Abstract

Poly(vinylidene fluoride) (PVDF) and its copolymers exhibit excellent piezoelectric properties and are potential materials for high efficiency energy harvesting devices. In this study, poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP) films are prepared by the solution casting method. The prepared film is then subjected to mechanical stretching and poling process. By adjusting the temperature of the poling process and the elongation ratio of the mechanical stretching process, the relative content of β-phase F(β) increases significantly, leading to high piezoelectric performance. The maximum output voltage of the PVDF-HFP films poled at 40°C reaches 3.67 V, 71% higher than that of the films poled at room temperature. Fourier transform infrared spectroscopy analysis (FTIR), XRD (X-ray diffraction), and differential scanning calorimetry are used to investigate the influences of mechanical stretching and poling process on the crystal structure to discover the enhancement mechanism. This work provides a straightforward and low-cost route to prepare high piezoelectric PVDF-HFP-based materials.

1 Introduction

Energy harvesting is a technology that collects distributed energy around the environment and converts it into usable electricity [1]. Current energy collection devices include solar energy collection devices, wind energy collection devices, vibration energy collection devices, etc. [2,3,4]. The power generation mechanisms are mainly static electricity, piezoelectric electricity, and electromagnetic electricity [4], among which the piezoelectric energy harvesting technology has the advantages of fast response, low cost, simple structure, no electromagnetic interference, convenient to handle, and so on ref. [5].

According to the material properties and composition, piezoelectric materials can be classified as single crystals, piezoelectric ceramics, piezoelectric polymers, and piezoelectric composites. Piezoelectric polymers mainly include poly(vinylidene fluoride) (PVDF) and its copolymers, polyvinylchloride and polypropylene [6], which possess the advantages of high chemical corrosion resistance, low mechanical impedance, and excellent flexibility [7], showing extraordinary promise for applications in energy harvesting [8]. PVDF and its copolymers possess the advantages of high piezoelectric coefficient, favorable biocompatibility, wide frequency response, promising flexibility, and easy processing. PVDF assesses at least five crystal phases, i.e., α, β, δ, γ, and ε. The α-phase is monoclinic and the chain configuration is TGTG’. The β-phase belongs to the orthomorphic system and the molecular chain configuration is TTT. The γ-phase is monoclinic and its chain structure is similar to that of the α-crystal phase [7]. Among the phases, the α-crystal phase is nonpolar, so it does not exhibit piezoelectricity. The β-crystal phase is the most strongly polar with excellent piezoelectricity [9]. In most cases, the α-phase dominates in the crystal parts of PVDF. Therefore, increasing the β-phase content plays an extremely important role in the improvement of PVDF’s piezoelectricity. At present, uniaxial stretching [10,11,12], high electric field poling [13,14,15], high pressure crystallization [16,17], and nanofillers additions [12,18,19] are commonly applied to increase the content of the β-crystal phase.

The influences of poling temperature on piezoelectric properties of materials have been studied in a multitude of reports [21,22,23,24]. The poling effects on the piezoelectric properties of 0–3 connectivity PZT Portland cement (PC) composites, including piezoelectric coefficient (d 33) and electromechanical coupling factor (k T), have been investigated by Jaitanong and Chaipanich. The results demonstrate that when the poling temperature is set at 130°C, the d 33 and k T reach the maximum values [20]. Some researchers also proposed that the piezoelectric ceramics with polycrystalline phase boundary are affected by poling temperature, and the piezoelectric constants are highly sensitive to the poling temperature [21,22,23,24].

As mentioned above, most of the published studies about the effects of poling temperature on the piezoelectric properties are focused on piezoelectric ceramics, with only a few on PVDF or other polymers. It was reported that under the poling electric field of 150 MV m−1 at 95°C, the nonpolar α-crystal phase can be transformed to the polar β-crystal phase [25]. Darestani et al. investigated the piezoelectric properties of piezoelectric PVDF films for separation processes. The specimen was heated from room temperature to 90 ± 10°C, while the poling electric field increased gradually from zero to 2 kV at a rate of ∼50 V min−1. The results show that the poling process dramatically changes the microstructure of the films [26]. Most studies emphasized that the structural evolution may be due to the internal rotation of the molecular chains induced by the electric field. It is in consistent with the β-phase formation and the rearrangement of the inherent dipoles in the matrix. In these studies, the effect of the poling on the structure of PVDF is mentioned only when the heating is also carried out during poling [25,26,27]. Besides, Jan proposed that the relative content of the β-crystal phase increases significantly when the poling temperature is set at 150°C [28]. As a conclusion, both the temperature and the poling electric field may have effects on the piezoelectric properties of the materials by affecting phase evolution and realignment of dipole moments. The content and orientation polarizability of the β-crystal phase are improved when poled at a proper temperature as shown in the experiments. After the optimal poling temperature was obtained, we also varied the elongation ratio during the stretching process to define the optimal preparation parameters.

2 Experiments

2.1 Materials

PVDF can form a number of different copolymers. Poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP) is a PVDF copolymer of low crystallinity, but high F content compared with PVDF; consequently, it exhibits better hydrophobicity than PVDF. Besides, PVDF-HFP also exhibits better flexibility and solidification. In terms of piezoelectric properties, when the mixing ratio of HFP is 5%, the piezoelectric coefficient d 31 of PVDF-HFP can reach 30 p CN−1, which is higher than that of PVDF [29].

The PVDF-HFP powder (Kynar Flex 2801) is produced by Arkema Inc. Its properties are shown in Table 1. The solvent is N,N-dimethylformamide (DMF) which can be commercially obtained from Shanghai Titan Scientific Co., Ltd.

The properties of PVDF-HFP

| Morphology | White powder | Density | 1.76–1.8 g cm−3 |

| Melting point | 140–145°C | Water absorption | 0.03% |

| Refractive index | 1.41 | Melt viscosity (232°C, 100 s−1) | 2,300–2,700 Pa s |

2.2 Preparation of piezoelectric films

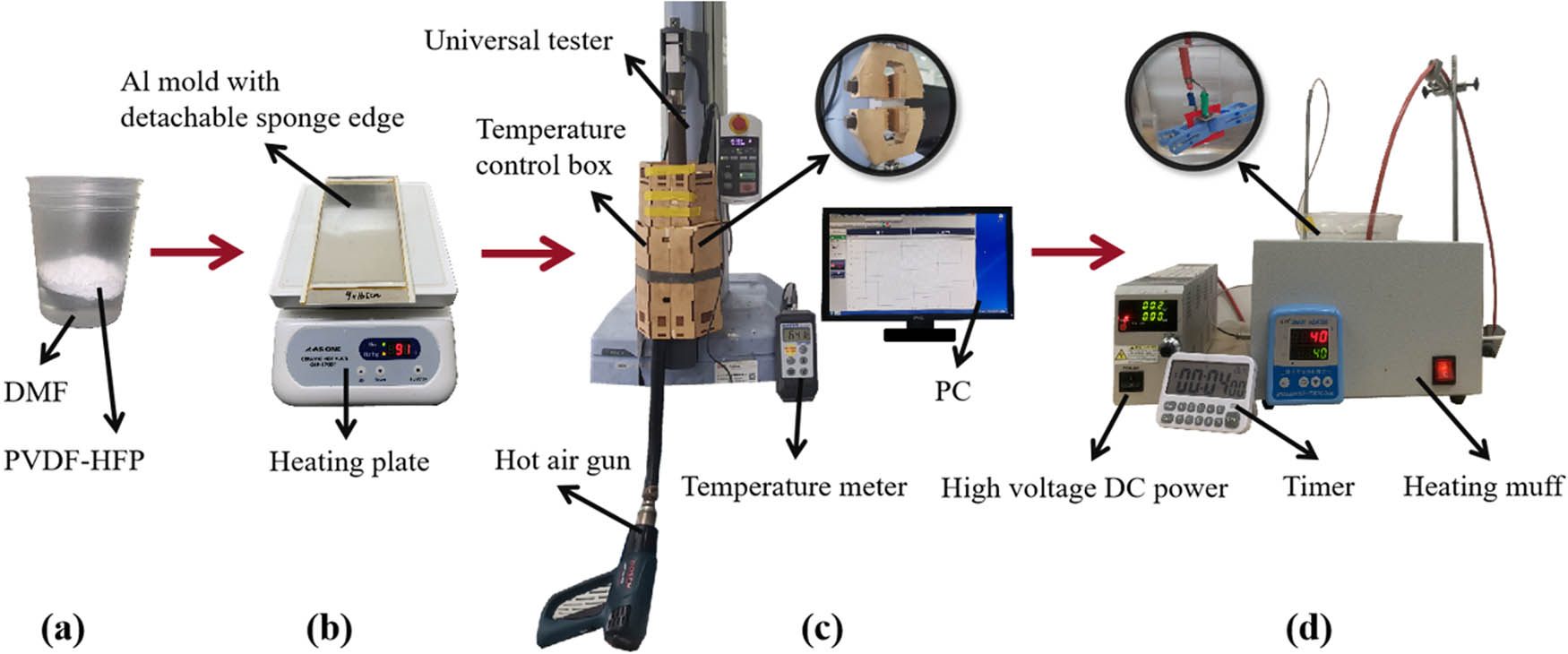

In this study, the solution casting method is used to prepare the initial crystallized films. The preparation process of the initial crystallization films mainly includes the following steps as shown in Figure 1: (1) add moderate PVDF-HFP powder into DMF solution (mass ratio: PVDF-HFP:DMF = 1:3) by a planetary machine for 5 min and an ultrasonic machine for 5 min, then by a planetary machine for 5 and 2 min (for defoaming). (2) Pour the DMF/PVDF-HFP mixture evenly onto a 2 mm-thick Al mold whose edges are formed by sponge tapes (9 cm × 16.5 cm) which are removed within 10 min after solution casting, and heat it at 90°C for 2 h; (3) Cut the samples for stretching from the middle of the initial crystallization films, the size is 5.5 cm × 4 cm (stretching direction). The thickness of the initial crystallized films ranges from 180 to 240 μm. (4) Press the initial crystallized film by a heavy flat mass for 24 h. (5) Stretch the films at about 60°C in a temperature-control box (±2°C) with a rate of 10 mm min−1 and an elongation ratio R of 4.5–5.5 [14]. The film stretching equipment is shown in Figure 1(c), which includes an EZ-LX tensile testing machine (Shimadzu Manufacturing Co. Ltd., Japan), a homemade temperature-control box, a digital heat gun, a digital thermometer, etc. The thickness of the stretched films is 50 to 90 μm, as shown in Figure 2. (6) Attach Al electrodes (t = 15 μm) on both sides of the film by CW2400 conductive epoxy adhesive and keep it for 24 h for complete curing. The poling process was carried out in silicone oil at various temperatures by a stepwise method. The voltage source is HJPQ-30P1 (Matsusada Precision Inc.). The initial electric field is 20 MV m−1, and the maximum electric field (denoted as E max) is 90 MV m−1. For each step, the poling time is 8 min, the rest time is 4 min, and the electric field increases by 10 MV m−1.

Preparation process of PVDF-HFP piezoelectric films: (a) solution, (b) initial crystallization, (c) uniaxial stretching, and (d) step-wise poling.

Images of stretched films with different elongation ratios.

To study the effects of poling temperature on the piezoelectric properties of PVDF-HFP, the poling temperature (denoted as T p) is set from 25 to 45°C, and the elongation ratio in the stretching process is kept at 5. Figure 1(d) shows the equipment for poling. The poling is carried out in silicone oil heated by a digital electric heating sleeve (±2°C). After the optimal poling temperature is determined, the elongation ratio varies from 3 to 6 to investigate its effects on piezoelectricity.

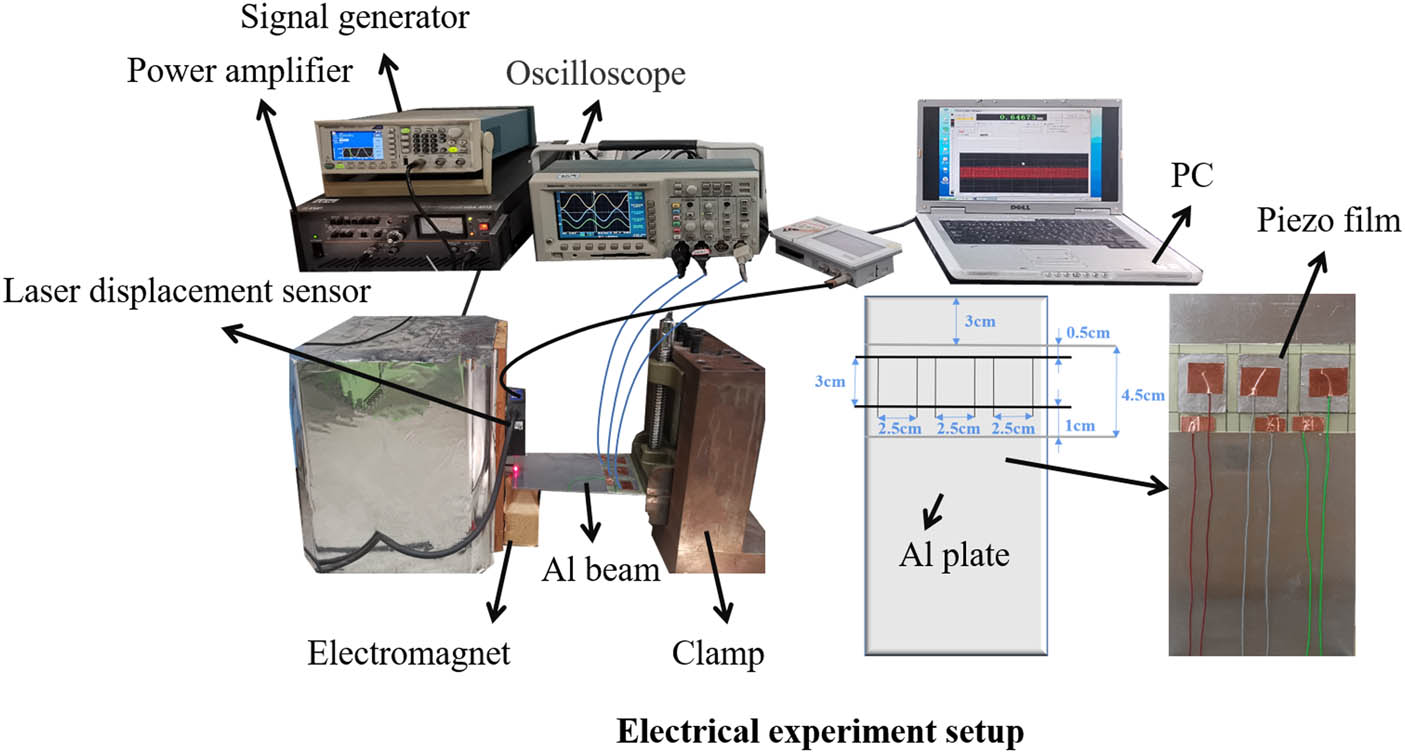

The measurement setup of the open circuit voltage is shown in Figure 3. The measurement method is introduced in a previous report [12] and in the Supporting information’s Section at the end of the paper.

Measurement setup of the open circuit voltage.

2.3 Characterization of piezoelectric films

FTIR spectra were used to identify the structure of the polymer backbone, the types and positions of substituents, and the structure of the molecular chains. The equipment used in this study was the Nicolet IS50 Fourier Transform Infrared Spectrometer (Thermo Fisher Scientific Co. Ltd., USA).

X-ray diffraction (XRD) is a technique for structural analysis of crystalline substances. In the characterization of polymers, XRD is mainly used for phase analysis and crystallinity degree determination. In this study, the equipment used for XRD was X ‘PERT POWDER X-ray diffractometer (Panaco Co. Ltd., Netherlands).

Differential scanning calorimetry (DSC) is a thermal analysis technique that measures the relationship between temperature and the power difference input into the sample and reference material. It can be used to study the thermal change in the reaction process such as melting, sublimation, and crystallization. The Netzsch DSC 214 Polyma differential scanning calorimeter was used in this study.

3 Results and discussion

3.1 Open circuit voltage

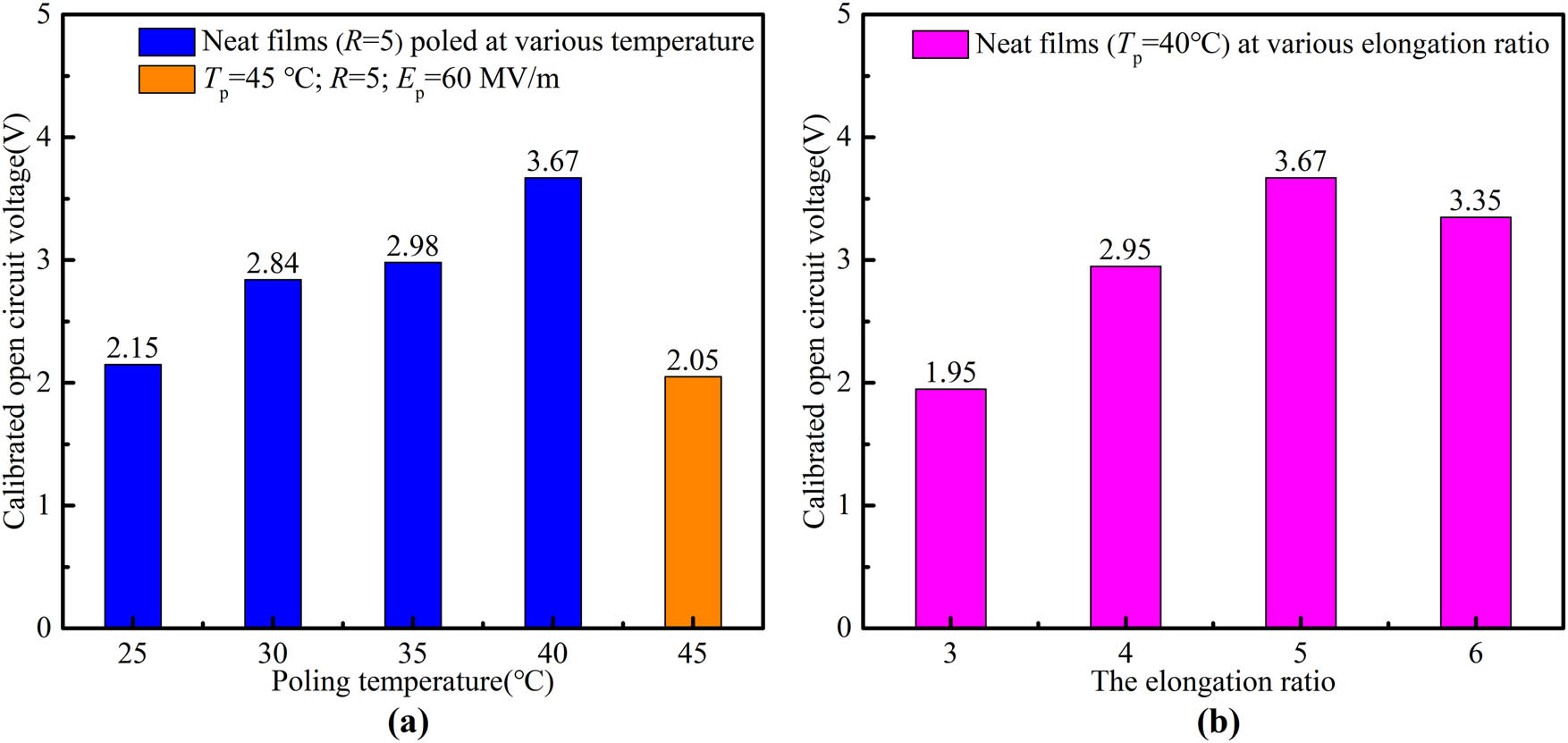

It was proved that the open circuit voltage V is proportional to the film thickness (t) and the displacement (u) of the end of the vibration cantilever [19]. Therefore, the concept of calibrated open circuit voltage (V c) is introduced in this study to evaluate the piezoelectric properties of different piezoelectric films. The calculation formula of V c is:

where V is the actual measured voltage, u is the displacement of the end of the aluminum plate, t is the film thickness, u 0 = 1.0 mm is the standard displacement, and t 0 = 100.0 μm is the standard thickness.

Figure 4(a) shows the relationship between the calibrated open circuit voltage and the poling temperature T p when the elongation ratio is kept at 5. It is shown that the open circuit voltage increases with the poling temperature. However, an excessively high temperature may lead to the electric breakdown at a relatively lower electric field. Figure 4(b) shows the relationship between the calibrated open circuit voltage and the elongation ratio R when the poling temperature is kept at 40°C. From the experimental results, it is observed that the open circuit voltage of PVDF-HFP films increases with poling temperature until 40°C. However, when the poling temperature rises to 45°C, electrical breakdown [30] occurs when the poling electric field intensity is higher than 60 MV m−1. As a result, when the poling temperature is set to 45°C, the maximum electric field of poling is 60 MV m−1 (For other samples, E max = 90 MV m−1). When T p is 40°C and R is 5, the calibrated open circuit voltage reaches the highest value of 3.67 V, which is 71% higher than that of the films poled at room temperature (2.15 V) (Figure 4(a)). When T p is 45°C and the maximum poling electric field E max is 60 MV m−1, the calibrated open circuit voltage is only 2.05 V. Thus, the optimal poling temperature in this study is determined to be 40°C.

The calibrated open circuit output voltages of PVDF-HFP films: (a) PVDF-HFP films (R = 5) poled at various temperatures; (b) PVDF-HFP films (T p = 40°C) stretched at various elongation ratios.

At the optimal poling temperature of 40°C, the open circuit voltages of films stretched by different elongation ratios (3–6) were also measured. The experimental results showed that the open circuit voltage increases with R until 5 (V c = 3.67 V) and then decreases (Figure 4(b)). It is found that the open circuit voltage increases with the elongation ratio and reaches the maximum value at R = 5 and then decreases. The phase transformation mainly occurs when R < 4, thus F(β) remains nearly unchanged when R > 4. However, the alignment of molecular chains along the stretching direction continues when the elongation ratio increases from 4 to 5, which leads to better piezoelectricity. But more crystalline defects are formed when the elongation ratio increases further, which results in the reduction of piezoelectricity. The experimental results indicate that R = 5 and T p = 40°C are the optimal parameters to produce high piezoelectric PVDF-HFP films.

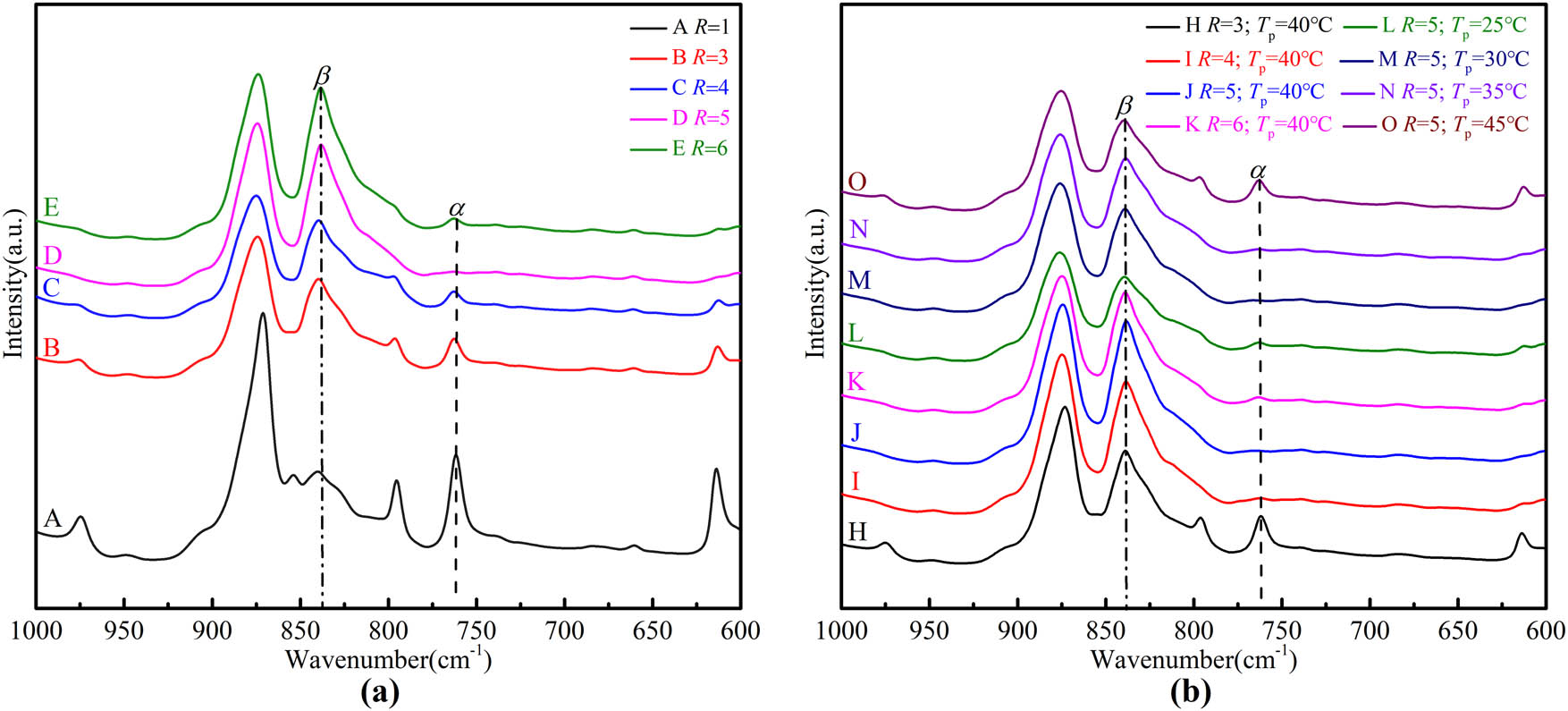

3.2 FTIR

For PVDF-HFP films, FTIR is usually used to investigate the crystal structure. The α-crystal phase is the most common crystal phase in the initial crystallized films (non-stretched) with characteristic peaks of 489, 614, 766, 795, 855, and 976 cm−1 [31]. The characteristic peaks of the β-phase are at 510, 840, and 1,279 cm−1 [32]. The relative fraction of the β-phase F(β) is an extremely important parameter in the preparation of PVDF piezoelectric films, which can be calculated by equation (2):

where K α is 6.1 × 104 cm2 mol−1, K β is 7.7 × 104 cm2 mol−1, and A α and A β are the areas of the absorption peaks near 766 and 840 cm−1, respectively [7]. In this work, the integrating range is the peak (766 cm−1 for A α and 840 cm−1 A β) ± 10 cm−1. For simplicity, the stretched films are denoted by S, and the stretched and poled films are denoted as SP.

As shown in Tables 2 and 3 and Figure 5, when the elongation ratio R is 5 and the maximum poling electric field E max is 90 MV m−1, almost only β-phase exists when the poling temperature is over 30°C. The F(β) of samples poled at 45°C and 60 MV m−1 is slightly lower than other samples. During the poling process, the electric field forces the dipole moments to align along the electric field direction, and thus the piezoelectricity is improved. Besides, for the samples of lower F(β), the induced stress by the electric field also promotes the α- to β-phase transformation to some extent. In Figure 5, the sample O (sample: R = 5, T p = 45°C) contains a substantial α-phase. It is attributed to the transformation from γ to α phase at a relative higher temperature. The relative lower electric field cannot increase the β-phase formation effectively [33]. When T p is 40°C, R is 5, and E max is 90 MV m−1, the samples generate the highest open circuit voltages as shown in Figure 4, indicating the complete realignment of dipole moments compared to other samples.

Relative fraction of β-phase F(β) of PVDF-HFP films poled at various temperatures (R = 5)

| T p (°C) | 25 | 30 | 35 | 40 | 45 (E p = 60 MV m−1) |

| F(β) (%) | 87 | 96 | 96 | 97 | 92 |

Relative fraction of β-phase F(β) of PVDF-HFP films stretched at various elongation ratios (T p = 40°C)

| R | 3 | 4 | 5 | 6 |

| S (%) | 61 | 74 | 80 | 76 |

| SP (%) | 68 | 93 | 97 | 96 |

F(β) of untreated films (R = 1) is 14%.

FTIR spectra of PVDF-HFP films: (a) stretched PVDF-HFP films at various elongation ratios. (b) Stretched and poled PVDF-HFP films at various elongation ratios (T p = 40°C) or various poling temperatures (R = 5).

3.3 XRD

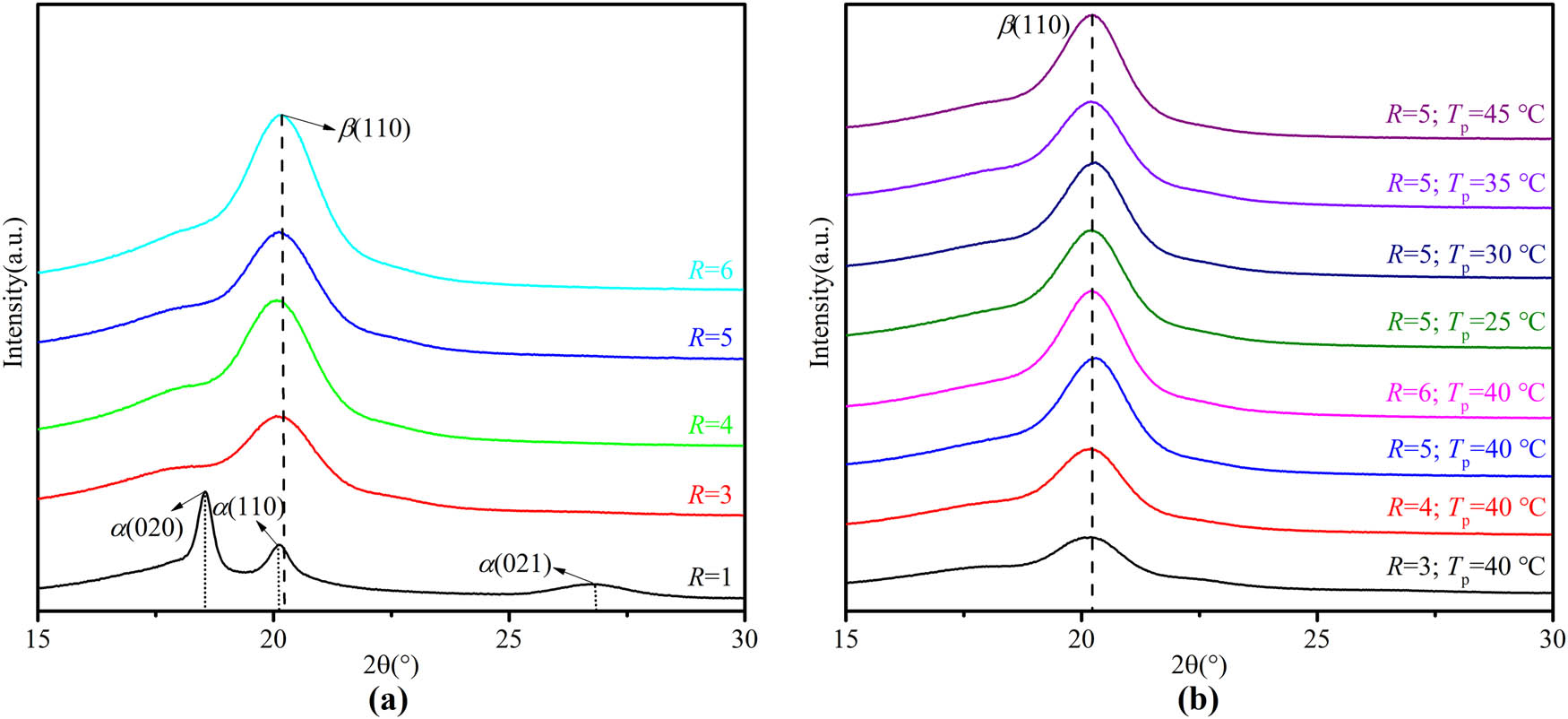

XRD was carried out by CuKα radiation with 2θ from 10° to 30° and the scan rate of 1° min−1. The characteristic peaks of the α- and β-crystal phases in PVDF and their copolymers are shown in Table 4. It should be noted that little shifts of characteristic peaks may exist in different experiments. As shown in Figure 6, the characteristic peaks of both α-phase and β-phase exist in the non-stretched samples. However, in the stretched samples, the characteristic peaks of the α-phase nearly disappear. Compared with the stretched films and poled samples, the spectra seem no obvious differences. Therefore, the α- to β-phase transformation mainly occurs in the stretching process. In the poling process, it is not so obvious since F(β) is quite high in the stretched films. The main effect of poling is the realignment of the dipole moments in the PVDF-HFP matrix, and thus piezoelectricity can be obtained.

| Crystal phase | Characteristic angles (plane) |

|---|---|

| α | 17.8°(020), 18.4°(100), 20.0°(110), 26.6°(021) |

| β | 20.4°(110,200), 36.3° |

XRD diffraction spectrogram of PVDF-HFP films: (a) stretched plus poled films at various elongation ratios (T p = 40°C) and various poling temperatures (R = 5); (b) stretched films at various elongation ratios.

According to the experimental results, the characteristic peaks appear at 18.5°, 20.1°, and 26.7° in the films before stretching, which correspond to the plane of the α-phase, but the characteristic peaks of the β-phase are not obvious. It can be seen that the β-phase is dominant in the samples after stretching and heated-poling (Figure 6(b)). Combining with the FTIR results, it can be concluded that the stretching is the main factor for high β-phase, and poling can promote the α- to β-phase transformation in the samples of low F(β). However, for high β-phase samples, it does little.

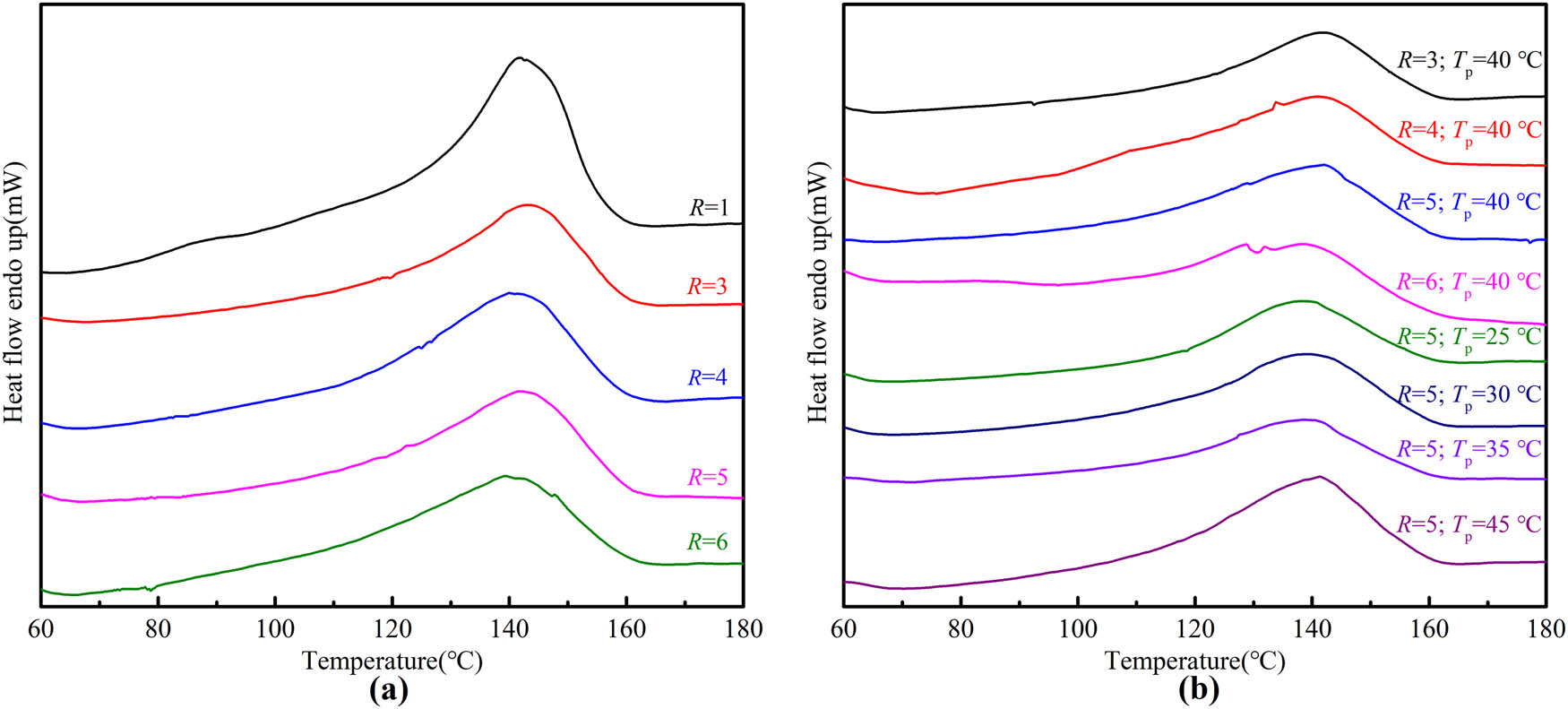

3.4 DSC

In the DSC process, the samples were cut into pieces of 3 mm2 × 3 mm2. The sample was first preserved at 40°C for 5 min and then heated from 40 to 200°C at a rate of 10°C min−1. The following equation was used to calculate the crystallinity degree (X c) of PVDF-HFP films [33]:

where ΔH

m is the melting enthalpy of the material which can be calculated by the DSC software, and

The crystallinity degree of PVDF-HFP films is shown in Tables 5 and 6, and the DSC spectra are shown in Figure 7. It is observed that the crystallinity degree of the PVDF-HFP films increases after stretching, indicating that the concentration stress applied on the amorphous area can force the molecular chains to form crystal structure, which is consistent with the published data by Cai et al. [35]. While the X c decrement was also reported [14], for higher draw ratios the polymer chains become more oriented, which results in the phase transformation accompanied by a decrease of the crystallinity degree. It reflects that the influence of stretching on crystallinity is complicated. In this work, the increase of X c is attributed to the stress work on the amorphous area which forces part of the molecular chains to align in the β-phase. On the other hand, crystallization defects may arise during the stretching process [36,37]. From Table 6, the crystallinity degree changes little after poling, indicating it works little on the crystallinty degree, because it cannot provide enough stress on the molecular chains in the amorphous region to form crystal structure [28]. The main effect of poling is the realignment of dipole moments, as reflected by the change of the open circuit voltage.

Crystallinity degree X c of PVDF-HFP films poled at various temperatures (R = 5)

| T p (°C) | 25 | 30 | 35 | 40 | 45 (E p = 60 MV m−1) |

| X c (%) | 37 | 40 | 37 | 41 | 40 |

Crystallinity degree of X c of PVDF-HFP stretched films at various elongation ratios (T p = 40°C)

| R | 3 | 4 | 5 | 6 |

| S (%) | 35 | 37 | 39 | 40 |

| SP (%) | 36 | 39 | 41 | 41 |

X c of untreated films (R = 1) is 28%.

DSC thermograms of PVDF-HFP films: (a) stretched PVDF-HFP films at various elongation ratios; (b) stretched plus poled PVDF-HFP films at various elongation ratios (T p = 40°C) and various poling temperatures (R = 5).

4 Conclusion

In this study, the influences of poling temperature and elongation ratios on phase transformation and output voltages of PVDF-HFP films are investigated. The FTIR and XRD spectra demonstrate that the α- to β-phase mainly occurs in the stretching process (R ≥ 3) due to molecular chain elongation caused by the external force. The poling temperature has strong effects on the piezoelectricity of PVDF-HFP films. It is found that the output open circuit voltage increases with the temperature until 40°C. While the temperature is 45°C, the poling fails when the electric field is over 60 MV m−1. Thus, the piezoelectricity cannot be further increased. The optimal parameters are defined as R = 5, T p = 40°C, and E max = 90 MV m−1. At this condition, the open circuit voltage reaches 3.67 V, 71% higher than that of samples poled at 25°C. The experimental method of heated-poling reported in this study is facile and of low cost for preparing efficient piezoelectric films.

-

Funding information: This work was financially supported by National Natural Science Foundation of China (No. 51703015) and Fundamental Research Funds for the Central Universities (No. 2020CDJQY-A008).

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

-

Data availability statement: The authors confirm that the data supporting the findings of this study are available within the article and its supplementary materials.

References

[1] Wan CY, Bowen CR. Multiscale-structuring of polyvinylidene fluoride for energy harvesting: the impact of molecular-, micro- and macro-structure. J Mater Chem A. 2017;5(7):3091–128.10.1039/C6TA09590ASearch in Google Scholar

[2] Schonecker A, Laas L, Gutjahr A, Wyers P, Reinink A, Wiersma B. Ribbon-growth-on-substrate: Progress in high-speed crystalline silicon wafer manufacturing. Photovoltaic Specialists Conference (PVSC). New Orleans, LA, USA: IEEE; 2002 May 19–24.10.1109/PVSC.2002.1190522Search in Google Scholar

[3] Abdelkefi A. Aeroelastic energy harvesting: a review. Int J Eng Sci. 2016;100:112–35.10.1016/j.ijengsci.2015.10.006Search in Google Scholar

[4] Kodali P, Mahidhar MN, Lokesh N, Prasad MVN, Sambandan S. Vibration energy harvesting. 2012 International Conference on Emerging Electronics (ICEE). Mumbai, India: IEEE; 2012 Dec 15–17.10.1109/ICEmElec.2012.6636258Search in Google Scholar

[5] Erturk A, Inman DJ. Piezoelectric energy harvesting. West Sussex: John Wiley & Sons; 2011.10.1002/9781119991151Search in Google Scholar

[6] Gai XZ. Direction of research and development and status for piezoelectric. China Ceram. 2008;44(5):9–13.Search in Google Scholar

[7] Martins P, Lopes AC, Lanceros-Méndez S. Electroactive phases of poly(vinylidene fluoride): determination, processing and applications. Prog Polym Sci. 2014;39(4):683–706.10.1016/j.progpolymsci.2013.07.006Search in Google Scholar

[8] Karen SK, Mandal D, Khatua BB. Self-powered flexible Fe-doped RGO/PVDF nanocomposite: an excellent material for a piezoelectric energy harvester. Nanoscale. 2015;7(24):10655–66.10.1039/C5NR02067KSearch in Google Scholar

[9] Kim GH, Hong SM, Seo Y. Piezoelectric properties of poly(vinylidene fluoride) and carbon nanotube blends: β-phase development. Phys Chem Chem Phys. 2009;11(44):10506–12.10.1039/b912801hSearch in Google Scholar

[10] Salimi A, Yousefi AA. Analysis method: FTIR studies of β-phase crystal formation in stretched PVDF films. Polym Test. 2003;22(6):699–704.10.1016/S0142-9418(03)00003-5Search in Google Scholar

[11] Gomes J, Serrado Nunes J, Sencadas V, Lanceros-Mendez S. Influence of the β-phase content and degree of crystallinity on the piezo- and ferroelectric properties of poly(vinylidene fluoride). Smart Mater Struct. 2010;19(6):065010.10.1088/0964-1726/19/6/065010Search in Google Scholar

[12] Wu L, Yuan W, Hu N, Wang Z, Chen C, Qiu J, et al. Improved piezoelectricity of PVDF-HFP/carbon black composite films. J Phys D Appl Phys. 2014;47(13):13502.10.1088/0022-3727/47/13/135302Search in Google Scholar

[13] Dadi S, Paul R, Michael W. The step-wise poling of VDF/TrFE copolymers. Ferroelectrics. 1996;186:255–8.10.1080/00150199608218078Search in Google Scholar

[14] Sencadas V, Gregorio R, Lanceros-Méndez S. α to β-phase transformation and microestructural changes of PVDF films induced by uniaxial stretch. J Macromol Sci Phys. 2009;48(3):514–25.10.1080/00222340902837527Search in Google Scholar

[15] Ting Y, Gunawan H, Sugono A, Chiu CW. A new approach of polyvinylidene fluoride (PVDF) poling method for higher electric response. Ferroelectrics. 2013;446(1):28–38.10.1080/00150193.2013.820983Search in Google Scholar

[16] Scheinbeim JI, Nakafuku C, Newman BA, Pae KD. High-pressure crystallization of poly(vinylidene fluoride). J Appl Phys. 1979;50(6):4399–405.10.1063/1.326429Search in Google Scholar

[17] Hattori T, Kanaoka M, Ohigashi H. Improved piezoelectricity in thick lamellar β-form crystals of poly(vinylidene fluoride) crystallized under high pressure. J Appl Phys. 1996;79(4):2016–22.10.1063/1.361055Search in Google Scholar

[18] Satish B, Sridevi K, Vijaya MS. Study of piezoelectric and dielectric properties of ferroelectric PZT-polymer composites prepared by hot-press technique. J Phys D Appl Phys. 2002;35(16):2048–50.10.1088/0022-3727/35/16/321Search in Google Scholar

[19] Shanks L, Siddiqui MR, Kliescikova J, Pearce N, Ariti C, Muluneh L, et al. High-performance flexible lead-free nanocomposite piezoelectric nanogenerator for biomechanical energy harvesting and storage. Nano Energy. 2015;15:177–85.10.1016/j.nanoen.2015.04.030Search in Google Scholar

[20] Jaitanong N, Chaipanich A. Effect of poling temperature on piezoelectric properties of 0–3 PZT-Portland cement composites. Ferroelectr Lett. 2008;35(1–2):17–23.10.1080/07315170801992179Search in Google Scholar

[21] Huan Y, Wang X, Zhang S, Gao R, Li L. Effect of poling temperature on piezoelectric coefficient in (Na0.52K0.4425Li0.0375)(Nb0.86Ta0.06Sb0.08)O3 ceramics. Phys Status Solidi A. 2013;210(12):2579–82.10.1002/pssa.201330040Search in Google Scholar

[22] Du HL, Zhou WC, Luo F, Zhu DM. An approach to further improve piezoelectric properties of K0.5Na0.5NbO3-based lead-free ceramics. Appl Phys Lett. 2007;91(20):202907.10.1063/1.2815750Search in Google Scholar

[23] Li BZ, Blendell JE, Bowman KJ. Temperature-dependent poling behavior of lead‐free BZT–BCT Piezoelectrics. J Am Ceram Soc. 2011;94(10):3192–4.10.1111/j.1551-2916.2011.04758.xSearch in Google Scholar

[24] Wu J, Xiao D, Wu W, Chen Q, Zhu J, Yang Z, et al. Composition and poling condition-induced electrical behavior of (Ba0.85Ca0.15)(Ti1-xZrx)O3 lead-free piezoelectric ceramics. J Eur Ceram Soc. 2012;32(4):891–8.10.1016/j.jeurceramsoc.2011.11.003Search in Google Scholar

[25] Ye Y, Jiang Y, Wu ZM, Zeng HJ. Phase transitions of poly(vinylidene fluoride) under electric fields. Integr Ferroelectr. 2006;80(1):245–51.10.1080/10584580600659423Search in Google Scholar

[26] Darestani MT, Coster HGL, Chilcott TC, Fleming S, Nagarajan V, An H. Piezoelectric membranes for separation processes: fabrication and piezoelectric properties. J Membr Sci. 2013;434:184–92.10.1016/j.memsci.2013.01.035Search in Google Scholar

[27] Darestani MT, Chilcott TC, Coster HGL. Effect of poling time on filtration properties of PVDF membranes treated in intense electric fields. Polym Bull. 2014;71(4):951–64.10.1007/s00289-014-1103-8Search in Google Scholar

[28] Kulek J, Hilczer B, Szlaferek A. Effect of the poling temperature on the dielectric properties of oriented PVDF film. Ferroelectrics. 1988;81:1329–32.10.1080/00150198808008883Search in Google Scholar

[29] Zhang LL, Guo SS. Progress in the ferroelectric poly(vinylidene fluoride) and its copolymers. Prog Phys. 2016;36(2):35–45.Search in Google Scholar

[30] Zhu XH. Effects of cross-linking method on insulation properties of cross-linked polyethylene [PhD dissertation]. Tientsin University; 2010.Search in Google Scholar

[31] Boccaccio T, Bottino A, Capannelli G, Piaggio P. Characterization of PVDF membranes by vibrational spectroscopy. J Membr Sci. 2002;210(2):315–29.10.1016/S0376-7388(02)00407-6Search in Google Scholar

[32] Li L, Zhang MQ, Rong MZ, Ruan WH. Studies on the transformation process of PVDF from α to β phase by stretching. RSC Adv. 2014;4(8):3938–43.10.1039/C3RA45134HSearch in Google Scholar

[33] Pramanick A, Misture S, Osti NC, Jalarvo N, Diallo SO, Mamontov E. Ferroelectric to paraelectric phase transition mechanism in poled PVDF-TrFE copolymer films. Phys Rev B Conden Matter. 2017;96(17):174103.10.1103/PhysRevB.96.174103Search in Google Scholar

[34] Lanceros-Méndez S, Mano JF, Costa AM, Schmidt VH. FTIR and DSC studies of mechanically deformed β-PVDF films. J Macromol Sci Phys. 2001;B40(3–4):517–27.10.1081/MB-100106174Search in Google Scholar

[35] Cai J, Hu N, Wu L, Liu Y, Li Y, Ning H, et al. Preparing carbon black/graphene/PVDF-HFP hybrid composite films of high piezoelectricity for energy harvesting technology. Compos Part A Appl Sci Manufac. 2019;121:223–31.10.1016/j.compositesa.2019.03.031Search in Google Scholar

[36] Cui Z, Hassankiadeh NT, Zhuang Y, Drioli E, Lee YM. Crystalline polymorphism in poly(vinylidene fluoride) membranes. Prog Polym Sci. 2015;51:94–126.10.1016/j.progpolymsci.2015.07.007Search in Google Scholar

[37] Ye H, Xu C, Meng N, Meng Z, Xu L. High energy density and charge–discharge efficiency of uniaxial stretched poly(vinylidene fluoride-hexafluoropropylene) film with electroactive phase conversion. J Mater Sci Mater Electron. 2018;29(8):6619–31.10.1007/s10854-018-8646-7Search in Google Scholar

[38] Mohammadi B, Yousefi AA, Bellah SM. Effect of tensile strain rate and elongation on crystalline structure and piezoelectric properties of PVDF thin films. Polym Test. 2007;26(1):42–50.10.1016/j.polymertesting.2006.08.003Search in Google Scholar

[39] Gregorio JrR, Nociti NCPD. Effect of PMMA addition on the solution crystallization of the alpha and beta phases of poly(vinylidene fluoride) (PVDF). J Phys D Appl Phys. 1995;28(2):432–6.10.1088/0022-3727/28/2/028Search in Google Scholar

[40] Gregorio JrR, CapitãO RC. Morphology and phase transition of high melt temperature crystallized poly(vinylidene fluoride). J Mater Sci. 2000;35(2):299–306.10.1023/A:1004737000016Search in Google Scholar

© 2021 Zhaonan Jin et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions