Abstract

Sintered carbon nanotube (CNT) blocks and porous CNT sponges were prepared, and their thermoelectric properties were measured. The maximum dimensionless thermoelectric figure-of-merit, ZT, at room temperature of the sintered single-walled carbon nanotube (SWCNT) block is 9.34 × 10−5, which is twice higher than that of the sintered multi-walled carbon nanotube (MWCNT) block in this work and also higher than that of other sintered MWCNT blocks reported previously. In addition, the porous MWCNT sponge showed an ultra-low thermal conductivity of 0.021 W/(m K) and significantly enhanced ZT value of 5.72 × 10−4 at room temperature and 1 atm. This ZT value is higher than that of other 3D macroscopic pure CNT materials reported. The pronounced enhancement of the ZT in the porous MWCNT sponge is attributed to the ultra-low density, ultra-high porosity, and interconnected structure of the material, which lead to a fairly low thermal conductivity and better Seebeck coefficient. The finding of this work provides an understanding for exploring potential enhancement mechanisms and improving the thermoelectric properties of CNT-based thermoelectric composites.

1 Introduction

Thermoelectric materials have attracted considerable attention because of their unique ability of direct conversion between thermal and electrical energy [1,2,3,4]. Performance of thermoelectric materials is given by the dimensionless figure-of-merit,

The dense CNT films, ropes, or fibers in microscale and nanoscale were found to have high ZT. These CNT materials have relatively high mass density, thus making a good power factor. Hone et al. [10] prepared aligned SWCNT films (thickness of 1.3 and 5 μm; mass density of 1.33 g/cm3) and nanotube ropes by filtration/deposition from suspension in strong magnetic fields, and the measured ZT reached 1 × 10−4 at room temperature. Zhou et al. [11] prepared a SWCNT interconnected film with a thickness of 600 nm. The grown SWCNT film exhibited an excellent power factor (2,482 μW/m K2) at room temperature, and the ZT of the SWCNT fiber obtained by twisting these films reached 0.014.

As for CNT composite materials, Toshima et al. [12] prepared a flexible composite thermoelectric film based on CNT by complexing nickel-coordinating polymers of vinyl tetrathiol and polyvinyl chloride film. A ternary composite film with a conductivity of 630 S/cm and a thermal conductivity of only 0.07 W/(m K) was obtained. The ZT of the composite film has reached 0.3 and is considered as one of the best performing CNT-based flexible films. Tan et al. [13] developed rGO/SWCNT hybrid aerogels with extreme low density 10 mg/cm3 by constructing 3D double-interconnected network porous microstructures. The hybrid aerogel reveals very low thermal conductivity and a high figure-of-merit of 8.03 × 10−3. These CNT composite materials generally have extreme low density and high porosity, thus leading to a fairly low thermal conductivity. However, most of the experimental studies on the CNT composite based nanofilm were conducted with only the power factor focused on, primarily because of the difficulty to accurately measure the thermal conductivity of thin film samples [14,15,16].

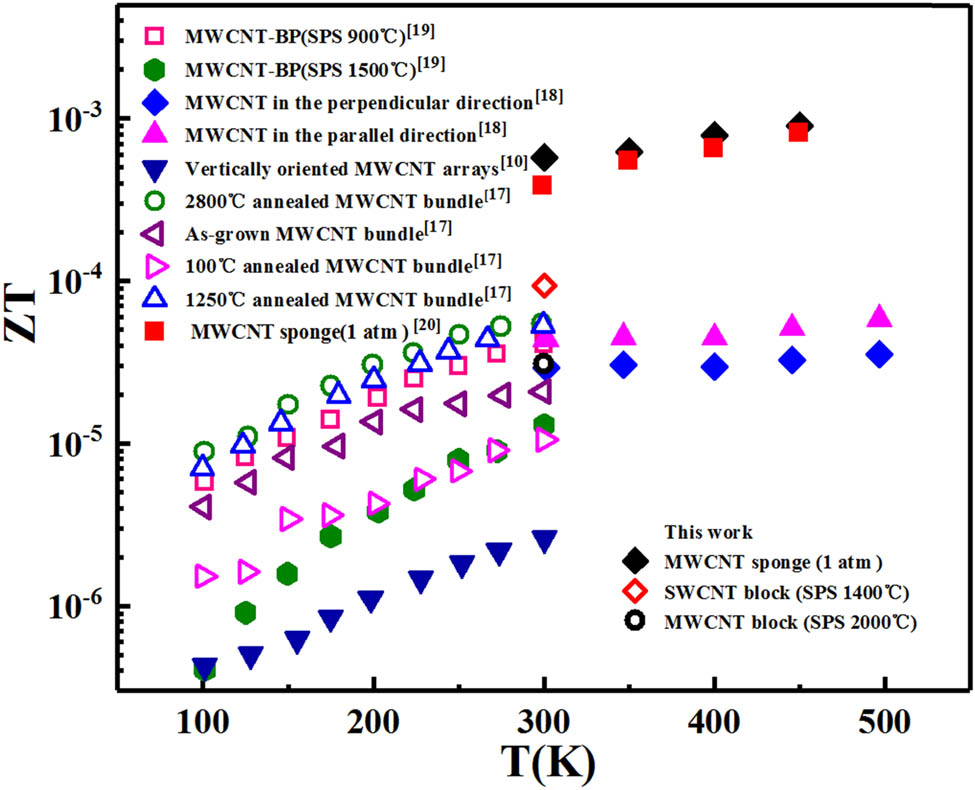

So far, the reported ZT of 3D macroscopic pure CNT materials is fairly low. Jin et al. [17] measured the thermoelectric properties of macroscopic bundles of long multi-walled carbon nanotube (MWCNT) annealed in argon (Ar) at 2,800°C, the ZT of the MWCNT bulk reached 5.4 × 10−5 at room temperature. Qin et al. [18] prepared bulk multi-walled CNT by spark plasma sintering (SPS). The thermoelectric properties of the bulk material were measured in the directions perpendicular and parallel to the pressure direction. Both the thermal conductivity and electrical conductivity show apparent anisotropy, but the thermoelectric power has close values in the two different directions and the ZT of SWCNT bulk reached 4.3 × 10−5 at room temperature. Yang et al. [19] prepared aligned MWCNT bulk samples by SPS method with the ZT value of 2.58 × 10−6 at room temperature. They also prepared and measured the SPS sintered multi-walled CNT buckypaper, and interestingly, the ZT at room temperature decreased from 4.07 × 10−5 to 1.29 × 10−5 when SPS temperatures increased from 900 to 1,500°C. Compared to the above 3D macroscopic pure CNT materials with high mass density, porous CNT sponges can exhibit better ZT. Chen et al. [20] prepared the MWCNT sponges by chemical vapor deposition (CVD) and found their ZT reached 3.85 × 10−4 in standard atmosphere at room temperature.

In this study, we focused on the thermal conductivity and thermoelectric properties of 3D macroscopic pure CNT materials, including the SPS sintered SWCNT and MWCNT bulk materials and MWCNT sponge. The objective of our work is to provide a clear understanding of the thermal conductivity and thermoelectric properties for pure CNT bulk materials via our comprehensive experimental research. This study could provide help in exploring potential enhancement mechanisms and improving the thermoelectric properties of CNT-based thermoelectric composites.

2 Experiment

The SWCNT and MWCNT powders for the preparation of the sintered CNT blocks are purchased from Chengdu Organic Chemicals Co. Ltd (Chinese Academy of Sciences). The purity of SWCNT is greater than 95%, and the SWCNT has an average outer diameter of 1–2 nm and an average length of 1–3 μm. The MWCNT has an average outer diameter of 4–6 nm, an average length of 0.5–2 μm, and purity greater than 98%. It should be noted that the length of both the SWCNT and MWCNT of the purchased samples is much shorter than those in the literature (e.g., an average length of 5–15 μm in ref. [9]), since we attempted to investigate whether shorter length CNT can enhance the ZT by the reduction in thermal conductivity.

The thermal conductivity of the two CNT stacked states was measured using a transient hot-wire method (TC3000E, XIA TECH, CHN). The resistivity, Seebeck coefficient, and thermal conductivity of the SPS sintered CNT bulk samples were measured using a PPMS (Quantum Design, PPMS-9) at a temperature of 300 K. The conductivity and Seebeck coefficient of CNT sponge were measured using a SBA 458 Nemesis (Netzsch). The thermal diffusivity was measured using a laser flash method (Netzsch LFA 467) after spray coated with graphite to enhance emissivity. The heat capacities were measured using a differential scanning calorimeter (TA Q5000). The measurements were performed in Ar atmosphere under normal pressure around 1 atm. The thermal conductivity k of the samples was calculated using

3 Results and discussions

3.1 Preparation of SPS sintered SWCNT and MWCNT blocks

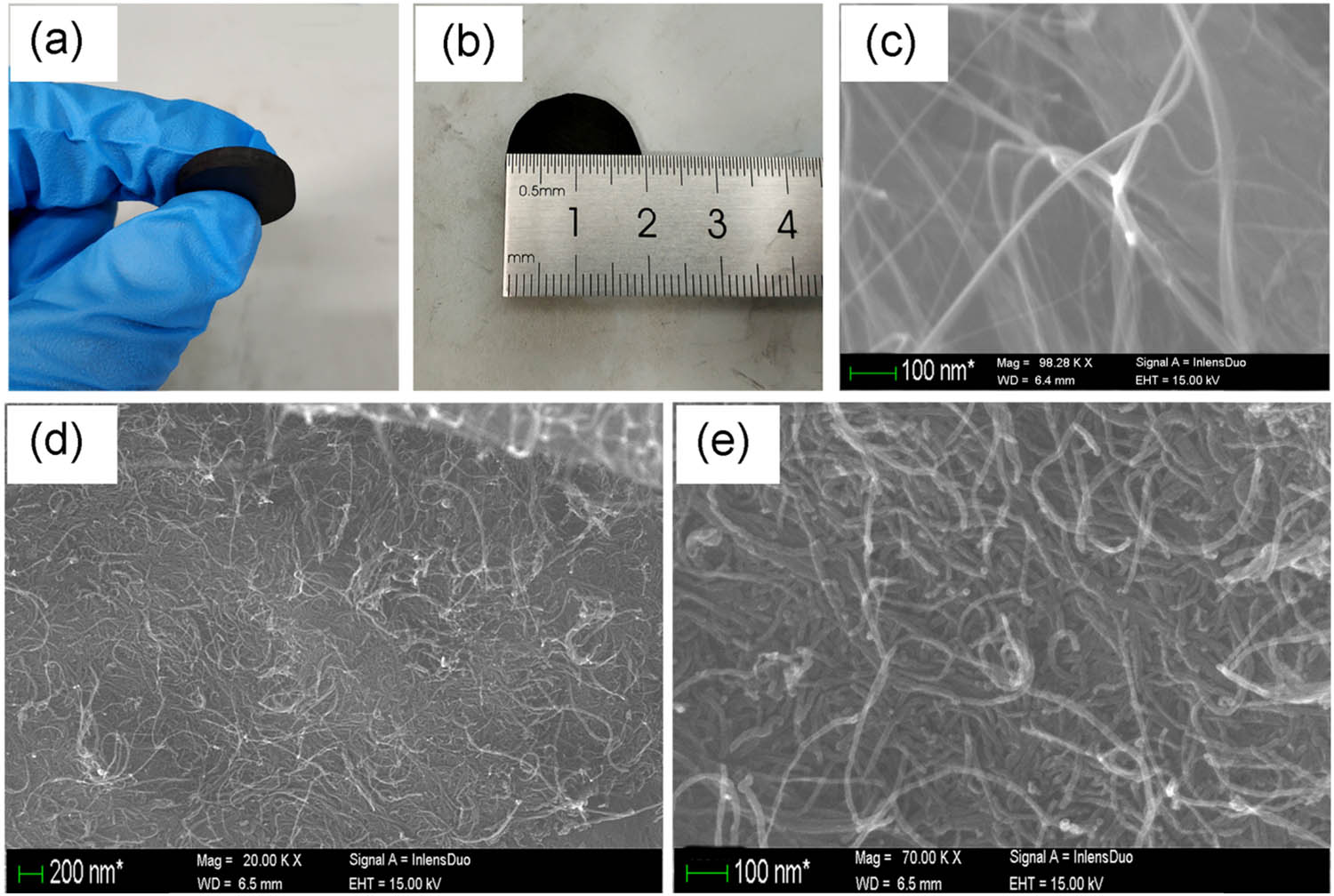

The CNT powder was stacked in a graphite mold (pore size ∼20 mm). Then, the powder was sintered using an SPS apparatus (SPS-20T-10, Shanghai Chen Hua Technology Co., China). A constant pressure of 40 MPa was maintained in all SPS experiments while changing the applied current density to achieve different SPS temperatures (T SPS). We sintered the CNTs at 1,200, 1,400, 1,600, 1,800, and 2,000°C in vacuum for 5 min. The obtained typical sintered CNT blocks are shown in Figure 1a and b.

(a) and (b) SPS sintered SWCNT blocks; (c) scanning electron microscopy (SEM) image of the polished surface; (d) and (e) low-resolution and high-resolution SEM image showing fracture surfaces of the bulk SWCNT materials.

3.2 Morphological characterization of SPS sintered SWCNT and MWCNT blocks

The microscopic morphology of the CNT macroscopic material was characterized by scanning electron microscopy (Zeiss, Merlin compact). Here we take the bulk SWCNT materials sintered at 2,000°C as an example. Figure 1c shows the SEM image of the polished surface of the sintered bulk SWCNT sample. It can be observed that some covalently bonded junctions are formed because of the local high temperature to join SWCNT together [21]. Similarly, local welding of SWCNT (inter-tube bonds) also can be observed on the fracture surfaces of the bulk SWCNT materials, as shown in Figure 1d and e.

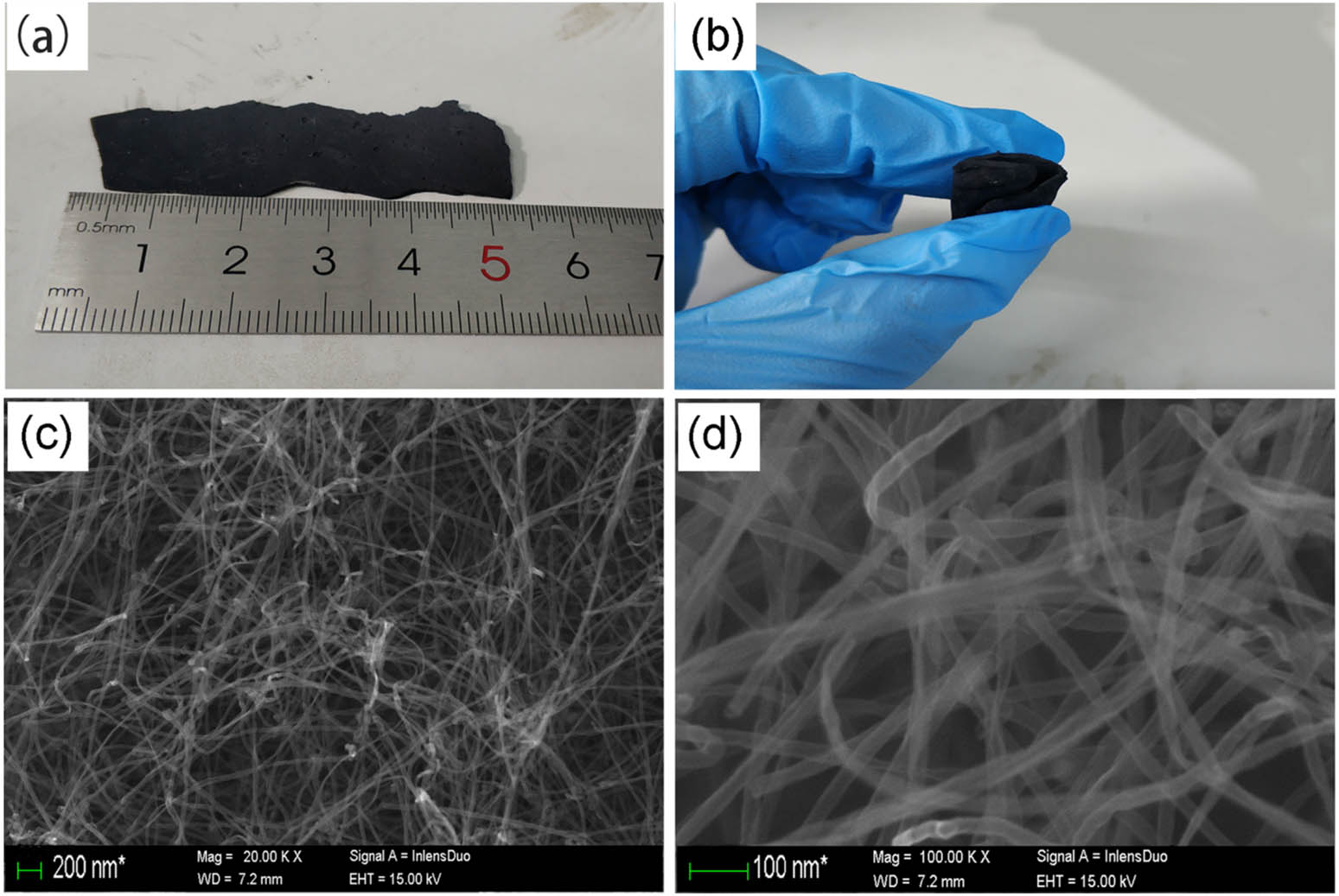

3.3 Preparation of CNT sponge

A MWCNT sponge using a CVD method by Gui et al. was prepared [22,23]. The main ingredient of the sponge is MWCNT, with purity of over 90%, which is consistent with previous reports. An MWCNT sponge with a density of 5.3 mg/cm3 (Figure 2a and b) was prepared. The as-grown MWCNT sponge is shown as a black carpet with a thickness of 2.37 mm (Figure 2b).

(a) and (b) Prepared MWCNT sponge; (c) and (d) low-resolution and high-resolution SEM image showing the random CNT network of sponges.

3.4 Structural and morphological characterizations of CNT sponge

The SEM image of the sponge is shown in Figure 2c and d shows more detailed microstructure of the sample. It can be observed that the CNT sponge is a 3D porous network structure in which CNTs are entangled with each other and self-assembled. We also observed that the CNTs had a very high void ratio. The CNT sponge has the characteristics of isotropy. SEM at higher magnifications shows that CNTs have uniform diameter with scarce iron catalyst remained. The average diameter of CNTs is around 30 nm.

3.5 Measurement results and discussion

Figure 3a demonstrates the change in measured thermal conductivity

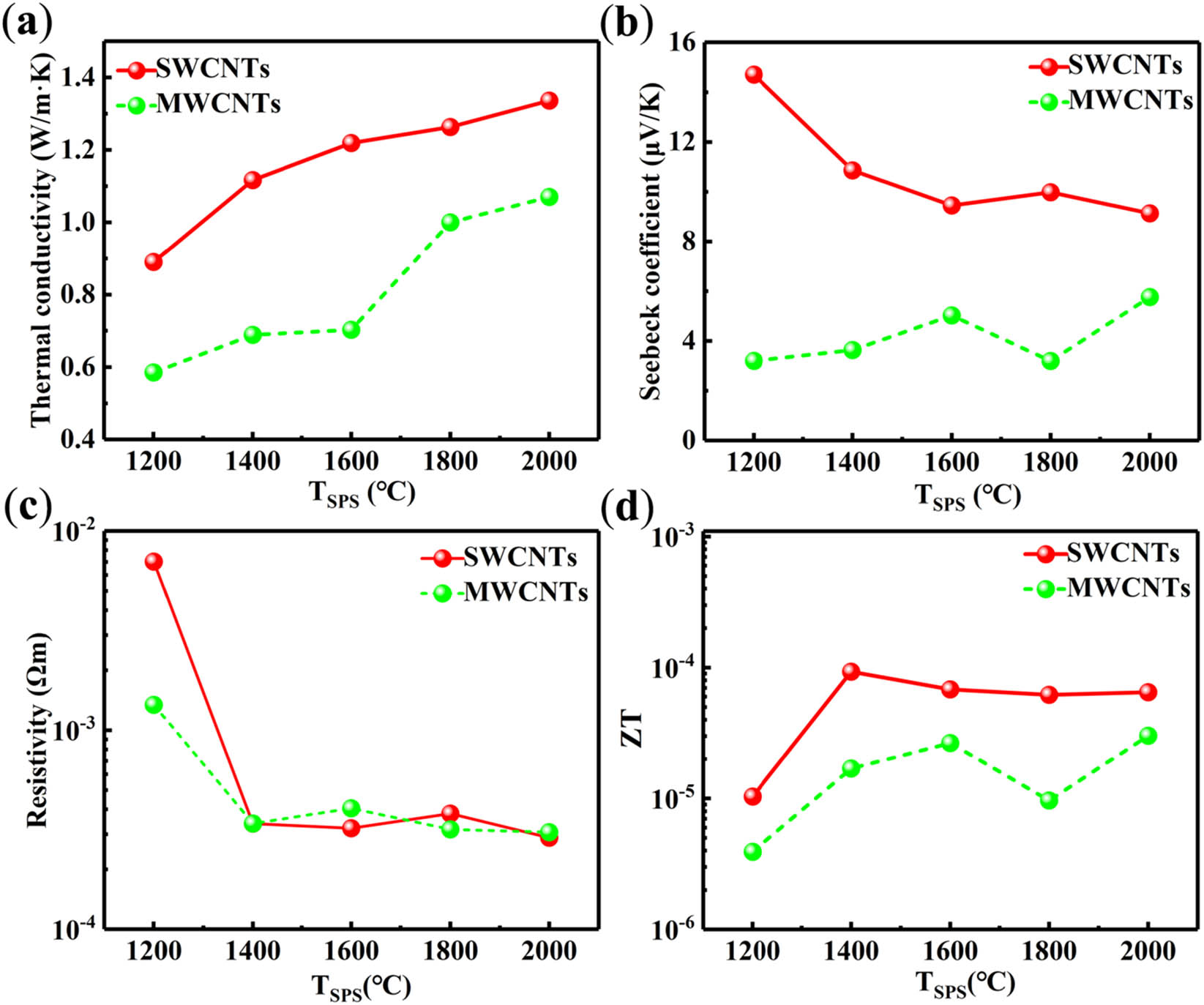

Figure 4(a–d) shows the thermal resistivity, Seebeck coefficient, resistivity, and calculated ZT values of the sintered CNT blocks at different SPS temperature (T SPS). With the increase in T SPS, the thermal conductivity at room temperature for SWCNT samples increases from 0.89 to 1.34 W/(m K) and that of the MWCNT samples increases from 0.59 to 1.07 W/(m K). Such increase in thermal conductivity is supposed to result from the increase in the mass density. Moreover, with the increase in the T SPS, more covalently bonded junctions between the tubes are formed via heat welding, and the overall tube–tube thermal resistance is decreased [27,28]. This could also explain that the thermal conductivity of the SPS sintered CNT blocks is significantly enhanced compared with the corresponding CNT packed bed. It should be noted that the thermal conductivities of the SPS sintered CNT blocks in this work are much lower than those in refs. [17–19,29,30] because our target is to improve the ZT value, and thus shorter CNTs were used.

SPS temperature dependence of (a) thermal conductivity; (b) Seebeck coefficient; (c) resistivity; (d) ZT; for single-wall and multi-walled CNT blocks.

The Seebeck coefficient

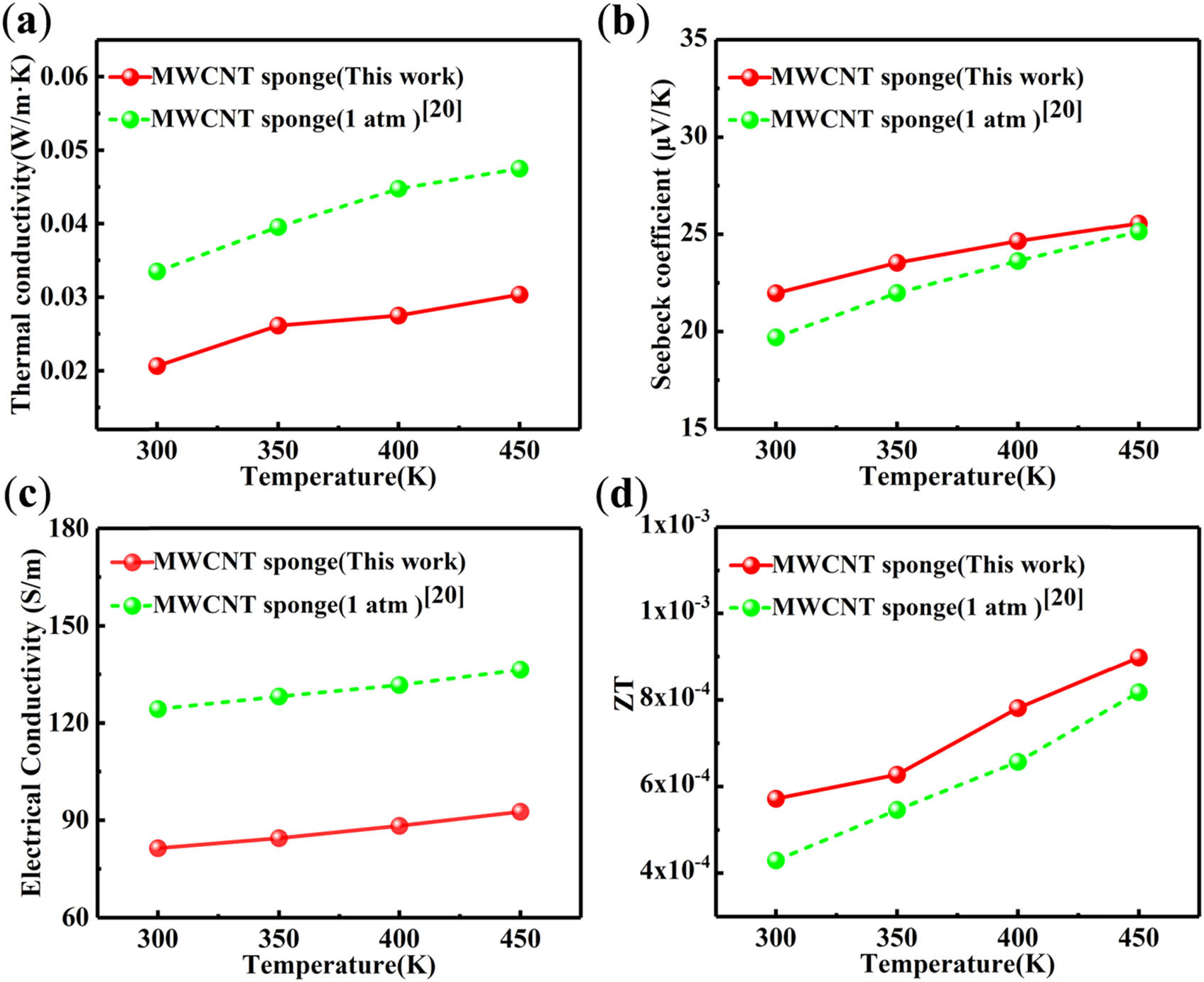

Figure 5(a–d) shows the thermal conductivity, Seebeck coefficient, electrical conductivity, and calculated ZT of the CNT sponge as a function of temperature, respectively, and compared with the thermoelectric properties of MWCNT sponges reported by Chen et al. [20]. The ultra-high porosity of the CNT sponge is responsible for the low thermal conductivity and good thermal insulation property. As shown in Figure 5a, the MWCNT sponges in this work exhibit an ultra-low thermal conductivity value of 0.021 W/(m K) which is 67% lower than that of the MWCNT sponges by Chen et al. [20] measured at a temperature of 300 K and 1 atm. The Seebeck coefficient is positive and increases as temperature increases, which is in agreement with those of CNT samples in other literature [19,20]. The positive Seebeck coefficient can be explained by hole-type majority carriers and the hole doping effect [20,31,32]. Figure 5(c) shows the comparison of the electrical conductivity of the sponges. It can be seen that the conductivity of our sponge is about 30% less than that by Chen et al. [20] because the mass density of our sponge is only about half of the latter. As shown in Figure 5(d), the ZT of the sponge shows a significant enhancement with a value of 5.72 × 10−4 at room temperature and 1 atm. In fact, the power factor,

Temperature dependence of (a) thermal conductivity; (b) Seebeck coefficient; (c) conductivity; (d) ZT; of the MWCNT sponges.

The comparison of ZT values between the results of this work and other 3D macroscopic pure CNT materials [10,17,18,19,20] is shown in Figure 6. The maximum ZT value of the MWCNT sintered block in this work is about 3.03 × 10−5, equivalent to the previously reported the MWCNT sintered block. The ZT value of the SWCNT sintered block is about three times as high as that of the MWCNT sintered block, higher than that of other CNT block materials. The ZT value of the MWCNT sponge prepared in this work reaches a maximum of 5.72 × 10−4 at room temperature and 1 atm, superior to other 3D macroscopic pure CNT materials and improved by an order of magnitude. However, it is worth mentioning that although the CNT sponge prepared in this paper has ultra-low thermal conductivity, the Seebeck coefficient and the conductivity are not superior.

Comparison of temperature dependence of ZT values for samples prepared in this paper and other macroscopic pure CNTs materials.

The sintered CNT bulk materials and CNT sponge represented two different routes in enhancing the thermoelectric figure of merit for 3D macroscopic pure CNT materials. The former attempts to improve ZT by increasing

4 Conclusion

In summary, the thermal conductivity and thermoelectric properties of sintered CNTs and porous CNT sponges were investigated. It is found that the maximum ZT at room temperature of the SPS sintered SWCNT blocks is 9.33 × 10−5, twice higher than that of the sintered MWCNT blocks in this work and also higher than that of other sintered MWCNT blocks reported previously. Therefore, SWCNT block is a better alternative than its MWCNT counterpart. Moreover, MWCNT sponge with super low mass density is prepared and measured. It was found that MWCNT sponges showed an ultra-low thermal conductivity of 0.021 W/(m K) and significantly enhanced ZT value of 5.72 × 10−4 at room temperature and 1 atm, which is higher than other reported 3D macroscopic pure CNT materials. The significant enhancement in ZT of the porous MWCNT sponges is attributed to the ultra-low density, ultra-high porosity, and interconnected structure of material, which lead to a fairly low thermal conductivity and better Seebeck coefficient. This work presents two different routes in enhancing the thermoelectric properties of CNT-based materials, and the finding provides a crucial understanding in exploring potential enhancement mechanisms.

Another contribution of this study is to bring readers a clear understanding of the thermal conductivity and thermoelectric properties for 3D macroscopic pure CNT materials via our comprehensive experimental research. Although many scholars have expected that the pure CNT bulk materials can be as promising thermoelectric materials, our work shows clearly that the ZT values achieved in 3D macroscopic pure CNT materials are still poor (on the level of 10−4 even it is significant enhanced) compared to the recent progress of thermoelectric field [33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49].

Acknowledgments

The authors thank Prof. Anyuan Cao and Dr. Yizeng Wu from Peking University for their kind support and assistance in the preparation of the samples of MWCNT Sponges.

-

Funding information: This research was supported by the National Natural Science Foundation of China (Grant Nos. 52076080 and 51576066) and the Natural Science Foundation of Hebei Province of China (Grant No. E2019502138).

-

Author contributions: Xueming Yang: conceptualization, methodology, validation, formal analysis, investigation, project administration, writing – original draft. Jixiang Cui: writing – review & editing, validation, data curation. Ke Xue: investigation, validation, writing – original draft. Yao Fu: writing – review and editing. Hanling Li: formal analysis, validation. Hong Yang: validation. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Chandel VS, Wang G, Talha M. Advances in modelling and analysis of nano structures: a review. Nanotechnol Rev. 2020;9(1):230–58.10.1515/ntrev-2020-0020Search in Google Scholar

[2] Lu W, Li S, Xu R, Zhang J, Li D, Feng Z, et al. Boosting thermoelectric performance of SnSe via tailoring band structure, suppressing bipolar thermal conductivity, and introducing large mass fluctuation. ACS Appl Mater Interfaces. 2019;11(48):45133–41.10.1021/acsami.9b17811Search in Google Scholar PubMed

[3] Alsalama MM, Hamoudi H, Abdala A, Ghouri ZK, Youssef KM. Enhancement of thermoelectric properties of layered chalcogenide materials. Rev Adv Mater Sci. 2020;59(1):371.10.1515/rams-2020-0023Search in Google Scholar

[4] Jung DH, Sharma A, Mayer M, Jung JP. A review on recent advances in transient liquid phase (TLP) bonding for thermoelectric power module. Rev Adv Mater Sci. 2018;53(2):147–60.10.1515/rams-2018-0011Search in Google Scholar

[5] Wang G, Chen Q, Gao M, Yang B, Hui D. Generalized locally-exact homogenization theory for evaluation of electric conductivity and resistance of multiphase materials. Nanotechnol Rev. 2020;9(1):1–16.10.1515/ntrev-2020-0001Search in Google Scholar

[6] Ma W, Liu Y, Yan S, Miao T, Shi S, Yang M, et al. Systematic characterization of transport and thermoelectric properties of a macroscopic graphene fiber. Nano Res. 2016;9(11):3536–46.10.1007/s12274-016-1231-6Search in Google Scholar

[7] Behdinan K, Moradi-Dastjerdi R, Safaei B, Qin Z, Chu F, Hui D. Graphene and CNT impact on heat transfer response of nanocomposite cylinders. Nanotechnol Rev. 2020;9(1):41–52.10.1515/ntrev-2020-0004Search in Google Scholar

[8] Dassan EGB, Anjang A, Rahman A, Shukur M, Abidin Z, Akil HM. Carbon nanotube-reinforced polymer composite for electromagnetic interference application: a review. Nanotechnol Rev. 2020;9(1):768–88.10.1515/ntrev-2020-0064Search in Google Scholar

[9] Prasher RS, Hu X, Chalopin Y, Mingo N, Lofgreen K, Volz S, et al. Turning carbon nanotubes from exceptional heat conductors into insulators. Phys Rev Lett. 2009;102(10):1–4.10.1103/PhysRevLett.102.105901Search in Google Scholar PubMed

[10] Hone J, Llaguno MC, Nemes NM, Johnson AT, Fischer JE, Walters DA, et al. Electrical and thermal transport properties of magnetically aligned single wall carbon nanotube films. Appl Phys Lett. 2000;77(5):666–8.10.1063/1.127079Search in Google Scholar

[11] Zhou W, Fan Q, Zhang Q, Li K, Cai L, Gu X, et al. Ultrahigh-power-factor carbon nanotubes and an ingenious strategy for thermoelectric performance evaluation. Small. 2016;12(25):3407–14.10.1002/smll.201600501Search in Google Scholar PubMed

[12] Toshima N, Oshima K, Anno H, Nishinaka T, Ichikawa S, Iwata A, et al. Novel hybrid organic thermoelectric materials:three-component hybrid films consisting of a nanoparticle polymer complex, carbon nanotubes, and vinyl polymer. Adv Mater. 2015;27(13):2246–51.10.1002/adma.201405463Search in Google Scholar PubMed

[13] Tan D, Zhao J, Gao C, Wang H, Chen G, Shi D. Carbon nanoparticle hybrid aerogels: 3D double-interconnected network porous microstructure, thermoelectric, and solvent-removal functions. ACS Appl Mater Interfaces. 2017;9(26):21820–8.10.1021/acsami.7b04938Search in Google Scholar PubMed

[14] Lee W, Hong CT, Kwon OH, Yoo Y, Kang YH, Lee JY, et al. Enhanced thermoelectric performance of bar-coated SWCNT/P3HT thin films. ACS Appl Mater Interfaces. 2015;7(12):6550–6.10.1021/acsami.5b00626Search in Google Scholar PubMed

[15] Li D, Luo C, Chen Y, Feng D, Gong Y, Pan C, et al. High performance polymer thermoelectric composite achieved by carbon-coated carbon nanotubes network. ACS Appl Energy Mater. 2019;2(4):2427–34.10.1021/acsaem.9b00334Search in Google Scholar

[16] Feng N, Gao C, Guo C, Chen G. Copper-phenylacetylide nanobelt/single-walled carbon nanotube composites: mechanochromic luminescence phenomenon and thermoelectric performance. ACS Appl Mater Interfaces. 2018;10(6):5603–8.10.1021/acsami.7b19167Search in Google Scholar PubMed

[17] Jin R, Zhou Z, Mandrus D, Ivanov IN, Eres G, Howe JY, et al. The effect of annealing on the electrical and thermal transport properties of macroscopic bundles of long multi-wall carbon nanotubes. Phys B Condens Matter. 2007;388(1–2):326–30.10.1016/j.physb.2006.06.135Search in Google Scholar

[18] Qin C, Shi X, Bai S, Chen L, Wang L. High temperature electrical and thermal properties of the bulk carbon nanotube prepared by SPS. Mater Sci Eng A. 2006;420(1–2):208–11.10.1016/j.msea.2006.01.055Search in Google Scholar

[19] Yang K, He J, Puneet P, Su Z, Skove MJ, Gaillard J, et al. Tuning electrical and thermal connectivity in multiwalled carbon nanotube buckypaper. J Phys Condens Matter. 2010;22(33):334215.10.1088/0953-8984/22/33/334215Search in Google Scholar PubMed

[20] Chen J, Gui X, Wang Z, Li Z, Xiang R, Wang K, et al. Superlow thermal conductivity 3D carbon nanotube network for thermoelectric applications. ACS Appl Mater Interfaces. 2012;4(1):81–6.10.1021/am201330fSearch in Google Scholar PubMed

[21] Zhang Z, Qi L, Shen X, Wang F, Lee SK. Microstructure and mechanical properties of bulk carbon nanotubes compacted by spark plasma sintering. Mater Sci Eng A. 2013;573:12–7.10.1016/j.msea.2013.03.001Search in Google Scholar

[22] Gui X, Cao A, Wei J, Li H, Jia Y, Li Z, et al. Soft, highly conductive nanotube sponges and composites with controlled compressibility. ACS Nano. 2010;4(4):2320–6.10.1021/nn100114dSearch in Google Scholar PubMed

[23] Gui X, Wei J, Wang K, Cao A, Zhu H, Jia Y, et al. Carbon nanotube sponges. Adv Mater. 2010;22(5):617–21.10.1002/adma.200902986Search in Google Scholar PubMed

[24] Volkov AN, Zhigilei LV. Heat conduction in carbon nanotube materials: Strong effect of intrinsic thermal conductivity of carbon nanotubes. Appl Phys Lett. 2012;101:4.10.1063/1.4737903Search in Google Scholar

[25] Volkov AN, Zhigilei LV. Scaling laws and mesoscopic modeling of thermal conductivity in carbon nanotube materials. Phys Rev Lett. 2010;104(21):3–6.10.1103/PhysRevLett.104.215902Search in Google Scholar PubMed

[26] Chalopin Y, Volz S, Mingo N. Erratum: Upper bound to the thermal conductivity of carbon nanotube pellets (Journal of Applied Physics (2009) 105 (084301)). J Appl Phys. 2010;108(3):2009–10.10.1063/1.3436629Search in Google Scholar

[27] Yang X, Chen D, Han Z, Ma X, To AC. Effects of welding on thermal conductivity of randomly oriented carbon nanotube networks. Int J Heat Mass Transf. 2014;70:803–10.10.1016/j.ijheatmasstransfer.2013.11.071Search in Google Scholar

[28] Zhang H, Li J, Yao K, Chen L. Spark plasma sintering and thermal conductivity of carbon nanotube bulk materials. J Appl Phys. 2005;97(11):11–6.10.1063/1.1927286Search in Google Scholar

[29] Li J, Wang L, He T, Jiang W. Transport properties of hot-pressed bulk carbon nanotubes compacted by spark plasma sintering. Carbon N Y. 2009;47(4):1135–40.10.1016/j.carbon.2008.12.041Search in Google Scholar

[30] Zhang H, Li J, Zhang B, Yao K, Liu W, Wang H. Electrical and thermal properties of carbon nanotube bulk materials: Experimental studies for the 328–958 K temperature range. Phys Rev B. 2007;75(20):1–9.10.1103/PhysRevB.75.205407Search in Google Scholar

[31] Ma W, Liu Y, Yan S, Miao T, Shi S, Xu Z, et al. Chemically doped macroscopic graphene fibers with significantly enhanced thermoelectric properties. Nano Res. 2018;11(2):741–50.10.1007/s12274-017-1683-3Search in Google Scholar

[32] Vavro J, Llaguno MC, Fischer JE, Ramesh S, Saini RK, Ericson LM, et al. Thermoelectric power of p-doped single-wall carbon nanotubes and the role of phonon drag. Phys Rev Lett. 2003;90(6):4.10.1103/PhysRevLett.90.065503Search in Google Scholar PubMed

[33] Shimizu S, Shiogai J, Takemori N, Sakai S, Ikeda H, Arita R, et al. Giant thermoelectric power factor in ultrathin FeSe superconductor. Nat Commun. 2019;10(1):1–7.10.1038/s41467-019-08784-zSearch in Google Scholar PubMed PubMed Central

[34] Zhao W, Liu Z, Sun Z, Zhang Q, Wei P, Mu X, et al. Super paramagnetic enhancement of thermoelectric performance. Nature. 2017;549(7671):247–51.10.1038/nature23667Search in Google Scholar PubMed

[35] Shautsova V, Sidiropoulos T, Xiao X, Güsken NA, Black NCG, Gilbertson AM, et al. Plasmon induced thermoelectric effect in graphene. Nat Commun. 2018;9(1):1–9.10.1038/s41467-018-07508-zSearch in Google Scholar PubMed PubMed Central

[36] Barnard AW, Zhang M, Wiederhecker GS, Lipson M, McEuen PL. Real-time vibrations of a carbon nanotube. Nature. 2019;566(7742):89–93.10.1038/s41586-018-0861-0Search in Google Scholar PubMed

[37] Elyamny S, Dimaggio E, Magagna S, Narducci D. High power thermoelectric generator based on vertical silicon nanowires. Nano Lett. 2020;20(7):4748–53.10.1021/acs.nanolett.0c00227Search in Google Scholar PubMed PubMed Central

[38] Tanaka H, Kanahashi K, Takekoshi N, Mada H, Mada H, Takenobu T. Thermoelectric properties of a semicrystalline polymer doped beyond the insulator-to-metal transition by electrolyte gating. Sci Adv. 2020;6(7):1–9.10.1126/sciadv.aay8065Search in Google Scholar PubMed PubMed Central

[39] Noh J, Tan J, Yadav DR, Wu P, Wu P, Xie KY, et al. Understanding of lithium insertion into 3d porous carbon scaffolds with hybridized lithiophobic and lithiophilic surfaces by in-operando study. Nano Lett. 2020;20(5):3681–7.10.1021/acs.nanolett.0c00618Search in Google Scholar PubMed

[40] Hu P, Lyu J, Fu C, Gong W, Lu W, Liao J, et al. Multi-functional aramid nanofiber/carbon nanotube hybrid aerogel films. ACS Nano. 2020;14(1):688–97.10.1021/acsnano.9b07459Search in Google Scholar PubMed

[41] Ichinose Y, Yoshida A, Horiuchi K, Fukuhara K, Komatsu N, Gao W, et al. Solving the thermoelectric trade-off problem with metallic carbon nanotubes. Nano Lett. 2019;19(10):7370–6.10.1021/acs.nanolett.9b03022Search in Google Scholar PubMed

[42] Dasbach M, Pyschik M, Lehmann V, Parey K, Rhinow D, Reinhardt HM, et al. Assembling carbon nanotube architectures. ACS Nano. 2020;14(7):8181–90.10.1021/acsnano.0c01606Search in Google Scholar PubMed

[43] Selim MM, El-Safty SA. Vibrational analysis of an irregular single-walled carbon nanotube incorporating initial stress effects. Nanotechnol Rev. 2020;9(1):1481–90.10.1515/ntrev-2020-0114Search in Google Scholar

[44] Jiang Q, Zhang Q, Wu X, Wu L. Interfacial characteristics of a carbon nanotube-polyimide nanocomposite by molecular dynamics simulation. Nanotechnol Rev. 2020;9(1):136–45.10.1515/ntrev-2020-0012Search in Google Scholar

[45] Liu J, van der Zee B, Alessandri R, Sami S, Dong J, Nugraha ML, et al. N-type organic thermoelectrics: demonstration of ZT > 0.3. Nat Commun. 2020;11(1):1–9.10.1038/s41467-020-19537-8Search in Google Scholar PubMed PubMed Central

[46] Wang X, Suwardi A, Lim SL, Wei F, Wu J. Transparent flexible thin-film p–n junction thermoelectric module. NPJ Flex Electron. 2020;4(1):1–9.10.1038/s41528-020-00082-9Search in Google Scholar

[47] Zaumseil J, Statz M. Charge and thermoelectric transport in polymer-sorted semiconducting single-walled carbon nanotube networks. Nano Lett. 2020;14:11.10.1021/acsnano.0c06181Search in Google Scholar

[48] Zhang D, Zhang Y, Miao M. Metallic conductivity transition of carbon nanotube yarns coated with silver particles. Nanotechnology. 2014;25(27):275702.10.1088/0957-4484/25/27/275702Search in Google Scholar PubMed

[49] Duan Q, Wang S, Wang Q, Li T, Chen S, Miao M, et al. Simultaneous improvement on strength, modulus, and elongation of carbon nanotube films functionalized by hyperbranched polymers. ACS Appl Mater Interfaces. 2019;11(39):36278–85.10.1021/acsami.9b12368Search in Google Scholar PubMed

© 2021 Xueming Yang et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions

![Figure 3

Thermal conductivity of the SWCNT and MWCNT packed bed as a function of density: (a) experimental results; (b) calculation results by Chalopin’s model [24] and Volkov’s model [26].](/document/doi/10.1515/ntrev-2021-0013/asset/graphic/j_ntrev-2021-0013_fig_003.jpg)