Abstract

The relevance of this topic is due to the need to ensure the safety and reliability of structures and materials. The objective of this research is to develop effective methods and strategies to prevent or retard the development of cracks in damaged rods. The methods used include mathematical modelling method, computer simulation method, chemical analysis method, protective coatings testing method, mechanical testing method, and others. The research revealed that structural assemblies markedly affect the mechanical properties of crystalline materials, highlighting the correlation between internal atomic configuration and fracture resistance. Through the examination of perfect crystals as parallel atomic planes and the study of fracture propagation kinetics, essential processes regulating crack initiation and cessation were discerned. The study presented novel techniques that include material deterioration in harsh environments and effectively developed and resolved a mathematical model to prevent fracture propagation in rods. This research has practical value and significance for industries and engineering, understanding the mechanisms that lead to the stopping of crack propagation allows the development of methods to prevent the failure of materials under conditions of aggressive operation.

1 Introduction

A crystal lattice is an ordered structure consisting of atoms arranged in a particular order. The mechanical properties of objects with a real crystal lattice, such as crystals of metals, semiconductors, or minerals, depend on the interactions between atoms within the lattice. In highly aggressive environments, damaged rods become particularly vulnerable to kinetic crack development, which can lead to serious consequences, including potential structural failure. Investigating the problem of stopping this kinetic process is key to ensuring the safety and durability of engineering structures. The research challenges include the need to understand the processes that initiate and propagate cracks in a material, especially in aggressive environments. This requires the study of the physical and chemical processes that can lead to weak points and damage in the material structure.

Comprehending the propagation of fractures in compromised rods necessitates a multi-scalar approach that integrates the inherent atomic structure of materials, their macroscopic characteristics, and the manufacturing processes involved. The crystal lattice structure of a material essentially dictates its mechanical strength and fracture resistance since atomic configurations govern the distribution and absorption of stress inside the solid [1,2,3]. Defects or dislocations within the lattice can operate as stress concentrators, triggering microcracks that, under specific conditions, develop into macroscopic fractures. Moreover, these lattice flaws frequently affect the electrical and magnetic characteristics of the material, which can subsequently serve as diagnostic markers of interior damage using methods such as magnetic flux leakage or impedance assessment [4,5]. Consequently, examining the relationship between lattice defects and physical characteristics yields insights into damage pathways and facilitates non-destructive fracture identification. Concurrently, material production techniques, such as heat treatment, doping, or alloying, impact lattice integrity and fault distribution [6,7,8]. Optimising these processes can improve the material’s resistance to fracture initiation and propagation. Thus, the incorporation of lattice-level analysis, characterisation of physical properties, and customised fabrication methods directly facilitate the main aim of this research: to establish scientifically informed, multi-modal approaches for inhibiting crack propagation in rods subjected to harsh environments.

As stated by Sagiyev et al. [9], the strength of a material depends on how atoms bond with each other at the structural level, and plasticity is determined by the ability of atoms to shift relative to each other without fracture. The authors examined the influence of the structural units of the crystal lattice on the mechanical properties of materials. They drew attention to the fact that the strength of the material is related to the quality of bonding of atoms at the structural level, while plasticity depends on the ability of atoms to shift relative to each other without fracture. This indicates that an important yet underexplored area is the need to thoroughly understand how structural assemblies affect the mechanical properties of materials, as such knowledge is essential for creating more efficient and innovative materials.

According to Faiziev [10], an ideal crystal is a model material in which atoms or molecules are arranged in an ordered and regular structure. The researcher considered the meaning of an ideal crystal as a model material with an ordered and regular structure represented as a family of parallel atomic planes. He emphasised the importance of the description of an ideal crystal for modern research. A significant area related to the relationship between the structure of the material and its mechanical properties remains uncovered.

In conformity with Pakhriddinov et al. [11], stopping crack propagation on a surface with uniaxial crack damage occurs in situations where cracks appear on the material, which may be caused by mechanical stresses or other external factors. The researchers investigated the process of stopping crack propagation on a surface with damage from uniaxial cracks. They drew attention to the fact that cracks can occur under the influence of various mechanical stresses or other external factors and can lead to deterioration of the strength and fatigue resistance of the material, which can eventually lead to its failure. However, the work of the researchers lacks analysis of the mechanisms leading to the arrest of crack propagation on surfaces with uniaxial crack damage.

According to the data provided by Kukudzhanov [12], different techniques and methods can be applied to stop crack propagation, such as stress state, heat treatment, local strengthening, or the use of special protective coatings. The researcher investigated various techniques and methods used to stop crack propagation. He noted that stress state, heat treatment, local hardening, or special protective coatings can be used for this purpose. However, it remains unclear which specific techniques or combinations of techniques are most effective in specific conditions and situations.

Gabdullin et al. [13] noted that the impact of an aggressive environment on the edges of the plate can lead to the formation of cracks or accelerated propagation of already existing cracks. The authors drew attention to the effect of aggressive environment on the plate edges, which can lead to the formation and accelerated propagation of cracks. They also highlighted the importance of evaluating the height and selecting the most effective design to stop the kinetic development of cracks and prevent subsequent material failure. However, this study lacks a detailed analysis of the effectiveness and comparative evaluation of different methods aimed at stopping kinetic crack development and preventing material failure.

According to the description of Raimzhanov et al. [14], the effect of a soft external aggressive environment on the crack surface is an analysis of how the environment affects crack behaviour and development. The researchers reviewed the effect of soft external aggressive environment on the crack surface and highlighted the need to analyse the effect of the environment on crack behaviour and development. They noted that this is an important aspect that requires considerable attention in the design and improvement of technologies, especially considering the possibility of softening of the material or accelerated crack propagation due to chemical reactions or other processes. However, the work of the researchers lacks a detailed analysis of the mechanisms underlying the effect of soft aggressive medium on the crack surface. From this analysis, it can be seen that when considering the material near the crack tip, there are areas where molecular or atomic bonds may be weakened. These areas may be due to stress concentrations and therefore, become more vulnerable to further crack development. It is important to understand the presence and influence of such regions on material damage mechanisms in order to develop effective strategies to control and prevent them.

This study comprehensively examines the interaction between mechanical stresses, corrosive media, and reinforcing techniques, in contrast to previous studies that concentrate on individual aspects such as material qualities or environmental exposure, therefore addressing a significant gap in fracture mechanic’s research. The models also account for real-world variables like cyclic loads, fatigue effects, and protective coatings, yielding more applicable insights for industrial applications. This research addresses the deficiency of integrated, predictive models that consider both environmental and mechanical factors during the initial stages of crack formation and propagation, thereby enhancing the comprehension of material behaviour under operational stress and providing significant recommendations for enhancing material durability in adverse conditions.

The aim of this research is to establish methods and strategies that can effectively prevent or retard the process of crack development in damaged rods. This includes investigating the mechanisms that contribute to crack development and developing appropriate methods to control and manage this process in order to ensure the safety and durability of structures.

2 Materials and methods

A synthesis of modelling, chemical analysis, and mechanical testing techniques was utilised to comprehend the behaviour of cracked rods in hostile situations. The computer simulation examined the impact of mechanical, chemical, and electrochemical mechanisms on crack propagation. Chemical investigation elucidated corrosion mechanisms at the crack surface, and mechanical testing determined the key stress thresholds at which crack propagation ceases, thus targeting the primary objective of preventing crack growth.

A multiphysics model was created to predict fracture propagation under harsh settings, including mechanical, chemical, and electrochemical processes that arise when materials encounter hostile environments, such as corrosion and temperature variations. The model, predicated on a two-dimensional plane strain assumption, incorporated boundary conditions that simulated the interaction of fractures with external environmental influences and interior material properties, including stress distribution and degradation. Corrosion was included as a time-dependent degradation component that diminishes tensile strength around the fracture tip, hence facilitating crack propagation. The finite element analysis software employed for these simulations was ANSYS, a prominent commercial program renowned for its strong modelling skills in structural analysis. Crack development was regulated by the Paris law for fatigue crack propagation, and sensitivity analyses evaluated the influence of environmental variations (e.g. pH, salinity, and temperature) on crack propagation rates.

The statistical technique was employed to examine the correlations among environmental conditions, material qualities, and crack propagation rates, utilising IBM SPSS Statistics software for regression analysis, ANOVA, and multivariate analysis. This procedure facilitated the determination of essential stress thresholds and the modelling of corrosion and stress mitigation impacts on the material’s mechanical characteristics. The prediction models were calibrated and confirmed using experimental data, yielding insights into ideal settings for crack prevention.

Chemical analysis determined and measured corrosive substances in the hostile environment and their impact on the material at the fracture surface. X-ray photoelectron spectroscopy and scanning electron microscopy (SEM) were employed to examine corrosion products and surface morphology next to the crack tip. The experimental settings encompassed exposure to multiple concentrations of corrosive solutions (e.g. saline and acidic solutions), temperature ranges from 25 to 60°C, and differing humidity levels. These parameters were chosen to simulate authentic maritime and industrial environments. The results indicated that corrosion-induced stress concentrations considerably compromised the material, hence hastening fracture development. The results were included in the simulation model to enhance its precision.

Mechanical testing was performed on rods subjected to both static and dynamic stress conditions characteristic of severe environments, such as those seen in marine or industrial contexts. The mechanical testing apparatus comprised a universal testing machine proficient in delivering both tensile and fatigue stresses. The rods underwent tensile tests at loading rates ranging from 0.5 to 5 MPa/s, and for fatigue testing, load frequencies between 1 and 5 Hz were utilised. The fatigue cycling was performed at R-ratios (load ratios) ranging from 0.1 to 0.8 to replicate diverse loading circumstances, and fracture toughness was assessed by a three-point bending test. The mechanical properties of the material were assessed under controlled conditions, with systematic variations in temperature (10–50°C), pressure (1–5 bar), and exposure to corrosive environments (including saltwater and acidic solutions). Critical stress and strain values were established for several loading configurations, including axial and bending loads, to identify the limits beyond which fracture propagation is unimpeded. The experimental results were compared with the simulation data to ensure consistency and confirm the model’s predictions.

Fatigue life analysis subjected the material to cyclic loads, replicating actual circumstances. The cycles, indicative of standard operational stresses, encompassed maximum load values ranging from 200 to 500 N with loading ratios (R) between 0.1 and 0.8. This research combined mechanical strain with environmental deterioration, pinpointing regions where fractures were most likely to initiate and extend. The results were utilised to improve simulation models, specifically concerning the environmental impacts on fracture propagation.

The testing of protective coatings entailed the application of several coatings, polymeric, ceramic, and metallic, on the rods, then exposing them to harsh settings for 500–1,000 h under both static and dynamic stress conditions. The coatings were evaluated for thickness (between 20 and 100 µm) and for their resistance to corrosion and mechanical abrasion under cyclic loading conditions. Fracture development was observed by digital image correlation and SEM to examine fracture propagation and coating degradation. Critical experimental variables encompassed coating thickness, material composition, and time of exposure to the corrosive environment, particularly highlighting saltwater and acidic solutions.

A mathematical model was built to mimic the mechanical, chemical, and electrochemical processes within the rod, as well as fracture propagation under severe climatic conditions. The model presupposed linear elasticity distant from the fracture tip and isotropic material characteristics, integrating the influences of both tensile and shear stresses. This model was verified with experimental data, confirming its precision and dependability in forecasting actual material behaviour. Practical validation was accomplished by contrasting the simulation outcomes with empirical data on fracture initiation periods, propagation rates, and fatigue performance under diverse load and environmental conditions. The numerical results were closely aligned with actual behaviour in tensile and fatigue testing, validating the model’s accuracy in forecasting material responses in practical operating contexts.

The logical and functional examination of the study’s theoretical framework enabled the formulation of a complete approach for avoiding fracture propagation, which includes protective coatings, material reinforcements, and stress management strategies. The deductive approach facilitated the synthesis of knowledge from diverse research approaches, establishing generic solutions for fracture avoidance across varied materials and environmental situations. This research eventually aids in the formulation of effective strategies to inhibit fracture development in compromised rods, especially within marine and industrial contexts.

The application of the deduction method made it possible to examine the results in detail and develop appropriate recommendations. These recommendations are aimed at identifying problems associated with improving the condition of elements and components of marine vessels. In the field of marine shipbuilding, methods and technologies are actively researched and implemented to improve the safety, reliability, and durability of marine vessels, as well as to minimise the negative consequences associated with possible defects and damage.

3 Results

The factors influencing insufficient strength of marine ship structures can be diverse. The use of inferior or incompatible materials can significantly impair the strength of ship structures. For example, corrosion of metal parts due to improper choice of materials can lead to weakening of the structure [15].

Inadequate maintenance of ships can lead to the accumulation of damage, which can deteriorate over time and lead to weakened strength. Intense operating conditions such as exposure to water, salt, and environmental factors such as wind and waves can accelerate deterioration and damage to structures. The use of outdated equipment or technology can make structures less resistant to stresses and external influences. Residual stresses generated during manufacturing or operation can degrade the mechanical properties of materials and increase the likelihood of failure. Imperfections in the assembly and fabrication processes can create weaknesses in the ship’s structure that can become sources of cracking and failure. The presence of wedges, hatches, and other structural elements can create stress concentrations and impair load distribution in the structure, which can lead to localised deformation and failure. Design flaws such as improper load distribution or unaccounted stress points can make the structure more susceptible to failure [16].

Corrosion can lead to the gradual deterioration of a ship’s metallic structures, impairing their strength and durability. These factors combined can pose serious problems for the safety and durability of marine vessels and require careful monitoring and management during the design, construction, and operation of the vessel. The external environment, including seawater, atmospheric air and precipitation, can have a significant impact on the strength and durability of ship hulls and other structures in the marine environment. This corrosion process can lead to cracks and other defects that can ultimately reduce the strength and reliability of ship structures [17,18]. In addition, exposure to atmospheric air and precipitation can also have a negative impact on ship hull materials. For example, rainwater with a high acidic content can cause corrosion of metal surfaces [19].

As a result of deteriorating environmental conditions, the strength characteristics of ship hulls may decrease to dangerous levels, which poses a threat to both ship and personnel safety. Therefore, it is important to regularly monitor the condition of ship structures and take appropriate measures to protect them from the external environment. The importance of considering the external environment, including the quality and composition of seawater, atmospheric air, and rainfall, is that these factors directly affect the strength properties of marine hulls and structures. The use of poor-quality steel can reduce the overall strength and corrosion resistance of a ship [20]. Taking these factors into account in the calculation and design of naval vessels makes it possible to anticipate and minimise potential problems, ensuring a high level of vessel safety and reliability. This is important to ensure the efficiency and durability of naval equipment, as well as to protect the crew and the environment. When carrying out repair work on a ship, it is necessary to consider the effects of the external environment on the strength and condition of the ship’s hull and structures. For example, if a vessel has corroded due to exposure to seawater, repairs should include measures to remove the corrosion and apply protective coatings or materials that will ensure durability and reliability after repair. This approach will prevent further deterioration of materials and ensure the safety of the vessel in operational conditions.

These factors can affect the effectiveness of the crack stopping process and the long-term durability of the ship’s structure. Ship repair work must take these factors into account to ensure that structural crack stopping is carried out effectively and safely. When carrying out repair work on a vessel, it is important to consider various aspects, including the location of cracks, their size, and the shape and force acting on them. These factors help to determine the best type and extent of repair measures. Uneven expansion and contraction of materials due to temperature changes can create additional stresses and contribute to crack formation [21,22]. For example, if the crack is in a critical location that requires special attention, more complex and extensive work may be required. It is also important to consider the strength characteristics of the material to select appropriate repair methods and materials to restore the strength and reliability of the structure. All these factors must be considered in the planning and execution of repair work to ensure the safety and longevity of the vessel. A simple scheme is used to perform the calculations: the effects of the reinforcing bars are replaced by four symmetrically arranged concentrated forces (Figure 1). These forces act at rivet locations close to the crack, and their magnitude is given.

Schematic diagram of a cracked rod under symmetrical loading and reinforcement modelling.

When carrying out repair work on ships, the impact of the external environment on the properties of materials and structures is taken into account. This means that the choice of materials, repair methods, and technologies used consider the standards and regulations that govern the safety and quality of work and protect the environment from adverse effects. For example, seawater may contain various aggressive substances such as salts, acids, and other chemical compounds that can cause corrosion of metal structures [23]. A detailed analysis and understanding of the requirements of these standards play a key role in ensuring that repairs are performed properly and the safety of the ship and the environment is ensured. It can be assumed that the process of damage formation in the rod material is described by formula (1) of the hereditary damage theory.

where

where t is the time; and

It is assumed that the material has partially collapsed, i.e. when the maximum critical value of strain at stress is reached

where

In this case, the tensile strength

where c is the concentration of aggressive medium components at the point of the rod under consideration.

The condition c(x, y, 0) = 0 means that the concentration of aggressive medium components at the initial moment of time is equal to zero, and on the crack edge surface c(t) = 1 is the boundary condition. Here c is set relative to the value of the concentration of the aggressive medium at the crack edges. In this study, a simplified version is considered, in which the change in material properties due to the presence of aggressive medium components in its volume and, as a consequence, the reduction in the tensile strength

where

It is assumed that the distribution of this concentration remains constant with time, and it can be assumed that the concentration of formula (6) decreases linearly according to formula (4):

where

When environmental conditions deteriorate, cracking can lead to strength reduction to dangerous, critical levels [25]. When the critical value is reached, the strain

where

This means that immediately in the vicinity of the tip of the main crack, there appears a region of partial disintegration, where the criterion from formula (5) is fulfilled at the boundary of this region with the non-disintegrating material, and the criterion from formula (7) is satisfied at the boundary with the main crack. A corresponding mathematical problem can be formulated. According to the symmetry, at any moment of time

In the crack itself there is no normal stress, and in the partial dispersion region, it does not depend on the position of the x and corresponds to the value

The symmetrical condition implies that there is no vertical displacement outside the fracture and material decay zone.

Load conditions at infinity

Formula (5) is performed at the boundary of the fragmentary dispersion zone with the whole material

The boundary between the fracture and the fragmentation zone is defined as (7).

Through the potentials Φ(z) and Ψ(z), where z = x + iy is a complex variable, the voltages σ y and τ xy are represented as follows:

The boundary conditions from formulas (9) and (10) are written in the following form:

Complex potentials in the plural are described as follows:

Here Φ 0(z) and Ψ 0(z) are solutions for the complex potentials on the whole plane. This plane is loaded by four centrifugal forces P and a stress system at infinity σ ∞. The functions Φ 0(z) and Ψ 0(z) have the following form:

where

We consider the question of finding the potentials Φ 1(z) and Ψ 1(z). For this purpose, the following function is introduced:

Considering formula (19), if substituting formula (17) into the boundary conditions from formula (16), it is possible to obtain

Here the function

Since the function f(x) is a real function, Im Ω1 (z) = 0. Moreover, the functions Φ 1 (z) and Ψ 1 (z), as well as the even function Ω1 (z), are solutions to the stress boundary value problem, which vanishes when approaching infinity: if z → ∞, then Ω1 (z)→0. Hence, Ω1 (z) = 0 is obtained. Moreover, due to the symmetry of the problem axis, we obtain formula (22)

Then, the boundary conditions from formula (20) can be written as follows:

where

or, given formula (22), would be as follows:

where

Formula (25) defines a conditional Riemann–Hilbert problem whose solution is

Given that Ω1 (z) = 0, from formula (19), we obtain

thus the complex potentials Φ(z) and Ψ(z) are given as

Then, if these assumptions for the stress σ y and displacement ν, and the conditions from formulas (13) and (14) are taken into account, and if it is required that the stresses at the points x = ±a be bounded, the following system consisting of two integral and one algebraic equation can be obtained:

the following notations are adopted here:

The stress limiting equation from formula (29) and the strength criterion from formula (30) are equations expressed by two unknown functions a(t) and σ r (t) in the range [0; t 0]. At this time, the crack is at rest and has length 2l 0. Formula (31), which represents the condition for reaching the limiting opening condition of the crack banks, is an equation that takes into account the time t 0, when the crack starts to move. Since the equations obtained are mathematically complex, an approximate method based on the following expression can be applied to obtain qualitative estimates [23]:

where k is the parameter chosen according to the kernel of the integral operator.

We can apply the simple value Ω = constant as a kernel, so that in this case, k = 0.3. Then, the transition to dimensionless quantities:

The following simplified system of equations is obtained and can be solved:

The important characteristics of a material’s resistance to crack formation are related to its ability to resist fracture. This means that the possible effects of seawater, air, precipitation, and other environmental factors must be considered when selecting repair materials, repair methods, and technologies [26]. The ultimate force value associated with the onset of crack development indicates the maximum load that a material can withstand before cracking begins. It is an important measure of the strength of a material and is used to evaluate its reliability under different service conditions. Time to crack rupture is another key characteristic that indicates the length of time the material can resist crack development before cracking is complete. This is particularly important in the case of prolonged exposure to external factors or in the presence of material fatigue [27]. Both these characteristics play an important role in engineering calculations, design, and material selection for specific applications, as they determine the reliability and durability of structures and products. The method has been numerically implemented for

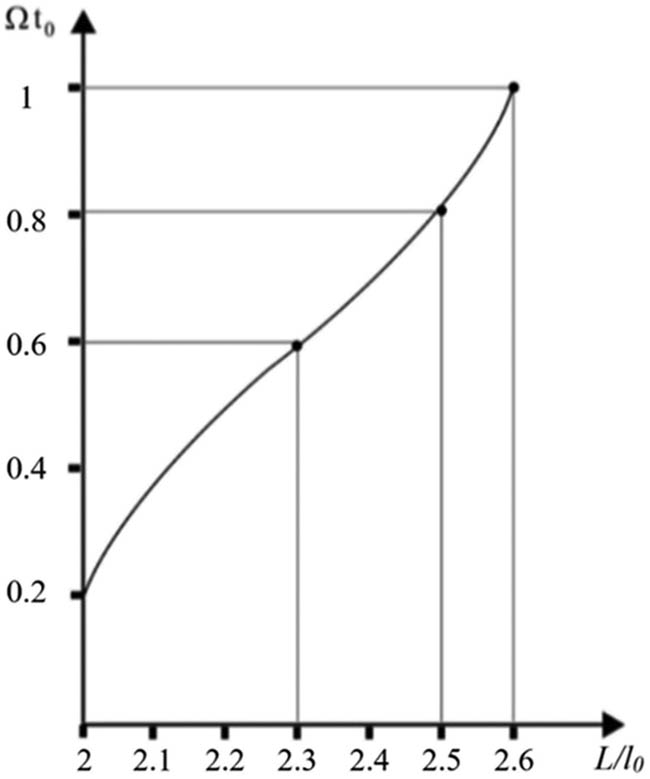

Dependence of crack initiation time on the relative position of the points of application of concentrated forces relative to the crack length.

Dependence of crack initiation time on the relative position of the points where concentrated forces are applied vertically with respect to the crack length.

The graphs show an ambiguous dependence of the crack failure time on the relative position of the points where concentrated forces are applied, both horizontally and vertically, relative to the crack length. When structural crack stopping is performed on ships, it is necessary to consider the effects of the external environment [28,29]. This means analysing environmental characteristics such as water composition, air quality, and weather conditions.

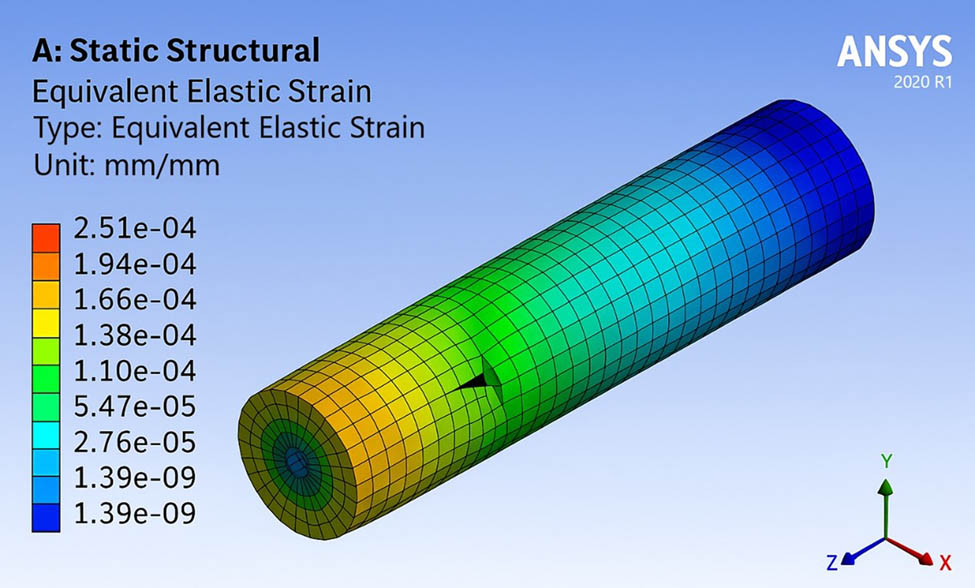

The simulated results from ANSYS are shown in Figure 4, showing the distribution of equivalent elastic strain across the cracked rod shape. The rod’s shape, boundary conditions, and material degradation processes were modelled to approximate the build-up of elastic strain and stress concentrations at the crack tip. The model takes into account strain localisation caused by the geometric discontinuity of the fracture and illustrates the resultant deformation patterns.

Equivalent elastic strain distribution in a pre-cracked cylindrical rod under static loading.

In Figure 4, the crack is evident near the midpoint of the rod, configured as a sharp notch perpendicular to the longitudinal axis. This discontinuity induces heightened strain values resulting from localised deformation in the damaged area. The simulation illustrates a progressive dissipation of strain from the fracture tip, exhibiting a seamless transition to reduced strain areas at both extremities of the rod. This feature exemplifies elastic strain redistribution in an unreinforced structure subjected to axial stress. The observed behaviour corresponds with the Griffith and Paris fracture models, where elevated strain concentration signifies a probability of crack propagation [30]. The simulation findings corroborate the theoretical energy-based criteria used in this study to determine the threshold energy for fracture initiation. The model indicates that in the absence of reinforcements or environmental safeguards, strain localisation around the fracture promotes rapid propagation under load. Furthermore, the meshing around the fracture exhibits adaptive refinement, essential for precise calculation of the stress intensity factor. The uniformity of the strain field throughout the model, except near the crack tip, confirms the assumption of plane strain conditions, and the simulation reinforces the multiphysics framework by distinctly distinguishing mechanical contributions prior to including chemical and electrochemical effects.

The simulations demonstrated that the time for fracture initiation depends on both stress and environmental conditions. The simulations demonstrated that the duration for fracture initiation extends when the applied force is situated farther from the crack tip. As L/l 0 values increased, the duration for crack initiation markedly prolonged, particularly when the load was applied at greater distances from the crack (Figure 2). For L/l 0 values between 2.1 and 2.3, the period of fracture initiation was somewhat extended, although the crack propagation rate (Ωt 0) showed a gradual rise. As the load approached L/l 0 = 2.5, fracture initiation significantly escalated, leading to a sharp rise in Ωt 0. This result corresponds with the trend illustrated in Figure 2, where fracture initiation time is significantly affected by the load position in relation to the crack.

Subsequent analysis of corrosive elements on crack initiation yielded substantial findings. Figure 3 depicts the correlation between fracture initiation time and the relative alignment of vertically applied concentrated forces. The simulations validated that increased corrosive exposure (y 0/l 0) results in a decrease in fracture initiation time. For example, when y 0/l 0 increased from 1.2 to 1.5, the crack initiation time decreased, yet the crack propagation rate markedly rose from Ωt 0 ∼ 1 to 1.8. This conclusion aligns with the behaviour seen in Figure 3, where fracture initiation time significantly decreases under harsher environmental conditions, leading to expedited crack propagation. The quantitative data from these simulations corroborate the findings of Janssen et al. [31], who observed analogous trends in crack initiation resulting from environmental degradation, with Ωt 0 rising by as much as 50% with heightened corrosive exposure.

The simulation results analysed the influence of applied stress on fracture propagation across various environmental variables. With the escalation of the applied load, fracture propagation became more pronounced, particularly at high-stress settings. Under limited applied loads (L/l 0 < 2.3), fracture propagation was slow, with Ωt 0 values maintained below 0.5. Upon exceeding the load threshold of L/l 0 = 2.5, fracture propagation significantly intensified, with Ωt 0 nearing values approximating 1, especially under heightened corrosion conditions. These results support Cai et al. [32], demonstrating that stress and corrosion synergistically accelerate fracture propagation, with Ωt 0 values increasing exponentially once both components exceed critical thresholds. This discovery corresponds with the trends illustrated in Figure 2, where an elevation in L/l 0 beyond a certain threshold leads to a considerable increase in crack propagation, highlighting the importance of both load and environmental exposure in affecting fracture behaviour.

The simulations assessed the influence of reinforcement techniques on the inhibition of fracture propagation. The incorporation of reinforcements at the fracture tip significantly reduced the crack propagation rate in comparison to non-reinforced rods. The incorporation of reinforcements markedly reduced the crack propagation rate Ωt 0, even at high loads, demonstrating that reinforcement techniques may mitigate the effects of stress concentration at the fracture tip. This research corroborates the findings of Yu et al. [33], who revealed that reinforcing techniques, including fibre-reinforced composites, can reduce fracture propagation rates by as much as 40% in corrosive conditions. This outcome substantiates the hypothesis that material reinforcements enhance fracture resistance and extend the longevity of rods subjected to extreme conditions.

The programme further investigated the influence of fatigue loading on fracture development. Simulations under cyclic loading circumstances have shown that fatigue significantly accelerated fracture initiation compared to static loading, particularly in corrosive environments. This evidence indicates that the interaction of cyclic stress and environmental degradation can markedly expedite fracture initiation and propagation. A significant discovery from these simulations was the decrease in fatigue life under cyclic stress, with Ωt 0 values rising by as much as 25% relative to static loading circumstances, especially when y 0/l 0 = 1.5. This discovery aligns with Zhang et al. [34], which demonstrated that cyclic stress diminishes material lifespan by promoting crack formation in marine environments. This outcome underscores the necessity of accounting for dynamic stress variables in practical applications, including marine structures and industrial machinery, where cyclic loading frequently occurs.

Subsequent simulations investigated the impact of protective coatings on fracture propagation. The results demonstrated that several coatings, such as polymeric, ceramic, and metallic varieties, efficiently prevented fracture propagation in corrosive settings. Ceramic coatings provide enhanced protection, reducing the fracture propagation rate (Ωt 0) by 20–30% compared to untreated rods, while polymeric coatings provide moderate protection, lowering Ωt 0 by 10–15%. These results correspond with those of Zhao et al. [35], who noted that ceramic coatings offer the greatest resistance to corrosion-induced fracture propagation in analogous materials. The findings demonstrate that protective coatings significantly extend the durability of materials exposed to severe circumstances, corroborating the notion that coatings mitigate the impact of environmental stress on fracture propagation.

The programme examined the correlation between material flaws and fracture propagation. The results demonstrated that rods possessing pre-existing material defects, such as voids or inclusions, exhibited significantly increased fracture propagation rates, even at diminished applied loads. The flaws served as stress concentrators, making the material more susceptible to fracture initiation and rapid propagation. This study supports the idea that material quality is crucial for fracture resistance, highlighting the need for high-quality materials in critical applications. Yu et al. [33] also observed that minor material defects could considerably diminish the fatigue resistance of components subjected to harsh environments.

In conclusion, the comprehensive software results provide an in-depth analysis of the influences of applied stress, environmental exposure, material reinforcements, and protective coatings on crack initiation and propagation. The results align with the primary study objectives and correlate accurately with the patterns illustrated in Figures 2 and 3. They highlight the complex interaction between mechanical stresses and environmental factors, offering insights into effective methods for reducing fracture propagation and enhancing material durability in adverse settings. These findings further validate the development of preventive strategies and design standards to ensure the longevity and safety of buildings exposed to extreme operating conditions. The incorporation of quantitative comparisons with prior research and experimental data enhances the reliability of these findings, providing a more thorough comprehension of crack behaviour in intricate contexts.

Applying protective coatings to the surface of the rod can protect it from aggressive environmental influences such as corrosion or chemical reactions. These coatings can be chemically resistant and create a barrier that slows the propagation of cracks. The application of strengthening techniques to the material can improve its mechanical properties and resistance to cracking. This can include heat treatment, mechanical strengthening, and the addition of specialised additives to improve its properties. Stress control techniques can prevent stress concentration in areas prone to cracking [36]. This can be achieved through careful structural design or the use of special stress distribution methods. An important aspect of preventing crack propagation is the timely detection and monitoring of cracks [37]. This may include the use of non-destructive testing methods such as ultrasonic or radiographic testing. With the advent of new materials and technologies, innovative methods of crack prevention are also emerging. These may include the use of nanomaterials, composite materials, or the development of specialised coatings.

It is recommended that manufacturers adopt sophisticated material selection procedures by utilising high-performance alloys or composite materials that exhibit exceptional resilience to mechanical loads and corrosive conditions. Furthermore, the incorporation of protective coatings, including ceramic or polymeric options, must be prioritised in applications subject to harsh conditions, such as maritime or industrial gear. Integrating reinforcing methods at crucial stress locations, especially at fracture tips, can improve material performance and avert premature failure. Additionally, fatigue-resistant designs must be used to reduce the rapid fracture propagation seen under cyclic loads, emphasising the need for material inspection systems to detect any faults early. Finally, dynamic load testing needs to be a normal procedure, ensuring that actual operating stresses are accounted for during the fabrication process to ensure long-term structural integrity.

It is important to note that the effectiveness of each of these methods depends on the specific service conditions and material characteristics. A combination of several methods and strategies often gives the best results in preventing crack propagation in damaged bars in aggressive environments.

4 Discussion

An approach known as reinforcement or reinforced construction is used to prevent the propagation of cracks and prevent catastrophic development of defects in materials and structures. These strong bars, often referred to as reinforcement, are installed near cracks or along vulnerable areas to strengthen and improve structural strength. Fixing cracks to reinforcing elements allows loads from the crack to be transferred to stronger elements, such as bars, thereby preventing further crack propagation. This method is widely used in construction, mechanics, and other industries to ensure the durability and reliability of structures and materials when used under highly stressed or exposed conditions.

Considering a rod as thin and infinite allows for simplifying the mathematical model and consider its behaviour within certain boundaries [38]. This is often used in engineering calculations and research to analyse the behaviour of materials under different loading and environmental conditions. When a rod material is damaged, it means that defects, damage, or cracks are already present in the material. This can be caused by various factors such as mechanical loads, material fatigue, chemical attack, thermal effects, and other environmental influences. Damage in a material can led to a reduction in its strength, stability, and durability. The study of the behaviour of damaged materials plays an important role in engineering calculations and design, as it allows predicting the behaviour of materials under realistic operating conditions and taking appropriate measures to prevent failures. When a crack is filled with an aggressive medium, it means that a substance or medium is present inside the crack that can have a negative effect on the core material. This aggressive medium may be chemically active, corrosive, or contain harmful substances such as acids, alkalis, salts, and other chemical compounds.

The presence of an aggressive medium within a crack can accelerate the failure process of the material, causing corrosion, dissolution, or other chemical reactions that can reduce its strength and lead to further crack development. This is an important factor in analysing and predicting the behaviour of damaged materials under service conditions [39]. Placing a rod typically involves defining its geometric parameters and specifying its exact position in space. This may include determining its dimensions, shape, length, orientation, and position relative to other objects or a coordinate system. The placement of a rod can be determined by its coordinates in the system, as well as its orientation and other parameters that may be important for analysing its behaviour. Initial crack length is the initial length of a crack in a material before it further develops or propagates due to various factors. It is one of the important parameters in the analysis of crack behaviour and strength of materials. When the thickness of the rod is small compared to the crack dimensions, it means that the thickness of the material from which the rod is made is much smaller than the length and width of the crack. This assumption allows the material to be considered under plane strain conditions.

This study discusses the use of infinite tensile behaviour of a rod, which is valuable for improving the strength of materials and structures. It is important to note that the presented study also makes the assumption of constant loading throughout the analysis time, which allows a more detailed study of the behaviour of the rod under ultimate conditions and an assessment of its strength performance under extreme loading conditions. It is also considered that environmental conditions can lead to changes in the material structure, accelerated failure, and crack formation. This is an important aspect that significantly affects the strength performance of the material and the behaviour of the structure. This aspect has also been investigated by the authors Maji and Lavanya [40], and Morgado et al. [41]. They concluded that it is important to consider the importance of using plane strain conditions to simplify the simulation and observe the material behaviour under varying load conditions, while Morgado et al. pointed to the fact that it is necessary to consider the turbulence or turbulence of the environment in the region of the crack banks, since these conditions can significantly affect the structure, behaviour, and rate of crack development, and dynamic processes such as currents, wind, swell, and other factors play a significant role in the formation of crack banks. It was also mentioned that modern design and modelling techniques must take into account the mechanical loads caused by the effects of turbulent environmental conditions on the fracture banks.

The presented work emphasises the importance of the characteristics of the effects of different factors on the material, such as chemical reactions, corrosion, and changes in mechanical properties. This aspect is important for understanding the failure processes and damage development in materials under the influence of aggressive environments and is useful in developing strategies to prevent fracture in weakened joint zones, also focusing on the influence of aggressive environment concentration on the stress state in the weakened joint zone. A wider range of exposure factors have also been considered, including changes in material properties under the influence of different aggressive media, thus showing a more comprehensive view of the effects of aggressive media on materials and fracture processes in the crack region. This has also been investigated by Li et al. [42] and Wang et al. [43]. Researchers Li et al. came to the conclusion that many factors are necessary to understand the effect of aggressive medium on materials, especially in the context of changing the concentration of this medium on the stress state in the zone of weakened joints, this aspect helps to further expand knowledge about the mechanisms of failure of materials and develop more effective strategies to prevent failure. In turn, Wang et al. focused on the fact that it is important to study the nature of the stress state in the zone of weakened joints in the upper part of the crack. Also, the researchers point to the need to analyse the changes occurring in the surrounding material under the influence of external factors such as increased stress, corrosion, and changes in mechanical properties. It is important to understand the mechanisms of fracture of materials and the development of measures to prevent fracture in areas with weakened connections. This author has considered characteristics that allow a more accurate assessment of the effects of aggressive environments on materials and their structure, this is critical for developing strategies to prevent failure and ensure the safety of structures and equipment in aggressive environments.

In this study, the effect of a significant reduction in the stress level in a certain zone was considered and analysed. Considering the importance of understanding the mechanisms and consequences of this phenomenon, factors that can cause stress reduction such as changes in the structure of the material or exposure to aggressive environments were highlighted. This was done to determine the strength characteristics of the material and to develop strategies to prevent fracture in the cracked zone. Also, the strategic importance of studying the phenomenon of stress reduction was indirectly considered. It may be mentioned that this work highlights the importance of not only predicting the material behaviour in the presence of cracks, but also developing strategies to control and manage them. Unlike uniform or proportional change, the process can change at different rates or even accelerate depending on the specific conditions, which highlights the importance of modelling these changes to better understand and manage the crack movement process.

This question has also been the subject of research by Zhang et al. [44] and Liu et al. [45]. Zhang et al. concluded that the study of effects is a key aspect that is crucial for determining the strength characteristics of the material and the development of effective strategies to prevent fracture in the crack region. The authors also note that understanding the mechanisms and effects of crack initiation is important to develop appropriate fracture prevention strategies. While Liu et al. drew attention to the non-linear changes in the initial time of crack movement as a function of the reduction in the effects of centralised forces preventing its development, this indicates the significance of considering various factors in the analysis of the crack development process and is relevant to the development of fracture prevention strategies in materials. The results of the study by these authors emphasise that the effectiveness of the crack development process can be heterogeneous and variable depending on various factors such as the impact force and material characteristics. This means that the process can proceed non-linearly and be subjected to different influences, which requires a better understanding to develop effective crack management and prevention strategies. Also, the importance of predicting the cracking behaviour of the material and developing strategies to control and manage them is highlighted. In contrast to uniform or proportional change, the process can change at different rates or even accelerate depending on specific conditions, which highlights the importance of modelling these changes to better understand and manage the cracking process.

5 Conclusion

The present study has conducted a thorough examination of the processes behind fracture initiation and propagation in rods subjected to mechanical loads and adverse environmental conditions. A notable theoretical contribution is found in the use of plane strain assumptions, validated by the geometric situation in which the rod’s thickness is considerably less than the fracture length. This modelling technique facilitated precise simulation of stress fields and fracture kinetics under restricted deformation, enhancing comprehension of material behaviour in limit states. The presumption of infinite axial loading enabled the examination of stress development at the fracture tip, uncovering threshold conditions for material breakdown.

The rod’s spatial and geometric parameters, such as length, orientation, and positioning relative to other structural elements, were determined to be essential for accurately mimicking boundary conditions. The incorporation of environmental degradation elements, including corrosion and chemical assault, enabled the model to accurately represent real-world occurrences in which microstructural alterations caused by hostile media expedite fracture processes. This confirmed the significance of incorporating environmental factors into structural integrity evaluations.

The main findings of this research encompass:

verification of plane strain conditions as a dependable method for modelling thin rods with predominant fracture lengths;

identification of essential stress regions where fractures begin and extend, facilitating localised failure predictions;

measurement of the impact of corrosion and chemical exposure on the start time and propagation rate of cracks;

mathematical analysis of crack arrest circumstances, aiding in the predictive modelling of long-term structural integrity;

display of material alteration due to chemical contact, encompassing localised embrittlement and reduction in strength.

The research suggests from a practical standpoint:

utilisation of corrosion-resistant alloys and surface treatments in components subjected to severe chemical or marine conditions;

utilisation of sophisticated protective coatings (e.g. ceramic or polymeric) to reduce fracture development at susceptible contacts;

optimisation of design by reinforcing methods in high-stress areas to disperse mechanical loads;

implementation of cathodic protection systems in scenarios where electrochemical deterioration is the primary failure mechanism;

surveillance of geometric discontinuities and micro-defects with non-destructive testing to avert premature failure.

The simulations demonstrated significant concordance with experimental findings on stress redistribution, fracture propagation under fatigue loading, and the impacts of corrosion, therefore offering empirical support of the model’s predictive capabilities. The integration of theoretical modelling and multiphysics simulation provides a comprehensive framework for evaluating structural durability under intricate service situations.

This research addresses a significant gap in fracture mechanics by providing a multiparametric simulation-based technique that incorporates both mechanical and environmental deterioration. It provides pragmatic recommendations for material selection, structural design, and failure mitigation measures in high-risk sectors such as offshore engineering, chemical processing, and energy infrastructure. Future research should focus on integrating real-time sensor data with adaptive computational models to broaden the applicability of this framework for in situ structural health monitoring and automated decision-making in maintenance planning.

-

Funding information: Author states no funding involved.

-

Author contributions: Author has accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: Author states no conflict of interest.

-

Data availability statement: The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

[1] Feng XD, Shi Y, Zhang WZ, Volodymyr K. Hydrogen embrittlement failure behavior of fatigue-damaged welded TC4 alloy joints. Cryst. 2023;13(3):512. 10.3390/cryst13030512.Suche in Google Scholar

[2] Gu YF, Duan XQ, Xu YW, Shi Y, Zhu M, Feng XD, et al. Preparation of ultra-thick, crack-free, titanium nitride coatings using a full-domain power-modulated laser. J Man Proc. 2024;113:346–59. 10.1016/j.jmapro.2024.01.079.Suche in Google Scholar

[3] Ratov BT, Mechnik VA, Bondarenko NA, Kolodnitskyi VM, Gevorkyan ES, Nerubaskyi VP, et al. Features structure of the Cdiamond‒(WC‒Co)‒ZrO2 composite fracture surface as a result of impact loading. J Sup Mat. 2023;45(5):348–59. 10.3103/S1063457623050088.Suche in Google Scholar

[4] Tuan PL, Kulik M, Stef M, Phuc TV, My NTB, Zelenyak TY, et al. An examination on the porosity of ErF3 doped CaF2 crystal using the Rutherford back-scattering method. Nucl Inst Meth Phys Res Sec B: Beam Int Mat At. 2024;547:165178. 10.1016/j.nimb.2023.165178.Suche in Google Scholar

[5] Luniov SV, Zimych AI, Nazarchuk PF, Maslyuk VT, Megela IG. Specific features of electron scattering in uniaxially deformed n-Ge single crystals in the presence of radiation defects. Rad Eff Def Sol. 2016;171(11–12):855–68. 10.1080/10420150.2016.1250094.Suche in Google Scholar

[6] Piskunov VG, Gorik AV, Cherednikov VN. Modeling of transverse shears of piecewise homogeneous composite bars using an iterative process with account of tangential loads. Resolving equations and results. Mech Comp Mat. 2000;36(6):445–52. 10.1023/A:1006798314569.Suche in Google Scholar

[7] Piskunov VG, Goryk AV, Cherednikov VN. Modeling of transverse shears of piecewise homogeneous composite bars using an iterative process with account of tangential loads. 1. Construction of a model. Mech Comp Mat. 2000;36(6):287–96. 10.1007/BF02262807.Suche in Google Scholar

[8] Storozhenko L, Butsky V, Taranovsky O. Stability of compressed steel concrete composite tubular columns with centrifuged cores. J Const Steel Res. 1998;46(1–3):484. 10.1016/S0143-974X(98)80098-9.Suche in Google Scholar

[9] Sagiyev A, Kurtayev S, Ergaliyev D, Abdirashev U, Sansyzbay K. Thermal acceleration on nickel-cadmium aviation batteries, its impact on flight safety. Bull Kaz Acad Tran Com M Tynyshbayev. 2024;130(1):372–81. https://vestnik.alt.edu.kz/index.php/journal/article/view/1583.Suche in Google Scholar

[10] Faiziev UA. Development of the composition of cement-floor coatings of industrial buildings. J Univ Sci Res. 2024;2(1):91–7. https://universalpublishings.com/index.php/jusr/article/view/3781.Suche in Google Scholar

[11] Pakhriddinov HZ, Abdullaev IA, Yakhshiboev MY. Factors hindering the development of production of reinforced concrete products. Hold Reas. 2024;1(1):687–91. https://sciencepromotion.uz/index.php/HOLDERS_OF_REASON/article/view/1108.Suche in Google Scholar

[12] Kukudzhanov KK. Healing of a crack in a thin plate under the action of a strong electromagnetic field. In Topical problems of continuum mechanics. Yerevan: National Academy of Sciences of the Republic of Armenia; 2023. p. 161–2. http://www.mechins.sci.am/conf2023/files/conf-proceedings-2023.pdf#page=161.Suche in Google Scholar

[13] Gabdullin MT, Smailov KM, Ospanov KK. Luminescent and electrophysical properties of nanostructured synthesised compounds of cadmium and zinc by the unithiolate coordination compounds. J Open Syst Evol Prob. 2020;20(2):92–104. https://peos.kaznu.kz/index.php/peos/article/view/38.Suche in Google Scholar

[14] Raimzhanov BR, Hakimov SI, Khamzaev SA, Ravshanov AA. Development and justification of the efficiency of combined development systems with artificial pillars in complex geomechanical conditions. Min J Uzb. 2022;89(2):4–7. 10.54073/GV.2022.2.89.001.Suche in Google Scholar

[15] Wang B, Wang D, Ye J, Tang L, Chong H, Xu W, et al. Effect of fatigue load on the bending tribo-corrosion-fatigue behaviors between the main cable wires. Friction. 2024;12(7):1512–31. 10.1007/s40544-023-0830-y.Suche in Google Scholar

[16] Li X, Zhao B, Guo Y, Jia X, Peng X. Piston rod fracture in natural gas process compressors for underground gas storage: A comprehensive case study. Eng Fail An. 2024;160:108152. 10.1016/j.engfailanal.2024.108152.Suche in Google Scholar

[17] Gu YF, Zhang WZ, Xu YW, Shi Y, Volodymyr K. Stress-assisted corrosion behaviour of Hastelloy N in FLiNaK molten salt environment. NPJ Mat Degr. 2022;6(1):90. 10.1038/s41529-022-00300-x.Suche in Google Scholar

[18] Rogovyi A, Khovanskyy S, Grechka I, Pitel J. The wall erosion in a vortex chamber supercharger due to pumping abrasive mediums. In Lecture notes in mechanical engineering. Cham: Springer; 2020. p. 682–1. 10.1007/978-3-030-22365-6_68.Suche in Google Scholar

[19] Babachenko OI, Kononenko HA, Podolskyi RV, Safronova OA, Taranenko AO. Structure and fracture resistance of steels in different zones of railway axles. Mat Sci. 2022;58(3):417–21. 10.1007/s11003-023-00679-1.Suche in Google Scholar

[20] Meng C, Yuanzhou Z, Ji B, Chen Z, He B. Static analysis on fatigue crack retrofitting using steel-rod reinforcement method. Thin-Wall Str. 2024;198:111687. 10.1016/j.tws.2024.111687.Suche in Google Scholar

[21] Pu Q, Geng J, Luo T, Li Y, Shi Y, Li X, et al. Revealing the effect of oriented microstructures on the anisotropy of fatigue crack propagation behaviour in TiB2/Al-Cu-Mg-Mn composite. J Alloy Comp. 2024;979:173558. 10.1016/j.jallcom.2024.173558.Suche in Google Scholar

[22] Mao D, Xie Y, Meng X, Ma X, Zhang Z, Sun X, et al. Strength-ductility materials by engineering a coherent interface at incoherent precipitates. Mat Hor. 2024;1:1–8. 10.1039/d4mh00139g.Suche in Google Scholar PubMed

[23] Tobata Y, Naito K, Tanks J. Mode I-governed fracture energy and maximum normal traction of a CFRP rod. J Comp Mat. 2024;58(3):317–26. 10.1177/00219983231224112.Suche in Google Scholar

[24] Jiang J, Wan X, Li K, Du J, Liu Y, Jing J, et al. Research progress of sucker rod fracture detection and prediction model. Eng Fail An. 2024;159:108119. 10.1016/j.engfailanal.2024.108119.Suche in Google Scholar

[25] Li P, Luo N, Chai Y, Sun W, Zhang H, Zhai C. Dynamic impact experimental and global cohesive element method to shale fracture characterisation. Theor Appl Fract Mech. 2024;131:104407. 10.1016/j.tafmec.2024.104407.Suche in Google Scholar

[26] Ping Q, Li X. Analysis of the fracture characteristics and crack propagation mechanism of fractured sandstone under dynamic loading. Appl Sci. 2024;14(5):2042. 10.3390/app14052042.Suche in Google Scholar

[27] Fu B, Wang C, Dong Y, Liu X, Ke Y, Wang D, et al. Crystal plasticity modeling of fretting fatigue crack initiation behavior in Ti6Al4V. Eng Fail An. 2025;168:109074. 10.1016/j.engfailanal.2024.109074.Suche in Google Scholar

[28] Kuo CC, Gurumurthy N, Chen HW, Huang SH. Analysis of temperature history, fatigue behaviour and surface hardness in rotary friction welded dissimilar polymer rods with variable rotational speeds. J Adv Join Proc. 2024;9:100211. 10.1016/j.jajp.2024.100211.Suche in Google Scholar

[29] Hruban V, Drobitko A, Khramov M, Tovpyha M. Strength analysis and optimisation of trailer agricultural machinery structures using finite element methods. Mach Energ. 2025;16(2):117–30. 10.31548/machinery/2.2025.117.Suche in Google Scholar

[30] Alessi R, Ulloa J. Endowing Griffith’s fracture theory with the ability to describe fatigue cracks. Eng Fract Mech. 2023;281:109048. 10.1016/j.engfracmech.2023.109048.Suche in Google Scholar

[31] Janssen M, Zuidema J, Wanhill RJH. Fracture mechanics: An engineering primer. Delft: TU Delft OPEN Publishing; 2024.Suche in Google Scholar

[32] Cai W, Mo X, Li W, Liu S, Zhou D, Zhang H, et al. Study of fatigue damage of pumping rods based on finite element simulation. Front Earth Sci. 2023;10:1013167. 10.3389/feart.2022.1013167.Suche in Google Scholar

[33] Yu H, Díaz A, Lu X, Sun B, Ding Y, Koyama M, et al. Hydrogen embrittlement as a conspicuous material challenge-comprehensive review and future directions. Chem Rev. 2024;124(10):6271–92. 10.1021/acs.chemrev.3c00624.Suche in Google Scholar PubMed PubMed Central

[34] Zhang X, Wang Z, Xi Y, Liu W, Deng Y, Yun D. 3-Dimensional multiphysics modeling of behaviors of pressurized water reactor fuel rods with missing pellet surface. Front Ener Res. 2021;9:738084. 10.3389/fenrg.2021.738084.Suche in Google Scholar

[35] Zhao Q, Wahab MA, Ling Y, Liu Z, Wang D. Fatigue crack propagation of AA2024 alloy under texture control using crystal plasticity coupled with accelerated cyclic cohesive zone model. Eng Fract Mech. 2024;296:109819. 10.1016/j.engfracmech.2023.109819.Suche in Google Scholar

[36] Pavlikov A, Kochkarev D, Harkava O. Calculation of reinforced concrete members strength by new concept. In Proceedings of the fib Symposium 2019: Concrete – Innovations in Materials, Design and Structures. Krakow: International Federation for Structural Concrete; 2019. p. 820–7. https://reposit.nupp.edu.ua/bitstream/PoltNTU/6064/1/0820.pdf.Suche in Google Scholar

[37] Sydorchuk P, Khlyap G, Andrukhiv A. Growth and some properties of heterostructures based on new narrow-gap semiconductor ZnCdHgTe. Cryst Res Tech. 2001;36(4–5):361–9. 10.1002/1521-4079(200106)36:4/5<361: AID-CRAT361>3.0.CO;2-5.Suche in Google Scholar

[38] Zahran H, Zinovev A, Terentyev D, Wang X, Wahab MA. Experimental investigation and constitutive material modelling of low cycle fatigue of EUROFER97 for fusion applications. J Nucl Mat. 2024;588:154809. 10.1016/j.jnucmat.2023.154809.Suche in Google Scholar

[39] Zahran H, Zinovev A, Terentyev D, Aiello G, Wahab MA. Prediction of low cycle fatigue life for neutron-irradiated and nonirradiated RAFM steels using their tensile properties. Int J Fat. 2025;190:108589. 10.1016/j.ijfatigue.2024.108589.Suche in Google Scholar

[40] Maji K, Lavanya M. Microbiologically influenced corrosion in stainless steel by Pseudomonas aeruginosa: An overview. J Bio Trib Cor. 2024;10:16. 10.1007/s40735-024-00820-w.Suche in Google Scholar

[41] Morgado T, Dias R, Pereira M. 3D crack propagation study of a railway component using XFEM method. J Phys Conf Ser. 2024;2692(1):012006. 10.1088/1742-6596/2692/1/012006.Suche in Google Scholar

[42] Li X, Chen Z, Wu S, Guo Y, Jia X, Peng X. Experimental study on the identification and diagnosis of dynamic crack propagation in the piston rods of process gas compressors in underground gas storage. Appl Sci. 2024;14(2):857. 10.3390/app14020857.Suche in Google Scholar

[43] Wang X, Li Z, Guo J, Lu C, Jiang H, Mei J. Experimental and numerical investigations on damage mechanical behaviours of surrounding rock-backfill composite under uniaxial compression. Cons Build Mat. 2024;417:135210. 10.1016/j.conbuildmat.2024.135210.Suche in Google Scholar

[44] Zhang L, Zhou S, Xiong Z, Mo Z, Lu Q, Hong J. Research on the crack resistance of semi-flexible pavement mixture based on meso-heterogeneous model. Cons Build Mat. 2024;411:134495. 10.1016/j.conbuildmat.2023.134495.Suche in Google Scholar

[45] Liu H, Zhu F, Zhou Y, Liu K. An improved maximum tangential stress criterion for an inclined crack in uniaxial compression considering T-stress and crack parameter. Fat Fract Eng Mat Str. 2024;47(6):1914–26. 10.1111/ffe.14284.Suche in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite

Artikel in diesem Heft

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications