Abstract

The instability of clay soil as a road subgrade due to its high shrinkage properties, results in frequent road damage. Therefore, adequate soil improvement is required to improve soil performance in order to satisfy post-construction stabilization requirements. Soil improvement is one of the efforts made to overcome it, such as the soil stabilization method. In recent years there has been an increase in research related to the chemical soil stabilization to improve the physical and mechanical properties of soils. The addition of chemicals such as palm bunch ash, lime, fly ash, and cement to clay soil results in hydration and pozzolanic reactions. This process results in changes in the physical and mechanical properties of the soil. The degree of soil stabilization is influenced by the type of additive, additive content, length of treatment, and soil mineralogy. This study discusses the changes that can affect clay soil when chemical stabilization is carried out, based on information provided by the authors.

1 Introduction

Clay soils have low bearing capacity, high shrinkage properties, high compressibility, and take a long time to consolidate. It also has a low shear strength values with variations of 20–40 kPa [1,2]. Low soil bearing capacity of a road can lead to construction failure [3,4]. High shrinkage conditions also have a major effect on road construction, in dry conditions it will shrink and in wet conditions it will expand [5,6]. Shrinkage expansion in clay soils is influenced by clay mineral content, moisture content, and loading conditions. Chemical soil stabilization on clay soil will affect the cation size of each chemical element and potassium cations do not absorb water so the nature of the soil containing potassium will not be expansive (soil shrinkage) to improve the physical and mechanical properties of clay soil and increase the bearing capacity of clay soil [6]. Some clay minerals such as montmorillonite have high volume changes when interacting with water. The inter-particle contact stress and shear strength of clay soils are reduced due to loss of water suction. Strength decreases and pore voids increase due to swelling of the soil as a result of increased water [7].

If the road subgrade is unable to provide stability and serviceability during the planned life, then soil improvement measures can be taken. Soil stabilization is a soil improvement method that aims to improve the physical and mechanical properties of soft soil [8,9,10]. Soil stabilization is the process of improving soil properties through many methods such as compaction, mixing with chemicals, and non-destructive methods [11]. Soil stabilization consists of mechanical and chemical stabilization. The purpose of chemical stabilization is to add chemicals (stabilizers) such as lime, fly ash, cement, and palm bunch ash to the soil [12,13]. There are two types of soil stabilizers: traditional stabilizers and non-traditional stabilizers. Lime, fly ash, cement, and palm bunch ash are traditional stabilizers, while asphalt is the non-traditional stabilizer [11,13].

Clays are formed from weathering due to chemical reactions that form a group arrangement of colloidal-sized particles with grain diameters smaller than 0.002 mm. Clay minerals are composed of aluminum octahedra and tetrahedral silica. Clay minerals are very sensitive to changes in moisture content, if there is a change in moisture content, then it will be followed by extreme volume changes. This will affect the characteristics and technical properties of clay soil such as permeability, stability, deformation characteristics, and stress distribution within the soil layers. Chemical soil stabilization in clay soil will affect the cation size of each chemical element and potassium cations do not absorb water so the nature of the soil containing potassium will not be expansive (soil shrinkage) to improve the physical and mechanical properties of clay soil and increase the bearing capacity of clay soil [14,15]. The behavior of each of these chemicals is different in its treatment or use on soil and has certain limitations. Condition of the soil to be improved is very important to know comprehensively, both the physical properties and chemical properties of the soil, especially those concerning the chemical composition of existing soil minerals. This is very decisive in choosing the type of stabilizer that is suitable for soil improvement, so that the desired improvement target can be achieved, by the characteristics and needs of the construction that will be built on the soil layer [10]. The mechanism of soil stabilization and the resulting properties after stabilization vary depending on the heterogeneity of soil composition, differences in micro and macrostructure, and differences in chemical reactions that occur in the soil due to the applied stabilizer mixture [11]. The selection of the dosage level of the stabilizer is largely determined by the type and mineralogical properties of the soil to be improved. Understanding soil characteristics is crucial for selecting the appropriate stabilizer materials for chemical soil improvement, as different soils react differently to various chemical additives. This ensures the chosen method effectively addresses the specific soil issues and achieves the desired outcome [10].

The amount of mineral valence, and cation size of each chemical element (description of specific surface), also determines the ionic substitution process in chemical reactions in soil. The ability of cation substitution is based on the specific surface of each type of clay. This mechanism will change the index properties of the chemical-amended soil due to the formation of a diffused double-layer thickness that can reduce the liquid limit, plastic limit, and plasticity index (PI) of the soil, which are included in the physical properties of the soil. Reducing the water content in the soil has the effect of reducing the shrinkage expansion properties of the soil to increase the bearing capacity of the soil such as increasing the value of California bearing ratio (CBR) of the soil and the free compressive strength value of the soil included in the mechanical properties of the soil [11].

The properties of chemical reactions that occur between soil minerals and the chemicals contained in stabilizers influence the effectiveness of soil stabilization. What must be avoided in the use of chemicals, is the spread of the chemical reaction process to soil masses that are not targeted for improvement. This is very detrimental to the environment, and can even be fatal if the reaction propagation zone reaches the soil mass that already supports other buildings. Thus the effect of the reaction propagation will have a direct impact on the building it supports, which can be in the form of deformation due to the decomposition of soil minerals, differential settlement of the affected building, and so on [11].

The presence of water greatly affects the properties of the clay soil. In fine-grained soils such as clays, the presence of water makes the specific surface area larger. Similarly, variations in water content will affect the plasticity properties of the soil. The negatively charged clay surface will attract cations (+) of calcium and water molecules (dipoles), leading to the formation of a multi-layered “water double layer.” Chemical reactions that occur in clay soil due to chemical additives cause the crystal conditions of Potassium (K+) ions to have a larger radius than Lithium (Li+) and Sodium (Na+) ions, thus potentially replacing them (ionic substitution). Conversely, in solution conditions, K+ is very easily substituted by Na+ and Li+ ions. Other specific properties of K+ ions include that K+ ions do not absorb water (H2O) and this property results in potassium-containing soils not being expansive. This process reduces water in clay soils and impacts the permeability of clay soils [11,14].

Several factors should be considered when selecting the type and method of soil improvement for any soil stabilization project. These include the type and characteristics of the soil, such as its chemical and physical properties and mineralogy; the type and requirements of the planned construction, particularly the construction load; the specific soil parameters that need improvement based on construction needs; the depth of the soil layer requiring treatment; the chemical and physical properties of the stabilizer; the cost-effectiveness of the stabilizer, especially in terms of repair efficiency; the availability of materials and equipment at the improvement site; and the existing environmental conditions [15,16]. Chemical soil stabilization of clay soils will affect the cation size thereby increasing the shear modulus of the soil, and the formation of diffused double-layer thickness thereby decreasing the liquid limit, the plastic limit of the soil, and the PI of the soil. Long-term reactions occur over days, weeks, months, and/or years. The reactions that occur at this stage are called pozzolanic reactions. The presence of H+ and OH− ions in the soil will greatly affect the acidity of the soil. The formation of anions in the soil indicates that the reaction will cause a decrease in the cation substitution capacity of the soil. If this kind of soil has technical parameters that do not support construction, the chemical stabilization action that can be taken is to use acidic stabilizers (pH < 7.00), because they can actively react to capture negative charges (anions) in the soil. Thus, anion substitution occurs, which will result in a more stable soil mass and better technical parameters [11].

The latest advancement of reference is the study of the stabilization of clay soil with Marble dust. Marble dust is a hardened metamorphic rock that has been exposed to hydrothermal processes. The manufacture of marble dust consists of grinding and cutting to produce non-plastic dust with a very fine particle size that is almost like a perfect grater. The addition of marble dust to clay soils reduces the liquid limit, plastic limit, and PI of the soil. Soil stabilization technology has made significant progress in recent years. Nanotechnology has opened up new possibilities in soil stabilization by introducing nanomaterials such as nano-silica, nano-clay, and nano-lime. These materials have a high surface area to volume ratio, allowing them to penetrate soil particles more effectively and improve soil stability. Nano-particles can fill the voids between soil particles, increasing soil density and strength. In addition, nanoparticles can chemically react with soil minerals to form stable compounds, further improving soil properties [17,18,19].

Soil stabilization with cement and lime has long been used and with the development of time slowly began to research industrial waste additives [14]. The purpose of soil stabilization is to increase soil strength, change soil technical properties such as compressibility, permeability, soil development potential, and sensitivity to changes in moisture content [16]. Fly ash is a traditional stabilizer derived from waste coal combustion [20,21]. Soil improvement with lime is more rapidly developing, because it has been more widely used for various infrastructure development purposes, both for highways, airplane runways, land reclamation, backfill in retaining wall construction, and so on. The use of lime as a stabilizer for soil improvement was used by the military during the Roman Empire, to build dirt roads to support the mobilization of troops and their war equipment. Chemical methods of soil improvement with lime was again developed more widely, during World War I and World War II, which was not only used in road construction but also applied to the construction of fighter runways and military transport aircraft [22,23]. Palm ash is a pozzolana without binder, a waste from burning palm fiber, rich in silica and low in lime (CaO) [24,25]. Cement is widely used for clay stabilization and the percentage used is usually 20% or higher [26].

The challenge faced by soil stabilization in the field is that it requires a lot of stabilizers in field conditions so the mixing process also needs to be considered so that the soil is evenly mixed. Duration of application also affects soil stabilization. The lime-soil reaction starts about 1 h after mixing. The time lag between soil-lime mixing and compaction in the field needs to be considered as does the delay in compaction. The time lag tends to bind the soil grains and thus increases the porosity of the soil through the formation of clods. These clods have individual grains and provide stronger resistance to compaction efforts, leading to reduced maximum dry density (MDD) and increased optimum moisture content (OMC) [10,27]. Chemical stabilization of clay soil changes its physical and mechanical properties. Chemical reactions that occur with clay mineral content result in reduced water content in clay so that the bearing capacity of the soil increases due to changes in its physical and mechanical properties. For road construction, if the bearing capacity of the soil is good, it will be able to carry the load on it and reduce the occurrence of land subsidence [27].

Specifically, the criteria for clay soils that are effective for chemical stabilization methods are acidic clay soil type (pH, 7.00), clay soil with high plasticity, high swelling potential, high compressibility, and high permeability [10,11,12]. All chemicals for stabilizers are carried out with different variations depending on the chemical reactions that occur in each stabilizer. In general, the addition of cement alone cannot improve the workability of clay soils, nor can lime alone bring the strength of highly expansive clays up to the desired level. However, the combined effect of cement and lime in proportions of 1:1 tends to give much higher strengths with better workability. When the pozzolan content in the soil is less, very little increase in strength is obtained by adding either lime or cement. Either by the addition of lime or cement. To overcome this problem, pozzolanic materials need to be added to the soil. Fly ash is one of the most widely used pozzolanic materials. This is partly due to the high percentage of silica present in it [5,6,28].

Chemical stabilization of clay soil changes the physical and mechanical properties of clay soil. Chemical reactions that occur with clay mineral content result in reduced water content in clay so that the bearing capacity of the soil increases due to the changes in its physical and mechanical properties. For road construction, if the bearing capacity of the soil is good, it will be able to carry the load on it and reduce the occurrence of land subsidence [10]. The innovation of this research is the chemical reaction that occurs in chemical stabilization that causes improved soil performance by changing the physical and mechanical properties of the soil so that it increases the bearing capacity of the soil.

This article reviews literature on the chemical stabilization of clay soils using palm bunch ash, lime, fly ash, and cement. It discusses the chemical composition of these stabilizers and their effects on the properties of clay soils. The stabilizers discussed in this article are traditional stabilization materials. This study explores the chemical reactions that occur during the stabilization process, the dominant parameters influencing soil stability, and their role in increasing the soil's bearing capacity.

The difference between this research and previous research is that this research describes various chemical stabilization literature on clay soils with materials that are often used, namely, cement and lime, as well as waste materials, such as fly ash from coal combustion residues and oil palm waste, namely, oil palm bunch ash. Researchers [1,24] investigated the chemical stabilization of expansive soil with lime, cement, and fly ash. Lim and Shakri [25] studied stabilization using waste materials, such as fly ash and rice husk ash, for soil stabilization purposes. Yao et al. [26] researched about chemical stabilization using lime, cement, chemical, fly ash, rice husk ash, bituminous, thermal, and electrical stabilization. The main contribution of this research is its potential use as a reference for studies on clay stabilization using palm bunch ash, lime, cement, and fly ash. It also provides insights into the variation of stabilizers and the types of soil that can be treated.

2 Stabilization of palm bunch ash

Oil palm bunch ash is the residue of burning oil palm bunches, in the form of flour and is very alkaline with a pH of 12 so that it can be used to neutralize acid in the soil [29,30]. Palm bunch ash is produced by the palm oil industry through burning palm kernel shells, fiber, and empty palm bunches, which are used as fuel to generate electricity at temperatures of 800–1,000°C. This waste is dumped around the mill and if left unchecked will damage the environment [30,31].

Basic oil palm bunch ash contains a large amount of burnt carbon, absorbing most of the superplasticizer carbon properties [32]. Some researchers conducted studies to remove most of the unburned carbon in the bottom ash of oil palm bunches by heating it at 500°C for approximately 60 min [32], thus reducing the loss on ignition (LOI) content and increasing SiO2 + Al2O3 + Fe2O3, which becomes finer and moves to the surface position. The color dark gray and gray produced by palm bunch ash is due to the heating process.

2.1 Chemical content of palm bunch ash

The chemical content of palm bunch ash taken from the studies of several researchers is shown in Table 1.

Chemical content of palm bunch ash based on literature

| Oxide | SiO2 | Al2O3 | Fe2O3 | K2O | CaO | MgO | Na2O | LOI | SiO2 + Al2O3 + Fe2O3 |

|---|---|---|---|---|---|---|---|---|---|

| Conc (%) [33] | 57.8 | 2.3 | 9.6 | 3.5 | 3.6 | 1.4 | 0.56 | 20.7 | 69.7 |

| Conc (%) [34] | 79.34 | 3.15 | 7.12 | 3.23 | 2.79 | 1.21 | — | — | 89.58 |

| Conc (%) [35] | 66.24 | 3.52 | 3.93 | 6.7 | 5.21 | 4.48 | 0.16 | 4.41 | 73.69 |

| Conc (%) [36] | 59.17 | 3.73 | 6.33 | 8.25 | 5.8 | 4.87 | 0.18 | 16.1 | 69.23 |

| Conc (%) [31] | 64.17 | 3.73 | 6.33 | 8.25 | 5.8 | 4.87 | 0,18 | — | 74.23 |

| Conc (%) [37] | 62.3 | 3.2 | 13.6 | 7.9 | 4.9 | 3.7 | — | — | 79.1 |

| Conc (%) [38] | 69.02 | 3.9 | 4.33 | 6.9 | 5.01 | 5.18 | 0.18 | 1.8 | 77.25 |

| Conc (%) [39] | 63.7 | 3.68 | 6.27 | 9.15 | 5.97 | 4.11 | — | — | 75.37 |

| Conc (%) [40] | 62.6 | 4.65 | 8.12 | 9.05 | 5.7 | 3.52 | — | 6.25 | 73.65 |

| Conc (%) [41] | 65.3 | 2.6 | 2.0 | 5.7 | 6.4 | 3.1 | 0.3 | 10.1 | 69.9 |

| Conc (%) [42] | 65.3 | 2.5 | 1.9 | 5.7 | 6.4 | 3.0 | 0.3 | 10.0 | 69.7 |

| Conc (%) [43] | 59.62 | 2.54 | 5.02 | 7.52 | 4.92 | 4.52 | 0.76 | 8.25 | 67.18 |

The amount of SiO2 increases as the fineness of the palm bunch ash increases. The strength and durability of soil stabilized with palm bunch ash is proportional to the amount of reactive silica present in the palm bunch ash [44]. Oil palm bunch ash contains more K2O, this is because the oil palm trees absorb K2O during cultivation. The difference in oxide content is due to the temperature during the combustion process, the part of the oil palm tree used, and the fineness of the particles produced [44]. According to American Society for Testing and Materials [45], SiO2 + Al2O3 + Fe2O3 content in palm bunch ash >50% so that it is classified as class C pozzolan and if the amount is >70%, it is included in class F pozzolan. Palm bunch ash has been successfully used in soft soil stabilization because it is rich in silica and low in lime (CaO) [24]. The physical properties of palm bunch ash are shown in Table 2.

Properties of palm bunch ash [24]

| No. | Testing | Results |

|---|---|---|

| 1. | Specific gravity (Gs) | 1.69 |

| 2. | Sieve analysis | |

| Sand (%) | 0.05 | |

| Silt (%) | 99.5 | |

| Clay (%) | 0.0 | |

| 3. | Classification [45] | Class F |

The classification of palm bunch ash based on ASTM C618 is shown in Table 3.

2.2 Stabilization effect of oil palm bunch ash on clay soil

Oil palm bunch ash when used as a stabilizer on clay soil has a good effect because oil palm bunch ash contains SiO2 chemistry as shown in Table 1, which is >50% [46]. The results of laboratory testing of clay stabilization with oil palm bunch ash are shown in Table 4.

Overview of research results of stabilization of loamy soil with palm bunch ash

| No. | Author | Testing model | Parameters researched | Research results |

|---|---|---|---|---|

| 1 | [47] | Laboratory testing of the effect of temperature and length of curing | Unconfined compression strength (UCS) | The addition of oil palm bunch ash increases the free compressive strength of soil at 14 days of curing at 600°C (room temperature) compared to 1,000°C |

| 2 | [3] | Laboratory testing of clay soil stabilization with palm bunch ash and cement | UCS | Addition of oil palm bunch ash and cement increases the free compressive strength value of soil |

| 3 | [46] | Laboratory testing of clay soil stabilization with palm bunch ash | Maximum dry weight, optimum moisture content, CBR, and UCS | The maximum dry weight, optimum moisture content, CBR, and free compressive strength of soil increased with the addition of palm bunch ash with 14 days of curing |

| 4 | [25] | Laboratory testing of soft soil stabilization with palm bunch ash and fiber | Soil shear strength | Increasing the shear strength of soil with the addition of oil palm bunch ash and fiber within 14 days of curing |

| 5 | [24] | Laboratory testing of soft soil stabilization with palm bunch ash and lime | CBR | The pozzolan used was classified F, which contains almost no silica and alumina, so it was combined with 5% lime for pozzolanic reaction. Stabilization of 3% oil palm bunch ash and 5% lime increased the CBR value of the soil |

| 6 | [48] | Laboratory testing of clay soil stabilization with palm bunch ash and cement | Soil shear strength | There was an increase in the cohesion value of the soil and the shear strength value of the soil also increased with 20% palm bunch ash and 10% cement |

| 7 | [49] | Laboratory testing of clay soil stabilization with palm bunch ash and cement | CBR | Stabilization of soil with oil palm bunch ash and cement improves soil CBR value |

| 8 | [50] | Laboratory testing of clay soil stabilization with palm bunch ash | Physical properties of soil and soil CBR | The addition of oil palm bunch ash changed the soil consistency limit by lowering the PI value. There was an increase in the CBR value of the subgrade at 7 days burial |

| 9 | [51] | Laboratory testing of clay soil stabilization with palm bunch ash | Soil shear strength | There is an increase in the shear strength of soil with the addition of oil palm bunch ash around 50–60% both the cohesion value and the angle of friction |

| 10 | [52] | Laboratory testing of clay soil stabilization with palm bunch ash | UCS | Oil palm bunch ash increases soil strength |

| 11 | [53] | Laboratory testing of clay soil stabilization with palm bunch ash | UCS and Soil shear strength | Soil shear strength and soil strength increase with the addition of palm bunch ash at 7 and 28 days of curing |

| 12 | [54] | Laboratory testing of clay soil stabilization with palm bunch ash | UCS | There was an increase in soil strength and a decrease in PI values with the addition of palm bunch ash and fly ash |

3 Stabilization of clay with lime

The use of lime as a soil stabilizer has been used since the twentieth century and was first applied to highways in the United States in 1924 [1]. China and India have used lime mixtures for the construction of dams, bridge foundations, and basements. The Romans have used soil mixtures with lime for road subbases [11]. Lime used for soil stabilization can increase the shear strength of soil for road, runway, and railway construction. Lime can chemically react with soil grains to change the mineral properties of the soil [12]. Calcium in lime which has positive ions can stimulate the creation of soil adhesion, reduce the PI, reduce water content, reduce soil shrinkage properties, and increase soil stability [55]. Soil improvement using lime stabilizer is classified as a cementation reaction. The reaction mechanism between clay and lime is divided into two stages [55]:

Immediate Reaction, which occurs within hours, causes a reduction in water content in the soil. This reaction takes place with the following mechanism: CaO + H2O → Ca(OH)2 + heat*). This reaction is followed by the process of flocculation and/or agglomeration of clay particles, indicated by changes in soil texture, which will lead to a decrease in plasticity, as well as an increase in the workability of soil.

Medium and long-term reaction, which occurs in days, weeks, months, and years. The reaction that occurs at this stage is called the pozzolanic reaction between lime and clay particles.

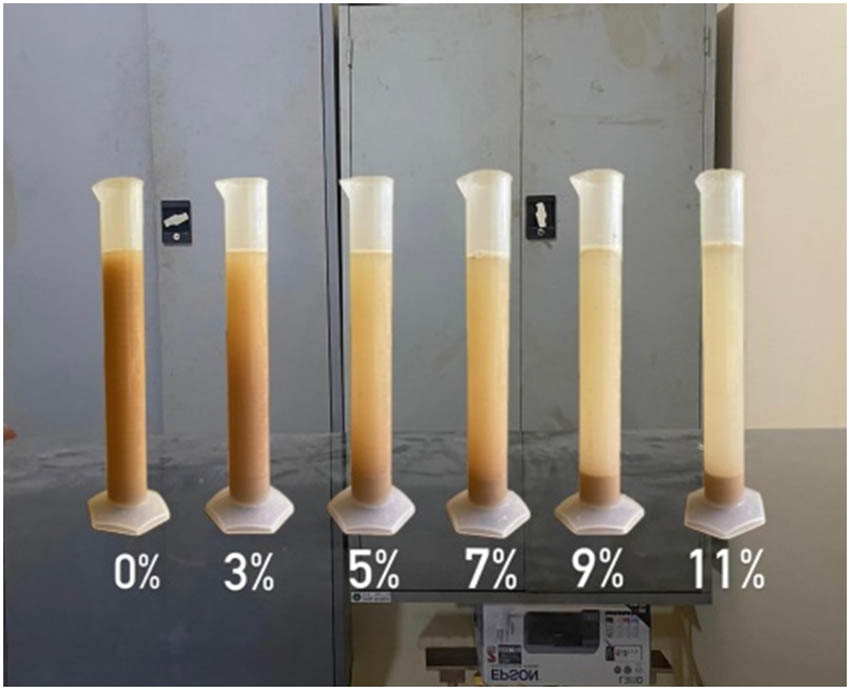

The mechanical properties of clay mixtures with lime stabilization have been carried out by many researchers, by conducting laboratory studies such as triaxial testing [12,56] and unconfined compressive strength [56,57,58]. The addition of lime to clay affects the settling rate. The more lime content, the more the settling rate increases. The more lime content, the more turbidity suspension process is favored, because the average particle size becomes smaller in suspension [23]. This is shown in Figure 1.

Precipitation processes due to lime addition.

The chemical theory of the reaction between lime and silicate, aluminate constituents in clay soils is complex [59] and includes cation exchange, flocculation and agglomeration, pozzolanic reactions, and carbonation [60]. These reactions affect changes in the physical, chemical, mineralogy, and microstructure of the treated soil [1]. Dissociation reaction of hydrated lime formed due to hydration of quicklime results in increased pH and high concentration of calcium ions in pore water [1,61]. An increase in pH can change the charge distribution on clay platelets, while calcium ions are released and lime replaces the exchangeable cations of the clay, leading to a reduction in the thickness of the double layer surrounding the clay [61].

3.1 Lime chemical content

Lime is generally obtained by burning limestone in a kiln with the quality of lime depending on the material and process of production. There are five types of lime, namely [62]:

High calcium and quick lime (CaO)

Hydrated and high calcium lime (Ca(OH)2)

Dolomitic lime (CaO + MgO)

Normal, hydrated dolomite lime (Ca(OH)2 + MgO)

Pressure, hydrated dolomite lime (Ca(OH)2 + MgO2)

The chemical content of lime is shown in Table 5.

Chemical content of lime based on literature

| Oxide | K2O | CaO | SiO2 | V2O5 | Cr2O3 | MnO | Fe2O3 |

|---|---|---|---|---|---|---|---|

| Conc (%) [63] | 0.02 | 66.3 | <0.03 | <0.01 | <0.03 | 0.01 | 0.1 |

| Conc (%) [15] | — | 61.62 | 2.55 | — | — | — | 0.66 |

| Conc (%) [23] | 0.07 | 71.58 | 2.13 | 0.01 | — | 0.01 | 0.23 |

| Conc (%) [5] | 0.03 | 95.03 | 0 | 0 | — | 0.60 | 0.08 |

| Conc (%) [28] | 0 | 93.35 | 0 | — | — | — | — |

| Conc (%) [64] | — | 56.1 | 1.38 | — | — | 0.13 | 0.12 |

| Conc (%) [65] | — | 63.60 | 4.11 | — | — | — | 2.70 |

When lime is used as a soil stabilizer, there will be a chemical reaction involving cation exchange because each soil particle carries an electrical charge. Soil particles have relatively weak ions on the surface, so they can be easily replaced with other ions. Water is attracted to soil particles but because it is already bound by exchangeable ions, the attracted water is replaced by a process called sorption [10]. This means that the mixture of lime in clay soil, and cation exchange that occurs in the absorbed water layer results in a decrease in soil plasticity so that the soil has a good bearing capacity, and is good for use as a subgrade or foundation [10,66,67]. The amount of lime required as stabilizers varies between 2 and 10% by weight of the soil. The greater the PI value, the greater the amount of lime required [10].

3.2 Stabilization effect of lime on clay soil

Clay minerals partially react with lime, where lime pozzolan is stimulated by cation exchange [1]. The percentage of lime content applied depends on the clay mineral content. Increased lime content results in increased soil strength and reduced deformation [1,68]. The results of laboratory testing of clay stabilization with lime are shown in Table 6.

Overview of research results stabilization of clay with lime

| No. | Author | Testing model | Parameters researched | Research results |

|---|---|---|---|---|

| 1 | [12] | Laboratory testing of stabilization of clay soil with lime | Index properties and shear strength of soil | The addition of lime variation increases the specific gravity and optimum moisture content of clay soil. The addition of lime to clay soil can increase the shear strength value of the soil |

| 2 | [6] | Laboratory testing of clay stabilization with lime, cement, and fly ash | CBR | There is an increase in the CBR value of soil with the addition of lime, cement, and fly ash |

| 3 | [5] | Laboratory testing of pH variation in clay stabilization with lime | Soil shear strength | The shear strength parameter of clay soil increases with the addition of lime at high pH 9 and low pH 3 |

| 4 | [4] | Laboratory testing of stabilization of clay soil with lime and plastic fiber on clay soil | UCS, split tensile strength, and CBR | The addition of lime can increase the compressive and tensile strength of soil. The role of fibers in soil stabilization with lime becomes more significant |

| 5 | [22] | Laboratory testing of the effect of temperature and curing time on reactivity and stabilization strength of limestone soil | UCS | Lime stabilization is applicable at lower temperatures when drying time is increased and thermal protection is provided |

| 6 | [56] | Laboratory testing of soil stabilization with lime and fiber | Soil shear strength and UCS | There was an increase in friction angle and cohesion values with the addition of lime and fiber. There is an increase in soil strength with the addition of these stabilizers |

| 7 | [57] | Laboratory testing of soil stabilization with lime and fiber | UCS | There is an increase in soil strength with the addition of lime and fiber |

| 8 | [58] | Laboratory testing of soil stabilization with lime and fiber | UCS | There was a high increase in soil stabilization with lime and fiber with a maximum curing time of 90 days |

| 9 | [69] | Laboratory testing of soil stabilization with lime | Soil shear strength | The longer treatment process on lime-stabilized soil, namely, 28, 90, and 180 days, increased the cohesion value and shear angle |

| 10 | [8] | Laboratory testing of soil stabilization with lime | CBR and UCS | There was a significant decrease in soil plasticity and maximum dry density increased due to the addition of lime to the clay soil. The CBR value and compressive strength of the soil increased due to the mixture of lime with clay |

| 11 | [70] | Laboratory testing of soil stabilization with lime and bagasse ash | CBR | Lime and bagasse ash combined at the optimal ratio of 4:1, the CBR results of stabilization of clay soil increased |

| 12 | [16] | Laboratory testing of clay stabilization with lime and cement in the presence of salt water | UCS | Increase in soil strength with lime and cement mixture and brine addition |

The increase in strength of clay soil occurs due to the reduction in plasticity and pozzolanic reaction in lime processing, which results in considerable hardening as seen in the magnitude of the resilience modulus [11]. There is a 20-fold increase in the modulus of resistance of montmorillonite clay when mixed with lime.

The National Lime Association recommends that PI values > 10% can be stabilized with lime. Based on the AASTHO classification of soil types A-4, A-5, A-6, A-7, A-2-6, and A-2-7 are suitable for stabilization with lime [71,72,73]. The process of flat particles and large particles in the clay sample produces a lot of particle bundles and forms a compact structure [23]. Lime-stabilized clay soil forms a white cement gel and Ca(OH)2 in the soil pore space when water is added [23]. Filling the pores between particles with lime results in a decrease in PI and an increase in compressive strength [10,23].

4 Stabilization of clay soil with fly ash

Fly ash is a finely graded material measuring 0.01–100 microns, which is produced from burning coal in power plants. It is finer than ordinary Portland cement consisting of silica and alumina and CaO, Fe2O3, TiO2, K2O, MnO, Na2O, and SO3 [1,74,75]. The main constituents of fly ash are silica and alumina. Fly ash class C has high calcium and is environmentally friendly for stabilizing clay soils, it can be used as an alternative to chemical additives such as cement and lime. The use of fly ash in clay stabilization can improve the physical and mechanical properties of clay soils. Highly plastic clay soil has a high sensitivity to calcium, so the addition of fly ash can reduce the liquid limit and shrinkage potential of clay soil [74]. Over the past few decades, fly ash has been called a problematic waste because it pollutes agricultural land. Fly ash is ranked as the fifth largest source of raw materials and waste that can be used for alternative infrastructure and geotechnical development [9].

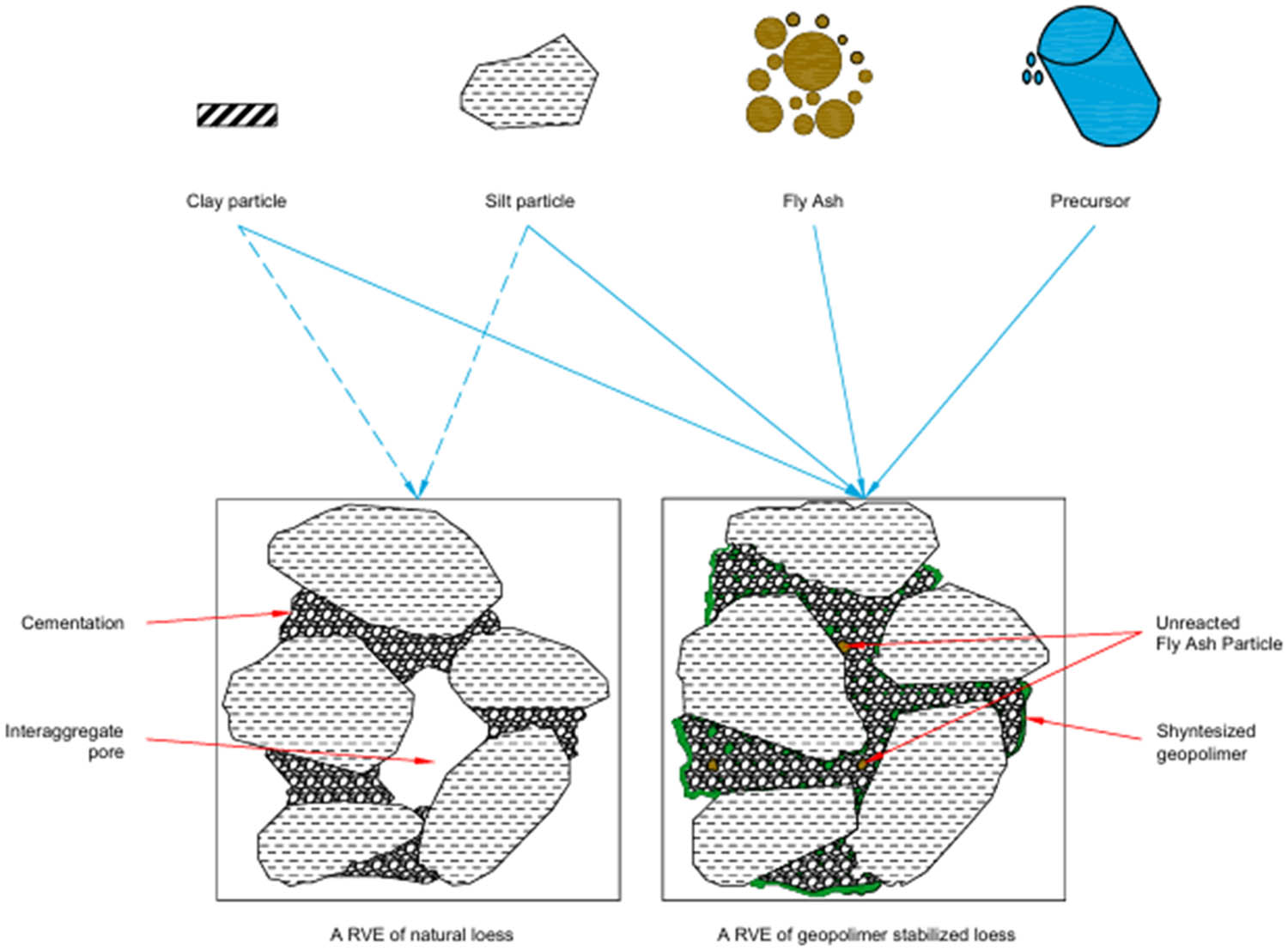

Fly ash is low in calcium and rich in aluminosilicate and is commonly used for geopolymer synthesis [76,77]. For decades, fly ash has been labeled as a problematic solid waste due to its conventional disposal method from thermal power plants and mills [78]. The type of class of fly ash based on ASTM C618-17-2019 [39] depends on the chemical composition and properties of the coal burned. Class C fly ash contains a lot of lime, CaO > 20%, and the sum of SiO2 + Al2O3 + Fe2O3 > 50%. Class F fly ash contains little lime, CaO < 10%, and the sum of SiO2 + Al2O3 + Fe2O3 > 70% [20,74]. Class F fly ash has pozzolanic properties while class C fly ash has pozzolanic properties and cement [74]. A conceptual microstructure model showing the stabilization mechanism of fly ash geopolymers is shown in Figure 2.

Conceptual microstructure model of fly ash geopolymer stabilization.

Clay particles are the main component that usually clump together to form clay aggregates that provide load-bearing capacity. Due to the special features of the loess formation process, we are characterized by the formation of open metastable structures and their mechanical properties depend on cementation/suction between particles [79]. The cementation bond and suction capacity of loess soils will decrease and eventually lead to collapse behavior when the loess is wetted or subjected to increased applied pressure [79].

The benefits of fly ash are as follows [1].

Drying agent

A large amount of water is absorbed by fly ash during the hydration process and can be used as a curing agent for moist soils, especially if rapid curing is desired.

Control of volume instability

Can reduce soil volume instability and reduce soil shrinkage expansion properties.

Strength improvement

The cement compounds and pozzolanic reactions of fly ash provide a cementing bond to the soil that increases its strength.

4.1 Fly ash chemical content

The chemical content of fly ash is shown in Table 7.

Fly ash chemical content based on literature

| Composition | SiO2 | Al2O3 | Fe2O3 | K2O | CaO | MgO | Na2O | LOI | SiO2 + Al2O3 + Fe2O3 |

|---|---|---|---|---|---|---|---|---|---|

| Conc (%) [79] | 52.06 | 20.54 | 5.5 | 0.69 | 14.07 | 3.29 | 0.94 | 0.1 | 78.1 |

| Conc (%) [80] | 51.11 | 25.56 | 12.48 | 0.70 | 4.30 | 1.45 | 0.77 | 0.57 | 89.15 |

| Conc (%) [74] | 48.20 | 22.30 | 5.30 | 1.20 | 15.80 | 1.20 | 1.50 | — | 75.80 |

| Conc (%) [81] | 36.00 | 16.80 | 17.64 | 1.83 | 26.73 | — | — | — | 70.44 |

| Conc (%) [82] | 66.88 | 25.12 | 2.41 | 1.83 | 1.69 | — | — | — | 94.41 |

| Conc (%) [83] | 50.2 | 22.5 | 5.17 | — | 20.3 | 0.51 | — | — | 77.87 |

| Conc (%) [84] | 59.40 | 33.99 | 1.21 | 0.64 | 27.68 | 0.42 | — | 0.21 | 94.6 |

| Conc (%) [85] | 49.72 | 15.15 | 9.30 | 2.00 | 13.1 | 2.97 | 2.37 | 1.00 | 74.17 |

| Conc (%) [78] | 45.00 | 30.00 | 10.00 | 4.00 | 30.00 | 6.00 | 2.00 | 0 | 85.00 |

| Conc (%) [86] | 58.8 | 21.1 | 1.1 | 2.4 | 3.4 | 1.1 | 0.4 | 3.4 | 81.00 |

| Conc (%) [87] | 54.9 | 25.8 | 6.9 | — | 9.7 | 1.8 | — | 6.0 | 87.6 |

| Conc (%) [65] | 40.60 | 19.06 | 5.34 | — | 24.00 | 2.00 | — | 6.00 | 65.00 |

The presence of silica in fly ash reacts with Ca2+ ions of lime to reduce the Ca2+ concentration. Since ettringite requires more Ca2+ ions, there is a reduction in the Ca2+ concentration, which tends to reduce the possibility of ettringite formation so that the swelling of sulfate is reduced [1]. Fly ash with high sulfate content can be beneficial to the total sulfate potential of lime-treated clay soils, which can exacerbate ettringite formation and swelling. Thus, fly ash can be a crucial factor for the selection of materials to limit sulfate in shrinkage expansion of lime-treated expansive soils [86].

Particles finer than 10 mm will tend to show better pozzolanic reactivity. Clay stabilized with fly ash having a higher CaO/SiO2, CaO/Al2O3 than CaO/(SiO2/Al2O3) ratio experiences higher pozzolanic activity as well as better engineering properties [87,88].

4.2 Stabilization effect of fly ash on clay soil

Fly ash increases the bearing capacity of clay soils and improves their physical and mechanical properties. Clay soils have a high sensitivity to calcium, so the addition of fly ash significantly lowers the liquid limit value and reduces the shrinkage expansion properties of the soil [1,89]. The results of laboratory testing of clay stabilization with fly ash are shown in Table 8.

Overview of research results stabilization of clay soil with fly ash

| No. | Author | Testing model | Parameters researched | Research results |

|---|---|---|---|---|

| 1 | [80] | Laboratory testing of clay stabilization with fly ash | UCS | Stabilization of clay soil with fly ash increases the compressive strength value of the soil |

| 2 | [74] | Laboratory testing of clay stabilization with fly ash to improve soil-bearing capacity | Maximum dry weight, optimum moisture content, CBR, and UCS | Maximum dry weight decreases with the addition of fly ash, there is an increase in CBR value and compressive strength of clay soil at 7% fly ash |

| 3 | [79] | Laboratory testing of clay stabilization with fly ash | UCS | Stabilization of clay soil with fly ash increases the compressive strength value of the soil and increases the Young’s modulus value |

| 4 | [86] | Laboratory testing of stabilization of clay soil with fly ash and lime | Maximum dry weight and optimum moisture content | High sulfate in fly ash reduces its effective role. The high LOI of coarse fly ash increases the optimum moisture content value and decreases the maximum dry weight |

| 5 | [85] | Laboratory testing of clay stabilization with fly ash and fiber | UCS | The fly ash content of the soil affects the stress and strain. The strength is significantly affected by the addition as well as the length and number of fibers provided. The addition of fly ash and fiber increases the strength of clay soil |

| 6 | [90] | Laboratory testing of cyclic behavior of fly ash stabilized clay soil | Stress and strain, soil modulus | Fly ash improves the cyclic performance of clay soils such as the achievable strain of the soil, the number of load cycles, and the cyclic shear modulus. Fly ash is required to maintain durability against applied loading |

| 7 | [77] | Laboratory testing of stabilization of clay soil with fly ash and slag | UCS | The addition of fly ash and slag increased the strength of the soil, proving an alternative to traditional cement or lime binders |

| 8 | [91] | Laboratory testing of clay stabilization with fly ash and bottom ash | UCS | The soil strength value increases with the curing time. The addition of fly ash and bottom ash increases the soil strength values |

| 9 | [92] | Laboratory testing of clay stabilization with fly ash | UCS | Loamy soil containing 10% fly ash increases the free compressive strength of the soil |

| 10 | [93] | Laboratory testing of stabilization of clay soil with fly ash and lime | UCS | Addition of fly ash and lime increases soil strength after 7 days and 28 days of curing |

| 11 | [94] | Laboratory testing of clay stabilization with fly ash | Atterberg limits and UCS | The addition of fly ash can reduce the PI and specific gravity of clay soil. The strength of clay soil increases with the addition of fly ash |

| 12 | [95] | Laboratory testing of clay stabilization with fly ash | UCS | The addition of fly ash improves the physical and mechanical properties of clay soil and increases the strength of clay soil, so fly ash is recommended for stabilization of clay soil |

Research related to the stabilization of clay soil with fly ash has been widely studied. Laboratory studies improved the physical and mechanical properties of the soil. Significant improvement occurs depending on the chemical content of fly ash and the length of curing, as shown in Figure 3.

![Figure 3

Stabilizer selection recommendations based on soil physical properties [9].](/document/doi/10.1515/jmbm-2025-0056/asset/graphic/j_jmbm-2025-0056_fig_003.jpg)

Stabilizer selection recommendations based on soil physical properties [9].

Scanning electron microscope (SEM) technique coupled with energy dispersive X-ray (EDX) is the best and most widely used method to identify the morphology (microstructure) and constituents of fly ash particles [74]. SEM-EDX analysis was used to describe the microstructure of the sample [74].

5 Stabilization of clay with cement

Besides lime, most popular chemical additive used for soil stabilization is Portland cement. Portland cement has been used for about 100 years in various places [96,97,98,99]. Portland cement is a fine heterogeneous compound consisting of four different oxides, namely, silicate (C3S), di-calcium silicate (C2S), tricalcium aluminate (C3A), and tetra calcium aluminoferrate (C4AF). For C is CaO, S is SiO2, F is Fe2O3, and H is H2O [1]. Cement has been widely used for stabilizers in clay soils as subgrade soils [100]. For stabilization of clay soil with cement, the cement content is larger than 20% [26]. Portland cement is a construction material that is often used in the construction world. But its manufacture causes wastage of energy because it requires a temperature of 1,450–1,550°C and has other properties that have an impact on the environment [76].

Cement stabilization is a mixture of cement, soil, and water to form a rigid and hard material when compacted, thus increasing the bearing capacity of the soil [101]. The use of cement as stabilization of clay soil improves the physical and mechanical properties of the soil, where observations show that the addition of cement reduces plasticity, liquid limit, and development potential of the soil significantly. Soil strength increases with the addition of cement to clay soil [96,102]. Stabilization of soil with cement is influenced by several factors [1]:

Cement ratio

Cement content

Burial period

Sulfate content and organic content

5.1 Chemical content of cement

Calcium silicate consists of silicate (C3S) and di-calcium silicate (C2S), resulting in a very analogous hydration [103]. Clay soil when mixed with cement and water, hydration will occur, calcium silicate releases calcium ions into the clay and forms the following compounds [104]:

2C3S + 6H2O → CSH + Ca(OH)2

2C2S + 4H2O → CSH + Ca(OH)2

Ca(OH)2 formed during the hydration of silicate (C3S) and di-calcium silicate (C2S) decomposes into OH− and Ca2+, furthermore Ca2+ ions contribute to the soil flocculation. It also reacts with pozzolanic materials such as silica and alumina present in the soil [1,105]. As a result, cementitious components are formed (calcium aluminate hydrate [CAH] and calcium silicate hydrate [CSH]) that lead to the strengthening of inter-particle bonds thereby improving soil strength performance. Cementitious soil improvement is a mixture of crushed soil, cement, and water, which is then subjected to a compaction process that will produce a new material called soil-cement material. The reaction of cement with soil material and water will create a hardened compound that improves the strength of the soil and the technical properties of the soil become stronger and more resistant to water [1,106]. The increase in strength mechanism due to the cementitious compound of pozzolan is shown in Figure 4 [106].

![Figure 4

Mechanism of strength development due to pozzolanic reaction [106].](/document/doi/10.1515/jmbm-2025-0056/asset/graphic/j_jmbm-2025-0056_fig_004.jpg)

Mechanism of strength development due to pozzolanic reaction [106].

The pozzolanic reaction takes place slowly over months or years, and can further strengthen the soil with reduced plasticity and increased gradation [106]. The chemical content of cement is shown in Table 9.

Chemical content of cement based on literature

| Composition | SiO2 | Al2O3 | Fe2O3 | K2O | CaO | MgO | Na2O | LOI |

|---|---|---|---|---|---|---|---|---|

| Conc (%) [103] | 20.18 | 4.41 | 2.40 | 0.14 | 65.66 | 0.66 | 0.06 | 2.50 |

| Conc (%) [107] | 21.7 | 7.5 | 2.9 | — | 54.7 | 1.7 | — | 3.4 |

| Conc (%) [108] | 39.41 | 11.63 | 3.35 | 1.21 | 36.35 | 5.52 | 0.32 | 0.02 |

| Conc (%) [104] | 19.66 | 5.48 | 3.72 | — | 62 | 2.87 | — | 3.55 |

| Conc (%) [109] | 21.60 | 4.13 | 4.57 | 0.56 | 64.44 | 1.06 | 0.11 | 0.76 |

| Conc (%) [110] | 30.32 | 11.83 | 3.24 | 1.09 | 50.90 | 1.60 | 0.69 | — |

| Conc (%) [111] | 21 | 5 | 4 | 1 | 65 | 1 | — | 4 |

| Conc (%) [96] | 21.60 | 4.13 | 4.57 | 0.56 | 64.44 | 1.06 | 0.11 | 0.76 |

| Conc (%) [32] | 20.59 | 4.90 | 3.21 | 0.90 | 63.80 | 0.90 | 0.05 | 2.48 |

| Conc (%) [112] | 21.60 | 4.13 | 4.57 | 0.56 | 64.44 | 1.06 | 0.11 | 0.76 |

| Conc (%) [113] | 18.30 | 4.68 | 2.32 | 0.57 | 66.80 | 1.59 | 0.28 | 0.21 |

5.2 Stabilization effect of cement on clay soil

Cement can be mixed with all types of soil, but it is most suitable for granular soils with high fineness and medium-plasticity clay soils in cement stabilization [1]. Cement admixture is recommended in soils with PI values <20%. Cement becomes difficult to mix with highly plastic clay soils as lumps will form, making mixing difficult [111]. Laboratory test results of stabilization of clay soil with cement are shown in Table 10.

Overview of results research on stabilization of loamy soil with cement

| No. | Author | Testing model | Parameters researched | Research results |

|---|---|---|---|---|

| 1 | [111] | Laboratory tests of stabilization of clay soil with cement on shrinkage expansion soil | UCS, liquid limit, and plasticity | The addition of cement resulted in increased strength and stiffness of the soil and reduced the shrinkage potential of the soil |

| 2 | [114] | Laboratory tests of stabilization of clay soil with cement on shrinkage expansion soil | UCS and plasticity | The addition of cement increases soil strength by a factor of 4–10 and decreases swelling potential by <1% |

| 3 | [26] | Laboratory tests of stabilization of clay soil with cement against strain and stress | UCS and soil modulus | The addition of cement increases soil strength and makes the strain modulus small due to addition of cement |

| 4 | [115] | Laboratory tests of stabilization of clay soil with cement and polypropylene fiber | UCS | There was an increase in soil strength with the addition of cement and polypropylene fiber |

| 5 | [116] | Laboratory tests of stabilization of clay soil with cement and polypropylene fiber | UCS | There is an increase in the strength of soil with the addition of cement and polypropylene fiber due to changes in the temperature in wet and dry conditions |

| 6 | [117] | Laboratory tests of stabilization of clay soil with cement | CBR | There was an increase in the CBR value of cement-stabilized soil |

| 7 | [118] | Laboratory tests of stabilization of clay soil with cement and fly ash | UCS | There is an increase in soil strength due to the addition of cement and fly ash to the soil |

| 8 | [119] | Laboratory tests of stabilization of clay soil with cement and fiber mixture | CBR and UCS | Stabilization of clay with cement and fiber addition, very effective in increasing CBR value and soil strength |

| 9 | [120] | Testing laboratory stabilization of clay soil with cement | UCS | The compressive strength of soil increases with the addition of cement in clay soil within 7 days of curing |

| 10 | [121] | Testing laboratory stabilization of clay soil with cement | Permeability | Liquid limit and plastic limit decrease with the addition of cement. The permeability coefficient of stabilized soil at 2% cement increased about 14 times greater than that of the native soil |

| 11 | [122] | Laboratory tests of stabilization of clay soil with cement and sawdust ash | UCS | There is an increase in the strength value of cement and sawdust ash stabilized clay soil |

| 12 | [123] | Laboratory tests of clay stabilization with cement and gypsum | CBR and UCS | CBR value and compressive strength of soil increased with the addition of cement and gypsum within 28 days of curing |

Less cement is required for low-plasticity clays and high cement is required for high-plasticity clays [1]. In high plasticity soils, the liquid limit will continue to decrease up to 6% cement, while in low plasticity soils the liquid limit value increases [124]. Microstructure and mineralogy studies using SEM, EDX spectroscopy, and X-ray diffraction were conducted to see the mechanism of chemical reaction of clay with cement [96].

EDX results confirmed the presence of Si and Ca in selected areas providing qualitative evidence for the gel formation of C–S–H specimens. Cement-stabilized specimens indicate that sodium silicate has geopolymerized [92]. Stabilization of clay soil with cement effectively increases the shear strength and compressive strength of the soil in a relatively short period [125].

6 Conclusion

This article presented a literature review of clay stabilization with chemicals such as palm bunch ash, lime, fly ash, and cement. The conclusions obtained are as follows:

Chemical stabilization can increase the strength of clay soils. The stabilization process depends on the percentage of additives, clay mineralogy, and the length of curing.

Palm bunch ash has been successfully used in clay soil stabilization because it is rich in silica and low in lime (CaO). The addition of palm bunch ash increases soil strength. The classification of palm bunch ash based on its pozzolanic properties is class C and class F.

Lime is suitable for highly plastic soils such as expansive clays. Lime mixtures in clay soils show a considerable increase in strength due to the development of pozzolan, which shows the effect of cement on soil particles. Based on AASTHO classification of soil types, A-4, A-5, A-6, A-7, A-2-6, and A-2-7 are suitable for stabilization with lime.

Fly ash has a low calcium content, so it does not produce significant soil strength as with lime and cement. Clay soils have a high sensitivity to calcium, so the addition of fly ash significantly lowers the liquid limit value and reduces the shrinkage expansion properties of the soil.

Cement is suitable for granular soils with low plasticity. Cement admixture in expansive clay soils can reduce the shrinkage expansion properties of the soil. Cement admixtures are recommended in soils with PI values <20%. Stabilization of soil with cement has higher strength when compared to lime. The strength is due to the formation of compounds due to the addition of cement.

As suggested, road construction on soft soil is one of the main problems faced by geotechnical engineers, one of the efforts to improve it is stabilization. Several stabilization techniques have their advantages and disadvantages. The selection of chemical stabilization methods must be considered so as not to impact the environment. This research can be a recommendation for engineers to choose the chemical stabilization method used.

Acknowledgments

The authors would like to acknowledge the valuable contributions of Universitas Lancang Kuning for providing support during the review process.

-

Funding information: Authors state no funding involved.

-

Author contributions: The authors confirm contribution to the study as follows: Study conception and design: Muthia Anggraini; data collection: Muthia Anggraini and Alfian Saleh; analysis and interpretation of results: Muthia Anggraini and Dian M. Setiawan; draft manuscript preparation: Muthia Anggraini and Dian M. Setiawan. All authors have accepted responsibility for the entire content of this manuscript and approved its submission.

-

Conflict of interest: Authors state no conflict of interest.

-

Data availability statement: All data generated or analyzed during this study are included in this published article.

References

[1] Barman D, Dash SK. Stabilization of expansive soils using chemical additives: A review. J Rock Mech Geotech Eng. 2022;14(4):1319–42.10.1016/j.jrmge.2022.02.011Search in Google Scholar

[2] Al-Kaream KWA, Fattah MY, Hameedi MK. Compressibility and strength development of soft soil by polypropylene fiber. Int J Geomate. 2022;22(93):91–7.10.21660/2022.93.3206Search in Google Scholar

[3] Muthia A, Alfian S. Compressive strength value of clay soil stabilization with palm oil fuel and cement. In The 5th International Seminar on Sustainable Urban Development; 2021.10.1088/1755-1315/737/1/012038Search in Google Scholar

[4] Dhar S, Hussain M. The strength behaviour of lime-stabilised plastic fibre-reinforced clayey soil. Road Mater Pavement Des. 2019;20(8):1757–78.10.1080/14680629.2018.1468803Search in Google Scholar

[5] Ghobadi MH, Abdilor Y, Babazadeh R. Stabilization of clay soils using lime and effect of pH variations on shear strength parameters. Bull Eng Geol Env. 2014 May;73(2):611–9.10.1007/s10064-013-0563-7Search in Google Scholar

[6] Pratikso RA, Mudiyono R, Situmorang A. Stabilization of expansive soil with lime, fly ash and cement. Int J Intell Syst Appl Eng. 2023;11(4s):491–7.Search in Google Scholar

[7] Fattah MY, Irshayyid EJ, Ayasrah M, Salim NM. Behavior of bentonite-sand mixture soil subjected to history load. Int J Eng Trans C Asp. 2025;38(3):558–69.10.5829/ije.2025.38.03c.05Search in Google Scholar

[8] Roohbakhshan A, Kalantari B. Stabilization of clayey soil with lime and waste stone powder. Civ Enviromental Eng. 2014;48(4):1313.Search in Google Scholar

[9] Mahvash S, López-Querol S, Bahadori-Jahromi A. Effect of class F fly ash on fine sand compaction through soil stabilization. Heliyon. 2017;3(3):e00274.10.1016/j.heliyon.2017.e00274Search in Google Scholar PubMed PubMed Central

[10] Archibong GA, Sunday EU, Okeke JC, Amadi OC. A review of the principles and methods of soil stabilization. Int J Adv Acad Res Sci. 2020;6(3):2488–9849.Search in Google Scholar

[11] Manzoor SO, Yousuf A. Stabilisation of soils with lime: a review. J Mater Env Sci. 2020;11(9):1538–51.Search in Google Scholar

[12] Hasan MFR, Utama IZ, Razzak AFA, Salimah A, Agung PAM. Clayshale stabilization using active natural lime to increase the shear strength of soil. In 3rd International Conference on Disaster Management; 2023. p. 1–9.10.1088/1755-1315/1173/1/012025Search in Google Scholar

[13] Jawad IT, Taha MR, Majeed ZH, Khan TA. Soil stabilization using lime: Advantages, disadvantages and proposing a potential alternative. Res J Appl Sci Eng Technol. 2014;8(4):510–20.10.19026/rjaset.8.1000Search in Google Scholar

[14] Rahmat MN, Ismail N. Strength properties of sustainable palm oil fuel ash (POFA)-stabilized landfill. In Proceedings of the Colloquium on Administrative Science and Technology; 2015. p. 533–44.10.1007/978-981-4585-45-3_51Search in Google Scholar

[15] Teddy Z, Annette B, Ainomugisha S. Blending lime with sugarcane bagasse ash for stabilizing expansive clay soils in subgrade. J Eng Technol Sci. 2021;53(5):210510.10.5614/j.eng.technol.sci.2021.53.5.10Search in Google Scholar

[16] Bakr RM. Stabilization of soft clay soil by deep mixing with lime and cement in the presence of salt water. Civ Eng Archit. 2024;12(1):78–96.10.13189/cea.2024.120107Search in Google Scholar

[17] Kumar A, Devi K. Application of nanotechnology in soil stabilization. J Build Mater Sci. 2023;5(2):25–36.10.30564/jbms.v5i2.5913Search in Google Scholar

[18] Kusuma RI, Mina E, Fathonah W, Bilhaq AA. The influence of marble waste powder on clay soil stabilization. Int J Adv Sci Eng Inf Technol. 2023;13(2):487–93.10.18517/ijaseit.13.2.17200Search in Google Scholar

[19] Kulanthaivel P, Soundara B, Velmurugan S, Naveenraj V. Experimental investigation on stabilization of clay soil using nano-materials and white cement. Mater Today Proc. 2021;45:507–11. 10.1016/j.matpr.2020.02.107.Search in Google Scholar

[20] Yilmaz Y, Coban HS, Cetin B, Edil TB. Use of standard and off-spec fly ashes for soil stabilization. J Mater Civ Eng. 2019;31(2):1–11.10.1061/(ASCE)MT.1943-5533.0002599Search in Google Scholar

[21] Arifin YF, Misnawati, Normelani E. The use of natural fiber from oil palm empty fruit bunches for soft soil stabilization. In The 2nd International Conference on Green Civil and Environmental Engineering; 2019.10.1088/1757-899X/669/1/012026Search in Google Scholar

[22] Zhang Y, Daniels JL, Cetin B, Baucom IK. Effect of temperature on pH, conductivity, and strength of lime-stabilized soil. J Mater Civ Eng. 2020;32(3):1–12.10.1061/(ASCE)MT.1943-5533.0003062Search in Google Scholar

[23] Zhu F, Li Z, Dong W, Ou Y. Geotechnical properties and microstructure of lime-stabilized silt clay. Bull Eng Geol Env. 2019;78(4):2345–54.10.1007/s10064-018-1307-5Search in Google Scholar

[24] Otoko GR, Fubara-Manuel I, Chinweike IS, Oyebode OJ. Soft soil stabilization using palm oil fibre ash. J Multidiscip Eng Sci Technol. 2016;3(5):4954–8.Search in Google Scholar

[25] Lim SY, Shakri MS. Stabilisation of soft soil using palm oil fuel ash and palm oil fibre. J Phys Conf Ser. 2019;1349(1):012109.10.1088/1742-6596/1349/1/012109Search in Google Scholar

[26] Yao K, Chen Q, Xiao H, Liu Y, Lee FH. Small-strain shear modulus of cement-treated marine clay. J Mater Civ Eng. 2020;32(6):1–12.10.1061/(ASCE)MT.1943-5533.0003153Search in Google Scholar

[27] Fondjo AA, Theron E, Ray RP. Stabilization of expansive soils using mechanical and chemical methods: a comprehensive review. Civ Eng Archit. 2021;9(5):1289–94.10.13189/cea.2021.090503Search in Google Scholar

[28] Al-Gharbawi ASA, Najemalden AM, Fattah MY. Expansive soil stabilization with lime, cement, and silica fume. Appl Sci. 2023;13(1):436.10.3390/app13010436Search in Google Scholar

[29] Onyelowe KC. Nanosized palm bunch ash (NPBA) stabilisation of lateritic soil for construction purposes. Int J Geotech Eng. 2019;13(1):83–91.10.1080/19386362.2017.1322797Search in Google Scholar

[30] Adebayo Mujedu K, Ab-Kadir MA, Ismail M. A review on self-compacting concrete incorporating palm oil fuel ash as a cement replacement. Constr Build Mater. 2020;258:119541.10.1016/j.conbuildmat.2020.119541Search in Google Scholar

[31] Ranjbar N, Behnia A, Alsubari B, Moradi Birgani P, Jumaat MZ. Durability and mechanical properties of self-compacting concrete incorporating palm oil fuel ash. J Clean Prod. 2016;112:723–30.10.1016/j.jclepro.2015.07.033Search in Google Scholar

[32] Chandara C, Sakai E, Azizli KAM, Ahmad ZA, Hashim SFS. The effect of unburned carbon in palm oil fuel ash on fluidity of cement pastes containing superplasticizer. Constr Build Mater. 2010;24(9):1590–3. 10.1016/j.conbuildmat.2010.02.036.Search in Google Scholar

[33] Nagaratnam BH, Mannan MA, Rahman ME, Mirasa AK, Richardson A, Nabinejad O. Strength and microstructural characteristics of palm oil fuel ash and fly ash as binary and ternary blends in self-compacting concrete. Constr Build Mater. 2019;202:103–20.10.1016/j.conbuildmat.2018.12.139Search in Google Scholar

[34] Safiuddin M, Mohd MH, Jumaat MZ. Fresh properties of self-consolidating concrete incorporating palm oil fuel ash as a supplementary cementing material. Chiang Mai J Sci. 2011;38(3):389–404.Search in Google Scholar

[35] Alsubari B, Shafigh P, Ibrahim Z, Alnahhal MF, Jumaat MZ. Properties of eco-friendly self-compacting concrete containing modified treated palm oil fuel ash. Constr Build Mater. 2018;158:742–54.10.1016/j.conbuildmat.2017.09.174Search in Google Scholar

[36] Alsubari B, Shafigh P, Jumaat MZ, Alengaram UJ. Palm oil fuel ash as a partial cement replacement for producing durable self-consolidating high-strength concrete. Arab J Sci Eng. 2014;39(12):8507–16.10.1007/s13369-014-1381-3Search in Google Scholar

[37] Safiuddin M, Salam MA, Jumaat MZ. Key fresh properties of self-consolidating high-strength POFA concrete. J Mater Civ Eng. 2014;26(1):134–42.10.1061/(ASCE)MT.1943-5533.0000782Search in Google Scholar

[38] Alsubari B, Shafigh P, Jumaat MZ. Utilization of high-volume treated palm oil fuel ash to produce sustainable self-compacting concrete. J Clean Prod. 2016;137:982–6.10.1016/j.jclepro.2016.07.133Search in Google Scholar

[39] Hassan IO, Ismail M, Forouzani P, Majid ZA, Mirza J. Flow characteristics of ternary blended self-consolidating cement mortars incorporating palm oil fuel ash and pulverised burnt clay. Constr Build Mater. 2014;64:253–60.10.1016/j.conbuildmat.2014.04.057Search in Google Scholar

[40] Mohammadhosseini H, Awal AA, Ehsan AH. Influence of palm oil fuel ash on mechanical properties of self-compacting concrete. Int J Sustain Constr Eng Technol. 2015;13(4):44–53.10.1007/s12046-015-0426-ySearch in Google Scholar

[41] Sata V, Jaturapitakkul C, Kiattikomol K. Influence of pozzolan from various by-product materials on mechanical properties of high-strength concrete. Constr Build Mater. 2007;21(7):1589–98.10.1016/j.conbuildmat.2005.09.011Search in Google Scholar

[42] Tangchirapat W, Jaturapitakkul C, Chindaprasirt P. Use of palm oil fuel ash as a supplementary cementitious material for producing high-strength concrete. Constr Build Mater. 2009;23(7):2641–6. 10.1016/j.conbuildmat.2009.01.008.Search in Google Scholar

[43] Awal ASMA, Shehu IA. Evaluation of heat of hydration of concrete containing high volume palm oil fuel ash. Fuel. 2013;105:728–31.10.1016/j.fuel.2012.10.020Search in Google Scholar

[44] Thomas BS, Kumar S, Arel HS. Sustainable concrete containing palm oil fuel ash as a supplementary cementitious material – a review. Renew Sustain Energy Rev. 2017;80:550–61.10.1016/j.rser.2017.05.128Search in Google Scholar

[45] American Society for Testing and Materials. ASTM C618-19 standard specification for coal fly ash and raw or calcined natural pozzolan for use in concrete. In American society for Testing and Materials; 2019. p. 1–5, www.astm.org.Search in Google Scholar

[46] Otunyo AW, Chukuigwe CC. Investigation of the impact of palm bunch ash on the stabilization of poor lateritic soil. Niger J Technol. 2018;37(3):600.10.4314/njt.v37i3.6Search in Google Scholar

[47] Onyelowe K. Effect of temperature changes on the unconfined compressive strength of OPC stabilized engineering soil with palm bunch ash, PBA as admixture. J Civ Env Res. 2016;8(3):20–7.Search in Google Scholar

[48] Waluyo T, Anggraini M, Dwi Putri L. The shear strength of clay stabilized with palm bunch ash and cement. Civilla J Tek Sipil Univ Islam Lamongan. 2023;8(2):215–22.10.30736/cvl.v8i2.1139Search in Google Scholar

[49] Komolafe OO, Osinubi KJ. Stabilization of lateritic soil with cement - oil palm empty fruit bunch ash blend for California bearing ratio base course requirement. In IOP Conference Series: Materials Science and Engineering; 2019.10.1088/1757-899X/640/1/012085Search in Google Scholar

[50] Toyeb M, Hakam A, Fauzan F, Andriani A. Palm oil fuel ash (Pofa) as agro-waste to modern stabilization on subgrade. J Tek Sipil. 2023;12(2):165–71.10.24815/jts.v12i2.34639Search in Google Scholar

[51] Mujah D, Rahman ME, Zain NHM. Performance evaluation of the soft soil reinforced ground palm oil fuel ash layer composite. J Clean Prod. 2015;95:89–100.10.1016/j.jclepro.2015.02.058Search in Google Scholar

[52] Mujah D. Compressive strength and chloride resistance of grout containing ground palm oil fuel ash. J Clean Prod. 2016;112:712–22.10.1016/j.jclepro.2015.07.066Search in Google Scholar

[53] Khasib IA, Norsyahariati N, Daud N, Azline N, Nasir M. Strength development and microstructural behavior of soils stabilized with palm oil fuel ash (POFA)-based geopolymer. Appl Sci. 2021;11(8):3572.10.3390/app11083572Search in Google Scholar

[54] Jafer H, Atherton W, Sadique M, Ruddock F, Loffill E. Stabilisation of soft soil using binary blending of high calcium fly ash and palm oil fuel ash. Appl Clay Sci. 2018;152:323.10.1016/j.clay.2017.11.030Search in Google Scholar

[55] Rahayu W. Durability and strength improvement of clayshale using various stabilized materials. In IOP Conference Series: Earth and Environmental Science; 2020.Search in Google Scholar

[56] Wei L, Chai SX, Zhang HY, Shi Q. Mechanical properties of soil reinforced with both lime and four kinds of fiber. Constr Build Mater. 2018;172:300–8. 10.1016/j.conbuildmat.2018.03.248.Search in Google Scholar

[57] Moghal AAB, Chittoori BCS, Basha BM, Al-Shamrani MA. Target reliability approach to study the effect of fiber reinforcement on UCS behavior of lime treated semiarid soil. J Mater Civ Eng. 2017;29(6):04017014.10.1061/(ASCE)MT.1943-5533.0001835Search in Google Scholar

[58] Boz A, Sezer A, Özdemir T, Hızal GE, Azdeniz Dolmacı Ö. Mechanical properties of lime-treated clay reinforced with different types of randomly distributed fibers. Arab J Geosci. 2018;11(6):1–14.10.1007/s12517-018-3458-xSearch in Google Scholar

[59] Maubec N, Deneele D, Ouvrard G. Influence of the clay type on the strength evolution of lime treated material. Appl Clay Sci. 2017;137:107–14. 10.1016/j.clay.2016.11.033.Search in Google Scholar

[60] Jha AK, Sivapullaiah PV. Mechanism of improvement in the strength and volume change behavior of lime stabilized soil. Eng Geol. 2015;198:53–64. 10.1016/j.enggeo.2015.08.020.Search in Google Scholar

[61] Vitale E, Deneele D, Paris M, Russo G. Multi-scale analysis and time evolution of pozzolanic activity of lime treated clays. Appl Clay Sci. 2017;141:36–45. 10.1016/j.clay.2017.02.013.Search in Google Scholar

[62] Kalita UC. Soil mechanics and foundation engineering. New Delhi: PHI; 2011. p. 267.Search in Google Scholar

[63] Abdi MR, Ghalandarzadeh A, Shafiei Chafi L. An investigation into the effects of lime on compressive and shear strength characteristics of fiber-reinforced clays. J Rock Mech Geotech Eng. 2021;13(4):885–98.10.1016/j.jrmge.2020.11.008Search in Google Scholar

[64] Abdalla TA, Salih NB. Hydrated lime effects on geotechnical properties of clayey soil. J Eng. 2020;26(11):150–69.10.31026/j.eng.2020.11.10Search in Google Scholar

[65] Ray P, Paul A, Ghosh S, Sarkar K, Sen RN. An experimental study on fly ash with lime and gypsum for quality improvement in pavement subgrade materials. SN Appl Sci. 2020;2(12):1–15. 10.1007/s42452-020-03852-2.Search in Google Scholar

[66] Noorzai M, Tangri A. Strength evaluation of clay soil using fly ash and lime. Int J Innov Technol Explor Eng. 2019;8(7):2822–7.Search in Google Scholar

[67] Krithiga N, Pujitha D, Palayam T, Revathy A. Soil stabilization using lime and fly ash. SSRG Int J Civ Eng. 2017;1:510–8.Search in Google Scholar

[68] Al-Mukhtar M, Lasledj A, Alcover JF. Behaviour and mineralogy changes in lime-treated expansive soil at 20°C. Appl Clay Sci. 2010;50(2):191–8. 10.1016/j.clay.2010.07.023.Search in Google Scholar

[69] Jia L, Guo J, Zhou Z, Fu Y, Yao K. Experimental investigation on strength development of lime stabilized loess. RSC Adv. 2019;9(34):19680–9.10.1039/C9RA01914FSearch in Google Scholar

[70] Barasa PK, Jonah K, Mulei SM. Stabilization of expansive clay using lime and sugarcane bagasse ash. Int J Sci Res. 2015;4(4):2112–7.Search in Google Scholar

[71] Little DN, Nair S, Herbert B. Addressing sulfate-induced heave in lime treated soils. J Geotech Geoenviron Eng. 2010;136(1):110–8.10.1061/(ASCE)GT.1943-5606.0000185Search in Google Scholar

[72] Bell FG. Lime stabilization of clay minerals and soils. Eng Geol. 1996;42(4):223–37.10.1016/0013-7952(96)00028-2Search in Google Scholar

[73] Little DN, Nair S. NCHRP. In Recommended practice for stabilization of subgrade soils and base materials. Texas: National Academy of Sciences; 2009.Search in Google Scholar

[74] Ozdemir MA. Improvement in bearing capacity of a soft soil by addition of fly ash. In ICTG 2016; 2016. p. 498–505.10.1016/j.proeng.2016.06.063Search in Google Scholar

[75] Rios S, Cristelo N, Viana da Fonseca A, Ferreira C. Structural performance of alkali-activated soil ash versus soil cement. J Mater Civ Eng. 2016;28(2):1–11.10.1061/(ASCE)MT.1943-5533.0001398Search in Google Scholar

[76] Garcia-Lodeiro I, Palomo A, Fernández-Jiménez A. An overview of the chemistry of alkali-activated cement-based binders. Handbook of alkali-activated cements, mortars and concretes. Sawston, Cambridge, UK: Woodhead Publishing; 2015. p. 19–47. 10.1533/9781782422884.1.19.Search in Google Scholar

[77] Arulrajah A. Evaluation of fly ash- and slag-based geopolymers for the improvement of a soft marine clay by deep soil mixing. Soils Found. 2018;58(6):1358–70, https://api.elsevier.com/content/article/eid/1-s2.0-S0038080618301227.10.1016/j.sandf.2018.07.005Search in Google Scholar

[78] Ahmaruzzaman M. A review on the utilization of fly ash. Prog Energy Combust Sci. 2010;36(3):327–63.10.1016/j.pecs.2009.11.003Search in Google Scholar

[79] Liu Z, Cai CS, Liu F, Fan F. Feasibility study of loess stabilization with fly ash-based geopolymer. J Mater Civ Eng. 2016;28(5):1–8.10.1061/(ASCE)MT.1943-5533.0001490Search in Google Scholar

[80] Abdullah HH, Shahin MA, Walske ML. Geo-mechanical behavior of clay soils stabilized at ambient temperature with fly-ash geopolymer-incorporated granulated slag. Soils Found. 2019;59(6):1906–20.10.1016/j.sandf.2019.08.005Search in Google Scholar

[81] Phummiphan I, Horpibulsuk S, Sukmak P, Chinkulkijniwat A, Arulrajah A, Shen SL. Stabilisation of marginal lateritic soil using high calcium fly ash-based geopolymer. Road Mater Pavement Des. 2016;17(4):877–91.10.1080/14680629.2015.1132632Search in Google Scholar

[82] Phetchuay C, Horpibulsuk S, Arulrajah A, Suksiripattanapong C, Udomchai A. Strength development in soft marine clay stabilized by fly ash and calcium carbide residue based geopolymer. Appl Clay Sci. 2016;127–128:134–42.10.1016/j.clay.2016.04.005Search in Google Scholar

[83] Nath BD, Molla MKA, Sarkar G. Study on strength behavior of organic soil stabilized with fly ash. Int Sch Res Not. 2017;2017:1–6.10.1155/2017/5786541Search in Google Scholar PubMed PubMed Central

[84] Indiramma P, Sudharani C, Needhidasan S. Utilization of fly ash and lime to stabilize the expansive soil and to sustain pollution free environment - an experimental study. Mater Today Proc. 2020;22:694–700. 10.1016/j.matpr.2019.09.147.Search in Google Scholar

[85] Yilmaz Y. Compaction and strength characteristics of fly ash and fiber amended clayey soil. Eng Geol. 2015;188:168–77. 10.1016/j.enggeo.2015.01.018.Search in Google Scholar

[86] McCarthy MJ, Csetenyi LJ, Sachdeva A, Dhir RK. Identifying the role of fly ash properties for minimizing sulfate-heave in lime-stabilized soils. Fuel. 2012;92(1):27–36. 10.1016/j.fuel.2011.07.009.Search in Google Scholar

[87] Rosa MG, Cetin B, Edil TB, Benson CH. Freeze–thaw performance of fly ash–stabilized materials and recycled pavement materials. J Mater Civ Eng. 2017;29(6):1–13.10.1061/(ASCE)MT.1943-5533.0001844Search in Google Scholar

[88] Dayioglu M, Cetin B, Nam S. Stabilization of expansive Belle Fourche shale clay with different chemical additives. Appl Clay Sci. 2017;146:56–69. 10.1016/j.clay.2017.05.033.Search in Google Scholar

[89] Noaman MF, Khan MA, Ali K, Hassan A. A review on the effect of fly ash on the geotechnical properties and stability of soil. Clean Mater. 2022;6:100151. 10.1016/j.clema.2022.100151.Search in Google Scholar

[90] Abdullah HH, Shahin MA, Walske ML, Karrech A. Cyclic behaviour of clay stabilised with fly-ash based geopolymer incorporating ground granulated slag. Transp Geotech. 2021;26:100430. 10.1016/j.trgeo.2020.100430.Search in Google Scholar

[91] Ash B, Nugroho SA, Zulnasari A, Fatnanta F, Putra AD. Mechanical behavior of clay soil stabilized with fly ash and bottom ash. Makara J Technol. 2022;26(1):1–7.10.7454/mst.v26i1.1444Search in Google Scholar

[92] Farichah H, Hutama DA, Solin DP. Evaluation of the strength characteristic of soil stabilized with fly ash. J PenSil. 2023;12(3):273–80.10.21009/jpensil.v12i3.37489Search in Google Scholar

[93] Andavan S, Pagadala VK. Experimental study on addition of lime and fly ash for the soil stabilization. Mater Today Proc. 2020;22:1065–9. 10.1016/j.matpr.2019.11.300.Search in Google Scholar

[94] Saravanan R, Thomas RS, Joseph M. A study on soil stabilization of clay soil using flyash. Int J Res Civ Eng Archit Des. 2013;1(2):33–7.Search in Google Scholar

[95] Ahmad S, Ashraf Husain SM, Ahmad S. Stabilization of low shear strength soil by using fly ash. IOSR J Mech Civ Eng. 2015;12(4):2278–1684.Search in Google Scholar

[96] Ma C, Chen B, Chen L. Experimental feasibility research on a high-efficiency cement-based clay stabilizer. KSCE J Civ Eng. 2018;22(1):62–72.10.1007/s12205-017-0782-8Search in Google Scholar

[97] Choobbasti AJ, Kutanaei SS. Microstructure characteristics of cement-stabilized sandy soil using nanosilica. J Rock Mech Geotech Eng. 2017;9(5):981–8. 10.1016/j.jrmge.2017.03.015.Search in Google Scholar

[98] Ates A. The effect of polymer-cement stabilization on the unconfined compressive strength of liquefiable soils. Int J Polym Sci. 2013;2013:356214.10.1155/2013/356214Search in Google Scholar

[99] Gupta T, Agrahari S, Rai N, Akhter Z, Kumar A. Experimental study of soil stabilization by adding cement, rice husk ash and bagasse ash. Int J Eng Res Technol. 2022;11:1–5, www.ijert.org.Search in Google Scholar

[100] Horpibulsuk S. Strength and microstructure of cement stabilized clay. Scanning electron microscopy. London, UK: IntechOpen; 2012.10.5772/35225Search in Google Scholar

[101] Sorsa A. Engineering properties of cement stabilized expansive clay soil. Civ Env Eng. 2022;18(1):332–9.10.2478/cee-2022-0031Search in Google Scholar

[102] Harianto T, Sitepu F. Strength improvement of cement stabilized soil by binder mineral additive. Lowl Technol Int. 2019;21(2):90–7.Search in Google Scholar

[103] Horkoss S, Escadeillas G, Rizk T, Lteif R. The effect of the source of cement SO3 on the expansion of mortars. Case Stud Constr Mater. 2016;4:62–72.10.1016/j.cscm.2015.12.004Search in Google Scholar

[104] Abbas ZH, Majdi HS. Study of heat of hydration of Portland cement used in Iraq. Case Stud Constr Mater. 2017;7:154–62.10.1016/j.cscm.2017.07.003Search in Google Scholar

[105] Chian SC, Chim YQ, Wong JW. Influence of sand impurities in cement-treated clays. Geotechnique. 2017;67(1):31–41.10.1680/jgeot.15.P.179Search in Google Scholar

[106] Prusinski JR, Bhattacharja S. Effectiveness of Portland cement and lime in stabilizing clay soils. Transp Res Rec. 1999;1(1652):215–27.10.3141/1652-28Search in Google Scholar

[107] Liu L, Zhou A, Deng Y, Cui Y, Yu Z, Yu C. Strength performance of cement/slag-based stabilized soft clays. Constr Build Mater. 2019;211:909–18. 10.1016/j.conbuildmat.2019.03.256.Search in Google Scholar

[108] Chian SC, Nguyen ST, Phoon KK. Extended strength development model of cement-treated clay. J Geotech Geoenviron Eng. 2016;142(2):1–7.10.1061/(ASCE)GT.1943-5606.0001400Search in Google Scholar

[109] Cong M, Longzhu C, Bing C. Experimental study on soft clay stabilized with cement-based stabilizer. In 15th Asian Regional Conference on Soil Mechanics and Geotechnical Engineering, ARC 2015: New Innovations and Sustainability; 2015. p. 2043–6.Search in Google Scholar

[110] Sharma K, Kumar A. Influence of rice husk ash, lime and cement on compaction and strength properties of copper slag. Transp Geotech. 2021;27:100464. 10.1016/j.trgeo.2020.100464.Search in Google Scholar

[111] Por S, Nishimura S, Likitlersuang S. Deformation characteristics and stress responses of cement-treated expansive clay under confined one-dimensional swelling. Appl Clay Sci. 2017;146:316–24.10.1016/j.clay.2017.06.022Search in Google Scholar

[112] Ma C, Qin Z, Zhuang Y, Chen L, Chen B. Influence of sodium silicate and promoters on unconfined compressive strength of Portland cement-stabilized clay. Soils Found. 2015;55(5):1222–32. 10.1016/j.sandf.2015.09.021.Search in Google Scholar

[113] Islam M. Effect of cement stabilization on the behavior of clay soil. In Bangladesh Geotechnical Conference; 2010.Search in Google Scholar

[114] Mahedi M, Cetin B, White DJ. Performance evaluation of cement and slag stabilized expansive soils. Transp Res Rec. 2018;2672(52):164–73.10.1177/0361198118757439Search in Google Scholar

[115] Zhang RJ, Lu YT, Tan TS, Phoon KK, Santoso AM. Long-term effect of curing temperature on the strength behavior of cement-stabilized clay. J Geotech Geoenviron Eng. 2014;140(8):1–12.10.1061/(ASCE)GT.1943-5606.0001144Search in Google Scholar

[116] Aryal S, Kolay PK. Long-term durability of ordinary Portland cement and polypropylene fibre stabilized kaolin soil using wetting-drying and freezing-thawing test. Int J Geosynth Gr Eng. 2020;6:1–5.10.1007/s40891-020-0191-9Search in Google Scholar