Abstract

This study investigates the mechanical and thermal enhancements achieved in polymer matrix composites (PMCs) through hybrid reinforcement using carbon, glass, and steel fibers. The composites were fabricated via the hand layup technique and evaluated through tensile and flexural testing, as well as thermogravimetric analysis (TGA), differential thermal analysis (DTA), and scanning electron microscopy (SEM). The results demonstrate that hybrid composites exhibit improved microstructural integrity, reduced voids, and enhanced interfacial bonding compared to individual fiber-reinforced composites. TGA and DTA analyses reveal delayed decomposition, lower mass loss rates, and smoother thermal transitions, highlighting superior thermal stability due to hybridization. Mechanical testing shows that carbon–steel composites achieve the highest tensile and flexural strengths, significantly surpassing their single-fiber counterparts. SEM analysis confirms the reduction in defects and superior fiber-matrix interaction in hybrid composites. This study underscores the potential of hybrid reinforcement to optimize the mechanical robustness and thermal efficiency of PMCs, making them ideal for high-performance applications in aerospace, automotive, and structural engineering.

1 Introduction

The integration of glass, carbon, and Kevlar fibers in high GSM laminates has shown promising results in achieving a balance of tensile, flexural, and impact resistance, as well as thermal stability, which are crucial for lightweight applications such as in aerospace structures [1]. The use of interpenetrating polymer networks (IPNs) with glass and carbon fibers further enhances moisture resistance and thermal stability, as demonstrated by the epoxy/vinyl ester reinforced glass fiber IPN laminate, which exhibited notable thermal stability and reduced void presence, crucial for maintaining mechanical integrity under hydrothermal conditions [2]. Additionally, the incorporation of carbon fibers and graphite flakes in polypropylene matrices has been shown to significantly improve heat dissipation and mechanical strength, with the optimal mixing ratio being critical for maximizing these properties [3]. The use of hybrid fibers, such as chopped Kevlar and carbon, in polybenzoxazine resins, has also been effective in enhancing both mechanical and thermal properties, attributed to improved interfacial adhesion and fiber dispersion [4]. Moreover, the introduction of graphene into carbon fiber composites has been shown to significantly boost thermal conductivity and mechanical properties, indicating the potential of graphene as a reinforcing agent in hybrid composites [5]. The addition of carbon fibers to graphene foam/polydimethylsiloxane composites further enhances tensile strength and thermal conductivity, demonstrating the synergistic effects of hybrid reinforcement [6]. Hybrid composites, such as those combining glass, flax, and carbon fibers, have been shown to improve both static and dynamic mechanical properties, highlighting the versatility of hybridization in tailoring composite performance [7]. Finally, the inclusion of graphite in polyoxymethylene copolymer/glass fiber composites has been optimized to enhance tribo-mechanical and thermal properties, underscoring the importance of precise material composition and processing techniques [8]. Collectively, these studies illustrate the multifaceted approach required to enhance the mechanical and thermal properties of polymer matrix composites (PMCs) through hybrid reinforcement, leveraging the unique properties of each fiber type to achieve superior performance. Steel-reinforced polymers (SRP) are gaining traction in civil engineering for their cost-effectiveness in structural repairs, such as bridges and buildings. These composites, made by embedding steel wire fabrics into polymeric matrices, significantly enhance mechanical strength and durability [9,10]. The benefits of SRP include reduced weight, enhanced resistance to environmental degradation, and lower maintenance costs [11,12]. Research shows that SRP can extend the service life of infrastructure while offering a sustainable repair alternative. The mechanical behavior of composite materials has been the subject of numerous studies. Srivastava [13] found sandwich structures suitable for various industries due to their excellent acoustic and thermal insulation properties, high corrosion resistance, and favorable flexural strength-to-weight ratios. Pandu and Sawanti [14] utilized finite element analysis software to analyze glass fiber-reinforced composites under mechanical loading. Studies by Ye et al. [15] and Kiran Kumar et al. [16] delved into the behavior of fiber-reinforced composites during thermo-mechanical processing and discussed carbon composites’ fabrication methods. The mechanical properties under different strain rates of glass fiber-reinforced phenolic and polyester resins were studied by Barré et al. [17], while Ghandour et al. [18] explored the mechanical characteristics of 3D woven polymeric composites. The work of Erkendirci et al. [19] utilizes Scanning Electron Microscopy (SEM) to perform micro-scale damage analysis of alumina-filled carbon-S2-glass (CG) and carbon-Kevlar-49 (CK) reinforced epoxy hybrid composites, identifying failure mechanisms such as fiber breakage, fiber pull-out, and matrix cracking [20]. Thermogravimetric analysis (TGA) is a crucial technique for studying the thermal stability and decomposition kinetics of materials. For instance, it has been applied to genetically different carbon-source materials like coal and biomass to determine de-volatilization kinetic parameters, revealing the influence of ash composition and morphology on thermal behavior [21]. TGA is also used in multistage decomposition studies, such as those involving foamed polyurethane, to model the kinetics of each decomposition stage [22]. Differential thermal analysis (DTA), on the other hand, is employed to assess thermal transitions and reactions in materials. It has been used to characterize dental materials and tooth structures, providing insights into melting ranges and reaction heats [23,24]. In the context of glass, DTA combined with dilatometry has been used to study transformation ranges and overheating phenomena, offering rapid characterization capabilities [25]. These techniques are not only applicable to traditional materials like metals and glasses but also extend to modern composites and polymers, where they help in understanding phase transitions and thermal transport properties [26,27]. The integration of these analytical methods provides a comprehensive understanding of material properties, essential for applications ranging from construction to advanced manufacturing [28]. The main objective of this study is to explore the enhancement of mechanical and thermal properties in PMCs reinforced with carbon, glass, and steel fibers. Through methods like tensile and flexural testing, TGA, DTA, and SEM, the study demonstrates that hybrid composites outperform single fiber composites in strength and stability. These improvements make hybrid composites suitable for high-performance applications in aerospace, automotive, and structural engineering, highlighting their potential for advancing composite material technology.

2 Materials and methods

2.1 Materials

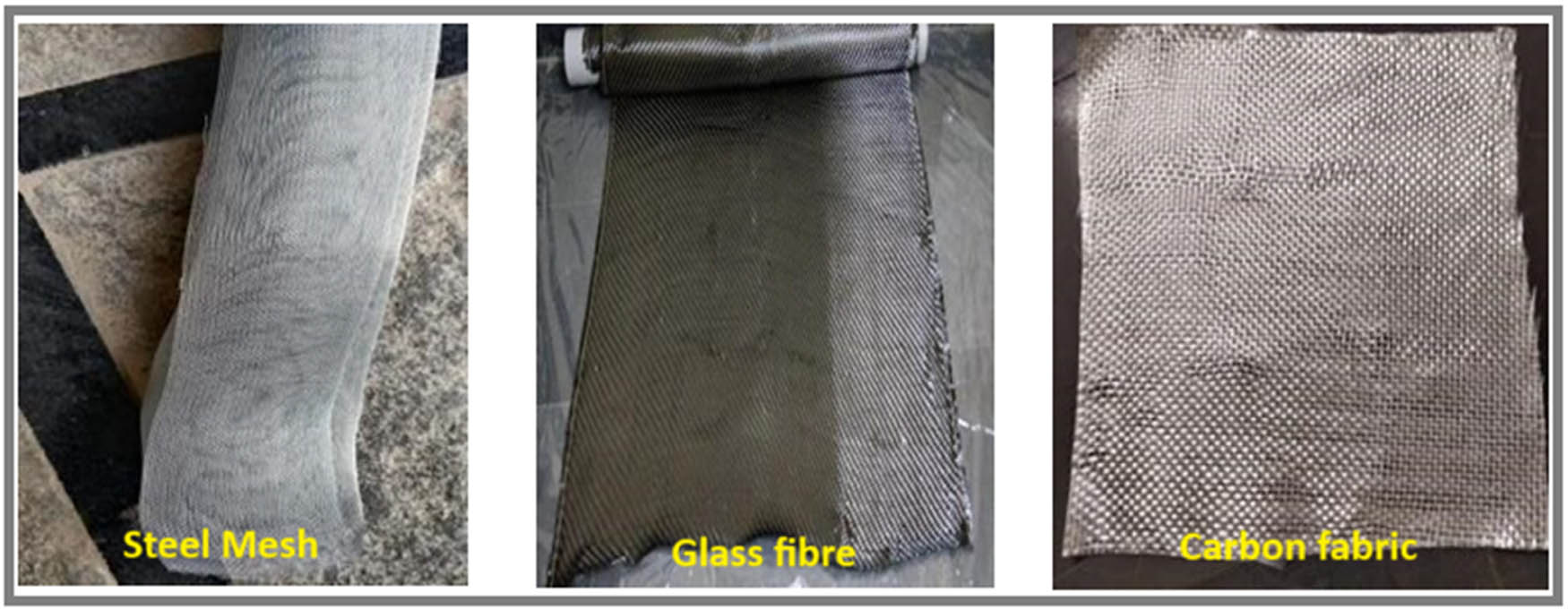

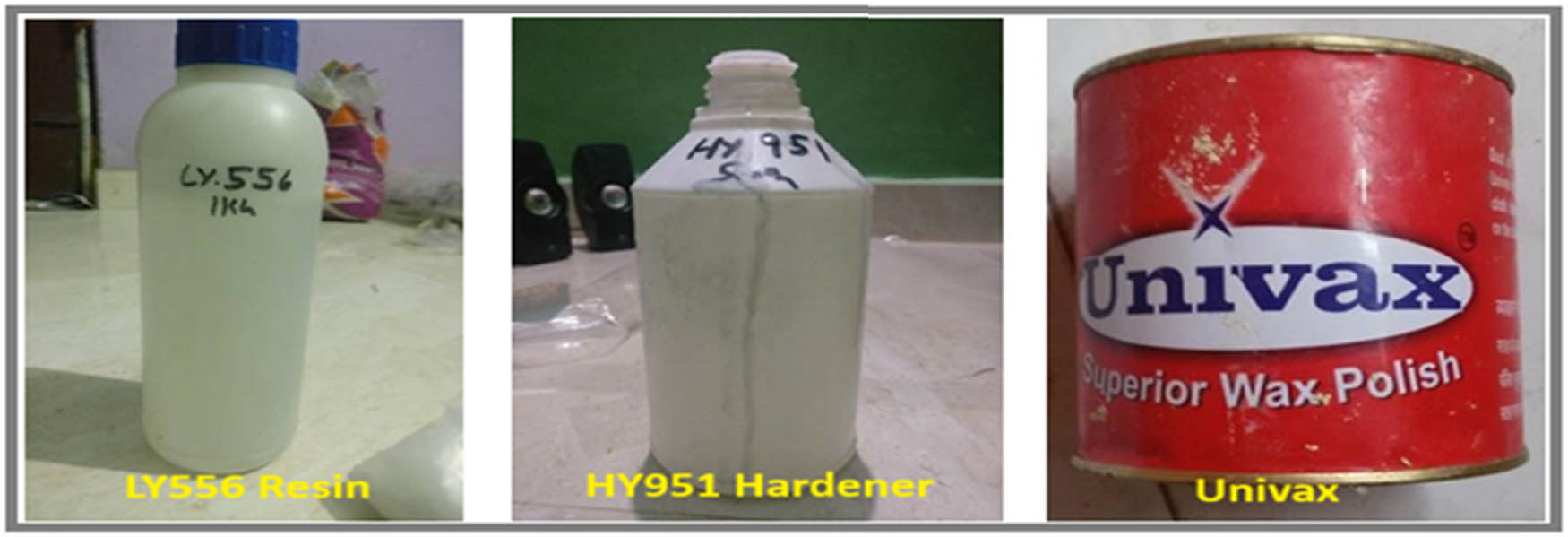

The materials used in this study include steel, carbon, and glass. In the present work, three specimens are prepared for each of carbon, glass, and steel laminates as per ASTM standards. The bi-directional carbon fabric (420 GSM), bi-directional glass fabric (420 GSM), and bi-directional steel mesh are shown in Figure 1. The physical properties of synthetic fiber is shown in Table 1. Whereas the common materials required for preparation of all the specimens (epoxy resin - LY 556; epoxy hardener - HY 951, and wax polish) are shown in Figure 2.

Steel, glass, and carbon fibers.

Physical properties of synthetic fiber

| Property | Glass fiber | Carbon fiber | Steel mesh |

|---|---|---|---|

| Density | 2.5–2.6 g/cm³ | 1.6–1.9 g/cm³ | 7.8–8.0 g/cm³ |

| Tensile strength | 2,000–3,500 MPa | 3,500–5,000 MPa | 500–2,800 MPa |

| Young’s modulus | 70–90 GPa | 230–600 GPa | 190–210 GPa |

| Thermal conductivity | 1–1.4 W/m K | 20–100 W/m K | 40–45 W/m K |

| Coefficient of thermal expansion | 5–10 µm/m°C | −0.1 to 1.5 µm/m°C | 12–13 µm/m°C |

| Specific strength | Moderate | High | Higher |

| Moisture resistance | Good, but can degrade in alkaline environments | Excellent | Moderate to good |

| Electrical conductivity | Non-conductive | Conductive | Conductive |

Resins and hardener used in fabrication.

2.2 Test procedure

The test procedure for evaluating the enhancements in PMCs reinforced with carbon, glass, and steel fibers is as follows. Initially, composites were prepared using the hand layup method, involving the careful layering of fibers and epoxy resin in a treated mold to prevent adherence, followed by degassing with a roller to ensure uniform resin distribution. After curing at room temperature for 24–36 h, the composites were demolded and machined into test specimens conforming to ASTM standards. Mechanical properties were then assessed through tensile and flexural testing using a universal testing machine, with additional thermal and microstructural analyses performed via TGA, DTA, and SEM. These tests collectively aimed to determine the composite materials’ mechanical strengths, thermal stability, and the interfacial bonding of the fibers within the matrix, highlighting the potential of hybrid reinforcement in enhancing the performance of polymer composites for advanced engineering applications.

2.3 Preparation of specimens

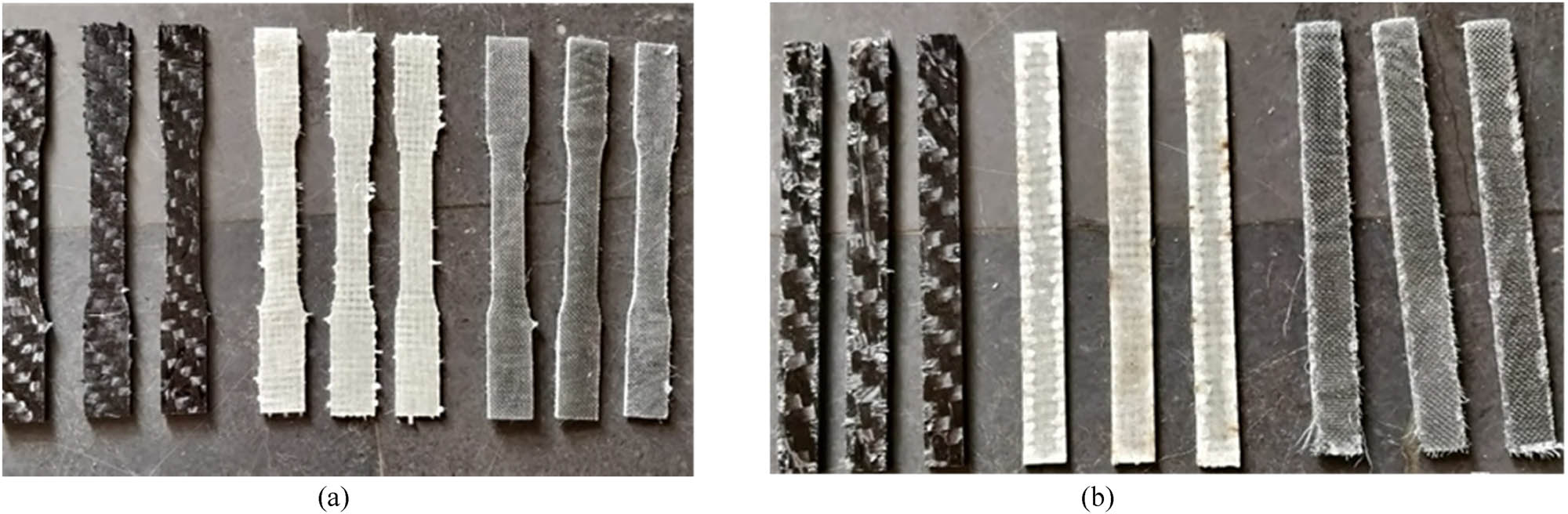

Specimens for the study as shown in Figure 3(a) and (b) were prepared using a controlled hand layup technique. Mold surfaces were first treated with an anti-adhesive gel to facilitate easy demolding. Bi-directional fabrics of carbon, glass, and steel mesh, pre-cut to specified sizes, were layered in the mold. These fabrics were selected for their mechanical properties and compatibility with the epoxy resin system. Epoxy resin, mixed with a hardener in a predetermined ratio, was applied to saturate the fibers thoroughly, ensuring complete penetration and adhesion, critical for forming a cohesive composite. A thin plastic sheet was then placed over each resin-covered layer, and pressure was applied with a roller to eliminate air bubbles and ensure even resin distribution. This process was repeated until the required thickness was achieved, and the assembly was left to cure at room temperature for 24–36 h.

(a) Prepared specimens and (b) specimens as per ASTM standards.

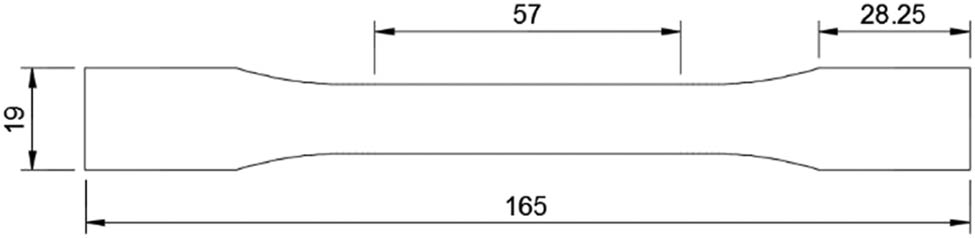

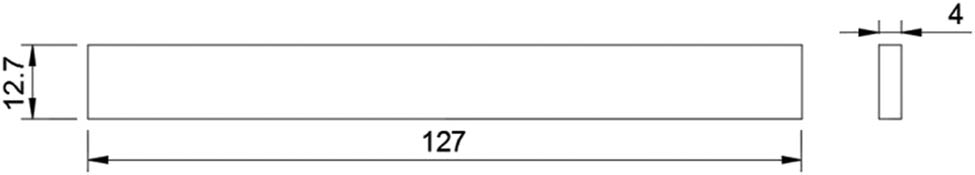

For mechanical testing, tensile specimens were cut according to ASTM D638 standard, typically shaped into a narrow “dog-bone” profile to allow consistent stress application, usually with a gauge length of about 50 mm, width around 10 mm, and total length of 115 mm. Flexural test specimens, prepared to meet another ASTM standard, were rectangular bars approximately 100 mm long, 15 mm wide, and 4 mm thick to accommodate the stresses of three-point or four-point bending tests. These dimensions ensure that the specimens can adequately withstand the applied forces during testing, providing reliable data on the composites’ mechanical properties.

Tensile testing specimen ASTM standard.

2.4 Tensile test

Tensile testing is a destructive testing procedure that provides details on the yielding power, flexibility, and tensile qualities of a metallic object. It establishes the highest level of stretching or elongation that a sample of plastic or composite material can bear before cracking. According to standards such as ASTM D 638, basic tension or flat-sandwich tension testing is commonly used for tensile testing of composite materials. Three specimens are prepared as per ASTM standards, as shown in Figure 4 for tensile strength.

Flexural testing specimen ASTM standard.

2.5 Flexural testing

Flexural testing, or transverse beam testing, evaluates how materials like composites, timber, and polymers respond to bending stress. Conducted on a universal testing device, this test involves placing a sample on two fixed anvils and applying force via one or more loading anvils. The 4-point bend test distributes pressure using two outer anvils, creating a uniform stress zone between them, while the 3-point bend test uses a single central anvil, concentrating stress directly under this point. Different fixtures are used depending on the sample type, as illustrated in the provided schematics for the beam bending test. The universal testing apparatus was used to conduct the Flexural test in this work. The composite material was initially cut in line with ASTM specifications. According to ASTM standards, the specimen is sliced into the testing size, as seen in Figure 5. The universal testing apparatus was used to conduct the Flexural test in this work is shown in Figure 6.

(a) UTM setup and (b) CNC machine setup.

Gold sputter coating process.

2.6 SEM

SEM analysis was conducted to study the microstructural characteristics and surface morphology of the specimens in detail. The investigation utilized a Hitachi S 3500 SEM, operated at an accelerated voltage of 10 kV, to capture high-resolution images of the fractured surfaces. Before analysis, the specimens were prepared by applying a thin layer of gold coating to their surfaces. This coating was essential to prevent the accumulation of electrostatic charges and to enhance the electrical conductivity, thereby ensuring the clarity and accuracy of the microscopic observations (Figure 7).

3 Results and discussion

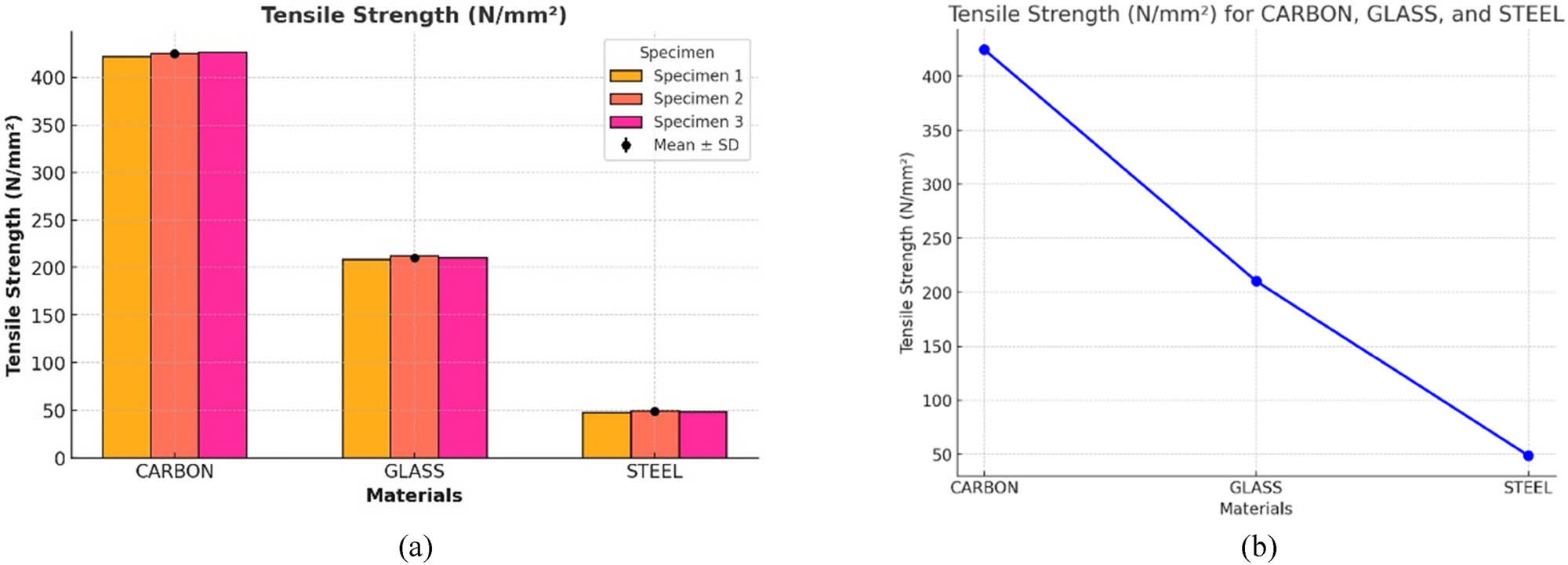

3.1 Tensile testing for carbon, glass, and steel PMC

The tensile strength of the specimens may exhibit slight variations due to manual inconsistencies inherent in the hand layup method. All observed values are presented in Table 2. To account for these variations, three specimens with identical laminates were prepared, and their tensile strengths were measured. Among the three, the highest value was selected as the representative tensile strength. The variations between samples were minimal, not exceeding 5 N/mm2, indicating consistent results across specimens. In terms of tensile strength, the carbon composite demonstrated the highest value, reaching 426.49 N/mm2, significantly outperforming both glass and steel. The comparative analysis, as depicted in Figure 8(a) and (b), highlights the substantial difference in tensile strength among carbon, glass, and steel samples. It is evident from the graph that the carbon matrix composite possesses a markedly superior tensile strength compared to its glass and steel counterparts.

Tensile strength comparative result of carbon, glass, and steel matrix composite material

| Carbon | Glass | Steel | |

|---|---|---|---|

| Specimen 1 | 421.95 | 208.27 | 47.92 |

| Specimen 2 | 425.69 | 212.35 | 49.66 |

| Specimen 3 | 426.49 | 210.14 | 48.56 |

(a) Tensile strength comparative result and (b) average tensile strength of carbon, glass, and steel.

The tensile strength of epoxy composites is highly dependent on the reinforcement material, critical for specific applications. Epoxy–glass composites show tensile strengths around 210 N/mm2, offering a good balance of performance and cost for structural uses, within the typical range of 200–250 N/mm2 as identified by Mohammed et al. [29]. Raajeshkrishna and Chandramohan [30] reported slightly lower strengths, between 150 and 200 N/mm2, for similar composites. Epoxy–carbon composites, highlighted by Selek and Sahin [31], exhibit much higher strengths, approximately 424.7 N/mm2, suitable for high-performance applications like aerospace and automotive due to superior carbon fibers. Conversely, epoxy-steel composites have lower strengths, around 50 N/mm2, mainly due to poor bonding at the steel–epoxy interface, with general strengths between 40 and 60 N/mm2 as noted by Callens et al. [32]. These variations underscore the importance of both material and interfacial properties in designing epoxy-based composites.

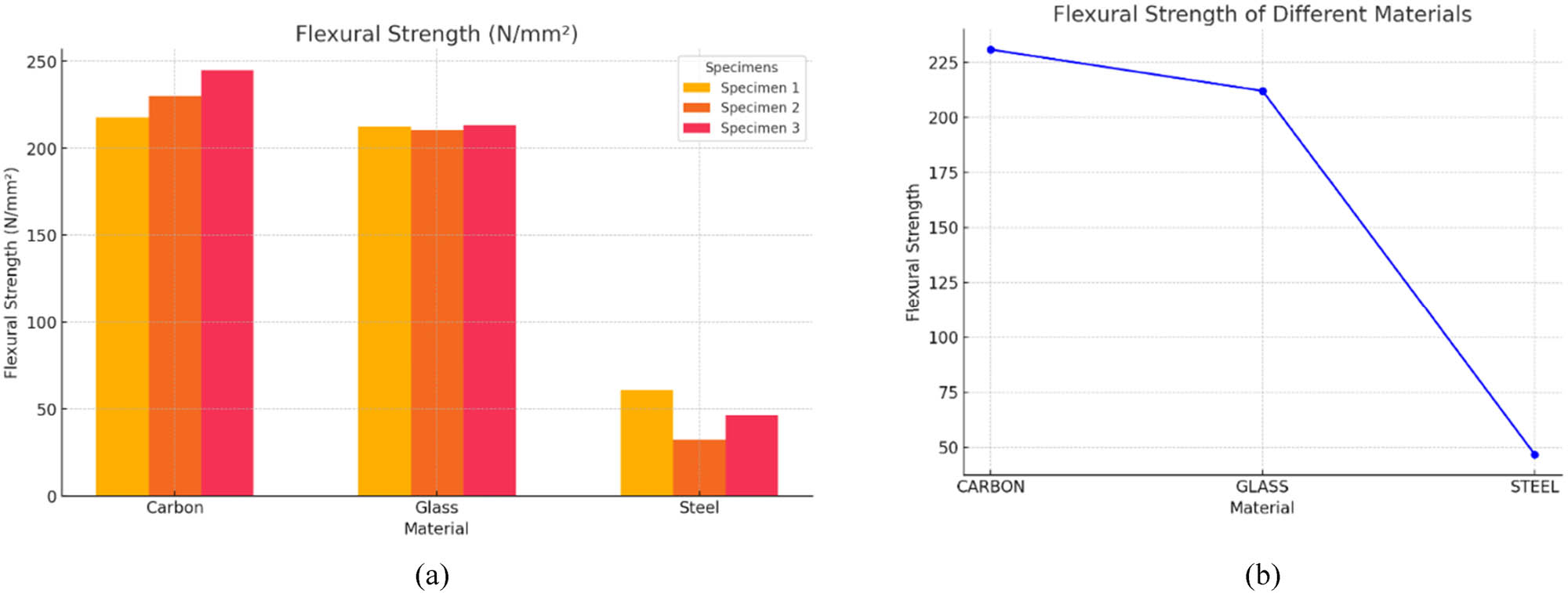

3.2 Flexural testing for carbon, glass, and steel PMC

Table 3 presents the flexural strength for steel, glass, and carbon samples, showing consistent results with variations within 10 N/mm2. The carbon sample exhibits the highest flexural strength at 244.76 N/mm2. Figure 9(a) and (b) graphically illustrates that the carbon matrix composite significantly outperforms the glass and steel composites in flexural strength, with glass showing moderately lower values and steel the least among the three.

Flexural strength comparative result of carbon, glass, and steel matrix composite material

| Carbon | Glass | Steel | |

|---|---|---|---|

| Specimen 1 | 217.86 | 212.54 | 61.07 |

| Specimen 2 | 230 | 210.39 | 32.37 |

| Specimen 3 | 244.76 | 213.32 | 46.5 |

(a) Flexural strength comparative result and (b) average values of flexural strength of carbon, glass, and steel.

The flexural strength of epoxy composites depends on the type of reinforcement used. Epoxy-glass composites typically have flexural strengths around 212 N/mm2, influenced by factors like fiber orientation and resin quality. Epoxy–carbon composites, benefiting from the stiffness of carbon fibers, show higher flexural strengths between 140 and 180 N/mm2. In contrast, epoxy–steel composites exhibit much lower strengths, ranging from 25 to 35 N/mm2, due to poor bonding and a flexibility mismatch with the epoxy matrix, which limits effective stress transfer during bending. This demonstrates steel’s limited role in enhancing flexural properties.

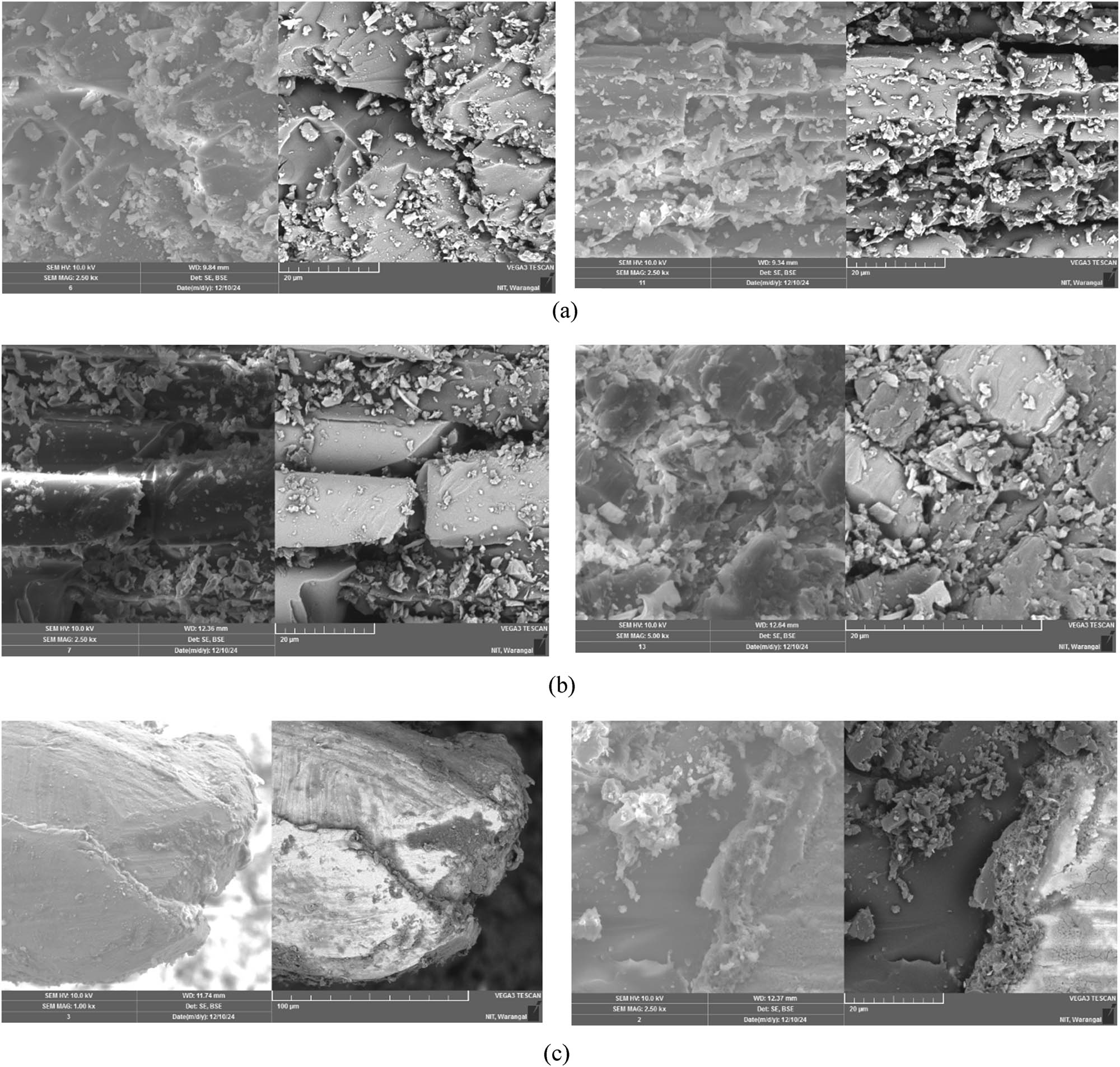

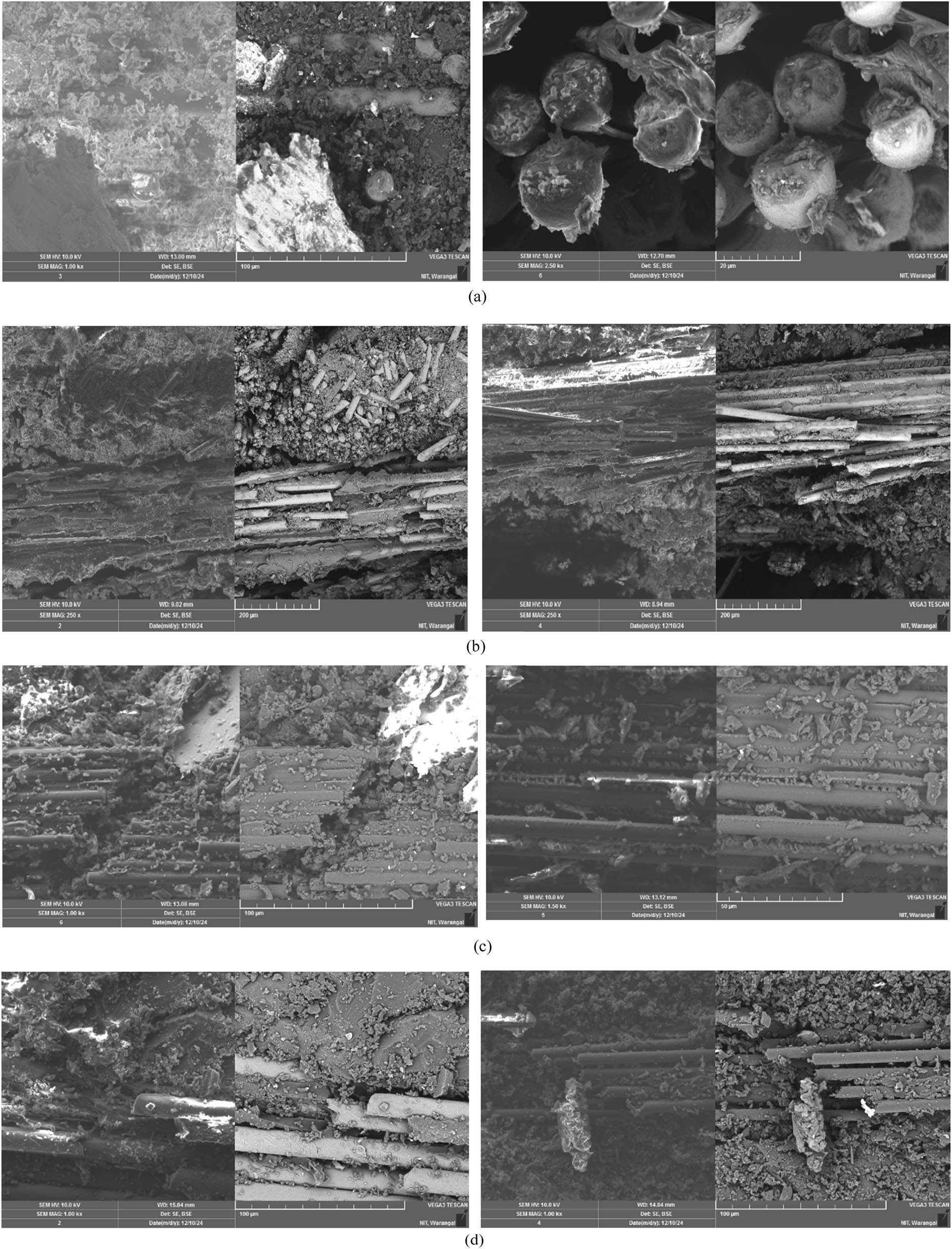

3.3 SEM

Figure 10(a)–(c) illustrates the microstructural morphology of hybrid and non-hybrid carbon, glass, and steel fiber composites at 500× magnification, highlighting structural enhancements from hybridization. SEM analysis shows carbon fiber composites with uniformly treated carbon layers displaying some surface irregularities and isolated voids, indicating weak interlayer bonding. Post-hybridization, these composites exhibit increased compactness and improved interfacial bonding, enhancing mechanical strength and durability. Glass fiber composites initially show sparse fiber coverage over a smooth matrix. Hybridization roughens the matrix surface, improving fiber-matrix bonding and mechanical interlocking. Steel fiber composites start with a smooth, uniform matrix, which becomes rugged and deeply textured after hybridization, indicating stronger matrix-fiber interaction that enhances load transfer and stress resistance. These SEM observations are crucial for understanding the impact of hybridization on the mechanical properties and structural integrity of composites, demonstrating the success of the hybridization process in enhancing material performance.

Cross section morphology of (a) carbon, (b) glass, and (c) steel.

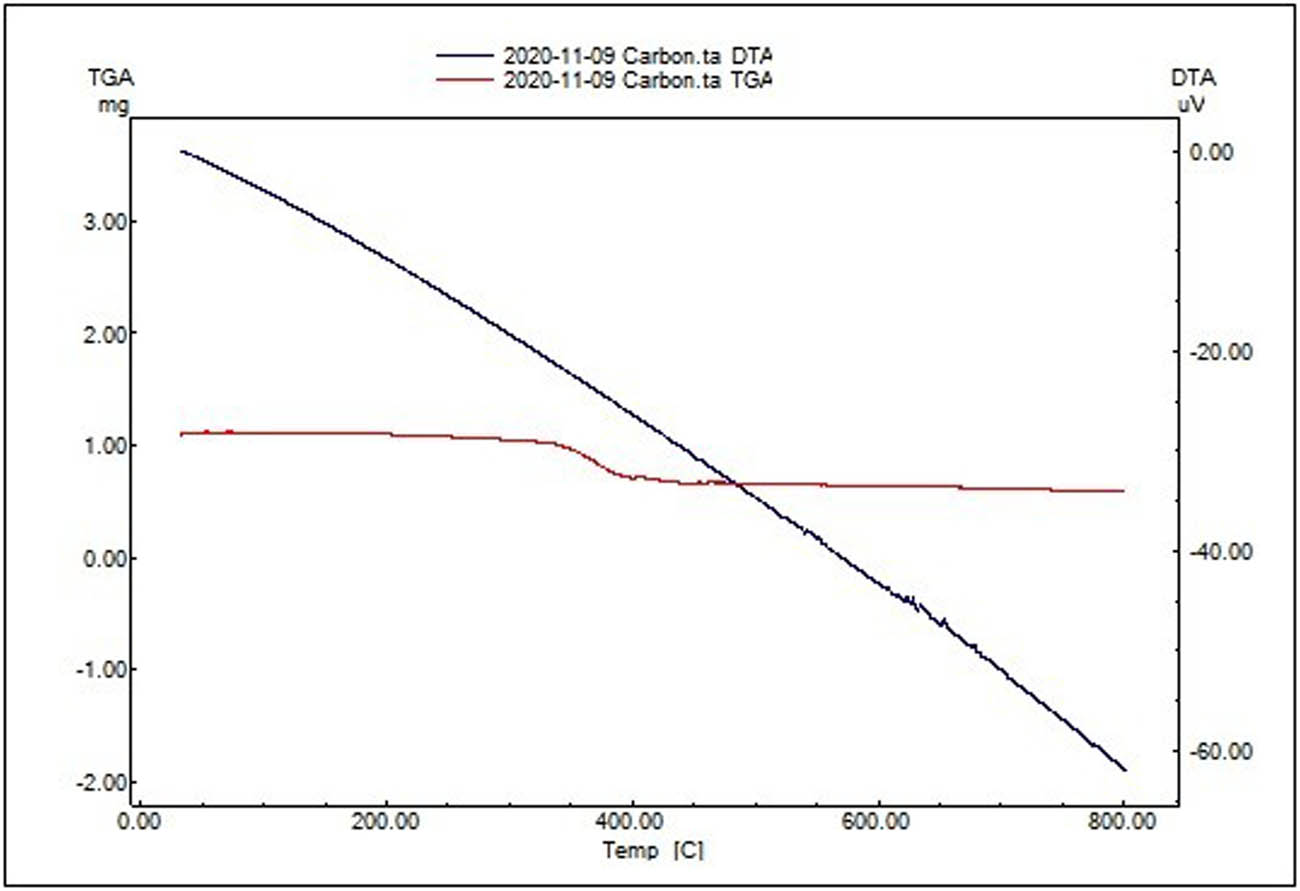

3.4 Thermal analysis of carbon

Figure 11 shows the thermal behavior of a carbon sample using TGA and DTA graphs. The TGA curve, represented by a red line, indicates stable thermal properties with negligible mass loss up to 200°C, suggesting an absence of moisture and volatile compounds. From 200 to 400°C, the mass loss increases, likely due to carbon structure breakdown or partial oxidation. After 400°C, the TGA curve plateaus, indicating the end of significant thermal reactions, possibly leaving behind ash or materials with high heat conductivity. The DTA curve, shown as a blue line, reveals minor endothermic reactions near 200°C and large exothermic peaks between 400 and 600°C, aligning with the mass loss observed in the TGA. Post 600°C, both curves stabilize, indicating no further thermal reactions, suggesting the sample’s stability and detailing its decomposition and oxidation patterns under increased temperatures.

TGA and DTA analysis of carbon.

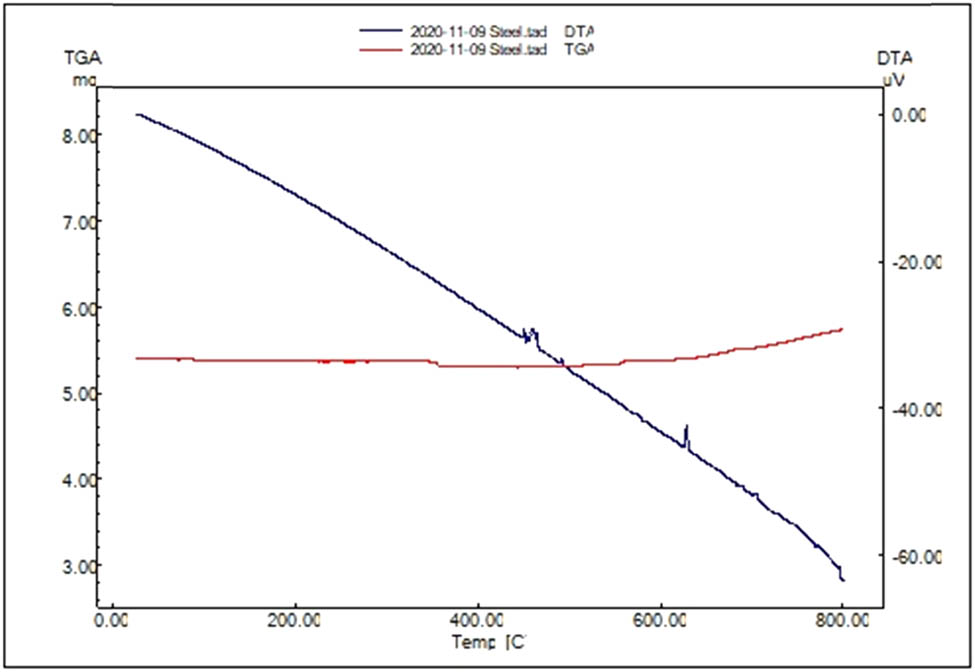

3.5 Thermal analysis of steel

The TGA and DTA in the red and blue lines respectively demonstrate the steel thermal behavior analysis. As shown in Figure 12, the TGA curve exhibits the decreasing mass of steel sample as the temperature augments. Moreover, a decrease in mass is constant across the whole range suggesting the loss is due to heat-induced decomposition of the solid material, while an increase in mass at higher regions can be contributed to the evaporating components present in the steel. Moreover, the DTA curve depicts the shifting of heat during material changes throughout different elevations. Although minor material changes do occur as shown by the blue lines, the absence of sudden shifts over DTA suggests that no significant exothermic or endothermic activity occurs. In essence, these data facilitate a better understanding of steel’s structural integrity in high temperature environments.

TGA and DTA analysis of steel.

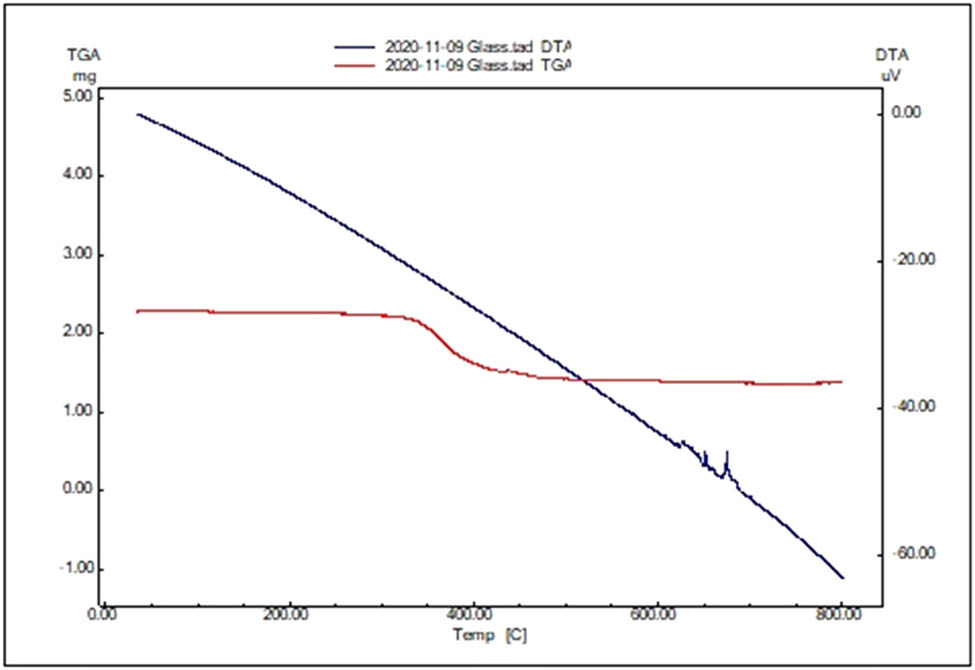

3.6 Thermal analysis of glass

The TGA and DTA of glass are illustrated in Figure 13. The red line is indicative of the TGA curve while the DTA curve is represented by the blue line. The TGA curve depicts gradual mass loss of the glass sample as the temperature increases. This is a progression regress as it depicts thermal decomposition and the release of volatile components. A mass loss phase exhibiting rapid thermal degradation steps in between the temperature range of 400 and 500°C. During the analysis, the DTA curve monitoring heat flow during thermal transitions was observed to be unchanging in the entire temperature range. While there would be minuscule alterations in the DTA curve, none were sharp enough to display any significant exothermic or endothermic reactions which were indicative of DTA peaks. These events depicted a small thermal event and the variations constituted as minute thermal events. The series of events described indicate a consistent thermal behavior of the glass with unswerving stability and also provide understanding regarding the decomposition of the glass and its heat flow during the heating process.

TGA and DTA analysis of glass.

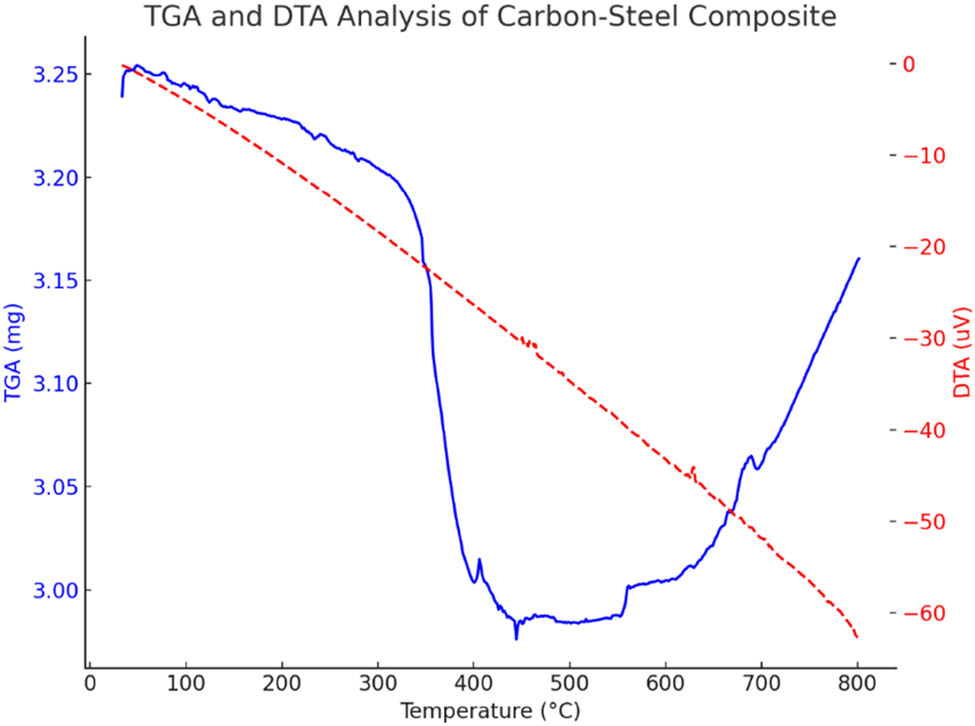

3.7 Thermal analysis of carbon–steel composite

The TGA and DTA analysis of the Carbon–Steel hybrid composite is depicted in Figure 14, which is equally important in tempering as it portrays the effects of hybridization on the thermal behavior of PMCs. The blue TGA curve illustrated shows the relationship between the mass loss and the temperature, in contrast to the red DTA curve which depicts heat flow and thermal transitions. Unlike the decomposition patterns of individual composites, the hybrid material has an improved thermal stability since it begins to decompose at a temperature of more than 250°C. The TGA graph depicts a gradual reduction in weight which signifies the decreased thermal susceptibility mainly caused by the bond between the carbon and steel fibers. Moreover, the integration of the carbon’s heat radiation properties and the steel’s high thermal conductivity resulted in a smoother DTA curve with fewer thermal spikes which in turn improved the heat distribution among the composite materials. These improvements indicate the efficiency of hybridization as a method for increasing the thermal properties of composites for structural and functional materials used in high temperature settings.

TGA and DTA analysis of carbon–steel composite.

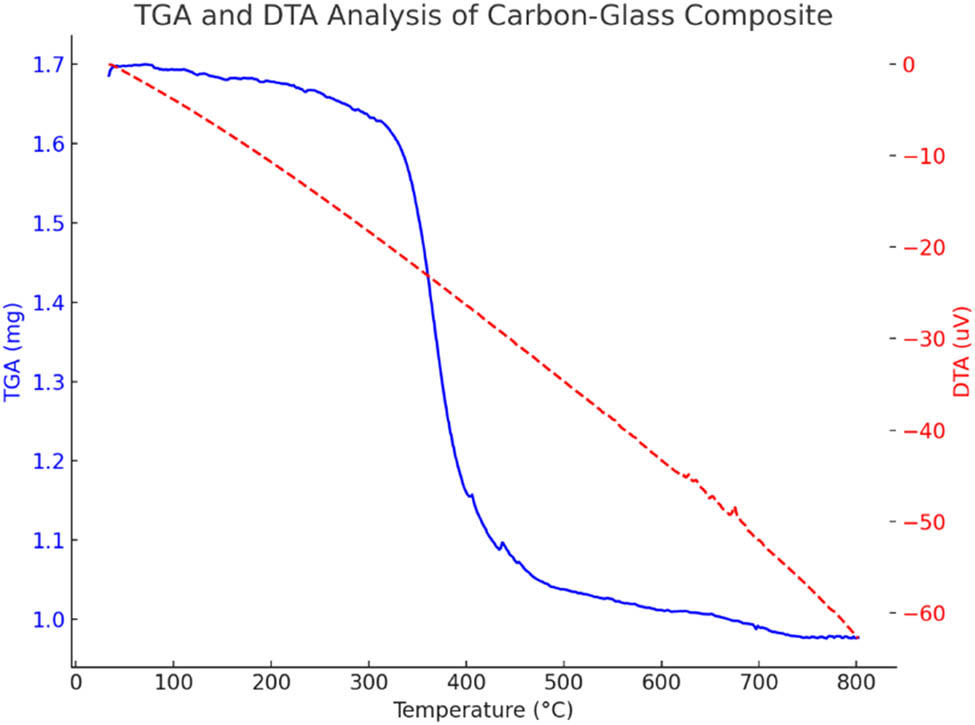

3.8 Thermal analysis of carbon–glass composite

Figure 15 shows TGA and DTA analysis of the carbon–glass composite hybrid, revealing how hybridization affects the thermal behavior of the composite. The TGA curve (blue) describes the thermal loss of the composite when the temperature increases and the DTA curve (red) shows heat flow within some physical transitions. The composite material has higher thermal stability with initial decomposition being seen at above 200°C. The gradual thermal loss that is increasingly shown in the TGA curve indicates reducing tendency of thermal degradation of the composite, which is as a result of the interaction between carbon and glass fibers. This interaction improves the strength of fiber-matrix bond such that it extends the onset of failure of the material. The DTA curve has less erratic behavior meaning that there is less variation in heat flow which means that the composite has higher thermal efficiency and conductivity. The use of carbon fibers helps in the conduction of heat while glass fibers are used to rather hold the structure during higher temperature applications. These combined effects alleviate thermal stress while increasing the performance of the hybrid composite accouterments at elevated temperatures.

TGA and DTA analysis of carbon-glass composite.

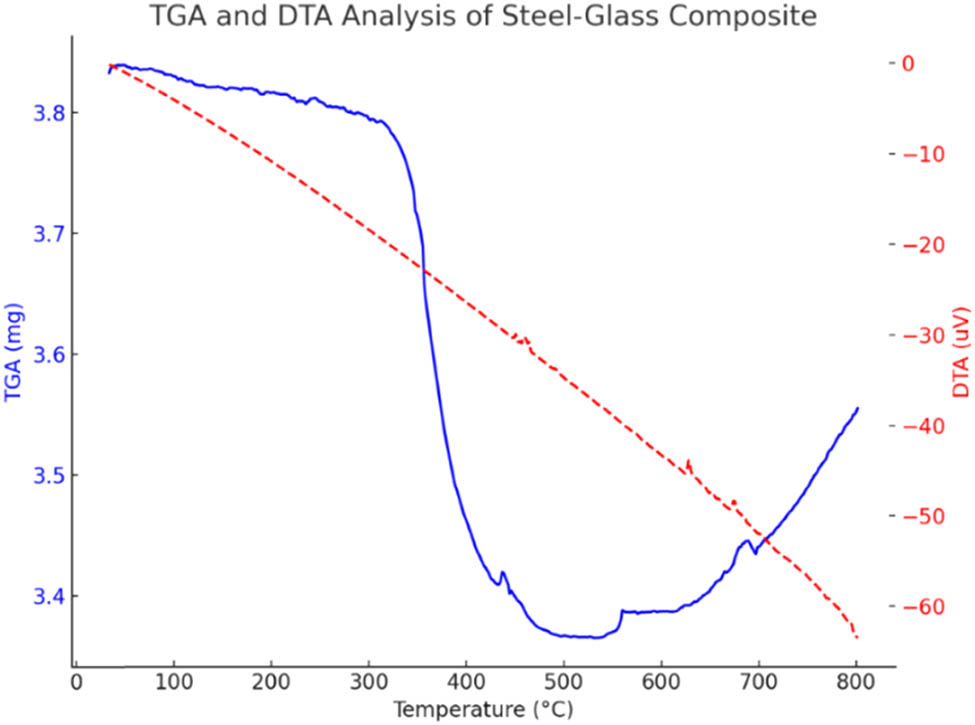

3.9 Thermal analysis of steel–glass composite

The hybridization of the TGA and DTA investigations of the steel–glass hybrid composite is depicted in Figure 16. The Le Chatelier method of thermal equilibrium is used to illustrate how heat flow changes with respect to temperature using a TGA. In other words, TGA focuses on mass loss with rising temperature while DTA looks at heat flow during thermal transitions. It was evident that the pressure of an external force enhanced the thermal stability of the hybrid composite by raising the point of decomposition of each material as compared to the single “composites.” These procedures begin with a TGA curve that looked like a steady decline indicating severe heat injury, the resulting mass loss being ascribed to the enhanced integration between the polymer and the fibers being used. This is further elucidated that as the bond strength increases due to the synergistic effects of bonding steel and glass, the thermal conductivity of steel increases, whereas glass acts as a thermal insulator at an elevated temperature. In addition, the tensile strength of the hybridization enhanced the mechanical properties of the TGA resulting in less thermal stress being induced in the material. Such advancements, it was illustrated, are advantageous as they demonstrate the efficacy of hybridization in enhancing the thermal performance of the steel–glass composite when another enhancement is integrated during the application of high temperature. The overall Summary of TGA results given in Table 4.

TGA and DTA analysis of steel–glass composite.

Summary of TGA results

| Composite type | Initial decomposition temp (°C) | Peak decomposition temp (°C) | Mass loss (%) | Residue (%) at 800°C |

|---|---|---|---|---|

| Carbon | ∼200 | ∼400–600 | ∼40–50 | ∼10–15 |

| Glass | ∼400 | ∼500 | ∼30–40 | ∼20–25 |

| Steel | ∼250 | ∼500 | ∼20–30 | ∼30–40 |

| Carbon–steel | >250 | ∼400–600 | ∼30–40 | ∼20–30 |

| Carbon–glass | >200 | ∼400–500 | ∼25–35 | ∼20–25 |

| Steel–glass | >250 | ∼400–500 | ∼20–30 | ∼30–40 |

3.10 SEM analysis of composites

The contradictions of composites were better explained by homogeneity, according to the SEM analysis as reviewed in Figure 17. The mechanical properties of the glass–steel composite are improved significantly owing to the strong bonding between glass and steel fibers. There are a few micro voids and cracks, most likely created by the processes; however, the general structure is still dense, making it easier to transfer a load from one fiber to another. With the glass–carbon composites, a better dispersion of carbon and glass fiber is observed with less void volume when compared with glass–steel fiber composites. The uniformity has dual benefits of facilitating better stress-distribution and reducing the rate of crack evolution which results in better performance than expected. Lower defect density and densified microstructure observed for the carbon–steel composite proved the merits of hybridization. Structural strength is added by steel fibers while thermal stability is enhanced by the carbon fibers. Fibre-matrix bonding in this composite is strong, and this significant bonding impact lowers interfacial spaces, thus enhancing thermal and mechanical properties. In this sense, SEM analysis complements the discussion of hybridization and its effects on the structural integrity of the composite [33,34].

(a) glass-steel, (b) glass-carbon, (c) carbon-steel (d) glass + carbon + steel cross section morphology.

4 Conclusion

Hybridization of carbon, glass, and steel fibers in PMCs significantly improves mechanical and thermal properties compared to individual fiber composites.

Mechanical performance:

Carbon–steel composites exhibit the highest tensile strength of 426.49 N/mm2 and flexural strength of 244.76 N/mm2, attributed to superior fiber-matrix bonding and reduced interfacial gaps.

Glass–carbon and steel–glass composites show balanced mechanical properties, suitable for applications requiring cost-efficiency and moderate performance.

Thermal stability:

TGA and DTA analyses confirm enhanced thermal stability in hybrid composites, with delayed decomposition onset and reduced mass loss, ensuring better performance under high-temperature conditions.

The synergistic interaction between fibers improves thermal conductivity, stress distribution, and heat dissipation in hybrid composites.

Microstructural integrity:

SEM analysis highlights the reduction in voids, improved interfacial bonding, and enhanced densification in hybrid composites, resulting in superior load distribution and durability.

Applications:

The enhanced properties of hybrid composites make them ideal candidates for high-performance applications in aerospace, automotive, and structural engineering sectors.

This study establishes hybrid reinforcement as a viable strategy for developing advanced composite materials with optimized mechanical and thermal characteristics.

-

Funding information: Authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article.

References

[1] Ishtiaq S, Saleem MQ, Naveed R, Harris M, Khan SA. Glass–Carbon–Kevlar fiber reinforced hybrid polymer composite (HPC): Part (A) mechanical and thermal characterization for high GSM laminates. Compos Part C: Open Access. 2024;14:100468.10.1016/j.jcomc.2024.100468Search in Google Scholar

[2] Priya KS, Vijaya Kumar KR, Suresh G, Ganesamoorthy R, Vezhavendhan R, Meenakshi CM. Long term accelerated influence on thermo-mechanical properties of glass/carbon fiber reinforced interpenetrating polymer network hybrid composites. J Reinf Plast Compos. 2022;8:07316844221099951.10.1177/07316844221099951Search in Google Scholar

[3] Kim KW, Han W, Kim BJ. Effects of mixing ratio of hybrid carbonaceous fillers on thermal conductivity and mechanical properties of polypropylene matrix composites. Polymers. 2022;14(10):1935.10.3390/polym14101935Search in Google Scholar PubMed PubMed Central

[4] Ghouti HA, Zegaoui A, Derradji M, Cai WA, Wang J, Liu WB, et al. Multifunctional hybrid composites with enhanced mechanical and thermal properties based on polybenzoxazine and chopped kevlar/carbon hybrid fibers. Polymers. 2018;10(12):1308.10.3390/polym10121308Search in Google Scholar PubMed PubMed Central

[5] Wang B, Li N, Cheng S, Hu F, Li G, Guo H, et al. Thermal conductivity and mechanical properties enhancement of CF/PPBESK thermoplastic composites by introducing graphene. Polym Compos. 2022;43(5):2736–45.10.1002/pc.26570Search in Google Scholar

[6] Zhao YH, Zhang YF, Bai SL, Yuan XW. Carbon fibre/graphene foam/polymer composites with enhanced mechanical and thermal properties. Compos Part B: Eng. 2016;94:102–8.10.1016/j.compositesb.2016.03.056Search in Google Scholar

[7] Mabrouk OM, Khair-Eldeen W, Hassanin AH, Hassan MA. Mechanical behavior of hybrid glass-flax-carbon fiber-reinforced polymer composites under static and dynamic loading. Polym Compos. 2024;45(17):16228–43.10.1002/pc.28902Search in Google Scholar

[8] Vikram K, Bhaumik S, Pramanik S. Impact of graphite on tribo-mechanical, structural, and thermal behaviors of polyoxymethylene copolymer/glass fiber hybrid composites via Taguchi optimization. Polym Compos. 2025;46(2):1768–87.10.1002/pc.29072Search in Google Scholar

[9] Amar TA, Kumar A, Yadav DK. A comparative study on the properties of carbon fiber-reinforced polymer composites developed by hand layup and vacuum bagging molding techniques. J Inst Eng India Ser D. 2024;106:1–3. 10.1007/s40033-023-00631-2.Search in Google Scholar

[10] Morampudi P, Namala KK, Gajjela YK, Barath M, Prudhvi G. Review on glass fiber reinforced polymer composites. Mater Today: Proc. 2021;43(1):314–9. 10.1016/j.matpr.2020.11.669.Search in Google Scholar

[11] Ozkan D, Gok MS, Karaoglanli AC. Carbon fiber reinforced polymer (CFRP) composite materials, their characteristic properties, industrial application areas and their machinability. In: Öchsner A, Altenbach H, editors. Engineering design applications III. Advanced structured materials. Vol. 124, Cham: Springer; 2020. 10.1007/978-3-030-39062-4_20.Search in Google Scholar

[12] Sathishkumar TP, Satheeshkumar S, Naveen J. Glass fiber-reinforced polymer composites – a review. J Reinf Plast Compos. 2014;33(13):1258–75. 10.1177/0731684414530790.Search in Google Scholar

[13] Srivastava VK. Impact behavior of sandwich GFRP-foam-GFRP composites. Int J Compos Mater. 2012;2(4):63–6.10.5923/j.cmaterials.20120204.04Search in Google Scholar

[14] Pandu PA, Sawanti DA. Experimental evaluation and analysis of Glass Fiber Reinforced Composite under mechanical loading by using FEA software. Int J Eng Res Technol. 2017;1(10):682–5.Search in Google Scholar

[15] Ye J, Wang Y, Li Z, Saafi M, Jia F, Huang B, et al. Failure analysis of fiber-reinforced composites subjected to coupled thermomechanical loading. Compos Struct. 2020;235:111756.10.1016/j.compstruct.2019.111756Search in Google Scholar

[16] Kiran Kumar N, Kiran BC, Rao BC, Hussain MM. A review on carbon reinforcements in glass fiber polymer matrix composites. In: Narasimham GSVL, Babu AV, Reddy SS, Dhanasekaran R, editors. Innovations in mechanical engineering. Lecture notes in mechanical engineering. Singapore: Springer; 2022. 10.1007/978-981-16-7282-8_46.Search in Google Scholar

[17] Barré S, Chotard T, Benzeggagh ML. Comparative study of strain rate effects on mechanical properties of glass fibre-reinforced thermoset matrix composite. Compos Part A: Appl Sci Manuf. 1996;27(12):1169–81. 10.1016/1359-835X(96)00075-9.Search in Google Scholar

[18] Ghandour AA, Selmy AI, Megahed M, Kabeel AM, Ibrahim A. The influence of glass fiber and copper wire z-binder on the mechanical properties of 3D woven polymeric composites. Fibers Polym. 2024;25:1417–28. 10.1007/s12221-024-00504-9.Search in Google Scholar

[19] Erkendirci ÖF, Avcı A, Dahil L, Kaya K, Kılıçtek S, Sezgin A. Experimental investigation of tensile and impact response of nano-alumina-filled epoxy hybrid composites reinforced with carbon-Kevlar and carbon-glass fabrics. Arab J Sci Eng. 2022;47:16135–48. 10.1007/s13369-022-06848-9.Search in Google Scholar

[20] Jiang L, Wang J, Xiao S, Li Y, Yang L. Dynamic tensile properties of carbon/glass hybrid fibre composites under intermediate strain rates via DIC and SEM technology. Thin-Walled Struct. 2023;190:110986.10.1016/j.tws.2023.110986Search in Google Scholar

[21] Saini R, Barma SD, Rao DS, Basu S, Mahajani SM. Thermo-kinetic study of genetically different carbon-source materials. ACS Omega. 2023;8(41):38704–14.10.1021/acsomega.3c06035Search in Google Scholar PubMed PubMed Central

[22] Mamleev V, Bourbigot S, Le Bras M, Duquesne S, Šesták J. Thermogravimetric analysis of multistage decomposition of materials. Phys Chem Chem Phys. 2000;2(20):4796–803.10.1039/b004357pSearch in Google Scholar

[23] Brauer GM, Termini DJ, Burns CL. Characterization of components of dental materials and components of tooth structure by differential thermal analysis. J Dental Res. 1970;49(1):100–10.10.1177/00220345700490010101Search in Google Scholar PubMed

[24] Lloyd CH. A differential thermal analysis (DTA) for the heats of reaction and temperature rises produced during the setting of tooth coloured restorative materials. J Oral Rehabil. 1984;11(2):111–21.10.1111/j.1365-2842.1984.tb00560.xSearch in Google Scholar PubMed

[25] Heide K, Haft R, Paulik J, Paulik F. Die anwendung des derivatographen zur gleichzeitigen dilatometrischen und differential-thermischen analyse von Gläsern. J Therm Anal. 1972;4:83–7.10.1007/BF02100953Search in Google Scholar

[26] Pratap A, Sharma K. Applications of some thermo-analytical techniques to glasses and polymers. J Therm Anal Calorim. 2012;107(1):171–82.10.1007/s10973-011-1816-ySearch in Google Scholar

[27] Mojumdar S, Sain M, Prasad R, Sun L, Venart J. Selected thermoanalytical methods and their applications from medicine to construction: part I. J Therm Anal Calorim. 2007;90(3):653–62.10.1007/s10973-007-8518-5Search in Google Scholar

[28] Myśliński P, Precht W, Staskiewicz J. Construction of a thermoanalyzer for DTA-TD-TMAG-T measurements on metals up to 1100°C. J Therm Anal. 1989;35:193–7.10.1007/BF01914278Search in Google Scholar

[29] Mohammed R, Badruddin IA, Shaik AS, Kamangar S, Khan AA. Experimental investigation on mechanical characterization of epoxy-E-glass fiber-particulate reinforced hybrid composites. ACS Omega. 2024;9(23):24761–73. 10.1021/acsomega.4c01365. PMID: 38882091; PMCID: PMC11170690.Search in Google Scholar PubMed PubMed Central

[30] Raajeshkrishna CR, Chandramohan P. Effect of reinforcements and processing method on mechanical properties of glass and basalt epoxy composites. SN Appl Sci. 2020;2:959.10.1007/s42452-020-2774-4Search in Google Scholar

[31] Selek S, Sahin Y. Tensile property of carbon reinforced epoxy composites for different directions. The Eurasia Proceedings of Science, Technology, Engineering & Mathematics (EPSTEM). Vol. 26, 2023. p. 135–41.10.55549/epstem.1409414Search in Google Scholar

[32] Callens MG, Gorbatikh L, Verpoest I. Tensile behaviour of ductile steel fibre/epoxy composites. Proceedings of the 15th European Conference on Composite Materials (ECCM); 2012.Search in Google Scholar

[33] Sangkeaw P, Thongchom C, Keawsawasvong S, Prasittisopin L. Mechanical properties and microstructure of cellulose fiber-and synthetic fiber-reinforced high-strength concrete. Arab J Sci Eng. 2025;50(3):2149–68.10.1007/s13369-024-08982-ySearch in Google Scholar

[34] Lawongkerd J, Jongvivatsakul P, Vichai K, Yodprasert K, Pikkuwayo C, Prasittisopin L, et al. Optimizing thermoelectric energy harvesting from concrete surfaces: a comparative study of graphite powder and steel fiber reinforcement. Sustain Resilient Infrastruct. 2025;10:1–4.10.1080/23789689.2025.2452106Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite

Articles in the same Issue

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite