Abstract

A mathematical model is developed to study laminar, nonlinear, non-isothermal, steady-state free convection boundary layer flow and heat transfer of a micropolar viscoelastic fluid from a vertical isothermal cone. The Eringen model and Jeffery’s viscoelastic model are combined to simulate the non-Newtonian characteristics of polymers, which constitutes a novelty of the present work. The transformed conservation equations for linear momentum, angular momentum and energy are solved numerically under physically viable boundary conditions using a finite difference scheme (Keller Box method). The effects of Deborah number (De), Eringen vortex viscosity parameter (R), ratio of relaxation to retardation times (λ), micro-inertia density parameter (B), Prandtl number (Pr) and dimensionless stream wise coordinate (ξ) on velocity, surface temperature and angular velocity in the boundary layer regime are evaluated. The computations show that with greater ratio of retardation to relaxation times, the linear and angular velocity are enhanced whereas temperature (and also thermal boundary layer thickness) is reduced. Greater values of the Eringen parameter decelerate both the linear velocity and micro-rotation values and enhance temperatures. Increasing Deborah number decelerates the linear flow and Nusselt number whereas it increases temperatures and boosts micro-rotation magnitudes. The study is relevant to non-Newtonian polymeric thermal coating processes.

1 Introduction

Coating hydrodynamics has been an area of considerable interest since the monumental paper by Landau and Levich (1942) in which an elegant formulation was developed for the thickness of the film of a fluid which is deposited on a plate withdrawn vertically from a bath at constant velocity. This work was however confined to Newtonian viscous fluids. In many modern industries non-Newtonian fluids are encountered e.g. in polymer coating processes (Lawrence and Zhou, 1991). Numerous researchers have therefore investigated coating dynamics of different stationary or rotating geometrical bodies (plates, cones, spheres, cylinders) with non-Newtonian liquids and have employed a range of mathematical constitutive equations. Jenekhe and Schuldt (1984) studied coating flows of power-law and Carreau fluids on spinning disks. Campanella et al. (1986) investigated dip coating of a circular cylinder in non-Newtonian power-law fluids. Zevallos et al. (2005) presented a finite element simulation of forward roll coating flows of viscoelastic liquids using both Oldroyd-B and FENE-P models. These studies however ignored heat transfer which may be critical in certain coating systems (Mitsoulis, 1986). The diffusion of heat can modify polymer properties significantly (Mark, 1996). Several authors have therefore studied thermofluid transport in non-Newtonian external coating flows. Cao and Cui (2015) examined Ostwald-DeWaele pseudo-plastic fluids in free convection flow in porous media. Choudhury and Das (2016) employed the Reiner-Rivlin second order differential viscoelastic model for reactive magnetized thermosolutal convection in porous media. Thirumurugan and Vasanthakumari (2016) utilized the Walters B viscoelastic model to investigate the thermosolutal convection in two-phase porous media transport. Prasad et al. (2013) and Subba Rao et al. (2016) investigated computationally the momentum and heat transfer characteristics in external boundary layer slip flow of a viscoplastic fluid from a cylinder.

The classical Navier–Stokes theory does not describe sufficiently the flow properties of polymeric fluids, colloidal suspensions, and fluids having certain additives. Eringen (1966) proposed therefore the theory of micropolar fluids which exhibit micro-rotation effects as well as micro-inertia. Micropolar fluids are fluids with microstructure. They belong to a class of fluids with non-symmetric stress tensor also known as polar fluids. Micropolar fluids include as a special case the conventional Navier-Stokes model of classical viscous fluids that we shall call ordinary fluids. Physically micropolar fluids consist of arbitrarily oriented particles suspended in a viscous medium. The formulation for micropolar fluid theory allows their implementation in boundary layer flows, of relevance to materials processing, and has resulted in considerable activity among researchers. Yacob et al., (2011) proposed a mathematical model to characterise the melting heat transfer in both stretching and shrinking sheet flows of a micropolar fluid. Prakash and Sinha (1976) applied micropolar fluid theory to simulate lubrication squeeze films for circular disks, deriving analytical expressions for film characteristics. Papautsky et al. (1999) employed micropolar fluid theory to study low speed flows in micro-machined rectangular metallic pipette arrays. Bhargava et al. (2016) analyzed the thermo-solutal convection in a cavity containing micro polar fluid with a variation finite element method. Latiff et al. (2015) used Maple software to analyse the multiple slip effects on transient forced bio convection flow of a micro polar nanofluid from a stretching/shrinking sheet with applications in materials fabrication. Alam et al. (2015) used Eringen’s micropolar model to study transient Falkner-Skan magnetic convection flows. Transport from external surfaces of curved bodies e.g. vertical cones has also stimulated some interest in recent years. Such flows are of relevance to chemical engineering systems and also materials synthesis. Cheng (2015) studied the free convection heat transfer from a non-isothermal permeable cone with suction and temperature-dependent viscosity. Solchana et al. (2016) analysed the momentum, heat and mass transfer behaviour of magneto hydrodynamic flow towards a vertical rotating cone in porous medium with thermophoresis and Brownian motion effects. Cheng (2015) examined the natural convection heat transfer about a vertical cone embedded in a porous medium with isothermal wall conditions. Yih (1999) studied the effect of thermal radiation flux on free convection about a truncated cone. Gorla et al. (1986) investigated the micro polar convection boundary layer flow from a cone.

An interesting model in non-Newtonian fluid mechanics is the viscoelastic Jeffrey fluid model. This model degenerates to a Newtonian fluid at a very high wall shear stress. This fluid model also approximates reasonably well the rheological behaviour of a wide range of industrial liquids including biotechnological detergents, physiological suspensions, dense foams, geological sediments, cosmetic creams, syrups, etc. Many researchers have explored a range of industrial and biological flow problems using the Jeffery model. Prasad et al. (2014) and Subba Rao et al. (2015) studied external Jeffery viscoelastic boundary layer flow from a circular cylinder using an implicit finite difference code and showed that with increasing Deborah numbers there is a fall in Nusselt number (heat transfer rate) and the skin-friction coefficient. Tripathi and Bég (2013) analysed peristaltic propulsion with thermal diffusion using the Jeffery model. Hayat et al. (2015) simulated the polymeric thermal flow from a stretching cylinder in Jeffery viscoelastic liquid. Further studies of viscoelastic transport phenomena with the Jeffery’s model include, Kodandapani et al. (2008), Nadeem et al. (2009), Hayat et al. (2012). The Jeffery model quite accurately describes the characteristics of relaxation and retardation times which arise in certain polymeric flows. Furthermore, this model utilizes time derivatives rather than converted derivatives, which facilitates numerical solutions in boundary value problems.

Relatively few studies have considered polymeric external boundary layer flows from curved bodies where the fluid possesses both microstructural and viscoelastic characteristics. Prasad et al. (2015) have studied nanoscale micropolar convection from a cylinder. However they did not consider viscoelastic effects. Thus, the objective of the current study is to examine the viscoelastic micropolar heat transfer in external boundary layer flow from a cone using the Jeffery non-Newtonian (2005) and Eringen micropolar models (2001). This is the novelty of this article.

2 Mathematical Model

The regime under investigation is natural convection boundary layer flows of incompressible viscoelastic micropolar fluid (polymeric liquid) from a vertical isothermal solid cone, as shown in Fig. 1. Both cone and liquid are maintained initially at the same temperature. Fourier’s law is assumed for heat conduction i.e. thermal relaxation effects are negated. Thermal stratification and dispersion are also neglected as is viscous heating. The flow is laminar, steady-state and the cone surface isothermal. These conditions correspond to steady polymeric convection in external boundary layer flow development on an axisymmetric cone geometry. Instantaneously the cone surface is raised to a temperature Tw> T∞, where the latter (ambient) temperature of the polymeric fluid is maintained as constant. The x-coordinate is measured along the slant surface of the cone from the origin (at the vertex) and the y - coordinate is directed normal to the cone surface. The cone has a semi-vertex angle of A.

Physical model and coordinate system

With the Boussinesq buoyancy and boundary layer approximations, the governing equations for the conservation of mass, momentum, micro-rotation and energy can be written in two-dimensional Cartesian coordinates (x, y) as follows:

Here r is the local radius of the truncated cone, and v are the velocity components in x and y directions, Tand are the temperature and angular velocity of the viscoelastic micropolar fluid, k and j are the vortex viscosity and micro inertia density, y* = (μ + 0.5k) j is the spin gradient viscosity,

Here T∞ is the free steam temperature. We introduce a stream function defined by the Cauchy-Riemannequations,

Here all parameters are defined in the notation at the end of the article. The following non-dimensional partial differential equations for momentum and energy conservation therefore emerge:

The eight corresponding dimensionless boundary conditions emerge as:

Here primes denote the differentiation with respect to non-dimensional transverse co-ordinateηHere we also define the micropolar material parameters:

The local Nusselt number of the inverted cone can be written as

In equation (12),

Here h is the local heat transfer coefficient and k is the thermal conductivity of the micropolar viscoelastic fluid.

3 Numerical Solution With Keller Box Implict Method

In this study the Keller-box implicit difference method is implemented to solve the non-linear eight order system of coupled boundary layer eqns. (7) – (9) subject to the boundary conditions (10). This method continues to be popular in boundary layer flows. Recent works employing Keller’s box scheme include Cheng (2008) for micropolar non-isothermal flow from a truncated cone, Bég et al. (2016) for micro polar wall plume dynamics in permeable systems, Malik et al. (2015) and Subba Rao et al. (2017) for magnetic polymeric flows and Gaffar et al. (2015) and Subba Rao et al. (2017, 2018) for viscoelastic heat transfer from curved bodies. Very few of these papers however have provided guidance for researchers as to customization of the Keller-box scheme to heat transfer problems. We have included details of the discretization procedure below. Implementation of Keller’s scheme involves the following four stages:

Reduction of the Nth order partial differential equation system to N first order equations

Finite Difference Discretization

Quasilinearization of Non-Linear Keller Algebraic Equations

Block-tridiagonal Elimination of Linear Keller Algebraic Equations

Step 1: Reduction of the nthorder partial differential equation system to n first order equations

New variables are introduced to Eqns. (7) – (9) subject to the boundary conditions (10) are first written as a system of first order equations. For this purpose, we reset Eqns. (7) – (9) as a set of simultaneous equations by introducing the new variables:

The associated boundary conditions are

Phase b: Finite Difference Discretization

A two dimensional computational grid is imposed on the ξ-η plane as sketched in Fig. 1. The stepping process is defined by:

where kn and hj denote the step distances in the ξ and η directions respectively.

If

We now state the finite-difference approximation of equations. (16) – (23) for the (ηj−1/2, ξn), below

where we have used the abbreviations

The boundary conditions are

Phase c: Quasilinearization of Non-Linear Keller Algebraic Equations

If we assume

Phase d: Block-tridiagonal Elimination of Linear Keller Algebraic Equations

The linear system is solved using the block-elimination method, since it possess a block-tridiagonal structure consists of variables or constants. The system consists of block matrices the complete linearized system is formulated as a block matrix system, where each element in the co-efficient matrix is a matrix itself. Then, this system is solved using the efficient Keller–box method. The numerical results are strongly influenced by the number of mesh points in both directions. After some trials in the η-directions (transverse i.e. radial coordinate) a larger number of mesh points are selected whereas in the ξ-directions (tangential coordinate) significantly less mesh points are necessary. The numerical algorithm is executed in MATLAB on a PC. The method demonstrates excellent stability, convergence and consistency (Keller, 1978).

4 Keller Box Method (KBM) Numerical Results and Discussion

Numerical values of skin-friction and heat transfer coefficient for different values of ξ while Pr =0.71, Sf =0.5 and ST=1.0 when β → ∞(Newtonian case).

| ξ | Alam et.al results [19] | Present results | ||

|---|---|---|---|---|

| f″(ξ, 0) | −Φ′(ξ, 0) | f″(ξ, 0) | −Φ′(ξ, 0) | |

| 0.0 | 0.891936 | 0.420508 | 0.892157 | 0.421782 |

| 0.5 | 0.896407 | 0.620748 | 0.897843 | 0.619852 |

| 1.0 | 0.856963 | 0.848082 | 0.848784 | 0.840231 |

| 1.5 | 0.779210 | 1.129365 | 0.771562 | 1.119786 |

| 2.0 | 0.674111 | 1.441742 | 0.675320 | 1.432852 |

| 3.0 | 0.434152 | 2.202662 | 0.412372 | 2.063725 |

Moreover, in order to verify the accuracy of present method, the analytical results obtained in the present work were compared with those available in the literature, obtaining an excellent agreement with those given in Alam et al. [19] for particular values of ξ. The table presents the influence of increasing the tangential coordinate ξ on the skinfriction and local nussult number results. Increaseing ξ, is found to decrease skinfriction and increse heat transfer rate. There is a vast change in skin friction and heat transfer rate when taking the larger values of ξ.

Comprehensive solutions have been obtained and are presented in Figs. 2 – 19. We examine the influence of several key parameters, namely Deborah number (De), ratio of relaxation to retardation times (λ), Prandtl number (Pr), micropolar parameter (R) i.e. vortex to dynamic viscosity ratio and micro-inertia density parameter (B). The effect of

Influence of De on velocity.

Influence of De on the temperature.

Influence of De on the angular velocity.

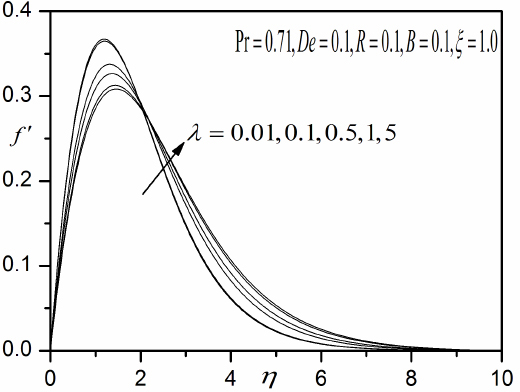

Influence of λ on the velocity.

Influence of λ on the temperature.

Influence of λ on the angular velocity.

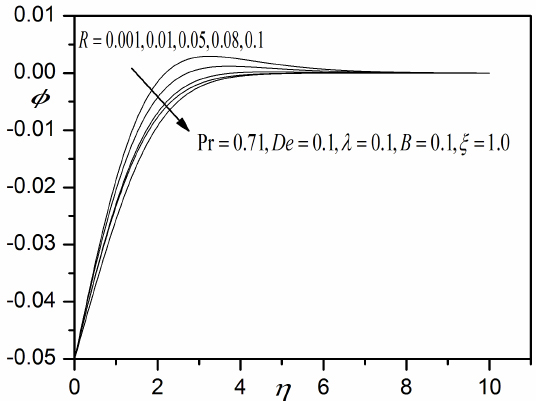

Influence of R on the velocity.

Influence of R on the temperature.

Influence of R on the angular velocity.

Influence of B on the velocity.

Influence of B on the temperature.

Influence of B on the angular velocity.

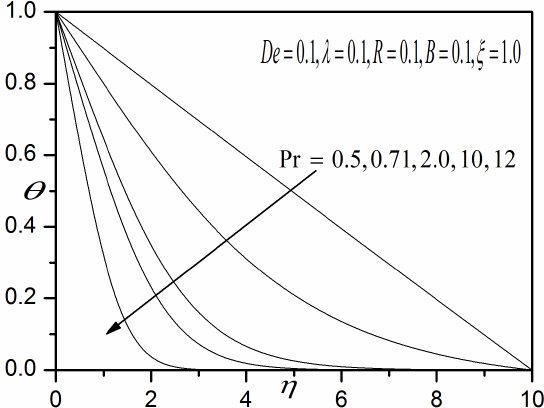

Influence of Pr on the velocity.

Influence of Pr on the temperature.

Influence of Pr on the angular velocity.

Influence of De on Nusselt number.

Influence of R on the Nusselt number.

Influence of Pr on the Nusselt number result.

the stream wise coordinate (ξ) is not explicitly examined. Default parameter values prescribed are: De = 0.1, λ = 0.1, Pr = 0.71, R = 0.1, B = 0.1, ξ = 1.0. In the graphs the angular velocity (g) is denoted asφ.

Figures 2 – 4, illustrate the influence of Deborah number on velocity (f′), temperature (θ) and angular velocity (Ø). Dimensionless velocity component (Fig. 2) is considerably reduced with increasing De values. De arises in connection with some higher order derivatives in the momentum boundary layer equations, (7), i.e.,

Figures 5 – 7 present the effect of the ratio of relaxation ()to retardation times i.e., λ on velocity (f′), temperature (θ) and angular velocity (Ø) distributions throughout the boundary layer regime. A significant increase in velocity is observed with increasing λ values. Conversely, temperature is markedly reduced with increasing values of λ. Also increasing λ is seen to increase the angular velocity significantly i.e. encourage spin of the micro-elements.

Velocity is significantly incresed with increasing λ. The polymer flow is therefore considerbly accelarated with an increase in relaxation time (or decrease in retardation time).

The mathematical model reduces to the Newtonian viscous flow model as λ → 0and De → 0, since this negates relaxation, retadation and elasticity effects.The momentum boundary layer equation in theese cases contracts to the familiar equation for Newtonian mixed convection from the cone:

Effectively with greater relaxation time of the polymer the thermal boundary layer thickness is reduced.

Figures 8 – 10 depicts the effect of the vortex viscosity parameter (R) on velocity,

Figures 11 – 13 depict the influence of velocity

Figures 14 – 16 represent typical profiles for (f′), temperature (θ) and angular velocity (Ø) for various values of Pr. It is observed that an increase in Pr decreases in velocity. The most prominent variation in profiles arises at intermediate distances from the cone surface. Furthermore, increasing Pr generates a substantial reduction in the fluid temperature and the thermal boundary layer thickness. At large Pr, the thermal boundary layer is thinner than at a smaller Pr. This is associated with the fact that for small Prandtl numbers the fluid has very high thermal conductivity. An increase in Pr from 0.5 through 0.71, 2.0, 10, 12 as shown in Fig. 14, substantially decelerates the flow i.e. reduces hydrodynamic boundary layer thickness. Similarly higher Prandtl number, which corresponds to lower thermal conductivity of the polymer results in a marked depression in temperatures (fig. 16). The lower thermal conductivity of denser polymers inhibits thermal diffusion via conduction heat transfer. Less heat is therefore conveyed from the cone surface (wall) into the boundary layer and thermal boundary layer thickness is decreased.

Increasing Pr as observed in Fig. 16, reduces angular velocity i.e stifles micro-element spin (angular deceleration).

Figures 17 – 19 presents the Nusselt Number comparisons for different values of De, R and Pr respectively: Increasing Deborah number, decrease the Nusselt number i.e reduces heat transfer from the viscoelastic micropolar fluid to the cone wall. Increasing vortex viscosity parameter, R is also seen to decrease the Nusselt number. Increasing Prandtl number, Pr is observed to enhance the Nusselt number since temperatures are reduced in the fluid and greater heat is convected to the cone surface. This inevitably has implications for cooling of thin film coatings.

5 Conclusions

A mathematical model has been developed for the buoyancy-driven, natural convection boundary layer flow of a viscoelastic micropolar fluid from a vertical isothermal cone. The Jeffery non-Newtonian and Eringen microstructural models have been used to simulate different rheological characteristics. The transformed boundary layer conservation equations have been solved with prescribed boundary conditions using the finite difference implicit Keller–box method which has second order accuracy. A comprehensive assessment of the effects of Deborah number De, ratio of retardation to relaxation timeλ, vortex viscosity parameter, Prandtl number Pr, micro-inertia density parameter B. Excellent convergence and stability characteristics are demonstrated by the Keller box scheme which is capable of solving very strongly nonlinear rheological problems.

The present simulations have shown that:

(i) Increasing Deborah number, De reduces velocity and Nusselt number whereas it increases temperature and angular velocity (micro-rotation of micro-elements).

(ii) Increasing ratio of retardation to relaxation time, λ increases the velocity and angular velocity whereas it reduces the temperature (and thermal boundary layer thickness).

(iii) Increasing Eringen vortex viscosity parameter, R decreases the velocity and angular velocity whereas it elevates temperature.

(iv) Increasing micro-inertia density parameter, B, reduces velocity and temperature whereas it enhances angular velocity.

(v) Increasing Prandtl number, Pr decreases velocity, temperature and angular velocity.

(vi) Increasing Deborah number and vortex viscosity parameter both depress Nusselt numberwhereas an increase in Prandtl number enhances the Nusselt number (heat transfer rate at the cone surface).

The current study has neglected rotation of the cone and therefore Coriolis body force effects, which are also relevant in polymer chemical processing operations, for example in spin coating processes. These will be considered in the near future.

Acknowledgement

This work is financially supported by the DST with reference no.SR/WOS-A/MS-09/2014(G). The authors appreciate the constructive comments of the reviewers which led to definite improvement in the paper. The authors are thankful to the management of Madanapalle Institute of Technology & Science, Madanapalle for providing research facilities in the campus.

References

[1] Landau L.D. and Levich B., Dragging of liquid by a plate, Acta Physiochim. USSR, 1942, 17, 42-54Suche in Google Scholar

[2] Lawrence C.J., Zhou W., Spin coating of non-Newtonian fluids, J. Non-Newtonian Fluid Mechanics, 1991, 39, 137-18710.1016/0377-0257(91)80010-HSuche in Google Scholar

[3] Samson Jenekhe A., Spencer B. Schuldt, Coating flow of non-Newtonian fluids on a flat rotating disk, Ind. Eng. Chem. Fundamen., 1984, 23(4), 432-43610.1021/i100016a009Suche in Google Scholar

[4] Osvaldo Campanella H., Jorge L. Galazzo, Ramón L. Cerro, Viscous flow on the outside of a horizontal rotating cylinder—II. Dip coating with a non-Newtonian fluid, Chemical Engineering Science, 1986, 41(11), 2707-271310.1016/0009-2509(86)80001-XSuche in Google Scholar

[5] Zevallos G.A., Carvalhoa M.S., Pasquali M. Forward roll coating flows of viscoelastic liquids, J. Non-Newtonian Fluid Mech., 130, 96-109 (2005).10.1016/j.jnnfm.2005.08.005Suche in Google Scholar

[6] Mitsoulis E., Fluid flow and heat transfer in wire coating: A review, Advances in Polymer Technology, 1986, 6, 467-48710.1002/adv.1986.060060405Suche in Google Scholar

[7] Mark J.E., Physical Properties of Polymers Handbook, AIP Press, Woodbury, New York, USA, 1996Suche in Google Scholar

[8] Yonghua Cao and Xiaomin Cui, Natural convection of power law fluids in porous media with variable thermal and mass diffusivity, International Journal of Heat and Technology, 2015, 33(2), 85-90.10.18280/ijht.330214Suche in Google Scholar

[9] Rita Choudhury and Bandita Das, Influence of visco-elasticity on MHD heat and mass transfer flow through a porous medium bounded by an inclined surface with chemical reaction, International Journal of Heat and Technology, 2016, 34(2), 332-33810.18280/ijht.340225Suche in Google Scholar

[10] K. Thirumurugan and R. Vasanthakumari, Double – diffusive convection of non - Newtonian Walters’ (MODELB′ viscoelastic fluid through brinkman porous medium with suspended particles, International Journal of Heat and Technology, 2016, 34(3), 357-36310.18280/ijht.340302Suche in Google Scholar

[11] Prasad V. R., Subba Rao A., Bhaskar Reddy N., Vasu B and Anwar Beg O., Modelling laminar transport phenomena in a Casson rheological fluid from a horizontal circular cylinder with partial slip, Proc. IMECHE Part E : J. Process Mechanical Engineering, 2013, 227(4), 309-32610.1177/0954408912466350Suche in Google Scholar

[12] Subba Rao. A, V.R.Prasad, K. Harshavalli and O. Anwar Bég, Thermal radiation effects on non- Newtonian fluid in a variable porosity regime with partial slip, J. Porous Media, 2016, 19(4), 313-32910.1615/JPorMedia.v19.i4.30Suche in Google Scholar

[13] Eringen A.C., Theory of micropolar fluids. J. Math. Mech., 1966, 16, 1–1610.21236/AD0469176Suche in Google Scholar

[14] Yacob N. A., Ishak A., Pop I., Melting heat transfer in boundary layer stagnation-point flow towards a stretching/shrinking sheet in a micro polar fluid, Computers & Fluids, 2011, 47, 16-2110.1016/j.compfluid.2011.01.040Suche in Google Scholar

[15] Prakash J. and Sinha P., Squeeze film theory for micro polar fluids, ASME J. Lubrication Tech., 1976, 98(1), 139-144.10.1115/1.3452749Suche in Google Scholar

[16] Papautsky. I. et al., Laminar fluid behaviour in micro channels using micro polar fluid theory, Sensors and Actuators, 1999, 73, 101-10810.1016/S0924-4247(98)00261-1Suche in Google Scholar

[17] Bhargava R., Sharma S., Bhargava P., Anwar Bég O. and Kadir A., Finite element simulation of nonlinear convective heat and mass transfer in a micropolar fluid-filled enclosure with Rayleigh number effects, Int. J. Applied Computational Mathematics, 2016, 10.1007/s40819-016-0180-9 (33pages)Suche in Google Scholar

[18] Latiff N. A., Uddin M. J., Anwar Bég O. and Ismail A. I. M., Unsteady forced bioconvection slip flow of a micropolar nanofluid from a stretching/shrinking sheet, Proc. IMECHE-Part N: J. Nanoengineering and Nanosystems, 2015, 10.1177/1740349915613817.Suche in Google Scholar

[19] M. S. Alam, Tarikul Islam and M. M. Rahman, Unsteady hydromagnetic forced convective heat transfer flow of a micropolar fluid along a porous wedge with convective surface boundary condition, International Journal of Heat and Technology 2015, 33(2), 115-122.10.18280/ijht.330219Suche in Google Scholar

[20] Cheng C-Y., Free convection heat transfer from a non-isothermal permeable cone with suction and temperature-dependent viscosity, J. Applied Science and Engineering, 2015, 18, 17-24Suche in Google Scholar

[21] Solchana C., Ashwinkumar. G. P. and Sandeep. N., Magneto hydrodynamic flow towards a vertical rotating cone in porous medium with thermophoresis and Brownian motion effects, Int. J. Advanced Science and Technology, 2016, 86, 61-7410.14257/ijast.2016.86.06Suche in Google Scholar

[22] Cheng C-Y., Natural convection heat transfer about a vertical cone embedded in a tridisperse porous media with constant wall temperature, Transport in porous media, 2015, 107, 765-77910.1007/s11242-015-0466-0Suche in Google Scholar

[23] Yih K.A., Effect of radiation on natural convection about a truncated cone, Int. J. Heat Mass Transfer, 1999, 42, 4299-430510.1016/S0017-9310(99)00092-7Suche in Google Scholar

[24] Gorla R. S. R., Schoren W. R. and Takhar H. S., Natural convection boundary layer flow of a micropolar fluid over an isothermal cone, Acta Mechanica, 1986, 61, 139-15210.1007/BF01176369Suche in Google Scholar

[25] Prasad V.R., Abdul Gaffar S., Keshava Reddy E. and Anwar Bég O., Numerical study of non-Newtonian boundary layer flow of Jeffrey’s fluid past a vertical porous plate in a non-Darcy porous medium, Int. J. Comp. Meth. Engineering Science & Mechanics, 2014, 15(4) 372-38910.1080/15502287.2014.915252Suche in Google Scholar

[26] Subba Rao. A, V.R. Prasad, N. Nagendra, (2015) Heat Transfer in a non-Newtonian Jeffrey’s fluid over a non-Isothermal Wedge, Procedia Engineering, Elsevier, 2015, 127C, 775-782; 10.1016/j.proeng.2015.11.412Suche in Google Scholar

[27] Tripathi D. and Anwar Bég O., Mathematical modelling of heat transfer effects on swallowing dynamics of viscoelastic flood bolus through the human oesophagus, Int. J. Thermal Sciences, 2013, 70, 41-5310.1016/j.ijthermalsci.2013.03.005Suche in Google Scholar

[28] Hayat T., Ashraf M.B., Shezad S.A. and Bayomi N.N., Mixed convection flow of viscoelastic nanofluid over a stretching cylinder, J. Brazilian Society of Mechanical Sciences and Engineering, 2015, 37, 849-85910.1007/s40430-014-0219-ySuche in Google Scholar

[29] Kodandapani M. and Srinivas S., Peristaltic transport of a Jeffery fluid under the effect of magnetic field in an asymmetric channel, Int. J. Nonlinear Mech., 2008, 43, 915-92410.1016/j.ijnonlinmec.2008.06.009Suche in Google Scholar

[30] Nadeem S. and Akbar N.S., Peristaltic flow of a Jeffrey’s fluid with variable viscosity in an asymmetric channel, Z. Naturforsch A, 2009, 64A, 713-72210.1515/zna-2009-1107Suche in Google Scholar

[31] Hayat T., Shehzad. S.A., Qasim M. and Obaidat. S., Radiative flow of Jeffery fluid in a porous medium with power law heat flux and heat source, Nuclear Engineering and Design, 2012, 243, 15-1910.1016/j.nucengdes.2011.11.005Suche in Google Scholar

[32] Prasad V. R., Gaffar S. A. and Anwar Bég O., Heat and mass transfer of a nanofluid from a horizontal cylinder to a micropolar fluid, AIAA J. Thermophysics Heat Transfer, 2015, 29, 1, 127-13910.2514/1.T4396Suche in Google Scholar

[33] Khadrawi, A.F., Al-Nimr. M.A. and Ali Othman, Basic viscoelastic fluid flow problems using the Jeffrey’s model, Chemical Engineering Science, 2005, 60, 7131-713610.1016/j.ces.2005.07.006Suche in Google Scholar

[34] Eringen A.C., Micro-continuum Field Theories: II- Fluent Media, Springer, New York, 2001Suche in Google Scholar

[35] Cheng C.Y., Natural convection of a micropolar fluid from a vertical truncated cone with power-law variation in surface temperature, Int. Comm. Heat Mass Transfer, 2008, 35, 39-4610.1016/j.icheatmasstransfer.2007.05.018Suche in Google Scholar

[36] Anwar Bég O., Sandile S. Motsa, Kadir A., Tasveer A. Bég and Islam M.N., Spectral quasilinear numerical simulation of micropolar convective wall plumes in high permeability porous media, J. Engineering Thermophysics, 2016, 25(4), 1-2410.1134/S1810232816040147Suche in Google Scholar

[37] Malik M.Y. et al., MHD flow of tangent hyperbolic fluid over a stretching cylinder: using Keller box method, J. Magnetism and Magnetic Materials, 2015, 395, 271-276, Iranica, 20(3), 467-476, 10.1016/j.scient.2013.02.013Suche in Google Scholar

[38] Subba Rao. A, V. R. Prasad, V. Nagaradhika, O. Anwar Beg, Heat Transfer in Viscoplastic Boundary Layer flow from a vertical permeable Cone with momentum and thermal wall slip: Numerical study. Heat Transfer Research, 2018, 49(3), 189-20410.1615/HeatTransRes.2017018153Suche in Google Scholar

[39] Gaffar S.A., Ramachandra Prasad. V, Keshava Reddy. E. and Anwar Bég O., Numerical study of non-Newtonian Jeffrey’s fluid from a permeable horizontal isothermal cylinder in non-Darcy porous medium, J of Brazilian Society of Mechanical Sciences and Engineering, 2015, 37, 1765-178310.1007/s40430-014-0301-5Suche in Google Scholar

[40] Subba Rao. A, V.R. Prasad, N. Bhaskar Reddy and O. Anwar Beg, Modelling Laminar Transport Phenomena In A Casson Rheological Fluid From An Isothermal Sphere With Partial Slip; Thermal science, 2015, 19(5), 1507-1519, 10.2298/TSCI120828098SSuche in Google Scholar

[41] A. Subba Rao, V. R Prasad, O. Anwar Beg and M. Rashidi, Free Convection Heat and Mass Transfer of a Nanofluid past a Horizontal Cylinder embedded in a non-Darcy porous medium; Journal of Porous Media, 2018, 21(3), 279-29410.1615/JPorMedia.v21.i3.60Suche in Google Scholar

[42] Subba Rao. A, V.R. Prasad, N. Bhaskar Reddy, O. Anwar Beg, Modelling Laminar Transport Phenomena in a Casson rheological fluid from a Semi-Infinite Vertical Plate with Partial Slip; Heat Transfer-Asian Research, 2015, 44(3), 272-291, DOI: 10.1002/htj.2111510.1002/htj.21115Suche in Google Scholar

[43] Subba Rao. A., Ramachandra Prasad V., Nagendra. N, Bhaskar Reddy. N and Anwar Beg O., Non-Similar computational solution for boundary layer flows of non-Newtonian fluid from an inclined plate with thermal slip, J. Applied Fluid Mechanics, 2016, 9, 795-80710.18869/acadpub.jafm.68.225.24664Suche in Google Scholar

[44] A. Subba Rao, CH. Amanulla, N. Nagendra, M. Surya Narayana Reddy and O. Anwar Beg, Hydro magnetic Non-Newtonian Nanofluid Transport Phenomena Past an Isothermal Vertical Cone with Partial Slip: Aerospace Nanomaterial Enrobing Simulation; Heat Transfer – Asian Research, 2018, 47(1), 203-23010.1002/htj.21299Suche in Google Scholar

[45] Keller H.B., Numerical methods in boundary-layer theory, Ann. Rev. Fluid Mech., 1978, 10, 417-43310.1146/annurev.fl.10.010178.002221Suche in Google Scholar

© 2019 K.Madhavi et al., published by De Gruyter

This work is licensed under the Creative Commons Attribution 4.0 Public License.

Artikel in diesem Heft

- Chebyshev Operational Matrix Method for Lane-Emden Problem

- Concentrating solar power tower technology: present status and outlook

- Control of separately excited DC motor with series multi-cells chopper using PI - Petri nets controller

- Effect of boundary roughness on nonlinear saturation of Rayleigh-Taylor instability in couple-stress fluid

- Effect of Heterogeneity on Imbibition Phenomena in Fluid Flow through Porous Media with Different Porous Materials

- Electro-osmotic flow of a third-grade fluid past a channel having stretching walls

- Heat transfer effect on MHD flow of a micropolar fluid through porous medium with uniform heat source and radiation

- Local convergence for an eighth order method for solving equations and systems of equations

- Numerical techniques for behavior of incompressible flow in steady two-dimensional motion due to a linearly stretching of porous sheet based on radial basis functions

- Influence of Non-linear Boussinesq Approximation on Natural Convective Flow of a Power-Law Fluid along an Inclined Plate under Convective Thermal Boundary Condition

- A reliable analytical approach for a fractional model of advection-dispersion equation

- Mass transfer around a slender drop in a nonlinear extensional flow

- Hydromagnetic Flow of Heat and Mass Transfer in a Nano Williamson Fluid Past a Vertical Plate With Thermal and Momentum Slip Effects: Numerical Study

- A Study on Convective-Radial Fins with Temperature-dependent Thermal Conductivity and Internal Heat Generation

- An effective technique for the conformable space-time fractional EW and modified EW equations

- Fractional variational iteration method for solving time-fractional Newell-Whitehead-Segel equation

- New exact and numerical solutions for the effect of suction or injection on flow of nanofluids past a stretching sheet

- Numerical investigation of MHD stagnation-point flow and heat transfer of sodium alginate non-Newtonian nanofluid

- A New Finance Chaotic System, its Electronic Circuit Realization, Passivity based Synchronization and an Application to Voice Encryption

- Analysis of Heat Transfer and Lifting Force in a Ferro-Nanofluid Based Porous Inclined Slider Bearing with Slip Conditions

- Application of QLM-Rational Legendre collocation method towards Eyring-Powell fluid model

- Hyperbolic rational solutions to a variety of conformable fractional Boussinesq-Like equations

- MHD nonaligned stagnation point flow of second grade fluid towards a porous rotating disk

- Nonlinear Dynamic Response of an Axially Functionally Graded (AFG) Beam Resting on Nonlinear Elastic Foundation Subjected to Moving Load

- Swirling flow of couple stress fluid due to a rotating disk

- MHD stagnation point slip flow due to a non-linearly moving surface with effect of non-uniform heat source

- Effect of aligned magnetic field on Casson fluid flow over a stretched surface of non-uniform thickness

- Nonhomogeneous porosity and thermal diffusivity effects on stability and instability of double-diffusive convection in a porous medium layer: Brinkman Model

- Magnetohydrodynamic(MHD) Boundary Layer Flow of Eyring-Powell Nanofluid Past Stretching Cylinder With Cattaneo-Christov Heat Flux Model

- On the connection coefficients and recurrence relations arising from expansions in series of modified generalized Laguerre polynomials: Applications on a semi-infinite domain

- An adaptive mesh method for time dependent singularly perturbed differential-difference equations

- On stretched magnetic flow of Carreau nanofluid with slip effects and nonlinear thermal radiation

- Rational exponential solutions of conformable space-time fractional equal-width equations

- Simultaneous impacts of Joule heating and variable heat source/sink on MHD 3D flow of Carreau-nanoliquids with temperature dependent viscosity

- Effect of magnetic field on imbibition phenomenon in fluid flow through fractured porous media with different porous material

- Impact of ohmic heating on MHD mixed convection flow of Casson fluid by considering Cross diffusion effect

- Mathematical Modelling Comparison of a Reciprocating, a Szorenyi Rotary, and a Wankel Rotary Engine

- Surface roughness effect on thermohydrodynamic analysis of journal bearings lubricated with couple stress fluids

- Convective conditions and dissipation on Tangent Hyperbolic fluid over a chemically heating exponentially porous sheet

- Unsteady Carreau-Casson fluids over a radiated shrinking sheet in a suspension of dust and graphene nanoparticles with non-Fourier heat flux

- An efficient numerical algorithm for solving system of Lane–Emden type equations arising in engineering

- New numerical method based on Generalized Bessel function to solve nonlinear Abel fractional differential equation of the first kind

- Numerical Study of Viscoelastic Micropolar Heat Transfer from a Vertical Cone for Thermal Polymer Coating

- Analysis of Bifurcation and Chaos of the Size-dependent Micro–plate Considering Damage

- Non-Similar Comutational Solutions for Double-Diffusive MHD Transport Phenomena for Non-Newtnian Nanofluid From a Horizontal Circular Cylinder

- Mathematical model on distributed denial of service attack through Internet of things in a network

- Postbuckling behavior of functionally graded CNT-reinforced nanocomposite plate with interphase effect

- Study of Weakly nonlinear Mass transport in Newtonian Fluid with Applied Magnetic Field under Concentration/Gravity modulation

- MHD slip flow of chemically reacting UCM fluid through a dilating channel with heat source/sink

- A Study on Non-Newtonian Transport Phenomena in Mhd Fluid Flow From a Vertical Cone With Navier Slip and Convective Heating

- Penetrative convection in a fluid saturated Darcy-Brinkman porous media with LTNE via internal heat source

- Traveling wave solutions for (3+1) dimensional conformable fractional Zakharov-Kuznetsov equation with power law nonlinearity

- Semitrailer Steering Control for Improved Articulated Vehicle Manoeuvrability and Stability

- Thermomechanical nonlinear stability of pressure-loaded CNT-reinforced composite doubly curved panels resting on elastic foundations

- Combination synchronization of fractional order n-chaotic systems using active backstepping design

- Vision-Based CubeSat Closed-Loop Formation Control in Close Proximities

- Effect of endoscope on the peristaltic transport of a couple stress fluid with heat transfer: Application to biomedicine

- Unsteady MHD Non-Newtonian Heat Transfer Nanofluids with Entropy Generation Analysis

- Mathematical Modelling of Hydromagnetic Casson non-Newtonian Nanofluid Convection Slip Flow from an Isothermal Sphere

- Influence of Joule Heating and Non-Linear Radiation on MHD 3D Dissipating Flow of Casson Nanofluid past a Non-Linear Stretching Sheet

- Radiative Flow of Third Grade Non-Newtonian Fluid From A Horizontal Circular Cylinder

- Application of Bessel functions and Jacobian free Newton method to solve time-fractional Burger equation

- A reliable algorithm for time-fractional Navier-Stokes equations via Laplace transform

- A multiple-step adaptive pseudospectral method for solving multi-order fractional differential equations

- A reliable numerical algorithm for a fractional model of Fitzhugh-Nagumo equation arising in the transmission of nerve impulses

- The expa function method and the conformable time-fractional KdV equations

- Comment on the paper: “Thermal radiation and chemical reaction effects on boundary layer slip flow and melting heat transfer of nanofluid induced by a nonlinear stretching sheet, M.R. Krishnamurthy, B.J. Gireesha, B.C. Prasannakumara, and Rama Subba Reddy Gorla, Nonlinear Engineering 2016, 5(3), 147-159”

- Three-Dimensional Boundary layer Flow and Heat Transfer of a Fluid Particle Suspension over a Stretching Sheet Embedded in a Porous Medium

- MHD three dimensional flow of Oldroyd-B nanofluid over a bidirectional stretching sheet: DTM-Padé Solution

- MHD Convection Fluid and Heat Transfer in an Inclined Micro-Porous-Channel

Artikel in diesem Heft

- Chebyshev Operational Matrix Method for Lane-Emden Problem

- Concentrating solar power tower technology: present status and outlook

- Control of separately excited DC motor with series multi-cells chopper using PI - Petri nets controller

- Effect of boundary roughness on nonlinear saturation of Rayleigh-Taylor instability in couple-stress fluid

- Effect of Heterogeneity on Imbibition Phenomena in Fluid Flow through Porous Media with Different Porous Materials

- Electro-osmotic flow of a third-grade fluid past a channel having stretching walls

- Heat transfer effect on MHD flow of a micropolar fluid through porous medium with uniform heat source and radiation

- Local convergence for an eighth order method for solving equations and systems of equations

- Numerical techniques for behavior of incompressible flow in steady two-dimensional motion due to a linearly stretching of porous sheet based on radial basis functions

- Influence of Non-linear Boussinesq Approximation on Natural Convective Flow of a Power-Law Fluid along an Inclined Plate under Convective Thermal Boundary Condition

- A reliable analytical approach for a fractional model of advection-dispersion equation

- Mass transfer around a slender drop in a nonlinear extensional flow

- Hydromagnetic Flow of Heat and Mass Transfer in a Nano Williamson Fluid Past a Vertical Plate With Thermal and Momentum Slip Effects: Numerical Study

- A Study on Convective-Radial Fins with Temperature-dependent Thermal Conductivity and Internal Heat Generation

- An effective technique for the conformable space-time fractional EW and modified EW equations

- Fractional variational iteration method for solving time-fractional Newell-Whitehead-Segel equation

- New exact and numerical solutions for the effect of suction or injection on flow of nanofluids past a stretching sheet

- Numerical investigation of MHD stagnation-point flow and heat transfer of sodium alginate non-Newtonian nanofluid

- A New Finance Chaotic System, its Electronic Circuit Realization, Passivity based Synchronization and an Application to Voice Encryption

- Analysis of Heat Transfer and Lifting Force in a Ferro-Nanofluid Based Porous Inclined Slider Bearing with Slip Conditions

- Application of QLM-Rational Legendre collocation method towards Eyring-Powell fluid model

- Hyperbolic rational solutions to a variety of conformable fractional Boussinesq-Like equations

- MHD nonaligned stagnation point flow of second grade fluid towards a porous rotating disk

- Nonlinear Dynamic Response of an Axially Functionally Graded (AFG) Beam Resting on Nonlinear Elastic Foundation Subjected to Moving Load

- Swirling flow of couple stress fluid due to a rotating disk

- MHD stagnation point slip flow due to a non-linearly moving surface with effect of non-uniform heat source

- Effect of aligned magnetic field on Casson fluid flow over a stretched surface of non-uniform thickness

- Nonhomogeneous porosity and thermal diffusivity effects on stability and instability of double-diffusive convection in a porous medium layer: Brinkman Model

- Magnetohydrodynamic(MHD) Boundary Layer Flow of Eyring-Powell Nanofluid Past Stretching Cylinder With Cattaneo-Christov Heat Flux Model

- On the connection coefficients and recurrence relations arising from expansions in series of modified generalized Laguerre polynomials: Applications on a semi-infinite domain

- An adaptive mesh method for time dependent singularly perturbed differential-difference equations

- On stretched magnetic flow of Carreau nanofluid with slip effects and nonlinear thermal radiation

- Rational exponential solutions of conformable space-time fractional equal-width equations

- Simultaneous impacts of Joule heating and variable heat source/sink on MHD 3D flow of Carreau-nanoliquids with temperature dependent viscosity

- Effect of magnetic field on imbibition phenomenon in fluid flow through fractured porous media with different porous material

- Impact of ohmic heating on MHD mixed convection flow of Casson fluid by considering Cross diffusion effect

- Mathematical Modelling Comparison of a Reciprocating, a Szorenyi Rotary, and a Wankel Rotary Engine

- Surface roughness effect on thermohydrodynamic analysis of journal bearings lubricated with couple stress fluids

- Convective conditions and dissipation on Tangent Hyperbolic fluid over a chemically heating exponentially porous sheet

- Unsteady Carreau-Casson fluids over a radiated shrinking sheet in a suspension of dust and graphene nanoparticles with non-Fourier heat flux

- An efficient numerical algorithm for solving system of Lane–Emden type equations arising in engineering

- New numerical method based on Generalized Bessel function to solve nonlinear Abel fractional differential equation of the first kind

- Numerical Study of Viscoelastic Micropolar Heat Transfer from a Vertical Cone for Thermal Polymer Coating

- Analysis of Bifurcation and Chaos of the Size-dependent Micro–plate Considering Damage

- Non-Similar Comutational Solutions for Double-Diffusive MHD Transport Phenomena for Non-Newtnian Nanofluid From a Horizontal Circular Cylinder

- Mathematical model on distributed denial of service attack through Internet of things in a network

- Postbuckling behavior of functionally graded CNT-reinforced nanocomposite plate with interphase effect

- Study of Weakly nonlinear Mass transport in Newtonian Fluid with Applied Magnetic Field under Concentration/Gravity modulation

- MHD slip flow of chemically reacting UCM fluid through a dilating channel with heat source/sink

- A Study on Non-Newtonian Transport Phenomena in Mhd Fluid Flow From a Vertical Cone With Navier Slip and Convective Heating

- Penetrative convection in a fluid saturated Darcy-Brinkman porous media with LTNE via internal heat source

- Traveling wave solutions for (3+1) dimensional conformable fractional Zakharov-Kuznetsov equation with power law nonlinearity

- Semitrailer Steering Control for Improved Articulated Vehicle Manoeuvrability and Stability

- Thermomechanical nonlinear stability of pressure-loaded CNT-reinforced composite doubly curved panels resting on elastic foundations

- Combination synchronization of fractional order n-chaotic systems using active backstepping design

- Vision-Based CubeSat Closed-Loop Formation Control in Close Proximities

- Effect of endoscope on the peristaltic transport of a couple stress fluid with heat transfer: Application to biomedicine

- Unsteady MHD Non-Newtonian Heat Transfer Nanofluids with Entropy Generation Analysis

- Mathematical Modelling of Hydromagnetic Casson non-Newtonian Nanofluid Convection Slip Flow from an Isothermal Sphere

- Influence of Joule Heating and Non-Linear Radiation on MHD 3D Dissipating Flow of Casson Nanofluid past a Non-Linear Stretching Sheet

- Radiative Flow of Third Grade Non-Newtonian Fluid From A Horizontal Circular Cylinder

- Application of Bessel functions and Jacobian free Newton method to solve time-fractional Burger equation

- A reliable algorithm for time-fractional Navier-Stokes equations via Laplace transform

- A multiple-step adaptive pseudospectral method for solving multi-order fractional differential equations

- A reliable numerical algorithm for a fractional model of Fitzhugh-Nagumo equation arising in the transmission of nerve impulses

- The expa function method and the conformable time-fractional KdV equations

- Comment on the paper: “Thermal radiation and chemical reaction effects on boundary layer slip flow and melting heat transfer of nanofluid induced by a nonlinear stretching sheet, M.R. Krishnamurthy, B.J. Gireesha, B.C. Prasannakumara, and Rama Subba Reddy Gorla, Nonlinear Engineering 2016, 5(3), 147-159”

- Three-Dimensional Boundary layer Flow and Heat Transfer of a Fluid Particle Suspension over a Stretching Sheet Embedded in a Porous Medium

- MHD three dimensional flow of Oldroyd-B nanofluid over a bidirectional stretching sheet: DTM-Padé Solution

- MHD Convection Fluid and Heat Transfer in an Inclined Micro-Porous-Channel