Abstract

Nonlinear stability of nanocomposite spherical and cylindrical panels reinforced by carbon nanotubes (CNTs), resting on elastic foundations and subjected to uniform external pressure in thermal environments is investigated in this paper. CNTs are embedded into matrix phase through uniform distribution (UD) or functionally graded (FG) distribution, and effective properties of CNT-reinforced composite are estimated through an extended rule of mixture. Governing equations are based on classical shell theory taking geometrical nonlinearity, initial geometrical imperfection and panel-foundation interaction into consideration. Approximate solutions of deflection and stress functions are assumed to satisfy simply supported boundary conditions and Galerkin method is applied to obtain nonlinear load-deflection relation. Numerical examples show the effects of volume fraction and distribution type of CNTs, in-plane condition of edges, curvature of panel, thermal environments, elastic foundations and imperfection size on the nonlinear response and snap-through instability of the curved panels. The present study reveals that efficiency of CNT distribution type depends on curvature of panel and in-plane behavior of boundary edges, and bifurcation type buckling response of pressure-loaded panels may occur at elevated temperature.

1 Introduction

Early works of material scientists [1, 2, 3, 4] shown that carbon nanotubes (CNTs) possess unprecedentedly extraordinary mechanical, electrical and thermal properties which no previous material has displayed. In addition to these superior properties is extremely large aspect ratio of CNTs. Accordingly, CNTs are usually used as advanced filler into polymer matrix to constitute carbon nanotube reinforced composite (CNTRC), a new class of nanocomposite. In addition, structural components made of the CNTRC are widely used in advanced engineering and are expected to have promising applications in aerospace science [5]. Motivated by first work of Shen [6], subsequent studies relating to response of functionally graded carbon nanotube reinforced composite (FG-CNTRC) structures have been performed. Linear and nonlinear bending behaviors and free vibration of FG-CNTRC plates have been investigated in works [7, 8, 9, 10] based on shear deformation theories and numerical approaches. Using theory of elasticity, Alibeigloo and co-worker [11, 12] have presented results for bending problem of FG-CNTRC plates with and without piezoelectric layers. Fantuzzi et al. [13] used generalized differential quadrature method to analyze free vibration of arbitrarily shaped functionally graded carbon nanotube-reinforced plates. Basing on a higher order shear deformation theory and finite element method, Mehar et al. [14, 15] studied nonlinear vibration of FG-CNTRC single layer and sandwich plates. Nonlinear bending analysis of thick FG-CNTRC plates under the combined thermo-mechanical load has been carried out in work of Mehar and Panda [16].

Liew and collaborators [17, 18, 19, 20] made use of numerical methods and first order shear deformation theory (FSDT) to analyze linear buckling of FG-CNTRC rectangular and skew plates with and without the support of elastic foundations under compressive loads. Linear buckling and free vibration responses for FG-CNTRC plates has been analyzed by Wang et al. [21] employing semi-analytical solutions and classical plate theory (CPT). Thermal buckling and postbuckling behaviors of FG-CNTRC plates have been dealt with in works of Shen and Zhang [22] utilizing two-step iteration technique, Tung [23] using Galerkin method and Kiani [24] making use of Ritz method. Investigations on postbucking and large deflection behavior for FG-CNTRC plates under mechanical loads have been performed by Zhang and Liew [25] and Lei et al. [26], respectively, using an element-free approach.

Static and dynamic responses of FG-CNTRC cylindrical panels have been investigated in works of Zhang et al. [27] basing on a numerical approach, Alibeigloo [28, 29, 30], Pourasghar and Chen [31] using an analytical approach and Mirzaei and Kiani [32] making use of Ritz method. Kiani [33] also used Ritz method with Gram-Schmidt shape functions for free vibration analysis of FG-CNTRC spherical panels. Linear buckling of FG-CNTRC cylindrical panels subjected to mechanical loads has been treated in works of Nasihatgozar et al. [34] based on an analytical approach accounting for effects of piezoelectric layers and Garcia et al. [35] utilizing a numerical approach. Nonlinear response and postbuckling of FG-CNTRC cylindrical panels subjected to lateral pressure in thermal environments have been analyzed by Shen and Xiang [36] and Shen [37] making use of a semi-analytical approach with a two-step perturbation technique. Based on a similar approach, Shen and Xiang have presented results of post-buckling analysis for FG-CNTRC cylindrical panels resting on elastic foundations in thermal environments and subjected to axial compression [38], uniform thermal loading [39] and combined mechanical loads [40]. Basing on meshless methods, Liew and co-workers [41, 42] examined the geometrically nonlinear response and postbuckling of FG-CNTRC cylindrical panels without elastic foundation under transverse mechanical loading and uniform axial compression, respectively.

Based on several higher order shear deformation theories and generalized differential quadrature method, Tornabene and co-workers [43, 44, 45] analyzed the static and free vibration responses of laminated composite plates and doubly curved shells reinforced by agglomerated CNTs. Using finite element method and a higher order shear deformation theory, nonlinear vibration and flexural behaviors of composite single layer and sandwich doubly curved shell panels reinforced by CNTs under mechanical and thermal loads have been investigated by Mehar and co-authors [46, 47, 48, 49, 50, 51, 52]. There is a limited number of investigations on the nonlinear stability of FG-CNTRC doubly curved panels. Recently, employing a two-step perturbation technique, Shen and Xiang [53] studied the postbuckling of pressure-loaded FG-CNTRC doubly curved panels resting on elastic foundation in thermal environments. More recently, an investigation on nonlinear thermomechanical response of FG-CNTRC doubly curved panels without elastic foundations under different mechanical loads has been given by Mehar and Pandar [54] using nonlinear finite element method. It is observed that, although research subject is quite similar, nonlinear pressure-deflection equilibrium paths in the works [53] and [54] are substantially different. Specifically, pressure-loaded FG-CNTRC doubly curved panels exhibit an extremum type buckling response and relatively intense snap-through phenomenon in the work [53], whereas these panels have no buckling response and pressure-deflection paths are benignly developed in the work [54]. Previous studies on ceramic-metal FGM structures [55, 56, 57] indicated that buckling response of pressure-loaded curved panels with tangentially restrained edges may change from extremum type at room temperature to bifurcation type at elevated temperature. Very recently, thermomechanical nonlinear stability of FG-CNTRC cylindrical panels with tangentially restrained edges under external pressure and axial compression has been analyzed by Tung and Trang [58, 59].

Motivated by previous works [55, 56, 57, 58, 59] and questions relating to type of buckling response of CNTRC doubly curved panels under thermomechanical load, the present paper uses an analytical approach and Galerkin method to investigate the nonlinear stability of CNTRC doubly curved panels resting on elastic foundations and subjected to uniform external pressure in thermal environments. Basic equations for CNTRC doubly curved panels are based on the classical shell theory accounting for Von Karman-Donnell nonlinear terms, initial geometrical imperfection and Pasternak type foundation interaction. Novel findings of the present study are that buckling type of pressure-loaded curved panels may be changed due to pre-existent thermal stresses at immovable edges and efficiency of CNT distribution is influenced by panel curvature and in-plane behavior of boundary edges. Moreover, separate and combined effects of CNT volume fraction, elastic foundations, imperfection size and thermal environments on the buckling pressures and load carrying capacity of CNTRC curved panels are analyzed in detail.

2 CNT-reinforced composite doubly curved panel on an elastic foundation

Fig. 1 shows a doubly curved nanocomposite shell panel resting on a two-parameter elastic foundation and defined in a coordinate system xyz origin of which is located at a corner and on the middle surface of shell panel, x and y are in-plane coordinates and z is perpendicular to the middle surface of the panel such that z = −h/2 and z = h/2 represent the top and bottom surfaces of the panel, respectively. The plan-form dimensions in x, y directions and uniform thickness of the panel are denoted by a, b and h, respectively, and principal radii of curvature in x, y directions are denoted by Rx, Ry, respectively. The panel is reinforced by single-walled carbon nanotubes (SWCNTs) in such a way that x axis is the aligned direction of CNTs. In this study, the SWCNTs are reinforced into isotropic polymer matrix according to uniform distribution (UD) or four types of functionally graded (FG) distribution, referred to as FG−Λ, FG-V, FG-O and FG-X, and volume fraction VCNT of CNTs corresponding to these types of distribution are defined as

Configuration and coordinate system of a doubly curved panel on an elastic foundation.

where

in which wCNT is the mass fraction of CNTs in the CN-TRC panel, ρCNT and ρm are the densities of the CNTs and matrix, respectively. Based on a micromechanical model, the overall mechanical properties of CNT-reinforced structures can be evaluated through Eshelby-Mori-Tanaka approach or theory of mixture. As shown in works of Tornabene and co-authors [43, 44, 45], the Eshelby-Mori-Tanaka approach allows to calculate the effective properties of an elastic medium with inclusions and is appropriate for CNT-reinforced structures with agglomerated carbon nanotubes, whereas the rule of mixture is simple to estimate overall properties of two-phase composites. An excellent agreement between results based on the Eshelby-Mori-Tanaka approach and those calculated according to the rule of mixture for buckling analysis of FG-CNTRC cylindrical panels is demonstrated in work of Garcia et al. [35]. In the present study, the effective Young’s moduli E11, E22 and shear modulus G12 of the CNTRC panel are determined according to the extended rule of mixture [6]

where

Similarly, effective Poisson’s ratio depending weakly on position can be estimated by

where

The effective coefficients of thermal expansion of the CNTRC in the longitudinal and transverse directions have the form as [6, 22]

where

3 Basic equations

Based on the classical shell theory (CST), the strains across the panel thickness are expressed as

where strains of the middle surface εx0,εy0, yxy0 and curvature changes kx, ky, kxy are related to displacement components u,v and w in the coordinate directions x, y and z, respectively, as

and herein subscript prime indicates the partial derivative, e.g. u,x = ∂u/∂x.

Stress-strain relations for a CNTRC panel in a thermal environment are expressed as

where

and ΔT is uniform temperature rise in comparison with thermal stress free state. The force and moment intensities of a CNTRC panel are related to the stress components by the equations

Through Eqs. (3), (6), (8) and (10), the constitutive relations are written in the form

where eij (i, j = 1 ÷ 3) and eklT (k, l = 1 ÷ 2) are defined as in works [58, 59].

Based on the CST, the nonlinear equilibrium equations of a geometrically imperfect doubly curved panel resting on an elastic foundation are

where w*(x, y) is a known function representing initial geometrical imperfection of the panel, q is external pressure uniformly distributed on the top surface of the panel and qf is panel-foundation interactive pressure represented through Pasternak model as

in which Δ denotes Laplace’s operator, k1 and k2 are modulus of Winkler springs and the stiffness of Pasternak shear layer, respectively.

Introduction of Eqs. (7) and (11) into Eqs. (12) gives the nonlinear equilibrium equation of a CNTRC doubly curved panel as

where coefficients ai1 (i = 1 ÷ 4) have been defined in the works [58, 59] and f (x, y) is a stress function defined as

Next, the strain compatibility equation of a geometrically imperfect doubly curved panel is [56]

From Eqs. (7), (11) and (15), the compatibility equation of a geometrically imperfect CNTRC doubly curved panel is rewritten in the form

where coefficients aj2 (j = 1 ÷ 6) have their definitions the same as in works [58, 59].

In this study, edges of CNTRC doubly curved panels are assumed to be simply supported. Depending on in-plane behavior at the edges, the following two cases of boundary conditions are considered.

Case 1: All edges of panel are simply supported and freely movable. The associated boundary conditions are expressed as

Case 2: All edges of panel are simply supported and immovable. In this case, boundary conditions are

where Nx0, Ny0 are compressive force intensities in the x and y directions, respectively, in the Case 1 and are fictitious compressive loads at immovable edges in the Case 2.

4 Formulations

One-term solution of deflection satisfying out-of-plane boundary conditions (18) is assumed as

where W is maximum deflection and βm = mπ/a, δn = nπ/b with m, n are positive integers representing numbers of half waves in the x and y directions, respectively. Similarly, the initial imperfection is assumed to be in the form of the deflection function

where μ denotes imperfection size. The stress function is assumed in the form

where A1,A2,A3 are constant coefficients and these coefficients are determined by placing Eqs. (19), (20) into the compatibility equation (17) as

Now, the solutions (19a,b) and (20) are substituted into the equilibrium equation (14) and applying Galerkin method for the resulting equation yield

where coefficients ai3 (i = 1 ÷ 4) are displayed in Eq. (34) in Appendix A and

4.1 CNTRC doubly curved panel with movable edges under external pressure

Consider a CNTRC doubly curved panel with all movable edges and only subjected to uniform external pressure. In this case, specialization of Eq. (22) for case of Nx0 = Ny0 = 0 gives the following nonlinear relation

This relation suggests a fact that pressure-loaded CN-TRC doubly curved panels will not deflect at mode shapes for which m and/or n is even. Furthermore, Eq. (24) indicates that pressure-deflection paths originate from the origin and, thus, pressure-loaded CNTRC doubly curved panels with movable edges have no bifurcation type buckling response.

4.2 Thermomechanical response of CNTRC doubly curved panel with immovable edges

Consider a CNTRC doubly curved panel with immovable edges resting on an elastic foundation, exposed to an elevated temperature and mechanically loaded by uniform external pressure. The immovability condition of boundary edges, i.e. u = 0 and v = 0 at edges x = 0, a and y = 0, b, respectively, are fulfilled according to average sense as

From Eqs. (7), (11) and (15), the following expressions are obtained

where a72 = (1 − v12v21)e11e21. Introduction of solutions (19) and (20) into Eqs. (26a,b) and putting the obtained expressions into Eqs. (25) yield the following results

where coefficients bij (i = 1 ÷ 3, j = 1 ÷ 2) are given in Eq. (36) in Appendix B. Now, introduction of

where coefficients b k3 (k = 1 ÷ 6) can be found in Eq. (B3) in Appendix B. Eq. (28) shows that the bifurcation type buckling response can occur for pressure-loaded CNTRC doubly curved panels with immovable edges exposed to elevated temperature, and bifurcation point pressures are predicted as

If temperature effects are ignored (i.e. ΔT = 0),

provided

in which

If geometry parameters, CNT distribution and volume fraction, foundation stiffness and imperfection size make condition (31) satisfied, CNTRC doubly curved panel will experience extremum type buckling response and upper, lower buckling pressures are respectively predicted as

5 Results and discussion

This section presents numerical results of the nonlinear stability analysis for CNTRC doubly curved panels made of Poly (methyl methacrylate), referred to as PMMA,as matrix material and reinforced by (10,10) SWCNTs. The temperature independent properties of the PMMA are vm = 0.34, αm = 45 × 10−6/K and Em = 2.5 GPa, and those of the (10,10) SWCNTs are [22]

First, the nonlinear response of a simply supported CNTRC cylindrical panel with movable edges resting on elastic foundations and under uniform external pressure is considered as verification part of the proposed approach. Load-deflection curves corresponding to two different types of CNT distribution are depicted by using closed-form expression (24) and are shown in Fig. 2 in comparison with results of Shen and Xiang [36] using a two-step perturbation technique. As can be seen, a good agreement is achieved in this comparison.

Comparison of load-deflection response for CNTRC cylindrical panels with movable edges under uniform external pressure, (m, n) = (1, 1).

The remainder of this section presents results of buckling and nonlinear response analyses for CNTRC cylindrical and spherical panels of square plan-form (a = b), side-to-thickness ratio b/h = 40 and mode shape (m, n) = (1, 1). Figs. 3 – 11 consider the CNTRC panels only subjected to uniform external pressure, whereas the nonlinear thermomechanical response of pressure-loaded CN-TRC

Comparison of nonlinear response of FG-CNTRC cylindrical and spherical panels under uniform external pressure.

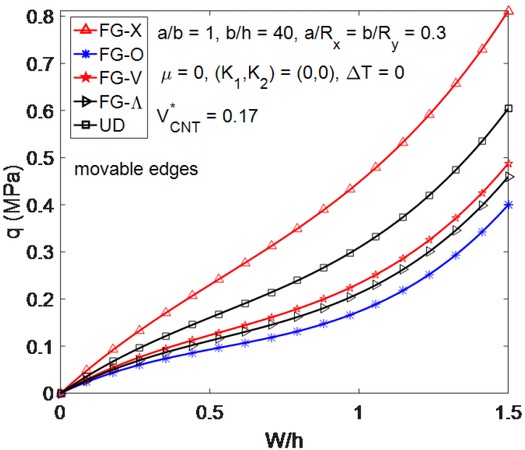

Effects of CNT distribution types on the nonlinear response of CNTRC spherical panels under uniform external pressure with movable edges.

Effects of CNT distribution types on the nonlinear response of CNTRC spherical panels under uniform external pressure with immovable edges.

Effects of CNT volume fraction on the nonlinear response of CNTRC spherical panels under uniform external pressure.

Effects of curvature and CNT distribution on the extremum type buckling pressures of CNTRC spherical panels with immovable edges.

Effects of imperfection and CNT volume fraction on the extremum type buckling pressures of CNTRC spherical panels with immovable edges.

Effects of curvature on the nonlinear response of FG-CNTRC spherical panels under uniform external pressure with immovable edges.

Effects of geometrical imperfection on the nonlinear response of FG-CNTRC spherical panels under uniform external pressure.

Effects of elastic foundations on the nonlinear response of FG-CNTRC spherical panels under uniform external pressure with immovable edges.

panels with immovable edges in thermal environments is analyzed in Figs. 12 – 16. In addition, for the sake of brevity, the panels are assumed to be geometrically perfect and without foundation interaction, unless otherwise specified. A comparison of the nonlinear response of CN-TRC spherical and cylindrical panels under external pressure is carried out in Fig. 3. This figure indicates that load-deflection path of cylindrical panel is higher than that of spherical panel as edges are movable, and load carrying capacity of spherical panel is better than that of cylindrical panel in the small region of deflection as edges are immovable. Figs. 4 and 5 examine the effects of five different patterns of CNT distribution on the nonlinear re-

Effects of CNT distribution types on the nonlinear thermomechanical response of FG-CNTRC spherical panels with immovable edges.

Comparisons of the nonlinear thermomechanical response of CNTRC cylindrical and spherical panels with immovable edges.

Effects of curvature and temperature on the nonlinear response of FG-CNTRC spherical panels on elastic foundation with immovable edges.

Effects of CNT volume fraction and elastic foundation on the nonlinear thermomechanical response of FG-CNTRC spherical panels with immovable edges.

Effects of imperfection and curvature parameters on the nonlinear thermomechanical response of FG-CNTRC spherical panels with immovable edges.

sponse of CNTRC spherical panels under uniform external pressure with movable and immovable edges, respectively. When all edges are movable, the load-deflection paths corresponding to FG-X and FG-O types of CNT distribution are the highest and lowest, respectively, and uniform distribution (UD) of CNTs results in higher load-deflection paths of CNTRC panels in comparison with those corresponding to the remaining three types of FG distribution (i.e. FG-V,FG − Λ and FG-O). It should be emphasized that the load bearing capability of FG-X panel is remarkably higher than that of UD, FG-V,FG − Λ and FG-O panels, and load-deflection curve of FG-V panel is slightly higher than that of FG − Λ panel as all edges are movable as demon-

strated in the Fig. 4. In a very alternative tendency, FG-V and FG−Λ types of CNT distribution give the highest and lowest pressure-deflection curves of CNTRC panels, respectively, when the deflection is small, and FG-X type yields the most beneficial nonlinear response of the panels in the deep region of deflection in the immovable case of in-plane restraint, as illustrated in the Fig. 5. This figure also indicates that intensity of snap-through response, measured by difference between upper and lower buckling pressures, of FG-V and FG-X CNTRC panels are very severe and benign, respectively. Next, Fig. 6 proves that load-deflection paths are considerably enhanced as CNT

volume fraction

Subsequently, Fig. 7 indicates that the upper buckling pressures of FG-V and FG − Λ CNTRC panels are the highest and lowest, respectively, and difference between upper buckling pressures corresponding to these types of FG dis-

tribution is increased as the panel is more curved. Fig. 8 assesses the effects of CNT volume fraction and imperfection size μ on the buckling pressures, in which positive and negative values of μ describe initial perturbation of panel surfaces towards concave and convex sides (i.e. positive and negative directions of deflection) of the panel, respectively. As can be seen, the upper buckling pressures are continuously decreased when the imperfection size μ is increased from −0.2 to 0.2 for CNTRC panels with and without foundation interaction. Furthermore, the rate of reduction of buckling pressures is faster for higher value of CNT volume fraction. Next, the nonlinear response of FG-X and FG-V CNTRC spherical panels with immovable edges and

different values of curvature is compared in Fig. 9. It is evident that load-deflection path corresponding to FG-X type is pronouncedly higher than that corresponding to FG-V type for relatively shallow panel (a/Rx = b/Ry = 0.1 in this example). Conversely, load carrying capability of FG-V panel is higher than that of FG-X panel as the panel is relatively more curved (a/Rx = b/Ry = 0.5 in this example). Fig. 10 shows the effects of initial geometrical imperfection on the nonlinear response of pressure-loaded CN-TRC spherical panels with movable and immovable edges. When edges are movable, initial imperfection has mild effect on the nonlinear response of the panel and load-deflection curve is enhanced due to increase in imperfection size μ as the deflection exceeds a definite value. In contrast, buckling point pressure, load bearing capacity and intensity of snap-through of the panels are considerably decreased as μ increases from −0.1 to 0.1 and edges are immovable. Overall, initial geometrical imperfection may change the curvature of panel and, as a result, has significant influence on the nonlinear response of the panel, especially for case of immovable edges. As final example for mechanical response analysis, Fig. 11 demonstrates an expected fact that buckling loads and nonlinear equilibrium paths of CNTRC panels are pronouncedly improved due to increase in CNT volume percentage and/or the support of elastic foundations. In addition, severity of snap-through phenomenon of CNTRC curved panels may be reduced, even prevented, because of elastic foundations, especially Pasternak type foundations.

The nonlinear thermomechanical response of pressure-loaded CNTRC doubly curved panels with immovable edges in thermal environments is analyzed in Figs. 12 – 16. Fig. 12 examines the effects of five different types of CNT distribution on the nonlinear thermomechanical stability of CNTRC spherical panels. As predicted in previous section, CNTRC curved panels exposed to a thermal environment and mechanically loaded by external pressure will experience a bifurcation type buckling response the nature of which may be explained as follows. Pre-existent thermal stress developed at immovable edges make the curved panel deflected outwards (i.e. negative direction of deflection) and external pressure must reach a definite value equaling bifurcation point pressure in order for the panel returns reference state. It is interesting to note that bifurcation buckling pressure of UD CNTRC panel is the highest and bifurcation buckling pressures corresponding to four types of FG distribution are almost the same. Another important remark is that CNTRC curved panels under thermomechanical load exhibit an unstable postbuckling response and intensity of snap-through instability is the weakest and strongest for FG-X and FG-V panels, respectively. Next, the nonlinear thermomechanical response of CNTRC spherical and cylindrical panels is compared in Fig. 13. It is observed that both bifurcation buckling load and postbuckling load capacity of CNTRC cylindrical panel is very much lower than those of CNTRC spherical panel. In other words, the CNTRC cylindrical panel is easily deteriorated under thermomechanical load, whereas the CNTRC spherical panel can withstand the harmful action of thermomechanical loading efficiently. Fig. 14 considers the effects played by curvature parameters a/Rx , b/Ryon the nonlinear response of pressure-loaded CNTRC spherical panels with immovable edges in thermal environments. In general, bifurcation type buckling pressure and postbuckling load bearing capability of CNTRC spherical panels are remarkably enhanced when the curvature of panel is increased. Specifically, the panel is buckled later and postbuckling strength is higher for larger value of curvature parameters. Next illustration relating to the effects of CNT volume fraction and elastic foundation on the nonlinear thermomechanical response of CNTRC spherical panels is displayed in Fig. 15. It is clear that bifurcation buckling pressures and initial postbuckling strength of the panels are significantly increased when the panels are enriched by CNTs. In particular, CNT-richer panels may experience a more intense snap-through phenomenon in deep region of postbuckling response. It is very interesting to note that bifurcation buckling pressures are not depended on elastic foundations, although these foundations have beneficial influences on load carrying capability of CNTRC spherical panels as the deflection is sufficiently large. Finally, the combined effects of the curvature and initial imperfection parameters on the nonlinear thermomechanical response of FG-CNTRC spherical panels on Pasternak foundation are given in Fig. 16. Evidently, both bifurcation point pressure and initial postbuckling strength (in small region of deflection) of the panels are basically decreased as the imperfection size μ is increased from −0.1 to 0.1. A worth note is gained is that more shallow CNTRC panel will exhibit an immediate snap-through response, whereas more curved CNTRC panel (a/Rx = b/Ry = 0.3 in this illustration) will experience a delayed snap-through response. More specifically, pressure-deflection curves are immediately dropped after bifurcation type buckling for small values of curvature, whereas pressure-deflection curves are increased in initial region of postbuckling deflection for larger values of curvature.

6 Concluding remarks

The geometrically nonlinear, buckling and postbuckling responses of pressure-loaded CNTRC doubly curved panels resting on elastic foundations in thermal environments have been presented. The results show that buckling loads and load carrying capability of CNTRC panels are enhanced when CNT volume fraction and/or stiffness parameters of elastic foundations are increased. In addition to this expected conclusion, the following remarks are reached:

Load-deflection paths of CNTRC doubly curved panel are lower and monotonically developed as edges are movable, whereas these paths are considerably higher and the panel may experience an extremum type buckling response followed by snap-through instability as edges are immovable.

Generally, the FG-X type of CNT distribution results in the best effects on the nonlinear response of doubly curved panels because the FG-X CNTRC panels have basically higher capabilities of buckling resistance and load bearing, and more benign snap-through response. Particularly, the FG-V type leads to the highest buckling pressure and the best capacity of load carrying among five types of CNT distribution for relatively curved panel with immovable edges.

Pressure-loaded CNTRC doubly curved panels with immovable edges exposed to elevated temperature may exhibit a bifurcation type buckling response. Bifurcation point pressure and thermomechanical postbuckling load capacity are remarkably enhanced when temperature and/or curvature of panel are elevated.

Initial geometrical imperfection can cause a change in the curvature and, as a result, significantly influences the nonlinear stability of the panel, especially for thermomechanically loaded CNTRC panels with immovable edges.

A Appendix

The coefficients ai3 (i = 1 ÷ 4)in Eqs. (22) are defined as

in which

B Appendix

The details of coefficients bij (i = 1 ÷ 3, j = 1 ÷ 2) in the Eqs. (27) are

in which

The details of coefficients b k3 (k = 1 ÷ 6) in the Eq. (28) are

References

[1] E.T. Thostenson, Z. Ren, T.W. Chou. Advances in the science and technology of carbon nanotubes and their composites: a review. Composites Science and Technology 2001; 61:1899-1912.10.1016/S0266-3538(01)00094-XSuche in Google Scholar

[2] E.T. Thostenson, C. Li, T.W. Chou. Nanocomposites in context. Composites Science and Technology 2005; 65:491-516.10.1016/j.compscitech.2004.11.003Suche in Google Scholar

[3] J.N. Coleman, U. Khan, W.J. Blau, Y.K. Gun’ko. Small but strong: A review of the mechanical properties of carbon nanotube-polymer composites. Carbon 2006; 44:1624-1652.10.1016/j.carbon.2006.02.038Suche in Google Scholar

[4] Z. Spitalsky, D. Tasis, K. Papagelis, C. Galiotis. Carbon nanotube-polymer composites: Chemistry, processing, mechanical and electrical properties. Progress in Polymer Science 2010; 35:357-401.10.1016/j.progpolymsci.2009.09.003Suche in Google Scholar

[5] O. Gohardani, M.C. Elola, C. Elizetxea. Potential and prospective implementation of carbon nanotubes on next generation aircraft and space vehicles: A review of current and expected applications in aerospace sciences. Progress in Aerospace Sciences 2014;70: 42-68.10.1016/j.paerosci.2014.05.002Suche in Google Scholar

[6] H.S. Shen. Nonlinear bending of functionally graded carbon nanotube-reinforced composite plates in thermal environments. Composite Structures 2009; 91:9-19.10.1016/j.compstruct.2009.04.026Suche in Google Scholar

[7] P. Zhu, Z.X. Lei, K.M. Liew. Static and free vibration analyses of carbon nanotube-reinforced composite plates using finite element method with first order shear deformation plate theory. Composite Structures 2012; 94:1450-1460.10.1016/j.compstruct.2011.11.010Suche in Google Scholar

[8] L.W. Zhang, Z.G. Song, K.M. Liew. Nonlinear bending analysis of FG-CNT reinforced composite thick plates resting on Pasternak foundations using the element-free IMLS-Ritz method. Composite Structures 2015; 128:165-175.10.1016/j.compstruct.2015.03.011Suche in Google Scholar

[9] P. Phung-Van, M. Abdel-Wahab, K.M. Liew, S.P.A. Bordas, H. Nguyen-Xuan. Isogeometric analysis of functionally graded carbon nanotube-reinforced composite plates using higher-order shear deformation theory. Composite Structures 2015; 123:137-149.10.1016/j.compstruct.2014.12.021Suche in Google Scholar

[10] Z.X. Lei, K.M. Liew, J.L. Yu. Free vibration analysis of functionally graded carbon nanotube-reinforced composite plates using the element-free kp-Ritz method in thermal environment. Composite Structures 2013; 106:128-138.10.1016/j.compstruct.2013.06.003Suche in Google Scholar

[11] A. Alibeigloo. Static analysis of functionally graded carbon nanotube-reinforced composite plate embedded in piezoelectric layers by using theory of elasticity. Composite Structures 2013;95:612-622.10.1016/j.compstruct.2012.08.018Suche in Google Scholar

[12] A. Alibeigloo, K.M. Liew. Thermoelastic analysis of functionally graded carbon nanotube-reinforced composite plate using theory of elasticity. Composite Structures 2013; 106:873-881.10.1016/j.compstruct.2013.07.002Suche in Google Scholar

[13] N. Fantuzzi, F. Tornabene, M. Bachiocchi, R. Dimitri. Free vibration analysis of arbitrarily shaped Functionally Graded Carbon Nanotube-reinforced plates, Composites Part B: Engineering 2017; 115: 384-408.10.1016/j.compositesb.2016.09.021Suche in Google Scholar

[14] K. Mehar, S. K. Panda, A. Dehengia, V.R. Kar. Vibration analysis of functionally graded carbon nanotube reinforced composite plate in thermal environment. Journal of Sandwich Structures and Materials 2016; 18: 151-173.10.1177/1099636215613324Suche in Google Scholar

[15] K. Mehar, S. K. Panda, T.R. Mahapatra. Thermoelastic nonlinear frequency analysis of CNT reinforced functionally graded sandwich structure. European Journal of Mechanics - A/Solids 2017; 65: 384-396.10.1016/j.euromechsol.2017.05.005Suche in Google Scholar

[16] K. Mehar, S. K. Panda. Thermoelastic analysis of FG-CNT reinforced shear deformable composite plate under various loadings. International Journal of Computational Methods 2017; 14(2): 1750019.10.1142/S0219876217500190Suche in Google Scholar

[17] Z.X. Lei, K.M. Liew, J.L. Yu. Buckling analysis of functionally graded carbon nanotube-reinforced composite plates using the element-free kp-Ritz method. Composite Structures 2013; 98:160-168.10.1016/j.compstruct.2012.11.006Suche in Google Scholar

[18] L.W. Zhang, Z.X. Lei, K.M. Liew. Buckling analysis of FG-CNT reinforced composite thick skew plates using an element-free approach. Composites Part B: Engineering 2015;75:36-46.10.1016/j.compositesb.2015.01.033Suche in Google Scholar

[19] L.W. Zhang, Z.X. Lei, K.M. Liew. An element-free IMLS-Ritz framework for buckling analysis of FG-CNT reinforced composite thick plates resting on Winkler foundations. Engineering Analysis with Boundary Elements 2015; 58:7-17.10.1016/j.enganabound.2015.03.004Suche in Google Scholar

[20] Z.X. Lei, L.W. Zhang, K.M. Liew. Buckling of FG-CNT reinforced composite thick skew plates resting on Pasternak foundations based on an element-free approach. Applied Mathematics and Computation 2015; 266:773-791.10.1016/j.amc.2015.06.002Suche in Google Scholar

[21] M. Wang, Z.M. Li, P. Qiao. Semi-analytical solutions to buckling and free vibration analysis of carbon nanotube-reinforced composite thin plates. Composite Structures 2016; 144:33-43.10.1016/j.compstruct.2016.02.025Suche in Google Scholar

[22] H.S. Shen, C.L. Zhang. Thermal buckling and postbuckling behavior of functionally graded carbon nanotube-reinforced composite plates. Materials and Design 2010; 31:3403-3411.10.1016/j.matdes.2010.01.048Suche in Google Scholar

[23] H.V. Tung. Thermal buckling and postbuckling behavior of functionally graded carbon-nanotube-reinforced composite plates resting on elastic foundations with tangential-edge restraints. Journal of Thermal Stresses 2017; 40(5):641-663.10.1080/01495739.2016.1254577Suche in Google Scholar

[24] Y. Kiani. Thermal post-buckling of FG-CNT reinforced composite plates. Composite Structures 2017; 159:299-306.10.1016/j.compstruct.2016.09.084Suche in Google Scholar

[25] L.W. Zhang, K.M. Liew. Postbuckling analysis of axially compressed CNT reinforced functionally graded composite plates resting on Pasternak foundations using an element-free approach. Composite Structures 2016; 138:40-51.10.1016/j.compstruct.2015.11.031Suche in Google Scholar

[26] Z.X. Lei, K.M. Liew, J.L. Yu. Large deflection analysis of functionally graded carbon nanotube-reinforced composite plates by the element-free kp-Ritz method. Computer Methods Applied Mechanics and Engineering 2013; 256:189-199.10.1016/j.cma.2012.12.007Suche in Google Scholar

[27] L.W. Zhang, Z.X. Lei, K.M. Liew, J.L. Yu. Static and dynamic of carbon nanotube reinforced functionally graded cylindrical panels. Composite Structures 2014; 111:205-212.10.1016/j.compstruct.2013.12.035Suche in Google Scholar

[28] A. Alibeigloo. Elasticity solution of functionally graded carbon nanotube-reinforced composite cylindrical panel subjected to thermo mechanical load. Composites Part B: Engineering 2016; 87:214-226.10.1016/j.compositesb.2015.09.060Suche in Google Scholar

[29] A. Alibeigloo. Thermoelastic analysis of functionally graded carbon nanotube reinforced composite cylindrical panel embedded in piezoelectric sensor and actuator layers. Composites Part B: Engineering 2016; 98:225-243.10.1016/j.compositesb.2016.05.010Suche in Google Scholar

[30] A. Alibeigloo. Free vibration analysis of functionally graded carbon nanotube-reinforced composite cylindrical panel embedded in piezoelectric layers by using theory of elasticity. European Journal of Mechanics, A/Solids 2014; 44:104-115.10.1016/j.euromechsol.2013.10.002Suche in Google Scholar

[31] A. Pourasghar, Z. Chen. Thermoelastic response of CNT reinforced cylindrical panel resting on elastic foundation using theory of elasticity. Composites Part B: Engineering 2016; 99:436-444.10.1016/j.compositesb.2016.06.028Suche in Google Scholar

[32] M. Mirzaei, Y. Kiani. Free vibration of functionally graded carbon nanotube reinforced composite cylindrical panels. Composite Structures 2016; 142:45-56.10.1016/j.compstruct.2015.12.071Suche in Google Scholar

[33] Y. Kiani. Free vibration of FG-CNT reinforced composite spherical shell panels using Gram-Schmidt shape functions. Composite Structures 2017; 159:368-381.10.1016/j.compstruct.2016.09.079Suche in Google Scholar

[34] M. Nasihatgozar, V. Daghigh, M. Eskandari, K. Nikbin, A. Simoneau. Buckling analysis of piezoelectric cylindrical composite panels reinforced with carbon nanotubes. International Journal of Mechanical Sciences 2016; 107:69-79.10.1016/j.ijmecsci.2016.01.010Suche in Google Scholar

[35] E.M. Garcia, L.T. Rodriguez, R.T. Castro, S. Andres. Buckling analysis of functionally graded carbon nanotube reinforced curved panels under axial compression and shear. Composites part B: Engineering 2017; 108:243-256.10.1016/j.compositesb.2016.10.002Suche in Google Scholar

[36] H.S. Shen, Y. Xiang. Nonlinear bending of nanotube-reinforced composite cylindrical panels resting on elastic foundations in thermal environments. Engineering Structures 2014; 80:163-172.10.1016/j.engstruct.2014.08.038Suche in Google Scholar

[37] H.S. Shen. Postbuckling of nanotube-reinforced composite cylindrical panels resting on elastic foundations subjected to lateral pressure in thermal environments. Engineering Structures 2016; 122:174-183.10.1016/j.engstruct.2016.05.004Suche in Google Scholar

[38] H.S. Shen, Y. Xiang. Postbuckling of axially compressed nanotube-reinforced composite cylindrical panels resting on elastic foundations in thermal environments. Composites Part B: Engineering 2014; 67:50-61.10.1016/j.compositesb.2014.06.020Suche in Google Scholar

[39] H.S. Shen. Xiang Y. Thermal postbuckling of nanotube-reinforced composite cylindrical panels resting on elastic foundations. Composite Structures 2015; 123:383-392.10.1016/j.compstruct.2014.12.059Suche in Google Scholar

[40] H.S. Shen, Y. Xiang. Nonlinear response of nanotube-reinforced composite cylindrical panels subjected to combined loadings and resting on elastic foundations. Composite Structures 2015; 131:939-950.10.1016/j.compstruct.2015.06.042Suche in Google Scholar

[41] L.W. Zhang, Z.X. Lei, K.M. Liew, J.L. Yu. Large deflection geometrically nonlinear analysis of carbon nanotube-reinforced functionally graded cylindrical panels. Computer Methods in Applied Mechanics Engineering 2014; 273:1-18.10.1016/j.cma.2014.01.024Suche in Google Scholar

[42] K.M. Liew, Z.X. Lei, J.L. Yu, L.W. Zhang. Postbuckling of carbon nanotube-reinforced functionally graded cylindrical panels under axial compression using a meshless approach. Computer Methods in Applied Mechanics and Engineering 2014; 268:1-17.10.1016/j.cma.2013.09.001Suche in Google Scholar

[43] F. Tornabene, N. Fantuzzi, M. Bacciocchi, E. Viola. Effect of agglomeration on the natural frequencies of functionally graded carbon nanotube-reinforced laminated composite doubly-curved shells. Composites Part B: Engineering 2016; 89: 187-218.10.1016/j.compositesb.2015.11.016Suche in Google Scholar

[44] F. Tornabene, N. Fantuzzi, M. Bacchiocchi. Linear static response of nanocomposite plates and shells reinforced by agglomerated carbon nanotubes. Composites Part B: Engineering 2017; 115: 449-476.10.1016/j.compositesb.2016.07.011Suche in Google Scholar

[45] F. Tornabene, M. Bacciocchi, N. Fantuzzi, J. N. Reddy. Multi-scale approach for thee-phase CNT/polymer/fiber laminated nanocomposite structures. Polymer composites In press, DOI: 10.1002/pc.24520Suche in Google Scholar

[46] K. Mehar, S. K. Panda, B. K. Patle. Thermoelastic vibration and flexural behavior of FG-CNT reinforced composite curved panel. International Journal of Applied Mechanics 2017; 9: 1750046.10.1142/S1758825117500466Suche in Google Scholar

[47] K. Mehar. Thermoelastic flexural analysis of FG-CNT doubly curved shell panel. Aircraft Engineering and Aerospace Technology 2018; 90: 11-23.10.1108/AEAT-11-2015-0237Suche in Google Scholar

[48] K. Mehar, S.K.Panda, T.Q. Bui, T.R. Mahapatra. Nonlinear thermoelastic frequency analysis of functionally graded CNT-reinforced single/doubly curved shallow shell panels by FEM. Journal of Thermal Stresses 2017;40: 899-916.10.1080/01495739.2017.1318689Suche in Google Scholar

[49] K. Mehar, S.K. Panda. Numerical investigation of nonlinear thermomechanical deflection of functionally graded CNT reinforced doubly curved composite shell panel under different mechanical loads. Composite Structures 2017; 161: 287-298.10.1016/j.compstruct.2016.10.135Suche in Google Scholar

[50] T.R. Mahapatra, K. Mehar, S.K. Panda, S. Dewangan, S. Dash. Flexural strength of functionally graded nanotube reinforced sandwich spherical panel. IOP conference series: Materials Science and Engineering 2017; 178: 012031.10.1088/1757-899X/178/1/012031Suche in Google Scholar

[51] K. Mehar, S.K. Panda, T.R. Mahapatra. Nonlinear frequency responses of functionally graded carbon nanotube-reinforced sandwich curved panel under uniform temperature field. International Journal of Applied Mechanics 2018; 10: 1850028.10.1142/S175882511850028XSuche in Google Scholar

[52] K. Mehar, S. K. Panda. Thermal free vibration behavior of FG-CNT reinforced sandwich curved panel using finite element method. Polymer Composites 2017. DOI: 10.1002/pc.24266.Suche in Google Scholar

[53] H.S. Shen, Y. Xiang. Postbuckling of pressure-loaded nanotube-reinforced composite doubly curved panels resting on elastic foundations in thermal environments. International Journal of Mechanics Sciences 2016; 107:225-234.10.1016/j.ijmecsci.2016.01.004Suche in Google Scholar

[54] K. Mehar, S.K. Panda. Numerical investigation of nonlinear thermomechanical deflection of functionally graded CNT reinforced doubly curved composite shell panel under different mechanical loads. Composite Structures 2017; 161:287-298.10.1016/j.compstruct.2016.10.135Suche in Google Scholar

[55] N.D. Duc, H.V. Tung. Nonlinear response of pressure-loaded functionally graded cylindrical panels with temperature effects. Composite Structures 2010; 92:1664-1672.10.1016/j.compstruct.2009.11.033Suche in Google Scholar

[56] H.V. Tung, N.D. Duc. Nonlinear response of shear deformable FGM curved panels resting on elastic foundations and subjected to mechanical and thermal loading conditions. Applied Mathematical Modelling 2014; 38:2848-2866.10.1016/j.apm.2013.11.015Suche in Google Scholar

[57] H.V. Tung. Nonlinear thermomechanical response of pressure-loaded doubly curved functionally graded material sandwich panels in thermal environments including tangential edge constraints. Journal of Sandwich Structures and Materials 2018; 20(8): 974-1008.10.1177/1099636216684312Suche in Google Scholar

[58] H.V. Tung, L.T.N. Trang. Imperfection and tangential edge constraint sensitivities of thermomechanical nonlinear response of pressure-loaded carbon nanotube-reinforced composite cylindrical panels. Acta Mechanica 2018; 229 (5): 1949-1969.10.1007/s00707-017-2093-zSuche in Google Scholar

[59] L.T.N. Trang, H.V. Tung. Thermomechanical nonlinear analysis of axially compressed carbon nanotube-reinforced composite cylindrical panels resting on elastic foundations with tangentially restrained edges. Journal of Thermal Stresses 2018; 41 (4): 418-438.10.1080/01495739.2017.1409093Suche in Google Scholar

[60] Y. Han, J. Elliott. Molecular dynamics simulations of the elastic properties of polymer/carbon nanotube composites. Computational Materials Science 2007; 39:315-323.10.1016/j.commatsci.2006.06.011Suche in Google Scholar

© 2019 Le Thi Nhu Trang and Hoang Van Tung, published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 Public License.

Artikel in diesem Heft

- Chebyshev Operational Matrix Method for Lane-Emden Problem

- Concentrating solar power tower technology: present status and outlook

- Control of separately excited DC motor with series multi-cells chopper using PI - Petri nets controller

- Effect of boundary roughness on nonlinear saturation of Rayleigh-Taylor instability in couple-stress fluid

- Effect of Heterogeneity on Imbibition Phenomena in Fluid Flow through Porous Media with Different Porous Materials

- Electro-osmotic flow of a third-grade fluid past a channel having stretching walls

- Heat transfer effect on MHD flow of a micropolar fluid through porous medium with uniform heat source and radiation

- Local convergence for an eighth order method for solving equations and systems of equations

- Numerical techniques for behavior of incompressible flow in steady two-dimensional motion due to a linearly stretching of porous sheet based on radial basis functions

- Influence of Non-linear Boussinesq Approximation on Natural Convective Flow of a Power-Law Fluid along an Inclined Plate under Convective Thermal Boundary Condition

- A reliable analytical approach for a fractional model of advection-dispersion equation

- Mass transfer around a slender drop in a nonlinear extensional flow

- Hydromagnetic Flow of Heat and Mass Transfer in a Nano Williamson Fluid Past a Vertical Plate With Thermal and Momentum Slip Effects: Numerical Study

- A Study on Convective-Radial Fins with Temperature-dependent Thermal Conductivity and Internal Heat Generation

- An effective technique for the conformable space-time fractional EW and modified EW equations

- Fractional variational iteration method for solving time-fractional Newell-Whitehead-Segel equation

- New exact and numerical solutions for the effect of suction or injection on flow of nanofluids past a stretching sheet

- Numerical investigation of MHD stagnation-point flow and heat transfer of sodium alginate non-Newtonian nanofluid

- A New Finance Chaotic System, its Electronic Circuit Realization, Passivity based Synchronization and an Application to Voice Encryption

- Analysis of Heat Transfer and Lifting Force in a Ferro-Nanofluid Based Porous Inclined Slider Bearing with Slip Conditions

- Application of QLM-Rational Legendre collocation method towards Eyring-Powell fluid model

- Hyperbolic rational solutions to a variety of conformable fractional Boussinesq-Like equations

- MHD nonaligned stagnation point flow of second grade fluid towards a porous rotating disk

- Nonlinear Dynamic Response of an Axially Functionally Graded (AFG) Beam Resting on Nonlinear Elastic Foundation Subjected to Moving Load

- Swirling flow of couple stress fluid due to a rotating disk

- MHD stagnation point slip flow due to a non-linearly moving surface with effect of non-uniform heat source

- Effect of aligned magnetic field on Casson fluid flow over a stretched surface of non-uniform thickness

- Nonhomogeneous porosity and thermal diffusivity effects on stability and instability of double-diffusive convection in a porous medium layer: Brinkman Model

- Magnetohydrodynamic(MHD) Boundary Layer Flow of Eyring-Powell Nanofluid Past Stretching Cylinder With Cattaneo-Christov Heat Flux Model

- On the connection coefficients and recurrence relations arising from expansions in series of modified generalized Laguerre polynomials: Applications on a semi-infinite domain

- An adaptive mesh method for time dependent singularly perturbed differential-difference equations

- On stretched magnetic flow of Carreau nanofluid with slip effects and nonlinear thermal radiation

- Rational exponential solutions of conformable space-time fractional equal-width equations

- Simultaneous impacts of Joule heating and variable heat source/sink on MHD 3D flow of Carreau-nanoliquids with temperature dependent viscosity

- Effect of magnetic field on imbibition phenomenon in fluid flow through fractured porous media with different porous material

- Impact of ohmic heating on MHD mixed convection flow of Casson fluid by considering Cross diffusion effect

- Mathematical Modelling Comparison of a Reciprocating, a Szorenyi Rotary, and a Wankel Rotary Engine

- Surface roughness effect on thermohydrodynamic analysis of journal bearings lubricated with couple stress fluids

- Convective conditions and dissipation on Tangent Hyperbolic fluid over a chemically heating exponentially porous sheet

- Unsteady Carreau-Casson fluids over a radiated shrinking sheet in a suspension of dust and graphene nanoparticles with non-Fourier heat flux

- An efficient numerical algorithm for solving system of Lane–Emden type equations arising in engineering

- New numerical method based on Generalized Bessel function to solve nonlinear Abel fractional differential equation of the first kind

- Numerical Study of Viscoelastic Micropolar Heat Transfer from a Vertical Cone for Thermal Polymer Coating

- Analysis of Bifurcation and Chaos of the Size-dependent Micro–plate Considering Damage

- Non-Similar Comutational Solutions for Double-Diffusive MHD Transport Phenomena for Non-Newtnian Nanofluid From a Horizontal Circular Cylinder

- Mathematical model on distributed denial of service attack through Internet of things in a network

- Postbuckling behavior of functionally graded CNT-reinforced nanocomposite plate with interphase effect

- Study of Weakly nonlinear Mass transport in Newtonian Fluid with Applied Magnetic Field under Concentration/Gravity modulation

- MHD slip flow of chemically reacting UCM fluid through a dilating channel with heat source/sink

- A Study on Non-Newtonian Transport Phenomena in Mhd Fluid Flow From a Vertical Cone With Navier Slip and Convective Heating

- Penetrative convection in a fluid saturated Darcy-Brinkman porous media with LTNE via internal heat source

- Traveling wave solutions for (3+1) dimensional conformable fractional Zakharov-Kuznetsov equation with power law nonlinearity

- Semitrailer Steering Control for Improved Articulated Vehicle Manoeuvrability and Stability

- Thermomechanical nonlinear stability of pressure-loaded CNT-reinforced composite doubly curved panels resting on elastic foundations

- Combination synchronization of fractional order n-chaotic systems using active backstepping design

- Vision-Based CubeSat Closed-Loop Formation Control in Close Proximities

- Effect of endoscope on the peristaltic transport of a couple stress fluid with heat transfer: Application to biomedicine

- Unsteady MHD Non-Newtonian Heat Transfer Nanofluids with Entropy Generation Analysis

- Mathematical Modelling of Hydromagnetic Casson non-Newtonian Nanofluid Convection Slip Flow from an Isothermal Sphere

- Influence of Joule Heating and Non-Linear Radiation on MHD 3D Dissipating Flow of Casson Nanofluid past a Non-Linear Stretching Sheet

- Radiative Flow of Third Grade Non-Newtonian Fluid From A Horizontal Circular Cylinder

- Application of Bessel functions and Jacobian free Newton method to solve time-fractional Burger equation

- A reliable algorithm for time-fractional Navier-Stokes equations via Laplace transform

- A multiple-step adaptive pseudospectral method for solving multi-order fractional differential equations

- A reliable numerical algorithm for a fractional model of Fitzhugh-Nagumo equation arising in the transmission of nerve impulses

- The expa function method and the conformable time-fractional KdV equations

- Comment on the paper: “Thermal radiation and chemical reaction effects on boundary layer slip flow and melting heat transfer of nanofluid induced by a nonlinear stretching sheet, M.R. Krishnamurthy, B.J. Gireesha, B.C. Prasannakumara, and Rama Subba Reddy Gorla, Nonlinear Engineering 2016, 5(3), 147-159”

- Three-Dimensional Boundary layer Flow and Heat Transfer of a Fluid Particle Suspension over a Stretching Sheet Embedded in a Porous Medium

- MHD three dimensional flow of Oldroyd-B nanofluid over a bidirectional stretching sheet: DTM-Padé Solution

- MHD Convection Fluid and Heat Transfer in an Inclined Micro-Porous-Channel

Artikel in diesem Heft

- Chebyshev Operational Matrix Method for Lane-Emden Problem

- Concentrating solar power tower technology: present status and outlook

- Control of separately excited DC motor with series multi-cells chopper using PI - Petri nets controller

- Effect of boundary roughness on nonlinear saturation of Rayleigh-Taylor instability in couple-stress fluid

- Effect of Heterogeneity on Imbibition Phenomena in Fluid Flow through Porous Media with Different Porous Materials

- Electro-osmotic flow of a third-grade fluid past a channel having stretching walls

- Heat transfer effect on MHD flow of a micropolar fluid through porous medium with uniform heat source and radiation

- Local convergence for an eighth order method for solving equations and systems of equations

- Numerical techniques for behavior of incompressible flow in steady two-dimensional motion due to a linearly stretching of porous sheet based on radial basis functions

- Influence of Non-linear Boussinesq Approximation on Natural Convective Flow of a Power-Law Fluid along an Inclined Plate under Convective Thermal Boundary Condition

- A reliable analytical approach for a fractional model of advection-dispersion equation

- Mass transfer around a slender drop in a nonlinear extensional flow

- Hydromagnetic Flow of Heat and Mass Transfer in a Nano Williamson Fluid Past a Vertical Plate With Thermal and Momentum Slip Effects: Numerical Study

- A Study on Convective-Radial Fins with Temperature-dependent Thermal Conductivity and Internal Heat Generation

- An effective technique for the conformable space-time fractional EW and modified EW equations

- Fractional variational iteration method for solving time-fractional Newell-Whitehead-Segel equation

- New exact and numerical solutions for the effect of suction or injection on flow of nanofluids past a stretching sheet

- Numerical investigation of MHD stagnation-point flow and heat transfer of sodium alginate non-Newtonian nanofluid

- A New Finance Chaotic System, its Electronic Circuit Realization, Passivity based Synchronization and an Application to Voice Encryption

- Analysis of Heat Transfer and Lifting Force in a Ferro-Nanofluid Based Porous Inclined Slider Bearing with Slip Conditions

- Application of QLM-Rational Legendre collocation method towards Eyring-Powell fluid model

- Hyperbolic rational solutions to a variety of conformable fractional Boussinesq-Like equations

- MHD nonaligned stagnation point flow of second grade fluid towards a porous rotating disk

- Nonlinear Dynamic Response of an Axially Functionally Graded (AFG) Beam Resting on Nonlinear Elastic Foundation Subjected to Moving Load

- Swirling flow of couple stress fluid due to a rotating disk

- MHD stagnation point slip flow due to a non-linearly moving surface with effect of non-uniform heat source

- Effect of aligned magnetic field on Casson fluid flow over a stretched surface of non-uniform thickness

- Nonhomogeneous porosity and thermal diffusivity effects on stability and instability of double-diffusive convection in a porous medium layer: Brinkman Model

- Magnetohydrodynamic(MHD) Boundary Layer Flow of Eyring-Powell Nanofluid Past Stretching Cylinder With Cattaneo-Christov Heat Flux Model

- On the connection coefficients and recurrence relations arising from expansions in series of modified generalized Laguerre polynomials: Applications on a semi-infinite domain

- An adaptive mesh method for time dependent singularly perturbed differential-difference equations

- On stretched magnetic flow of Carreau nanofluid with slip effects and nonlinear thermal radiation

- Rational exponential solutions of conformable space-time fractional equal-width equations

- Simultaneous impacts of Joule heating and variable heat source/sink on MHD 3D flow of Carreau-nanoliquids with temperature dependent viscosity

- Effect of magnetic field on imbibition phenomenon in fluid flow through fractured porous media with different porous material

- Impact of ohmic heating on MHD mixed convection flow of Casson fluid by considering Cross diffusion effect

- Mathematical Modelling Comparison of a Reciprocating, a Szorenyi Rotary, and a Wankel Rotary Engine

- Surface roughness effect on thermohydrodynamic analysis of journal bearings lubricated with couple stress fluids

- Convective conditions and dissipation on Tangent Hyperbolic fluid over a chemically heating exponentially porous sheet

- Unsteady Carreau-Casson fluids over a radiated shrinking sheet in a suspension of dust and graphene nanoparticles with non-Fourier heat flux

- An efficient numerical algorithm for solving system of Lane–Emden type equations arising in engineering

- New numerical method based on Generalized Bessel function to solve nonlinear Abel fractional differential equation of the first kind

- Numerical Study of Viscoelastic Micropolar Heat Transfer from a Vertical Cone for Thermal Polymer Coating

- Analysis of Bifurcation and Chaos of the Size-dependent Micro–plate Considering Damage

- Non-Similar Comutational Solutions for Double-Diffusive MHD Transport Phenomena for Non-Newtnian Nanofluid From a Horizontal Circular Cylinder

- Mathematical model on distributed denial of service attack through Internet of things in a network

- Postbuckling behavior of functionally graded CNT-reinforced nanocomposite plate with interphase effect

- Study of Weakly nonlinear Mass transport in Newtonian Fluid with Applied Magnetic Field under Concentration/Gravity modulation

- MHD slip flow of chemically reacting UCM fluid through a dilating channel with heat source/sink

- A Study on Non-Newtonian Transport Phenomena in Mhd Fluid Flow From a Vertical Cone With Navier Slip and Convective Heating

- Penetrative convection in a fluid saturated Darcy-Brinkman porous media with LTNE via internal heat source

- Traveling wave solutions for (3+1) dimensional conformable fractional Zakharov-Kuznetsov equation with power law nonlinearity

- Semitrailer Steering Control for Improved Articulated Vehicle Manoeuvrability and Stability

- Thermomechanical nonlinear stability of pressure-loaded CNT-reinforced composite doubly curved panels resting on elastic foundations

- Combination synchronization of fractional order n-chaotic systems using active backstepping design

- Vision-Based CubeSat Closed-Loop Formation Control in Close Proximities

- Effect of endoscope on the peristaltic transport of a couple stress fluid with heat transfer: Application to biomedicine

- Unsteady MHD Non-Newtonian Heat Transfer Nanofluids with Entropy Generation Analysis

- Mathematical Modelling of Hydromagnetic Casson non-Newtonian Nanofluid Convection Slip Flow from an Isothermal Sphere

- Influence of Joule Heating and Non-Linear Radiation on MHD 3D Dissipating Flow of Casson Nanofluid past a Non-Linear Stretching Sheet

- Radiative Flow of Third Grade Non-Newtonian Fluid From A Horizontal Circular Cylinder

- Application of Bessel functions and Jacobian free Newton method to solve time-fractional Burger equation

- A reliable algorithm for time-fractional Navier-Stokes equations via Laplace transform

- A multiple-step adaptive pseudospectral method for solving multi-order fractional differential equations

- A reliable numerical algorithm for a fractional model of Fitzhugh-Nagumo equation arising in the transmission of nerve impulses

- The expa function method and the conformable time-fractional KdV equations

- Comment on the paper: “Thermal radiation and chemical reaction effects on boundary layer slip flow and melting heat transfer of nanofluid induced by a nonlinear stretching sheet, M.R. Krishnamurthy, B.J. Gireesha, B.C. Prasannakumara, and Rama Subba Reddy Gorla, Nonlinear Engineering 2016, 5(3), 147-159”

- Three-Dimensional Boundary layer Flow and Heat Transfer of a Fluid Particle Suspension over a Stretching Sheet Embedded in a Porous Medium

- MHD three dimensional flow of Oldroyd-B nanofluid over a bidirectional stretching sheet: DTM-Padé Solution

- MHD Convection Fluid and Heat Transfer in an Inclined Micro-Porous-Channel