Abstract

This work is aimed at improving the mechanical properties of AA7075 by adding TiB2 reinforcements by using ex situ method. The squeeze casting process was used in the manufacturing of metal matrix composites with varying weight concentrations (1.5, 3, and 4.5%) of TiB2 particles. The effects of change in the TiB2 weight % on the tensile strength, hardness, and wear rate of the composite were studied. The distribution of the TiB2 reinforcements in the matrix was observed during the microstructure examination qualitatively. Experimental results confirmed that the hardness was significantly increased as compared to the base alloy. The increase was about 26% as compared to the as-cast AA7075. Both the yield and ultimate tensile strengths of the AA7075/TiB2 composite were higher than that of the base alloy. The tensile strength increased to 354 MPa (18% increase as compared to the as-cast alloy). The enhancement of the strength of the composite is due to the addition of TiB2 reinforcement particles and proper wettability between the matrix and reinforcement material. The fractography analysis revealed the presence of small and shallow dimples, which serve as an indication of the level of ductility that was retained within the composite material, even after the incorporation of TiB2 particles into the matrix.

1 Introduction

AA7075 holds unique characteristics like high strength-to-density ratio, tensile strength, and yield strength, combined with higher elongation. There are several uses for AA7075 in the automotive, mechanical, aerospace, and marine industries. It is used for machine parts, airplanes, and other uses that require greater strength [1]. AA7075 is applied in both machinery and ordnance applications. Metal matrix composites (MMCs) based on aluminum with different reinforcement percentages have been studied by many researchers. The matrix material of MMCs is made of metals or metallic alloys. The majority of materials utilized are lightweight metals and alloys, including titanium, aluminum, and their alloys. Due to their superior mechanical qualities, resistance to radiation, and high-temperature capabilities, MMCs have an advantage over other composites [2]. One of the main environmental issues is global warming, which is caused by CO2 emissions. Therefore, solutions are being sought in the form of environmentally ecological substitute materials for steel. MMCs provide an eco-friendly and cost-effective substitute for steel elements [3]. The total energy required to create the finished product, or embodied energy (EE), is influenced by the manufacturing process used to create aluminum matrix composites. According to studies, aluminum matrix composites often have lower EEs than steel, which means that they can save energy during production [4]. Numerous kinds of reinforcements, such as carbides (SiC, ZrC, TiC), oxides (SiO2, Al2O3), aluminides (Al4Mo, Al3Ti, Al3Zr), nitrides (A0lN, Si3N4), and borides (ZrB2, TiB2), have been used to produce composite materials utilizing a variety of production processes. Al and magnesium, which have low energy requirements, are suitable for material recycling in metal matrix composites, and their machined chips and waste can be recycled directly as the matrix material. In order to create sustainable MMCs, there is also a growing trend of investigating agricultural waste and industrial byproducts as green reinforcement [5]. To create sustainable MMCs, several researchers have experimented with different reinforcement combinations. Few researchers have employed a single reinforcement to create MMCs with desirable properties; others have used a combination of reinforcements. The reinforcements used in the manufacturing of MMCs are nonmetallic and made of common ceramic particles like Al2O3, B4C, SiC, C, B, TiB2, and BN. High tensile and compressive strength are two desirable properties of reinforcing materials that make them highly sought after. Additionally, these materials are preferred due to their lower density, reliable dimensional stability, stability at high temperatures, and excellent mechanical and chemical compatibility [6]. Because of its superior mechanical and physical properties – such as its high hardness, high melting point, and high elastic modulus – TiB2 is regarded as a cutting-edge ceramic reinforcement [7]. Components with a broader range of service temperatures and conditions that are pertinent to renewable energy applications like offshore wind turbines and geothermal energy can be made from the Al–TiB2 composite due to its superior thermal stability, machinability, and corrosion resistance. At a comparatively modest cost, the Al–TiB2 composite provides exceptional strength and resistance to wear [8]. Al/TiB2 composites are frequently used in high-tech structural and functional applications, such as those in the aerospace, defense, and automotive industries, because of the combination of exceptional characteristics of TiB2’s reinforcement. These composites are most frequently used in cutting tools, impact-resistant structures, crucibles, and wear-resistant coatings as well [9].

2 Literature review

To create lightweight MMCs, it is essential to examine the various combinations of matrix and reinforcements used by various researchers, along with the methods used for the fabrication of the composite materials. An extensive literature review was carried out on MMCs, different materials used for the fabrication of MMCs, processing techniques used for the fabrication of aluminum-based metal matrix composites, and the mechanical behavior of aluminum matrix composites. Lee et al. [10] investigated the fracture characteristics of MMCs based on AA7075 with carbon fiber as reinforcement. The purpose of the research was to ascertain the strain rate and evaluate the effect of temperature on the properties of the composites. According to the findings, temperature and strain rate both had an impact on the composite stress. Rajan et al. [11] found the effect of the addition of TiB2 reinforcements on the sliding wear of AA7075/TiB2 composites. The study showed that TiB2 particles increase the wear resistance of composite materials across the whole temperature range. The corrosion behavior of AA7075 and AA7075/Al2O3 composites was examined by Shanbhag et al. [12] to reveal that the corrosion rate of AA7075 exhibited a positive correlation with the reinforcing volume, indicating that an increase in the volume of reinforcement increased the corrosion rate. As per the study, AA7075 experiences much more severe corrosion in seawater than it does in an industrial environment. Reddy et al. [13] developed a special composite with AA7075 and E-glass short fibers with fly ash as reinforcing particles to show that the addition of reinforcements enhanced the mechanical characteristics. MMCs were created with AA7075 and basalt short fibers as reinforcement to examine the connection between the temperature and the thermal expansion coefficient [14]. The results showed an increase in CTE with increasing temperature and a decrease with increasing basalt fiber inclusion. Balaji et al. [15] utilized the stir-casting process to create gear using AA7075/SiC MMCs. The MMCs were the subject of numerous experiments to evaluate their mechanical behavior. The inclusion of SiC caused a noticeable increase in the mechanical characteristics of AMCs when compared to as-cast AA6061. Imran et al. [16] produced an AA7075/graphite/bagasse-ash-based MMC to reveal that the inclusion of bagasse-ash increased the tensile strength and hardness value. When more TiC particles were added to the slurry, the wear resistance increased, according to research by Veeravalli et al. [17], who employed the stir casting technique to study the wear characteristics of the AA7075/TiC composite. In order to demonstrate a notable improvement in tensile strength along with hardness value, a compo casting process was used to create MMCs with fly ash cenosphere and graphite [18]. AA7075-based nanocomposites were developed to demonstrate an enhancement in UTS and hardness due to Al2O3 nanoparticles [19]. A novel reactive approach was used to create AA7075-based composites with the sedimentation of TiB2 reinforcements using the viscosity test [20]. After particle settlement, the correlation between microstructure and particle concentration was investigated in the research. In another study, the impact of the titanium diboride concentration on the compressive characteristics, microstructure, nano-hardness, and wear characteristics was examined for AA7075/TiB2 MMCs [21]. In situ TiB2 particle-reinforced AA7075 MMCs were fabricated to examine the tensile behaviors and fracture characteristics [22]. The research demonstrated that temperature has a notable effect on the ductility of composite, whereas strain rate has a lesser impact. A unique approach was used to check the coefficient of friction of the nanocomposites manufactured using AA7075 and TiB2, which resulted in the reduction of the wear properties [23]. The study carried out by Deshmukh et al. [24,25] examined the properties of AA6061/TiB2 composites manufactured by the stir casting method. The findings of their research indicate that the inclusion of TiB2 reinforcements leads to improvements in the tensile and hardness properties of the composites. Manojkumar and Kant Mehta [26] determined the effect of TiB2 on the mechanical properties of the composites prepared using AA7075 by the stir-casting route. Different composites were created by reinforcing varying amounts of titanium diboride (2, 4, and 6 wt%) powder. The study revealed an increase in the hardness and tensile properties of composites. Han et al. [27] used mechanical testing, microscopic characterization, and numerical simulations to study the fracture behavior of an in situ TiB2 particle-reinforced AA7075 composite under different stress levels. It was observed that the material’s fracture mechanism primarily involves interfacial debonding and particle fracture.

Most of the research on MMCs has been carried out by incorporating SiC, B4C, and Al2O3 as reinforcement in the Al matrix. However, limited research work has been reported on aluminum-based MMCs reinforced with TiB2 due to higher raw material costs, higher density, and poor wettability of TiB2 with aluminum melt. An extensive review of the AA7075 literature reveals that several researchers have tried to create Al/TiB2 MMCs by using the in situ casting method. However, in the case of the in situ method, TiB2 particle agglomeration segregates the grain boundary and lowers the strength when the amount of TiB2 incorporation exceeds a specific value, negating the advantages of TiB2 particle grain refining [28]. Despite several publications on AMCs constructed with various types of reinforcements, research on AA7075/TiB2 composites using ex situ techniques is still lacking. A thorough analysis of the literature in this area reveals that researchers have typically taken into account the amount of reinforcement in the range of 1–10 wt% of TiB2 for both in situ and ex situ procedures. While conducting optimization of the process parameters during the initial stages [24], it was observed that the stir casting procedure resulted in high porosity in the prepared composites. The main problems with the stir casting method include porosity and an uneven distribution of reinforcing particles. Lightweight AA6061/TiB2 composites were produced utilizing the squeeze casting method with varying reinforcement levels (0, 1.5, 3, and 4.5 weight %) to show an increase of 33.27% in hardness and 26.12% increase in tensile strength [29]. In addition to the experiments carried out during this research, authors also carried out experiments with the addition of 0.5 and 5.5% TiB2. It was observed that with an increase in TiB2 above 5%, the agglomeration of the reinforcement particles occurs. Hence, it was decided to consider reinforcement % as 1.5, 3, and 4.5 by weight.

Given the lack of fundamental information related to the liquid melt processing of Al/TiB2 composites, we focused on the development of AA7075/TiB2 composites, using the squeeze casting method by considering the problem associated with inhomogeneous distribution of particles, porosity, and wettability. To reduce the porosity and improve the mechanical properties of MMCs, the stir-casting method is combined with the squeezing process. In the current research, aluminum-based MMCs were produced with various amounts (1.5, 3 and 4.5% by weight) of TiB2 reinforcements utilizing the squeeze casting method to mitigate the porosity defect encountered during the stir casting process.

3 Experimental details

3.1 Composite fabrication

The cylindrical rods of AA7075 were procured from Bharat Aerospace Metals, Mumbai, India. Table 1 lists the ingredients in AA7075, demonstrating that zinc is a significant alloying ingredient in AA7075 alloy, and it is combined with copper magnesium to provide various levels of strength. The basic mechanical properties of AA7075 and TiB2 are presented in Tables 2 and 3, respectively.

Chemical composition of AA7075

| Element | Mg | Si | Fe | Cu | Ti | Cr | Zn | Mn | Al |

|---|---|---|---|---|---|---|---|---|---|

| Weight % | 2.9 | 0.2 | 0.2 | 1.7 | 0.3 | 0.5 | 5.7 | 0.2 | 88.2 |

Mechanical properties of AA7075 [30]

| Element | Ultimate tensile strength (MPa) | Yield stress (MPa) | Elastic modulus (GPa) |

|---|---|---|---|

| AA7075 (standard) | 570 | 505 | 72 |

Properties of TiB2 at 20°C [31]

| Element | Bulk modulus (GPa) | Density (g/cm3) | Elastic modulus (GPa) | Hardness (GPa) | Shear modulus (GPa) |

|---|---|---|---|---|---|

| TiB2 | 240 | 4.5 | 565 | 25 | 255 |

The materials used (AA7075 and TiB2) in the manufacturing of the composites are shown in Figures 1 and 2, respectively.

AA7075 material used during the composite manufacturing.

TiB2 powder used during the composite manufacturing.

TiB2 powder with an average particle size of 5.5 µm and purity of 99% was used during the investigation. The TiB2 powder was bought from Vijay Commercial House in Mumbai, India. The creation of AA7075/TiB2 composites used a modified stir and squeeze casting approach. The reinforcement percentage, stirring speed, and melt temperature were selected after optimization of the parameters [24].

Figure 3 illustrates the experimental steps involved in the squeeze casting method that combines hydraulic forging and stir casting.

Steps involved in the squeeze casting method.

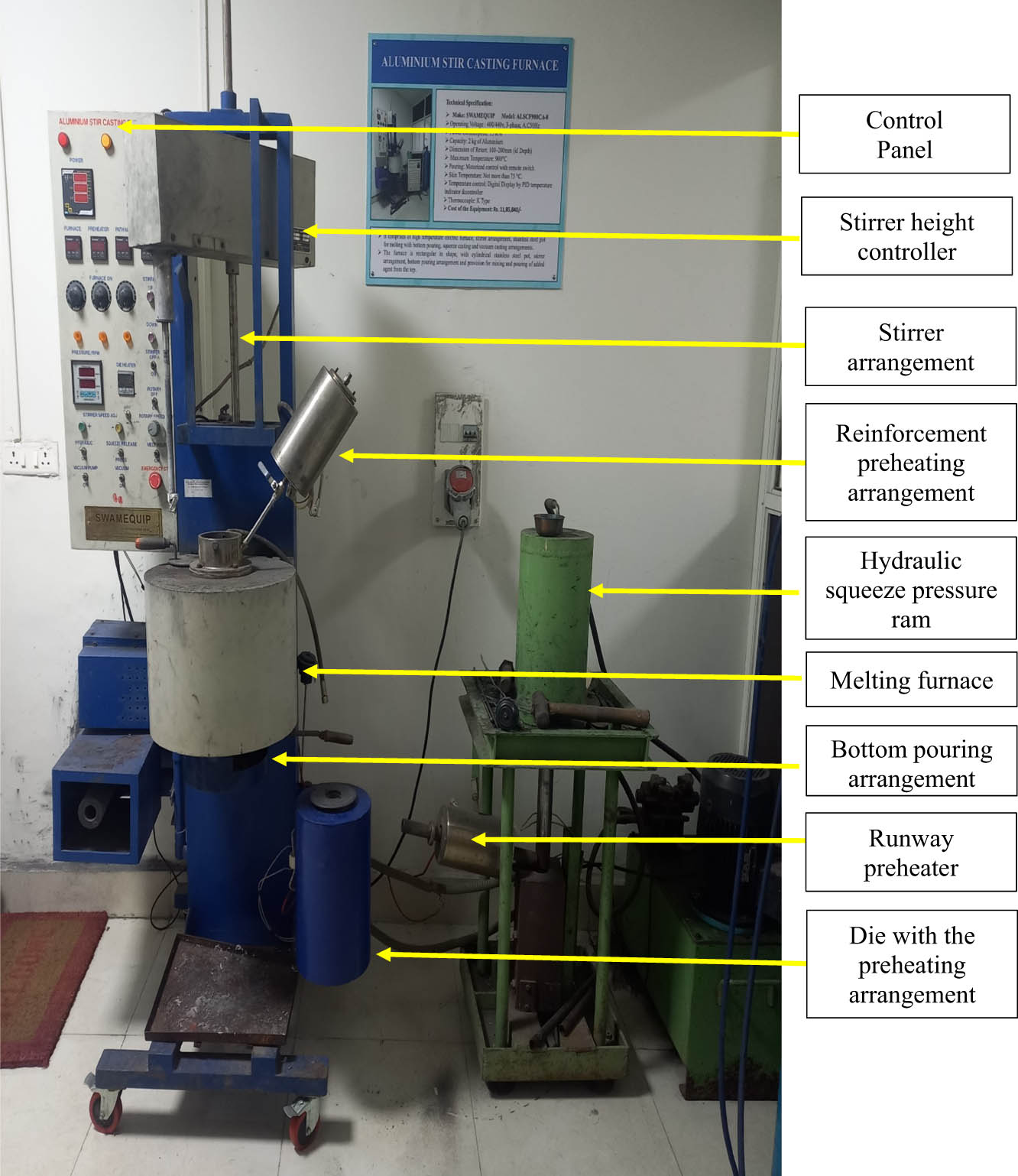

Figure 4 shows the arrangement of a modified stir casting and squeeze casting setup used during this research.

Modified stir and squeeze casting setup.

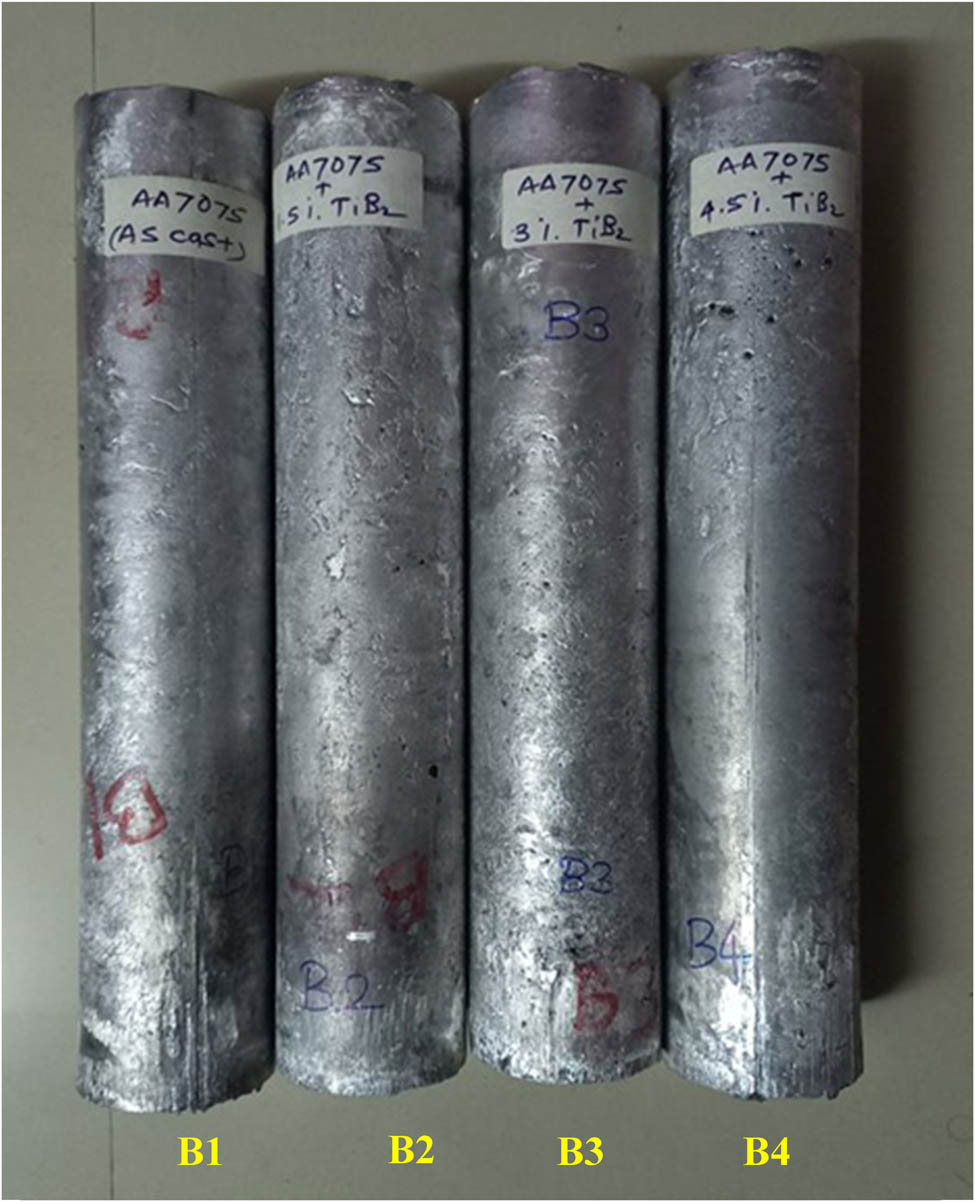

The two-blade stirrer with an upward and downward motion arrangement was used to obtain a uniform distribution of the TiB2 inside the AA7075 molten material without any agglomeration. AA7075 was melted inside the furnace at a temperature of 750°C, and the stirrer was constantly rotated at 700 rpm by an electric motor for 10 min to create a vortex. Magnesium cubes (1 weight %) were gradually added to the melted alloy as a wetting agent. TiB2 reinforcements were preheated and added at the vortex region to achieve homogeneous dispersion of the particles [24,25]. After thorough mixing and churning, the bottom of the furnace was opened. A runway preheater was connected between the bottom outlet of the furnace and the mold to transfer the molten metal to the die. The die was preheated for 30 min at a temperature of 300°C prior to pouring of molten mixture. This liquid metal was immediately forged at 120 MPa pressure using a hydraulic press for 25 s. The sample was removed from the mold after complete cooling and solidification. From the design of experiments, it was found that the TiB2 reinforcement% is the most influential parameter. To check the role of wt% of TiB2 in the mechanical properties of composites, it was decided to consider the TiB2% as 1.5, 3.0, and 4.5. Figure 5 depicts the AA7075/TiB2 composites prepared by the squeeze casting method. Table 4 shows the nomenclature used while marking the composite specimens with varying % of TiB2.

AA7075/TiB2 squeeze cast composites.

Coding of the composite specimens

| Sample name | Matrix material | TiB2 wt% | Mg wt% |

|---|---|---|---|

| B1 | AA7075 | 0 | 0 |

| B2 | AA7075 | 1.5 | 1 |

| B3 | AA7075 | 3.0 | 1 |

| B4 | AA7075 | 4.5 | 1 |

3.2 Composite characterization

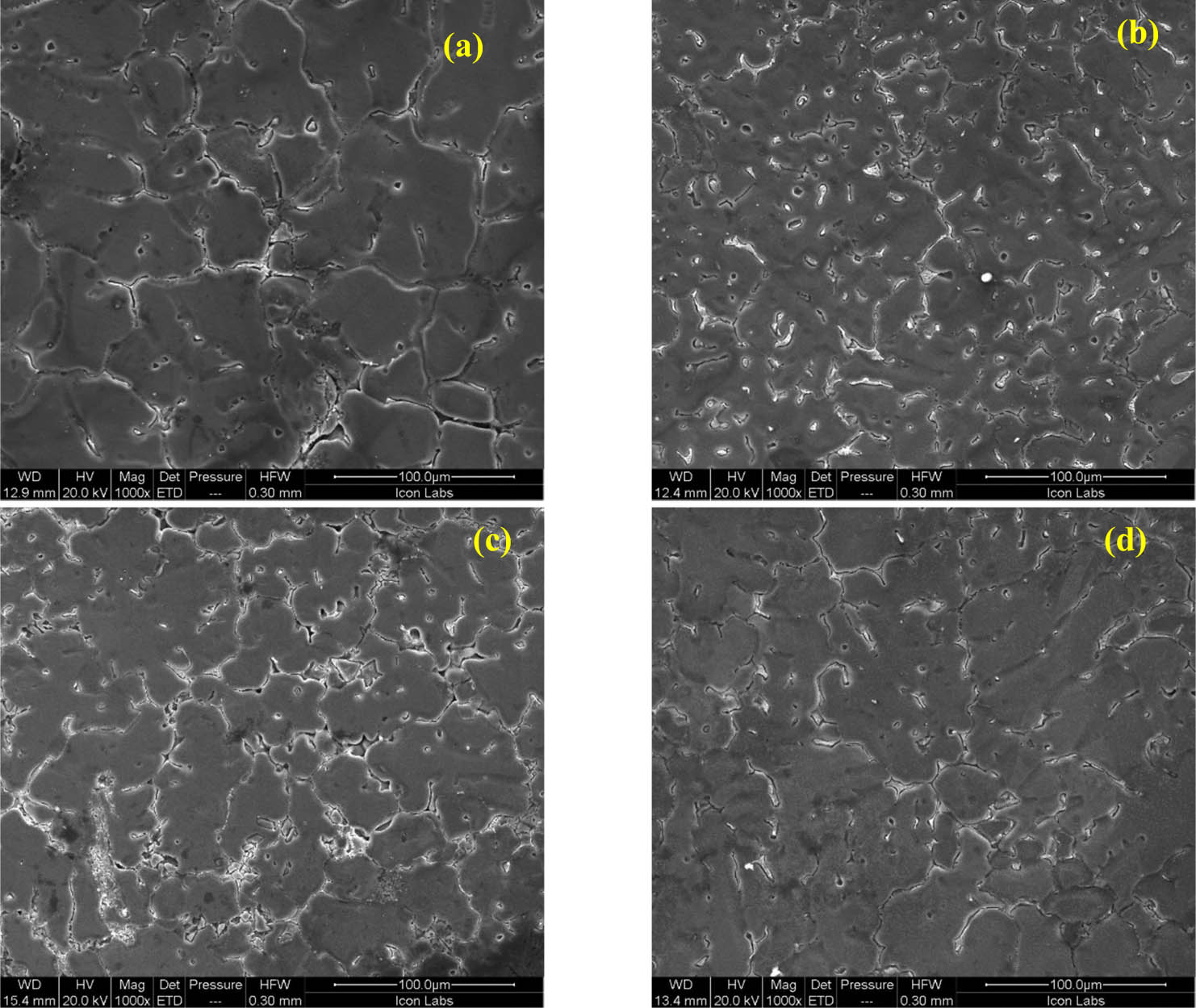

The distribution of reinforcing particles has a considerable impact on the behavior and characteristics of the particulate-reinforced MMCs. For carrying out microstructural analysis, all fabricated composites were cut as per the sample requirement. Standard procedures were utilized to polish the surfaces, and Keller’s reagent was employed for etching the polished surfaces. A field emission scanning electron microscope (FESEM; Quanta 200F) was used to conduct microstructural analysis. Figure 6(a)–(d) displays SEM micrographs of the AA7075/TiB2 composites.

SEM micrographs of (a) pure AA7075, (b) AA7075 with 1.5 wt% TiB2, (c) AA7075 with 3 wt% TiB2, and (d) AA7075 with 4.5 wt% TiB2.

A scanning electron micrograph of pure AA7075 with varied grain sizes is shown in Figure 6(a). In Figure 6(b)–(d), tiny and fine (appearing glossy) TiB2 particles can be detected. These micrographs indicate that TiB2 reinforcements were evenly distributed throughout the AA7075 material to produce the MMCs with the best possible characteristics.

3.3 Hardness measurement

Hardness is the resistance to indentation and is determined by the depth of indentation. The hardness measurements were conducted following the guidelines outlined in the ASTM standard E384-22 on samples of both as-cast AA7075 and its composites with varying percentages of TiB2. In this study, a Wilson Hardness Tester fitted with a diamond indenter was employed. A load of 500 gf is applied to the polished samples for a dwell duration of 10 s. The specimen surface’s diagonal indentations were measured for length and hardness values using an optical microscope. To avoid the possibility of the indenter resting on the hard reinforcing particles, the test was conducted at five distinct locations. Five readings were taken at each of these locations. Therefore, a total of 25 indentations were performed for each sample to determine the average hardness value.

3.4 Tensile test and fractography analysis

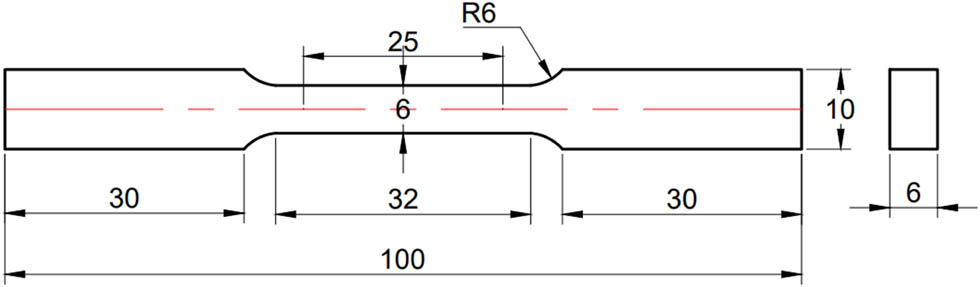

The tensile strength of the manufactured composites was characterized by using a universal testing machine. The tensile testing samples were cut from the respective composites as per the required size using a wire electrical discharge machine (EDM). Flat tensile samples were created in the form of large dumbbells as per the ASTM E8/E8M-2021 standard. The investigation focused on evaluating the tensile characteristics of the manufactured composites under ambient conditions, employing a strain rate of 0.5 mm/min using the INSTRON UTM of model BISS and with a load capacity of 100 kN. Three samples from each casting were tested for tensile strength, and the average of the results was evaluated. The data for each sample, including maximum force, tensile strain at break, tensile strength, modulus, and ultimate tensile strength, were recorded in digital form and stored for later processing. The standard procedure was followed to conduct the test. Figure 7 depicts the schematic illustration of the flat tensile sample according to ASTM E8/E8M-2021 standard, and Figure 8(a)–(c) depicts the prepared specimens with various weight percentages of TiB2 for different trials. Scanning electron microscopy was used to examine the fracture surfaces of the broken specimens.

Schematic illustration of the flat tensile specimen.

Tensile specimens of fabricated MMCs: (a) Trial 1, (b) Trial 2, and (c) Trial 3.

3.5 Wear measurement

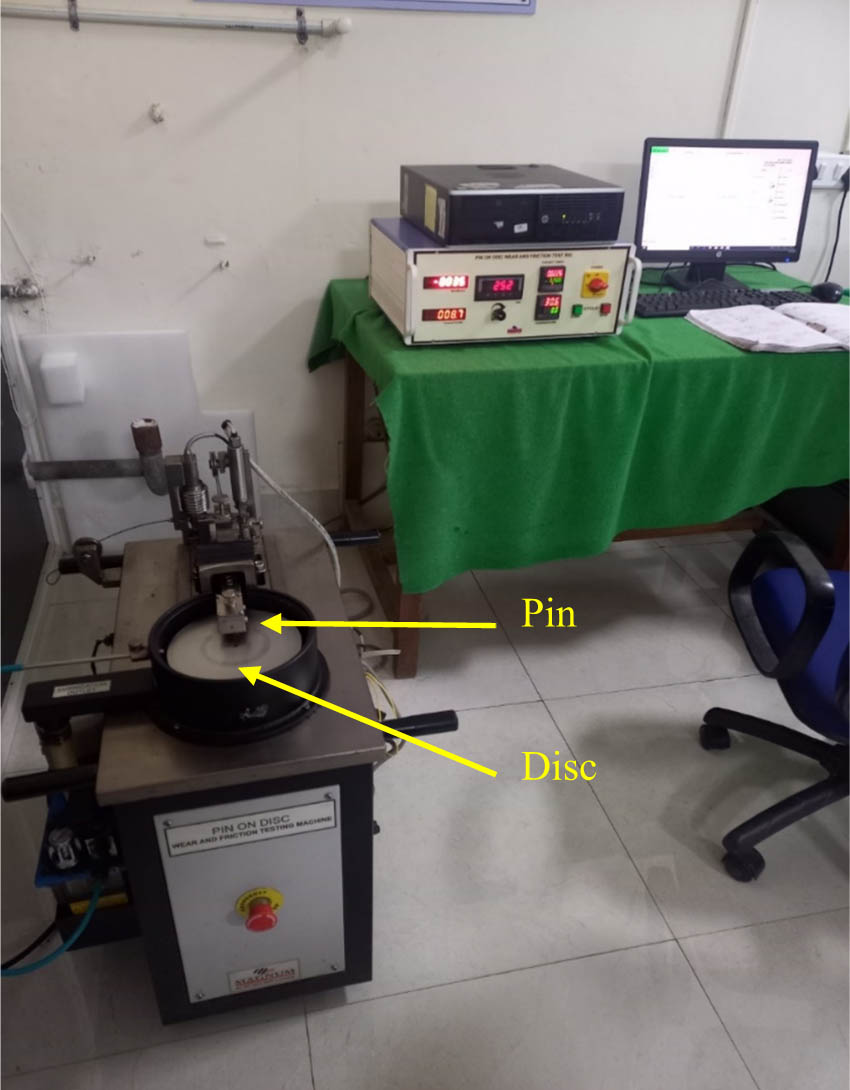

The dry sliding wear behavior of in situ Al/TiB2 composites has been widely documented in the literature. However, to the best of the authors’ knowledge, the wear behavior and friction mechanism of Al/TiB2 ex situ composites are yet to be reported by researchers. An evaluation of the wear characteristics of the composite specimen was carried out using a wear test. A pin-on-disk wear and friction test rig (MAGNUM) were used to measure wear. The test was conducted according to ASTM G99-05 specifications. A wire EDM process was used to cut pins from the AA7075/TiB2 composites with a diameter of 10 mm and a length of 25 mm, as shown in Figure 9. Figure 10 shows the wear rate testing device with the specimen installed on it.

Wear test samples for the AA7075/TiB2 composites.

Wear rate testing device with the specimen installed.

A disc with a diameter of 165 mm, constructed of EN-31 steel with hardness 58–60 HRC and a roughness of 0.274 µm, was used. The measurements were carried out for base alloy as well as three composites with varying percentages of reinforcement against the EN-31 steel disc. Loads of 10, 20, 30, and 40 N were applied at a sliding velocity of 1 m/s for a distance of approximately 1,000 m. The frictional force was continuously measured during the wear testing to ascertain the coefficient of friction.

4 Results and discussion

4.1 Microstructure analysis

The different micrographs of the composites show that TiB2 particles are dispersed throughout the aluminum matrix quite uniformly. Grain refinement of the matrix material was observed with an increase in the weight percentage of TiB2 reinforcements. The inclusion of reinforcement in different proportions led to the homogenization of the specimens, and a reduction in dendrites was observed. The solidification process significantly influenced the pattern of particle dispersion in the composite microstructure. Additionally, the reinforcement/matrix interfaces are nearly porosity-free because of the increased wettability achieved by adding magnesium and heating the TiB2 particles prior to their addition to the melt. Figure 11 displays the EDS spectrum obtained for the AA7075 composite, which contains 3 wt% TiB2.

EDS of AA7075 composite with 3 wt% TiB2.

According to these results, it can be clearly seen that there are two different peak phases: one is an Al-rich region, and the other region is predominantly Ti with few elements of B. In addition, the results of elemental mapping confirmed the distribution of Ti, B, Mg, Fe, Cu, Si, Cr, and Al in the composite with 4.5 wt% TiB2.

4.2 Hardness

Hardness measurements aid in determining the impact of reinforcement particles within the matrix alloy. MMC’s extraordinary hardness is a result of strong interfacial connections and a well-generated microstructure. The graph illustrates that AA7075/TiB2 composites display a significantly higher level of hardness compared to as-cast AA7075, attributed to the incorporation of TiB2 particles into the aluminum matrix. With an increase in TiB2 content, the hardness of the samples increased by about 12, 13, and 26%, respectively, compared to the as-cast AA7075. The AA7075 with 4.5 wt% TiB2 composite has the highest hardness value of 161.87 HV. Table 5 shows the hardness measurements of the AA7075/TiB2 composites. The hardness of composites increased due decreasing grain size of the matrix material. Matrix transfers load to reinforcement resulting in hardness improvement. Proper wettability (extent of bonding) and fabrication method help in improving the hardness of the composites.

Hardness measurements of the AA7075/TiB2 composites

| Sample no | Sample | Set 1 | Set 2 | Set 3 | Set 4 | Set 5 | Average hardness (HV) |

|---|---|---|---|---|---|---|---|

| B1 | AA7075 (As cast) | 121.14 | 131.94 | 133.32 | 133.16 | 122.60 | 128.43 |

| B2 | AA7075 + 1.5% TiB2 | 142.10 | 143.88 | 137.04 | 145.20 | 138.08 | 144.86 |

| B3 | AA7075 + 3.0% TiB2 | 138.54 | 141.08 | 149.48 | 146.70 | 149.58 | 145.08 |

| B4 | AA7075 + 4.5% TiB2 | 136.40 | 156.08 | 178.80 | 161.42 | 176.64 | 161.87 |

Figure 12 displays the outcomes of hardness tests performed on AA7075 with various TiB2 percentages. In comparison to the AA7075 matrix, the TiB2 particles exhibit greater stiffness and hardness, which increases the matrix’s resistance to plastic deformation. The increased hardness is attributed to the grain refinement and presence of TiB2 particles in the matrix. In a microindentation test, the material exhibits elastic behavior outside of the localized region below the indentation, where severe plastic flow occurs as the indenter travels below [23]. The concentration of particles increases locally just below the indentation compared to regions distant from the depression, thereby enhancing resistance to deformation.

Hardness values of the composites with the addition of TiB2 reinforcements.

As the weight percentage of TiB2 in the matrix increases, hard particles are concentrated more and more below the indentation, which causes particle crowding and a decrease in inter-particle space. Thus, an increase in the weight percentage of reinforcement in the matrix is expected to increase hardness values. During the homogenization of the mixture, matrix material transfers the load to reinforcement, resulting in hardness improvement. Proper wettability between the matrix and reinforcement, along with the use of the proper fabrication method, also helps in improving the hardness of the composites.

4.3 Tensile strength

The strength of discontinuously reinforced MMCs is highly structure-sensitive. The microstructures of matrix, matrix and particulate interface, shapes, and weight percentages of reinforcement affect the overall tensile behavior of the composites [32]. The tensile strength and percentage elongation of the AA7075/TiB2 composites are shown in Table 6.

Tensile strength and % elongation of the AA7075/TiB2 composites

| Sample no | Sample | Average ultimate tensile strength (MPa) | Average elongation (%) |

|---|---|---|---|

| B1 | AA7075 (as-cast) | 231.17 | 1.01 |

| B2 | AA7075 – 1.5% TiB2 | 295.91 | 1.61 |

| B3 | AA7075 – 3.0% TiB2 | 315.96 | 1.44 |

| B4 | AA7075 – 4.5% TiB2 | 353.64 | 1.93 |

Figure 13 depicts the tensile stress–strain curve for the AA7075/TiB2 composites. It demonstrates that the quantity of reinforcements affects the UTS of the AA7075/TiB2 composites. As the reinforcing percentage increases, the ultimate tensile strength also increases. The increase in UTS primarily stems from the increased density of thermally induced dislocations and the reduction in the matrix grain size with increasing particulate content [33]. The mechanical characteristics of the matrix and reinforcement are affected by the adhesion between them. Proper adhesion between matrix and reinforcement also influences the tensile strength of the composites. The best specimen had a final tensile strength of 353.6 MPa and contained 4.5% TiB2. The increased strength did not affect the ductility adversely. The fact that the total elongation of the produced composites exceeded or remained constant as that of base alloy suggests that adding reinforcements improved the ductility of the composite. The disparity in the coefficient of thermal expansion (CTE) between the reinforcement and the matrix at room temperature induces a greater number of dislocations, making deformation more challenging and consequently leading to higher yield strength. It was also observed in the fabricated composites that the UTS is greater than its yield strength, indicating that strain hardening had occurred beyond yielding. The strain hardening rate of the composite is affected by particle content and increases as the particulate concentration increases [33].

Tensile stress – tensile strain curve for the AA7075/TiB2 composites.

4.4 Fractography analysis

The fractured specimen from the tensile test was observed under a scanning electron microscope (SEM). Figure 14 displays the findings of a scanning electron microscope examination of broken surfaces for the AA7075/TiB2 composites. From the SEM images, it is evident that the main causes of fracture were the formation of voids. The formation of dimples on all fracture surfaces of the composites is a common feature, indicating an overall ductile behavior of the composites. Figure 14(b) depicts the formation of a crack on the broken surface. Particle cracking was visible during the fracture process, while some of the larger particles were broken into tiny pieces. This may be attributed to the resistance offered by the hard TiB2 particles dispersed throughout the matrix. Tiny dimples were seen on the fractured surface in Figure 14(c) and (d). Fractography revealed fine shallow dimples for AA7075/TiB2 composites, indicating the amount of ductility retained by the composite despite the addition of reinforcements. The SEM image of the fracture surfaces revealed that the initial cracks were created by microvoids, and the propagation of these cracks led to ductile fracture [34].

SEM micrographs of fracture surface for (a) AA7075 as-cast, (b) AA7075 with 1.5 wt% TiB2, (c) AA7075 with 3 wt% TiB2, and (d) AA7075 with 4.5 wt% TiB2.

4.5 Wear

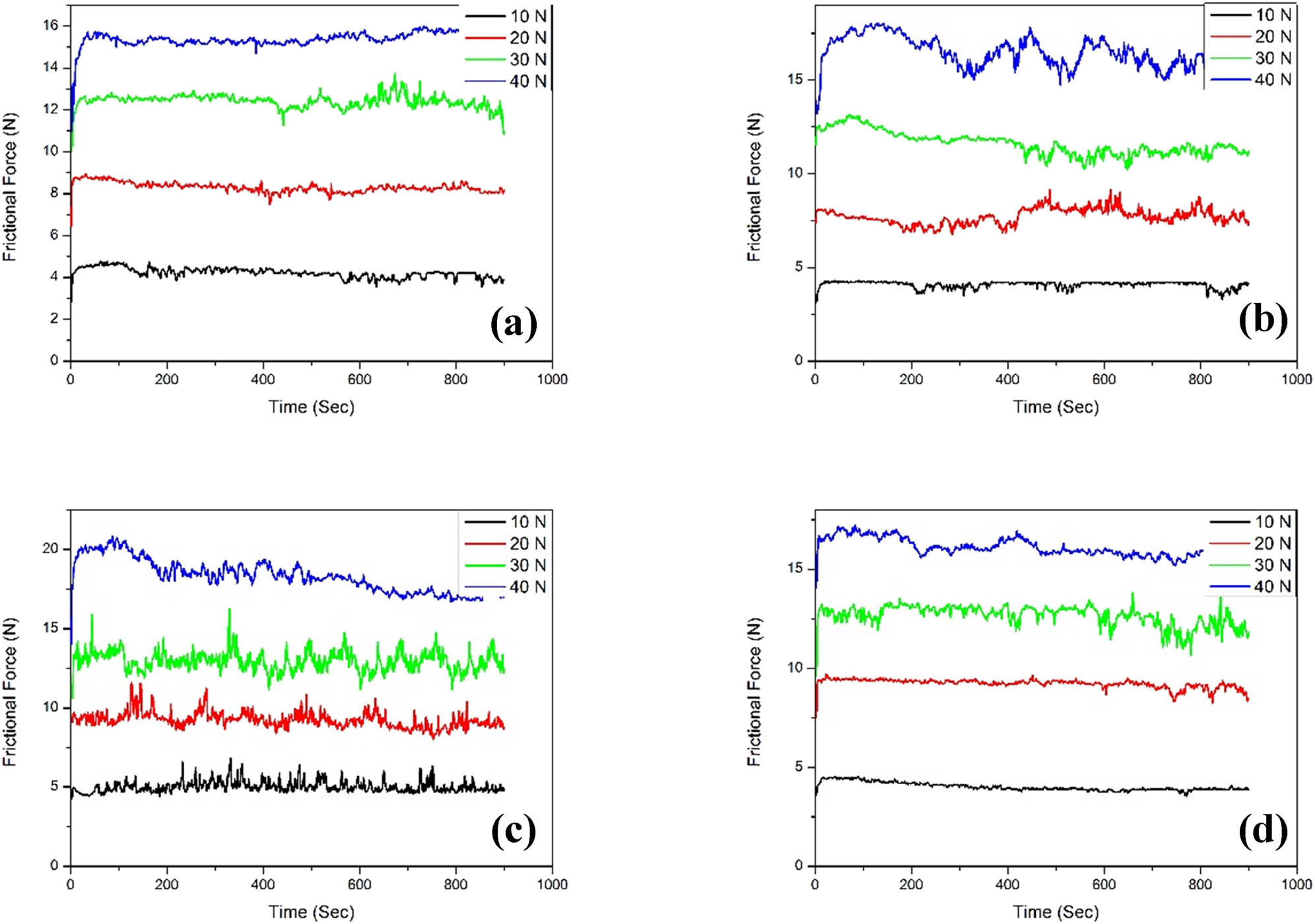

The wear mechanism of the samples can be comprehended by examining the worn surfaces and wear debris. Scanning electron microscopy was employed to analyze the wear surfaces of the specimens. The graphs of frictional force (N) vs time (s) were plotted to determine the effect of various loads and different combinations of TiB2 percentages on the composites. Figure 15(a)–(d) shows that the increase in load increases the frictional force.

Frictional force vs time for (a) AA7075 as-cast, (b) AA7075 with 1.5 wt% TiB2, (c) AA7075 with 3 wt% TiB2, and (d) AA7075 with 4.5 wt% TiB2.

The numbers also demonstrate that when load increases, frictional force and, thus, coefficient of friction (COF) decrease. The lower value of COF was due to increased TiB2 concentration and minimum load, thereby reducing wear. When composites are tested at lower loads, the frictional force varies over a larger range, whereas at greater loads, the frictional value is nearly constant. In other words, the development of a stable mechanical mixed layer (MML) and a significant reduction in the debris size is responsible for the decrease in frictional force at higher loads. Figure 16 depicts the change in wear rate (mm3/N m) for AA7075 as-cast and its TiB2 composites under increasing loads (10, 20, 30, and 40 N). AA7075 and its composites have more wear loss at higher loads. The wear rate increases with an increase in the load, which ranges from 10 to 40 N. At maximum load, the sliding surface and the pin reach the highest temperature.

Wear rate (mm3/Nm) for the AA7075/TiB2 composite.

There is an increase in the wear rate in proportion to the applied load for as-cast AA7075 and the TiB2 composites due to the temperature increase accompanying higher load. The wear loss of the composites diminishes as TiB2 reinforcement weight percentages increase in the matrix alloy. The high hardness of TiB2 particles, which serves as a barrier for material loss, can be linked to the improved wear resistance of composites with TiB2 reinforcement. The wear rate is quite low at loads of 10 N, 20 N, and 30 N. However, the wear rates of composites tested at 40 N increased by about 2–3 times as compared to those at 10 N. Therefore, it may be concluded that at lower loads (less than 30 N), the wear rate does not strongly correlate with the TiB2 percentage. Such a sudden increase in the wear rate above 30 N could be caused by a modification in the alloy’s or composites’ wear mode. The composite containing the maximum weight percentage of TiB2 shows a wear rate decrease of approximately seven times compared to the base alloy under a 40 N load. The notable reduction in wear rates for the composite with 4.5 wt% TiB2 particles can be ascribed to the refinement of the Al matrix, along with a higher quantity of TiB2 particles that shield the softer α-Al matrix [25]. With an increased concentration of TiB2 particles, the average size of the Al matrix decreases by constraining their growth. Consequently, a smaller particle size distribution is expected to be more effective in sustaining higher loads. SEM micrographs of the worn surfaces for the AA7075/TiB2 composite specimens are shown in Figure 17(a)–(d). Sliding directions are indicated in the SEM images by an arrow. Small cracks, debris, and some grooves were observed on the surface of the sample. Figure 17(b)–(d) shows the presence of abrasive grooves along the sliding direction with delamination at places caused by the contact between the steel disc and specimen pin. The figure shows that there were numerous scratches on the worn surfaces. This implies that abrasive wear is the main wear mechanism. When the as-cast AA7075 and AA7075/TiB2 composite wear surfaces are examined under reduced magnification, a clear pattern of ridges and grooves that run parallel to one another in a sliding direction is observed [35]. SEM images for different composites showed larger wear debris particles with an increase in load. Debris refers to the materials detached from the surface due to sliding action, indicating significant adhesion compared to abrasion, which results in a higher wear rate. Delamination occurs due to the interaction between the two sliding surfaces, generating small particles and leading to relatively smooth surfaces because of the deformation of rough surfaces in contact [20]. After sufficient sliding action, the friction force begins to decrease or remains constant due to the tearing of layers, resulting in the lowest coefficient of friction.

SEM micrographs of wear tracks: (a) as cast AA7075, (b) AA7075 with 1.5 wt% TiB2, (c) AA7075 with 3 wt% TiB2, and (d) AA7075 with 4.5 wt% TiB2.

5 Conclusions

Particulate-reinforced MMCs have been shown to improve the mechanical characteristics of AA7075. The difficulty, however, is in achieving homogeneous reinforcement dispersion. The inhomogeneities result in variations in the mechanical properties. In the present work, fabrication of sustainable AA7075/TiB2 MMCs was done and analysis of microstructural characteristics along with mechanical properties was carried out. The results of this study are summarized below.

Squeeze casting was used to successfully create eco-friendly AMMCs using AA7075 as a matrix material and TiB2 as reinforcement with reinforcement percentages of 1.5, 3.0, and 4.5. The microstructural analysis revealed a uniform distribution of the TiB2 particles in the AA7075.

The hardness of the resulting composite materials exhibited an upward trend with the progressive increase in the weight percent of the TiB2 particles. The highest hardness value for the AA7075/4.5 wt% TiB2 composite was 162 HV, which was 26% higher than that of the as-cast AA7075.

Increasing TiB2 reinforcement enhanced the tensile strength. For the AA7075/4.5 wt% TiB2 composite, the tensile strength increased to 354 MPa (18% increase compared to as-cast alloy). The ductility of the AA7075/TiB2 composites remained almost constant.

As-cast AA7075 and its composites with varying wt% of TiB2 particles consisted of fine shallow dimples. Despite the inclusion of reinforcement, ductile rupture was found to be the major fracture mechanism in a fractography examination.

The wear and friction characteristics of the manufactured composites were evaluated using a pin-on-disc test apparatus. The reduction in wear loss of the composites was observed with an increase in the weight percentages of TiB2 reinforcement.

Acknowledgments

The authors express their gratitude to Defence Institute of Advanced Technology, Pune, for their assistance in carrying out the current research.

-

Funding information: Authors state no funding involved.

-

Author contributions: Samadhan Deshmukh: conceptualization, methodology, and original draft preparation. Asha Ingle: writing – review; supervision, and project administration. Dineshsingh Thakur: resources, supervision, and project administration. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors declare no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article.

References

[1] Suresh S, Gowd GH, Deva Kumar MLS. Experimental investigation on mechanical properties of Al 7075/Al2O3/Mg NMMC’s by stir casting method. Sadhana – Acad Proc Eng Sci. 2019;44:1–10.10.1007/s12046-018-1021-9Search in Google Scholar

[2] Ramanathan A, Krishnan PK, Muraliraja R. A review on the production of metal matrix composites through stir casting – Furnace design, properties, challenges, and research opportunities. J Manuf Process. 2019;42:213–45.10.1016/j.jmapro.2019.04.017Search in Google Scholar

[3] Wąsik A, Leszczyńska-Madej B, Madej M. Sustainability in the manufacturing of eco-friendly aluminum matrix composite materials. Sustain. 2024;16:903. 10.3390/su16020903.Search in Google Scholar

[4] Amirtharaj J, Mariappan M. Exploring the potential uses of aluminium metal matrix composites (AMMCs) as alternatives to steel bar in Reinforced Concrete (RC) structures-A state of art review. J Build Eng. 2023;80:108085.10.1016/j.jobe.2023.108085Search in Google Scholar

[5] Seetharaman S, Subramanian J, Singh RA, Wong WLE, Nai MLS, Gupta M. Mechanical properties of sustainable metal matrix composites: A review on the role of green reinforcements and processing methods. Technologies. 2022;10:32. 10.3390/technologies10010032.Search in Google Scholar

[6] Deshmukh S, Joshi G, Ingle A, Thakur D. An overview of aluminium matrix composites: Particulate reinforcements, manufacturing, modelling and machining. Mater Today Proc. 2021;46:8410–6.10.1016/j.matpr.2021.03.450Search in Google Scholar

[7] Sethi D, Acharya U, Medhi T, Shekhar S, Roy BS. Microstructural and mechanical property of friction stir welded Al7075/TiB2 aluminium matrix composite. Mater Today Proc. 2019;46:9180–6.10.1016/j.matpr.2020.01.198Search in Google Scholar

[8] Li X, Das H, Pole M, Li L, Soulami A, Grant GJ, et al. Exceptional strength and wear resistance in an AA7075/TiB2 composite fabricated via friction consolidation. Mater Des. 2024;242:113006.10.1016/j.matdes.2024.113006Search in Google Scholar

[9] Pazhouhanfar Y, Eghbali B. Microstructural characterization and mechanical properties of TiB2 reinforced Al6061 matrix composites produced using stir casting process. Mater Sci Eng A. 2018;710:172–80.10.1016/j.msea.2017.10.087Search in Google Scholar

[10] Lee WS, Sue WC, Lin CF. The effects of temperature and strain rate on the properties of carbon-fiber-reinforced 7075 aluminum alloy metal-matrix composite. Compos Sci Technol. 2000;60:1975–83.10.1016/S0266-3538(00)00083-XSearch in Google Scholar

[11] Rajan HM, Ramabalan S, Dinaharan I, Vijay SJ. Effect of TiB2 content and temperature on sliding wear behavior of AA7075/TiB2 in situ aluminum cast composites. Arch Civ Mech Eng. 2014;14:72–9.10.1016/j.acme.2013.05.005Search in Google Scholar

[12] Shanbhag VV, Yalamoori NN, Karthikeyan S, Ramanujam R, Venkatesan K. Fabrication, surface morphology and corrosion investigation of Al 7075-Al2O3 matrix composite in sea water and industrial environment. Procedia Eng. 2014 Jan;97:607–13.10.1016/j.proeng.2014.12.289Search in Google Scholar

[13] Reddy MS, Chetty SV, Premkumar S, Reddappa HN. Influence of reinforcements and heat treatment on mechanical and wear properties of Al 7075 based hybrid composites. Procedia Mater Sci. 2014;5:508–16.10.1016/j.mspro.2014.07.294Search in Google Scholar

[14] Ezhil Vannan S, Paul Vizhian S, Karthigeyan R. Investigation on the influence of basalt fiber on thermal properties of Al7075/basalt fiber metal matrix composites. Procedia Eng. 2014;97:432–8.10.1016/j.proeng.2014.12.267Search in Google Scholar

[15] Balaji V, Sateesh N, Hussain MM. Manufacture of aluminium metal matrix composite (Al7075-SiC) by stir casting technique. Mater Today Proc. 2015;2:3403–8.10.1016/j.matpr.2015.07.315Search in Google Scholar

[16] Imran M, Khan AA, Megeri S, Sadik S. Study of hardness and tensile strength of Aluminium-7075 percentage varying reinforced with graphite and bagasse-ash composites. Resour Technol. 2016;2:81–8.10.18799/24056529/2016/2/50Search in Google Scholar

[17] Veeravalli RR, Nallu R, Mohammed Moulana Mohiuddin S. Mechanical and tribological properties of AA7075-TiC metal matrix composites under heat treated (T6) and cast conditions. J Mater Res Technol. 2016;5:377–83.10.1016/j.jmrt.2016.03.011Search in Google Scholar

[18] Kumarasamy SP, Vijayananth K, Thankachan T, Muthukutti GP. Investigations on mechanical and machinability behavior of aluminum/flyash cenosphere/Gr hybrid composites processed through compocasting. J Appl Res Technol. 2017;15:430–41.10.1016/j.jart.2017.05.005Search in Google Scholar

[19] Kannan C, Ramanujam R. Comparative study on the mechanical and microstructural characterisation of AA 7075 nano and hybrid nanocomposites produced by stir and squeeze casting. J Adv Res. 2017;8:309–19.10.1016/j.jare.2017.02.005Search in Google Scholar PubMed PubMed Central

[20] Gan GS, Gao Q, Yang B, Gan SD. Effect sedimentation of TiB2 particles on the microstructure of 7075 Al alloy. Adv Mater Res. 2014;904:50–3.10.4028/www.scientific.net/AMR.904.50Search in Google Scholar

[21] Jiang B, Zhenglong L, Xi C, Peng L, Nannan L, Yanbin C. Microstructure and mechanical properties of TiB2-reinforced 7075 aluminum matrix composites fabricated by laser melting deposition. Ceram Int. 2019;45:5680–92.10.1016/j.ceramint.2018.12.033Search in Google Scholar

[22] Wang H, Zhang H, Cui Z, Chen Z, Chen D, Wang H. Investigation on the high-temperature ductility and fracture mechanisms of an in-situ particle reinforced Al matrix composite 7075Al/TiB2. Mater Sci Eng A. 2019;764:138263.10.1016/j.msea.2019.138263Search in Google Scholar

[23] Pan S, Saso T, Yu N, Sokoluk M, Yao G, Umehara N, et al. New study on tribological performance of AA7075-TiB2 nanocomposites. Tribol Int. 2020;152:106565. 10.1016/j.triboint.2020.106565.Search in Google Scholar

[24] Deshmukh S, Ingle A, Thakur D. Optimization of stir casting process parameters in the fabrication of aluminium based metal matrix composites. Mater Today Proc. 10.1016/j.matpr.2023.08.023. Epub ahead of print 2023.Search in Google Scholar

[25] Deshmukh S, Ingle A, Thakur D. Experimental investigation on mechanical properties of TiB2 reinforced AA6061 metal matrix composites fabricated by stir casting process. Mater Today Proc 10.1016/j.matpr.2023.08.169. Epub ahead of print 2023.Search in Google Scholar

[26] Manojkumar S, Kant Mehta K. Effect of TiB2 on mechanical and corrosion properties of Al 7075/TiB2/Gr composite prepared by stir casting. Mater Today Proc. 2023;91:62–6.10.1016/j.matpr.2023.05.033Search in Google Scholar

[27] Han WA, Zhang HM, Cui ZS, Zhe CH, Dong CH. Ductile fracture behavior of in situ TiB2 particle reinforced 7075 aluminum matrix composite in various stress states. Trans Nonferrous Met Soc China (Engl Ed). 2023;33:2272–86.10.1016/S1003-6326(23)66258-2Search in Google Scholar

[28] Poria S, Sutradhar G, Sahoo P. High temperature tribological behavior of stir-cast Al-TiB2 metal matrix composites. Surf Rev Lett. 2018;25:1–18.10.1142/S0218625X18501226Search in Google Scholar

[29] Deshmukh S, Ingle A, Thakur D. Investigation on mechanical properties of AA6061/TiB2 metal matrix composites fabricated by squeeze casting process. NanoWorld J. 2023;9(S4):94–9. 10.17756/nwj.2023-s4-017.Search in Google Scholar

[30] Zakaria KA, Suhadak FH, Ali MB, Abdullah S, Ghazali MJ. Influence of mechanical properties on load sequence effect and fatigue life of aluminium alloy. J Mech Eng Sci. 2017;11:2469–77.10.15282/jmes.11.1.2017.6.0227Search in Google Scholar

[31] Munro RG. Nanch. J Res Natl Inst Stand Technol. 2000;105:709.10.6028/jres.105.057Search in Google Scholar PubMed PubMed Central

[32] Raj R, Thakur DG. Qualitative and quantitative assessment of microstructure in Al-B4C metal matrix composite processed by modified stir casting technique. Arch Civ Mech Eng. 2016;16:949–60.10.1016/j.acme.2016.07.004Search in Google Scholar

[33] Raj R, Thakur DG. Effect of particle size and volume fraction on the strengthening mechanisms of boron carbide reinforced aluminum metal matrix composites. Proc Inst Mech Eng Part C J Mech Eng Sci. 2019;233:1345–56.10.1177/0954406218771997Search in Google Scholar

[34] Subramaniam B, Natarajan B, Kaliyaperumal B, Chelladurai SJ. Wear behaviour of aluminium 7075 - Boron carbide- coconut shell fly ash reinforced hybrid metal matrix composites. Mater Res Express. 2019;6:449–56.10.1007/s41230-018-8105-3Search in Google Scholar

[35] Suresh S, Moorthi NSV. Process development in stir casting and investigation on microstructures and wear behavior of TiB2 on A16061 MMC. Procedia Eng. 2013;64:1183–90.10.1016/j.proeng.2013.09.197Search in Google Scholar

© 2025 the author(s), published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite

Articles in the same Issue

- Research Articles

- Probing microstructural evolution and surface hardening of AISI D3 steel after multistage heat treatment: An experimental and numerical analysis

- Activation energy of lime cement containing pozzolanic materials

- Optimizing surface quality in PMEDM using SiC powder material by combined solution response surface methodology – Adaptive neuro fuzzy inference system

- Experimental study of the mechanical shear behaviour of steel rebar connectors in timber–concrete structure with leafy wood species

- Development of structural grade lightweight geopolymer concrete using eco-friendly materials

- An experimental approach for the determination of the physical and mechanical properties of a sustainable geopolymer mortar made with Algerian ground-granulated blast furnace slag

- Effect of using different backing plate materials in autogenous TIG welding on bead geometry, microhardness, tensile strength, and fracture of 1020 low carbon steel

- Uncertainty analysis of bending response of flexoelectric nanocomposite plate

- Leveraging normal distribution and fuzzy S-function approaches for solar cell electrical characteristic optimization

- Effect of medium-density fiberboard sawdust content on the dynamic and mechanical properties of epoxy-based composite

- Mechanical properties of high-strength cement mortar including silica fume and reinforced with single and hybrid fibers

- Study the effective factors on the industrial hardfacing for low carbon steel based on Taguchi method

- Analysis of the combined effects of preheating and welding wire feed rates on the FCAW bead geometric characteristics of 1020 steel using fuzzy logic-based prediction models

- Effect of partially replacing crushed oyster shell as fine aggregate on the shear behavior of short RC beams using GFRP rebar strengthened with TRC: Experimental and numerical studies

- Micromechanic models for manufacturing quality prediction of cantula fiber-reinforced nHA/magnesium/shellac as biomaterial composites

- Numerical simulations of the influence of thermal cycling parameters on the mechanical response of SAC305 interconnects

- Impact of nanoparticles on the performance of metakaolin-based geopolymer composites

- Enhancing mechanical and thermal properties of epoxy-based polymer matrix composites through hybrid reinforcement with carbon, glass and steel

- Prevention of crack kinetic development in a damaged rod exposed to an aggressive environment

- Ideal strain gauge location for evaluating stress intensity factor in edge-cracked aluminum plates

- Experimental and multiscale numerical analysis of elastic mechanical properties and failure in woven fabric E-glass/polyester composites

- Optimizing piezoelectric patch placement for active repair of center-cracked plates

- Experimental investigation on the transverse crushing performance of 3D printed polymer composite filled aluminium tubes

- Review Articles

- Advancing asphaltic rail tracks: Bridging knowledge gaps and challenges for sustainable railway infrastructure

- Chemical stabilization techniques for clay soil: A comprehensive review

- Development and current milestone of train braking system based on failure phenomenon and accident case

- Rapid Communication

- The role of turbulence in bottom-up nanoparticle synthesis using ultrafast laser filamentation in ethanol

- Special Issue on Deformation and Fracture of Advanced High Temperature Materials - Part II

- Effect of parameters on thermal stress in transpiration cooling of leading-edge with layered gradient

- Development of a piezo actuator-based fatigue testing machine for miniature specimens and validation of size effects on fatigue properties

- Development of a 1,000°C class creep testing machine for ultraminiature specimens and feasibility verification

- Special Issue on Advances in Processing, Characterization and Sustainability of Modern Materials - Part II

- Surface integrity studies in microhole drilling of Titanium Beta-C alloy using microEDM

- Experimental investigation on bacterial concrete by using Cantabro loss and UPV

- Influence of gas nitriding on the surface layer of M50 NiL steel for aerospace-bearing applications

- Experimental investigation on the spectral, mechanical, and thermal behaviors of thermoplastic starch and de-laminated talc-filled sustainable bio-nanocomposite of polypropylene

- Synthesis and characterization of sustainable hybrid bio-nanocomposite of starch and polypropylene for electrical engineering applications

- Microstructural and mechanical characterization of Al6061-ZrB2 nanocomposites fabricated by powder metallurgy

- Effect of edge preparation on hardness and corrosion behaviour of AA6061-T651 friction stir welds

- Mechanical improvement in acetal composites reinforced with graphene nanotubes and Teflon fibers using loss functions

- Experimental investigation on the mechanical properties of aluminum-based metal matrix composites by the squeeze casting method

- Investigation on punch force–displacement and thickness changes in the shallow drawing of AA2014 aluminium alloy sheets using finite element simulations

- Influence of liquid nitriding on the surface layer of M50 NiL steel for bearing applications

- Mechanical and tribological analyses of Al6061-GO/CNT hybrid nanocomposites by combined vacuum-assisted and ultrasonicated stir casting method

- Strengthening of structures with bacterial concrete for effective crack repair and durability enhancement

- Unique approaches in developing novel nano-composites: Evaluating their mechanical and tribological characteristics

- Load-carrying capacity of highly compact rigid deployable booms

- Investigating the influence of SiC and B4C reinforcements on the mechanical and microstructural properties of stir-casted magnesium hybrid composites

- Evaluation of mechanical and performance characteristics of bitumen mixture using waste septage ash as partial substitute

- Mechanical characterization of carbon/Kevlar hybrid woven 3D composites

- Development of a 3D-printed cervical collar using biocompatible and sustainable polylactic acid

- Mechanical characterization of walnut shell powder-reinforced neem shell liquid composite

- Special Issue on Structure-energy Collaboration towards Sustainability Societies

- Effect of tunneling conductivity of CNTs on the EMI shielding effectiveness of nanocomposite in the C-band

- Evaluation of the effect of material selection and core geometry in thin-walled sandwich structures due to compressive strength using a finite element method

- Special Issue on Sustainability and Development in Civil Engineering - Part III

- The optimum reinforcement length for ring footing resting on sandy soils resisting inclined load

- Special Issue on Advanced Materials in Industry 4.0

- Cross-dataset evaluation of deep learning models for crack classification in structural surfaces

- Mechanical and antibacterial characteristics of a 3D-printed nano-titanium dioxide–hydroxyapatite dental resin-based composite