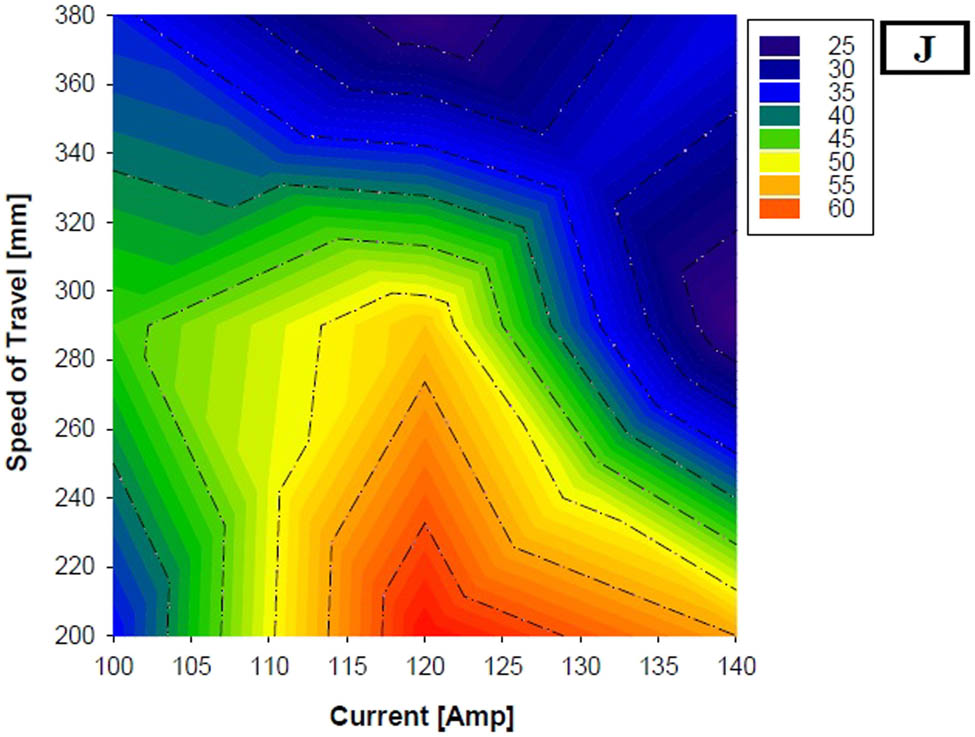

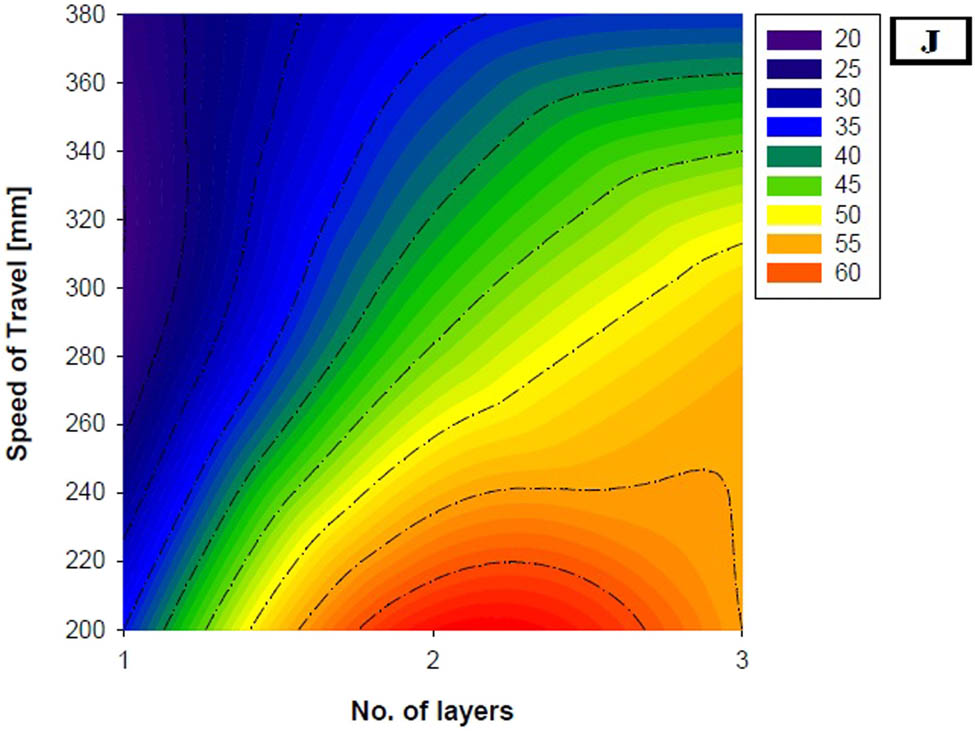

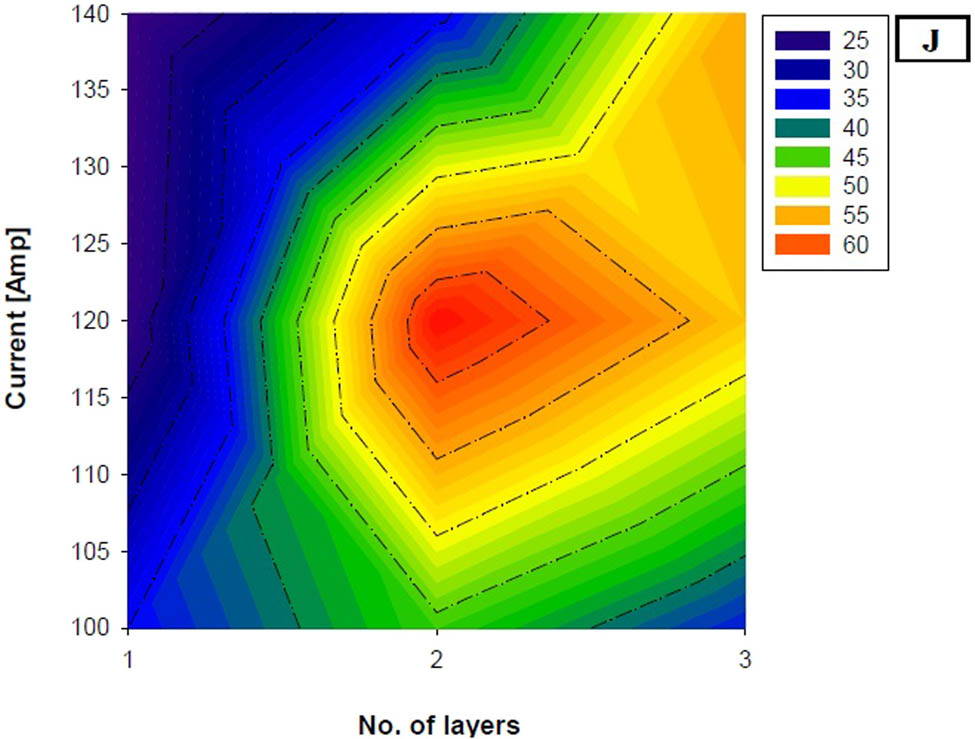

Figure 5 shows the contour for the variation of impact value with the current (A) and the speed of travel (B). It can be seen that the maximum value of impact occurred when the current used is 120 amp and the speed of travel is 200 mm/min. The variation of the impact with the number of layers (C) and speed of travel (B) is shown in Figure 6. The maximum value of impact occurred when the number of layers is two and the speed of travel is 200 mm/min. Figure 7 illustrates the variation of the impact with the number of layers (C) and the current (A). It was also observed that the highest value of impact occurred when the number of layers is two and the current was 120 amp.

Variation of the impact with current and speed of travel.

Variation of the impact with number of layers and speed of travel.

Variation of the impact with number of layers and current.

In the above figures, the variation of response behavior corresponding to the functional parameters (input) was observed. The main objective of this analysis is to obtain high value of impact as much as possible, i.e., to find the optimal zone for the two parameters when keeping the third parameter constant (the value of the third parameter should be within the allowable range).

Also, it can be observed from Figure 5 that a high value of impact can be obtained when the range current applied is between 115 and 130 amp and the speed of travel is equal to 200 mm/min. Furthermore, a high value of impact was obtained, as shown in Figure 6, when the range of speed of travel was between 200 and 230 mm/min and the use of two hardfacing layers. It was found from Figure 7 that when a low speed of travel was applied and two layers were used, the value of impact is high.

3.2 Optimization and chemical analyses

In this section, we investigated the optimization for the conditions of hardfacing to obtain the high value of impact as much as possible. Also, carried out a deep study to find the optimal range for the input parameters and how can obtain the safe area to get the allowable impact value.

The setting conditions for hardfacing should be achieved in the experimental work accurately and carefully to ensure obtaining a high value of impact.

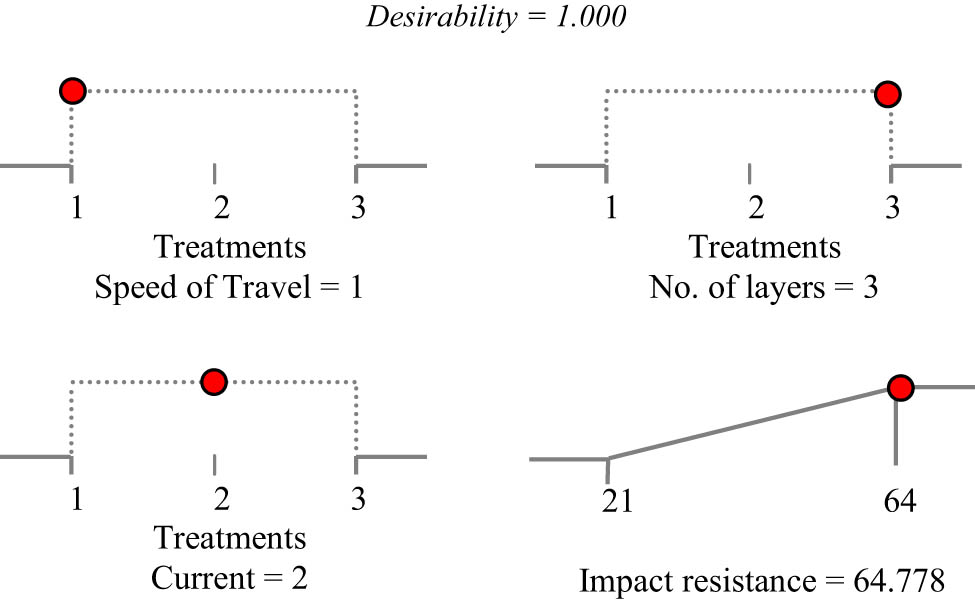

Figure 8 illustrates the high impact value (the desired objective) corresponding to the optimal parameters. The results of this figure proved that the optimal value for the current is 120 amp, the number of layers is two, and the speed of travel is kept at a low value of 200 mm/min.

Optimized input settings (Ramp scheme) (Desirability = 1.000).

The spectra analyzer device was used to analyze the chemical composition for all specimens. The knowledge based on the literature proved that the pickup phenomena and the dilution have a significant effect on the chemical analysis of the deposit of weld. So, there will be a significant change of weld deposit in the distribution of elements between the surface and the line of fusion. It provides the list of chemical compositions of the specimens used in this work. It was found that the significant elements are chromium, silicon, and manganese, where Si and Cr are α stabilizer, but Mn is γ stabilizers. All of elements are considered solid solution strengtheners. Cr is also considered as carbide-forming element and at the same time it works together with Si and Mn to shift the TTT diagram to the left which ensures the formation of hard and touch martensite where Mn has a toughening effect. In this work, it was found that the base metal and weld metal have carbon percentages close to each other. Therefore, the carbon percentage of most specimens is close to each other regardless of the number of applied layers. On the other hand, the difference in other main elements (i.e., Cr, Si, and Mn) is notable due to the utilization of various settings of parameters that enable the function of pickup and the dilution process. In specimen Nos. 1, 6, and 8 the carbon pickup from the base metal pickup to the weld deposit was noticed, and the reason behind such results is using only one layer of hardfacing. It was found also that the percentage of the weight of the manganese, silicon, and chromium are less than the corresponding nominal values (Table 3). Migration of some of the elements (Mn, Si, and Cr) to the base metal happened because of the big difference in the chemical composition between the selected electrode and the proposed base metal. Based on the obtained results, it can be concluded that the chemical composition of the selected electrode is approximately equal to the standard values where hardface is done with two and three layers for the specimens. It means that the dilution between the weld metal and the base metal and the pickup of carbon is decreased.

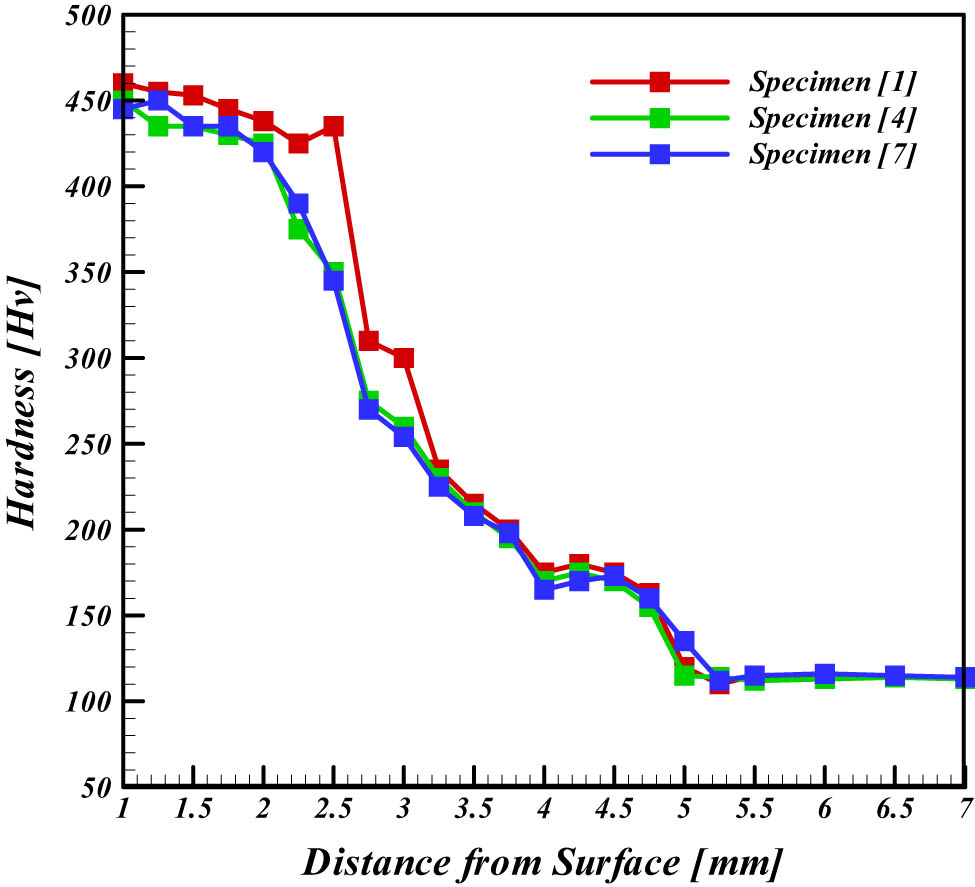

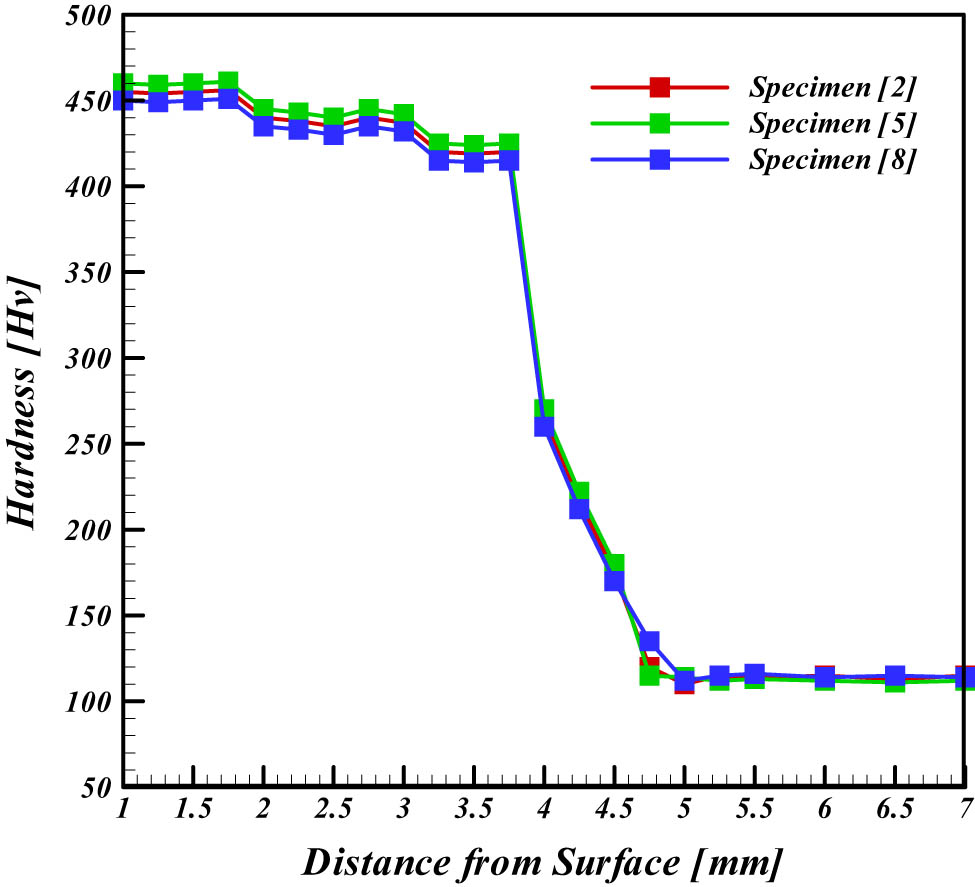

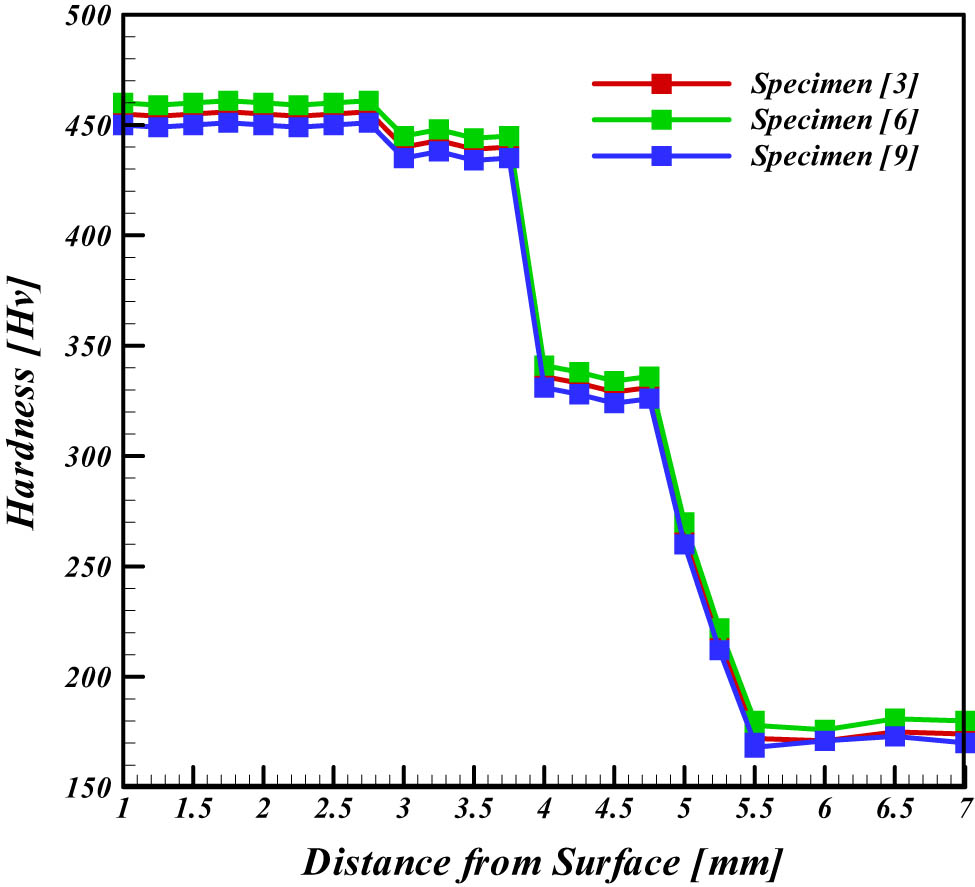

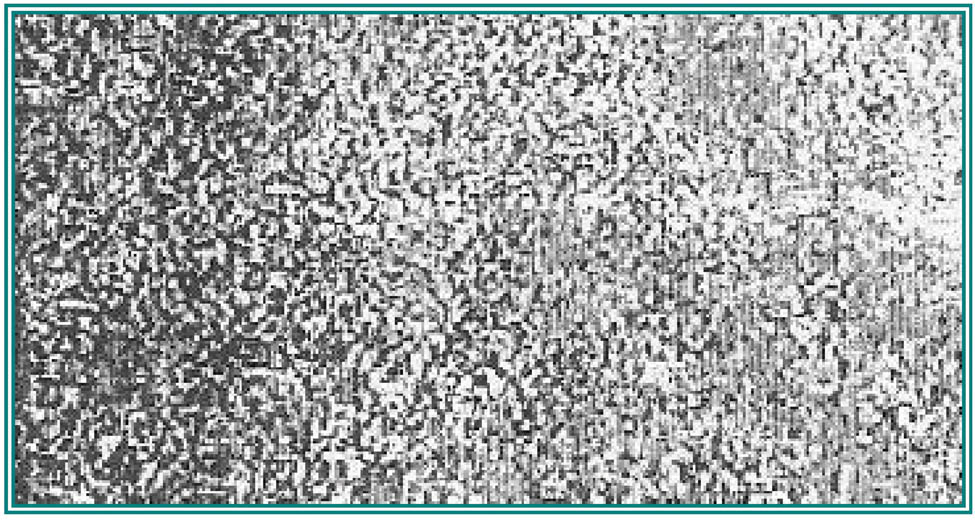

3.3 Hardness results

It can be seen from the results of the hardness that a significant difference between the specimens is observed as shown in Figures 9–11. These differences occurred owing to using various values for the factors of input and the settings. The thickness of the specimen can be divided into three regions: the first one is called weld deposit, the second one is the heat affected, and the last one is the base metal. When using one layer for hardface, the disturbance appeared in the profile across heat-affected region of specimens 1, 4, and 7. Owing to the pickup and dilution processes, it moved back to the heterogeneous type of chemical examination. On the other hand, when more than one layer (two and three layers) was used for hardfacing of the specimens, the profile generally goes down. The reason for obtaining such a result because of applying number of the layer is two, where this layer is considered like the tempering (self-type) for the first layer and heat-affected region. The results from Figure 12 show the presence of the martensitic structures in all specimens. The cooling that occurred during the process allows the hard structure to appear that consists of the following elements: silicon, manganese, and chromium. The hardness level of the deposit of weld can be increased by heat treatment.

Variation of hardness with distance from surface for specimens hardfacing with one layer.

Variation of hardness with distance from surface for specimens hardfacing with two layers.

Variation of hardness with distance from surface for specimens hardfacing with three layers.

Microstructure of the deposit of weld.

4 Conclusions

This research article presented a deep study of the effective parameters (speed of travel, welding current, and number of layers) that affected the hardfacing of the selected plate. It also presented the optimization approach to find the optimal values of effective parameters to obtain the highest impact value for the specific working conditions. The results illustrated the variation of the hardness with the base metal. Furthermore, the chemical analysis of the weld deposit was carried out.

Promising results of the hardfacing process was obtained based on the selected electrode (E1-UM-450). It was found that using one layer of hardfacing and a fast speed for travel negatively affected the value of impact resistance; therefore, more than one layer for hardfacing should be used (two or three layers) with a relatively low speed of travel to obtain better results. Where the disturbance at the heat-affected region has appeared when one layer for hardfacing. Finally, it was found that the optimal values of the effective parameters are speed of travel = 200 mm/min, current 120 amp, and number of layers = 2.

Acknowledgments

The author would like to thank Mustansiriyah University (www.uomustansiriyah.edu.iq), College of Engineering, Department of Materials Engineering, Baghdad, Iraq, for its support in the present work.

-

Funding information: Author states no funding involved.

-

Author contribution: The author has accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: Author states no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article.

References

[1] Srikarun B, Muangjunburee P. The effect of iron-based hardfacing with chromium powder addition onto low carbon steel. Mater Today: Proc. 2018 Jan;5(3):9272–80.10.1016/j.matpr.2017.10.100Search in Google Scholar

[2] Pawar S, Jha AK, Mukhopadhyay G. Effect of different carbides on the wear resistance of Fe-based hardfacing alloys. Int J Refract Met Hard Mater. 2019 Jan;78:288–95.Search in Google Scholar

[3] Saadat A, Shiran MK, Amini K, Bakhtiari H, Samimi B. Effect of molybdenum on metallurgical and wear properties of Fe–Cr–C hard facing alloy. Prot Met Phys Chem Surf. 2019 Sep;55:942–50.10.1134/S2070205119050228Search in Google Scholar

[4] Foster J, Cullen C, Fitzpatrick S, Payne G, Hall L, Marashi J. Remanufacture of hot forging tools and dies using laser metal deposition with powder and a hard-facing alloy Stellite 21®. J Remanufacturing. 2019 Oct;9:189–203.10.1007/s13243-018-0063-9Search in Google Scholar

[5] Chen CX, Zuo YQ, Liu BX, Xue HT, Ma B, Li XC. Microstructure and wear resistance of nano titanium dioxide strengthening hardfacing material. Vacuum. 2019 Apr;162:175–82.10.1016/j.vacuum.2019.01.045Search in Google Scholar

[6] Arsić DM, Ivanović I, Sedmak A, Lazić MM, Kalaba DV, Ceković I, et al. Experimental and numerical study of temperature field during hard-facing of different carbon steels. Therm Sci. 2020;24(3):2233–41.10.2298/TSCI190717338ASearch in Google Scholar

[7] Ebimobowei ZM, Emmanuel A, Adegbindin AJ. Mechanical strengthening and microstructural evolutions of Ni-B based hardfacing alloys influenced by titanium additions. Adv Mater. 2019;8:41–7.10.11648/j.am.20190802.11Search in Google Scholar

[8] Shrimali R, Kumar M, Pandey S, Sharma V, Kaushik L, Singh K. A robust Taguchi combined AHP approach for optimizing AISI 1023 low carbon steel weldments in the SAW process. Int J Interact Des Manuf (IJIDeM). 2023 Aug;17(4):1959–77.10.1007/s12008-023-01307-7Search in Google Scholar

[9] Manukonda S, Bijjam RR. Wear resistance of stellite-6/TiC coating on stainless steel 316L produced by laser cladding process. In Annales de Chimie Science des Matériaux. France: Lavoisier; 2023 Apr, Vol. 47, No. 2.10.18280/acsm.470203Search in Google Scholar

[10] Sözeri M, Özdemir U, Fındık T, Karakoç H. Comparative study of hardfacing applications on structural steel surfaces to improve ballistic properties. Mater Today Commun. 2024 Mar;38:107733.10.1016/j.mtcomm.2023.107733Search in Google Scholar

[11] Tandon D, Li H, Pan Z, Yu D, Pang W. A review on hardfacing, process variables, challenges, and future works. Metals. 2023 Aug;13(9):1512.10.3390/met13091512Search in Google Scholar

[12] Pawar S, Jha AK, Mukhopadhyay G. Effect of different carbides on the wear resistance of Fe-based hardfacing alloys. Int J Refract Met Hard Mater. 2019 Jan;78:288–95.10.1016/j.ijrmhm.2018.10.014Search in Google Scholar

[13] Liu H, Yuan X, Rao L, Liu S, Shi Z, Zhou Y, et al. Refinement mechanism of NbC by CeO2 in hypereutectic Fe–Cr–C hardfacing coating. J Alloy Compd. 2019 Jan;770:1016–28.10.1016/j.jallcom.2018.08.162Search in Google Scholar

[14] Chippendale D. Cost reduction to the mining industry through the use of hardfacing ground engaging tools. Queensland University, Department of Mining, Mineral and Materials. Proje Tezi; 2000.Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite

Articles in the same Issue

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite