Abstract

This study examines the rheological properties of shear thickening fluid (STF) enhanced by additives such as multi-walled carbon nanotubes (MWCNTs), polyvinylpyrrolidone (PVP), and nano-silica (SiO2) at different mass fraction ratios. The rheological properties of the liquid (MWCNTs–PVP/SiO2–STF) and the effect of the rheological properties of the STF under different plate spacing of the rheometer were investigated. The optimal mass fraction mixing ratio was also studied. The MWCNTs–PVP/SiO2–STF system with different PVP mass fractions was fabricated using ultrasonic technology and the mechanical stirring method. Then, the steady-state rheological test of the MWCNTs–PVP/SiO2–STF system was carried out with the aid of the rheometer facility. Dynamic rheological and temperature sensitivity tests on the MWCNTs–PVP/SiO2–STF system with 0.1 and 0.15% PVP mass fractions were performed. The rheological test results show that the MWCNTs–PVP/SiO2–STF system has a significant shear thickening effect when the PVP mass fraction is increased from 0 to 0.15%. When the PVP mass fraction is 0.1% and the plate spacing is 1 mm, the system exhibits the best shear thickening performance. This is based on the following facts: the viscosity can be achieved as 216.75 Pa s; the maximum energy storage and energy consumption capabilities can be observed. As a result, PVP can significantly enhance the shear thickening performance of the MWCNTs/SiO2–STF system.

1 Introduction

Shear thickening fluid (STF) [1,2,3,4] is a composite material formed by uniformly dispersing micro-nano particles in a dispersion medium. Under normal conditions, it has a certain fluidity, but when external energy forces its shear rate to exceed a certain threshold, the STF viscosity will increase non-linearly and instantaneously and change from a fluid to a hard solid-like state [5,6,7,8]. The system has fast response speed, reversible physical form process, and exhibits excellent energy absorption and energy consumption ability. As a result of its remarkable energy absorption, it is widely used in body armor, engineering shock absorption [9,10,11,12,13,14], and other fields.

At present, some scholars prepare new STF systems by changing the dispersed phase and adding modified additives [15,16,17] to obtain STF with better rheological properties. Wei et al. [18] prepared the MWCNT/SiO2–STF by using the strong adsorption characteristics of multi-walled carbon nanotubes (MWCNTs) on nano-silica (SiO2). They explored the rheological properties of the new STF. Shang Xu et al. [19] studied the effects of polyvinylpyrrolidone (PVP) of different molecular weights on the rheological properties and stability of MWCNTs. His experiment showed that when the molecular weight of PVP is K30, the degree of adhesion on the surface of MWCNTs is higher, which is conducive to the dispersion of MWCNTs. Liu et al. [20] combined triethoxysilane ((3-aminopropyl)triethoxysilane) modified glass fiber with conventional electrolyte to prepare an impact-resistant electrolyte. The electrolyte maintains good electrochemical stability and shear thickening effect when subjected to the action of a large shearing force. Nakonieczna et al. [21] added MWCNTs to the shear thickening solution of modified polypropylene glycol and amorphous silica. The impact test results show that MWCNTs can effectively enhance the impact resistance of the STF. Fu et al. [22] studied the confined compression behavior of STF by using concentrated submicron particles of styrene. The experimental results show that the compressibility of STF begins to decrease when the applied compressive stress is greater than 4 MPa.

PVP [23,24,25,26] is an amphiphilic polymer with a special structure. It can interact both with water and oils. It has film-forming, cohesive, solubilizing effects, and can be used as a polymer surfactant with superior performance. MWCNT [27,28,29,30,31] is a quantum material whose axial dimension is in the order of microns and the radial dimension is in the order of nanometer. It has extremely high composite material reinforcement performance. The combination of the above two materials can greatly change the surface morphology of the composite material, which is useful to improve the shear thickening performance of the composite material. Hashim et al. [32] found that the existence of the Al4C3 phase of the MWCNT/aluminum matrix and the physical conditions of the MWCNT determine the strength of the interface bond. Ijaz Khan et al. [33] studied asymmetrical peristaltic flow conical channels constrained by MWCNTs. Experiments show that the viscosity of nanomaterials depends on the volume fraction and temperature of nanoparticles. Zhuang et al. [34] used nitrogen-doped carbon nanotube carriers to support nickel nanoparticles to make them have the hydrogen oxidizing activity of platinum group metals. Its catalytic performance has been increased by 33 times, and the material has shown great potential in the field of high-performance fuel cell catalysis. Abbasi et al. [35] used TiO2 nanoparticles of different concentrations to attach MWCNTs to explore its rheological properties. The results show that MWCNT–TiO2 exhibits shear thickening behavior. Liu et al. [36] used PVP to modify SiO2 and affected its shear thickening effect by changing the interface effect of nano-SiO2, providing a new method for optimizing SiO2-based STF. Sun et al. [37] used energy spectrometer and other methods to microscopically characterize nano-zirconia (ZrO2), nano-silica (SiO2), and ZrO2/SiO2 powders. And they further explored the rheological properties of ZrO2/SiO2–STF. Li et al. [38] used PVP coating to fill and cover the graphene surface in thermoplastic polyurethane (TPU)/graphene nanomaterials. PVP as a dispersant for TPU/reduced graphene oxide composite materials can effectively enhance the material interface interaction, and the modification effect of PVP coating on the TPU/graphene nanomatrix can increase the stress in the low modulus region. Wang et al. [39] studied the use of PVP to modify the surface of ZnO nanoparticles to improve their interface properties. The experimenters used PVP to coat silicon dioxide on the surface of ZnO, and the two were tightly combined through strong hydrogen bonds to form a continuous thin layer. This new material can effectively reduce the photocatalytic activity and improves its material durability.

To summarize, MWCNTs have excellent catalytic adsorption performance, while PVP has great advantages in the surface modification of materials and in improving the interface properties of composite materials. At present, some scholars have discussed the effect of the two materials on the rheological properties of the STF in the experiment. They did not study whether the two can be used in combination to modify the STF to improve its rheological properties. Therefore, this study will explore the rheological properties of the MWCNTs–PVP/SiO2–STF system. The experiment determines the shear thickening performance of the optimal system under steady-state conditions by testing the MWCNTs–PVP/SiO2–STF system with different mixing ratios. Then, the optimal plate spacing of the STF is selected based on the steady-state conditions of the obtained optimal system under different plate spacings. Based on the above conclusions, the experimental modulus relationship under dynamic conditions characterizes the rheological properties of the MWCNTs–PVP/SiO2–STF system under the optimal plate spacing of the rheometer. Finally, the influence of temperature on the rheological properties of the MWCNTs–PVP/SiO2–STF system was explored.

2 Experimental study

2.1 Materials

Nanosilica powder with an average particle size of 12 nm was purchased from the Chinese Chemical Company Reckitt Benckiser. Polyethylene glycol PEG200 was purchased from Shandong Yousuo Chemical Technology Co., Ltd, China. Its hydroxyl value is 510–623 mg KOH/g, and it is a stable transparent liquid at room temperature. PVP (PVP K30 analytical grade) with a pale yellow powder appearance was purchased from Xilong Science Co., Ltd. MWCNTs with a black powder appearance were purchased from China Hengqiu Nano Reagent Co., Ltd. Its inner diameter is 2–6 nm, outer diameter is 9–18 nm, and length is 3–12 μm.

2.2 STF preparation

Before preparing the MWCNTs–PVP/SiO2–STF system, put the SiO2 particles in a vacuum drying oven for 8 h. During the preparation process, the experiment should maintain a constant temperature water bath environment [40]. First, take 200 mL PEG200 and the corresponding mass of MWCNTs powder into the beaker, and mechanically stir until they become uniform. Second, during the stirring process, SiO2 and PVP powders are gradually added according to the requirements of different mixing ratios of the MWNT–PVP/SiO2–STF system. Then use an ultrasonic oscillator [41] to continuously shake the container until the mixed nanoparticles are uniformly dispersed in the PEG200. Finally, put the configured MWCNTs–PVP/SiO2–STF in a vacuum drying oven at 108°C for 24 h. After taking it out, a stable MWCNTs–PVP/SiO2–STF system can be obtained.

2.3 Rheological test

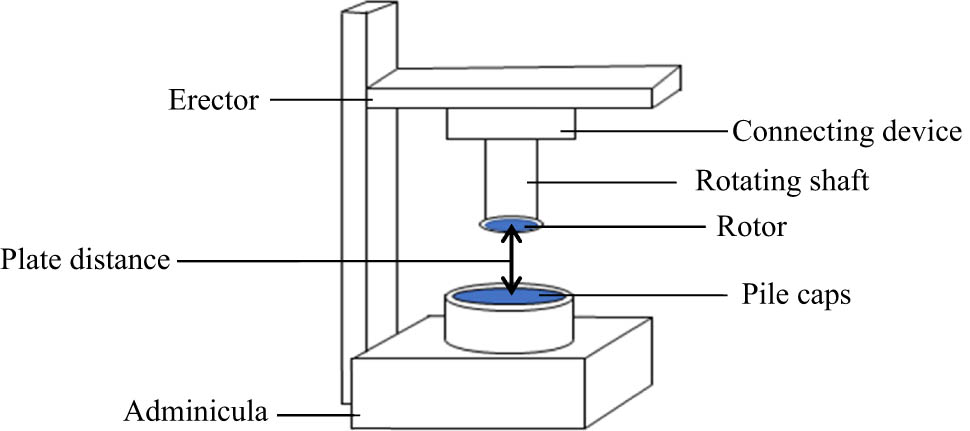

The AR2000 rheometer from the American TA Company (Figure 1) was used to test the steady-state and dynamic flow performance of MWCNTs–PVP/SiO2–STF with different mixing ratios. Each sample was randomly selected from five locations in the corresponding beaker for sampling and testing. The diameter of the plate rotor was 30 mm, and the distance between the plates was 1 mm. The specific tests conducted are as follows: (1) under the conditions of a temperature of 25°C and a shear rate sweep range of 0.1–1,000/s, a steady-state rheological test of MWCNTs/SiO2–STF with different mixing ratios was performed. (2) Under the fixed angular frequency of 80 rad/s and a strain sweep range of 0.1–2,000%, the optimal mix ratio MWCNTs/SiO2–STF was dynamically tested. (3) Under the fixed strain amplitude of 75, 150, 300, and 600% and a frequency sweep range of 0.1–600 rad/s, the optimal mix ratio MWCNTs/SiO2–STF was tested dynamically.

Schematic of rheometer device.

2.4 Temperature sensitivity test

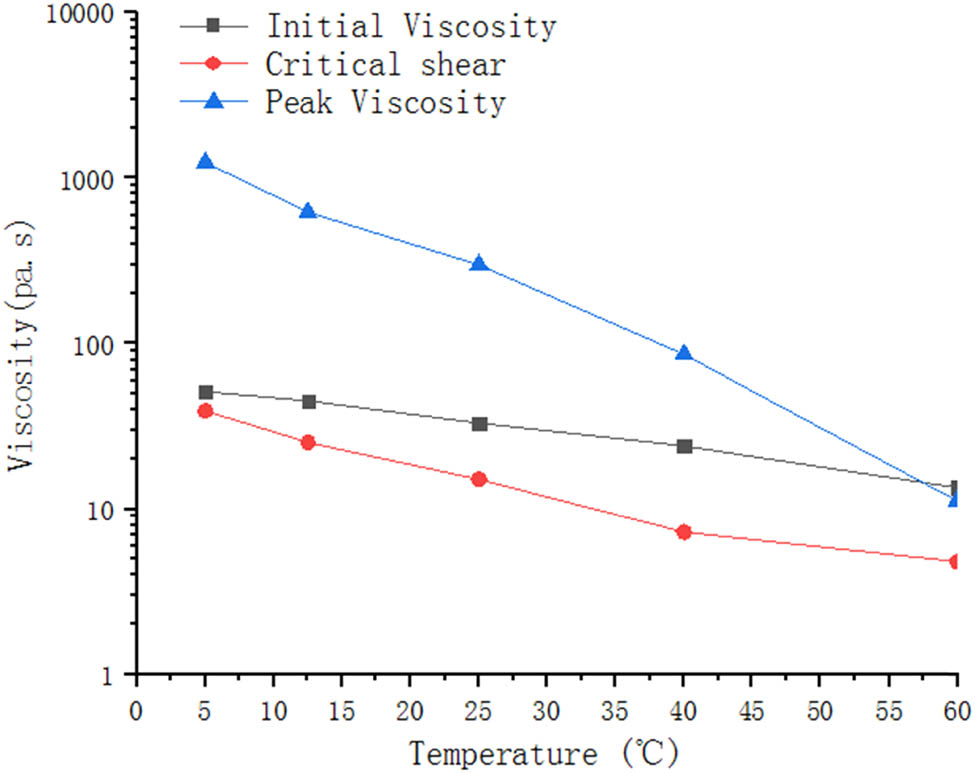

The temperature sensitivity test of the MWCNTs–PVP/SiO2–STF system with a PVP mass fraction of 0.1% was carried out using the AR2000 rheometer of the American TA Company. The diameter of the test plate rotor was 30 mm, and the plate spacing was 1 mm. The specific test is as follows: under temperatures of 5, 12.5, 25, 40, and 60°C and a shear rate scanning range of 0.1–1,000/s, conduct steady-state rheological tests on the shear thickeners with different mixing ratios.

3 Results and discussion

3.1 Steady-state rheological performance

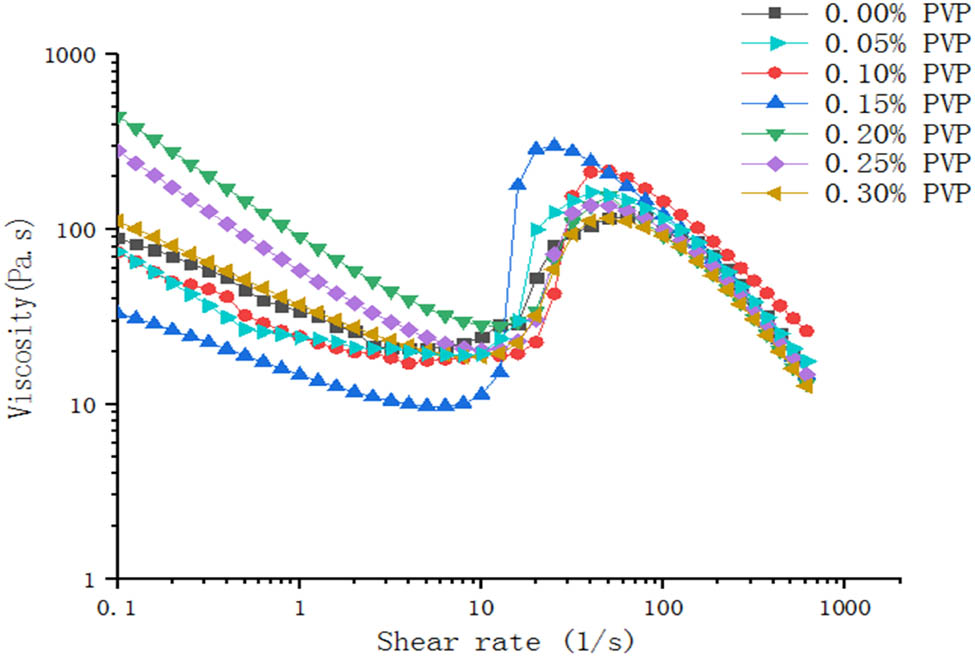

Figure 2 shows the shear viscosity–shear rate change curve of the MWCNTs–PVP/SiO2–STF system with different PVP mass fraction ratios under the shear rate scanning range of 0.1–1,000/s. It can be seen from Figure 2 that when compared with the MWCNTs/SiO2–STF system, the MWCNTs–PVP/SiO2–STF system has good shear thickening performance. Its viscosity peaks are greatly increased, and the critical shear rate is significantly reduced.

The steady-state rheological properties of the MWCNTs–PVP/SiO2–STF system with different mass fraction ratios.

It can also be seen from Figure 2 that with the increase of the PVP mass fraction, the viscosity curve of the system does not show the regularity of consistent changes. Before the mass fraction of PVP reaches 0.15%, the initial viscosity of the system gradually decreases and the peak viscosity gradually increases with the increase of the mass fraction of PVP. The reason is that the MWCNTs–PVP/SiO2–STF system has dispersibility and adhesion to MWCNTs due to PVP. It coats the surface of MWCNTs so that the clustered MWCNTs are separated. In addition, the PVP attached to MWCNTs can form a new type of MWCNTs–PVP particles with a relatively large width and rough surface. The structure of the new particle is flocculent. When external factors increase the shear rate of the system, the new MWCNTs–PVP particles with a flocculent structure are more likely to adsorb a large amount of SiO2 particles. Therefore, a new type of “particle clusters” with a larger number, larger volume, and more fullness can be formed, which hinders the flow of the STF system, resulting in a decrease in the initial viscosity of the system and an increase in the peak viscosity. But when the PVP quality score reaches 0.15%, due to the continuous increase of PVP, the PVP has the same interface effect on both the MWCNTs and the SiO2 particles. Therefore, when external factors increase the shear rate of the system, the different molecular groups covering a large amount of PVP repel each other, and the peak viscosity of the system decreases. With the continuous increase in the PVP mass fraction, the critical shear rate of the MWCNTs–PVP/SiO2–STF system decreased first and then increased. It further shows the process of PVP with different mass fractions adhering to the MWCNTs and SiO2 particles. The priority and effect of PVP on the selection of the two different materials of MWCNTs and SiO2 are verified from the side.

Table 1 of this test shows that the MWCNTs–PVP/SiO2–STF system with a PVP mass fraction of 0.15% has the most obvious shear thickening effect. Compared to the STF without PVP, its peak viscosity increased from 118.993 to 299.554 Pa s, an increase of 151.74%. At the same time, its critical shear rate is reduced from 15.85 to 12.59/s, a decrease of 20.57%. The main reason may be that PVP coats the surface of MWCNTs to form an interface layer, which increases the surface area and roughness of MWCNTs. PVP disperses the gathered MWCNTs, so that the MWCNTs/SiO2–STF system forms a large number of “particle clusters” with uniform and stable dispersion of the system. At the same time, a large number of particle clusters can adsorb more SiO2 particles on the rough MWCNTs surface. As the spacing of the particle clusters becomes smaller, it is easier to form an agglomeration effect to enhance the shear thickening performance of the system. Consider the influence of the parameter range of the peak viscosity rate of the rheological properties of the MWCNTs–PVP/SiO2–STF system. The shear thickening performance of the MWCNTs–PVP/SiO2–STF system with a PVP mass fraction of 0.10% is the most significant. The peak viscosity rate parameter range of the system is 25.63–187.20/s. At the same time, compared to the system without PVP, its peak viscosity increased from 118.993 to 216.750 Pa s, an increase of 82.15%. It can meet the requirements of maintaining excellent energy consumption of the STF in a wide range of speeds.

The rheological characteristic parameters of the MWCNTs–PVP/SiO2–STF system with different mass fractions of PVP

| Percentage composition | Critical shear rate (/s) | Critical viscosity (Pa.s) | Peak viscosity (Pa.s) | Peak rate interval |

|---|---|---|---|---|

| 0.00% MWCNTs–PVP/SiO2–STF | 15.85 | 28.7633 | 118.993 | [25.12, 153.83] |

| 0.05% MWCNTs–PVP/SiO2–STF | 15.85 | 29.8263 | 163.619 | [19.95, 153.83] |

| 0.10% MWCNTs–PVP/SiO2–STF | 25.12 | 22.5848 | 216.750 | [25.63, 187.20] |

| 0.15% MWCNTs–PVP/SiO2–STF | 12.59 | 15.1553 | 299.554 | [15.85, 153.83] |

| 0.20% MWCNTs–PVP/SiO2–STF | 19.95 | 34.1166 | 156.772 | [31.63, 124.81] |

| 0.25% MWCNTs–PVP/SiO2–STF | 19.95 | 30.4075 | 138.161 | [25.12, 153.83] |

| 0.30% MWCNTs–PVP/SiO2–STF | 25.12 | 25.1202 | 115.257 | [31.63, 124.81] |

All modified samples showed obvious shear thinning and shear thickening than MWCNT/SiO2–STF. The reason is that PVP has dispersibility for MWCNTs and can increase its surface roughness. This makes the number of this new type of “particle clusters” far greater than the number of agglomerated MWCNTs. When compared with MWCNT/SiO2–STF, the MWCNTs–PVP/SiO2–STF system has more “particle clusters” and smaller average spacing. Therefore, the critical shear rate of the latter is lower and the peak viscosity is larger, which has an obvious shear thickening effect.

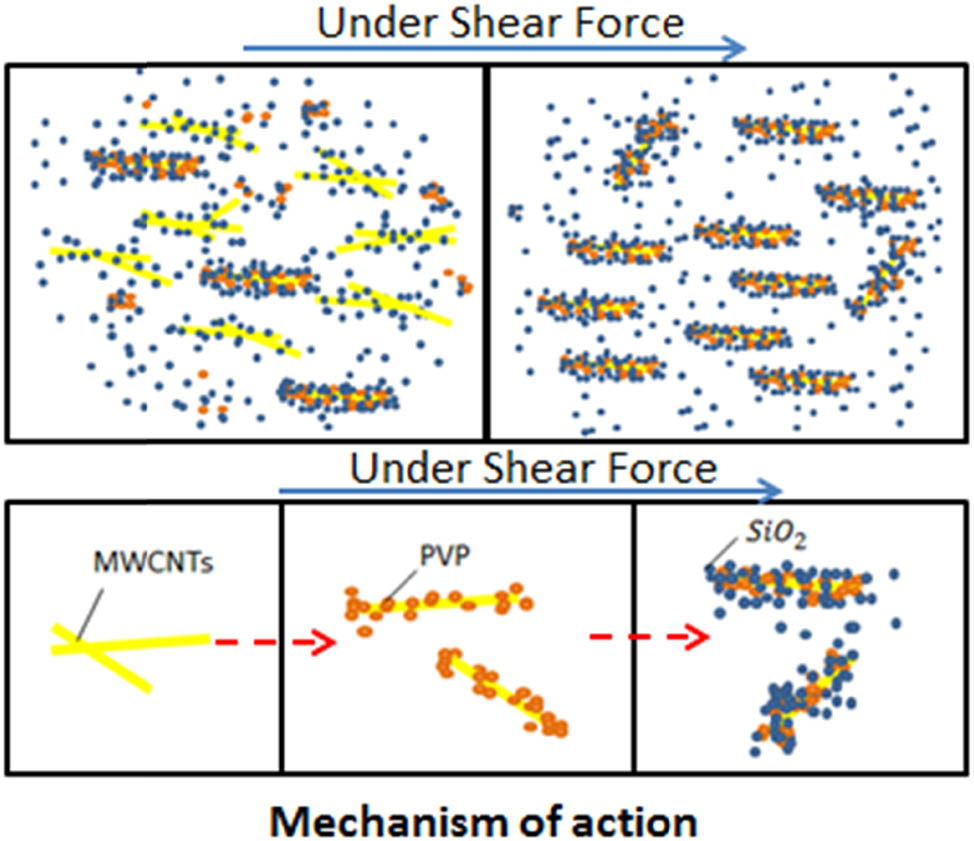

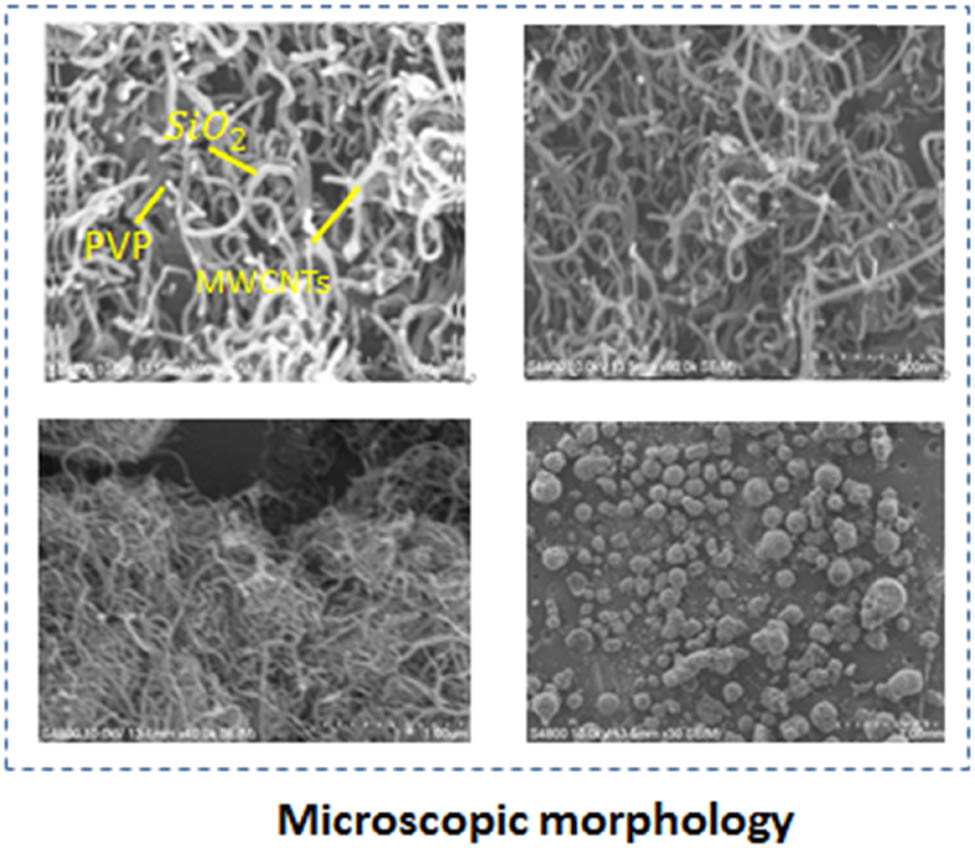

The scanning electron microscopic experiment was carried out on the MWCNTs–PVP/SiO2 particles and the MWCNTs/SiO2 particles (Figure 3 shows the mechanism of action and Figure 4 shows the microscopic morphology). Explore the material composite relationship and the dispersion of nanomaterials from a microscopic point of view. Specific performance: On the one hand, compared to the MWCNTs/SiO2 system in the MWCNTs–PVP/SiO2–STF system, the increase in the PVP content at the beginning can effectively disperse the agglomerated MWCNTs and reduce the initial viscosity. On the other hand, the number and unique structure of the “new particle clusters” hinder the flow of the system under external forces and increase the peak viscosity. Therefore, the new system is superior to the shear thickening performance of the MWCNTs/SiO2 system. When the mass fraction of PVP increases to 0.15%, its peak viscosity significantly increases to 299.554 Pa s. The reason is that after the PVP content is approximately equals to the “critical content,” a large number of new particle clusters are formed. The new type of particle cluster has a flocculent structure with a rough surface, which can act synergistically with SiO2. Although the number of particle clusters increases, the average spacing between the particles is reasonable. This makes the initial viscosity low and the peak viscosity high, showing a strong shear thickening effect. This shows that the system has reached the best mix ratio. After further increasing the PVP mass fraction, the initial viscosity of the MWCNTs–PVP/SiO2–STF system increased sharply and then began to decrease. The reason is that after a large amount of PVP is grafted with MWCNTs, the remaining part of PVP is modified around the SiO2 particles. This results in the formation of a large number of particle clusters, which leads to a sharp increase in the initial viscosity of the fluid. Due to the continuous addition of PVP, the periphery of the two particle clusters contains PVP particles. This increases the molecular force between the clusters of particles. Therefore, the initial and peak viscosities of the fluid have decreased. This also shows once again that the 0.15% sample system has reached the optimal state. Although continuing to increase the PVP content can increase the initial viscosity, the shear thickening performance of the system weakens as the peak viscosity decreases significantly. Therefore, the content of MWCNTs can be increased according to actual demand to control its rheological properties. It can be seen from Figure 2 that compared to the MWCNTs/SiO2 system, the critical shear rate and the peak shear rate of the MWCNTs–PVP/SiO2–STF system have a larger gap, because the structure of the new particle clusters in the MWCNTs–PVP/SiO2–STF system has a strong adsorption effect on SiO2. This makes the shear thickening effect more likely to occur under the action of a shear force. Considering the influence of the shear rate range of the system in actual engineering applications, the comprehensive rheological parameters of the 0.1% PVP sample are more in line with the requirements.

The MWCNTs–PVP/SiO2 formation process.

Scanning electron microscopic imaging of MWCNTs–SiO2 particles.

As the number of “particle clusters” in the MWCNTs–PVP/SiO2–STF system increases and the average spacing decreases, the initial test plate spacing may hinder the formation of new “particle clusters.” This may make the outer layer of MWCNTs–PVP particles unable to effectively adsorb SiO2 particles. As a result, a new type of “particle cluster” of MWCNTs–PVP/SiO2–STF of suitable size cannot be formed, which weakens the effect of the “particle cluster.” This will affect the accuracy of the experimental results. Therefore, based on the above experimental conclusions, the PVP with the optimal mix ratio was selected for the steady-state rheological tests under different plate spacings.

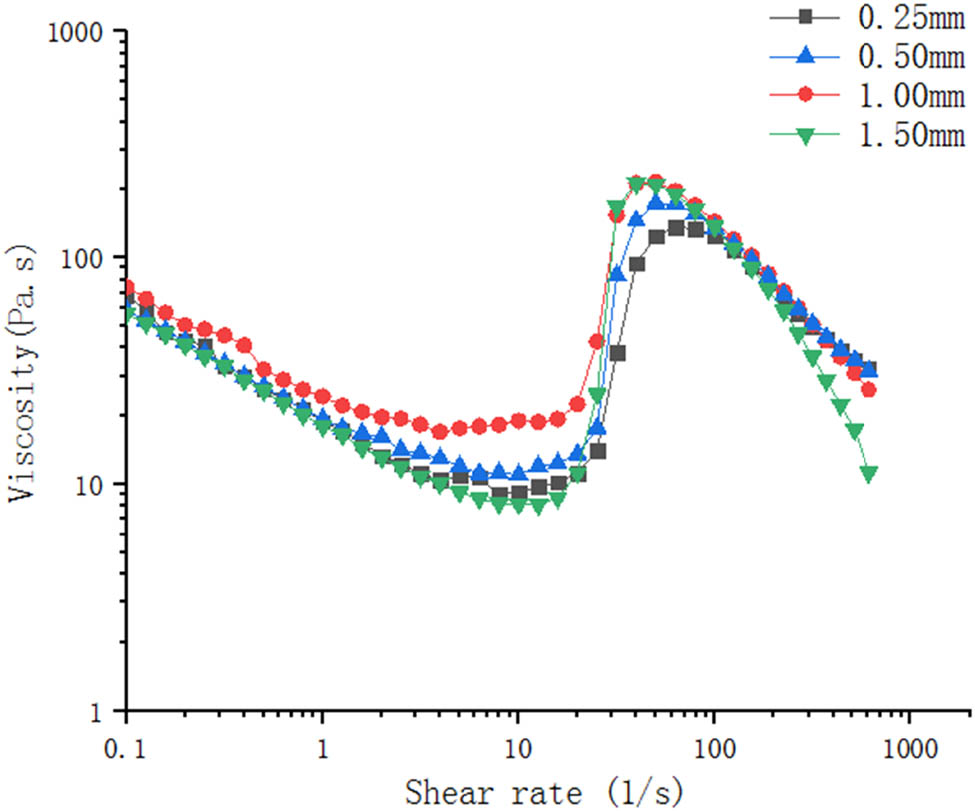

Figure 5 shows the effect of the rheometer on the steady-state rheological properties of the 0.1% PVP sample under different plate spacing. It can be seen from Figure 5 that the MWCNTs–PVP/SiO2–STF system has a significant impact on the system under conditions of different plate spacing. Changing the plate spacing can not only significantly reduce the critical shear rate of the system, but also significantly increase the peak apparent viscosity.

Steady-state rheological properties of 0.1% PVP samples with different plate spacing.

From Table 2, it is concluded that the peak viscosity of MWCNTs–PVP/SiO2–STF with a PVP mass fraction of 0.1% was increased by 17.79, 3.19, 58.37, and 29.07% compared with the MWNT/SiO2 system under the same inter-plate spacing. When the distance between the plates is doubled and quadrupled from 0.25 mm, the peak viscosity of the system increases and the critical shear rate decreases. The possible reason is that the PVP dispersed and agglomerated MWCNTs resulted in the formation of a larger number of new “particle clusters.” When the spacing between the plates is 0.25–0.5 mm, the plates hinder the formation of new particle clusters. When the plate spacing increases from 0.5 to 1.0 mm, the shear thickening phenomenon is significant. The above phenomenon may be due to the appropriate size and uniform distribution of the new “particle clusters” in the system. It can exhibit good shear thickening under the condition of 0.1 mm plate spacing. When the plate spacing is further increased to 1.5 mm, the increase in the spacing between plates increases the average spacing of the new particle clusters. Therefore, the peak viscosity is reduced.

The rheological characteristics of the two systems under different plate spacings

| STF | Clearance distance (mm) | Critical shear rate (/s) | Critical viscosity (Pa.s) | Peak viscosity (Pa.s) |

|---|---|---|---|---|

| 0.10% MWCNTs–PVP/SiO2–STF | 0.25 | 39.8195 | 93.9988 | 137.274 |

| 0.10% MWCNTs–PVP/SiO2–STF | 0.50 | 31.6268 | 83.5023 | 174.553 |

| 0.10% MWCNTs–PVP/SiO2–STF | 1.00 | 25.1202 | 42.7383 | 216.75 |

| 0.10% MWCNTs–PVP/SiO2–STF | 1.50 | 25.1202 | 24.9262 | 213.937 |

| MWCNTs/SiO2–STF | 0.25 | 39.8237 | 43.699 | 116.493 |

| MWCNTs/SiO2–STF | 0.50 | 15.8514 | 96.7629 | 169.163 |

| MWCNTs/SiO2–STF | 1.00 | 25.1203 | 81.0411 | 136.864 |

| MWCNTs/SiO2–STF | 1.50 | 15.8493 | 65.1486 | 165.76 |

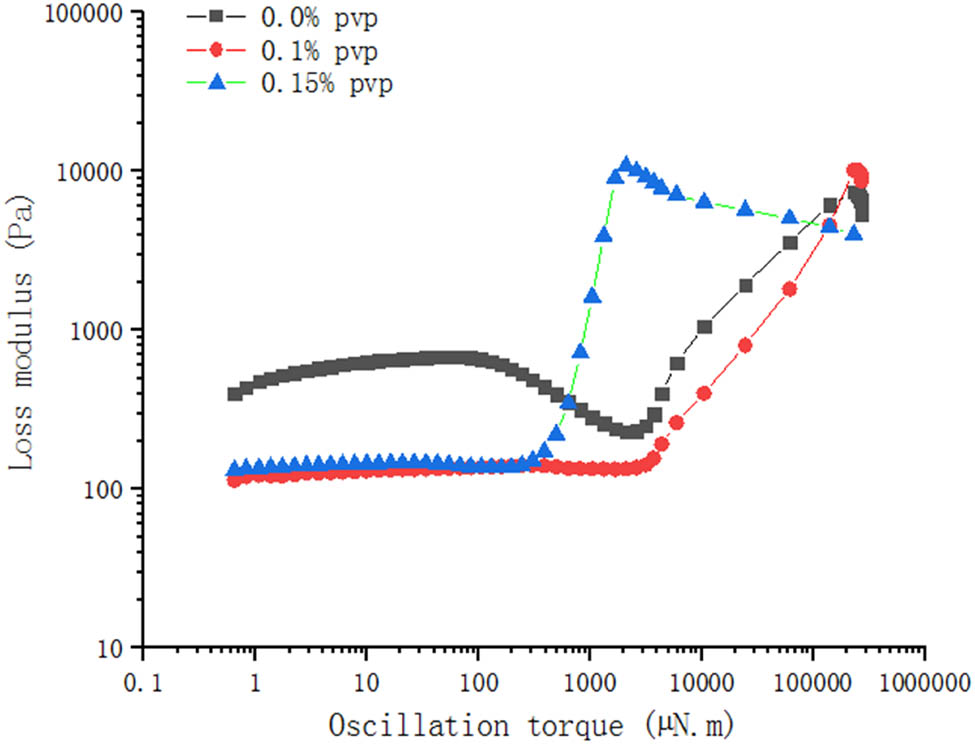

3.2 Dynamic rheological performance

It can be seen from the above research that the steady-state rheology of 0.15% MWCNTs–PVP/SiO2–STF system has a significant shear thickening performance. Therefore, this section mainly studies the dynamic rheological properties of the 0.15% MWCNTs–PVP/SiO2–STF system.

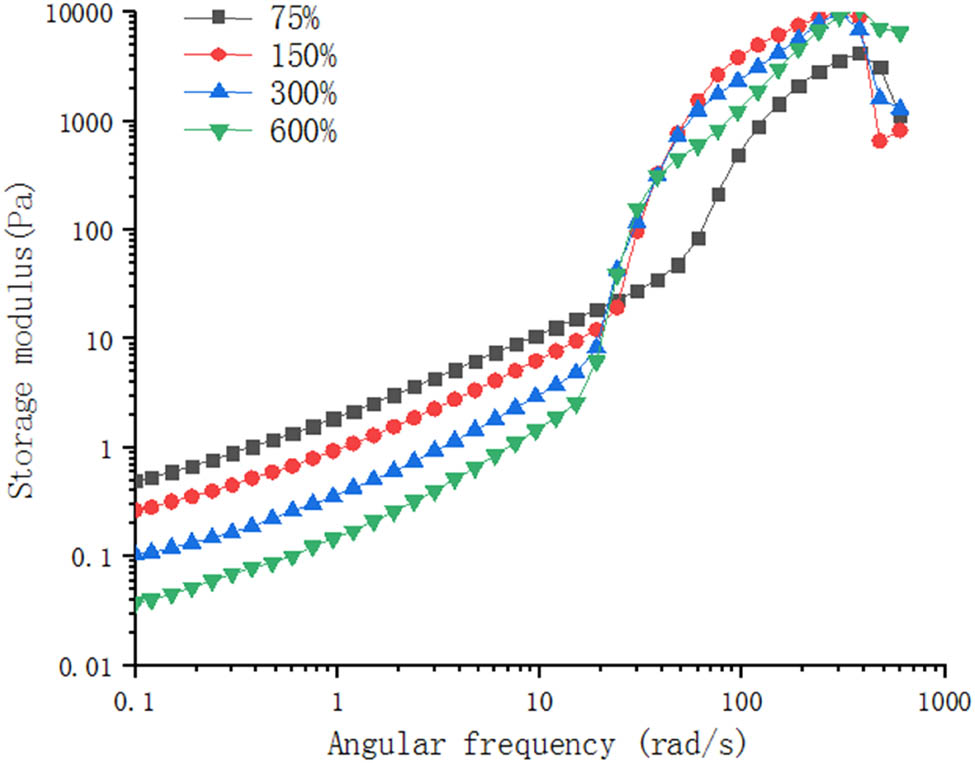

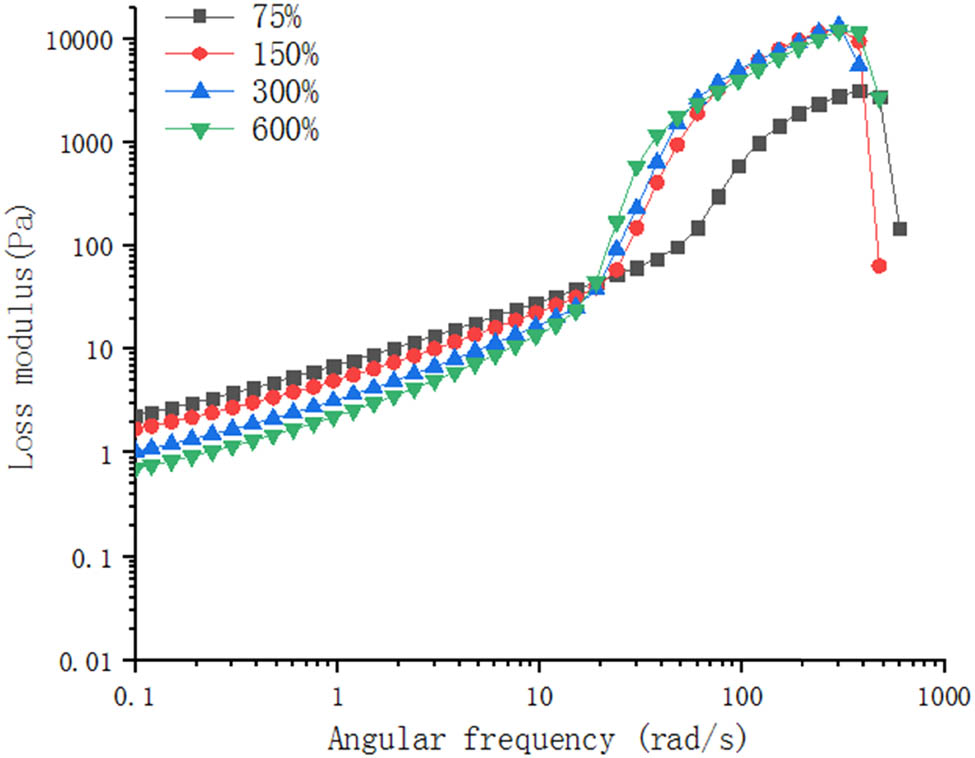

It can be seen from Figure 6 that when the strain amplitude increases from 75 to 600%, the storage modulus of the system first increases and then decreases as the angular frequency increases. The energy dissipation modulus increases with the increase of the angular frequency, and the critical angular frequency decreases with the increase in the strain amplitude. Although the storage modulus decreases significantly with the increase in the strain amplitude when the angular frequency is small, the peak storage modulus is almost unaffected. Compared to the storage modulus, the dissipation modulus exhibits similar behavior. For example, the peak energy storage of the 0.15% MWCNTs–PVP/SiO2–STF system increased from 4280.61 to 10949.50 Pa and the peak energy consumption increased from 3199.05 to 12279.10 Pa. The peak energy storage increases by about 255.79%, and the peak energy consumption increases by 383.84%. In addition, a comparison of Figures 6 and 7 shows that the energy dissipation modulus is always above the storage modulus. This shows that the system is based on energy consumption. The energy consumption of the system indicates that the STF has the potential to reduce structural vibration.

The relationship between the storage modulus and frequency of the 0.15% MWCNTs–PVP/SiO2–STF system.

The relationship between the energy dissipation modulus and the frequency of the 0.15% MWCNTs–PVP/SiO2–STF system.

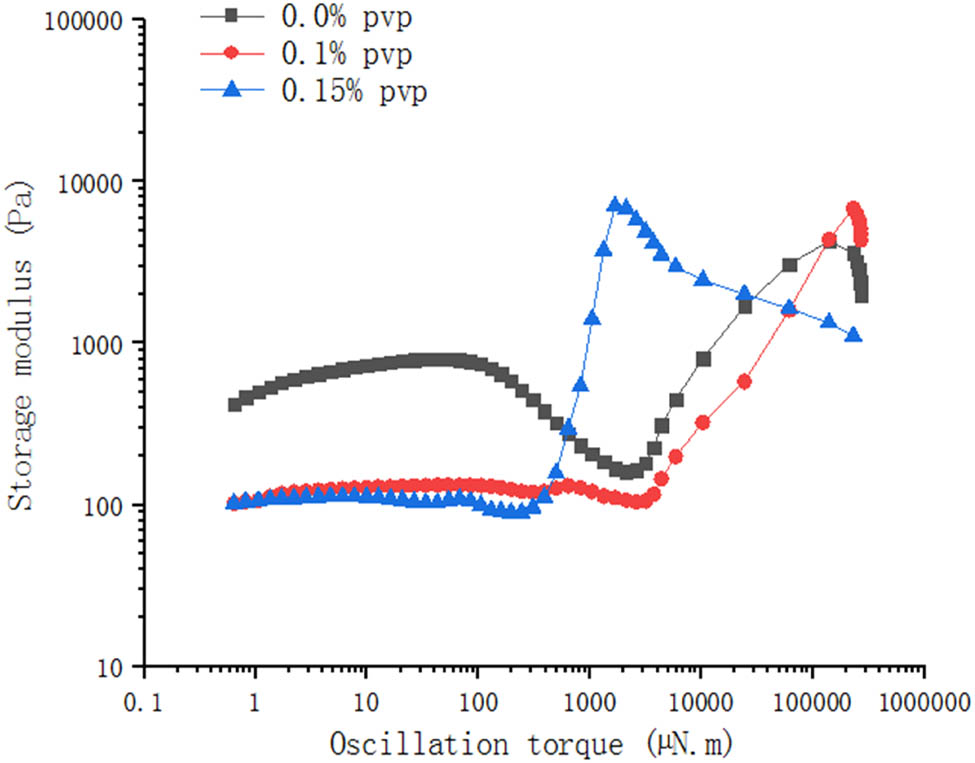

It can be seen from Figures 8 and 9 that when the strain amplitude increases continuously, the storage modulus and energy dissipation modulus of 0.15% MWCNTs–PVP/SiO2–STF increase compared to the other two systems. At the same time, its critical strain amplitude becomes smaller, showing a stable shear thickening ability. When the angular frequency is 80 rad/s, the peak energy storage and peak energy consumption of the 0.15% MWCNTs–PVP/SiO2–STF system are 7061.69 and 10827.3 Pa, respectively, and its peak energy consumption is increased by about 53.32%. In addition, its energy consumption curve is always greater than the energy storage curve. It is more obvious in the range of high strain amplitude. This indicates that the 0.15% MWCNTs–PVP/SiO2–STF system not only exhibits good elastic behavior under low stress, but also has significant energy dissipation ability under high stress.

The MWCNTs–PVP/SiO2–STF system storage modulus and the strain relationship curve.

The relationship between the energy dissipation modulus and the strain on the MWCNTs–PVP/SiO2–STF system.

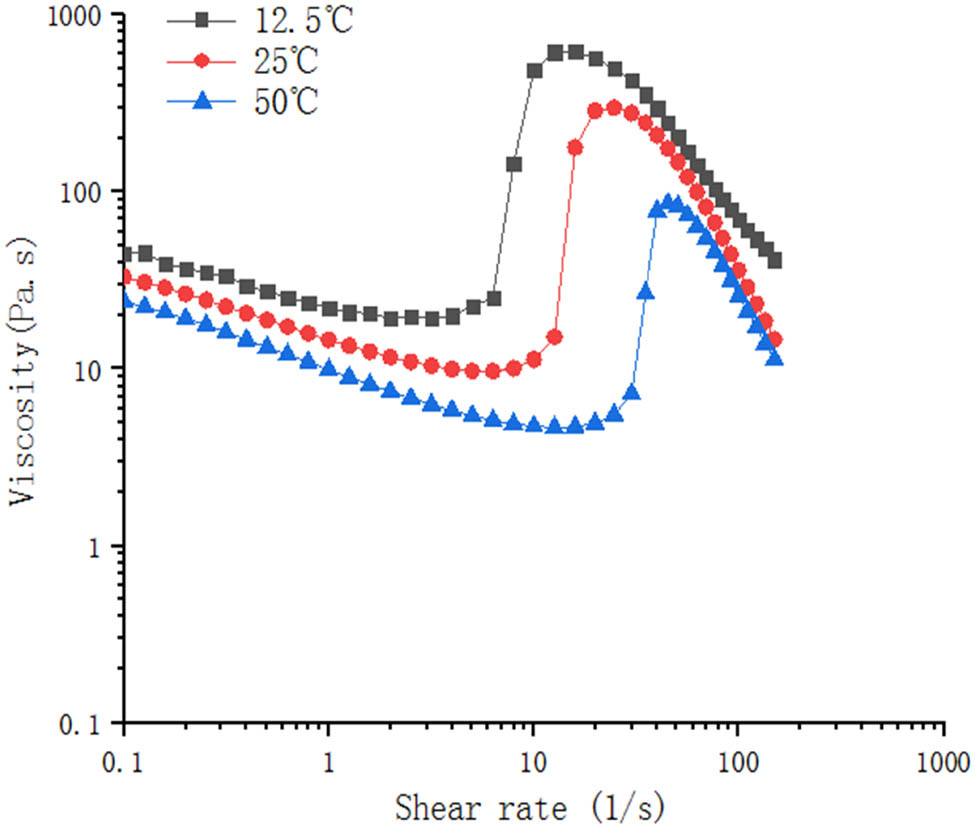

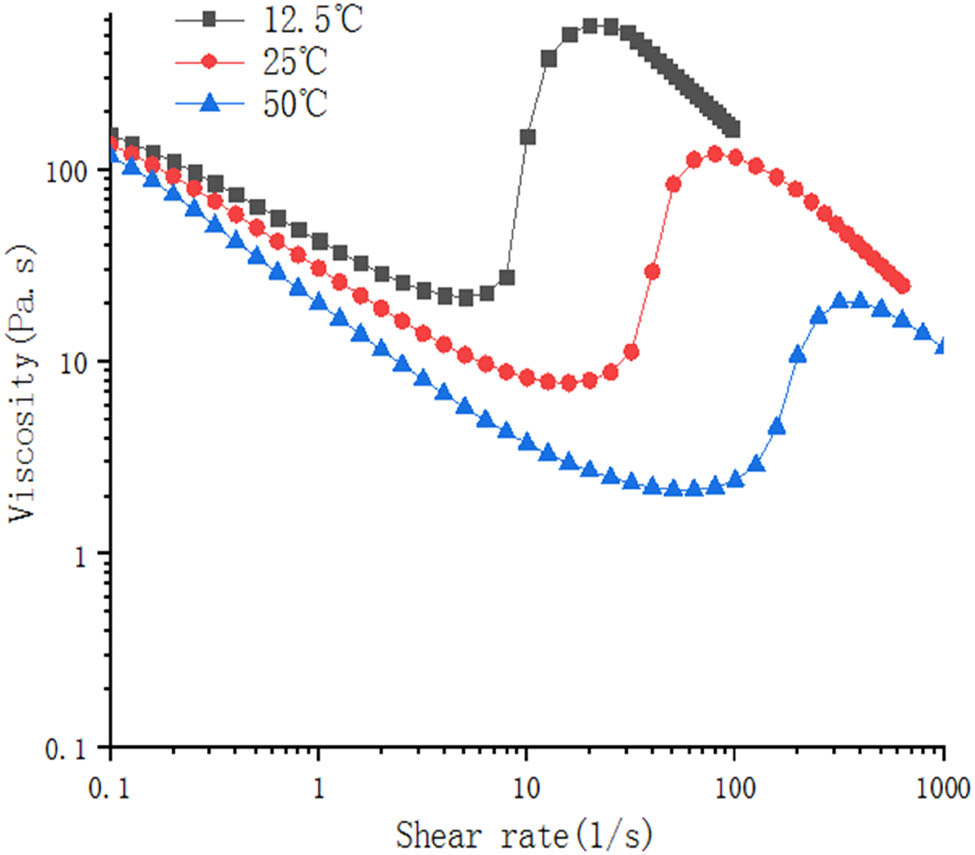

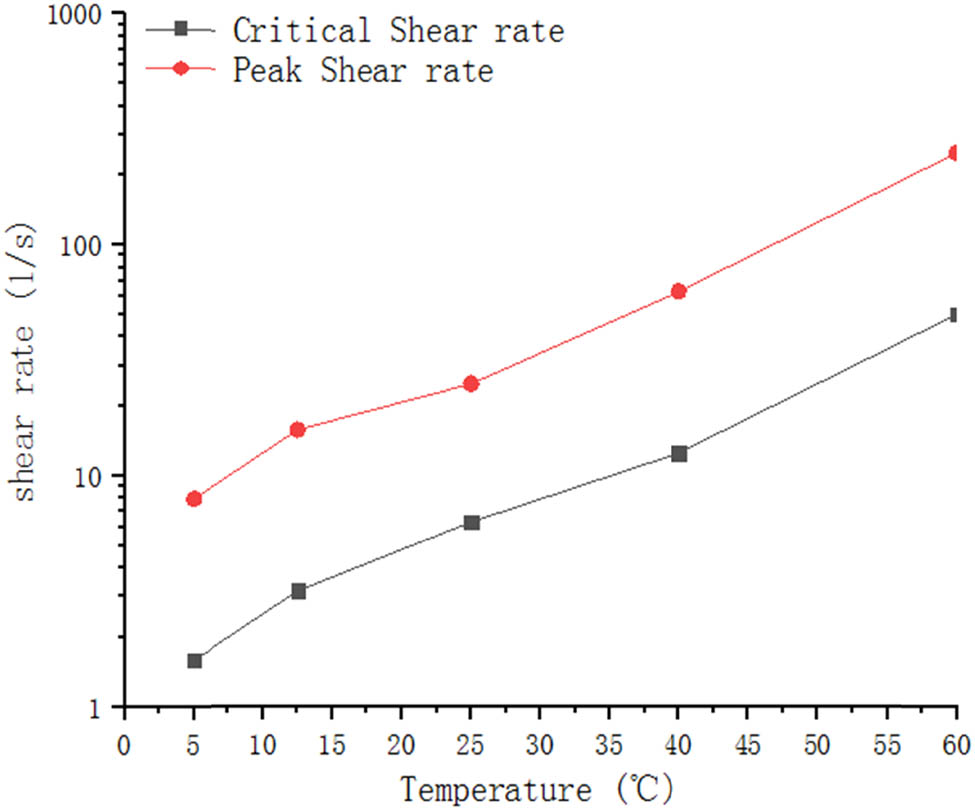

3.3 Temperature sensitivity

It can be seen from Section 3.2 that the MWCNTs–PVP/SiO2–STF system has excellent rheological properties. To further explore the practical applicability of the MWCNTs–PVP/SiO2–STF system, in this section, the influence of ambient temperature on the rheological properties of the system is studied in detail. It can be observed from Figures 10 and 11 that both the systems have significant shear thinning and shear thickening at the tested temperatures. On the whole, the apparent viscosity of both increases greatly as the temperature decreases. However, the influence of temperature on the shear thickening behavior is significantly greater than its influence on the shear thinning behavior. For example, when the temperature of the MWCNTs–PVP/SiO2–STF system increases from 12.5 to 40°C, the apparent viscosity corresponding to a shear rate of 0.1/s decreases only by 46.56%. At the same time, the peak apparent viscosity reduction rate can reach 86.19%. This is because the temperature rise intensifies the Brownian motion of the molecules. The process of forming particle clusters by molecules is more difficult, resulting in a decrease in the viscosity of the system.

The steady-state viscosity-shear rate curves of the MWCNTs–PVP/SiO2–STF system at different temperatures.

The steady-state viscosity-shear rate curves of the MWCNTs/SiO2–STF system at different temperatures.

It can be seen from Figures 12 and 13 that the shear thickening effect of the MWCNTs–PVP/SiO2–STF system is greatly affected by temperature changes. The shear thickening coefficient (the ratio of the peak viscosity to the critical viscosity) decreases with increasing temperature. For example, when the temperature of the 0.15% MWCNTs–PVP/SiO2–STF system increases from 5 to 12.5, 25, 40, and 60°C, the corresponding shear thickening effects are 31.65, 24.64, 19.77, 11.90, and 2.34, respectively. Its reduction rates are 22.15, 19.76, 39.81, and 80.34%. The reason may be that at higher temperatures, the PVP is not conducive to the combination of MWNT and SiO2 particles. In addition, the hydrogen bonding force is weakened at high temperatures, which is not conducive to the dispersion of particles in polyethylene glycol. Therefore, the shear mechanical properties of the system decrease with the increase in temperature.

The shear rate of the 0.15% MWCNTs–PVP/SiO2–STF system changes with temperature.

The apparent viscosity of the 0.15% MWCNTs–PVP/SiO2–STF system changes with temperature.

4 Conclusion

In this study, MWCNTs–PVP/SiO2–STF systems with different mixing ratios were developed. The shear thickening mechanism of the MWCNTs–PVP/SiO2–STF system was investigated through the rheological performance test. The effect of PVP mass fraction, plate spacing, and temperature on the rheological properties of MWCNTs–PVP/SiO2–STF system was investigated. Experiments show that the shear thickening performance of the MWCNTs–PVP/SiO2–STF system has potential research value in the field of engineering vibration reduction and isolation. The main findings can be summarized as:

PVP provides dispersibility and adhesion ability to MWCNTs. It can be compounded to form a new particle cluster structure with a large amount of cotton-like coarse surfaces. The new particle cluster contains SiO2 nano particles which can effectively improve the shear thickening effect of the fluid.

The system tends to be unstable after the PVP content reaches 0.3%. However, excellent shear thickening performance within the range of reasonable mixing ratio can be achieved. When the mass fraction of PVP reaches 0.15% and the distance between the test plates is 1 mm, the shear thickening performance of the MWCNTs–PVP/SiO2–STF system is shown to be most effective. At this configuration, the initial viscosity of the MWCNTs–PVP/SiO2–STF system does not change much, but the peak viscosity is relatively large and the critical shear rate is relatively small.

The dynamic performance test shows that the MWCNTs–PVP/SiO2–STF system has better energy storage and energy consumption capabilities compared to the MWCNT/SiO2–STF system.

The temperature sensitivity test shows that the temperature sensitivity of the MWCNTs–PVP/SiO2–STF system is similar to that of MWCNT/SiO2–STF. Therefore, PVP can significantly improve the shear thickening performance of the system without affecting temperature sensitivity.

-

Funding information: This research is financially supported by the Ministry of Science and Technology of China (Grant No. 2018YFC1504303), the National Science Foundation of China (Grant No. 52078310 and 51878420), Xingliao Talents project by Liaoning Province (Project No. : XLYC1902038) and the Key Research and Development Program of Liaoning Province (Grant No. 2017231010).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and have approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Nguyen D-N, Dao TP, Prakash C, Singh S, Pramanik A, Krolczyk G, et al. Machining parameter optimization in shear thickening polishing of gear surfaces. J Mater Res Technol. 2020;9(3):5112–26.10.1016/j.jmrt.2020.03.028Search in Google Scholar

[2] Sun L, Lv Y, Wei M, Sun H, Zhu J. Shear thickening fluid based on silica with neodymium oxide nanoparticles. Bull Mater Sci. 2020;43(1):1–6.10.1007/s12034-020-02134-2Search in Google Scholar

[3] Qin J, Zhang G, Shi X. Viscoelasticity of shear thickening fluid based on silica nanoparticles dispersing in 1-butyl-3-methylimidizolium tetrafluoroborate. J Dispers Sci Technol. 2015;37(11):1599–606.10.1080/01932691.2015.1125297Search in Google Scholar

[4] He Q, Gong X, Xuan S, Jiang W, Chen Q. Shear thickening of suspensions of porous silica nanoparticles. J Mater Sci. 2015;50(18):6041–9.10.1007/s10853-015-9151-5Search in Google Scholar

[5] Dong H, Dai Y, Zhang X, Zhang Z, Fu S, Zhong Z. Effect of zirconia nanoparticles on the rheological properties of silica-based shear thickening fluid. Mater Res Expr. 2018;5(5):055705.10.1088/2053-1591/aac255Search in Google Scholar

[6] Tichý J. Regularity of planar flows for shear-thickening fluids under perfect slip boundary conditions. Electron J Differ Equ. 2014;2014:1–20.Search in Google Scholar

[7] Crispo F. On the regularity of shear thickening viscous fluids. Chinese Ann Math. 2009;30(3):273–80.10.1007/s11401-007-0539-7Search in Google Scholar

[8] Delhommelle J. Onset of shear thickening in a simple fluid. Eur Phys J E – Soft Matter. 2004;15(1):65–9.10.1140/epje/i2004-10038-8Search in Google Scholar PubMed

[9] Kośla K, Olejnik M, Olszewska K. Preparation and properties of composite materials containing graphene structures and their applicability in personal protective equipment. Rev Adv Mater Sci. 2020;59(1):215–42.10.1515/rams-2020-0025Search in Google Scholar

[10] Yeh S-K, Lin JJ, Zhuang HY, Chen YC, Chang HC, Zheng JY, et al. Light shear thickening fluid (STF)/Kevlar composites with improved ballistic impact strength. J Polym Res. 2019;26(6):1–13.10.1007/s10965-019-1811-8Search in Google Scholar

[11] Dixit P, Ghosh A, Majumdar A. Hybrid approach for augmenting the impact resistance of p-aramid fabrics: grafting of ZnO nanorods and impregnation of shear thickening fluid. J Mater Sci. 2019;54(20):13106–17.10.1007/s10853-019-03830-zSearch in Google Scholar

[12] Gürgen S, Kuşhan MC. The effect of silicon carbide additives on the stab resistance of shear thickening fluid treated fabrics. Mech Adv Mater Struct. 2017;24(16):1381–90.10.1080/15376494.2016.1231355Search in Google Scholar

[13] Qin J, Zhang G, Shi X. Study of a shear thickening fluid: the suspensions of monodisperse polystyrene microspheres in polyethylene glycol. J Dispers Sci Technol. 2017;38(7):935–42.10.1080/01932691.2016.1216435Search in Google Scholar

[14] Lee B-W, Kim C-G. Computational analysis of shear thickening fluid impregnated fabrics subjected to ballistic impacts. Adv Comp Mater. 2012;21(2):177–92.10.1080/09243046.2012.690298Search in Google Scholar

[15] Wei M, Sun L, Zhang C, Qi P, Zhu J. Shear-thickening performance of suspensions of mixed ceria and silica nanoparticles. J Mater Sci. 2019;54(1):346–55. 10.1007/s10853-018-2873-4.Search in Google Scholar

[16] Saraloğlu Güler E. Rheological behaviours of silica/water, silica/PEG systems and mechanical properties of shear thickening fluid impregnated Kevlar composites. Bull Mater Sci. 2018;41(4):1.10.1007/s12034-018-1628-9Search in Google Scholar

[17] Acosta M, Wiesner VL, Martinez CJ, Trice RW, Youngblood JP. Effect of polyvinylpyrrolidone additions on the rheology of aqueous, highly loaded alumina suspensions. J Am Ceram Soc. 2013;96(5):1372–82.10.1111/jace.12277Search in Google Scholar

[18] Wei M, Lv Y, Sun L, Sun H. Rheological properties of multi-walled carbon nanotubes/silica shear thickening fluid suspensions. Colloid Polym Sci. 2020;298(3):243–50.10.1007/s00396-020-04599-3Search in Google Scholar

[19] Xu S, Xiwei J, Jian X, Bocun Z, Weiguang G. The effect of polyvinylpyrrolidone with different molecular weights on the dispersion properties of multi-walled carbon nanotubes. J East China Univ Sci Technol (Nat Sci Ed). 2019;45(06):883–90.Search in Google Scholar

[20] Liu K, Cheng CF, Zhou L, Zou F, Liang W, Wang M, et al. A shear thickening fluid based impact resistant electrolyte for safe Li-ion batteries. J Power Sources. 2019;423:297–304.10.1016/j.jpowsour.2019.03.056Search in Google Scholar

[21] Nakonieczna P, Wierzbicki Ł, Wróblewski R, Płociński T, Leonowicz M. The influence of carbon nanotube addition on the properties of shear thickening fluid. Bull Mater Sci. 2019;42(4):1–4. 10.1007/s12034-019-1860-y.Search in Google Scholar

[22] Zhang K, Tang W, Fu K. Compressive behaviour of shear-thickening fluid with concentrated polymers at high strain rates. Mater Des. 2018;140:295–306.10.1016/j.matdes.2017.12.009Search in Google Scholar

[23] Evstropiev SK, Kulagina AS, Evstropyev KS, Kolobkova EV, Nikonorov NV, Soshnikov IP, et al. The Influence of polyvinylpyrrolidone molecular weight on the structure and the spectral and nonlinear optical properties of composite materials with CdS/ZnS nanoparticles. Opt Spectrosc. 2018;125(5):640–5.10.1134/S0030400X18110103Search in Google Scholar

[24] Wu H, Xin Y. Molecular dynamics and MesoDyn simulations for the miscibility of polyvinyl alcohol/polyvinyl pyrrolidone blends. Rubber Comp Plast. 2017;46(2):69–76.10.1080/14658011.2017.1280642Search in Google Scholar

[25] Zhang Y, Zhang C, Wang W, Du X, Dong W, Han B, et al. One-step synthesis of Polyvinylpyrrolidone-reduced graphene oxide-Pd nanoparticles for electrochemical sensing. J Mater Sci. 2016;51(13):6497–508.10.1007/s10853-016-9949-9Search in Google Scholar

[26] Krasnou I, Tarabukina E, Melenevskaya E, Filippov A, Aseyev V, Hietala S, et al. Rheological behavior of poly(vinylpyrrolidone)/fullerene C60 complexes in aqueous medium. J Macromol Sci, Part B, Phys. 2008;47(3):500–10.10.1080/00222340801955289Search in Google Scholar

[27] Ahmad SI, Hamoudi H, Abdala A, Ghouri ZK, Youssef KM. Graphene-reinforced bulk metal matrix composites: synthesis, microstructure, and properties. Rev Adv Mater Sci. 2020;59(1):67–114.10.1515/rams-2020-0007Search in Google Scholar

[28] Lebedev SM, Amitov ET, Mikutskiy EA. Biodegradable electrically conductive polycaprolacton-based composites filled with carbon nanotubes. Rus Phys J. 2020;62(10):1753–62.10.1007/s11182-020-01903-0Search in Google Scholar

[29] Nakonieczny Damian S, Magdalena A, Zbigniew P. Surface modification methods of ceramic filler in ceramic-carbon fibre composites for bioengineering applications – a systematic review. Rev Adv Mater Sci. 2020;59(1):586–605.10.1515/rams-2020-0024Search in Google Scholar

[30] Sanjeevi B, Loganathan K. Synthesis of multi wall carbon nanotubes nanofluid by using two step method. Therm Sci. 2020;24(1B):519–24.10.2298/TSCI190414430SSearch in Google Scholar

[31] Oliva-Lamarca Y, Fresco-Cala B, Cárdenas, S. Synthesis, characterization, and application of chemically interconnected carbon nanotube monolithic sorbents by photopolymerization in polypropylene caps. Anal BioAnal Chem. 2019;411(15):3291–9.10.1007/s00216-019-01795-1Search in Google Scholar PubMed

[32] Hashim H, Salleh MS, Omar MZ. Homogenous dispersion and interfacial bonding of carbon nanotube reinforced with aluminum matrix composite. Rev Adv Mater Sci. 2019;58(1):295–303.10.1515/rams-2019-0035Search in Google Scholar

[33] Ijaz Khan M, Farooq S, Hayat T, Shah F, Alsaedi A. Numerical simulation for entropy generation in peristaltic flow with single and multi-wall carbon nanotubes. Int J Numer Methods Heat Fluid Flow. 2019;29(12):4684–705.10.1108/HFF-02-2019-0148Search in Google Scholar

[34] Zhuang Z, Giles SA, Zheng J, Jenness GR, Caratzoulas S, Vlachos DG, et al. Nickel supported on nitrogen-doped carbon nanotubes as hydrogen oxidation reaction catalyst in alkaline electrolyte. Nat Commun. 2016;7:10141.10.1038/ncomms10141Search in Google Scholar PubMed PubMed Central

[35] Abbasi S, Zebarjad SM, Baghban SHN, Youssefi A, Ekrami-Kakhki MS. Experimental investigation of the rheological behavior and viscosity of decorated multi-walled carbon nanotubes with TiO nanoparticles/water nanofluids. J Therm Anal Calorim. 2016;123(1):81–9.10.1007/s10973-015-4878-4Search in Google Scholar

[36] Liu M, Chen Q, Wang S, Wang S, Bai L, Sang M, et al. PVP immobilized SiO2 nanospheres for high-performance shear thickening fluid. J Nanopart Res. 2017;19:234.10.1007/s11051-017-3911-xSearch in Google Scholar

[37] Wei M, Sun L, Zhang C, Qi P, Zhu J. Rheological properties of shear thickening fluid of zirconia and silica nanoparticles mixed system. Cailiao Daobao/Mater Rep 2019;(3312):1969–74.Search in Google Scholar

[38] Li X, Deng H, Li Z, Xiu H, Qi X, Zhang Q, et al. Graphene/thermoplastic polyurethane nanocomposites: Surface modification of graphene through oxidation. Polyvinyl pyrrolidone coating and reduction. Compos Part A. 2019;68:264–75.10.1016/j.compositesa.2014.10.016Search in Google Scholar

[39] Wang J, Tsuzuki T, Tang B, Cizek P, Sun L, Wang X. Synthesis of silica-coated ZnO nanocomposite: the resonance structure of polyvinyl pyrrolidone (PVP) as a coupling agent. Colloid Polym Sci. 2010;288(18):1705–11.10.1007/s00396-010-2313-8Search in Google Scholar

[40] Aboud SR, Al-Bermany AK, Megahed N. Effect of temperature on some rheological properties of polyvinyl pyrrolidone (PVP). Egypt J Solids. 2009;32(1):81–8.10.21608/ejs.2009.148779Search in Google Scholar

[41] Majumdar D, Bhattacharya S. Sonochemically synthesized hydroxy-functionalized graphene-MnO nanocomposite for supercapacitor applications. J Appl Electrochem. 2017;47(7):789–801.10.1007/s10800-017-1080-3Search in Google Scholar

© 2021 Li Sun et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions