Abstract

The aim of this research is to investigate the potential application of septage ash (SA) as a partial substitute for conventional fillers in Bitumen mixes. The study’s purpose was to evaluate the mechanical and performance characteristics of Bitumen mixes by incorporating varying amounts of SA into the filler. To achieve this, bitumen mix samples were prepared with different concentrations of SA (5, 10, 15, and 20% of the filler weight). The study’s initial focus was on analyzing the physical properties of the samples and determining the fundamental parameters of tiny crystallites using X-ray diffraction and specific surface area. Additionally, the strength, stiffness, resistance to velocity, temperature effects, and impact of water on the mixture were carefully evaluated by conducting Marshall stability tests, indirect tensile strength, Cantabro tests, Freezing and Thawing (F&T) tests, and Moisture susceptibility tests to determine their durability in the presence of water. The findings of this study indicate that incorporating SA improved the strength by 32%, reduced fine loss by 23% at an optimal 5.35% bitumen content, and increased moisture sensitivity by 15%. Overall, the experimental results suggest that waste SA can be used as a sustainable solution to improve the mechanical performance of the surface.

1 Introduction

The incorporation of waste products in the bituminous mixes has attracted the interest of experts in the past few years because of modern environmental issues and advances in road construction technology. Recycled concrete aggregate, fly ash, and industrial waste-based artificial aggregates have been studied to replace part of the conventional materials in the bituminous mixtures [1,2]. Results of these studies were considered encouraging since they demonstrate positive shifts in mechanical properties and, at the same time, increases durability yet decreasing effect on the environment. For instance, interaction between fly ash and recycled concrete aggregate used in porous asphalt mixtures have shown the capability of offsetting negative impacts on mechanical properties [1]. Similarly, the use of industrial waste-based artificial aggregates processed under accelerated carbonation has shown improvements in anti-rutting properties, moisture damage resistance, and skid resistance of bituminous mixtures [2]. Furthermore, the application of waste materials such as paper sludge ash and re-refined acidic sludge in cold bitumen emulsion mixes and warm mix asphalt, respectively, has yielded favorable results in terms of mechanical performance and durability [3,4]. Given the success of these waste materials in bituminous mixtures, it is worthwhile to explore the potential of waste septage ash (SA) as a partial substitute in bitumen mixtures. This approach aligns with the growing trend of incorporating alternative materials in road construction to enhance sustainability and reduce environmental impact while maintaining or improving the performance characteristics of the resulting mixtures [5,6].

In the fields of road construction and pavement engineering, this trend has manifested in the exploration of waste materials as potential fillers in bitumen mixtures. Bitumen, a crucial component in road construction, traditionally relies on mineral fillers to enhance its performance. However, the extraction and processing of these conventional fillers often incur significant environmental and economic costs. Consequently, researchers and engineers have focused on waste materials as alternative fillers to lessen the environmental effect of road building while possibly increasing the mechanical qualities of bitumen pavements [7–9]. This approach addresses the challenge of waste management and aligns with the principles of a circular economy, in which waste is viewed as a valuable resource rather than a disposal problem [10].

The use of waste products as fillers in bitumen mixes provides a multitude of potential benefits. From an environmental perspective, it reduces the demand for virgin materials, minimizes landfill usage, and decreases the carbon footprint associated with filler production and transportation [11]. Economically, this can lead to cost savings in road construction projects by reducing material costs and potentially improving pavement longevity. Moreover, certain waste materials were discovered to boost the performance of bitumen mixes, thereby improving rutting, moisture susceptibility, and thermal cracking resistance [12]. The spectrum of waste materials studied was large and varied, including fly ash from coal burning, waste plastic, recycled glass, steel slag, and various forms of construction and demolition waste. Each of these materials imparts unique properties to Bitumen mixtures, necessitating thorough research to understand their impact on both short-term performance and long-term durability of pavements [13].

However, the incorporation of waste materials as fillers into bitumen mixtures is challenging. The variation in the content and qualities of waste materials can lead to inconsistencies in bitumen performance, requiring rigorous quality control measures [14]. There are also worries about possible leaching of harmful substances from certain waste materials, which necessitates comprehensive environmental impact assessments. Additionally, the long-term behavior of pavements containing waste materials requires field trials and monitoring programs [15]. Despite these challenges, the potential benefits of using waste materials as fillers in bitumen mixtures have sparked significant research interest. As environmental restrictions grow increasingly rigorous and the push for sustainable construction practices intensifies, the development of effective strategies for incorporating waste materials into bitumen mixtures is likely to become increasingly important in pavement engineering [16].

1.1 Research objectives

The primary objective of using waste SA in bitumen mixtures is to enhance sustainability by repurposing waste material as a partial substitute for traditional fillers.

This reduces dependency on virgin materials, minimizes environmental impact, and addresses waste management issues.

The research aims to improve bitumen mixtures’ mechanical and performance properties while promoting a circular economy approach.

By integrating SA, the study explores the potential for cost savings, enhanced durability, and environmental benefits, aligning with sustainable development goals in pavement engineering.

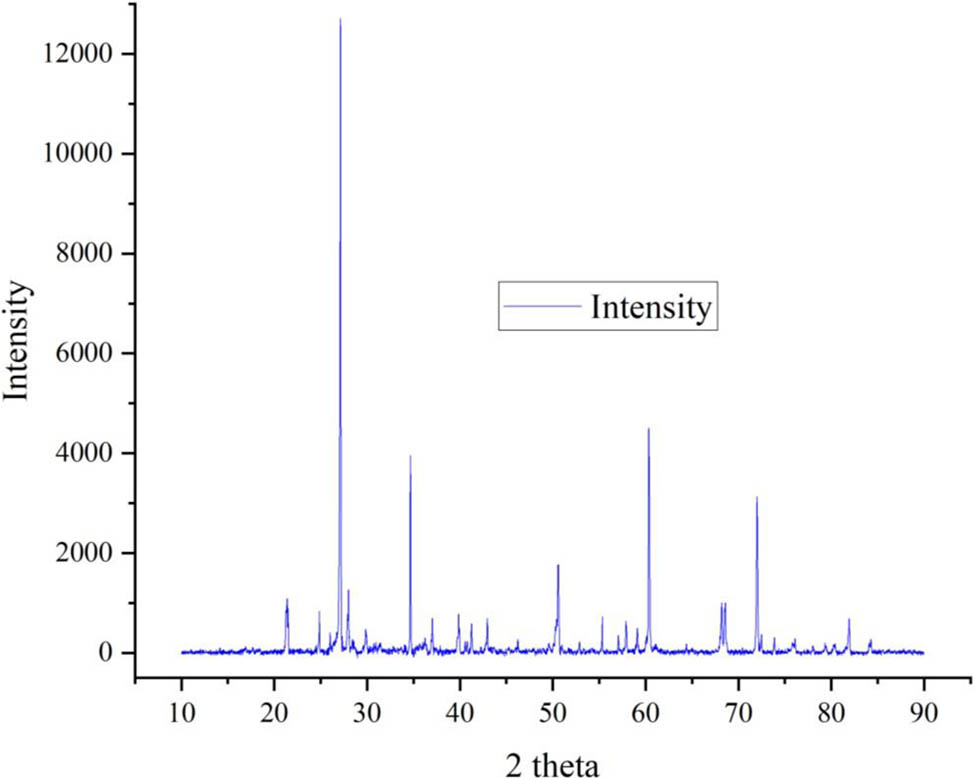

Initially, the SA sample was tested for X-ray diffraction (XRD) to identify the structure and components inside the molecules. Based on the XRD results, the sample consists of dominant phase accounting for 60–70% of the sample, the secondary phase accounting for 20–30%, and the minor phase accounting for 10–20%. The estimated size of the crystallites in the sample is 30–50 nm based on the SEM image of the SA. The highest point had an angle of approximately 25.5° and a relative intensity of 100%. Additional notable peaks are observed at approximately 31.5°, 55.5°, and 67.5°. The crystal symmetry was probably reduced, possibly to monoclinic or orthorhombic, exhibiting uneven spacings and peak intensities. As illustrated in Figure 1, XRD is a flexible nondestructive technique for characterizing the physical properties of materials such as powder, solid, and liquid samples. This makes possible examination of formation features like phase distribution, crystal structure, and orientation. As shown in Figure 1, various substances consist of small crystalline particles [39].

X-ray diffraction (XRD) of the septage ash.

1.2 Research methodology

In this experimental work, waste SA was a partial replacement of the filler with respect to the weight of the filler. An XRD test was conducted for the SA properties and intensity concerning 2 theta. Prior to sample preparation, the specific surface area (SSA) of the particle size distribution was evaluated to determine the feasibility of incorporating fillers into the bitumen mixture, ensuring a comprehensive understanding of the material’s properties for optimal mix design. Samples were prepared by varying the SA to 0, 5, 10, 15, and 20% in the bitumen mix. The study evaluates critical mechanical properties such as Marshall stability (MS), tensile strength, compressive strength, stiffness, and moisture resistance. These properties assess the load-bearing capacity, deformation, and durability of bitumen mixtures with SA. The Cantabro and F&T tests analyze abrasion resistance and resilience under environmental stress. By examining these parameters, the research aims to validate SA’s potential to improve the structural and performance characteristics of bitumen mixtures, ensuring they meet industry standards for strength, durability, and stability.

2 Materials

2.1 Aggregate

Aggregates were acquired from a nearby crusher and were subsequently examined to determine their size and form, both of which are crucial factors for their suitability for pavement applications. There were certain constraints to this investigation. The results of the combined data with limitations are presented in Table 1, highlighting the necessary characteristics for pavement construction: ASTM C 131, ASTM C535, ASTM D 5821, ASTM C127, and ASTM C127.

Test results for aggregates according to ASTM methods with limitations

| Name of experiment | Result | Limitations | ASTM designation |

|---|---|---|---|

| Values | |||

| Los Angeles abrasion test | 42% | Max. 45% | ASTM C 131 |

| Aggregate impact test | 19.46% | Max. 24% | ASTM C535 |

| Crushing strength test | 28.07 | Max 30% | ASTM D 5821 |

| Specific gravity Test | 2.65 | 2.5–3.0 | ASTM C127 |

| Water absorption Test | 0.165 | 0.1 to 2% | ASTM C127 |

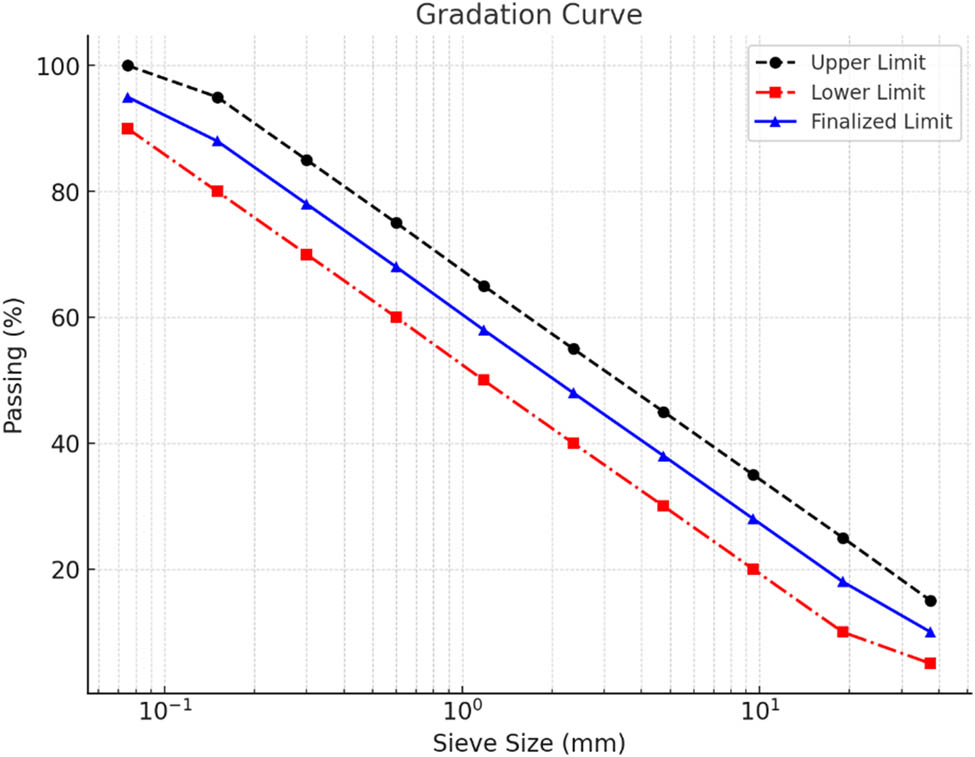

2.2 Sampling of aggregate

The ingredients were selected using the job mix formula from Figure 2 gradation chart of ingredients with limits. As shown in Figure 3, the particle percentage was determined for bitumen grade [17–19]. The middle limit (red color) was considered for the mix. The mean value was used to calculate the percentage of aggregates utilized in the combination, and the median value in Table 2 was used to pick the aggregate gradation, as shown in Figure 6.

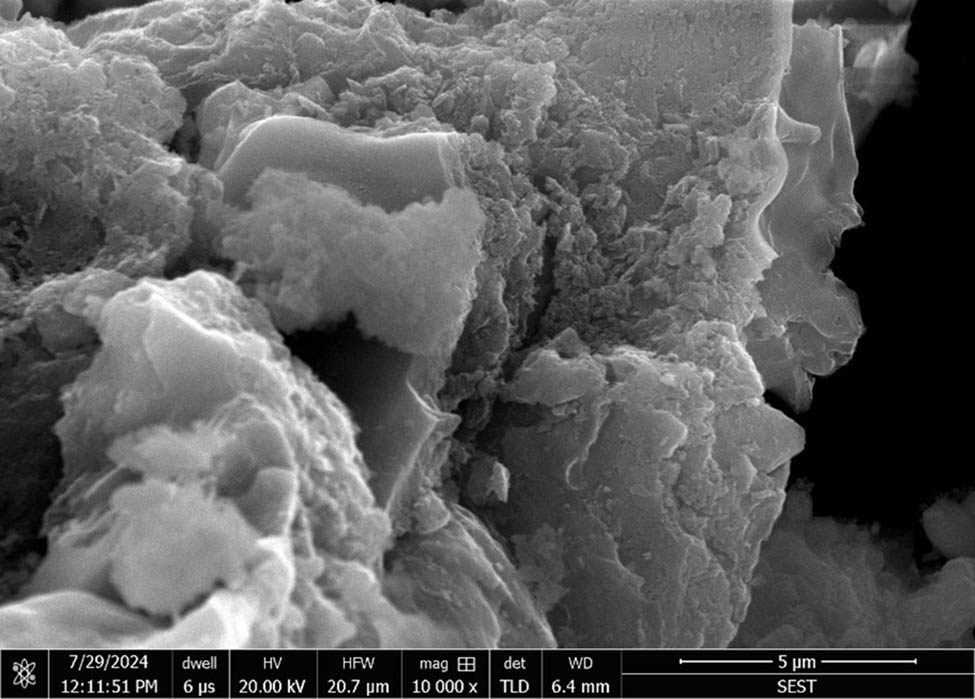

SEM image of septage ash.

Gradation chart of the mix.

Gradation of constituents for bitumen concrete

| Sieve size (mm) | Upper limit (%) | Lower limit (%) | Finalized passing (%) |

|---|---|---|---|

| 19 | 100 | 95 | 98 |

| 13.2 | 95 | 85 | 90 |

| 9.5 | 90 | 78 | 85 |

| 4.75 | 75 | 60 | 68 |

| 2.36 | 60 | 45 | 52 |

| 1.18 | 45 | 30 | 38 |

| 0.6 | 30 | 18 | 25 |

| 0.3 | 20 | 10 | 15 |

| 0.15 | 12 | 5 | 10 |

| 0.075 | 8 | 2 | 5 |

2.3 Bitumen

The research work utilized VG 30 grade bitumen. To verify compliance with ASTM standards, essential testing was done on the product, and the relevant findings, together with their associated limitations, are shown in the accompanying table. Table 3 displays the bitumen testing results following ASTM standards, including any restrictions or limits [20–22].

Test results for the bitumen according to ASTM testing with limitations

| Test name | Value | Limitation | ASTM designation |

|---|---|---|---|

| Ductility test | 42.5 cm | Min 40 cm | ASTM D113-17 |

| Flash and fire point test | 280° and 320°C | Min 220°C | ASTM D8254-19 |

| Penetration test | 67 mm | 50–70 mm | ASTM D5/D5M-13 |

| Softening point test | 54°C | Min 47°C | ASTM D36/D36M-12 |

| Specific gravity test | 1.01 | 0.9–1.02 | ASTM D2726 |

| Viscosity test | 2,500 | 2,400–3,600 | ASTM D4402 |

2.4 Filler (SA)

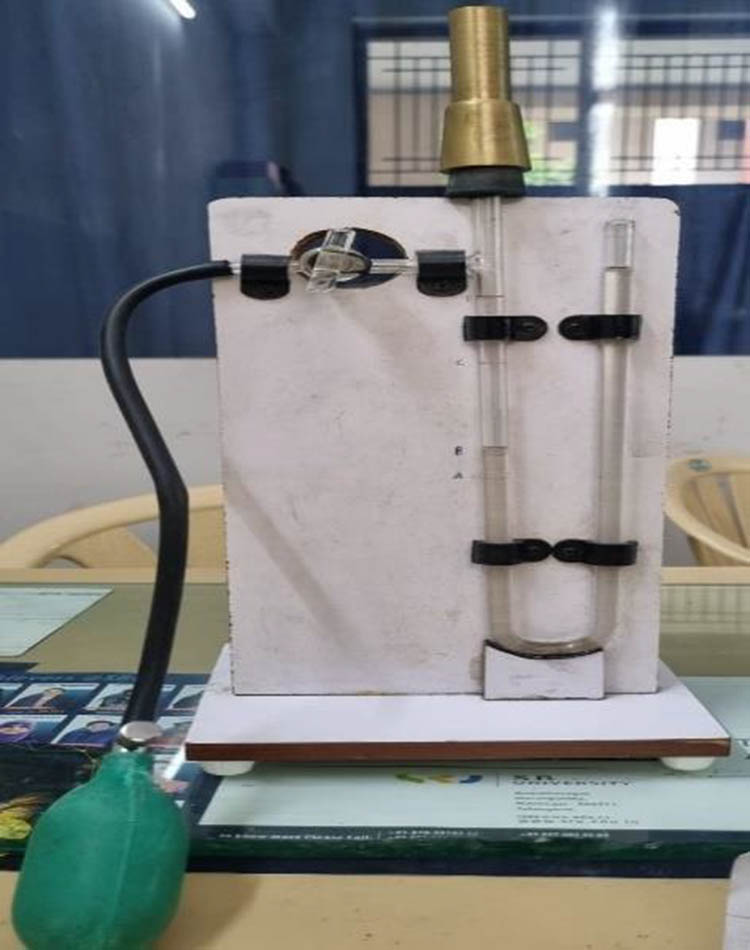

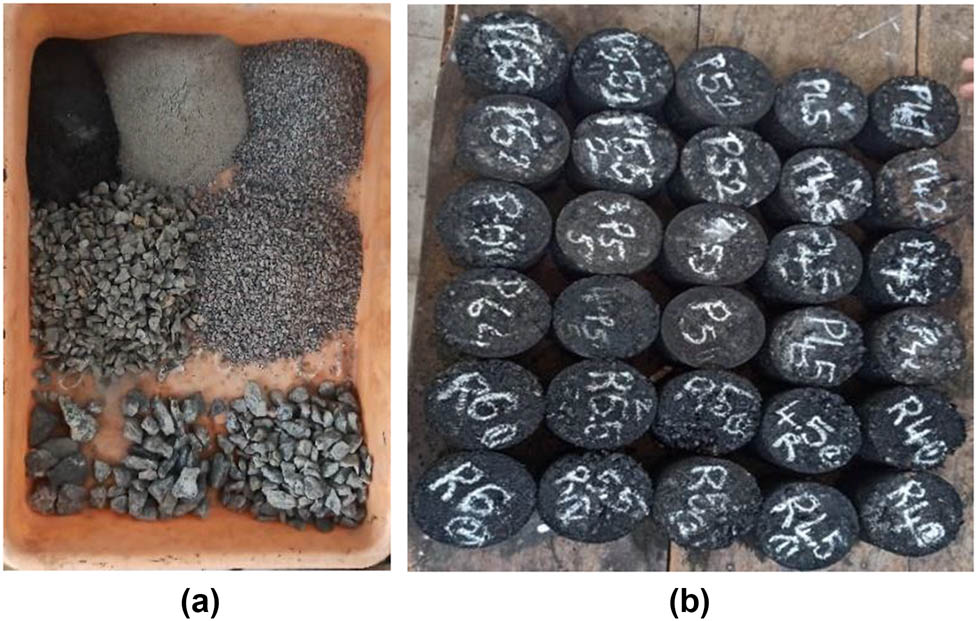

SA, which is leftover material from septic tanks, is used in bitumen mixtures to provide rigidity and reduce empty spaces, thereby resulting in denser pavement structures [23–26]. Local authorities incinerate this ash at temperatures between 1,400 and 1,500°C, resulting in black-colored ash that is disposed in landfills. Figure 3 shows SA collected from the treatment plant. The basic properties of the SA are listed in Table 4. The elements and characterization of the filler were calculated using the SSA measured by the Blaine air permeability apparatus (IS5516) (Figures 4 and 5).

The basic properties of SA

| Component | CaO | Al2O3 | SiO2 | Fe2O3 | P2O5 | Specific gravity | SSA (cm2/g) |

|---|---|---|---|---|---|---|---|

| Weight (%) | 5–15 | 10–20 | 40–60 | 5–15 | 01–5 | 3.58 | 5981.89 |

Waste septage ash.

Blaine air permeability apparatus for specific surface area.

3 Experimental study

3.1 Marshal stability test

The MS test apparatus, which is illustrated in Figure 6, is used in determining the durability of the bitumen mixtures. These are the specimen mold assembly, the specimen extractor, the compaction hammer, the compaction pedestal, the breaking head, the loading machine, and the flow meter as shown in Figure 4 (ASTM D6927-15, 2015).

Marshall stability apparatus.

3.2 Preparation and testing of sample

The process involved the fusion of 1,200 g of aggregates and exposing them to heat in an oven until the required mixing temperature was achieved. Bitumen was added to achieve a viscosity of 170°C. The heated mixtures were transferred to a mold, subjected to 50 hammer strokes for compression, and subsequently removed. The sample was then allowed to cool and its mass was measured to determine its density, thus facilitating the calculation of void properties [27,28]. The specimens were heated to 60 ± 1°C using a water bath or oven. The lower half of the breaking head was positioned and the upper part was mounted. Subsequently, the assembly was placed in a test apparatus. The flow meter was adjusted to a zero reading and the load was systematically increased at a consistent rate of 50 mm/min until it reached its highest possible value. The maximum load measurements in Newtons were concurrently recorded [29,30]. The ingredients and prepared samples are shown in Figure 6(a) and (b).

3.3 Volumetric properties

Voids in the Mineral Aggregate (VMA), air voids (AV), dry bulk density, and voids filled with bitumen (VFB) were measured using ASTM D2726 (for VMA) and ASTM D3203 (for AV, dry bulk density, and VFA). Consequently, they were acquired using Eqs. (1) and (2) [27,28].

The saturated surface dry (SSD) reflects the weight of dry samples when they are completely wetted on the surface (g).

SGmax refers to the highest specific gravity of a combination as established following the ASTM D2041 standard.

Where CA, FA, F, and B are the coarse aggregate, fine aggregate, filler, and bitumen, respectively, by the weight of the mix.

Ps represents the overall percentage of the aggregate in the complete mix, whereas Gsb represents the bulk-specific gravity of the aggregate.

3.4 Indirect tensile strength (ITS) test

The ITS tests used ASTM D 4123 methodology to evaluate the tensile strength of a cylindrical specimen. The specimen was subjected to diametric compression at a consistent rate of 50.8 mm/min, which caused tension along its diameter. The equation representing the greatest tensile strength is formulated as follows [29]:

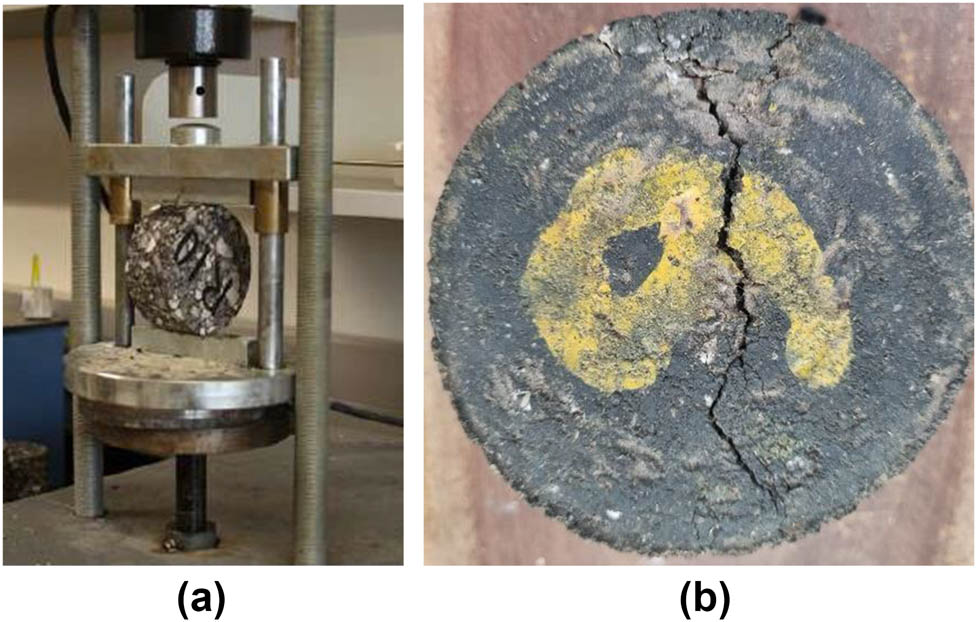

In this context, “ITS” represents the indirect tensile test, measured in kilopascals (kPa). “Pmax” denotes the highest force applied during the test, expressed in kilonewtons (KN). “H” refers to the height of the specimen, measured in meters (m), whereas “D” denotes the specimen’s diameter also measured in meters (m) (Figure 7).

(a) Ingredient used for the mix and (b) prepared samples.

A popular way for material testing is to evaluate its tensile strength. The ITS tests were conducted using the methods outlined in ASTM D 4123. The experimental approach utilized to determine the tensile strength of the cylindrical specimen involved subjecting it to diametrical compression at a consistent rate of 50.8 mm/min (2 in/min), as shown in Figure 8(a). This process induced a state of tension along the specimen diameter that was subjected to a load. The equation representing the highest tensile strength can be expressed using Eq. (4). To determine the weight of the blends, the specimens were allowed to reach ambient temperature after molding. The density can be calculated using bulk-specific gravity or saturated-surface dry-weight techniques. Moisture-removal techniques have also been used. Maintaining the temperature between 25 and 3°C is crucial. The test results and cracking pattern of the sample after loading are shown in Figure 8(b), respectively.

(a) Indirect tensile strength test and (b) cracking pattern of sample after loading.

3.5 Cantabro test

This procedure measures the abrasion loss in compacted Hot-Mix Asphalt (HMA) specimens using a Los Angeles abrasion machine shown in Figure 9(a). Cantabro loss, a percentage of weight loss, indicates the durability of the low-rutting bitumen, porous friction course, and hot-mix cold laid. The test can be conducted on other HMA mixtures and the results are reported as the average percentage loss [41].

where CL is the Cantabro loss, %, A is the initial weight of the test specimen; and B is the final test specimen weight.

(a) Los Angeles abrasion test machine and (b) samples after testing.

Following the molding process, the specimens are let to cool down to the surrounding temperature before being weighed. The density of the porous friction course mixes was determined by using either the bulk-specific gravity or the weight of the mixture when it is saturated and surface dry. The specimens were dehydrated using dimensional analysis. Ensure that temperature levels are maintained within the range of 60–3°C to achieve precision and reliability. Prior to testing, the samples are subjected to a 24 h period of heat conditioning in a chamber or oven. The specimens are positioned inside a testing apparatus located in Los Angeles, as seen in Figure 9(a), and undergo rotation at a speed of 30–33 rpm for a total of 300 revolutions. Discard loose samples after 300 revolutions [41]. The total deterioration of the sample after 300 revolutions provided resistance to raveling, as shown in Figure 8(b).

3.6 F&T test

Pavement degradation can be caused by traffic loads and cyclic climatic activities, leading to thermal fractures and low-temperature distress. In cold places, bitumen pavements face issues due to repeated thermal stresses and moisture-related consequences. This test, F&T cycles used to assess the performance of rubberized bitumen concrete under severe conditions. Samples were generated for a 5-day aging technique to analyze the impact of cyclic temperatures, ice, and moisture on the deterioration of rubberized materials. The volumetric, mechanical, and durability tests were conducted at specified intervals (0, 1, 5, and 10 cycles). The results suggest that rubberized bitumen concrete may be more resilient under severe conditions. Based on ASTM C666/C666-M, each sample was soaked in water at the temperature of 23 ± 2°C (room temperature) for 48 h after the curing time and before the F&T cycles. Following the conditioning phase, the F&T cycles commenced with a freezing phase programmed to achieve a temperature of −18 ± 2°C and held for a duration of 3 h (180 min). It was followed by a thawing phase conducted in cold water to reach a temperature of +4 ± 2°C and maintained for 1.5 h (90 min) [24].

3.7 Marshall quotient (MQ)

The MQ or rigidity ratio was used to evaluate the resistance of the bituminous mixes to rutting. The relationship between the flow value and MS values was observed in compacted Marshall specimens after failure. Higher MQ values indicated enhanced rigidity and load dispersion, leading to superior resistance to deformation and rutting. The Indian specification mandates a MQ range of 2–5 kN/mm to create bitumen mixtures resistant to rutting and prevent excessively brittle bituminous concrete mixtures [31–33].

3.8 Retained Marshall stability (RMS) tests

The water resistance of the bituminous mixes was assessed using the RMS test and modified Lottman test. This test, which is not included in the current Indian specification, is simpler and requires less time and resources than other tests. Six Marshall specimens were created for each combination and divided into two groups. The samples in Group I underwent water conditioning, whereas those in Group II were unconditioned. Table 5 represents the results. The mean stability calculations were performed for each group, and the MS was represented as a percentage using standard equations [34–36].

where RMS is the retained Marshall stability (%),

RMS for conditioned and unconditioned samples

| Bitumen % | Conditioned in Pascals | Unconditioned in Pascals | RMS (%) |

|---|---|---|---|

| 4 | 2238.08 | 2109.61 | 94.26 |

| 4.5 | 2478.50 | 2315.16 | 93.41 |

| 5 | 2639.45 | 2416.68 | 91.56 |

| 5.5 | 2839.79 | 2538.48 | 89.39 |

| 6 | 2741.21 | 2416.92 | 88.17 |

According to MoRTH (2001), bituminous mixes should have a minimum RMS value of 75% to ensure satisfactory moisture resistance.

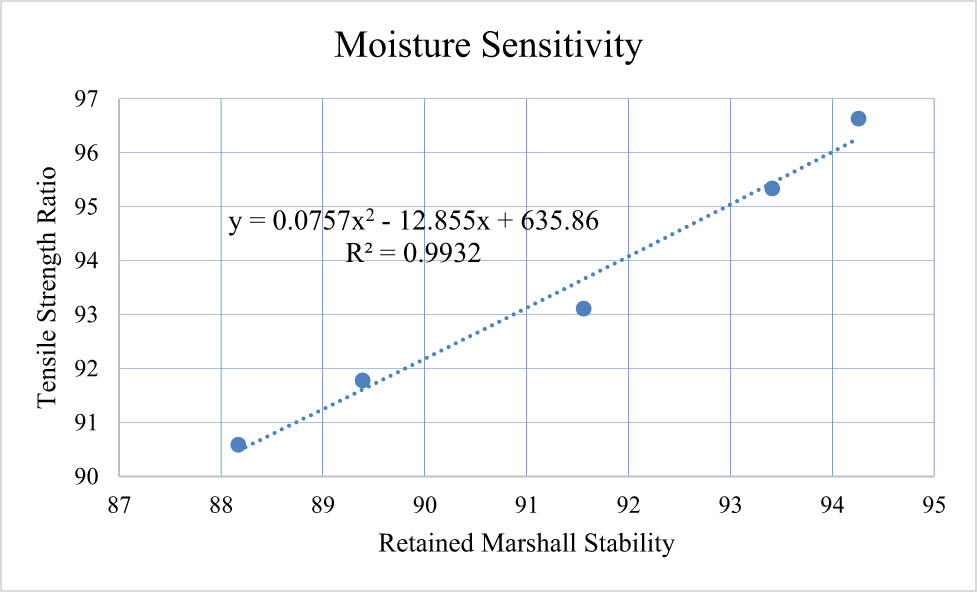

3.9 Moisture sensitivity analysis

The table shows the RMS and tensile strength ratio (TSR) of various bituminous mixtures. Higher TSR and RMS levels are thought to improve the moisture resistance. The TSR (RMS) values declined as the filler content increased, indicating an increased moisture sensitivity. The visible bitumen coating acts as a protective barrier, ensuring durability and moisture resistance. A reduction in oxidative stress leads to a decrease in the process of aging F&T, resulting in decreased moisture resistance. This pattern aligns with the findings of previous studies [16,37–40].

4 Results and discussion

4.1 Effect of SA on flow and MS

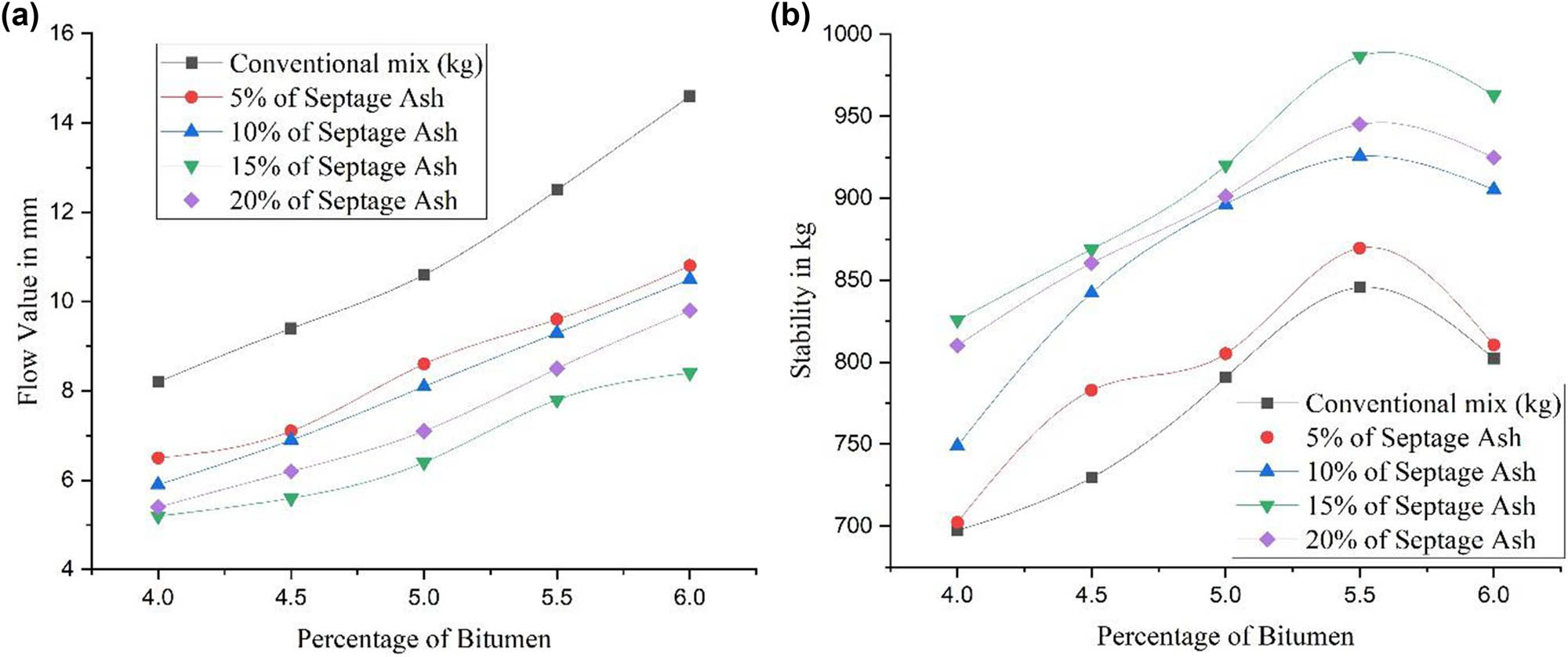

The MS rating of a bitumen mixture is the maximum load that it can bear during testing, whereas Marshall flow is the deformation of the specimen when the load decreases. Marshall stiffness was determined by dividing the MS by the flow, resulting in kN/mm. The ideal percentage of bitumen increased by 5.5% when SA was substituted into the MS, indicating that these materials improved the rigidity and adhesiveness of the mixtures.

Figure 10(a) proves the correlation between bitumen content in the absolute and the flow value in the case of the application of asphalt mixes with the addition of SA in different proportions. The mix that contains no SA is considered the control mix; as indicated earlier, it contains all the conventional material. The flow value improves when the blends contain a higher proportion of bitumen as is expected in view of the fact that it serves as both a binder to the aggregate and a lubricant to the mix. In fact, mixes with 5, 10, 15, and 20% SA content prove to provide slightly better flow values than the conventional 5% bitumen content. This means that SA, which has filler properties, may improve mix fluidity at a lower content of bitumen. But this influence reduces as the bitumen content rises and the flow values of all the mixes are generally approached. The flow behavior of asphalt mixes has therefore been established with varying bitumen contents and SA contents in this analysis.

(a) Flow value and (b) Marshall stability.

In Figure 10(b), the graph relates MS values measured in kg to various percentages of bitumen, namely, 4.0, 4.5, 5.0, 5.5, and 6.0% of the mix as well as to the mix proportion of SA. The conventional mix presents the lowest stability value ranging from 700 to 840 kg at 5.5% bitumen. As the percentage of SA increases, the stability values tend to increase with small fluctuations (5%, 10%, 15%, and 20%). The blend with 15% of SA shows the highest density is 997 kg and consumed at 5.5% of the bitumen content. All mixtures have facilities in this aspect as they follow a trend similar to each other where stability rises with an increase in bitumen content and reaches its optimum at 5.5% bitumen, though at the top level of 6.0% bitumen, the value declines. For the 10% SA, the slump is between 750 and 920 kg while for the 15% SA mix and 20% SA mix, the slump is slightly higher than the normal mix but not as high as that of 15% SA.

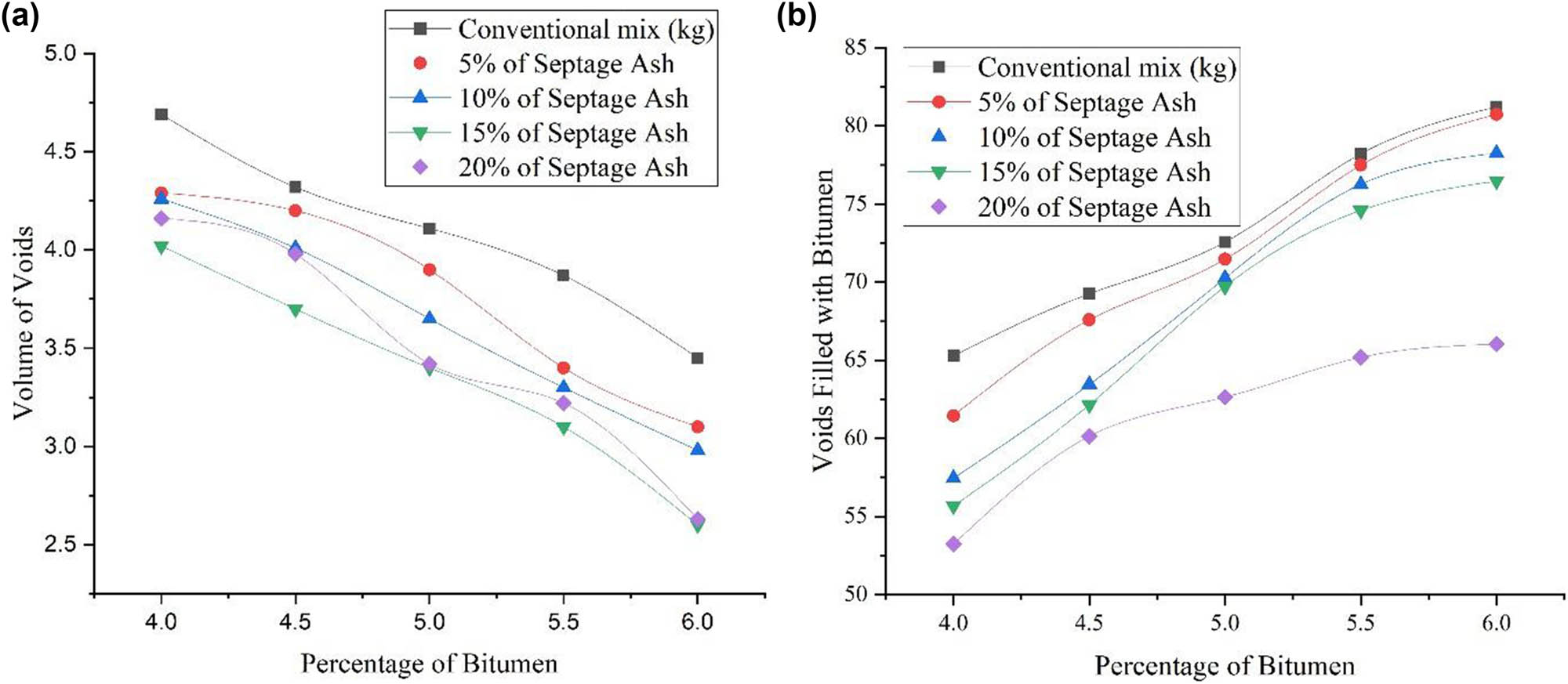

4.2 Effect of SA on volumetric properties

The volumetric mechanical qualities of bitumen concrete mixtures are greatly influenced by their properties’ durability, and performance in real-world applications. Techniques such as specific gravity determination, AV study, mineral aggregate void assessment, and bitumen void-filling void analysis are used to evaluate these characteristics and can calculated using Eqs. (1)–(3). The volumetric parameters are shown in Figure 11.

(a) Volume of voids/air voids and (b) voids filled with bitumen.

Figure 11(a) shows the percentage of bitumen on the volume of voids/AV with the SA substitution level in an ascending scale: 0, 5, 10, 15, and 20%. The outcomes further confirm that there is increased reduction in the voids as the quantity of bitumen as well as SA is increased. For the conventional mix, when SA content is 0%, voids reduce from 4.5% at 4% of bitumen to 3.0% at 6% of bitumen, making a gradual compacting curve of the material. At 5% SA, the voids decrease from 4.4 to 2.9%, which shows slightly better condition than conventional concrete mix. Similarly, voids decrease from 10% SA to 8% with 15% substitution, and 6% with 20% substitution and with 6% bitumen, 2.7 and 2.6% were obtained, respectively. This trend indicates that SA improves the compactness of the mix.

In Figure 11(b), the graph depicts the interaction between the percentage of bitumen and, the VFB based on the SA replacement of the following: 0, 5, 10, 15, and 20%. The traditional blend (0% SA) results in VFB accumulation of about 70% at 4% of bitumen, rising to 80% at 6% of the same; a clear implication that improved bitumen filling is obtained with higher content. Starting at 5% SA, the VFB is at approximately 68% for 4% bitumen and rises to 78% for 6% bitumen and exhibits a trend somewhat lower than that of the VFA. The 10% SA mix has the following VFB: 66% at 4% bitumen, up to 77% at 6% bitumen, showing only a slightly poorer filling efficiency. However, while it rises to both 15% and 20% ash content, the VFB reduced greatly. For 20% ash, it is 55% at 4% bitumen and rises to only 65% at 6% bitumen, implying diminished bitumen contact and bonding capacity at higher ash content.

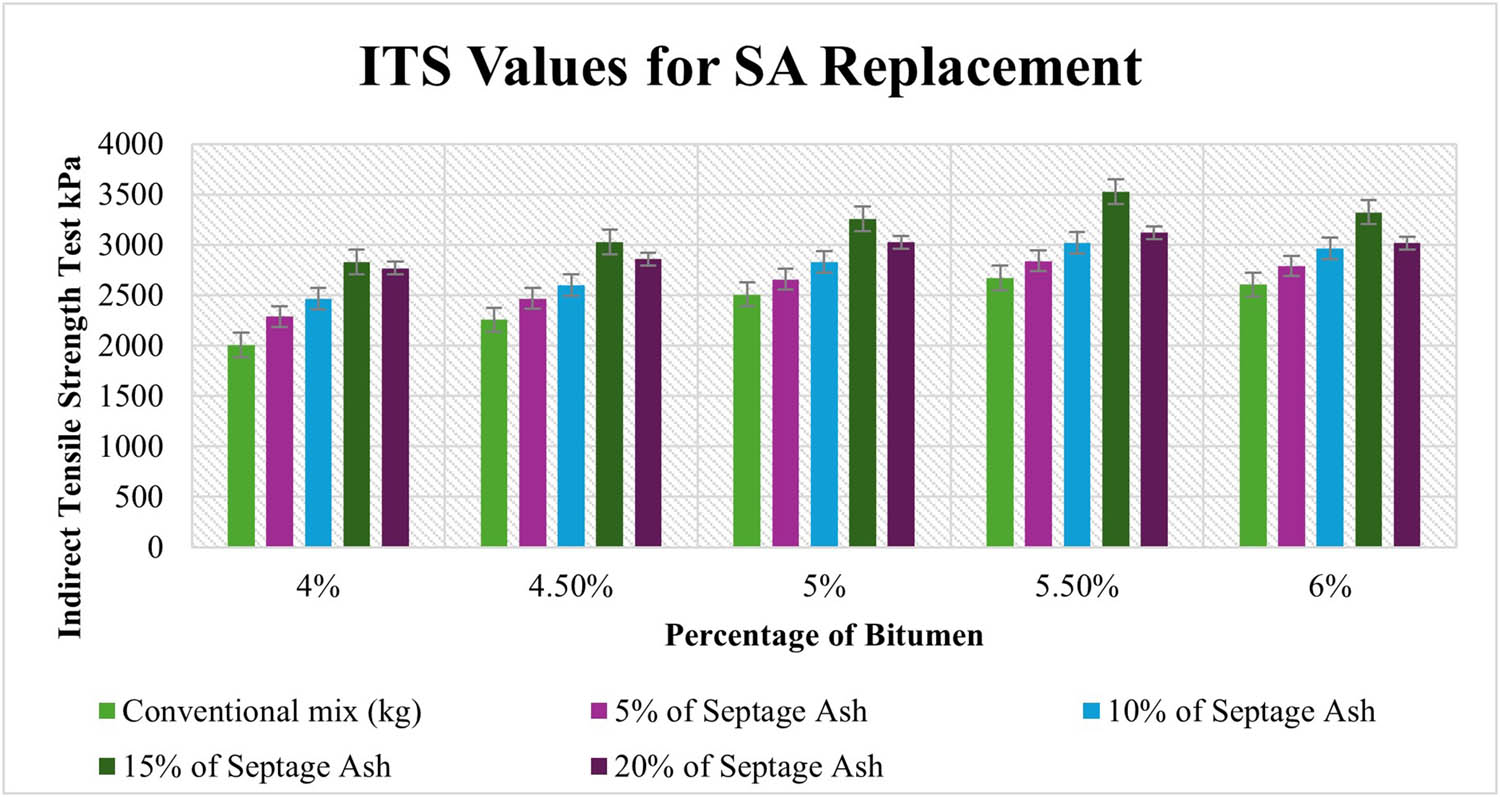

Figure 12 represents the ITS with different asphalt content (4–6%) and different replacement of SA 0, 5, 10, 15, and 20%. ITS values for the base mix (0% SA) ranges from approximately 2,200 kPa at 4% by bitumen up to about 3,500 kPa at 5.5% by bitumen and slightly decreases at 6%. For 5% SA, the ITS values are a little higher, starting from 2,300 kPa at 4% bitumen to a maximum of 3,600 kPa at 5.5% bitumen and a minimum of 3,400 kPa at 6%. The average ITS values increases up to the 5.5% bitumen and then slightly reduces, the value lies around 2,100 at 4% SA mix and 3,500 KPa at 5.5%. However, ITS values decrease with an increase in SA content in the mixes (15 and 20%). When 20% SA is specified, the ITS values reduce drastically, starting at 1,800 kPa at 4% of bitumen and jumping to 3,000 KPA at 5.5% of the bitumen. This trend suggests that about 5–10% replacement SA improves ITS while excessive SA (15–20%) compromises the tensile strength because of poor interfacial adhesion and poor aggregate bitumen interaction.

Indirect tensile strength values.

4.3 Effect of SA on hardness

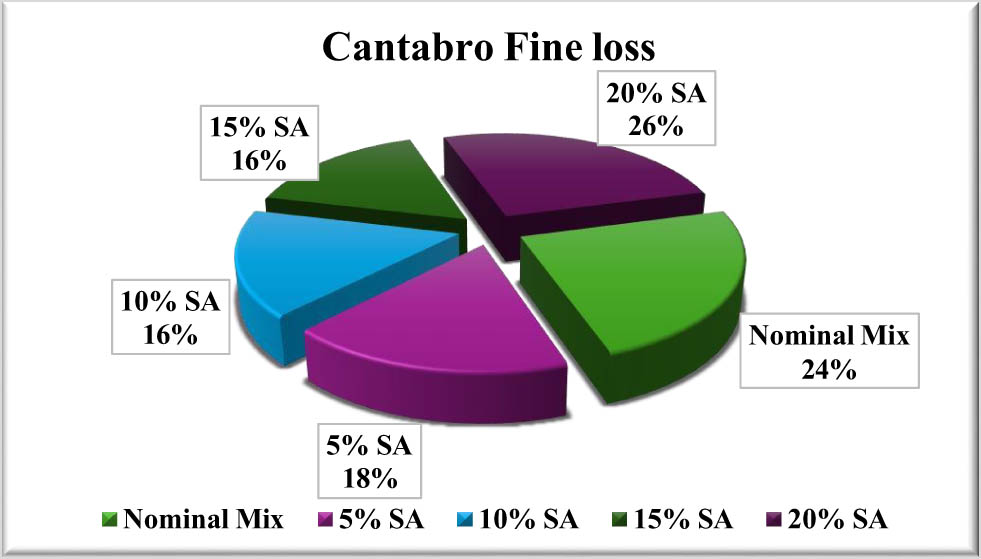

Hardness refers to the ability of a substance to withstand the frictional forces generated by vehicle motion. The Cantabro test measures the hardness, and the fine loss percentage is calculated using different ratios of SA loss, based on the interlock and stiffness characteristics of the nominal mix.

The Cantabro fine loss test results are presented in the form of a pie chart in order to show the proportion of fine particles lost for various kinds of asphalt mix formulations. The result revealed that the nominal mix had the highest percentage of fine loss at 24%, which implies that this mix is more prone to loss of fine materials. This is accompanied by the 20% Stone Mastic Asphalt (SMA) mix with 26% loss indicating that even though SA increases the content of mix stability a particular formulation of this mix has registered more loss of fines. However, the 15 and 10% SA mixes demonstrated a significantly improved fine loss of 16%. This may mean that the intermediate SA percentages offered by the mixes above might have offered the right balance between stability and resistance to fine loss than the nominal mix and the 20% SA mix. The 5% SA mix on the other hand recorded a fine loss of 18%, which was slightly higher than the 15 and 10% SA mixes. These results demonstrate how fine loss works in concrete with varying factors to affect fine aggregates in asphalt mixes. The distribution of SA is another important figure, though other factors such as aggregate gradations, amount of binder and level of compaction also have an impact. Knowledge of these interactions is a powerful tool to create and produce high-strength and long-service asphalt pavements that can cope with traffic and climate loads as shown in Figure 13.

Cantabro fine loss.

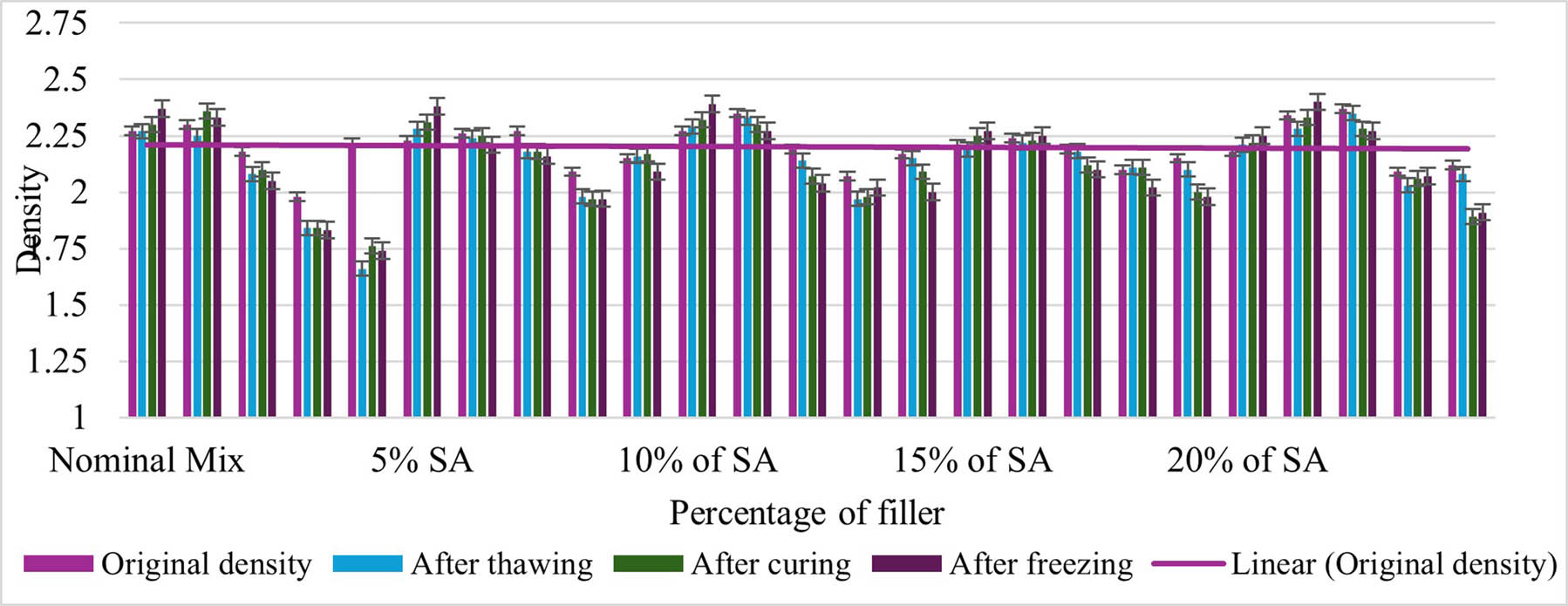

4.4 Test results of volumetrical changes in F&T test

The density fluctuations for each cycle are determined in Figure 14. Before transitioning to subsequent cycles, density calculations were used to assess volumetric changes. Figure 14 shows the density variations after F&T tests for SA mixes. According to Figure 14, the density fluctuations were greater in the nominal mix. The density variations were compared with the original sample. The volume and density of the bitumen decreased by 5.5% when 15% SA was added, mostly because the voids were filled with ash, resulting in increased compatibility. According to ASTM C666/C666-M, each sample was soaked in water at a temperature of 23 ± 2°C (room temperature) for 48 h after the curing time and before the F&T cycles. The F&T cycles commenced after the conditioning phase. The freezing phase was adjusted to achieve a temperature of −18 ± 2°C and lasted for 3 h (180 min). This was then followed by the thawing phase, which was conducted in cold water to reach a temperature of +4 ± 2°C and lasted for 1.5 h (90 min).

Density variations after freezing and thawing test for SA mixes.

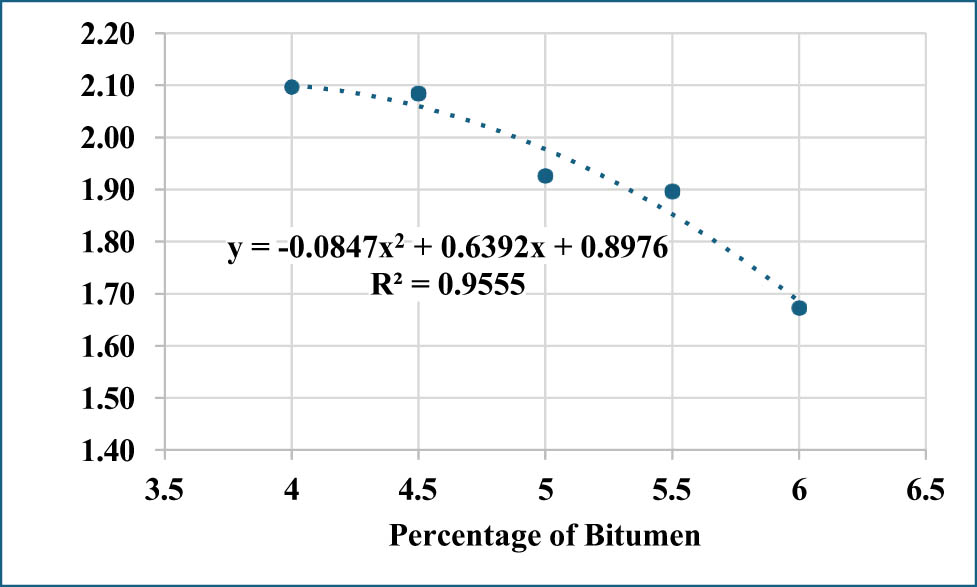

4.5 Test results on MQ

MS quotient value is the ratio of the stability to the flow value, which quantifies the load-bearing capacity and deformation per unit loading and represents the strength value of the mix. The results show a higher strength than that of the original mix, as shown in Figure 15.

Marshall stability.

4.6 Effects of SA on moisture sensitivity

The moisture sensitivity impact was determined by calculating the ratios of the RMS and TSR of the conditioned and unconditioned samples while altering the proportion of bitumen. Figure 16 illustrates the correlation between the RMS and the TSR. Enhancements were made to the mechanical and durability characteristics. Figure 16 demonstrates that the presence of extra particles hindered the entry of moisture into the mix, hence diminishing the strength and impact of moisture. According to the results, bitumen mixtures containing up to 15% SA exhibit improved resistance to moisture-induced deterioration, suggesting that this material may increase pavement longevity in damp environments [37,38,41–43].

Retained Marshall stability and tensile strength ratio.

5 Validation of Anova test results for different test results

Single-factor ANOVA (Analysis of Variance) is a statistical technique used to compare the means of three or more groups based on a single independent variable. It determines whether significant differences exist between group means, assuming normal distribution and homogeneity of variance.

The primary objective of the single-factor ANOVA in Table 6 was to assess the impact of the filler SA and nominal mix with bitumen concentration (B) on the properties of the mixes. The significance level was set at p < 0.05. Statistical analysis showed that the type of filler and the amount of bitumen have an impact on various properties of the bitumen mixture, including the MS, flow value, ITS, and Cantabro test, and volumetric parameters such as volume of voids and voids filled with bitumen, RMS, and moisture sensitivity. The findings suggest that an F-crit value larger than 1 validates the practical importance of these findings. The results of this test showed that the interaction between the two independent variables (A × B, filler type, and bitumen concentration) had a significant effect (p < 0.05) on all the dependent variables. The above F crit (0.05 < specific value) values of all results mention the adhesion between the filler SA and other ingredients in the mix shown in Figure 7(c). Considering this, according to the data of the single-factor ANOVA statistical analysis, the result values are p < 0.05 with the exception of moisture susceptibility and the other elements meet the conditions for being a filler to the bitumen mix.

Single-factor ANOVA results for normal and SA replaced mix

| Test | Source of variation | SS | df | MS | F | P-value | F crit |

|---|---|---|---|---|---|---|---|

| Retained Marshall stability | Between groups | 16234612.7 | 2 | 8,117,306 | 757.3071 | 9.36 × 10−11 | 4.256495 |

| Within groups | 96467.808 | 9 | 10718.65 | ||||

| Total | 16331080.5 | 11 | |||||

| Marshall stability | Between groups | 3022801.71 | 5 | 604560.3 | 185.9347 | 2.26 × 10−18 | 2.620654 |

| Within groups | 78035.1862 | 24 | 3251.466 | ||||

| Total | 3100836.9 | 29 | |||||

| ITS Test | Between groups | 1410074.72 | 4 | 352518.7 | 11.78087 | 0.000157 | 3.055568 |

| Within groups | 448844.737 | 15 | 29922.98 | ||||

| Total | 1858919.46 | 19 | |||||

| Cantabro test results | Between groups | 276.292136 | 4 | 69.07303 | 3.389378 | 0.036459 | 3.055568 |

| Within groups | 305.688967 | 15 | 20.37926 | ||||

| Total | 581.981103 | 19 | |||||

| Moisture sensitivity | Between groups | 0.04205 | 1 | 0.04205 | 0.006109 | 0.940244 | 5.987378 |

| Within groups | 41.30235 | 6 | 6.883725 | ||||

| Total | 41.3444 | 7 | |||||

| Flow value | Between groups | 50.973 | 4 | 12.74325 | 4.497089 | 0.013793 | 3.055568 |

| Within groups | 42.505 | 15 | 2.833667 | ||||

| Total | 93.478 | 19 | |||||

| VFB | Between groups | 385.86945 | 4 | 96.46736 | 2.742651 | 0.067923 | 3.055568 |

| Within groups | 527.59555 | 15 | 35.17304 | ||||

| Total | 913.465 | 19 | |||||

| The volume of voids Vv | Between groups | 1.35137 | 4 | 0.337843 | 1.520968 | 0.246216 | 3.055568 |

| Within groups | 3.33185 | 15 | 0.222123 | ||||

| Total | 4.68322 | 19 |

SS–Sum of squares; df–degrees of freedom; MS–mean square; F–F-ratio; P-value–probability value; F crit–critical F-value.

6 Conclusion

Within the scope of this research, the qualities of bitumen mix Grade 2 prepared with SA and normal fillers typically used in pavement manufacturing were investigated. The main findings are summarized as follows:

Suitability of SA as filler: SA demonstrated properties comparable to conventional fillers such as fly ash, cement, and brick powder, making it a viable partial substitute in bitumen mixtures.

Optimal replacement ratio: The study identified that a 15% replacement of traditional filler with SA yielded the best mechanical and performance characteristics, enhancing the overall quality of the bitumen pavement.

Improved mechanical properties: Incorporating SA increased the strength of the bitumen mix by 32% and reduced fine loss by 23%, indicating enhanced durability and resistance to deformation.

Enhanced moisture resistance: Bitumen mixtures with up to 15% SA showed improved resistance to moisture-induced damage, suggesting better performance in wet environments.

Reduced volumetric changes: The addition of SA minimized density fluctuations during F&T cycles, indicating better stability under environmental stress.

Sustainable waste management: Utilizing SA as a filler aligns with sustainable practices by repurposing waste material, reducing landfill usage, and lowering the environmental impact of road construction.

Cost-effective solution: The use of SA offers potential cost savings in road construction by reducing the reliance on virgin materials and improving pavement longevity.

The study findings indicate that SA possesses qualities that qualify it as a suitable filler material for Grade 2 mixes.

7 Recommendations/future scope

Subsequent research should prioritize an extended assessment of the effectiveness of bitumen mixtures containing SA in real-world scenarios. Furthermore, it is crucial to evaluate the ecological consequences of using SA for road construction to guarantee long-term viability.

-

Funding information: Authors state no funding involved.

-

Author contributions: Neduri Prabhanjan contributed to the design and implementation of the research, the analysis of the results, and the writing of the manuscript. Dr. K. Rajesh Kumar conceived the original concept and supervised the project. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: The datasets generated during and/or analyzed during the current study are available from the corresponding author upon reasonable request.

References

[1] Abbas FA, Alhamdo MH. Enhancing the thermal conductivity of hot-mix asphalt. Results Eng. 2023;17:100827. 10.1016/j.rineng.2022.100827.Search in Google Scholar

[2] Aljassar AH, Metwali S, Ali MA. Effect of filler types on Marshall stability and retained strength of asphalt concrete. Int J Pavement Eng. 2004;5(1):47–51. 10.1080/10298430410001733491.Search in Google Scholar

[3] Arabani M, Tahami SA, Taghipoor M. Laboratory investigation of hot mix asphalt containing waste materials. Road Mater Pavement Des. 2017;18(3):713–29. 10.1080/14680629.2016.1189349.Search in Google Scholar

[4] ASTM. Standard test method for flash and fire points by cleveland open cup tester. Annu Book ASTM Stand. 2007;1:1–10.Search in Google Scholar

[5] ASTM D3549/D3549M-16. Standard test method for thickness or height of compacted bituminous paving mixture specimens. ASTM International, West Conshohocken, PA. Vol. 4, 2016. 10.1520/D3549_D3549M-16.Search in Google Scholar

[6] ASTM D6927-15. Standard test method for Marshall stability and flow of asphalt mixtures. ASTM International, West Conshohocken, PA. 2015. 10.1520/D6927-15.Search in Google Scholar

[7] Cao L, Li L, Yang H, Zhou T, Dong Z. Gradation design and performance evaluation of modified asphalt mixture for bridge asphalt plug joint design. Constr Build Mater. 2023;367:130211. 10.1016/j.conbuildmat.2022.130211.Search in Google Scholar

[8] Chen MZ, Lin JT, Wu SP, Liu CH. Utilization of recycled brick powder as alternative filler in asphalt mixture. Constr Build Mater. 2011;25(4):1532–6. 10.1016/j.conbuildmat.2010.08.005.Search in Google Scholar

[9] Colbert B, You Z. The properties of asphalt binder blended with variable quantities of recycled asphalt using short term and long term aging simulations. Constr Build Mater. 2012;26(1):552–7. 10.1016/j.conbuildmat.2011.06.057.Search in Google Scholar

[10] Dhiman A. Role of filler in the enhancement of properties of bituminous mixes: A review. Int J Res Appl Sci Eng Technol. 2017;5(8):1150–5. 10.22214/ijraset.2017.8162.Search in Google Scholar

[11] ASTM D3203/D32203M-17. Standard test method for percent air voids in compacted dense and open bituminous paving mixtures. ASTM International, West Conshohocken, PA. Vol. 4, 2017. 10.1520/D3203.Search in Google Scholar

[12] ASTM D36/D36M-14. Standard test method for softening point of bitumen (ring-and-ball apparatus). ASTM International, West Conshohocken, PA. Vol. 4, 2014. 10.1520/D0036_D0036M-14.Search in Google Scholar

[13] Hossain A. Influence of fly ash as mineral filler in bituminous mix design. Trends Civ Eng Archit. 2018;3(1):1–10. 10.32474/tceia.2018.03.000156.Search in Google Scholar

[14] Hossain MU, Ng ST, Dong Y, Amor B. Strategies for mitigating plastic wastes management problem: A lifecycle assessment study in Hong Kong. Waste Manag. 2021;131:412–22. 10.1016/j.wasman.2021.06.030.Search in Google Scholar PubMed

[15] Huang Y, Bird RN, Heidrich O. A review of the use of recycled solid waste materials in asphalt pavements. Resour Conserv Recycl. 2007;52(1):58–73. 10.1016/j.resconrec.2007.02.002.Search in Google Scholar

[16] Alnealy KT. Effect of using waste material as filler in bituminous mix design. Am J Civ Eng. 2015;3(3):88. 10.11648/j.ajce.20150303.16.Search in Google Scholar

[17] Khasawneh MA, Sawalha AA, Aljarrah MT, Alsheyab MA. Effect of aggregate gradation and asphalt mix volumetrics on the thermal properties of asphalt concrete. Case Stud Constr Mater. 2023;18:e01725. 10.1016/j.cscm.2022.e01725.Search in Google Scholar

[18] Kuity A, Das A. Homogeneity of filler distribution within asphalt mix – A microscopic study. Constr Build Mater. 2015;95:497–505. 10.1016/j.conbuildmat.2015.07.043.Search in Google Scholar

[19] Kuity A, Jayaprakasan S, Das A. Laboratory investigation on volume proportioning scheme of mineral fillers in asphalt mixture. Constr Build Mater. 2014;68:637–43. 10.1016/j.conbuildmat.2014.07.012.Search in Google Scholar

[20] Mahto SK, Sinha S. Influence of rice husk ash on moisture susceptibility of warm mix asphalt using chemical based ad ditive. Mater Today Proc. 2023;79(3):258–63. 10.1016/j.matpr.2023.06.118.Search in Google Scholar

[21] Kumar V, Coleri E. Effects of finer gradation, temperature, warm mix additives, and compaction methods on density and performance of asphalt mixtures. Constr Build Mater. 2023;394:132226. 10.1016/j.conbuildmat.2023.132226.Search in Google Scholar

[22] Li H, Cui C, Temitope AA, Feng Z, Zhao G, Guo P. Effect of SBS and crumb rubber on asphalt modification: A review of the properties and practical application. J Traffic Transp Eng (English Ed). 2022;9(5):836–63. 10.1016/j.jtte.2022.03.002.Search in Google Scholar

[23] Mistry R, Karmakar S, Roy TK. Experimental evaluation of rice husk ash and fly ash as alternative fillers in hot-mix asphalt. Road Mater Pavement Des. 2019;20(4):979–90. 10.1080/14680629.2017.1422791.Search in Google Scholar

[24] Mohajerani A, Burnett L, Smith JV, Markovski S, Rodwell G, Rahman MT, et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour Conserv Recycl. 2020;155:104679. 10.1016/j.resconrec.2020.104679.Search in Google Scholar

[25] Mohi I, Din U, Marik S. Influence of fillers on paving grade bitumen. Int J Innov Res Sci Eng Technol. 2007;3297:12549–54. 10.15680/IJIRSET.2015.0412167.Search in Google Scholar

[26] Montgomery DC. ASTM D113-99 - Ductility of bituminous materials. Am Assoc State Highw Transp Stand. 1999;113(5):1–3.Search in Google Scholar

[27] Mukhtar N, Hasan MRM, Shariff KA, Van Den Bergh W. Relationship between the physicochemical and electrostatic charge characteristics of filler materials on the morphological and adhesive Pull-Off tensile strength of asphalt mastics. Constr Build Mater. 2022;346:128343. 10.1016/j.conbuildmat.2022.128343.Search in Google Scholar

[28] Neduri P, Sahithi G, Golla SY, Preethi S, Ramya G, Anuhya D. Strength evaluation of glass powder impregnated asphalt mix. Mater Today Proc. 2020;39:771–5. 10.1016/j.matpr.2020.09.506.Search in Google Scholar

[29] Pasandín AR, Pérez I. Overview of bituminous mixtures made with recycled concrete aggregates. Constr Build Mater. 2015;74:151–61. 10.1016/j.conbuildmat.2014.10.035.Search in Google Scholar

[30] Pasandín AR, Pérez I, Ramírez A, Cano MM. Moisture damage resistance of hot-mix asphalt made with paper industry wastes as filler. J Clean Prod. 2016;112:853–62. 10.1016/j.jclepro.2015.06.016.Search in Google Scholar

[31] Prabhanjan N, Golla SY, Sahithi G, Chandu B, Rathore RS, Guruprasad M, et al. The effect of partial replacement of micro silica in asphalt mix. IOP Conf Ser Mater Sci Eng. 2020;981(3):032054. 10.1088/1757-899X/981/3/032054.Search in Google Scholar

[32] Rashed AM, Al-Hadidy AI. Comparative performance of DG mixes and SMA mixes with waste crumb rubber as aggregate replacement. Case Stud Constr Mater. 2023;19:e02615. 10.1016/j.cscm.2023.e02615.Search in Google Scholar

[33] ASTM. Indirect tensile test-ASTM code. ASTM International, West Conshohocken, PA. 10.1520/D7369-11.2.Search in Google Scholar

[34] Selsal Z, Karakas AS, Sayin B. Effect of pavement thickness on stress distribution in asphalt pavements under traffic loads. Case Stud Constr Mater. 2022;16:e01107. 10.1016/j.cscm.2022.e01107.Search in Google Scholar

[35] Slebi-Acevedo CJ, Lastra-González P, Castro-Fresno D, Vega-Zamanillo Á. Experimental evaluation and recyclability potential of asphalt concrete mixtures with polyacrylonitrile fibers. Constr Build Mater. 2022;317:125829. 10.1016/j.conbuildmat.2021.125829.Search in Google Scholar

[36] Sudarsanan N, Kim YR. A critical review of the fatigue life prediction of asphalt mixtures and pavements. J Traffic Transp Eng (English Ed). 2022;9(5):808–35. 10.1016/j.jtte.2022.05.003.Search in Google Scholar

[37] You L, Long Z, You Z, Ge D, Yang X, Xu F, et al. Review of recycling waste plastics in asphalt paving materials. J Traffic Transp Eng (English Ed). 2022;9(5):742–64. 10.1016/j.jtte.2022.07.002.Search in Google Scholar

[38] Zangooeinia P, Moazami D, Bilondi MP, Zaresefat M. Improvement of pavement engineering properties with calcium carbide residue (CCR) as filler in Stone Mastic Asphalt. Results Eng. 2023;20:101501. 10.1016/j.rineng.2023.101501.Search in Google Scholar

[39] Zghair Chfat AH, Yaacob H, Kamaruddin NHM, Al-Saffar ZH, Jaya RP. Effects of nano eggshell powder as a sustainable bio-filler on the physical, rheological, and microstructure properties of bitumen. Results Eng. 2024;22:102061. 10.1016/j.rineng.2024.102061.Search in Google Scholar

[40] Zhao Y, Chen M, Wu S, Zhu Y, Zhou X, Yang C, et al. Feasibility assessment of palmitamide derived from waste edible oil as a warm mix asphalt additive. Constr Build Mater. 2023;401:132972. 10.1016/j.conbuildmat.2023.132972.Search in Google Scholar

[41] Texas DoT. Cantabro loss. TxDoT. 2014;150 mm:3–5.Search in Google Scholar

[42] Wong TLX, Hasan MRM, Peng LC. Recent development, utilization, treatment and performance of solid wastes additives in asphaltic concrete worldwide: A review. J Traffic Transp Eng (English Ed). 2022;9(5):693–724. 10.1016/j.jtte.2022.06.003.Search in Google Scholar

[43] Yilmaz M, Kök BV, Kuloğlu N. Effects of using asphaltite as filler on mechanical properties of hot mix asphalt. Constr Build Mater. 2011;25(11):4279–86. 10.1016/j.conbuildmat.2011.04.072.Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite

Articles in the same Issue

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite