Abstract

In this study, similar aluminum alloys AA5052 with additional carbon fiber-reinforced polymer composite (CFRP) interlayer were selected to investigate the effect of welding parameters (rotational speed and dwell time) on the mechanical properties, joint efficiency, and microstructure of friction stir spot weld joint. The maximum tensile shear load was 1779.6 N with joint efficiency of 14.6% obtained at rotational speed of 2,000 rpm and 2 s dwell time, which is 39.5% higher than the value at low rotational speed 850 rpm and 2 s dwell time. Meanwhile, the maximum microhardness 58 HV was attained in the keyhole region at rotational speed of 2,000 rpm and dwell time of 5 s, which is 22.4% higher compared to low rotational speed. The SEM-EDS results reveal the presence of intermetallic compounds (Al–Mg–C), which enhance the intermetallic bonding between elements.

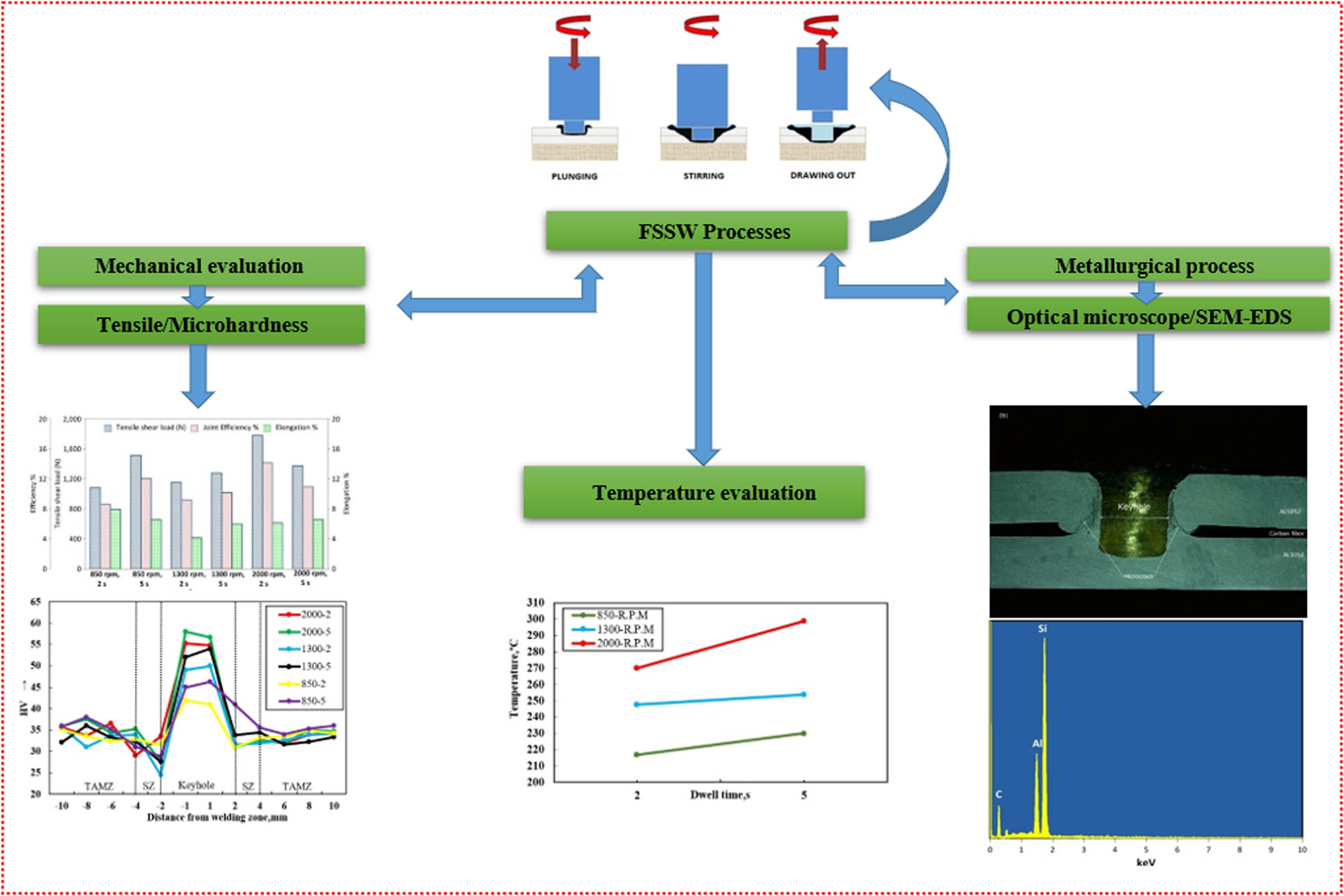

Graphical abstract

1 Introduction

There is an increasing demand for lightweight structures, especially in transportation sector [1]. Recently, applications of lightweight materials such as aluminum, magnesium, and metal foams, as typical porous materials [2], have been increased in automotive and aerospace industries [3]. Also, it is a critical challenge to reduce the weight in these industries to improve the performance of vehicle and airplane [4]. Light weight structure designs can be achieved by using composite materials, which are high cost-intensive and yet not suitable for mass production due to the necessity of manual processing [5]. In recent years, composite materials have triggered worldwide investigations to manufacture improved structures with superior mechanical characteristics [6] same as laminated composite plates [7]. Carbon fiber-reinforced composites (CFRPs) have excellent thermal and mechanical properties and are commonly applied in the fabrication of polymer–matrix composites [8]. Composite and nanocomposite materials are utilized as a lightweight material [9]. CFRP industry is developing by constant growth of demand from defense and aerospace to automotive sectors [10]. In the past decades, nanocomposite and composite materials have attracted great attention because of their exclusive improving and properties’ effects on specific mechanical performance which are not easy to achieve with other materials [11]. New micro- and nano-technologies used in fabrication of advanced materials have been resulted in lightweight structures with a large range of applications [12]. Despite the fact that the extraordinary mechanical characteristics of CFRPs make them an attractive option for designers, they have to outperform existing lightweight structural automotive materials [13], whereas carbon nanotubes are suitable for electrical and thermal application [14]. Moreover, reinforcing core layer with CNTs leads to remarkable drop and increase in thermal and mechanical buckling resistances, respectively [15]. Rezaei et al. [16] proposed the effect of fiber length on thermomechanical properties of carbon fiber. The results show that short carbon fiber-reinforced polypropylene thermal stability increased by increasing the length of carbon fiber. Therefore, extensive research has been performed on the application of conventional pitch-based CFRPs in improving and optimizing the characteristics of a wide variety of structures [17]. The machining of CFRP composites types is carried out mainly on plain-woven carbon fiber and epoxy resin matrix, including directional, unidirectional, and multidirectional CFRP laminates [18]. Aluminum alloys are one of the most promising lightweight materials due to their corrosion resistance, high specific stiffness, strength, high recyclability, and impact resistance [19]. Friction stir spot welding FSSW is a solid state joining technique and has been applied to aluminum alloys such as 2,000 and 5,000 series [20]. These alloys are apt to solidification and liquation cracking, which can be avoided by friction stir spot welding [21]. FSSW is an advanced form of friction welding which is mostly used to weld the similar and dissimilar alloys [22]. FSSW provides reduction in energy consumption up to 90 and 40% in capital cost compared to resistance spot welding (RSW) [23]. Also, the formation of stirring zone in FSSW requires a small amount of heat generation which reduces welding time and energy consumption [24]. Procesov [25] showed the comparison between FSSW and RSW of AA5005 alloy. The results showed that the mechanical performance of FSSW joint was higher than RSW and concluded that FSSW could be an alternative to RSW. The most important parameter for heat input in friction stir spot welding is rotational speed [26] and peak temperature increased with increased rotational speed [27]. The temperature should be less than melting point of metals during the processes [28]. Rana et al. [29] presented the effect of different rotational speed on FSSW; the optimal rotational speed was 1,800 rpm for high mechanical performance. High rotation speed causes high temperature, and as a result, more intensive stirring and mixing of the material and that energy was positively connected to the bonding area with long weld strength [30]. Due to fixed pin length and shoulder, only a single lap joint could be welded with constant thickness during friction stir spot welding [31]. Dwell time is another parameter affecting FSSW and provides the heat required for the formation of stir zone and bonding region between upper and lower sheets [32]. Long dwell times should be applied for metals with high melting points to generate required heat for plasticity flow material [33]. Also, less than one second would be small softening in heat-affected zone for heat-treated aluminum alloys [34]. Rafiei et al. [35] investigated the mechanical properties of dissimilar friction welding of aluminum (AA5052)-magnesium and aluminium (AA2024)-copper. The processes parameters were rotational speed 1,250 rpm and feed rate 160 mm/min. The hardness was low in heat-affected zone and thermal-mechanical-affected zone (TMAZ) due to welding defects such as hook defect. Also, residual stress is considered as a defect on welding quality [36]. Khosa et al. [37] evaluated the effect of thermomechanical during FSSW of AA6082-T6. The result showed that the effect of temperature on the microstructure and mechanical properties was severe due to the deformation and material flow of welded sample. Kubit et al. [38] studied additional sealant interlayer in AA7075-T6 alloy. The obtained results show that the joint properties of weld joint could be improved by optimal thickness of interlayer. Sadoun et al. [39] evaluated the effect of interlayer in dissimilar aluminum AA2024 and AA7075 alloys. The obtained result showed 18% improvement in joint strength due to grain refinement compared to without interlayer joint. Andre et al. [40] improved the adhesion mechanisms and mechanical performance of aluminum AA2024-T3 and CFRP with 100 μm PPS film additional interlayer fiction spot welding. The effect of micro-mechanical interlocking at the interface of interlayer achieved with sandblasted specimens was clear. The optimal tensile shear force was 3,068 N, due to effect on contact surface area. Also, sandblasting was found to be the most effective treatment which maximized joint mechanical performance. Andre et al. [41] investigated the effects of rotating speed and joining pressure on the mechanical strength and microstructure of friction spot welding of carbon fiber and aluminum AA2024-T3 with 100 μm PPS film interlayer. They reported that lap shear force was increased from 2,700 to 3,070 N, which was higher than those for joints without interlayer because of their improved micro-mechanical interlocking, better load distribution, and larger bonding area. Temperature was measured on surface which ranged from 325 to 417°C. In the microstructure of two bonding interfaces, the PPS into the crevices of aluminum and CFRP entrapment by aluminum deformed. However, in joints without interlayer, a transition zone with high air bubbles was created between adhesion zone and plastically deformed zone. Abed et al. [42] proposed the effect of friction stir spot welding of AA6061-T6 with copper interlayer and found that the increase of dwell time and plunge depth was beneficial to the formation of joint and directly increased tensile shear load. Joint formation was improved with cupper interlayer addition and this improvement could be related to the increase of bonding area and intermetallic compound from the reaction of metal and interlayer. High load fracture occurred in cupper interlayer rather than those without interlayer. However, interlayer considerably increases the protection of weld against corrosive environments [43]. The reaction between aluminum and carbon fiber during welding processes caused to form aluminum carbide (Al4C3) at temperatures above 500°C, which negatively affected the performance of interfacial layer in composites [44].

In the current study, the effect of welding parameters and CFRP interlayer on the mechanical and microstructural properties of welding joints has been investigated in FSSW joint process. The objective of this study is to evaluate the effect of CFRP interlayer on the performance of mechanical properties (tensile shear load and microhardness) and microstructural properties (SEM-EDS) and joint efficiency of the weld joints.

2 Experimental work

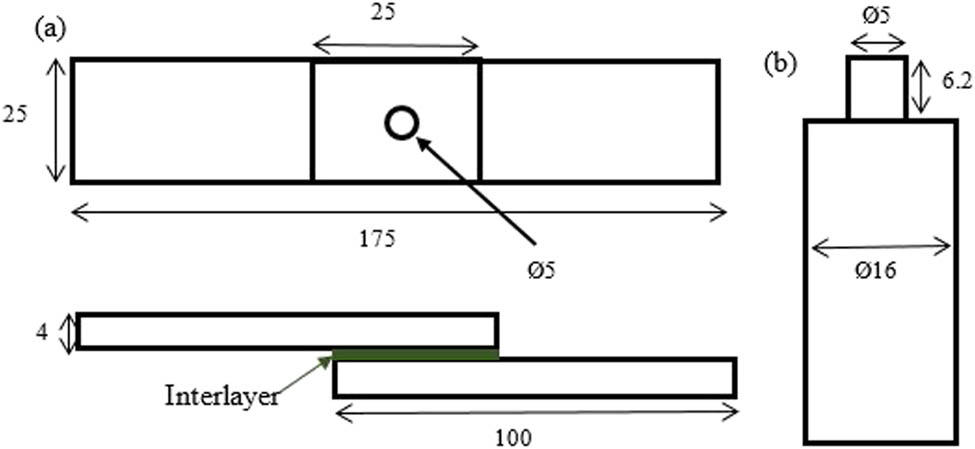

Aluminum alloy AA5052 plates were chosen in this study. The dimensions of the plate were 100 mm × 25 mm × 4 mm, based on American Welding Society standard (AWS C1.1M/C1.1:2012) [42] as showed in Figure 1(a). CFRP with thickness 0.5 mm was applied as interlayer between similar aluminum sheets. For each combination of process parameters, three replicates were made. The surface of material was cleaned using alcohol to remove contaminants that could generate oxides. The tool was rotated at high speed, then forced into workpiece until the shoulder contacted top metal surface.

(a) Schematic diagram of lab joint (mm); (b) tool dimension (mm).

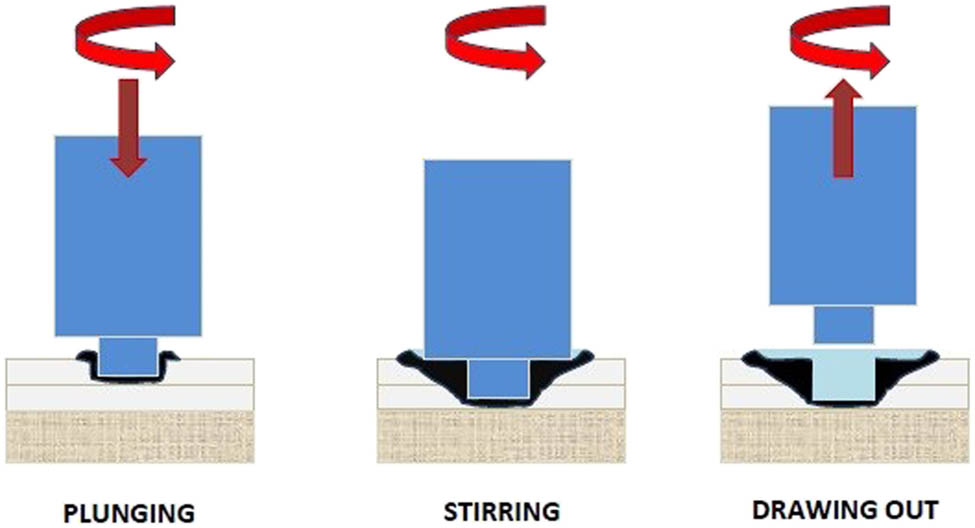

The tool was made from steel alloy AISI 4340 (UNS G43400), as showed in Figure 1b. The length of the pin was 6.2 mm and its diameter was 5 mm with cylindrical design. Friction stir spot welding consists of three stages: plunging, stirring, and retracting, as showed in Figure 2.

Friction stir spot welding processes.

The experimental full factorial design with two level (rotation speed and dwell time) was chosen for joining processes, as illustrated in Table 1.

Two-level 2k full factorial design: experiments defined by normalized parameters (rotation speed and dwell time)

| Sample no. | Std order | Run order | Rotational speed | Dwell time (s) |

|---|---|---|---|---|

| 1 | 2 | 1 | 850 | 5 |

| 2 | 5 | 2 | 200 | 2 |

| 3 | 1 | 3 | 850 | 2 |

| 4 | 4 | 4 | 1,300 | 5 |

| 5 | 6 | 5 | 2,000 | 5 |

| 6 | 3 | 6 | 1,300 | 2 |

In this study, temperature evolution on the top surfaces of aluminum was monitored during friction stir spot welding (Thermometer PCE-T390). The maximum process temperature was considered as the highest temperature measured on the top surfaces of aluminum sheets. The mechanical performance of joints was evaluated through tensile shear load by using universal tensile test machine (INSTRON-5582). Three identical samples were tested for each joining condition. Load rate was adjusted at 3 mm/min for all specimens and were mounted on the jaws of the machine. Joint efficiency (η) of AA5052 with CFRP was obtained by applying the following equation [45].

Microhardness values were evaluated using Vickers test with Vickers hardness of 4.903 N and dwell time 20 s. Several indents were made at 10 mm intervals along cross section from weld center to investigate microhardness profile. Microstructure analysis was conducted in the cross section of the joint by optical microscope. Also, in microstructure evaluation, energy dispersive spectroscopy (SEM-EDS) was applied.

3 Results and discussions

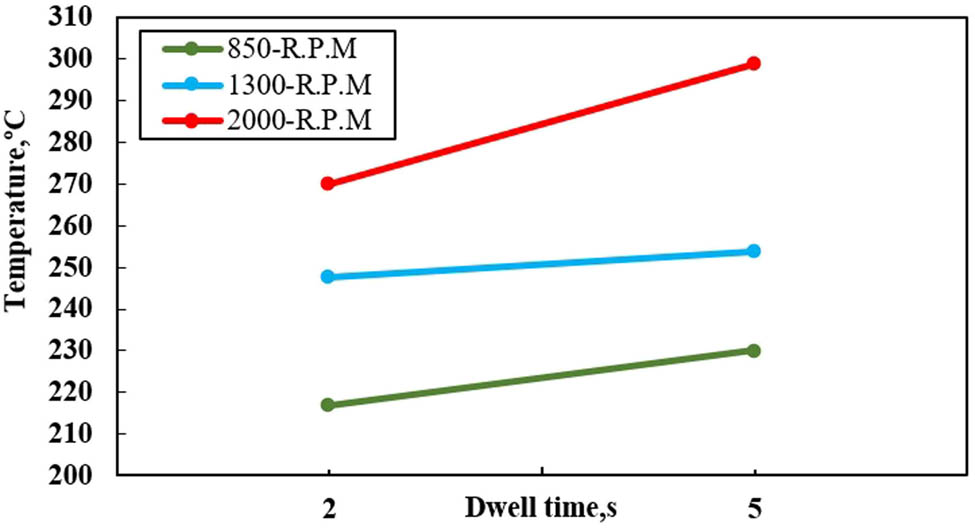

3.1 Temperature evaluation

Figure 3 shows peak temperature of aluminum and CFRP interlayer at different rotational speed and dwell time. The peak temperature was about 298.5°C at rotational speed 2,000 rpm and dwell time 5 s, while the minimum temperature was 216.9°C at rotational speed 850 rpm and dwell time 2 s. Generally, Al4C3 compound could not be formed due to low temperature during the FSSW processes. Also, it was clear that the increase of dwell time from 2 to 5 s at all rotating speeds directly affected temperature, dramatically increasing it by up to 10%. Heat generation at the surface of aluminum was not high enough to melt the interlayer at the interface in the whole overlapped area. This was due to the lower thermal conductivity of CFRP (0.19 W/m K) than aluminum [46].

Evolution of friction spot joining process temperature.

3.2 Tensile shear load

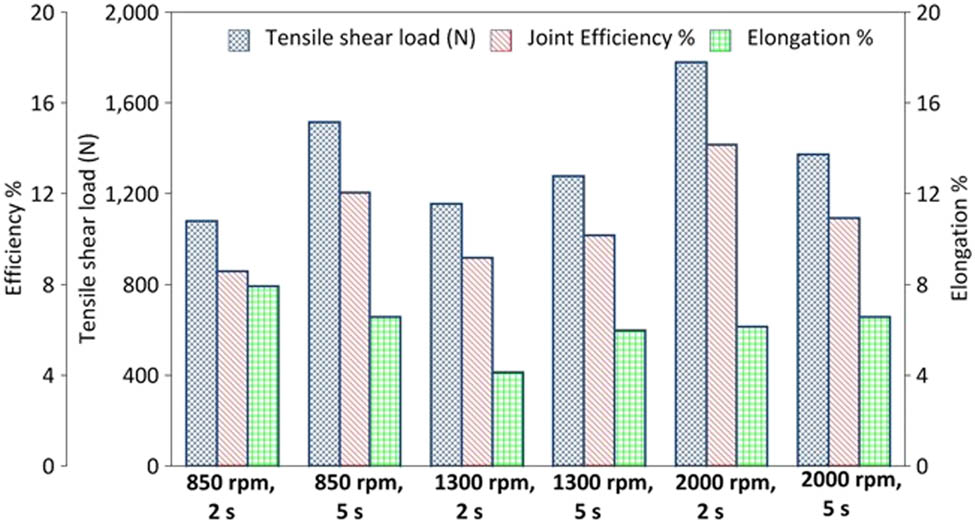

The results of tensile shear load of AA5052 FSSW joints are showed in Figure 4. Maximum tensile of 1779.6 N was produced at rotational speed 2,000 rpm and dwell time 2 s with 14.6% joint efficiency, while minimum tensile occurred at 850 rpm and dwell time 2 s was 1,373 N. In addition, the results showed that increase of rotational speed from 850 to 2,000 rpm at 2 s dwell time with 39.5% improvement in tensile shear load was obtained. It was necessary to decrease the distribution of intermetallic compounds to have high tensile and avoid poor performance of welding [45]. The highest tensile shear load could be related to the large bonding area and good load distribution in FSSW process [47]. On the other hand, increase of dwell time from 2 to 5 s and a 9% decline in tensile shear load at low to high rotational speeds caused to increase heat input that led to overheat the material in weld region, which induced the grain growth and eventually decreased tensile shear load [41,48]. High heat input was developed due to high dwell time, which led to initiate the cracks in the weld interface and reduce the tensile shear load [49]. The maximum elongation of 8% was founded at rotational speed of 850 rpm and 2 s of dwell time. Large elongation could be due to large joint area and increased amount of CFRP attached to aluminum surface [50].

Tensile shear load (N), elongation (%), and efficiency (%) of FSSW.

3.3 Microhardness

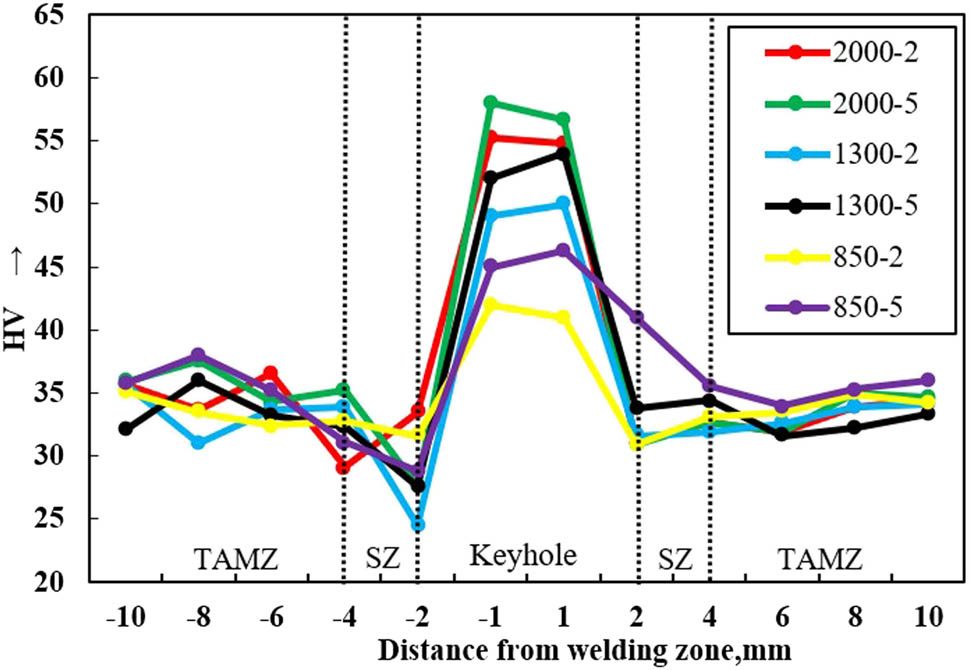

Rotational speed and dwell time are significant parameters in FSSW processes, such that increase of dwell time from 2 to 5 s at all rotational speeds directly increased microhardness. Microhardness profile is illustrated in Figure 5. Maximum microhardness value was 58 HV which was obtained at 2,000 rpm rotating speed and 5 s dwell time in keyhole, whereas minimum value was 24.5 HV obtained at 1,300 rpm rotational speed and 2 s dwell time in stir zone (SZ). The graph showed the highest microhardness in keyhole area rather than SZ and TMAZ. In key hole area, 29% improvement was achieved by increasing rotational speed and dwell time. This was due to mixing and incorporating CFRP and aluminum during FSSW processes. Hardness test results provided further support to the fact that large amounts of CFRP were uniformly dispersed in the matrix over large region. However, heat generation during FSSW minimized microhardness in TMAZ region. Large amounts of geometrically necessary dislocations (GNDs) [51,52] induced during FSSW are thought to be an important reason of strengthening. There was a large difference in the coefficient of thermal expansion (CTE) between AA5052 (23.8X10-6 K-1) and CFRP (5.5X10-6 K-1) along transverse and longitudinal directions, respectively. The mismatch of CTE led to the generation of GNDs during FSSW [44]. Hence, hardness in SZ and TMAZ could be attributed to the comprehensive effect of variations in grain size and strengthening of precipitates [53].

Microhardness distributions of welds at different rotational speed and dwell time.

3.4 Microstructure

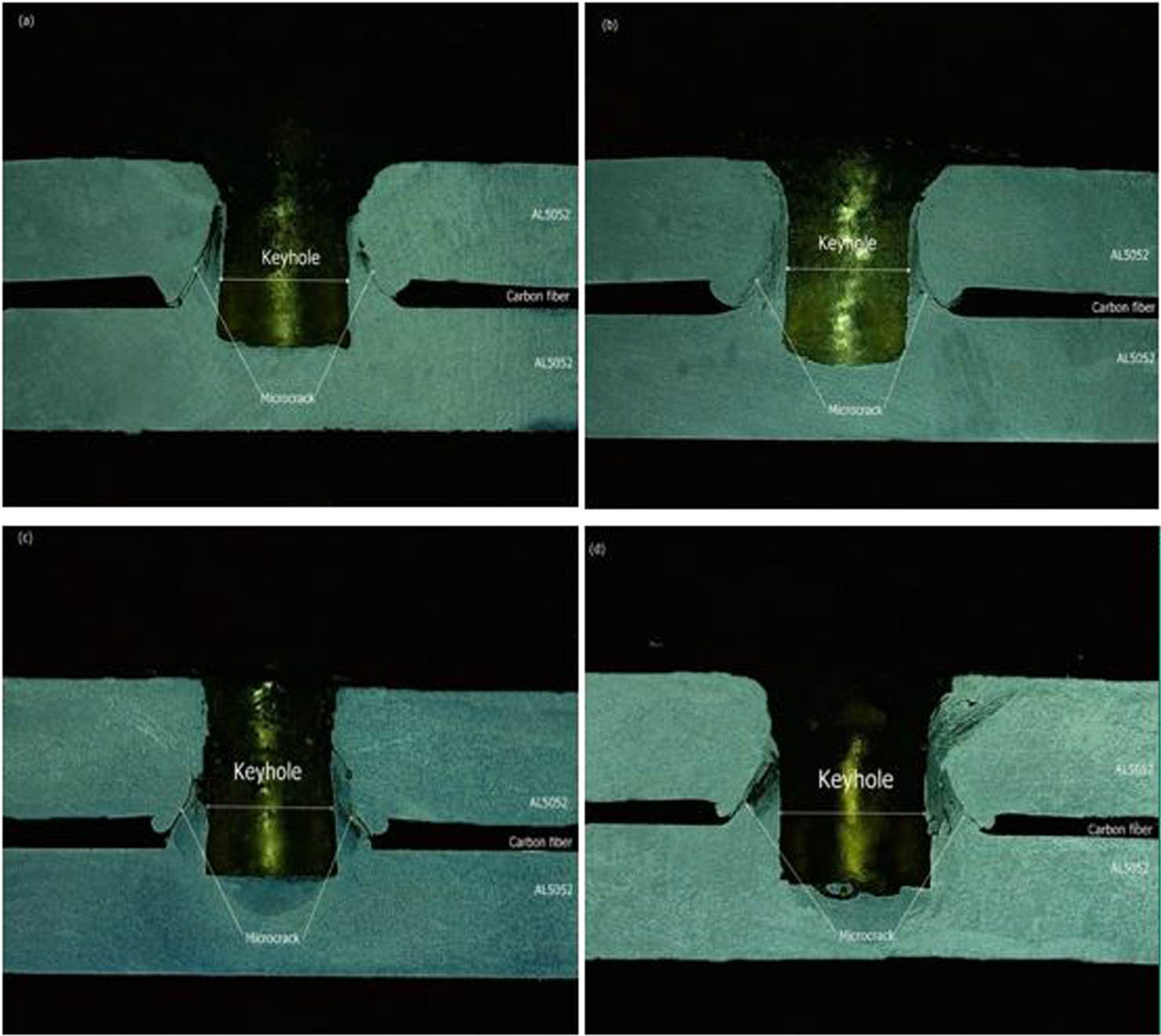

The microstructure of AA5052 with CFRP interlayer was presented in this study. Weld microstructure depended on the type of the process applied, welding parameters, and workpiece material properties such as thermal conductivity and external cooling conditions [49]. Nub was slightly inserted into thermoplastic composite part, which consequently increased mechanical interlocking between joining partners and contributed to joint mechanical strength under shear loading [54]. The samples of rotational speed 850 rpm and dwell times 2 and 5 s had lower mechanical performance compared with those at 2,000 rpm. The main reason for this was low heat input during FSSW process, which was not enough to melt interlayer to improve microhardness, as shown in Figure 6(a and b). In the cross section joint of 1,300 rpm and 5 s, crack was observed under tool pin after welding. Cracks on right and left sides rapidly extended along the top surface to pull out the entire joint from the upper plate. In the hook defect, the crack initiation was identified and extended along the hook toward the top surface to pull out stir zone; meanwhile, cracks at hook defect on the left side extended along the hook toward the bottom of stir zone. The joint broke along the interface and only a small part was pulled out. Microcracks in stirring zone were clear and their number was increased by increasing rotational speed and dwell time, as showed in Figure 6(c).

Cross section of the welding of samples (a) 850 rpm and 2 s. (b) 850 rpm and 5 s. (c) 1,300 rpm and 5 s. (d) 2,000 rpm and 2 s.

In cross section joint at rotation speed 2,000 rpm and dwell time 2 s, interlayer was melted and squeezed out of the center to the edges of the joint. This was due to high temperatures (about 298.5°C) during welding process which led to the melting of interlayer at the center of the joint. This occurred due to lower molten viscosity associated with higher frictional energy generation in this region [46]. The molten polymer could flow into crevices on aluminum surface during joining process. This caused micro-mechanical interlocking between parts, leading to increased tensile shear load, as showed in Figure 6(d) [55].

According to the microstructural characteristics of grain size and precipitates, it was found that weld structure was symmetrical with respect to tool axis. FSSW produced SZ or nugget and TMAZ, which could be identified in sequence from keyhole periphery towards base material. During tool penetration in friction stir spot welding, rapid strain rates and heating were imposed by rotating tool. In conventional friction stir spot welding method, a stir zone structure containing fine equaled grains fully develops near the end of penetration process when the tool is almost completely penetrated into sheets. Evidence of such cracking was also noted in AA7075 refill friction stir spot welds, as reported by Shen et al. [20]. The formation of a shiny surface on friction stir spot welds combination of material and welding parameters may be prone cracking. Plastic deformation and high temperature induced local melting and it was argued that liquation and solidification occurred repeatedly due to oscillating temperature resulting in nonequilibrium solidus temperature. This paper (SEM-EDS) analyzed the welds produced at rotational speed 2,000 rpm and dwell time 2 s. Similar aluminum alloys made strong bonds with CFRP.

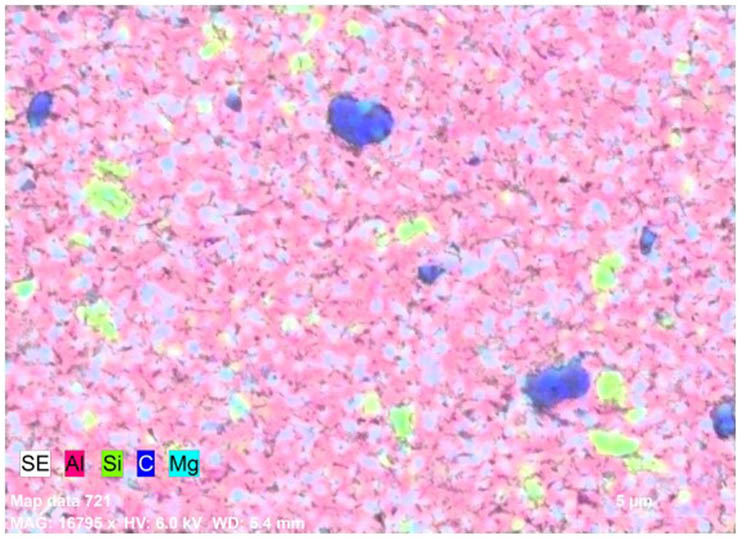

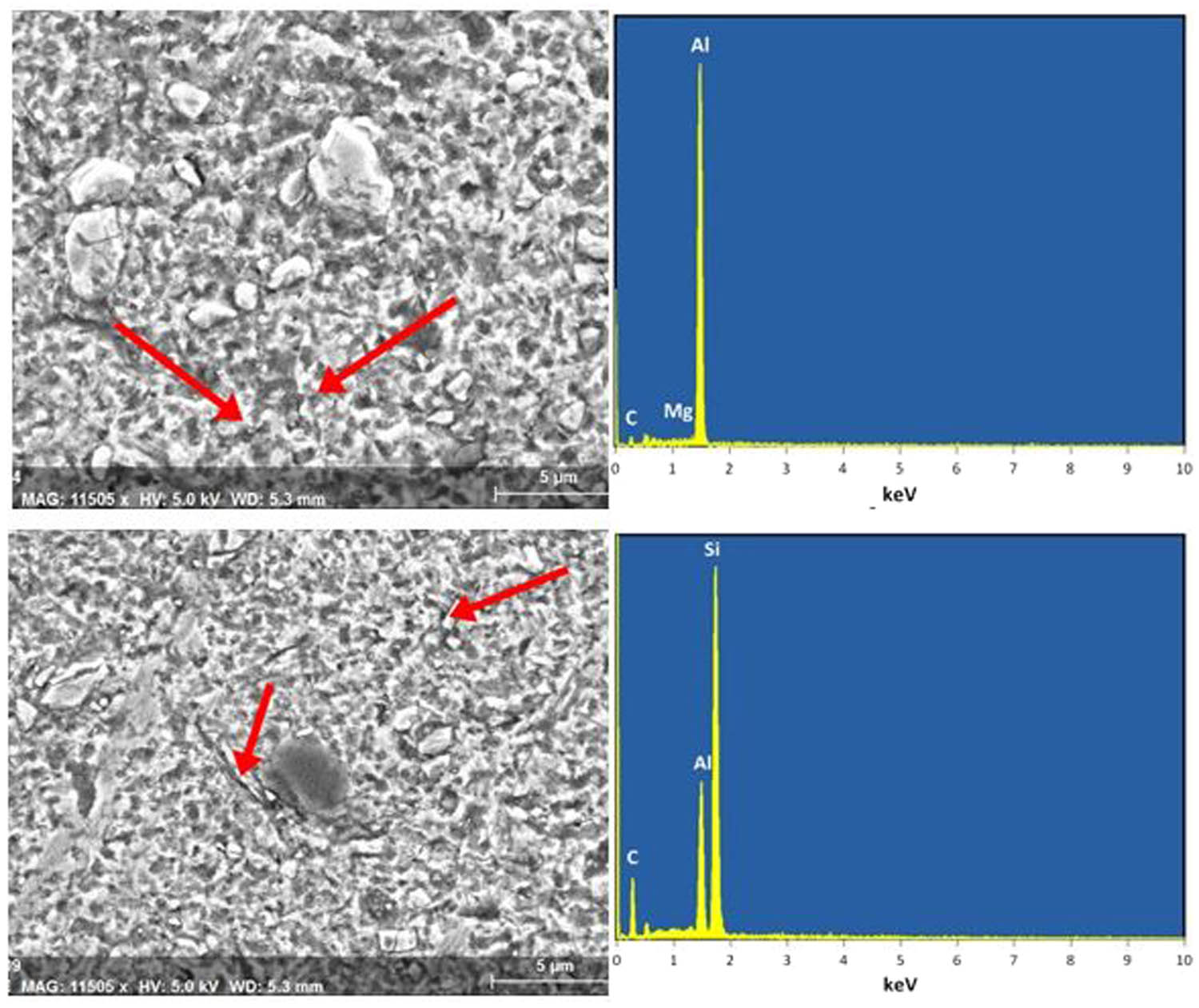

It is necessary to uniformly distribute CFRP in the matrix for fabricating aluminum alloys with CFRP and the results showed that the concentration of aluminum and carbon elements confirmed chemical bonding between aluminum and molten CFRP interlayer. Also, SEM-EDS analysis was performed to the compositions, to take place and form intermetallic compound. Dwell time was the main effect parameter to provide time for the diffusion. Figure 7 presents an SEM-EDS mapping microanalysis to identify the chemical intermetallic composition of the phases present in the welding joint and disruptions of carbon particles into the matrix, which might significantly affect structures and their properties.

Element distribution of Al and CFRP joint.

Moreover, aluminum carbide (Al4C3) was not observed because of low heat input during welding processes (Max. 298.5°C). Contact and bonding between CFRP and AA5052 was high due to thermal-mechanical effect.

The presence of Al, Mg, and C elements was proved, as illustrated in Figure 8, which indicated the presence of strong bonding, and there may be mechanical interlocking leading to high adhesive forces at joint areas which was due to the presence of carbon molecular bonding. [56]. Also, Figure 8 shows ternary intermetallic compound (Al–Si–C) and these elements mixed together due to heat input during friction processes between aluminum and CFRP [57,58]. These compounds might increase microhardness by about 58% in keyhole rather than in SZ and TMAZ [59]. In addition, more carbon fiber increased microhardness. On the other hand, more fiber reduced the distance between aluminum and fibers and increased stress, which decreased the strength of composites [60].

SEM-EDS analyses of friction stir spot welding zone: 2,000 rpm and 2 s dwell time.

4 Conclusions

The current study demonstrated that similar aluminum alloys 5052 with additional CFRP interlayer were successfully joined by applying friction stir spot welding. The effect of tool rotational speed and dwell time on mechanical performance and microstructure was investigated. The following conclusions were drawn:

The maximum tensile shear load was obtained at rotational speed 2,000 rpm and 2 s dwell time with joint efficiency of 14.61%. The increase of tensile load due to heat input melted CFRP interlayer and squeezed out of the center, whereas low rotational speed had low value of tensile shear load. Consequently, this decrease in tensile shear load may be due to the formation of microcracks within the stir zone.

The maximum hardness was observed at rotational speed 2,000 rpm and 5 s dwell time, which gradually reduced by decreasing rotational speed and dwell time. The increase in key hole area was due to plastic deformation rather than SZ and TMAZ. Carbon fiber interlayer and welding parameters showed significant effect on microhardness result. This was due to highly different coefficients of thermal expansion, mixing, and incorporating between AA5052 sheets and CFRP interlayer.

In the microstructural, the main discrete regions observed in FSSW joints are SZ and TMAZ. Interlayer was melted and squeezed out of the center of edge joint due to high heat input during the processes. Scanning electron microscope showed welding defects such as cracks which were clearly observed on the left and right sides of keyhole and were increased by increasing welding parameters. Also, SEM-EDS analysis was applied to observe the intermetallic compound and their element distribution. The elements such as Al, Mg, and C increase the mechanical performance.

-

Funding information: The authors state no funding involved.

-

Author contributions: All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: The authors state no conflict of interest.

References

[1] Dong H, Tang Z, Li P, Wu B, Hao X, Ma C. Friction stir spot welding of 5052 aluminum alloy to carbon fiber reinforced polyether ether ketone composites. Mater Des. 2021;201:109495.10.1016/j.matdes.2021.109495Search in Google Scholar

[2] Gao W, Qin Z, Chu F. Wave propagation in functionally graded porous plates reinforced with graphene platelets. Aerosp Sci Technol. 2020;102:105860.10.1016/j.ast.2020.105860Search in Google Scholar

[3] Lambiase F, Grossi V, Di Ilio A, Paoletti A. Feasibility of friction stir joining of polycarbonate to CFRP with thermosetting matrix. Int J Adv Manuf Technol. 2020;106(5):2451–62.10.1007/s00170-019-04814-8Search in Google Scholar

[4] Cinar Z, Asmael M, Zeeshan Q, Safaei B. Effect of springback on A6061 sheet metal bending: a review. J Kejuruteraan. 2021;33(1):13–26.10.17576/jkukm-2021-33(1)-02Search in Google Scholar

[5] Frketic J, Dickens T, Ramakrishnan S. Automated manufacturing and processing of fiber-reinforced polymer (FRP) composites: an additive review of contemporary and modern techniques for advanced materials manufacturing. Addit Manuf. 2017;14:69–86.10.1016/j.addma.2017.01.003Search in Google Scholar

[6] Sahmani S, Safaei B. Large-amplitude oscillations of composite conical nanoshells with in-plane heterogeneity including surface stress effect. Appl Math Modell. 2021;89:1792–813.10.1016/j.apm.2020.08.039Search in Google Scholar

[7] Safaei B. The effect of embedding a porous core on the free vibration behavior of laminated composite plates. Steel Compos Struct. 2020;35(5):659–70.Search in Google Scholar

[8] Behdinan K, Moradi-Dastjerdi R, Safaei B, Qin Z, Chu F. Hui D. Graphene and CNT impact on heat transfer response of nanocomposite cylinders. Nanotechnol Rev. 2020;9(1):41–52.10.1515/ntrev-2020-0004Search in Google Scholar

[9] Moradi-Dastjerdi R, Behdinan K. Free vibration response of smart sandwich plates with porous CNT-reinforced and piezoelectric layers. Appl Math Modell. 2021;96:66–79.10.1016/j.apm.2021.03.013Search in Google Scholar

[10] Heggemann T, Homberg W. Deep drawing of fiber metal laminates for automotive lightweight structures. Compos Struct. 2019;216:53–7.10.1016/j.compstruct.2019.02.047Search in Google Scholar

[11] Fan F, Sahmani S, Safaei B. Isogeometric nonlinear oscillations of nonlocal strain gradient PFGM micro/nano-plates via NURBS-based formulation. Compos Struct. 2021;255:112969.10.1016/j.compstruct.2020.112969Search in Google Scholar

[12] Fattahi A, Safaei B, Moaddab E. The application of nonlocal elasticity to determine vibrational behavior of FG nanoplates. Steel Compos Struct. 2019;32(2):281–92.Search in Google Scholar

[13] Tripathi K, Vincent F, Castro M, Feller J. Flax fibers–epoxy with embedded nanocomposite sensors to design lightweight smart bio-composites. Nanocomposites. 2016;2(3):125–34.10.1080/20550324.2016.1227546Search in Google Scholar

[14] Talebizadehsardari P, Eyvazian A, Asmael M, Karami B, Shahsavari D, Mahani RB. Static bending analysis of functionally graded polymer composite curved beams reinforced with carbon nanotubes. Thin-Walled Struct. 2020;157:107139.10.1016/j.tws.2020.107139Search in Google Scholar

[15] Moradi-Dastjerdi R, Behdinan K, Safaei B, Qin Z. Buckling behavior of porous CNT-reinforced plates integrated between active piezoelectric layers. Eng Struct. 2020;222:111141.10.1016/j.engstruct.2020.111141Search in Google Scholar

[16] Rezaei F, Yunus R, Ibrahim N. Effect of fiber length on thermomechanical properties of short carbon fiber reinforced polypropylene composites. Mater Des. 2009;30(2):260–3.10.1016/j.matdes.2008.05.005Search in Google Scholar

[17] Yu T, Soomro SA, Huang F, Wei W, Wang B, Zhou Z, et al. Naturally or artificially constructed nanocellulose architectures for epoxy composites: a review. Nanotechnol Rev. 2020;9(1):1643–59.10.1515/ntrev-2020-0116Search in Google Scholar

[18] Asmael M, Safaei B, Zeeshan Q, Zargar O, Nuhu AA. Ultrasonic machining of carbon fiber–reinforced plastic composites: a review. Int J Adv Manuf Technol. 2021;113:3079–120.10.1007/s00170-021-06722-2Search in Google Scholar

[19] Lapčík L, Vašina M, Lapčíková B, Hui D, Otyepková E, Greenwood RW, et al. Materials characterization of advanced fillers for composites engineering applications. Nanotechnol Rev. 2019;8(1):503–12.10.1515/ntrev-2019-0045Search in Google Scholar

[20] Shen Z, Ding Y, Gerlich AP. Advances in friction stir spot welding. Crit Rev Solid State Mater Sci. 2020;45(6):457–534.10.1080/10408436.2019.1671799Search in Google Scholar

[21] Ilman MN. Microstructure and mechanical properties of friction stir spot welded AA5052-H112 aluminum alloy. Heliyon. 2021;7(2):e06009.10.1016/j.heliyon.2021.e06009Search in Google Scholar PubMed PubMed Central

[22] Nasir T, Asmaela M, Zeeshana Q, Solyalib D. Applications of machine learning to friction stir welding process optimization. J Kejuruteraan. 2020;32(1):171–86.10.17576/jkukm-2020-32(2)-01Search in Google Scholar

[23] Feng Z, Santella M, David S, Steel R, Packer S, Pan T, et al. Friction stir spot welding of advanced high-strength steels–a feasibility study. SAE Trans. 2005;114:592–8.10.4271/2005-01-1248Search in Google Scholar

[24] Saunders N, Miles M, Hartman T, Hovanski Y, Hong S-T, Steel R. Joint strength in high speed friction stir spot welded DP 980 steel. Int J Precis Eng Manuf. 2014;15(5):841–8.10.1007/s12541-014-0407-9Search in Google Scholar

[25] Procesov EPO. Experimental comparison of resistance spot welding and friction-stir spot welding processes for the en aw 5005 aluminum alloy. Mater Tehnol. 2011;45(5):395–9.Search in Google Scholar

[26] Su P, Gerlich A, North T, Bendzsak G. Energy generation and stir zone dimensions in friction stir spot welds. SAE Trans. 2006;115:717–25.10.4271/2006-01-0971Search in Google Scholar

[27] Gerlich A, Yamamoto M, North T. Strain rates and grain growth in Al 5754 and Al 6061 friction stir spot welds. Metall Mater Trans A. 2007;38(6):1291–302.10.1007/s11661-007-9155-0Search in Google Scholar

[28] Kumar Rajak D, Pagar DD, Menezes PL, Eyvazian A. Friction-based welding processes: friction welding and friction stir welding. J Adhes Sci Technol. 2020;34(24):2613–37.10.1080/01694243.2020.1780716Search in Google Scholar

[29] Rana PK, Narayanan RG, Kailas SV. Effect of rotational speed on friction stir spot welding of AA5052-H32/HDPE/AA5052-H32 sandwich sheets. J Mater Process Technol. 2018;252:511–23.10.1016/j.jmatprotec.2017.10.016Search in Google Scholar

[30] Paidar M, Mehrez S, Ojo O, Mohanavel V, Babaei B, Ravichandran M. Modified friction stir clinching of AA6061-T6/AA5754-O joint: effect of tool rotational speed and solution heat treatment on mechanical, microstructure, and fracture behaviors. Mater Charact. 2021;173:110962.10.1016/j.matchar.2021.110962Search in Google Scholar

[31] Li M, Zhang C, Wang D, Zhou L, Wellmann D, Tian Y. Friction stir spot welding of aluminum and copper: a review. Materials. 2020;13(1):156.10.3390/ma13010156Search in Google Scholar PubMed PubMed Central

[32] Paidar M, Ali KA, Mohanavel V, Mehrez S, Ravichandran M, Ojo O. Weldability and mechanical properties of AA5083-H112 aluminum alloy and pure copper dissimilar friction spot extrusion welding-brazing. Vacuum. 2021;187:110080.10.1016/j.vacuum.2021.110080Search in Google Scholar

[33] Al-Sabur R, Jassim AK, Messele E. Real-time monitoring applied to optimize friction stir spot welding joint for AA1230 Al-alloys. Mater Today Proc. 2021;42:2018–24.10.1016/j.matpr.2020.12.253Search in Google Scholar

[34] Ahmad R, Asmael M. Effect of aging time on microstructure and mechanical properties of AA6061 friction stir welding joints. Int J Automot Mech Eng. 2015;11:2364.10.15282/ijame.11.2015.17.0198Search in Google Scholar

[35] Rafiei R, Shamanian M, Fathi M, Khodabakhshi F. Dissimilar friction-stir lap-welding of aluminum-magnesium (AA5052) and aluminum-copper (AA2024) alloys: microstructural evolution and mechanical properties. Int J Adv Manuf Technol. 2018;94(9–12):3713–30.10.1007/s00170-017-0964-zSearch in Google Scholar

[36] Glaissa MAA, Asmael M, Zeeshan Q. Recent applications of residual stress measurement techniques for FSW joints: A. J Kejuruteraan. 2020;32(3):357–71.10.17576/jkukm-2020-32(3)-01Search in Google Scholar

[37] Khosa SU, Weinberger T, Enzinger N. Thermo-mechanical investigations during friction stir spot welding (FSSW) of AA6082-T6. Weld World. 2010;54(5):R134–46.10.1007/BF03263499Search in Google Scholar

[38] Kubit A, Wydrzynski D, Trzepiecinski T. Refill friction stir spot welding of 7075-T6 aluminium alloy single-lap joints with polymer sealant interlayer. Compos Struct. 2018;201:389–97.10.1016/j.compstruct.2018.06.070Search in Google Scholar

[39] Sadoun A, Meselhy A, Deabs A. Improved strength and ductility of friction stir tailor-welded blanks of base metal AA2024 reinforced with interlayer strip of AA7075. Results Phys. 2020;16:102911.10.1016/j.rinp.2019.102911Search in Google Scholar

[40] Manente André N, Goushegir SM, Scharnagl N, dos Santos JF, Canto LB, Amancio-Filho ST. Composite surface pre-treatments: Improvement on adhesion mechanisms and mechanical performance of metal–composite friction spot joints with additional film interlayer. J Adhes. 2018;94(9):723–42.10.1080/00218464.2017.1378101Search in Google Scholar

[41] André NM, Goushegir SM, Dos Santos JF, Canto LB, Amancio-Filho ST. Friction Spot Joining of aluminum alloy 2024-T3 and carbon-fiber-reinforced poly (phenylene sulfide) laminate with additional PPS film interlayer: Microstructure, mechanical strength and failure mechanisms. Composites, Part B. 2016;94:197–208.10.1016/j.compositesb.2016.03.011Search in Google Scholar

[42] Abed BH, Salih OS, Sowoud KM. Pinless friction stir spot welding of aluminium alloy with copper interlayer. Open Eng. 2020;10(1):804–13.10.1515/eng-2020-0090Search in Google Scholar

[43] Sharma A, Sharma VM, Gugaliya A, Rai P, Pal SK, Paul J. Friction stir lap welding of AA6061 aluminium alloy with a graphene interlayer. Mater Manuf Processes. 2020;35(3):258–69.10.1080/10426914.2020.1718694Search in Google Scholar

[44] Cao X, Shi Q, Liu D, Feng Z, Liu Q, Chen G. Fabrication of in situ carbon fiber/aluminum composites via friction stir processing: evaluation of microstructural, mechanical and tribological behaviors. Composites, Part B. 2018;139:97–105.10.1016/j.compositesb.2017.12.001Search in Google Scholar

[45] Khidhir GI, Baban SA. Efficiency of dissimilar friction welded 1045 medium carbon steel and 316L austenitic stainless steel joints. J Mater Res Technol. 2019;8(2):1926–32.10.1016/j.jmrt.2019.01.010Search in Google Scholar

[46] André NM, Goushegir SM, Santos J, Canto LB, Amancio-Filho ST, editors. On the microstructure and mechanical performance of Friction Spot Joining with additional film interlayer. Proceedings of the annual technical conference of society of plastics engineers (ANTEC 2014). USA: Society of Plastics Engineers; 2014.Search in Google Scholar

[47] Campilho R, Pinto A, Banea MD, da Silva LF. Optimization study of hybrid spot-welded/bonded single-lap joints. Int. J Adhes Adhes. 2012;37:86–95.10.1016/j.ijadhadh.2012.01.018Search in Google Scholar

[48] Nasir T, Kalaf O, Asmael M. Effect of rotational speed, and dwell time on the mechanical properties and microstructure of dissimilar AA5754 and AA7075-T651 aluminum sheet alloys by friction stir spot welding. Mater Sci. 2021. 10.5755/j02.ms.26860.Search in Google Scholar

[49] Asmael M, Glaissa M. Effects of rotation speed and dwell time on the mechanical properties and microstructure of dissimilar aluminum‐titanium alloys by friction stir spot welding (FSSW). Materialwiss Werkstofftech. 2020;51(7):1002–8.10.1002/mawe.201900115Search in Google Scholar

[50] André NM, Goushegir SM, dos Santos JF, Canto LB, Amancio-Filho ST. Influence of the interlayer film thickness on the mechanical performance of AA2024-T3/CF-PPS hybrid joints produced by friction spot joining. Weld Int. 2018;32(1):1–10.10.1080/09507116.2017.1347319Search in Google Scholar

[51] Devaraju A, Kumar A, Kotiveerachari B. Influence of addition of Grp/Al2O3p with SiCp on wear properties of aluminum alloy 6061-T6 hybrid composites via friction stir processing. Trans Nonferrous Met Soc. 2013;23(5):1275–80.10.1016/S1003-6326(13)62593-5Search in Google Scholar

[52] Gao H, Huang Y. Geometrically necessary dislocation and size-dependent plasticity. Scr Mater. 2003;48(2):113–8.10.1016/S1359-6462(02)00329-9Search in Google Scholar

[53] Shen Z, Yang X, Zhang Z, Cui L, Li T. Microstructure and failure mechanisms of refill friction stir spot welded 7075-T6 aluminum alloy joints. Mater Des. 2013;44:476–86.10.1016/j.matdes.2012.08.026Search in Google Scholar

[54] Amancio-Filho S, Bueno C, Dos Santos J, Huber N, Hage Jr E. On the feasibility of friction spot joining in magnesium/fiber-reinforced polymer composite hybrid structures. Mater Sci Eng A. 2011;528(10–11):3841–8.10.1016/j.msea.2011.01.085Search in Google Scholar

[55] Esteves J, Goushegir S, Dos Santos J, Canto L, Hage Jr E, Amancio-Filho S. Friction spot joining of aluminum AA6181-T4 and carbon fiber-reinforced poly (phenylene sulfide): Effects of process parameters on the microstructure and mechanical strength. Mater Des. 2015;66:437–45.10.1016/j.matdes.2014.06.070Search in Google Scholar

[56] Khodabakhshi F, Haghshenas M, Sahraeinejad S, Chen J, Shalchi B, Li J, et al. Microstructure-property characterization of a friction-stir welded joint between AA5059 aluminum alloy and high density polyethylene. Mater Charact. 2014;98:73–82.10.1016/j.matchar.2014.10.013Search in Google Scholar

[57] Shorowordi KM, Haseeb A, Celis JP. Tribo-surface characteristics of Al–B4C and Al–SiC composites worn under different contact pressures. Wear. 2006;261(5–6):634–41.10.1016/j.wear.2006.01.023Search in Google Scholar

[58] Arrabal R, Pardo A, Merino M, Mohedano M, Casajús P, Merino S. Al/SiC thermal spray coatings for corrosion protection of Mg–Al alloys in humid and saline environments. Surf Coat Technol. 2010;204(16–17):2767–74.10.1016/j.surfcoat.2010.02.030Search in Google Scholar

[59] Chandran P, Sirimuvva T, Nayan N, Shukla A, Murty SN, Pramod S, et al. Effect of carbon nanotube dispersion on mechanical properties of aluminum-silicon alloy matrix composites. J Mater Eng Perform. 2014;23(3):1028–37.10.1007/s11665-013-0835-1Search in Google Scholar

[60] Junaedi H, Abdo HS, Khalil KA, Almajid AA, editors. Aluminum–carbon metal matrix composites: effect of carbon fiber and aspect ratio on the mechanical properties. Adv. Mater. Res. 2015;1123:119–22.10.4028/www.scientific.net/AMR.1123.119Search in Google Scholar

© 2021 Omer Kalaf et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 International License.

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions

Articles in the same Issue

- Research Articles

- Improved impedance matching by multi-componential metal-hybridized rGO toward high performance of microwave absorption

- Pure-silk fibroin hydrogel with stable aligned micropattern toward peripheral nerve regeneration

- Effective ion pathways and 3D conductive carbon networks in bentonite host enable stable and high-rate lithium–sulfur batteries

- Fabrication and characterization of 3D-printed gellan gum/starch composite scaffold for Schwann cells growth

- Synergistic strengthening mechanism of copper matrix composite reinforced with nano-Al2O3 particles and micro-SiC whiskers

- Deformation mechanisms and plasticity of ultrafine-grained Al under complex stress state revealed by digital image correlation technique

- On the deformation-induced grain rotations in gradient nano-grained copper based on molecular dynamics simulations

- Removal of sulfate from aqueous solution using Mg–Al nano-layered double hydroxides synthesized under different dual solvent systems

- Microwave-assisted sol–gel synthesis of TiO2-mixed metal oxide nanocatalyst for degradation of organic pollutant

- Electrophoretic deposition of graphene on basalt fiber for composite applications

- Polyphenylene sulfide-coated wrench composites by nanopinning effect

- Thermal conductivity and thermoelectric properties in 3D macroscopic pure carbon nanotube materials

- An effective thermal conductivity and thermomechanical homogenization scheme for a multiscale Nb3Sn filaments

- Friction stir spot welding of AA5052 with additional carbon fiber-reinforced polymer composite interlayer

- Improvement of long-term cycling performance of high-nickel cathode materials by ZnO coating

- Quantum effects of gas flow in nanochannels

- An approach to effectively improve the interfacial bonding of nano-perfused composites by in situ growth of CNTs

- Effects of nano-modified polymer cement-based materials on the bending behavior of repaired concrete beams

- Effects of the combined usage of nanomaterials and steel fibres on the workability, compressive strength, and microstructure of ultra-high performance concrete

- One-pot solvothermal synthesis and characterization of highly stable nickel nanoparticles

- Comparative study on mechanisms for improving mechanical properties and microstructure of cement paste modified by different types of nanomaterials

- Effect of in situ graphene-doped nano-CeO2 on microstructure and electrical contact properties of Cu30Cr10W contacts

- The experimental study of CFRP interlayer of dissimilar joint AA7075-T651/Ti-6Al-4V alloys by friction stir spot welding on mechanical and microstructural properties

- Vibration analysis of a sandwich cylindrical shell in hygrothermal environment

- Water barrier and mechanical properties of sugar palm crystalline nanocellulose reinforced thermoplastic sugar palm starch (TPS)/poly(lactic acid) (PLA) blend bionanocomposites

- Strong quadratic acousto-optic coupling in 1D multilayer phoxonic crystal cavity

- Three-dimensional shape analysis of peripapillary retinal pigment epithelium-basement membrane layer based on OCT radial images

- Solvent regulation synthesis of single-component white emission carbon quantum dots for white light-emitting diodes

- Xanthate-modified nanoTiO2 as a novel vulcanization accelerator enhancing mechanical and antibacterial properties of natural rubber

- Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2

- Ultrasound-enhanced biosynthesis of uniform ZnO nanorice using Swietenia macrophylla seed extract and its in vitro anticancer activity

- Temperature dependence of hardness prediction for high-temperature structural ceramics and their composites

- Study on the frequency of acoustic emission signal during crystal growth of salicylic acid

- Controllable modification of helical carbon nanotubes for high-performance microwave absorption

- Role of dry ozonization of basalt fibers on interfacial properties and fracture toughness of epoxy matrix composites

- Nanosystem’s density functional theory study of the chlorine adsorption on the Fe(100) surface

- A rapid nanobiosensing platform based on herceptin-conjugated graphene for ultrasensitive detection of circulating tumor cells in early breast cancer

- Improving flexural strength of UHPC with sustainably synthesized graphene oxide

- The role of graphene/graphene oxide in cement hydration

- Structural characterization of microcrystalline and nanocrystalline cellulose from Ananas comosus L. leaves: Cytocompatibility and molecular docking studies

- Evaluation of the nanostructure of calcium silicate hydrate based on atomic force microscopy-infrared spectroscopy experiments

- Combined effects of nano-silica and silica fume on the mechanical behavior of recycled aggregate concrete

- Safety study of malapposition of the bio-corrodible nitrided iron stent in vivo

- Triethanolamine interface modification of crystallized ZnO nanospheres enabling fast photocatalytic hazard-free treatment of Cr(vi) ions

- Novel electrodes for precise and accurate droplet dispensing and splitting in digital microfluidics

- Construction of Chi(Zn/BMP2)/HA composite coating on AZ31B magnesium alloy surface to improve the corrosion resistance and biocompatibility

- Experimental and multiscale numerical investigations on low-velocity impact responses of syntactic foam composites reinforced with modified MWCNTs

- Comprehensive performance analysis and optimal design of smart light pole for cooperative vehicle infrastructure system

- Room temperature growth of ZnO with highly active exposed facets for photocatalytic application

- Influences of poling temperature and elongation ratio on PVDF-HFP piezoelectric films

- Large strain hardening of magnesium containing in situ nanoparticles

- Super stable water-based magnetic fluid as a dual-mode contrast agent

- Photocatalytic activity of biogenic zinc oxide nanoparticles: In vitro antimicrobial, biocompatibility, and molecular docking studies

- Hygrothermal environment effect on the critical buckling load of FGP microbeams with initial curvature integrated by CNT-reinforced skins considering the influence of thickness stretching

- Thermal aging behavior characteristics of asphalt binder modified by nano-stabilizer based on DSR and AFM

- Building effective core/shell polymer nanoparticles for epoxy composite toughening based on Hansen solubility parameters

- Structural characterization and nanoscale strain field analysis of α/β interface layer of a near α titanium alloy

- Optimization of thermal and hydrophobic properties of GO-doped epoxy nanocomposite coatings

- The properties of nano-CaCO3/nano-ZnO/SBR composite-modified asphalt

- Three-dimensional metallic carbon allotropes with superhardness

- Physical stability and rheological behavior of Pickering emulsions stabilized by protein–polysaccharide hybrid nanoconjugates

- Optimization of volume fraction and microstructure evolution during thermal deformation of nano-SiCp/Al–7Si composites

- Phase analysis and corrosion behavior of brazing Cu/Al dissimilar metal joint with BAl88Si filler metal

- High-efficiency nano polishing of steel materials

- On the rheological properties of multi-walled carbon nano-polyvinylpyrrolidone/silicon-based shear thickening fluid

- Fabrication of Ag/ZnO hollow nanospheres and cubic TiO2/ZnO heterojunction photocatalysts for RhB degradation

- Fabrication and properties of PLA/nano-HA composite scaffolds with balanced mechanical properties and biological functions for bone tissue engineering application

- Investigation of the early-age performance and microstructure of nano-C–S–H blended cement-based materials

- Reduced graphene oxide coating on basalt fabric using electrophoretic deposition and its role in the mechanical and tribological performance of epoxy/basalt fiber composites

- Effect of nano-silica as cementitious materials-reducing admixtures on the workability, mechanical properties and durability of concrete

- Machine-learning-assisted microstructure–property linkages of carbon nanotube-reinforced aluminum matrix nanocomposites produced by laser powder bed fusion

- Physical, thermal, and mechanical properties of highly porous polylactic acid/cellulose nanofibre scaffolds prepared by salt leaching technique

- A comparative study on characterizations and synthesis of pure lead sulfide (PbS) and Ag-doped PbS for photovoltaic applications

- Clean preparation of washable antibacterial polyester fibers by high temperature and high pressure hydrothermal self-assembly

- Al 5251-based hybrid nanocomposite by FSP reinforced with graphene nanoplates and boron nitride nanoparticles: Microstructure, wear, and mechanical characterization

- Interlaminar fracture toughness properties of hybrid glass fiber-reinforced composite interlayered with carbon nanotube using electrospray deposition

- Microstructure and life prediction model of steel slag concrete under freezing-thawing environment

- Synthesis of biogenic silver nanoparticles from the seed coat waste of pistachio (Pistacia vera) and their effect on the growth of eggplant

- Study on adaptability of rheological index of nano-PUA-modified asphalt based on geometric parameters of parallel plate

- Preparation and adsorption properties of nano-graphene oxide/tourmaline composites

- A study on interfacial behaviors of epoxy/graphene oxide derived from pitch-based graphite fibers

- Multiresponsive carboxylated graphene oxide-grafted aptamer as a multifunctional nanocarrier for targeted delivery of chemotherapeutics and bioactive compounds in cancer therapy

- Piezoresistive/piezoelectric intrinsic sensing properties of carbon nanotube cement-based smart composite and its electromechanical sensing mechanisms: A review

- Smart stimuli-responsive biofunctionalized niosomal nanocarriers for programmed release of bioactive compounds into cancer cells in vitro and in vivo

- Photoremediation of methylene blue by biosynthesized ZnO/Fe3O4 nanocomposites using Callistemon viminalis leaves aqueous extract: A comparative study

- Study of gold nanoparticles’ preparation through ultrasonic spray pyrolysis and lyophilisation for possible use as markers in LFIA tests

- Review Articles

- Advance on the dispersion treatment of graphene oxide and the graphene oxide modified cement-based materials

- Development of ionic liquid-based electroactive polymer composites using nanotechnology

- Nanostructured multifunctional electrocatalysts for efficient energy conversion systems: Recent perspectives

- Recent advances on the fabrication methods of nanocomposite yarn-based strain sensor

- Review on nanocomposites based on aerospace applications

- Overview of nanocellulose as additives in paper processing and paper products

- The frontiers of functionalized graphene-based nanocomposites as chemical sensors

- Material advancement in tissue-engineered nerve conduit

- Carbon nanostructure-based superhydrophobic surfaces and coatings

- Functionalized graphene-based nanocomposites for smart optoelectronic applications

- Interfacial technology for enhancement in steel fiber reinforced cementitious composite from nano to macroscale

- Metal nanoparticles and biomaterials: The multipronged approach for potential diabetic wound therapy

- Review on resistive switching mechanisms of bio-organic thin film for non-volatile memory application

- Nanotechnology-enabled biomedical engineering: Current trends, future scopes, and perspectives

- Research progress on key problems of nanomaterials-modified geopolymer concrete

- Smart stimuli-responsive nanocarriers for the cancer therapy – nanomedicine

- An overview of methods for production and detection of silver nanoparticles, with emphasis on their fate and toxicological effects on human, soil, and aquatic environment

- Effects of chemical modification and nanotechnology on wood properties

- Mechanisms, influencing factors, and applications of electrohydrodynamic jet printing

- Application of antiviral materials in textiles: A review

- Phase transformation and strengthening mechanisms of nanostructured high-entropy alloys

- Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials

- Catalytic defense against fungal pathogens using nanozymes

- A mini-review of three-dimensional network topological structure nanocomposites: Preparation and mechanical properties

- Mechanical properties and structural health monitoring performance of carbon nanotube-modified FRP composites: A review

- Nano-scale delivery: A comprehensive review of nano-structured devices, preparative techniques, site-specificity designs, biomedical applications, commercial products, and references to safety, cellular uptake, and organ toxicity

- Effects of alloying, heat treatment and nanoreinforcement on mechanical properties and damping performances of Cu–Al-based alloys: A review

- Recent progress in the synthesis and applications of vertically aligned carbon nanotube materials

- Thermal conductivity and dynamic viscosity of mono and hybrid organic- and synthetic-based nanofluids: A critical review

- Recent advances in waste-recycled nanomaterials for biomedical applications: Waste-to-wealth

- Layup sequence and interfacial bonding of additively manufactured polymeric composite: A brief review

- Quantum dots synthetization and future prospect applications

- Approved and marketed nanoparticles for disease targeting and applications in COVID-19

- Strategies for improving rechargeable lithium-ion batteries: From active materials to CO2 emissions