Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

-

Hua Yu

and Shizhong Wei

Abstract

To meet the requirements of automatic production, a new type of green BAl88Si cored solder was developed. The lap brazing experiments were carried out with copper and aluminum as brazing substrates. The microstructure, phase composition, and corrosion behavior of solder joint interface were studied by field emission scanning electron microscopy, energy dispersive spectroscopy, transmission electron microscopy, electron backscattering diffraction, tensile testing machine, and electrochemical workstation. The results show that the brazing joint of Cu/BAl88Si/Al is metallurgical bonding, and the brazing joint of Cu/BAl88Si/Al is composed of Cu9Al4, CuAl2, a-Al, (CuAl2 + a-Al + Si) ternary eutectic. In addition, there is no obvious preference for each grain in the brazing joint, and there are S texture {123}<634>, Copper texture {112}<111>, and Brass texture {110}<112>. The interface of Cu9Al4/CuAl2 is a non-coherent crystal plane and does not have good lattice matching. The average particle size of CuAl2 is 11.95 µm and that of Al is 28.3 µm. However, the kernel average misorientation (KAM) value at the brazed joint interface is obviously higher than that at the brazed joint interface copper, so the defect density at the brazed joint interface aluminum is higher than that at the brazed joint interface copper. At the same time, due to poor corrosion resistance at the interface on the aluminum side of the brazed joint, serious corrosion spots and corrosion cracks occur at the same time, which leads to the shear performance of the brazed joint decreasing by about 75% after salt spray test for 240 h.

1 Introduction

Copper is widely used in the manufacture of thermal components in refrigeration fields such as air conditioners and refrigerators, aerospace, and power industries because of its excellent thermal conductivity and electrical conductivity. But copper prices have long soared as resources have become increasingly scarce [1,2,3]. In addition, copper has a higher density, which leads to a higher quality of copper. Especially, the use of copper parts in automobiles and airplanes will improve the quality, which contradicts the concept of energy-saving and emission reduction [4,5]. Copper–aluminum composite metal joints are widely used in aerospace, air conditioning, household appliance refrigeration, and other industries and have high application value [6,7]. Aluminum and its alloys have low density, good thermal conductivity, and electrical conductivity [8]. Therefore, in some parts, aluminum can partially or completely replace copper products, thereby greatly reducing the production costs and realizing the complementary advantages of the two metals [9,10].

The connection of Cu–Al dissimilar metals is the key technique. At present, the connection of Cu–Al dissimilar metals mainly includes mechanical connection, pressure welding, and brazing [11,12,13]. In the process of mechanical connection, due to the active chemical properties of aluminum, a dense oxide protective film was formed in the air. The film has a very high resistivity and is very stable under normal conditions, which seriously affects the electrical conductivity and thermal properties of the copper–aluminum connection point, resulting in premature failure of the copper–aluminum connection point [14]. In the process of press welding, the welding joint of different copper and aluminum metals with good performance can be obtained. However, there are a series of problems in pressure welding, such as high welding cost, complex process, poor adaptability to complex welding parts, long production cycle, etc., which restrict the application of pressure welding in different copper and aluminum welding [15,16]. However, brazing has a series of advantages such as low cost, simple equipment, and large-scale production. It has gradually become a research focus in the industry and has good development prospects. Therefore, brazing is widely used in the connection of two different metals, copper and aluminum, resulting in a joint with high strength and good airtightness [17,18]. Copper and aluminum brazing mainly use Zn–Al, Sn–Zn, and Al–Si brazing materials [19,20,21]. Al–Si brazing materials have good plasticity and are easy to be processed and formed. Compared with Zn–Al brazing filler metal, Al–Si brazing filler metal has better corrosion resistance, and the strength of the brazed joint is much higher than that of Sn–Zn brazing filler metal, so Al–Si brazing filler metal is more suitable for joining dissimilar metals of copper and aluminum [22,23]. However, there are few reports on the corrosion behavior of brazed Cu–Al joints with Al–Si base brazing filler metals. Huang, Ye et al. mainly studied the effects of Zn–Al and Sn–Zn filler metals on the corrosion microstructure and shear strength with the content of alloy element and salt spray test time [24,25].

At the same time, in the traditional brazing process, the composite application form of brazing filler metal and brazing flux usually adopts the way of placing brazing filler metal on brazing parent metal in advance or sticking brazing flux on solid brazing filler metal. This method greatly increases the pre-welding process and operation time and adds a variable during the brazing process, which affects the consistency and quality stability of welding. In addition, to ensure the quality of brazing, excessive brazing flux is often added, which will pollute the air and harm the health of operators and cause brazing flux waste [26]. Therefore, a new type of BAl88Si solder was prepared in this experiment, which meets the requirements of green manufacturing and is suitable for automatic and intelligent welding technology [27]. In addition, intermetallic compounds are the inevitable mesophase in copper–aluminum brazed joints. These hard and brittle intermetallic compounds with high resistivity will greatly reduce the performance of brazed joints and affect the integrity and stability of the joints [28,29]. However, there are few reports on the interfacial microstructure and lattice mismatch of intermetallic compounds in BAl88Si brazed Cu/Al joints.

Therefore, the lattice mismatch, texture preference orientation, and corrosion behavior of the interfacial phase in the brazed Cu–Al joint of BAl88Si were analyzed. The innovative combination of lattice mismatch and KAM value at the brazing interface and corrosion behavior at the brazing interface are helpful to study corrosion protection of copper and aluminum brazed joints in the outdoor wet environment.

2 Test materials and methods

2.1 Test material

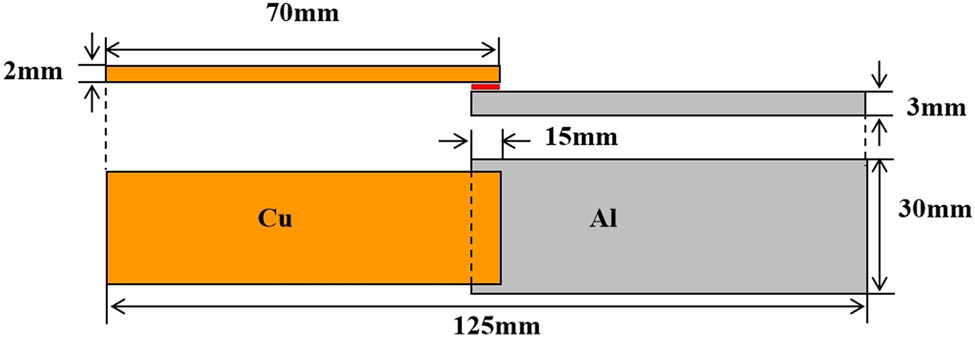

The substrate materials used in the induction brazing experiment are copper plates and aluminum plates. The sizes of the experimental matrix materials are 70 mm × 20 mm × 2 mm and 70 mm × 30 mm × 3 mm, respectively. The chemical compositions of the basic materials and BAl88Si new solders are shown in Table 1.

Chemical composition of matrix material

| Materials | Cu | Al | Si | Others |

|---|---|---|---|---|

| T2 Copper | Base | — | — | ≦0.1 |

| 1060 Aluminum | — | Base | — | ≦0.4 |

| BAl88Si | — | 88 | 10 | ≦2 |

2.2 Experimental method

Pretreatment of the experimental substrate before induction brazing: the substrate surface was polished with 400#, 600#, and 800# sandpaper in sequence, and the polished steel plate was cleaned with alcohol ultrasonic wave. At the same time, mark a scale on the filler metal every 20 mm to quantify the filler metal during welding.

Induction brazing: the brazed joint is in the form of a lap joint, as shown in Figure 1. The lap length of the joint is 15 mm, and the substrate is fixed on the special fixture according to the lap length. Start the induction brazing machine for heating, and the current is set to 240 A. When the temperature reaches 580℃, keep the temperature for 10 s. After cooling with hollow air, the joint reaches room temperature, and the residual brazing flux and the oxide film on the surface of the substrate are removed by mechanical cleaning. The 10 mm × 10 mm joints are cut on the brazed lap joint by wire cutting, and the wire-cut joints are inlaid and polished.

Model of the CU–Al brazing lap joint.

After induction brazing, first, the electrochemical tests were carried out on the Cu–Al joint. The scanning speed in the experimental parameters was set to 1 mV/s, and the scanning range in the electrochemical experiment was set to ±250 mV. In the whole electrochemical experiment, the electrolyte solution composed of 3.5% sodium chloride salt and deionized water was chosen, and the solution temperature was room temperature. Second, the inlaid sample and the welded joint are put into a salt spray test box, and the sodium chloride solution with a concentration of 3.5% was poured into the saltwater tank. During the test, the temperature in the cabinet was adjusted to 35℃, and the welding samples were taken out at 0, 24, 96, 168, 240, and 480 h, respectively. Three samples were taken out at a time, rinsed with water, dried, and stored.

The morphology of the brazing joint was observed by scanning electron microscope (SEM). The composition and texture of each phase of the brazing joint were measured by energy dispersive spectrometer, electron backscatter diffraction (EBSD), and field emission scanning electron microscope. Transmission samples at the Cu/BAl88Si/Al interface were prepared by FIB technology for the first time, and the interface and phase boundary structure of the brazed joint were characterized and analyzed.

3 Results and discussion

3.1 Microstructure of the interface region of brazed joint

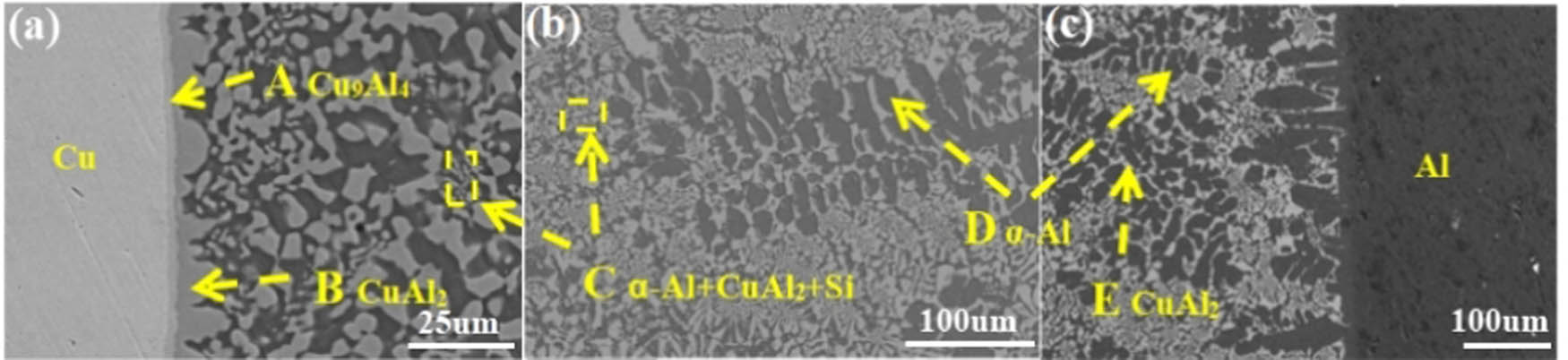

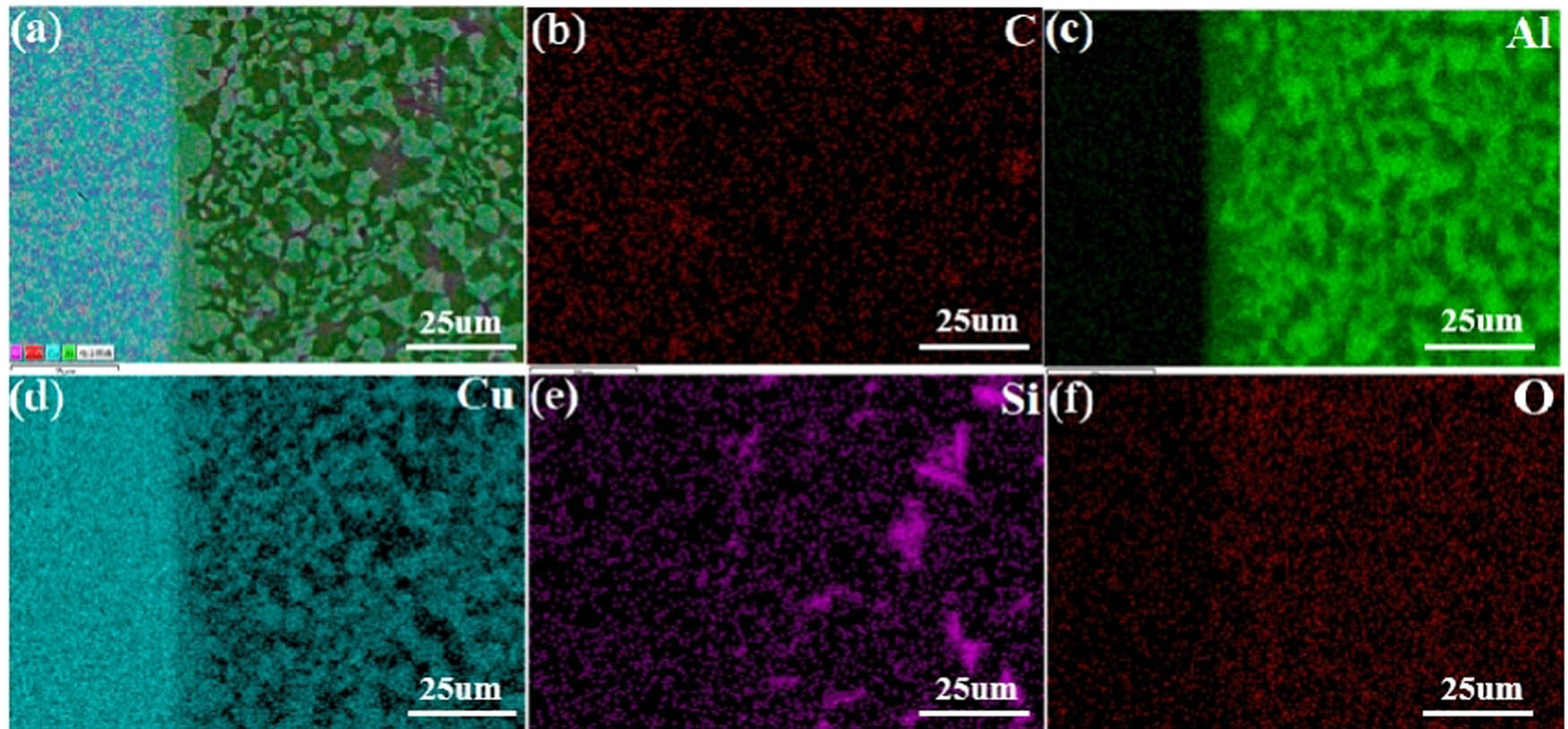

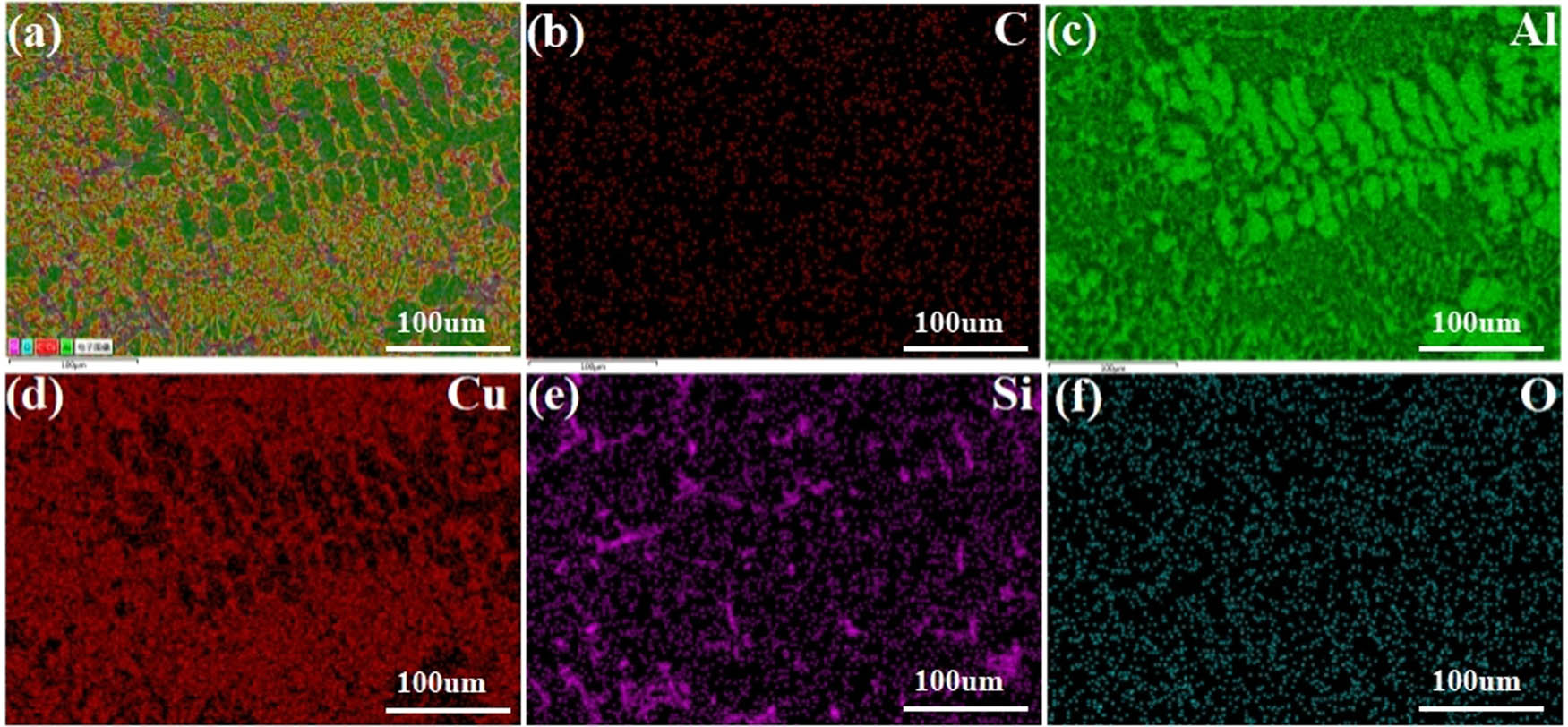

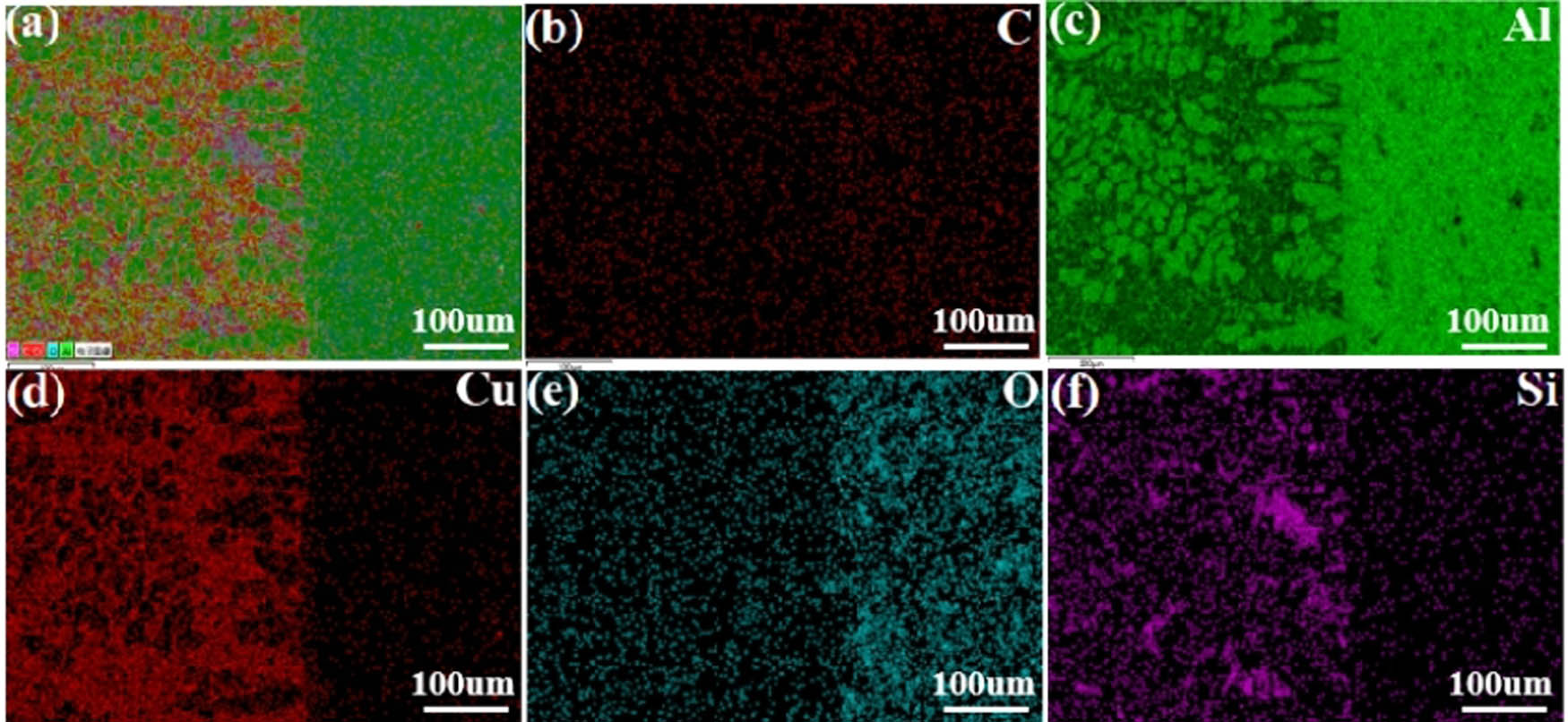

Figure 2 shows a scanning electron microscope image of the microstructure of the Cu/BAl88Si/Al brazing joint. Figure 2(a) shows the microstructure of brazed joints near copper. Figure 2(b) shows the micro-morphology of the middle region of the brazed joint. Figure 2(c) shows the microstructure of the brazing joint near aluminum. It can be seen from Figure 2(a) and (c) that the solder alloy has achieved good metallurgical bonding with the base metal without forming cracks or voids. Two dense intermetallic compound layers were formed at the brazing interface near Cu, with a thickness of 7–15 µm. The intermetallic compounds away from the copper interface of brazed joints tend to grow in brazed joints. In Figure 2(a)–(c), there is no obvious dense intermetallic compound at the brazing interface far from the copper side. It is composed of gray-white skeleton phase, dendritic gray-black phase, and obvious needle-like eutectic phase. Therefore, each phase in Figure 2 is subjected to energy spectrum analysis and surface analysis. The experimental results are shown in Table 1, Figures 3–5. From the surface scanning results, it can be seen that Cu elements in the base metal and brazed joint have been fully diffused, and Cu elements are mainly concentrated in the dense intermetallic compounds near the Cu side interface, as well as gray-white skeleton phase and needle-like eutectic phase in brazed joint, but the content of dendrites in the brazed joint is relatively small. At the same time, the results of surface scanning show that the total aluminum content in the gray-black phase of brazing dendrite is the highest, while the total aluminum content of needle eutectic phase, gray-white skeleton phase, and intermetallic compounds near the copper side gradually decreases. The surface scanning results showed that Si elements were obviously agglomerated in the dendrite gray-black phase and uniformly distributed in other phases of the brazing seam. The analysis results are shown in Table 2. According to the results in Table 2 and related literature, it can be inferred that the intermetallic compound formed near the interface of the copper side in Figure 2(a) is Cu9Al4, and the intermetallic compound beside Cu9Al4 is CuAl2 the gray-white skeleton phase in the brazing joint is presumed to be CuAl2, gray-black dendrite phase is presumed to be α-Al, and the needle-like eutectic ternary eutectic α-Al + CuAl2 + Si [30]. At the brazing temperature, due to the high affinity between copper and aluminum, the molten Al–Si brazing alloy wetted the surface of the copper substrate, and the copper atoms diffused into the Al–Si brazing alloy. During the cooling process, the Cu9Al4 phase with high copper atom content forms on the copper/brazing interface. With a further decrease of brazing temperature, the concentration of copper atoms decreases based on Gibbs free energy, and a second IMC CuAl2 phase was formed on the surface of the Cu9Al4 phase. In the brazing zone, Cu phase and α-Al (Cu) solid solutions are formed by diffusing copper atoms and Al–Si solder. With the decrease of temperature, the copper atoms diffused into the brazing area react with the filler metal to form ternary eutectic α-Al + CuAl2 + Si [31].

Scanning electron microscope image of the brazing joint of BAl88Si filler metal: (a) microstructure of the brazing joint interface on the copper side, (b) microstructure of brazing seam, and (c) microstructure of the brazed joint interface on the aluminum side.

EDS distribution diagram of Cu side brazing joint interface: (a) surface scanning, (b) C, (c) Al, (d) Cu, (e) Si, and (f) O.

EDS distribution of brazing seam: (a) surface scanning, (b) C, (c) Al, (d) Cu, (e) Si, and (f) O.

EDS distribution diagram of brazing seam on the CU side: (a) surface scanning, (b) C, (c) Al, (d) Cu, (e) Si, and (f) O.

Physical phase energy spectrum of BAl88Si solder brazing joint

| Measuring point | W(Al) | W(Cu) | W(Si) | W(Sb) | W(C) |

|---|---|---|---|---|---|

| a | 30.16 | 69.84 | — | — | — |

| b | 69.76 | 30.24 | — | — | — |

| c | 85.2 | 10.68 | 4.12 | — | — |

| d | 98.12 | — | — | — | 1.88 |

| e | 68.21 | 29.79 | — | — | 2 |

3.2 Phase analysis of the interface region of brazed joint

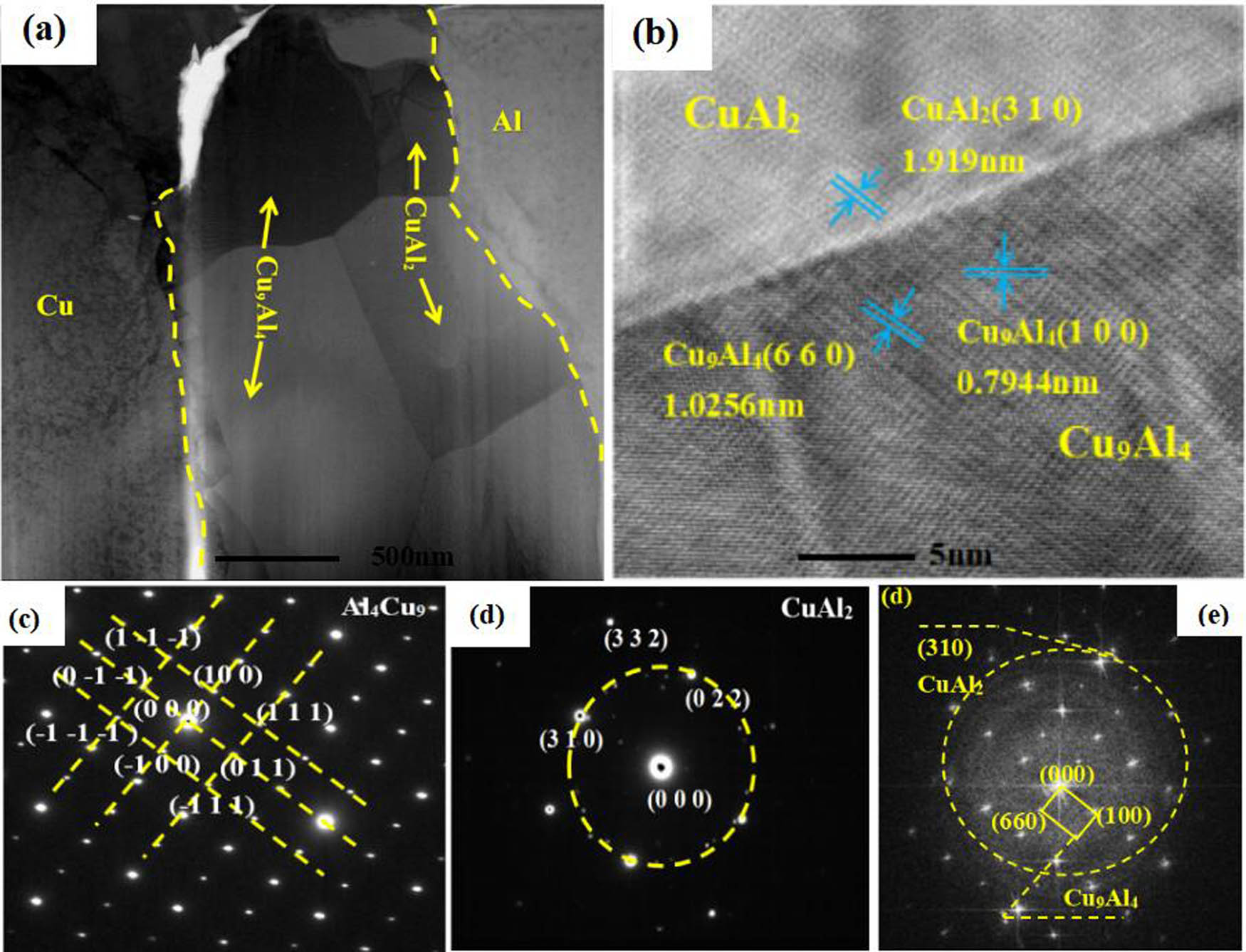

Figure 6 shows a transmission electron microscope (TEM) image of the copper and brazing joint area. Figure 6(a) shows low-power TEM images, and Figure 6(b)–(e) shows electron diffraction patterns of different microscopic regions in Figure 6(a). There are two kinds of reaction products between copper-based metal and BAl88Si solder at the brazing interface near the copper side. According to the SAED calibration in Figure 6(c) and (d), these two intermetallic compounds are CuAl2 and Cu9Al4, which is consistent with the results of the above energy spectrum analysis. Figure 6(b) shows the inverse fast fourier transform (IFFT) image of the interface between the CuAl2 and Cu9Al4 metal compounds. In the fast Fourier transform corresponding to high-resolution TEM (Figure 6(e)), the (660) and (100) crystal planes of Cu9Al4 and the (310) and (310) crystal planes of Cu9Al4 are marked by calibrated diffraction points. The interplanar distances between the two planes are dCuAl2 (310) = 1.919 nm, dCu9Al4 (660) = 1.025 nm, and dCu9Al4 (100) = 0.7944 nm. Therefore, the lattice mismatch ratio of CuAl2 (310)/Cu9Al4 (660) crystal plane is 0.466, and the lattice mismatch ratio of CuAl2 (310)/Cu9Al4 (100) interface is 0.586, so there is no good semi-coherent interface [32].

TEM image of interface between BAl88Si solder and Cu base metal: (a) low power TEM image of Cu and brazing joint interface, (b) Cu9Al4/CuAl2, interface IFFT image, (c) CuAl2 SAED, (d) Cu9Al4 SAED, and (e) Cu9Al4/CuAl2 interface FFT.

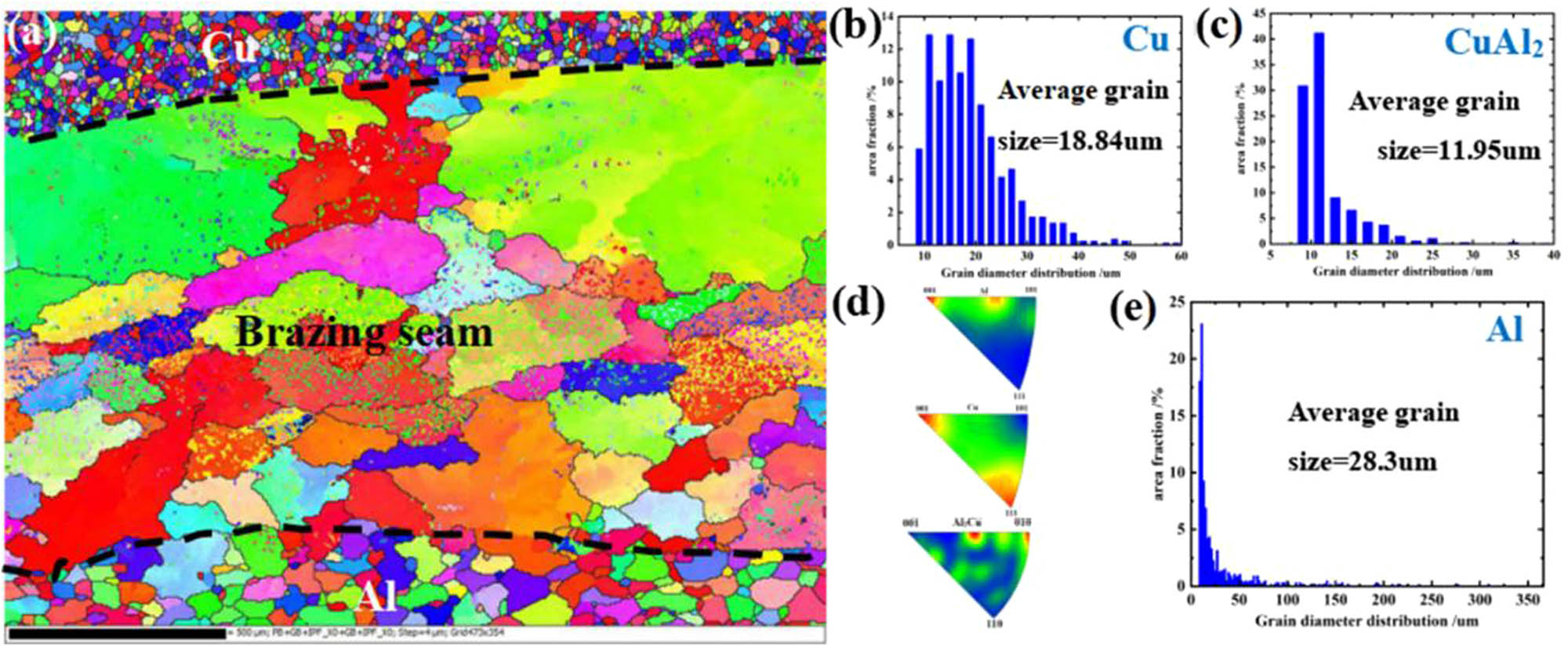

The crystallographic information of the interface region of the brazed joint was obtained by EBSD, and the microstructure of the interface region was further proved, as shown in Figure 7. It can be seen from Figure 7(a) that every grain in the brazed joint is anisotropic and has no obvious preferred orientation [33]. At the same time, the grain size at the copper interface of the brazed joint was significantly larger than that at the aluminum interface. Therefore, the grain size of the brazed joint was also analyzed, and the analysis results are shown in Figure 7(b), (c), and (e). Comparing the grain size of the three phases, the average grain size of CuAl2 is at least 11.95 µm, while the average grain size of Al is at most 28.3 µm. This is mainly due to the fact that Al grains in the molten brazing filler metal grow up continuously during the brazing process, and the heat transfer capacity of Cu is higher than that of Al, which makes the thermal energy on the fixture continuously transfer to the Cu side interface filler metal after brazing.

BAl88Si brazing joint EBSD image: (a) IPF map of the interface region, (b) grain size diagram of Cu, (c) grain size diagram of CuAl2, (d) inverse polar diagram of CuAl and CuAl2 and (e) grain size diagram of Al.

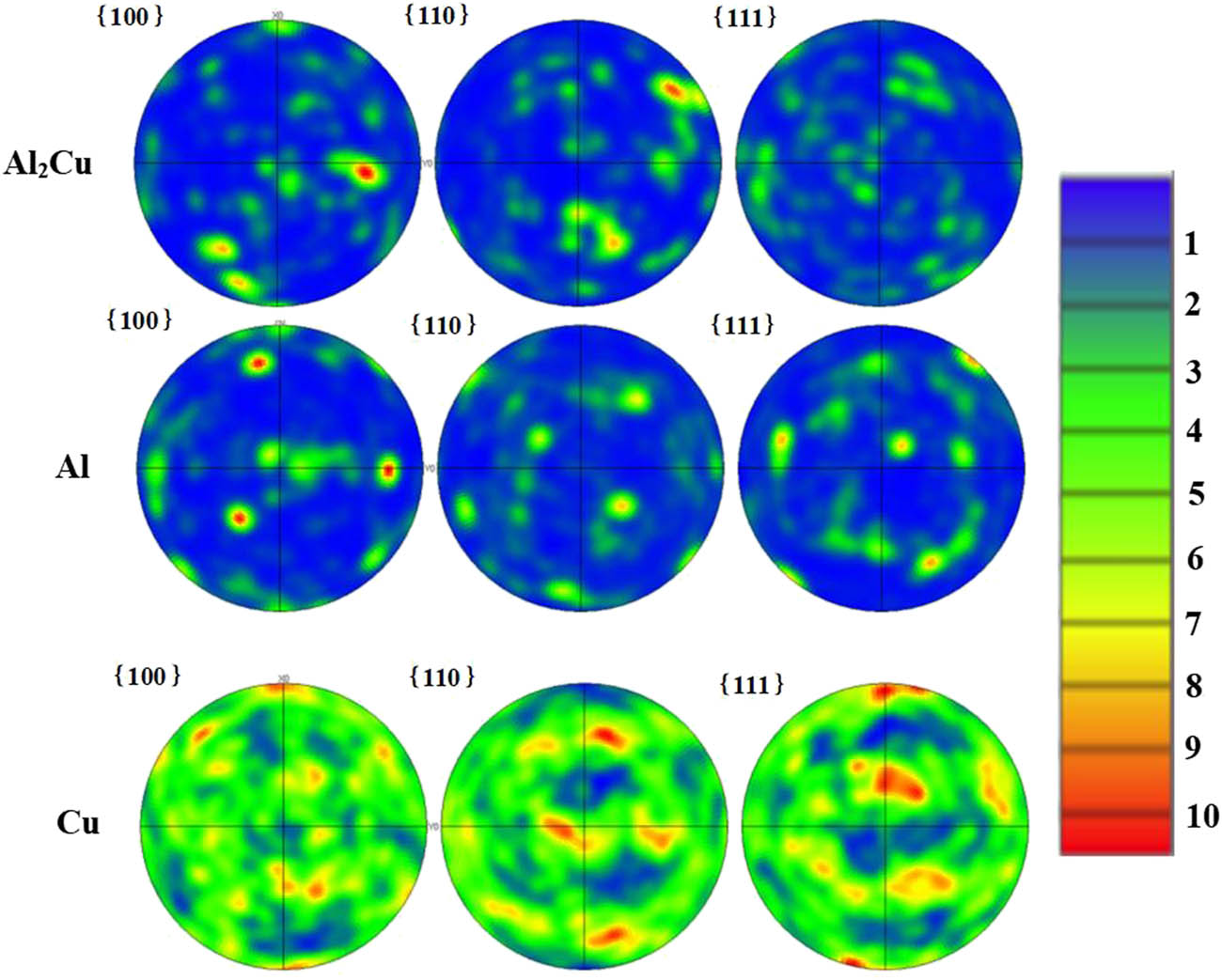

To further analyze the grain orientation characteristics of Cu, Al, and CuAl2, by processing EBSD data, the polar diagram of each phase is obtained, as shown in Figure 8. Compared with the standard texture, there are S texture {123}<634>, Copper texture {112}<111>, and Brass texture {110}<112> in the brazing joint [34].

Pole figures of Cu, Al, and Al2Cu in the BAl88Si brazing point.

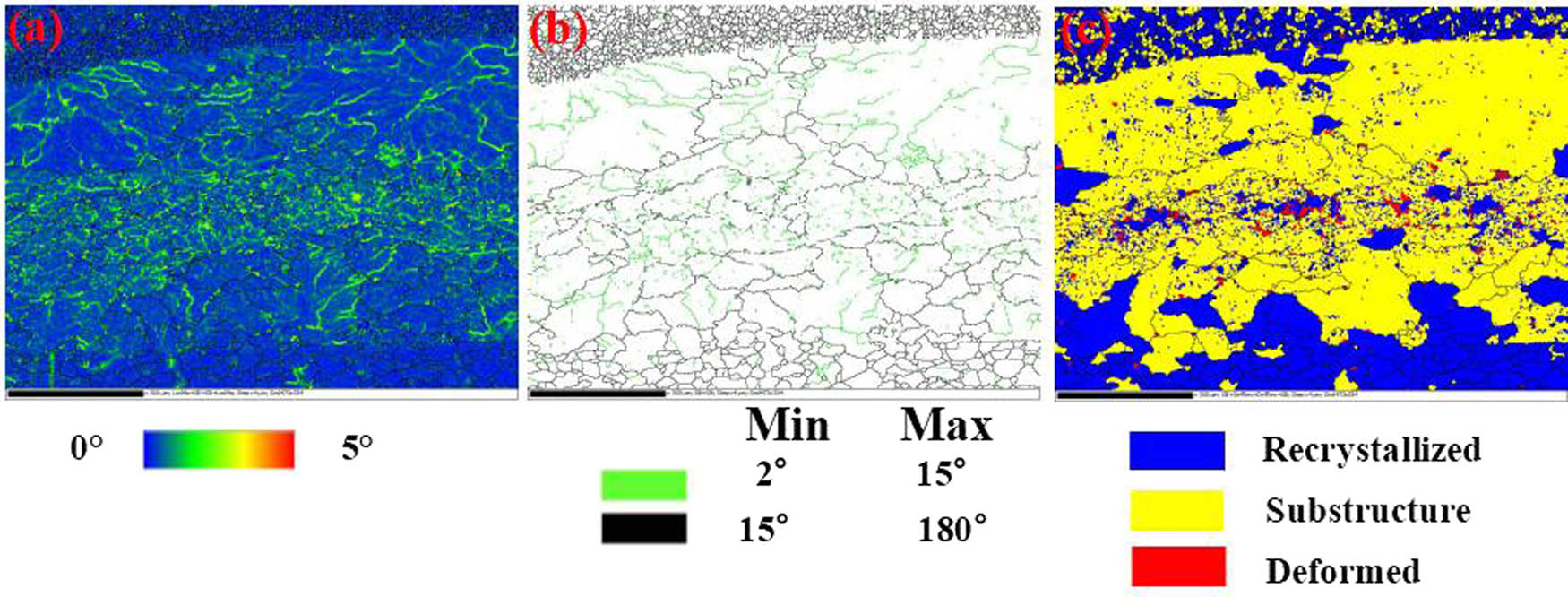

Figure 9(a) shows the KAM diagram corresponding to the inverted diagram of Figure 9(d), from which the distortion density and distribution at the interface of brazing joints can be explained. It can be seen from the figure that the KAM value on the brazed joint aluminum interface is obviously higher than that at the brazed joint copper interface, which means that defect density on the brazed joint aluminum interface is higher than that on the brazed joint copper interface [35]. Figure 9(b) shows the distribution of grain boundaries in the brazed joint. It can be seen that there is a grain boundary with a large angle at the interface of brazing joint Al, which means that the grain size at the interface of brazing joint Al is smaller and more uniform than that at the Cu interface. Figure 9(c) is the recrystallization diagram of the brazed connection. It can be seen that the KAM value at the brazing joint Cu side interface is lower than the KAM value at the brazing joint aluminum side interface, so the grain boundary migration rate at the aluminum side interface is higher than that at the Cu side interface in the recrystallization process [36].

(a) KAM diagram, (b) grain boundary diagram, and (c) recrystallation diagram of brazing joints.

3.3 Corrosion behaviors of brazed joints

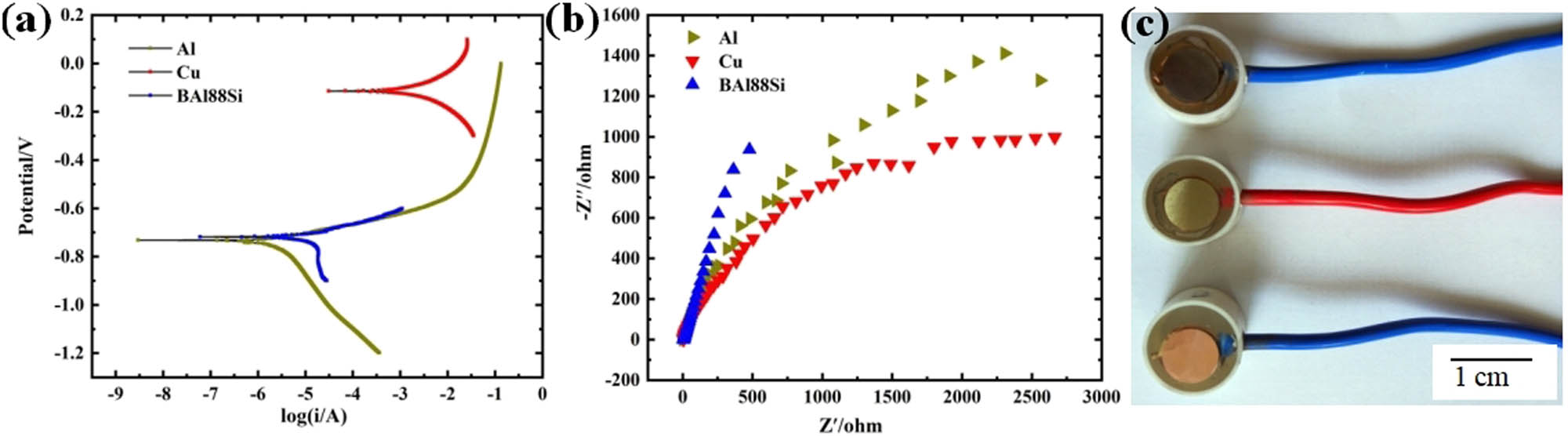

Figure 10 is the electrochemical test chart of brazing, copper, and aluminum, wherein Figure 10(a) is a Tafel curve. Figure 10(b) is the impedance curve and Figure 10(c) is the electrochemical sample graph. By comparing figures, it can be found from Figure 10(a) and (b) that the maximum corrosion potential of copper is −0.096 V and the impedance radius is the smallest. However, Al and brazing seam corrosion potential are both lower than Cu, which are −0.831 and −0.757 V, respectively, and the impedance radius is larger. And the corrosion current density of the brazed joint is 8.456 × 105. Therefore, when the copper-aluminum joint is placed in the salt spray test chamber, the corrosion resistance of the copper side interface of the brazed joint is significantly higher than that of the aluminum side interface of the brazed joint [37].

Image of electrochemical results: (a) Tafel polarization curves of the solder and base metal; (b) electrochemical impedance spectroscopy of the solder and base metal, and (c) diagram of samples for electrochemical tests.

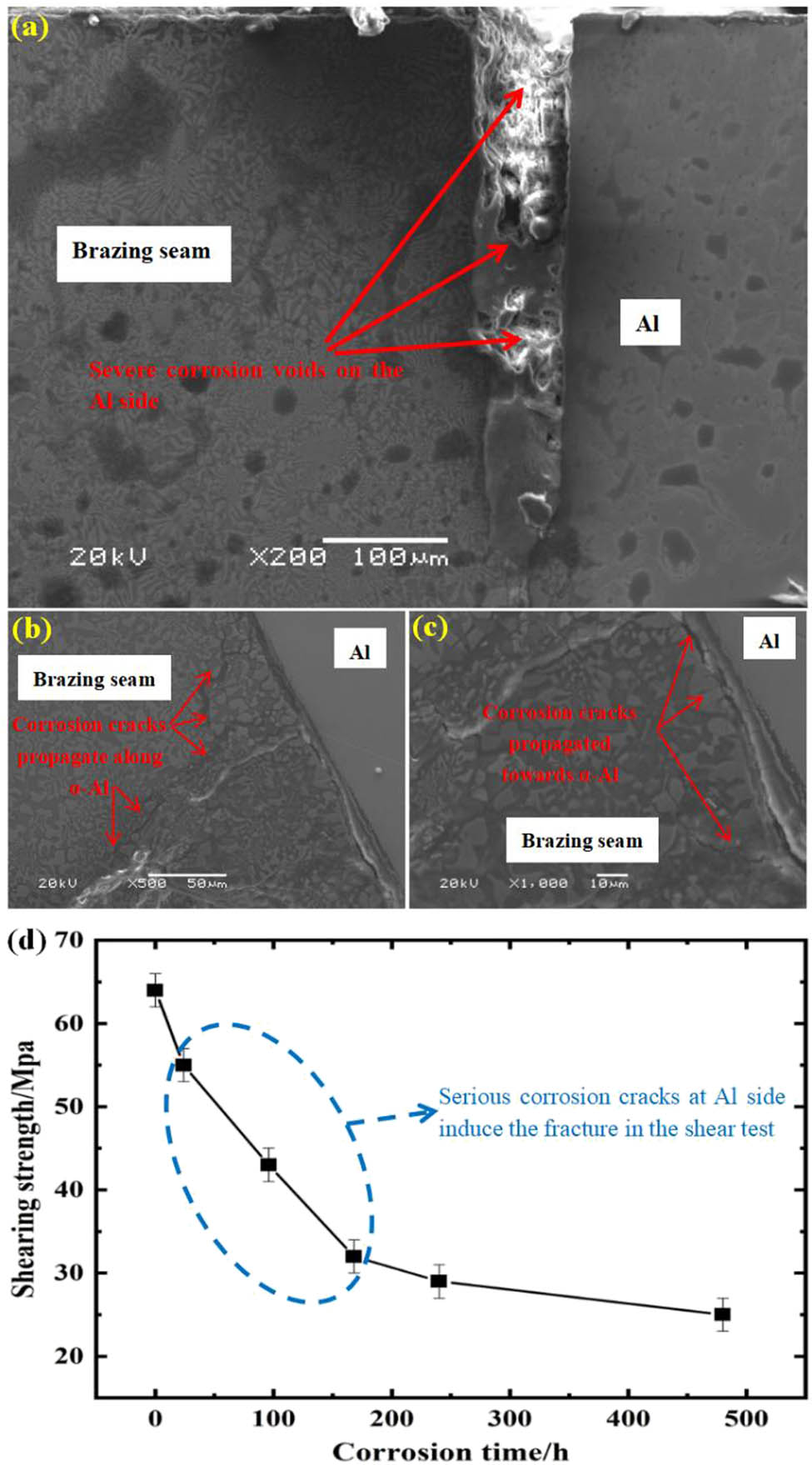

After the neutral salt spray test for 480 h, the microscopic corrosion morphology and shear performance of the brazed joint in each period are shown in Figure 11. Figure 11(a) shows the microscopic corrosion morphology of the brazed joint at 480 h; it can be clearly seen that pitting pits with a depth of 140−170 μm are formed at the aluminum interface of the brazed joints, which is consistent with the conclusion that the corrosion resistance of the aluminum interface is low. Figure 11(b) shows the corrosion crack morphology after 96 h of salt spray corrosion, and Figure 11(c) is an enlarged view of Figure 11(b). It can be clearly observed that cracks have been formed at the interface between the aluminum side and the brazed joint, and the corrosion crack continues to spread with a-Al. During the shear test, the stress corrosion crack tip of the diffusion layer becomes the stress concentration point, which will seriously reduce the mechanical properties of the joint [38]. This is because the radius of Cl− in the salt spray test is very small, so it can be adsorbed on the surface of the sample and combined with cations in the metal on the surface of the sample to form soluble chloride and then become pitting corrosion nuclei [39]. In this way, the pitting core can corrode the surface of the substrate, and the pitting core will continue to grow, which will lead to the dissolution of the metal anode and gradually becoming pitting pits. This is how the pits observed in Figure 11(a) are generated. The neutral salt spray corrosion is electrochemical corrosion, in which metal is the anode and the other areas are the cathode, thus forming a corrosion cell.

(a) Typical microstructure of brazing seam after salt spray test, (b) microstructure of corrosion crack propagation in the Brazed joint, (c) enlarged image of (b), and (d) shearing strength of joints brazed after salt spray tests.

Reduction reaction takes place in the cathode:

Aluminum is oxidized at the anode:

As the progress of redox reaction, the anions generated by the cathode attract the cations to move to the cathode, while the actions generated by the anode attract Cl− to move to the anode, and the corrosion continues. With the decrease of pH value in local corrosion pits, pitting corrosion expands and deepens, and the number and area of small pitting corrosion pits increase and gradually expand to the surrounding area and develop into comprehensive corrosion [40].

It can be seen from Figure 11d. The shear strength of the joint before the salt spray test was 64 MPa. With the increase of salt spray corrosion time, the overall shear strength of the sample decreased significantly. The tensile strength decreased by nearly 50% at 96 h, and by nearly 75% at 240 h. In the first 240 h, the tensile strength of the sample decreased obviously, which was mainly due to the corrosion crack at the Al side interface of the brazed joint, which reduced the mechanical properties of the joint to the greatest extent, which was consistent with the microstructure analysis mentioned above.

4 Conclusion

The experimental results show that the copper–aluminum joint brazed with new green BAl88Si brazing filler metal can obtain good metallurgical bonding as a whole, and no cracks and voids are formed. The interface at the brazed Cu side is composed of two layers of dense intermetallic compounds with a thickness of 7−15 µm, Cu9Al4 and CuAl2. The lattice mismatch rate of the crystal surface of CuAl2 (310)/Cu9Al4 (660) and the interface of CuAl2 (310)/Cu9Al4 (100) is 0.466 and 0.586, respectively. Therefore, there is no good semi-coherent interface between these two intermetallic compounds. The interface away from brazing copper is mainly composed of gray skeleton phase CuAl2, dendrite gray-black phase a-Al, and obvious needle eutectic phase ternary eutectic a-Al + CuAl2 + Si. The mean grain size of CuAl2 in the brazed joint is 11.95 µm, while that of Al was 28.3 µm. However, the KAM value of the brazed joint aluminum interface is obviously higher than that of the brazed joint copper interface, so the defect density of the brazed joint aluminum interface is higher than that of the brazed joint copper interface. At the same time, due to poor corrosion resistance at the aluminum interface of the brazed joint, serious pitting corrosion and corrosion cracks appeared, resulting in the shear performance of the brazed joint decreased by nearly 75% in the first 240 h.

Acknowlegment

The authors gratefully acknowledge funding from the Key Projects of Strategic International Scientific and Technological Innovation Cooperation (grant no. 2016YFE0201300); project (SKLABFMT201902) supported by the State Key Laboratory of Advanced Brazing Filler Metals and Technology, Zhengzhou Research Institute of Mechanical Engineering, Zhengzhou, China; project (20A430013) supported by the Education Department of Henan Province, China.

-

Funding information: Key Projects of Strategic International Scientific and Technological Innovation Cooperation (grant no. 2016YFE0201300); project (SKLABFMT201902) supported by the State Key Laboratory of Advanced Brazing Filler Metals and Technology, Zhengzhou Research Institute of Mechanical Engineering, Zhengzhou, China; project (20A430013) supported by the Education Department of Henan Province, China.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Wang XG, Li XG, Yan FJ, Wang CG. Effect of heat treatment on the interfacial microstructure and properties of Cu–Al joints. Weld World. 2016;61(1):1–10.10.1007/s40194-016-0393-xSearch in Google Scholar

[2] Krishna BV, Venugopal P, Rao KP. Effect of heat treatment and interlayer on weld strength and microstructure of solid state joints between Cu and Al powder metallurgical preform tubes. Sci Technol Weld Join. 2005;10(3):259–67.10.1179/174329305X39293Search in Google Scholar

[3] Wan JB, Liu YC, Wei C, Jiang P, Gao ZM. Effect of the soldering time on the formation of interfacial structure between Sn–Ag–Zn lead-free solder and Cu substrate. J Mater Sci Mater Electron. 2008;19(12):1160–8.10.1007/s10854-007-9505-0Search in Google Scholar

[4] Lee WB, Bang KS, Jung SB. Effects of intermetallic compound on the electrical and mechanical properties of friction welded Cu/Al bimetallic joints during annealing. J Alloy Compd. 2005;390(1–2):0–219.10.1016/j.jallcom.2004.07.057Search in Google Scholar

[5] Xia CZ, Li YJ, Puchkov UA, Gerasimov SA, Wang J. Crack analysis near vacuum brazing interface of Cu/Al dissimilar materials using Al–Si brazing alloy. Mater Sci Technol. 2009;25(3):383–7.10.1179/174328408X262409Search in Google Scholar

[6] Shinozaki K, Koyama K. Development of Al/Cu dissimilar brazing joint controlled form of intermetallic compound. Mater Sci Forum. 2007;539:4075–80.10.4028/0-87849-428-6.4075Search in Google Scholar

[7] Wang XG, Yan FJ, Li XG, Wang CG. Induction diffusion brazing of copper to aluminium. Sci Technol Weld Join. 2017;22(2):170–5.10.1080/13621718.2016.1209625Search in Google Scholar

[8] Feng JC, He P. High frequency induction contact reactive brazing of aluminum to stainless steel. Trans Nonferrous Met Soc China. 2005;15(S2):11–5.Search in Google Scholar

[9] Mao Z, Xie J, Wang A, Wang W, Li Y, Ma D. Interfacial microstructure and bonding strength of copper/aluminum clad sheets produced by horizontal twin-roll casting and annealing. Mater Res Express. 2018;6(1):016505.10.1088/2053-1591/aae2a1Search in Google Scholar

[10] Yang M, Peng H, Lin T. Effect of brazing conditions on microstructure and mechanical properties of Al2O3/Ti—6Al—4V alloy joints reinforced by TiB whiskers. J Mater Sci & Technol. 2013;29(10):961–70.10.1016/j.jmst.2013.05.009Search in Google Scholar

[11] Zhang L, Yu H, Ma J, Zhong S, Jiu Y, Wei S, et al. Microproperties and interface behavior of the BAg25TS brazed joint. Vacuum. 2019;169:108928.10.1016/j.vacuum.2019.108928Search in Google Scholar

[12] Kim HG, Kim SM, Lee JY, Choi MR, Choe SH, Kim KH, et al. Microstructural evaluation of interfacial intermetallic compounds in Cu wire bonding with Al and Au pads. Acta Materialia. 2014;64:356–66.10.1016/j.actamat.2013.10.049Search in Google Scholar

[13] Pouranvari M, Abbasi M. Dissimilar gas tungsten arc weld-brazing of Al/steel using Al–Si filler metal: microstructure and strengthening mechanisms. J Alloy Compd. 2018;749:S0925838818310946.10.1016/j.jallcom.2018.03.224Search in Google Scholar

[14] Lee EJ, Patel A, Acedillo RR, Bachynski JC, Barrett I, Basile E, et al. Research on the corrosion resistance of Cu–Al joints brazed with flux-cored Zn-2Al filler metal. Mater Res Express. 2019;6(5):2053.Search in Google Scholar

[15] Xia CZ, Li YJ, Wang J, Ma HJ. Microstructure and phase constitution near interface of Cu/Al vacuum brazing. Mater Sci Technol. 2007;23(7):815–8.10.1179/174328407X168946Search in Google Scholar

[16] Xia C, Li Y, Puchkov UA, Gerasimov SA, Wang J. Microstructure and phase constitution near the interface of Cu/Al vacuum brazing using Al–Si filler metal. Vacuum. 2008;82(8):799–804.10.1016/j.vacuum.2007.11.007Search in Google Scholar

[17] Yan F, Xu D, Wu SC, Sun Q, Wang C, Wang Y. Microstructure and phase constitution near the interface of Cu/3003 torch brazing using Al–Si–La–Sr filler. J Mech Sci Technol. 2012;26(12):4089–96.10.1007/s12206-012-0884-7Search in Google Scholar

[18] Ghasemi S, Shanaghi A, Chu PK. Nano mechanical and wear properties of multi-layer Ti/TiN coatings deposited on Al 7075 by high-vacuum magnetron sputtering. Thin Solid Films. 2017;638:96–104.10.1016/j.tsf.2017.07.049Search in Google Scholar

[19] Palit D, Meier AM. Reaction kinetics and mechanical properties in the reactive brazing of copper to aluminum nitride. J Mater Sci. 2006;41(21):7197–209.10.1007/s10853-006-0920-zSearch in Google Scholar

[20] Peng D, Kaihua C, Rongshi X. Mechanical properties of aluminum-copper joint by laser penetration brazing. Chin J Lasers. 2011;38(6):0603009.10.3788/CJL201138.0603009Search in Google Scholar

[21] Long WM, Lu QB, He P, Xue SB, Wu MF, Xue P. In situ synthesis of Al–Si–Cu alloy during brazing process and mechanical property of brazing joint. J Mater Eng. 2016;44(6):17–23.Search in Google Scholar

[22] Kim IK, Hong SI. Effect of heat treatment on the bending behavior of tri-layered Cu/Al/Cu composite plates. Mater Des. 2013;47:590–8.10.1016/j.matdes.2012.12.070Search in Google Scholar

[23] Pugal D, Kim KJ, Aabloo A. An explicit physics-based model of ionic polymer-metal composite actuators. J Appl Phys. 2011;110(8):084904.10.1063/1.3650903Search in Google Scholar

[24] Huang S, Long WM, Lu QB, Jiu YT, Zhong SJ. Research on the corrosion resistance of Cu-Al joints brazed with flux-cored Zn-2Al filler metal. Mater Res Express. 2019;6–5.10.1088/2053-1591/ab057cSearch in Google Scholar

[25] Ye Z, Yang H, Huang J, Yang J, Chen S. A novel Zn-Al-Si corrosion resistant filler metal for Cu/Al brazing. Mater Lett. 2017;206:(nov. 1):201–4.10.1016/j.matlet.2017.07.025Search in Google Scholar

[26] Xu C, Lang Q, Wang Q, Chen Y, Yan J, Chen S. Microstructure and mechanical properties of ultrasound-assisted soldered Al-50 wt%Si/Al-27 wt%Si joints for automotive applications. JOM. 2019;71(6):2025–32.10.1007/s11837-019-03337-7Search in Google Scholar

[27] JI F, Xue S, Lou J, Lou Y, Wang S. Microstructure and properties of Cu/Al joints brazed with Zn–Al filler metals. Trans Nonferrous Met Soc China. 2012;22(2):281–7.10.1016/S1003-6326(11)61172-2Search in Google Scholar

[28] Feng J, Songbai X, Wei D. Reliability studies of Cu/Al joints brazed with Zn–Al–Ce filler metals. Mater Des. 2012;42:156–63.10.1016/j.matdes.2012.05.028Search in Google Scholar

[29] Tang J, Zhang L, Zhou T, Sun Z, Kong L, Jing L, et al. Growth characterization of intermetallic compounds at the Cu/Al solid state interface. Mater Res Express. 2019;6(10):106544.10.1088/2053-1591/ab3171Search in Google Scholar

[30] Yu H, Zhang L, Cai F, Zhong S, Ma J, Bao L, et al. Microstructure and mechanical properties of brazing joint of silver-based composite filler metal. Nanotechnol Rev. 2020;9:1034–43.10.1515/ntrev-2020-0083Search in Google Scholar

[31] Pei Y, Huang T, Chen F, Pang B, Guo J, Xiang N, et al. Microstructure and fracture mechanism of Ti/Al layered composite fabricated by explosive welding. Vacuum. 2020;181:109596.10.1016/j.vacuum.2020.109596Search in Google Scholar

[32] Hsu HC, Chien JH, Chu LM, Ju SP, Feng YT, Fu SL. Nanoscale bondability study on copper-aluminum intermetallic compound using molecular dynamics simulation. Microsystems, Packaging, Assembly & Circuits Technology Conference. IEEE; 2013.10.1109/IMPACT.2013.6706686Search in Google Scholar

[33] Battiston E, Salvatici MC, Lavacchi A, Gatti A, Di Marco S, Mugnai L. Functionalization of a nanostructured hydroxyapatite with copper(II) compounds as pesticide: in situ TEM and ESEM observations of treated Vitis vinifera L. leaves. Pest Manag Sci. 2018;74(8):1903–15.10.1002/ps.4892Search in Google Scholar PubMed

[34] Ali ZI, Ghazy OA, Meligi G, Saleh HH, Bekhit M. Copper nanoparticles: synthesis, characterization and its application as catalyst for p-Nitrophenol reduction. J Inorg Organomet Polym Mater. 2018;8:1–11.10.1007/s10904-018-0780-4Search in Google Scholar

[35] Wei Y, Sun F, Tan S, Liang S. Study on microstructure and performance of transient liquid phase bonding of Cu/Al with Al-based interlayers. Vacuum. 2018;154:18–24.10.1016/j.vacuum.2018.04.036Search in Google Scholar

[36] Yan MF, Zhu YD, Zhang YX, Zhang ML. Combining thermo-diffusing titanium and plasma nitriding to modify C61900 Cu–Al alloy. Vacuum. 2016;126:41–4.10.1016/j.vacuum.2016.01.015Search in Google Scholar

[37] Tang J, Zhang L, Zhou T, Sun Z, Kong L, Jing L, et al. Growth characterization of intermetallic compounds at the Cu/Al solid state interface. Mater Res Express. 2019;6(10):407–18.10.1088/2053-1591/ab3171Search in Google Scholar

[38] Xu B, Tong WP, Liu CZ, Zhang H, Zuo L, He JC. Effect of high magnetic field on growth behavior of compound layers during reactive diffusion between solid Cu and liquid Al. J Mater Sci Technol. 2011;9:90–4.10.1016/S1005-0302(11)60155-2Search in Google Scholar

[39] Gueydan A, Domengès B, Hug E. Study of the intermetallic growth in copper-clad aluminum wires after thermal aging. Intermetallics. 2014;50:34–42.10.1016/j.intermet.2014.02.007Search in Google Scholar

[40] Yu H, Zhang L, Cai F, Zhong S, Ma J, Zhang Y, et al. Interface microstructure and growth mechanism of brazing Cu/Al joint with BAl88Si filler metal. Vacuum. 2020;181:109641.10.1016/j.vacuum.2020.109641Search in Google Scholar

© 2021 Hua Yu et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions