Abstract

The special mechanical properties and cost-effectiveness of cement-based mortar make it a good material to be used in the rehabilitation and maintenance of structures. In such usage, the production of high-strength mortar (HSM) reinforced with fibers is highly required for enhancing the mechanical properties and extending the service life of mortar. Therefore, the study examined the optimal fiber content for a case study of HSM incorporating silica fume and reinforced with mono/hybrid steel and polypropylene fibers (PPFs). Thirteen mixes with different fiber volume fractions of mono/hybrid steel and PPFs were designed in the current study. The impact of the fiber content was evaluated based on flowability, compressive strength, splitting tensile strength, flexural strength, ultrasonic pulse velocity, and water absorption. The results show that both steel and PPFs have a negative effect on the flowability of tested HSM mixes. Regarding the investigation properties of HSM mixes, the results show that incorporating steel fibers improves the properties of HSM, in particular the content of 1.25%, while the addition of PPFs has little effect. It is also noted that in the case of incorporating hybrid fibers into HSM mixes, it is found that the improvement of properties existed for the HSM mix with a hybrid fiber of 1.3% steel fibers and 0.2% PPFs.

1 Introduction

Cement mortar is the most popular material that is used in the construction field due to its special characteristics. It has high strength in compression, good durability, low permeability, and good fire resistance. On the contrary, cement mortar also has some drawbacks, which include low tensile and flexural strengths, low toughness, and weak crack resistance, which, in turn, affects the useful lifespan of cement mortar and requires extensive and adequate maintenance [1]. Therefore, the development of high-strength mortar (HSM) is one of the priorities of the civil engineering community because adequate cement mortar is of high influence to the success of the maintenance process of structures. To this end, different approaches have been implemented to develop HSM; one of these approaches is the incorporation of fibers into the matrix of cement mortar [2,3,4,5]. The efficiency of fibers that are added to the cement-based composite is governed by the fiber volume, the physical characteristics of the matrix and fibers, and the bond strength between them [6]. However, it is well known that silica fume (SF), due to high pozzolanic action, is an inescapable material that is used to partially substitute cement in concrete or mortar. It is a silica-based material, and the implementation of such material in mortar production contributes to densifying the structure of mortar and enhancing the mechanical and durability properties of the resulting mortar [7]. However, SF causes the mortar to have an additional brittle composition. Thus, for the production of mortar, it must take into account not only the strength properties and adequate durability but also the ductility of the resulting mortar. This can be achieved by incorporating fibers into the mortar [8].

The basic applications of cement mortar are as a binder in masonry construction and for plastering of reinforced concrete members and masonry walls. Fiber-reinforced cement mortar is mainly used in reinforced concrete structures for repair and rehabilitation purposes. Furthermore, it has recently applied for masonry wall retrofitting to reduce the risk of out-of-plane behavior during seismic situations [9,10].

According to previous studies, different fiber types were used for reinforcing cement-based composite, such as carbon, steel, glass, polymeric (nylon, polypropylene, polyethylene), and natural (sisal, coir, jute, cellulose, wood). Moreover, fibers have different shapes and sizes, depending on the fiber diameter. Fibers may be classified into micro- and macro-fibers; indeed, micro-fibers are active in controlling microcracks, and macro-fibers are efficient in controlling macroscopic cracks [11].

The wide use of steel fibers in concrete studies indicates that steel is the most commonly used fiber for reinforcing concrete and mortar. Steel fibers have large civil engineering applications such as in airport runways, slope stabilization, factories and hangar floors, field concretes, dam structures, tunnel shotcrete applications, and concrete pipes [12]. However, using steel fibers has several drawbacks, including the high cost in comparison with other fibers, the possibility of corrosion, and its high density that augments the self-weight of the structure. Furthermore, due to the high stiffness of the steel fiber, its incorporation in concrete and mortar has a passive effect on the ductility and, thus, lowers the post-cracking toughness [13].

Nevertheless, polypropylene fiber (PPF) has low density, low price, acceptable tensile strength, low modulus of elasticity, high fracture strain, high alkaline resistance, and ease of production [11,14]. Moreover, due to the low melting point of PPFs, there is a common tendency to use these fibers in concrete to decrease the possibility of spalling under exposure to elevated temperatures [15].

The high strength and high modulus of elasticity of the steel fibers would improve the strength but it cannot enhance ductility. On the other hand, PPFs with low modulus of elasticity have an active effect on crack control, ductility, and toughness because toughness represents the area under the stress–strain curve that increases with ductility [16]. Therefore, the hybridization of non-metallic and metallic fibers could improve both the ductility and strength properties of concrete or mortar and reduce the cost of fibers. Furthermore, the incorporation of hybrid fibers contributes to the control of cracks at various size levels and at different curing ages. Strong fibers arrest macrocracks, whereas flexible fibers control the nucleation and propagation of microcracks. A considerable amount of research has been devoted to the combination of different fibers. Slosarczyk [4] investigated the effect of using hybrid metallic (steel) and non-metallic (polypropylene) fibers on the compressive and flexural strengths of cement mortars. The results showed that flexural and compressive strengths increased by 27 and 5%, respectively, for cement mortar with fiber content (2% steel + 1% polypropylene). Dawood and Ramli [17] studied the mechanical properties of cement mortar incorporating hybrid fibers with a total volume fraction of 2%. They found that mixing fibers (0.25% barchip + 0.25% palm + 1.5% steel) led to important improvement in flexural toughness and strength with percentages of 140, 44, and 9% for flexural, splitting tensile, and compressive strengths, respectively. Koksal et al. [18] investigated the changes in durability and physicomechanical characteristics of mortar due to the addition of hybrid basalt and micro-steel fibers. They detected the highest increase of 62% in compressive strength for a mix with 20% SF and fiber volume percentages of 0.75% steel + 0.3% basalt. Moreover, the maximum increase in flexural strength of 27% was obtained using a mix without SF and with 0.5% steel + 0.9% basalt fibers. However, a maximum reduction in water absorption of 14% resulted in a mixture with 20% SF and 0.75% steel + 0.9% basalt fibers. In another experimental study, Sridhar and Prasad [19] indicated that for an engineered cementitious composite, the addition of hybrid fibers with a volume fraction of 1.5% polyvinyl alcohol + 0.5% steel produced an improvement in compressive strength and flexural strength of 20 and 42%, respectively. Son et al. [5] studied the effect of different combinations of hooked steel and polyvinyl alcohol fibers on the tensile performance of the cementitious composite. They obtained maximum tensile strength and toughness for the combination of fibers at 1.5% steel + 0.5% polyvinyl alcohol.

These studies show a general consent about the favorable effect of hybridization of ferrous and nonferrous fibers on the mechanical properties of cement mortar. However, there is no consent about the better fiber types and the optimal mixing proportions of these types and this leads to a conclusion that each result is limited to its particular case study and cannot be generalized.

The aim of this study is to investigate the optimal fiber content for a new case study of HSM, including SF and reinforced with single/hybrid metallic (steel) and nonmetallic (polypropylene) fibers.

2 Experimental program

In this study, 13 HSM mixes were designed in three test groups reinforced with fibers in addition to the reference mix, and all the tested mixes contained SF. These HSM mixes were developed and tested to evaluate the optimal fiber content with respect to flowability, mechanical properties (compressive, splitting, and flexural strengths), ultrasonic pulse velocity, and water absorption. The first group included six mixes reinforced only with micro-steel fiber (STF) with volume fractions of 0.25, 0.50, 0.75, 1.00, 1.25, and 1.50%, whereas the second group included three mixes reinforced with micro-PPF (PPF) with volume fractions of 0.2, 0.4, and 0.6 %. The third group mixes included three mixes that were reinforced with hybrid fibers of STF and PPF with volume fractions of 1.3% STF and 0.2% PPF, 1.1% STF and 0.4% PPF, and 0.9% STF and 0.6% PPF. For comparison, a reference mix of HSM without fibers was also developed and tested.

2.1 Material properties

As a binder, the ordinary Portland OPC (commercial mark is Al-mass) is the cement type that was utilized in the experiments. The chemical composition (% by weight) of cement is illustrated in Table 1. The chemical testing results of this cement demonstrate its compliance with the requirements of Iraqi Standards IQS [20]. Furthermore, physical testing shows that this cement has a fineness of 340 m2/kg and a relative density of 3.15. Table 1 also displays the characteristics of SF employed in this experimental investigation, complied with ASTM C1240 [21]. Natural sand was used as a fine aggregate in this investigation. The gradation of sand was in accordance with IQS No. 45 [22]. The specific gravity and water absorption of this sand were 2.65 and 0.6%, respectively. To achieve the necessary flowability of fresh mortar, a superplasticizer (SP) agent, commercially known as Visco-Creat 5930-L, in compliance with ASTM C494 [23], was used.

Chemical compounds of OPC and SF with the limitations of specifications

| Component | OPC (%) | IQS/5/2019 (42.5R) | SF (%) | ASTM C1240 |

|---|---|---|---|---|

| CaO | 64.78 | — | 0.81 | — |

| SiO | 22.10 | — | 89.31 |

|

| Al2O3 | 4.78 | — | 0.62 | — |

| Fe2O3 | 3.19 | — | 0.46 | — |

| MgO | 1.76 |

|

— | — |

| SO3 | 2.45 |

|

0.88 | — |

| L.O.I | 1.78 |

|

4.12 |

|

| IR | 0.21 |

|

— | — |

| C3S | 53.57 | — | — | — |

| C2S | 23.01 | — | — | — |

| C3A | 7.28 | — | — | — |

| C4AF | 9.70 | — | — | — |

Figure 1(a) and (b) shows the micro steel fibers (STF) and micro PPFs (PPF) utilized throughout the experimental study, and Table 2 presents the main properties of these fibers as provided by the manufacturing companies. Both fibers have a straight shape and nearly equal average length but with a 6 times higher aspect ratio for the PPFs. Fibers were added to each HSM mix so that they are randomly distributed and oriented within the matrix and, as a result provide load resistance in all directions.

Fibers used in this study: (a) micro steel fibers (STF) and (b) micro PPFs.

Properties of micro steel and PPFs as provided by the manufacturer

| Property | STF | PPF |

|---|---|---|

| Specific gravity | 7.83 | 0.91 |

| Tensile strength | 2,400 MPa | (400–500) MPa |

| Melting point | 1,500°C | 160°C |

| Length | 13 mm | 12 mm |

| Diameter | 0.2 mm | 0.032 mm |

| Aspect ratio (L f/D f) | 65 | 375 |

2.2 Mix proportions of the tested HSM mixes

The current study included the preparation and testing of 13 HSM mixes, and the mix proportions and details of all HSM mixes are illustrated in Table 3. Constant quantities of OPC, SF, fine aggregate, and water were used in all mixes. In contrast, the SP quantity was changed from 1.2 to 1.6 (% by binder weight) so that the flow characteristics of fresh mixes were kept within the desired range. The mix code for each mix denoted the HSM that was reinforced with different volume proportions of STF, PPF, and hybrid fibers; for instance, the code of the mix M1.1STF + 0.4PPF refers to HSM reinforced with hybrid fibers 1.1% STF and 0.4% PPF.

Mix proportions of HSM

| Mix code | Cement kg/m3 | SF kg/m3 | Fine aggregate kg/m3 | Water/binder (w/b) % | SP % | STF % | PPF % | STF + PPF % |

|---|---|---|---|---|---|---|---|---|

| M0 | 700 | 120 | 1,500 | 0.24 | 1.2 | — | — | — |

| M0.25STF | 700 | 120 | 1,500 | 0.24 | 1.2 | 0.25 | — | — |

| M0.50STF | 700 | 120 | 1,500 | 0.24 | 1.2 | 0.50 | — | — |

| M0.75STF | 700 | 120 | 1,500 | 0.24 | 1.2 | 0.75 | — | — |

| M1.00STF | 700 | 120 | 1,500 | 0.24 | 1.3 | 1.00 | — | — |

| M1.25STF | 700 | 120 | 1,500 | 0.24 | 1.3 | 1.25 | — | — |

| M1.50STF | 700 | 120 | 1,500 | 0.24 | 1.3 | 1.50 | — | — |

| M0.2PPF | 700 | 120 | 1,500 | 0.24 | 1.4 | — | 0.20 | — |

| M0.4PPF | 700 | 120 | 1,500 | 0.24 | 1.5 | — | 0.40 | — |

| M0.6PPF | 700 | 120 | 1,500 | 0.24 | 1.5 | — | 0.60 | — |

| M1.3STF + 0.2PPF | 700 | 120 | 1,500 | 0.24 | 1.6 | — | — | 1.3 + 0.2 |

| M1.1STF + 0.4PPF | 700 | 120 | 1,500 | 0.24 | 1.6 | — | — | 1.1 + 0.4 |

| M0.9STF + 0.6PPF | 700 | 120 | 1,500 | 0.24 | 1.6 | — | — | 0.9 + 0.6 |

2.3 Preparing and testing of HSM mixes

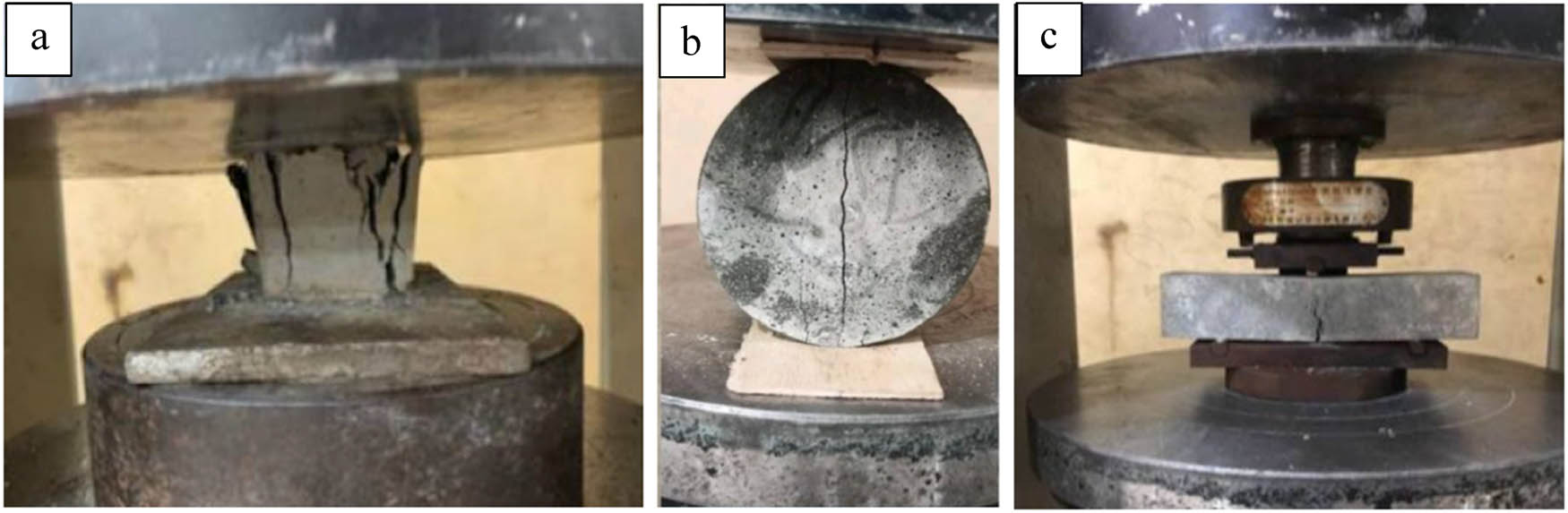

Thirteen HSM mixes were prepared to evaluate the effect of fiber content on the properties of these mixes, and the specimens for each mix were prepared under standard conditions using the standard molds corresponding to each test. After 24 h, the specimens were demolded and immersed in a water tank until the testing time. In order to compare the various characteristics of the tested mortar mixes, several tests were implemented in the present study. Regarding the mortar in the fresh state, a flowability test was performed, and the test protocol was carried out in compliance with ASTM C1437 [24]. The flow diameter of each sample was measured as the average of two perpendicular diameters. In fact, the quantity of the superplasticizer given in Table 3 was selected to maintain the flow diameter within the interval of 200 ± 10 mm for all mixes. With respect to the hardened state of mortar, the mechanical strength tests (compressive strength, splitting tensile strength, and flexural strength) were carried out. In addition, ultrasonic pulse velocity and water absorption tests were also implemented. For each HSM mix, cubes of 50 mm were cast and tested for compressive strength at ages 28 and 56 days. The test procedure was done in accordance with ASTMC109/109 M [25]. Concerning the tensile resistance, the splitting tensile test was conducted on a (100 × 200) mm cylinder at the ages of 28 and 56 days, and the test was done according to the procedure outlined in ASTM C496 [26]. The flexural strength test was measured on (50 × 50 × 300) mm prisms at ages 28 and 56 days, and this test followed the procedure outlined in ASTM C78/C78M [27]. Figure 2 shows some samples at failure under compression, tensile splitting, and flexural stresses applied by the appropriate testing setup.

Samples at failure: (a) compressive test, (b) splitting tensile test, and (c) flexural test.

To measure the propagation velocity of longitudinal stress waves through mortar, the nondestructive ultrasonic pulse velocity test was implemented on mortar cubes of 100 mm sides, following the test procedure outlined in ASTM C597 [28]. Similar to the strength tests, the tests of ultrasonic pulse velocity were performed at the ages of 28 and 56 days.

As one of the durability tests, a water absorption test was carried out in accordance with ASTM C642 [29] on the mortar samples aged 28 days in order to measure the pore space volume of the mortar.

For accuracy and to account for within-test variability (repeatability), each test result is shown in the Results and Discussion section) as the average value of three measured results that were obtained from repeating the test on three samples.

3 Results and discussion

3.1 Flowability

The flowability test was done for the tested HSM mixes in the fresh state, and the results of the flowability test are summarized in Table 4. It is clear that the incorporation of STF in the HSM mixes decreases the flowability; therefore, the dosage of SP was increased to attain the desired flowability. Furthermore, the impact of PPF on the flowability of HSM was more pronounced than the effect of STF. These findings are in consent with the common idea that the existence of fibers in HSM obstructs the free flow of HSM [30]. A possible explanation for the reduction in the flowability values could be attributed to the increase in the cohesion of fresh mortar due to the addition of fibers. Besides, the negative impact on the flowability is due to the formation of clumps of fibers in the mortar matrix [31].

Results of the flowability test

| Mix code | M0 | M0.25STF | M0.50STF | M0.75STF | M1.00STF | M1.25STF | M1.50STF | M0.2PPF | M0.4PPF | M0.6PPF | M1.3STF + 0.2PPF | M1.1STF + 0.4PPF | M0.9STF + 0.6PPF |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Flow mm | 210 | 210 | 200 | 195 | 195 | 190 | 185 | 200 | 200 | 190 | 205 | 195 | 190 |

3.2 Compressive strength

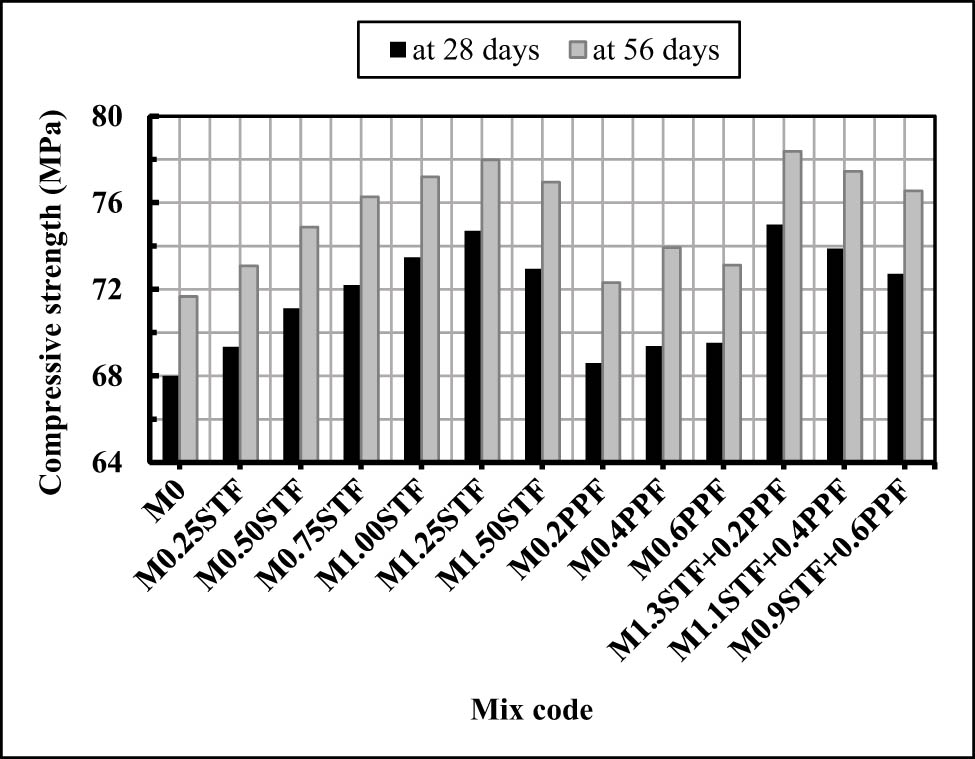

Compressive strength is the most important property of concrete and mortar; it is then used to quantify the quality and strength of concrete. Figure 3 depicts the compressive strength at 28 and 56 days of the tested HSM mixes of the present work. It can be generally noticed that for all tested HSM mixes, the development of compressive strength increased with the age of the tested specimens. At ages 28 and 56 days, compared to the compressive strength of reference mix M0, the HSM mixes reinforced with STF, PPF, and hybrid fibers showed an increase in compressive strength. This can be attributed to the pozzolanic characteristics of SF and to the capability of adopted fibers to restrain the widening and delay the rate of growth of cracks and to decrease the concentration of stress at the tip of cracks [31,32]. Besides, the compressive strength of mixes reinforced with different fibers increases as the volume fractions of fiber increase, excluding the M1.50STF mix, M1.1STF + 0.4PPF, and M0.9STF + 0.6PPF mixes, where the compressive strength decreased in comparison to M1.25STF and M1.3STF + 0.2PPF. The reason behind this behavior of such mixes is because of the ball’s phenomenon of utilized fibers. On the other hand, it can be seen from Figure 3 that the values of the compressive strength for HSM reinforced with PPF fibers were higher than that of the M0 mix but were lower than that of the HSM mixes reinforced with STF and hybrid STF with PPF. This can be attributed to the weak interfacial adhesion between PPF fibers and the matrix of HSM mixes. Additionally, it is also observed from Figure 3 that among all the tested mixes, the M1.25STF mix and M1.3STF + 0.2PPF mix showed the highest values of compressive strength. For instance, the compressive strength values at 28 and 56 days for the M1.25STF mix and M1.3STF + 0.2PPF mix were increased by 9.9, 8.8% and 10.3, 9.1%, respectively, in comparison to the M0 mix.

Compressive strength (MPa) at ages 28 and 56 days for the tested HSM mixes.

In fact, the close results of the mix M1.3STF + 0.2PPF and the mix M1.25STF are consistent with the objective of the present study in which we are looking for the optimum hybridization of nonmetallic fibers with the metallic one in order to gain the positive characteristics of nonmetallic fibers without deteriorating the compressive strength.

3.3 Splitting tensile strength

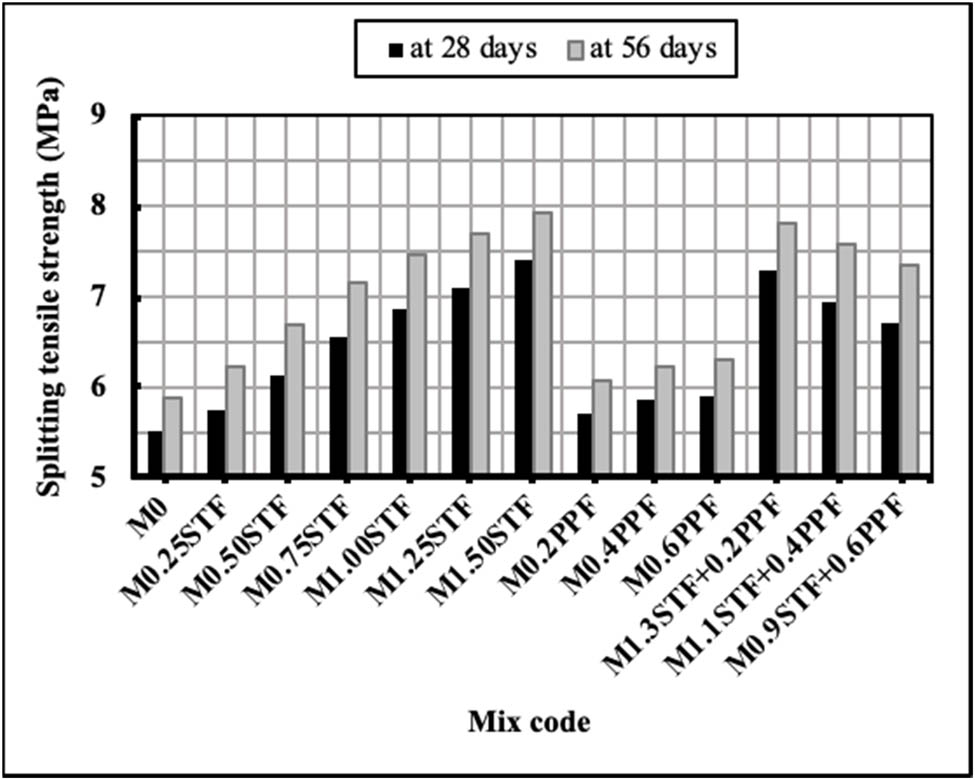

The values of splitting tensile strength of all HSM mixes are presented in Figure 4. A similar trend to the compressive strength was observed for the splitting tensile strength results at ages 28 and 56 days; however, the increase in the splitting tensile strength compared to that of reference mix M0 for the studied mixes is more than that for the compressive strength. This is because the inclusion of fiber into the brittle matrix of mortar leads to a lowering in the width of cracks and a sequential improvement in the splitting tensile strength [32,33]. From this figure, it can be seen that the splitting tensile strength increases as the volume fractions of fibers increase, excluding the hybrid mixes M1.1STF + 0.4PPF and M0.9STF + 0.6PPF, where the splitting strength values decreased in comparison to M1.3STF + 0.2PPF. Compared to the M0 mix, the HSM mixes reinforced with PPF fibers exhibited higher values of splitting tensile strength at the ages of 28 and 56 days, but these mixes showed lower values than that of the HSM mixes that were reinforced with STF or hybrid STF with PPF. Also, it can be seen that the M1.50STF and M1.3STF + 0.2PPF showed the highest increase in splitting tensile strength values by 34, 35% and 32, 33% at 28 and 56 days, respectively, in comparison to the splitting tensile strength of M0.

Splitting tensile strength (MPa) at ages 28 and 56 days for the tested HSM mixes.

As shown in Figure 4, the results of the mix M1.3STF + 0.2PPF and mix M1.5STF are very close. In fact, this is good news since the cost and weight of the steel fibers are higher than that of PPFs; consequently, using the optimal hybridization of fibers can lead to a more economical mix with close strengths (compared with mixes reinforced with steel fibers only) and low costs.

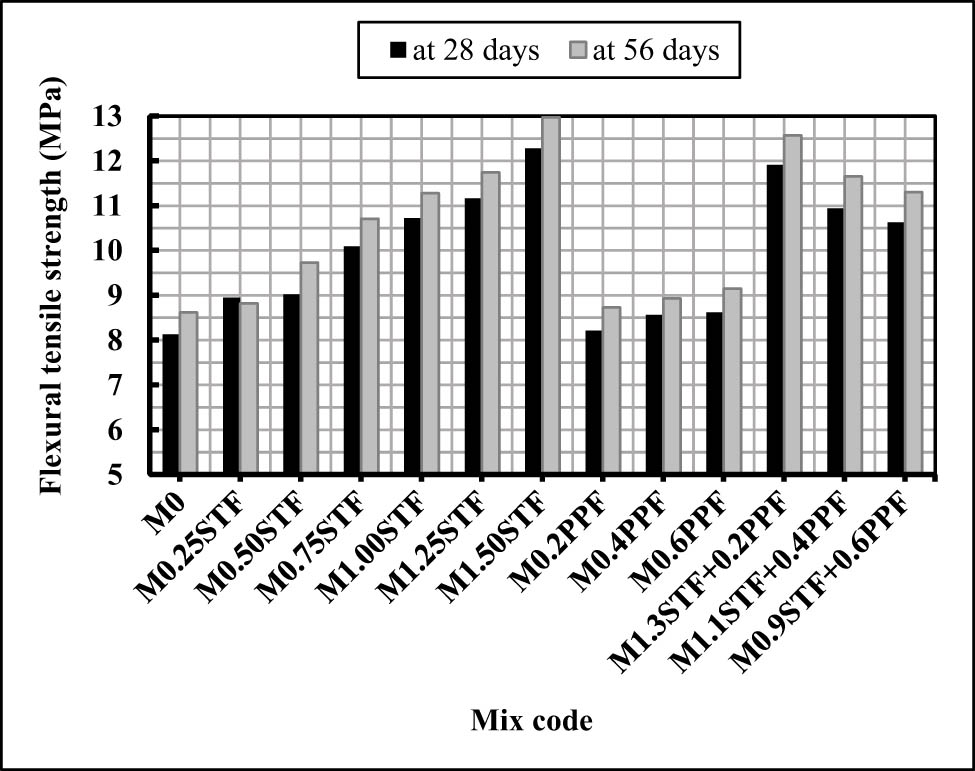

3.4 Flexural strength

Like the splitting tensile strength, as shown in Figure 5, the use of STF in the HSM mixes leads to an important improvement in the flexural strength. As shown in Figure 5, the flexural strength of HSM incorporated with STF was up to 51% higher than that of the reference mix M0. In contrast, HSM mixes reinforced with PPF showed a slight enhancement in the flexural strength in comparison to the flexural strength of the M0 mix. As can be seen, the increment compared to the M0 mix in the flexural strength of PPF-reinforced HSM mixes ranges from 1 to 6.1%, depending on the fiber percentage and testing age. This can be attributed to the fact that PPF has a lower elastic modulus and tensile strength compared to those of STF. Therefore, they only bridged on microcracks and did not have a chief influence on the flexural strength [33]. The results shown in Figure 5 further reveal the benefit of hybridization, which among the hybrid fibers-reinforced HSM, the increment in the flexural strength of the M1.3STF + 0.2PPF mix was 47% (i.e., only 4% less than that of the M1.50STF mix and 10% better than the M1.250STF mix). Consequently, hybridization of fibers has a positive impact on the reduction of cost.

Flexural strength (MPa) at ages 28 and 56 days for the tested HSM mixes.

As shown in Figure 5, the results of the mix M1.3STF + 0.2PPF and mix M1.5STF are very close. Actually, this result agrees with the aim of the present study that the hybrid fiber composite has the benefits of nonmetallic fibers without a significant loss in strength.

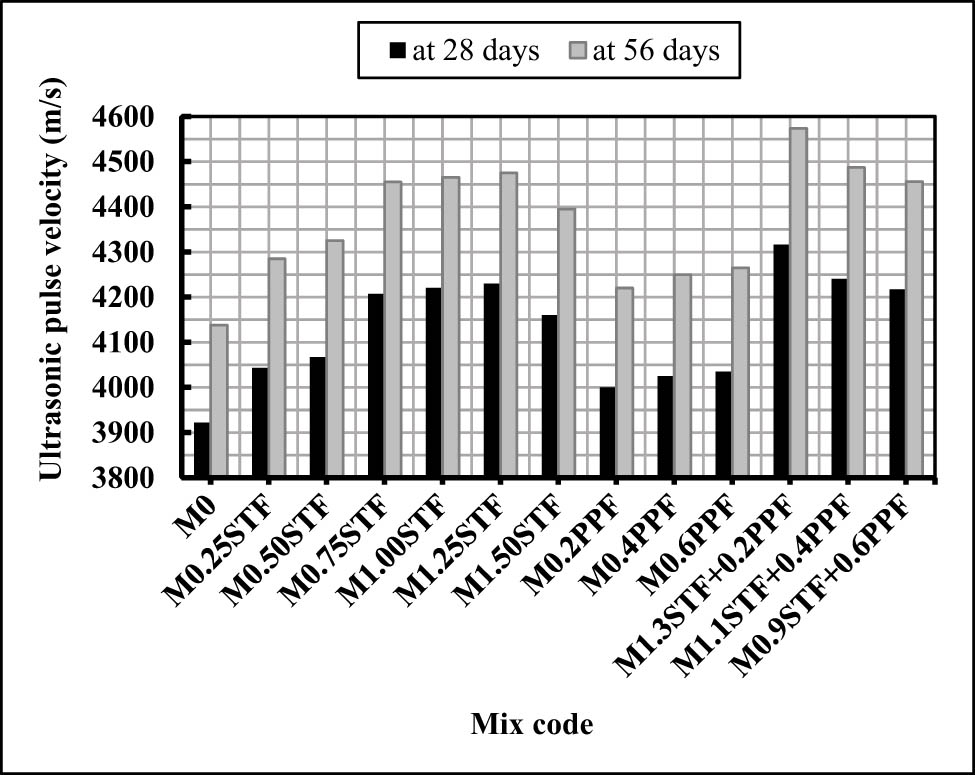

3.5 Ultrasonic pulse velocity

Ultrasonic pulse velocity test is commonly applied for in situ evaluation of compressive strength and homogeneity of concrete and mortar in the existing structures. Therefore, investigating the effect of fibers on this evaluation is valuable. Figure 6 shows the results of ultrasonic pulse velocity UPV for the tested HSM mixes at ages of 28 and 56 days. These results reveal the enhancement in the ultrasonic pulse velocity values when the STF is present. The inclusion of 1.5% of these fibers in the HSM mix augments the magnitude of ultrasonic pulse velocity from 3,922 to 4,160 m/s at 28 days. Utilizing 1.25% by volume of STF allowed for the greatest ultrasonic pulse velocity value of 4,230 m/s at 28 days. In fact, the inclusion of STF yields a considerable compressive strength due to the enhancement in the mechanical bond strength within the mortar matrix [34]. However, the inclusion of PPF causes a small increase in the UPV as the percentage of PPF fibers increases.

Ultrasonic pulse velocity at ages 28 and 56 days for the tested HSM mixes.

Alternatively, the findings for hybrid fiber mixes reveal a better increase in ultrasonic velocity values with fiber inclusions. The mortar mix M1.3SF + 0.2PPF provides the highest UPV magnitude of 4,316 m/s, which was attained at 28 days of age.

In fact, the results for UPV shown in Figure 6 are consistent with the findings of compressive strength shown in Figure 3 because both figures exhibit the same trend with a maximum improvement of 10% obtained for the mix M1.3SF + 0.2PPF. This confirms that UPV is relevant to the compressive strength capacity of HSM.

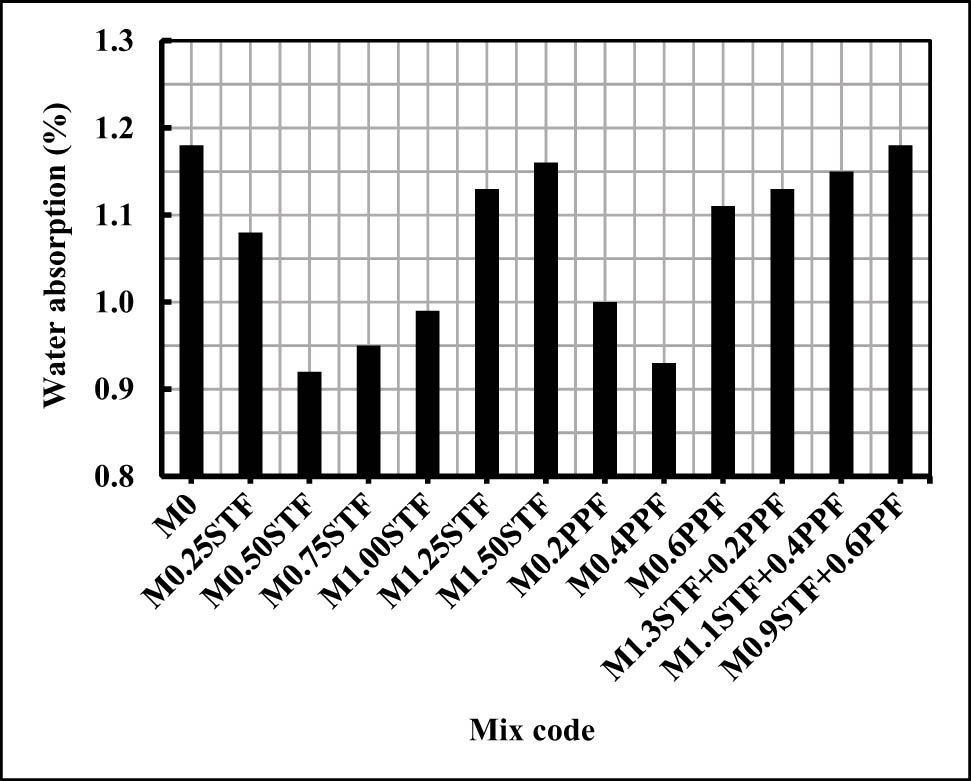

3.6 Water absorption

Water absorption is the principal property of the durability of mortar, which is a measure of pore volume and permeability of mortar. In this study, the water absorption test was adopted as an index for the porosity of the tested HSM. Moreover, it provides useful information about the permeable pore volume inside HSM and the interconnectivity of these pores. The 28-day water absorption percentage of various HSM mixes of the current study is summarized in Figure 7. It shows that the inclusion of steel fibers reduces water absorption. For example, the M0.50STF mix attained the lowest water absorption among all other mixes reinforced with STF. The results of micro PPF-reinforced HSM mixes show a behavior similar to that of HSM reinforced by micro steel fibers, and the addition of these fibers causes a reduction in water absorption. This is due to the role of the micro-fiber in blocking the continuous pores within HSM, thereby decreasing the susceptibility of water absorption [35]. Regarding using the hybrid fibers in HSM mixes, the mix 1.3STF + 0.2PPF has the best performance among the other hybrid mixes. It was noticed that increasing the micro-PPFs percentage to 0.6 in hybrid fiber-reinforced resulted in higher absorption. The observation of the current study indicates that the incorporation of a higher percentage of micro-PPFs in hybrid fiber-reinforced HSM increases the thickness and porosity of the transition zone, which, in turn, increases water absorption.

Water absorption (%) at the age of 28 days for the tested HSM mixes.

4 Conclusions

The present work aims to study the effect of mono-fibers and hybrid fibers (steel and polypropylene) on several strength and durability characteristics of high-strength cement mortar (HSM) with SF. The main findings of this case study were the following:

The compressive strength of HSM at the age of 28 days increases with the increase in volume fraction of the integrated STF from 0.25 to 1.5%, with the highest strength increment of 9.9% occurring at a steel percentage of 1.25%. The influence of PPF is less pronounced since the increase in the volume fraction of these fibers within the interval 0.2–0.6% leads to a maximum increment in compressive strength of only 2.3%. However, for the hybrid fiber mixes, the highest strength increment of 10.3% was obtained for the mix with 1.3% steel + 0.2% polypropylene, and the development of compressive strength reduces as the volume proportion of steel fibers decreases and that of PPFs increases.

The use of STF or PPF increases the splitting tensile strength with fiber percentage. The largest increment in splitting tensile strength of 34% occurred when the mix had 1.5% of only steel fibers, while this increment was only 7% for the mixes with mono-PPFs. For the mixes with hybrid fibers, a maximum augmentation of 32% occurred for the mix with fiber proportions of 1.3% steel + 0.2% polypropylene.

Similar to the splitting tensile strength, the flexural strength of HSM shows the highest improvement of 51% for 1.5% single steel fibers, and this improvement reduces to 47% for the hybrid fiber mix of 1.3% steel + 0.2% polypropylene. However, this increment is only 6% for the mix with 0.6% of single PPFs.

The findings obtained from the ultrasonic pulse velocity test are in accordance with the results of the compressive strength test, and this emphasizes the correlation between ultrasonic pulse velocity and compressive strength.

The presence of fibers (single or hybrid) produces a reduction in water absorption of HSM but in an irregular pattern with a maximum reduction of 22, 21 and 4% for mixes with 0.5% mono-steel, 0.4% mono-polypropylene, and 1.3% steel + 0.2% polypropylene hybrid fibers, respectively.

For the list of properties considered in this study, one can find that the incorporation of fibers into HSM leads to the following enhancing order: flexural strength > splitting strength > water absorption > compressive strength and ultrasonic pulse velocity.

The results observed from testing the compressive strength, splitting tensile strength, flexural strength, and ultrasonic pulse velocity at the age of 56 days show a similar trend to the results obtained at 28 days age.

According to the obtained results of the current study, it can be concluded that the HSM reinforced with 1.25% STF and hybrid HSM mix that was reinforced with 1.3STF + 0.2PPF represent the mixes with optimum content of fibers that gain desired properties.

-

Funding information: Authors state no funding involved.

-

Author contributions: All authors have contributed to this manuscript and approved their responsibility for its entire content.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: All experimental data of this study are given in the manuscript.

References

[1] Nayak JR, Bochen J, Gołaszewska M. Experimental studies on the effect of natural and synthetic fibers on properties of fresh and hardened mortar. Constr Build Mater. 2022;347:128550.10.1016/j.conbuildmat.2022.128550Search in Google Scholar

[2] Jassam SH, Qasim OA, Maula BH. Effect of fiber type on high strength concrete mechanical properties. Int Rev Civ Eng. 2022;13(2):146–55.10.15866/irece.v13i2.20868Search in Google Scholar

[3] Pi Z, Huang S, Xu J, Chen Z, Li H, Shen Y, et al. The reinforcement mechanism of basalt and polypropylene fibers on the strength, toughness and crack resistance of tailing mortar. Constr Build Mater. 2024;419:135531.10.1016/j.conbuildmat.2024.135531Search in Google Scholar

[4] Slosarczyk A. The influence of non-metallic and metallic fibres on the mechanical properties of cement mortars. In International Symposium on Brittle Matrix Composite, Vol. 10, 2012.10.1533/9780857099891.167Search in Google Scholar

[5] Son M, Kim G, Kim H, Lee S, Nam J, Kobayashi K. Effects of the strain rate and fiber blending ratio on the tensile behavior of hooked steel fiber and polyvinyl alcohol fiber hybrid reinforced cementitious composites. Cem Concr Compos. 2020;106:103482.10.1016/j.cemconcomp.2019.103482Search in Google Scholar

[6] Newman J, Choo BS. Advanced concrete technology 3: processes. Great Britain: Elsevier; 2003.10.1016/B978-075065686-3/50288-3Search in Google Scholar

[7] Shannag MJ. High strength concrete containing natural pozzolan and silica fume. Cem Concr Compos. 2000;22(6):399–406.10.1016/S0958-9465(00)00037-8Search in Google Scholar

[8] Nili M, Afroughsabet V. The effects of silica fume and polypropylene fibers on the impact resistance and mechanical properties of concrete. Constr Build Mater. 2010;24(6):927–33.10.1016/j.conbuildmat.2009.11.025Search in Google Scholar

[9] Ranjan N, Banerjee S, Nayak S, Das S. Exploring applicability of recycled nylon fiber reinforced mortar in joints and plaster to enhance the bond strength, in-plane and out-of-plane capacity of masonry structures. J Build Eng. 2023;72:106744.10.1016/j.jobe.2023.106744Search in Google Scholar

[10] Facconi L, Lucchini SS, Minelli F, Plizzari GA. Analytical model for the in-plane resistance of masonry walls retrofitted with steel fiber reinforced mortar coating. Eng Struct. 2023;275:115232.10.1016/j.engstruct.2022.115232Search in Google Scholar

[11] Li Z, Zhou X, Ma H, Hou D. Advanced concrete technology. USA: John Wiley & Sons; 2011.Search in Google Scholar

[12] Guler S, Akbulut ZF. Workability, physical & mechanical properties of the cement mortars strengthened with metakaolin and steel/basalt fibers exposed to freezing-thawing periods. Constr Build Mater. 2023;394:132100.10.1016/j.conbuildmat.2023.132100Search in Google Scholar

[13] Marsidi NNS, Chin SC. Effect of elevated temperature of hybrid fibres on the mechanical performance of cement mortar. Mater Today: Proc. 2023;107:172–8.10.1016/j.matpr.2023.09.116Search in Google Scholar

[14] Win TT, Jongvivatsakul P, Jirawattanasomkul T, Prasittisopin L, Likitlersuang S. Use of polypropylene fibers extracted from recycled surgical face masks in cement mortar. Constr Build Mater. 2023;391:131845.10.1016/j.conbuildmat.2023.131845Search in Google Scholar PubMed PubMed Central

[15] Hiremath P, Yaragal SC. Performance of polypropelene and polyester fibres-reinforced reactive powder concretes at elevated temperatures. Constr Build Mater. 2023;373:130862.10.1016/j.conbuildmat.2023.130862Search in Google Scholar

[16] Vairagade VS, Dhale SA. Hybrid fibre reinforced concrete–a state of the art review. Hybrid Adv. 2023;3:100035.10.1016/j.hybadv.2023.100035Search in Google Scholar

[17] Dawood ET, Ramli M. High strength characteristics of cement mortar reinforced with hybrid fibres. Constr Build Mater. 2011;25(5):2240–7.10.1016/j.conbuildmat.2010.11.008Search in Google Scholar

[18] Koksal F, Yıldırım MS, Benli A, Gencel O. Hybrid effect of micro-steel and basalt fibers on physico-mechanical properties and durability of mortars with silica fume. Case Stud Constr Mater. 2021;15:e00649.10.1016/j.cscm.2021.e00649Search in Google Scholar

[19] Sridhar R, Prasad R. Study on mechanical properties of hybrid fiber reinforced engineered cementitious composites. Rev Rom Mater. 2019;49(3):424–33.Search in Google Scholar

[20] Central Organization for Standardization and Quality Control (2019). IQS No. 5: Portland Cement.Search in Google Scholar

[21] American Society for Testing and Materials (2015). ASTM C1240: Standard Specification for Silica Fume Used in Cementitious Mixtures.Search in Google Scholar

[22] Central Organization for Standardization and Quality Control (1984). IQS No. 45: Aggregate.Search in Google Scholar

[23] American Society for Testing and Materials (2017). ASTM C494/C494M: Standard specification for chemical admixtures for concrete.Search in Google Scholar

[24] American Society for Testing and Materials (2007). ASTM C1437: Standard test method for flow of hydraulic cement mortar.Search in Google Scholar

[25] American Society for Testing and Materials (2016). ASTM C109/C109M: Standard test method for compressive strength of hydraulic cement mortars (using 2-in or [50-mm] cube specimens).Search in Google Scholar

[26] American Society for Testing and Materials (2004). ASTM C496/C496M: Standard test method for splitting tensile strength of cylindrical concrete specimens.Search in Google Scholar

[27] American Society for Testing and Materials (2016). ASTM C78/C78M: Standard test method for flexural strength of concrete (using simple beam with third –point loading).Search in Google Scholar

[28] American Society for Testing and Materials (2002). ASTM C597: Standard test method for pulse velocity through concrete.Search in Google Scholar

[29] American Society for Testing and Materials (2009). ASTM C642: Standard test method for density, absorption, and voids in hardened concrete.Search in Google Scholar

[30] Alsadey S, Salem M. Influence of polypropylene fiber on strength of concrete. Am J Eng Res. 2016;5(7):223–6.Search in Google Scholar

[31] Alomayri T, Ali B, Raza SS, Ahmed H, Hamad M. Investigating the effects of polypropylene fibers on the mechanical strength, permeability, and erosion resistance of freshwater and seawater mixed concretes. J Mar Sci Eng. 2023;11(6):1224.10.3390/jmse11061224Search in Google Scholar

[32] Fallah S, Nematzadeh M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr Build Mater. 2017;132:170–87.10.1016/j.conbuildmat.2016.11.100Search in Google Scholar

[33] Sahmaran M, Yaman IO. Hybrid fiber reinforced self-compacting concrete with a high-volume coarse fly ash. Constr Build Mater. 2007;21(1):150–6.10.1016/j.conbuildmat.2005.06.032Search in Google Scholar

[34] Felekoğlu B, Türkel S, Altuntaş Y. Effects of steel fiber reinforcement on surface wear resistance of self-compacting repair mortars. Cem Concr Compos. 2007;29(5):391–6.10.1016/j.cemconcomp.2006.12.010Search in Google Scholar

[35] Jawad HS, Al-Haydari IS. Sustainable use of polypropylene fibers as a cement mortar reinforcement. Int J Eng. 2022;35(8):1494–500.10.5829/IJE.2022.35.08B.05Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite

Articles in the same Issue

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite