Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

-

Revati Radakisnin

, Mohd Ridzuan Mohd Jamir

Abstract

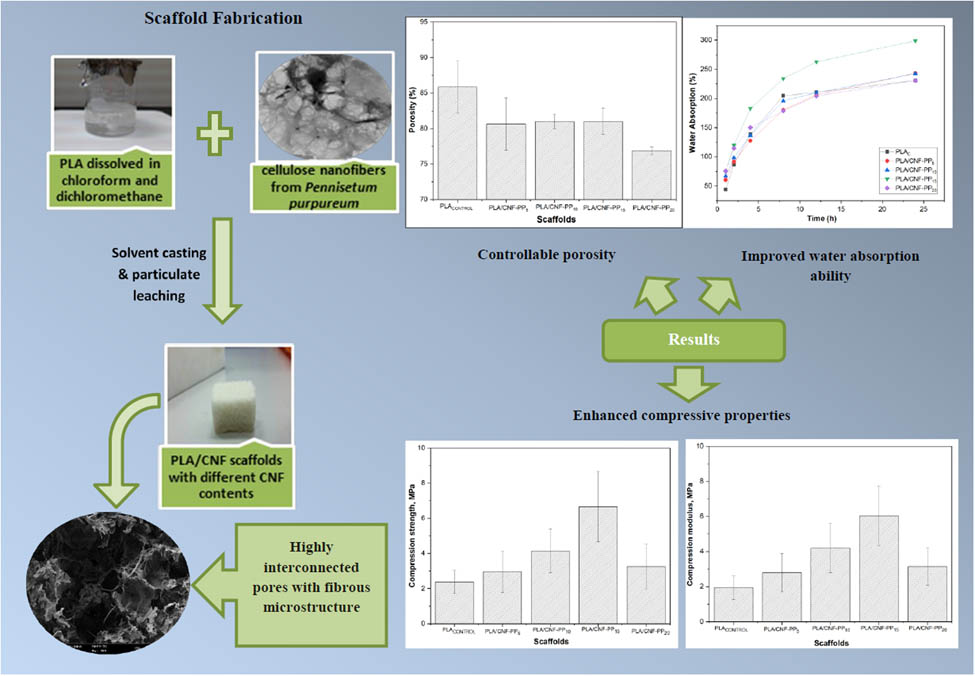

This study aimed to prepare and characterise polylactic acid (PLA) reinforced with cellulose nanofibre (CNF) from a Pennisetum purpureum-based composite scaffold and determine its structural and mechanical properties. Porous scaffolds with CNF compositions of 5‒20 wt% in the PLA matrix were developed using solvent casting and particulate leaching of its porogen at 90 wt% of loadings. Morphology studies using field emission scanning electron microscopy revealed that the scaffolds had well-interconnected pores with an average pore size range of 67‒137 µm and porosity >76%. X-ray diffraction confirmed the interconnectivity and homogeneity of the pores and the fibrous structure of the scaffolds. The compressive strength of the fabricated scaffolds varied between 2.34 and 6.66 MPa, while their compressive modulus was between 1.95 and 6.04 MPa for various CNF contents. Furthermore, water absorption and thermal degradation studies showed that the scaffold had good hydrophilicity and improved thermal stability. These findings highlight the need to modify the pore structure and mechanical performance simultaneously for tissue engineering. Thus, this study concludes that the developed PLA scaffolds reinforced with CNF from Pennisetum purpureum are potential candidates for cell attachment and extracellular matrix generation.

Graphical abstract

Abbreviations

- CNF

-

cellulose nanofibre

- CNF-PP

-

cellulose nanofibres from Pennisetum purpureum

- DTG

-

derivative thermogravimetry

- ECM

-

extracellular matrix

- FESEM

-

field emission scanning electron microscopy

- FTIR

-

Fourier transform infrared

- PLA

-

polylactic acid

- TGA

-

thermogravimetric analysis

- XRD

-

X-ray diffraction

1 Introduction

Soft tissue is comprised of a variety of tissues, including skin, fat, tendons, muscles, nerves, articular cartilage, blood vessels, and fascia. Its role in the human body includes supporting, surrounding, and combining the body structure and internal organs [1]. Autologous implantation has been traditionally used to repair and regenerate damaged or diseased tissues and organs. Due to complications associated with autologous transplantations, such as rapid loss in volume and easily absorb approximately 40–60% of soft tissue cells, remain feasible, as reported by Yuksel et al. [2]. The constraints associated with existing treatments have led researchers to develop new biological replacements to overcome the limitations of current clinical treatments by exploring alternative biomaterials, such as polymeric scaffolds incorporated with nanocellulose.

With the development and emergence of nanotechnology, cellulose, the most abundant material on earth, revitalised and gained significant attention as a novel and leading material in the form of nanocellulose [3]. Nanocellulose is a unique and vital natural material extracted from cellulose (found in bacteria, animals, and plants) in the form of nanostructures. Typically, nanocellulose can be classified as cellulose nanofibres (CNFs), cellulose nanocrystals, and bacterial cellulose [4,5,6]. Generally, CNFs can be obtained from plants, especially from bast fibres or wood, by chemical or mechanical treatment [7]. Therefore, CNF is a promising biomaterial that has been highly recommended for use in tissue engineering and regenerative medicine as a reinforcement of polymeric scaffolds for cell culture. The most common features when outlining the importance of CNFs are their high specific surface area, hydrophilicity, renewability, adjustable morphological and mechanical reinforcements, biocompatibility, biodegradability, and non-toxicity, as mentioned by Hickey and Pelling [8]. Associated with tissue engineering and regenerative medicine topics, these factors facilitate polymeric scaffolds with reinforced CNF with enhanced properties, such as high mechanical strength, surface modifications, and biological properties.

Pennisetum purpureum, commonly known as Napier grass, comprises cellulose, hemicellulose, and lignin in the proportions of 46, 34, and 20%, respectively [9]. It grows rapidly and requires minimal nutrient supplementation. CNFs from Pennisetum purpureum were chosen for this study because they are an abundant and sustainable resource found across many Asian countries [10]. Recent studies have confirmed the use of Pennisetum purpureum fibres as a suitable reinforcement [11]. Reddy et al. studied the structural and chemical composition of Napier grass fibres and found morphological differences between the treated and untreated fibres, with improved tensile properties identified in the former [9]. Subsequently, Ridzuan et al. explored the potential of Pennisetum purpureum as reinforcement for polymer composites. They found that alkaline treatment increased the surface roughness and improved the tensile stress of the fibres [12]. A further study by De Araújo Morandim-Giannetti et al. evaluated the effect of delignification conditions on Napier grass and proved the suitability of Napier grass as a source for composites with low degradation under optimal conditions for the industrial processes of bleaching and pulping [13]. Many studies have highly recommended the use of CNFs as fillers in polymeric scaffolds [14,15]. Radakisnin et al. synthesised CNFs from Pennisetum purpureum using ball milling assisted by acid hydrolysis treatment [16]. They found that chemical and mechanical treatments had a minimal effect on its cellulosic properties; as a result, the thermal stability and the effective surface area available for contact were enhanced. More recently, researchers have begun to study the benefits of nanocomposites in biomedical applications [17], providing evidence for using CNFs from Pennisetum purpureum as reinforcement in polymeric scaffolds.

In tissue engineering, polylactic acid (PLA) has been approved by the Food and Drug Administration for use in the controlled release of drugs and biodegradable polymers [14,15]. As PLA is the most common and medically approved material, it has been widely used to produce scaffolds, as well as due to its superior biodegradability and biocompatibility [18]. Dai et al. mentioned that PLA is widely used in the field of tissue-engineered repair, and it decomposed into pyruvate and glycolate and hydrolysed into water (H2O) and carbon dioxide (CO2) eventually in vivo [19]. It can also be degraded into lactic acid, where the degradation time of PLA can be altered via copolymerisation [17,20,21]. In addition, this polymer is non-toxic and is removed by the body using the normal metabolic system [22]. Recently, several researchers have developed PLA scaffolds as preliminary support platforms in tissue engineering [18,23]. However, PLA scaffolds exhibit poor mechanical performance and hydrophobicity. Donate et al. regarded that PLA exhibits low osteoconductivity, inadequate cell adhesion on its surface, and intrinsic acidic degradation [24].

Therefore, PLA reinforced with CNFs from Pennisetum purpureum is viewed as highly favourable as a biocomposite in tissue engineering [14,25]. If both materials can be incorporated, CNFs will be able to neutralise the acidic degradation produced by PLA. Furthermore, the reinforcement of CNFs could improve the mechanical properties, especially its microstructure, to facilitate the bioactivity of the scaffolds [26]. According to Peng et al., solvent casting and particulate leaching is a traditional construction method used to fabricate scaffolds with a macroporous structure for soft tissue engineering [27]. However, effectively blending PLA with CNFs using solvent casting and particulate leaching remains a challenge due to the behaviour of CNFs, which tend to agglomerate. Ultrasonication is a reliable mechanical method to disperse CNFs in liquids where they increase the dispersion by breaking the agglomerations in aqueous suspensions. However, the efficiency is highly dependent on the applied force of the probe reported by Chanda and Bajwa [28]. Hence, ultrasonication can be used during the fabrication process to resolve this and produce scaffolds with well-dispersed CNF particles.

This study evaluates the performance of PLA scaffolds reinforced with various CNFs from Pennisetum purpureum using solvent casting and particulate leaching techniques. The porosity and microstructural properties of the scaffolds were evaluated under fixed environmental conditions, and the pore size of each scaffold was measured using ImageJ. The compressive strength and modulus were measured using a cantilever stress–strain tester machine to analyse the influence of compressive strength, modulus, CNF composition, and the contribution of porogens to the scaffolds. Based on these findings, PLA scaffolds with various CNFs from Pennisetum purpureum were formulated, and their properties, including water absorption, structural morphologies, and thermal properties, were determined.

2 Materials and methods

2.1 Materials

CNFs from Pennisetum purpureum (Napier fibres) were developed using Napier grass supplied from a local plantation (Bukit Kayu Hitam, Kedah, in northern peninsular Malaysia). Dichloromethane (DCM), chloroform, and ethanol were obtained from Thermo Fisher Scientific (Waltham, MA, USA). Analytical grade sodium chloride (NaCl) was purchased from Merck (Darmstadt, Germany) and was used as a porogen. Medical grade PLA (M W 60,000) used to fabricate scaffolds was acquired from Sigma-Aldrich (Missouri, United States).

2.2 Preparation of PLA/CNFs composite

Porous PLA/CNFs from Pennisetum purpureum (CNF-PP) scaffolds were fabricated using solvent casting and particulate leaching. First, PLA pellets with known weight were dissolved in an organic solvent to achieve a viscous solution of 1.2 g/20 mL. The ratio of chloroform to DCM was kept constant at 1:1. Next, the PLA solution was stirred using a magnetic stirrer and heated at 70°C for 30 min. Then, CNFs from Pennisetum purpureum were dispersed in the PLA solution. To uniformly disperse CNF-PP in the PLA solution, the mixture was ultrasonicated for 10 min at 40% amplitude to eliminate any CNF-PP agglomerates. As a result, the contents of CNF-PP were selected as 0, 5, 10, 15, and 20 wt%, as illustrated in Table 1. Subsequently, the addition of porogen to the PLA/CNF-PP solution was blended at a ratio of 9:1. Thus, prior to mixing the porogen-PLA/CNF-PP mixture and stirring for 2 h, the PLA/CNF-PP mixture was ready for casting. Subsequently, the cast scaffold was oven-dried overnight at 40°C. Next, the prepared scaffolds were immersed in deionised water for three days to leach out the salt (porogen) and form the composite scaffolds, which were refreshed every 8 h to remove the salt residual entirely. Subsequently, oven drying was carried out for the salt-leached scaffolds at room temperature for two days, and the resultant PLA/CNF-PP scaffolds were prepared. Details on the structural, morphological, and thermal properties of CNFs from Pennisetum purpureum (CNF-PP) are described in detail in a previous study [16].

Composition, porosity, and average pore size of CNFs-reinforced PLA-based scaffolds

| Scaffold samples | CNF content (wt%) | Porogen content (%) | Porosity (%) | Average pore size (µm) |

|---|---|---|---|---|

| PLAC | 0 | 90 | 85.87 | 134.00 ± 40.18 |

| PLA/CNF-PP5 | 5 | 90 | 80.63 | 136.68 ± 67.31 |

| PLA/CNF-PP10 | 10 | 90 | 80.98 | 102.98 ± 41.63 |

| PLA/CNF-PP15 | 15 | 90 | 81.01 | 81.48 ± 24.23 |

| PLA/CNF-PP20 | 20 | 90 | 76.89 | 67.58 ± 18.96 |

2.3 Morphological study using field emission scanning electron microscopy (FESEM)

The morphological analysis of the PLA scaffolds reinforced with various CNFs from Pennisetum purpureum was characterised by FESEM (Zeiss Merlin; Jena, Germany) at an accelerating voltage of 20 kV. Each specimen was cut to an approximate dimension of 10 mm × 10 mm. The samples were mounted on aluminium stubs and subsequently sputter-coated with gold to avoid unwanted charges and to enhance conductivity. The surface morphology, pore size, and interconnectivity of the pores of the scaffolds were also evaluated in this testing. The pore sizes of each scaffold were further measured from the FESEM images using ImageJ software.

2.4 Porosity measurements

As mentioned by Lopes et al. [22] and Massai et al. [29], in the generally adopted theoretical model, the microstructure of a porous scaffold can be obtained internally by dividing the pore space into a collection of single pores, where it can be defined as parts of the void space limited by solid surfaces. Thus, the porosity of the scaffold can be described as a void fraction of the scaffolds.

The porosity of the scaffolds was evaluated using the ethanol displacement technique. Archimedes’ principle of buoyancy was used for the porosity tests. Absolute ethanol was used as a liquid displacement as it easily penetrated the pores and did not induce shrinkage or swelling as a non-solvent of the scaffold composite. The initial weight of dry scaffolds, W 1, was measured and then the dry scaffold was immersed in ethanol with a known weight, W ethanol, in a specimen bottle. A series of low-pressurisation cycles above the ethanol saturation pressure were conducted to force ethanol into the pores [30]. The process was repeated until no air bubbles were observed on the surface of the specimens. Subsequently, the total weight of the ethanol and ethanol-impregnated scaffold was recorded as W 2. The samples were then kept in ethanol for 2 h. The ethanol-impregnated scaffold was removed, and the residual ethanol weight was recorded as W 3. The void volume of the scaffold is calculated as follows:

The total volume of the scaffold was calculated as:

The accessible porosity was determined as the ratio of the volume of the void scaffold to the total volume of the scaffold, as follows:

2.5 X-ray diffraction (XRD) analysis

XRD was performed to determine the crystalline systems present in each scaffold using a D2 phase Bruker diffractometer with Cu-Kα radiation (λ = 1.5418 Å) at 30 mA and 40 kV. The diffraction pattern of the scaffolds was scanned in the range of 10° < 2θ < 80° at a scan rate of 4°/min and a step size of 0.02° in continuous mode. The crystallinity index (CrI) was estimated using the peak height method, as shown in equation (4):

where I 200 and I am represent the intensities of the crystalline and amorphous regions of the scaffolds, respectively.

2.6 Fourier transform infrared (FTIR) analysis

Infrared spectra were used to identify the functional groups present in the scaffolds. The scaffolds were analysed using FTIR spectroscopy (RX1; Perkin-Elmer, UK). The ground precipitate of the scaffolds was mixed with KBr. The absorption spectra were recorded in the range of 400–4,000 cm−1 with a resolution of 1 cm−1.

2.7 Thermogravimetric analysis (TGA)

The thermal stability of PLA scaffolds with different compositions of CNFs from Pennisetum purpureum was evaluated using a TG analyser and derivative thermogravimetry (DTG 60H; Shimadzu, Japan). Scaffolds weighing 10 mg were mounted on an alumina crucible and evaluated over a temperature range of 30–800°C under a nitrogen atmosphere at a heating rate of 20°C/min.

2.8 Water absorption measurements

The water absorption measurements were evaluated using a simplified method. The specimens were cut with a dimension of 10 mm × 10 mm × 10 mm, dried to a constant weight, W DRY, and then immersed and soaked in distilled water at room temperature of 25°C for the required time (1, 2, 4, 8, 12, and 24 h). The soaked specimens were then removed from the distilled water and weighed, and the excess water on the surface of the specimens was gently blotted with a filter paper to obtain W WET. The percentage of water absorption for the specimens at various times was calculated as follows:

where W DRY and W WET are the weights of the dried scaffolds and wet scaffolds at the required times, respectively [31]. For each scaffold, four specimens were tested, and the mean values were recorded.

2.9 Mechanical analysis

The compression strength and modulus properties of the scaffolds were determined to evaluate the effect of CNF-PP addition on the mechanical properties of the PLA scaffolds. Testing was performed according to ASTM D695-96 [32] standard using an Autograph AG-X Plus Universal Tensile Tester machine (Shimadzu). The specimens were cut into rectangular sections (13 mm thickness × 25 mm length × 13 mm width). The test was carried out at a cross-head speed of 1.0 mm/min using a 10 kN load cell. In order to obtain flat surfaces, the top and bottom layers of the scaffolds were detached. The dimensions of the specimens were measured manually before testing using a Vernier calliper. The compression strength of the scaffolds was determined as the stress at which the samples were compressed to 30% of their original thickness. The compression modulus was measured from the slope of the stress–strain curve. Five samples were evaluated for each scaffold, and the average values were recorded.

3 Results and discussion

3.1 Morphology and porosity study of scaffolds

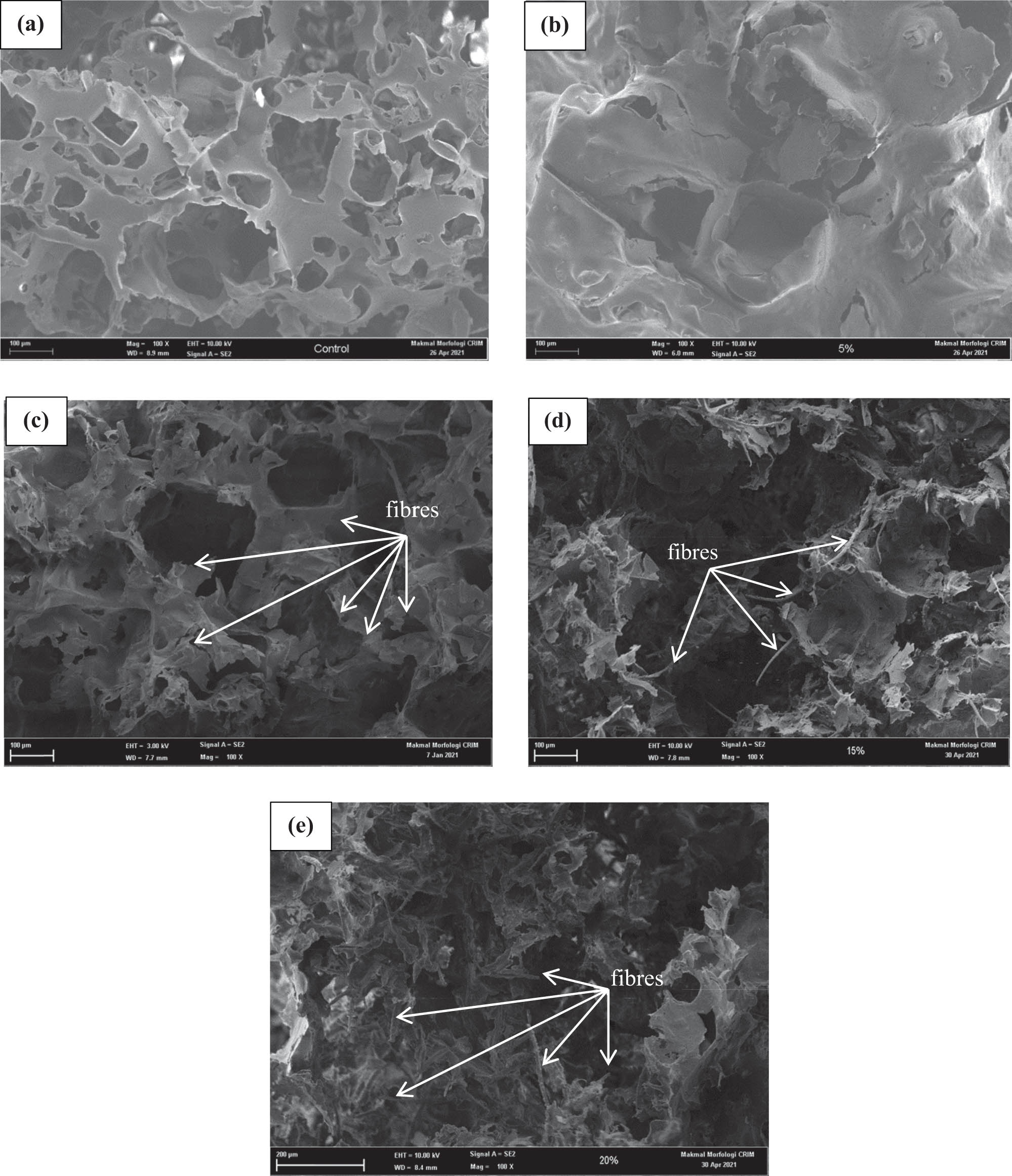

For biocompatibility in tissue engineering, a scaffold should have an ideal pore size, porosity, high interconnectivity, and good cytotoxicity to enhance cell attachment and proliferation [33]. In the present study, CNFs from Pennisetum purpureum as a reinforcement filler to control pore size and porosity to promote good cytocompatibility, were introduced. Figure 1 shows the FESEM images of PLA scaffolds with different CNF contents. It is clear that the addition of CNF decreased the pore size, as reported by Zhang and Cui [34], who obtained similar findings. The average pore sizes estimated from the FESEM measurements are listed in Table 1. Figure 1(a)–(e) show that the produced PLA/CNF scaffolds had a highly interconnected pore structure. Moreover, when the CNF content was increased, the overall homogeneity of the scaffold structure was significantly enhanced, leading to a reduction in the pore size. In addition, surface roughness is a crucial factor affecting cell adhesion, growth, and maturation, as mentioned by Cai et al. [35]. Therefore, increases in CNF content will greatly enhance the surface roughness of the scaffolds to aid extracellular matrix (ECM) generation.

FESEM structure of (a) PLACONTROL, (b) PLA/CNF-PP5, (c) PLA/CNF-PP10, (d) PLA/CNF-PP15, and (e) PLA/CNF-PP20.

Based on Figure 1(a) and (b), the surfaces of the PLAC and PLA/CNF5 scaffolds were smoother and more uniform. In contrast, a rough and irregular surface was observed on the PLA/CNF-PP10, PLA/CNF-PP15, and PLA/CNF-PP20 scaffolds, caused by the dispersion of CNFs. In the pore walls, fibrous structures were visible in the FESEM images (Figure 1d and e). The distributions of the CNFs on the cross-sectional surface of the scaffolds were uniform, illustrating that the biocomposite scaffolds with uniform distribution of CNFs were obtained and attached strongly to the PLA matrix. Image analysis indicated that the average pore sizes were reduced by 134 ± 40.18, 136.68 ± 67.31, 102.98 ± 41.63, 81.48 ± 24.23, and 67.58 ± 18.96 µm for PLAC, PLA/CNF-PP5, PLA/CNF-PP10, PLA/CNF-PP15, and PLA/CNF-PP20, respectively. The exact values of the pore size were measured using ImageJ software. As shown in Table 1, although increasing the CNF content reduced the pore size or porosity, this trend continued for CNF concentrations above 15 wt%. As described, the PLA/CNF scaffold with 20 wt% of CNFs had the smallest pores and the lowest porosity among all the scaffolds. As shown in Figure 1(e), the arrangement of the CNF network was denser and, as estimated, led to a decrease in the porosity of PLA/CNF-PP20. This finding could be attributed to the changes in viscosity and conductivity and was influenced by the CNF content, as reported in a previous study [36]. These results illustrate the strong effects of CNF reinforcement on the pore structure of the fabricated scaffolds and their influence on the cell adhesion and proliferation of the PLA/CNF scaffolds.

Large standard deviations were obtained for all scaffolds, with average pore sizes in the range of 67–137 µm. The largest average pore sizes were observed for the pure PLA scaffold and scaffold containing minimal CNFs (PLA/CNF-PP5). When comparing the scaffolds with different CNF contents, PLA/CNF-PP15 showed a relatively homogenous surface structure and was highly interconnected. Therefore, due to its average pore size, homogeneity, interconnectivity, and porosity, PLA/CNF-PP15 was considered ideal for tissue engineering. Based on the FESEM analysis shown in Figure 1(d), PLA/CNF-PP15 had a well-entangled network of CNFs on the pore walls. This fibrous structure and the roughness of the pore wall may enhance cell fixation and allow for the development of an ECM after implantation. This is attributed to the fact that the surface roughness of the scaffold aids vascularisation, that is, the amount of diffusion to and from the implanted scaffold for nutrient/oxygen supply and the removal of waste products [30,31,32]. Based on these findings, micropore sizes below 50 µm allow for scaffold vascularisation (removal of waste products and the supply of nutrients for cells), while pore sizes above 100 µm (large pores) support scaffold colonisation by fibroblasts [33,34,35,37,38,39].

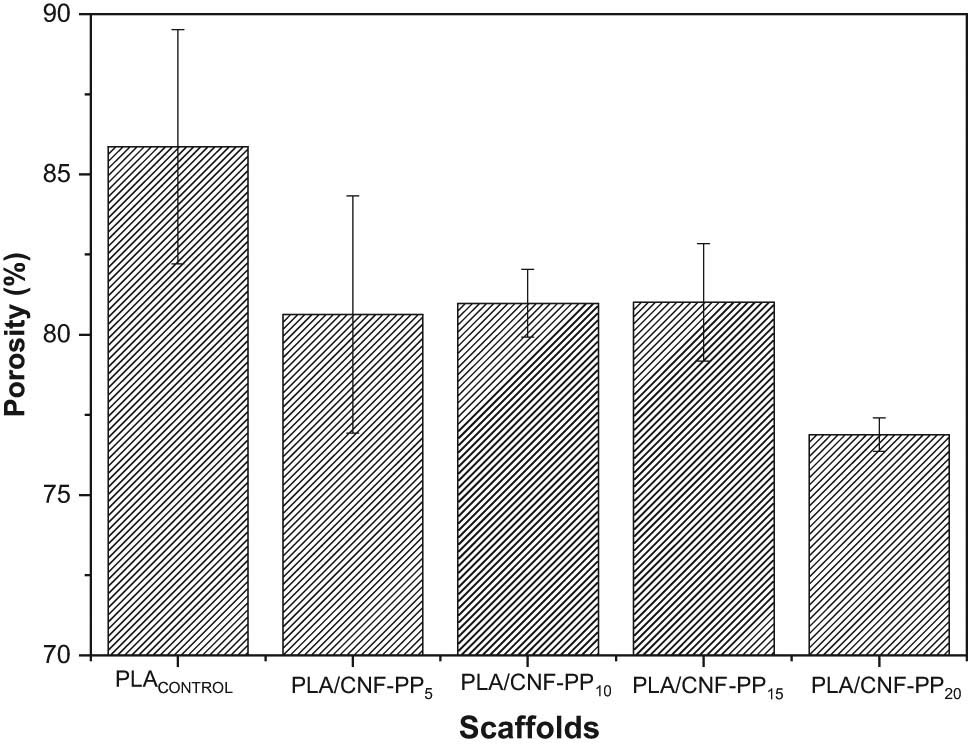

Figure 2 shows the porosity percentage of the PLA-based biocomposite scaffolds with various CNF contents. Porosity is the percentage of void space, measured by calculating the volume of voids over the total volume. Ethanol was used to prevent the scaffolds’ expansion and collapse due to air drying. The calculated porosities are displayed in Table 1, illustrating that all the fabricated scaffolds showed an ideal porosity [36,40]. The percentage of scaffold porosity was enhanced by 85.87, 80.63, 80.98, 81.01, and 76.89% in PLAC, PLA/CNF-PP5, PLA/CNF-PP10, PLA/CNF-PP15, and PLA/CNF-PP20, respectively. These results indicate that porosity decreases with an increasing CNF content. These findings are in agreement with the FESEM observations.

Porosity measurements of PLA scaffolds with different CNF contents.

Interestingly, PLA/CNF-PP5, PLA/CNF-PP10, and PLA/CNF-PP15 were found to have similar porosities irrespective of the CNF content. When the CNF content increased while maintaining a constant polymer matrix to porogen ratio (1:9), the density tended to increase due to the denser packing of the CNF network and, as predicted, this led to a decrease in porosity [41,42]. This also contributes to the deposition of CNFs on the pore walls, reducing the availability of void areas. Among the scaffolds, those with 20 wt% of CNF (PLA/CNF-PP20) showed the lowest porosity of 76.89%, contributing to the compact arrangement of the CNF network. This also led the scaffold to have a structure with a reduced homogeneity. These results indicate that the reinforcement of CNFs on PLA-based scaffolds plays an important role in controlling the porosity of the scaffolds. On the other hand, researchers have found that a higher porosity may weaken the mechanical performance of the scaffolds, which is not desirable in tissue engineering [21,43,44]. Therefore, cell viability and proliferation can be developed by modifying the pore size, porosity, or both [45].

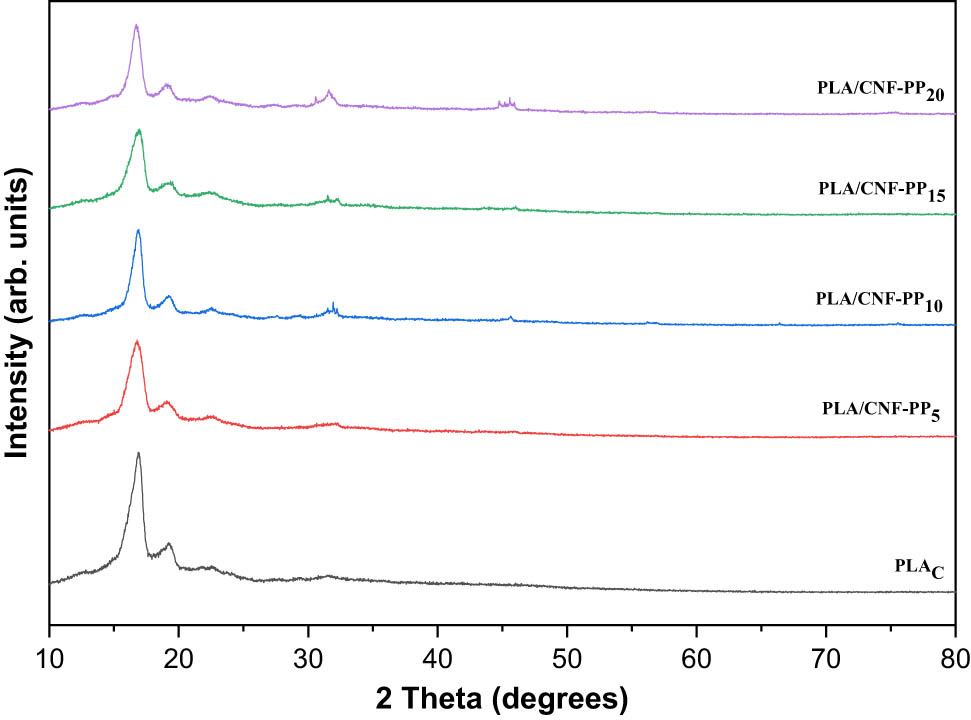

3.2 XRD analysis

XRD measurements were performed to determine the crystalline structure of the biocomposite scaffolds after reinforcing different CNF contents with a PLA matrix. Figure 3 shows the XRD spectra of the PLA/CNF scaffolds. Generally, the shape of the XRD patterns acquired from the PLA scaffolds with different CNF contents from Pennisetum purpureum were similar to those of the pure PLA scaffold, despite the weakening of diffraction peaks in the PLA/CNF scaffolds with an increasing CNF content. The characteristic peaks of CNF from Pennisetum purpureum were not observed in the diffraction pattern of the PLA/CNF scaffolds. After the addition of CNF, the intensity of the characteristic peaks was reduced. Broad diffraction with a major semi-crystalline peak was observed at 2θ = 16.8°, while another minor peak was observed at 2θ = 19.3°.

XRD analysis of PLA scaffolds with different CNF contents.

The crystallinity percentage of the PLA/CNF scaffolds was calculated using the XRD diffraction patterns. As shown in Table 2, the crystallinity of the PLAC, PLA/CNF-PP5, PLA/CNF-PP10, PLA/CNF-PP15, and PLA/CNF-PP20 scaffolds was 65.66, 62.09, 61.48, 61.91, and 61.26%, respectively. These results indicate that an increased CNF content in PLA/CNF scaffolds decreases their crystallinity. The PLAC scaffold showed the highest degree of crystallinity at 65.66%, where sharper diffraction was demonstrated with an intense peak at 16.8° compared to PLA scaffolds with CNF reinforcements. The difference in crystallinity between scaffolds with varying CNF contents did not differ significantly. The crystallite size was calculated using the Scherrer equation; the crystallite sizes of the PLAC, PLA/CNF-PP5, PLA/CNF-PP10, PLA/CNF-PP15, and PLA/CNF-PP20 scaffolds were 4.22, 4.04, 3.03, 3.04, and 2.96 nm, respectively. The interplanar spacings of the PLAC, PLA/CNF-PP5, PLA/CNF-PP10, PLA/CNF-PP15, and PLA/CNF-PP20 scaffolds were 5.30, 5.30, 5.28, 5.29 and 5.31, respectively. Based on the varying contents of CNF in the PLA/CNF scaffolds, the crystallisation readings showed slight differences in the interplanar spacing. Similarly, Ma et al. also studied the XRD of a PLA/hydroxyapatite/graphene oxide nanocomposite, and apart from weakening the diffraction peak of PLA, they also obtained a diffraction pattern similar to that of the nanocomposites [46].

XRD analysis data of PLA scaffolds with different CNF contents

| Sample name | Crystallite size (D, nm) | Interplanar spacing (Å) | Crystallinity (%) |

|---|---|---|---|

| PLAC | 4.22 | 5.30 | 65.66 |

| PLA/CNF-PP5 | 4.04 | 5.30 | 62.09 |

| PLA/CNF-PP10 | 3.03 | 5.28 | 61.48 |

| PLA/CNF-PP15 | 3.04 | 5.29 | 61.91 |

| PLA/CNF-PP20 | 2.96 | 5.31 | 61.26 |

As shown in Figure 3, the degree of crystallinity of the PLA/CNF scaffolds was influenced by two factors: (1) the addition of CNFs and (2) the CNF content distinguishing the interfacial bonding between the polymer matrix and fillers. By varying the CNF content in the PLA/CNF scaffolds, the crystalline structure of the scaffolds could be altered. This may impact the mechanical behaviour and degradability of the fabricated scaffolds. Nevertheless, based on the results and interpretations, it can be concluded that the PLA/CNF scaffolds contain similar diffraction patterns, which may be attributed to the concept that all the scaffolds possess similar microstructures and compositions. This is consistent with the findings from the FTIR spectrum (Figure 4).

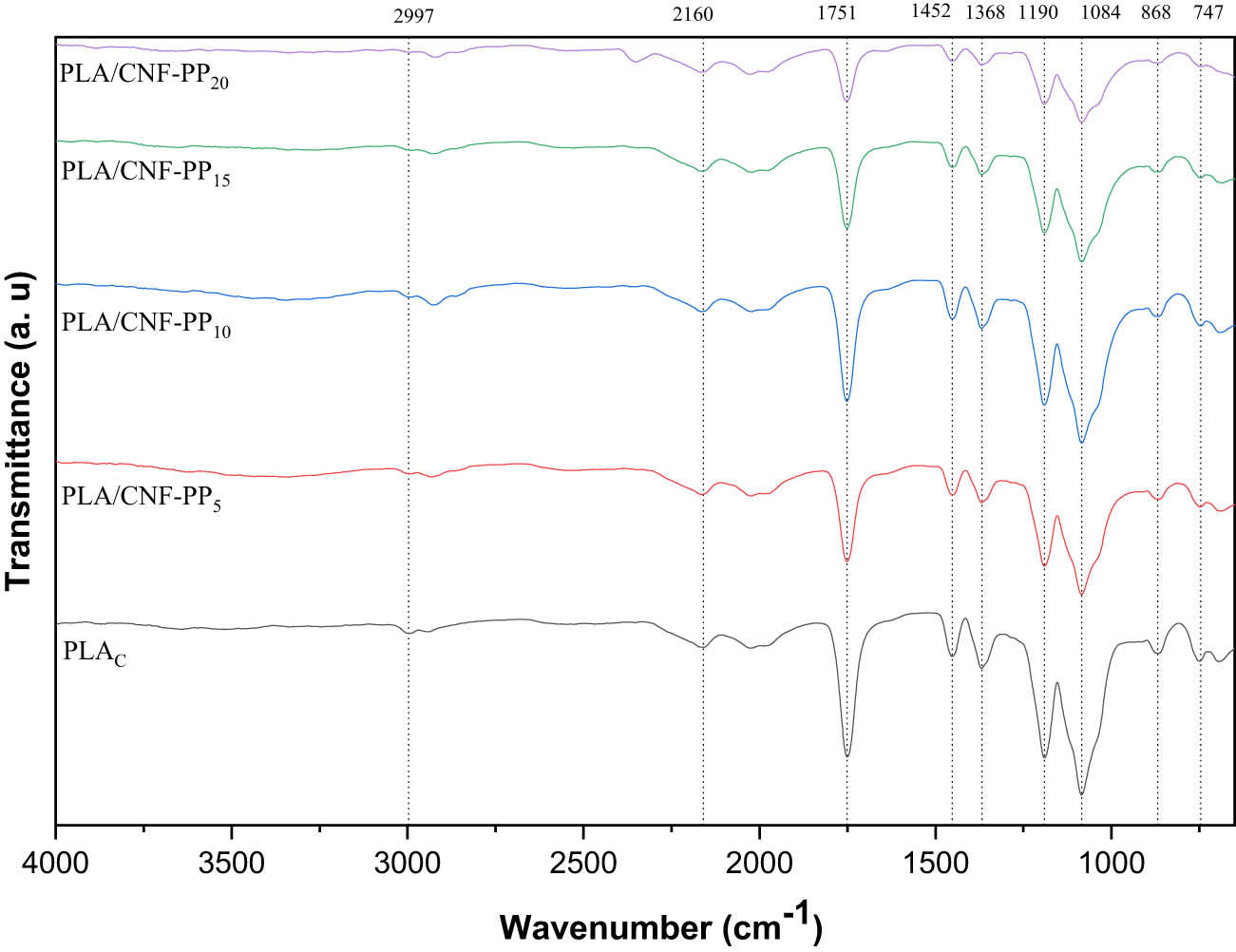

FTIR analysis of PLA scaffolds with different CNF contents.

3.3 FTIR analysis

IR spectroscopy is commonly used to interpret functional groups and identify intermolecular and intramolecular elements in scaffolds [47]. The most relevant FTIR results of the pure PLA and PLA scaffolds reinforced with various CNF contents from Pennisetum purpureum are shown in Figure 4. The weak absorption band at 2,997 cm−1 was assigned to the C–H3 stretching vibration. A band shift related to the CH3 stretching in the monomer in 2,997–2,923 cm−1 was observed in the PLA scaffolds with a varying content of CNF from Pennisetum purpureum. These bands, which show a shift in monomer, also displayed a change in peak intensity, indicating the distribution of the polymeric chains. The –C≡C– stretching vibration appeared weak and broadband at 2,160 cm−1. The absorption band corresponding to the C═O stretching vibration found at 1,751 cm−1 belonged to the ester group. The band around 1,452 cm−1 was related to the C–H3 bending vibration, whereas C–H bending and C–O stretching vibrations were observed at 1,368 and 1,190 cm−1, respectively. At 1,084 cm−1, a C–C vibration was detected in PLA/CNF scaffolds. The absorption bands observed at 868 and 747 cm−1 indicated the presence of aromatic C–H bending. Based on the results, all scaffolds demonstrated identical bands, indicating no change in the chemical structure despite variations in the CNF content. However, differences were observed among the intensities of the stretching bands of the scaffolds. In elaboration, the intensities of the absorption band at 1,751 cm−1 of pure PLA were greater than that of PLA scaffolds reinforced with CNF, which can be associated with the overlapping effects of CNF content. In addition, the original strong band of the PLA element at 1,084 cm−1 was found to become significantly weaker and broader with an increased CNF content. These results indicate that the main spectrum characteristics of the pure PLA scaffold were very similar to those of the PLA scaffolds reinforced with a varying CNF content from Pennisetum purpureum, demonstrating an apparent cross-linking between the PLA (carboxyl group) and CNF (hydroxyl group) of the prepared scaffolds, which is in agreement with the literature [48,49,50,51,52,53].

3.4 Thermal analysis

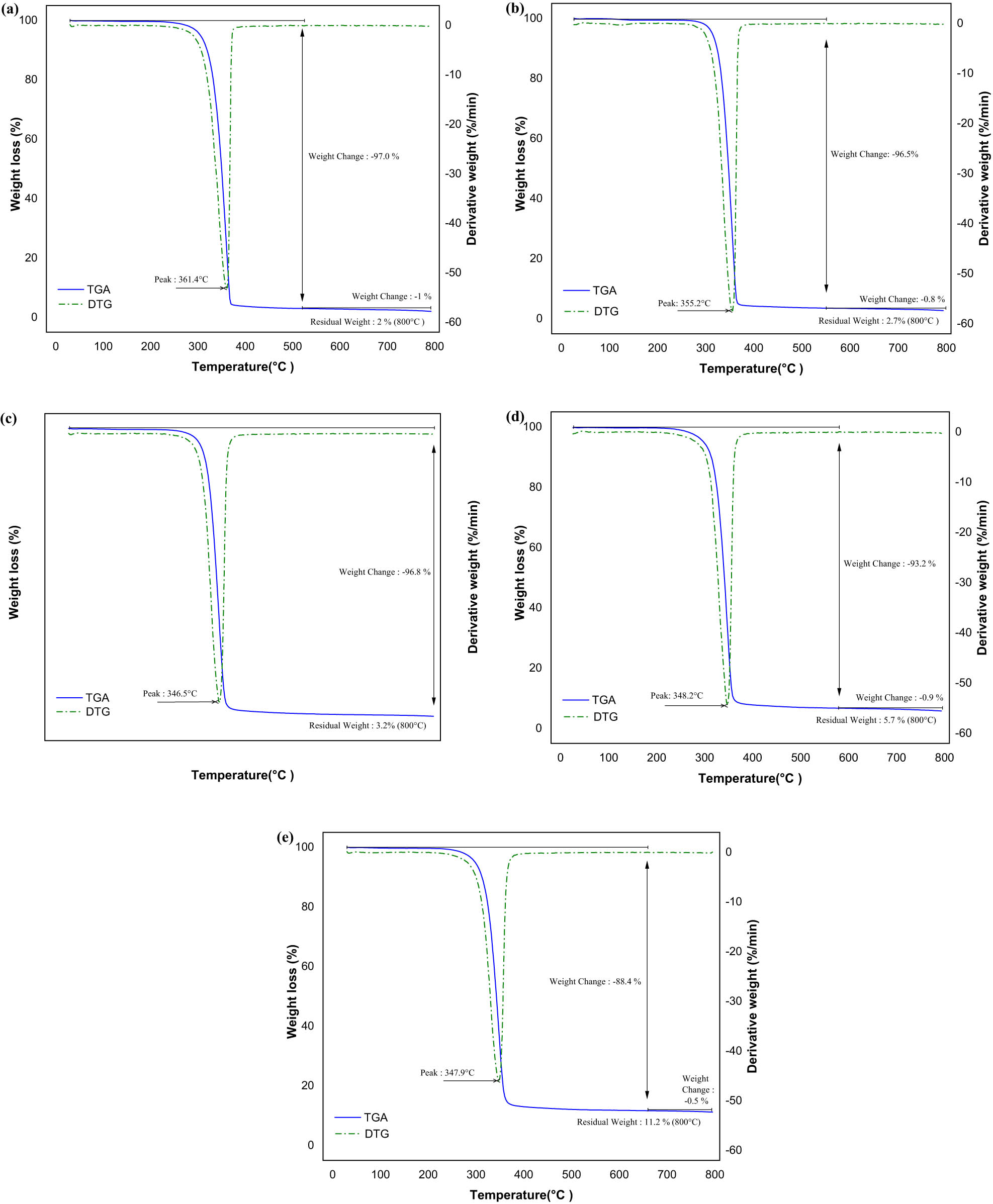

The effect of CNF reinforcement on the thermal behaviour of PLA/CNF composite scaffolds was studied using TGA. The TG curves illustrate the thermal stability of the composite scaffolds, while the DTG curves indicate the decomposition temperature of the composite scaffolds. Therefore, the TG and DTG curves as a function of the temperature or time of the PLA/CNF composite scaffolds were collected, as displayed in Figure 5(a)–(e). The thermal parameters, including the initial degradation temperature, degradation temperature at 50% weight loss, final degradation temperature, and weight of char residue, are summarised in Table 3 for all the composite scaffolds.

TGA and DTG analysis of (a) PLACONTROL, (b) PLA/CNF-PP5, (c) PLA/CNF-PP10, (d) PLA/CNF-PP15, and (e) PLA/CNF-PP20.

TGA results obtained for the PLAC, PLA/CNF-PP5, PLA/CNF-PP10, PLA/CNF-PP15, and PLA/CNF-PP20 scaffolds

| Sample name | Initial degradation temperature (°C) | Degradation at 50% weight loss (°C) | Final degradation temperature (°C) | Char residue weight at 800°C (%) |

|---|---|---|---|---|

| PLAC | 324.9 | 349.9 | 361.4 | 2.0 |

| PLA/CNF-PP5 | 321.2 | 346.1 | 355.2 | 2.7 |

| PLA/CNF-PP10 | 310.0 | 340.0 | 346.5 | 3.2 |

| PLA/CNF-PP15 | 305.7 | 340.7 | 348.2 | 5.7 |

| PLA/CNF-PP20 | 299.9 | 342.5 | 347.9 | 11.2 |

The initial degradation temperature of the PLAC, PLA/CNF-PP5, PLA/CNF-PP10, PLA/CNF-PP15, and PLA/CNF-PP20 scaffolds was 324.9, 321.2, 310.0, 305.7, and 299.9°C, respectively. Therefore, it is evident that the values of the scaffolds reinforced with CNF showed a considerable decrease. The initial degradation temperature of the PLA/CNF scaffolds was 25°C lower than that of PLACONTROL. The decrease in the initial degradation temperature of these scaffolds was attributed to the incorporation of CNFs into the PLA matrix, where the polymer chain may be restricted by the dispersion of CNF [45,54,55,56,57]. Table 3 shows the degradation temperatures of all scaffolds at 50% of weight loss. In the case of the PLAC, PLA/CNF-PP5, PLA/CNF-PP10, PLA/CNF-PP15, and PLA/CNF-PP20 scaffolds, these values were 349.9, 346.1, 340.0, 340.7, and 342.5°C, respectively. The degradation temperature decreased slightly as the CNF content increased. The thermal stabilisation of the PLA/CNF scaffolds could be attributed to the dispersion of CNF in the PLA matrix, which influences the interfacial bonding between the PLA matrix and CNF filler.

In addition, the final degradation temperatures of the PLAC, PLA/CNF-PP5, PLA/CNF-PP10, PLA/CNF-PP15, and PLA/CNF-PP20 scaffolds were 361.4, 355.2, 346.5, 348.2, and 347.9°C, respectively. Thus, the thermal stability of the PLA/CNF scaffolds was significantly reduced by increasing the CNF content. Figure 5(b)–(e) show that the values of the initial and final degradation temperatures of the PLA/CNF scaffolds were lower than that of PLACONTROL. A similar finding was also obtained in the case of silver nanoparticles/cellulose studied by Indira Devi et al. [11]. The TG curves of the PLA/CNF scaffolds are illustrated in Figure 5(a)–(e). By analysing the curves, the percentage of char residue weight after the thermal analysis appears to reflect the influence of the CNF reinforcements on the PLA matrix. The PLAC, PLA/CNF-PP5, PLA/CNF-PP10, PLA/CNF-PP15, and PLA/CNF-PP20 scaffolds had char residue weight percentages of 2.0, 2.7, 3.2, 5.7, and 11.2%, respectively. Thus, the char residue weight of the PLA/CNF scaffolds after TGA analysis was less than 12% of the total weight. However, the char residue weights of the PLA/CNF scaffolds were higher than that of PLACONTROL. This is predictable because PLA is almost completely degraded, while CNF remains in the form of residue even at 800°C. In addition, improvements in char formation may be attributed to the high heat resistance exerted by the CNF reinforcements [58].

With the reinforcement of CNF from Pennisetum purpureum, the thermal behaviour of the PLA/CNF scaffolds did not change significantly, and the findings for all the scaffolds were similar. As shown in the figures, the TG and DTG curves revealed that all the scaffolds degraded via a single-stage weight loss with an approximately narrow temperature range, illustrating the uniform solubility of CNF in the PLA matrix. Therefore, the reinforcement of CNF from Pennisetum purpureum in the PLA matrix slightly increased the release rate of the scaffolds; hence, the thermal stability of the PLA/CNF scaffolds was reasonably reduced. The results obtained from the thermal analysis showed that the biocomposite scaffolds based on the PLA and CNFs from Pennisetum purpureum as reinforcement are in good agreement with the findings for the thermal decomposition of polymer CNF composites [10,17,47].

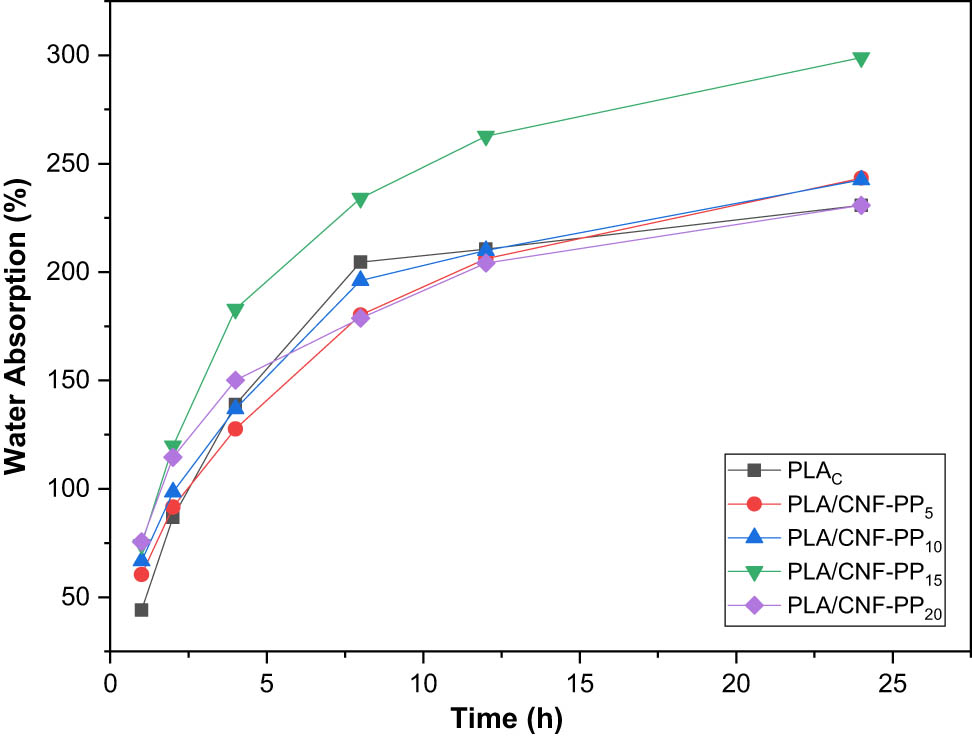

3.5 Water absorption measurement

The ability of a scaffold to absorb water can be considered an important criterion for evaluating fluid uptake from the surrounding medium [59]. Hence, this measurement plays a crucial role as an indicator of the suitability of a scaffold for tissue engineering. The percentages of water absorption for scaffolds with various CNF contents are shown in Figure 6. The water absorption behaviour of PLA scaffolds reinforced with CNF from Pennisetum purpureum was found to follow non-Fickian in nature [60], whereas the surface area to volume ratio, scaffold size, structure, and the chemistry at the nanoscale control the diffusion and absorption of the scaffolds [8]. For PLA/CNF-PP5, it was found that by adding up to 5 wt% of CNF, the percentage of water absorption showed an increasing trend compared to that of PLAC. By further increasing the CNF content, a similar trend was observed for PLA/CNF-PP10, where the percentage of water absorption of PLA/CNF-PP5 and PLA/CNF-PP10 was almost the same. These occurrences occurred because of the hydroxyl group, which acts as a binder between PLA and CNF. In PLA/CNF-PP15, it is evident that by adding 15 wt% of CNF, the water absorption ability of the scaffold showed the most satisfactory improvement. However, at the highest CNF content (20 wt%), the water absorption of the scaffold was lower than that of the scaffolds with CNF. This may be due to the compact arrangement of CNF with the PLA matrix, which influences the porosity and interconnectivity of the PLA matrix with fillers in the scaffold. These findings are supported by the FESEM images and porosity measurements shown in Figures 1(e) and 2. Similarly, Ilyas et al. also studied the water absorption of bionanocomposites by mixing sugar palm nanocrystalline cellulose with sugar palm starch using the solution casting method. They mentioned that the high crystallisation of nanocellulose concentration in the nanocomposites might attribute to the decrease in the coefficient of diffusion and equilibrium water uptake of the nanocomposites [61]. Based on these results, CNF from Pennisetum purpureum has a good hydrophilic feature. Therefore, it can be concluded that the addition of CNF to scaffolds increases the ability of the scaffolds to absorb water significantly, as shown in Figure 6. Even though the PLA matrix is not a useful candidate for cell attachment and proliferation, the reinforcement of CNF not only enhances the mechanical strength and structural properties but also help to improve the hydrophilicity of the scaffolds, which contributes to a friendly environment for cell culture.

Water absorption measurements of PLA scaffolds with different CNF contents as a function of soaking time.

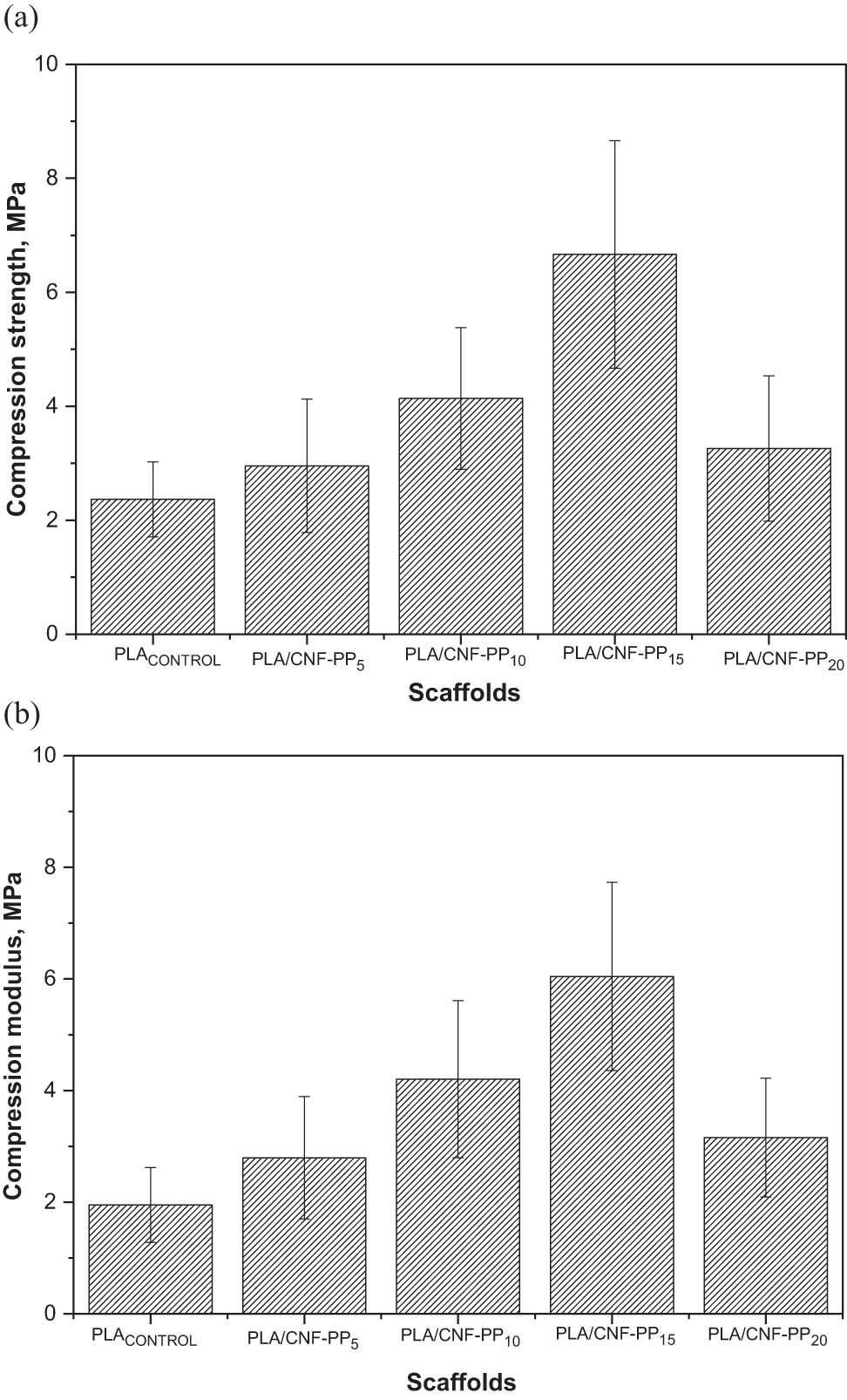

3.6 Mechanical properties

The influence of the addition of CNFs from Pennisetum purpureum on the mechanical performance of the fabricated scaffolds was investigated through compressive tests. According to reviews, an ideal scaffold for tissue regeneration should steadily transfer stress to the newly formed tissue during cell proliferation; thus, an appropriate material and fabrication technique are crucial for tuning both the microstructure and mechanical properties [62]. Table 4 presents the mechanical properties of pure PLA and PLA scaffolds reinforced with 5, 10, 15, and 20 wt% of CNF from Pennisetum purpureum. The compressive strength and modulus were approximately 70% of the initial height of the samples. The PLAC scaffold had an average compressive strength of 2.37 ± 0.65 MPa and a compressive modulus of 1.95 ± 0.67 MPa. On the other hand, the PLA/CNF-PP5 and PLA/CNF-PP10 scaffolds had an average compressive strength of 2.96 ± 1.17 and 4.13 ± 1.24 MPa, and a compressive modulus of 2.79 ± 1.10 and 4.20 ± 1.41 MPa, respectively. Thus, the compressive strength increased by 25 and 74% from PLAC to PLA/CNF-PP5 and PLA/CNF-PP10 scaffolds, while the compressive modulus increased by 43 and 115% from PLAC to PLA/CNF-PP5 and PLA/CNF-PP10 scaffolds, respectively. Meanwhile, the compressive strength of the PLA/CNF-PP15 and PLA/CNF-PP20 scaffolds were 6.66 ± 1.99 and 3.26 ± 1.27 MPa, while the compressive modulus of the PLA/CNF-PP15 and PLA/CNF-PP20 scaffolds were 6.04 ± 1.69 and 3.16 ± 1.06 MPa, respectively. Thus, the compressive strength increased by 181 and 38% from the PLAC to PLA/CNF-PP15 and PLA/CNF-PP20 scaffolds, whereas the compressive modulus increased by 210 and 62% from the PLAC to PLA/CNF-PP15 and PLA/CNF-PP20 scaffolds, respectively.

Mechanical properties of PLA scaffolds with different CNF contents

| Samples | Compression strength (MPa) | Increase (%) | Compression modulus (MPa) | Increase (%) |

|---|---|---|---|---|

| PLACONTROL | 2.37 ± 0.65 | 0 | 1.95 ± 0.67 | 0 |

| PLA/CNF-PP5 | 2.96 ± 1.17 | 25 | 2.79 ± 1.10 | 43 |

| PLA/CNF-PP10 | 4.13 ± 1.24 | 74 | 4.20 ± 1.41 | 115 |

| PLA/CNF-PP15 | 6.66 ± 1.99 | 181 | 6.04 ± 1.69 | 210 |

| PLA/CNF-PP20 | 3.26 ± 1.27 | 38 | 3.16 ± 1.06 | 62 |

As expected, the reinforcement of CNFs from Pennisetum purpureum improved both the compressive strength and modulus of the fabricated scaffolds, which clearly illustrates the specific advantage of PLA/CNF composites in the preparation of scaffolds for tissue engineering. PLA/CNF-PP15 displayed a significantly higher compressive strength and modulus than scaffolds with different CNF compositions. On the other hand, the enhancement of the compression properties of PLA/CNF scaffolds may be associated with the dispersion of CNFs. The rigid network of hydrogen bonding between PLA and CNFs resulted in an excellent load transfer from the polymer matrix to the CNFs. However, the increment of CNFs from 15 to 20 wt% led to a noticeable decrease in the compression properties, as shown in Table 4. As shown in Figure 7(a) and (b), PLA/CNF-PP20 showed a marked decrease in compressive strength and compressive modulus, approximately 38 and 62%, respectively, compared to PLA/CNF-PP10 and PLA/CNF-PP15. Thus, despite the fact that the reinforcement of CNFs improves their mechanical properties, CNFs tend to agglomerate at higher contents and may cause poor performance [63]. In addition, a weak microstructure and heterogeneous porosity were subjected to higher CNF content, as proven by the PLA/CNF-PP20 scaffold. Nasri-Nasrabadi et al. [64] and Shuai et al. [65] investigated the influence of the addition of CNFs to starch and nano-hydroxyapatite to poly(lactide-co-glycolide). In both studies, the reinforcement of fillers showed a marked increase in the compression properties of the composite scaffolds. However, when the filler content was increased over 15–30 wt%, the compressive properties decreased.

(a) Compression strength and (b) compression modulus of PLA scaffolds with different CNF contents.

The compressive strength of trabecular bone differs depending on bone density (2‒10 MPa) [66,67]. As previously mentioned, CNFs from Pennisetum purpureum were found to improve the compression properties of the PLA composite scaffolds; values significantly similar to those of trabecular bone were obtained for all the scaffolds. Soft tissue substitute composites must have mechanical properties identical to those of the host tissue. When the difference between compression modulus is large, a heterogeneous distribution of load will be created, leading to the failure of the implant [68]. However, this study demonstrated that the combination of PLA and CNFs from Pennisetum purpureum allowed for the fabrication of scaffolds with higher strength, modulus, and rigidity.

4 Conclusion

In this study, PLA scaffolds reinforced with CNFs from Pennisetum purpureum with interconnected pores were developed using solvent casting and particulate leaching techniques. The morphology of the scaffolds was found to vary depending on the content of the CNFs. In addition, FESEM images showed that the scaffolds had good porosity and interconnected pores, a high surface area, and good fluid retention capacity, which in turn encouraged cell attachment and proliferation. The XRD and FTIR spectra showed no significant changes in the PLA matrix structure by reinforcing the CNFs. The decomposition temperature of the composite scaffolds was lower than that of the PLA control due to interfacial bonding between the PLA matrix and the CNF fillers. The water absorption of the scaffold was enhanced by the inclusion of fillers up to 15 wt%, while PLA with 20 wt% fillers showed a decreasing trend due to the compact arrangement of CNFs, as illustrated in the FESEM images. The tendency of CNFs to agglomerate plays a crucial criterion in improving the hydrophilicity of the composite scaffolds. TGA analysis indicated a considerable decrease as the CNF content increased. The reinforcement of 15 wt% CNFs enhanced the compressive strength by approximately 181% and compressive modulus by 210%. However, a further increase in the CNF content to 20 wt% (PLA/CNF-PP20) led to a significant decrease in the compressive strength and modulus. The compressive strength and modulus of the scaffolds were found to be within the range of properties shown for trabecular bone. These results suggest that PLA/CNF scaffolds with a maximum of 15 wt% of CNF from Pennisetum purpureum have the potential for use in tissue engineering as a biomaterial.

Acknowledgements

The authors gratefully acknowledge i-CRiM, Universiti Kebangsaan Malaysia, for providing the analytical services.

-

Funding information: The Ministry of Higher Education Malaysia financed this research through the Fundamental Research Grant Scheme (FRGS/1/2019/TK05/UNIMAP/03/5).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Pei B, Wang W, Fan Y, Wang X, Watari F, Li X. Fiber-reinforced scaffolds in soft tissue engineering. Regen Biomater. 2017;4(4):257–68.10.1093/rb/rbx021Search in Google Scholar PubMed PubMed Central

[2] Yuksel E, Choo J, Wettergreen M, Liebschner M. Challenges in soft tissue engineering. Semin Plast Surg. 2005;19(3):261–70.10.1055/s-2005-919721Search in Google Scholar

[3] Chakrabarty A, Teramoto Y. Recent advances in nanocellulose composites with polymers: a guide for choosing partners and how to incorporate them. Polym (Basel). 2018;10(5):517.10.3390/polym10050517Search in Google Scholar PubMed PubMed Central

[4] Asim M. Nanocellulose: preparation methods and applications. In: Cellulose-reinforced nanofibre composites. Sawston, UK: Woodhead Publishing; 2017. p. 261–76.10.1016/B978-0-08-100957-4.00011-5Search in Google Scholar

[5] Kargarzadeh H, Ioelovich M, Ahmad I, Thomas S, Dufresne A. Methods for extraction of nanocellulose from various sources. Handbook of Nanocellulose and Cellulose Nanocomposites. Weinheim, Germany: Wiley-VCH; 2017. p. 1–49.10.1002/9783527689972.ch1Search in Google Scholar

[6] Shak KPY, Pang YL, Mah SK. Nanocellulose: recent advances and its prospects in environmental remediation. Beilstein J Nanotechnol. 2018;9(1):2479–98.10.3762/bjnano.9.232Search in Google Scholar PubMed PubMed Central

[7] Kian LK, Saba N, Jawaid M, Sultan MTH. A review on processing techniques of bast fibers nanocellulose and its polylactic acid (PLA) nanocomposites. Int J Biol Macromol. 2019;121:1314–28.10.1016/j.ijbiomac.2018.09.040Search in Google Scholar PubMed

[8] Hickey RJ, Pelling AE. Cellulose biomaterials for tissue engineering. Front Bioeng Biotechnol. March 2019;7:1–15.10.3389/fbioe.2019.00045Search in Google Scholar PubMed PubMed Central

[9] Reddy KO, Maheswari CU, Shukla M, Rajulu AV. Chemical composition and structural characterisation of Napier grass fibers. Mater Lett. 2012;67(1):35–8.10.1016/j.matlet.2011.09.027Search in Google Scholar

[10] Haameem MJA, Majid MSA, Afendi M, Marzuki HFA, Fahmi I, Gibson AG. Mechanical properties of Napier grass fibre/polyester composites. Compos Struct. 2016;136:1–10.10.1016/j.compstruct.2015.09.051Search in Google Scholar

[11] Indira Devi MP, Nallamuthu N, Rajini N, Varada Rajulu A, Hari Ram N, Siengchin S. Cellulose hybrid nanocomposites using Napier grass fibers with in situ generated silver nanoparticles as fillers for antibacterial applications. Int J Biol Macromol. 2018;118:99–106.10.1016/j.ijbiomac.2018.06.019Search in Google Scholar

[12] Ridzuan MJM, Abdul Majid MS, Afendi M, Aqmariah Kanafiah SN, Zahri JM, Gibson AG. Characterisation of natural cellulosic fibre from Pennisetum purpureum stem as potential reinforcement of polymer composites. Mater Des. Jan. 2016;89:839–47.10.1016/j.matdes.2015.10.052Search in Google Scholar

[13] De Araújo Morandim-Giannetti A, Albuquerque TS, De Carvalho RKC, Araújo RMS, Magnabosco R. Study of ‘Napier grass’ delignification for production of cellulosic derivatives. Carbohydr Polym. 2013;92(1):849–55.10.1016/j.carbpol.2012.09.095Search in Google Scholar

[14] Bacakova L, Pajorova J, Bacakova M, Skogberg A, Kallio P, Kolarova K, et al. Versatile application of nanocellulose: from industry to skin tissue engineering and wound healing. Nanomaterials. 2019;9(2):164.10.3390/nano9020164Search in Google Scholar

[15] Jorfi M, Foster EJ. Recent advances in nanocellulose for biomedical applications. J Appl Polym Sci. 2015;132(14):1–19.10.1002/app.41719Search in Google Scholar

[16] Radakisnin R, Majid MSA, Jamir MRM, Jawaid M, Sultan MTH, Tahir MFM. Structural, morphological and thermal properties of cellulose nanofibers from Napier fiber (Pennisetum purpureum). Mater (Basel). 2020;13(18):4125.10.3390/ma13184125Search in Google Scholar

[17] Jian W, Hui D, Lau D. Nanoengineering in biomedicine: current development and future perspectives. Nanotechnol Rev. 2020;9(1):700–15.10.1515/ntrev-2020-0053Search in Google Scholar

[18] Madhavan Nampoothiri K, Nair NR, John RP. An overview of the recent developments in polylactide (PLA) research. Bioresour Technol. 2010;101:8493–501.10.1016/j.biortech.2010.05.092Search in Google Scholar

[19] Dai W, Yang Y, Yang Y, Liu W. Material advancement in tissue-engineered nerve conduit. Nanotechnol Rev. 2021;10(1):488–503.10.1515/ntrev-2021-0028Search in Google Scholar

[20] Oksman K, Skrifvars M, Selin J-F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos Sci Technol. 2003;63(9):1317–24.10.1016/S0266-3538(03)00103-9Search in Google Scholar

[21] Xiao L, Wang B, Yang G, Gauthier M. Poly(Lactic Acid)-based biomaterials: synthesis, modification and applications. Biomed Sci Eng Technol. 2006;11:247–82.10.5772/23927Search in Google Scholar

[22] Lopes MS, Jardini AL, Filho RM. Poly (lactic acid) production for tissue engineering applications. Procedia Eng. 2012;42:1402–13.10.1016/j.proeng.2012.07.534Search in Google Scholar

[23] Grémare A, Guduric V, Bareille R, Heroguez V, Latour S, L’heureux N, et al. Characterization of printed PLA scaffolds for bone tissue engineering. J Biomed Mater Res A. 2018;106(4):887–94.10.1002/jbm.a.36289Search in Google Scholar PubMed

[24] Donate R, Monzón M, Alemán-Domínguez ME, Ortega Z. Enzymatic degradation study of PLA-based composite scaffolds. Rev Adv Mater Sci. 2020;59(1):170–5.10.1515/rams-2020-0005Search in Google Scholar

[25] Navarro M. 3D printed PLA-based scaffolds. Organogenesis. 2013;9(4):239–44.10.4161/org.26048Search in Google Scholar PubMed PubMed Central

[26] Dave HK, Rajpurohit SR, Patadiya NH, Dave SJ, Sharma KS, Thambad SS, et al. Compressive strength of PLA based scaffolds: effect of layer height, infill density and print speed. Int J Mod Manuf Technol. 2019;11(1):21–7.Search in Google Scholar

[27] Peng Z, Tang P, Zhao L, Wu L, Xu X, Lei H, et al. Advances in biomaterials for adipose tissue reconstruction in plastic surgery. Nanotechnol Rev. 2020;9(1):385–95.10.1515/ntrev-2020-0028Search in Google Scholar

[28] Chanda S, Bajwa DS. A review of current physical techniques for dispersion of cellulose nanomaterials in polymer matrices. Rev Adv Mater Sci. 2021;60(1):325–41.10.1515/rams-2021-0023Search in Google Scholar

[29] Massai D, Pennella F, Gentile P, Gallo D, Ciardelli G, Bignardi C, et al. Image-based three-dimensional analysis to characterise the texture of porous scaffolds. Biomed Res Int. 2014;2014:161437.10.1155/2014/161437Search in Google Scholar PubMed PubMed Central

[30] Tairov EA. Method of measuring void fraction in a channel with porous media. Thermophys Aeromechanics. 2020;27(2):313–6.10.1134/S0869864320020134Search in Google Scholar

[31] Choudhury M, Mohanty S, Nayak S. Effect of different solvents in solvent casting of porous PLA scaffolds – in biomedical and tissue engineering applications. J Tissue Sci Eng. 2014;6(1):1–7.10.1166/jbt.2015.1243Search in Google Scholar

[32] ASTM D695-96, Standard Test Method for Compressive Properies of Rigid Plastics, ASTM International, West Conshohocken, PA, 2021.Search in Google Scholar

[33] Doulabi AH, Mequanint K, Mohammadi H. Blends and nanocomposite biomaterials for articular cartilage tissue engineering. Mater (Basel). 2014;7(7):5327–55.10.3390/ma7075327Search in Google Scholar

[34] Zhang Z, Cui H. Biodegradability and biocompatibility study of poly(chitosan-g-lactic acid) scaffolds. Molecules. 2012;17:3243–58.10.3390/molecules17033243Search in Google Scholar

[35] Cai S, Wu C, Yang W, Liang W, Yu H, Liu L. Recent advance in surface modification for regulating cell adhesion and behaviors. Nanotechnol Rev. 2020;9(1):971–89.10.1515/ntrev-2020-0076Search in Google Scholar

[36] Naseri N, Lenart G, Kristiina O. 3-Dimensional porous nanocomposite scaffolds based on cellulose nanofibers for cartilage tissue engineering: tailoring of porosity and mechanical performance. R Soc Chem. 2016;6:5999–6007.10.1039/C5RA27246GSearch in Google Scholar

[37] Hagen R. Basics of PLA. Bioplastics Mag. 2005;4:38–40.Search in Google Scholar

[38] Chung HJ, Park TG. Surface engineered and drug releasing pre-fabricated scaffolds for tissue engineering. Adv Drug Deliv Rev. 2007;59:249–62.10.1016/j.addr.2007.03.015Search in Google Scholar

[39] Bartis D, Pongrácz J. Three dimensional tissue cultures and tissue engineering. In: Teaching Materials: Medical Biotechnology Master’s Program. Debrecen: University of Pécs; 2011. p. 15.Search in Google Scholar

[40] Loh QL, Choong C. Three-dimensional scaffolds for tissue engineering applications: role of porosity and pore size. Tissue Eng B Rev. 2013;19(6):485–502.10.1089/ten.teb.2012.0437Search in Google Scholar

[41] Bartoš M, Suchý T, Foltán R. Note on the use of different approaches to determine the pore sizes of tissue engineering scaffolds: what do we measure? Biomed Eng Online. 2018;17(1):1–15.10.1186/s12938-018-0543-zSearch in Google Scholar

[42] Chen G, Ushida T, Tateishi T. Development of biodegradable porous scaffolds for tissue engineering. Mater Sci Eng C. 2001;17(1):63–9.10.1016/S0928-4931(01)00338-1Search in Google Scholar

[43] Ma PX. Scaffolds for tissue fabrication. Mater Today. 2004;7:30–40.10.1016/S1369-7021(04)00233-0Search in Google Scholar

[44] Razak SIA, Sharif NFA, Rahman WAA. Biodegradable polymers and their bone applications: a review. Int J Basic Appl Sci. 2012;12:31–49.10.1533/9780857097149.31Search in Google Scholar

[45] Lien SM, Ko LY, Huang TJ. Effect of pore size on ECM secretion and cell growth in gelatin scaffold for articular cartilage tissue engineering. Acta Biomater. 2009;5(2):670–9.10.1016/j.actbio.2008.09.020Search in Google Scholar PubMed

[46] Ma H, Su W, Tai Z, Sun D, Yan X, Liu B, et al. Preparation and cytocompatibility of polylactic acid/hydroxyapatite/graphene oxide nanocomposite fibrous membrane. Chin Sci Bull. 2012;57(23):3051–8.10.1007/s11434-012-5336-3Search in Google Scholar

[47] Niu X, Feng Q, Wang M, Guo X, Zheng Q. In vitro degradation and release behavior of porous poly(lactic acid) scaffolds containing chitosan microspheres as a carrier for BMP-2-derived synthetic peptide. Polym Degrad Stab. 2009;94(2):176–82.10.1016/j.polymdegradstab.2008.11.008Search in Google Scholar

[48] Tang D, Tare RS, Yang LY, Williams DF, Ou KL, Oreffo ROC. Biofabrication of bone tissue: approaches, challenges and translation for bone regeneration. Biomaterials. 01-Mar-2016;83:363–82.10.1016/j.biomaterials.2016.01.024Search in Google Scholar

[49] Loh QL, Choong C. Three-dimensional scaffolds for tissue engineering applications: Role of porosity and pore size. Tissue Eng B Rev. 2013;19(6):485–502.10.1089/ten.teb.2012.0437Search in Google Scholar

[50] Sehaqui H, Zhou Q, Berglund LA. High-porosity aerogels of high specific surface area prepared from nanofibrillated cellulose (NFC). Compos Sci Technol. Sep. 2011;71(13):1593–9.10.1016/j.compscitech.2011.07.003Search in Google Scholar

[51] Sehaqui H, Salajková M, Zhou Q, Berglund LA. Mechanical performance tailoring of tough ultra-high porosity foams prepared from cellulose i nanofiber suspensions. Soft Matter. Apr. 2010;6(8):1824–32.10.1039/b927505cSearch in Google Scholar

[52] Ploypetchara N, Suppakul P, Atong D, Pechyen C. Blend of polypropylene/poly(lactic acid) for medical packaging application: physicochemical, thermal, mechanical, and barrier properties. Energy Procedia. 2014;56:201–10.10.1016/j.egypro.2014.07.150Search in Google Scholar

[53] Bulota M, Budtova T. PLA/algae composites: Morphology and mechanical properties. Compos Part A Appl Sci Manuf. 2015;73:109–15.10.1016/j.compositesa.2015.03.001Search in Google Scholar

[54] Shokrolahi F, Mirzadeh H, Yeganeh H, Daliri M. Fabrication of poly(urethane urea)-based scaffolds for bone tissue engineering by a combined strategy of using compression moulding and particulate leaching methods. Iran Polym J. Jan. 2011;20(8):645–58.Search in Google Scholar

[55] Chen G, Ushida T, Tateishi T. Scaffold design for tissue engineering. Macromol Biosci. 2002;2(2):67–77. Wiley Online Library. [Online]. Available: https://onlinelibrary.wiley.com/doi/abs/10.1002/1616-5195%2820020201%292%3A2%3C67%3A%3AAID-MABI67%3E3.0.CO%3B2-F [Accessed: 10-Jun-2021].10.1002/1616-5195(20020201)2:2<67::AID-MABI67>3.0.CO;2-FSearch in Google Scholar

[56] Lee SH, Teramoto Y, Endo T. Cellulose nanofiber-reinforced polycaprolactone/polypropylene hybrid nanocomposite. Compos Part A Appl Sci Manuf. Feb. 2011;42(2):151–6.10.1016/j.compositesa.2010.10.014Search in Google Scholar

[57] Xiong R, Hameed N, Guo Q. Cellulose/polycaprolactone blends regenerated from ionic liquid 1-butyl-3-methylimidazolium chloride. Carbohydr Polym. Sep. 2012;90(1):575–82.10.1016/j.carbpol.2012.05.080Search in Google Scholar PubMed

[58] Cheung HY, Lau KT, Tao XM, Hui D. A potential material for tissue engineering: Silkworm silk/PLA biocomposite. Compos Part B Eng. 2008;39:1026–33.10.1016/j.compositesb.2007.11.009Search in Google Scholar

[59] Tohamy KM, Mabrouk M, Soliman IE, Beherei HH, Aboelnasr MA. Novel alginate/hydroxyethyl cellulose/hydroxyapatite composite scaffold for bone regeneration: In vitro cell viability and proliferation of human mesenchymal stem cells. Int J Biol Macromol. January 2018;112:448–60.10.1016/j.ijbiomac.2018.01.181Search in Google Scholar PubMed

[60] Maslinda AB, Abdul Majid MS, Ridzuan MJM, Afendi M, Gibson AG. Effect of water absorption on the mechanical properties of hybrid interwoven cellulosic-cellulosic fibre reinforced epoxy composites. Compos Struct. 2017;167:227–37.10.1016/j.compstruct.2017.02.023Search in Google Scholar

[61] Ilyas RA, Sapuan SM, Ishak MR, Zainudin ES. Development and characterisation of sugar palm nanocrystalline cellulose-reinforced sugar palm starch bionanocomposites. Carbohydr Polym. August 2018;202:186–202.10.1016/j.carbpol.2018.09.002Search in Google Scholar PubMed

[62] Raia NR, McGill M, Marcet T, Vidal Yucha SE, Kaplan DL. Soft tissue engineering. Biomaterials Science. Amsterdam, Netherlands: Elsevier; 2020. p. 1399–414.10.1016/B978-0-12-816137-1.00087-8Search in Google Scholar

[63] Kaushik A, Singh M, Verma G. Green nanocomposites based on thermoplastic starch and steam exploded cellulose nanofibrils from wheat straw. Carbohydr Polym. 2010;82(2):337–45.10.1016/j.carbpol.2010.04.063Search in Google Scholar

[64] Nasri-Nasrabadi B, Mehrasa M, Rafienia M, Bonakdar S, Behzad T, Gavanji S. Porous starch/cellulose nanofibers composite prepared by salt leaching technique for tissue engineering. Carbohydr Polym. Aug. 2014;108(1):232–8.10.1016/j.carbpol.2014.02.075Search in Google Scholar PubMed

[65] Shuai C, Yang B, Peng S, Li Z. Development of composite porous scaffolds based on poly(lactide-co- glycolide)/nano-hydroxyapatite via selective laser sintering. Int J Adv Manuf Technol. Oct. 2013;69(1–4):51–7.10.1007/s00170-013-5001-2Search in Google Scholar

[66] Revati R, Abdul Majid MS, Ridzuan MJM, Normahira M, Mohd Nasir NF, Rahman Y MN, et al. Mechanical, thermal and morphological characterisation of 3D porous Pennisetum purpureum/PLA biocomposites scaffold. Mater Sci Eng C. 2017;75:752–9.10.1016/j.msec.2017.02.127Search in Google Scholar PubMed

[67] Sheng L, Jiang R, Zhu Y, Ji Y. Electrospun cellulose nanocrystals/polycaprolactone nanocomposite fiber mats. J Macromol Sci Part B Phys. May 2014;53(5):820–8.10.1080/00222348.2013.861311Search in Google Scholar

[68] Weaver JCJK. Cancellous bone: Its strength and changes with aging and an evaluation of some methods for measuring its mineral content. J Bone Jt Surg. 1966;48A:289–9.10.2106/00004623-196648020-00007Search in Google Scholar

© 2021 Revati Radakisnin et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies