Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

-

Nimmagadda Srilatha

, Vaka Venkata Durga Sahithi

Abstract

This study based on Mg-based hybrid composites investigates the impact of silicon carbide (SiC) and boron carbide (B4C) reinforcements on the mechanical and microstructural properties of magnesium (Mg) hybrid composites fabricated via the novel vacuum-assisted stir casting. Three hybrid Mg composites, MC1 (Mg-2 wt% SiC-3 wt% B4C), MC2 (Mg-3 wt% SiC-2 wt% B4C), and MC3 (Mg-2.5 wt% SiC-2.5 wt% B4C) were fabricated to evaluate the influence of variations in reinforcement ratios on mechanical, microstructural and hardness of the composites. Results showed that magnesium composite MC2 exhibited the highest compressive strength and microhardness, which is attributed to the optimal load transfer and refined grains by SiC, whereas MC3 achieved the best ultimate tensile strength. The microstructural analysis confirmed uniformly dispersed particles without agglomeration. These findings suggest that SiC- and B4C-reinforced Mg hybrid composites offer enhanced strength, hardness, and wear resistance, making them suitable for high-performance applications in aerospace and automotive industries.

1 Introduction

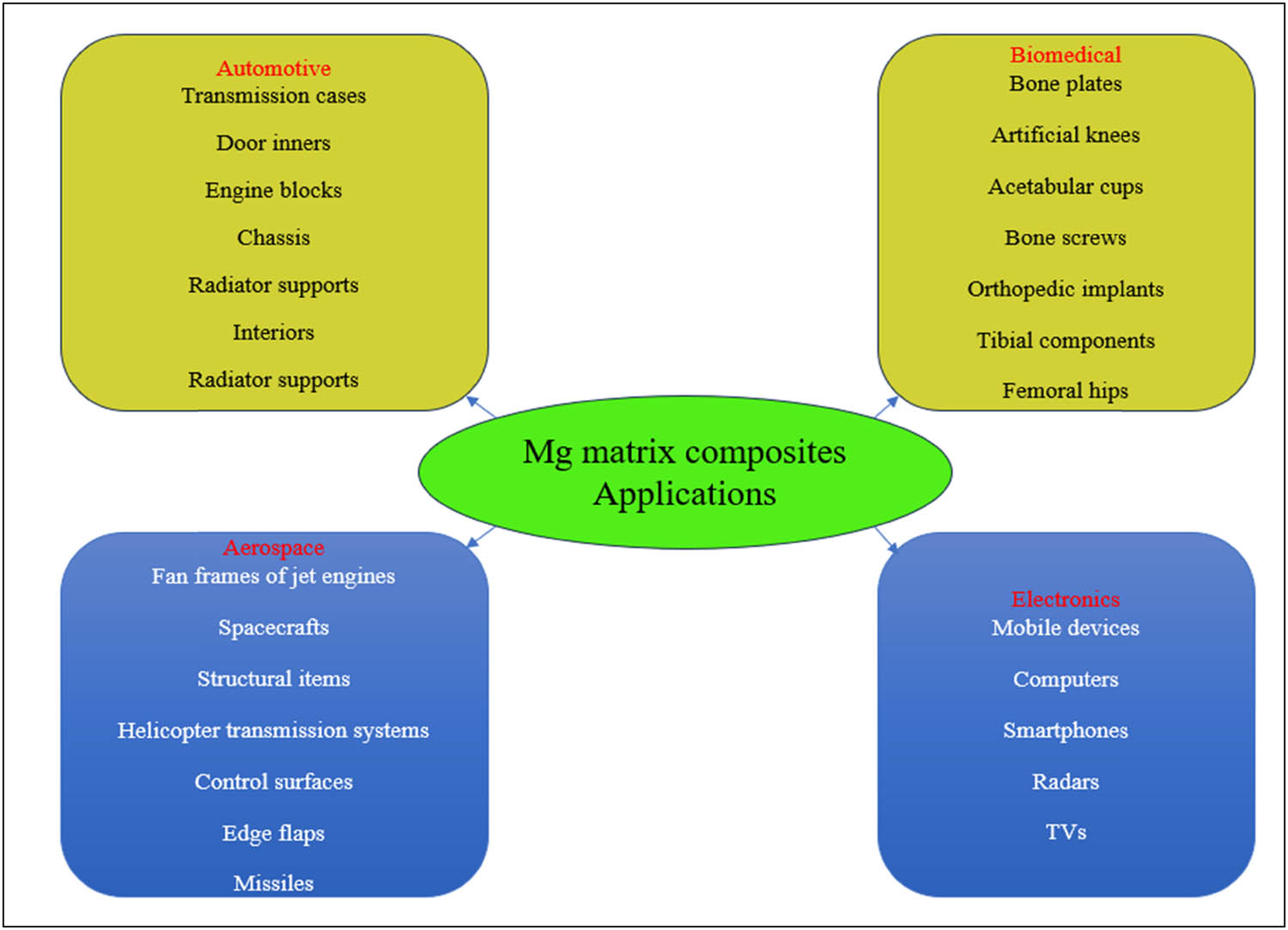

Aluminum and its alloys have demonstrated themselves to be the most dependable lightweight materials in recent decades, and they have been extensively utilized in the production of space and automotive components. Because of their low-density and high specific strength, which can reduce fuel consumption and carbon emissions, magnesium and its composites have found substantial applications as listed in Figure 1. Unfortunately, the low strength, low modulus, inadequate resistance to creep at elevated temperatures, and wear resistance of applications for magnesium alloys are limited [1]. Consequently, to enhance the base metals’ qualities, reinforcements are required. The lightest metal structural material available, magnesium matrix composites offer greater creep and wear resistance at high temperatures, high strength, and high elasticity over monolithic magnesium or magnesium alloys [2,3]. In particular, magnesium is the lightest structural metal, weighing 33% less than aluminum. Unfortunately, some disadvantages that limit the application of magnesium alloys under service circumstances include their high oxidation rate and low wear resistance [4,5]. Nevertheless, metal matrix composites based on magnesium can be used to get around these restrictions. The creation of magnesium-based composites is a demanding task since magnesium can oxidize or cause nanoparticles to aggregate [6,7].

Applications of Mg-based MMC.

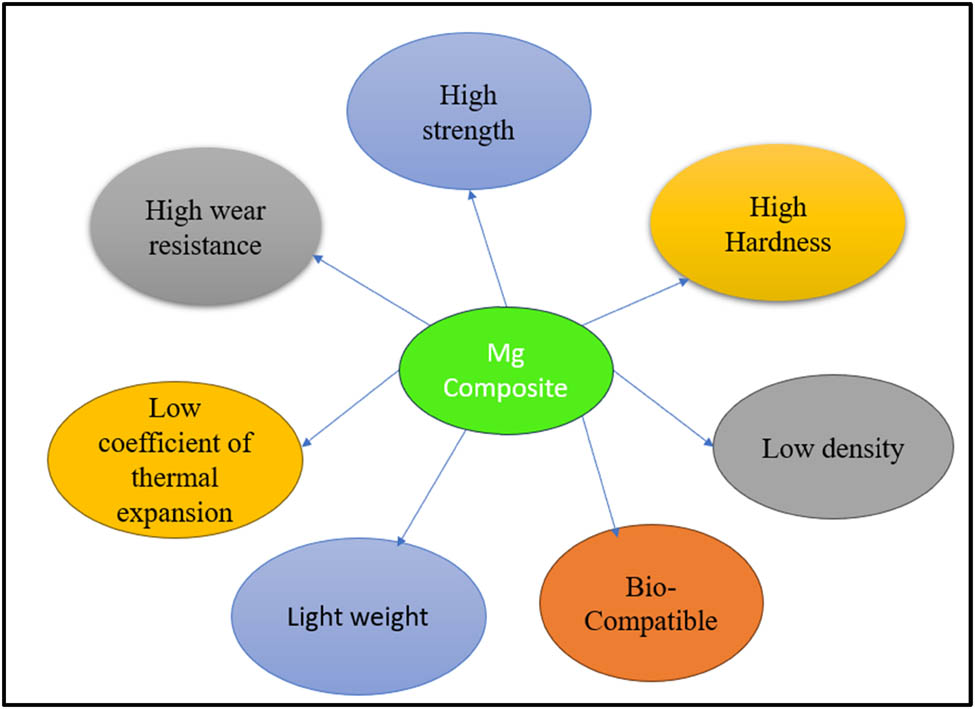

When reinforced with different materials, magnesium metal matrix composites show excellent mechanical properties like high strength, high elasticity, and hardness at extreme temperatures as listed in Figure 2. When it comes to composite materials, the choice of reinforcement is crucial [8]. Under the specified operating conditions, reinforcement material shall have a non-reactive nature and be thermally stable. The size and distribution of the reinforcing particles are key factors in improving the mechanical qualities of metal matrix composite (MMC). Particulate-reinforced metal matrix composites, however, can be made using a variety of methods, including spray deposition, powder metallurgy, and stir casting [9,10].

Different magnesium matrix composite properties.

Some of the commonly used reinforcements like SiC improve magnesium and its alloys’ ultimate tensile strength, yield strength, hardness, ductility, and wear resistance [11]. Al2O3 reinforcement results in strong compressive strength and good creep resistance. The effective load transmission between the plastic flow in the matrix and the fibers causes creep strengthening [12]. The addition of carbon nanotubes to magnesium matrix composites improves their wettability, bonding strength, and tensile strength. However, the basal plane texture may become weaker as a result of the CNT addition [13,14]. One of the known hardest elements is boron carbide (B4C). Its fracture toughness and elastic modulus are high. The incorporation of magnesium with B4C improves the hybrid composite s hardness, wear resistance, flexural strength, and interfacial bonding strength [15].

The impact of particle size on the microstructure and mechanical properties of the SiCp/AZ91 magnesium matrix composite was examined by Wang et al. [10]. Submicron SiCp particle volume fractions as low as 2% in composites significantly impacted the strengthening and refining of the grain. Agglomerated submicron SiC particles caused mechanical characteristics to decrease as the volume percentage rose to 5 and 10%. The strengthening impact increased as the volume fraction increased. Using an ultrasonic technique, Zhao-Hui et al. [11] created a magnesium matrix composite enhanced with SiC nanoparticles. According to the microstructural assessment, ultrasonic vibration can help distribute the nanoparticles evenly and effectively throughout magnesium alloys. When compared to matrix alloy, the mechanical characteristics of composites were much better and their grains were more polished. The heterogeneous nucleation of ϸ-Mg can be facilitated by SiC nanoparticles. The microstructure and mechanical characteristics of particulate-reinforced magnesium matrix composites were assessed by Deng et al. [12] at a high temperature and 50% lower height. Using neutron diffraction, the texture of the forged composites was assessed. During forging, a robust basal plane texture developed, and as the forging temperature rose, the texture’s intensity decreased. The hot forging greatly increased the particle distribution. The microstructure and mechanical characteristics of SiC-reinforced magnesium composites made using spark plasma sintering technology were assessed by Sajuri et al. [13]. The investigation revealed that the optimal sintering temperatures for the magnesium and AZ31 alloy were 585 and 552°C, respectively. Hardness and tensile strength – two mechanical properties – rose as the SiC content rose to 10 wt%. The aggregation of SiC particles causes the tensile strength to diminish with further increases in SiC concentration. The decrease in the interfacial bonding strength between the matrix and reinforcement was seen as a result of the agglomeration of SiC particles. The B4C particulate-reinforced magnesium metal matrix composites with varying volume fractions (10, 15, and 20 vol% B4C) were created by Jiang et al. [14]. The microstructure’s characterization showed that the B4C particle distribution in the matrix was necklaced. MgO and MgB2 production was revealed by X-ray diffraction (XRD) analysis in B4C/Mg composites. The composites’ hardness and wear resistance increased dramatically when B4C particle content rose from 10 to 20 vol%. A novel technique for manufacturing B4C particulate-reinforced magnesium-matrix composites was put forth by Yao and Chen [15]. Enhancing the wettability of the metal melt infiltration composite production process is necessary. The ceramic performs with the metal melting. Shen et al. [16] have examined the mechanical behavior of a lanthanum-doped magnesium alloy, AZXE7111 (Mg–7Al–1Zn–1Ca–1La, all in weight percent), extruded at various temperatures. Comparing the unreinforced AZ91D alloy and AZ91D-B4C composites examined by Aattisuhgan [17], graphite-reinforced hybrid composites showed less wear loss. On the other hand, at 800 rpm and 40 mm/min travel speed, the inclusion of Al2O3 reinforced in a magnesium (AZ91 alloy) matrix with 0.8 vol% Al2O3 demonstrated optimal hardness and wear resistance [18]. For Mg MMCs, 10, 20, and 30 wt% additions of SiC particles were made. The porosity of the composites changed dramatically, while the density did not. The Mg/30 wt% SiC particle composite showed notable improvements in hardness, tensile strength, and compressive strength [19,20]. The Mg-10% SiC + 10 wt% Al2O3 sample had the maximum hardness and the Mg-5% SiC + 5 wt% Al2O3 sample had the best wear resistance [21]. The hardness of reinforced magnesium was higher than that of non-reinforced magnesium [9,22]. This work examined the effects of SiC, and B4C, as reinforcing materials on the microstructural and mechanical characteristics of Mg-based MMC [23,24].

2 Experimentation

2.1 Materials

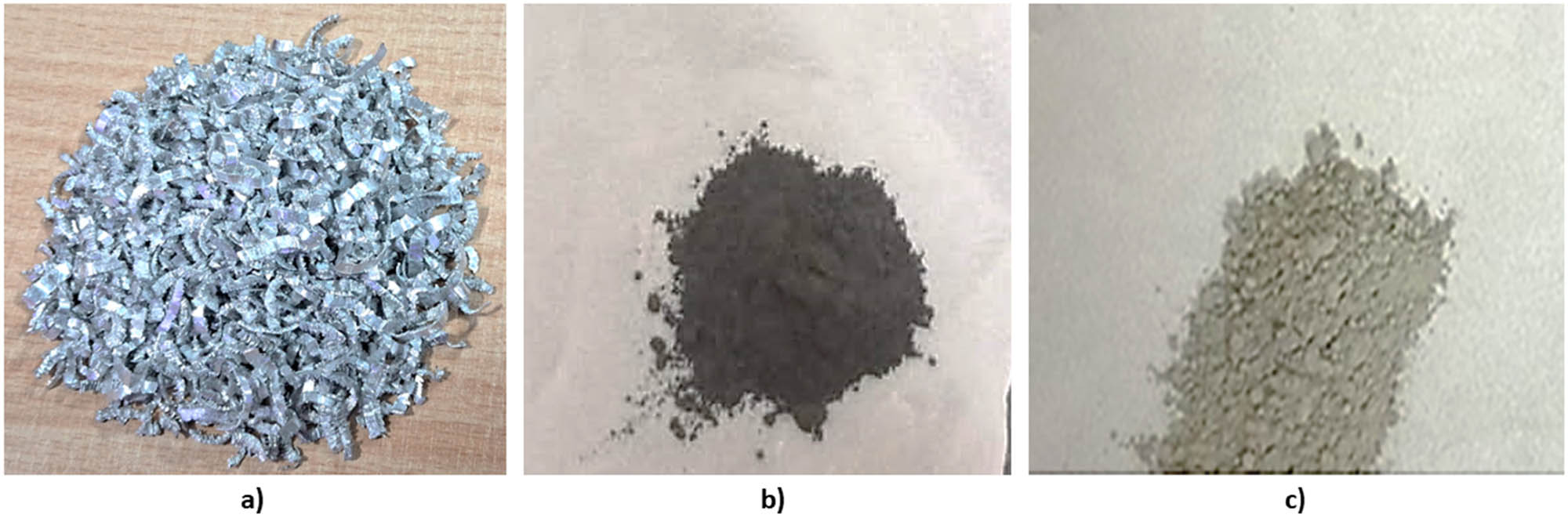

To fabricate the hybrid composite, the selected matrix material is Mg and the selected reinforcements are silicon carbide (SiC) and B4C. The turnings of Mg were procured to ensure a lower content of impurities and also easy melting of the matrix. Both the reinforcements procured are ceramic particles of purity of 99.5%. The SiC powder has an average particle size of 40 µm and is white in color. The B4C powder also has a particulate structure with an average particle size of 150 µm and is black in color. The physical images of the procured materials are shown in Figure 3.

Images of the procured materials: (a) magnesium turnings, (b) SiC, and (c) B4C.

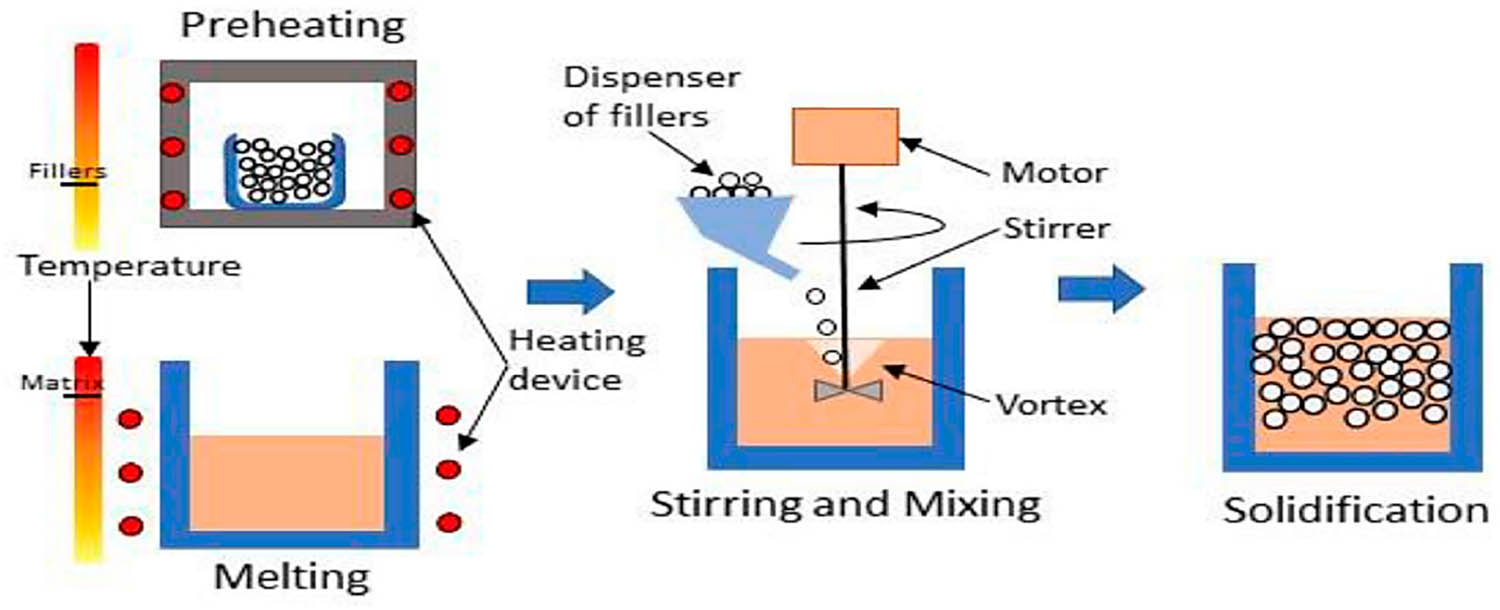

2.2 Hybrid composite fabrication

The Mg turnings of 97.5 wt% were melted at a temperature of 720°C under a protective gas mixture (80% Argon [Ar] and 20% SF6) within the furnace of a vacuum-assisted stir casting machine. Subsequently, the microparticles of SiC and B4C were added as reinforcements by varying their compositions as shown in Table 1 to fabricate the desired magnesium hybrid composites (MHCs).

The compositions of the prepared MHCs

| Sample code | Magnesium matrix (wt%) | Reinforcement 1 SiC (wt%) | Reinforcement 2 B4C (wt%) |

|---|---|---|---|

| MC1 | 95 | 2 | 3 |

| MC2 | 95 | 3 | 2 |

| MC3 | 95 | 2.5 | 2.5 |

Prior to addition, the reinforcements were heated initially at 200°C to eliminate any presence of moisture or unwanted impurities. To prevent oxidation of the MHCs, a stir casting machine with a gas purging facility was selected and the entire process of stir casting was performed in a controlled, inert atmosphere comprising 80:20 Ar:SF6 ratio. 300 rpm of stirring speed and 25 min of stirring duration were employed to ensure uniform dispersion of the reinforcement particles within the composite. The melt temperature was maintained at 700°C in the furnace. The mould cavity was maintained in a vacuum and the air was pumped out. This was done to ensure that no oxidation occurs within the casting during the pouring time. This process also eliminates porosity and a nice, dense casting is formed which is devoid of any casting defects. Vacuum-assisted stir casting was chosen to minimize porosity, oxidation, and agglomeration during fabrication, ensuring dense and defect-free composites. The process parameters are shown in Table 2.

The operating parameters of the stir-casting machine

| S. no. | Description | Specification |

|---|---|---|

| 1 | Furnace temperature | 800°C |

| 2 | Melt temperature | 700°C |

| 3 | Preheater temperature | 200°C |

| 4 | Mould temperature | 200°C |

| 5 | Gas flowrate | 2 LPM |

| 6 | Argon–sulfur hexafluoride ratio | 80–20 |

| 7 | Stirrer speed | 300 rpm |

| 8 | Stirring duration | 25 min |

The typical stir-casting set-up is represented in Figure 4. The final casting was obtained after allowing it to be cooled naturally under ambient conditions. Three MHC samples MC1 (Mg-2SiC-3B4C), MC2 (Mg-3SiC-2B4C), and MC3 (Mg-2.5SiC-2.5B4C) of varying reinforcement compositions have been prepared of dimensions 300 mm length, 15 mm width, and 15 mm thickness.

Stir casting set-up.

2.3 Tensile test

The dog bone-shaped tensile test samples, of the MHCs were cut using wire-cut electrical discharge machine (WEDM) from the obtained casting. The ASTM E8 standard was followed for tensile testing of MHCs. The cut samples are represented in Figure 5. A universal testing machine of Instron, WTI Company having a crosshead speed of 0.01 mm/s was used for the study. The testing was done at Osmania University, Hyderabad.

Dimensions of the tensile test specimen as per ASTM standards.

2.4 Compressive test

The compressive test samples of the MHCs were cut according to the ASTM E9 standards into a 10 mm cube through WEDM. The testing was done at Osmania University Hyderabad. A universal testing machine of Instron, WTI Company, was used for the study.

2.5 XRD test

The XRD test was done on the fabricated MHCs with Cu-Kα radiation. 45 kV was the operating voltage and 40 mA was the operating of current. The XRD was done to know about the various phase components within the MHC. The scanning of the MHC samples was done through a 20°–80° incidence angle over 2θ range. The XRD analysis was carried out to identify the phases as well as the reaction products within the fabricated MHCs. The specimens needed for XRD test were cut into a square of 10 mm side and 5 mm thickness and subsequently ground to make it free of errors. The X-ray diffractometer’s geometry is such that the sample spins at an angle θ in the collimated X-ray beam path, while the X-ray detector is mounted to an arm and rotates at an angle of 2θ to collect the diffracted X-rays. With the help of a goniometer, an instrument that measures the angle, is measured by rotating the sample.

2.6 Microhardness

The microhardness indentation tests were performed on the samples cut out from the composite casting obtained from the vacuum-assisted stir-casting machine using Vickers Hardness Tester available at Adityapur Auto Cluster (Hi-tech Lab & Business Centre), Jamshedpur. Prior to the test, the cut samples were prepared as per the ASTM standards. The specimens were polished with SiC emery papers of different grits up to 2,500 grits to eliminate all kinds of impurities and obtain a smooth surface [25]. This was followed by polishing the samples on a disc polishing machine which makes use of a diamond paste of 1 µm particle size. The paste acted as a fine polishing agent over the material surface to obtain a mirror-like surface. To perform the Vickers hardness test, a diamond indenter with a square base and having 136° vertex angle was used and a load of 100 gf was applied. The dwell time of the applied load was 10 s. The impression made due to the application of the load was analyzed and the microhardness value was determined. To obtain the average microhardness, the values were analyzed at five different locations on each of the specimens.

2.7 Microstructural characterization

The observation of the composite’s microstructure was accomplished through a scanning electron microscope. The composite samples were cut into a cube of dimensions of 10 mm3. The samples were cut from the obtained casting and prepared so as to be observed under the SEM. Emery papers of different grades were used to polish the surface of the cut composite sample and also to remove any unwanted contaminations. This ensured that the sample was free of impurities and also ready to be observed under SEM.

3 Results and discussion

3.1 Microstructure analysis

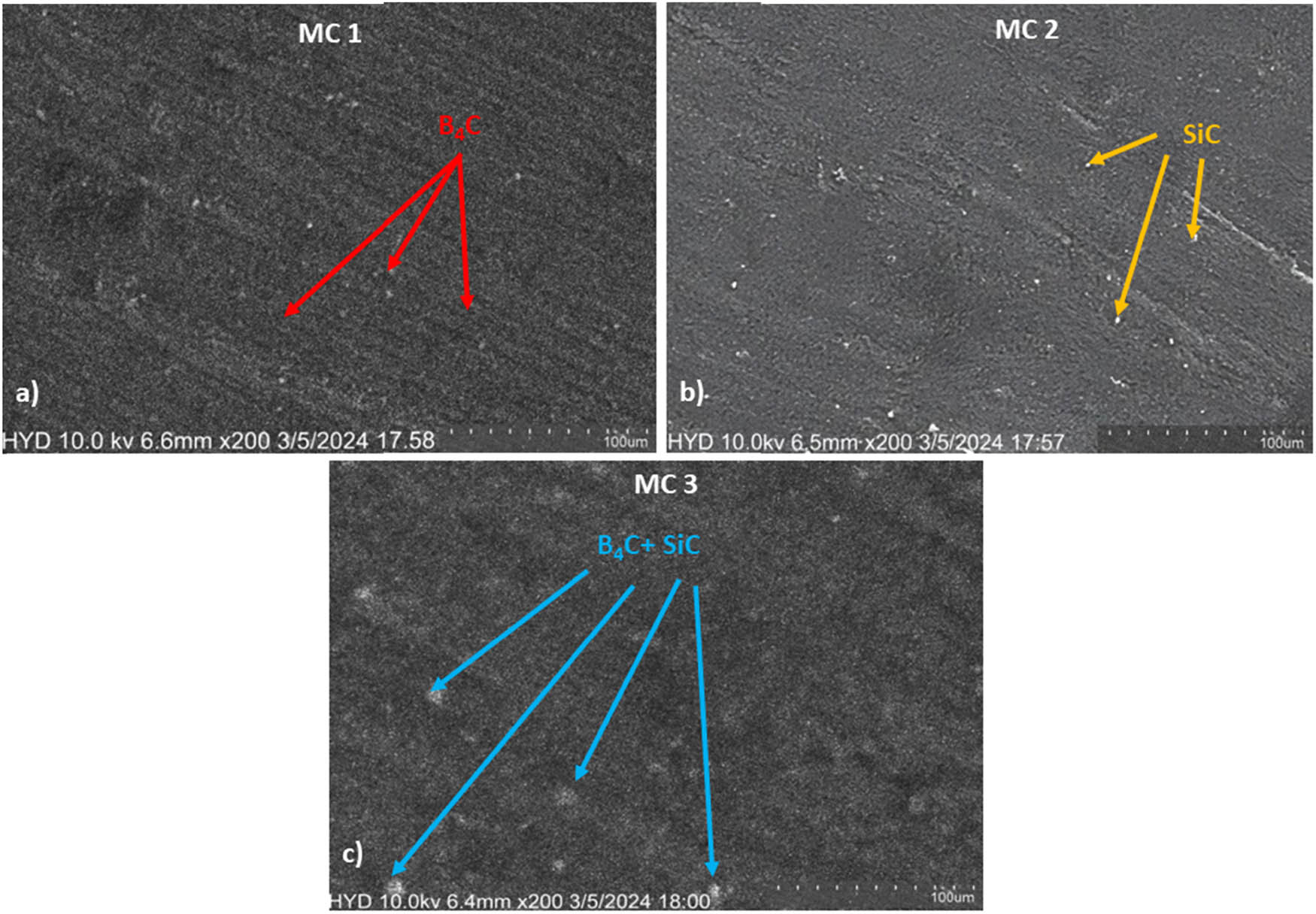

The microstructure of the fabricated MHCs has been imaged via scanning electron microscopy. The SEM images of the samples MC1, MC2, and MC3 are represented in Figure 6. It can be seen in the SEM images that the morphologies of all the composites are similar. Also, from the SEM images it can be observed that the fabricated MHCs are devoid of cavities. This is a clear indication that good quality castings have been produced and the selected stir casting parameters are best suited for the fabrication of the composites. Good quality castings possess good mechanical strength. In the sample MC1, comprising of a higher quantity of B4C, uniformly dispersed particles of B4C are strikingly visible in the form of dark precipitates. The precipitation of B4C in the form of dark precipitates increases with increasing content of B4C in the magnesium matrix [23]. The particles of B4C are depicted using red arrows in Figure 6a). The visibility of SiC particles in MC1 is negligible. In the hybrid composite sample MC2, which comprises a higher concentration of SiC than B4C, uniformly dispersed particles of SiC are strikingly visible, but there is no visibility of the B4C particles. It has been depicted in yellow arrows in Figure 6b. The properties of SiC make it the most suitable for magnesium matrix as it has a significant, positive impact on the strength and hardness of a composite. Moreover, SiC reinforcement is inexpensive compared to other materials [24]. As seen in the sample MC3, a proper amalgamation of both the reinforcements SiC and B4C can be seen. Moreover, this is spread uniformly across the entire composite [26]. This signifies that the composites prepared are capable of exhibiting exceptional mechanical properties. One good aspect of the fabricated composite is that there are no clusters or agglomeration of the reinforcement seen anywhere. The composite thus shall exhibit enhanced properties uniformly throughout its area.

SEM images of the fabricated MHCs: (a) MC1 (Mg-2SiC-3B4C), (b) MC2 (Mg-3SiC-2B4C), and (c) MC3 (Mg-2.5SiC-2.5B4C).

3.2 XRD analysis

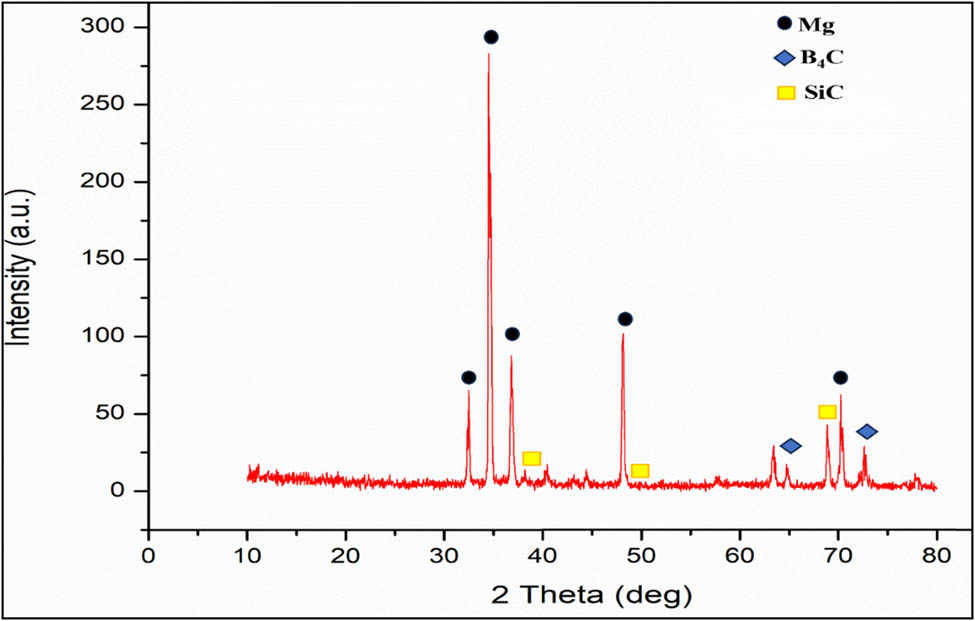

The XRD analysis of MHC, S3 Mg-1.5SiC-1.5B4C, is seen in Figure 7. The XRD patterns show a wide range of diffraction peaks which can be associated with Mg, SiC, and B4C structures. Among all the peaks, α Mg is the main phase in the composite as it is exhibited via high-intensity peaks. The peaks of Mg at 2θ values of 32°, 34°, 37°, 48°, and 70° demonstrate the hexagonal close-packed (HCP) structure of Mg crystal with (1 0 0), (0 0 2), and (1 0 1) planes. The observed peaks of SiC and B4C are much smaller in comparison to Mg which is an indication that there is the presence of the reinforcements in small quantities. The peaks of SiC and B4C are seen at 2θ angles 38°, 49°, and 70° of (2 0 0), (2 2 0), and (3 1 1) planes and 36.11°, 65.19°, and 72° of (1 1 1), (2 2 0), and (3 2 1) planes, respectively. There are no indicators or the formation of any intermetallic compounds within the MHC. This is another proof of a good quality composite formed.

XRD patterns of the Mg hybrid composite sample MC3.

3.3 Tensile test

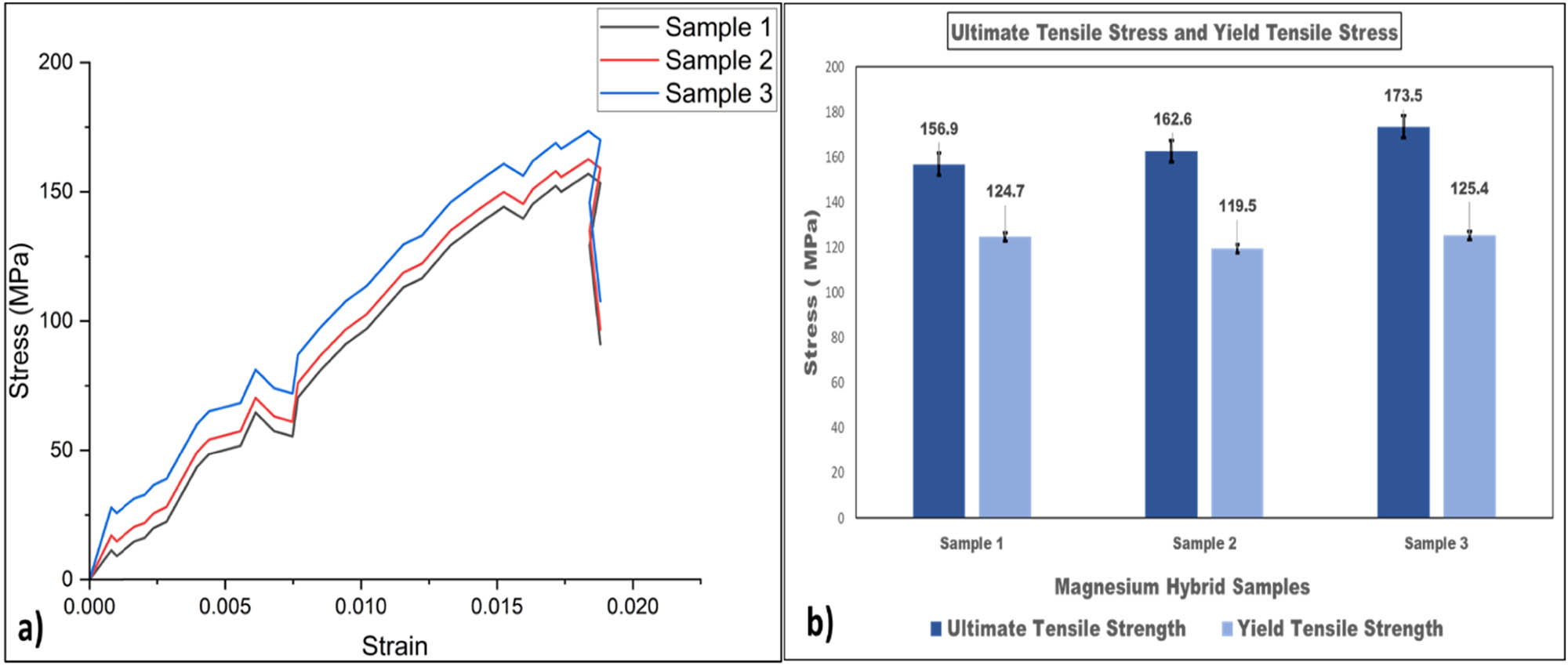

Figure 8(a) represents the stress–strain curve of the composite samples, after carrying out the tensile test on the UTM. The values of yield tensile stress (YTS), ultimate tensile stress (UTS), and percentage elongation of the samples are 124.7 MPa, 156.9 MPa, and 5.76% for MC1, 119.5 MPa, 162.6 MPa, and 5.51% for MC2, and 125.4 MPa, 173.5 MPa, and 5.34% for MC3, respectively. The values of the tensile strength obtained are much superior than that of pure Mg which is about 100.47 MPa [27].

(a) Stress–strain curves of the composite samples obtained in the tensile test. (b) Bar graphs indicating the UTS and YTS values of the composite samples.

The graphs in Figure 8 indicate that adding SiC and B4C has significantly enhanced the strength of the composites. Grain refining during the solidification process is responsible for the increased YTS and ultimate tensile strength. This increase in both tensile and yield strength follows the Hall–Patch relation, which is described by the following equation [28]:

In this formula, σ y represents the yield strength, σ 0 is a constant that accounts for friction stress within the material, K y is a constant that measures how much grain boundaries strengthen the material, and d is the average grain size. The value of K y is influenced by the number of slip systems, which are specific planes and directions in the crystal structure that allow dislocations to move and cause deformation. Typically, metals with face-centered cubic or body-centered cubic structures offer multiple ways to deform. Interestingly, even HCP metals like magnesium can exhibit significant flexibility under specific conditions. For magnesium, the HCP structure makes grain size crucial. Smaller grains introduce more boundaries, hindering the movement of defects known as dislocations. This increased resistance to dislocation movement ultimately enhances the metal’s yield strength [29].

The presence of SiC and B4C reinforcements also improves the load-bearing capacity of the composite, as these particles have a much higher modulus of elasticity compared to the magnesium matrix. This disparity means that the ceramic particles can carry more of the applied load, resulting in an overall increase in the tensile strength of the composite. Additionally, these reinforcements can refine the grain size of the magnesium matrix through a process known as grain boundary pinning, which also contributes to the enhanced strength.

However, it is important to note that while the tensile strength increases with the addition of SiC and B4C, this may also lead to a reduction in ductility. The ceramic particles can act as stress concentrators, making the composite more prone to cracking under high strain.

The stress–strain curve in Figure 8 clearly demonstrates that adding 2.5 wt% to each of both the reinforcements to the composites enhances the yield and tensile strength, meaning that they can handle greater stress before starting to deform. This is clearly evident in sample 3 consisting of equal quantities of SiC and B4C. This is an indication that both reinforcements contribute toward the enhancement of material strength. However, the increased quantity of SiC reinforcement also causes a reduction in tensile strain, indicating that the material loses some of its flexibility and becomes less ductile. This is evident in sample MC2 with 3 wt% of SiC. In simpler terms, although the composites become stronger and can bear more load, they also become more brittle and less capable of stretching or bending without breaking. Also, the samples with a higher quantity of reinforcement SiC exhibited better tensile properties than the sample with a higher B4C weight percentage. SiC and B4C reinforcements can significantly enhance the tensile strength of magnesium (Mg) composites. When these ceramic particles are added to magnesium, they act as strengthening agents, distributing the load more effectively across the composite and impeding the movement of dislocations, which are defects in the crystal structure that can lead to deformation. The high hardness and strength of SiC and B4C particles contribute to this effect, making the Mg composites more resistant to tensile stress.

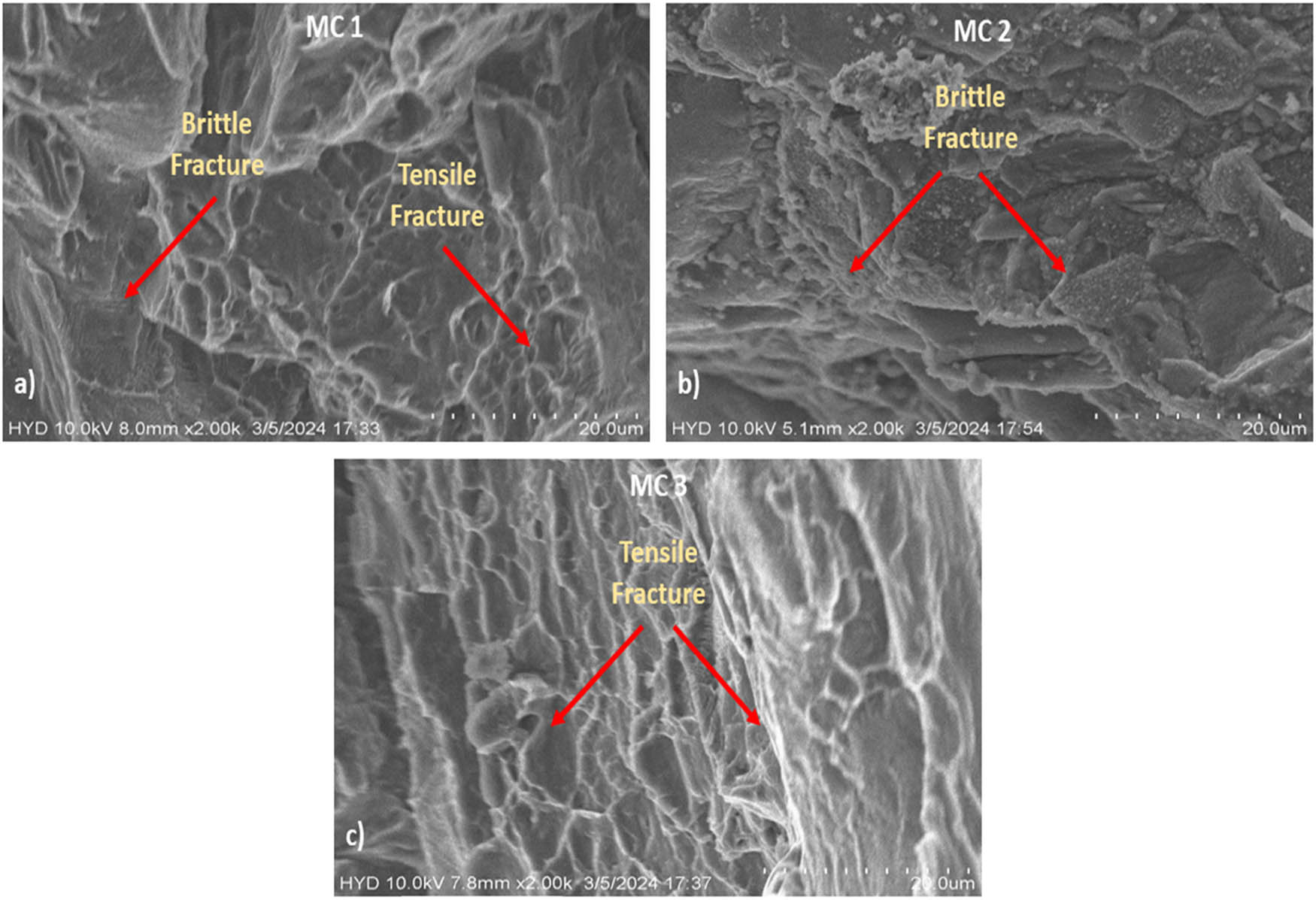

In magnesium (Mg) composites with both B4C and SiC reinforcements, the resulting microstructure has a big impact on how the material fractures. The B4C particles create more interfaces within the composite, which act as obstacles to crack growth, making the composite stronger and harder. This leads to a more complex fracture surface. Adding B4C and SiC also improves the material’s fracture toughness by promoting crack deflection and bridging at the interfaces between the magnesium matrix and the reinforcement particles. This better stress distribution slows down crack growth and results in a more ductile failure. When these composites break, they often show a mix of ductile dimpling and brittle failure patterns, thanks to the hard reinforcement particles. Cracks typically start at the interfaces but are often slowed or redirected within the more flexible magnesium, which helps make the material tougher overall.

Figure 9 represents the tensile fracture morphologies of the composites MC1 (Mg-2SiC-3B4C), MC2 (Mg-3SiC-2B4C), and MC3 (Mg-2.5SiC-2.5B4C), respectively. In the composite sample MC1, from the fractography images, it can be observed that there is the presence of both tensile and brittle fractures. This is also called a mixed-mode fracture. The presence of SiC particles has resulted in the formation of cleavages and micro-cracks which indicates brittle fracture. Due to the presence of B4C, there is the formation of dimples which indicates tensile fracture. Due to the high concentration of B4C, it can be seen that the percentage of dimples is higher than that of the cleavages. This is an indication that high content of B4C leads to tensile fractures. In the case of MC2 sample due to the existence of 3 wt% SiC, it can be seen that the composite exhibits brittle fracture. SiC usually favors a balance between strength and ductility, enhancing ultimate tensile strength while providing some brittleness, especially at higher concentrations. Though there is an increase in the tensile strength, it is due to the presence of B4C. SiC also adds to the tensile strength; however, its high content has led to brittle fracture. In the composite sample MC3 with equal weight percentages (2.5 wt% each) of SiC and B4C, the fractography image shows only tensile fracture, and thus, it has the highest value of UTS among all the composite samples. This is an indication that both the reinforcements add to the tensile strength and also it is the presence of B4C and SiC that led to this fracture morphology.

Tensile fracture morphologies of (a) sample MC1, (b) sample MC2, and (c) sample MC3.

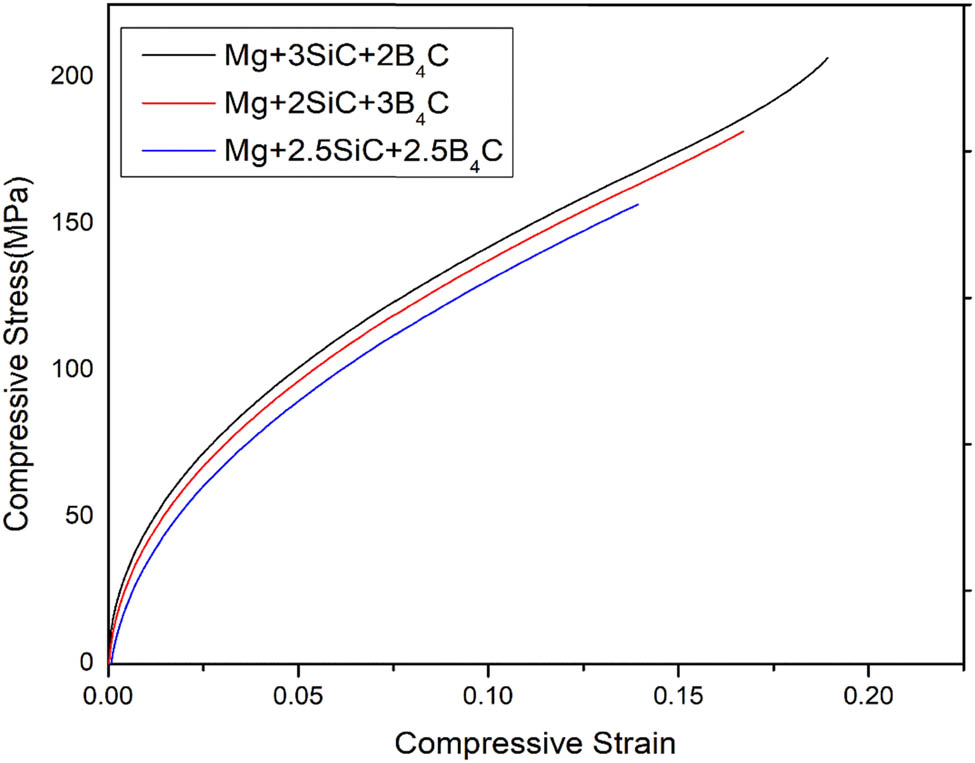

3.4 Compressive test

The results obtained from the compression test of the composite specimens are plotted in Figure 10. The UCS values of the composites MC1 (Mg-2SiC-3B4C) 206.82 MPa, MC2 (Mg-3SiC-2B4C) 181.81 MPa, and MC3 (Mg-2.5SiC-2.5B4C) 156.82 MPa, respectively.

The compressive stress–strain curve of the fabricated magnesium composite samples.

From the stress–strain curve of the compressive strength, it can be clearly observed that the sample MC2 comprising 3 wt% of SiC and 2 wt% B4C exhibits the highest compressive strength as compared to MC2 and MC3. This is due to the fact that SiC particles have a significant effect in enhancing the compressive properties in the Mg-based composite due to better load distribution and fewer stress concentrations at the particle–matrix interface, which contributes to overall strength. Moreover, an increase in SiC particles increases the compressive strength. This is due to the refined grains which occurs when increasing the percentage of SiC particulate. Also, B4C reinforcement improves interfacial bonding between the matrix and reinforcing particles, which is crucial for enhancing the compressive strength of the Mg composites. The least compressive strength is seen in MC3 with 2.5 wt% each of both the SiC and B4C reinforcements. This is due to the fact that the presence of a high weight fraction of B4C (2.5 wt%) reinforces ductility and toughness in the composite than the compression strength. Also, the B4C particles enhance overall strength and facilitate a more favorable ductile fracture mode by more efficiently absorbing energy during deformation.

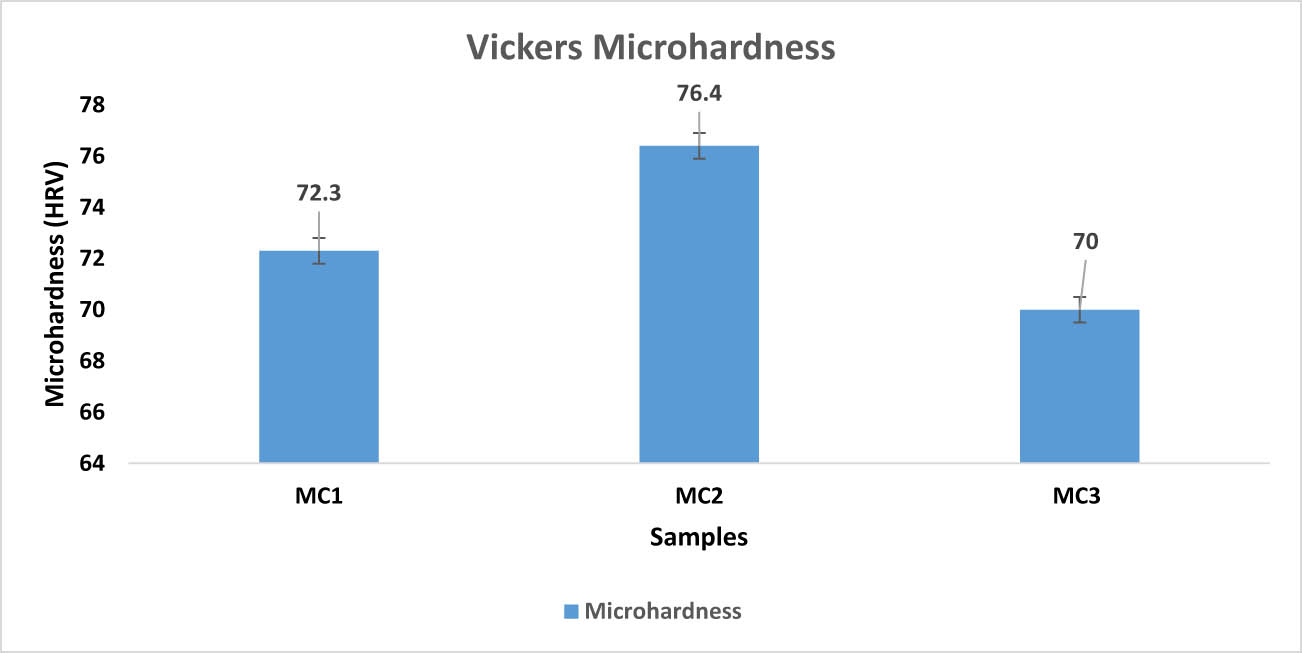

3.5 Microhardness

The Vickers microhardness test was carried out on the magnesium composite samples as represented in the bar graphs in Figure 11. The microhardness values obtained for samples MC1 (Mg-2SiC-3B4C), MC2 (Mg-3SiC-2B4C), and MC3 (Mg-2.5SiC-2.5B4C) are 72.3, 76.4, and 71.2, respectively.

Vickers microhardness values of the composites.

All the obtained microhardness values are close to each other. It is to be understood that both SiC and B4C significantly enhance the microhardness of the magnesium-based composites, but they do so through different mechanisms. SiC tends to provide greater strength by forming hard phases and improving load transfer, whereas B4C enhances both hardness and toughness due to its superior interfacial bonding and structural attributes. As per the obtained values, it can be seen that the maximum hardness value has been observed in the MC2 MHC which consists of 3 wt% of SiC and 2 wt% of B4C. This is due to the fact that, at 3 wt%, an ideal dispersion of SiC particles within the magnesium matrix is achieved, facilitating the transfer of stress from the matrix to the SiC particles under applied loads, resulting in enhanced resistance to deformation and improved hardness. Effective load transfer and microstructural strengthening are the prime reasons for this. Adding 2 wt% B4C greatly boosts microhardness. The inherent features of B4C particles increase the composite’s toughness and resistance to deformation.

4 Conclusions

The following are the conclusions of the fabricated magnesium-based hybrid composites comprising SiC and B4C as the reinforcements via the process of stir casting.

Microstructural analysis revealed uniform dispersion of both SiC and B4C particles without agglomeration, contributing to consistent mechanical performance across the composite material.

The XRD analysis confirmed the absence of intermetallic compounds, indicating a high-quality composite that retains the properties of the reinforcements without undesirable phase formations.

The addition of SiC and B4C reinforcements significantly improved the mechanical properties of magnesium composites, with optimized samples showing higher tensile and compressive strength, microhardness, and wear resistance.

The sample MC3 with equal reinforcement distribution (2.5 wt% each of SiC and B4C) exhibited the highest UTS ultimate tensile strength, implying a balanced reinforcement impact that enhances tensile properties without sacrificing ductility.

The composite with 3 wt% SiC and 2 wt% B4C (MC2) exhibited the highest microhardness and compressive strength due to the refined grain structure and superior load transfer capabilities of SiC.

Thus, from the study conducted, it can be said that Mg-based hybrid composites reinforced with SiC and B4C have promising potential for high-performance applications requiring lightweight materials with enhanced strength, hardness, and durability. In the fabricated hybrids, by considering all of the factors like tensile strength, compressive strength, hardness, and uniform microstructural dispersion of the reinforcements, it can be said that the composite MC2 (3 wt% SiC and 2 wt% B4C) is the best suited for high-performance applications that require superior material characteristics.

-

Funding information: Authors state no funding involved.

-

Author contributions: Nimmagadda Srilatha: conceptualization, methodology, investigation, Venkata Satya Prasad Somayajula: conceptualization, methodology, investigation, writing – original draft, Vaka Venkata Durga Sahithi: writing – review and editing, Polakonda Chandan: review and editing, and Abhinav Cheruku: review and editing. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article.

References

[1] Ravichandran M, Veerappan G, Dhinakaran V, Katiyar JK. Optimization of tribo-mechanical properties of boron carbide reinforced magnesium metal matrix composite. Proc Inst Mech Eng Part J: J Eng Tribol. 2022;236(9):1814–26.10.1177/13506501211030070Suche in Google Scholar

[2] Kaczmar JW, Pietrzak K, Włosiński W. The production and application of metal matrix composite materials. J Mater Process Technol. 2000;106(1–3):58–67; Gu J, Zhang X, Qiu Y. Damping behaviors of magnesium matrix composites reinforced with Cu-coated and uncoated SiC particulates. Compos Sci Technol. 2005;65:1736–42.Suche in Google Scholar

[3] Kumar A, Pandey PM. Study of the influence of microwave sintering parameters on the mechanical behaviour of magnesium-based metal matrix composite. Proc Inst Mech Eng Part C: J Mech Eng Sci. 2021;235(13):2416–25.10.1177/0954406220951236Suche in Google Scholar

[4] Li J, Wang F, Weng W, Zhang Y, Wang M, Wang H. Characteristic and mechanical properties of magnesium matrix composites reinforced with Mg2B2O5w and B4Cp. Mater Des. 2012;37:533–6.10.1016/j.matdes.2011.12.013Suche in Google Scholar

[5] Prasad SS, Prasad SB, Verma K, Mishra RK, Kumar V, Singh S. The role and significance of Magnesium in modern day research-A review. J Magnes Alloy. 2022;10(1):1–61.10.1016/j.jma.2021.05.012Suche in Google Scholar

[6] Prasad SV, Singh S, Prasad SB. A review on the corrosion process in magnesium. AIP Conf Proc. 2021;2341(1):040008.10.1063/5.0050016Suche in Google Scholar

[7] Makhlouf AS. Intelligent stannate-based coatings of self-healing functionality for magnesium alloys. In Intelligent coatings for corrosion control. Oxford, United Kingdom: Butterworth-Heinemann; 2015. p. 537–55.10.1016/B978-0-12-411467-8.00015-5Suche in Google Scholar

[8] Alahelisten A, Bergman F, Olsson M, Hogmark S. On the wear of aluminium and magnesium metal matrix composites. Wear. 1993;165(2):221–6.10.1016/0043-1648(93)90338-MSuche in Google Scholar

[9] Chen L, Yao Y. Processing, microstructures, and mechanical properties of magnesium matrix composites: a review. Acta Metall Sin (Engl Lett). 2014;27:762–74.10.1007/s40195-014-0161-0Suche in Google Scholar

[10] Wang XJ, Hu XS, Liu WQ, Du JF, Wu K, Huang YD, et al. Ageing behavior of as-cast SiCp/AZ91 Mg matrix composites. Mater Sci Eng: A. 2017;682:491–500.10.1016/j.msea.2016.11.072Suche in Google Scholar

[11] Zhao H, Yuan T, Zeng C, Peng W, Sun Z, Hu H. Microstructure and mechanical properties of steel wire reinforced Mg matrix composites fabricated by composite extrusion. Composites. Communications. 2023;43:101711.10.1016/j.coco.2023.101711Suche in Google Scholar

[12] Deng KK, Wang XJ, Wu YW, Hu XS, Wu K, Gan WM. Effect of particle size on microstructure and mechanical properties of SiCp/AZ91 magnesium matrix composite. Mater Sci Eng: A. 2012;543:158–63.10.1016/j.msea.2012.02.064Suche in Google Scholar

[13] Sajuri Z, Miyashita Y, Mutoh Y, Hosokai Y. Effect of texture on fatigue properties of an extruded AZ61 magnesium alloy plate. Key Eng Mater. 2004;274:193–8.10.4028/www.scientific.net/KEM.274-276.193Suche in Google Scholar

[14] Jiang QC, Wang HY, Ma BX, Wang Y, Zhao F. Fabrication of B4C particulate reinforced magnesium matrix composite by powder metallurgy. J Alloy Compd. 2005;386(1–2):177–81.12.10.1016/j.jallcom.2004.06.015Suche in Google Scholar

[15] Yao Y, Chen L. Processing of B4C particulate-reinforced magnesium-matrix composites by metal-assisted melt infiltration technique. J Mater Sci Technol. 2014;30(7):661–5.10.1016/j.jmst.2014.06.005Suche in Google Scholar

[16] Shen J, Kondoh K, Jones TL, Mathaudhu SN, Kecskes LJ, Wei Q. Mechanical properties of Mg alloys AMX602 and AZXE7111 under Quasi-Static and dynamic loading. Magnes Technol. 2012;2016:371–5.10.1002/9781118359228.ch68Suche in Google Scholar

[17] Zeng X, Zhang Y, Lu C, Ding W, Wang Y, Zhu Y. Precipitation behavior and mechanical properties of a Mg–Zn–Y–Zr alloy processed by thermo-mechanical treatment. J Alloy Compd. 2005;395(1–2):213–9.10.1016/j.jallcom.2004.10.070Suche in Google Scholar

[18] Deng KK, Wu K, Wu YW, Nie KB, Zheng MY. Effect of submicron size SiC particulates on microstructure and mechanical properties of AZ91 magnesium matrix composites. J Alloy Compd. 2010;504(2):542–7.10.1016/j.jallcom.2010.05.159Suche in Google Scholar

[19] Bharathi P, Sampath Kumar T. Latest research and developments of ceramic reinforced magnesium matrix composites – A comprehensive review. Proc Inst Mech Eng Part E: J Process Mech Eng. 2023;237(3):1014–35.10.1177/09544089221126044Suche in Google Scholar

[20] Saranu RK, Chanamala R, Putti SR, Mallarapu GK. Investigation of microstructures, mechanical properties of AZ91E hybrid composite reinforced with silicon carbide and fly ash. Silicon. 2021;13:2145–56.10.1007/s12633-020-00671-3Suche in Google Scholar

[21] Dey A, Pandey KM. Magnesium metal matrix composites-a review. Rev Adv Mater Sci. 2015;42(1):58–67.Suche in Google Scholar

[22] Rashad M, Pan F, Tang A, Asif M, She J, Gou J, et al. Development of magnesium-graphene nanoplatelets composite. J Compos Mater. 2015;49(3):285–93.10.1177/0021998313518360Suche in Google Scholar

[23] Nie KB, Wang XJ, Wu K, Xu L, Zheng MY, Hu XS. Fabrication of SiC particles-reinforced magnesium matrix composite by ultrasonic vibration. J Mater Sci. 2012;47:138–44.10.1007/s10853-011-5780-5Suche in Google Scholar

[24] Suneesh E, Sivapragash M. Comprehensive studies on processing and characterization of hybrid magnesium composites. Mater Manuf Process. 2018;33(12):1324–45.10.1080/10426914.2018.1453155Suche in Google Scholar

[25] Somayajula VS, Prasad SB, Singh S. Influence of mechanical and the corrosion characteristics on the surface of magnesium hybrid nanocomposites reinforced with HAp and rGO as biodegradable implants. Surf Rev Lett. 2024;31(3):2450021.10.1142/S0218625X24500215Suche in Google Scholar

[26] Kavimani V, Soorya Prakash K, Thankachan T. Investigation of graphene-reinforced magnesium metal matrix composites processed through a solvent-based powder metallurgy route. Bull Mater Sci. 2019;42:1–9.10.1007/s12034-018-1720-1Suche in Google Scholar

[27] Aydin F, Sun Y, Emre Turan M. Influence of TiC content on mechanical, wear and corrosion properties of hot-pressed AZ91/TiC composites. J Compos Mater. 2020;54(2):141–52.10.1177/0021998319860570Suche in Google Scholar

[28] Selvamani ST, Premkumar S, Vigneshwar M, Hariprasath P, Palanikumar K. Influence of carbon nano tubes on mechanical, metallurgical and tribological behavior of magnesium nanocomposites. J Magnes Alloy. 2017;5(3):326–35.10.1016/j.jma.2017.08.006Suche in Google Scholar

[29] Somayajula VS, Prasad SB, Singh S. Sustainable manufacturing of advanced Mg-Zn-HAp/rGO hybrid nanocomposites and evaluation of mechanical and microstructural properties. Int J Internet Manuf Serv. 2023;9(2–3):180–200.10.1504/IJIMS.2023.132745Suche in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite

Artikel in diesem Heft

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite