Abstract

Welding and relevant studies are indispensable to employ high-entropy alloys for practical applications. In this study, Al0.3CoCrCu0.3FeNi high-entropy alloy with single FCC phase was used to make “bead-on-plate” friction stir welds at different rotational speeds, and the effects on microstructure and mechanical properties were studied. Several banded structures containing oxide or nitride particles were observed in the stir zone (SZ), and the chemical wear of the polycrystalline cubic boron nitride tool was confirmed. The microhardness distribution of the welds showed higher hardness in the SZ because of grain refinement and the presence of deformed grains. The electron backscattered diffraction results suggested that the high-entropy alloy with low stacking-fault energy experienced recrystallization during friction stir welding, which was similar to other conventional materials with low stacking-fault energy.

1 Introduction

High-entropy alloys (HEAs) have been attracting considerable attention worldwide since Yeh et al. proposed these materials because of their novel concept and exceptional properties [1]. Numerous studies on HEAs have been conducted, which resulted in a considerable amount of information and the establishment of theories. Miracle and Senkov made a comprehensive review on HEAs and related concepts [2], including the history of development, thermodynamics, taxonomy, microstructures, and various properties. On the other hand, Yeh et al. reviewed the different definitions for HEAs and four core effects of HEAs he proposed earlier [3]. With abundant research on the principles and properties of HEAs being conducted, an important step for the development of HEAs should be on their applications.

Welding plays a crucial role in the applications of alloys. However, only a few studies have investigated the welding of HEAs. Wu et al. studied the weldability of the well-known CoCrFeMnNi HEA using electron beam welding and gas tungsten arc welding [4,5]. Good results were obtained, but the coarse grain structure in the fusion zone might cause negative effects on some applications. Among the various types of welding, friction stir welding (FSW) is a relatively new but promising approach. During FSW, the metal plates are stirred by a plunged rotating tool and joined without melting by tool rotation. Thus, deformation occurs, and recrystallization is activated by friction heat [6]. This welding method has been applied to various structural materials with thorough studies, including Ti–6Al–4V titanium alloy, aluminum alloys, and Inconel alloy 600 [7–9]. FSW is applied to different kinds of alloys because of its special advantages, such as solid-state joining, no requirement for filler materials, and high feasibility of dissimilar welding [10,11].

As for FSW of HEAs, several studies have been conducted. Zhu et al. [12,13] first tested the FSW of Al0.3CoCrFeNi and Co16Cr28Fe28Ni28 HEAs at two different welding speeds. They studied the cross-sectional microstructure, mechanism of recrystallization, shear texture, and microhardness of the welds. In addition, Jo et al. applied FSW to CoCrFeMnNi [14], and the tensile tests of the welds demonstrated a slight increase in yield strength along with 9% loss in elongation after FSW. All previous results of FSW of HEAs showed good weld appearance without notable defects, which imply the high possibility of using FSW to join HEAs. However, the effects of different rotational speeds on the welds have not yet been determined.

In this study, the aging and precipitation behavior of the newly designed Al0.3CoCrCu0.3FeNi was first elucidated. According to previous studies [15], Al addition has been demonstrated to give rise to the formation of the second phase at room temperature, normally of BCC/B2 structure, in single face-centered cubic (FCC) HEAs. Moreover, the presence of the BCC phase in the FCC matrix can significantly increase the difficulty in processing at room temperature [16]. However, the newly designed Al0.3CoCrCu0.3FeNi HEA was proved to be single FCC [17] and was treated with bead-on-plate FSW at four different rotational speeds from 200 to 500 rpm to further evaluate the weldability of the HEAs under FSW. The microstructure, mechanical properties, grain orientations, and texture of the welds were then examined. In addition, banded structures in the stir zone (SZ), which were also observed in the friction-stir welded Al0.3CoCrFeNi and Co16Cr28Fe28Ni28 HEAs [12,13], were examined in this research.

During this research, it was found that microstructure and microhardness of the welds varied based on the traveling distance of FSW (supplementary Figures S1–S3). As a result, given the fact that properties observed at longer traveling distance (farther away from the starting point of welding) should provide more stable and reliable information for applications of FSW with larger scale, all the examined parts of the welds in this study were at least 60–70 mm away from the starting point of welding.

2 Experimental procedure

Ingots of Al0.3CoCrCu0.3FeNi with a size of 40 × 20 × 10 mm3 were produced by vacuum arc melting with a mixture of constituent elements with purity higher than 99.95 mass% under an argon atmosphere (after a vacuum of 3.3 Pa was reached) at least four times to ensure compositional homogeneity.

To elucidate the aging and precipitation behavior, the ingots were first homogenized at 1,100°C for 6 h (at 1,373 K for 21,600 s), water quenched, and then aged at different temperatures from 400 to 900°C for 1 h (from 673 to 1,173 K for 3,600 s). Then the ingots underwent the Vickers hardness tests with a load of 3 kgf (29.4 N) and a dwelling time of 10 s. X-ray diffraction analysis of the as-homogenized alloy used BRUKER D2 PHASER with Cu-Kα radiation, and the scanning rate was 0.14 degree/s. The alloy was aged at 800°C for 100 h (at 1,073 K for 3,60,000 s) and electro-etched in 30% HNO3–C2H5OH solution to observe the precipitates. For the FSW trials, the arc-melted ingots were cold rolled into 110 × 25 × 3 mm3 plates (∼70% reduction of thickness) and homogenized at 1,100°C for 6 h (at 1,373 K for 21,600 s) and water quenched.

Four bead-on-plate FSW trials were performed at different rotational speeds, i.e., 200, 300, 400, and 500 rpm (Figure 1), with the corresponding Z loads of 35, 30, 21–23, and 20–22 kN. The shoulder diameter, plunge depth, and welding speed were kept constant at approximately 14.3 mm, 2 mm, and 60 mm/min (0.001 m/s), respectively. A Q60 welding tool (MegaStir, USA), consisting of 60% polycrystalline cubic boron nitride (pcBN) and 40% W–25% Re alloy with a convex scrolled shoulder, was used (Figure 2). Argon shielding was employed around the tool during FSW to reduce surface oxidation. The schematic illustration of the bead-on-plate FSW is shown in Figure 3, and the principal directions of the FSW geometry are denoted as normal direction (ND), transverse direction (TD), and welding direction (WD). All the examined parts of the welds were at least 60–70 mm away from the starting point of welding to obtain more stable results.

Appearances of the bead-on-plate welds at rotational speeds of (a) 200, (b) 300, (c) 400, and (d) 500 rpm.

Geometry and dimension of the welding tool.

Schematic illustration of bead-on-plate friction stir welding.

All microstructural analyses of the welds, including the electron probe microanalysis (EPMA) and electron backscattered diffraction (EBSD), were performed on the ND–TD cross section. The microstructure was examined using a JEOL JSM-IT100 scanning electron microscope equipped with an Oxford x-act energy-dispersive X-ray spectroscopy (EDS) detector. Chemical etching was conducted by immersion in waterless Kalling’s etchant (ASTM E 407 designation is 95 Kalling’s 2), which consists of 0.5 g of CuCl2, 10 mL of HCl, and 10 mL of C2H5OH. The grain sizes were measured by ImageJ software. EPMA was conducted using a JEOL JXA-8500F HyperProbe Electron Probe Microanalyzer equipped with eight analyzing crystals capable of analyzing elements from atomic number of 4 (Be) to 92 (U). The oxygen/nitrogen content was analyzed using a HORIBA EMGA-620W oxygen/nitrogen analyzer.

A Mitutoyo hardness testing machine was used for the Vickers hardness tests. A spacing of 0.5 mm, a depth from surface of 0.5 and 1.0 mm, a 0.5 kg (4.9 N) of applied load, and 12 s of dwelling time were used for the microhardness distribution of the welds. The average hardness in the SZ at the depth of 1.0 mm was used to determine the Hall–Petch relationship of the resulting Al0.3CoCrCu0.3FeNi to avoid the influence of surface oxide layer. The Hall–Petch relationship of the annealed Al0.3CoCrCu0.3FeNi was constructed by measuring the average grain size and hardness after cold rolling and annealing at 1,000°C for 2, 5, and 20 h (at 1,273 K for 7,200, 18,000, and 72,000 s).

EBSD analyses were performed using HITACHI SU8010 and JOEL JSM-7800F field emission scanning electron microscopes equipped with Oxford EBSD detectors. The special boundary maps were constructed using a 15° criterion to differentiate the low-angle boundaries (LABs) from the high-angle boundaries (HABs), and the angle of Σ3 boundaries was defined as 60° with the misorientation that satisfies Brandon criterion. The grain misorientation map was constructed using grain-based evaluation criteria, in which a 2° minimum angle θc was adopted to define a subgrain. If the internal average misorientation in a grain exceeded θc, the grain was classified as deformed. If the internal average misorientation was under θc but the misorientation from subgrain to subgrain was above θc, then the grain was classified as substructured. Grains with an average internal misorientation lower than θc were classified as recrystallized. The inverse pole figures show the orientations of the grains along the ND.

3 Results and discussion

3.1 Microstructure of as-homogenized state and as-aged state

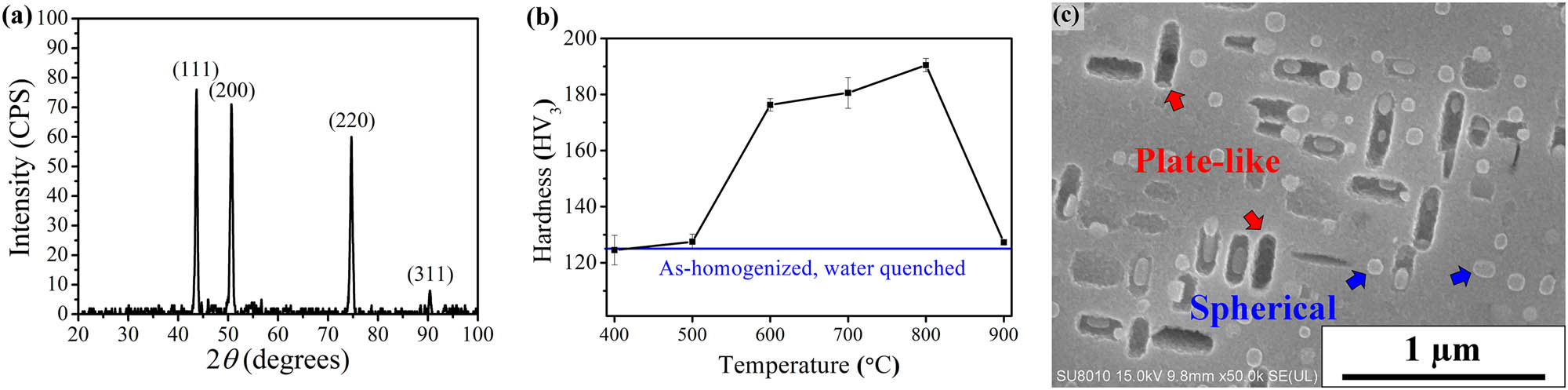

After homogenization at 1,100°C for 6 h and water quenching, the XRD pattern of Al0.3CoCrCu0.3FeNi (Figure 4(a)) suggested that the HEA was of single FCC phase. Aging at intermediate temperature (i.e., 600–800°C) for 1 h resulted in the hardening of the HEA (Figure 4(b)). The increase in hardness resulted from precipitation hardening, although the nanoprecipitates were too small to be observed. Thus, prolonged aging was adopted (800°C for 100 h) to analyze the precipitates, and plate-like and spherical precipitates were observed (Figure 4(c)). According to a previous investigation into the precipitation behavior of the Al0.3CoCrCu0.5FeNi HEA by Tsai et al. [18], these precipitates should be rich in Al, Ni, and Cu, with an L12-ordered FCC structure.

(a) XRD pattern of the as-homogenized Al0.3CoCrCu0.3FeNi high-entropy alloy (HEA). (b) Vickers hardness of the HEA aged at different temperatures for 1 h after homogenization. (c) The microstructure of the HEA after homogenization and aging at 800°C for 100 h showed two types of precipitates.

3.2 Microstructure of the plates after welding

The four HEA plates that underwent bead-on-plate FSW showed good appearance and surface integrity with a keyhole (Figure 1). Part of the material was extruded to the surface during the plunging of the tool, and the surface of the HEA plates was subject to oxidation, although argon shielding was employed. The cross sections of the welds showed a typical macrostructure of alloys welded by FSW. The alloys had a basin-shaped SZ at the center (circled by red dash lines), a narrow thermal–mechanical-affected zone (TMAZ) enclosing the SZ (unmarked), and the base metal (BM) as delineated in Figure 5(a–d). The grains inside the SZ underwent severe deformation and recrystallization and were thus refined from ∼500 µm to less than 10 µm. The refined grain sizes in the SZ were 1.7 ± 0.4 µm (200 rpm), 4.1 ± 1.2 µm (300 rpm), 4.7 ± 1.4 µm (400 rpm), and 6.1 ± 2.2 µm (500 rpm), as measured excluding twins and small deformed grains. The grain size became larger as higher rotational speed was applied, and this phenomenon could be attributed to the higher energy output and friction heat provided for recrystallization and grain growth [6].

Cross-sectional macrostructure of the welds at rotational speed of (a) 200, (b) 300, (c) 400, and (d) 500 rpm.

Aside from the aforementioned typical macrostructure, several banded structures were also observed in Figure 5(a–d) primarily at the advancing side of the SZ. Fraction of the banded structures decreased with decreasing rotational speed, and the banded structures were hardly observed at 200 rpm. These structures can be classified into bright bands (BBs), dark bands (DBs), and wide bands (WBs). Different kinds of particles, with sizes that usually range from 0.4 to 2 µm, were found at the grain boundaries of these bands. The results from the EDS analysis of the composition of the particles in the banded structures are shown in Table 1. These particles were mainly oxides or nitrides rich in Al with a comparatively higher content of Cr. Al and Cr are elements with higher chemical activity compared to the others in the BM. Thus, these elements tend to form a compound first, while the HEA is subject to oxidation or other chemical reactions. EPMA was conducted to understand the exact composition of the particles. The results suggested that BB and DB contained mostly Al2O3 and a small fraction of Cr2O3, but Al2O3 and AlN were found in the WB. The EPMA maps presented in Figure 6 show the AlN and Al2O3 particles in the WB.

Energy-dispersive X-ray spectroscopy results of the particles in different banded structures (unit: at%)

| Element | N | O | Al | Cr | Fe | Co | Ni | Cu |

|---|---|---|---|---|---|---|---|---|

| Bright band (BB) | 0 | 54 ± 9 | 26 ± 8 | 9 ± 7 | 4 ± 3 | 3 ± 3 | 3 ± 3 | 1 ± 1 |

| Dark band (DB) | 0 | 46 ± 8 | 28 ± 3 | 7 ± 3 | 6 ± 3 | 6 ± 3 | 5 ± 3 | 2 ± 1 |

| Wide band (WB) | 32 ± 9 | 0 | 28 ± 8 | 10 ± 3 | 9 ± 3 | 9 ± 3 | 9 ± 3 | 2 ± 1 |

| Base metal (BM) | 0 | 0 | 6.5 | 21.7 | 21.7 | 21.7 | 21.7 | 6.5 |

EPMA mapping in the WB showing the spatial distribution of (a) Al, (b) Cr, (c) O, and (d) N and (e) image of backscattered electrons.

Figure 7(a) shows the microstructure in the normal SZ, in which oval pores were observed at the grain boundaries after chemical etching. After conducting EDS mapping prior to etching, in which the absence of second-phase precipitates was confirmed, and EBSD analyses, which showed small grains surrounded with LABs, these oval pores were believed to be caused by the etching of deformed grains, which are grains not fully recrystallized with higher residual strain. Jo et al. reported a higher fraction of LABs in the SZ compared to other regions of friction-stir-welded CoCrFeMnNi HEA [14]. This result also suggested that the material in the SZ remained deformed after FSW.

Secondary electron images of the microstructure in the (a) normal SZ, (b) BB, (c) DB, and (d) WB. (a), (b), and (c) are the results at rotational speed of 300 rpm, and (d) is the result at 400 pm.

The microstructure in the normal SZ were compared to those in BB, DB, or WB (Figure 7(b–d)). Less deformed grains (oval pores) were found in the banded regions. This phenomenon was probably due to the different nucleation mechanisms of recrystallization during FSW. The oxide and nitride particles in the banded structures could serve as additional heterogeneous nucleation sites, which reduced the energy required for recrystallization. This phenomenon resulted in less deformed grains in these regions. A similar phenomenon with smaller grain size in the area where particles were dispersed had been reported by Zhu et al. as particle-stimulated nucleation [13].

The formation of BB and DB, in which numerous Al2O3 and some Cr2O3 particles were found, was speculated to have resulted from the stirring of the surface oxide layer during the FSW. The formation of WB should be related to chemical tool wear, which occurred during FSW and led to some AlN particles, products of chemical reaction between the tool and the HEA, and some tool debris that created deep scratches in the WB (Figure 5(c and d)). The EPMA results showed that the debris consisted of 56.6 ± 1.0 at% B and 43.4 ± 1.0 at% N, which was likely to be pcBN from the tool [19]. These bands appeared mostly on the advancing side because of the mechanisms of material flow during FSW [6]. The flow of materials during FSW can help explain the accumulation of particles at specific locations [20], in this case, the advancing side.

Oxygen/nitrogen analysis of the weld at 300 rpm was performed, and the results are shown in Figure 8(a). The SZ on the advancing side evidently contained higher contents of N and O. The greater content of N supports the suggestion of chemical tool wear, while the higher content of O in the SZ should result from the contribution of oxides in the BB and DB. Park et al. found a similar chemical tool wear in friction-stir-welded austenitic stainless steels using pcBN tool [21].

(a) The results of oxygen/nitrogen analysis of the weld at 300 rpm. (b) The schematic illustration of the regions analyzed. (AS: advancing side; RS: retreating side.)

3.3 Mechanical properties of the welds

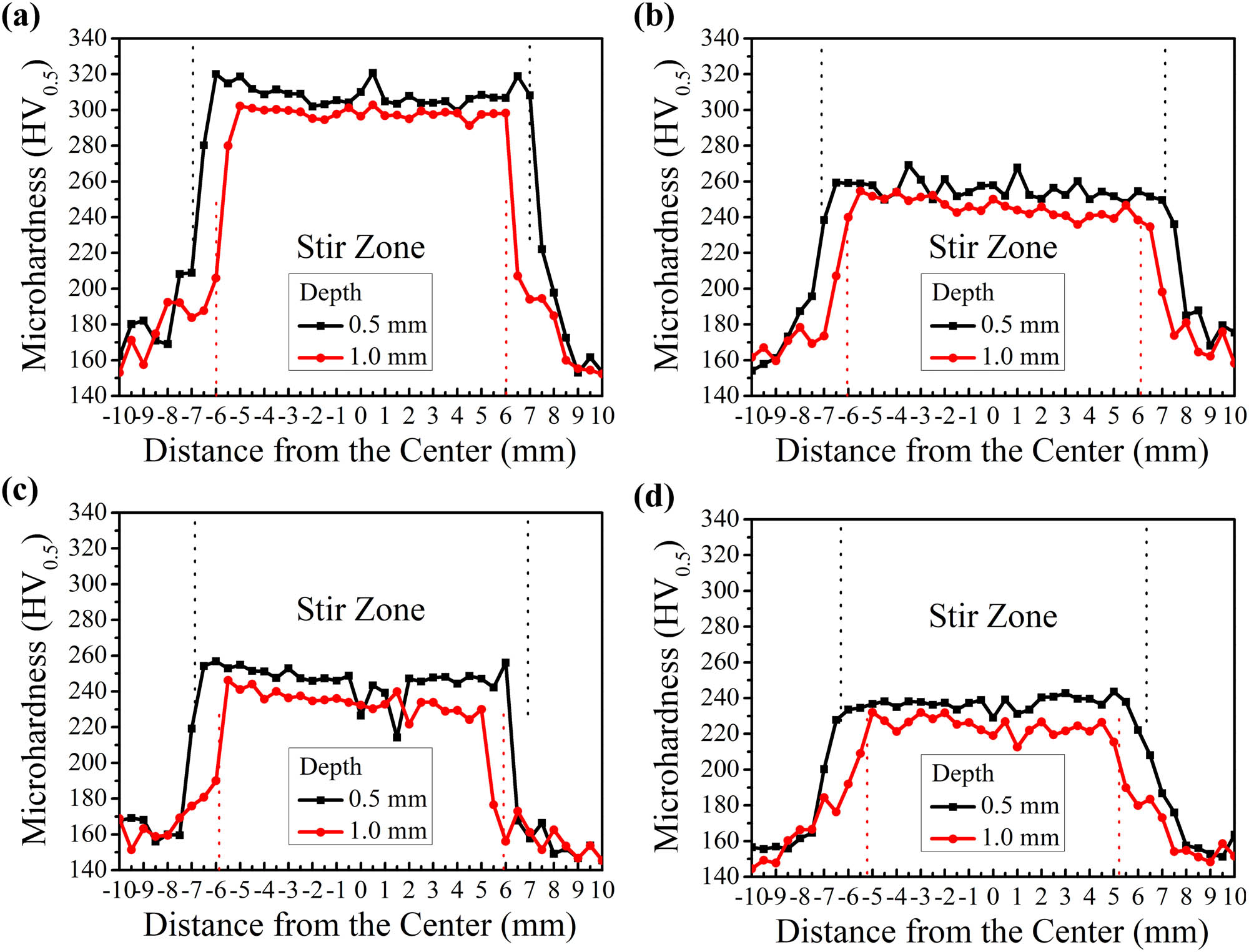

Figure 9(a–d) show the microhardness distribution at two depths, 0.5 and 1.0 mm, of the welds produced at the different rotational speeds, which clearly reflect the hardening by grain refinement within the SZ. After FSW, the microhardness within the SZ had significantly increased to 220 or above from the original value of the BM (homogenized and water quenched), which is 147 ± 4. The higher hardness at the depth of 0.5 mm, compared to that at the depth of 1.0 mm, was believed to result from the influence of the surface oxide layer, in which oxide particles were dispersed. In addition, the banded structures did not have significant effects on the hardness of the welds, because the advancing side of the weld, where the banded structures were mostly located, did not show higher hardness compared with the retreating side. Comparison of the microhardness results at different rotational speeds showed that higher rotational speed caused larger grain size in the SZ such that the average hardness in SZ would then be lower based on the concept of strengthening/hardening of grain boundaries. However, the contribution of the deformed grains to the hardness should also be considered. As the rotational speed and grain size in the SZ decreased, the number of deformed grains in the SZ apparently increased and became more uniformly distributed, especially when the rotational speed decreased from 300 to 200 rpm (Figure 10). This phenomenon suggests that at lower rotational speed, the SZ of the friction-stir-welded HEA would be more deformed and therefore obtain a higher hardness in addition to the strengthening/hardening effects of grain boundaries. Hence, the revised Hall–Petch equation for hardness in the SZ of friction-stir-welded Al0.3CoCrCu0.3FeNi should be as follows:

where H is the hardness, H0 is the materials’ intrinsic hardness, kH is the hardening coefficient, d is the grain size, T is the contribution from twin boundaries, and D(d) represents the hardening from deformed grains and a function of refined grain size.

Microhardness distribution of the welds at (a) 200, (b) 300, (c) 400, and (d) 500 rpm. (The dotted lines represent the border of SZ at two depths.)

Microstructures in the SZ of the HEA at (a) 200, (b) 300, (c) 400, and (d) 500 rpm after chemical etching.

Sato et al. proposed that Al alloys undergoing FSW tend to have a higher kH because of the greater density of dislocations in the SZ [22]. Liu et al. reported that CoCrFeMnNi possesses a high hardening efficiency because of the severe lattice distortion effect of HEAs [23], which was proposed by Yeh [3]. Nevertheless, the kH calculated from the results of the friction-stir-welded Al0.3CoCrCu0.3FeNi with Hall–Petch equation (Figure 11), rather than the revised one, has a value of 201.5 HVµm1/2, much higher than 69 HVµm1/2 of CoCrFeMnNi calculated by Liu et al. [23] and 90 HVµm1/2 of friction-stir-welded Co18Fe28Ni28Cr28 calculated by Zhu et al. [13]. The Hall–Petch relationship of the annealed Al0.3CoCrCu0.3FeNi is presented in Figure 11, in which a kH of 101.9 HVµm1/2 and an H0 of 141.9 were calculated. To explain the higher hardness in SZ and the discrepancy between the FSW and annealing results, the revised Hall–Petch equation, equation (1), should be adopted.

Hall–Petch relationship of the annealed and friction-stir-welded Al0.3CoCrCu0.3FeNi.

After substituting the parameters of the annealed HEA into the revised Hall–Petch equation (equation (1)) and neglecting the effect of T (based on the EBSD results showing less than 4.06% of Σ3 boundaries in the SZ), the values of D(d) at different rotational speeds can then be solved. The results are shown in Table 2. It shows that D(d) is a decreasing function of rotational speed or grain size. The larger increase in D(d), from 53 to 77, as the rotational speed decreased from 300 to 200 rpm also matches the microstructural observation in Figure 10(a and b), in which the number of deformed grains increased significantly when the rotational speed decreased from 300 to 200 rpm.

Values of D(d) calculated by equation (1)

| Rotational speed (rpm) | Grain size in SZ (µm) | Hardness in SZ (HV0.5) | D(d) (HV0.5) |

|---|---|---|---|

| 200 | 1.7 | 297 | 77 |

| 300 | 4.1 | 245 | 53 |

| 400 | 4.7 | 234 | 45 |

| 500 | 6.1 | 224 | 41 |

3.4 Orientations and texture of grains

EBSD analyses of the weld at 300 rpm were performed to understand the recrystallization and texture developed during FSW. Figure 12(a) shows the special boundary map at the border between SZ and TMAZ on the retreating side. Grain bulging, which is related to discontinuous recrystallization, and grain subdivision, which is related to continuous recrystallization, were observed near the edge of SZ. However, this study could not determine which process was dominant. Figure 12(b and c) show the inverse pole figure and the misorientation map in the SZ on the retreating side. The orientation of the grains in the SZ was quite uniform, but a great number of deformed grains (navy blue) and substructured grains (light blue) remained. This phenomenon again supported the presence of deformed grains in SZ.

The special boundary map of the friction-stir-welded Al0.3CoCrCu0.3FeNi HEA at the border between SZ and TMAZ was similar to that of the friction-stir-welded superaustenitic stainless steel reported by Minorov et al. [24]. However, the refined grains in the SZ of the friction-stir-welded HEA had less Σ3 boundaries or twins. HEAs tend to possess low stacking-fault energy according to the research by Zaddach et al. [25]. This characteristic probably explains the similarity in the special boundary map between the HEA and superaustenitic stainless steel, which also belongs to materials with low stacking-fault energy. Moreover, the similarity of special boundary map between the two alloys suggested that the recrystallization behavior of the HEA during FSW might be dominated by its low stacking-fault energy.

(a) Special boundary map at the edge of the stir zone on the retreating side, (b) inverse pole figure, and (c) misorientation map in the SZ. In (a and c), the LAB, HAB, and Σ3 boundaries are depicted as green, black, and red lines, respectively. For (c), the colors navy blue, light blue, and white represent deformed, substructured, and recrystallized grains, respectively. The shear plane normal (SPN) and the shear direction (SD) of the three figures are as indicated.

(a) {110}, and (b) {111} pole figures of the weld produced at rotational speed of 300 rpm presented in ND-TD-WD reference frame.

The texture of friction-stir-welded materials is generally accepted to be close to simple shear texture, with the shear direction parallel to the tangent of the probe (pin) [26], which is the part of the tool that plunges into the weld. The {110} and {111} pole figures of the HEA weld at rotational speed of 300 rpm were obtained by analyzing a 500 × 300 µm area in the SZ on the retreating side, approximately 4.3 mm away from the weld center (Figure 13). However, the maximum intensity in the pole figures was only 1.7 multiples of uniform density, which was too low for further discussion of texture formation. The cause of the weak texture in the HEA is currently unknown and requires further study of textural evolution in the HEA during FSW.

4 Conclusions

The aging and precipitation behavior of the newly designed Al0.3CoCrCu0.3FeNi HEA were examined. The HEA was treated with bead-on-plate FSW at four different rotational speeds, and the welds were analyzed. The following conclusions could be drawn:

Aging at intermediate temperature from approximately 600 to 800°C resulted in the precipitation hardening of Al0.3CoCrCu0.3FeNi HEA. The precipitates were deduced to be spherical and platelike, rich in Al, Ni, and Cu, and having L12 structure.

The bead-on-plate welds showed good appearance and typical cross-sectional microstructure of friction-stir-welded alloys (i.e., SZ, TMAZ, and BM). The material in the SZ underwent grain refinement because of the severe deformation and recrystallization during FSW.

Deformed grains formed in the SZ because of the insufficient recrystallization, which led to higher hardness in the SZ.

Banded structures containing Al2O3, Cr2O3, or AlN particles, such as BB, DB, and WB, were observed in the SZ and primarily on the advancing side. BB and DB might have formed because of the stirring of the surface oxide layer, while the WB could be the consequence of chemical wear of the pcBN tool. These banded structures did not have significant effects on the microhardness of the welds.

The microhardness distribution of the welds reflected hardening in the SZ by grain refinement and the formation of deformed grains. When a higher rotational speed was applied, larger grain size and less deformed grains in the SZ caused lower hardness in the SZ. The revised Hall–Petch relationship is useful in calculating the contribution of grain boundaries and deformed grains to the hardness.

The special boundary map at the border between SZ and TMAZ provided evidence of continuous and discontinuous recrystallization, but it was hard to determine which process was dominant during FSW.

Acknowledgments

The present work was supported by the Ministry of Science and Technology grant numbers MOST 109-2634-F-007-024, MOST 108-3017-F-007-002, and MOST 106-2218-E-007-019. The support provided by the High-Entropy Materials Center from the Featured Areas Research Center Program within the framework of the Higher Education Sprout Project by the Ministry of Education in Taiwan is greatly appreciated.

References

[1] Yeh, J. W., S. K. Chen, S. J. Lin, J. Y. Gan, T. S. Chin, T. T. Shun, et al. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Advanced Engineering Materials, Vol. 6, No. 5, 2004, pp. 299–303.10.1002/adem.200300567Search in Google Scholar

[2] Miracle, D., and O. Senkov. A critical review of high entropy alloys and related concepts. Acta Materialia, Vol. 122, 2017, pp. 448–511.10.1016/j.actamat.2016.08.081Search in Google Scholar

[3] Yeh, J. W. Physical metallurgy of high-entropy alloys. JOM-Journal of the Minerals Metals & Materials Society, Vol. 67, No. 10, 2015, pp. 2254–2261.10.1007/s11837-015-1583-5Search in Google Scholar

[4] Wu, Z., S. A. David, Z. Feng, and H. Bei. Weldability of a high entropy CrMnFeCoNi alloy. Scripta Materialia, Vol. 124, 2016, pp. 81–85.10.1016/j.scriptamat.2016.06.046Search in Google Scholar

[5] Wu, Z., S. A. David, D. N. Leonard, Z. Feng, and H. Bei. Microstructures and mechanical properties of a welded CoCrFeMnNi high-entropy alloy. Science and Technology of Welding and Joining, Vol. 23, No. 7, 2018, pp. 585–595.10.1080/13621718.2018.1430114Search in Google Scholar

[6] Mishra R. S., and Z. Y. Ma, Materials Science and Engineering R, Vol. 50, No. 1–2, 2005, pp. 1–78.10.1016/j.mser.2005.07.001Search in Google Scholar

[7] Threadgill, P. L., A. J. Leonard, H. R. Shercliff, and P. J. Withers. Friction stir welding of aluminium alloys. International Materials Reviews, Vol. 54, No. 2, 2009, pp. 49–93.10.1179/174328009X411136Search in Google Scholar

[8] Mironov, S., Y. S. Sato, and H. Kokawa. Friction-stir welding and processing of Ti-6Al-4V titanium alloy: A review. Journal of Materials Science and Technology, Vol. 34, No. 1, 2018, pp. 58–72.10.1016/j.jmst.2017.10.018Search in Google Scholar

[9] Sato, Y. S., P. Arkom, H. Kokawa, T. W. Nelson, and R. J. Steel. Effect of microstructure on properties of friction stir welded Inconel Alloy 600. Materials Science and Engineering A, Vol. 477, No. 1–2, 2008, pp. 250–258.10.1016/j.msea.2007.07.002Search in Google Scholar

[10] Uzun, H., C. D. Donne, A. Argagnotto, T. Ghidini, and C. Gambaro. Friction stir welding of dissimilar Al 6013-T4 To X5CrNi18-10 stainless steel. Materials Design, Vol. 26, No. 1, 2005, pp. 41–46.10.1016/j.matdes.2004.04.002Search in Google Scholar

[11] Sato, Y. S., H. Kokawa, H. T. Fujii, Y. Yano, and Y. Sekio. Mechanical properties and microstructure of dissimilar friction stir welds of 11Cr-ferritic/martensitic steel to 316 stainless steel. Metallurgical and Materials Transactions. A, Physical Metallurgy and Materials Science, Vol. 46A, No. 12, 2015, pp. 5789–5800.10.1007/s11661-015-3152-5Search in Google Scholar

[12] Zhu, Z. G., Y. F. Sun, M. H. Goh, F. L. Ng, Q. B. Nguyen, H. Fujii, et al. Friction stir welding of a CoCrFeNiAl0.3 high entropy alloy. Materials Letters, Vol. 205, 2017, pp. 142–144.10.1016/j.matlet.2017.06.073Search in Google Scholar

[13] Zhu, Z. G., Y. F. Sun, F. L. Ng, M. H. Goh, P. K. Liaw, H. Fujii, et al. Friction-stir welding of a ductile high entropy alloy: Microstructural evolution and weld strength. Materials Science and Engineering A, Vol. 711, 2018, pp. 524–532.10.1016/j.msea.2017.11.058Search in Google Scholar

[14] Jo, M. G., H. J. Kim, M. Kang, P. P. Madakashira, E. S. Park, J. Y. Suh, et al. Microstructure and mechanical properties of friction stir welded and laser welded high entropy alloy CrMnFeCoNi. Metals and Materials International, Vol. 24, No. 1, 2018, pp. 73–83.10.1007/s12540-017-7248-xSearch in Google Scholar

[15] Kumar, J., N. Kumar, S. Das, N. Gurao, and K. Biswas. Effect of Al addition on the microstructural evolution of equiatomic CoCrFeMnNi alloy. Transactions of the Indian Institute of Metals, Vol. 71, No. 11, 2018, pp. 2749–2758.10.1007/s12666-018-1443-4Search in Google Scholar

[16] Wani, I., G. D. Sathiaraj, M. Ahmed, S. Reddy, and P. P. Bhattacharjee. Evolution of microstructure and texture during thermo-mechanical processing of a two phase Al0.5CoCrFeMnNi high entropy alloy. Materials Characterization, Vol. 118, 2016, pp. 417–424.10.1016/j.matchar.2016.06.021Search in Google Scholar

[17] Wu, C. S., P. H. Tsai, C. M. Kuo, and C. W. Tsai. Effect of atomic size difference on the microstructure and mechanical properties of high-entropy alloys. Entropy (Basel, Switzerland), Vol. 20, No. 12, 2018, pp. 967.10.3390/e20120967Search in Google Scholar PubMed PubMed Central

[18] Tsai, M. H., H. Yuan, G. Cheng, W. Xu, K. Y. Tsai, C. W. Tsai, et al. Morphology, structure and composition of precipitates in Al0.3CoCrCu0.5FeNi high-entropy alloy. Intermetallics, Vol. 32, 2013, pp. 329–336.10.1016/j.intermet.2012.07.036Search in Google Scholar

[19] Zhang, Y., Y. S. Sato, H. Kokawa, S. H. C. Park, and S. Hirano. Stir zone microstructure of commercial purity titanium friction stir welded using pcBN tool. Materials Science and Engineering A, Vol. 488, No. 1–2, 2008, pp. 25–30.10.1016/j.msea.2007.10.062Search in Google Scholar

[20] Ma, Z. Y., S. R. Sharma, and R. S. Mishra. Effect of friction stir processing on the microstructure of cast A356 aluminum. Materials Science and Engineering A, Vol. 433, No. 1–2, 2006, pp. 269–278.10.1016/j.msea.2006.06.099Search in Google Scholar

[21] Park, S. H. C., Y. S. Sato, H. Kokawa, K. Okamoto, S. Hirano, and M. Inagaki. Boride formation induced by pcBN tool wear in friction-stir-welded stainless steels. Metallurgical and Materials Transactions. A, Physical Metallurgy and Materials Science, Vol. 40, No. 3, 2009, pp. 625–636.10.1007/s11661-008-9709-9Search in Google Scholar

[22] Sato, Y. S., S. H. C. Park, and H. Kokawa. Microstructural factors governing hardness in friction-stir welds of solid-solution-hardened Al alloys. Metallurgical and Materials Transactions. A, Physical Metallurgy and Materials Science, Vol. 32, No. 12, 2001, pp. 3033–3042.10.1007/s11661-001-0178-7Search in Google Scholar

[23] Liu, W. H., Y. Wu, J. Y. He, T. G. Nieh, and Z. P. Lu. Grain growth and the Hall–Petch relationship in a high-entropy FeCrNiCoMn alloy. Scripta Materialia, Vol. 68, No. 7, 2013, pp. 526–529.10.1016/j.scriptamat.2012.12.002Search in Google Scholar

[24] Mironov, S., Y. S. Sato, H. Kokawa, H. Inoue, and S. Tsuge. Structural response of superaustenitic stainless steel to friction stir welding. Acta Materialia, Vol. 59, No. 14, 2011, pp. 5472–5481.10.1016/j.actamat.2011.05.021Search in Google Scholar

[25] Zaddach, A. J., C. Niu, C. C. Koch, and D. L. Irving. Mechanical properties and stacking fault energies of NiFeCrCoMn high-entropy alloy. JOM-Journal of the Minerals Metals & Materials Society, Vol. 65, No. 12, 2013, pp. 1780–1789.10.1007/s11837-013-0771-4Search in Google Scholar

[26] Fonda, R. W., and K. E. Knipling. Texture development in friction stir welds. Science and Technology of Welding and Joining, Vol. 16, No. 4, 2011, pp. 288–294.10.1179/1362171811Y.0000000010Search in Google Scholar

© 2020 Po-Ting Lin et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Article

- Electrochemical reduction mechanism of several oxides of refractory metals in FClNaKmelts

- Study on the Appropriate Production Parameters of a Gas-injection Blast Furnace

- Microstructure, phase composition and oxidation behavior of porous Ti-Si-Mo intermetallic compounds fabricated by reactive synthesis

- Significant Influence of Welding Heat Input on the Microstructural Characteristics and Mechanical Properties of the Simulated CGHAZ in High Nitrogen V-Alloyed Steel

- Preparation of WC-TiC-Ni3Al-CaF2 functionally graded self-lubricating tool material by microwave sintering and its cutting performance

- Research on Electromagnetic Sensitivity Properties of Sodium Chloride during Microwave Heating

- Effect of deformation temperature on mechanical properties and microstructure of TWIP steel for expansion tube

- Effect of Cooling Rate on Crystallization Behavior of CaO-SiO2-MgO-Cr2O3 Based Slag

- Effects of metallurgical factors on reticular crack formations in Nb-bearing pipeline steel

- Investigation on microstructure and its transformation mechanisms of B2O3-SiO2-Al2O3-CaO brazing flux system

- Energy Conservation and CO2 Abatement Potential of a Gas-injection Blast Furnace

- Experimental validation of the reaction mechanism models of dechlorination and [Zn] reclaiming in the roasting steelmaking zinc-rich dust process

- Effect of substituting fine rutile of the flux with nano TiO2 on the improvement of mass transfer efficiency and the reduction of welding fumes in the stainless steel SMAW electrode

- Microstructure evolution and mechanical properties of Hastelloy X alloy produced by Selective Laser Melting

- Study on the structure activity relationship of the crystal MOF-5 synthesis, thermal stability and N2 adsorption property

- Laser pressure welding of Al-Li alloy 2198: effect of welding parameters on fusion zone characteristics associated with mechanical properties

- Microstructural evolution during high-temperature tensile creep at 1,500°C of a MoSiBTiC alloy

- Effects of different deoxidization methods on high-temperature physical properties of high-strength low-alloy steels

- Solidification pathways and phase equilibria in the Mo–Ti–C ternary system

- Influence of normalizing and tempering temperatures on the creep properties of P92 steel

- Effect of temperature on matrix multicracking evolution of C/SiC fiber-reinforced ceramic-matrix composites

- Improving mechanical properties of ZK60 magnesium alloy by cryogenic treatment before hot extrusion

- Temperature-dependent proportional limit stress of SiC/SiC fiber-reinforced ceramic-matrix composites

- Effect of 2CaO·SiO2 particles addition on dephosphorization behavior

- Influence of processing parameters on slab stickers during continuous casting

- Influence of Al deoxidation on the formation of acicular ferrite in steel containing La

- The effects of β-Si3N4 on the formation and oxidation of β-SiAlON

- Sulphur and vanadium-induced high-temperature corrosion behaviour of different regions of SMAW weldment in ASTM SA 210 GrA1 boiler tube steel

- Structural evidence of complex formation in liquid Pb–Te alloys

- Microstructure evolution of roll core during the preparation of composite roll by electroslag remelting cladding technology

- Improvement of toughness and hardness in BR1500HS steel by ultrafine martensite

- Influence mechanism of pulse frequency on the corrosion resistance of Cu–Zn binary alloy

- An interpretation on the thermodynamic properties of liquid Pb–Te alloys

- Dynamic continuous cooling transformation, microstructure and mechanical properties of medium-carbon carbide-free bainitic steel

- Influence of electrode tip diameter on metallurgical and mechanical aspects of spot welded duplex stainless steel

- Effect of multi-pass deformation on microstructure evolution of spark plasma sintered TC4 titanium alloy

- Corrosion behaviors of 316 stainless steel and Inconel 625 alloy in chloride molten salts for solar energy storage

- Determination of chromium valence state in the CaO–SiO2–FeO–MgO–CrOx system by X-ray photoelectron spectroscopy

- Electric discharge method of synthesis of carbon and metal–carbon nanomaterials

- Effect of high-frequency electromagnetic field on microstructure of mold flux

- Effect of hydrothermal coupling on energy evolution, damage, and microscopic characteristics of sandstone

- Effect of radiative heat loss on thermal diffusivity evaluated using normalized logarithmic method in laser flash technique

- Kinetics of iron removal from quartz under ultrasound-assisted leaching

- Oxidizability characterization of slag system on the thermodynamic model of superalloy desulfurization

- Influence of polyvinyl alcohol–glutaraldehyde on properties of thermal insulation pipe from blast furnace slag fiber

- Evolution of nonmetallic inclusions in pipeline steel during LF and VD refining process

- Development and experimental research of a low-thermal asphalt material for grouting leakage blocking

- A downscaling cold model for solid flow behaviour in a top gas recycling-oxygen blast furnace

- Microstructure evolution of TC4 powder by spark plasma sintering after hot deformation

- The effect of M (M = Ce, Zr, Ce–Zr) on rolling microstructure and mechanical properties of FH40

- Phase evolution and oxidation characteristics of the Nd–Fe–B and Ce–Fe–B magnet scrap powder during the roasting process

- Assessment of impact mechanical behaviors of rock-like materials heated at 1,000°C

- Effects of solution and aging treatment parameters on the microstructure evolution of Ti–10V–2Fe–3Al alloy

- Effect of adding yttrium on precipitation behaviors of inclusions in E690 ultra high strength offshore platform steel

- Dephosphorization of hot metal using rare earth oxide-containing slags

- Kinetic analysis of CO2 gasification of biochar and anthracite based on integral isoconversional nonlinear method

- Optimization of heat treatment of glass-ceramics made from blast furnace slag

- Study on microstructure and mechanical properties of P92 steel after high-temperature long-term aging at 650°C

- Effects of rotational speed on the Al0.3CoCrCu0.3FeNi high-entropy alloy by friction stir welding

- The investigation on the middle period dephosphorization in 70t converter

- Effect of cerium on the initiation of pitting corrosion of 444-type heat-resistant ferritic stainless steel

- Effects of quenching and partitioning (Q&P) technology on microstructure and mechanical properties of VC particulate reinforced wear-resistant alloy

- Study on the erosion of Mo/ZrO2 alloys in glass melting process

- Effect of Nb addition on the solidification structure of Fe–Mn–C–Al twin-induced plasticity steel

- Damage accumulation and lifetime prediction of fiber-reinforced ceramic-matrix composites under thermomechanical fatigue loading

- Morphology evolution and quantitative analysis of β-MoO3 and α-MoO3

- Microstructure of metatitanic acid and its transformation to rutile titanium dioxide

- Numerical simulation of nickel-based alloys’ welding transient stress using various cooling techniques

- The local structure around Ge atoms in Ge-doped magnetite thin films

- Friction stir lap welding thin aluminum alloy sheets

- Review Article

- A review of end-point carbon prediction for BOF steelmaking process

Articles in the same Issue

- Research Article

- Electrochemical reduction mechanism of several oxides of refractory metals in FClNaKmelts

- Study on the Appropriate Production Parameters of a Gas-injection Blast Furnace

- Microstructure, phase composition and oxidation behavior of porous Ti-Si-Mo intermetallic compounds fabricated by reactive synthesis

- Significant Influence of Welding Heat Input on the Microstructural Characteristics and Mechanical Properties of the Simulated CGHAZ in High Nitrogen V-Alloyed Steel

- Preparation of WC-TiC-Ni3Al-CaF2 functionally graded self-lubricating tool material by microwave sintering and its cutting performance

- Research on Electromagnetic Sensitivity Properties of Sodium Chloride during Microwave Heating

- Effect of deformation temperature on mechanical properties and microstructure of TWIP steel for expansion tube

- Effect of Cooling Rate on Crystallization Behavior of CaO-SiO2-MgO-Cr2O3 Based Slag

- Effects of metallurgical factors on reticular crack formations in Nb-bearing pipeline steel

- Investigation on microstructure and its transformation mechanisms of B2O3-SiO2-Al2O3-CaO brazing flux system

- Energy Conservation and CO2 Abatement Potential of a Gas-injection Blast Furnace

- Experimental validation of the reaction mechanism models of dechlorination and [Zn] reclaiming in the roasting steelmaking zinc-rich dust process

- Effect of substituting fine rutile of the flux with nano TiO2 on the improvement of mass transfer efficiency and the reduction of welding fumes in the stainless steel SMAW electrode

- Microstructure evolution and mechanical properties of Hastelloy X alloy produced by Selective Laser Melting

- Study on the structure activity relationship of the crystal MOF-5 synthesis, thermal stability and N2 adsorption property

- Laser pressure welding of Al-Li alloy 2198: effect of welding parameters on fusion zone characteristics associated with mechanical properties

- Microstructural evolution during high-temperature tensile creep at 1,500°C of a MoSiBTiC alloy

- Effects of different deoxidization methods on high-temperature physical properties of high-strength low-alloy steels

- Solidification pathways and phase equilibria in the Mo–Ti–C ternary system

- Influence of normalizing and tempering temperatures on the creep properties of P92 steel

- Effect of temperature on matrix multicracking evolution of C/SiC fiber-reinforced ceramic-matrix composites

- Improving mechanical properties of ZK60 magnesium alloy by cryogenic treatment before hot extrusion

- Temperature-dependent proportional limit stress of SiC/SiC fiber-reinforced ceramic-matrix composites

- Effect of 2CaO·SiO2 particles addition on dephosphorization behavior

- Influence of processing parameters on slab stickers during continuous casting

- Influence of Al deoxidation on the formation of acicular ferrite in steel containing La

- The effects of β-Si3N4 on the formation and oxidation of β-SiAlON

- Sulphur and vanadium-induced high-temperature corrosion behaviour of different regions of SMAW weldment in ASTM SA 210 GrA1 boiler tube steel

- Structural evidence of complex formation in liquid Pb–Te alloys

- Microstructure evolution of roll core during the preparation of composite roll by electroslag remelting cladding technology

- Improvement of toughness and hardness in BR1500HS steel by ultrafine martensite

- Influence mechanism of pulse frequency on the corrosion resistance of Cu–Zn binary alloy

- An interpretation on the thermodynamic properties of liquid Pb–Te alloys

- Dynamic continuous cooling transformation, microstructure and mechanical properties of medium-carbon carbide-free bainitic steel

- Influence of electrode tip diameter on metallurgical and mechanical aspects of spot welded duplex stainless steel

- Effect of multi-pass deformation on microstructure evolution of spark plasma sintered TC4 titanium alloy

- Corrosion behaviors of 316 stainless steel and Inconel 625 alloy in chloride molten salts for solar energy storage

- Determination of chromium valence state in the CaO–SiO2–FeO–MgO–CrOx system by X-ray photoelectron spectroscopy

- Electric discharge method of synthesis of carbon and metal–carbon nanomaterials

- Effect of high-frequency electromagnetic field on microstructure of mold flux

- Effect of hydrothermal coupling on energy evolution, damage, and microscopic characteristics of sandstone

- Effect of radiative heat loss on thermal diffusivity evaluated using normalized logarithmic method in laser flash technique

- Kinetics of iron removal from quartz under ultrasound-assisted leaching

- Oxidizability characterization of slag system on the thermodynamic model of superalloy desulfurization

- Influence of polyvinyl alcohol–glutaraldehyde on properties of thermal insulation pipe from blast furnace slag fiber

- Evolution of nonmetallic inclusions in pipeline steel during LF and VD refining process

- Development and experimental research of a low-thermal asphalt material for grouting leakage blocking

- A downscaling cold model for solid flow behaviour in a top gas recycling-oxygen blast furnace

- Microstructure evolution of TC4 powder by spark plasma sintering after hot deformation

- The effect of M (M = Ce, Zr, Ce–Zr) on rolling microstructure and mechanical properties of FH40

- Phase evolution and oxidation characteristics of the Nd–Fe–B and Ce–Fe–B magnet scrap powder during the roasting process

- Assessment of impact mechanical behaviors of rock-like materials heated at 1,000°C

- Effects of solution and aging treatment parameters on the microstructure evolution of Ti–10V–2Fe–3Al alloy

- Effect of adding yttrium on precipitation behaviors of inclusions in E690 ultra high strength offshore platform steel

- Dephosphorization of hot metal using rare earth oxide-containing slags

- Kinetic analysis of CO2 gasification of biochar and anthracite based on integral isoconversional nonlinear method

- Optimization of heat treatment of glass-ceramics made from blast furnace slag

- Study on microstructure and mechanical properties of P92 steel after high-temperature long-term aging at 650°C

- Effects of rotational speed on the Al0.3CoCrCu0.3FeNi high-entropy alloy by friction stir welding

- The investigation on the middle period dephosphorization in 70t converter

- Effect of cerium on the initiation of pitting corrosion of 444-type heat-resistant ferritic stainless steel

- Effects of quenching and partitioning (Q&P) technology on microstructure and mechanical properties of VC particulate reinforced wear-resistant alloy

- Study on the erosion of Mo/ZrO2 alloys in glass melting process

- Effect of Nb addition on the solidification structure of Fe–Mn–C–Al twin-induced plasticity steel

- Damage accumulation and lifetime prediction of fiber-reinforced ceramic-matrix composites under thermomechanical fatigue loading

- Morphology evolution and quantitative analysis of β-MoO3 and α-MoO3

- Microstructure of metatitanic acid and its transformation to rutile titanium dioxide

- Numerical simulation of nickel-based alloys’ welding transient stress using various cooling techniques

- The local structure around Ge atoms in Ge-doped magnetite thin films

- Friction stir lap welding thin aluminum alloy sheets

- Review Article

- A review of end-point carbon prediction for BOF steelmaking process