Abstract

Despite its growing recognition as a sustainable alternative to cement composites, geopolymer mortar faces performance limitations that hinder its practical application, prompting researchers to explore novel enhancement strategies, including incorporating nanomaterials, to improve its properties. Investigating the effects of various weight percentages (1, 2, 3, and 4%) of nano-silica and nano-silicon carbide on the density, microstructure, compressive and flexural strength, and abrasion resistance of metakaolin-based geopolymer mortar composites is the aim of this work. The experimental results carried out in this study demonstrate that nanoparticles can significantly change the properties of the geopolymer mortar. These changes caused increasing density, compressive, flexural, and tensile strengths, as well as wear resistance with improvement rates of 5.5, 44, 43, 52, and 41%, respectively, due to the changes in the microstructure of the geopolymer matrix, resulting from its incorporation. The present study showed that the addition of nanomaterials enhanced durability and resistance to environmental degradation, which means that structures will require less maintenance and fewer repairs, leading to lower environmental impact over the lifecycle of structures.

1 Introduction

Geopolymers are a new family of cementitious materials that, over time, may replace traditional Portland cement composites altogether. Geopolymer composites have lower energy in manufacturing and give much lower carbon dioxide emissions compared to Portland cement production [1]. Geopolymers are the result of the alkaline activation of a variety of source binders that are rich in silicate and aluminum, such as fly ash and metakaolin, along with GGBFS [2]. To enhance the performance and characteristics of the geopolymer, many types of nanoparticles have been introduced into geopolymers within the last 10 years. Nanotechnology has become one of the most dynamic fields of research. During the last 20 years, its importance has grown steadily due to its advanced scientific and technological innovations and practical applications. The impacts of nanoparticles on the microstructure, durability, mechanical, physical, and fresh characteristics of the geopolymer composites have been extensively studied [3].

Rathinam et al. assessed 10–90% slag-fly ash geopolymer after modification with 1, 2, 3, and 4 wt% of nano-silica. The addition of 1% of nano-silica achieved the best results in terms of the initial setting time, compressive and flexural strength, workability, and water absorption [4]. Coffetti et al. integrated nano-titanium dioxide into the alkali-activated slag-based mortar to determine the rheological and mechanical properties as well as self-cleaning ability. Under natural and accelerated conditions, self-cleaning was better after the addition of nano-titanium oxide, while there were no noticeable changes in the mechanical and rheological properties. They demonstrated that alkali content had a significant role in improving the mortar’s photocatalytic efficiency [5].

Maiti et al. added different sizes of nano-titanium oxide to the fly ash geopolymer mortar. Five percent of nano-titanium oxide, sized 30 nm, improved the tensile and compressive strength to 6.8 and 53.6 MPa, respectively. Moreover, better durability was achieved due to a denser matrix, lower porosity, and surface roughness as a result of adding nano-titanium oxide [6].

Phokha et al. assessed the mechanical and magnetic properties of the geopolymer after the addition of different concentrations of nano-BaFe12O19 and nano-BFO (1, 3, and 5 wt%). Their results demonstrated that the resulting composite possesses ferromagnetic activity at room temperature, which was manifested by hysteresis loops and increasing magnetism as the percent of BFO increased. Furthermore, nano-BFO filled the gaps in the (N–A–S–H) gel structure, which contributed to a dense and compact geopolymer, resulting in about 7% increase in the composite’s compressive strength as the nano-BFO increased from 0 to 3% [7].

Dişçi and Polat investigated the impact of substituting 1,2,3 wt% perlite with nano-Al2O3 and nano-CaO on the properties of the geopolymer under different curing conditions. According to their results, nano-Al2O3 improved the compressive strength significantly, especially when combining heat treatment with ambient temperature curing. Nanoparticles reduce the porosity and cracks in concrete. On the other hand, there was no significant effect on the concrete’s geopolymerization pace [8].

Janowska-Renkas et al. examined the electrical conductivity of the fly ash–graphene–glass powder geopolymer mortar by analyzing resistivity. They used scanning microscopy and XRD to investigate the microstructure. A significant increase in conductivity was achieved as a result of adding graphene in addition to an enhancement in the strength of the geopolymer containing fly ash [9].

Tang and collaborators integrated 3-aminopropyltriethoxy silane (APTS) and graphene oxide (GO) into geopolymers to address specific challenges. They found that APTS inhibited condensation and dissolution processes, affecting workability, while GO accelerated the process of geopolymerization. In a sodium silicate alkaline environment, the GO-APTS structure remained stable, improving nanosheet dispersion within the composite. Compared to reference and pure GO, GO-APTS composites showed improved workability, transport properties, and significant tensile strength at 7 and 28 days, indicating enhanced mechanical performance [10].

Tanyildizi and coworkers examined in their study the freeze–thaw resistance of metakaolin and fly ash-based 3D-printed geopolymer mortars with different dosages (0.25, 0.5, and 0.75%) of nano-ZnO. The results indicated that the ultimate resistance to freeze–thaw of the prepared geopolymer was obtained at 0.5% nano-ZnO with a retention rate of 95.72% in the compressive strength [11].

Hashemi and coworkers developed a sulfate-resistant geopolymer mortar containing nano-silica (0, 1.0, and 2.0% binder weight replacement). The study showed that adding (1%) nano-silica causes a higher bond strength (both tensile and shear) of mixtures cured in an environment containing sodium sulfate [12].

The current work focused on studying the influence of adding oxide (SiO2) and non-oxide (SiC) ceramic nanoparticles at different ratios on the strengthening mechanism and the performance of the geopolymer mortar.

2 Materials

2.1 Metakaolin

Metakaolin was used as a binder in the geopolymer mortar composite preparation in this work and was purchased from Iraqi local markets. Elemental composition analysis was carried out using an X-ray fluorescence (XRF) analyzer, as illustrated in Table 1, which is compatible with the specification of ASTM C618 [13].

Chemical structure of the metakaolin sample

| Oxide | Metakaolin (%) |

|---|---|

| Al2O3 | 33.34 |

| SiO2 | 61.12 |

| Fe2O3 | 2.41 |

| CaO | 1.31 |

| MgO | 0.18 |

| K2O | 0.62 |

| Na2O | 0.88 |

| TiO2 | 0.13 |

2.2 Fine aggregates (sand)

In this work, naturally occurring fine aggregates with a grain size of 4.75 mm were obtained from the Karbala Governorate’s Al-Ekhadir region. Before use, it was cleaned and sieved. The grade, chemical makeup, and physical characteristics of the fine aggregates met the Iraqi standard requirements for IQS (No. 45/1984) [14], as illustrated in Tables 2 and 3.

Grading of fine aggregates

| Sieve no. | Sieve size (mm) | Passing (weight%) | Spec. limit according to IQS No45/1984 zone (2) |

|---|---|---|---|

| 1 | 9.5 | 100 | 100 |

| 2 | 4.75 | 90.55 | 90–100 |

| 3 | 2.36 | 78.31 | 75–100 |

| 4 | 1.18 | 63.1 | 55–90 |

| 5 | 0.6 | 43.51 | 35–59 |

| 6 | 0.3 | 14.64 | 8–30 |

| 7 | 0.15 | 0.02 | 0–10 |

Properties of sand

| Properties | Value | IQS 45-1984 Iraqi Standard limits |

|---|---|---|

| Density (kg/m3) | 1,598 | — |

| Specific gravity | 2.7 | — |

| Absorption (%) | 0.71 | — |

| Fineness modulus | 3.1 | — |

| Fine materials that pass through a 75 μm sieve | 1.3 | 3% maximum |

| Sulfate content (%) | 0.36 | 0.5% maximum |

2.3 Alkaline activator

A mixture of NaOH and Na2SiO3 solutions serves as the alkaline activator. NaOH flakes were dissolved in distilled water and then mixed with sodium silicate at a constant Na2SiO3/NaOH ratio of 2.5/1. The former was made at a concentration of 16 M.

2.4 Nanoparticles

Two types of nanoparticles were used in this work: nano-SiO2 and nano-SiC, with different quantities (1, 2, 3, and 4% by the total weight of the dry components represented by metakaolin and sand). Table 4 shows the properties of the nanoparticles used in this work.

Properties of nano-SiO2 and nano-SiC

| Property | Nano-SiO2 | Nano-SiC |

|---|---|---|

| Color | White powder | Gray powder |

| Density (g/cm3) | 2.17 | 3.2 |

| Particle size (nm) | 30 nm | 20 nm |

| Purity (%) | 99.8 | 99.5 |

2.5 High-range water-reducing admixture

In this investigation, MasterGlenium®54 superplasticizer (SP), a high-range water reducer, was used to increase the workability of the geopolymer mortar. A set quantity of 3% superplasticizer was applied to each geopolymer mixture.

3 Experimental route

3.1 Mix proportion

In this study, metakaolin was mixed with nanoparticles at weight percentages of 0, 1, 2, 3, and 4%. The dry components were at a 1:1 ratio. All mixes employed a constant Na2SiO3/NaOH ratio of 2.5 and a constant liquid-to-binder (L/B) ratio of 0.60. Table 5 shows the mix proportions design for all mixes.

Mix proportions for all mixtures of the geopolymer mortar composites

| Mix | Metakaolin (g) | Fine aggregate (g) | NaOH (16 M) | Na2SiO3:NaOH 2.5:1 | n-SiO2 (wt%) | n-SiO2 (g) | n-SiC (wt%) | n-SiC (g) |

|---|---|---|---|---|---|---|---|---|

| Control | 450 | 450 | 64.28 | 160.71 | ||||

| 1-nSiO2 | 445.5 | 445.5 | 64.28 | 160.71 | 1% | 9 | ||

| 2-nSiO2 | 441 | 441 | 64.28 | 160.71 | 2% | 18 | ||

| 3-nSiO2 | 436.5 | 436.5 | 64.28 | 160.71 | 3% | 27 | ||

| 4-nSiO2 | 432 | 432 | 64.28 | 160.71 | 4% | 36 | ||

| 1-nSiC | 445.5 | 445.5 | 64.28 | 160.71 | 1% | 9 | ||

| 2-nSiC | 441 | 441 | 64.28 | 160.71 | 2% | 18 | ||

| 3-nSiC | 436.5 | 436.5 | 64.28 | 160.71 | 3% | 27 | ||

| 4-nSiC | 432 | 432 | 64.28 | 160.71 | 4% | 36 |

3.2 Preparation of geopolymer composites

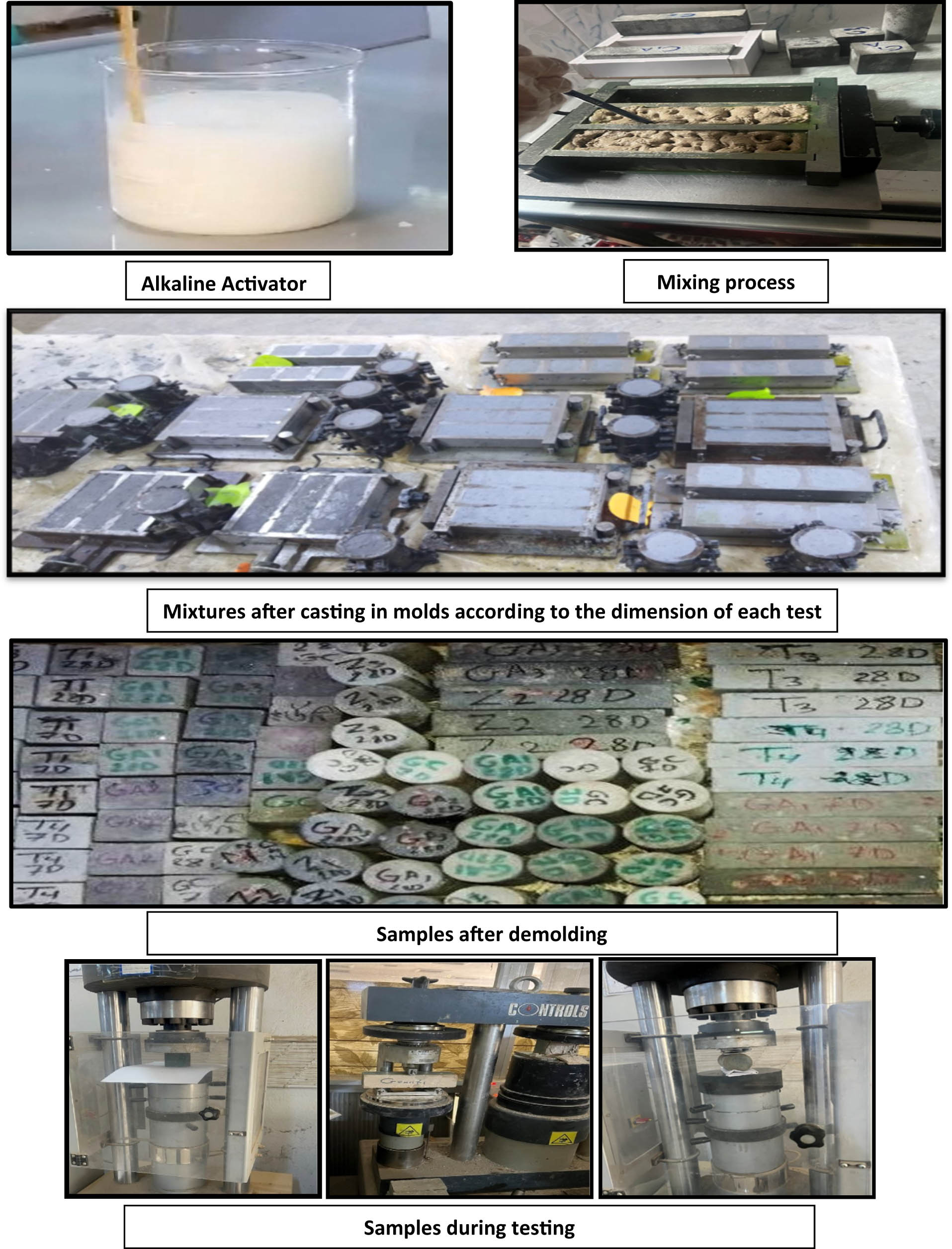

The first step in preparing the composite was the manual mixing of the dried components, including metakaolin, fine aggregates, and nanoparticles, for approximately 5–0 min until a uniform mixture was formed. To guarantee homogeneity, the wet ingredients – the alkaline activator and superplasticizer – were next added to the dry ingredients, and the mixture was stirred once more for 5–10 min. After that, the geopolymer mixture was put into steel molds that were customized to have the cube (50 mm × 50 mm × 50 mm), prism (160 mm × 40 mm × 40 mm), or cylinder shape (50 mm × 100 mm) needed for each test. A thin layer of oil was used to enhance the removal of the samples from the molds and prevent sticking, which was applied to the surface inside the walls before pouring the composite. The pouring process was done in three layers. Each layer was vibrated for 1–2 min using a vibrating table to prevent the tapping of air in the composite. After that, the sample surface was refined, covered by a plastic sheet, and left to cast at ambient temperature for 24 h. Figure 1 shows the steps of the experimental work.

The steps of the experimental work.

3.3 Curing process

After 24 h, the samples were removed from the molds and cured in two steps. First, the samples were placed inside a furnace for 3 h at 100°C. Second, the samples were left to cure at ambient temperature for 7 and 28 days.

4 Results and discussion

4.1 Microstructural analysis

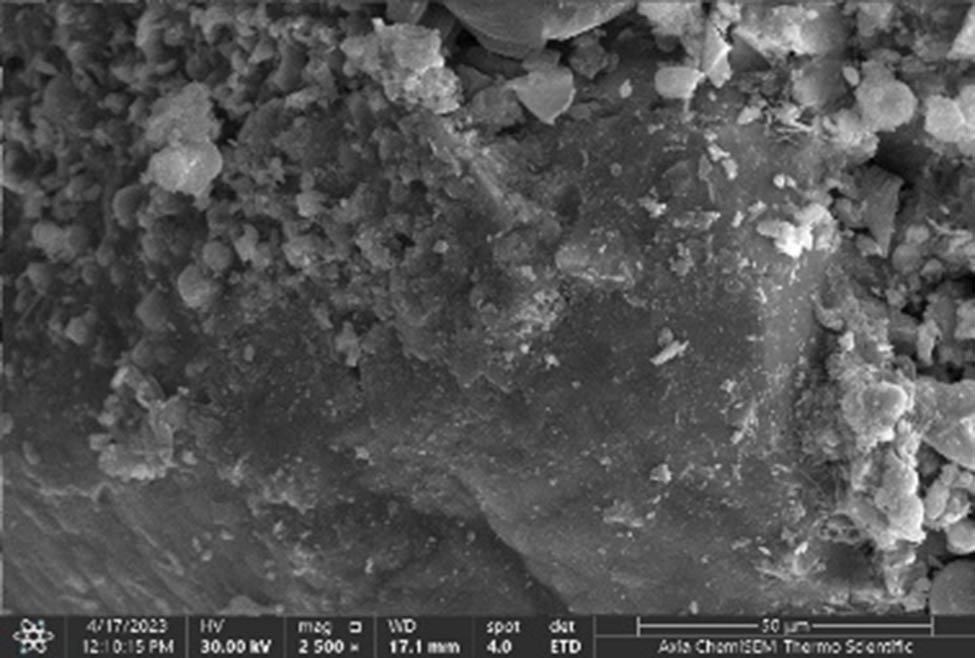

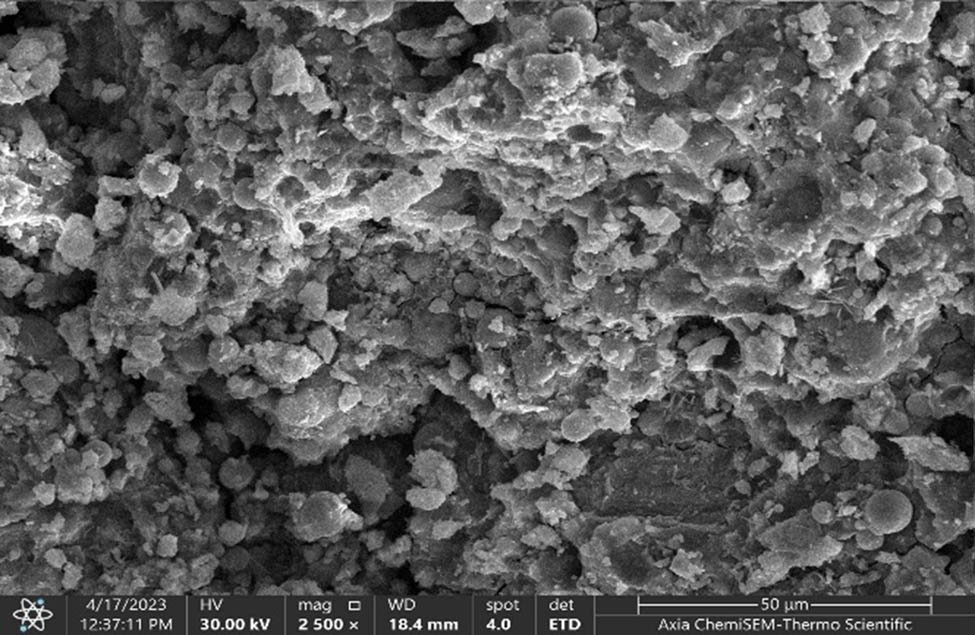

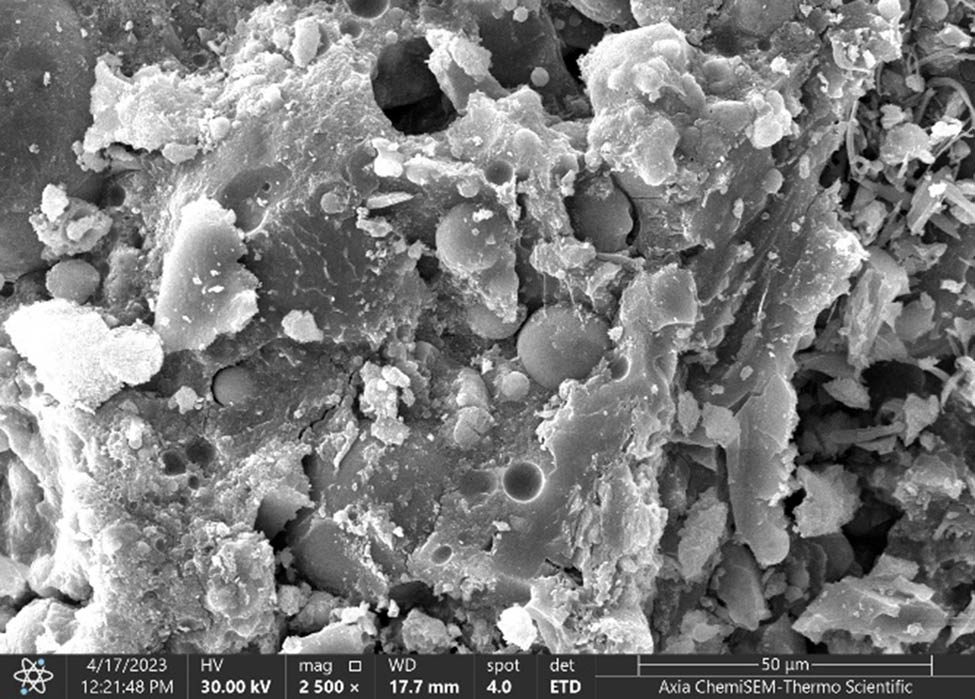

After 3 h of curing at 100°C, scanning electron microscopy (SEM) was performed. The results of SEM are shown in Figures 2 and 3. According to the SEM results, curing at such a high temperature has a considerable effect on the polymerization of the composite and promotes the gel stage creation. Fewer porosities and more uniform microstructures were achieved after 28 days of curing, unlike curing for 7 days, which means that a longer time is needed for the polymerization process to be completed and for the creation of the gel phase.

SEM image of the geopolymer following a 7-day cure procedure.

SEM image of the geopolymer following a 28-day curing procedure.

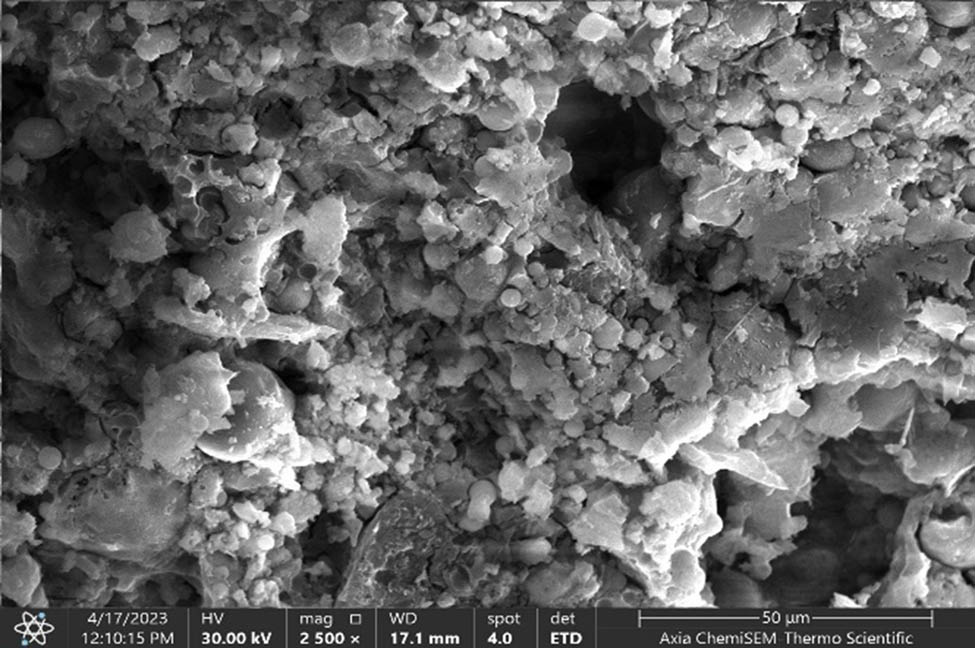

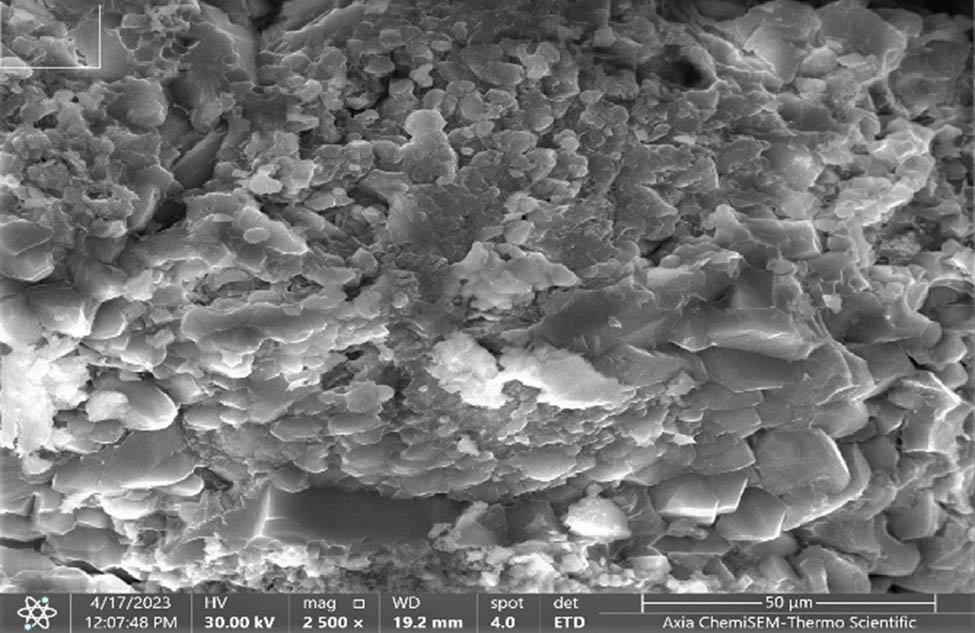

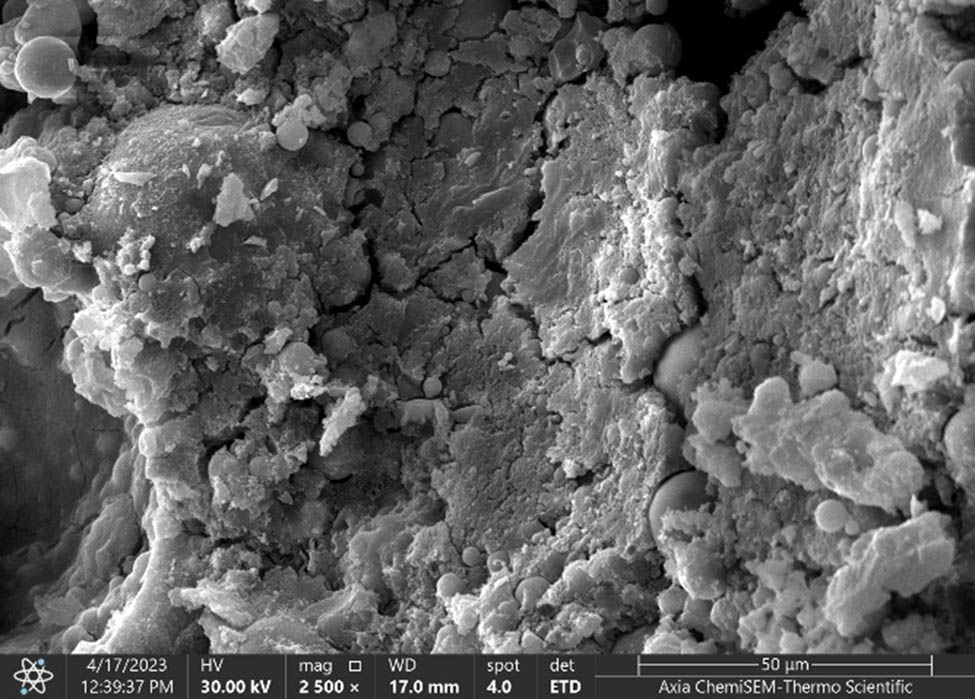

The impact of nanoparticles on the microstructure of the geopolymer is shown in Figures 4 and 5. By closing the gaps in the structure and creating a thick and uniform microstructure, it was found that the addition of (3%) nano-silica significantly altered the microstructure of the geopolymer, as shown in Figure 4. Also, the addition of the nano-silica to the combination enhanced the geopolymer’s polymerization process and resulted in greater gel formation by increasing the degree of silicate ion dissolution in the alkaline activator. Additionally, it was found that when the addition % increased, certain gaps were created as a result of these nanoparticles clumping together, as shown in Figure 6. Figure 5, on the other hand, shows how the nano-silicon carbide affected the geopolymer’s microstructure. The results indicated that the incorporation of 2% of these particles is essential for altering the geopolymer’s structure by inhibiting the grain growth through effective dispersion, particularly at an addition ratio of 2%, which yields a fine and unified microstructure.

SEM image of the geopolymer filled with 3% n-SiO2 after a 28-day cure procedure.

SEM image of the geopolymer filled with 2% n-SiC after a 28-day curing procedure.

SEM image of the geopolymer filled with 4% n-SiO2 after a 28-day curing procedure.

In this context, it was shown that an increase in the addition ratio resulted in the aggregation of nanoparticles inside the structure, leading to the formation of distinct gaps and flaws in the microstructure, as shown in Figure 7.

SEM image of the geopolymer filled with 4% n-SiC after a 28-day curing procedure.

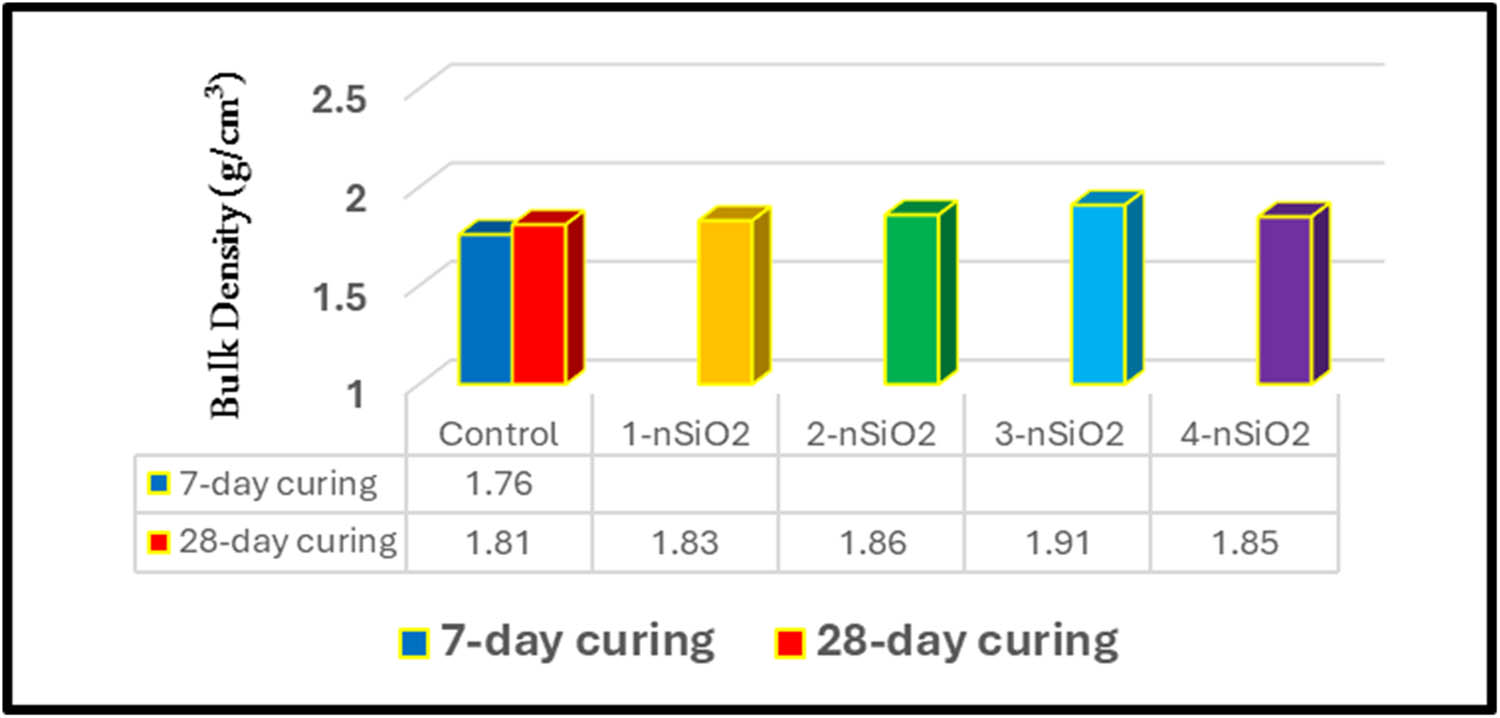

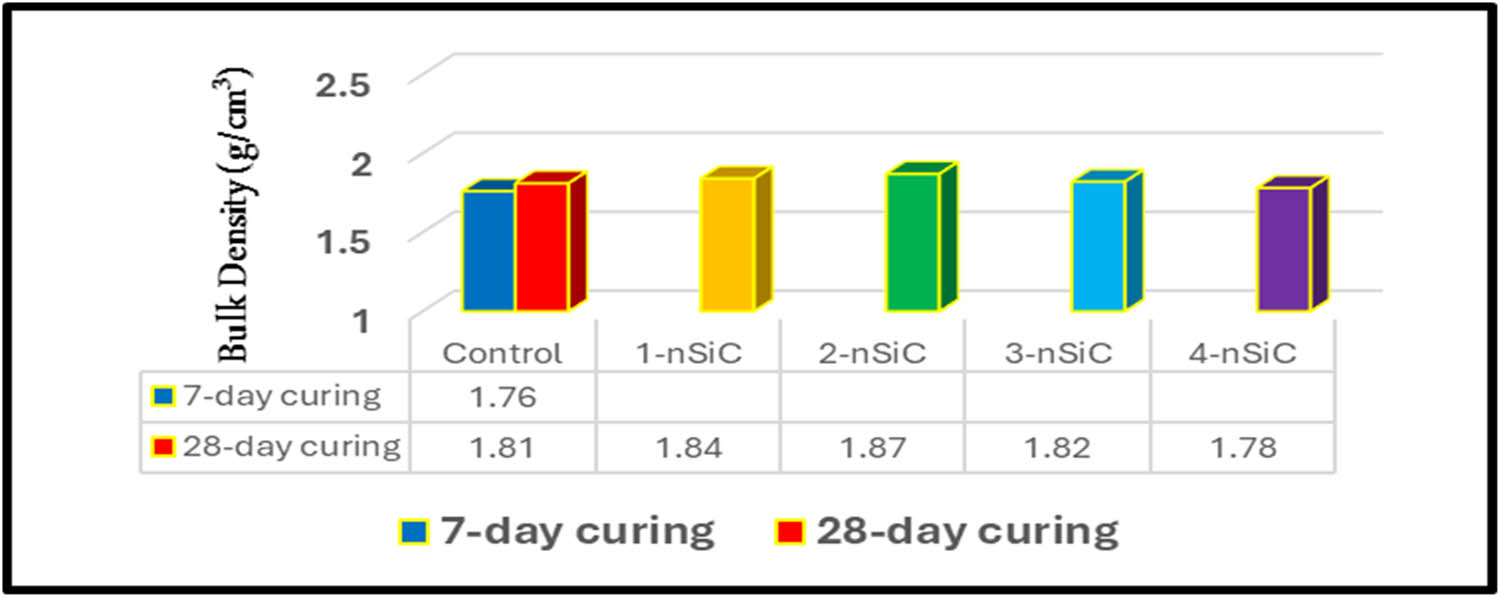

4.2 Density measurements

The geopolymer’s density changes with the curing time, and the impact of nanoparticles on the density values at day 28 of the curing process are shown in Figures 8 and 9. It was found that the curing time had a significant impact on the density change. Because the polymerization process requires sufficient time to complete the reaction process and minimize the porosity inside the structure, the density increased gradually throughout the 28 curing days before reaching a high value. It was found that the addition of nano-SiO2 causes a discernible increase in density, which increases to 3% with the weight fraction of nano-SiO2.

Density values of the geopolymer at various nano-SiO2 weight fractions.

Density values of the geopolymer at various nano-SiC weight fractions.

According to SEM images, this behavior is explained by the function of nano-SiO2 in sealing the holes in the geopolymer microstructure and gel formation, and hence raising the density. The density values were then found to decrease, as shown in Figure 8. The optimal density for the addition of nano-SiC was achieved at a ratio of 1%; as the addition percentage increased, the density declines, as shown in Figure 9.

Because of their consistent distribution at low dosages (1%), the tiny particle size of these particles helps to fill the spaces within the structure and reduce porosity; hence, the density values improved. The concentration of these particles within the structure, as shown in the SEM images, is the cause of the decrease in values beyond this ratio. Moreover, nano-SiO2 particles had a greater effect on the density than the nano-SiC particles.

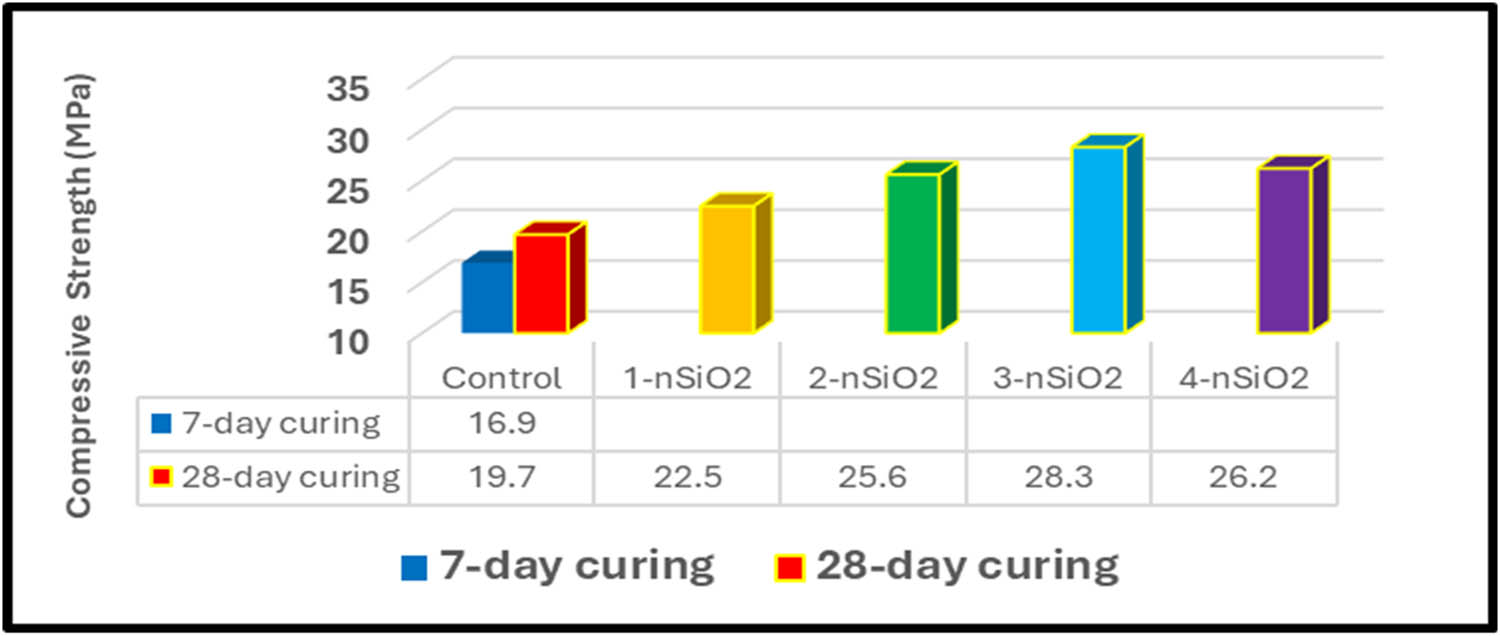

4.3 Compressive strength

Compressive strength testing was done in this study in compliance with ASTM C109-2 [15]. Three cubic samples (50 mm × 50 mm × 50 mm) were assessed at 7 and 28 days post-curing in a furnace to determine the average compressive strength for each combination. The fluctuation in the compressive strength values of the geopolymer mortar with varying weight fractions of nano-SiO2 following the curing process is shown in Figure 10. The experimental findings showed that the concentration of the nano-silica and the curing conditions had a significant impact on the compressive strength values, with an improvement rate of 43%.

Compressible strength values of the geopolymer materials at different weight fractions of nano-SiO2.

It was found that as the curing time increased, the dense microstructure formed as a result of the completion of the polymerization process and the formation of the gel that bonded the constituents together, increasing the geopolymer’s compressive strength.

In the same situation, a 3% increase in nano-silica concentration raises the compressive strength of the geopolymer mortar. Following that, there was a modest decline in the strength at a ratio of 4%. Reactive nano-silica, which has a more exothermic interaction with metakaolin’s components, is the cause of this increase in strength. Because they can operate as nucleation sites for the development of additional (N–A–S–H) gel, which gives the combination its harder qualities, and this reaction enhances the geopolymerization mechanism [16]. More compressive strength values will result from the components’ increased bonding due to the excessive gel formation.

The density of a material is closely linked to its compressive strength, with increased density resulting in enhanced compressive strength. The use of nano-silica powder occludes the nano- and micropores of the structure, hence enhancing the compressive strength values. It was observed that the compressive values diminished slightly at 4% weight, attributable to the presence of an unreacted silica ratio resulting from the concentration of these particles. The impact of nano-SiC at various weight fractions on the compressive strength of mortar made of geopolymer materials is shown in Figure 11.

Compressible strength values of the geopolymer materials at different weight fractions of nano-SiC.

According to the data, the addition of these nanoparticles by up to 2% clearly increased the compressive strength. The strong connection with the matrix and the excellent dispersion of these particles are responsible for this increase. In composite materials, bonding plays a crucial role in the load transmission process from the matrix to the reinforcing phase (particles), which raises the material’s compressive strength. However, the presence of these ceramic particles prevents the production of a fine microstructure with high compressive strength by impeding the growth of grains inside the geopolymer matrix [17].

The compressive strength then noticeably decreases when the weight fraction of these particles is increased to 4% because of the clear agglomeration of particles caused by their heterogeneity and difficulty in dispersing within the matrix, which creates some structural gaps [18]. Additionally, it was discovered that nano-SiO2 played a larger role in increasing the compressive strength than nano-SiC. This is because nano-SiO2 contributes to the polymerization process and the formation of gels that boost strength, whereas nano-SiC strengthens the material by forging a strong bond with the matrix and has no influence on the polymerization process.

4.4 Flexural strength

The flexural strength tests of the geopolymer mortar with different percentages of nano-SiO2 during the curing process were performed according to ASTM C 293-03 [19] standard, and the results are shown in Figure 12. An average of three prism specimens, each measuring 160 mm × 40 mm × 40 mm, was used to test the flexural strength of different geopolymer mortar formulations. After being treated in the furnace, the specimens were evaluated at two distinct ages: 7 and 28 days.

Flexural strength values of the geopolymer at various weight fractions of nano-SiO2.

The results demonstrate that as the curing time increases, the flexural strength enhances. Moreover, the integration of nano-SiO2 improves the flexural strength slightly until 2 wt% because of the strong bonds between the components caused by nano-SiO2. At 3 and 4 wt% of nano-SiO2, the strength decreased slightly. The increase in the geopolymer stiffness and brittleness may be the cause of the decrease in flexural strength. Conversely, it was found that the addition of nano-SiC, as shown in Figure 13, significantly increased the flexural resistance values, which increased to 2% wt as the weight fraction of these particles increased. This increase in flexural strength is the result of these hard particles’ ability to improve the brittle fracture behavior of geopolymer cement by delaying and halting the formation of fractures caused by stress. Because of the previously described agglomeration tendency of these particles, which results in cavities in the structure, the flexural strength value decreases as the weight fraction increases by 4% wt.

Flexural strength values of the geopolymer at various weight fractions of nano-SiC.

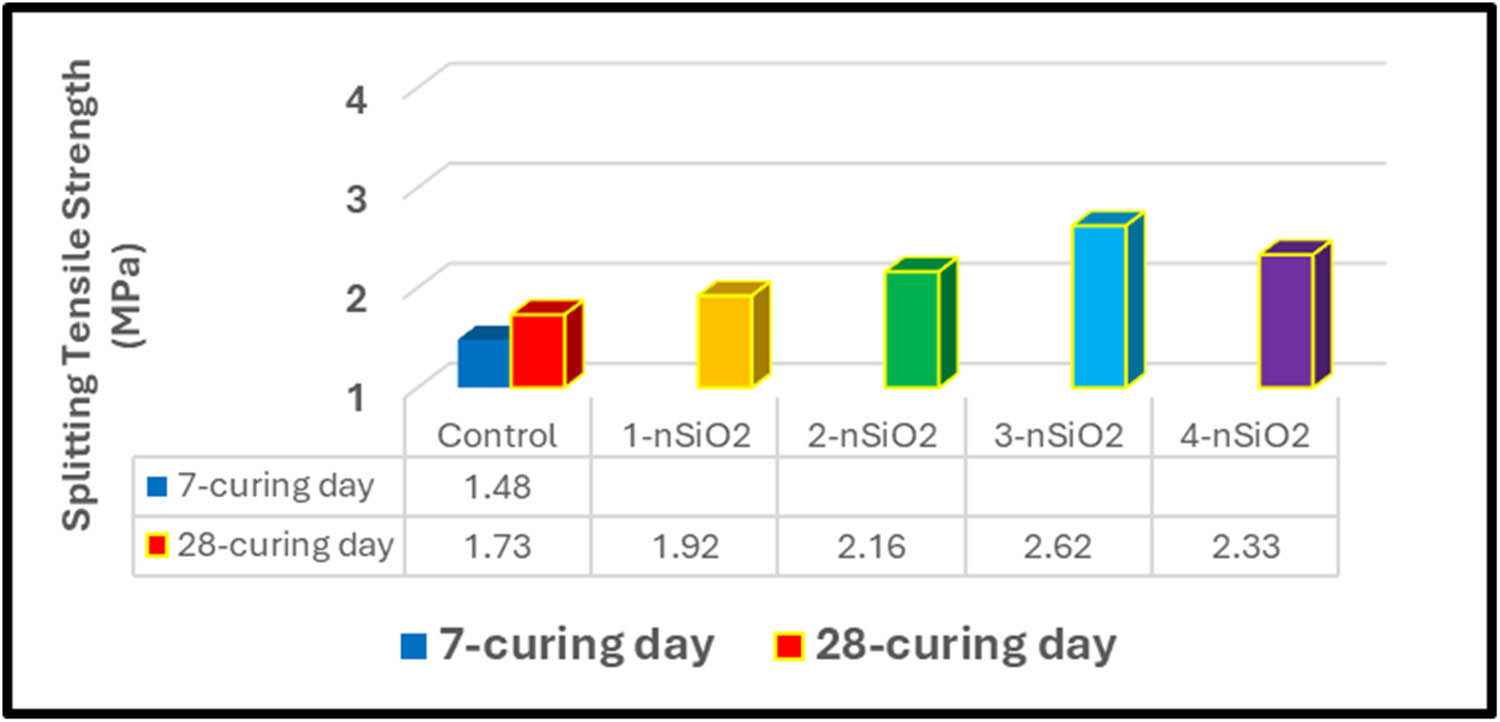

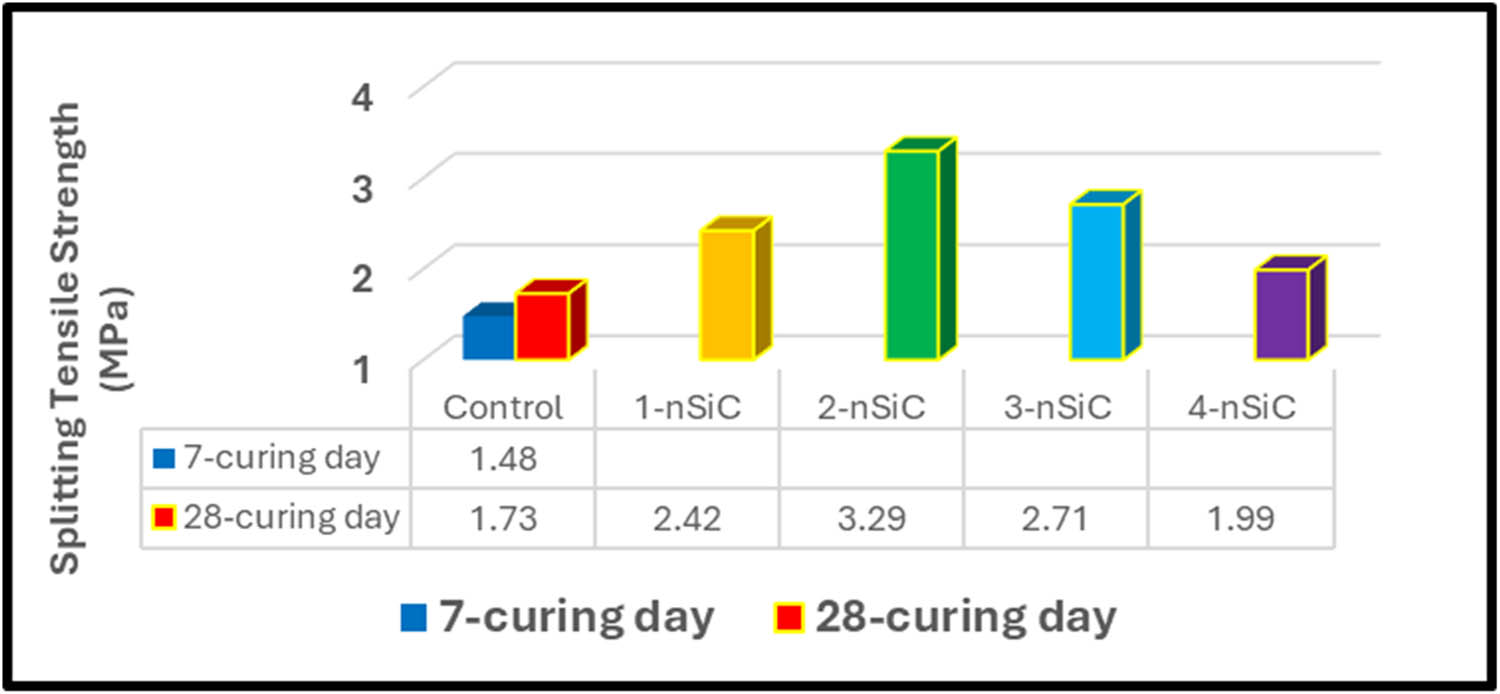

4.5 Splitting tensile strength

The splitting tensile test was performed in this investigation to evaluate the fracture resistance of the geopolymer mortar, following the ASTM C496 [20] standard. Following the curing procedure, cylindrical mortar specimens of 50 mm × 100 mm were made and examined. While the geopolymer mortar exhibits excellent performance under compressive loads, it is also crucial to evaluate its tensile properties as they determine its resistance to cracking. The splitting tensile strength results for all geopolymer mixtures are shown in Figures 14 and 15. These results exhibited a similar trend to the flexural test, confirming the previous findings that nano-SiC outperformed nano-SiO2 in terms of enhancing geopolymer mortar’s fracture resistance [21].

Splitting tensile strength values of the geopolymer at various weight fractions of nano-SiO2.

Splitting tensile strength values of the geopolymer at various weight fractions of nano-SiC.

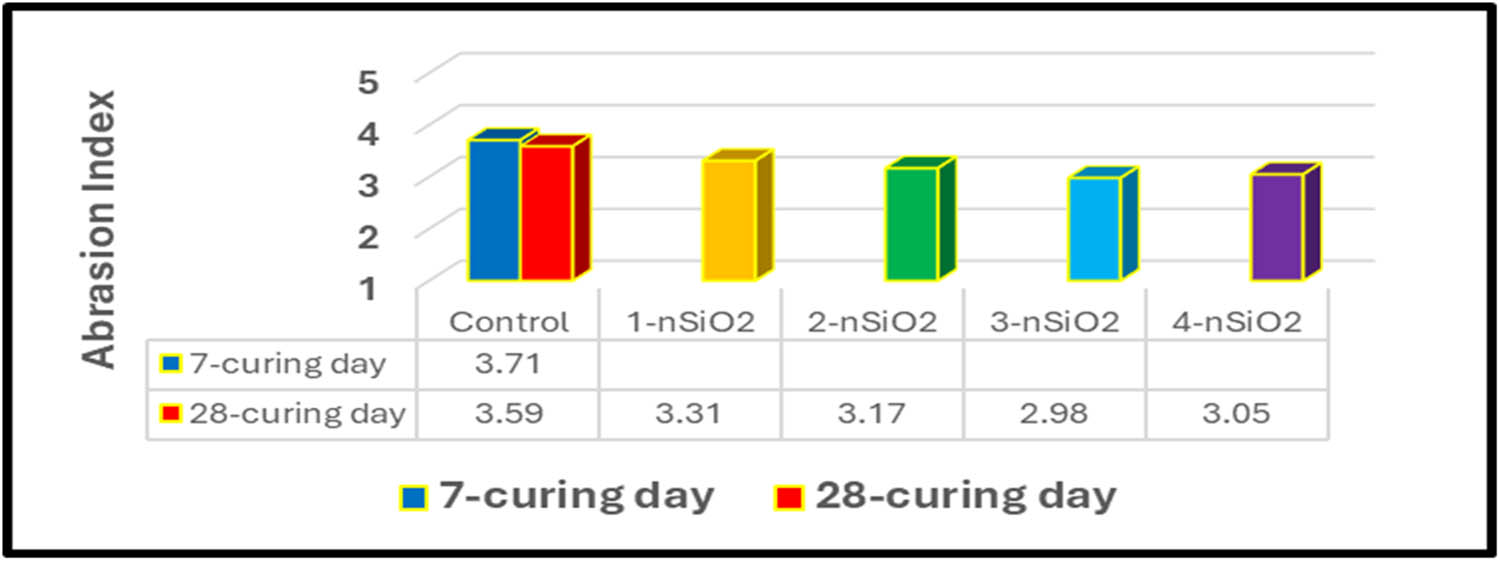

4.6 Abrasion resistance

The experiment was carried out following the British standard EN-1338:2003 [22]. The procedure involved subjecting the top surface of the samples to controlled abrasion using fused alumina. For the abrasion, a large steel wheel of 200 mm in diameter and 70 mm in breadth was employed. Its Brinell hardness ranged from 203HB to 245HB. A minimum of 100 mm × 100 mm × 70 mm should be the size of the test specimens. The abrasion index, which quantifies the abrasion resistance, was calculated using the following equation:

where WL represents the weight loss, and WI represents the initial weight of the sample.

The impact of nanoparticles on the synthesized geopolymer’s resistance to wear is shown in Figures 16 and 17. Compared to the effect of nano-SiO2, the results show that the addition of nano-SiC has a significant impact on the wearing resistance values. This result may be ascribed to the high hardness and stiffness of nanoparticles, which are interconnected reliably to the geopolymer framework, bringing about a high interfacial region between the geopolymer matrix and nano-SiC particles that leads to impeding mortar abrasion [23].

Abrasion index values of the geopolymer at weight fractions of various nano-SiO2.

Abrasion index values of the geopolymer at various weight fractions of nano-SiC.

Also, the nanoparticles enhance abrasion resistance by improving the microstructure, strengthening the interfacial bonding, and reducing the friction due to the smooth and hard surfaces of these particles (e.g., SiC). Moreover, nanoparticles act as crack arrestors within the geopolymer matrix. When microcracks form due to abrasive forces, the nanoparticles can bridge these cracks, preventing them from propagating further. This crack-bridging mechanism enhances the toughness and durability of the material, making it more resistant to abrasion. It was also noticed that there is a similar behavior as in the rest of the properties, where the wear resistance value decreases gradually at high percentages of nanomaterials added and for the same reasons that were previously explained.

5 Conclusions

A key element in enhancing the characteristics of geopolymer mortar is the curing process parameters, such as temperature and duration.

The enhancement in geopolymer’s performance depends principally on the role of the nanoparticles in the geopolymerization process, their homogeneous distribution within the geopolymer structure, and their ability to impede the movement of the cracks and the growth of granules.

The addition of nanoparticles plays a vital role in improving the mechanical properties in different ways. Nano-SiO2 had the greatest effect on improving the compressive strength and density by increasing the degree of silicate ions dissolved in the alkaline activator, producing more N–A–S–H gel responsible for strength. Instead, nano-SiC enhances the flexural and splitting strength through its role in hindering the emergence and movement of cracks.

The reinforcement mechanism depends on the type and effectiveness of the nanoparticles. Silica is a reactive powder that contributes to the geopolymerization process and improves the strength, while silicon carbide does not contribute to the polymerization process because it is inert with high hardness and strength, dispersed within a structure that contributes to hindering the formation and movement of cracks.

The optimal dosages of nano-SiO2 and nano-SiC in geopolymer composites are determined by their respective roles in the geopolymerization process, dispersion characteristics, and their impact on the mechanical properties and workability. Nano-SiO2 at 3% maximizes geopolymerization and microstructure refinement, while nano-SiC at 1–2% provides the best balance of mechanical reinforcement without causing agglomeration or excessive brittleness.

The addition of nanoparticles enhanced the abrasion resistance of the geopolymer mortar, with a noticeable influence of nano-SiC on the wear resistance values compared to nano-SiO2.

Nanoparticles tend to agglomerate due to their high surface energy, which can negatively affect the homogeneity and performance of the composite, in addition to the difficulty of achieving uniform dispersion in large-scale production.

This study presented high specification building materials that can be used in construction and infrastructure, fire-resistant materials, and the oil and gas industry.

Acknowledgments

The authors would like to gratefully thank Mustansiriyah University, https://uomustansiriyah.edu.iq/Baghdad, Iraq, for supporting this work.

-

Funding information: The authors state that no funding was involved.

-

Author contributions: Hamza M. Kamal designed the study. Hamza M. Kamal, Mohammed J. Kadhim, and Layla M. Hasan performed the experiments. Mohammed J. Kadhim analyzed the data. Hamza M. Kamal and Layla M. Hasan wrote the paper. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article.

References

[1] Pan HH, Wang C-K, Tia M, Su Y-M. Influence of water-to-cement ratio on piezoelectric properties of cement-based composites containing PZT particles. Constr Build Mater. April 2020;239:117858.10.1016/j.conbuildmat.2019.117858Search in Google Scholar

[2] Sumesh M, Johnson Alengaram U, Jumaat MZ, Mo KH, Alnahhal MF. Incorporation of nano-materials in cement composite and geopolymer based paste and mortar – A review. Constr Build Mater. Sept 2017;148:62–84.Search in Google Scholar

[3] Singh NB, Saxena SK, Kumar M. Effect of nanomaterials on the properties of geopolymer mortars and concrete. Mater Today: Proc. 2018;5(3, Part 1):9035–40.10.1016/j.matpr.2017.10.018Search in Google Scholar

[4] Rathinam K, Sakthivel S, Vigneshwaran SP, Vinayagamoorthy M, Naveen Kumar U. Properties of nano silica modified cement less geopolymer composite mortar using fly ash and GGBS. Mater Today: Proc. 2022;62(Part 2):535–42.10.1016/j.matpr.2022.03.589Search in Google Scholar

[5] Coffetti D, Crotti E, Coppola L. Long-term properties of self-cleaning alkali-activated slag-based mortars with titanium dioxide nanoparticles. Constr Build Mater. Aug 2023;392:131976.10.1016/j.conbuildmat.2023.131976Search in Google Scholar

[6] Maiti M, Sarkar M, Maiti S, Malik MA, Xu S. Modification of geopolymer with size-controlled TiO2 nanoparticle for enhanced durability and catalytic dye degradation under UV light. J Clean Prod. May 2020;255:120183.10.1016/j.jclepro.2020.120183Search in Google Scholar

[7] Phokha S, Boonserm K, Chirawatkul P, Chanlek N, Kidkhunthod P, Sata V, et al. Investigation of the magnetic and mechanical performance of fly ash Geopolymer/BaFe12O19 nanocomposites. Radiat Phys Chem. Aug 2023;209:110995.10.1016/j.radphyschem.2023.110995Search in Google Scholar

[8] Dişçi E, Polat R. The influence of nano-CaO and nano-Al2O3 and curing conditions on perlite-based geopolymer concrete produced by the one-part mixing method. Constr Build Mater. Sept 2022;346:128484.10.1016/j.conbuildmat.2022.128484Search in Google Scholar

[9] Janowska-Renkas E, Zdrojek M, Kozioł M, Kaliciak-Kownacka A. Effect of composition of geopolymer composites containing fly ash and waste glass powder on their durability and resistivity demonstrated in presence of a nanocarbon additive in a form of graphene. Measurement. April 2023;211:112616.10.1016/j.measurement.2023.112616Search in Google Scholar

[10] Tang ZQ, Sui H, de Souza FB, Sagoe-Crentsil K, Duan W. Silane-modified graphene oxide in geopolymer: Reaction kinetics, microstructure, and mechanical performance. Cem Concr Compos. May 2023;139:104997.10.1016/j.cemconcomp.2023.104997Search in Google Scholar

[11] Tanyildizi H, Seloglu M, Coskun A. The effect of nano zinc oxide on freeze-thaw resistance of 3D-printed geopolymer mortars. J Build Eng. Nov 2024;96:110431.10.1016/j.jobe.2024.110431Search in Google Scholar

[12] Hashemi A, Mousavi SS, Nazarpour H, Dehestan M. Effect of nano-SiO2 and sulfate solutions curing on bond strength of GGBFS-based geopolymer repairing mortar. Constr Build Mater. July 2024;435:136778.10.1016/j.conbuildmat.2024.136778Search in Google Scholar

[13] ASTM C618. Standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. Designation: C618 – 22.Search in Google Scholar

[14] Iraqi Specifications No. (45), 1984 for aggregates of natural resources used for concrete and construction.Search in Google Scholar

[15] ASTM C 109/C 109M – 07. Standard test method for compressive strength of hydraulic cement mortars (Designation: C 109/C 109M – 07, 2010).Search in Google Scholar

[16] Arpitha BJ, Parthasarathy P. Effect of nano-alumina and graphene oxide on the behavior of geopolymer composites: A state of the art of review. Mater Today: Proc. April 2023.10.1016/j.matpr.2023.03.708Search in Google Scholar

[17] Ahmed HU, Mohammed AA, Mohammed AS. The role of nanomaterials in geopolymer concrete composites: A state-of-the-art review. J Build Eng. May 2022;49:104062.10.1016/j.jobe.2022.104062Search in Google Scholar

[18] Samuvel Raj R, Prince Arulraj G, Anand N, Kanagaraj B, Lubloy E, Naser MZ. Nanomaterials in geopolymer composites: A review. Dev Built Environ. March 2023;13:100114.10.1016/j.dibe.2022.100114Search in Google Scholar

[19] ASTM C 348 – 18. Standard test method for flexural strength of hydraulic-cement mortars. (Designation: C 348 – 18, 2010).Search in Google Scholar

[20] ASTM C496-96. Standard test method for splitting tensile strength of cylindrical concrete specimens. Designation: C496/C496M.Search in Google Scholar

[21] Rashad AM. Effect of nanoparticles on the properties of geopolymer materials. Mag Concr Res. March 2019;71(24):1283–301.10.1680/jmacr.18.00289Search in Google Scholar

[22] BS EN 1338:2003. Concrete paving blocks. requirements and test methods current. 2003.Search in Google Scholar

[23] Sumesh M, Alengaram UJ, Jumaat MZ, Mo KH, Alnahhal MF. Incorporation of nano-materials in cement composite and geopolymer based paste and mortar – A review. Constr Build Mater. Sept 2017;148:62–84.10.1016/j.conbuildmat.2017.04.206Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite

Articles in the same Issue

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite