The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

-

Han Yi Tan

, Teck Yong Tou

und Seong Shan Yap

Abstract

Ultrafast laser filamentation in liquids based on nonlinear optical phenomenon is a new method for bottom-up nanoparticle synthesis. The process is able to synthesize nanomaterials such as nanodiamonds from the liquid precursor. However, the process occurs in a transparent liquid medium and the generation is limited to the interaction volume of the laser beam. In the current work, the effects of turbulence on ultrafast laser filamentation are investigated in an attempt to increase the generation rate. A fixed laser energy, at about ten times the threshold of filamentation in ethanol, is used to ensure persistent filamentation below the vaporization limit. Turbulence in the ethanol precursor was introduced by a high laser repetition rate, mechanical motion, and ultrasonication. The effects were investigated by absorbance measurements of the ethanol sample after laser filamentation, which correlates with the concentration of nanoparticles. For a fixed number of laser pulses, higher absorbance was observed on the sample prepared using a higher repetition rate (53% for 3 kHz compared to 1 kHz). The absorbance of the sample obtained by laser filamentation with cuvette motion increased by ∼22% compared to the stationary sample. Finally, when laser synthesis was performed with ultrasonication, the highest increase in absorbance was obtained (∼61%). The mechanisms that contributed to the increase are discussed.

1 Introduction

Bottom-up synthesis has the advantage of producing nanostructures with fewer defects, a more homogeneous distribution of size and shape, and a simpler process. It is normally obtained in chemical processes, but the progress in laser technology offers an alternate energy source for the synthesis process. Ultrafast laser pulses, especially with the high intense energy pulses in ultrashort duration, interact with solids, liquids, and gases in a unique way to generate various types of nanomaterials. Ultrafast laser filamentation is a process where intense laser pulses self-focus and defocus in a transparent media to form filaments. It is generated by an optical non-linear process that involves the dynamic balance of Kerr self-focusing effect and plasma defocusing [1,2]. It is manifested as a streak of colorful plasma emission during the interaction of an ultrafast laser pulse with transparent media. Laser filamentation has been used for remote sensing [3,4,5], lightning guiding in air [6], and refractive index modification in solid glass [7,8].

Recent advances show that laser filamentation not only ionizes but also dissociates or recombines molecules, i.e., laser filamentation-induced chemical reaction [9]. An example is the formation of NH molecules from the dissociation of nitrogen and water [10]. Additionally, hydrogenated amorphous carbon was observed during the filamentation of the Ti-sapphire laser in ethylene gas [11]. Our previous study on filamentation also showed that nanodiamonds can be synthesized directly from ethanol without any additives [12,13]. Single-nanometer-sized Au nanoparticles were obtained from fs laser irradiation of an aqueous mixture of HAuCl4 and n-hexane in aqueous HAuCl4 [14]. The ultrafast laser filamentation process ionizes the medium that acts as a precursor for nanoparticle formation. Such a physical process minimizes the chemical process and is able to produce single-digit nanoparticles.

In our previous study on laser filamentation interaction in ethanol, stronger dissociation of ethanol into carbon species was detected at higher laser energy based on the optical emission spectra and absorbance measurement. However, the process is limited by the localized region of interactions along the filaments. Thus, in the current work, we explore several methods to enhance the yield of the process by introducing turbulence to the liquid medium during the process without direct contact and with an ethanol precursor. The methods are high laser repetition rate, mechanical movement, and ultrasonication.

2 Experimental

A femtosecond laser system (Amplitude Systemes, s-Pulse HP) with a pulse duration of 500 fs at a central wavelength of 1,025 nm was used for nanoparticle synthesis. Ethanol solution (Aldrich, 99.4% purity) was used as a precursor for the synthesis without any additives. As shown in Figure 1, the laser pulses irradiated from the laser were guided by a laser mirror toward a plano-convex lens (f = 50 cm), and the laser beam was focused on the ethanol-containing quartz cuvette (1 cm × 1 cm × 4.5 cm). The ethanol filled up to 3 cm height, and the geometrical focus of the laser pulse was focused 1 cm below the ethanol meniscus.

Experiment setup for nanoparticle synthesis using ultrafast laser filamentation (dimension not to scale). The image on the right is the real-time image captured during ultrafast laser filamentation in ethanol. The colorful, bright emissions are filamentation plasma.

The laser repetition rate was varied from 0.5 to 3 kHz, while the laser energy was fixed in the range of 460–560 µJ, where laser filamentation occurred readily and consistently. The number of pulses for irradiation was fixed at 1.8 million; thus, the synthesis duration for different repetition rates was 10–30 min. The laser energy was well above the critical power of self-focusing, which was 1.51 MW (0.8 µJ). Subsequently, movement was introduced to the liquid externally (Table 1). A motorized stage was used to move the cuvette during the synthesis along a linear axis back and forth at a speed of 2 cm/s during laser filamentation. The experiment was repeated for laser repetition rates of 1 and 3 kHz. The results are compared with the reference sample that has no motion. In the last experiment, the effect of ultrasonication during the process was studied. The cuvette was positioned at the center of the water-filled ultrasonic cleaner (35 W, 40 kHz). The absorbance of the samples was measured by using a deuterium-halogen light source and a spectrometer (Avantes 3648, 183–753 nm).

Experimental conditions for fs laser filamentation in ethanol

| Repetition rate (kHz) | Duration (min) | Source of turbulence |

|---|---|---|

| 1 | 60 | Cuvette not moving |

| 1 | 60 | Moving cuvette at 2 cm/s |

| 3 | 10 | Cuvette not moving |

| 3 | 10 | Moving cuvette 2 cm/s |

| 1 | 30 | No ultrasonication |

| 1 | 30 | With ultrasonication |

3 Results and discussion

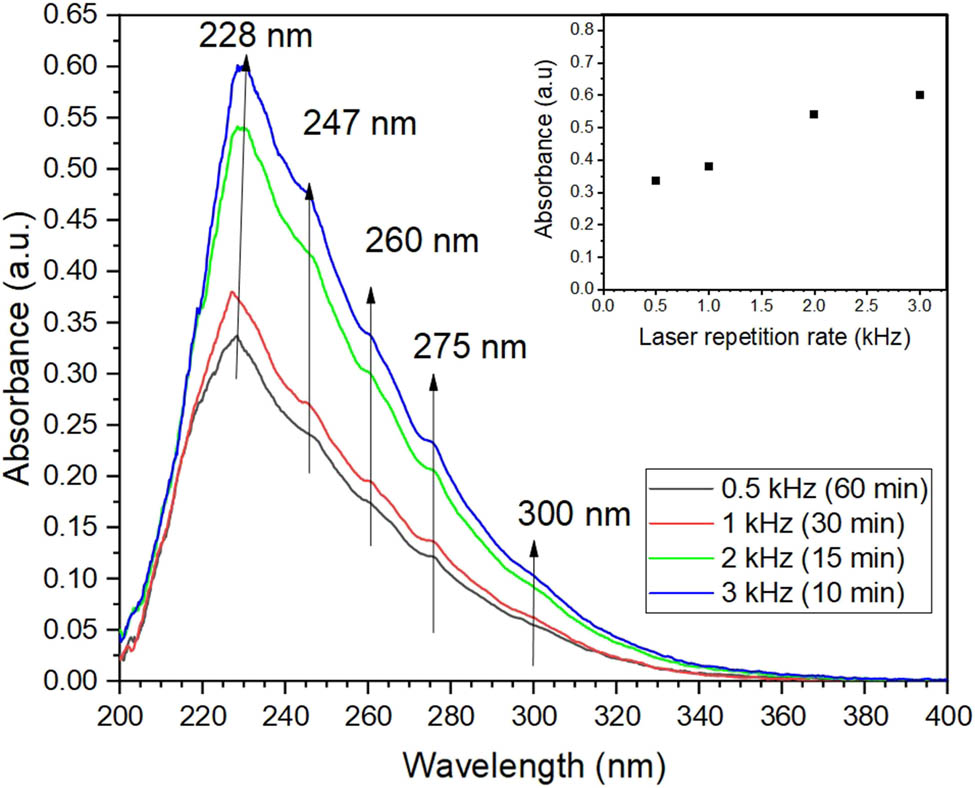

Figure 2 shows the absorbance of the sample subjected to laser filamentation for a fixed laser parameter and the number of laser pulses at repetition rates from 0.5 to 3 kHz. The same peaks were detected for all the samples, indicating that the properties of the sample are the same. The absorbance peak at 228–235 nm was observed, followed by lower intensity peaks at 247, 260, 275, and 300 nm. The peak at 228 nm is the intrinsic absorbance of the diamond (5.4 eV), while 247 nm is attributed to π–π* transition of C═C bonds. The contribution of the absorbance peak at 260 nm is unclear, but the peaks at 275 and 300 nm are due to the n–π* transition of the C═O bond [15,16]. The intensity of the peak increases as the repetition rate increases (Figure 2, inset). The results indicate that more nanoparticles are formed at a higher laser repetition rate. The intensity of the absorbance peak obtained at 3 kHz was 53% higher than that synthesized at 1 kHz. It was also noted that the same spectra (<5% difference) were obtained after 2 weeks. The increase in the intensity of the peaks was also observed consistently if the duration of laser filamentation was increased [13].

Absorbance of the ethanol sample irradiated for 1.8 million pulses at different repetition rates. The inset shows the increase in intensity of the absorbance peak with laser repetition rate.

Subsequently, the absorbance of samples without and with movements were recorded at laser repetition rates of 1 and 3 kHz. The normalized absorbance of the samples is shown in Figure 3(a) and (b). At the same repetition of 1 kHz, cuvette movement results in a higher change in absorbance. The intensity of the absorbance peak of the ethanol sample synthesized with cuvette movements increased by ∼22%. At 3 kHz, the effects of moving the cuvette only increased the absorbance by 4%. The effect was insignificant at a high laser repetition rate. The results show that the movement of the cuvette did not improve much on the synthesis of nanoparticles at 3 kHz. Finally, the liquid motion was introduced during laser filamentation by ultrasonication at a laser repetition rate of 1 kHz. Figure 3(c) shows the normalized absorbance of the samples. The intensity of the absorbance peak increased by 61% when ultrasonication was used. There was no change in absorbance when only ultrasonication was used.

Normalized absorbance of the ethanol sample without and with stage motion at laser repetition rates of 1 kHz (a) and 3 kHz (b). Normalized absorbance of the ethanol sample by only ultrasonication, laser irradiation, and the combination of both at a laser repetition rate of 1 kHz (c).

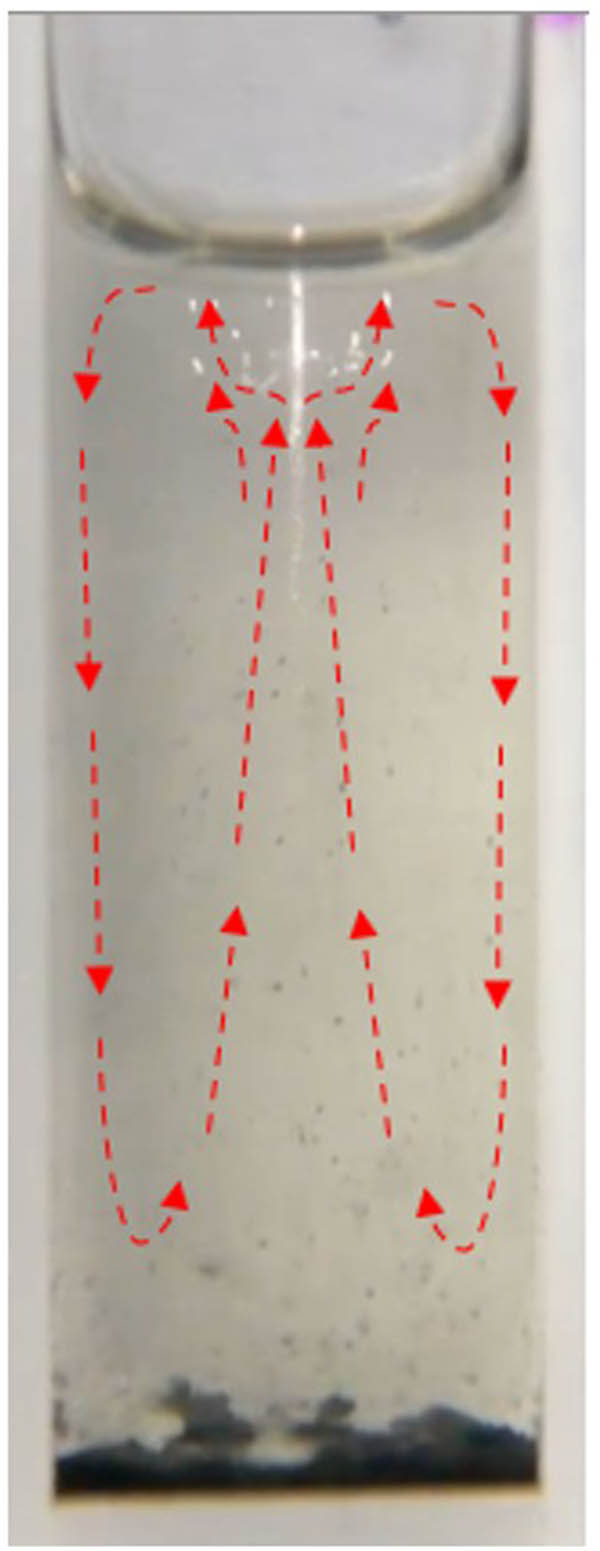

During ultrafast laser interaction with ethanol, plasma was produced where ionization occurred in ethanol [13]. As a result, the electrons were accelerated to the surroundings and heated the ethanol because of the temperature gradient induced along the filament. When filamentation occurred in a stationary cuvette, the liquid surrounding the filament was pushed to the sidewall of the cuvette, while the liquid below the filament moved upward to fill up and thus generate a flow that depended on the laser repetition rate. In a separate experiment, the flow was visualized by adding fine carbon powder to ethanol during laser filamentation. The fluid flow trajectory can be traced from the motion of the fine carbon powder (Figure 4). The liquid that was pushed to the sidewall by the filaments proceeded to flow to the lower side of the filament to fill up the region, as reported in another work [17]. This leads to the formation of a circular movement in the region where filamentation occurs.

Filamentation in ethanol in the presence of fine carbon powder with the direction of fluid flow indicated by the red arrow.

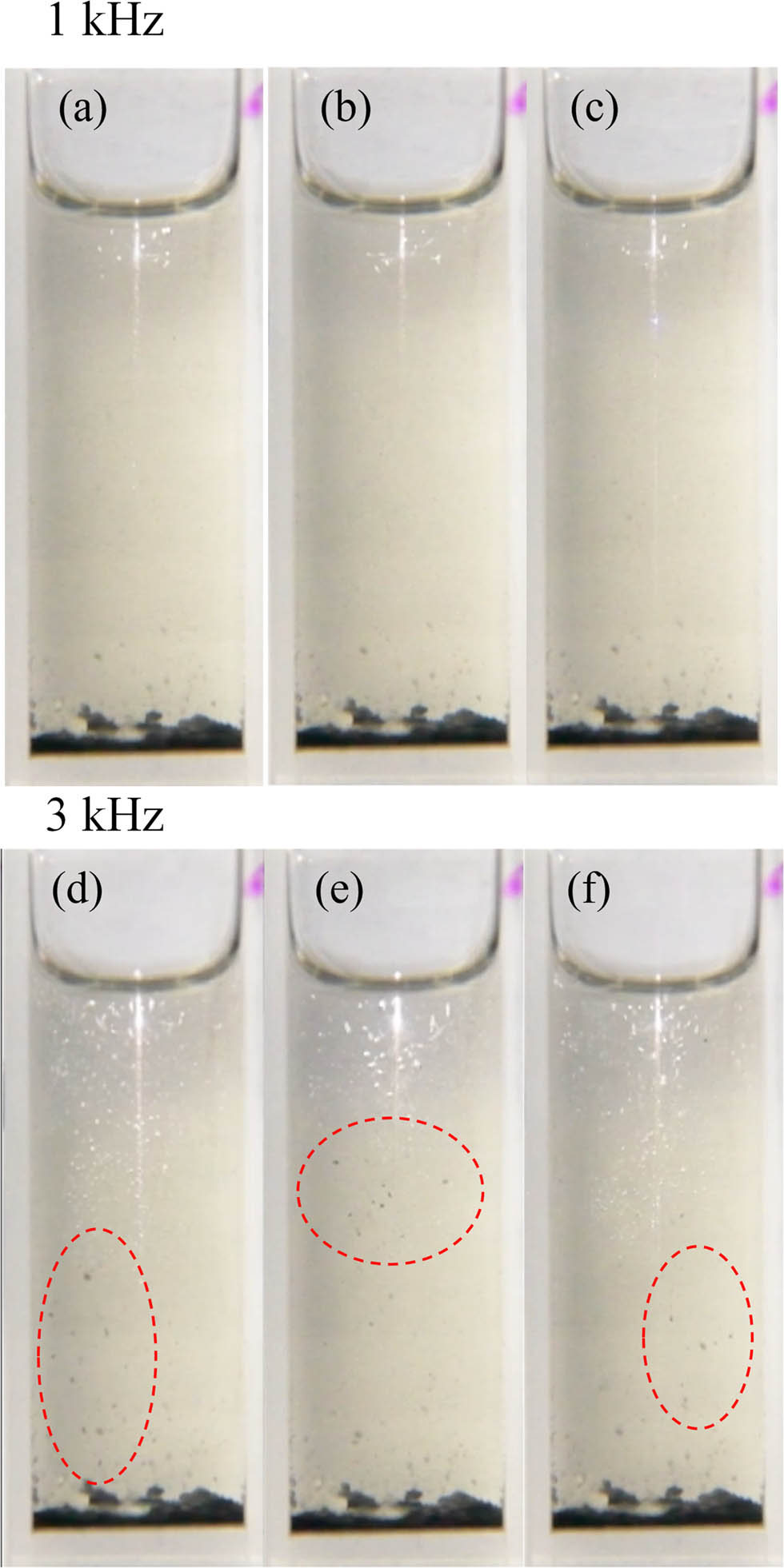

At a high laser repetition rate, the heat generated is higher [18]. The stronger heat gradient from the interaction zones to the surrounding increased the flow of ethanol to a larger volume. The higher generated heat also increases the rate of the ethanol movement. The ethanol molecules are more energetic because of the induced heat. The carbon powder located at the bottom of the cuvette flows along the flow current in the cuvette and moves upward (Figure 5). At a high repetition rate, the induced flow is able to cover a wider area. The larger coverage of the flow loop and more energetic molecules result in dissociation being more effective.

Side view of fine carbon powder motion: (a)–(c) 0, 5, and 10 s of laser irradiation at 1 kHz (stationary); and (d)–(f) 0, 5, and 10 s of laser irradiation at 3 kHz (stationary). The red-dashed circle indicates the carbon powder flowing around.

When filamentation occurs in a stationary cuvette, the movement of ethanol is limited to the region close to the filament. However, when the process was performed with the movement of the cuvette, both the filament position and the pressure gradient in the liquid changed, causing additional movement in the ethanol precursor. The changing flow creates random turbulence on the flow and allows more fresh ethanol outside the flow loop to flow in. As a result, a higher rate of dissociation and also probability for nucleation are obtained.

However, when filamentation in ethanol occurs at a high repetition rate with the movement of the cuvette, there is only a small change in the absorbance. The movement of the cuvette did not increase the absorbance significantly (Figure 3b). The maximum rate of dissociation might have been reached. As the coverage of the flow loop is larger, the size of the cuvette could limit the flow. Finally, ultrasonication vibrates and agitates ethanol at high frequency throughout the volume of ethanol, and thus, the effect is the most significant.

Intrinsically, turbulence in the interaction medium could lower the threshold of multiple filamentations, leading to a higher number of filaments being generated, as observed in air [19]. In another report, turbulence in the medium also enhanced THz generation by multiple chaotically distributed femtosecond filaments in the air [20]. The contribution of this effect is low compared to the improvement in circulation of the precursor molecules because of the nonlinear process. However, it is regenerative as more filaments generate stronger turbulence. As the rate of dissociation also depends on the number of filaments generated, more nanoparticles could be generated with turbulence in addition to the hydrodynamic flow. Based on these results, the use of ultrasonication during ultrafast laser filamentation is the most cost-effective method to increase the yield of nanoparticle synthesis.

4 Conclusion

Ultrafast laser filamentation leads to nanoparticle formation from liquid precursors via an interesting nonlinear optical phenomenon that leads to nanodiamond formation from ethanol. This method can potentially be used to generate single-digit nanoparticles for biomedical applications. The fs laser beam interacts with the liquid precursor for the formation, but the process is limited to the volume of interaction. In an attempt to increase the yield of nanoparticle generation in ultrafast laser filamentation, turbulence is introduced to the process by a higher laser repetition rate, motion of the cuvette container, and ultrasonication. The increase in absorbance, which indicates the higher formation of nanodiamonds, is apparent by using a higher laser repetition rate, although the number of laser pulses is fixed. Next, the sample movement or ultrasonication during the process increases the absorbance. Ultrasonication led to the highest increase in absorbance. The stronger turbulence increases the circulation of the precursor molecules to the interaction zones, thereby contributing to higher absorbance; in addition, turbulence can also promote filamentation and multifilament formation to generate more nanoparticles.

-

Funding information: The authors acknowledge the support from TM R&D (MMUE/240106). S. S. Yap wishes to acknowledge the support from the Xiamen University Malaysia Research Fund (XMUMRF/2023-C11/IPHY/0003).

-

Author contributions: Han Yi Tan and Guang Liang Ong: data curation and original draft; Carlos Federico Sanz-Navarro and Siaw Foon Lee: writing – review and editing; Chen Hon Nee and Seong Shan Yap: resources, investigation, experiment, and supervision; and Teck Yong Tou and Seong Ling Yap: resources and final investigation. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: All data generated or analysed during this study are included in this published article.

References

[1] Chin SL. Femtosecond laser filamentation. Vol. 55, New York: Springer; 2010. 10.1007/978-1-4419-0688-5.Suche in Google Scholar

[2] Couairon A, Mysyrowicz A. Femtosecond filamentation in transparent media. Phys Rep. 2007;441:47–189. 10.1016/j.physrep.2006.12.005.Suche in Google Scholar

[3] Chin SL, Xu HL, Luo Q, Théberge F, Liu W, Daigle JF, et al. Filamentation “remote” sensing of chemical and biological agents/pollutants using only one femtosecond laser source. Appl Phys B Lasers Opt. 2009;95:1–12. 10.1007/s00340-009-3381-7.Suche in Google Scholar

[4] Thul D, Bernath R, Bodnar N, Kerrigan H, Reyes D, Peña J, et al. The mobile ultrafast high energy laser facility - A new facility for high-intensity atmospheric laser propagation studies. Opt Lasers Eng. 2021;140:106519. 10.1016/j.optlaseng.2020.106519.Suche in Google Scholar

[5] Xu HL, Chin SL. Femtosecond laser filamentation for atmospheric sensing. Sensors. 2011;11:32–53. 10.3390/s110100032.Suche in Google Scholar PubMed PubMed Central

[6] Wang TJ, Wei Y, Liu Y, Chen N, Liu Y, Ju J, et al. Direct observation of laser guided corona discharges. Sci Rep. 2015;5:1–8. 10.1038/srep18681.Suche in Google Scholar PubMed PubMed Central

[7] Eaton SM, Zhang H, Herman PR, Yoshino F, Shah L, Bovatsek J, et al. Heat accumulation effects in femtosecond laser-written waveguides with variable repetition rate. Opt Express. 2005;13:4708. 10.1364/opex.13.004708.Suche in Google Scholar PubMed

[8] Bérubé J-P, Bernier M, Vallée R. Femtosecond laser-induced refractive index modifications in fluoride glass. Opt Mater Express. 2013;3:598. 10.1364/ome.3.000598.Suche in Google Scholar

[9] Chin SL. Femtosecond laser filamentation induced phenomena and applications. Prog. Ultrafast Intense Laser Sci. XV. Cham: Springer International Publishing; 2020. p. 1–19. 10.1007/978-3-030-47098-2_1.Suche in Google Scholar

[10] Yuan S, Wang T, Lu P, Leang Chin S, Zeng H. Humidity measurement in air using filament-induced nitrogen monohydride fluorescence spectroscopy. Appl Phys Lett. 2014;104:091113. 10.1063/1.4867267.Suche in Google Scholar

[11] Matsuda A, Hayashi T, Kitaura R, Hishikawa A. Femtosecond laser filamentation in gaseous ethylene: Formation of hydrogenated amorphous carbon. Chem Lett. 2017;46:1426–9. 10.1246/cl.170613.Suche in Google Scholar

[12] Nee CH, Yap SL, Tou TY, Chang HC, Yap SS. Direct synthesis of nanodiamonds by femtosecond laser irradiation of ethanol. Sci Rep. 2016;6:1–8. 10.1038/srep33966.Suche in Google Scholar PubMed PubMed Central

[13] Nee CH, Lee MC, Poh HS, Yap SL, Tou TY, Yap SS. Plasma synthesis of nanodiamonds in ethanol. Compos Part B Eng. 2019;162:162–6. 10.1016/j.compositesb.2018.10.071.Suche in Google Scholar

[14] Okamoto T, Nakamura T, Sakota K, Yatsuhashi T. Synthesis of single-nanometer-sized gold nanoparticles in liquid-liquid dispersion system by femtosecond laser irradiation. Langmuir. 2019;35:12123–9. 10.1021/ACS.LANGMUIR.9B01854/SUPPL_FILE/LA9B01854_SI_001.PDF.Suche in Google Scholar

[15] Tan D, Zhou S, Xu B, Chen P, Shimotsuma Y, Miura K, et al. Simple synthesis of ultra-small nanodiamonds with tunable size and photoluminescence. Carbon. 2013;62:374–81. 10.1016/j.carbon.2013.06.019.Suche in Google Scholar

[16] Luo Z, Lu Y, Somers LA, Johnson ATC. High yield preparation of macroscopic graphene oxide membranes. J Am Chem Soc. 2009;131:898–9. 10.1021/ja807934n.Suche in Google Scholar PubMed

[17] Liu F, Yuan S, Zuo Z, Li W, Ding L, Zeng H. Laser filamentation induced bubbles and their motion in water. Opt Express. 2016;24:13258. 10.1364/oe.24.013258.Suche in Google Scholar

[18] Tan HY, Ong GL, Nee CH, Yap SL, Poh HS, Tou TY, et al. Thermal-induced effects on ultrafast laser filamentation in ethanol. Opt Laser Technol. 2023;163:109350. 10.1016/j.optlastec.2023.109350.Suche in Google Scholar

[19] Liu J, Zhang Z, Shang B, Chu C, Sun L, Zhang N, et al. Enhancement of multi-filament generation and filament-induced fluorescence by turbulence. Opt Commun. 2022;517:128290. 10.1016/j.optcom.2022.128290.Suche in Google Scholar

[20] Babushkin PA, Bulygin AD, Geints YE, Kabanov AM, Oshlakov VK, Petrov AV, et al. Turbulence-enhanced THz generation by multiple chaotically-distributed femtosecond filaments in air. Opt Laser Technol. 2024;179:111322. 10.1016/j.optlastec.2024.111322.Suche in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Artikel in diesem Heft

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite

Artikel in diesem Heft

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite